Heat capacity type neodymium glass flaky laser

A neodymium glass and laser technology, applied in the field of lasers, can solve the problems of output laser drift, large and complex structure of the laser system, etc., and achieve the effects of avoiding influence, uniform and stable laser, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

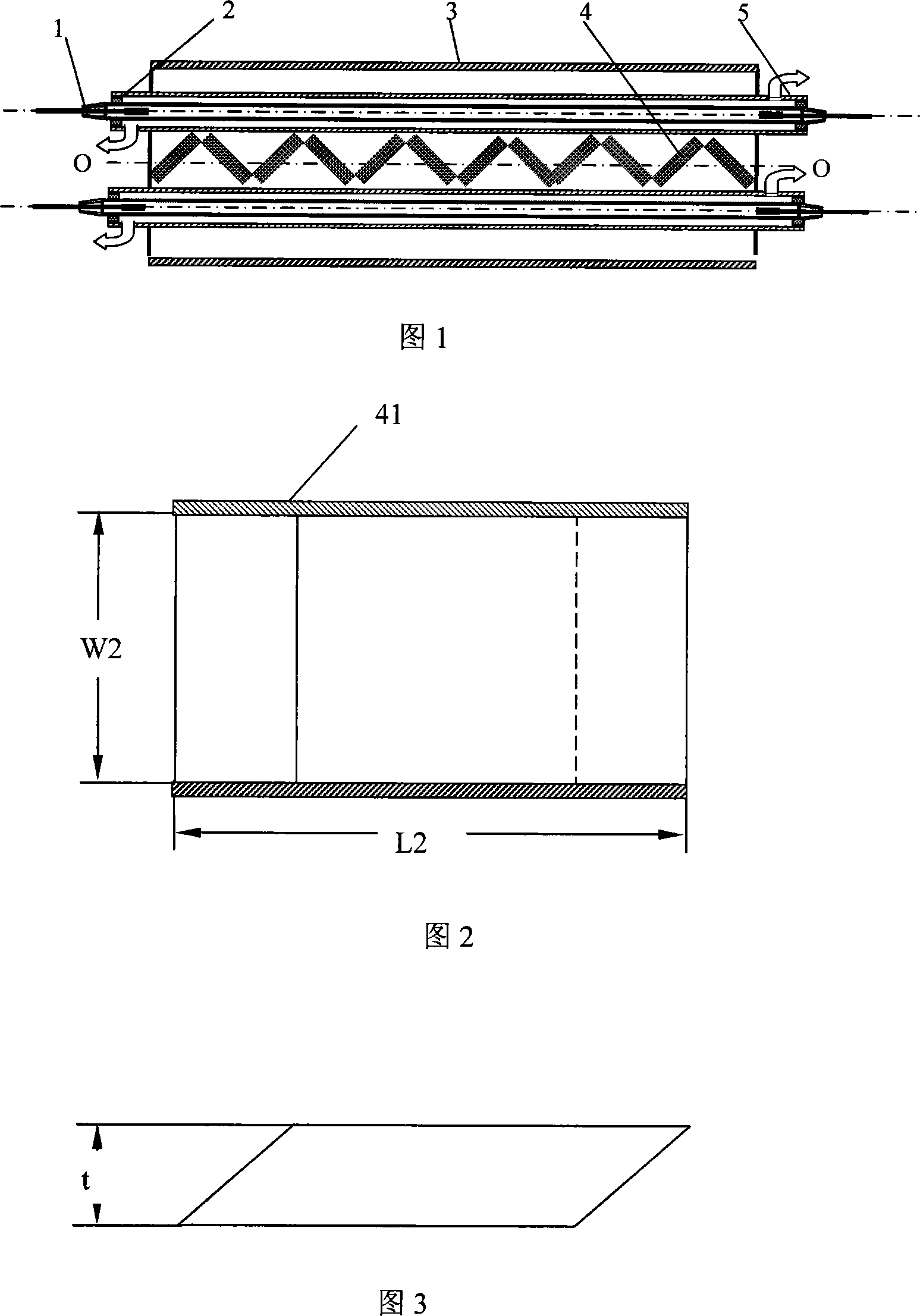

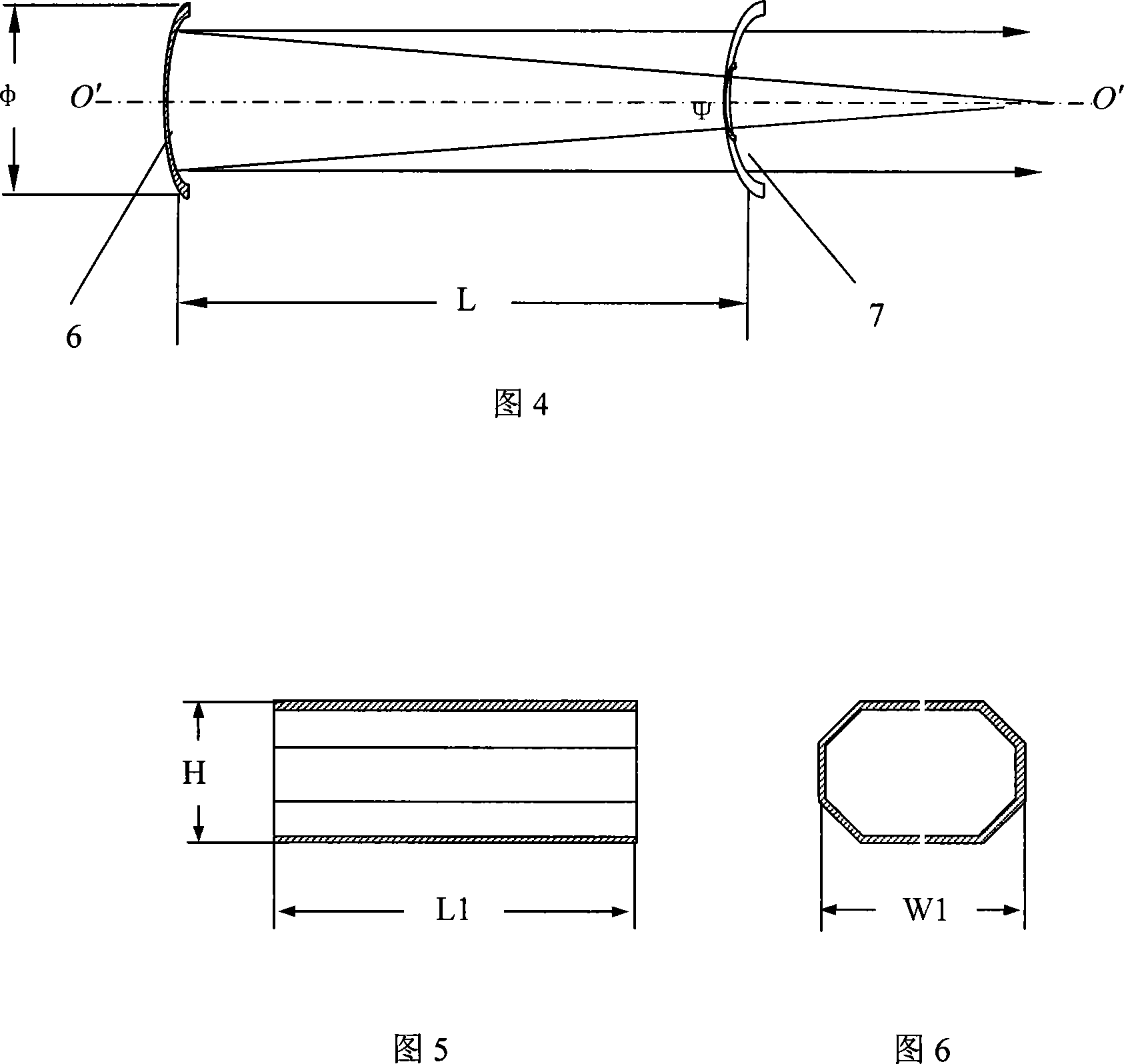

[0016] As shown in the figure, a heat capacity neodymium glass sheet laser includes a resonant cavity and an octagonal silver-plated reflector 3. The resonant cavity is a virtual confocal cavity including a total reflection mirror 6 and an output mirror 7. The total reflection mirror 6 and the diameter φ of the output mirror 7 is 100mm, the cavity length L of the resonant cavity is 100cm, the length L1 of the reflector 3 is 650mm, the width W1 is 250mm, and the height H is 150mm, and the reflector 3 is fixedly provided with twelve pieces of length L2 is 80mm, the width W2 is 54mm, the thickness t is the laser glass sheet 4 of 20mm, the laser glass sheet 4 is set at 45° to the optical axis, the optical axis O-O of the laser glass sheet 4 and the optical axis O'-O' of the resonant cavity Coincidentally, two pumping lamps 1 with a discharge chann...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com