Strand spinneret discharge process for polymerization reaction of 11-amino undecanoic acid monomer

A technology of monomer polymerization and undecanoic acid, which is applied in the field of 11-aminoundecanoic acid monomer polymerization reaction injection tape discharge, can solve the problems of unbalanced product quality, slow discharge speed, poor operability, etc., and achieve quality Balanced, fast discharge speed, and the effect of solving the difficulty of discharge

Inactive Publication Date: 2008-10-22

山西宏远科技股份有限公司

View PDF0 Cites 4 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

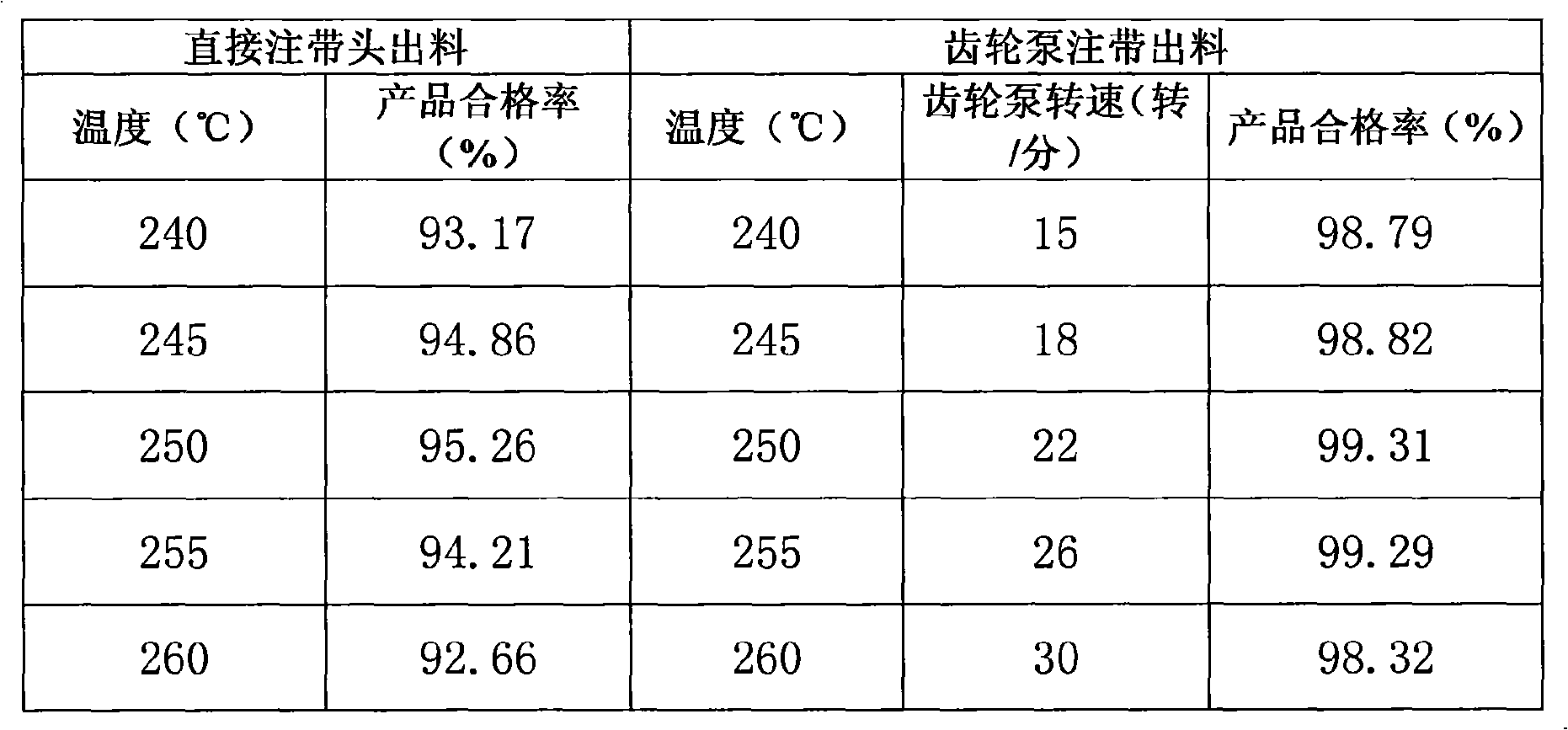

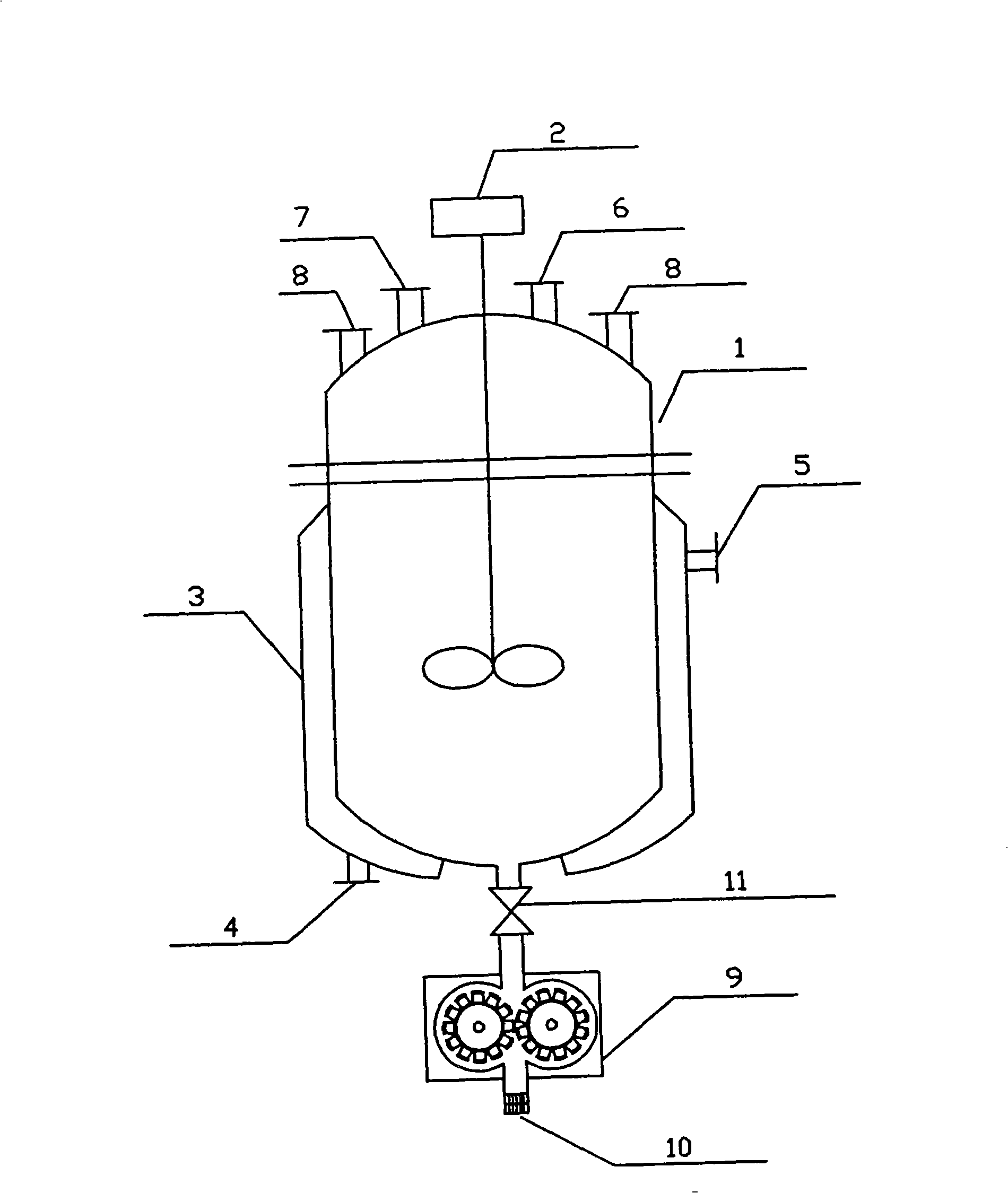

In order to solve the problem that the existing polyundecamide resin adopts kettle-type polymerization, the discharge speed of the device directly injecting the head and discharging the material is slow and uneven. As the discharge time prolongs, the viscosity increases, and the discharge increases Difficulties, resulting in unbalanced product quality, poor operability and other problems, and provide a 11-amino undecanoic acid monomer polymerization injection belt discharge method

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention belongs to the castor oil-producing nylon-11 engineering plastic manufacture technical field, in particular to a method for injecting belt discharging after 11-amino undecanoic acid monomer polymerization reaction. The method solves the problems that the prior poly-undecanoyl amine resin adopts the kettle type polymerization, a direct injecting belt head discharging device has low discharging speed, the discharging is not even, and is more viscous and difficult with the discharging time prolonged, the quality of the whole product is not balanced, and the maneuverability is bad, etc. In a polymerization kettle, the 11-amino undecanoic acid monomer is polymerized to generate the poly-undecanoyl amine resin at a temperature of between 230 and 260 DEG C, an injecting belt wheel pump is adopted to pressurize and the discharging injecting belt head produces the product; in the technique, the preserved temperature of the injecting belt wheel pump is between 240 and 260 DEG C, the rotating speed of the wheel pump is between 15 and 30 RPM. The method has the advantages that the discharging speed is high, the discharging is even, the problem of the difficult discharging in the later period is solved, the quality is balanced, the maneuverability is strong, the purchase and installation as well as use are easy, and the investment is saved.

Description

11-aminoundecanoic acid monomer polymerization reaction injection belt discharge method technical field The invention belongs to the technical field of producing nylon-11 engineering plastics from castor oil, and specifically relates to a method for polymerizing 11-aminoundecanoic acid monomer for injection and discharge in the process flow. Background technique Polyundecamide plant engineering plastics (H[NH(CH2)10CO]nOH) is an important high-tech new material, an important variety of polyamide engineering plastics, and an irreplaceable resin. It uses castor oil as raw material. Compared with other products, it has low density, high mechanical strength, stable performance, acid and alkali resistance, and excellent electrical insulation performance. Due to these excellent and unique properties, it is widely used in many fields such as automobile industry, electronic appliances, medical equipment, ordnance and civil industry. The existing castor oil route synthesis nylon-1...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08G69/08

Inventor 赵学严

Owner 山西宏远科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com