Speed adjustment mechanism for conical plate type continuously variable transmission and conical plate type continuously variable transmission

A technology of continuously variable transmission and speed regulating mechanism, which is applied in the direction of instruments, controlled components, mechanical equipment, etc. It can solve the problems of affecting the life of bearings, insufficient compact axial size, and excessive heat generation of bearings, and achieves compact structure, axial Dimension simplification, effect of offsetting additional bending moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

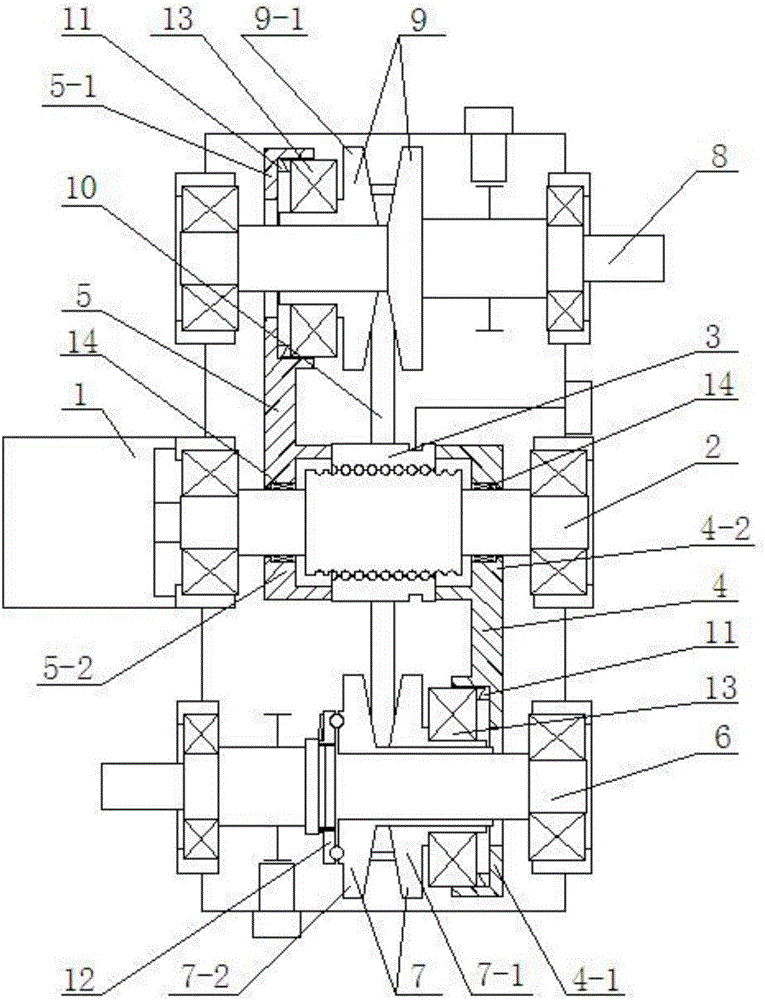

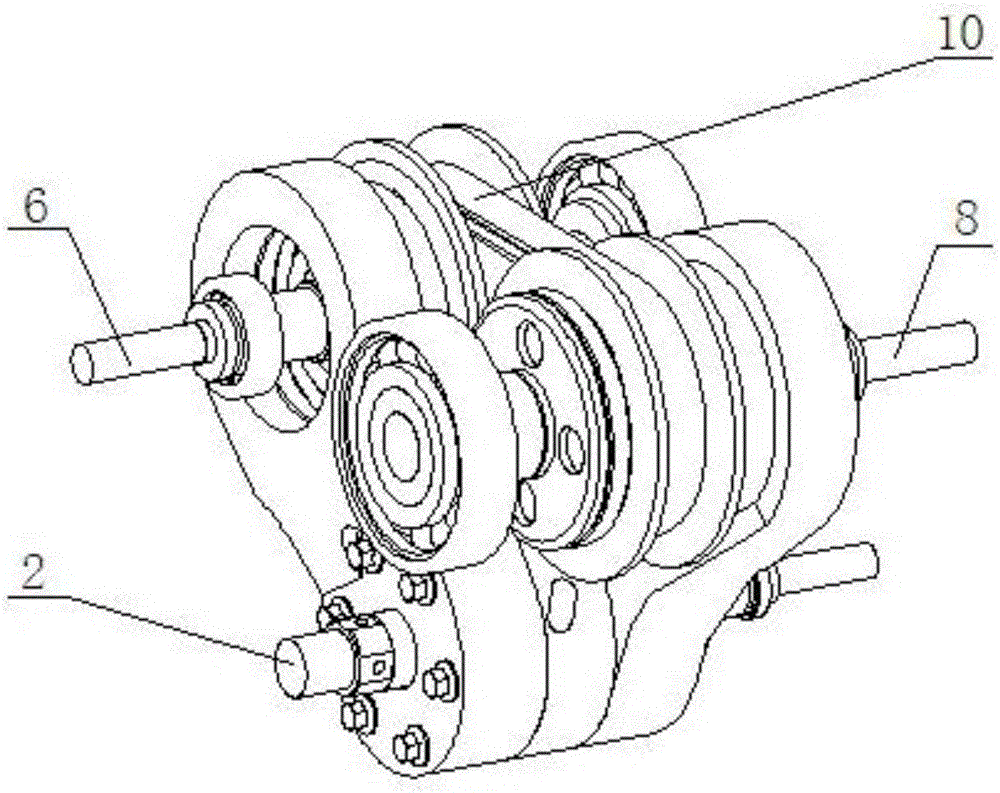

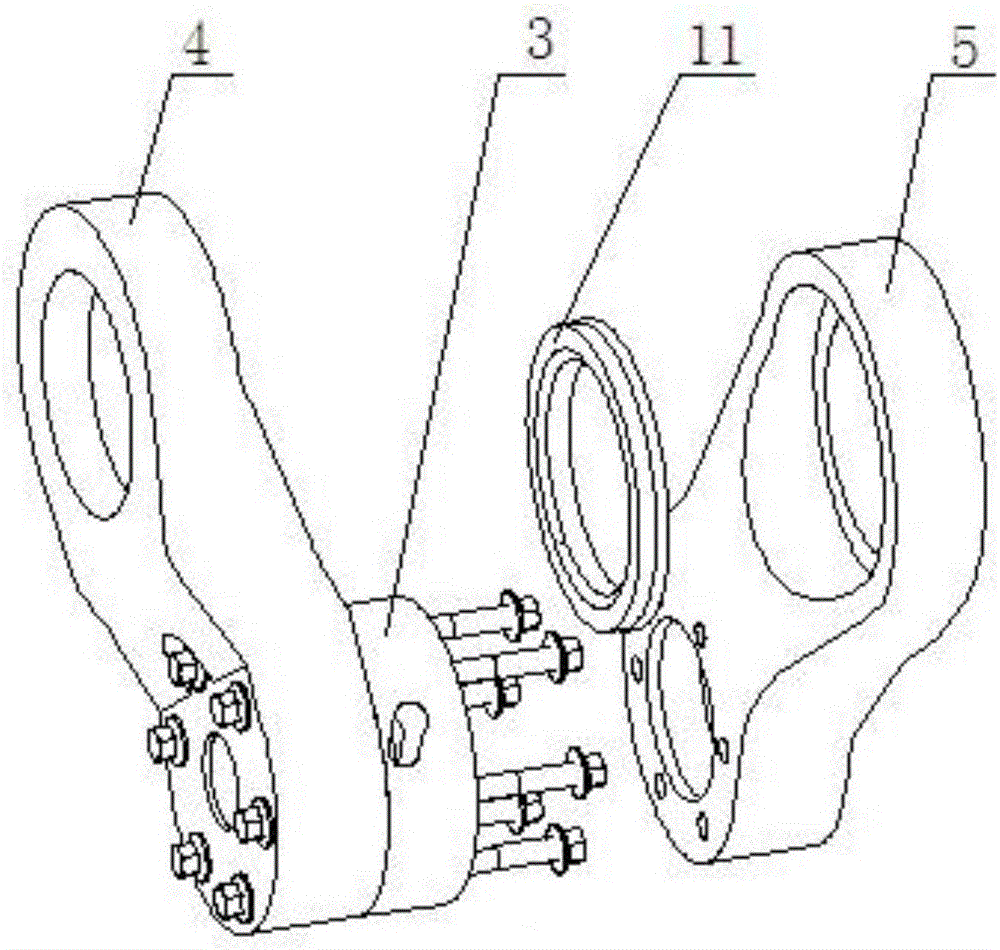

[0026] see Figure 1~3 , A conical disc type continuously variable transmission speed regulating mechanism, including a driver 1, a drive shaft connected with the driver 1 shaft 2, a drive nut 3 sleeved on the drive shaft 2 in the form of a screw pair, and two ends of the drive nut 3 And the first shift fork 4 and the second shift fork 5 are fixed on the driving nut 3. The first shift fork 4 has a first movable cone 7-1 sleeved on the transmission driving shaft 6 and pressed against the transmission driving shaft 6 The first working part 4-1 and the second shift fork 5 have a second working part 5-1 sleeved on the transmission driven shaft 8 and pressed against the second moving cone 9-1 on the transmission driven shaft 8.

[0027] The first fork 4 and the second fork 5 respectively have a first support portion 4-2 and a second support portion 5-2 sleeved on the drive shaft 2 to improve the rigidity of the first fork 4 and the second fork 5 A support bearing 14 is provided betwe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com