Patents

Literature

97 results about "Scotch yoke" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

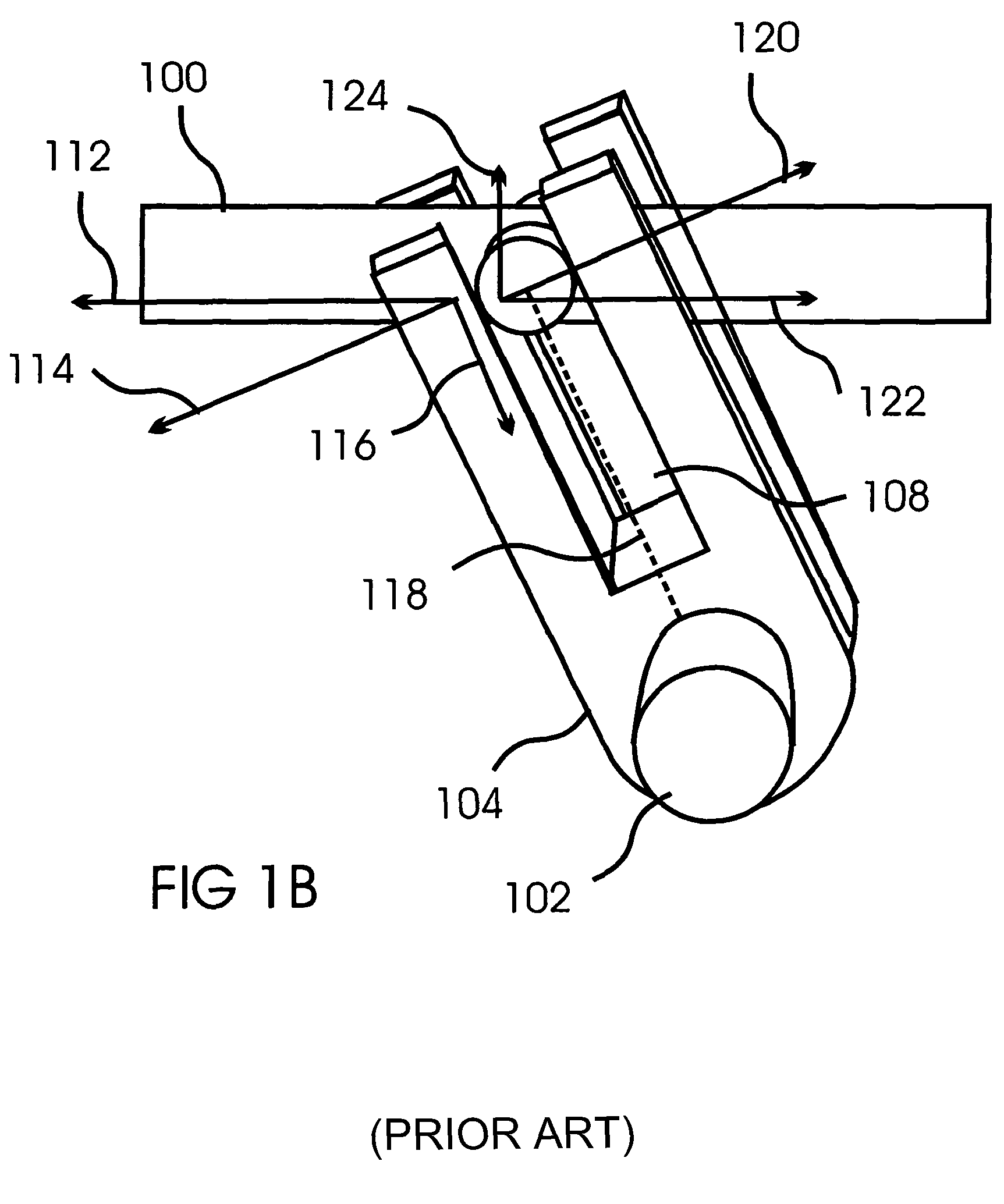

The Scotch Yoke (also known as slotted link mechanism) is a reciprocating motion mechanism, converting the linear motion of a slider into rotational motion, or vice versa. The piston or other reciprocating part is directly coupled to a sliding yoke with a slot that engages a pin on the rotating part. The location of the piston versus time is simple harmonic motion, i.e., a sine wave having constant amplitude and constant frequency, given a constant rotational speed.

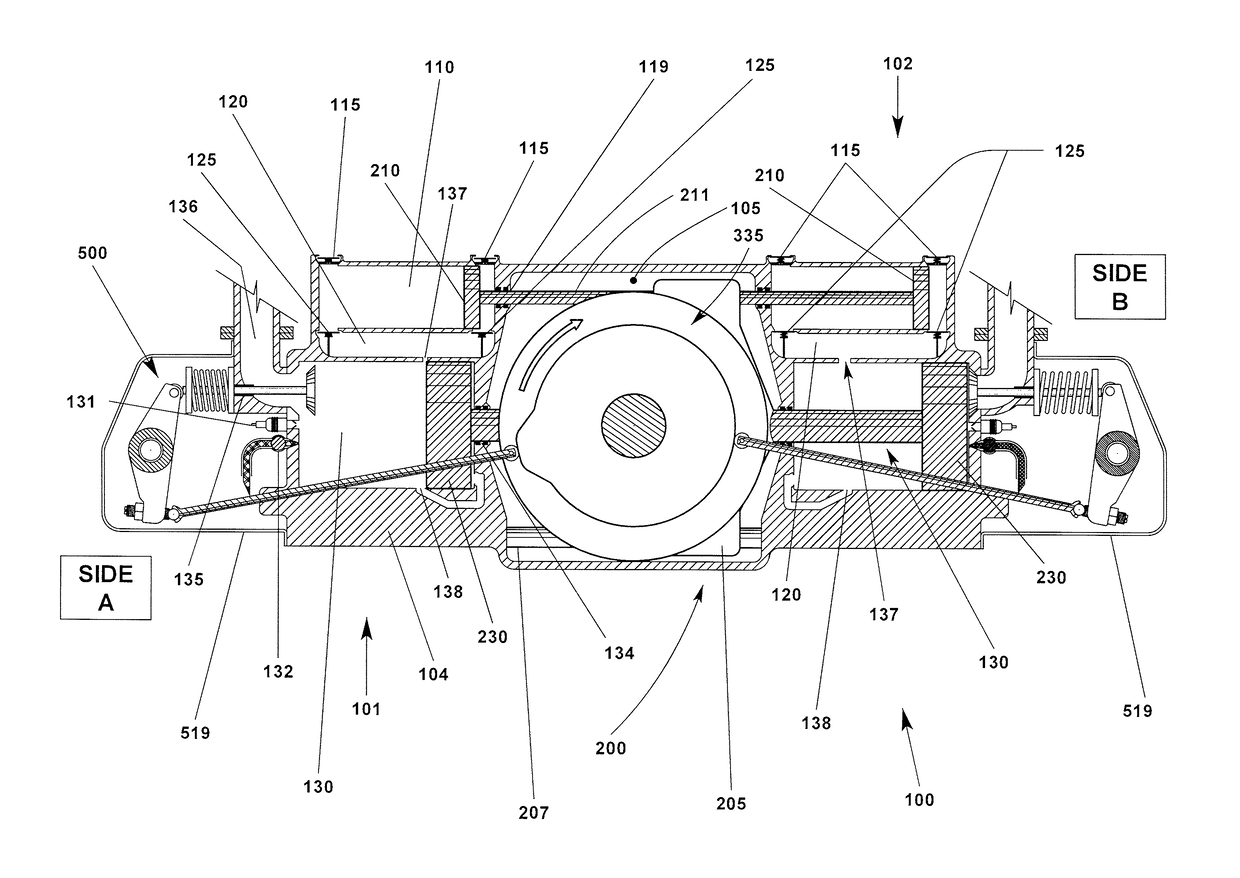

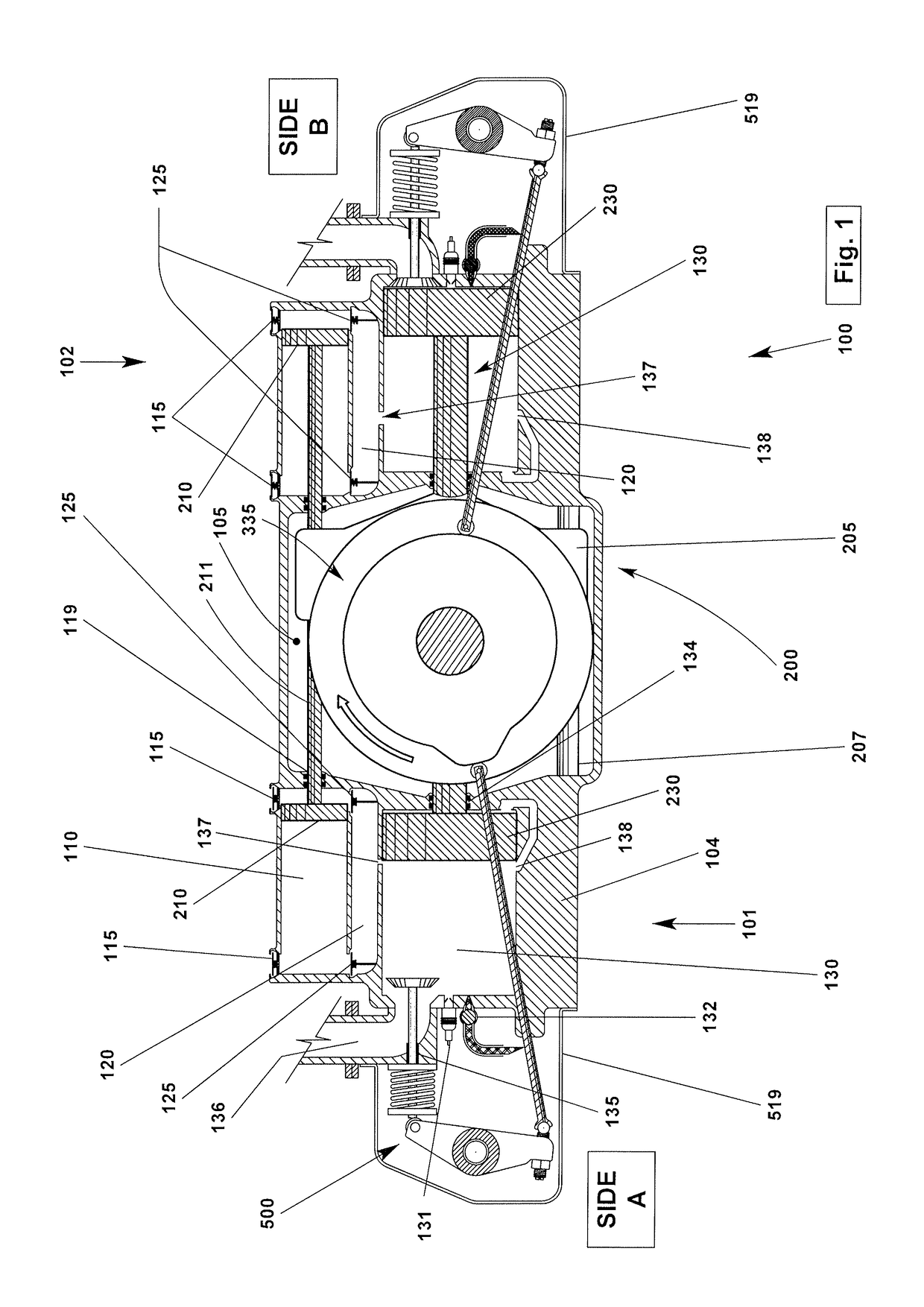

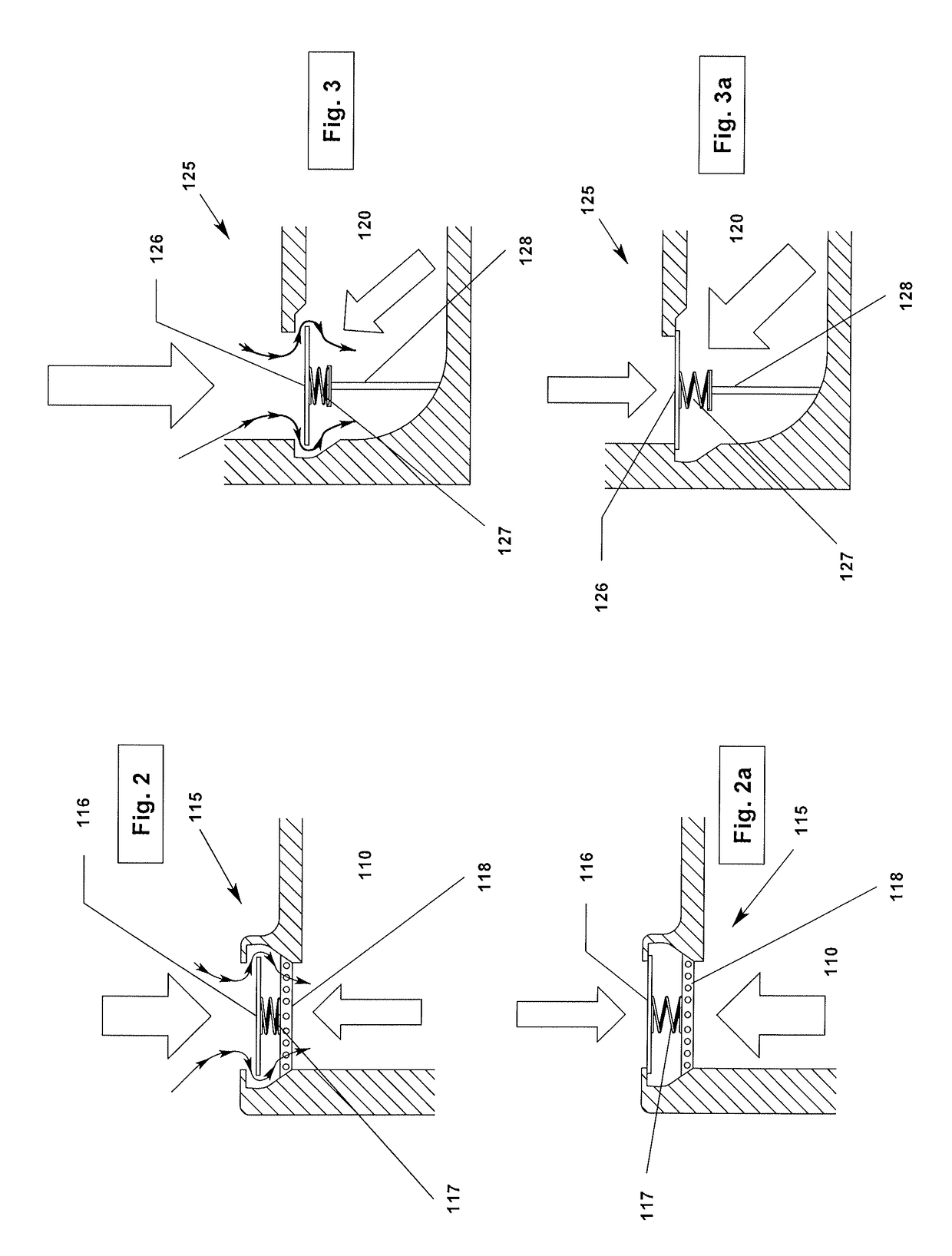

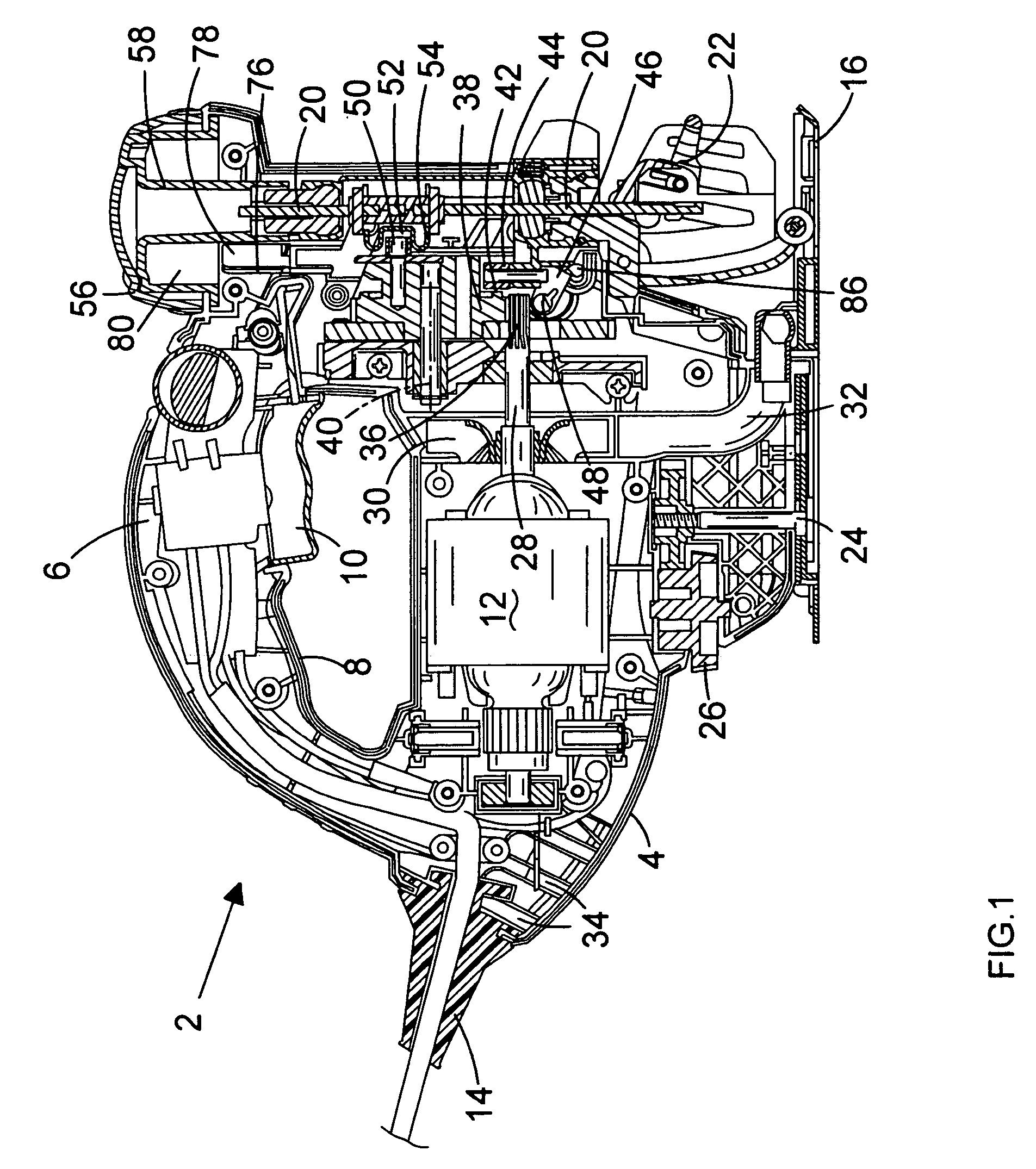

Opposed piston internal combustion engine with inviscid layer sealing

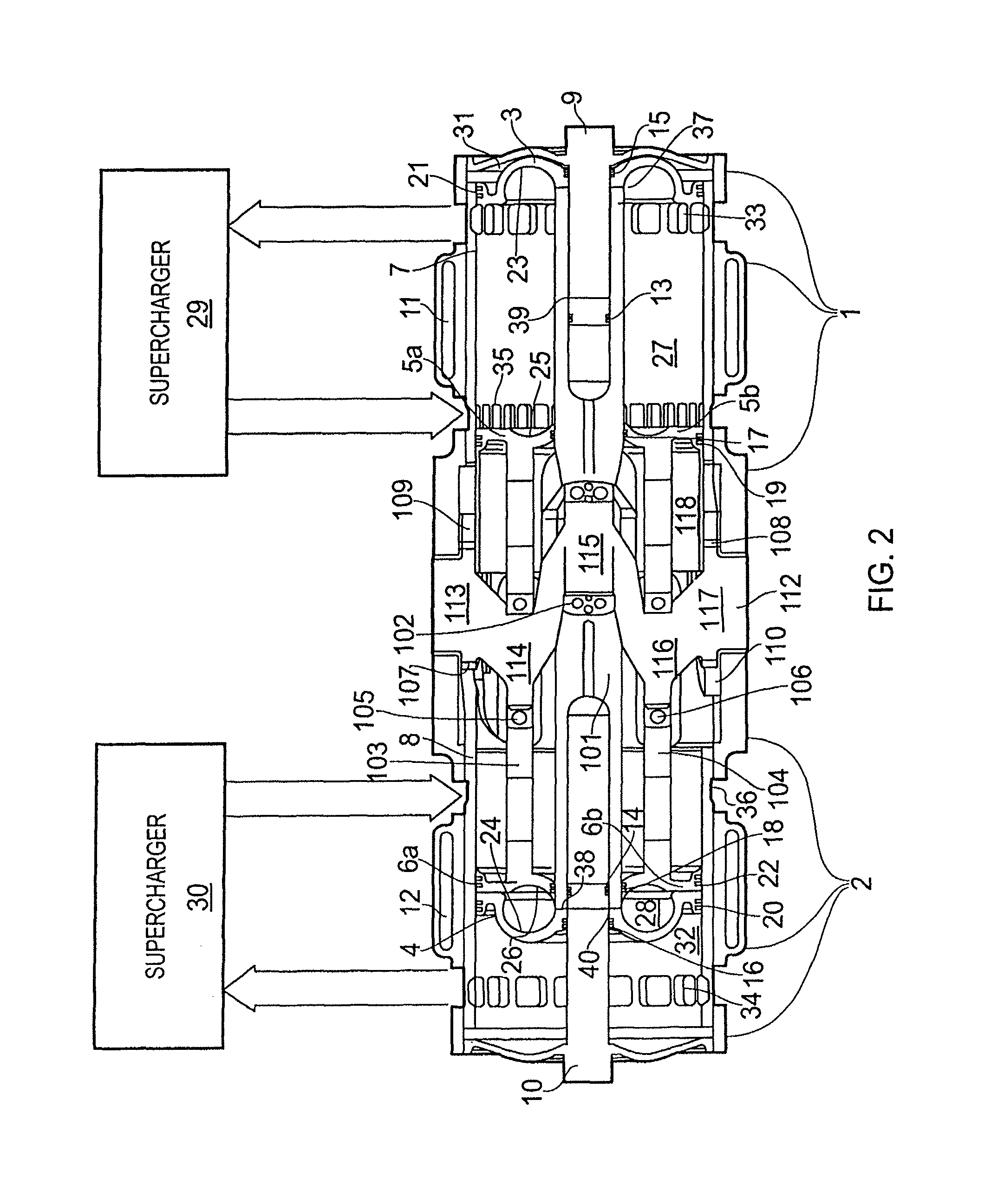

InactiveUS9909492B2Close toleranceAccurate concentricityCombustion enginesReciprocating piston enginesDetonationCombustion

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

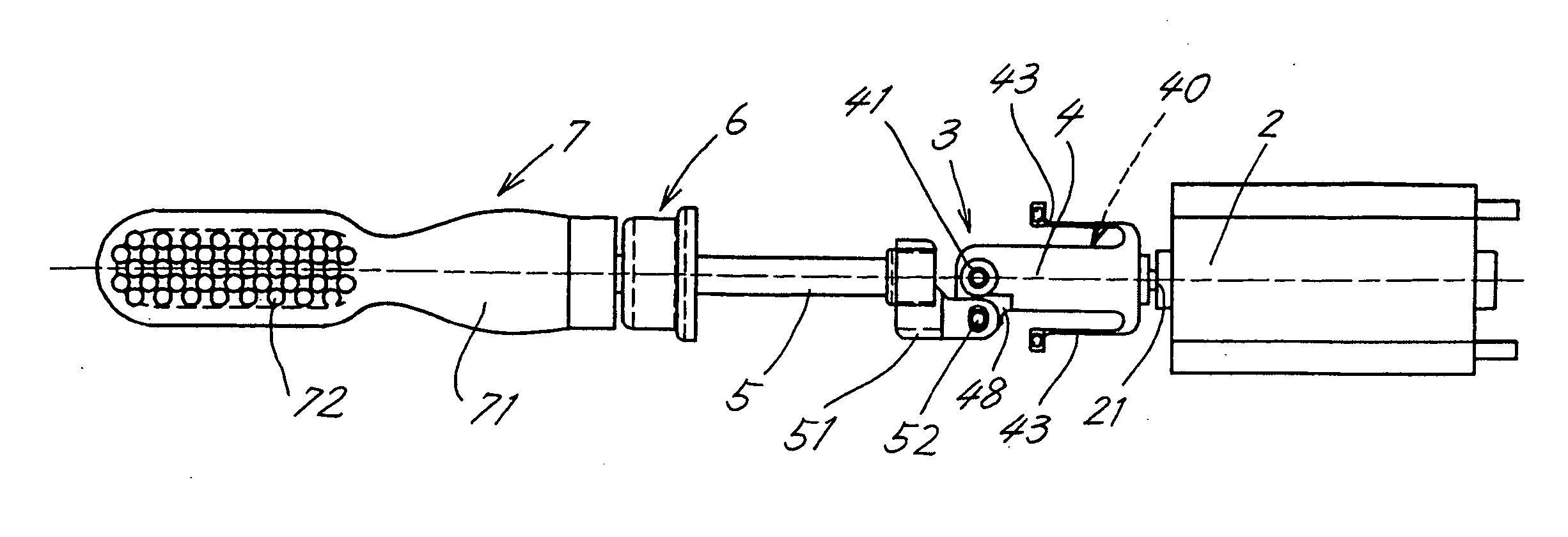

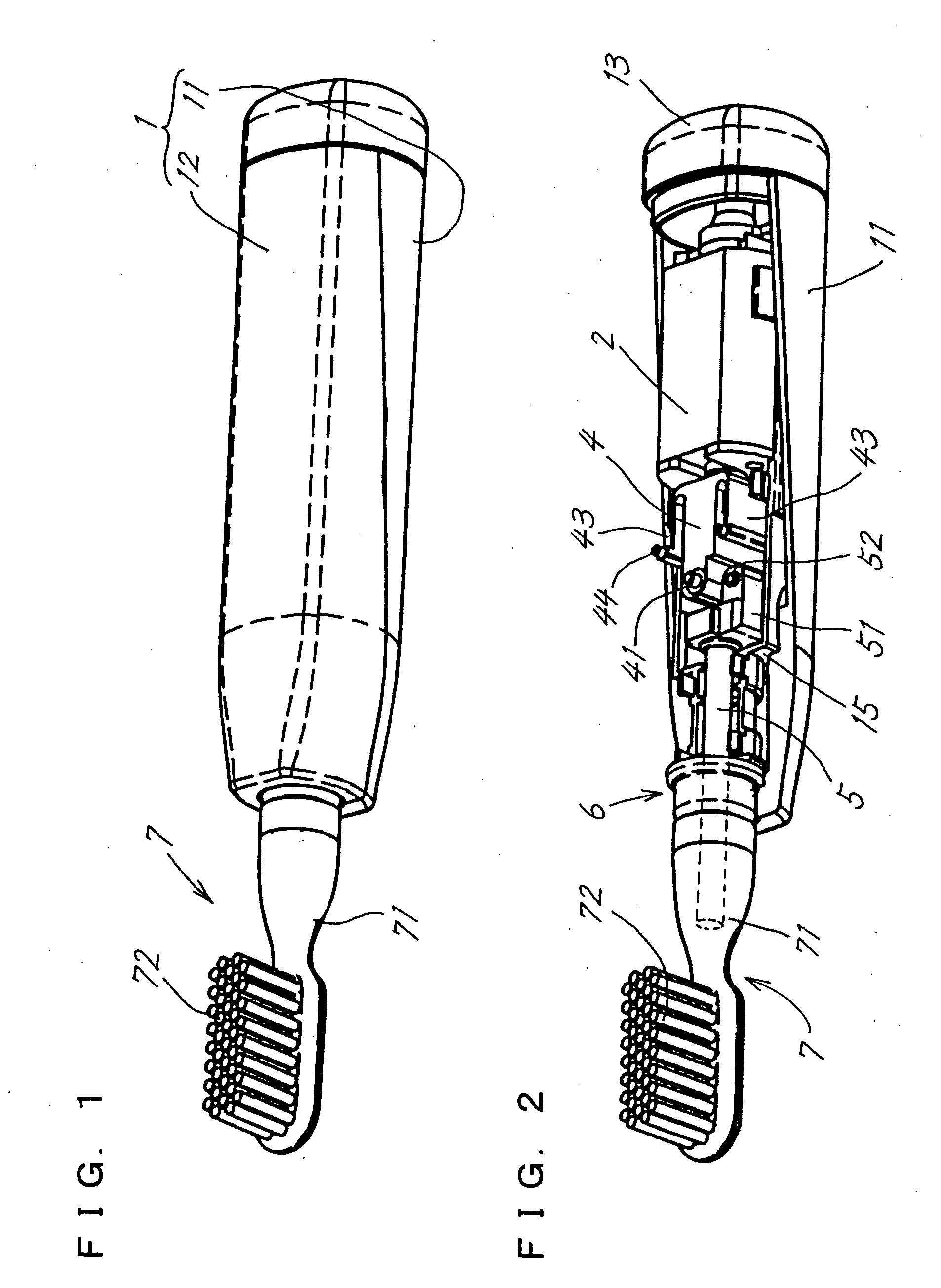

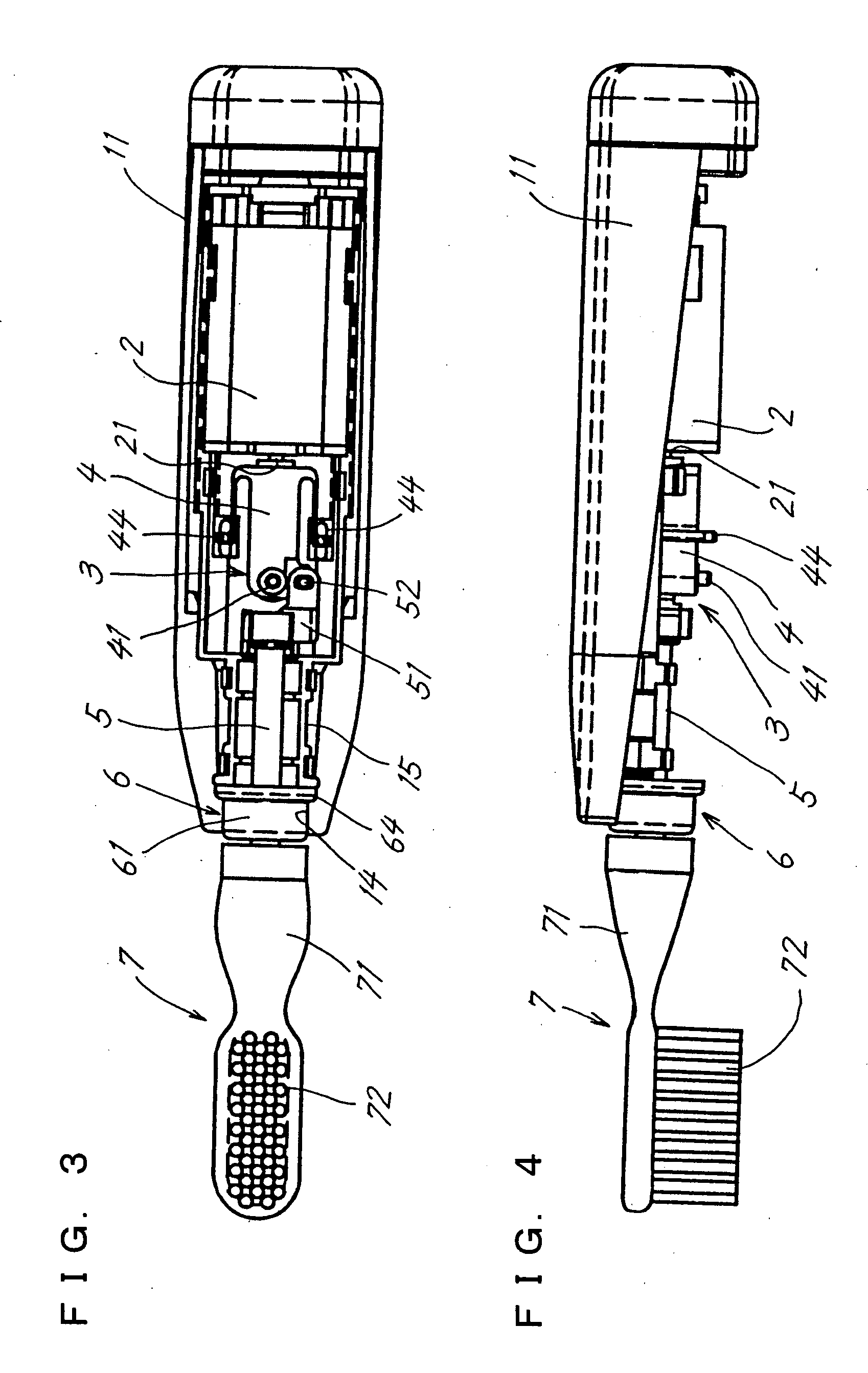

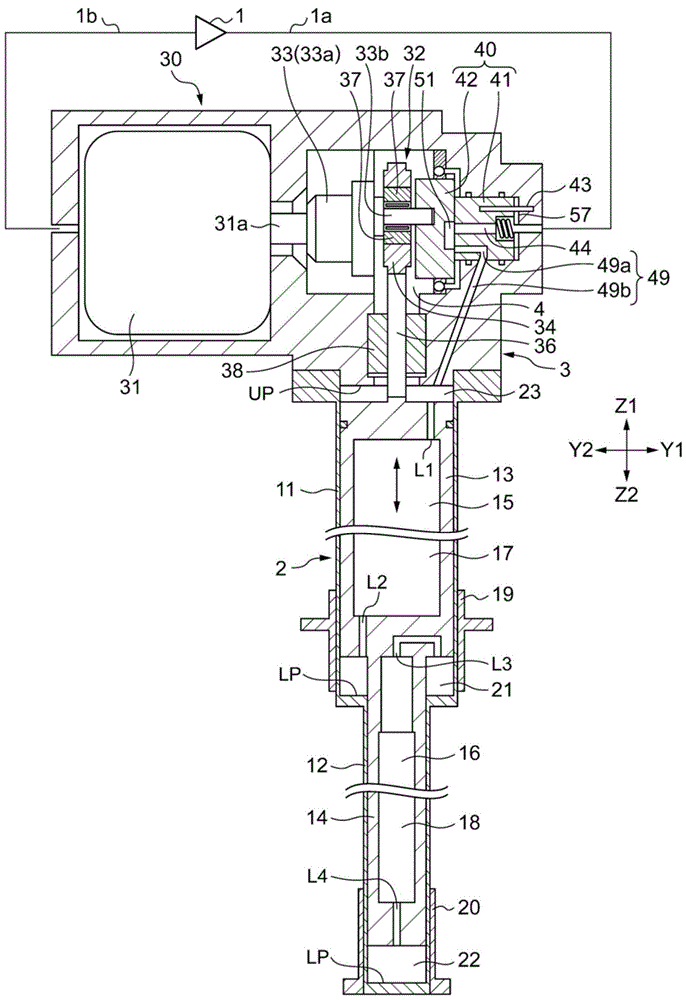

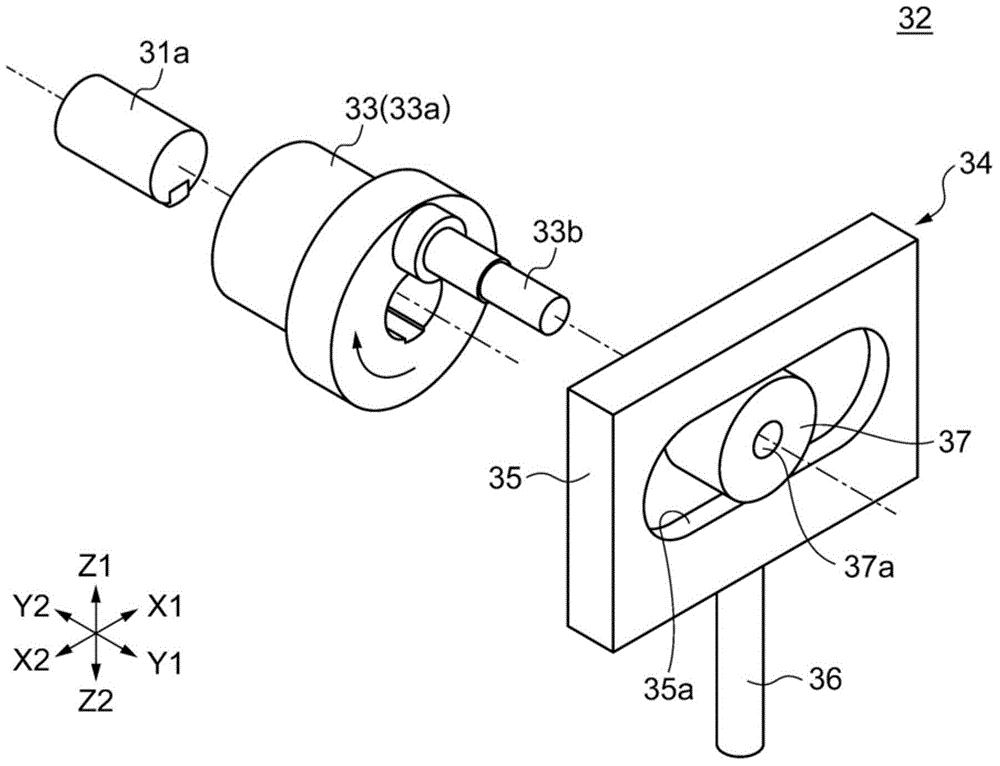

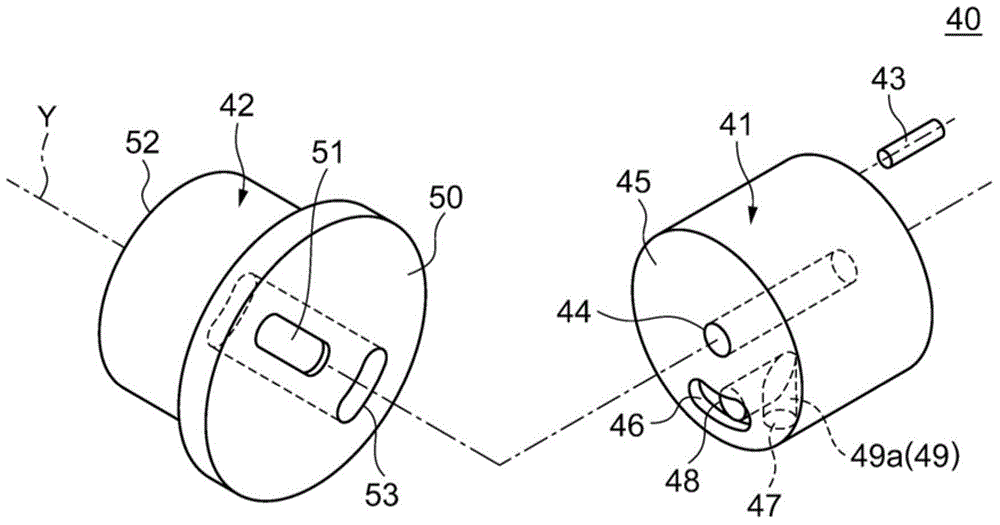

Electric toothbrush

InactiveUS20060101598A1Reduce irregularitiesRemove noiseMechanical apparatusCarpet cleanersReciprocating motionElectric machine

An electric toothbrush wherein the number of revolution of a motor shaft is in match with the frequency of reciprocating motion of the brush. A motor (2) housed in a tubular case (1) is coupled to a reciprocating shaft (5) slidably extending through the forward end of the case by a scotch yoke mechanism (40) for converting one turn of rotation of the motor shaft (21) into one stroke of reciprocating pivotal movement of a pivotal body (4), and by motion conversion means (3) for converting one stroke of reciprocating movement of the pivotal body (4) into one stroke of linear reciprocating motion of the reciprocating shaft (5).

Owner:SANYO ELECTRIC CO LTD

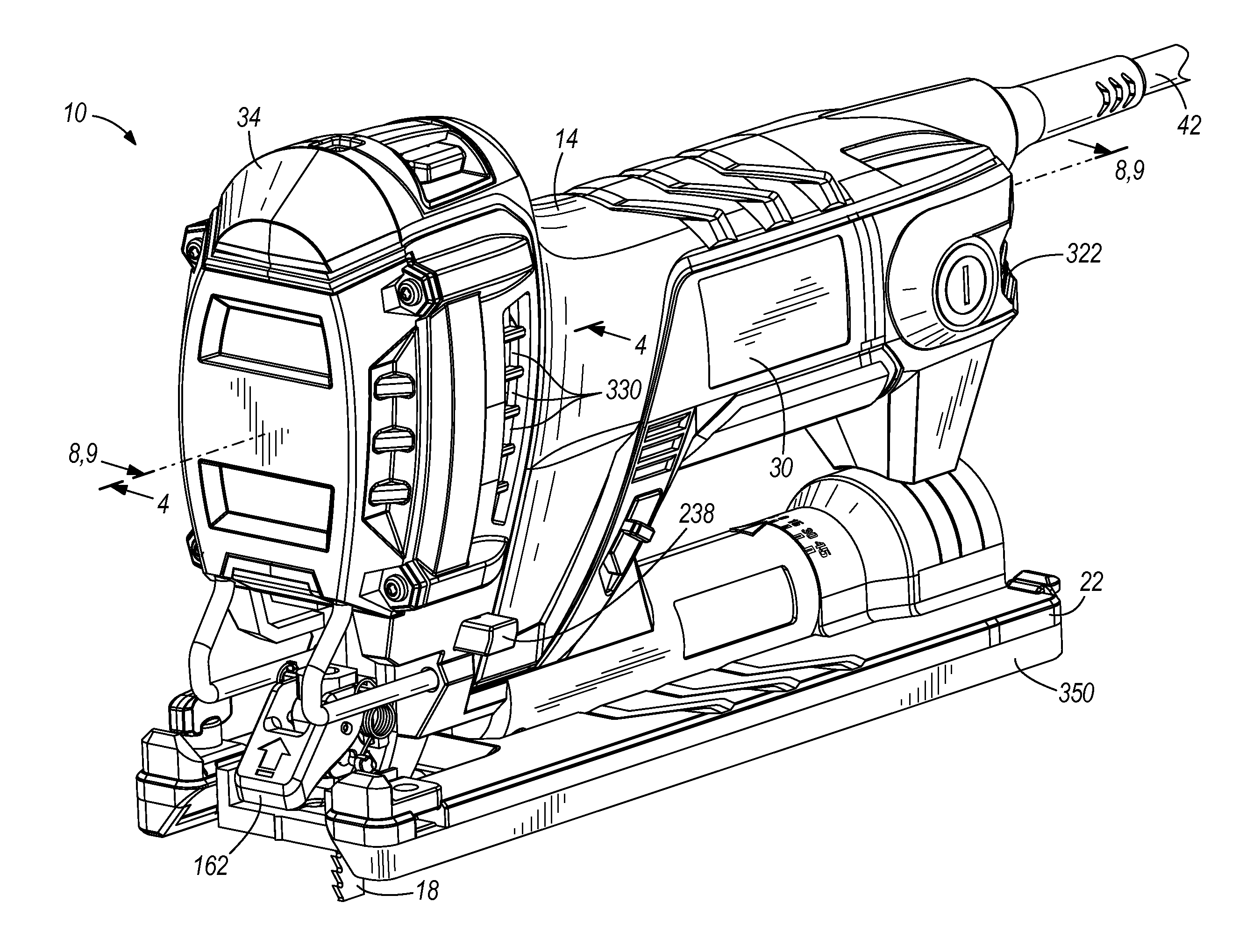

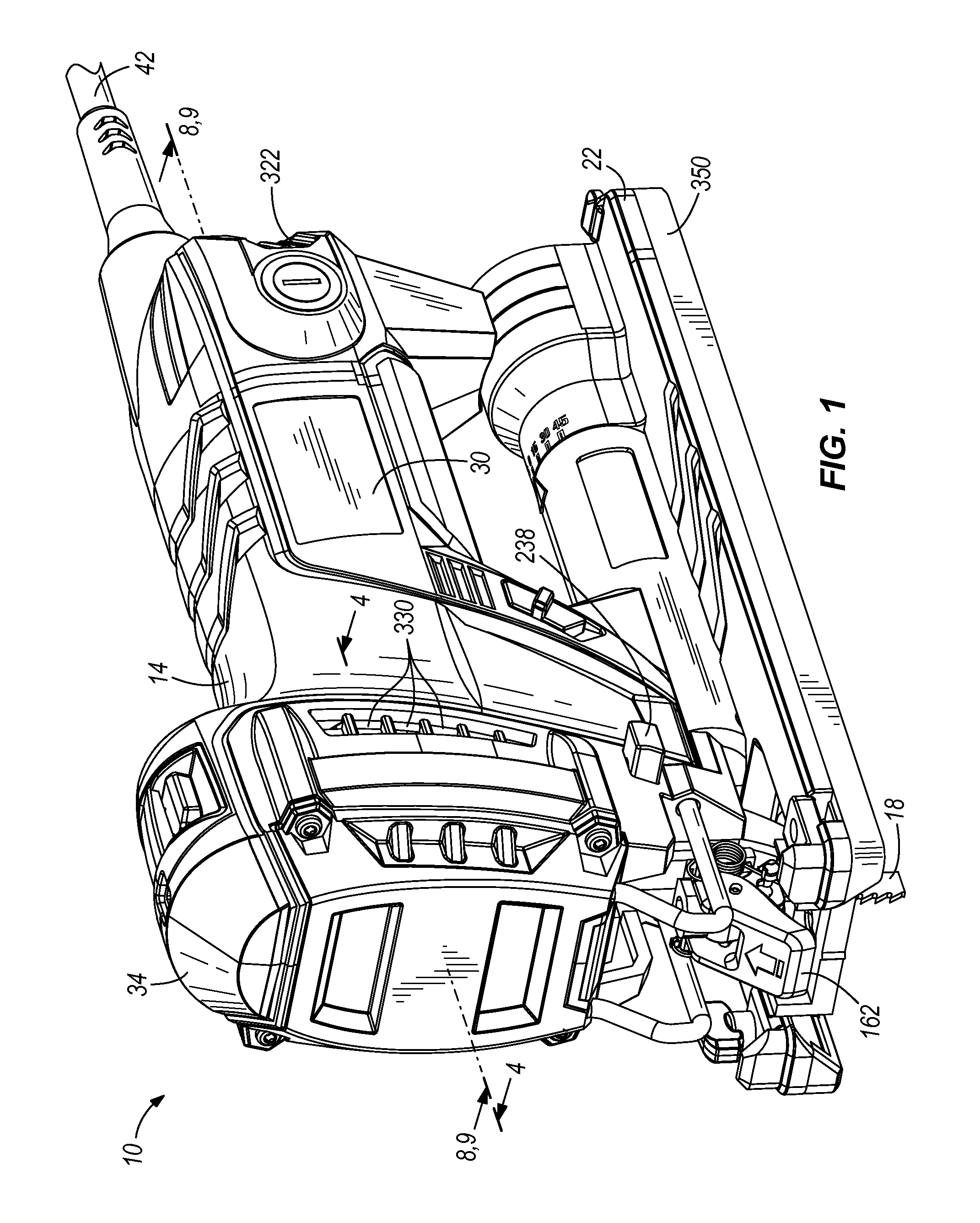

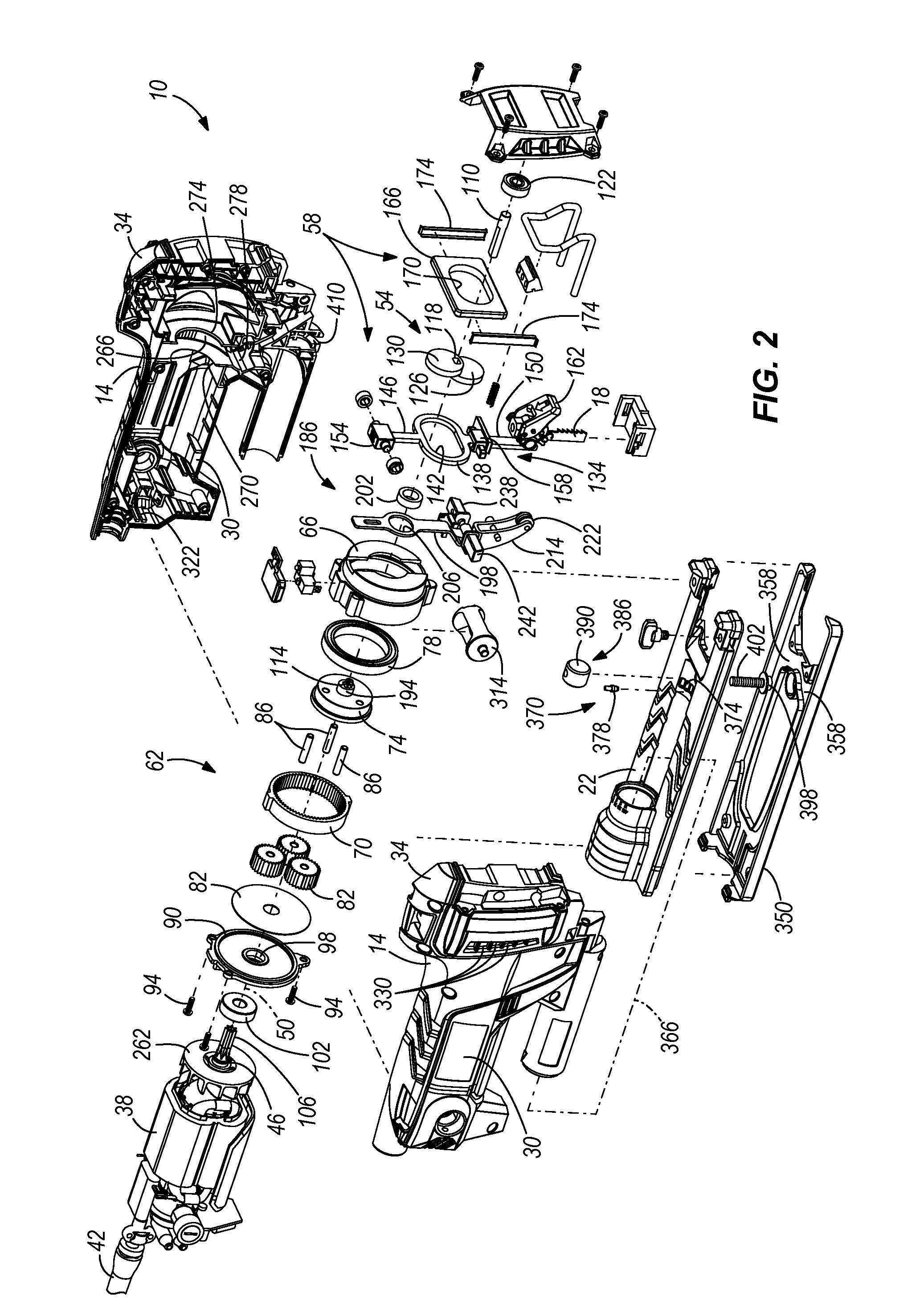

Power tool with reciprocating blade

A power tool includes a housing, a motor supported by the housing and having an output shaft, a planetary transmission coupled to the output shaft and having an output carrier, a dual-eccentric scotch yoke mechanism coupled to the output carrier and drivable by the planetary transmission in response to rotation of the output shaft, and a blade coupled to the dual-eccentric scotch yoke mechanism for movement in a reciprocating manner.

Owner:TECHTRONIC POWER TOOLS TECHNOLOGY LTD

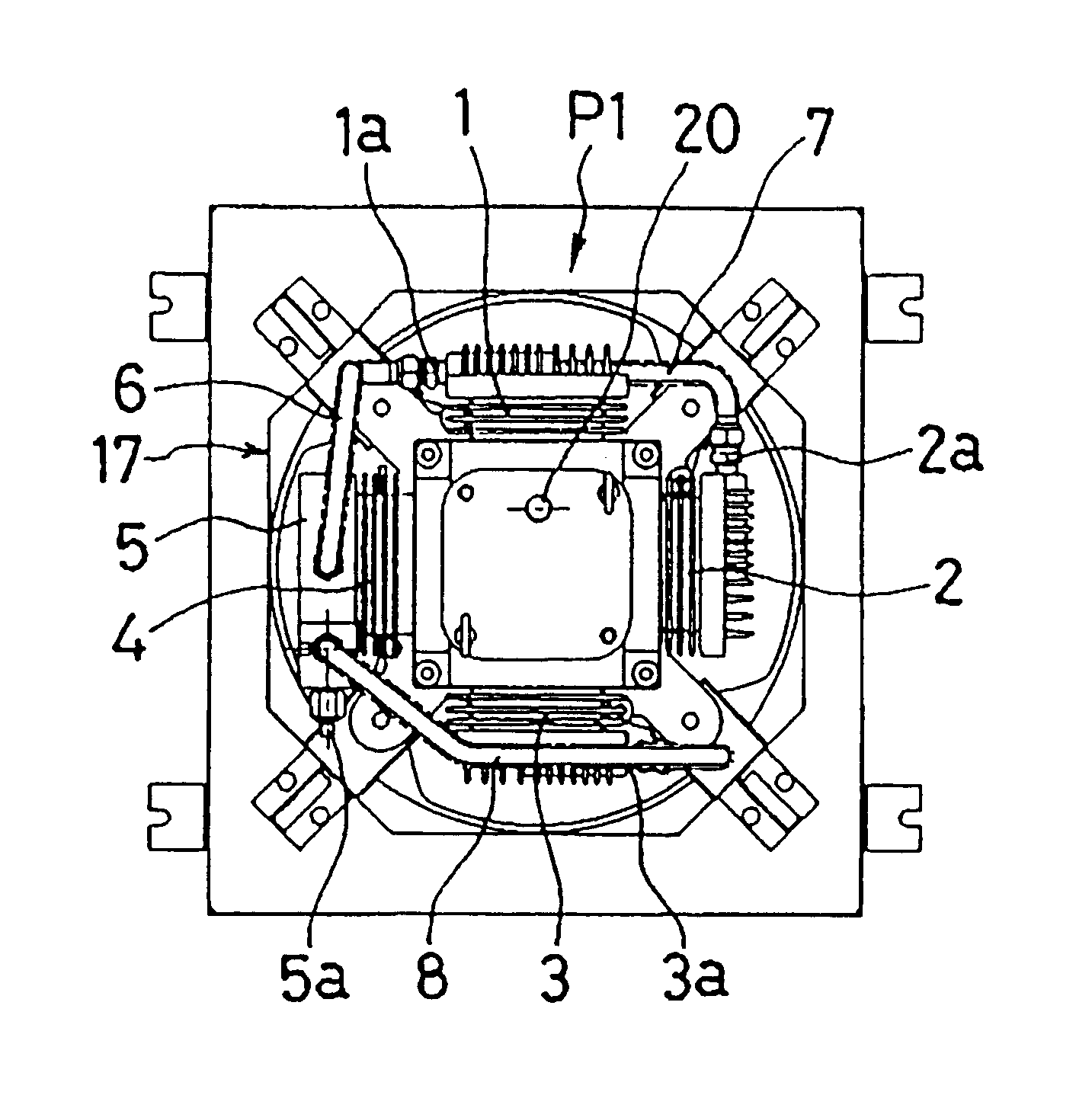

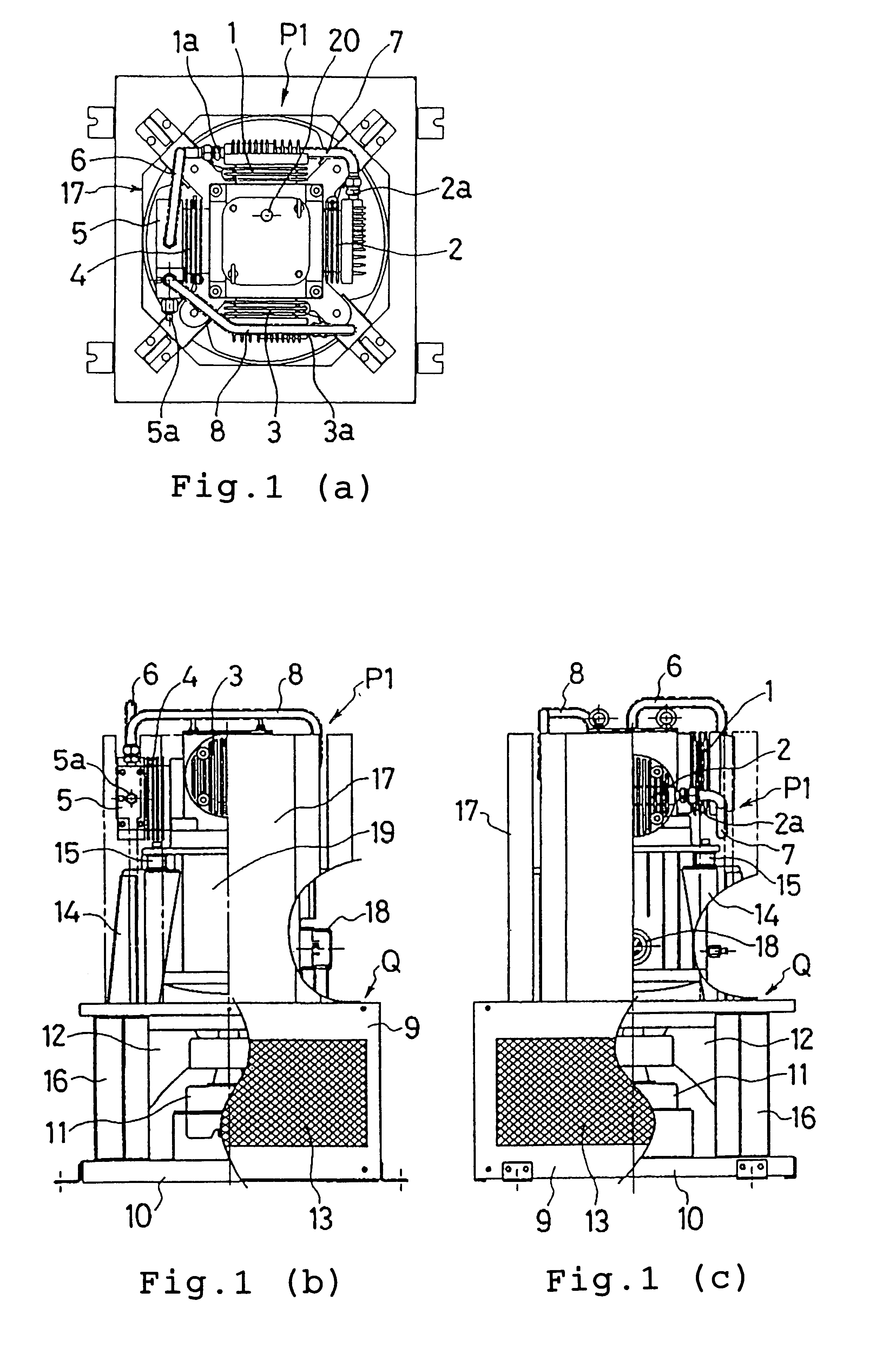

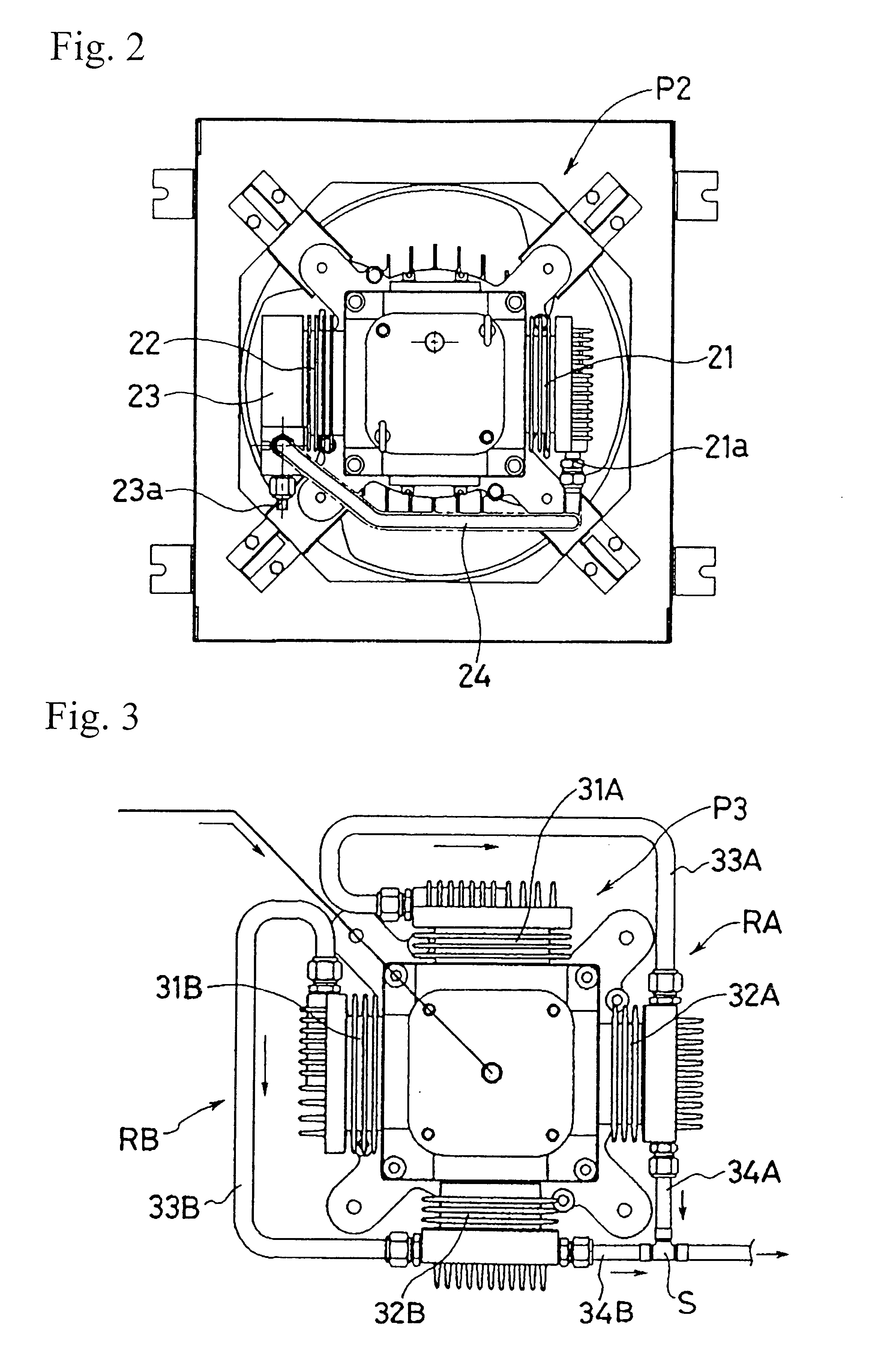

Reciprocating compressor

InactiveUS6589024B2Reduce pulsationImprove discharge capacityPositive displacement pump componentsMulti-stage pumpsElectricityCylinder head

A reciprocating compressor provided with a plurality of gas compression means having a cylinder and a piston, the piston of each gas compression means is cooperated with the, compressor by converting a rotating motion of a crankshaft provided on an electric drive source to a reciprocating motion by a scotch yoke mechanism, wherein an increase of the volume of discharged gas can be achieved without designing a gas compression means to be wide or without increasing the number thereof, a pulsation of discharged gas can be decreased by an attachment of an expression muffler on the cylinder head so as to decrease a vibration and noise of the compressor, an attachment of the fly wheel to the crankshaft and an adjustment of the shaft with the crankshaft can be improved easily, further compressed gas flows are joined and discharged in concentration, thereby the pulsation of discharged gas can be restrained.

Owner:SANYO ELECTRIC CO LTD

Body pulsating method and apparatus

Owner:ELECTROMED INC

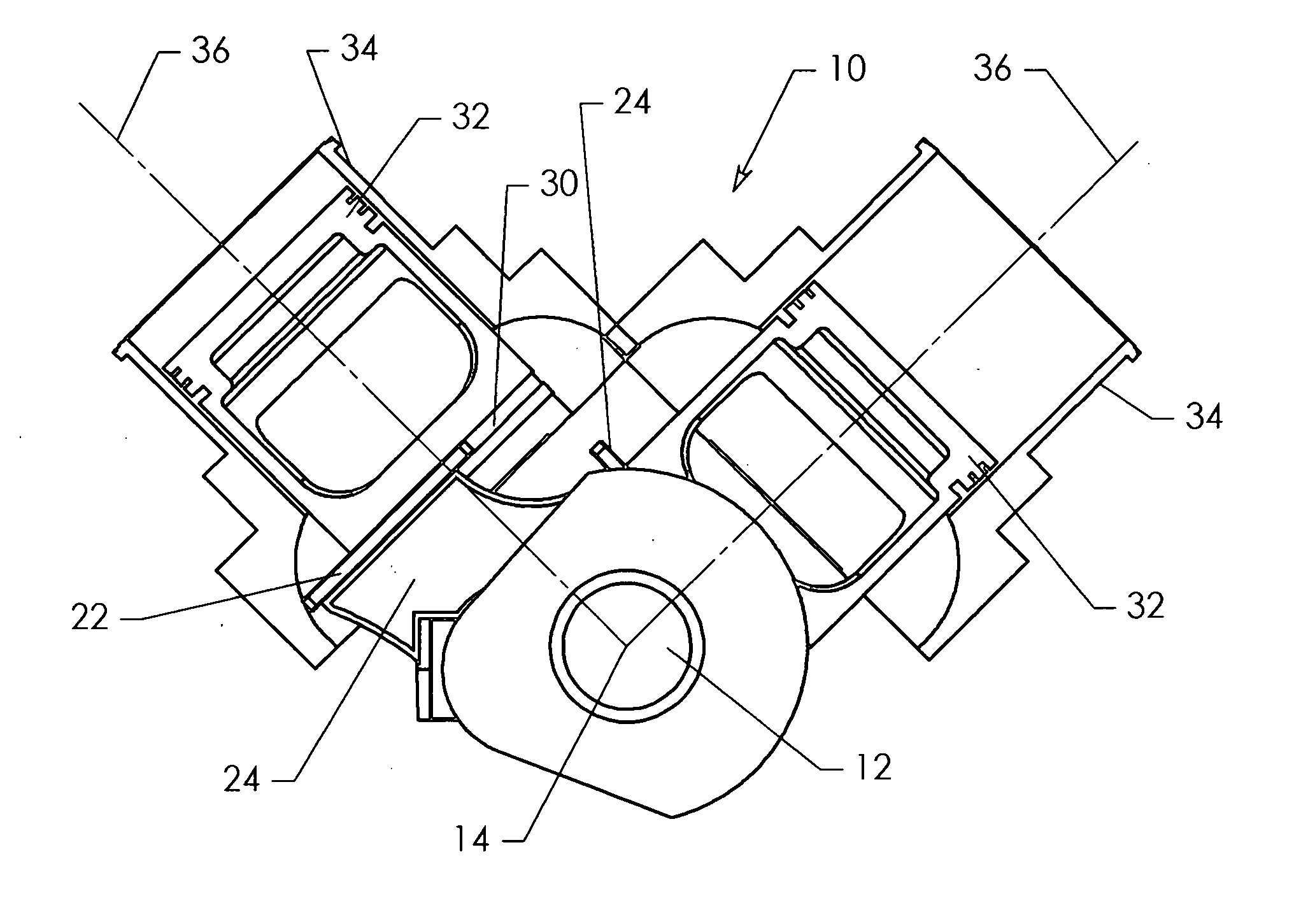

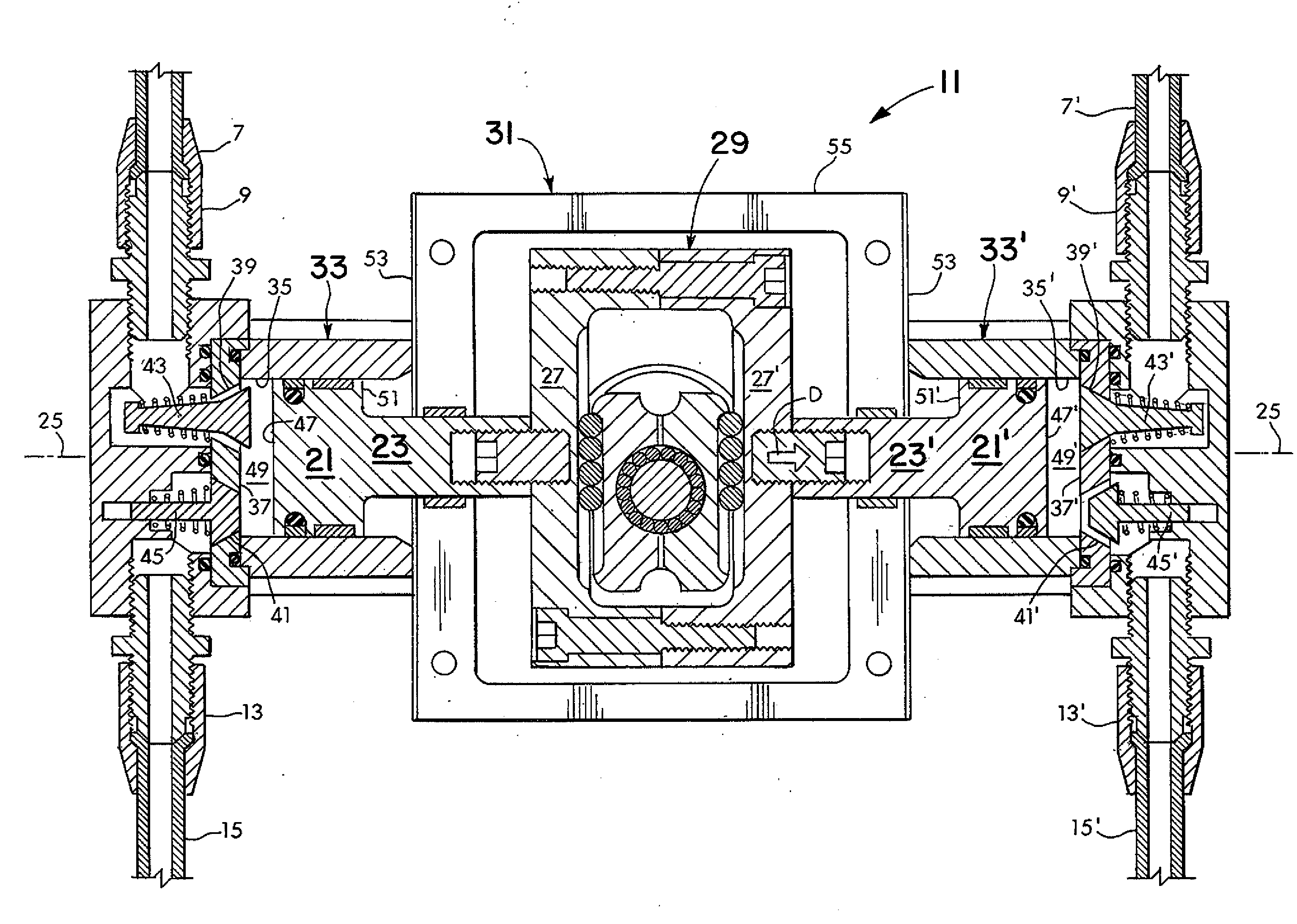

Flat yoke valve actuator

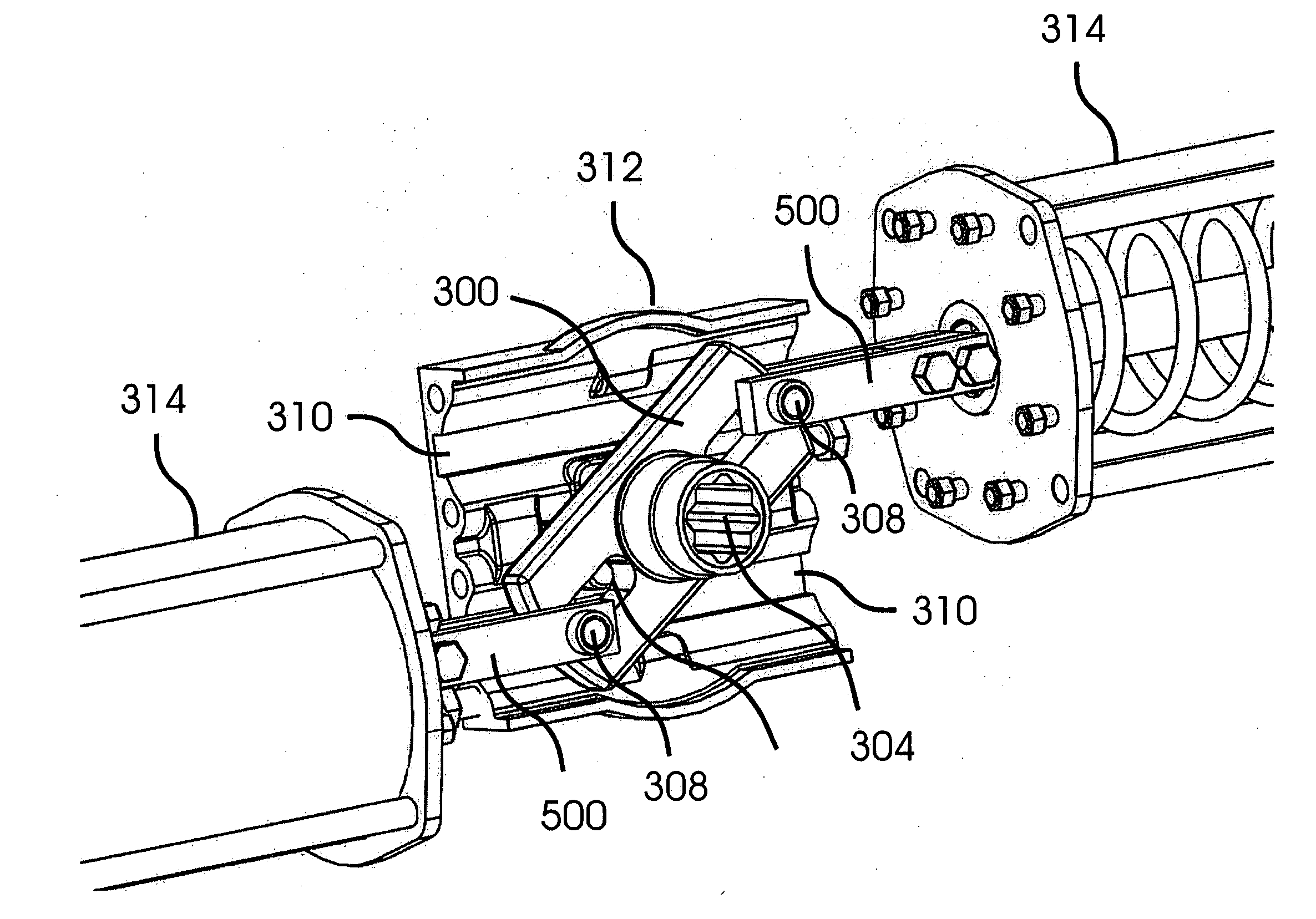

ActiveUS20080202263A1Balance weightReduce frictionOperating means/releasing devices for valvesGearingSymmetric designValve actuator

A Scotch yoke actuator is disclosed with a dual yoke and a diagonally symmetric design. A pair of shafts and pushing devices apply equal, opposing forces to the yoke, causing end loading forces applied to a rotatable shaft attached to the center of the yoke to be cancelled. In embodiments, the weight of the pushing devices is balanced about the yoke, each shaft extends in only one direction from the yoke, and / or the shafts are supported only by the yoke and the pushing devices. In embodiments that use yoke pins, the yoke pins include rollers or bearings to reduce friction, and / or two pair of yoke pin slots support protruding ends of the yoke pins. The yoke pin slots can extend to edges of a yoke housing face, allowing easy shaft removal and reinstallation, and each shaft can include a split end with extensions on opposing sides of the yoke.

Owner:HOLTGRAVER EDWARD GEORGE

Motor

A push-push type fluid pressure actuated motor has one or more radial opposed cylinder sets each having a pair of pistons, a connecting rod, and a Scotch-yoke connection to a crankshaft. An intake rotor valve at one face of the cylinder block and an exhaust rotor valve at an opposite face of the cylinder block are mounted on and rotate with the crankshaft. The rotor valves admit pressurized fluid to the cylinder and allow discharge of spent fluid from the cylinders.

Owner:POWERVERDE

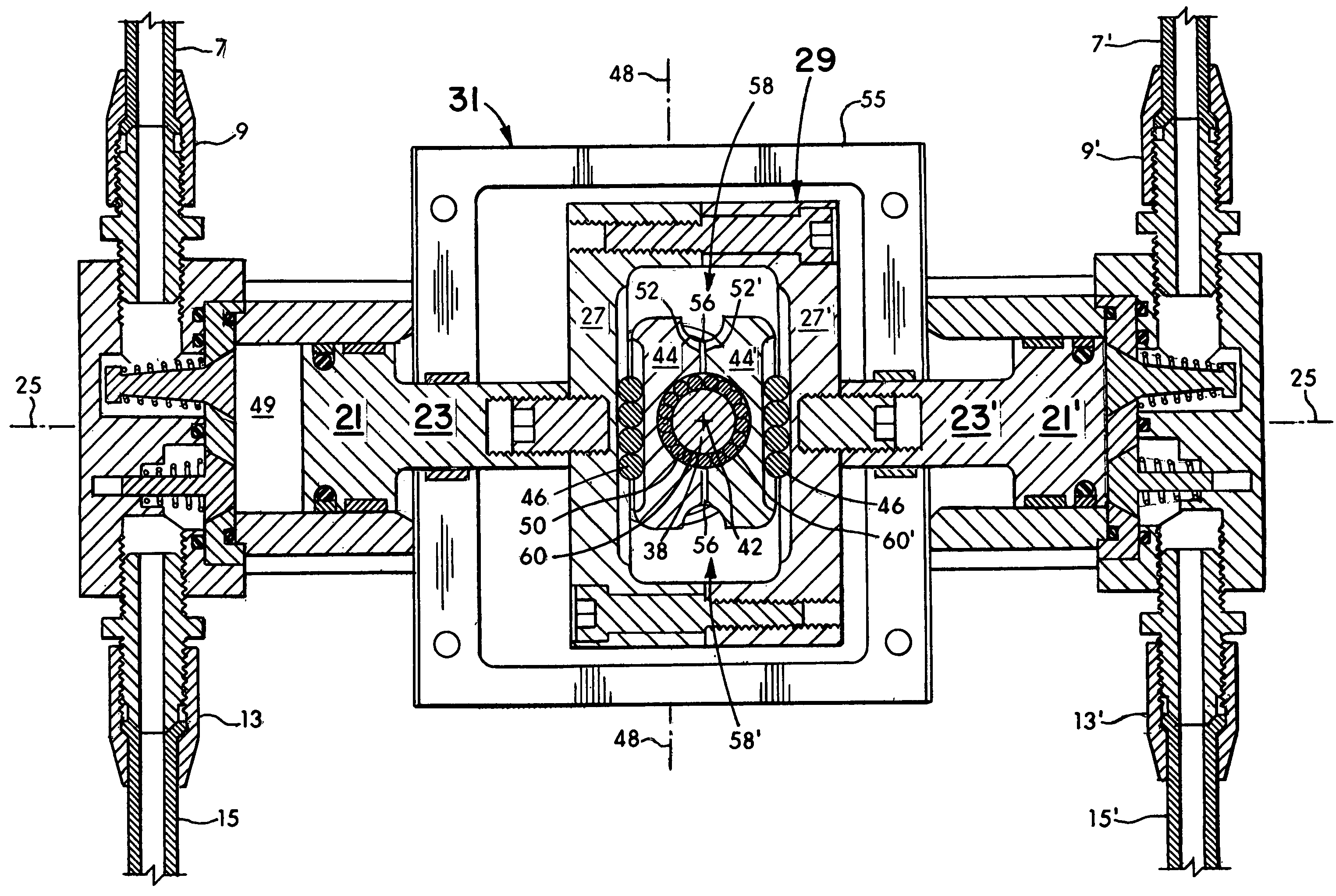

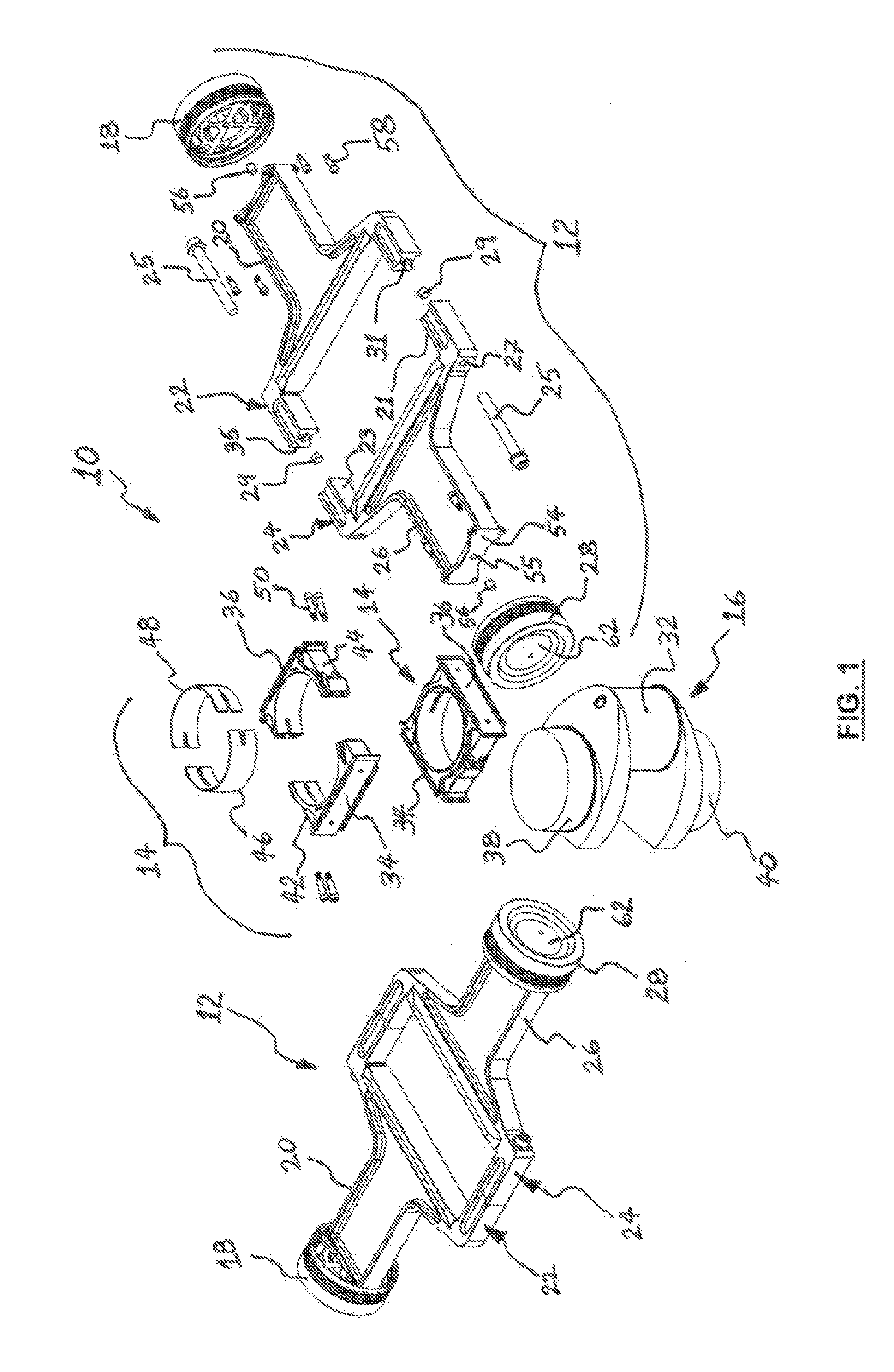

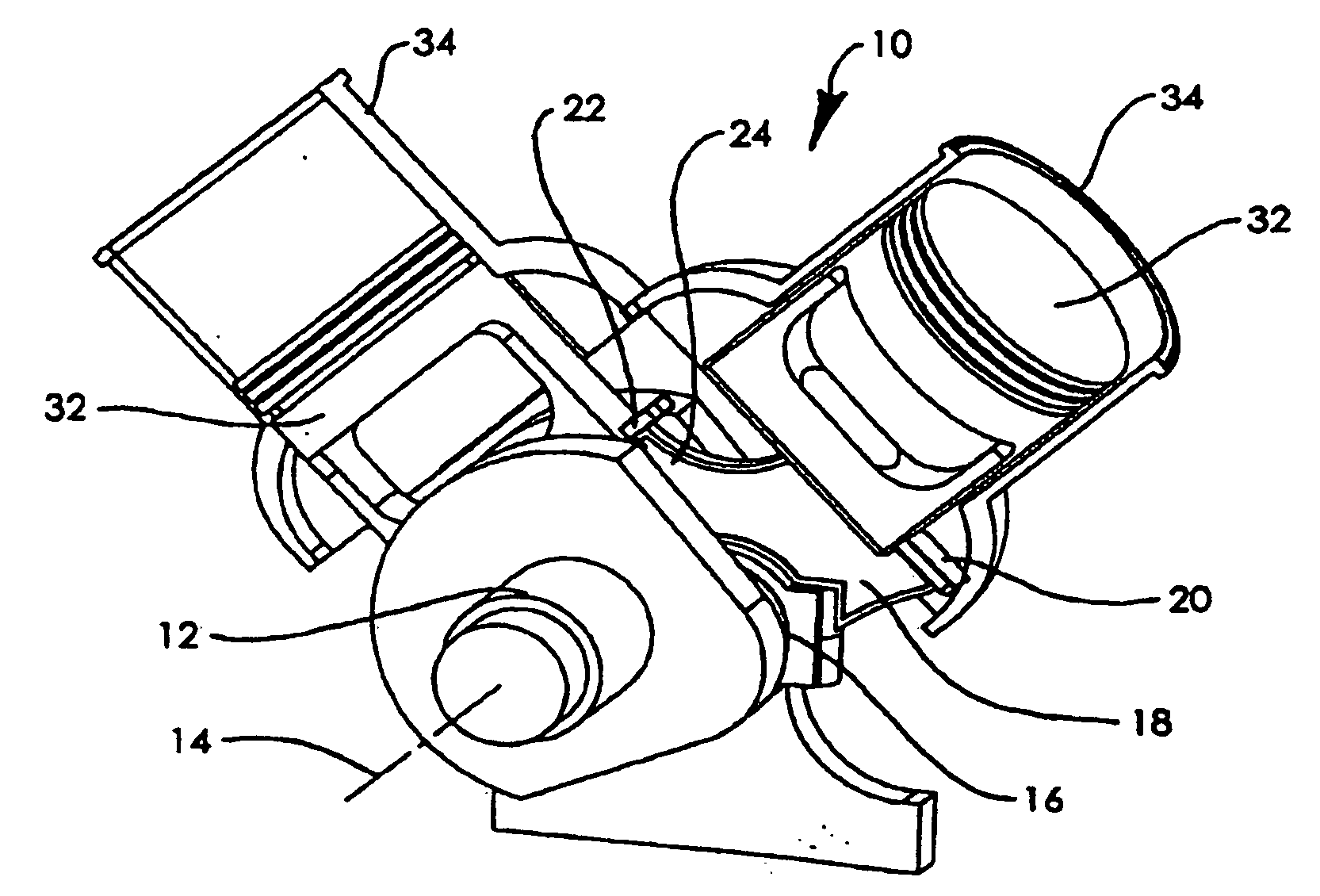

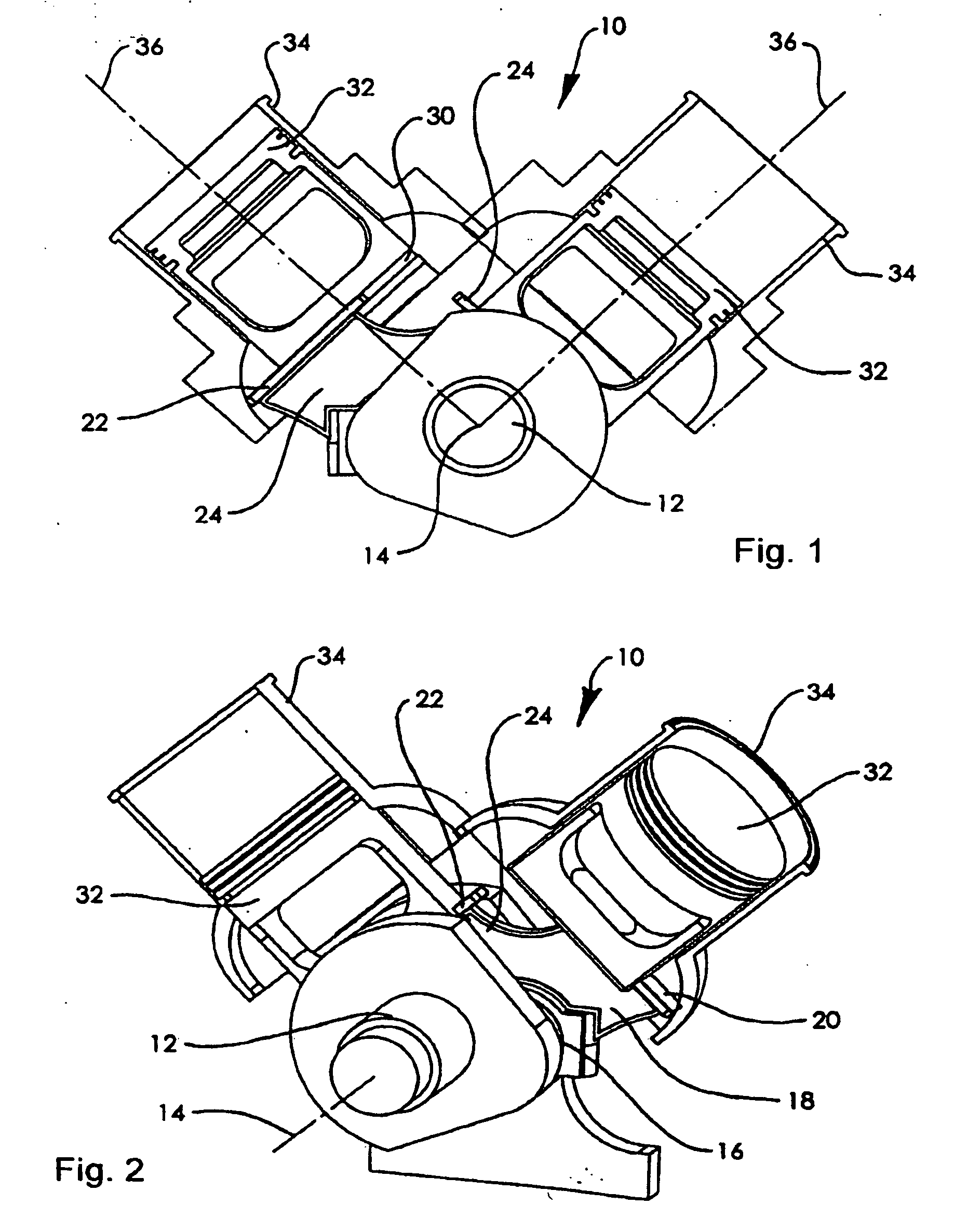

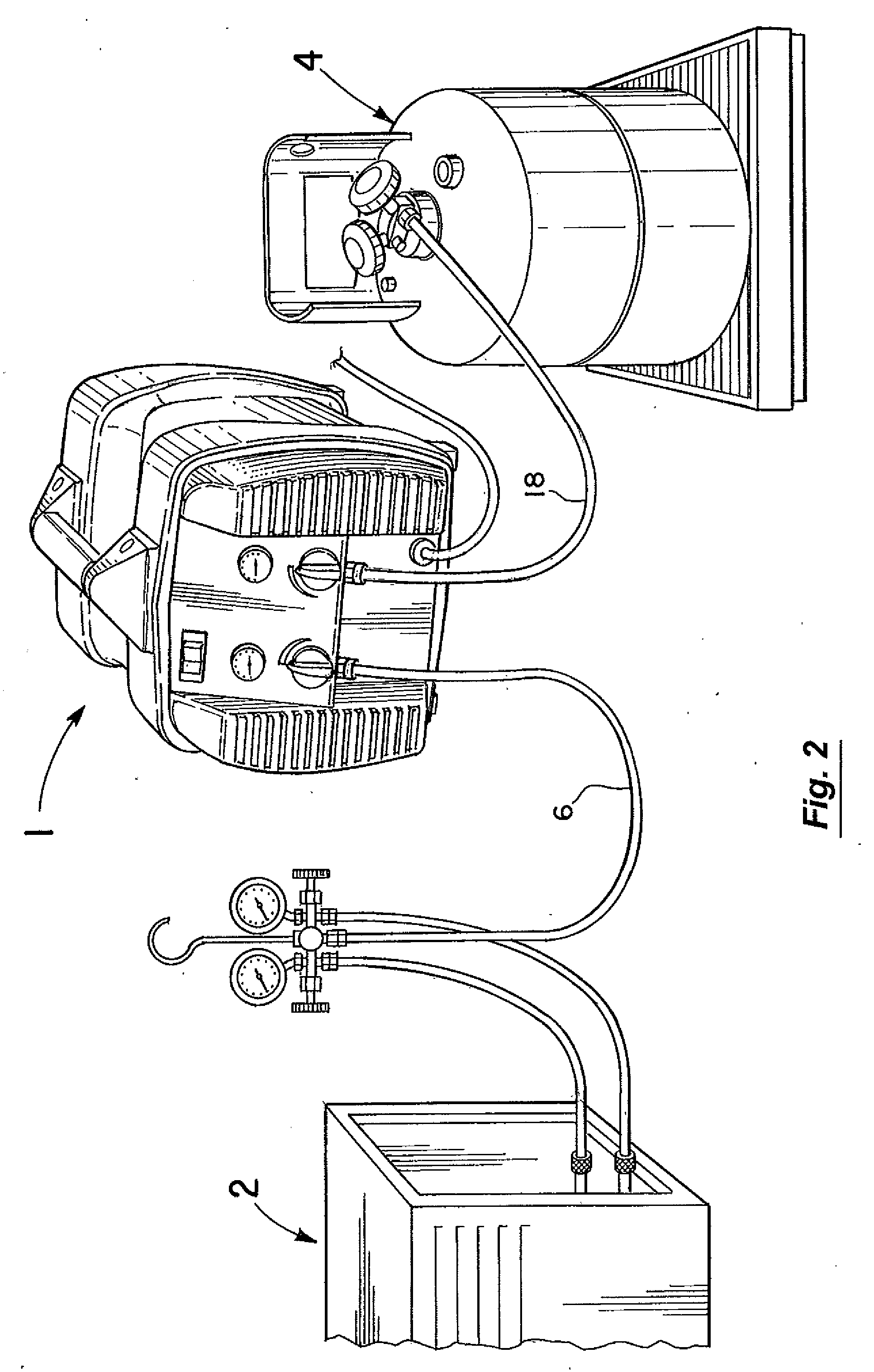

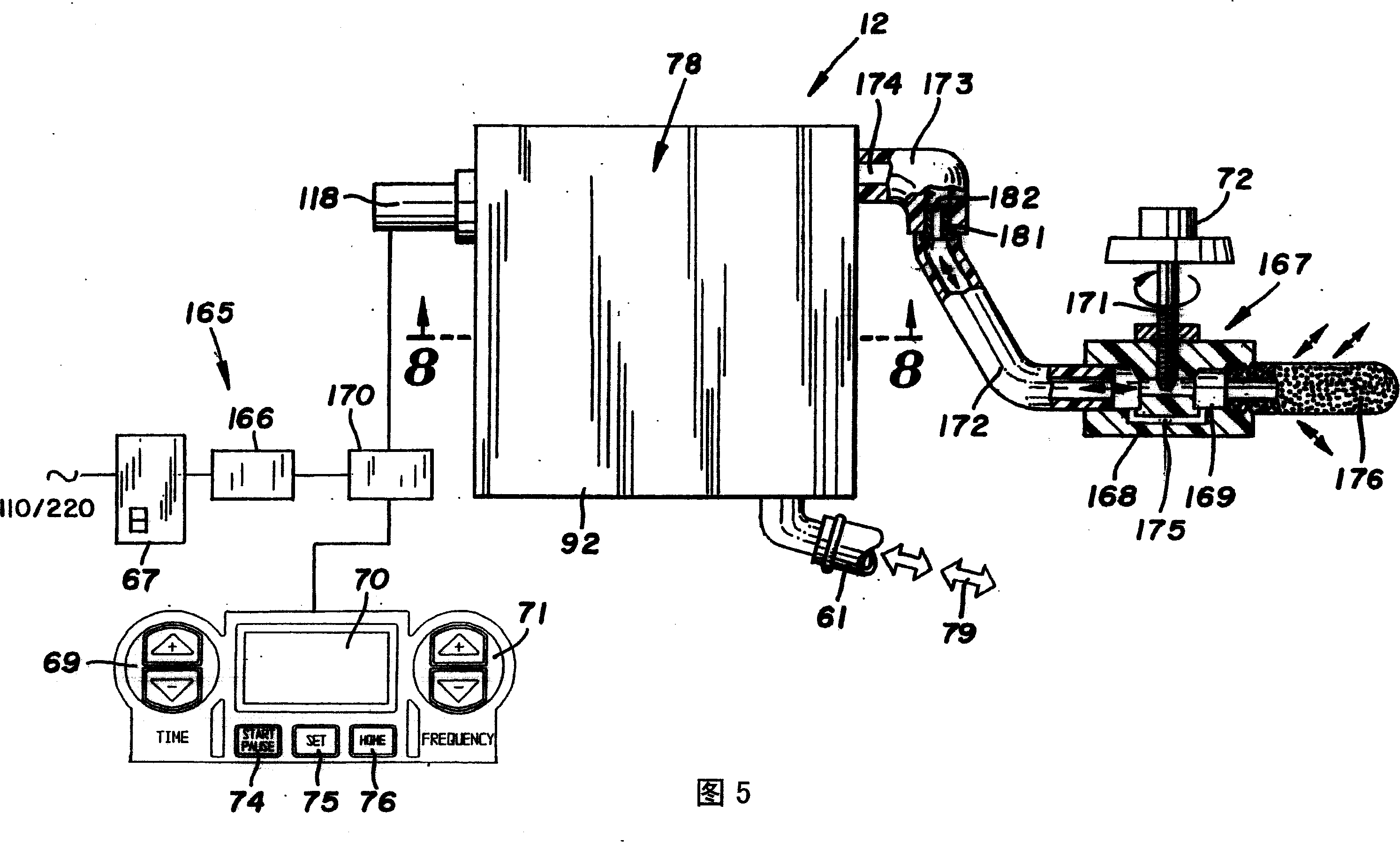

Portable, refrigerant recovery unit

A portable, refrigerant recovery unit for transferring refrigerant from a refrigeration system to a storage tank. The recovery unit includes two, opposed piston heads rigidly attached to respective piston rods that extend along a common fixed axis. The piston rods are rigidly attached to the yoke member of a scotch yoke arrangement. In operation, incoming refrigerant from the system is simultaneously and continuously directed to the opposing piston heads wherein the forces of the pressurized refrigerant on them counterbalance or neutralize one another. The scotch yoke arrangement includes a two-piece slide mechanism mounted about a cylindrical crank pin and a single piston embodiment is additionally disclosed.

Owner:SUNDHEIM GREGORY S

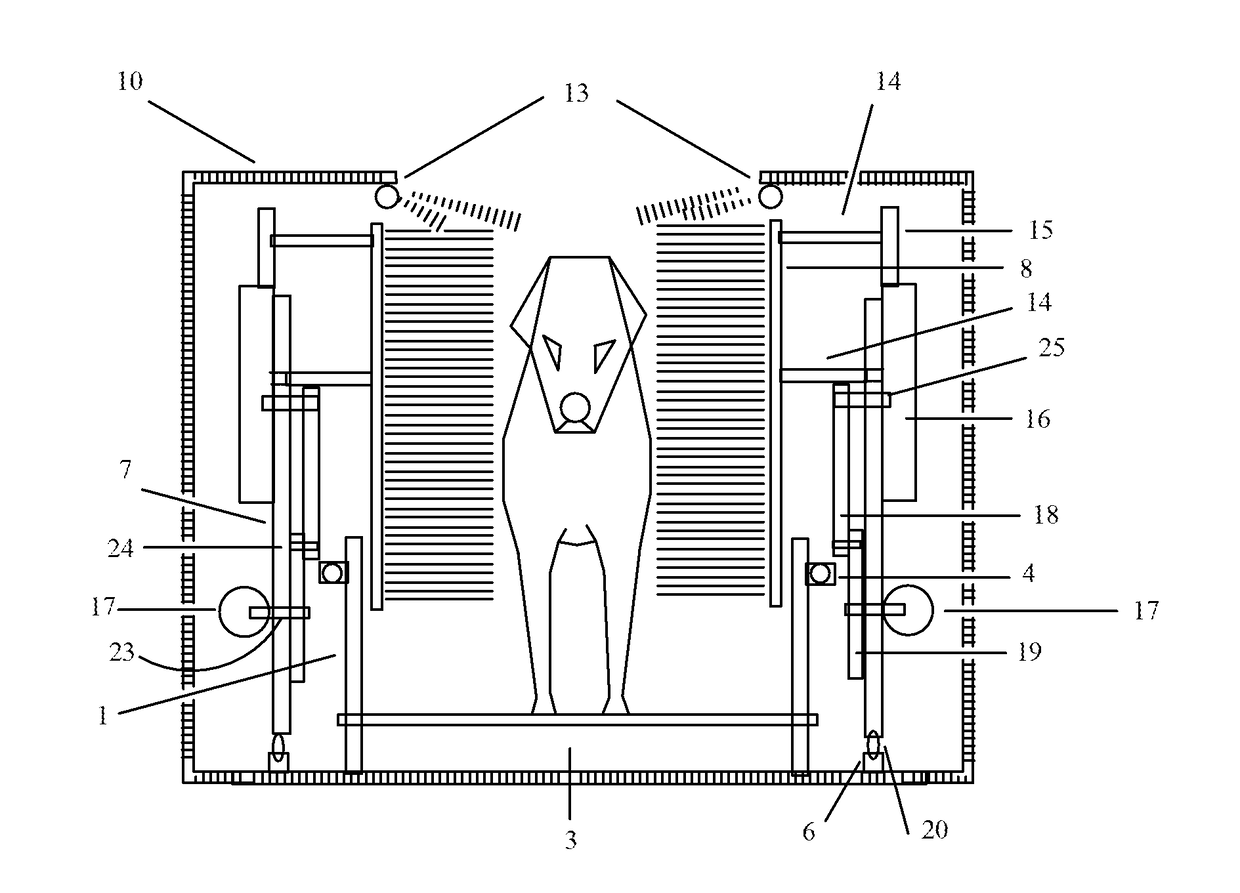

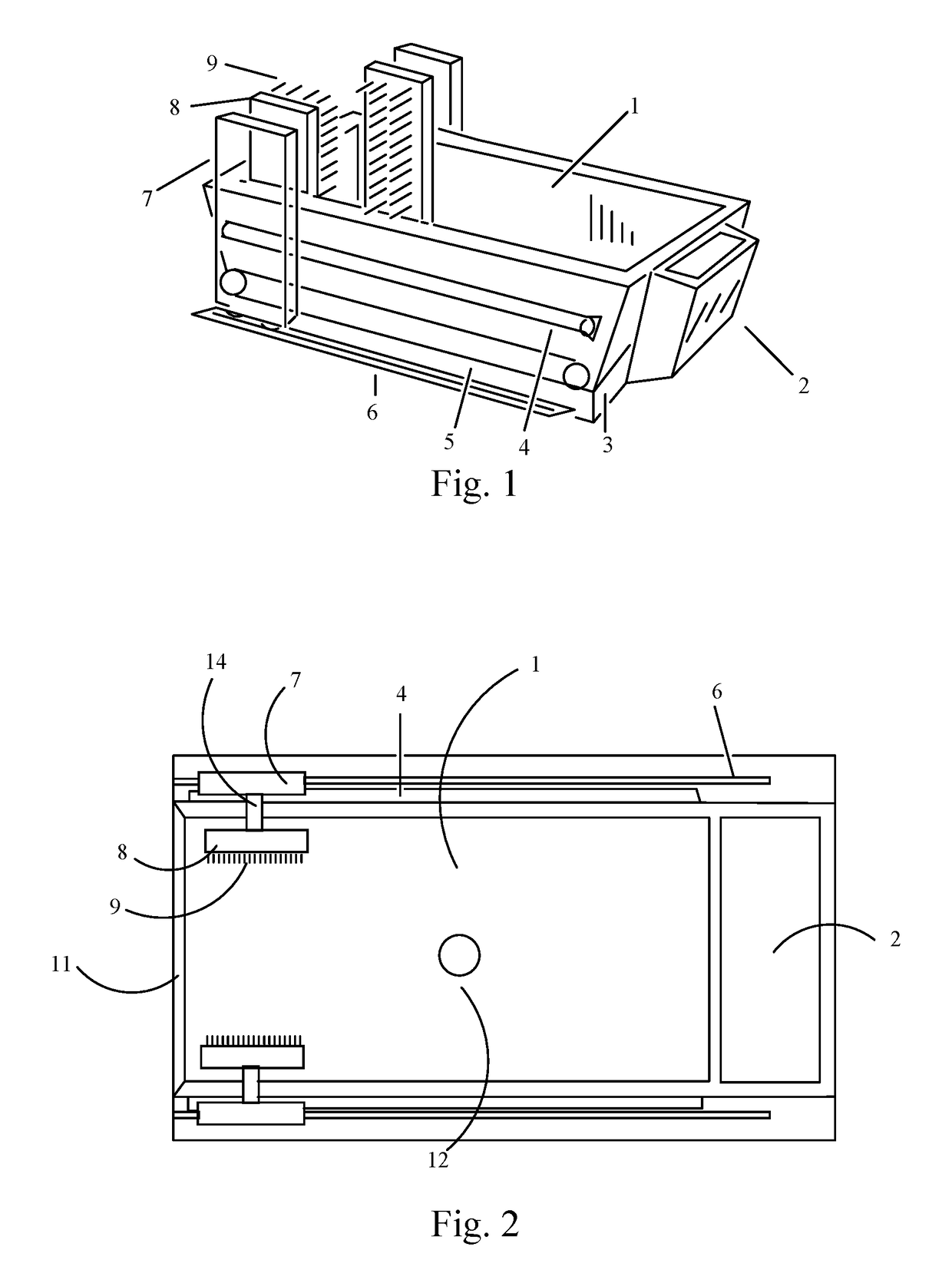

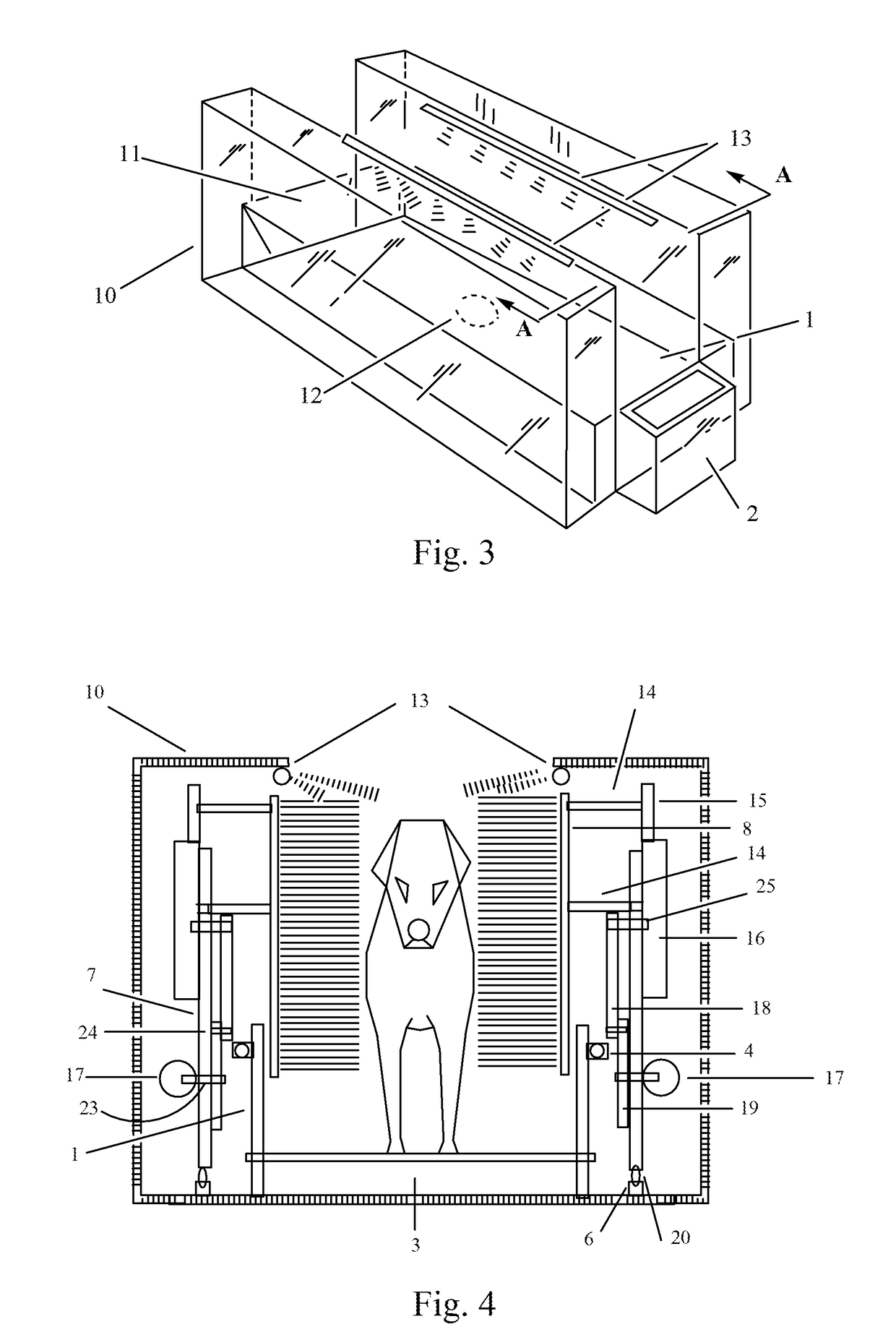

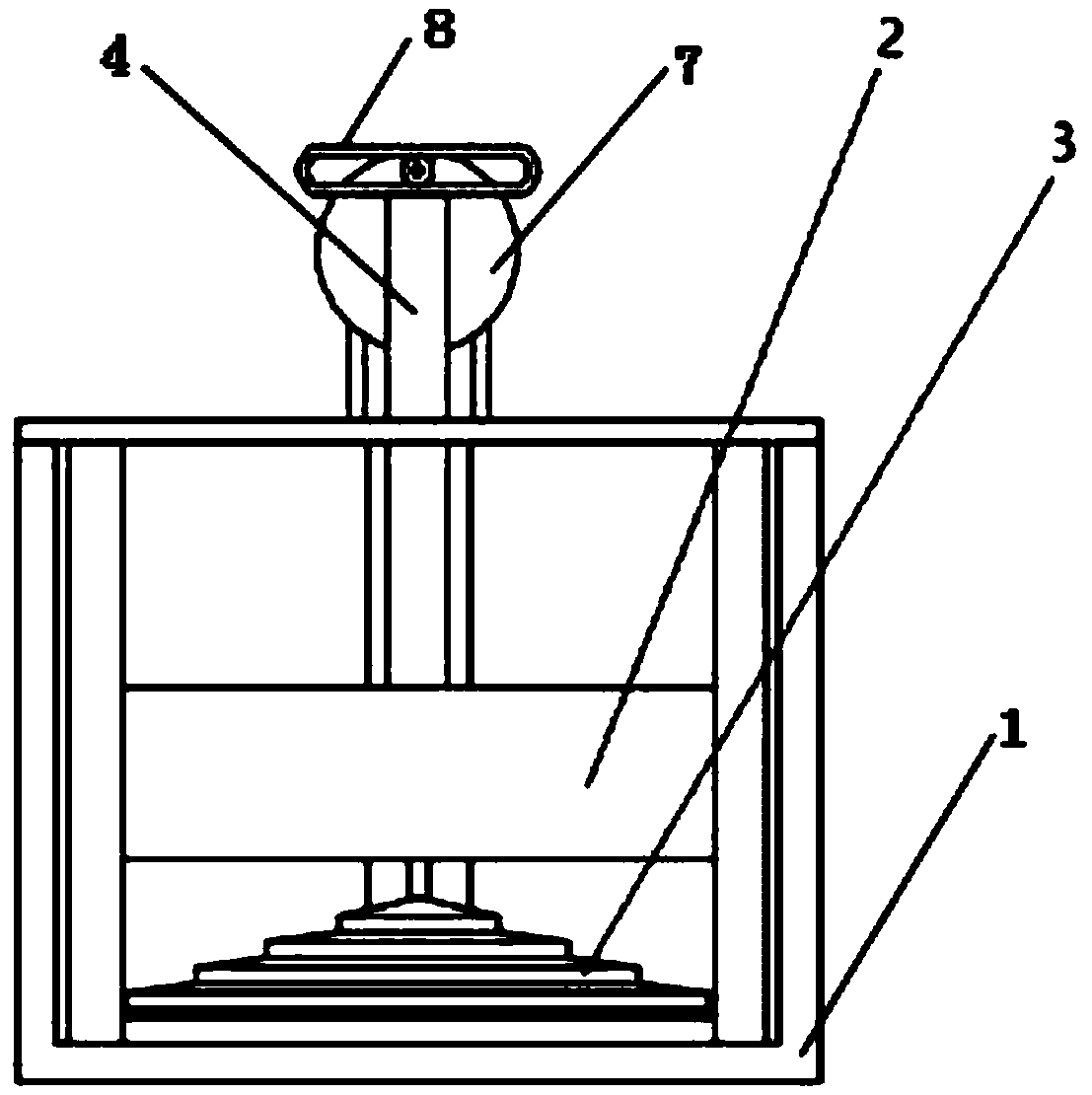

Automatic dog washing machine

An automatic washing apparatus for dogs and alike animals comprises a washing tub, a brushing plate and a horizontally moving carrier board on each side of the tub. Each brushing plate is attached to a vertically moving crank slider through horizontal extension arms. Each crank slider is motorized by a motor and situated on a carrier board. In other embodiments the brush plates are driven by other mechanical mechanisms such as Scotch Yoke, Whitworth quick return, cam slider, reciprocating gear rack or rotation to rotation mechanisms using gears or pulleys and belts. The carrier boards are mobilized through pulley and belt, and wheels on rails. The movement is guided by a guiding rail. The tub includes a door and a drain on the floor and a waste water compartment beneath the floor. The brushing plates and carrier boards are enclosed under two side covers. The apparatus further provides a water spraying system including spraying tubings, a water tank and a water pump.

Owner:ZHANG WEIJIAN

Energized Fluid Motor and Components

InactiveUS20090013681A1Good thrustHigh densityServomotor componentsRotary clutchesControl theoryCrankshaft

A motor comprising a least one piston slideable within a cylinder with a seal, a plurality of valves, means to determine the position of the valves and a head of the piston, means to select the ports in which to transfer energized fluid / exhaust in and out of the cylinder, and a scotch yoke. The cylinder comprising at least a first set of ports and a second set of ports. The ports disposed in a wall of the cylinder. The valves coupled and slideable to allow a selective transfer of an energized fluid in, and an exhaust out, of the cylinder via the ports. The scotch yoke operatively interacting with a crankshaft, the piston operatively connected to the scotch yoke such that, when the energized fluid moves the piston, torque is applied to the crankshaft, and the valves are repositioned to allow the energized fluid to enter the cylinder on the opposite side of the head of the piston and the exhaust to exit the cylinder.An apparatus comprising a motor and an engine having a first fuel supplier supplying an oxidizer and a second fuel supplier supplying a dense fuel. The engine producing power to drive a ducted fan. The apparatus optionally comprising a hydraulic system.

Owner:COURTRIGHT GEOFFREY B

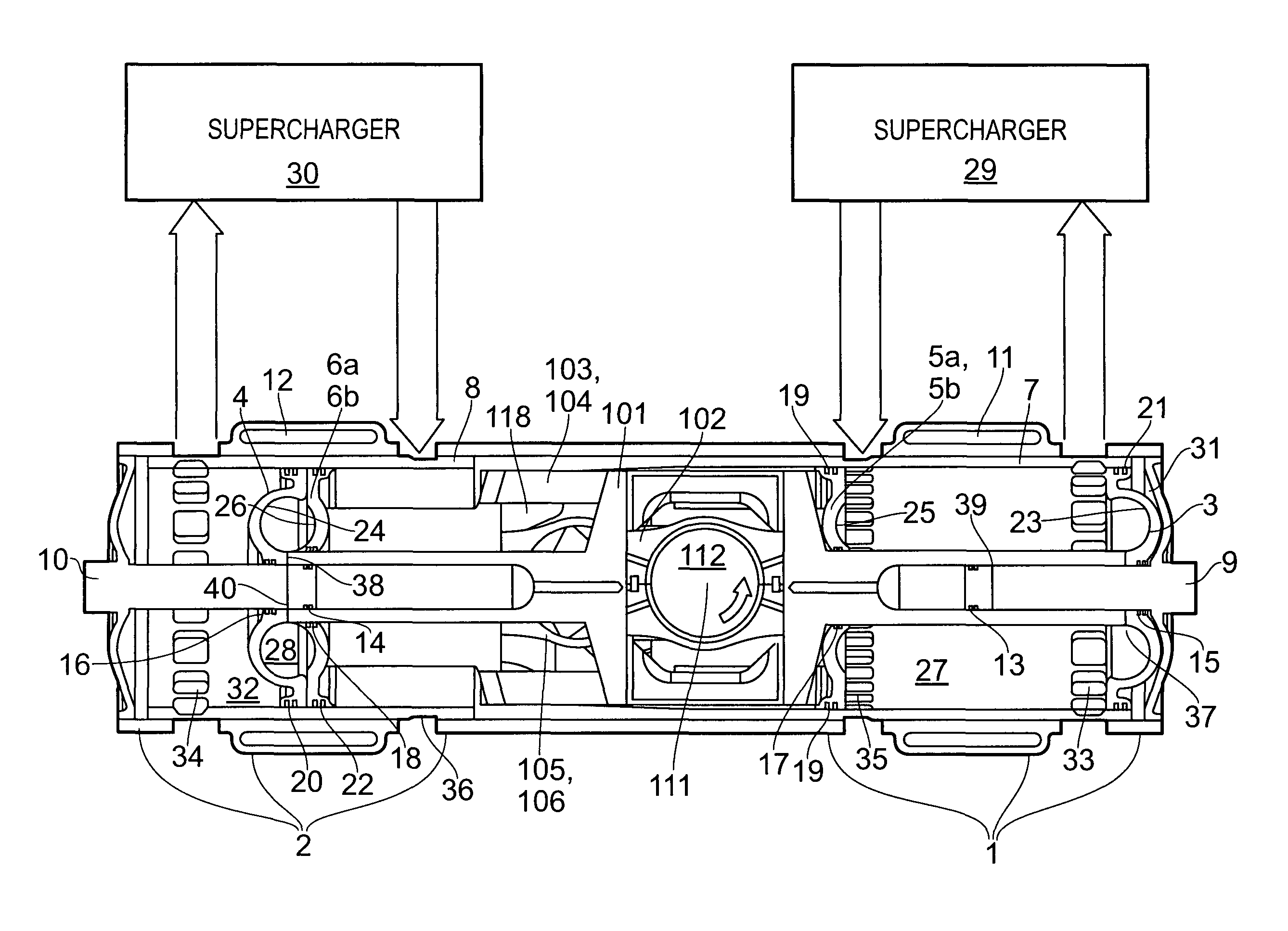

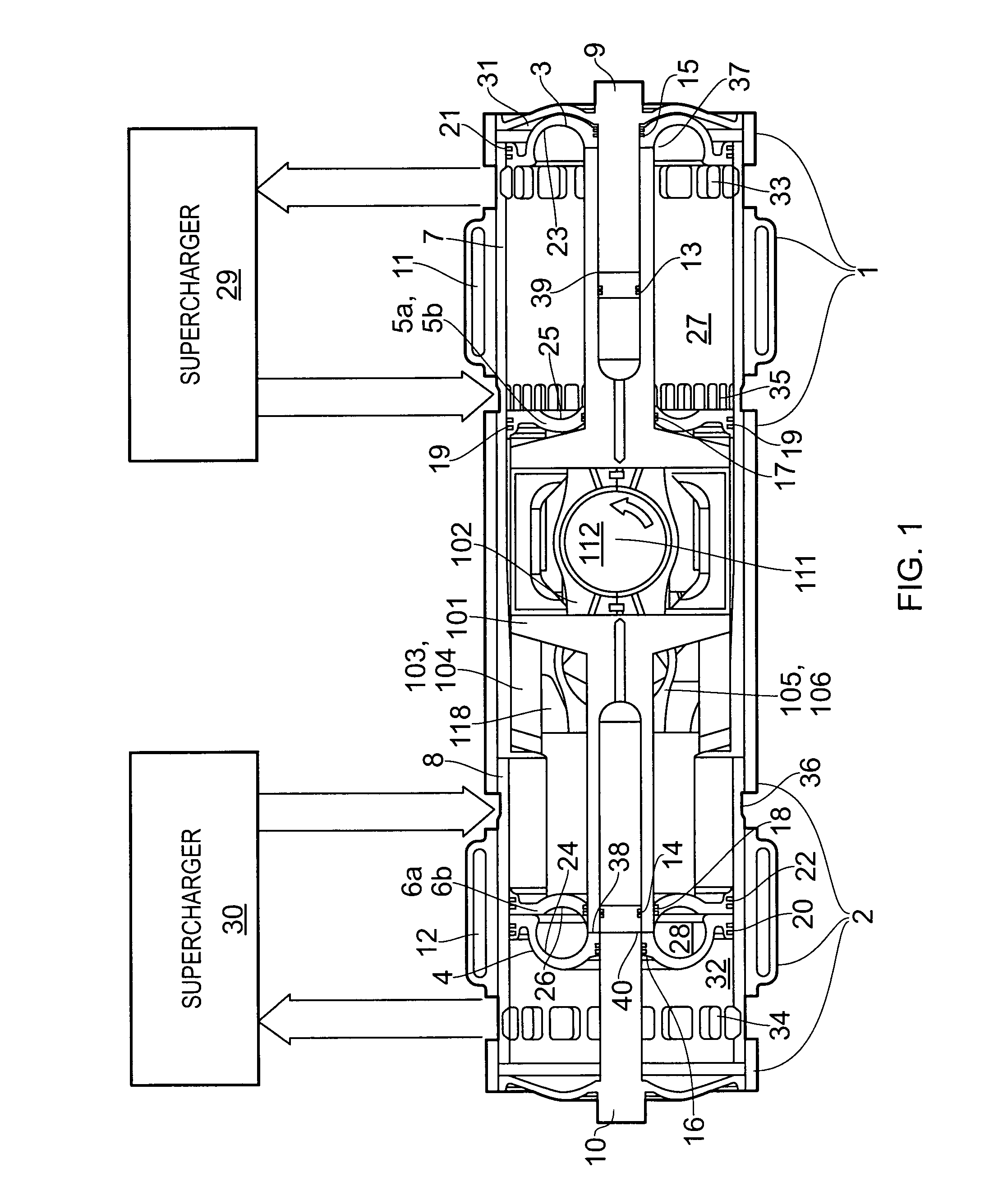

Internal combustion engines

ActiveUS8499726B2Reduce quality problemsImprove performanceConnecting rodsInternal combustion piston enginesCombustionInternal combustion engine

The invention provides a 2-stroke internal combustion engine comprising two opposed cylinders, each cylinder housing two opposed pistons and having at least one exhaust port and at least one intake port, and a crankshaft having asymmetrically arranged journals and scotch-yoke mechanisms for driving the journals from the pistons. The pistons in each cylinder operate to open its exhaust port or ports before its intake port or ports and to close its exhaust port or ports before its intake port or ports.

Owner:COX POWERTRAIN LTD

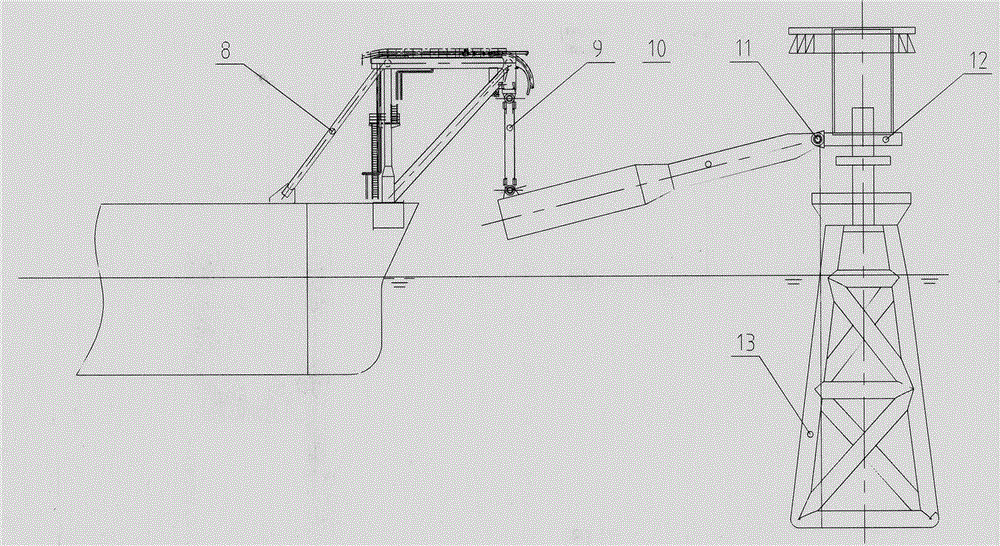

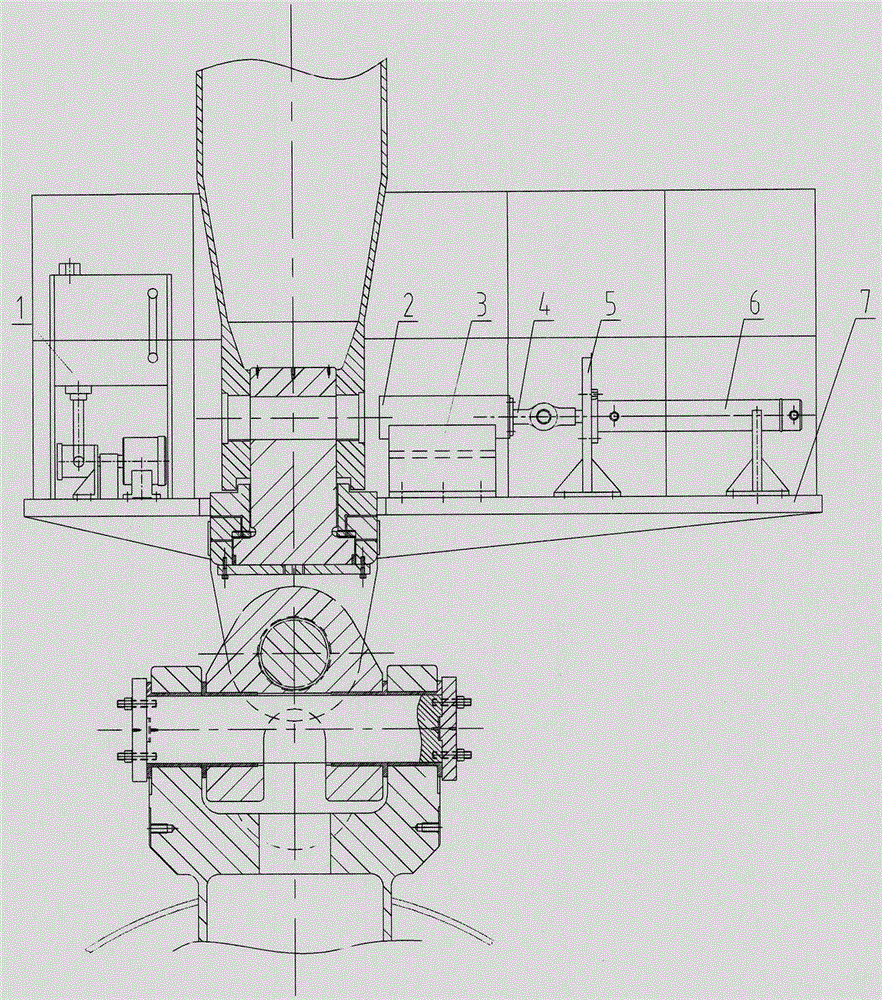

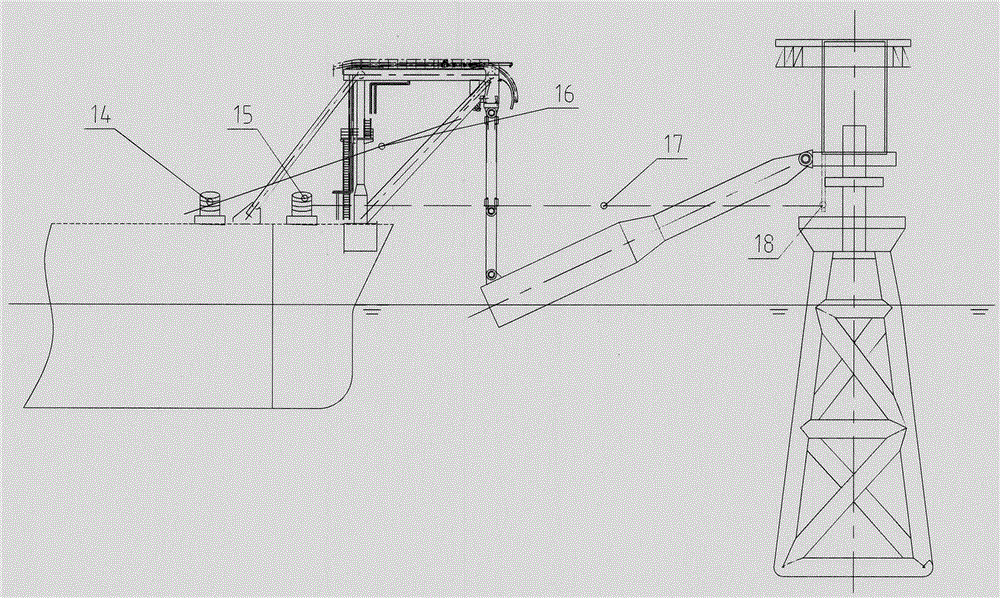

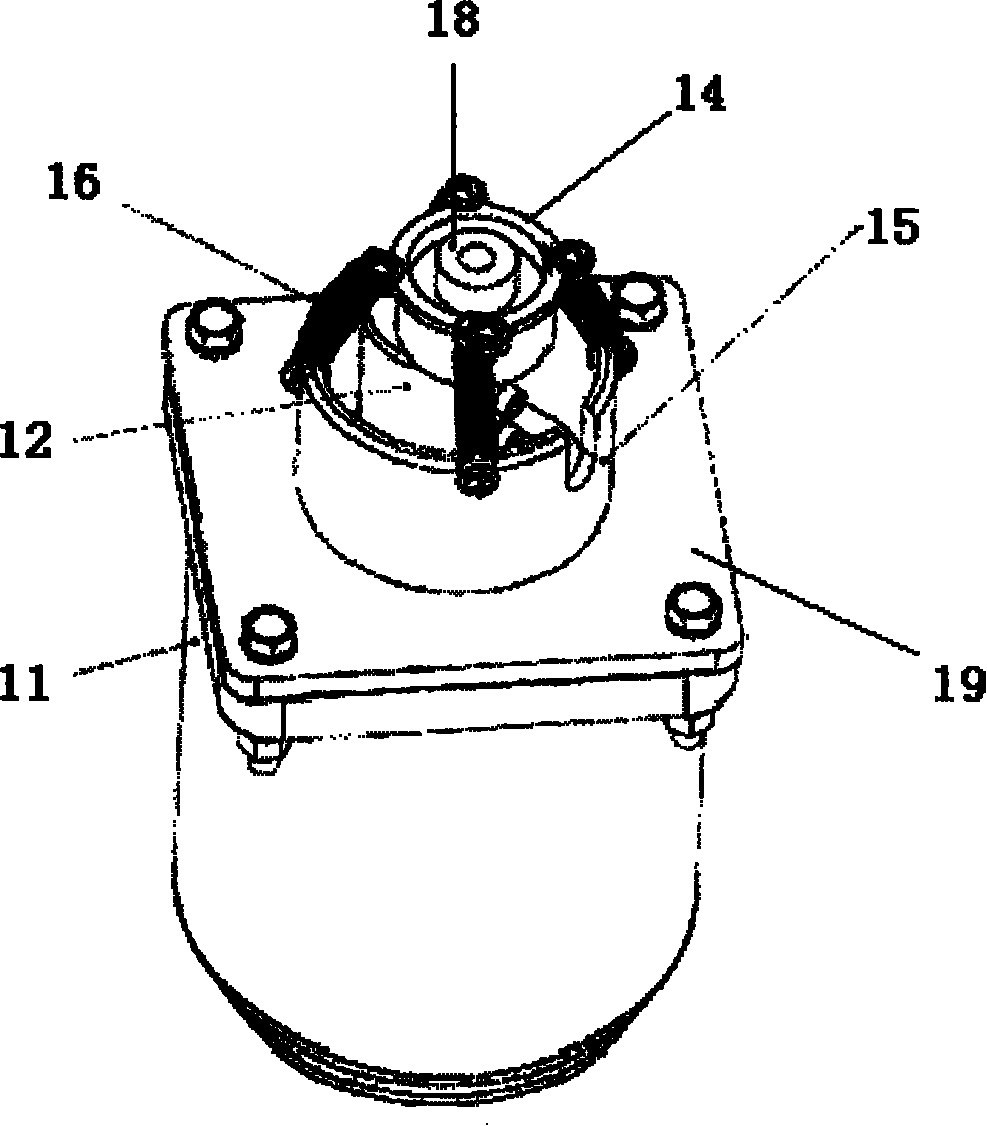

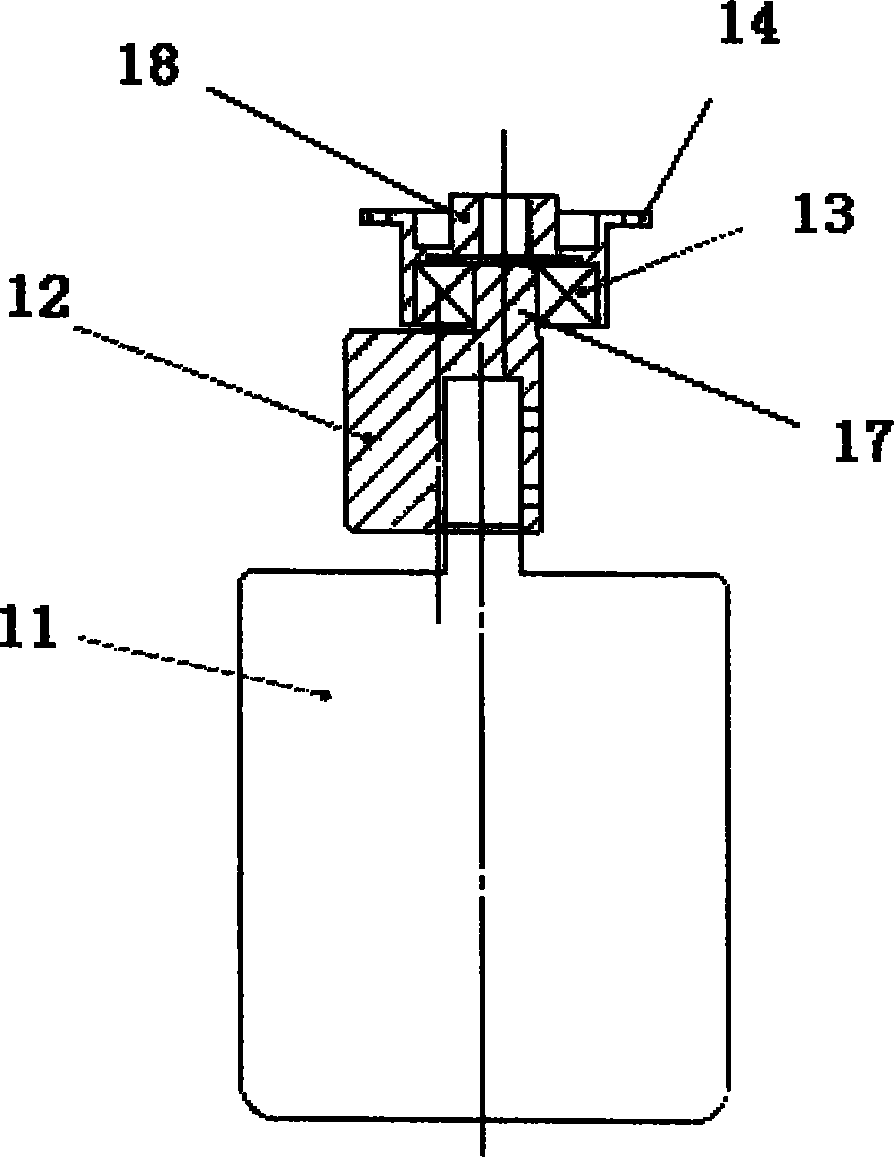

Device for quick release of soft yoke and mooring leg in single-point mooring system

ActiveCN106240744AImprove reliabilityImprove securityMooring equipmentHydraulic cylinderManufacturing cost reduction

The invention discloses a device for quick release of a soft yoke and a mooring leg in a single-point mooring system and relates to the technical field of single-point mooring. A hydraulic pump station is adopted to pull a guide pin shaft to move, so that quick release of the soft yoke and the mooring leg in the single-point mooring system is achieved. The device comprises a hydraulic pump station, a guide base, a guide pin shaft, a lug ring head, an installation support, a hydraulic cylinder and a support platform. In the action of quick release, the hydraulic pump station provides a power source to drive the hydraulic cylinder to move, the hydraulic cylinder is assembled on the installation support, the lug ring head is connected with the guide pin shaft and a piston rod of the hydraulic cylinder, and the guide pin shaft, the guide base and the hydraulic cylinder are coaxially installed; in this way, borne friction force is reduced during pulling of the guide pin shaft, time for pulling out of the pin shaft is shortened, and quick release of the soft yoke and the mooring leg in the single-point mooring system is achieved. The device is simple in structure and ingenious in concept; the reliability and safety of the single-point mooring system are improved; meanwhile, production is easy, assembly and replacement are convenient, and manufacturing cost can be reduced greatly.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND +1

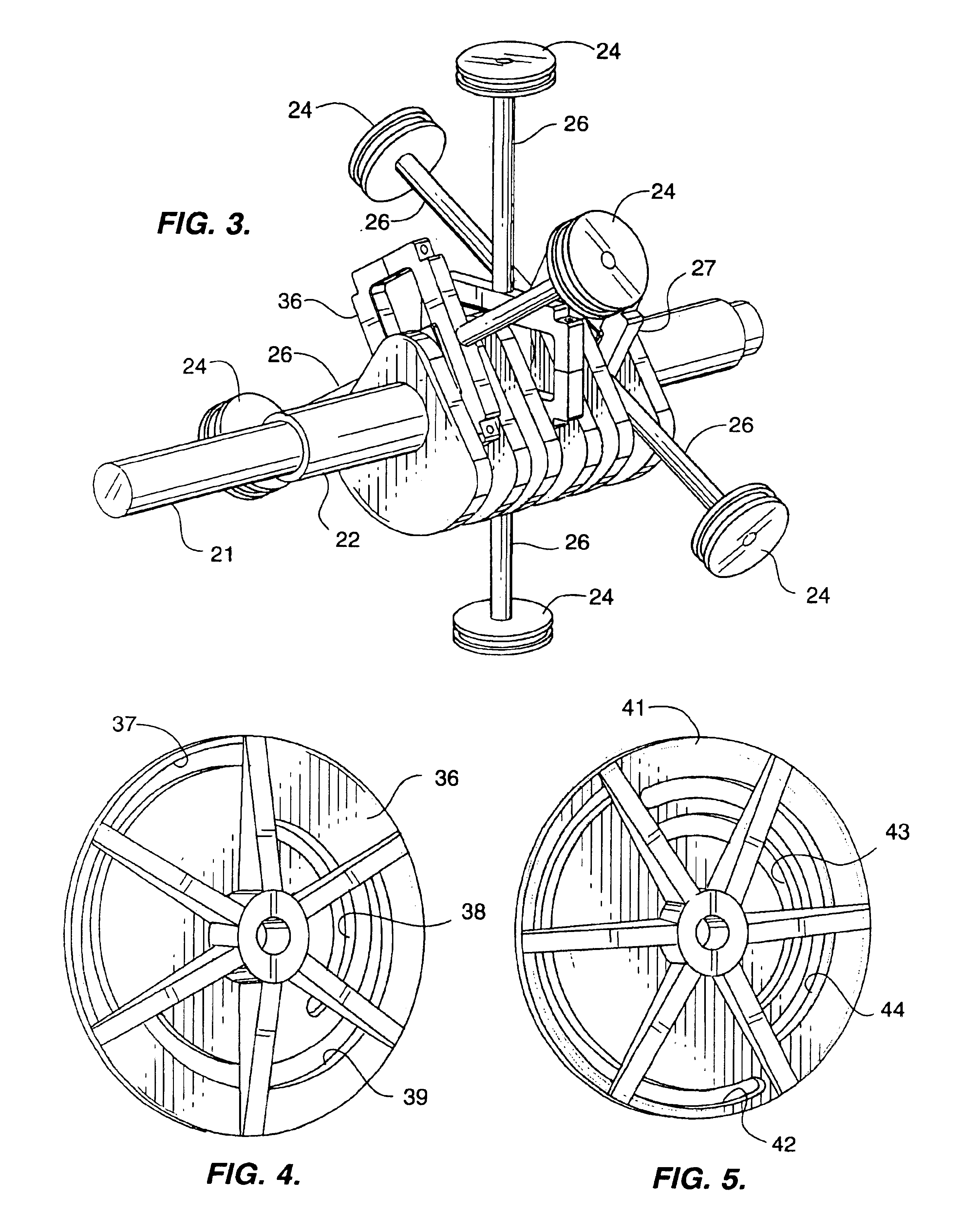

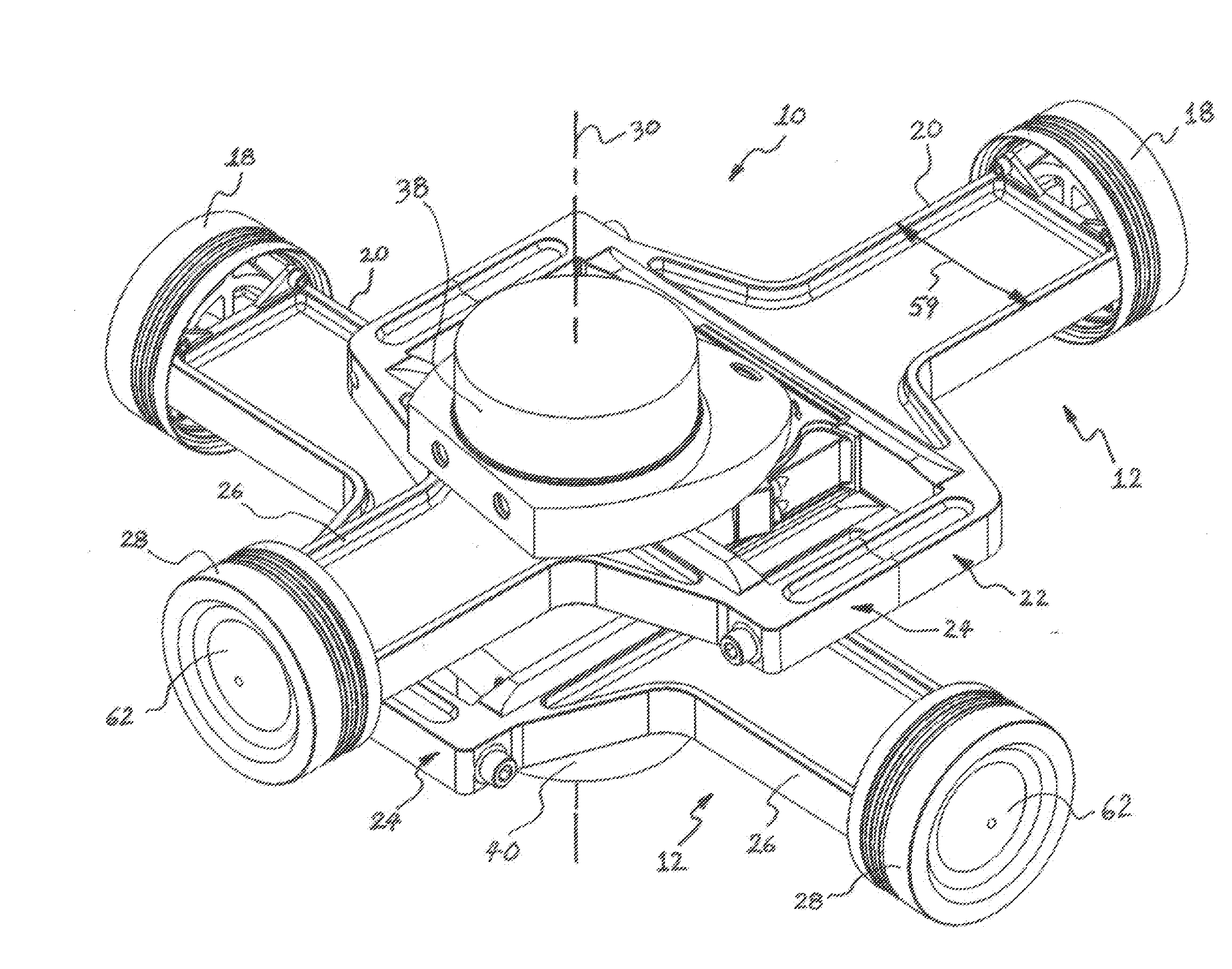

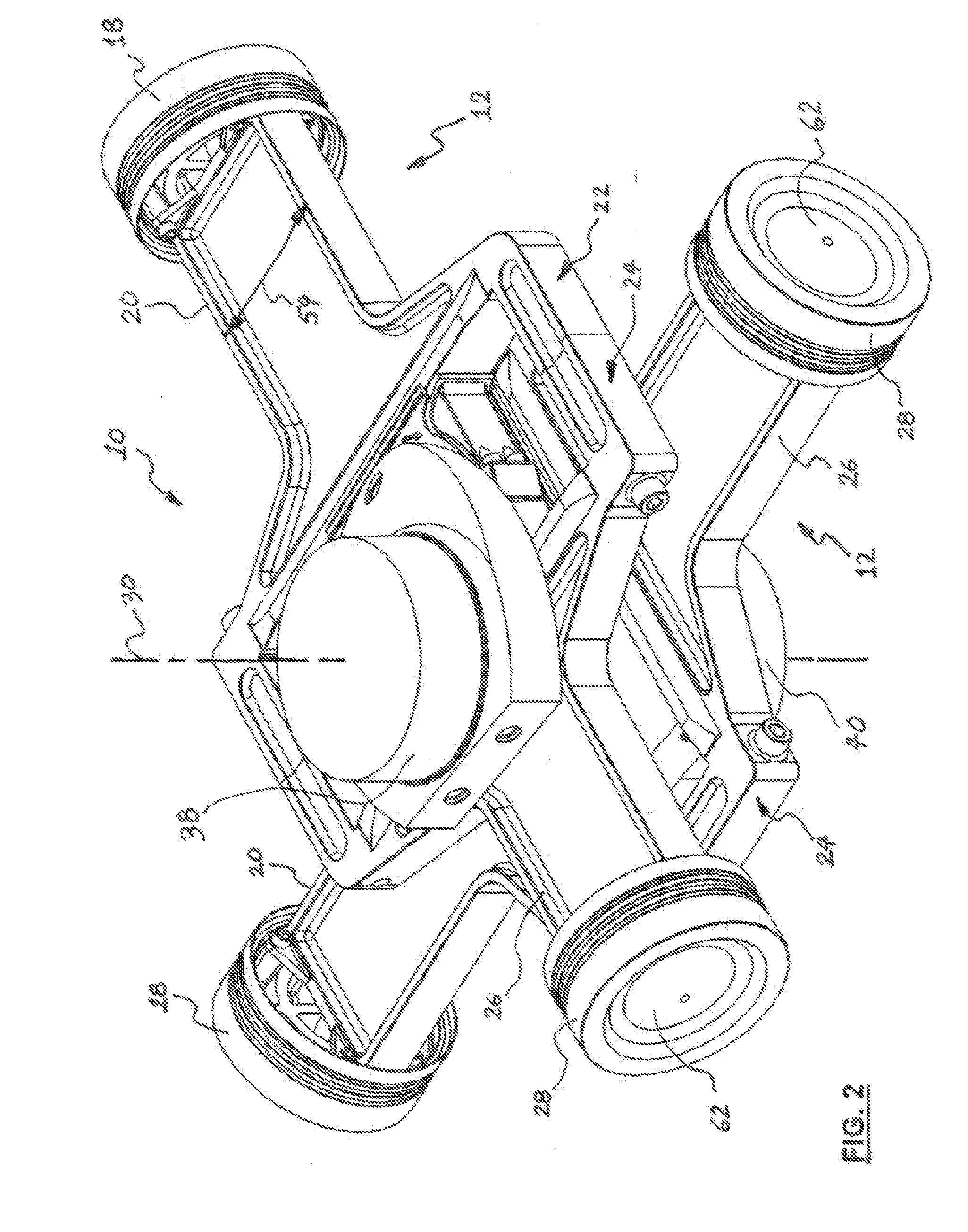

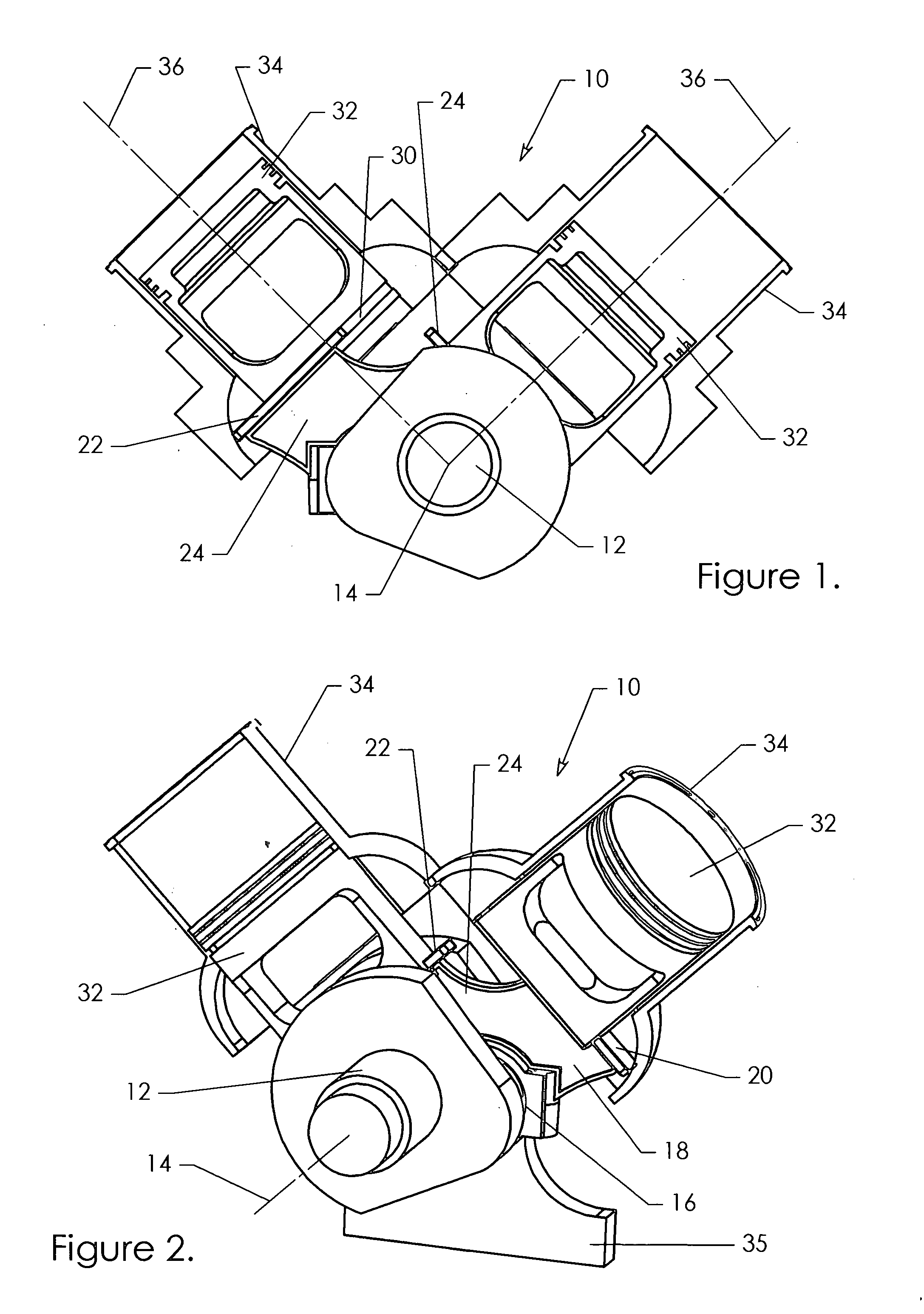

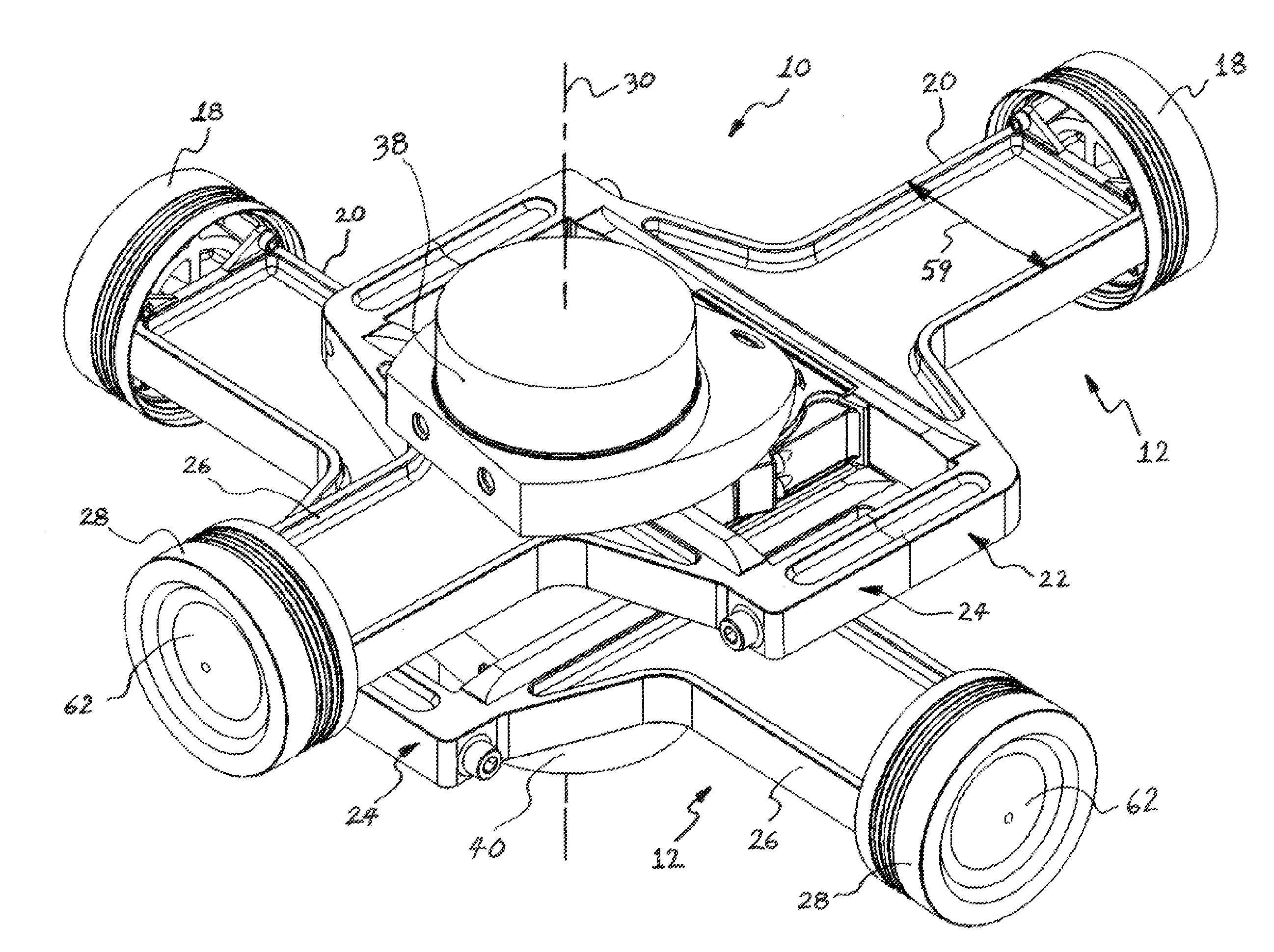

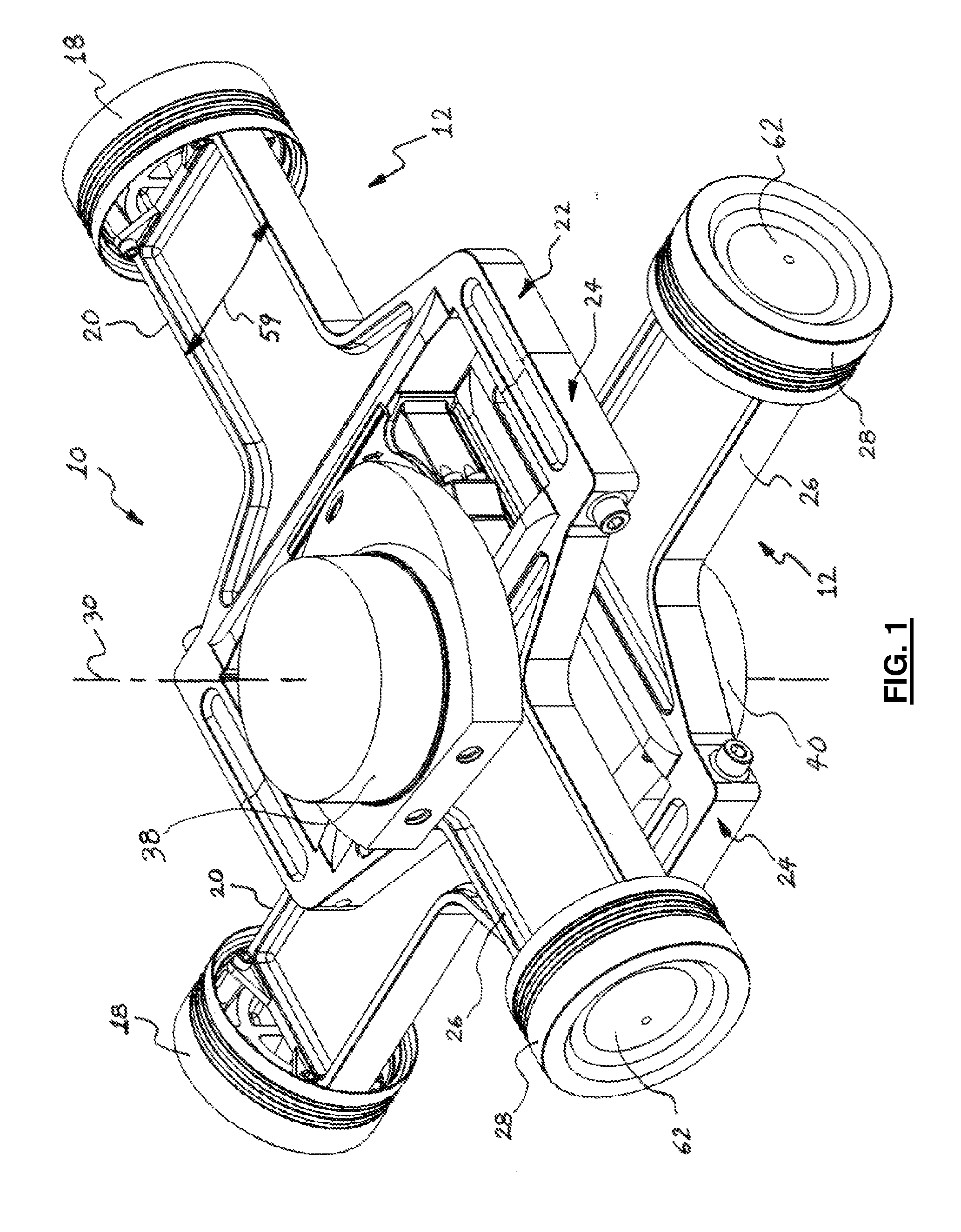

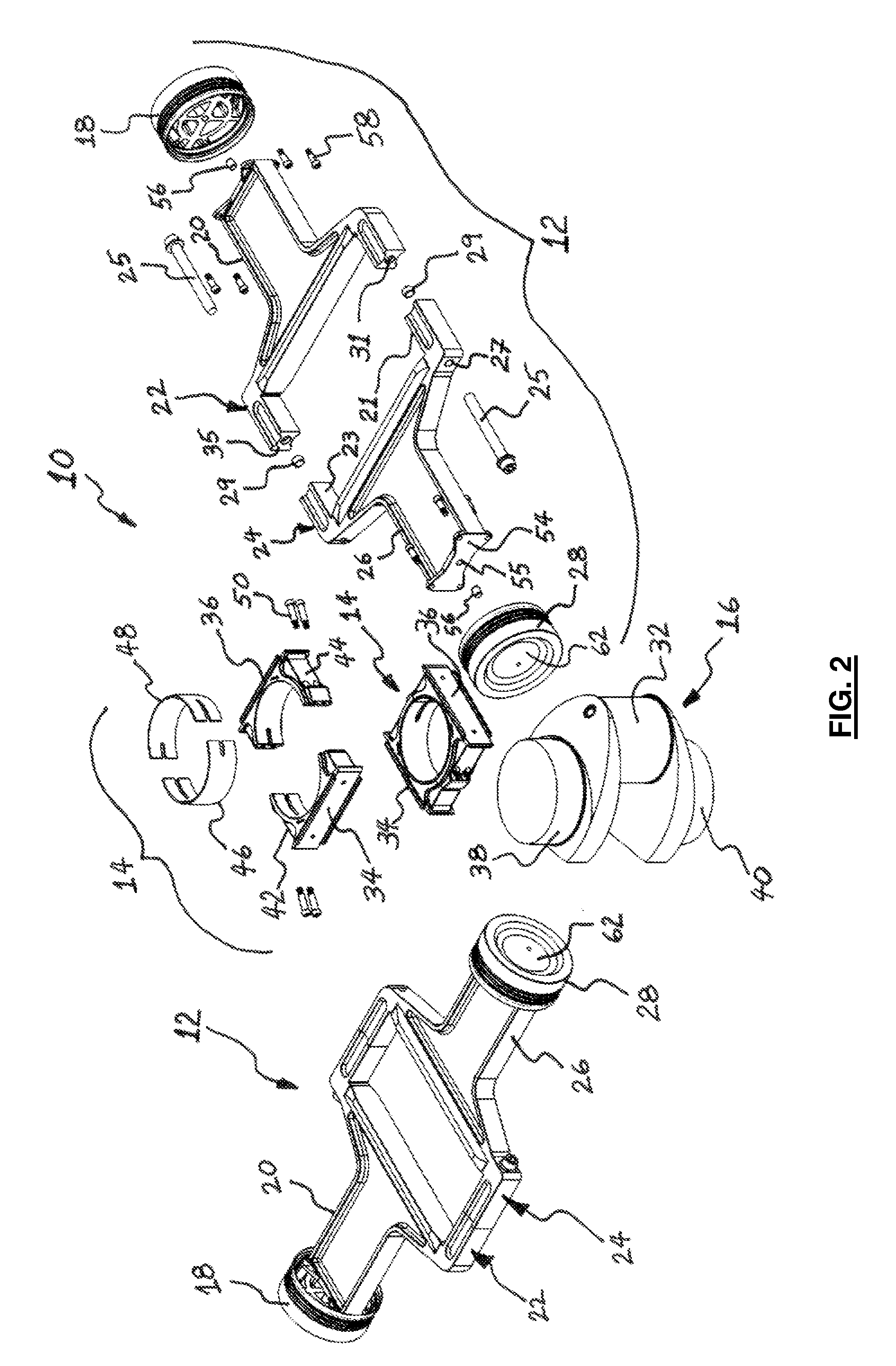

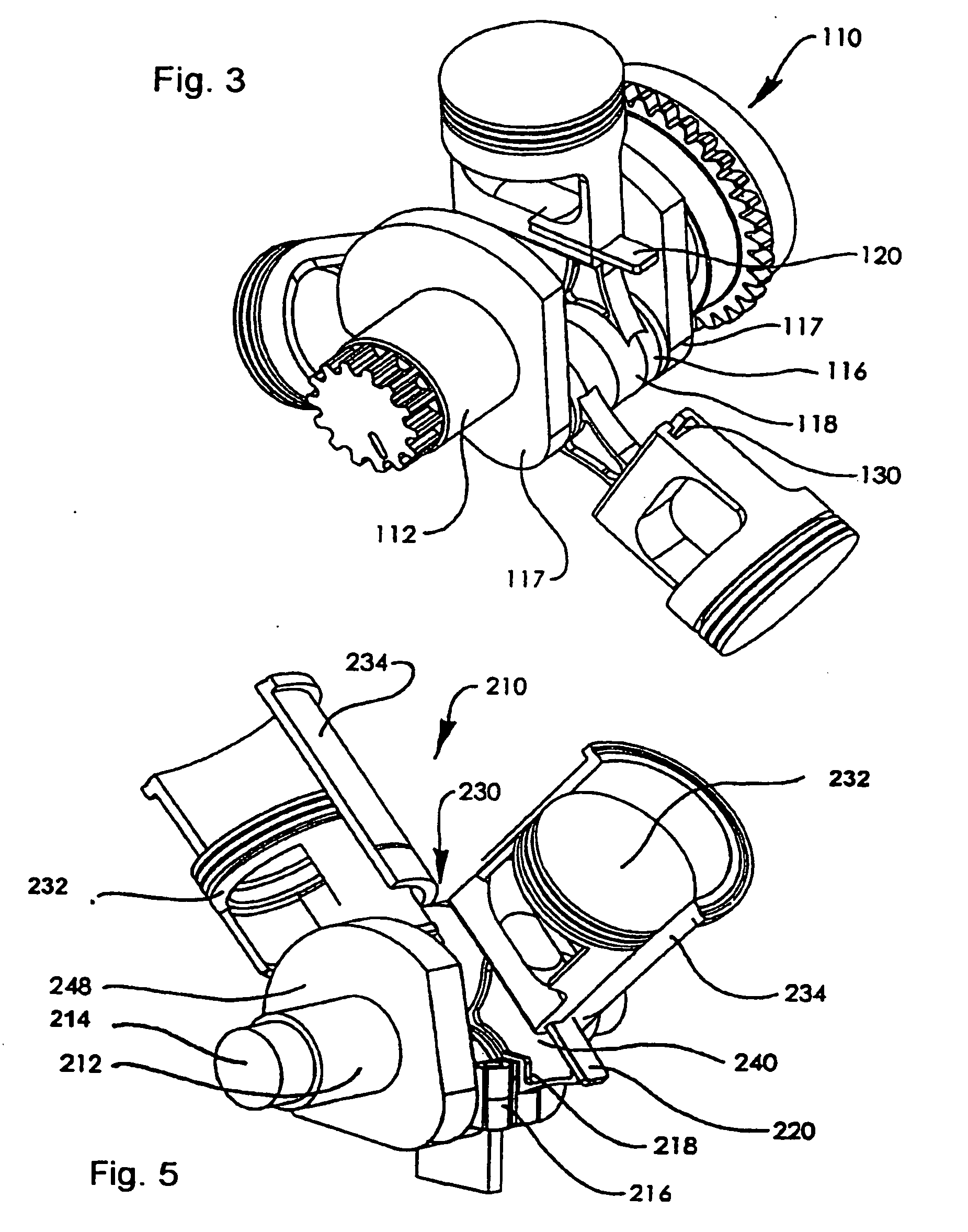

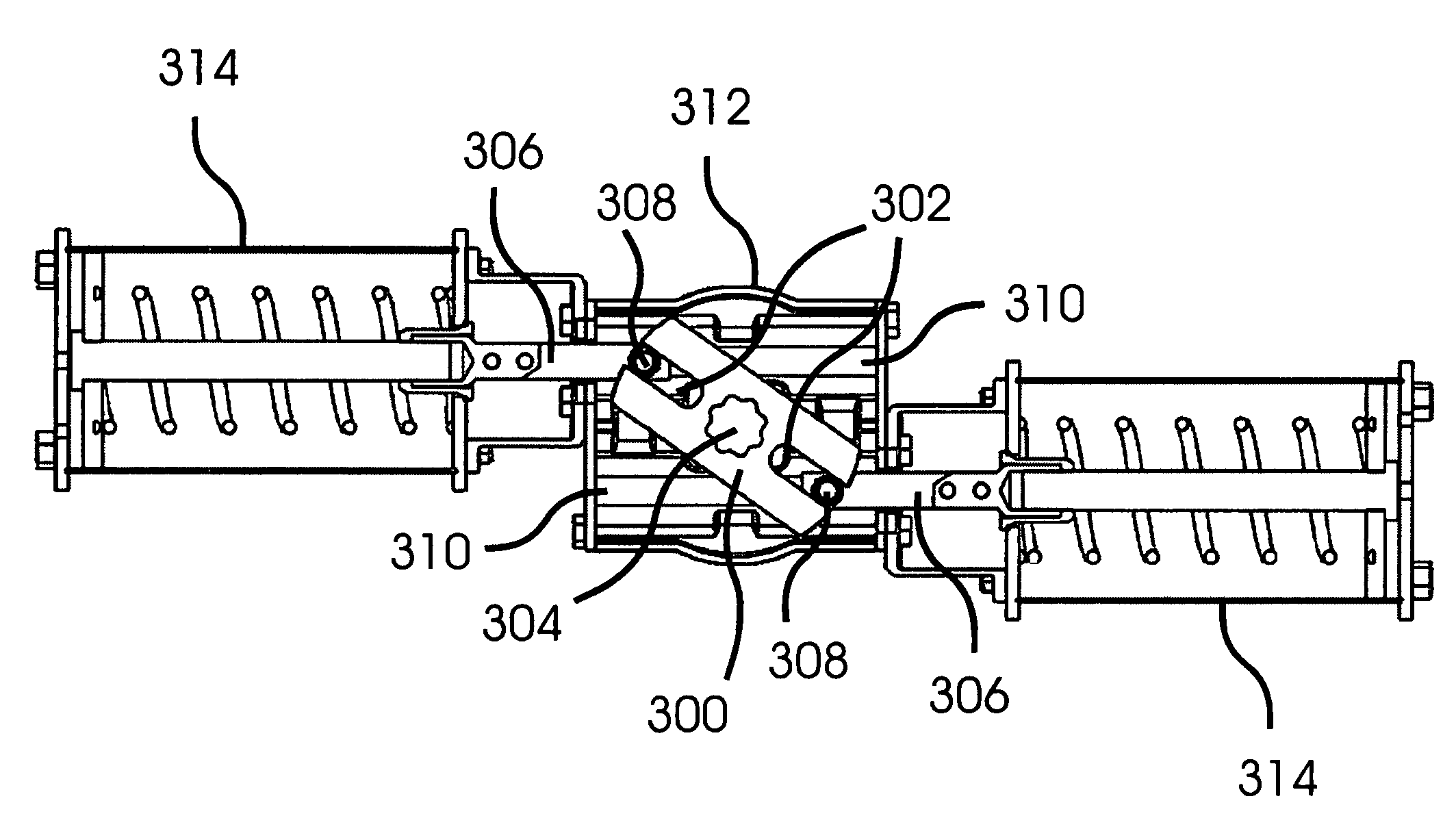

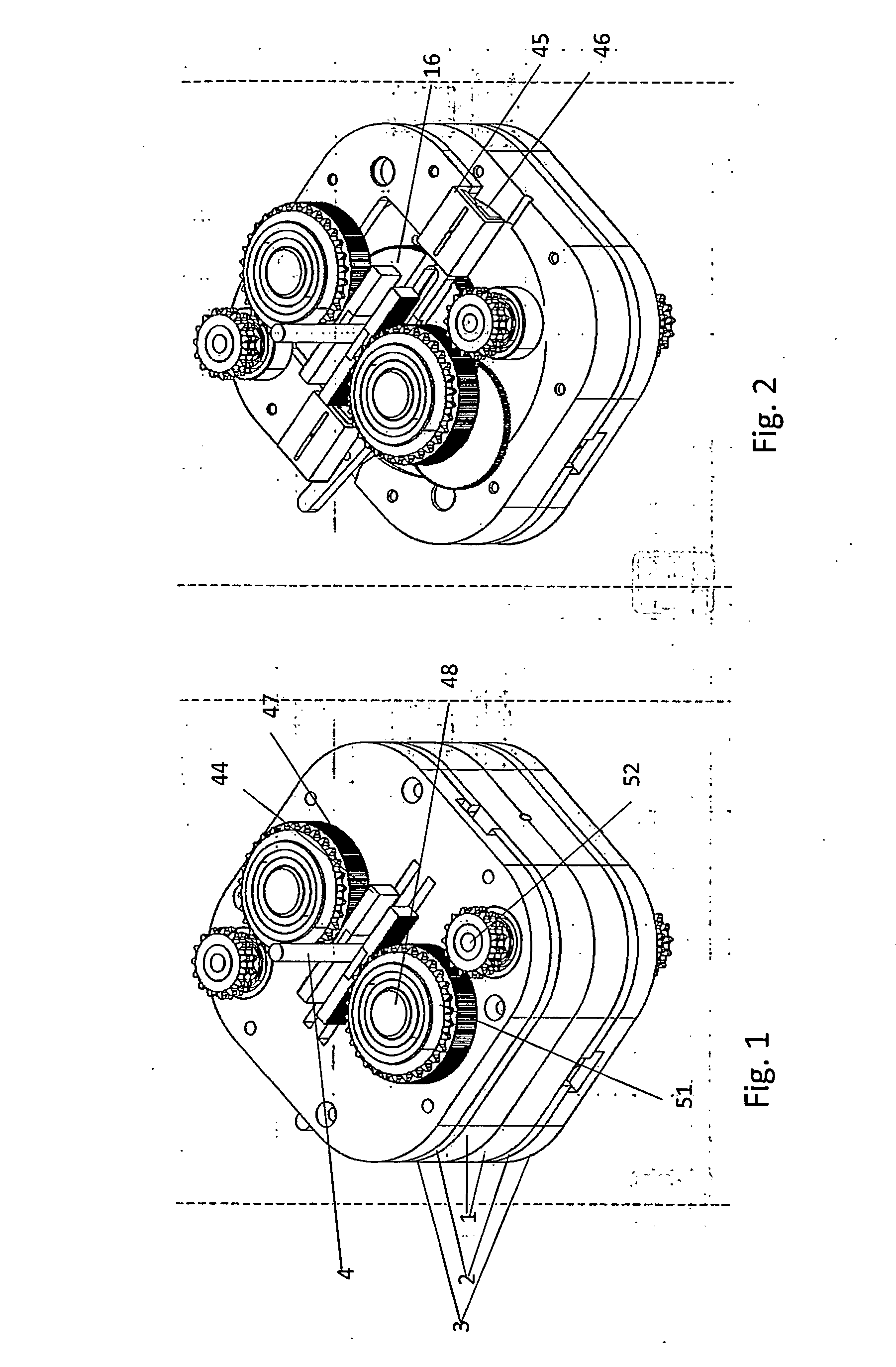

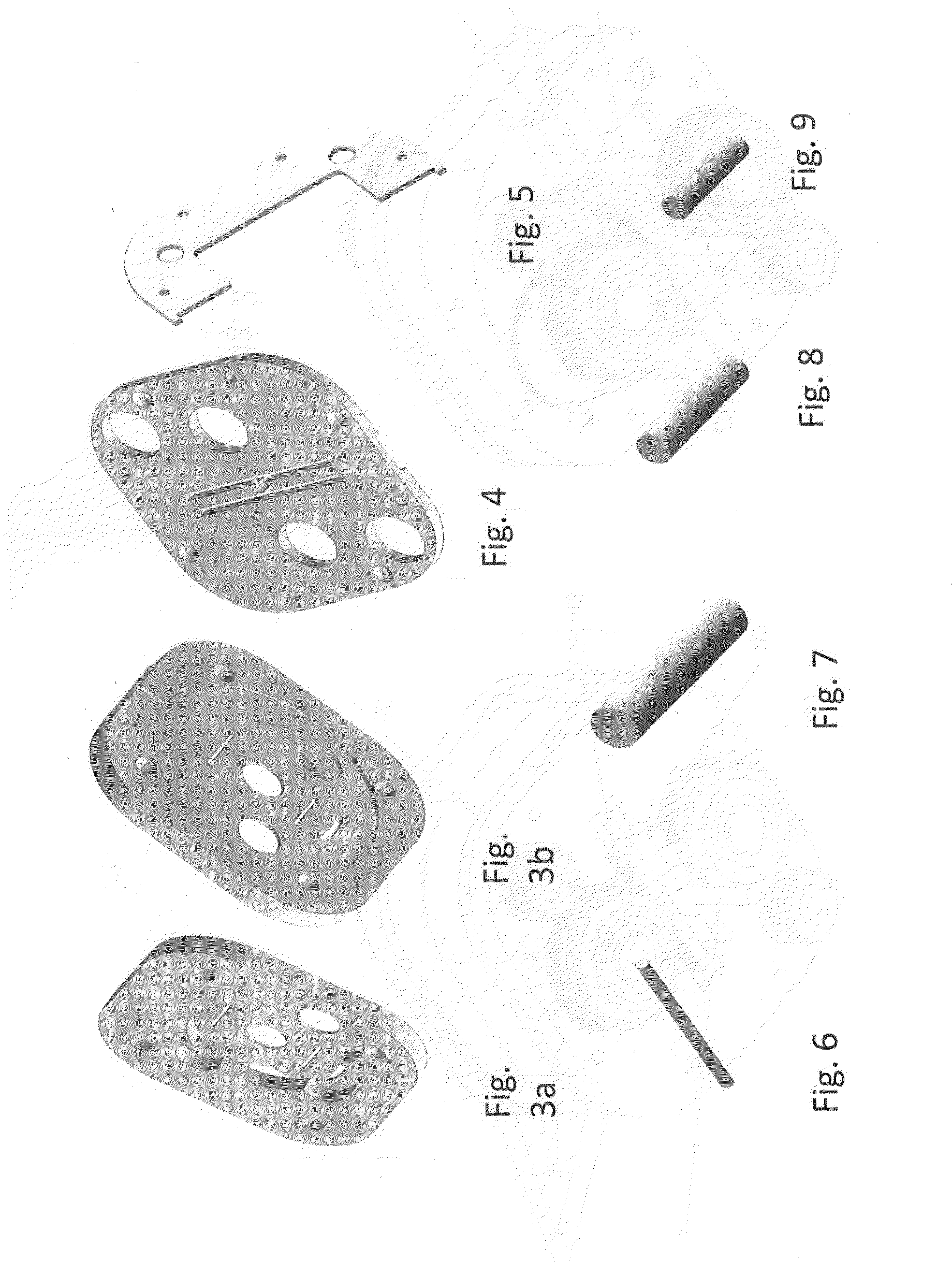

Double-acting scotch yoke assembly for x-engines

ActiveUS20120272758A1Improve efficiencyImprove performanceGearingCombustion enginesScotch yokeEngineering

A Double-Acting Scotch Yoke (DASY) assembly includes a first yoke; a second yoke attached to the first yoke at a first flat-to-flat interface; a first piston attached to the first yoke at a second flat-to-flat interface; and a second, opposing piston attached to the second yoke at a third flat-to-flat interface. The planes of all of the flat-to-flat interfaces are perpendicular to a common, center axis of the first and second pistons. An X-engine crank train includes a plurality of DASY assemblies.

Owner:DIGGS MATTHEW BYRNE

Internal combustion engine

InactiveUS20070079787A1High pressureInternal combustion piston enginesPistonsCombustion chamberFiring order

The invention has many aspects. One aspect is that of an internal combustion engine (8010) that has a piston (8020) within a cylinder (8022) and has a crankcase (8012), defining a combustion chamber (8024) and crank volume (8026). A passageway (8032 and 8034) links the combustion chamber (8024) and the crank volume (8026). There is provided valve means (8038) for selectively closing the linking passageway and valve means (8030) for selectively closing and inlet to the crank volume (8026). In another aspect, there is an improvement to a scotch yoke fluid device. A displaceable member for relieving pressure in a variable volume chamber in the cylinder where combustion is occurring is provided. The invention includes a method of varying power output of a scotch yoke device, by choosing cylinder angle, pin angle and firing order in various ways. The invention also deals with other aspects of scotch yoke designs.

Owner:RAFFAELE PETER ROBERT +1

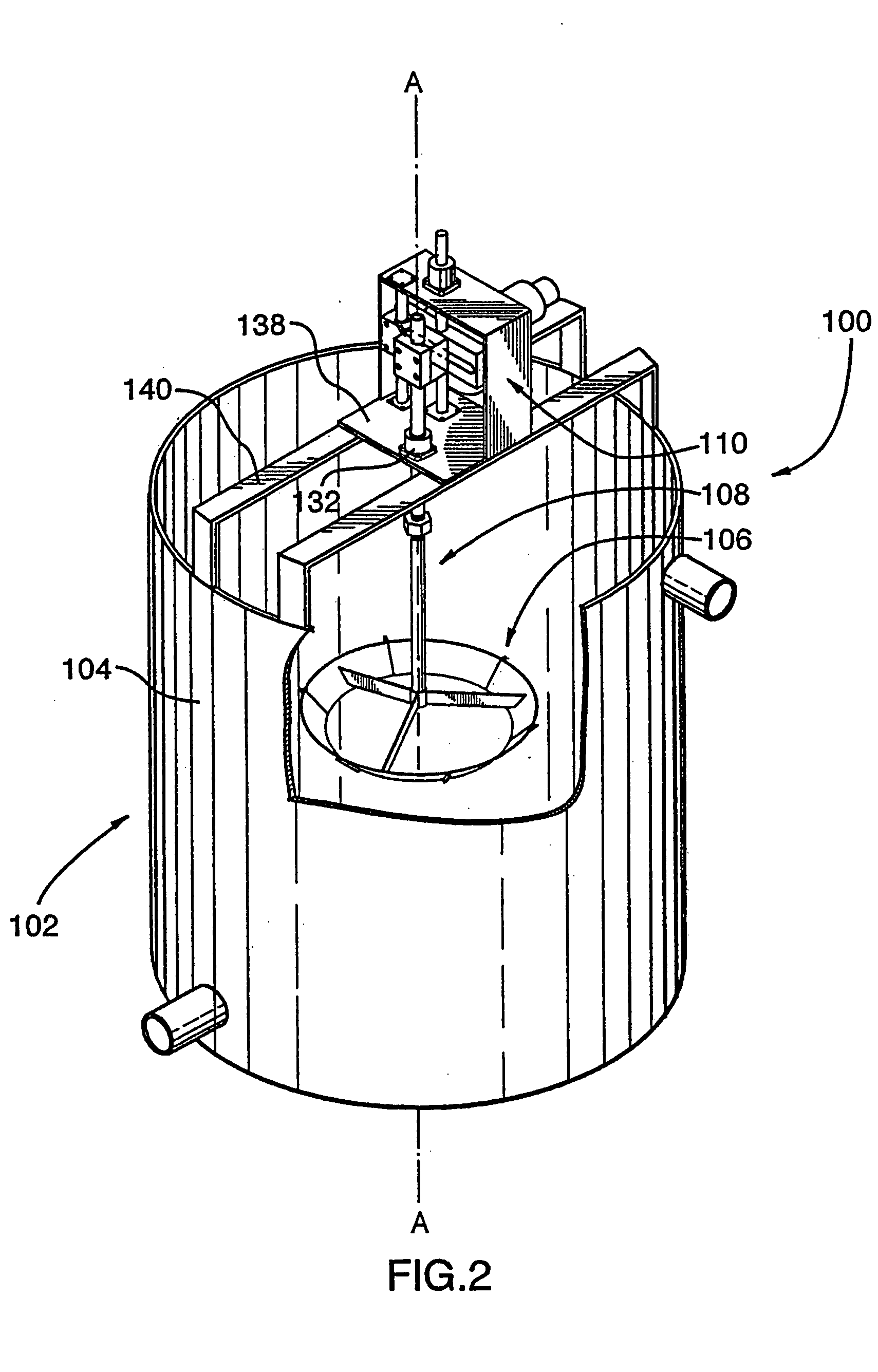

Mixing apparatus

InactiveUS20050174883A1Shaking/oscillating/vibrating mixersRotary stirring mixersEngineeringKnife blades

A mixer apparatus for use with a vessel centered about a longitudinal axis is disclosed. The mixer has a blade which: defines a central head axis; has a first end and a second end. The second end defines an inside blade diameter “ID” and the first end defines an outer blade diameter “OD”. The blade is positioned within and coaxial to the vessel. A scotch yoke, operatively connected to the blade by a shaft, effects reciprocating longitudinal movement of the blade through a stroke “S”, with a duration “T” for each cycle, wherein 175≲0.36×OD2 / ID2×S / T≲250 when OD, ID and S are expressed in inches, and T is expressed in minutes.

Owner:ENERSAVE FLUID MIXERS

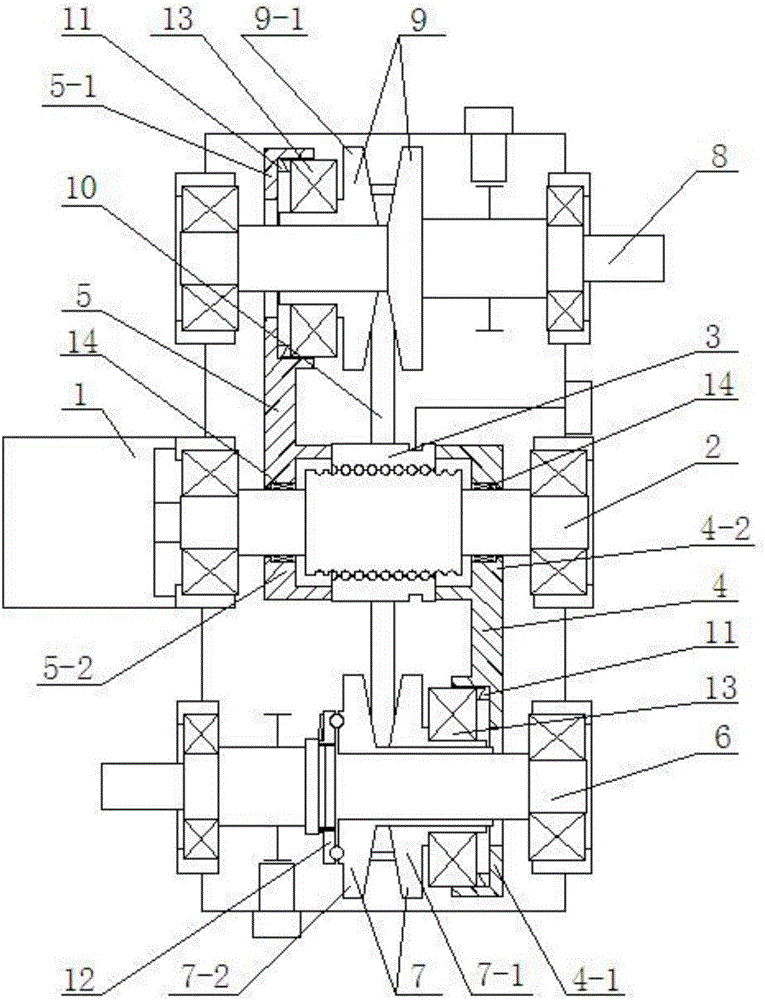

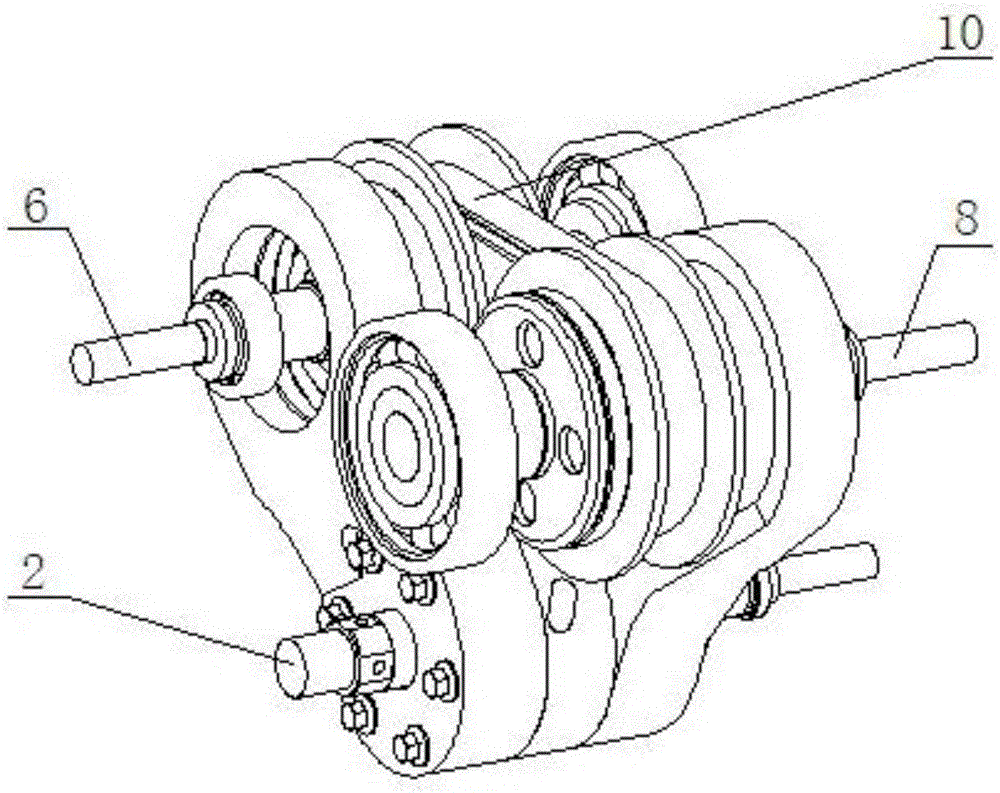

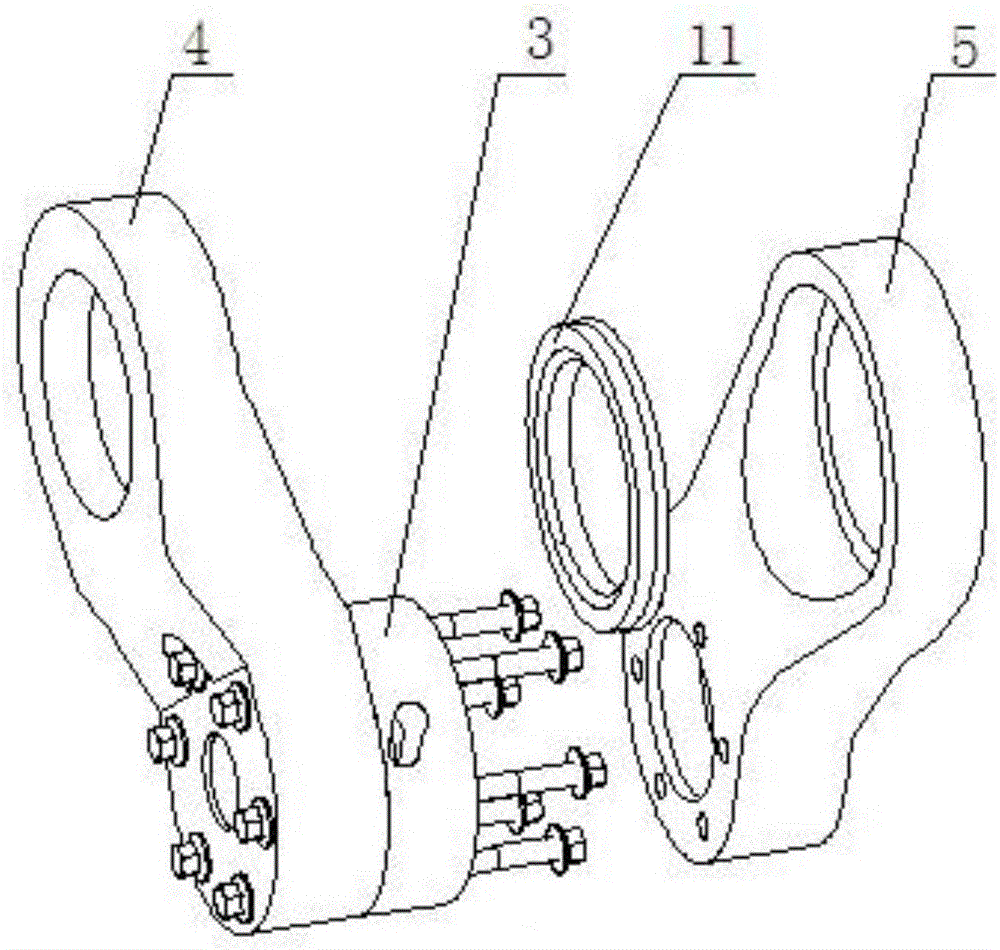

Speed adjustment mechanism for conical plate type continuously variable transmission and conical plate type continuously variable transmission

ActiveCN106641143ASimplified Axial DimensionsReduce axial sizeControlled membersGearing controlDrive shaftEngineering

The invention relates to the technical field of vehicle speed transmissions, in particular to a speed adjustment mechanism for a conical plate type continuously variable transmission and the conical plate type continuously variable transmission. The speed adjustment mechanism for the transmission comprises a drive shaft coupled to a driver, a drive nut sleeving the drive shaft, and a first shifting fork and a second shifting fork at two ends of the drive nut, wherein the first shifting fork has a first work part pressed against a first movable conical plate on a driving shaft; the second shifting fork has a second work part pressed against a second movable conical plate on a driven shaft; and the first and second shifting forks also respectively have first and second support parts, which respectively sleeve the drive shaft so as to improve the stiffness of the first and second shifting forks. The axial dimensions of the speed adjustment mechanism are greatly simplified, so that the structure of the conical plate continuously variable transmission equipped with the speed adjustment mechanism is more compact, and in addition, the costs for manufacturing, machining, mounting, maintenance and so on are lowered.

Owner:CHANGZHOU DONGFENG CVT

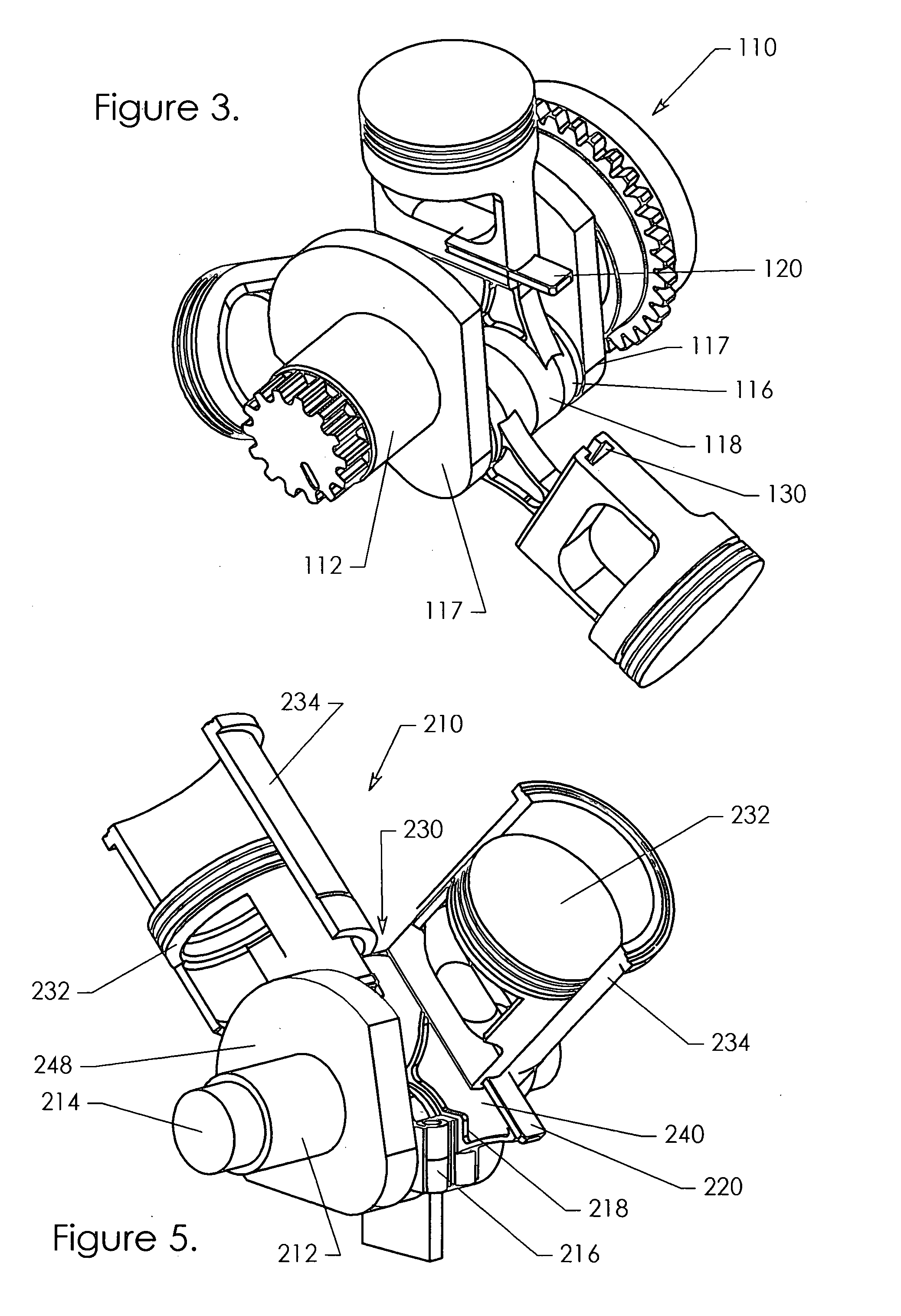

X-engine assembly with perfect balance

ActiveUS20130098335A1Improve balanceSimple packagingPlungersTrunk pistonsReciprocating motionEngineering

An X-Engine assembly includes four cylinder banks which are located on two intersecting planes with the crankshaft axis being on the line of the intersection of the two planes, and having a Double-Acting Scotch Yoke (DASY) power conversion system that couples the reciprocating motion of the pistons with the rotating crankshaft to provide pure sinusoidal piston motion. A series of DASY X-Engine configurations that satisfy even-firing for both 2-stroke and 4-stroke, and other engine cycles, achieve perfect balance with regard to vibrating forces and moments that are all zero, and all configurations have zero torsional vibration of the crankshaft resulting from the reciprocating masses.

Owner:DIGGS MATTHEW BYRNE

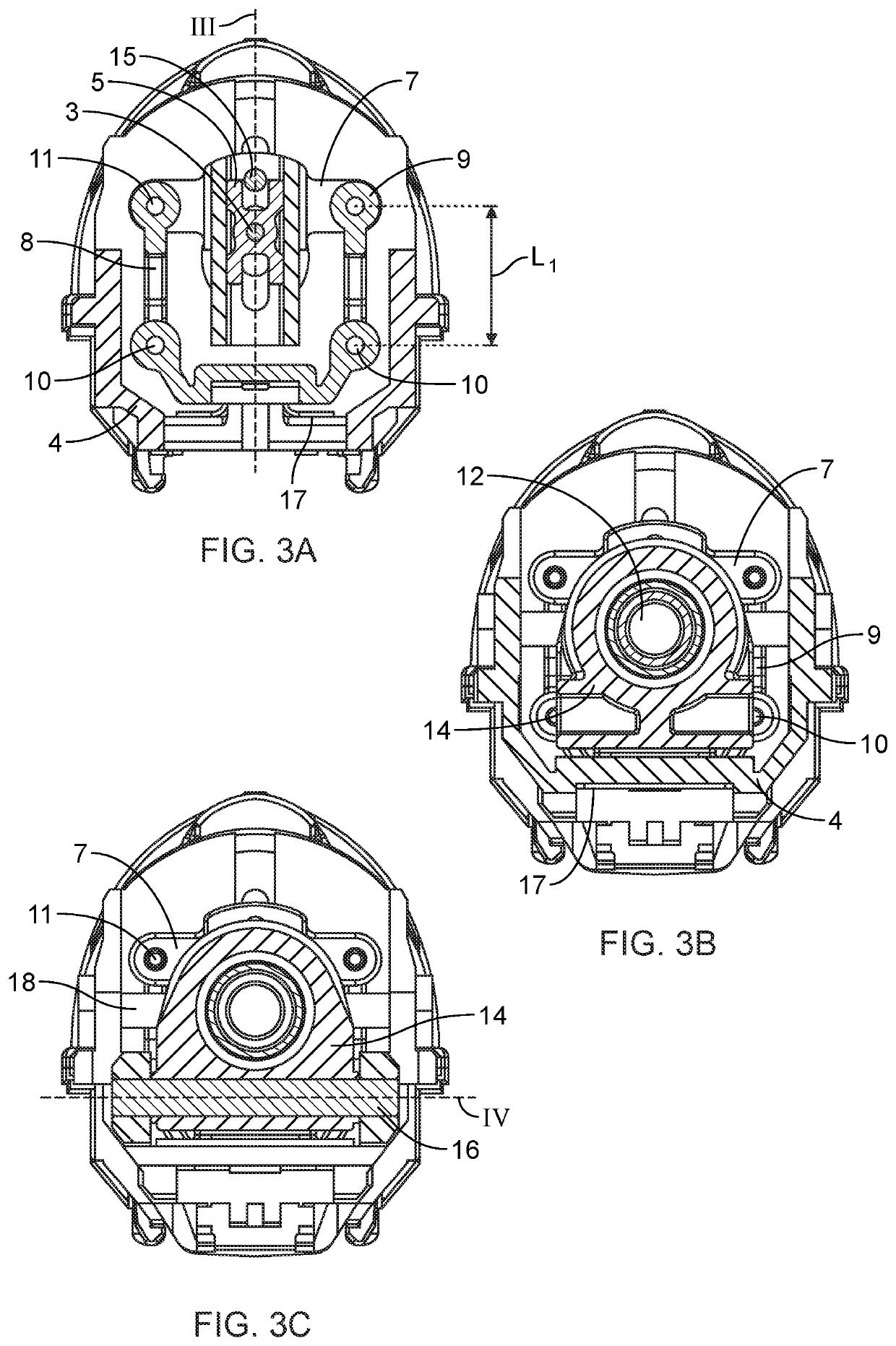

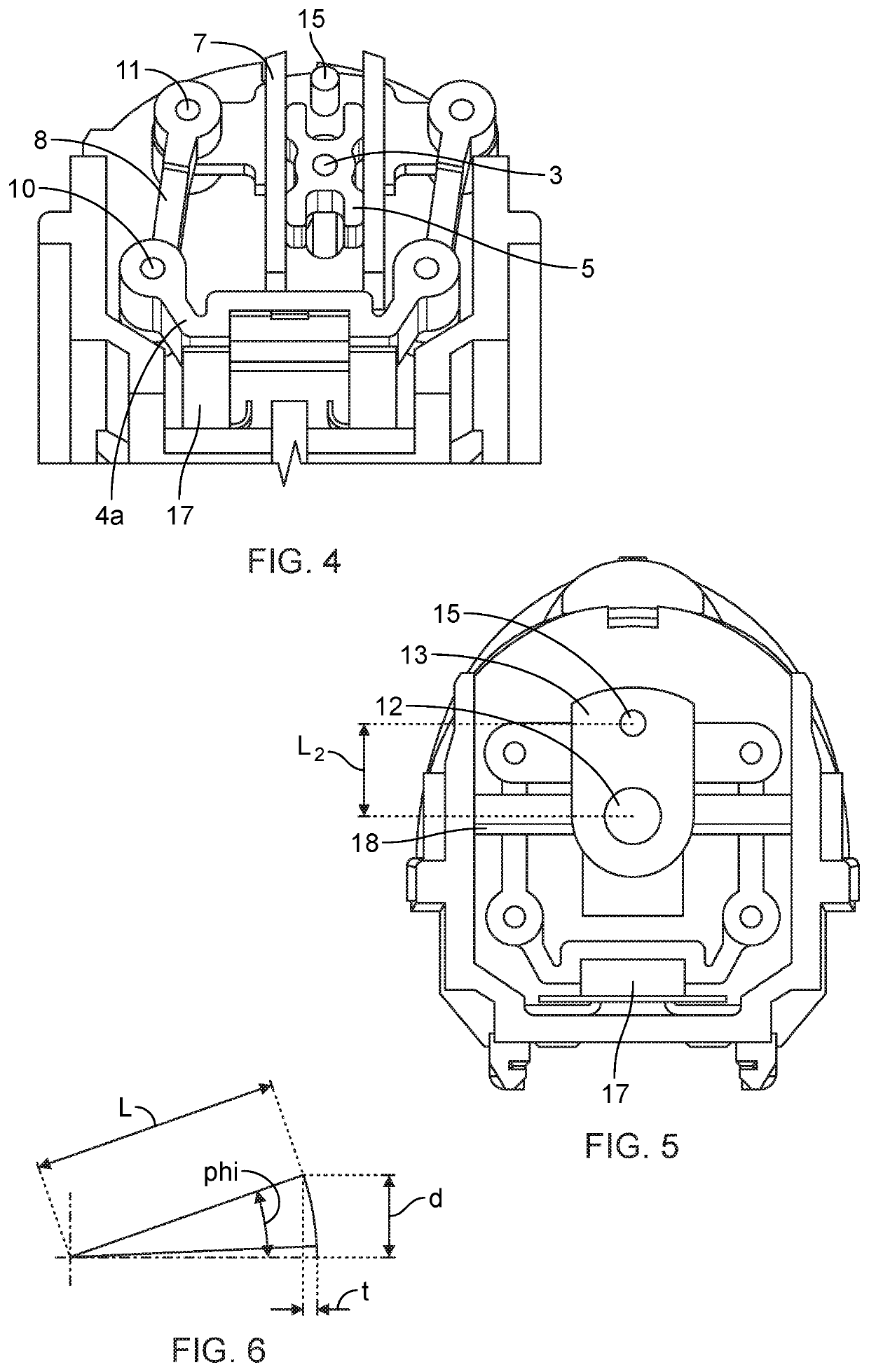

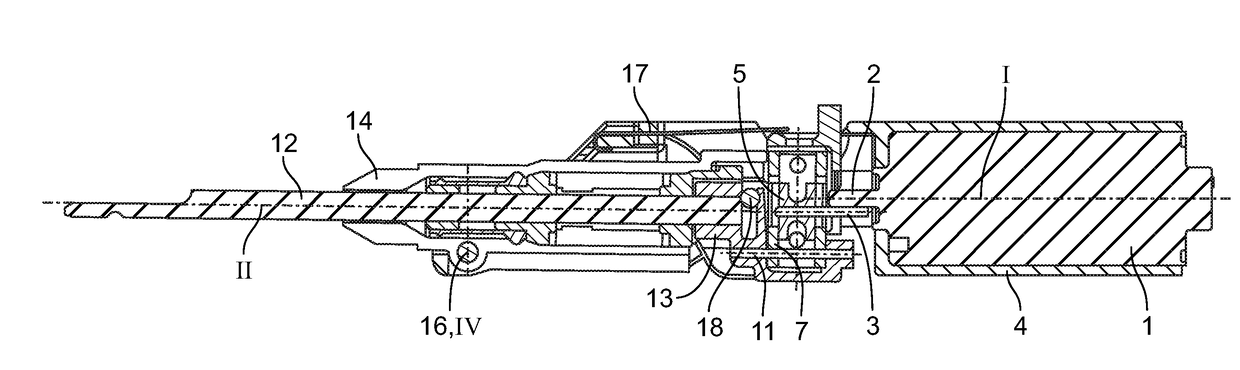

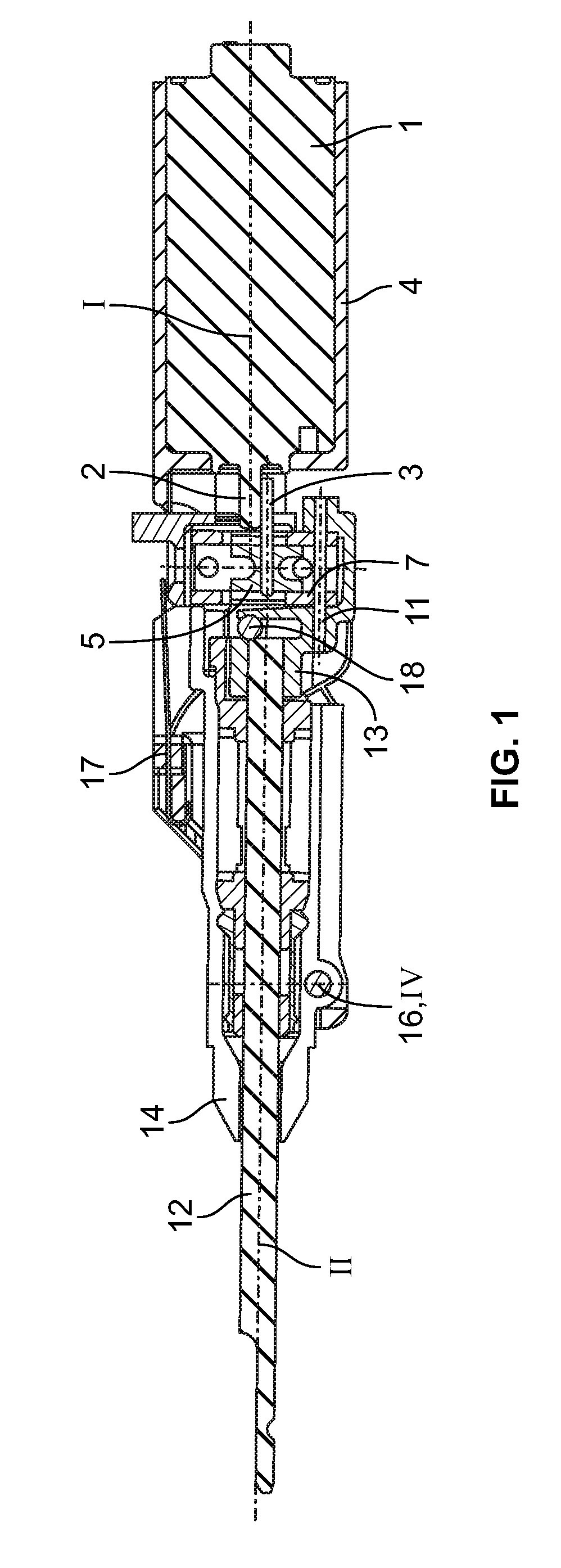

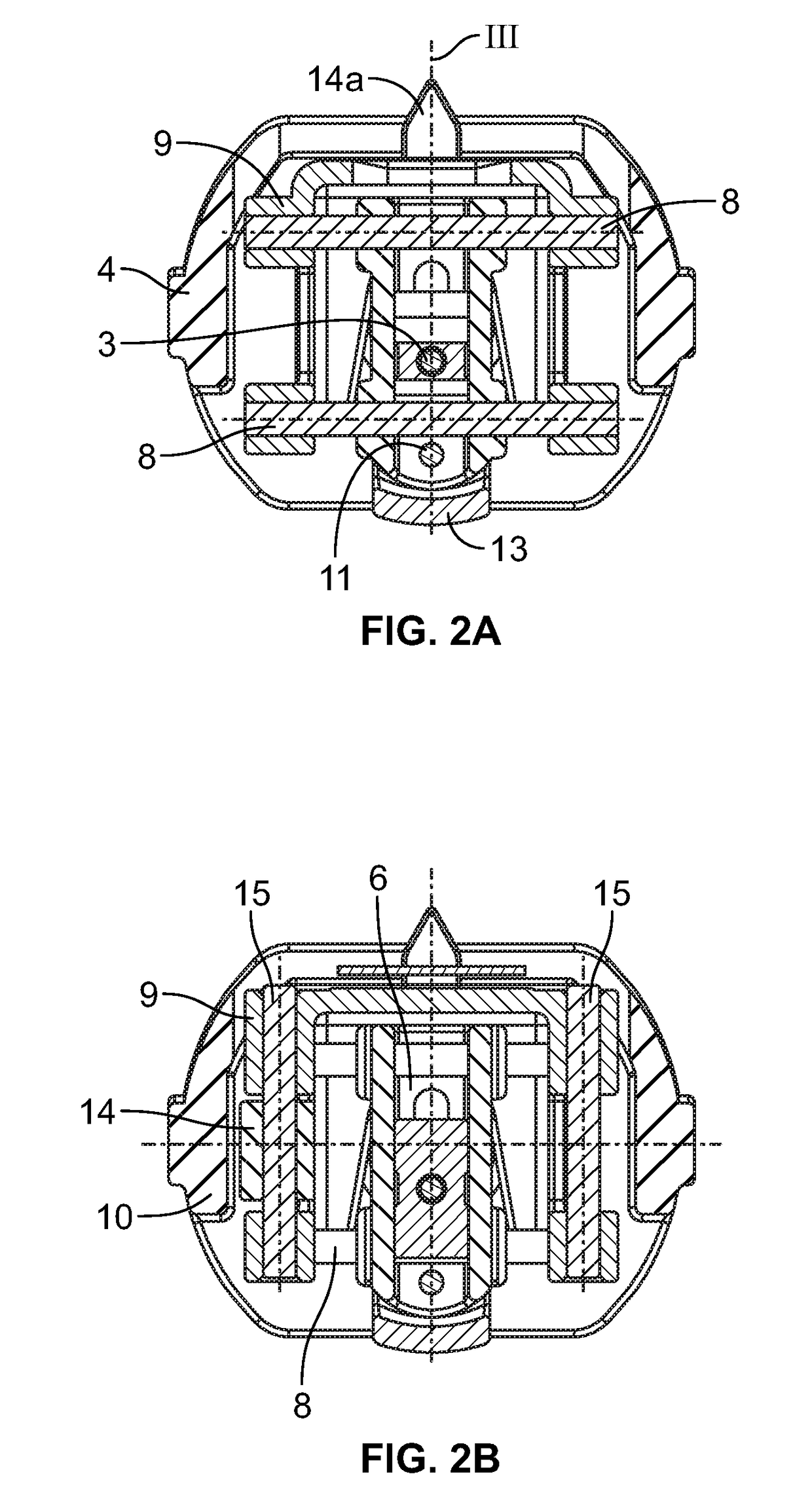

Electrically driven device

An electrically driven device includes a housing, an electric motor with a drive shaft having a first rotary axis and a drive pin connected to the drive shaft eccentrically with respect to the rotary axis, and a driven shaft having a second rotary axis and mounted in the housing for performing a pivoting about the second rotary axis. The driven shaft is coupled to the drive shaft by a gear mechanism including a scotch yoke mechanism converting a rotary motion of the drive shaft into a reciprocating motion of the driven shaft. The scotch yoke mechanism includes a cross slider having a sliding support extending perpendicular to the first rotary axis and receiving the drive pin either directly or through a sliding block with a bearing receiving the drive pin. The cross slider is guided in the housing by at least two pivotable links. The driven shaft is coupled to the cross slider by an arm, converting a rotary motion of the drive shaft into a reciprocating of the driven shaft.

Owner:BRAUN GMBH

Reciprocating fluid machines

InactiveUS20070079698A1Improve balancePositive displacement pump componentsCrankshaft bearingsMechanical engineeringScotch yoke

The invention provides a scotch yoke type fluid device which includes a scotch yoke element. The scotch yoke element may be a channel, a rail, a channel and a rail, a bore or a bore and a rail. The scotch yoke element defines a longitudinal path, along which the big end of the device reciprocates, relative to the piston. The device includes restricting means which move along a defined path and which constrain the piston or the scotch yoke element or a connecting rod for the piston to move along the defined path. At least part of the restricting means is located transversely of the longitudinal path of the scotch yoke element, and within the piston footprint.

Owner:RAFFAELE PETER ROBERT +1

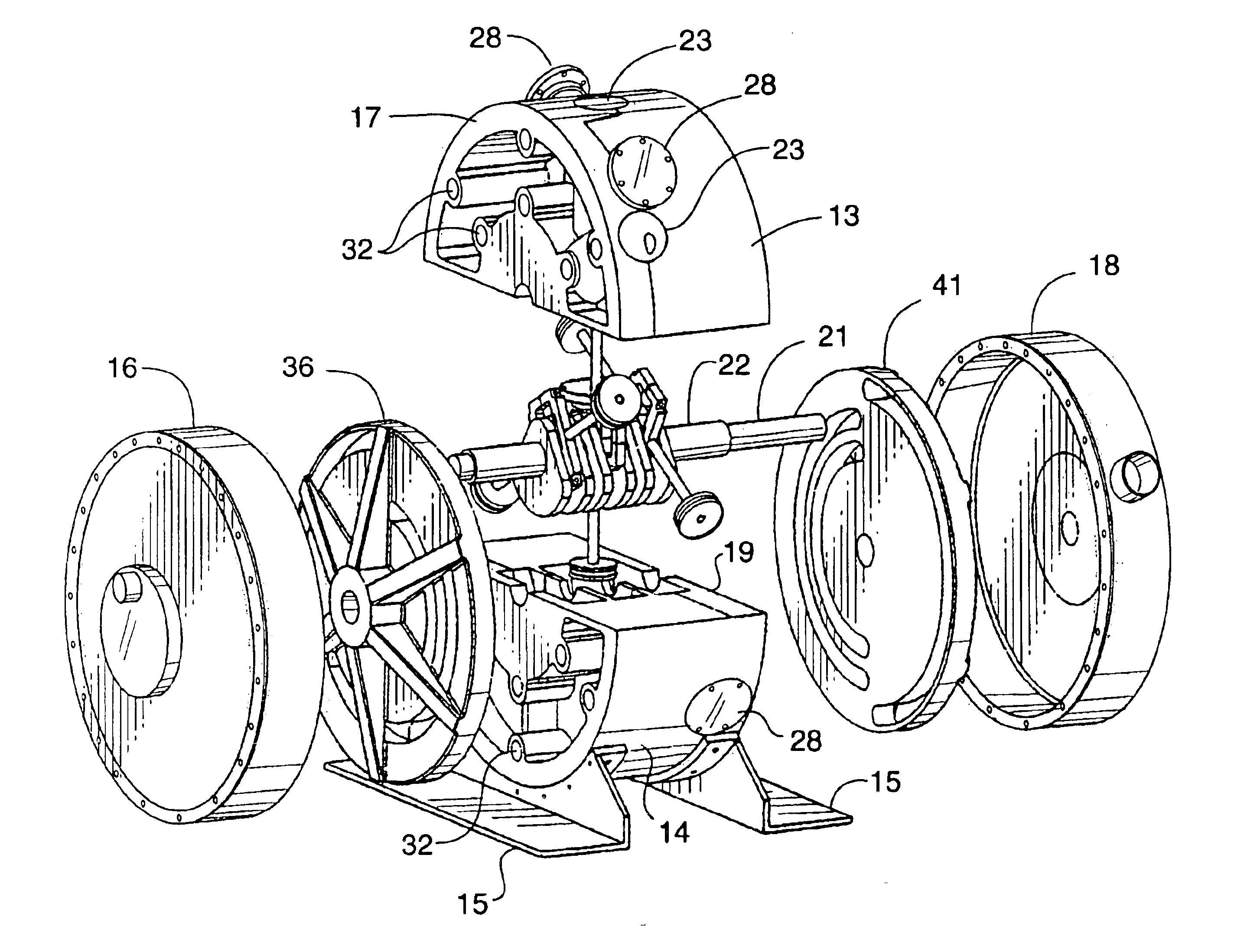

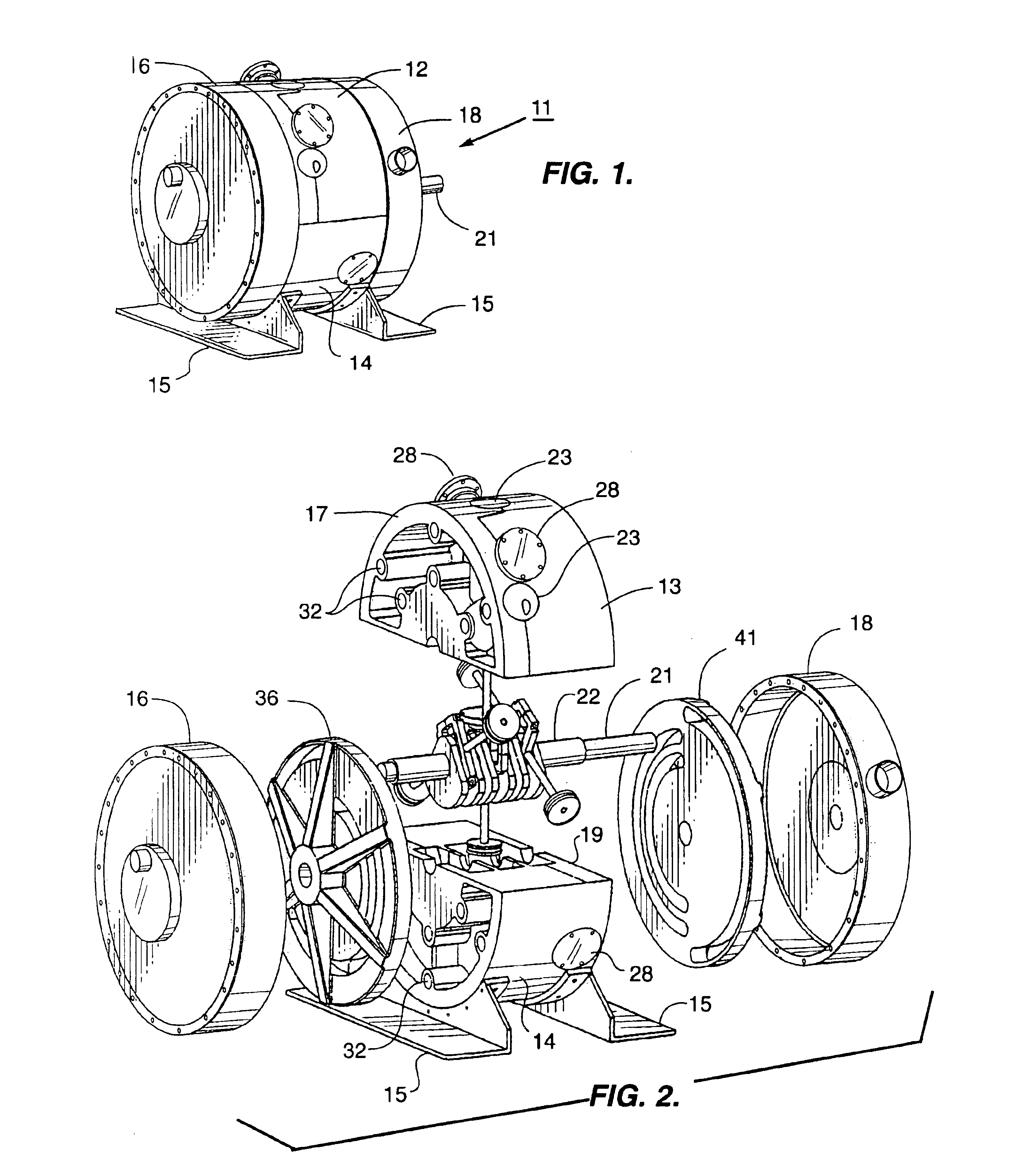

Portable, refrigerant recovery unit

ActiveUS20110120242A1Avoid any exposure to any contaminantPositive displacement pump componentsGearingRefrigerant reclamationCrank

A portable, refrigerant recovery unit for transferring refrigerant from a refrigeration system to a storage tank. The recovery unit includes two, opposed piston heads rigidly attached to respective piston rods that extend along a common fixed axis. The piston rods are rigidly attached to the yoke member of a scotch yoke arrangement. In operation, incoming refrigerant from the system is simultaneously and continuously directed to the opposing piston heads wherein the forces of the pressurized refrigerant on them counterbalance or neutralize one another. The scotch yoke arrangement includes a two-piece slide mechanism mounted about a cylindrical crank pin and a single piston embodiment is additionally disclosed.

Owner:SUNDHEIM GREGORY S

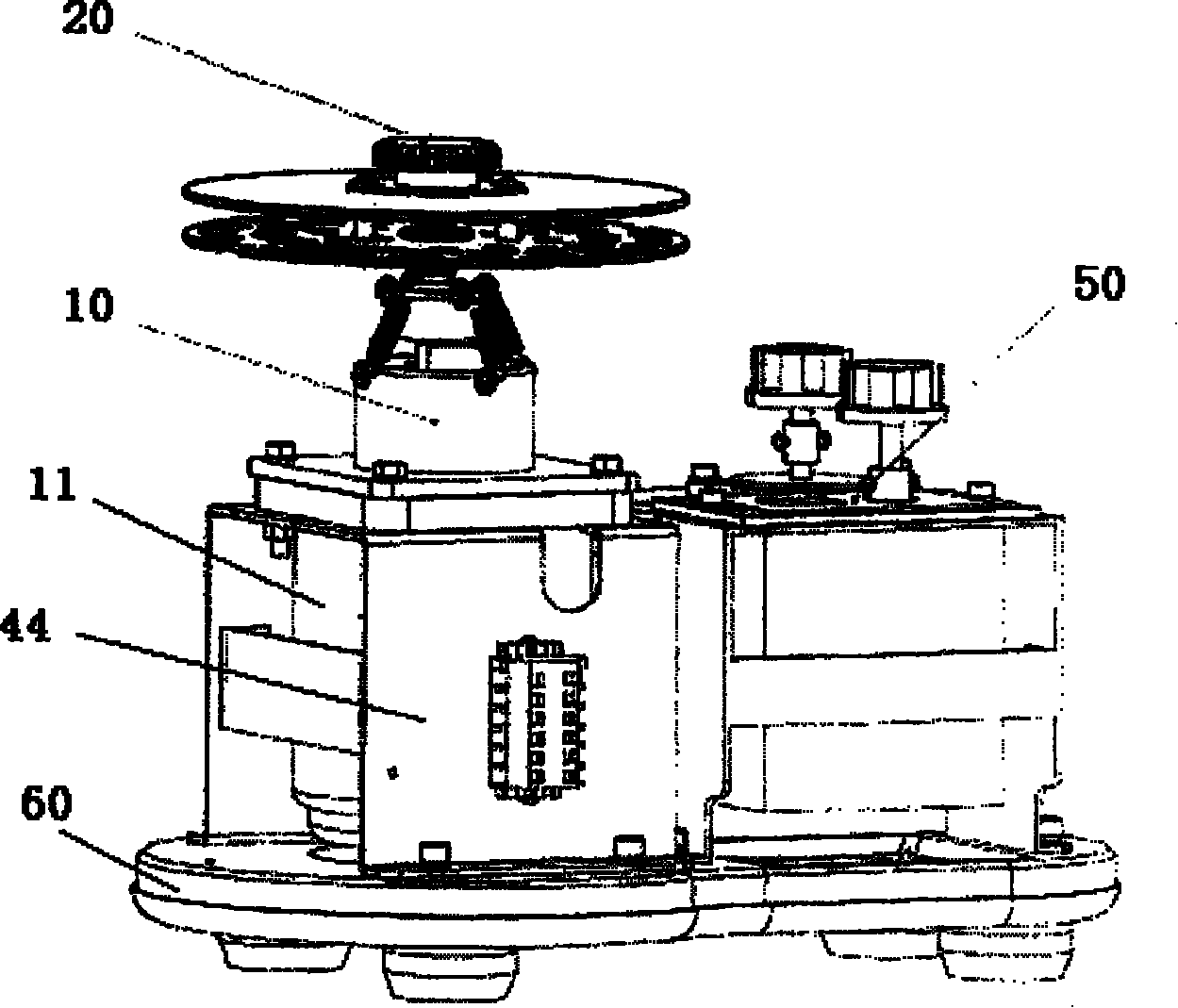

Sintered abrasive grain crushing device and method

PendingCN109663628APrevent splashGuaranteed cutting edge qualityGrain treatmentsReciprocating motionStile

The invention relates to a sintered abrasive grain crushing device and method. The device comprises a rack, a hammer head, a hammer seat, a connecting rod, a scotch yoke and a motor. The hammer head and the hammer seat are each of a step structure with four or more stages, the step faces are inclined faces inclined downwards, and the hammer seat is overall of a circular table structure. When the hammer head and the hammer seat are buckled, the buckling gap of the two stages of steps on the bottommost layer is zero, and the buckling gaps of other steps are sequentially increased from bottom totop. The hammer seat is fixed to the bottom of the rack. The top of the hammer head is fixedly connected with the connecting rod. The top of the connecting rod is fixedly connected with the scotch yoke, an output shaft of the motor is arranged in the scotch yoke, and the scotch yoke is driven by the motor to drive the connecting rod to do vertical reciprocating motion. The device has the advantages that the multi-step hammer head and hammer seat structure is adopted, the crushing efficiency is effectively improved, and splashing of abrasive grain scraps is avoided; and by means of the design of sliding pins and sliding grooves, it is effectively guaranteed that the hammer head only does straight-up and straight-down reciprocating crushing motion, and then the cutting edge quality of an abrasive grain surface grinding phase is guaranteed.

Owner:UNIV OF SCI & TECH LIAONING

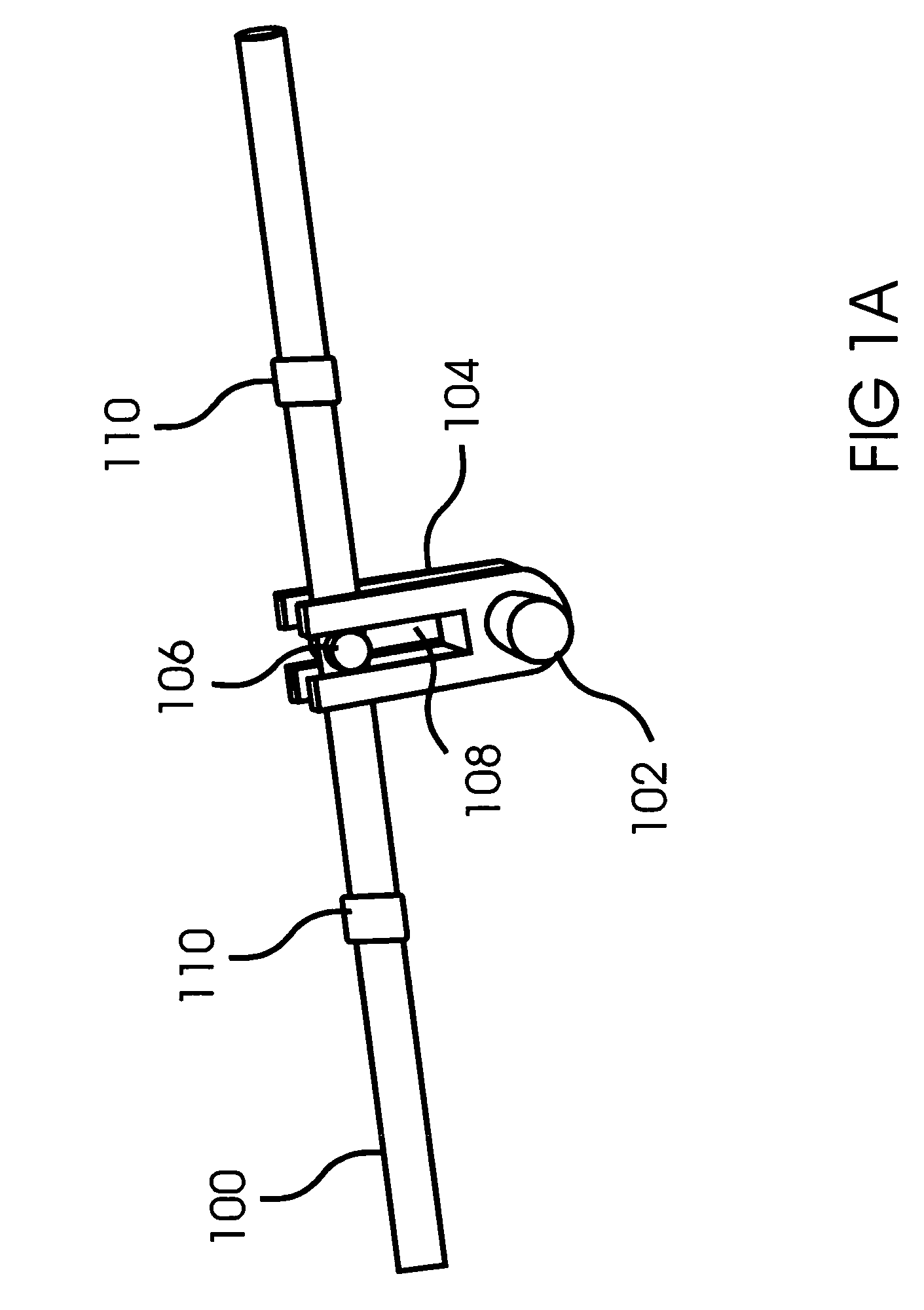

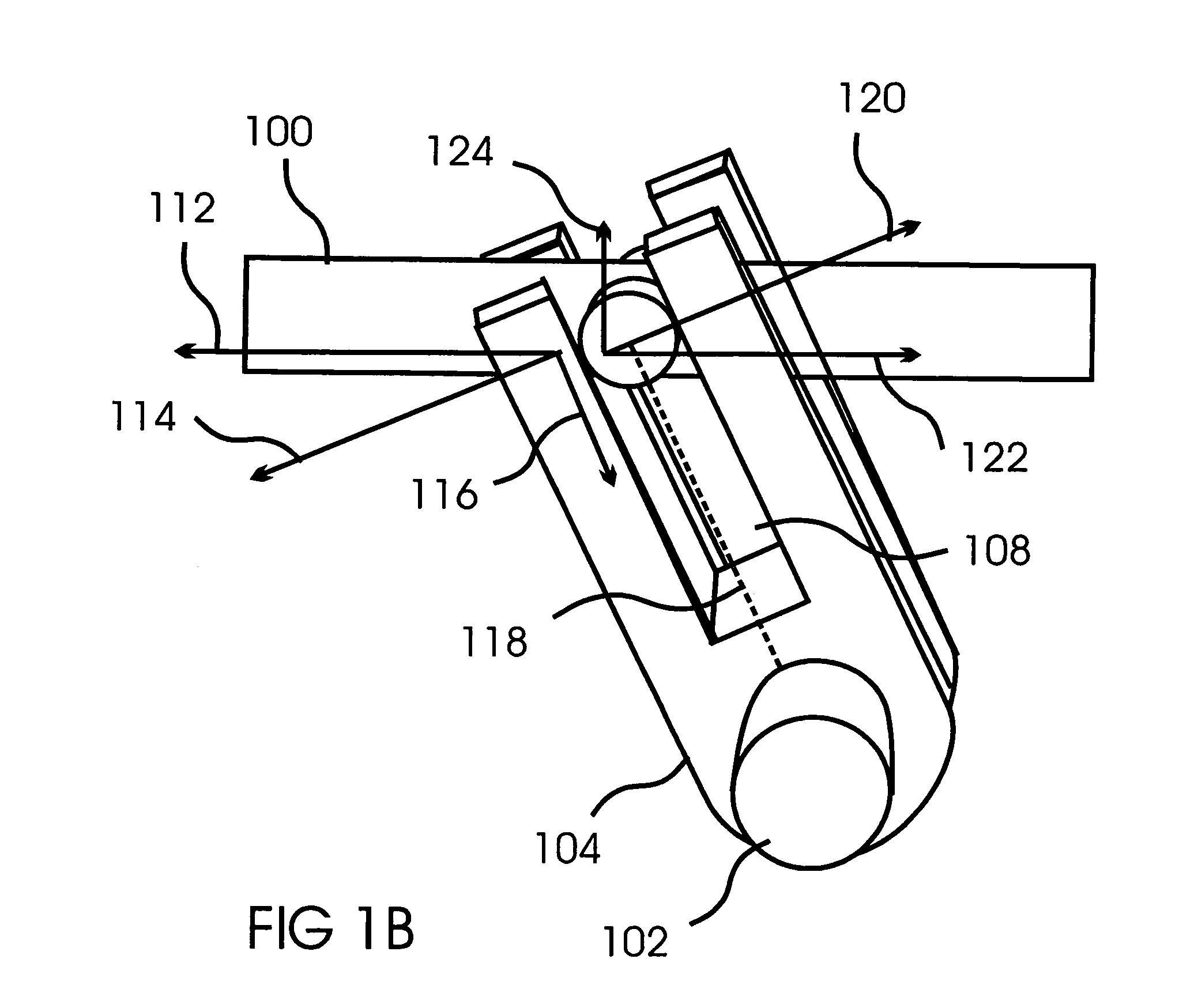

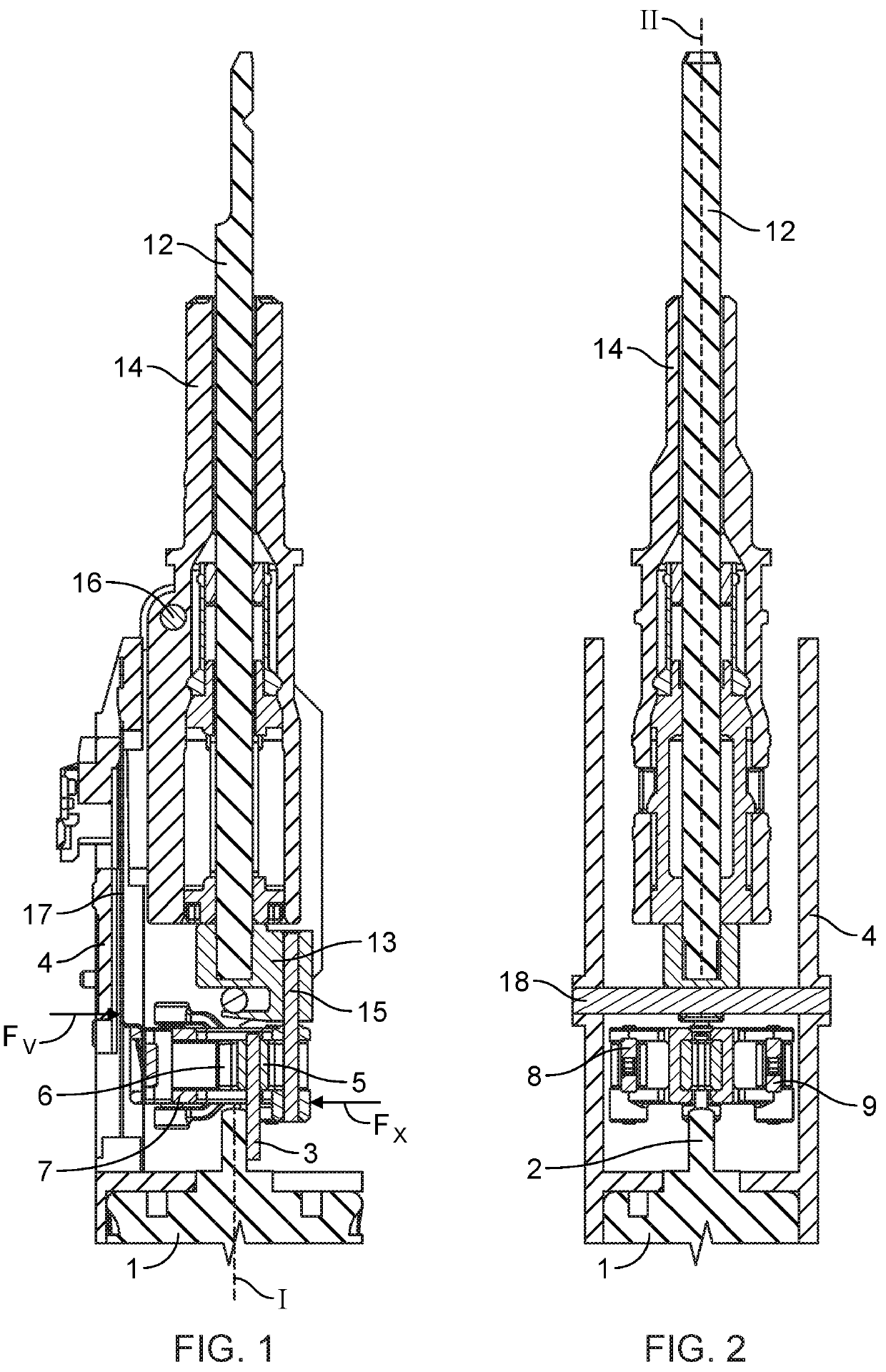

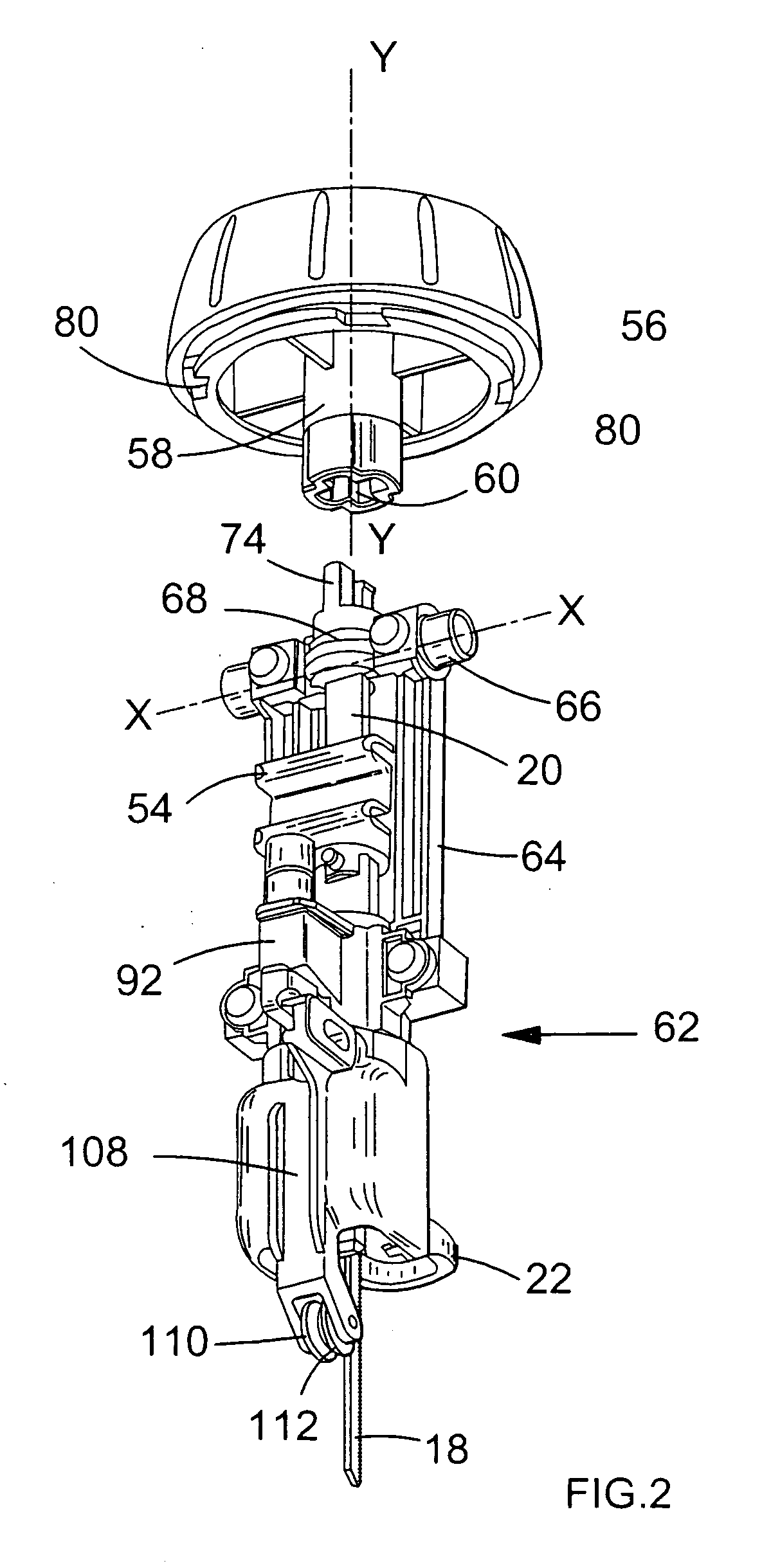

Output shaft assembly for power tool and power tool incorporating such assembly

InactiveUS20050257383A1Easy constructionLow costMetal sawing devicesGang saw millsReciprocating motionPower tool

An output shaft assembly for a jigsaw having a tool housing, a motor arranged in the tool housing, and an output shaft adapted to be driven in a reciprocating motion relative to the tool housing by means of the motor and to support jigsaw blade for reciprocating motion of the blade relative to the tool housing is disclosed. The output shaft assembly comprises an output shaft (20) of generally flat cross section and having a pair of generally D-shaped inserts (94) to form a region of generally circular external cross-section to allow the output shaft (20) to pivot relative to a scotch yoke mechanism (54) for driving the output shaft in a reciprocating motion relative to the tool housing. A jigsaw incorporating the output shaft assembly is also disclosed.

Owner:BLACK & DECKER INC

Flat yoke valve actuator

ActiveUS8087316B2Reduce frictionOperating means/releasing devices for valvesGearingSymmetric designValve actuator

A Scotch yoke actuator is disclosed with a dual yoke and a diagonally symmetric design. A pair of shafts and pushing devices apply equal, opposing forces to the yoke, causing end loading forces applied to a rotatable shaft attached to the center of the yoke to be cancelled. In embodiments, the weight of the pushing devices is balanced about the yoke, each shaft extends in only one direction from the yoke, and / or the shafts are supported only by the yoke and the pushing devices. In embodiments that use yoke pins, the yoke pins include rollers or bearings to reduce friction, and / or two pair of yoke pin slots support protruding ends of the yoke pins. The yoke pin slots can extend to edges of a yoke housing face, allowing easy shaft removal and reinstallation, and each shaft can include a split end with extensions on opposing sides of the yoke.

Owner:HOLTGRAVER EDWARD GEORGE

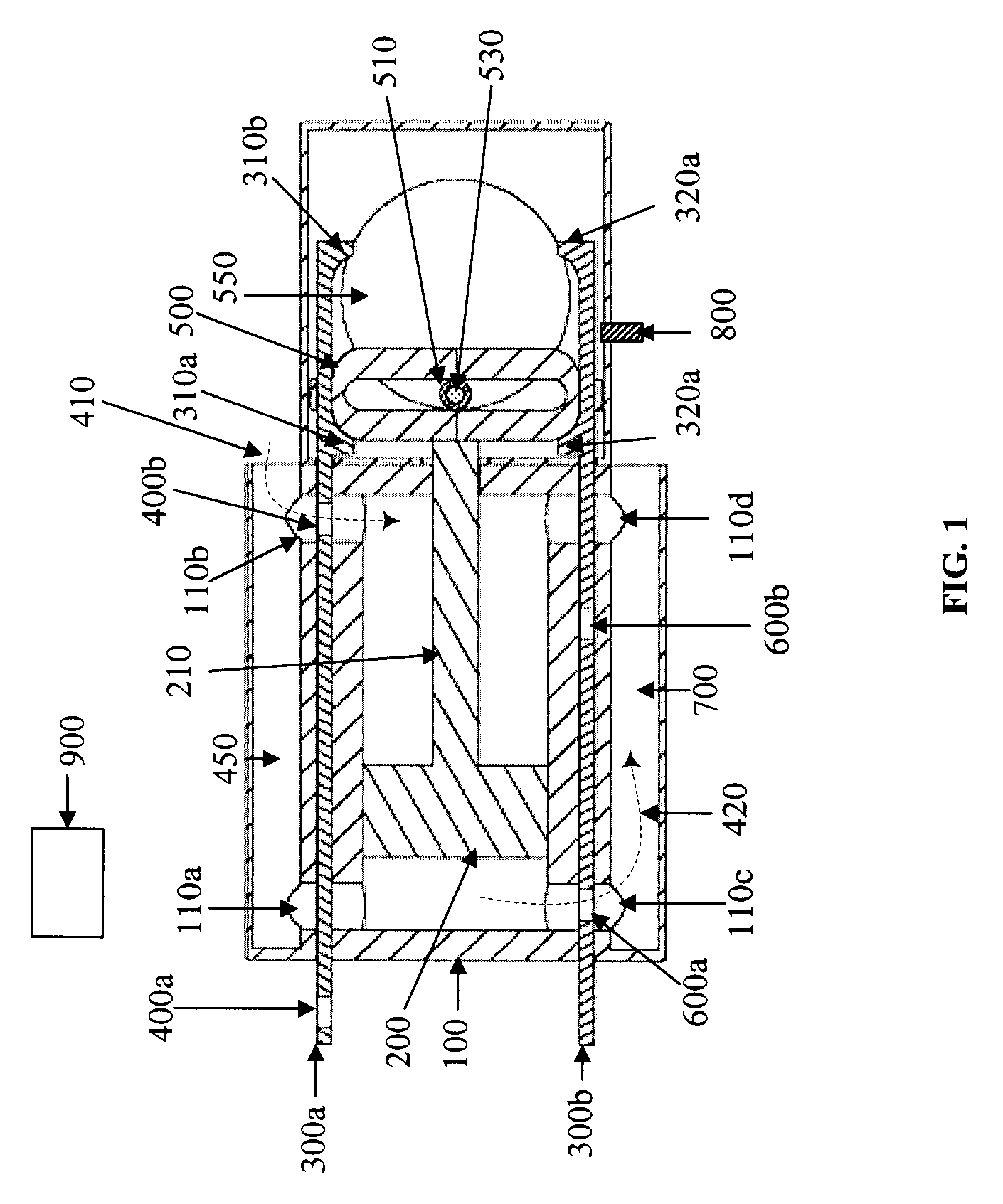

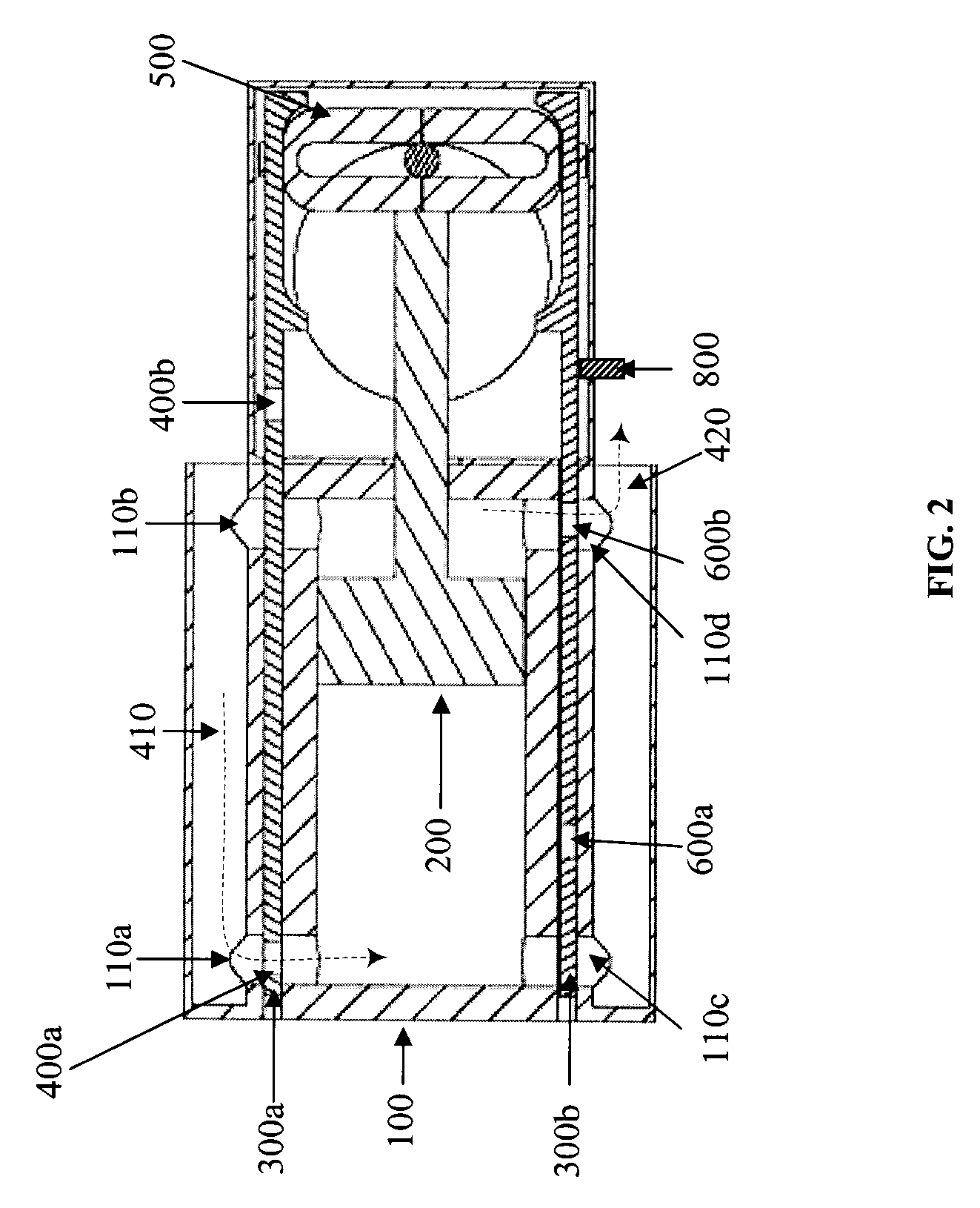

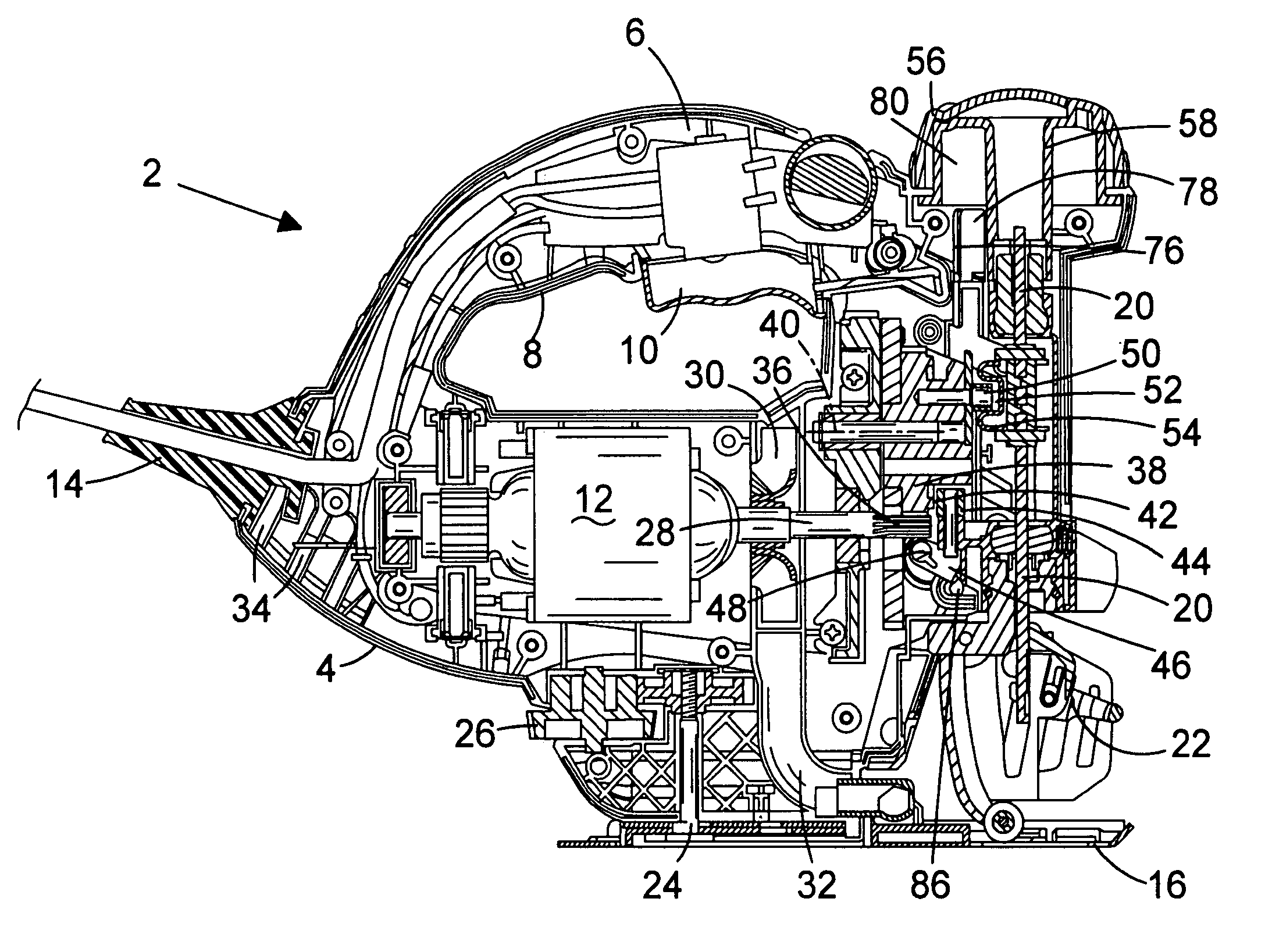

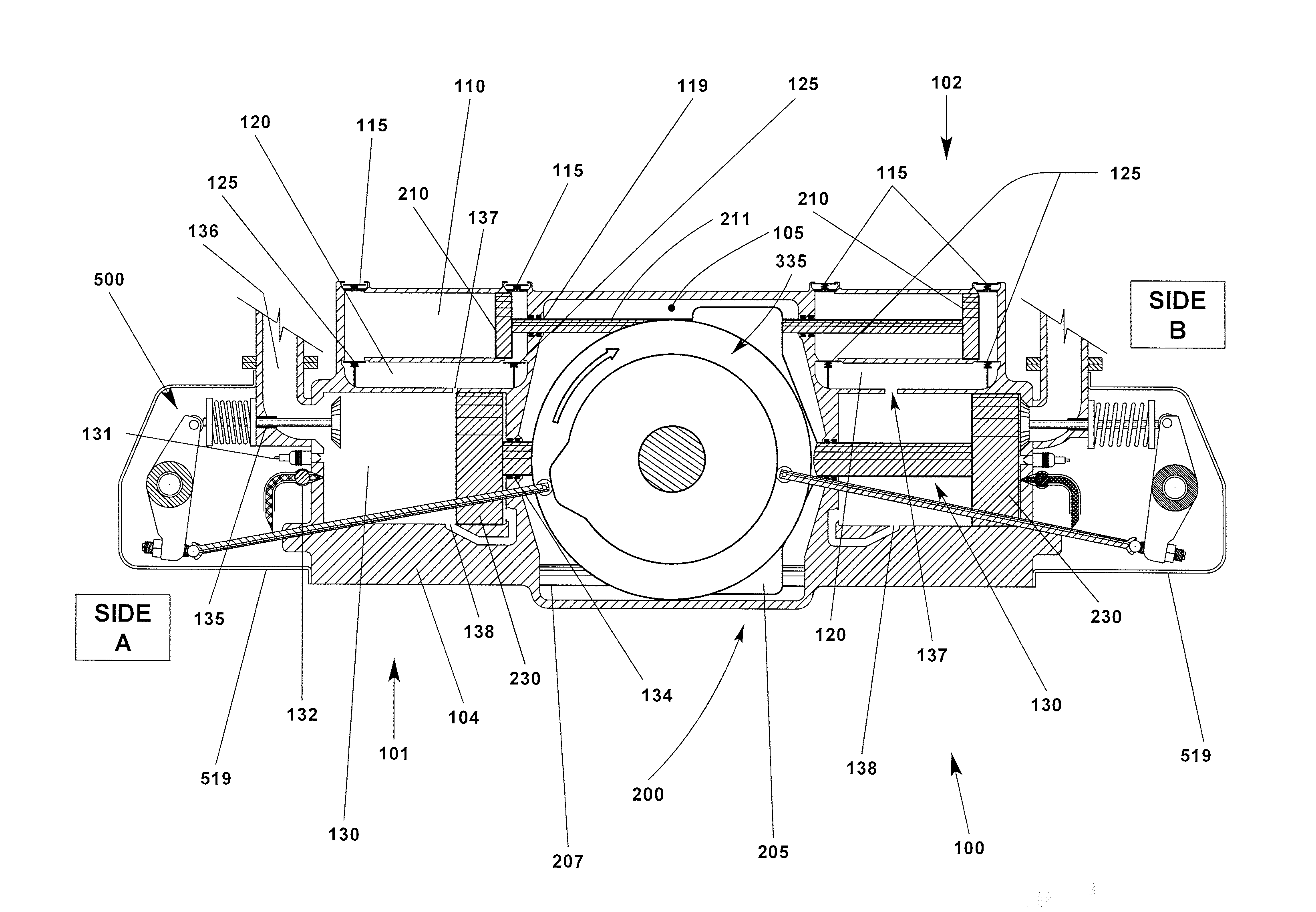

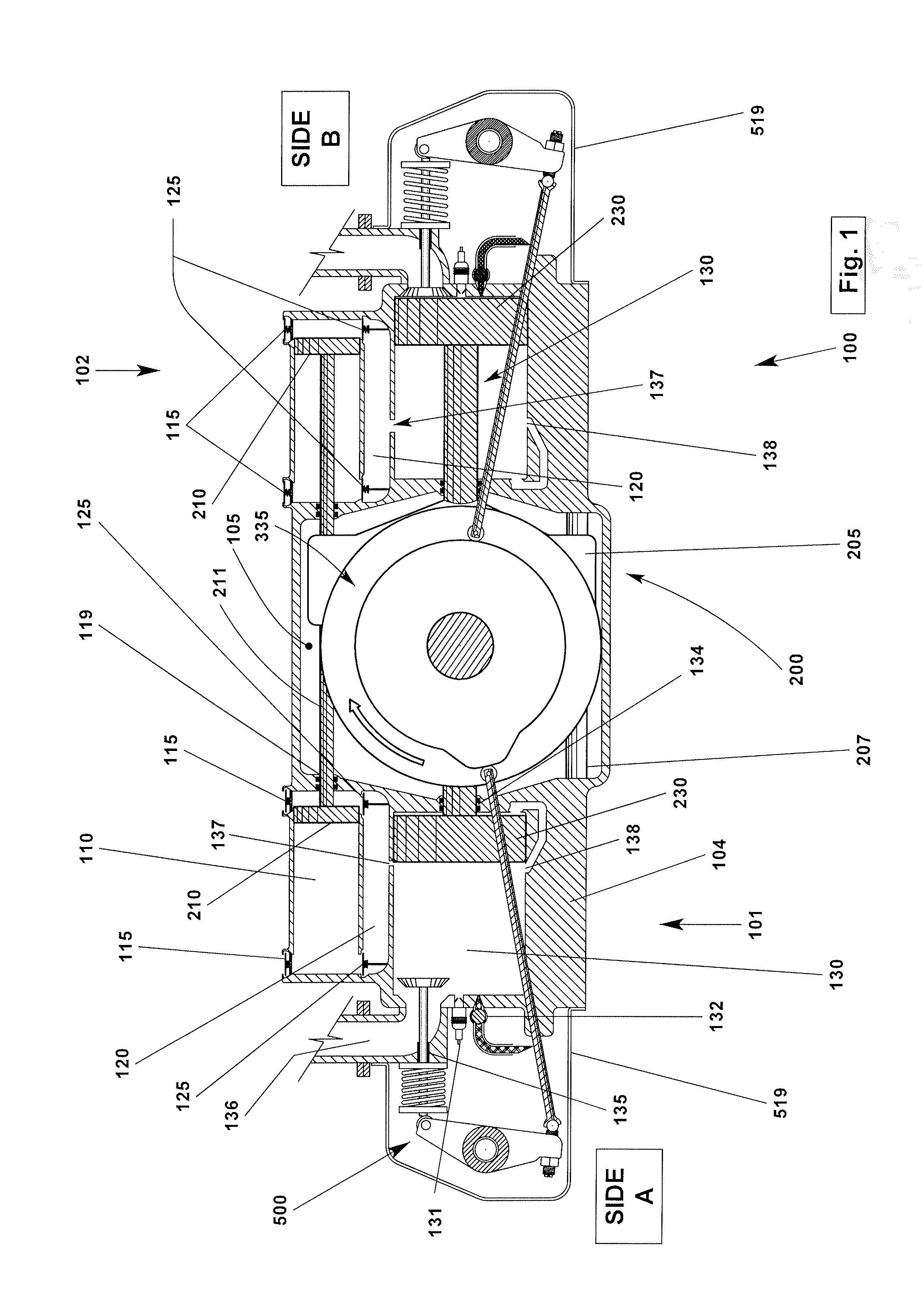

Opposed piston internal combustion engine with inviscid layer sealing

InactiveUS20140318518A1Accurate concentricityWell mixedCombustion enginesReciprocating piston enginesCombustionDetonation

An opposed-piston engine that forms an inviscid layer between pistons and the respective cylinder walls. In an aspect, the opposed-piston engine utilizes a Scotch yoke assembly that includes rigidly connected opposed combustion pistons. In an aspect, the Scotch yoke assembly is configured to transfer power from the combustion pistons to a crankshaft assembly. In an aspect, the crankshaft assembly can be configured to have dual flywheels that are internal to the engine, and can be configured to assist with an exhaust system, a detonation system, and / or a lubrication system.

Owner:PRIME GRP ALLIANCE

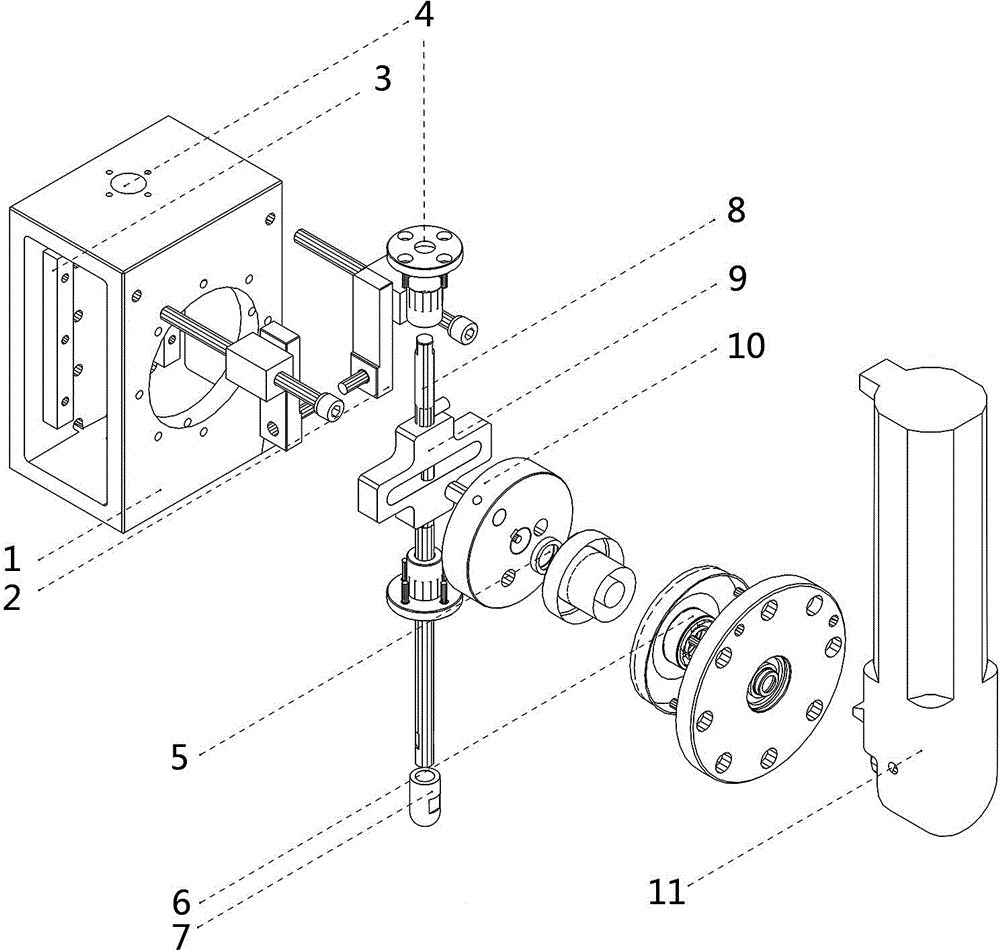

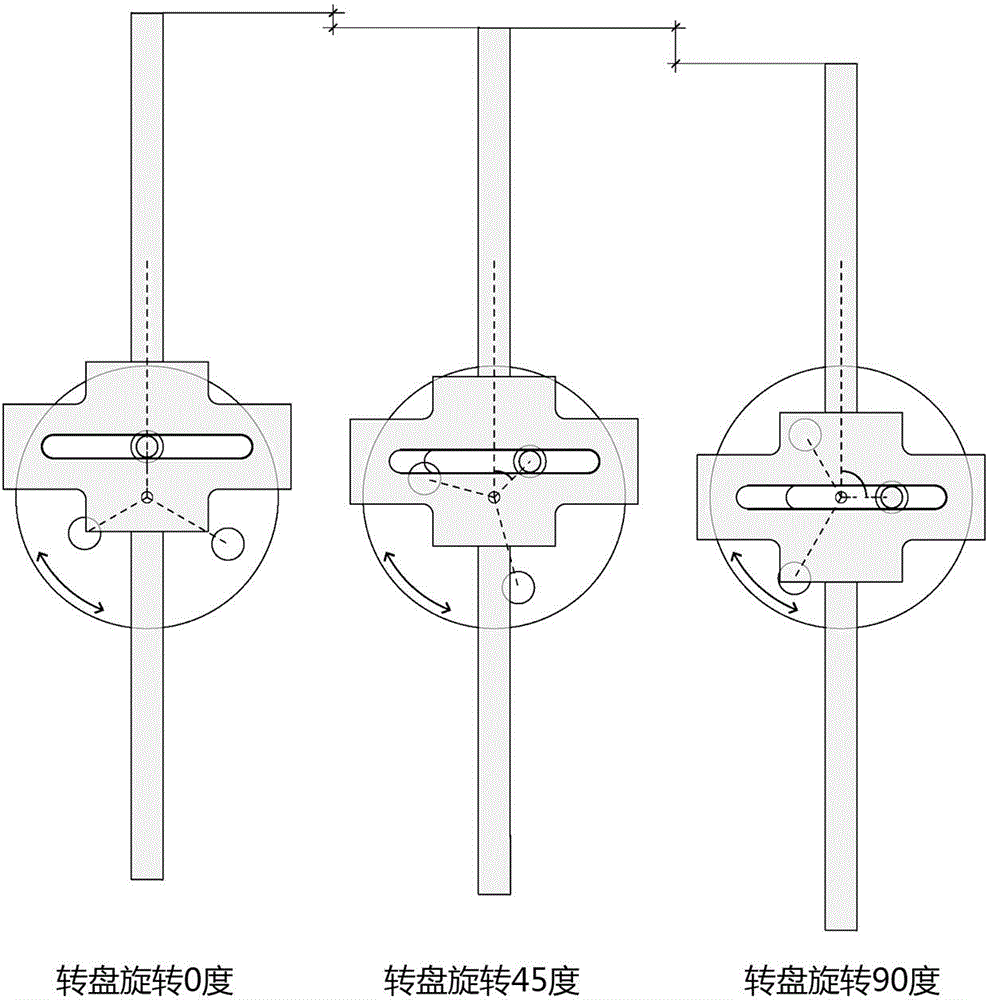

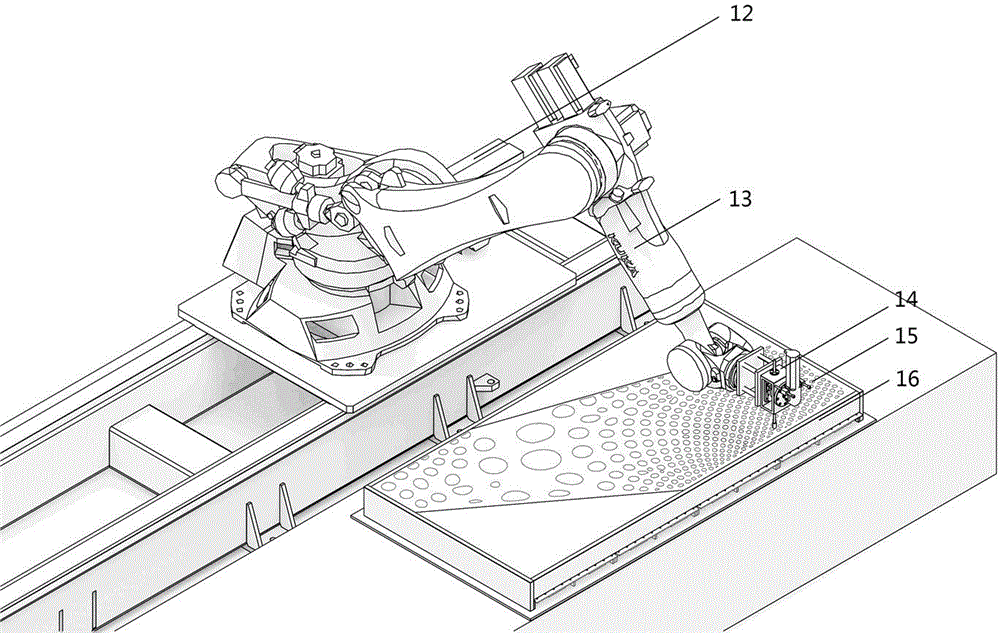

Metal hammering machining tool applied to robotic arm

The invention provides a metal hammering machining tool applied to a six-axis robotic arm. The metal hammering machining tool applied to the six-axis robotic arm is composed of an aluminum alloy supporting frame, an aluminum alloy cable clamp, a hammering head and a direct current motor. The hammering head is composed of a steel striking head, steel rods, a scotch yoke, a rotary disk, a collar, bearings and a fixed disk. The two steel rods in an upper and lower arrangement mode are connected through the Scottish yoke. The steel striking head is arranged at the bottom of the steel rods. One end of the upper steel rod is inserted into the linear bearing at the top of the aluminum alloy supporting frame. One end of the lower steel rod is inserted into the linear bearing at the bottom of the aluminum alloy supporting frame. One side of the aluminum alloy supporting frame is provided with a round hole. The direct current motor is arranged at the round hole and fixed to the aluminum alloy supporting frame through the aluminum alloy cable clamp. A rotating shaft of the direct current motor is inserted into the bearings. The bearings, the fixed disk, the collar and the rotary disk are concentrically mounted together to form a whole fixed to the aluminum alloy supporting frame through screws. An eccentric shaft of the rotary disk is inserted into the scotch yoke. The metal hammering machining tool applied to the six-axis robotic arm is simple in structure and easy to operate.

Owner:上海一造科技有限公司

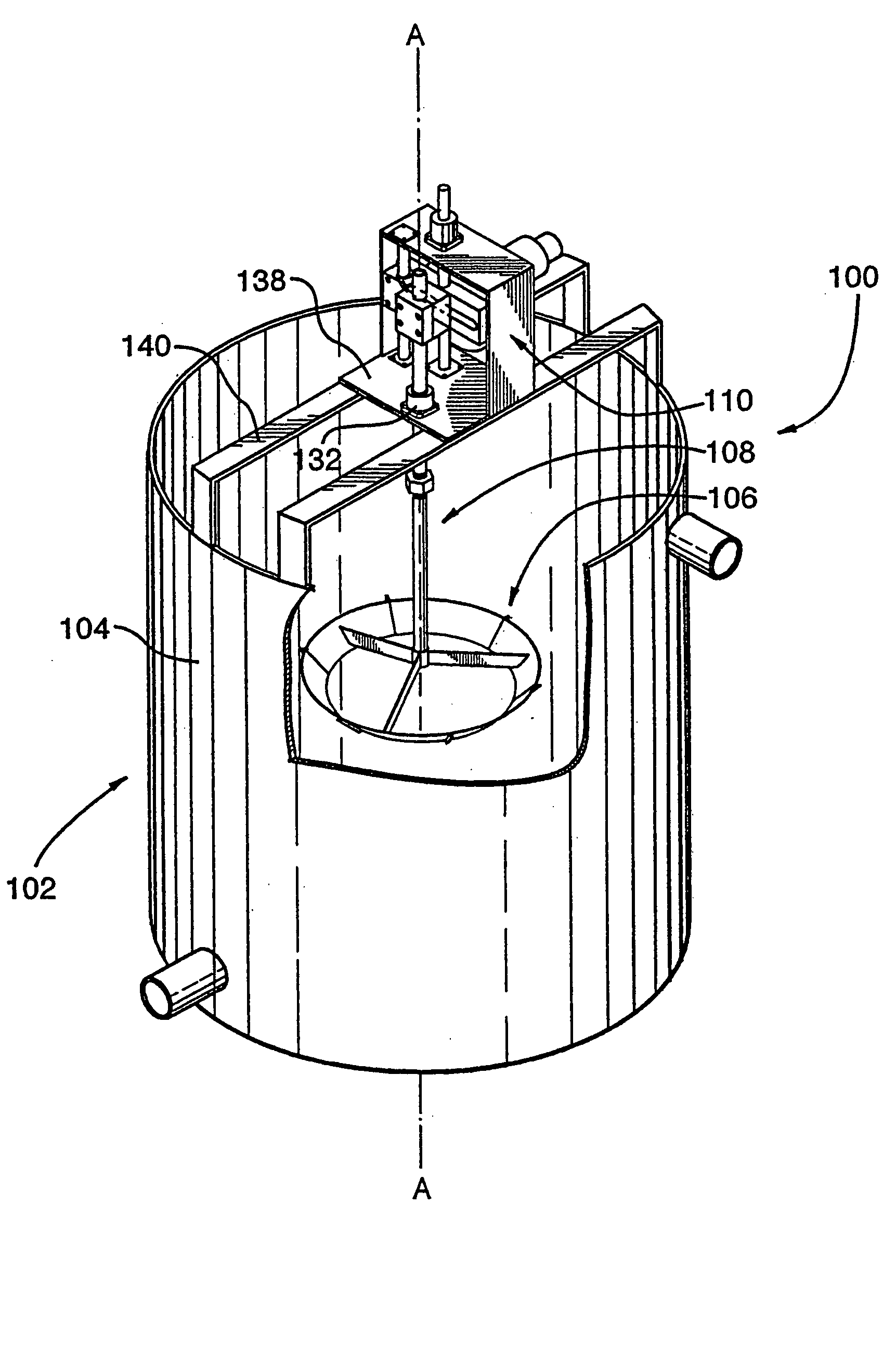

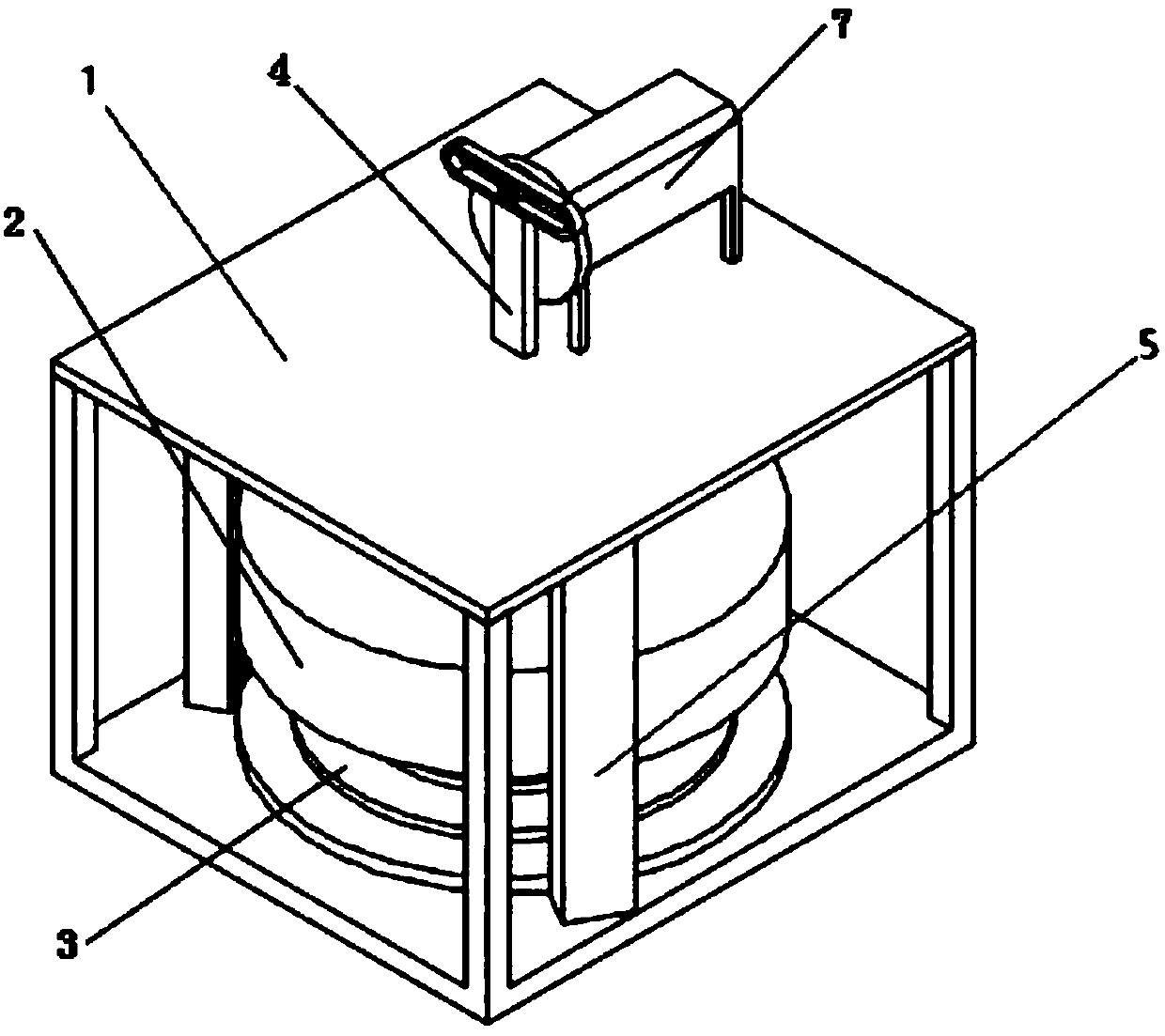

Nucleic acid extraction device

ActiveCN101205246AAchieve uniform preparationReduce cross contaminationSugar derivativesSugar derivatives preparationControl systemEngineering

The invention relates to a nucleic acid extracting device, which is characterized in that the nucleic acid extracting device comprises an oscillator component, a sample holder component, a control system and a frame; the oscillator component comprises an electric motor, an eccentric sleeve connected on the output shaft of the electric motor, a bearing connected on the eccentric shaft of the eccentric sleeve and a bearing sleeve connected on the external ring of the bearing; a threaded sleeve integrated with the bearing sleeve is arranged at the top of the bearing sleeve and a rotation stopping sleeve is arranged on the retaining plate of the electric motor; a plurality of extension springs are connected between the rotation stopping sleeve and the bearing sleeve; the sample holder component comprises a test tube stand, a plurality of sample tubes inserted and arranged on the test tube stand and a scotch yoke arranged at the top of the sample tube; the top of the scotch yoke is connected with a locking cover and the top of the locking cover is connected with a locking handle; the bottom screw rod of the locking handle passes through the locking cover, the scotch yoke and the test tube stand so as to be fixed in the threaded sleeve of the oscillator component and the scotch yoke is elastically connected with the test tube stand. The invention can be used for extracting the nucleic acids of the microorganicsms such as the bacteria (G+ bacteria, G-bacteria, mycobacterium), fungi (yeast, white candida), viruses, etc., including the extraction of the RNA.

Owner:CAPITALBIO CORP +1

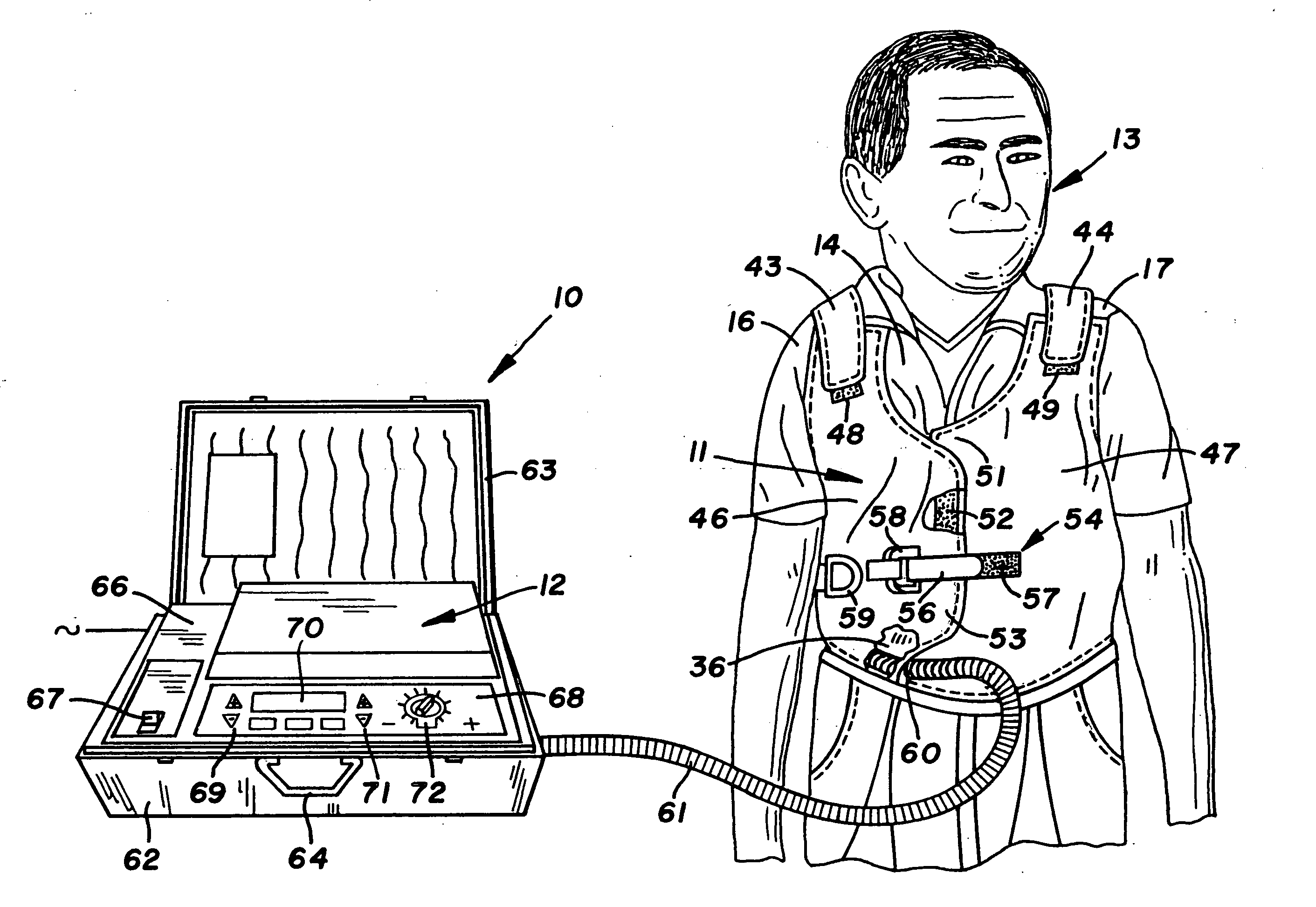

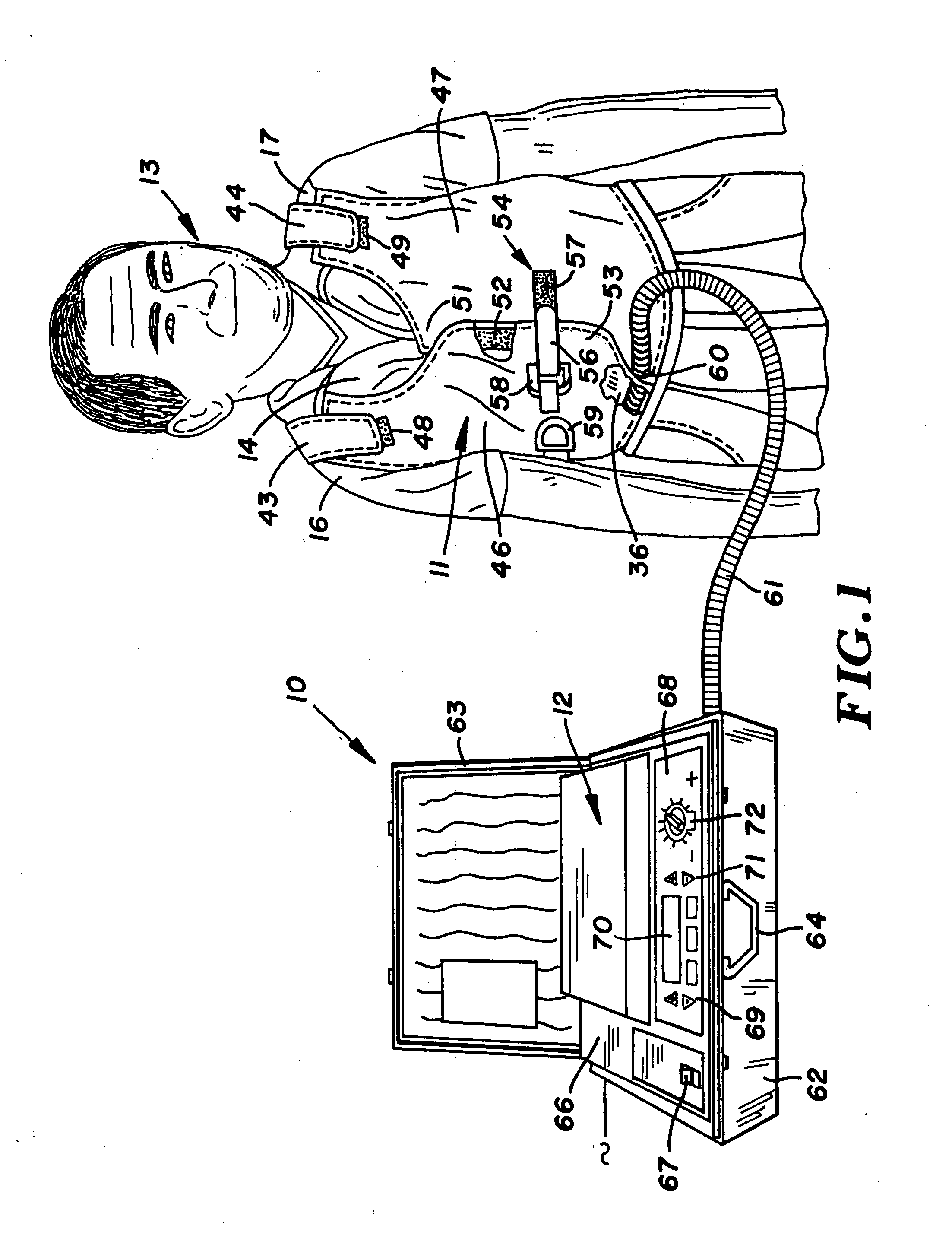

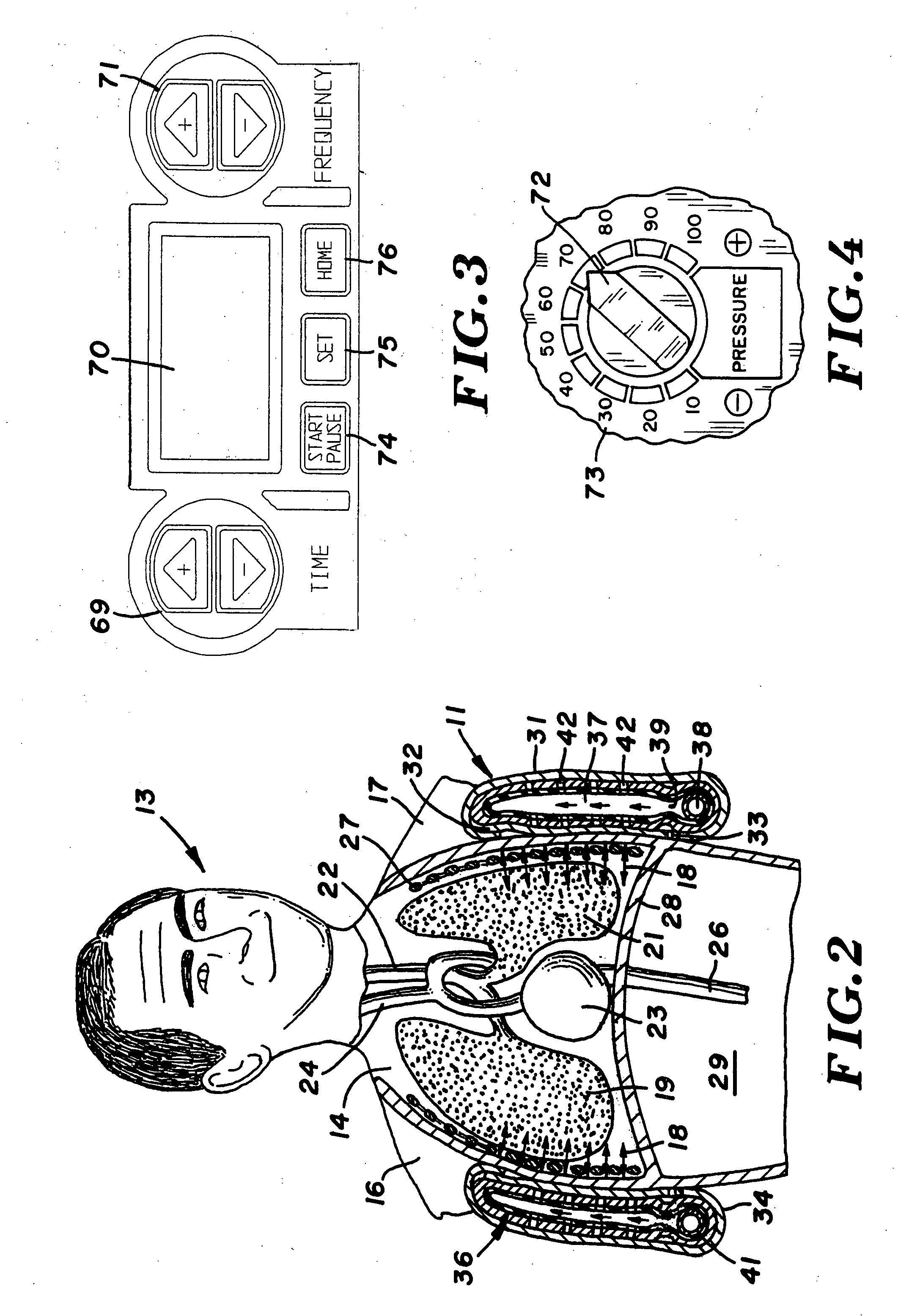

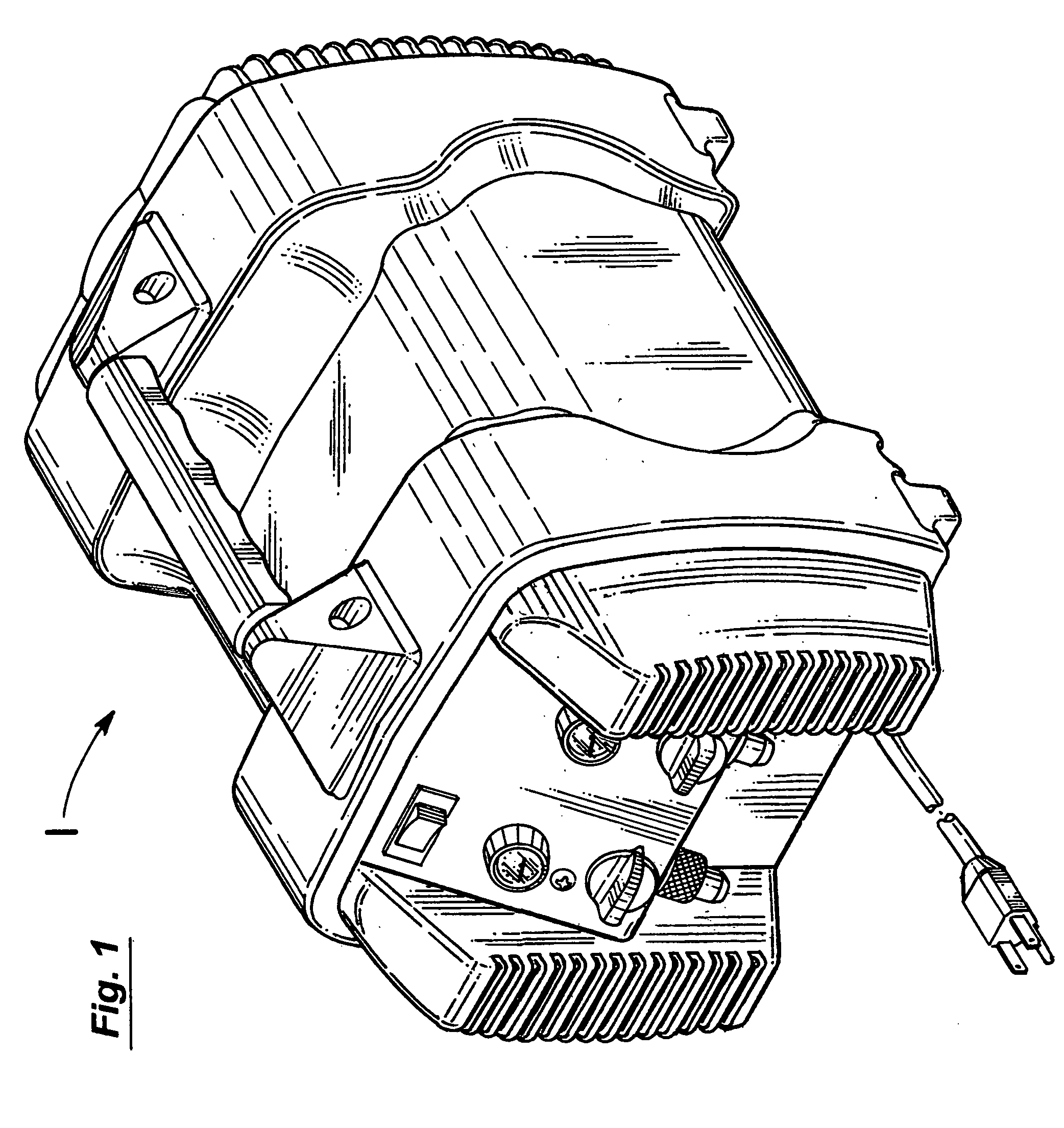

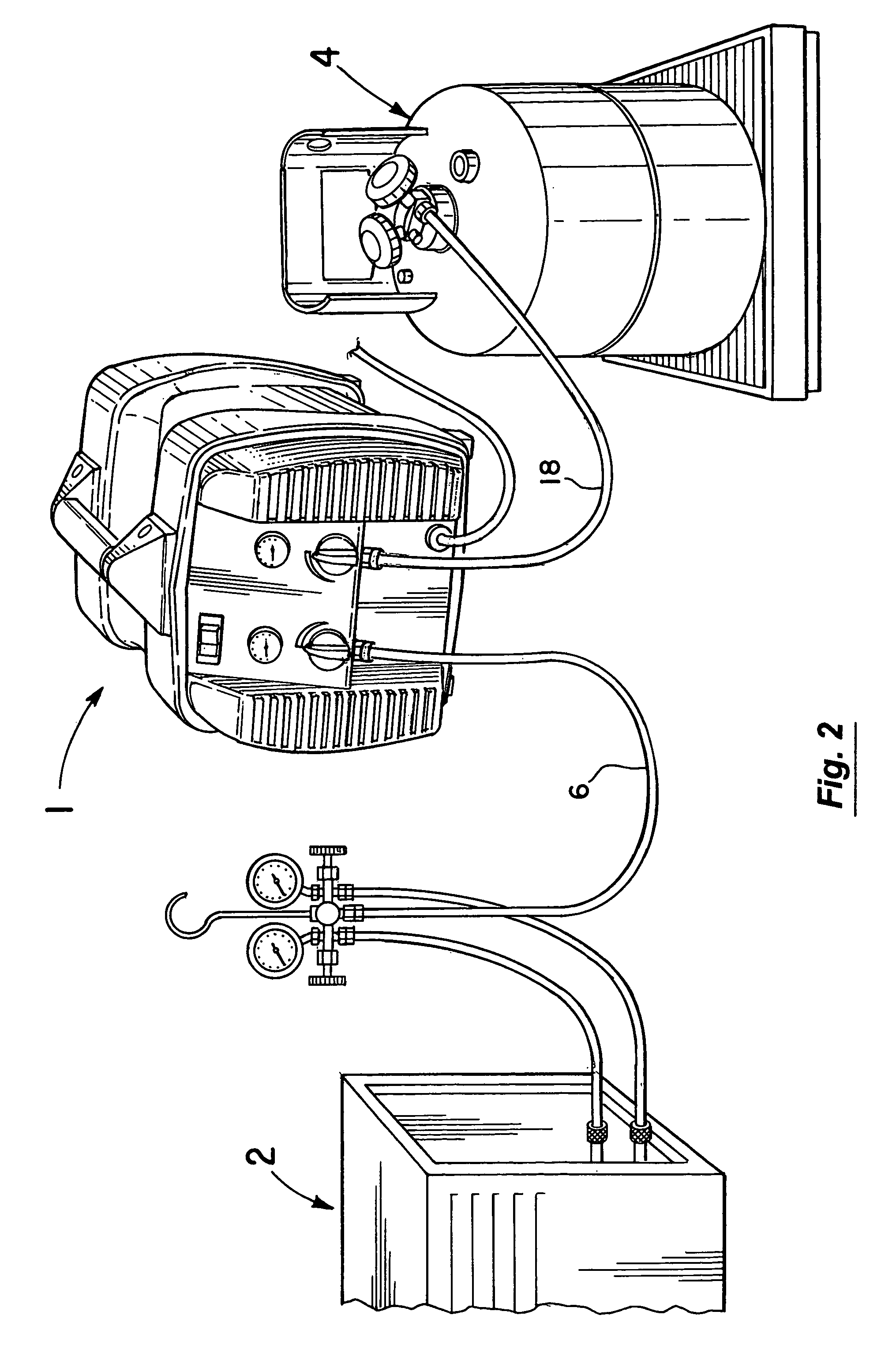

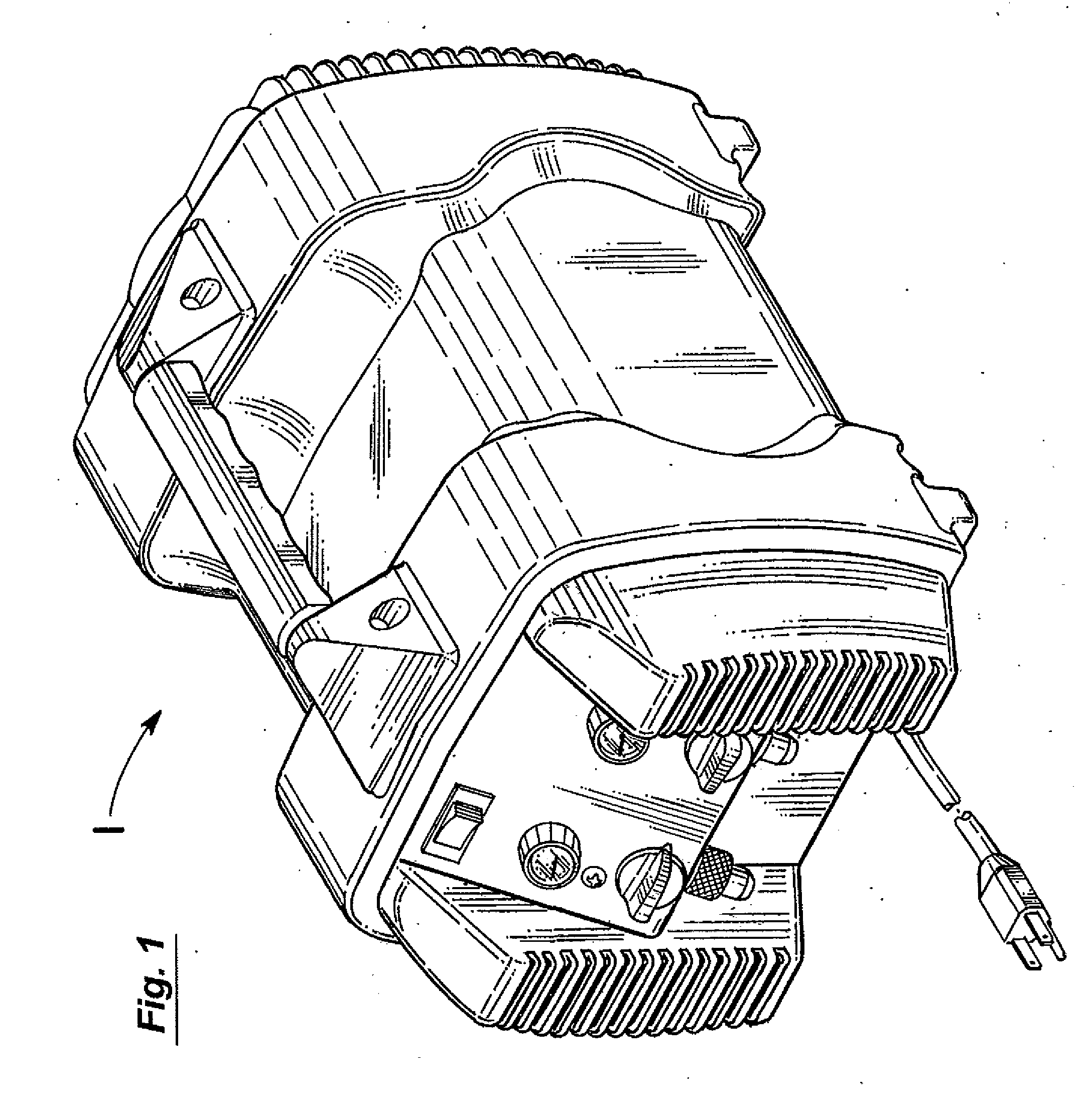

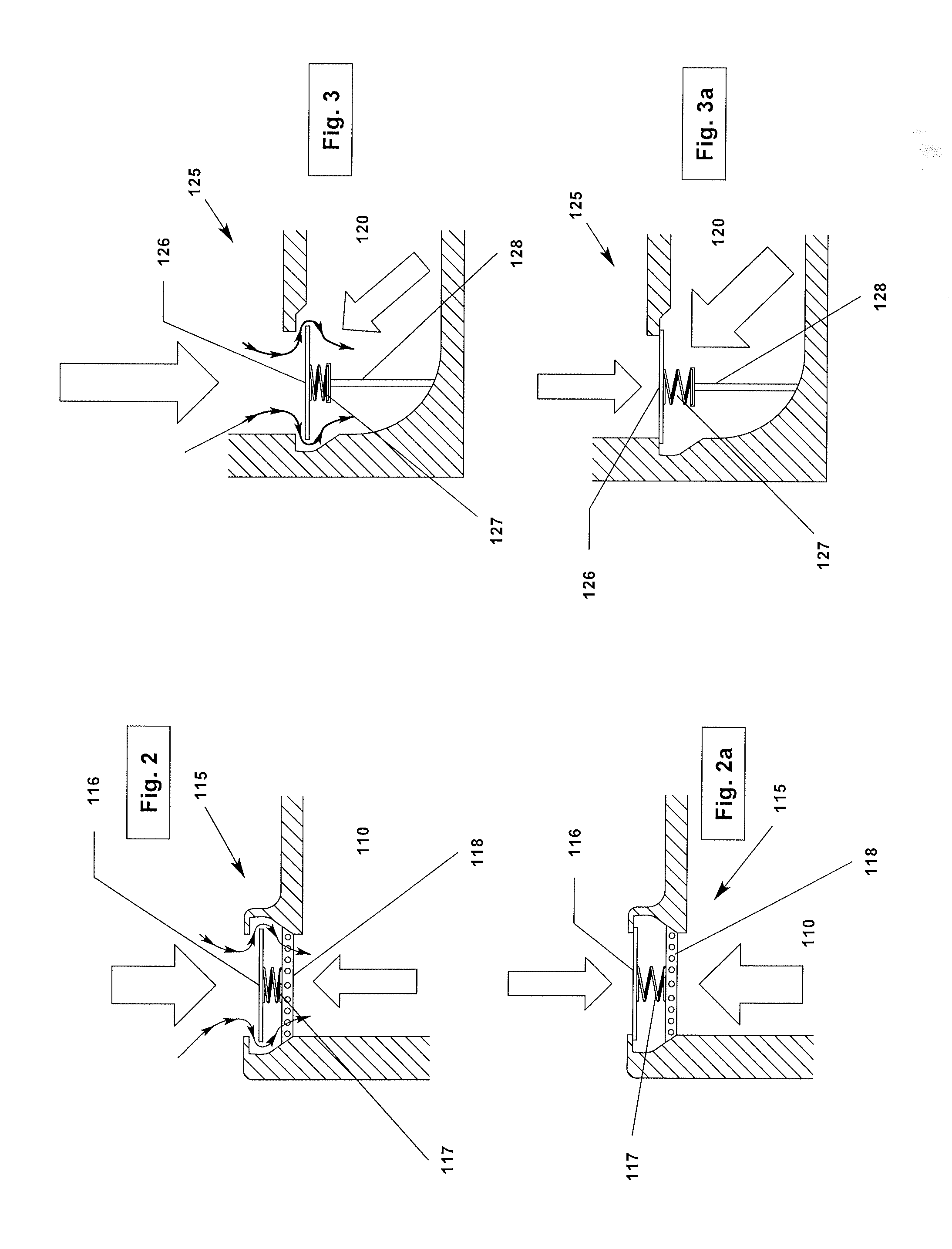

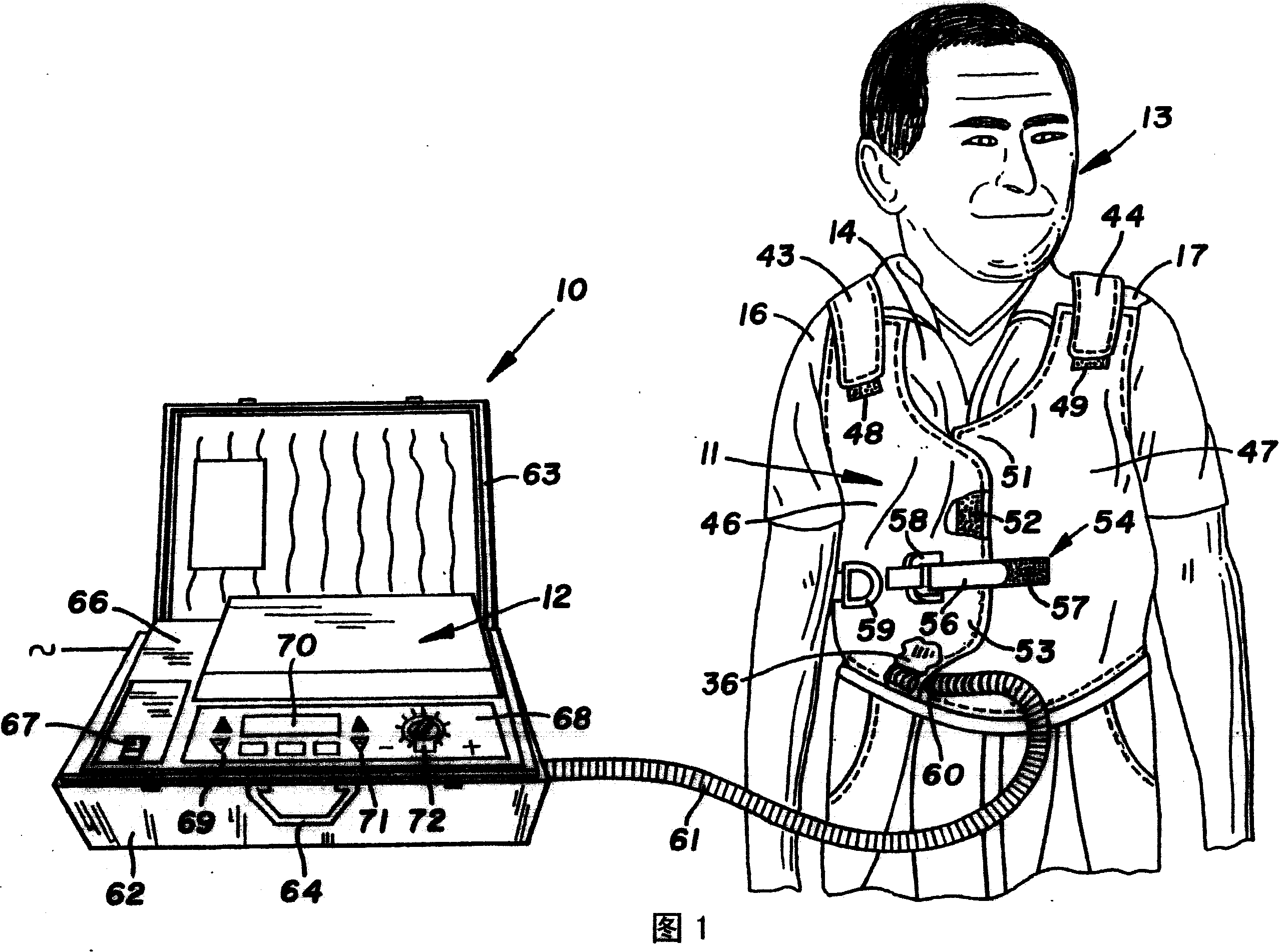

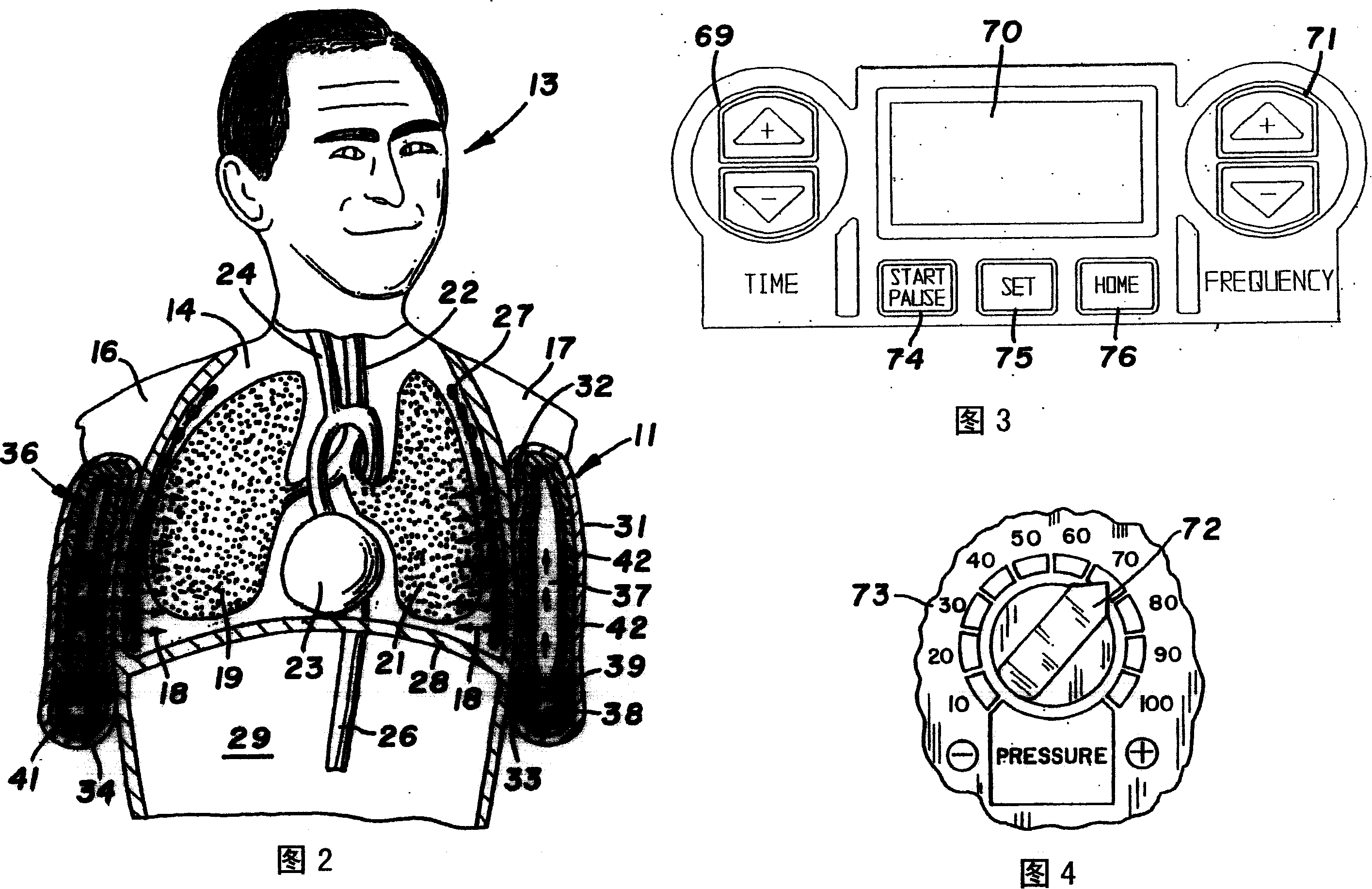

Body pulsating method and apparatus

A vest for a human body has an air core coupled to a pulsator operable to subject the vest to pulses of air which applies and releases high frequency pressure forces to the body. The pulsator has two diaphragms connected to a brushless electric dc motor with rotary to reciprocating linear motion transmitting mechanisms comprising scotch yokes having anti-lash assemblies operable to generate air pulses in an air pulsing chamber. The diaphragms also increase the pressure in a manifold chamber. A check valve connects the manifold chamber with a pulsing chamber to allow pressurized air to flow from the manifold chamber into the pulsing chamber. An air flow control valve in communication with the manifold chamber is used to adjust the pressure of the air in the manifold and pulsing chambers. A programmable motor controller adjusts the duration of operation and speed of the motor to vary the operational time and frequency of the air pulses.

Owner:ELECTROMED INC

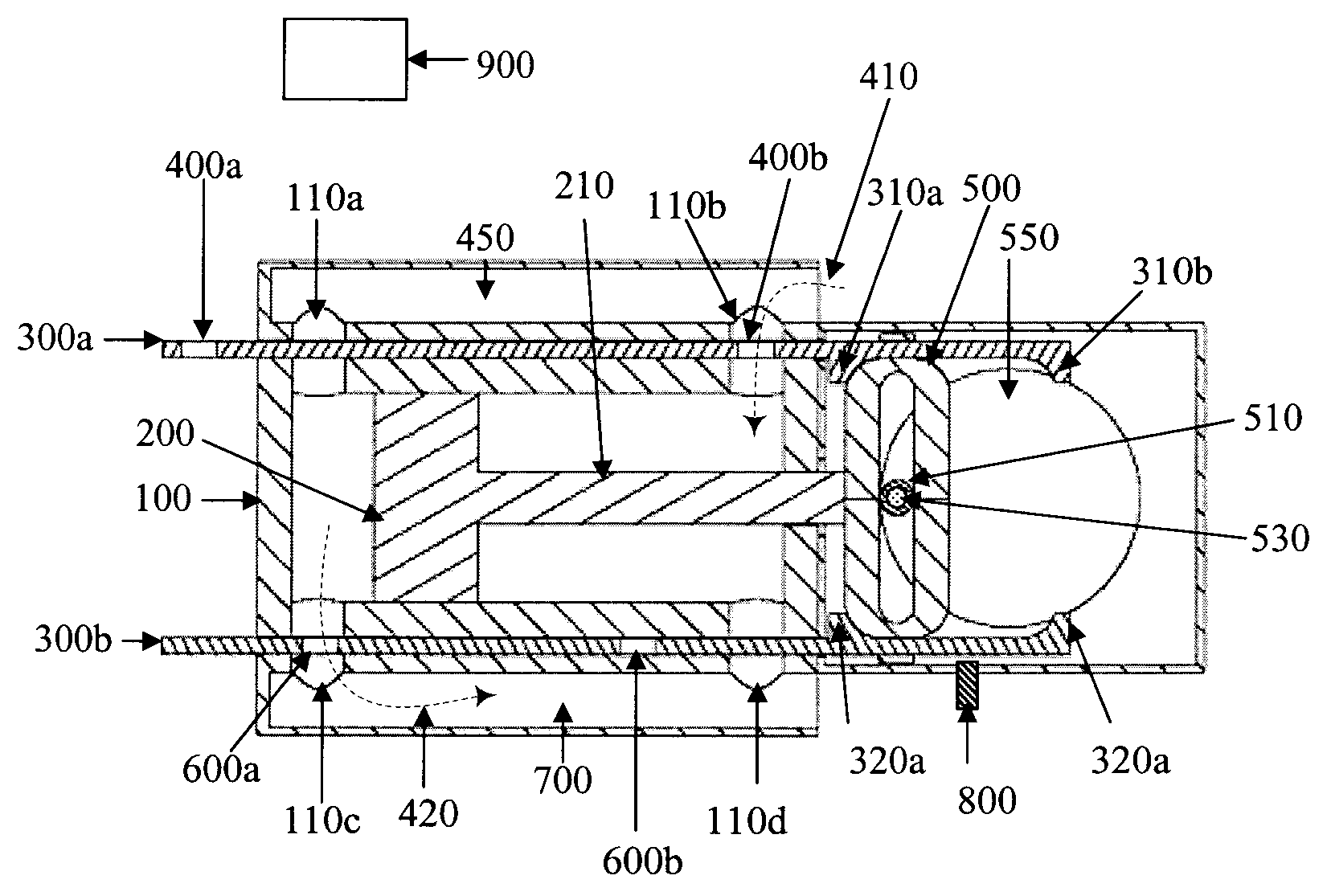

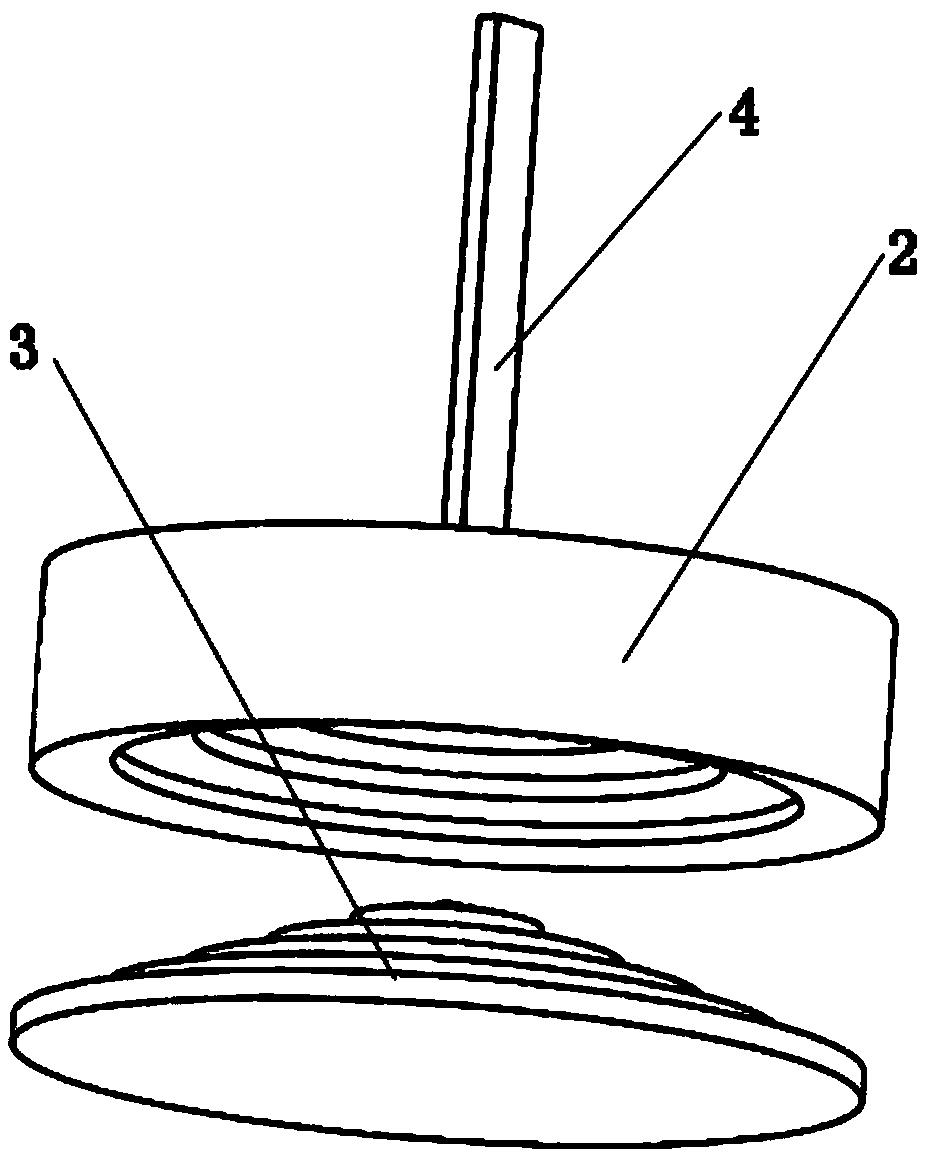

Cryogenic refrigerator

ActiveCN104422192AShorten the overall lengthCompression machinesRefrigeration componentsEngineeringRefrigerant

In a cryogenic refrigerator, a scotch yoke mechanism includes an eccentric rotating body and a yoke plate that reciprocates by rotation of the eccentric rotating body. A displacer is connected to a yoke plate so as to reciprocate together with the yoke plate. A cylinder houses a displacer, and an expansion space for refrigerant gas is formed in a space with the displacer. An airtight container is provided on a high-temperature side of the cylinder and includes a housing space housing a scotch yoke mechanism and receive the refrigerant gas discharged from the expansion space. The airtight container includes a supporting unit that supports a side portion of the yoke plate so as to restrict tilting of the yoke plate around a rotary shaft of the eccentric rotating body.

Owner:SUMITOMO HEAVY IND LTD

Electrically driven device

An electrically driven device includes an electric motor with a drive shaft having a first rotary axis and a drive pin eccentrically thereto, and a driven shaft having a second rotary axis and mounted for pivoting motion. The driven shaft is coupled to the drive shaft by a scotch yoke mechanism, converting a rotary motion of the drive shaft into a reciprocating pivoting motion of the driven shaft. The scotch yoke mechanism includes a cross slider having a sliding support extending perpendicular to the first rotary axis and receiving the drive pin either directly or by a sliding block having a bearing receiving the pin. The cross slider is axially guided to move in an axial direction perpendicular to the first rotary axis and to the extension of the sliding support. The driven shaft is coupled to the cross slider by a pivotable crank arm, thereby converting a rotary motion of the drive shaft into a reciprocating motion of the driven shaft.

Owner:BRAUN GMBH

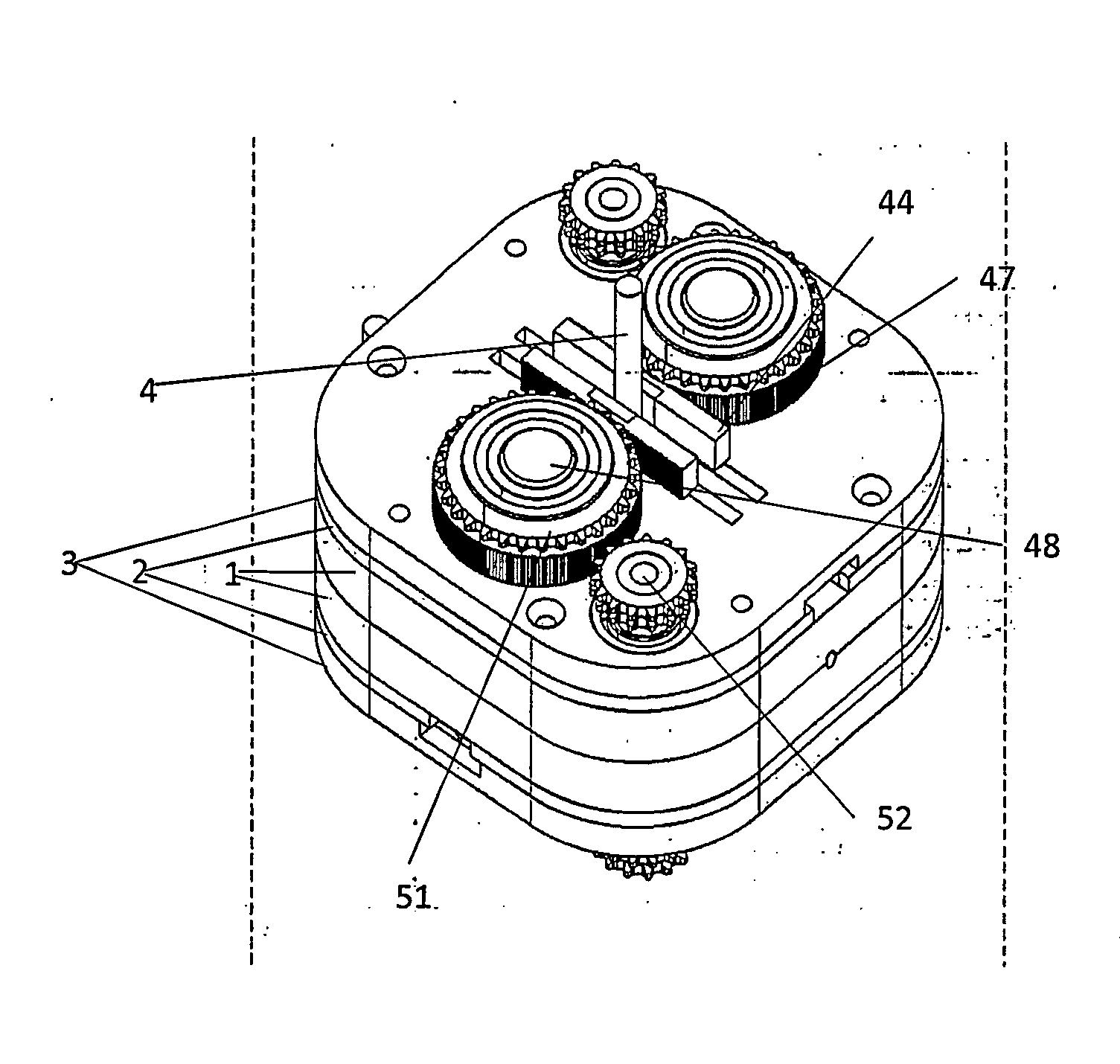

Continuous variable transmission with uniform input-to-output ratio that is non-dependent on friction

ActiveUS20150267794A1Uniform and stable outputSmall sizeFriction gearingsControl theoryContinuous variable

This invention is a continuous variable transmission. This invention uses a mechanism known as “scotch yoke” principle to change the ratio of the input and output in the transmission. This invention uses a set of non-circular gears and circular gears to modify the input received from a system to deliver a steady and uniform output. It employs a unique way to change the ratio between the input and output of the transmission. Three very simple mechanisms are used to achieve changing the ratio. The option of reverse, park, and neutral gear mechanisms are integrated into this design. This invention offers a co-axial input to output feasibility.

Owner:RAJENDRAN RAJA RAMANUJAM +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com