Lithium battery material powder conveying pump

A technology for conveying pumps and powders, which is applied in the field of lithium battery processing equipment. It can solve the problems of periodic sudden changes in material concentration, unfavorable assembly line production operations, and easy wear and tear of peristaltic pumps, achieving stable and uniform discharge, long service life, The material is fine and uniform

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

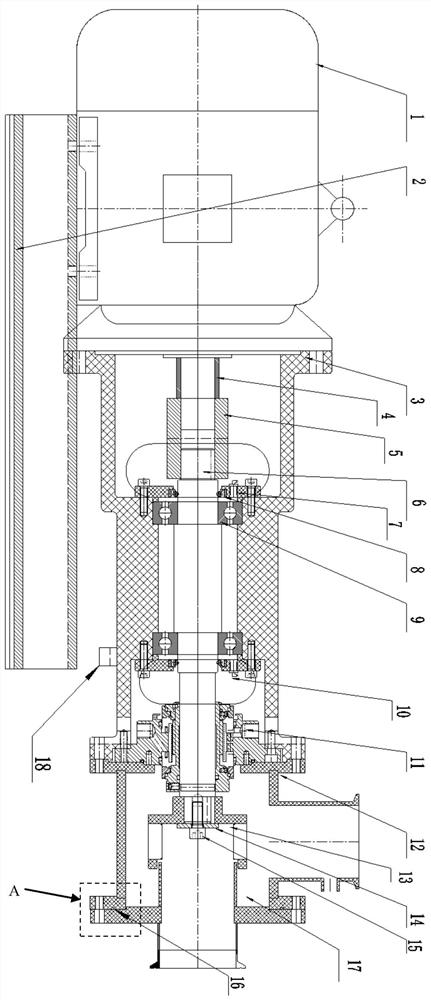

[0020] like figure 1 and 2 As shown, the lithium battery material powder delivery pump includes a power mechanism, a transmission mechanism and a pump body;

[0021] The power mechanism includes a motor 1 and a base 2, the base 2 fixes the motor 1 by bolts, the rotating shaft of the motor 1 is arranged to the right and the housing of the motor 1 is provided with a trumpet-shaped mounting seat around the rotating shaft;

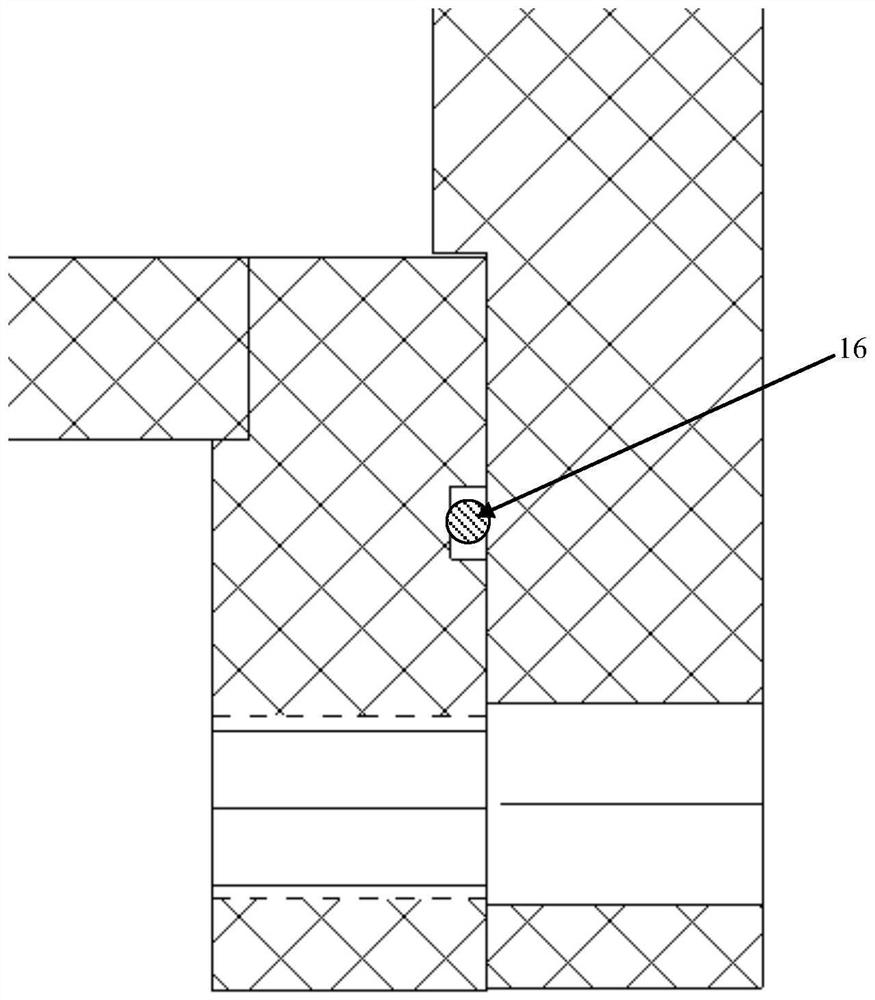

[0022] The transmission mechanism includes a bearing seat 3, a shaft coupling 5, a main shaft 6 and two sets of deep groove ball bearings 9. The left end surface of the bearing seat 3 is fixed on the trumpet-shaped mounting seat of the motor 1 shell by bolts, and the inside of the bearing seat 3 The main shaft 6 is installed through two sets of deep groove ball bearings 9, and the inner wall of the bearing seat 3 corresponds to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com