Patents

Literature

118results about How to "Good thrust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Catheter

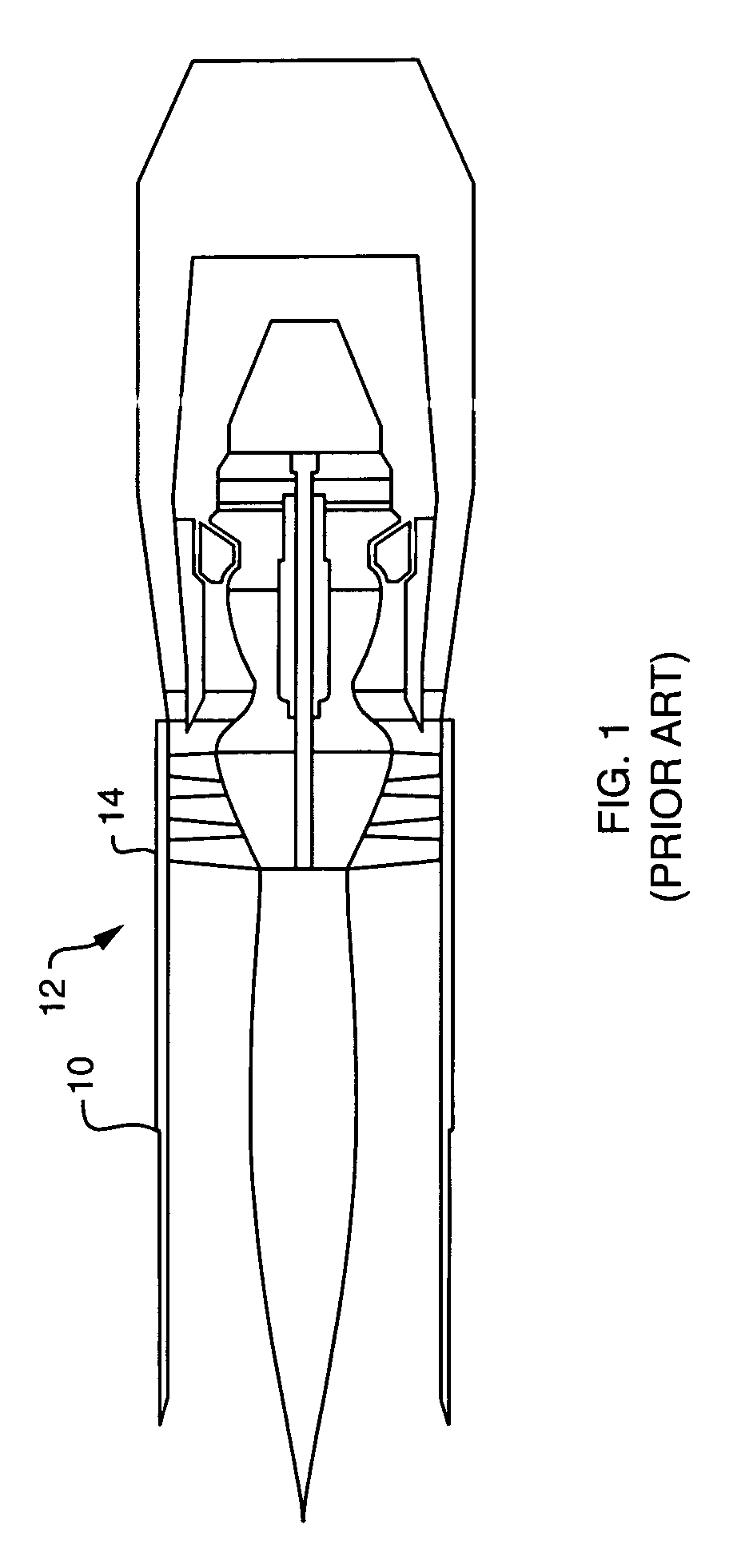

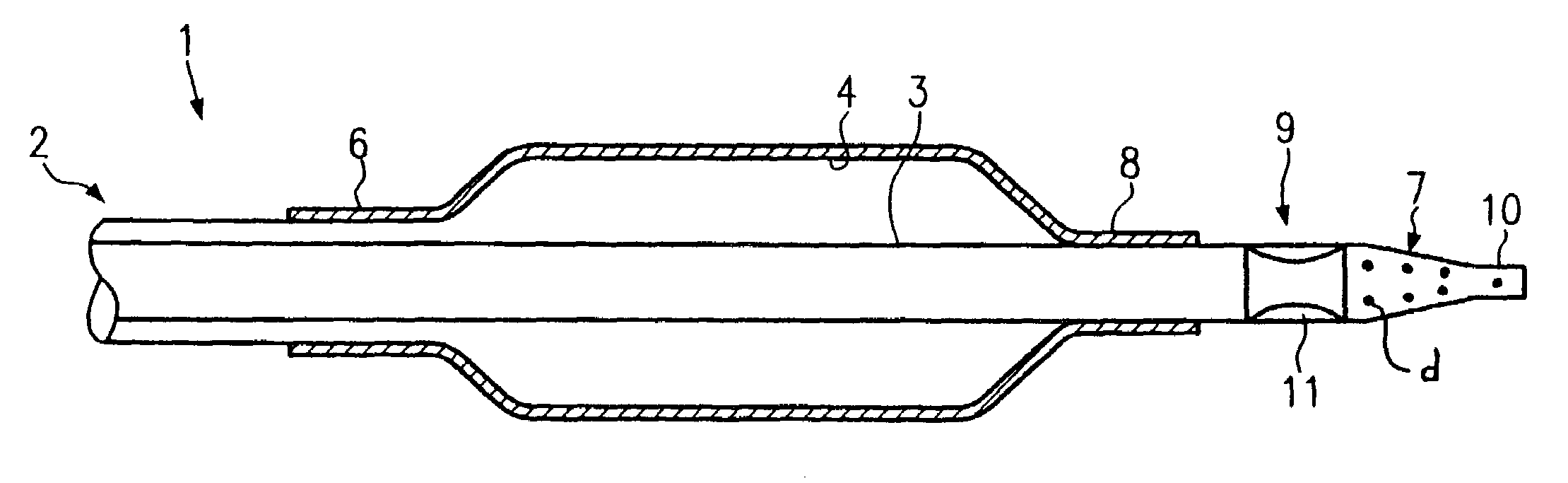

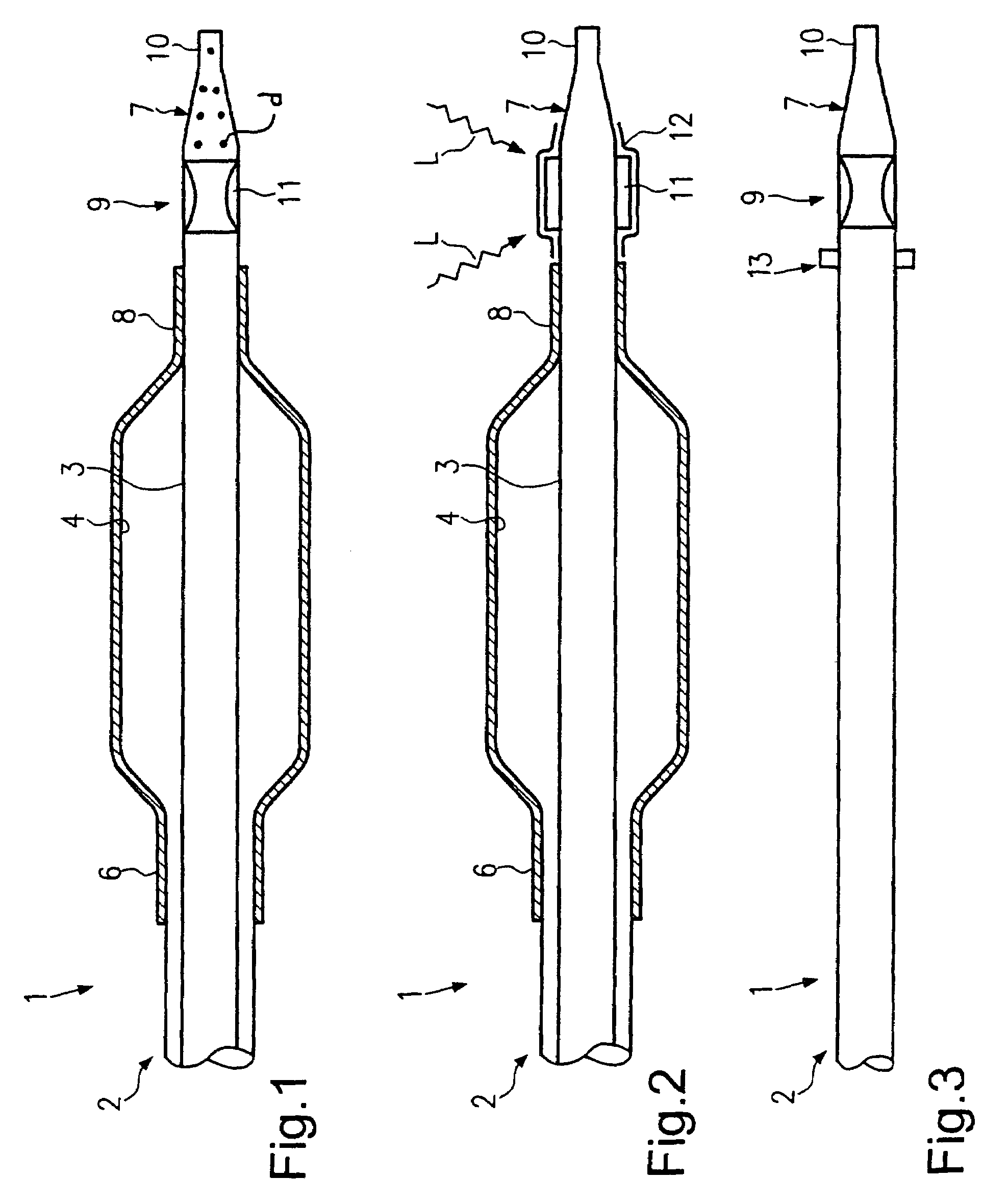

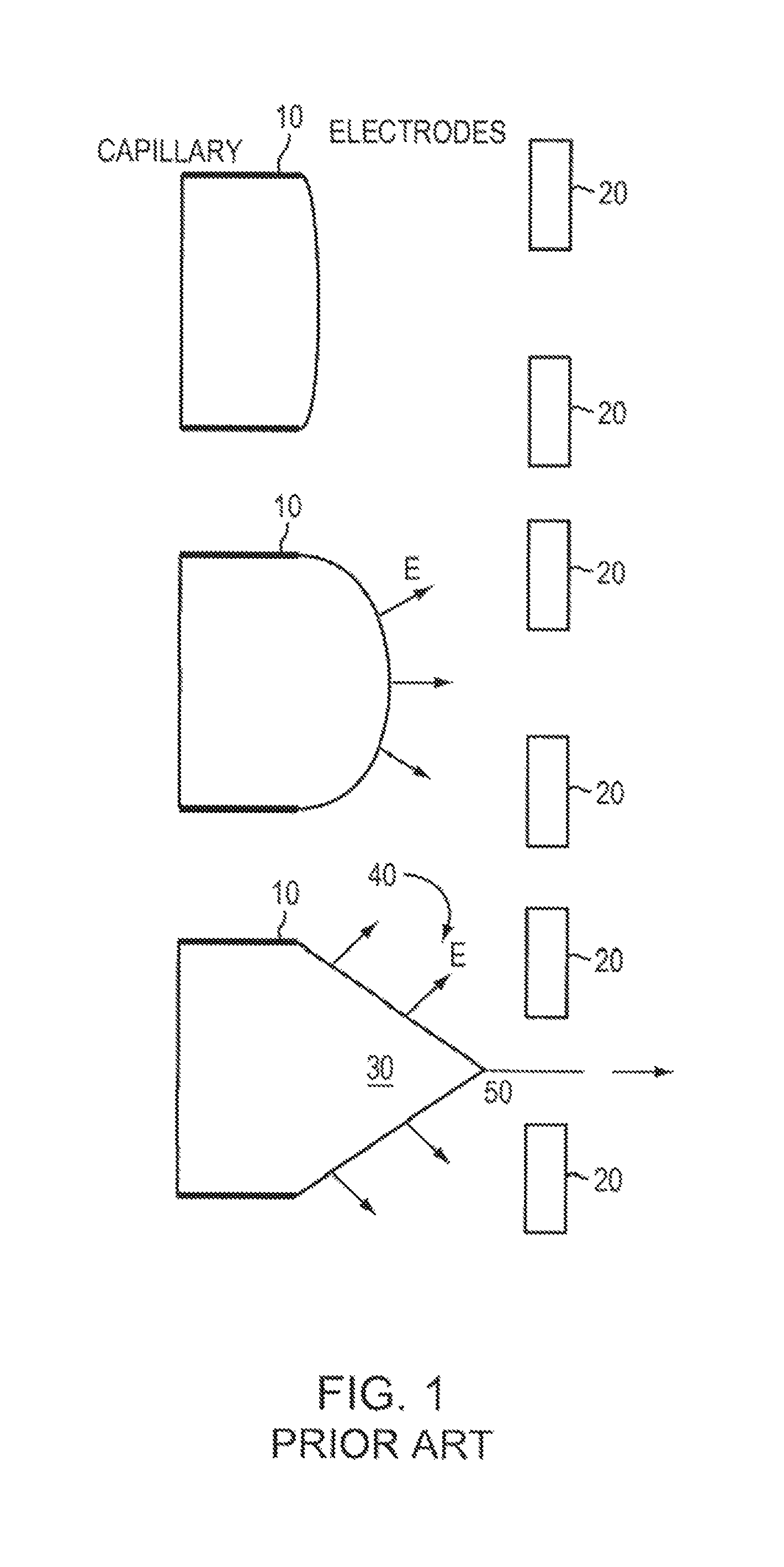

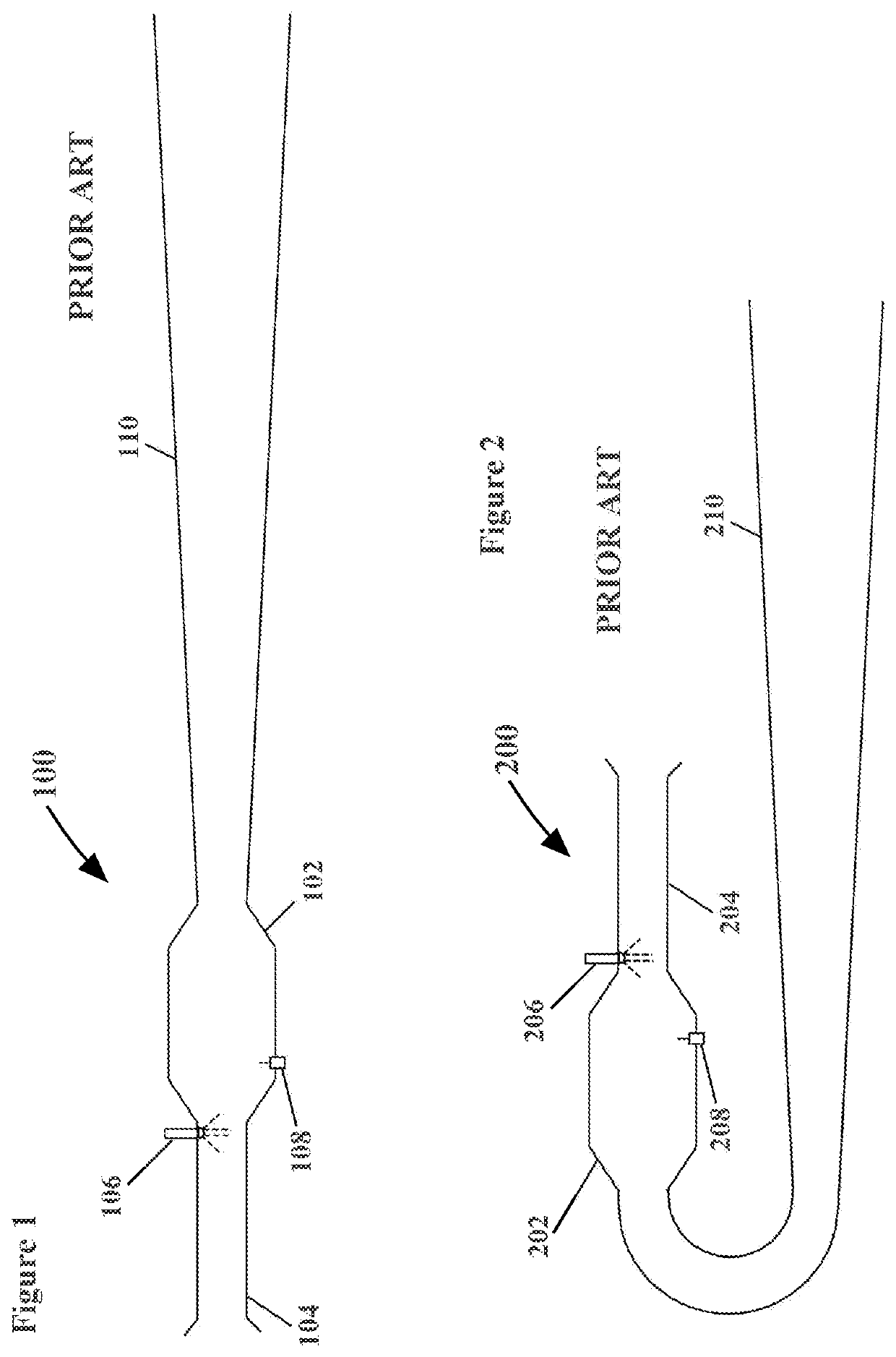

InactiveUS7018372B2Maintaining trackabilityDrag minimizationCatheterIntravenous devicesCatheter device

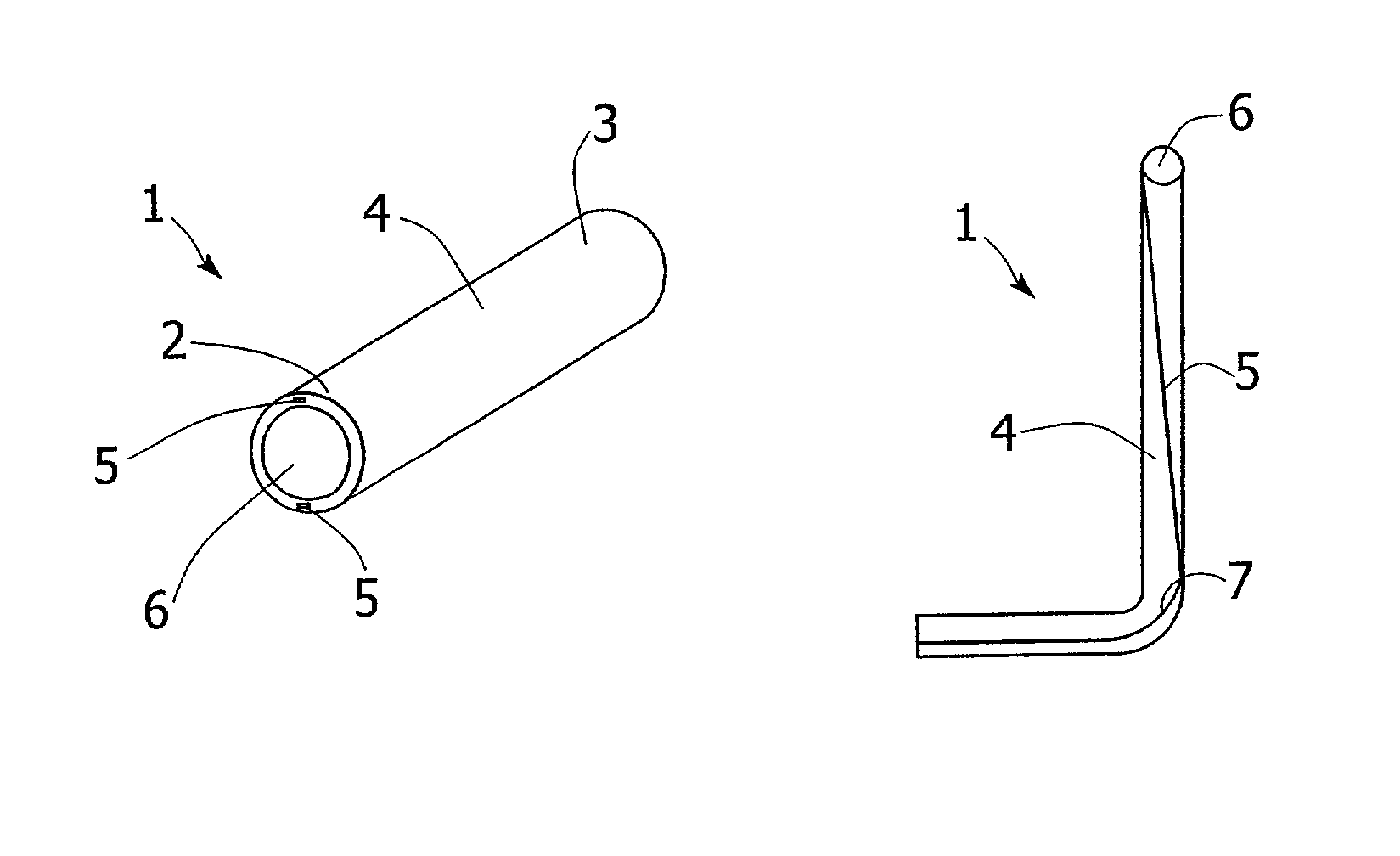

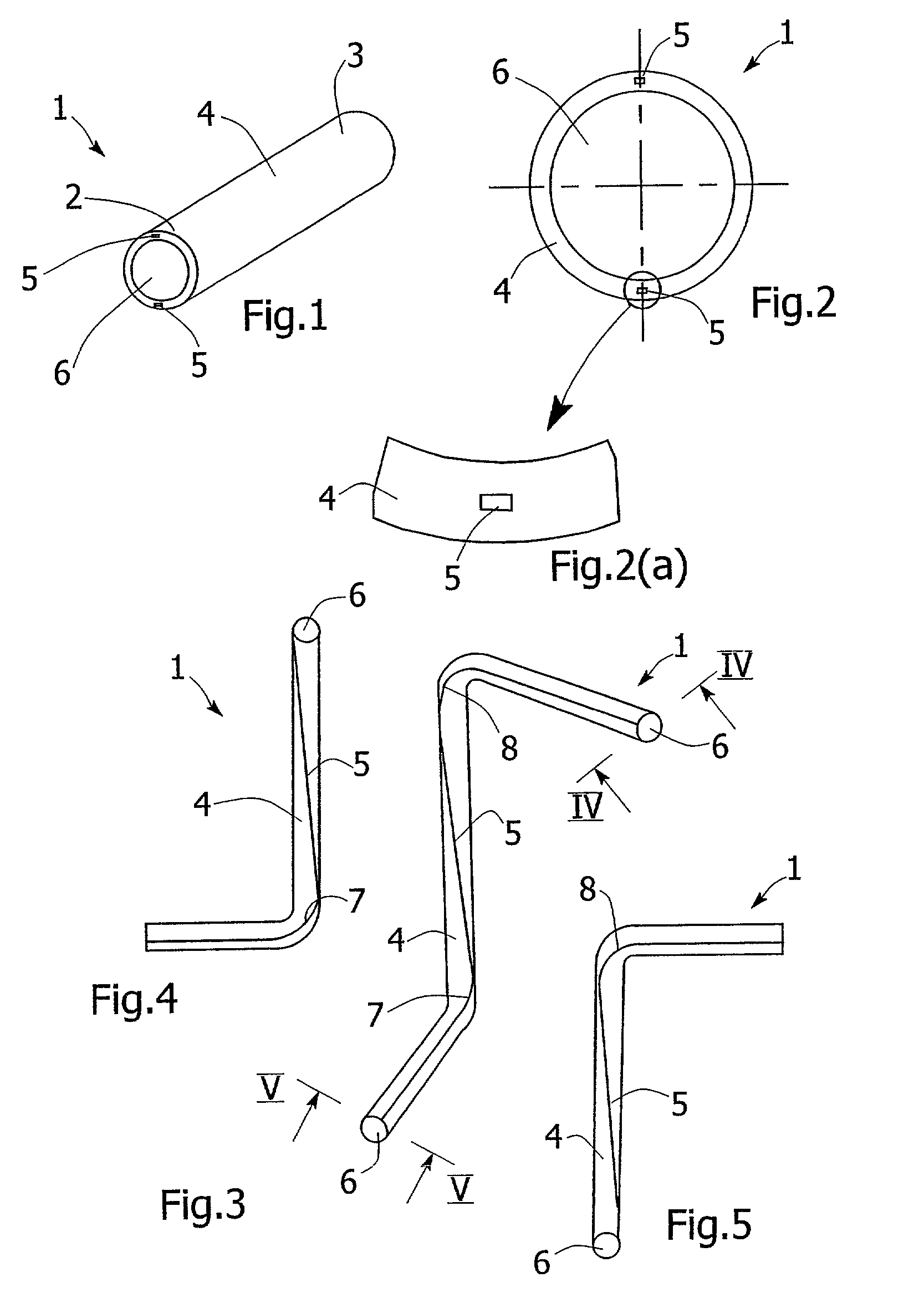

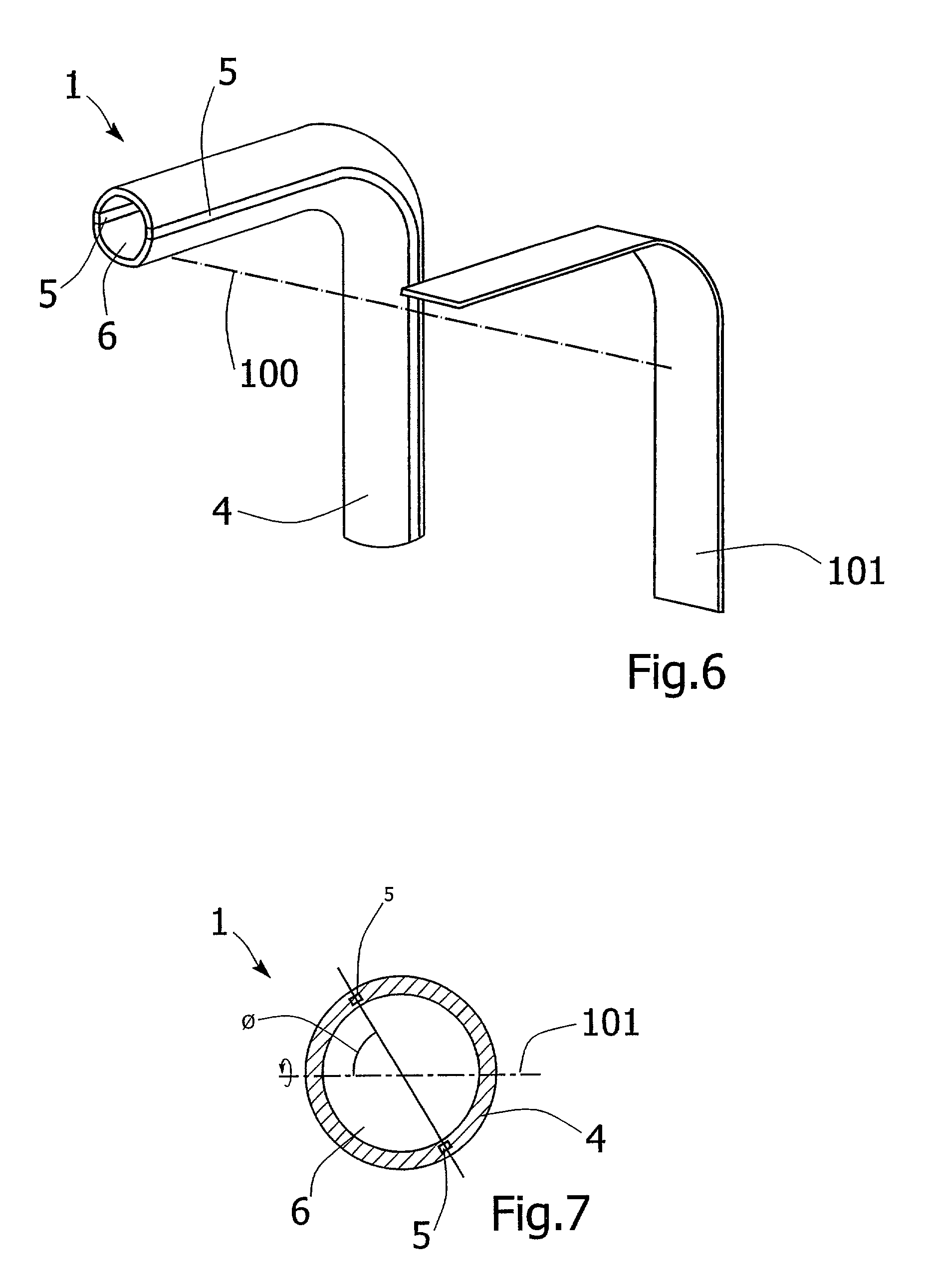

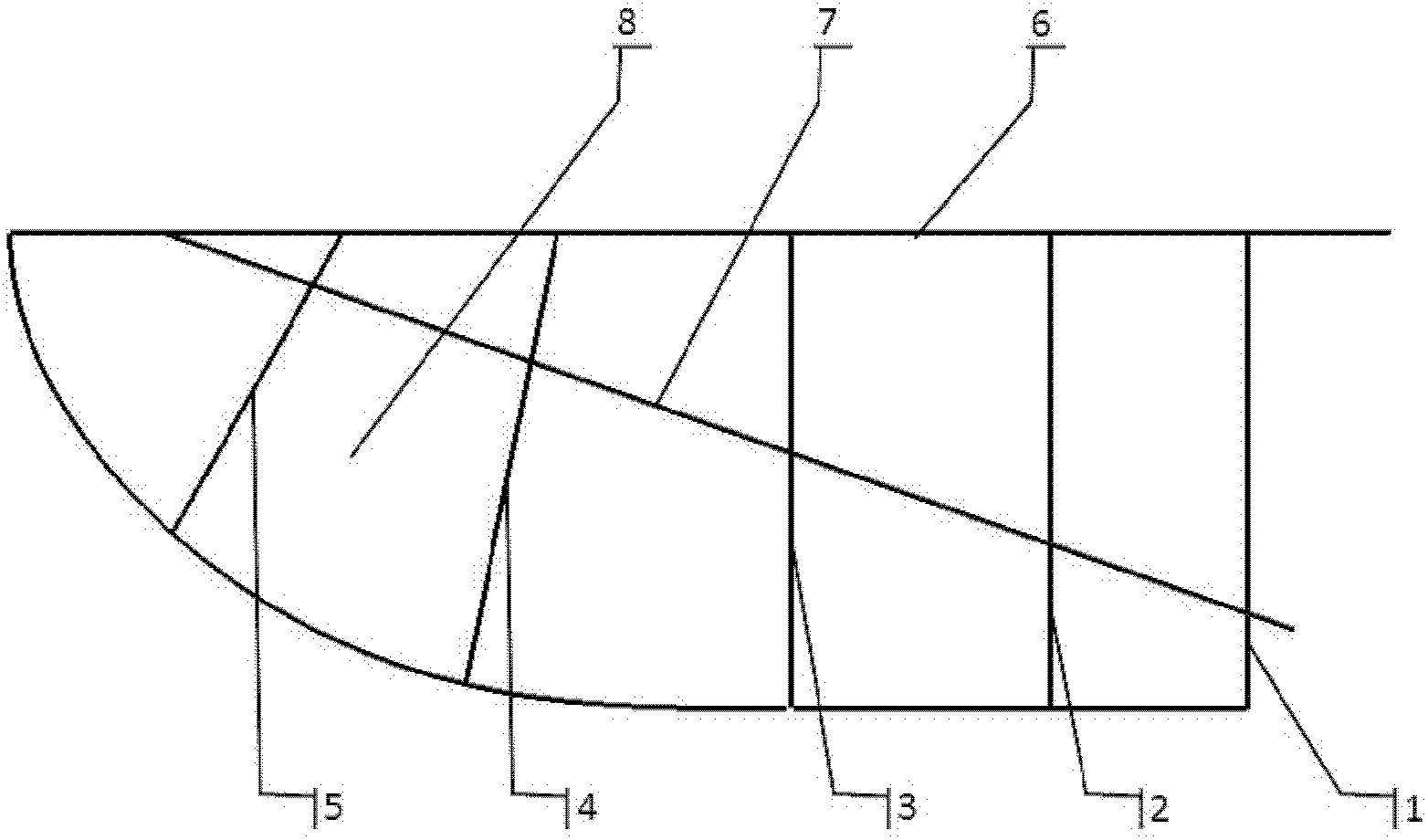

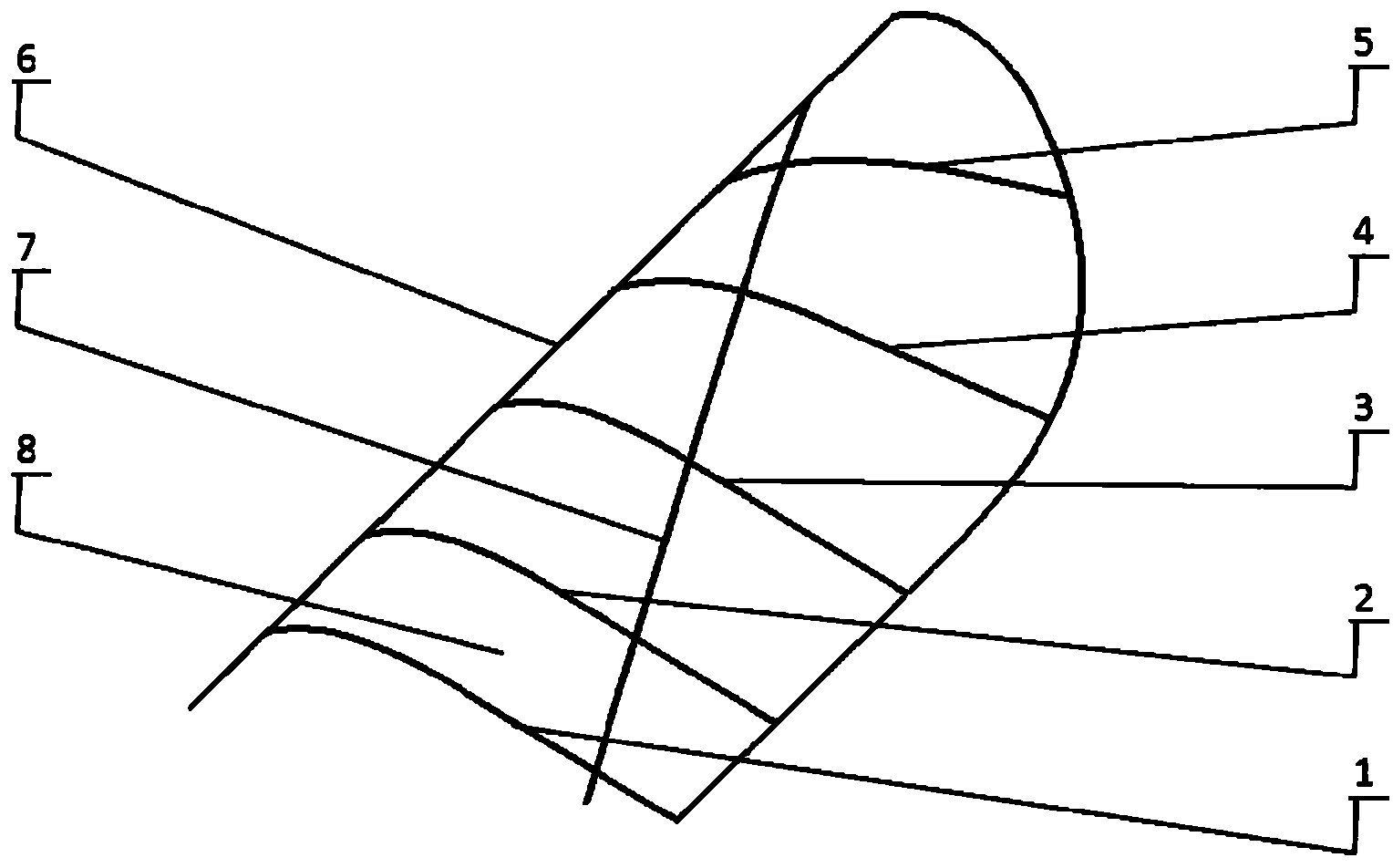

A catheter 1 suitable for advancement through a body passageway of a patient. The catheter 1 comprises a catheter body 4 which is flexible to provide the necessary trackability for the catheter 1 to advance through a body passageway, and two stainless steel reinforcement wires 5 extending along the catheter body 4 which provide the necessary pushability to advance the catheter 1 through the passageway. The reinforcements 5 are positioned diametrically opposed to one another by approximately 180 degrees on opposite sides of the longitudinal axis of the catheter 1, and the catheter body 4 is relatively soft and twistable. This configuration enables the entire catheter 1 to spontaneously twist during advancement so that the reinforcements 5 orientate themselves along a plane of neutral bending during advancement of the catheter 1. In this way, any resistance to the trackability of the catheter 1 due to the stiff reinforcements 5 is minimized.

Owner:SALVIAC +1

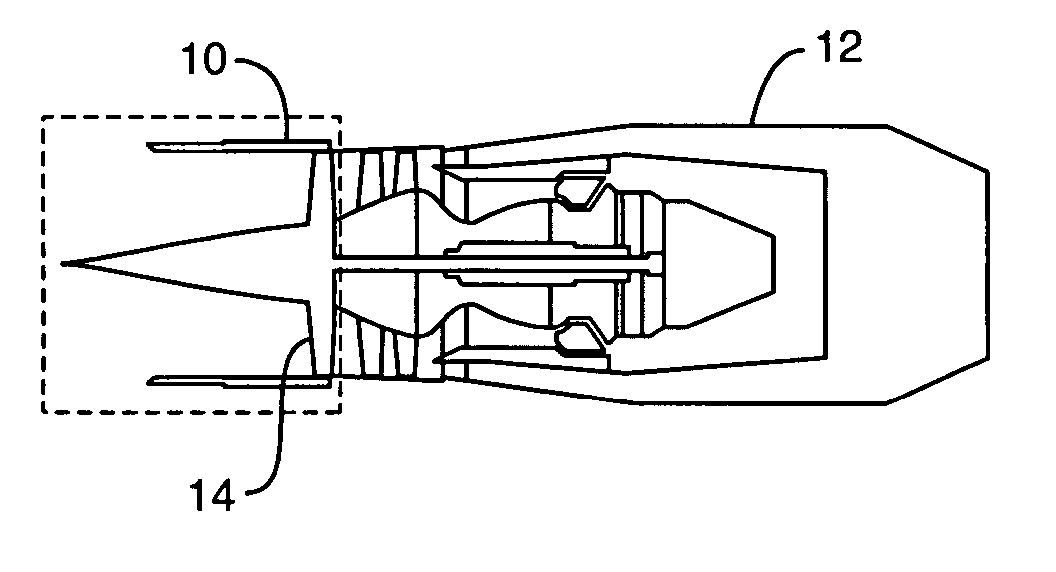

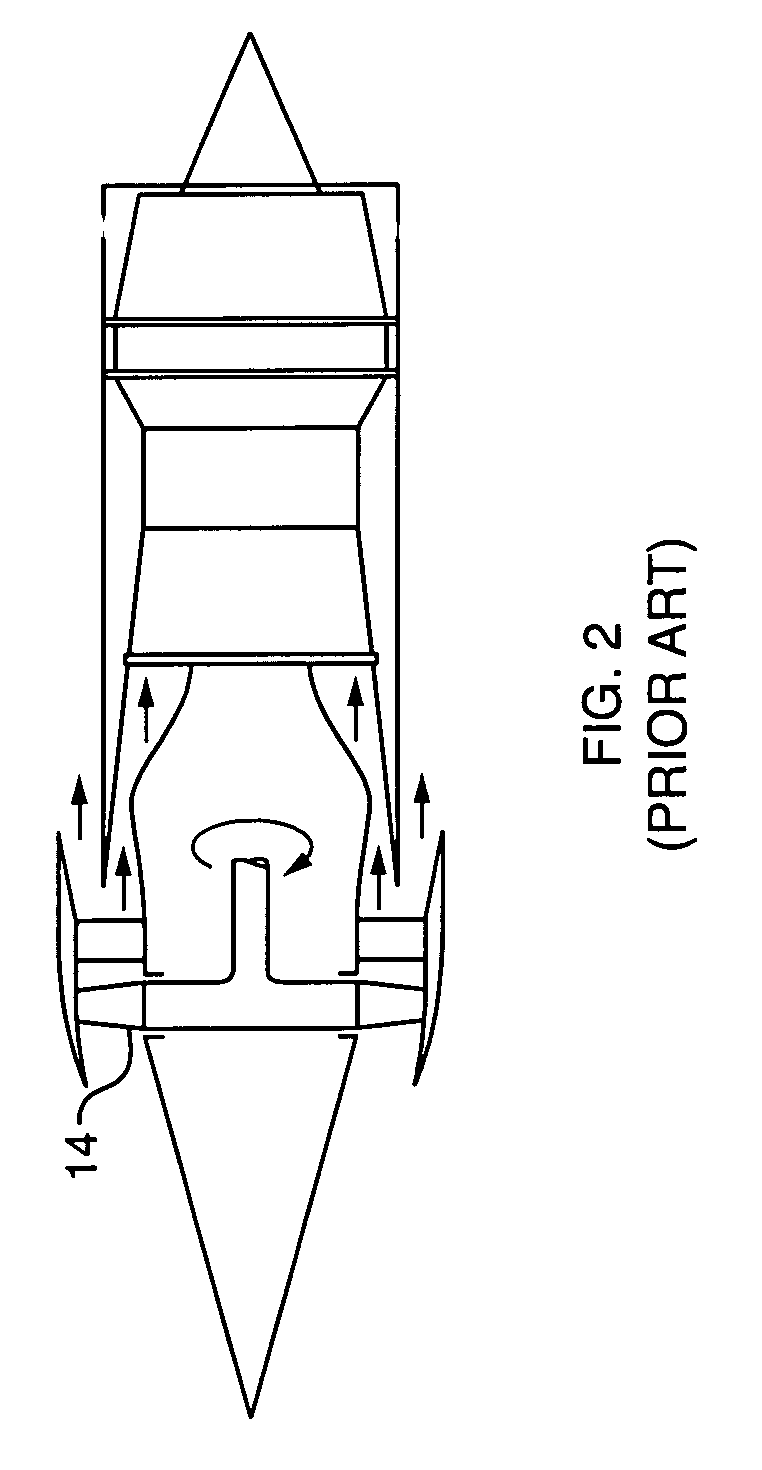

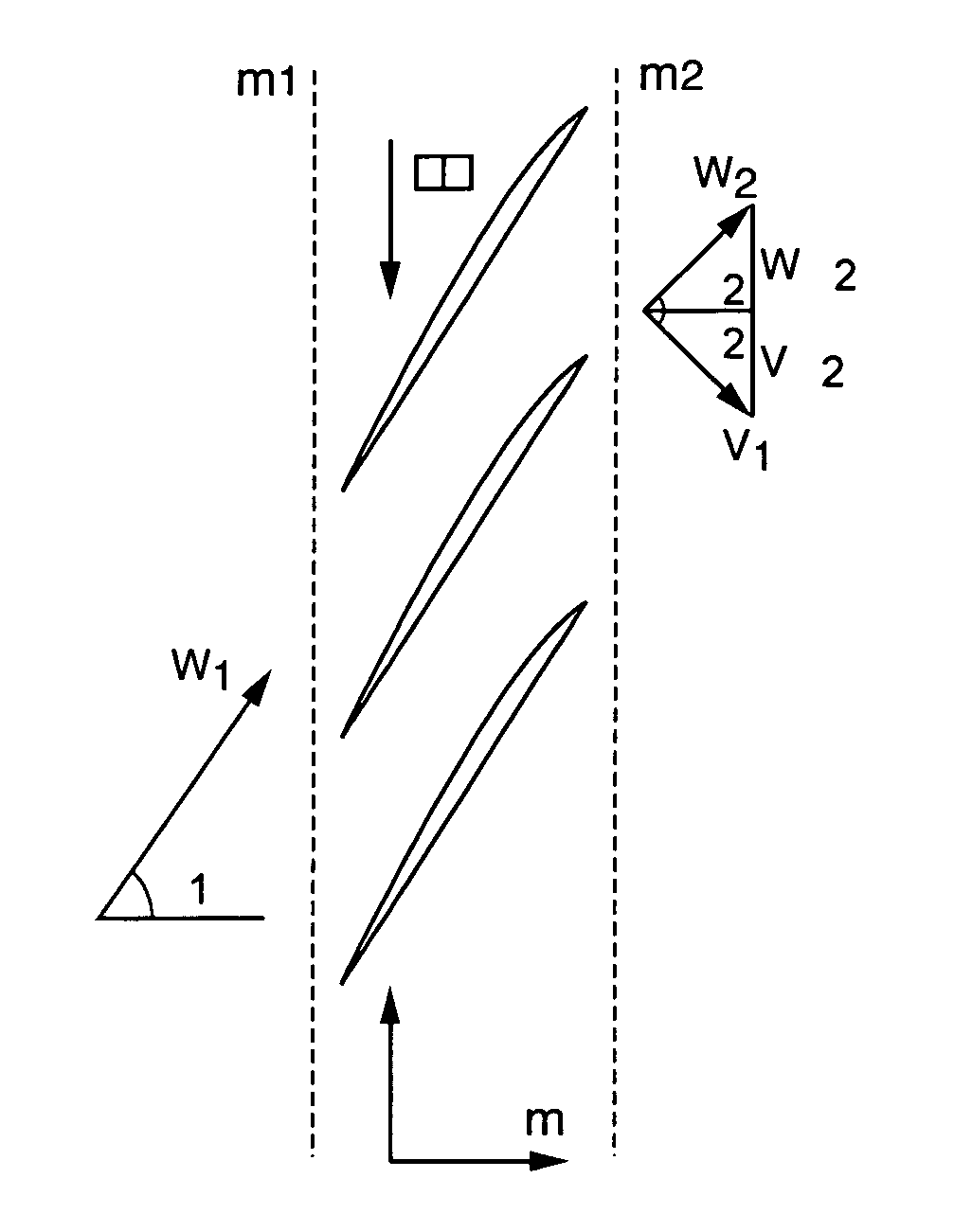

Jet engine inlet-fan system and design method

InactiveUS20060179818A1Improve performanceIncrease pressureSupersonic fluid pumpsEfficient propulsion technologiesJet engineDesign methods

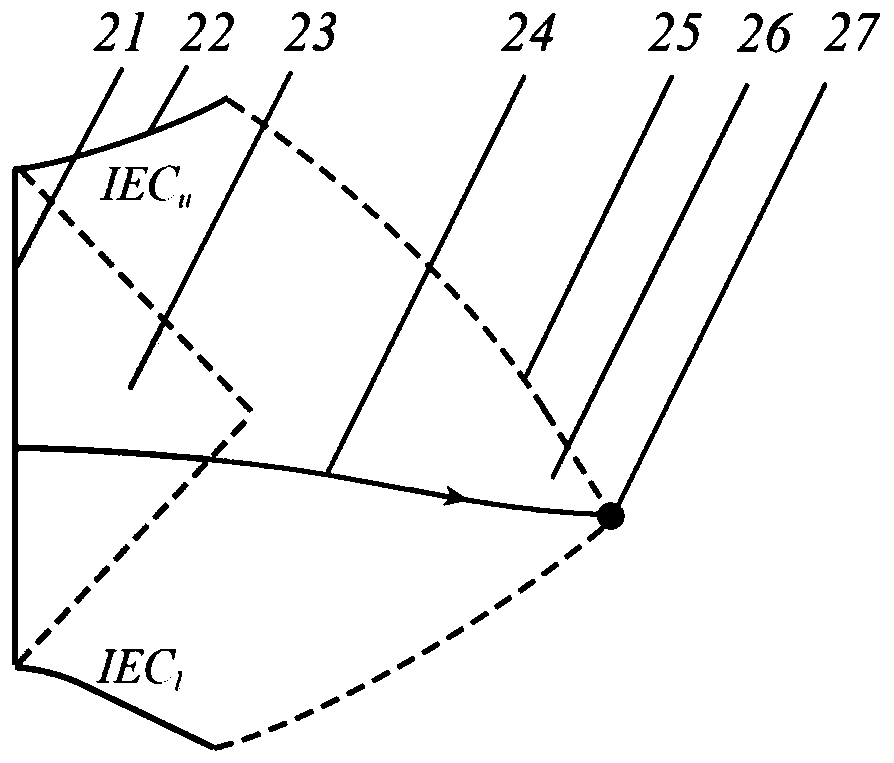

A supersonic aircraft engine axial fan that includes a rotating blade row having blades that receive a supersonic entry flow in the absolute frame and decelerate the flow to a lower supersonic or subsonic velocity exit flow while adding work to the flow to increase stagnation pressure. It is preferred that the lower velocity be subsonic. When the fan is combined with a suitably designed inlet, the propulsion system is compact and lighter in weight than conventional engines for supersonic aircraft.

Owner:MASSACHUSETTS INST OF TECH

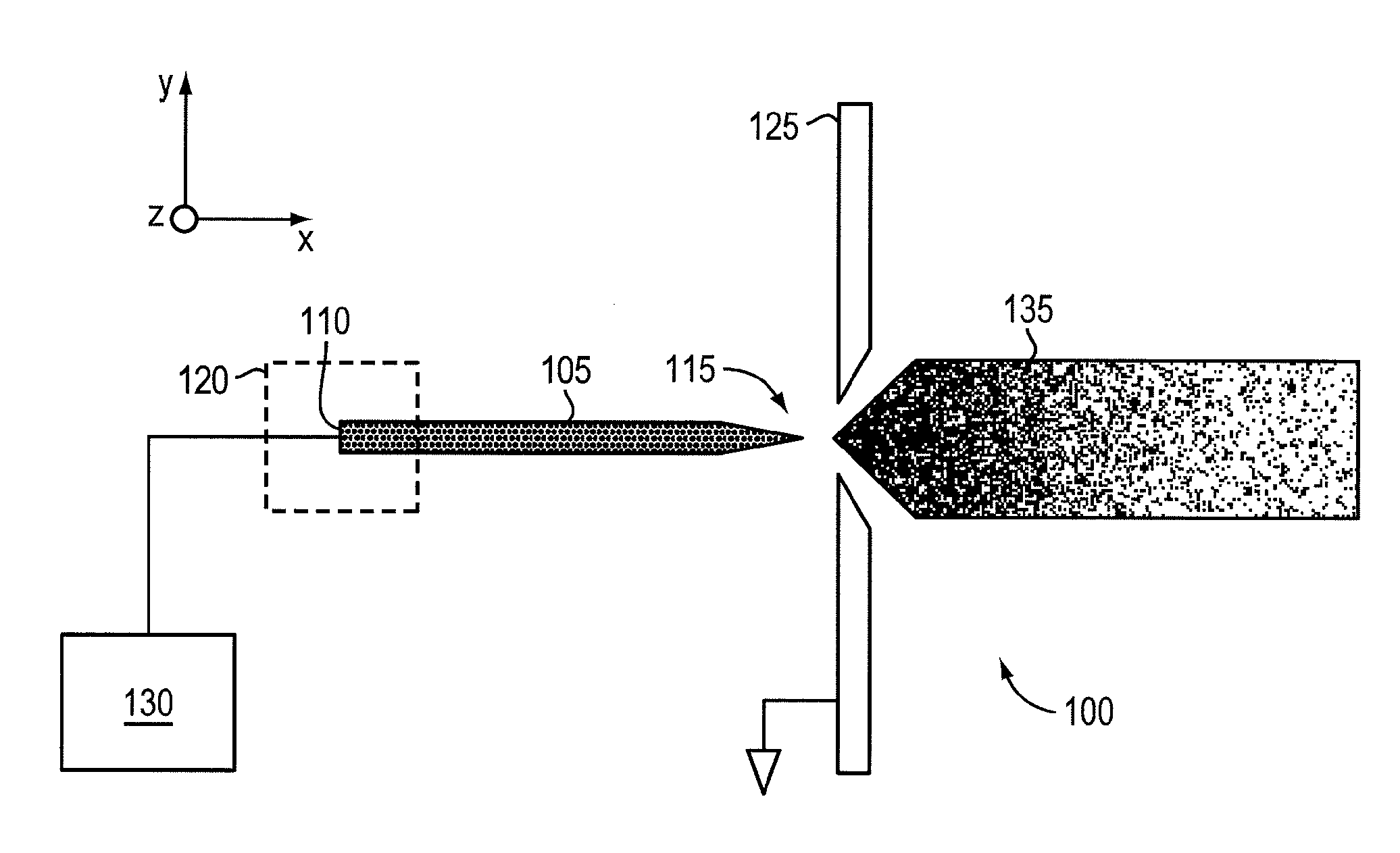

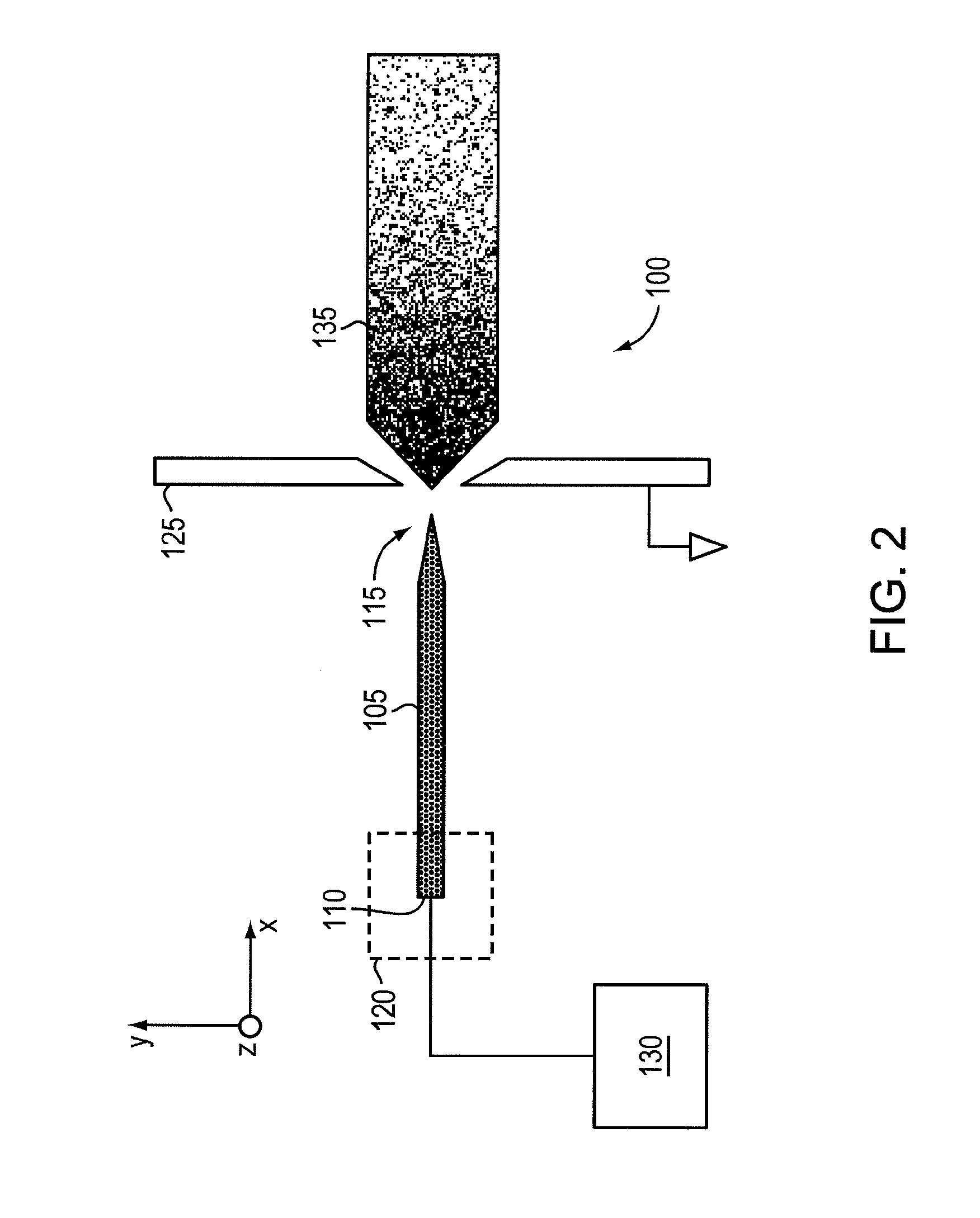

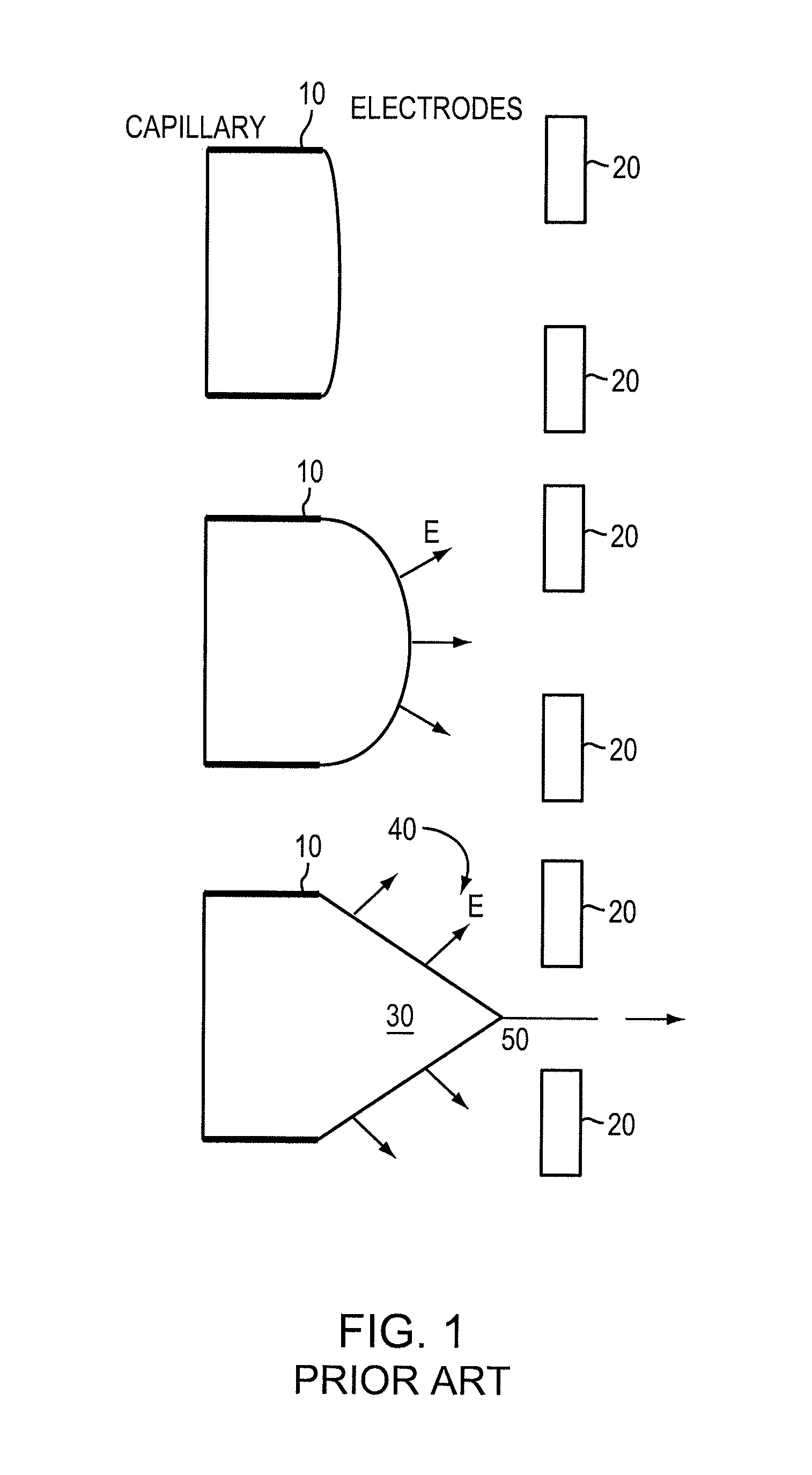

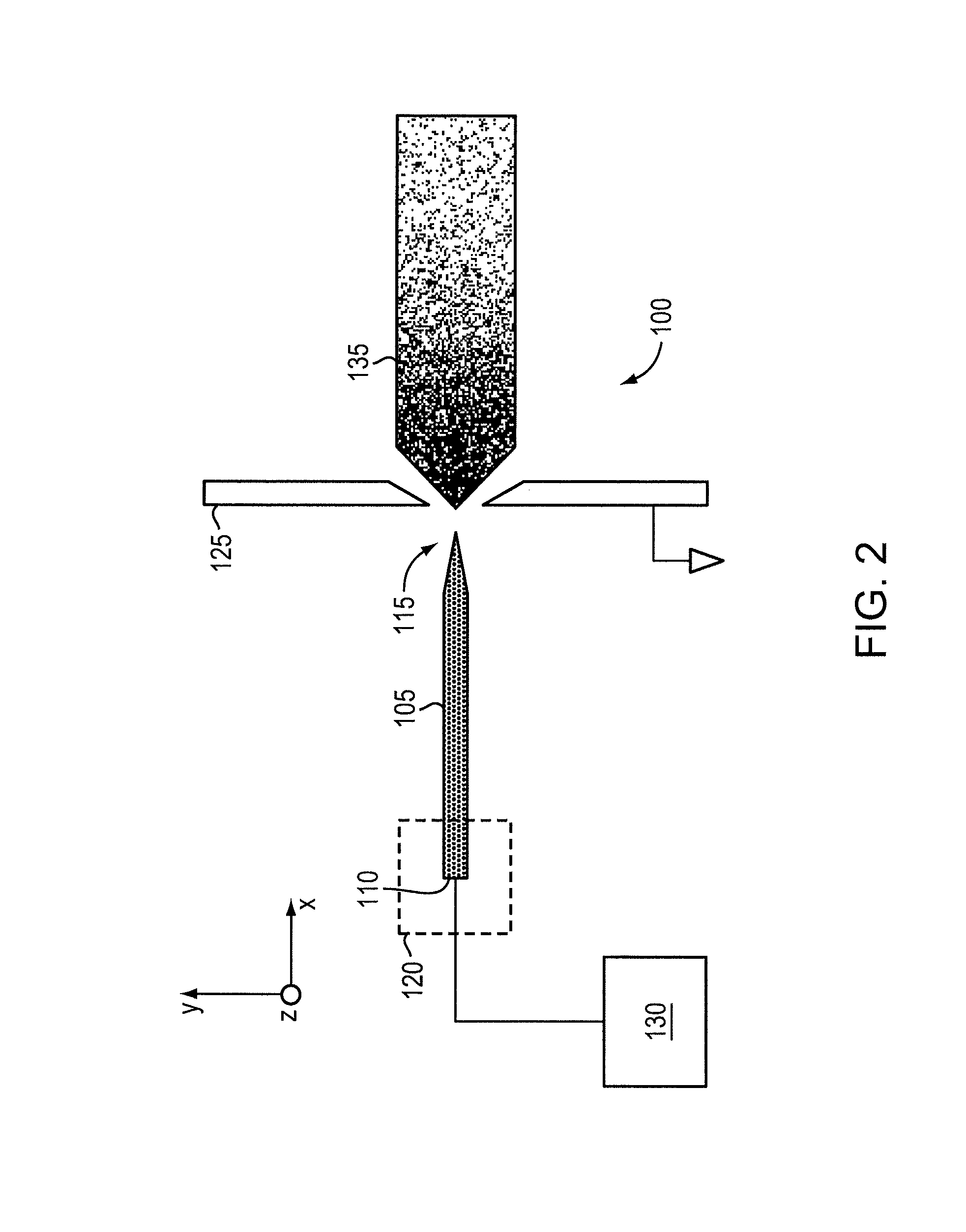

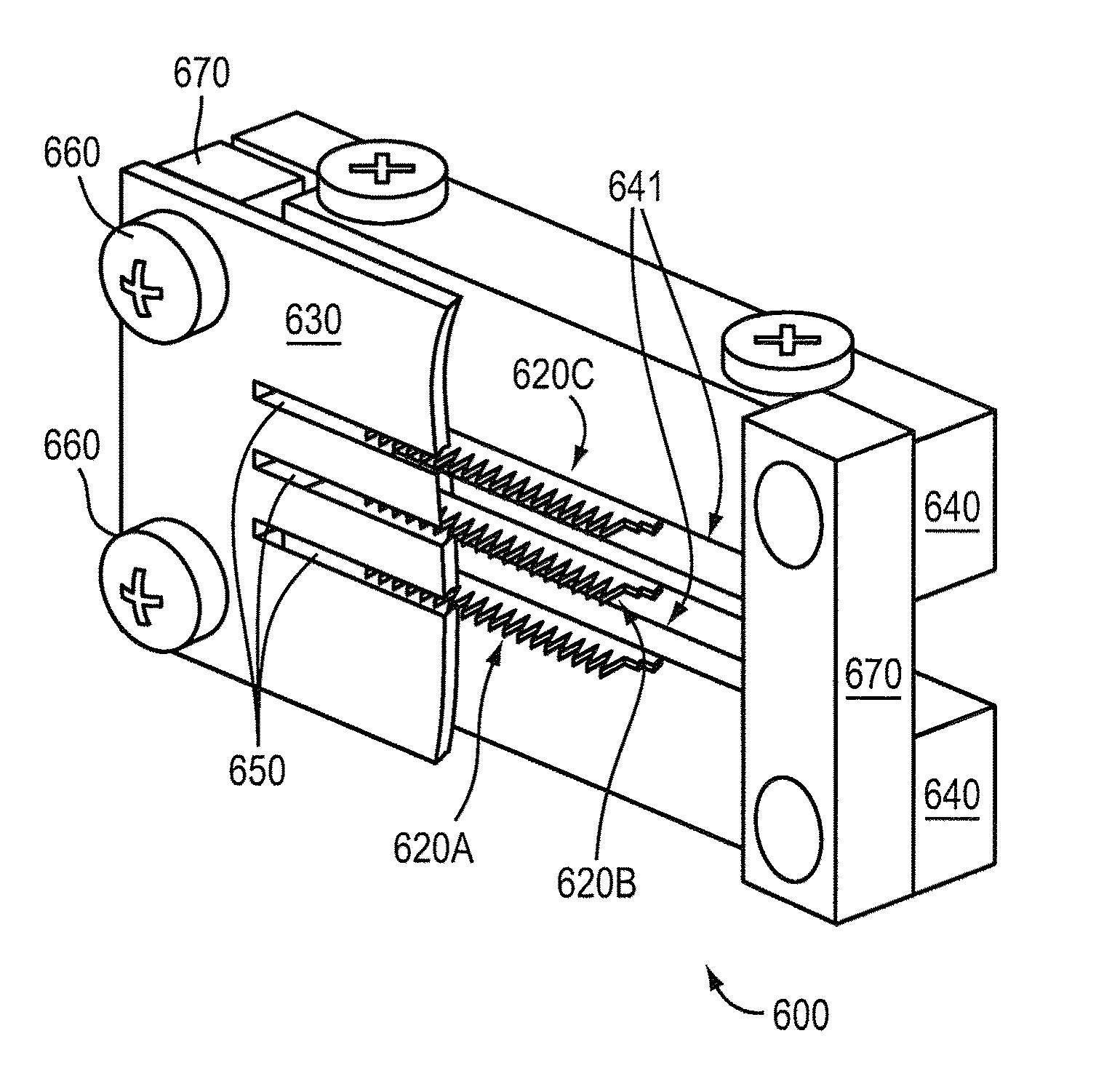

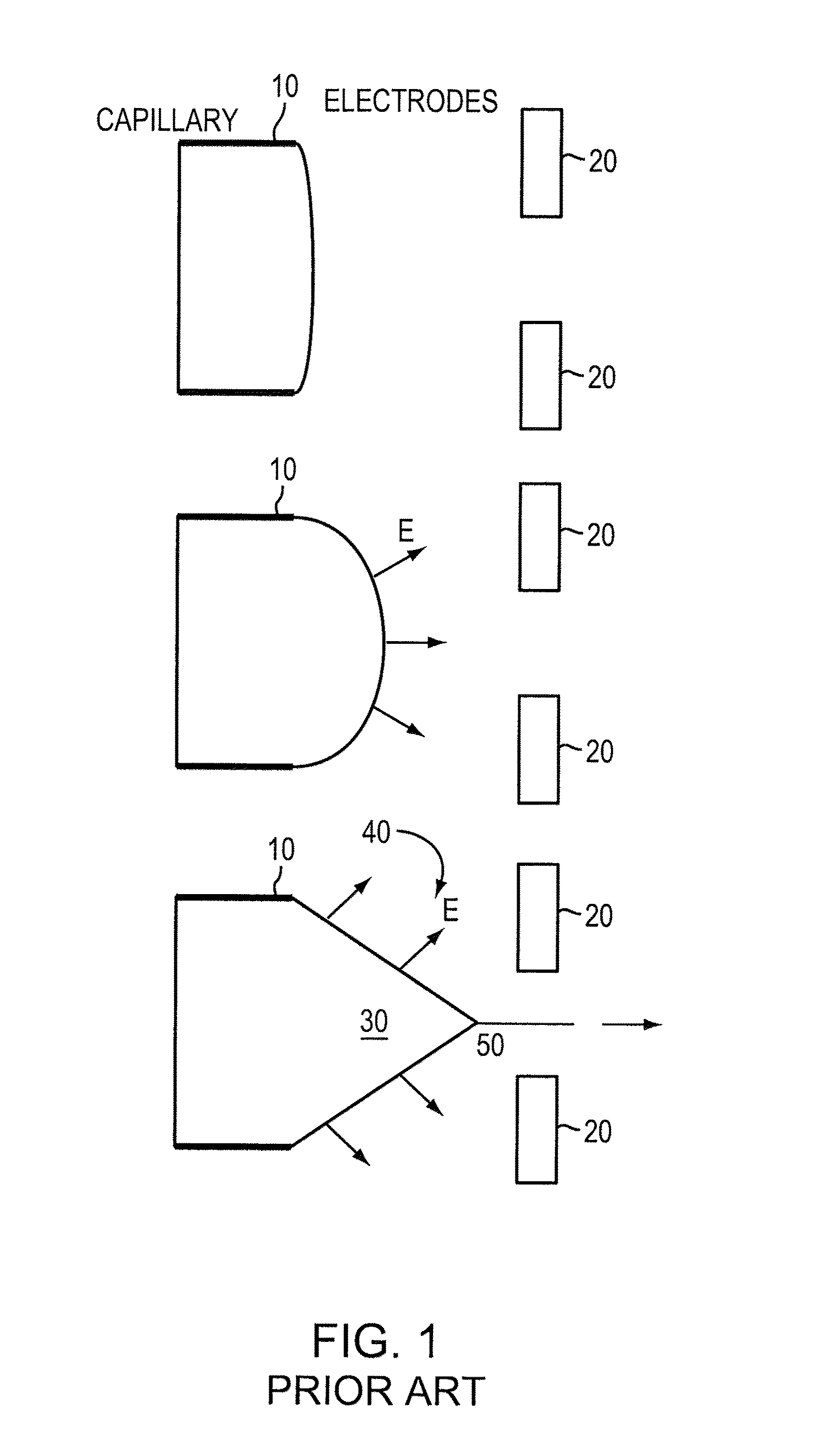

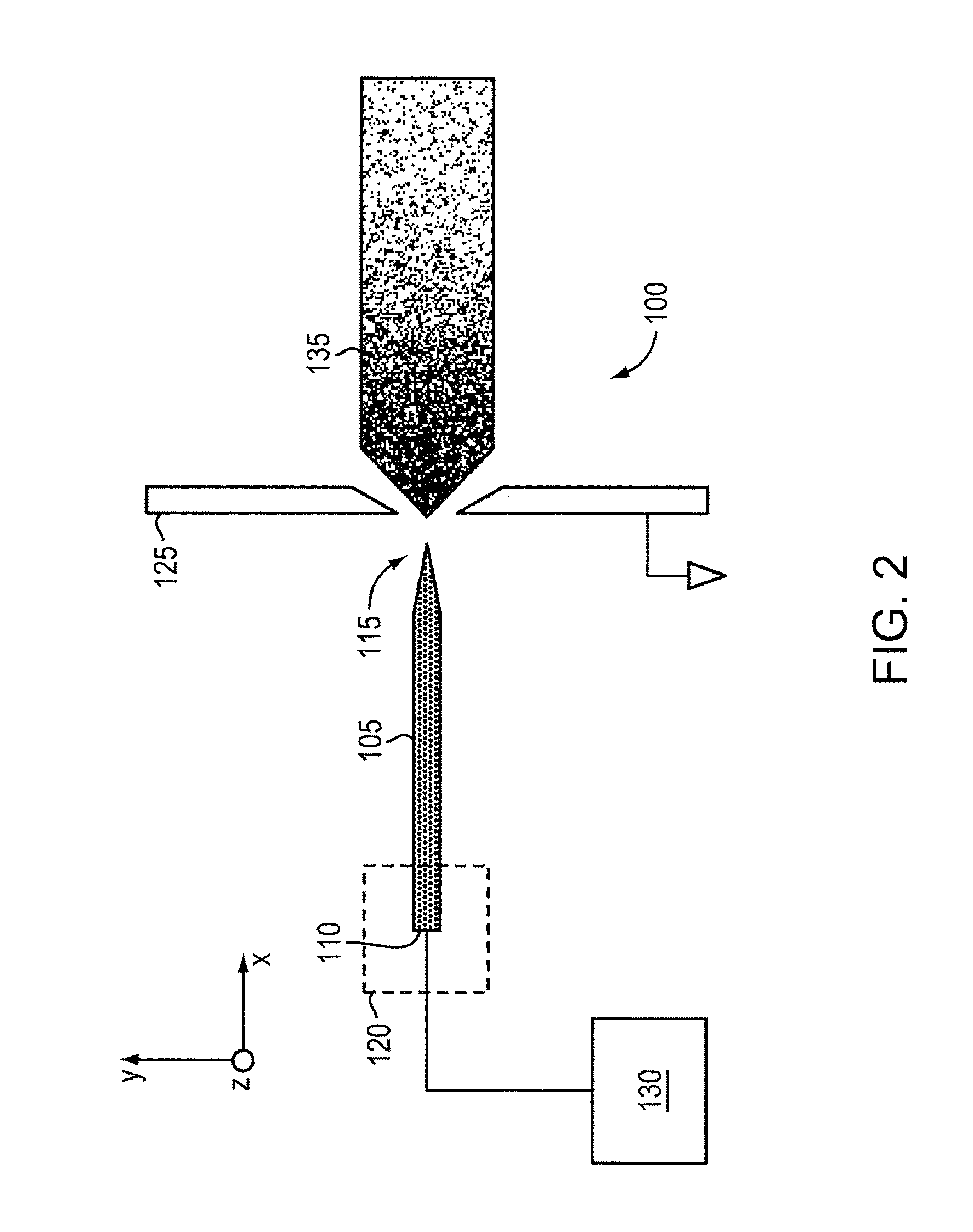

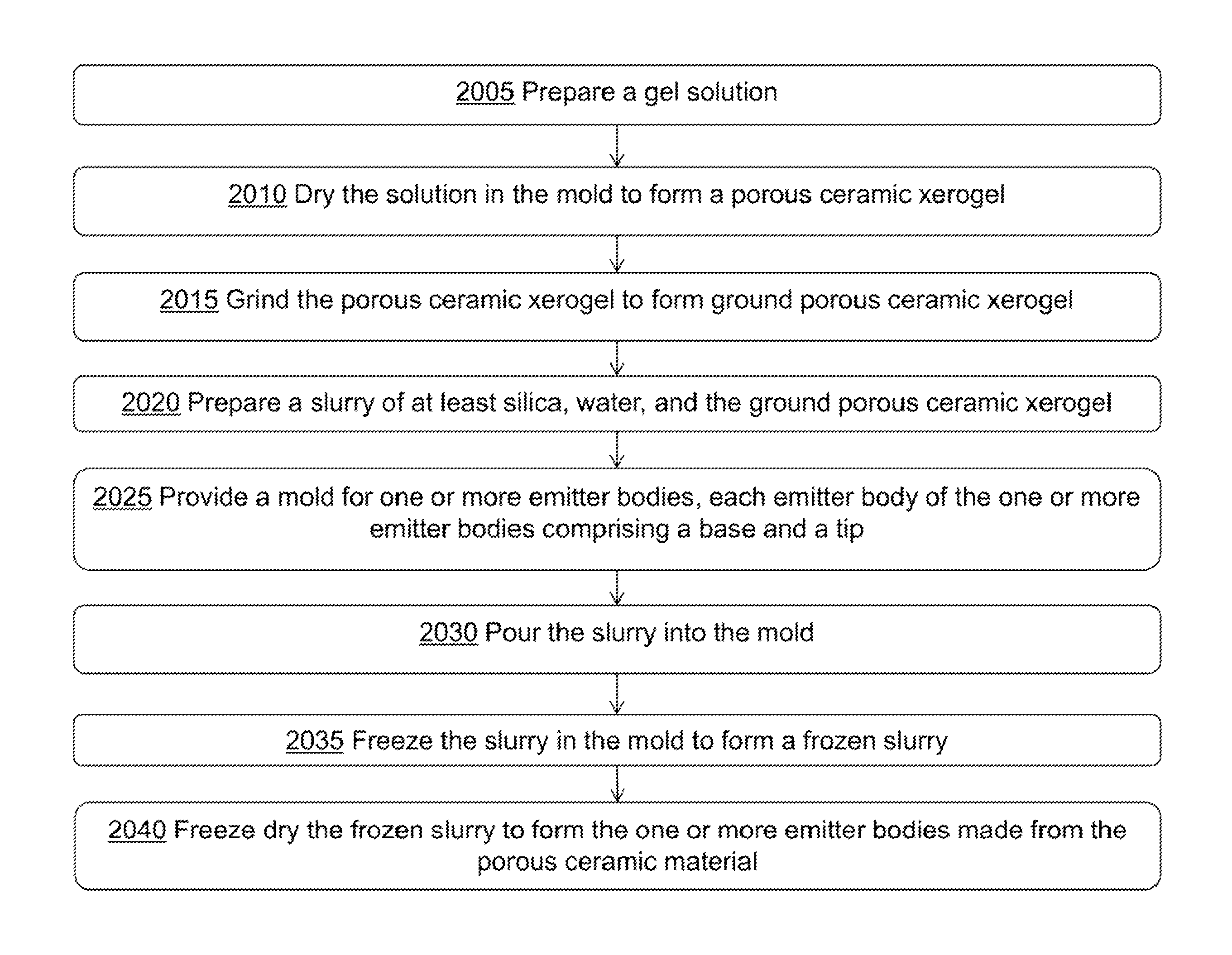

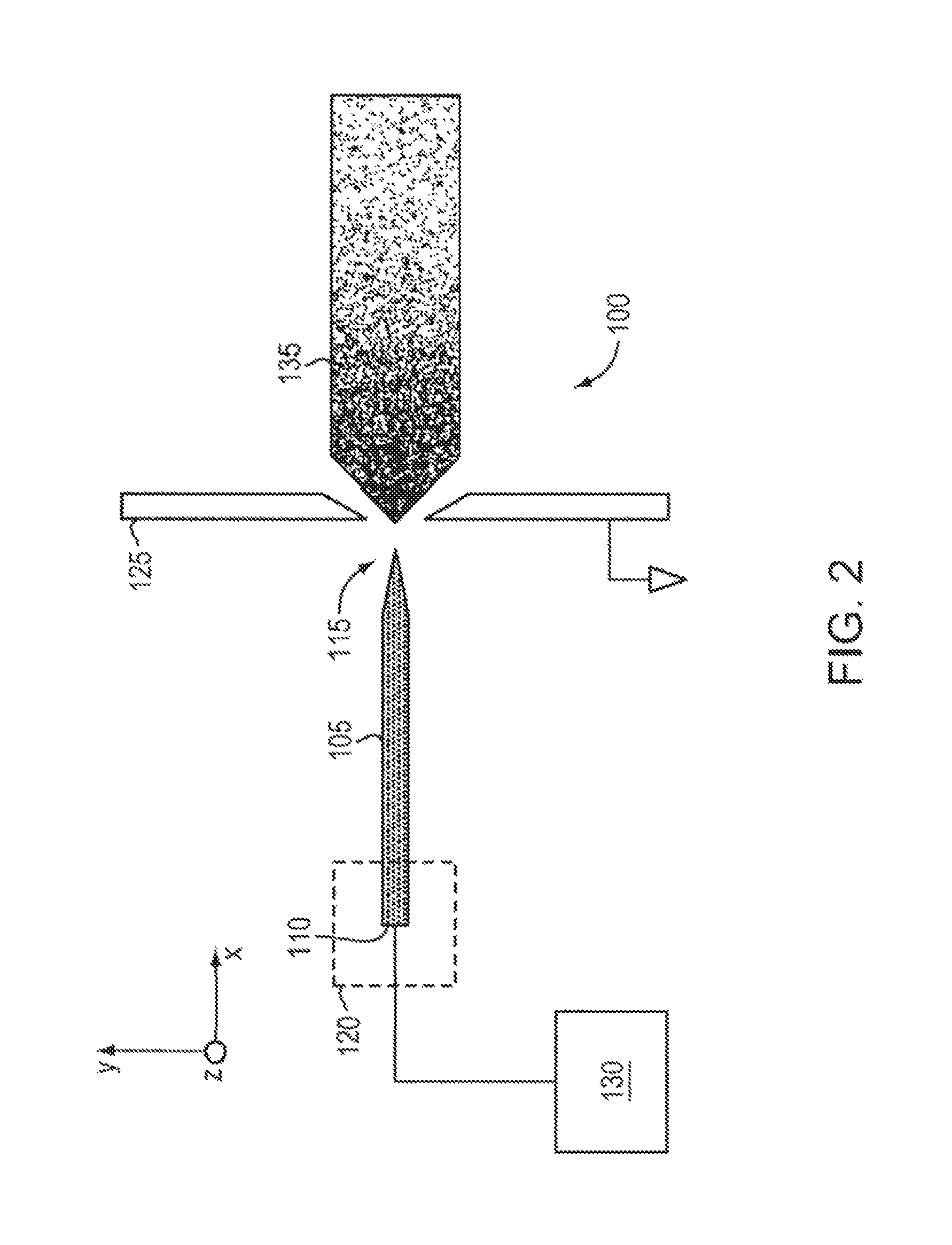

Method and Apparatus for a Porous Metal Electrospray Emitter

ActiveUS20110210265A1Increased capillary flow capacityReduce complexityElectrolysis componentsParticle separator tubesRoom temperatureMolten salt

An ionic liquid ion source can include a microfabricated body including a base and a tip. The microfabricated body can be formed of a porous metal compatible (e.g., does not react or result in electrochemical decaying or corrosion) with an ionic liquid or a room-temperature molten salt. The microfabricated body can have a pore size gradient that decreases from the base of the body to the tip of the body, so that the ionic liquid can be transported through capillarity from the base to the tip.

Owner:MASSACHUSETTS INST OF TECH

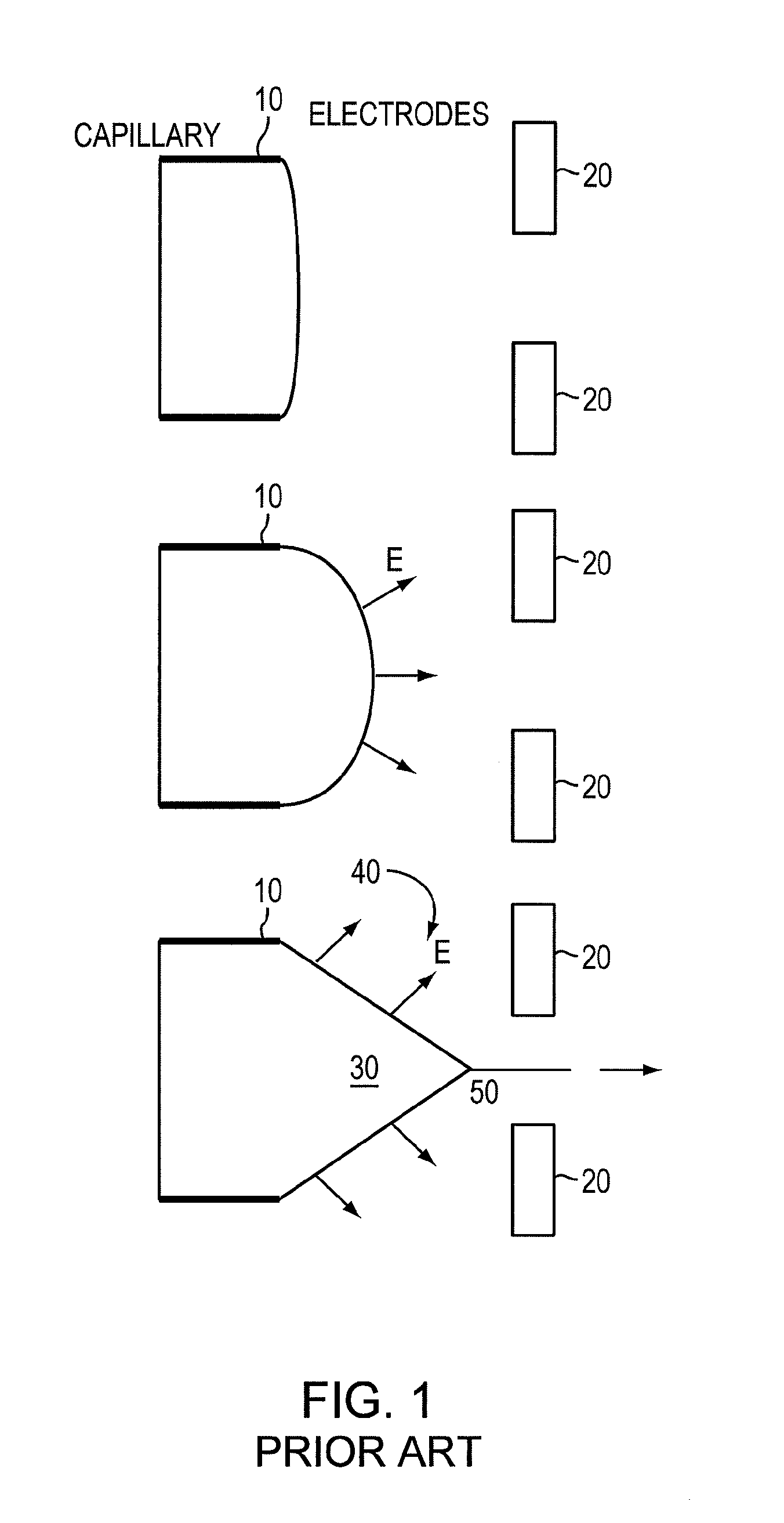

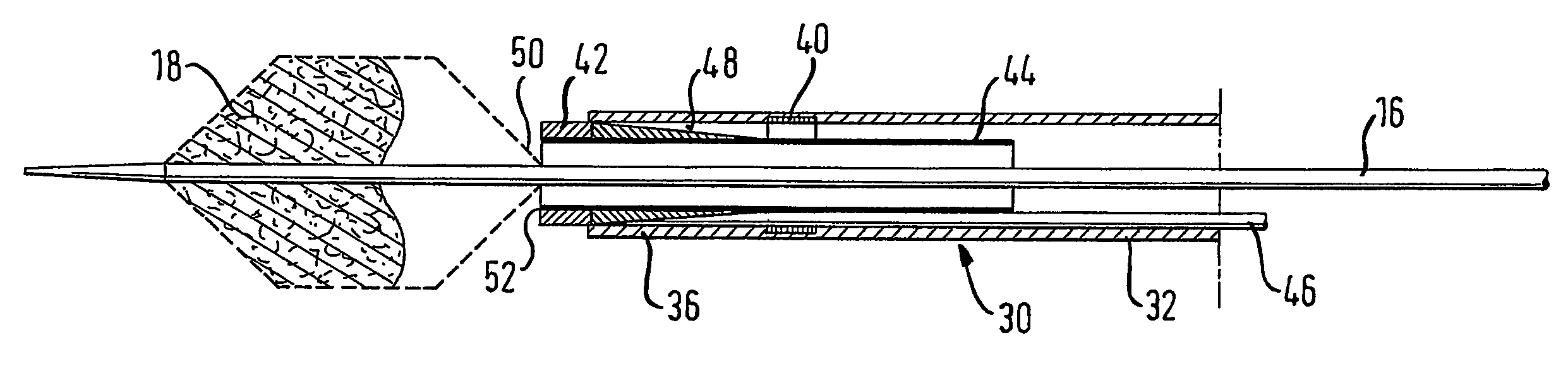

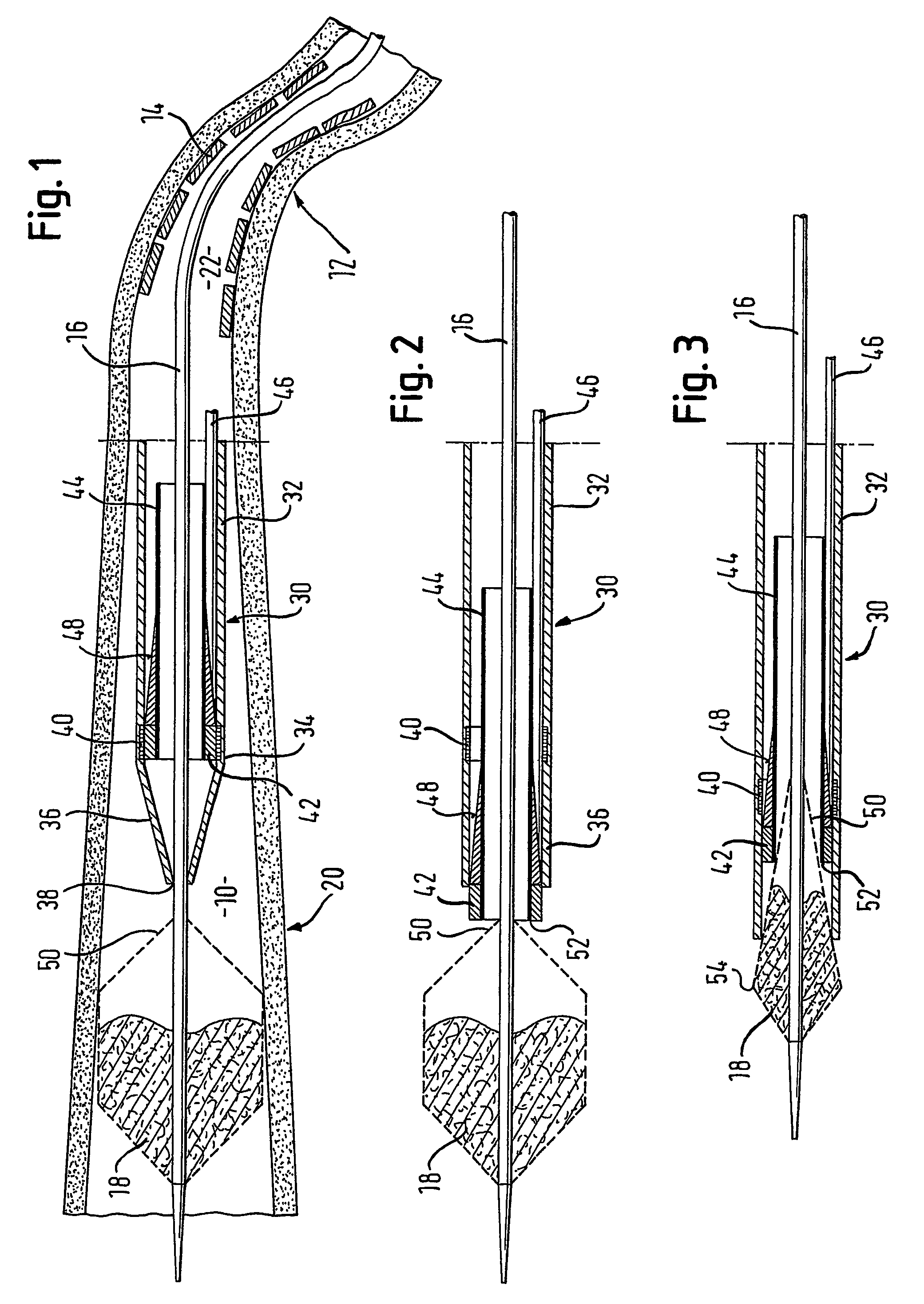

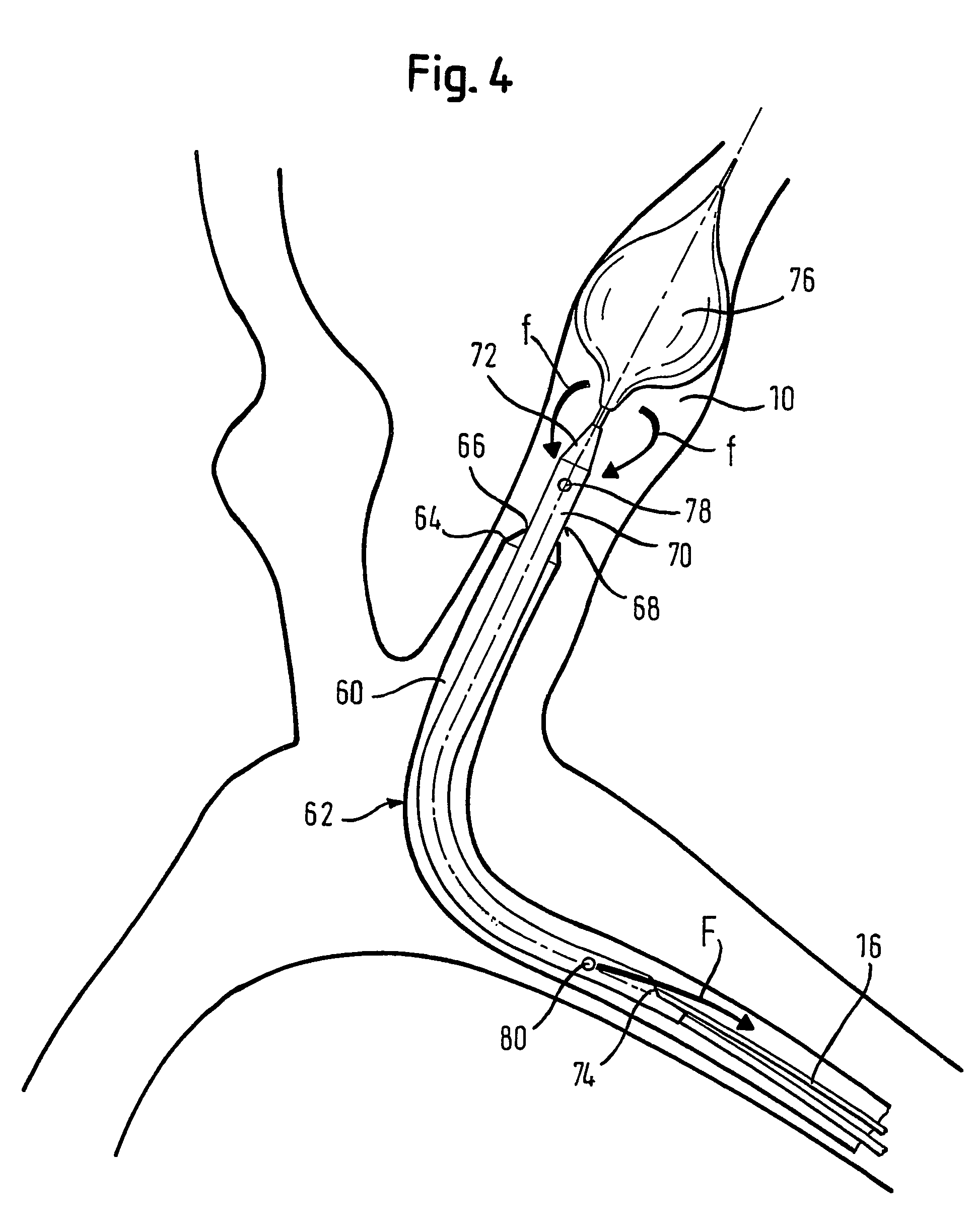

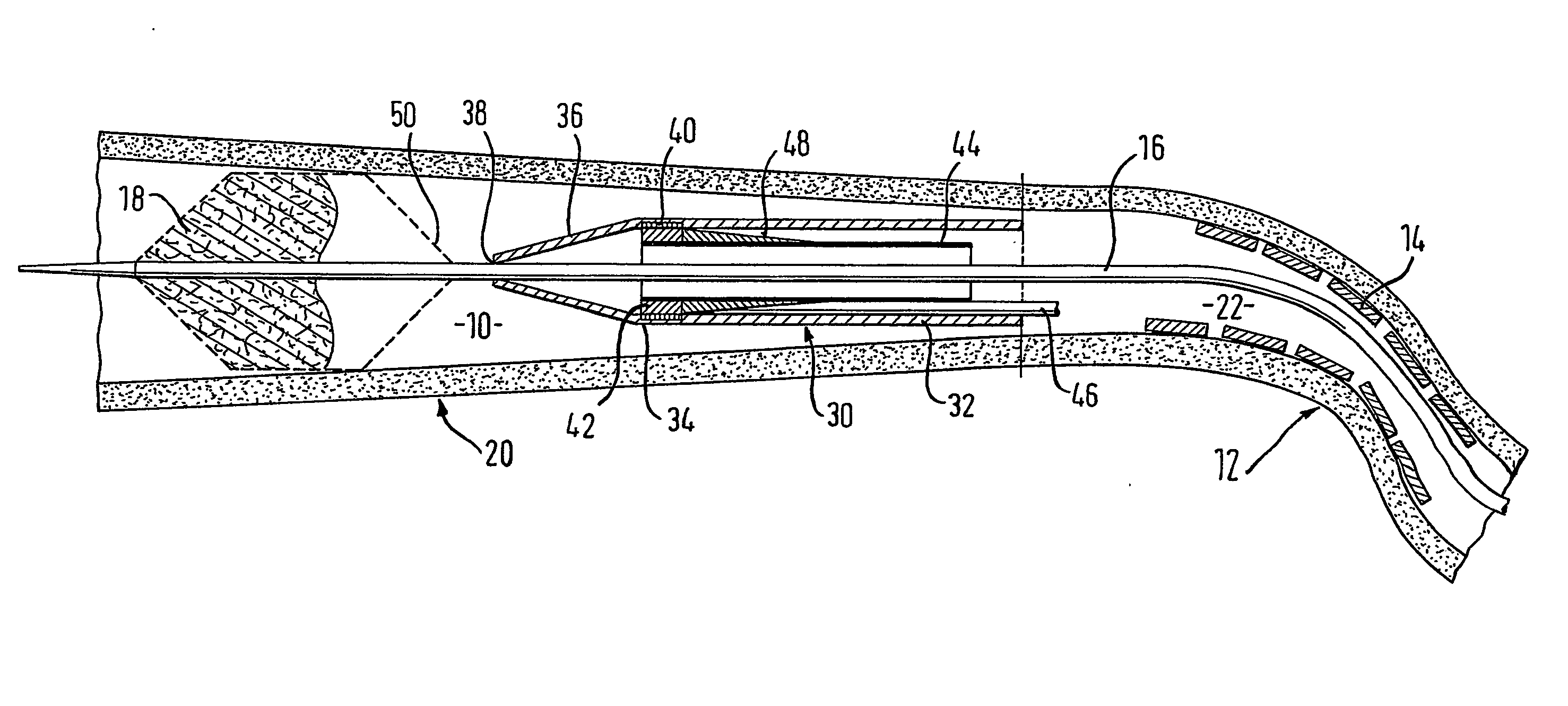

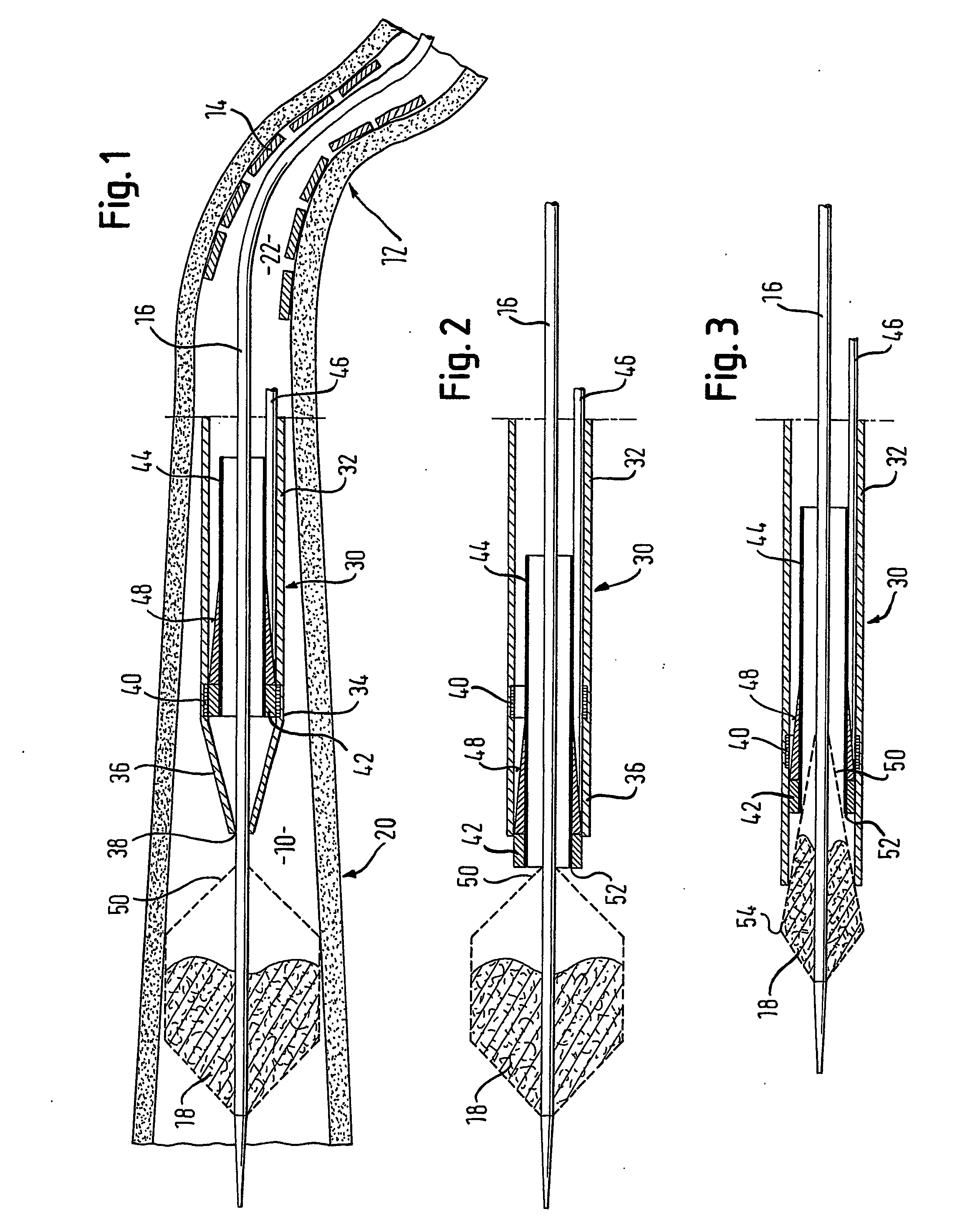

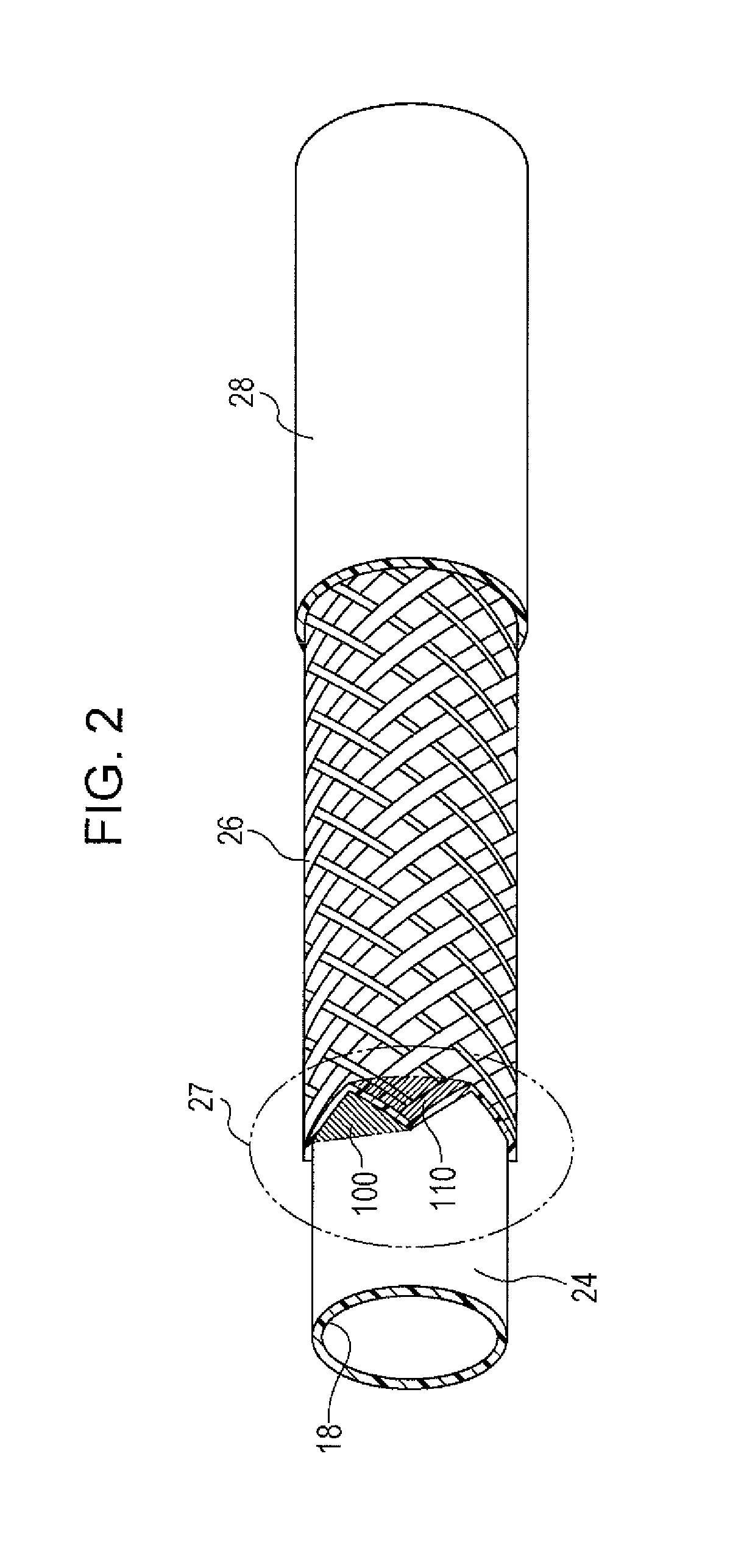

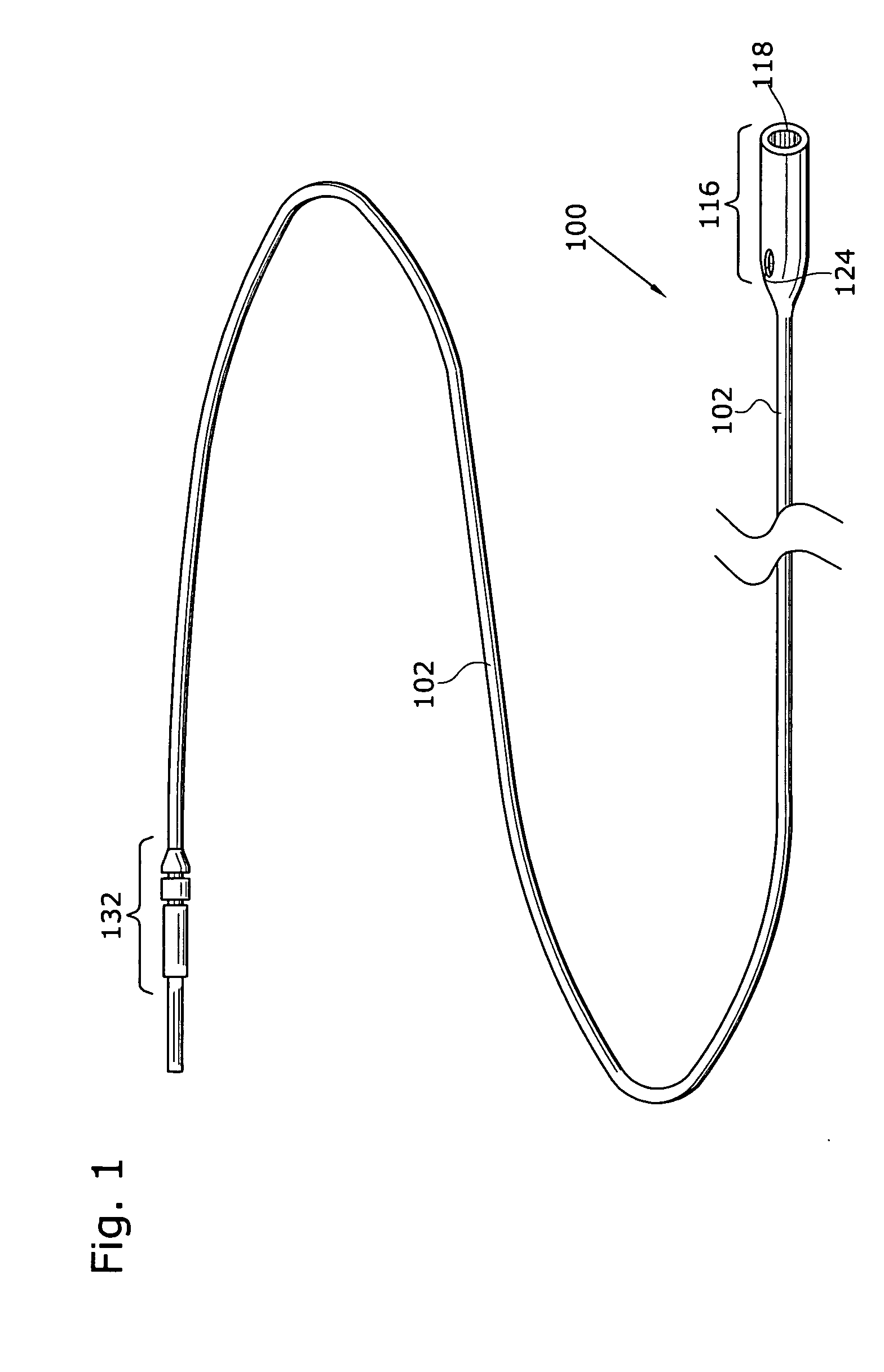

Retrieval catheter

ActiveUS7854746B2Improve buckling resistanceLower resistanceStentsEar treatmentDilatorCatheter device

A retrieval catheter having a wall that defines a catheter lumen and a distal tip that is tapered towards an open distal orifice that defines the distal end of the lumen, the wall over the length of said tapered tip being distensible to allow the orifice to expand, and a distender within the lumen that can be urged distally along the lumen such that the distender presses radially outwardly the catheter wall within the distal tip, so as to distend said orifice.

Owner:CR BARD INC

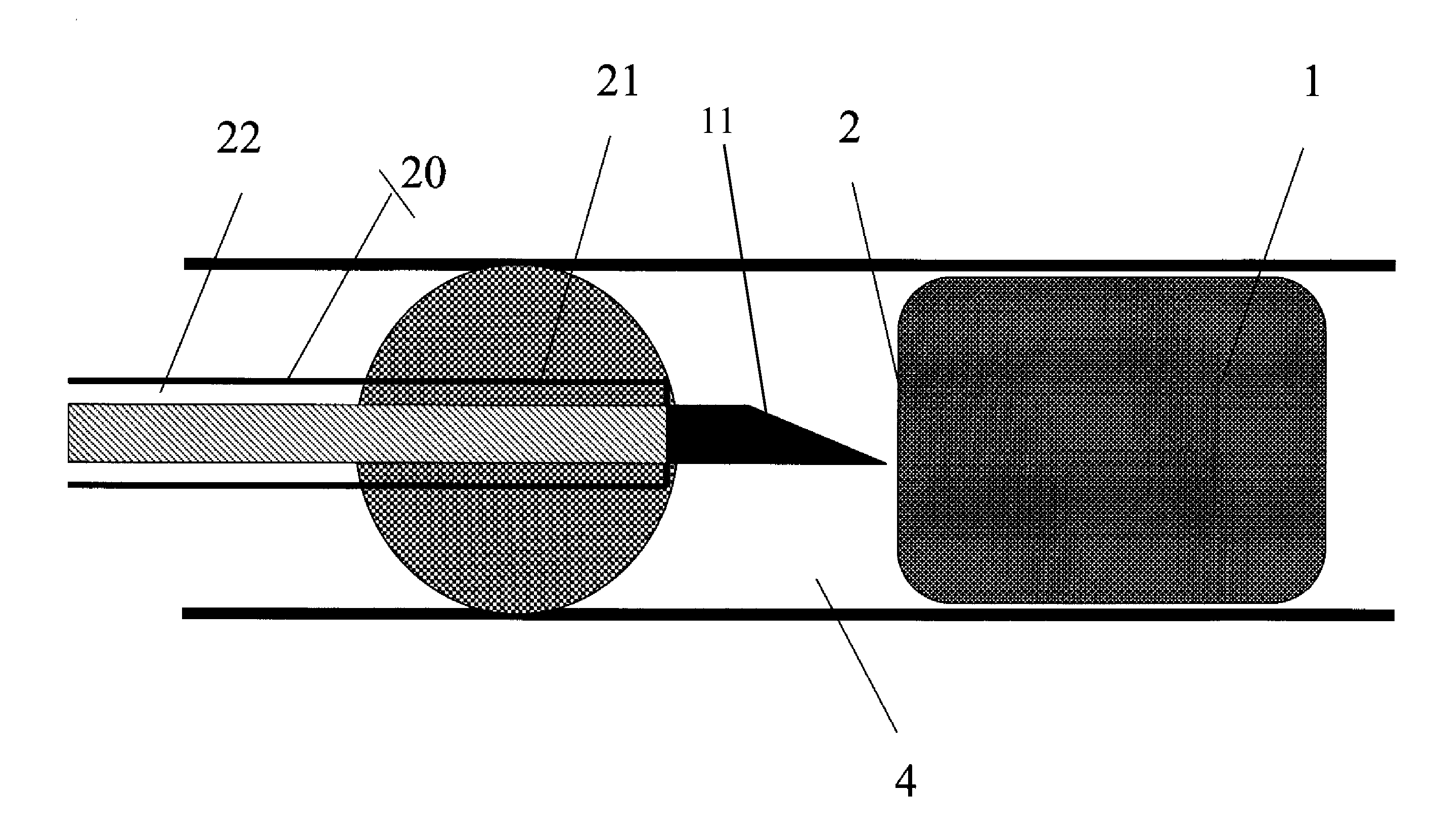

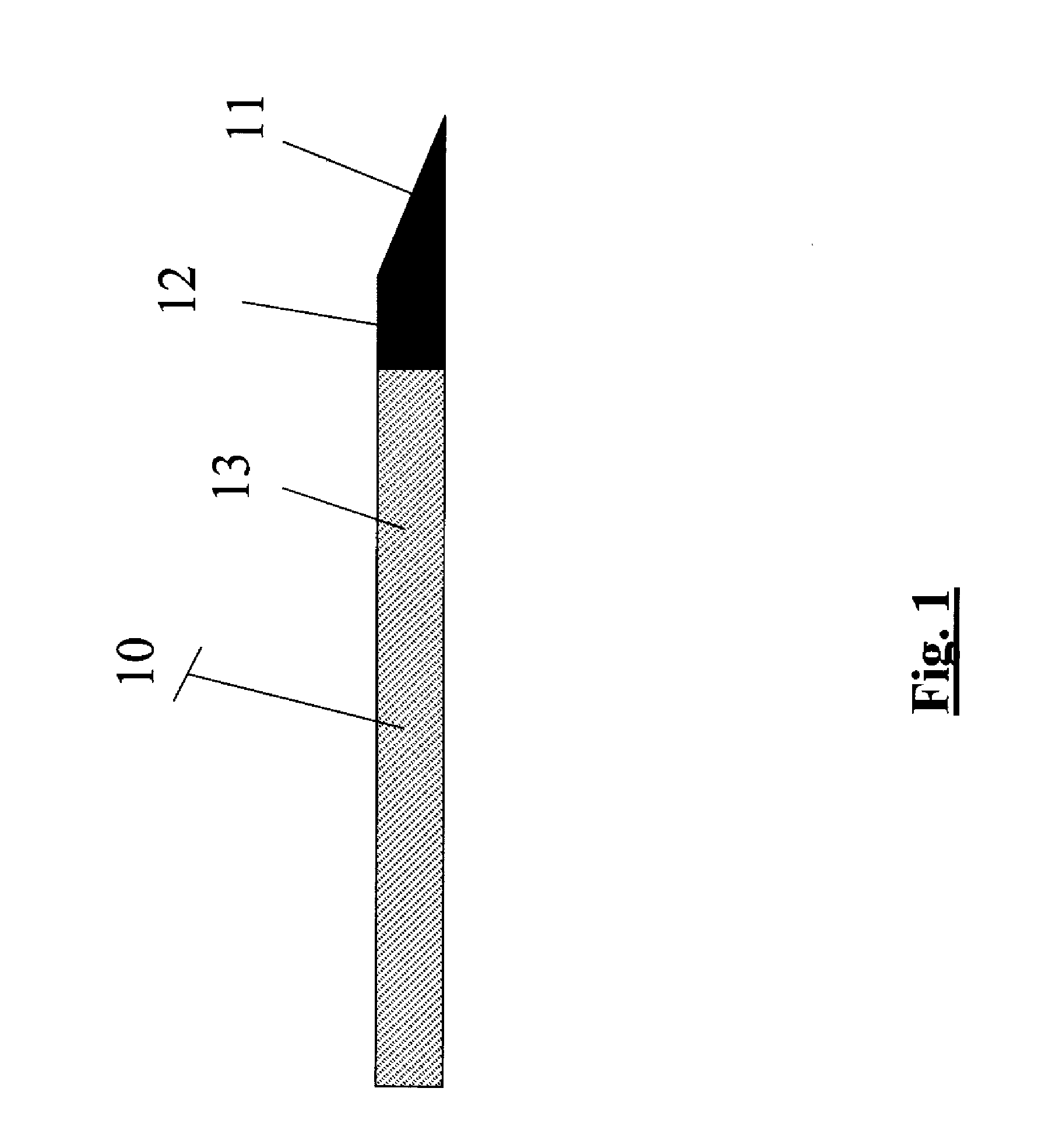

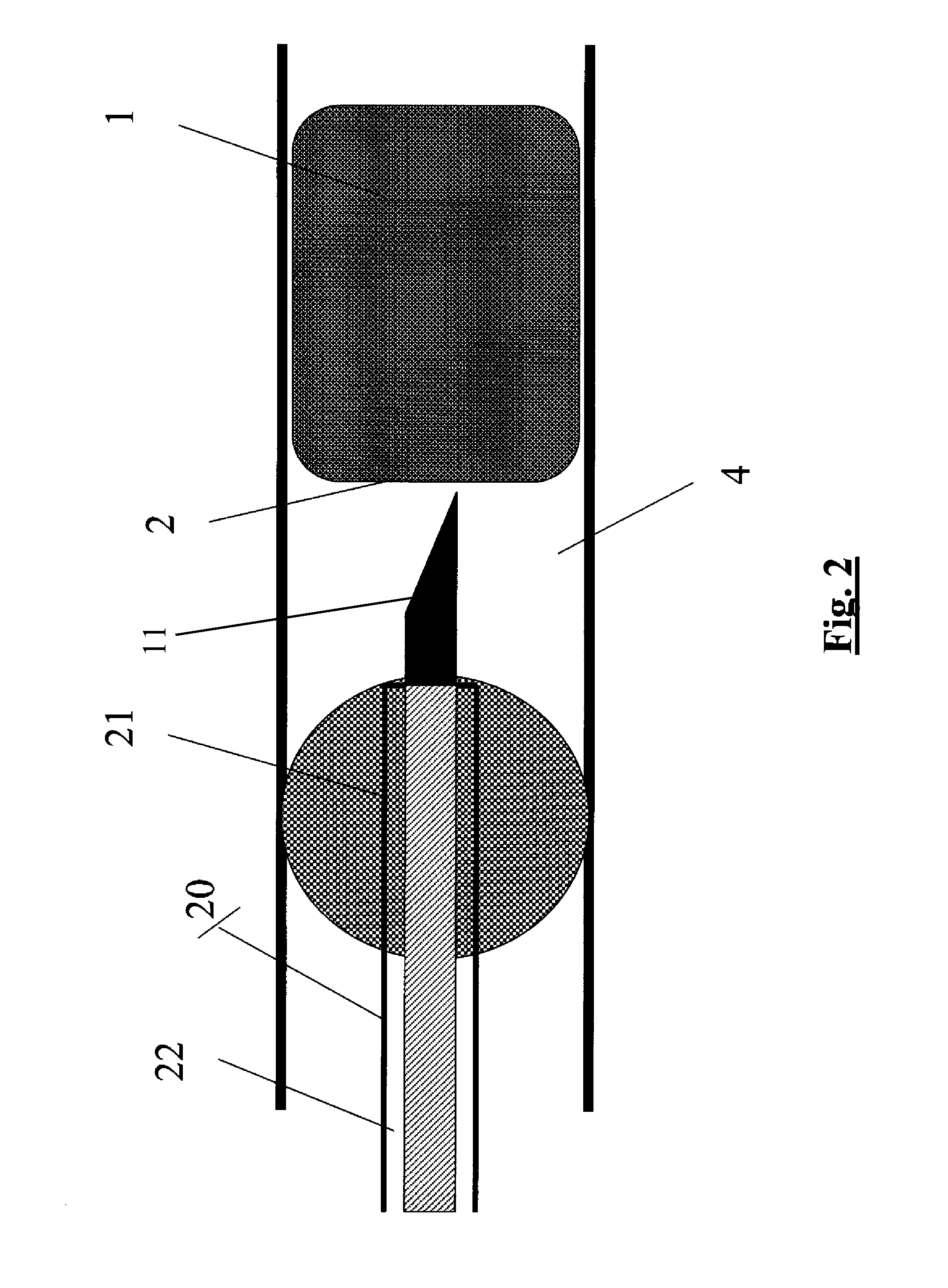

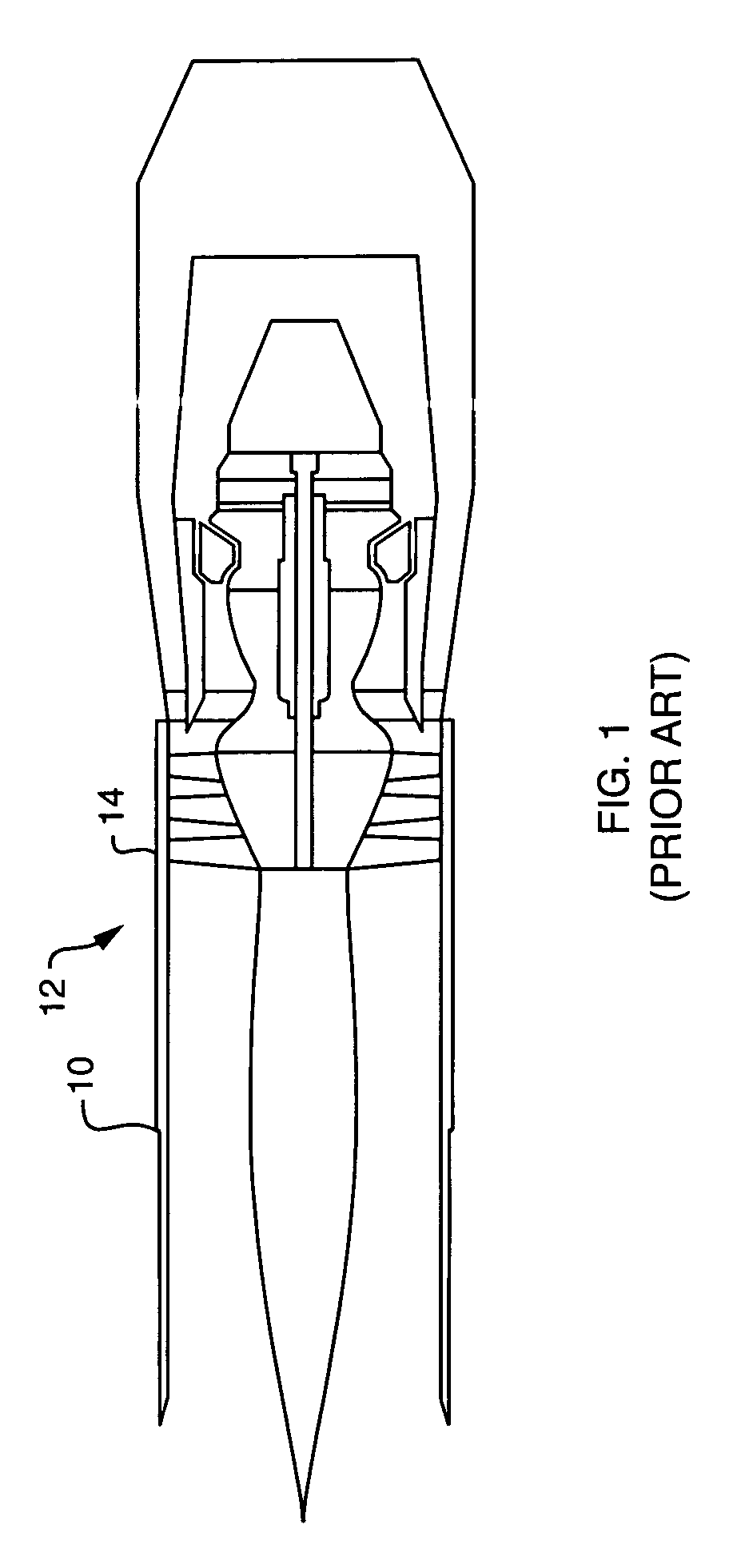

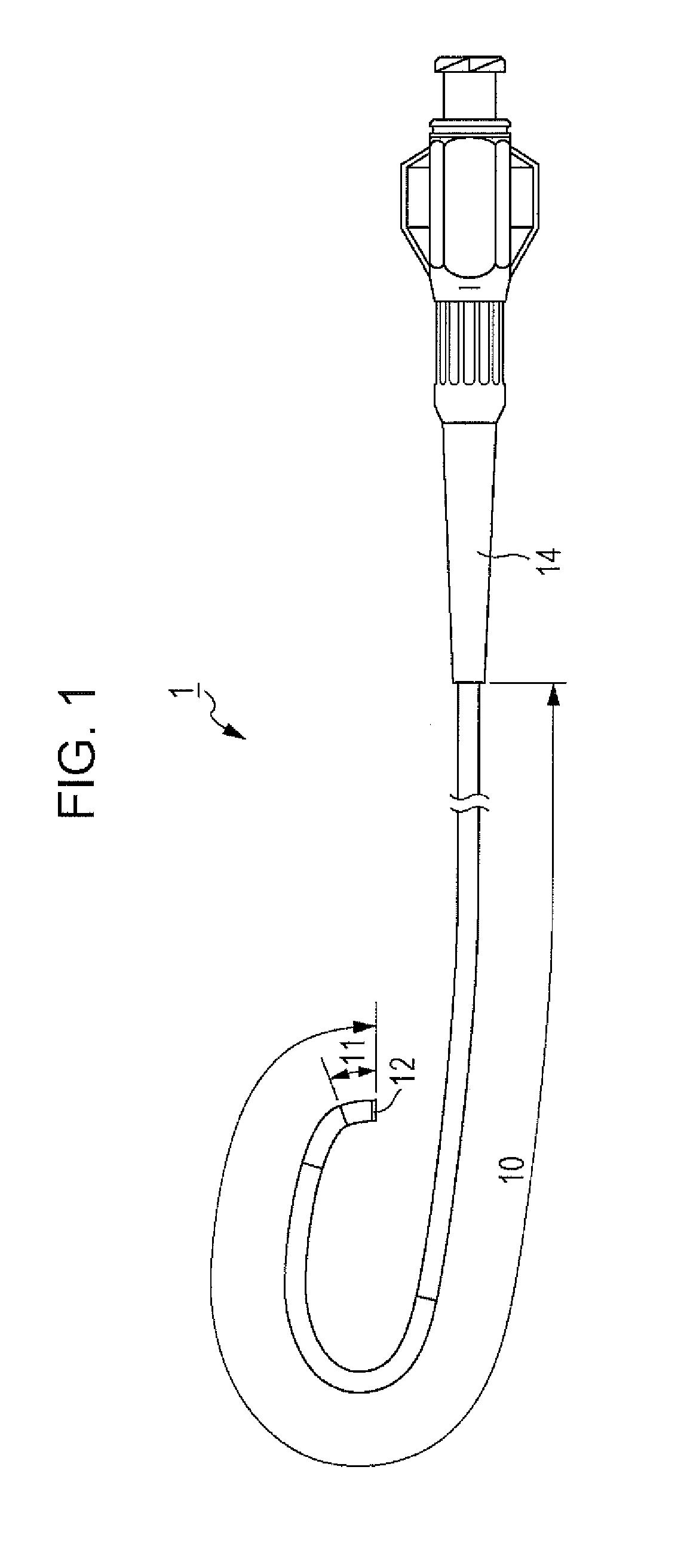

Lancet micro-catheter

InactiveUS20120265229A1Reducing device wall-thicknessIncrease flexibilityBalloon catheterSurgical needlesMedicineCatheter device

A micro-catheter (10) including a hypo-tube including a proximal section (13) and a distal section (12) and a sharp tip (11) formed at a distal end of the distal section (12), characterized in that the proximal section (13) of the micro-catheter (10) is formed with a plurality of cuts (23) which are not perpendicular to a longitudinal axis of the proximal section (13), the cuts (23) being made partially around a circumference of the proximal section (13) with uncut portions separating the cuts (23) from one another.

Owner:BOSTON SCI SCIMED INC

Catheter and method of manufacturing same

InactiveUS7972324B2Increase flexibilityImprove stabilityStentsBalloon catheterCatheterSacroiliac joint

A catheter basically has a catheter shaft in which a catheter tip of which is provided with a joint made of a material which is more flexible than the material of the catheter shaft. The joint is disposed between the distal end of the catheter shaft and the distal end of the catheter tip. The front end consists of a material being the same or more rigid than that of the catheter shaft.

Owner:ABBOTT INT ENTERPRISES LTD

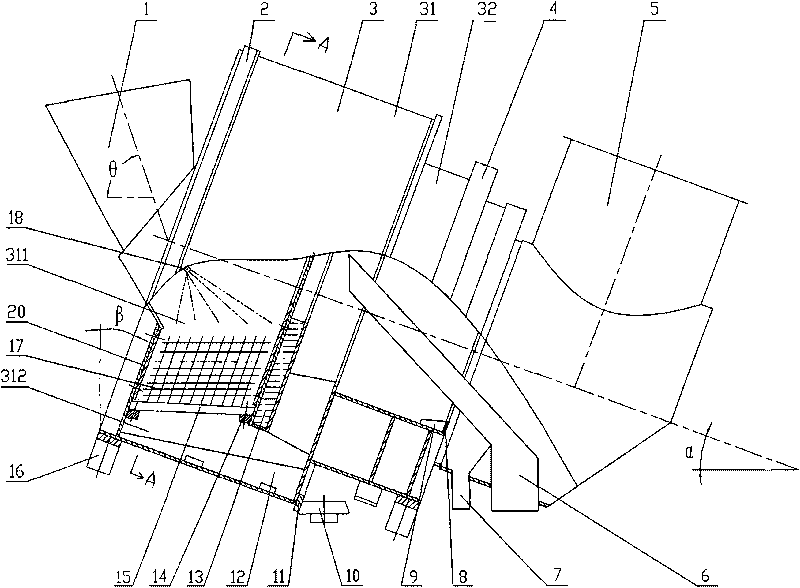

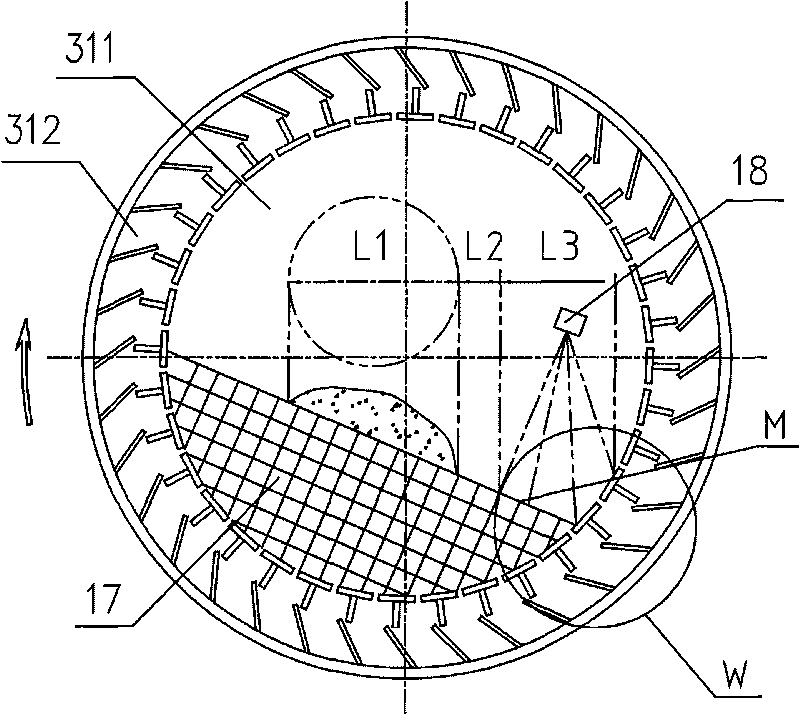

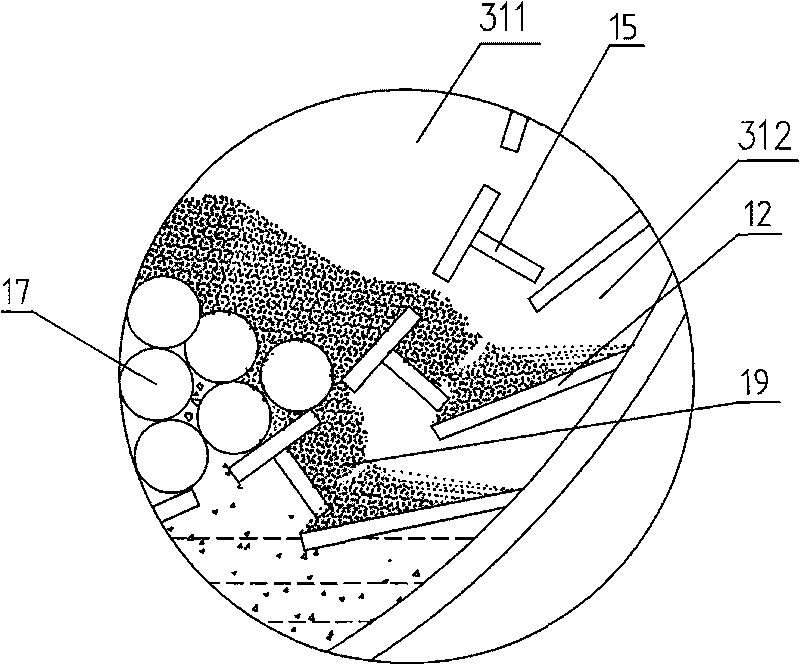

High-temperature slag handling technology by tilting roller process and device

ActiveCN101760572AImprove performanceUniform particle sizeRecycling and recovery technologiesSlagWater spray

The invention discloses a high-temperature slag handling technology by the tilting roller process and a high-temperature slag handling device. The handling technology includes that high-temperature metallurgical slag is poured into a rotating working barrel body with a certain angle of inclination in the axial direction by a loading hopper; the slag in a front barrel body of the working barrel body is fast cooled by a cooling medium and the cooling water sprayed by a spray head in sequence and then crushed; the cooled and crushed slag particles are driven to drop from the gaps among cage bars and the gaps between the cage bars and a barrel body shoveling plate into a lower chamber filled with the cooling water to be cooled for the second time; along with the rotation of the working barrel body, the slag particles soaking in the cooling water in the lower chamber are carried to the upper part of the front barrel body by the barrel body shoveling plate provided with dewatering holes, poured into an open discharging chute and conveyed out of the device; the cooling water that carries fine slag particles and is separated by the barrel body shoveling plate flows to a rear barrel body, and the fine slag particles separated and intercepted by a netty slag-water separating device arranged on the rear barrel body are sent to the discharging chute and conveyed out of the device by a small shoveling plate arranged on the internal side surface of the rear barrel body.

Owner:BAOSHAN IRON & STEEL CO LTD

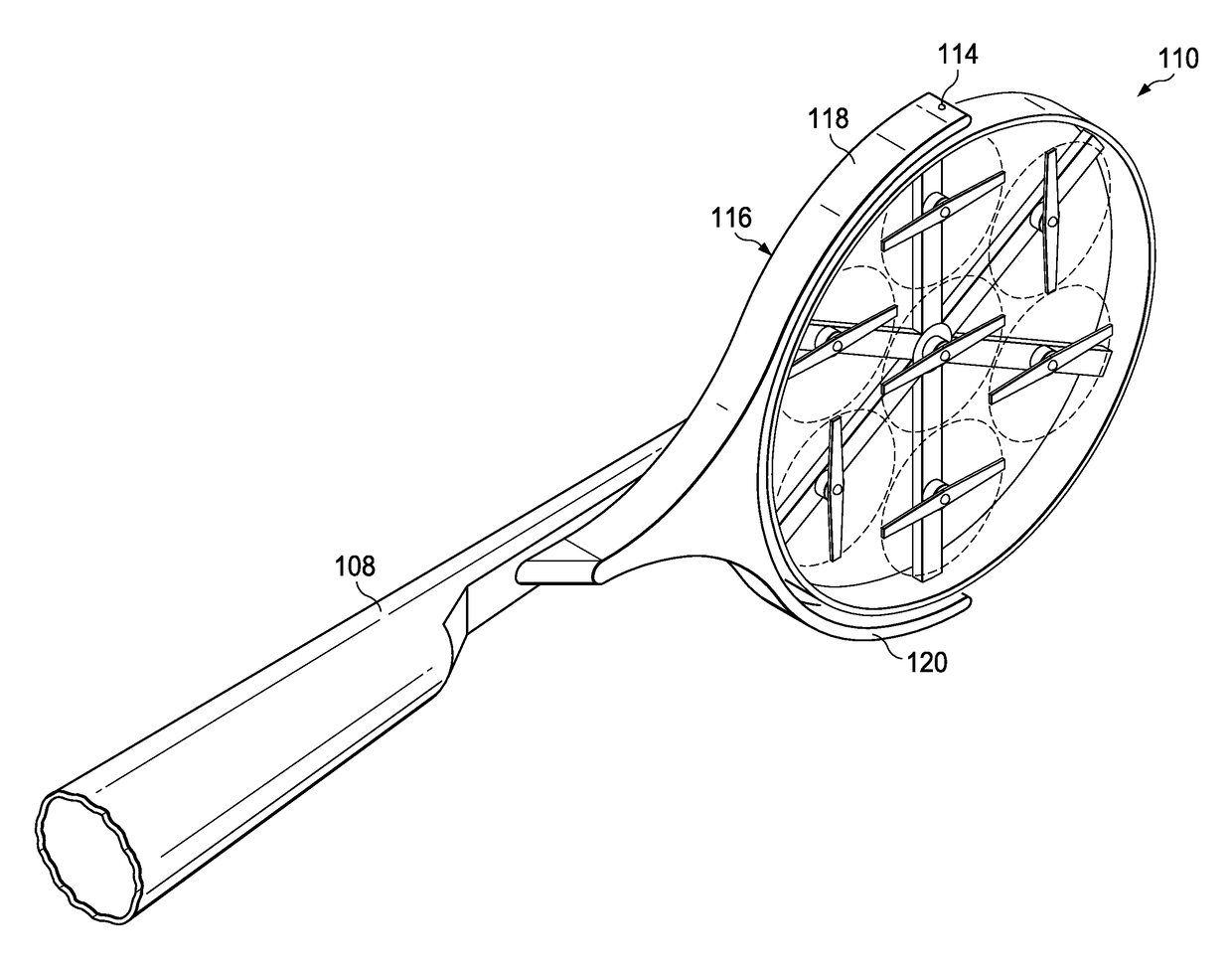

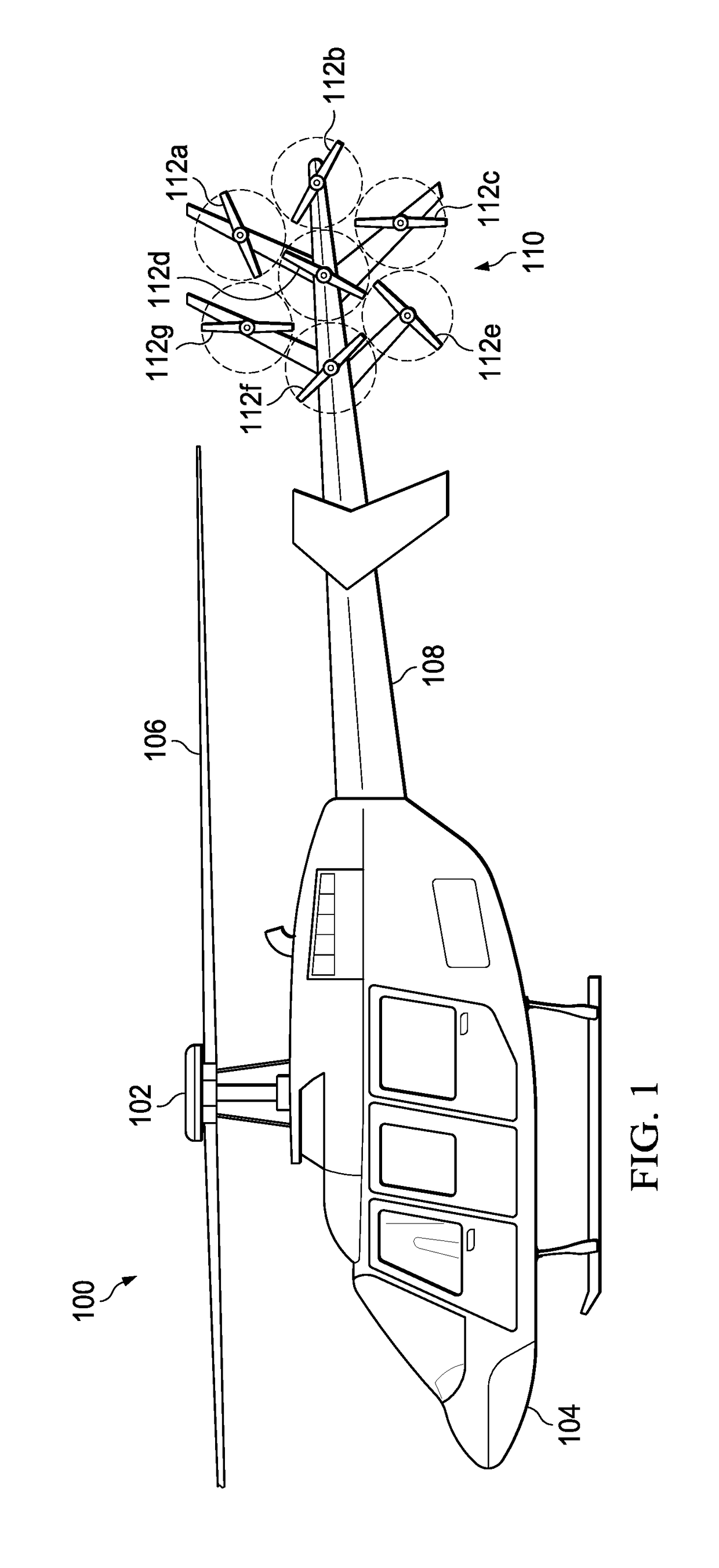

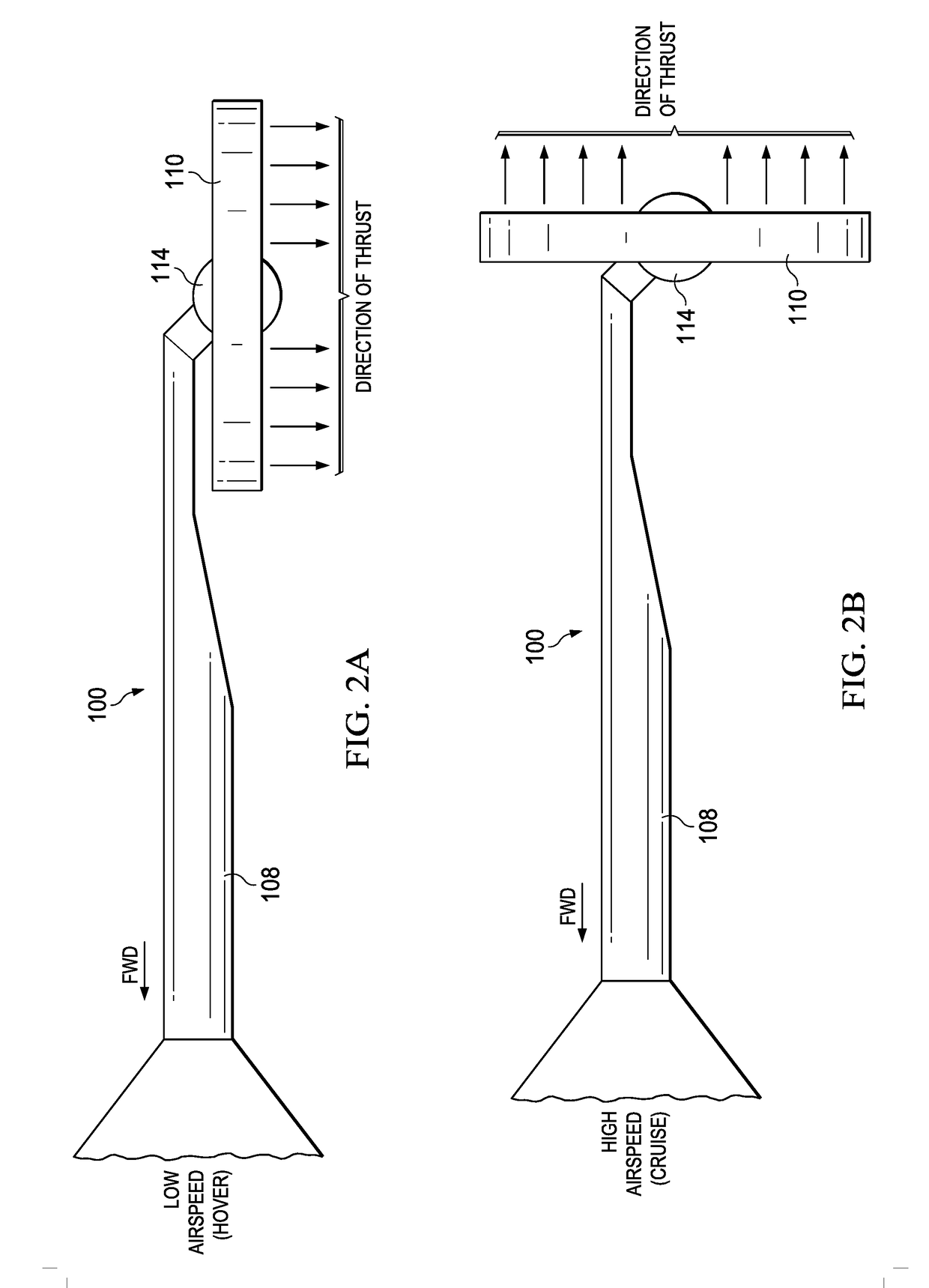

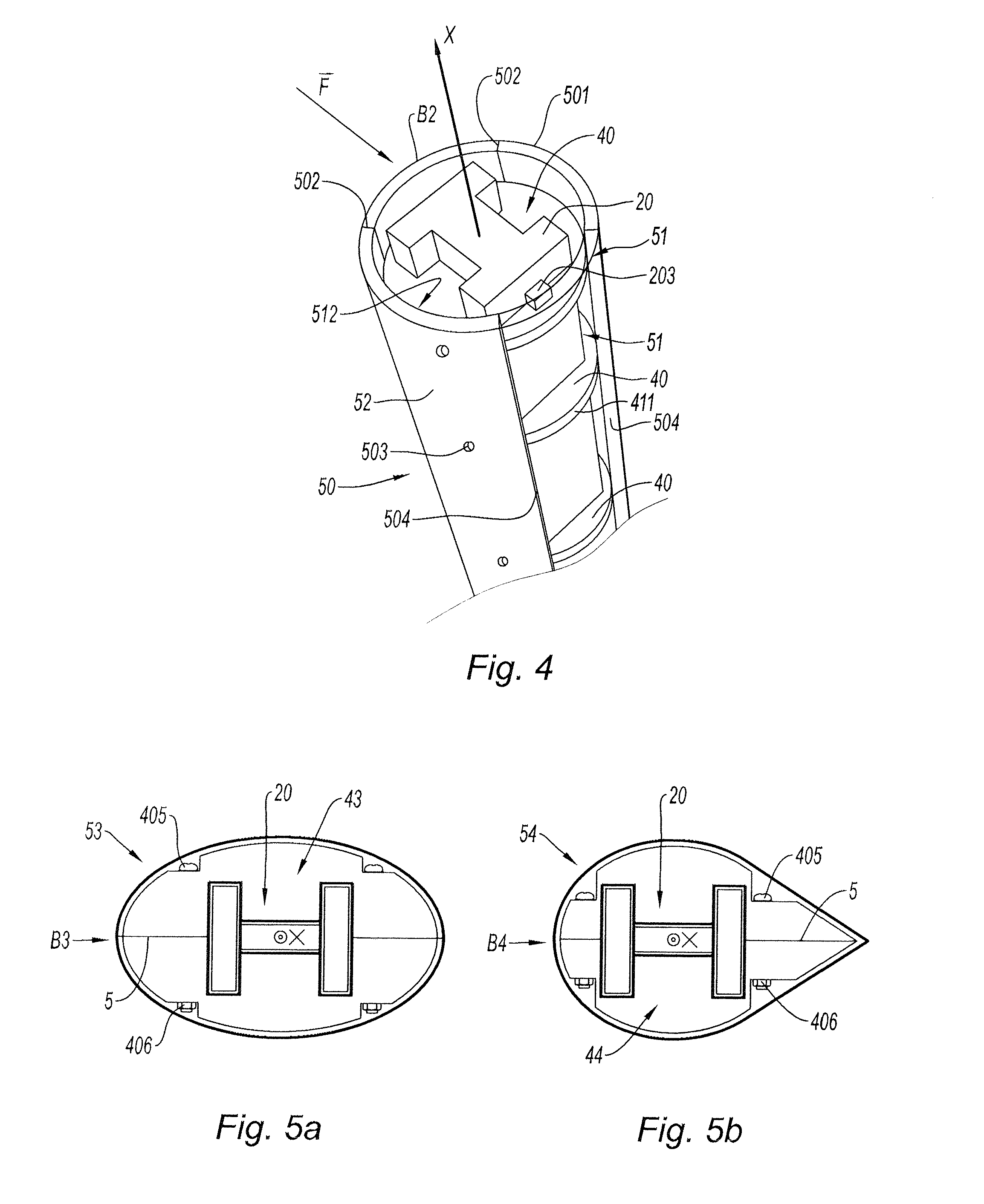

Variable Directional Thrust for Helicopter Tail Anti-Torque System

The present invention includes an anti-torque assembly for a helicopter comprising a plurality of fixed blade pitch motors mounted on one or more pivots on the tail boom of the helicopter, wherein the plurality of fixed blade pitch motors on the one or more pivots are adapted to be oriented substantially in-plane with a tail boom of a helicopter during a first mode of operation that comprises a hover mode and wherein the fixed blade pitch motors are adapted to be oriented substantially off-plane from the tail boom of the helicopter during a second mode of helicopter operation that is different from the first mode.

Owner:TEXTRON INNOVATIONS

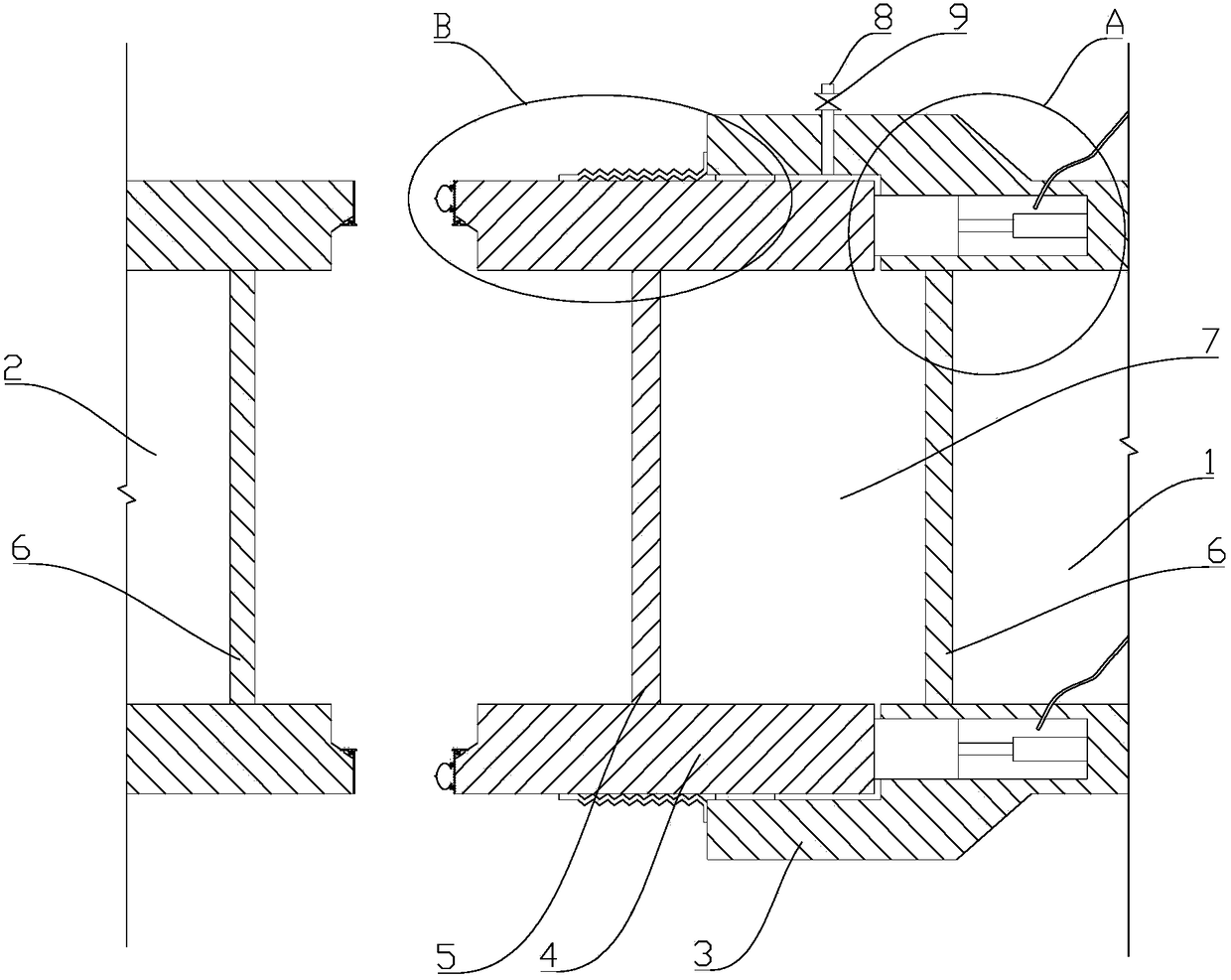

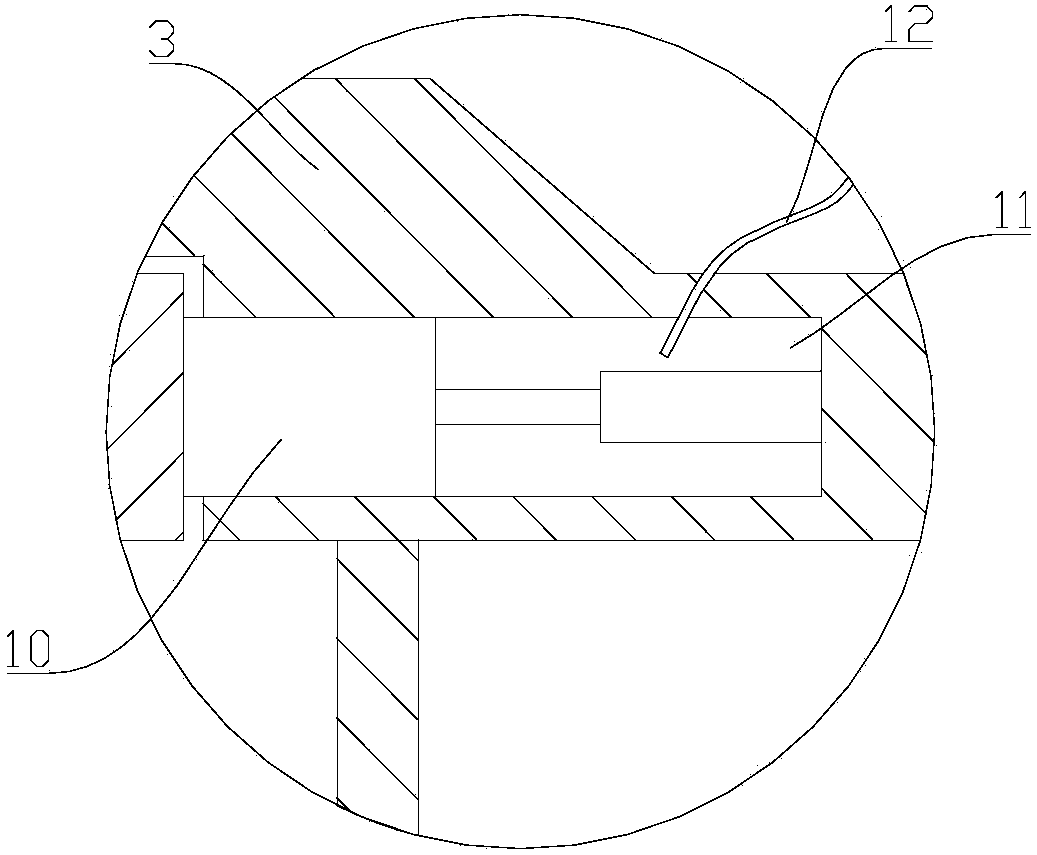

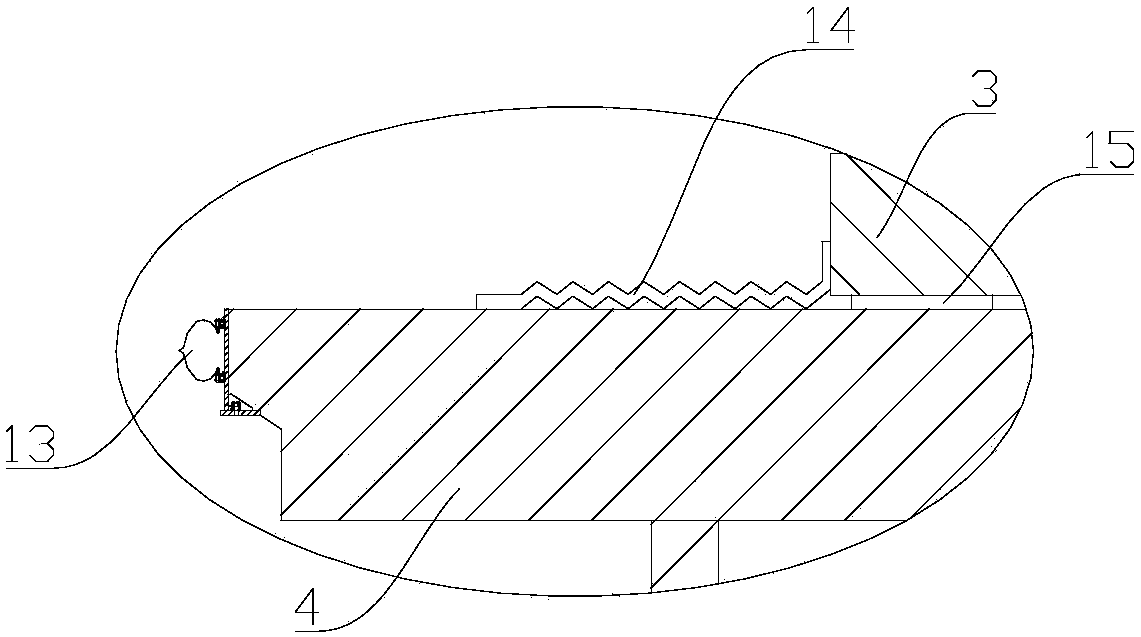

Jacking-pushing-type final joint for immersed tunnel and butt-joint construction method thereof

ActiveCN108385728AThrust achievedEnsure safetyArtificial islandsHydro energy generationButt jointEngineering

The invention provides a jacking-pushing-type final joint for an immersed tunnel and a butt-joint construction method thereof, and belongs to the technical field of immersed tunnel construction. Underwater water stop and push stop of the final joint after jacking pushing can be quickly and effectively achieved, the water stop and push stop effects are good, and the safety is high. The jacking-pushing-type final joint comprises a connecting bearing opening formed in a to-be-mounted pipe segment, further comprises a jacking pushing piece, and further comprises a water stop assembly. A jacking pipe section is sleeved with the connecting bearing opening, a cavity capable of containing the jacking pushing piece is formed in the connecting bearing opening, and a grouting pipe is pre-embedded inthe cavity. The water stop assembly comprises three water stop belts; the first water stop belt is arranged at the end face of the pushed-out end of the jacking pipe section; the second water stop belt and the third water stop belt are both arranged on the periphery of the jacking pipe section; the second water stop belt can extend along with pushing out of the jacking pipe section; one end of thesecond water stop belt is fixedly connected to the jacking pipe section, and the other end of the second water stop belt is fixedly connected to the connecting bearing opening; and the third water stop belt is connected between the jacking pipe section and the connecting bearing opening in a sleeved mode.

Owner:CCCC FIRST HARBOR ENG +2

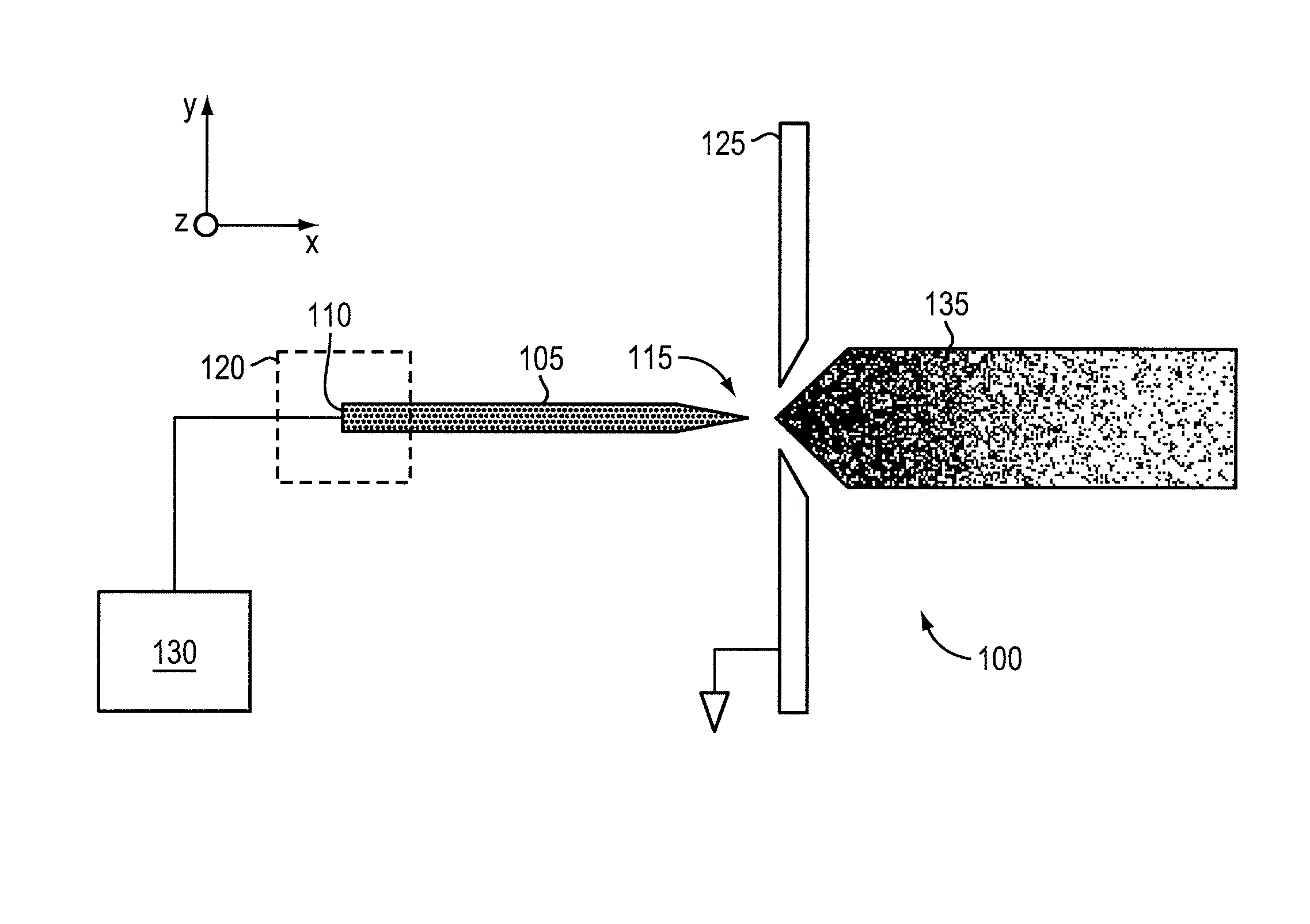

Method and apparatus for a porous metal electrospray emitter

ActiveUS8324593B2High currentImprove liquidityElectrolysis componentsParticle separator tubesRoom temperatureMolten salt

An ionic liquid ion source can include a microfabricated body including a base and a tip. The microfabricated body can be formed of a porous metal compatible (e.g., does not react or result in electrochemical decaying or corrosion) with an ionic liquid or a room-temperature molten salt. The microfabricated body can have a pore size gradient that decreases from the base of the body to the tip of the body, so that the ionic liquid can be transported through capillarity from the base to the tip.

Owner:MASSACHUSETTS INST OF TECH

Method and apparatus for a porous electrospray emitter

ActiveUS8791411B2High currentImprove liquidityElectrolysis componentsMaterial analysis by optical meansRoom temperatureMolten salt

An ionic liquid ion source can include a microfabricated body including a base and a tip. The body can be formed of a porous material compatible with at least one of an ionic liquid or room-temperature molten salt. The body can have a pore size gradient that decreases from the base of the body to the tip of the body, such that the at least one of an ionic liquid or room-temperature molten salt is capable of being transported through capillarity from the base to the tip.

Owner:MASSACHUSETTS INST OF TECH

Method and apparatus for a porous electrospray emitter

ActiveUS8785881B2High currentImprove liquidityParticle separator tubesMaterial analysis by optical meansMolten saltRoom temperature

An ionic liquid ion source can include a microfabricated body including a base and a tip. The body can be formed of a porous material compatible with at least one of an ionic liquid or room-temperature molten salt. The body can have a pore size gradient that decreases from the base of the body to the tip of the body, such that the at least one of an ionic liquid or room-temperature molten salt is capable of being transported through capillarity from the base to the tip.

Owner:MASSACHUSETTS INST OF TECH

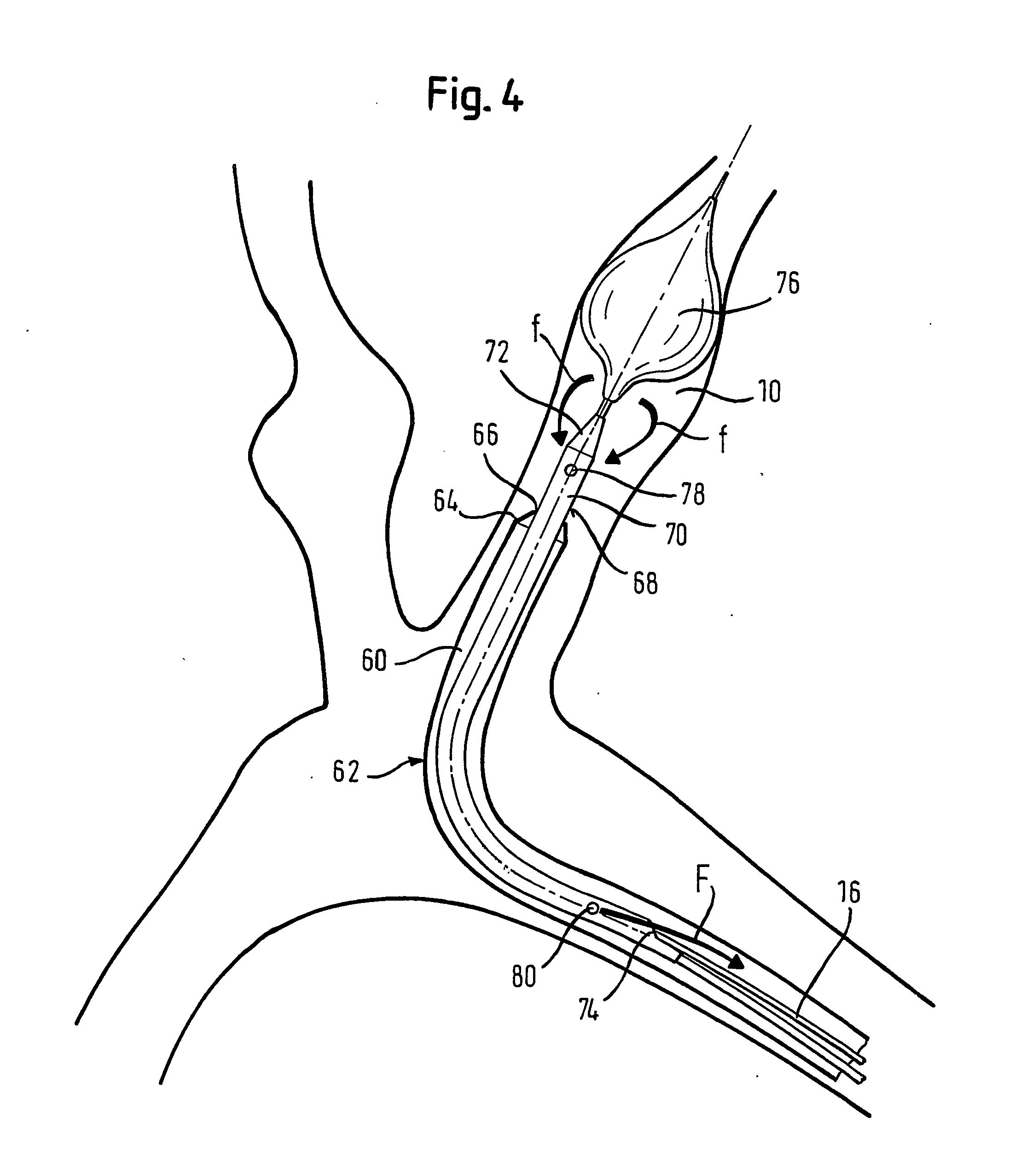

Retrieval catheter

A retrieval catheter (30) for retrieving from a bodily lumen a device (48) attached to the distal end of a pull line (16), the catheter having a wall (32) that defines a catheter lumen (22) and a distal tip (36) that is tapered towards an open distal orifice (38) that defines the distal end of the lumen, the wall over the length of said tapered tip being distensible to allow the orifice to expand, the catheter having: a distender within the lumen that can be urged distally along the lumen such that the distender presses radially outwardly the catheter wall within the distal tip, so as to distend said orifice; the distender having a distal end annulus and a proximal end annulus (42) separated by a radially outward-facing circumferential wall and an axial lumen extending through the distender between said distal and proximal annuli; a pusher shaft (46) that extends from the distender proximally along the catheter lumen to proximally beyond the proximal end of the catheter lumen and that is arranged to push the distender distally until the distal end annulus is distal of the catheter distal orifice and the open distal orifice of the catheter is distended; whereby, with said pull line extending from the device to be retrieved through the lumen of the distender and the lumen of the catheter, the device can be pulled proximally by the pull line relative to the catheter until at least the most proximal part of the device slides over the distal end annulus of the distender into the lumen of the distender.

Owner:CR BARD INC

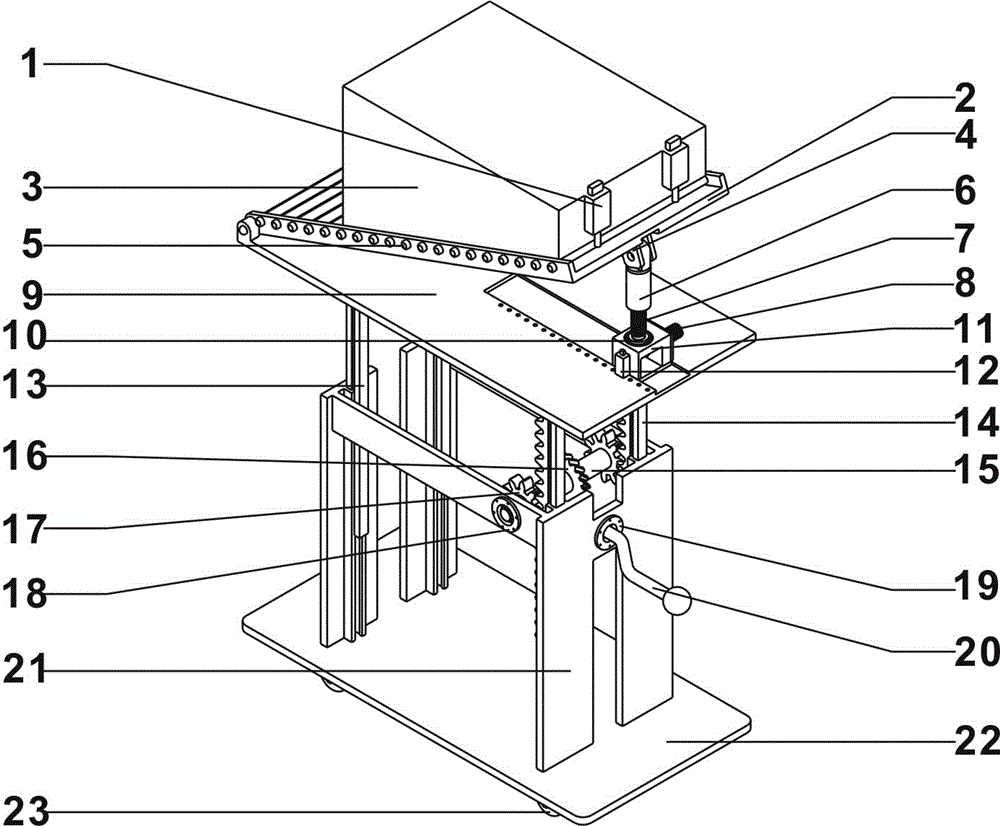

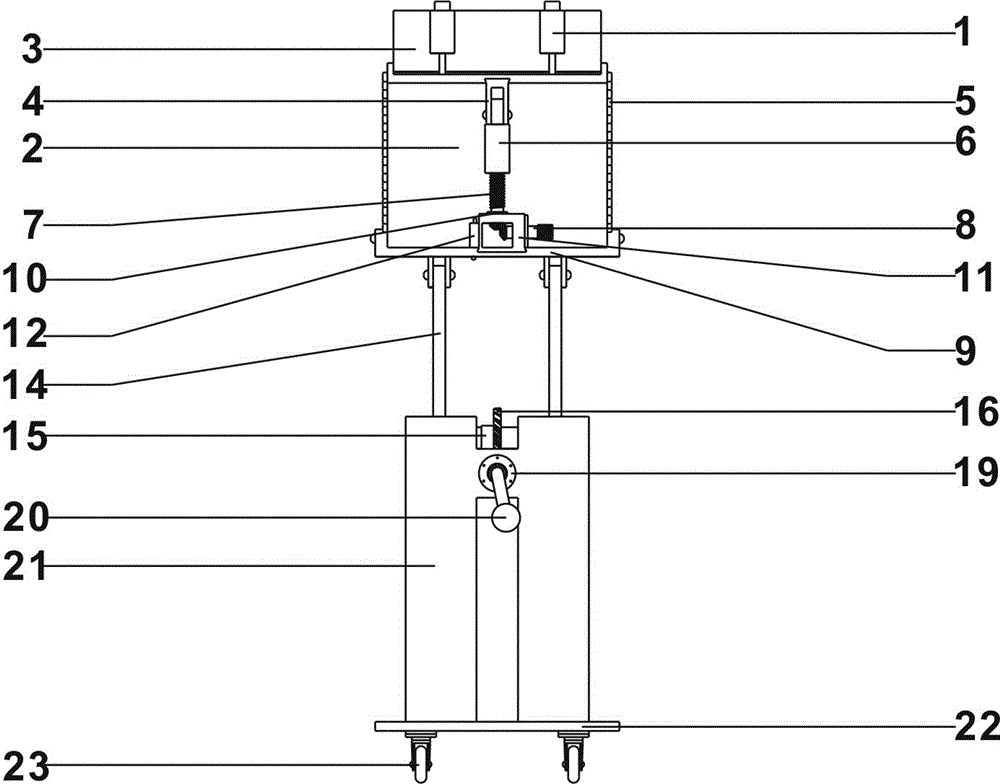

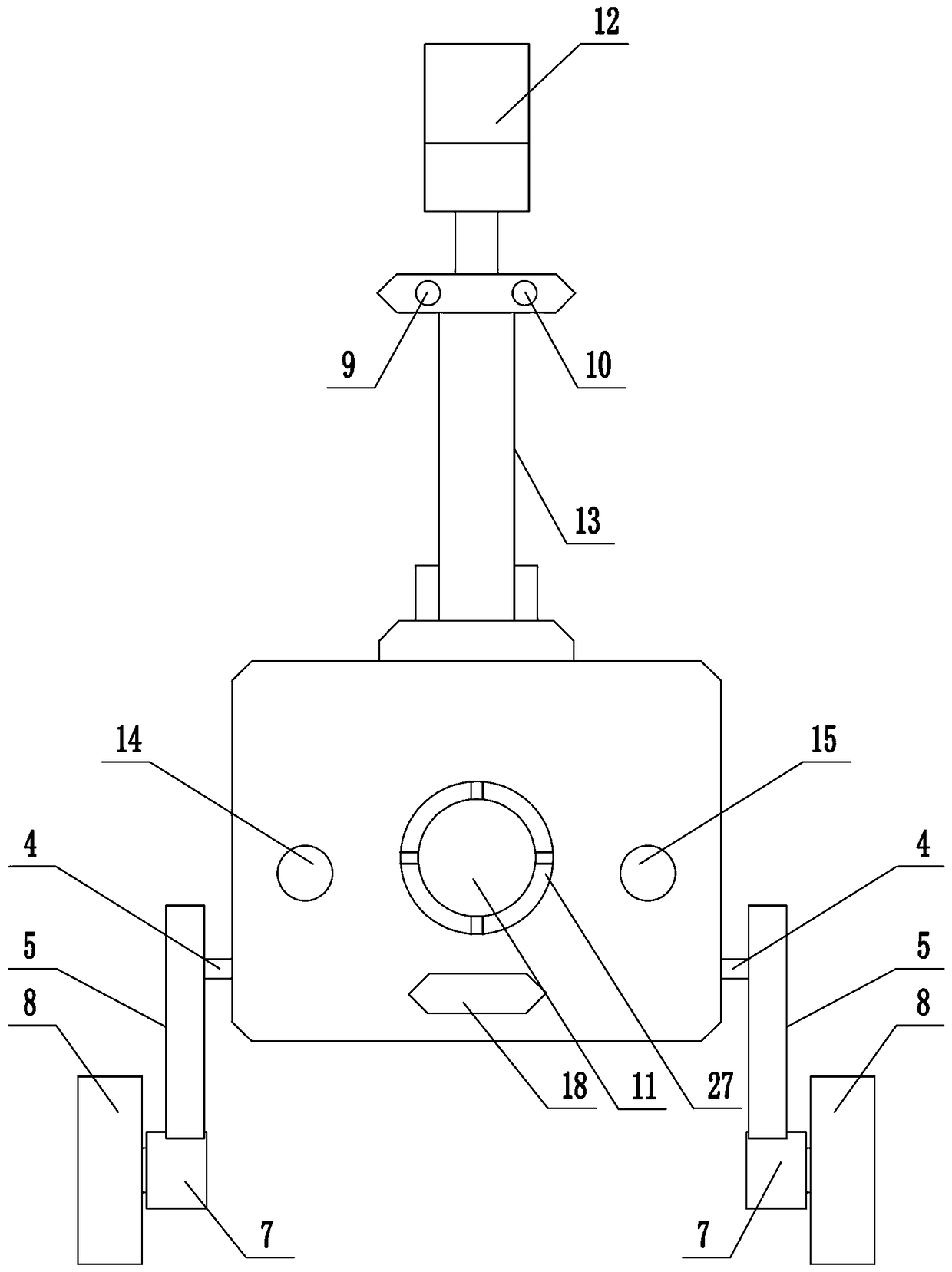

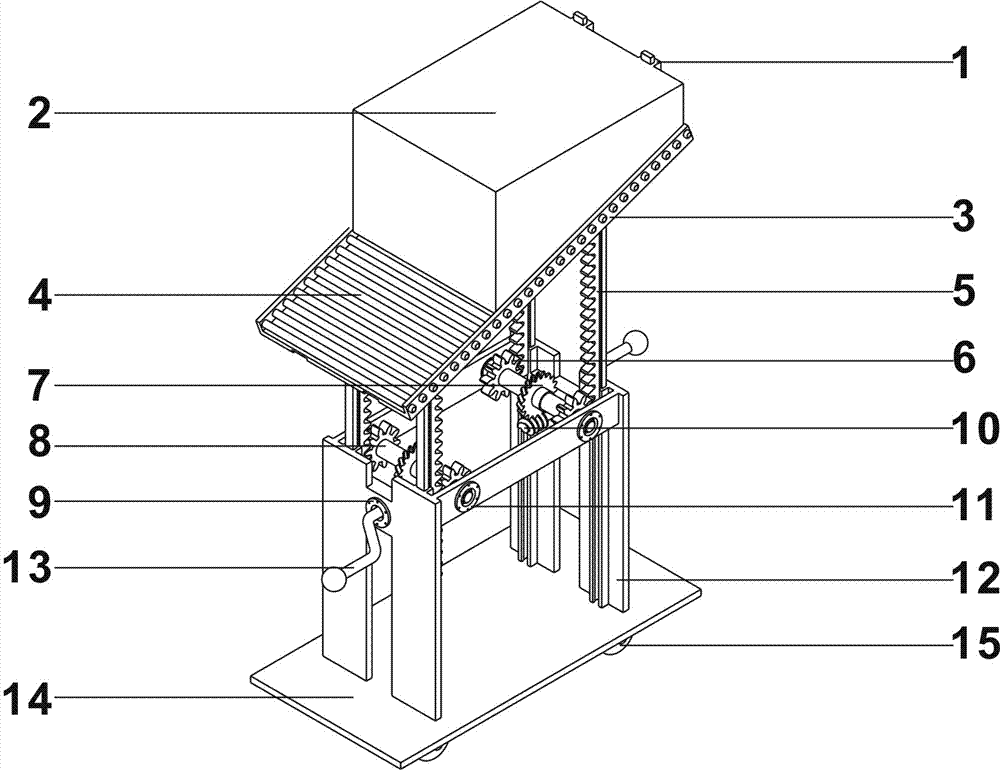

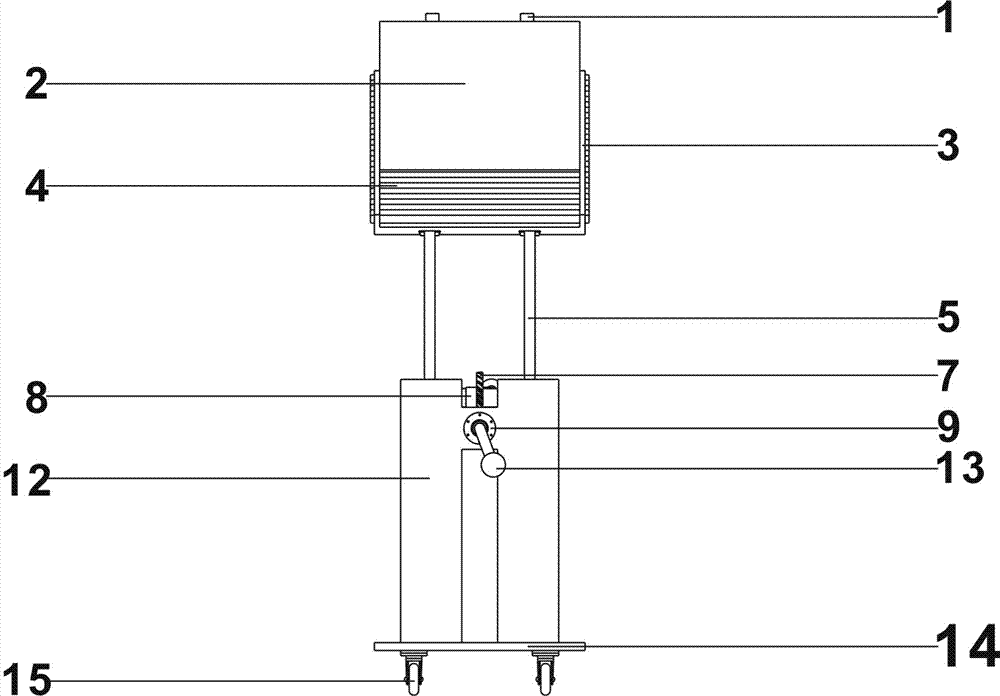

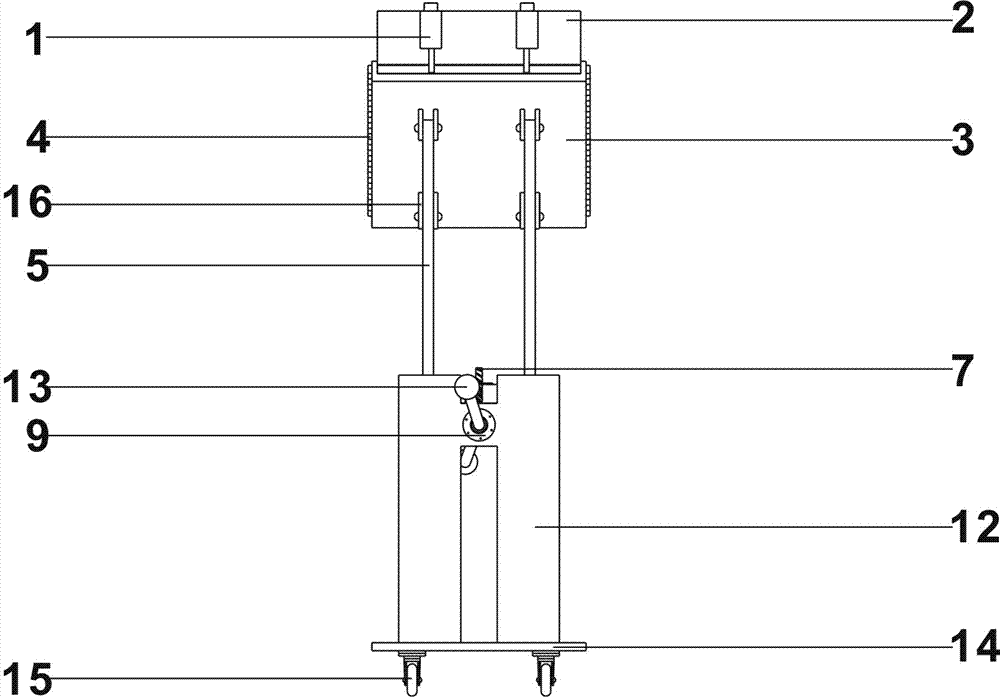

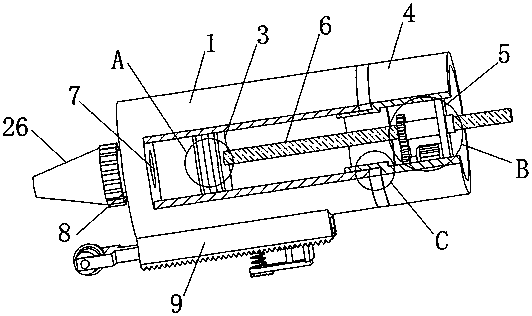

Manual lifting deadweight loading device for landslide physical model test

ActiveCN102980785AReduce production intensitySimple structureStructural/machines measurementLandslidePhysical model

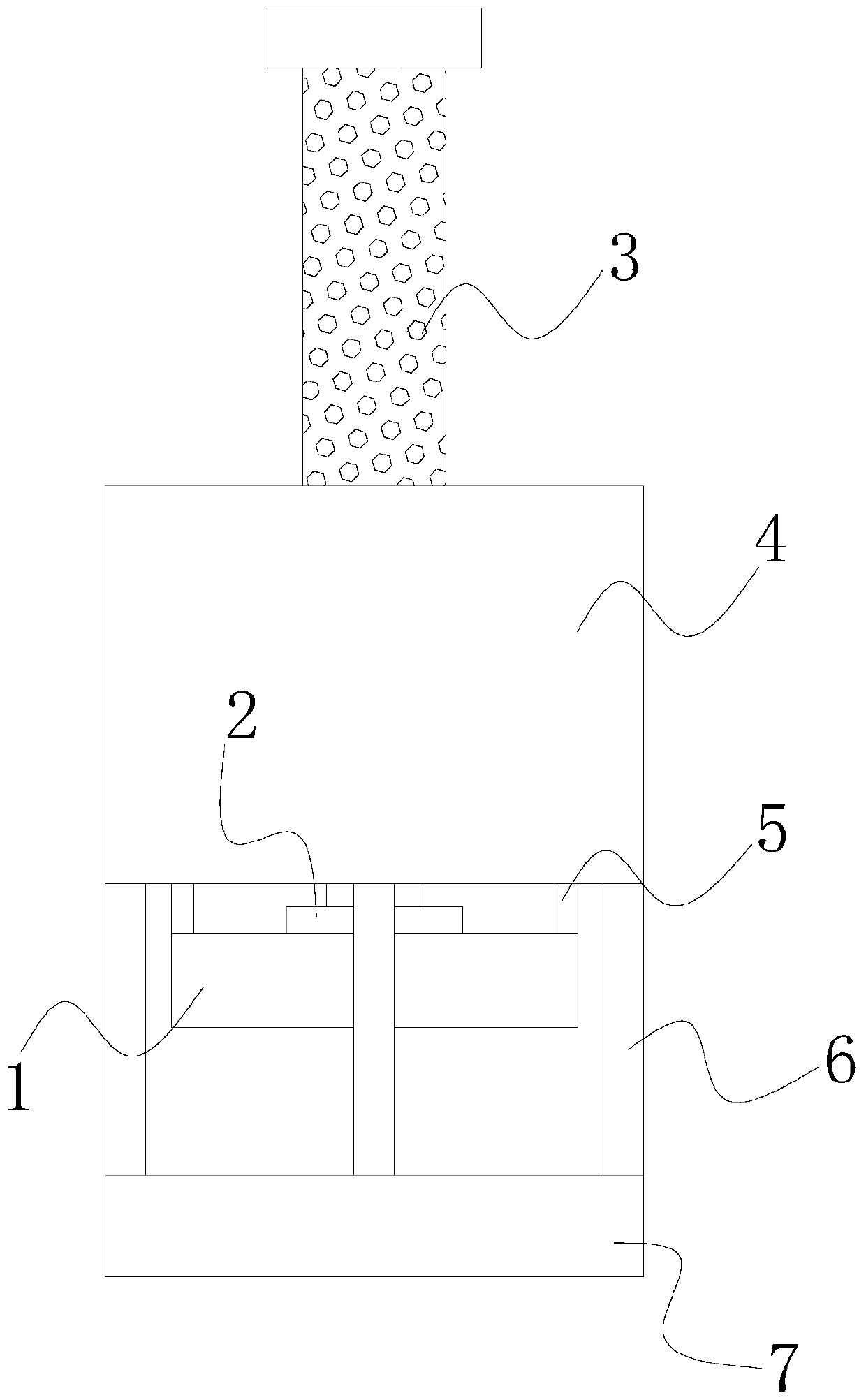

The invention discloses a manual lifting deadweight loading device for a landslide physical model test, which comprises a bottom plate, a lifting mechanism, an angle adjustment mechanism and a thrust loading mechanism, wherein the lifting mechanism is positioned on the bottom plate; the upper end of the lifting mechanism is connected with the angle adjustment mechanism; the lifting mechanism is used for driving the lifting of the angle adjustment mechanism; the angle adjustment mechanism comprises a support plate, a slide panel, a screw rod, a sleeve and a horizontal knob; the support plate is connected with the upper end of the lifting mechanism; the front end of the support plate is articulated with the front end of the slide panel; the screw rod is arranged at the rear end of the support plate in a supporting manner; the sleeve is sleeved at the upper part of the screw rod; the screw rod is connected with the sleeve by screw threads; the lower end of the screw rod is engaged with the end part of the horizontal knob by a bevel gear; the rotation of the horizontal knob can drive the screw rod to rotate; the top end of the sleeve is articulated with a slide connecting block; the slide connecting block is contacted with the rear part of the bottom surface of the slide panel; the thrust loading mechanism comprises a loading platform used for bearing weight; the bottom surface of the loading platform is slidingly matched with the top surface of the slide panel; and the loading platform can slide back and forth along the slide panel.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

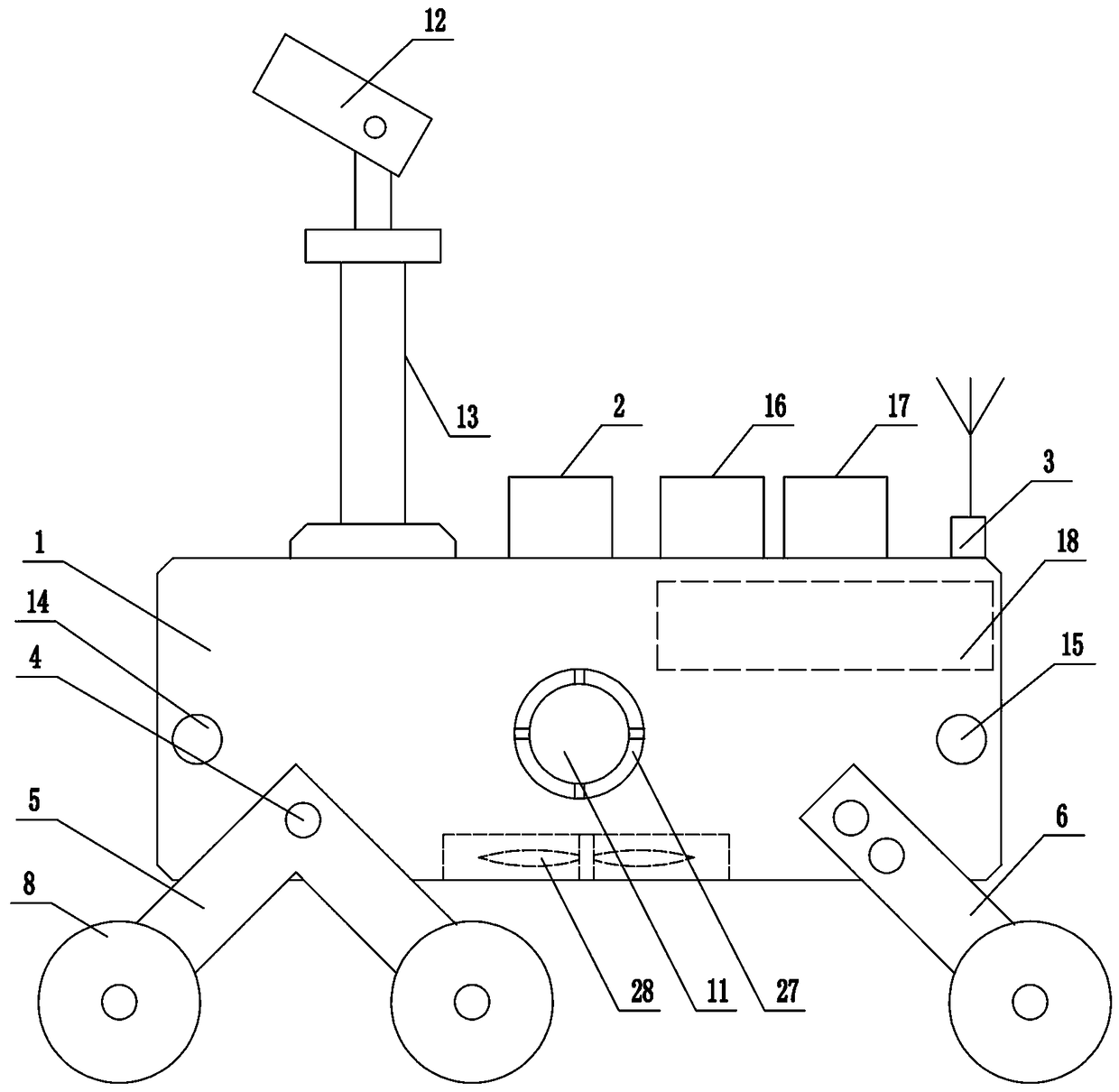

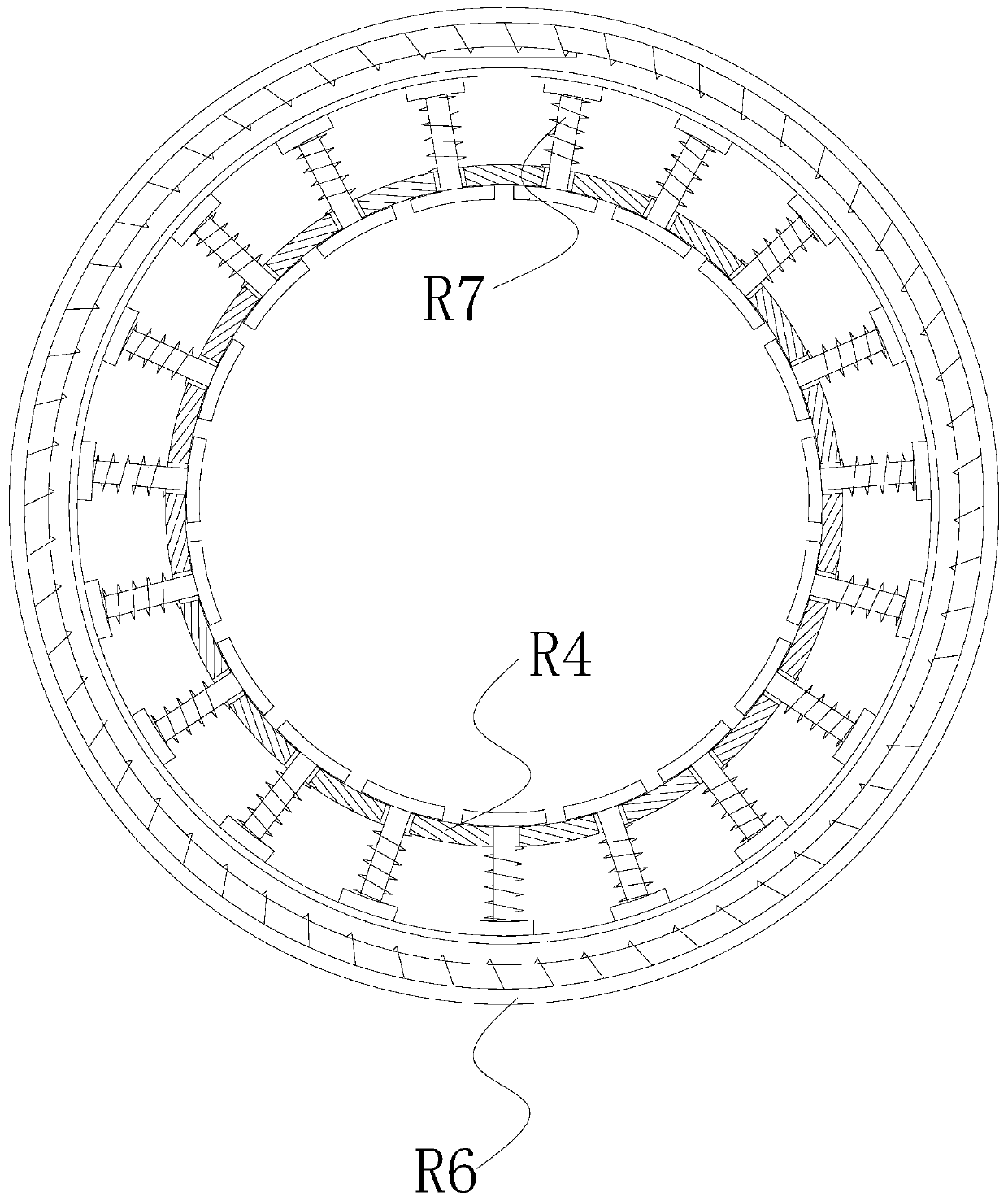

Converting station fire disaster early warning inspecting robot

PendingCN109509320AGood thrustAchieve free rotationFire alarm electric actuationManipulatorFire - disastersDrive motor

The invention belongs to the technical field of intelligent equipment, and particularly relates to a converting station fire disaster early warning inspecting robot. A robot body and a walking device,a monitoring device, a control device, a communication device and a navigation positioning device which are arranged on the robot body are included, the walking device comprises two V-shaped crank arms and two obliquely arranged supporting frames, the ends of the V-shaped crank arms and the supporting frames are provided with driving motors, rolling wheels are in transmission connection with output shafts of the driving motors. The robot has the advantages that functions of climbing stairs and entering cable ditches are achieved, equipment of cable ditches and the like and indoor and outdoorenvironments of a converting station can be automatically inspected according to preset time and routes, fire disaster potential safety hazards of heat generating points, electric sparks, flame spots,smoke sensing spots and the like can be timely discovered, functions of fire disaster early warning and alarming of an unmanned converting station are achieved, and the robot has the application prospects of being popularized in the fields of warehouses, oil depots and the like.

Owner:PINGDINGSHAN POWER SUPPLY ELECTRIC POWER OF HENAN +1

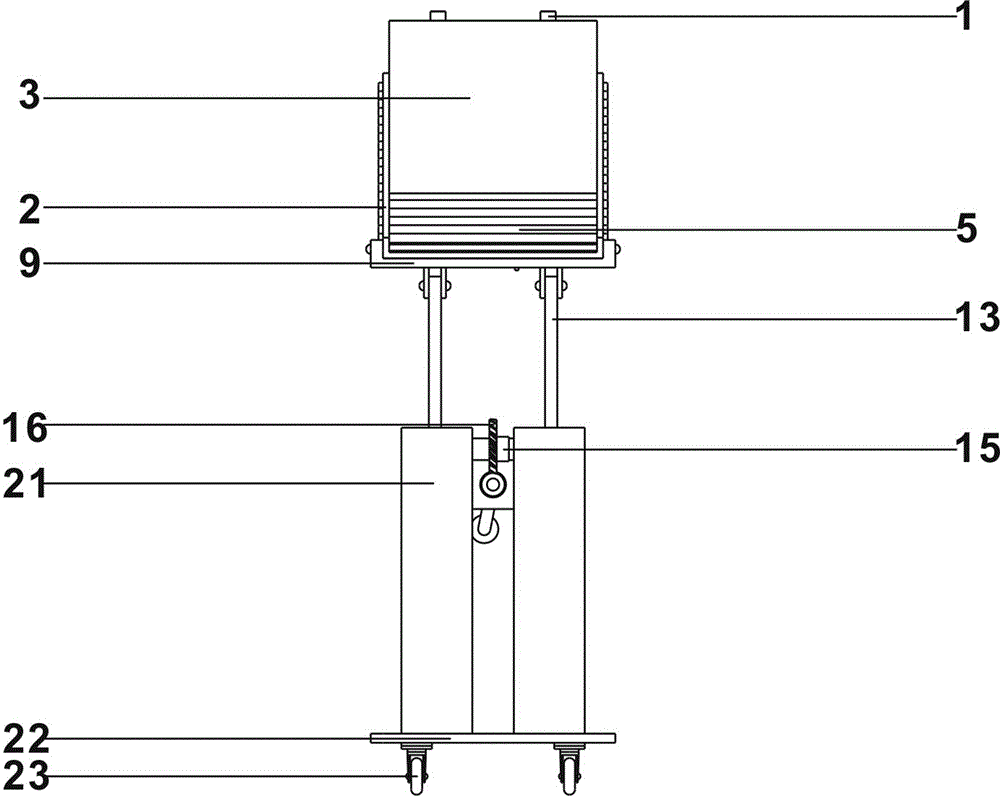

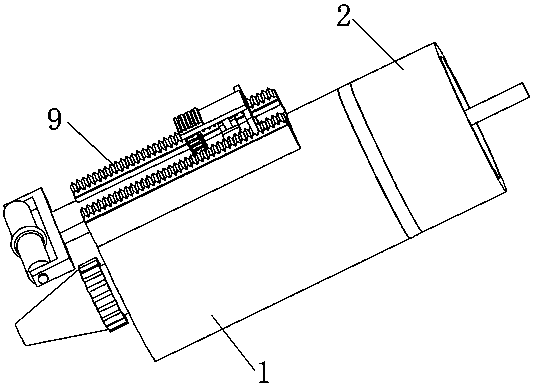

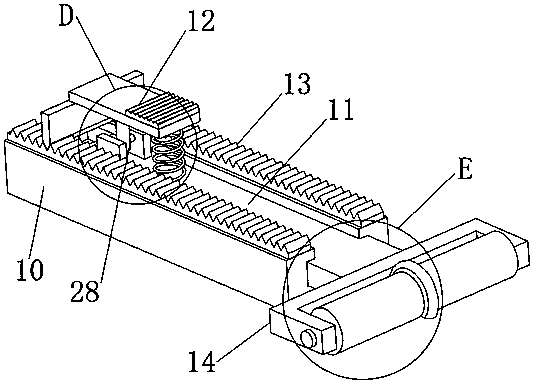

Manual rack type dead-weight loading device for landslide physical model test

ActiveCN103033607AReduce production intensitySimple structureEarth material testingDrive shaftLandslide

The invention discloses a manual rack type dead-weight loading device for a landslide physical model test. The device comprises a bottom plate, a sliding surface adjusting mechanism and a thrust loading mechanism, wherein the sliding surface adjusting mechanism is located on the bottom plate and comprises a sliding panel, two groups of racks and gears which are mutually meshed, two transmission shafts, two groups of worm wheels and worms which are mutually meshed, two rocking handles and a guide holder; the guide holder is fixed on the bottom plate; vertical guide grooves are formed at the front part and the rear part of the guide holder respectively; one group of racks are located in the guide groove at the front part of the guide holder, while the other group of racks are located in the guide groove at the rear part of the guide holder; each group of racks and one of worm wheels are arranged on the guide holder through the transmission shafts; each worm is connected with one of the rocking handles; the front end of the sliding panel is hinged with the tops of the group of racks which are located at the front part of the guide holder, while the rear end of the sliding panel is arranged on the group of racks which are located at the rear part of the guide holder; the thrust loading mechanism comprises a loading platform; the bottom of the loading platform is in sliding fit with the top surface of the sliding panel; and the loading platform can slide along the sliding panel forth and back.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

Jet engine inlet-fan system and design method

InactiveUS7845902B2Improve performanceIncrease pressureSupersonic fluid pumpsBlade accessoriesJet engineDesign methods

A supersonic aircraft engine axial fan that includes a rotating blade row having blades that receive a supersonic entry flow in the absolute frame and decelerate the flow to a lower supersonic or subsonic velocity exit flow while adding work to the flow to increase stagnation pressure. It is preferred that the lower velocity be subsonic. When the fan is combined with a suitably designed inlet, the propulsion system is compact and lighter in weight than conventional engines for supersonic aircraft.

Owner:MASSACHUSETTS INST OF TECH

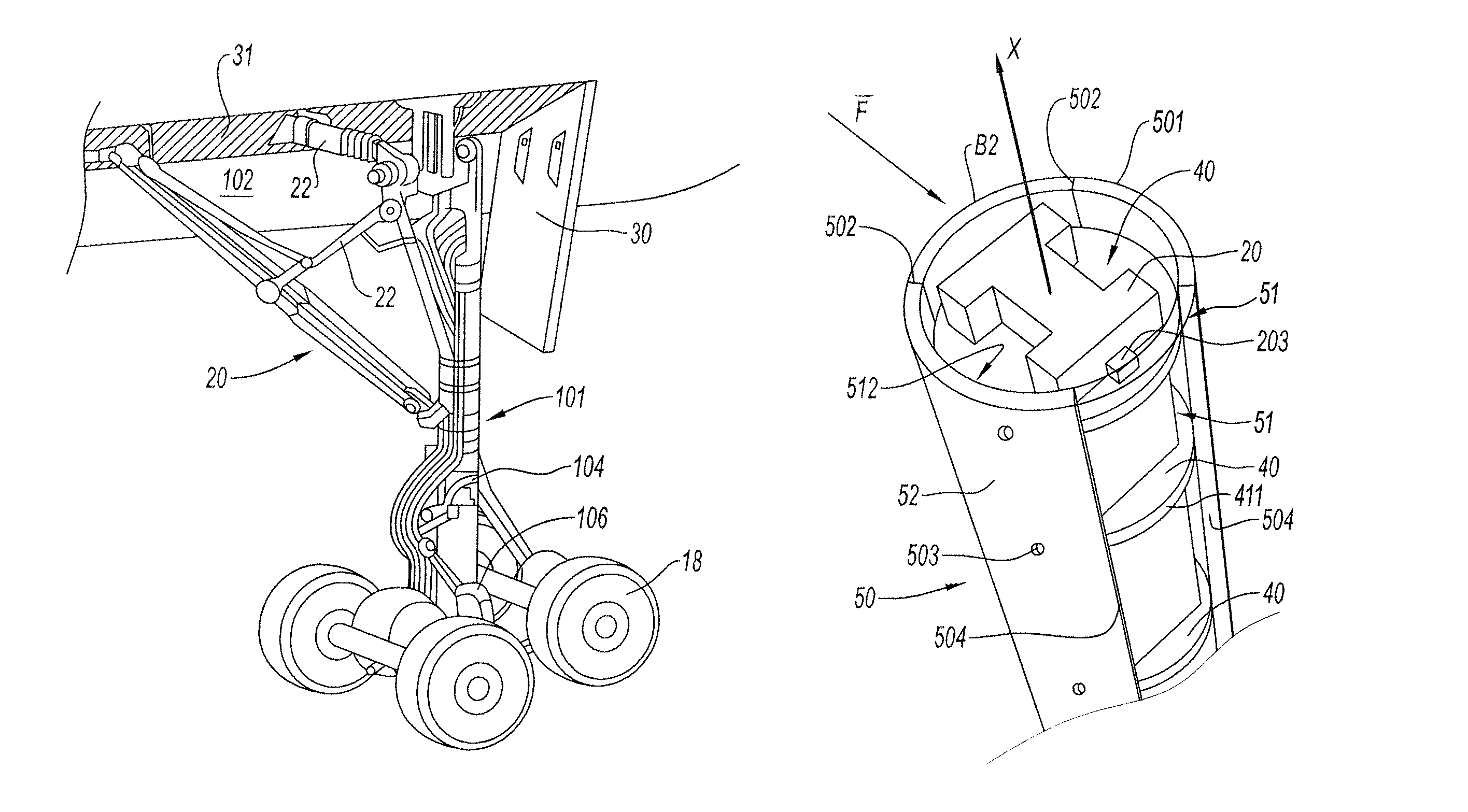

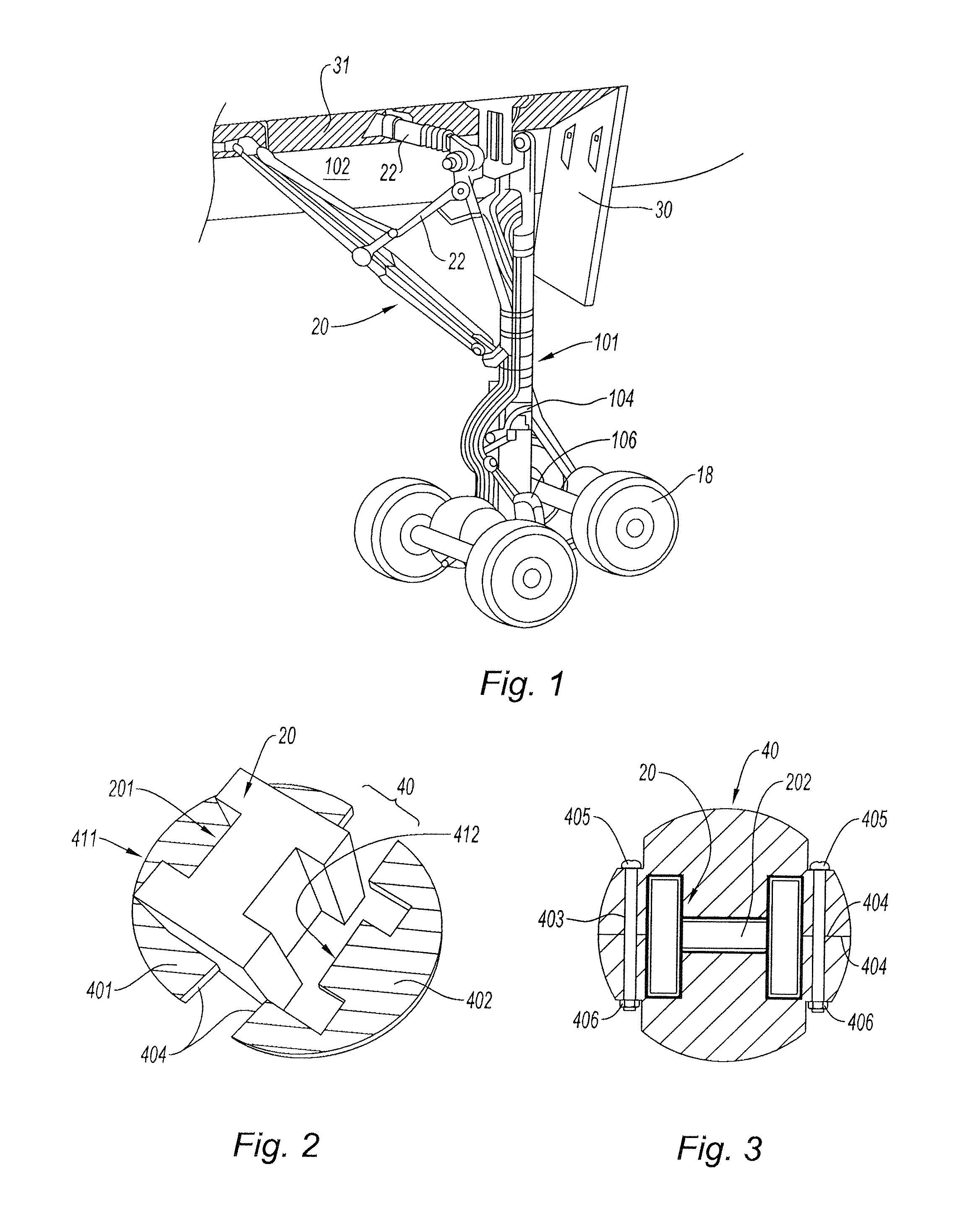

Aero-acoustic optimisation method for complex-section mechanical parts and corresponding mechanical part and landing gear

ActiveUS8668164B2Reduce drag and aerodynamic noiseGood thrustLayered productsExtrusion containersMechanical componentsEngineering

An apparatus and method are provided for reducing the drag caused by a complex-section part in an airflow, for example the landing gear of an aircraft, making it possible to optimize the lift / drag ratio and to reduce the aerodynamic noise by reducing the local noise source. To do so, the complex-section part is masked with a special casing. More specifically, the aero-acoustically optimized complex-section metal mechanical part is fitted with an aerodynamically shaped cover made of several longitudinal parts articulated with hinges to facilitate their installation. This cover is attached to at least two supports placed away from one another along the axis of the part, each support locally mating with the section of the part.

Owner:AIRBUS OPERATIONS (SAS)

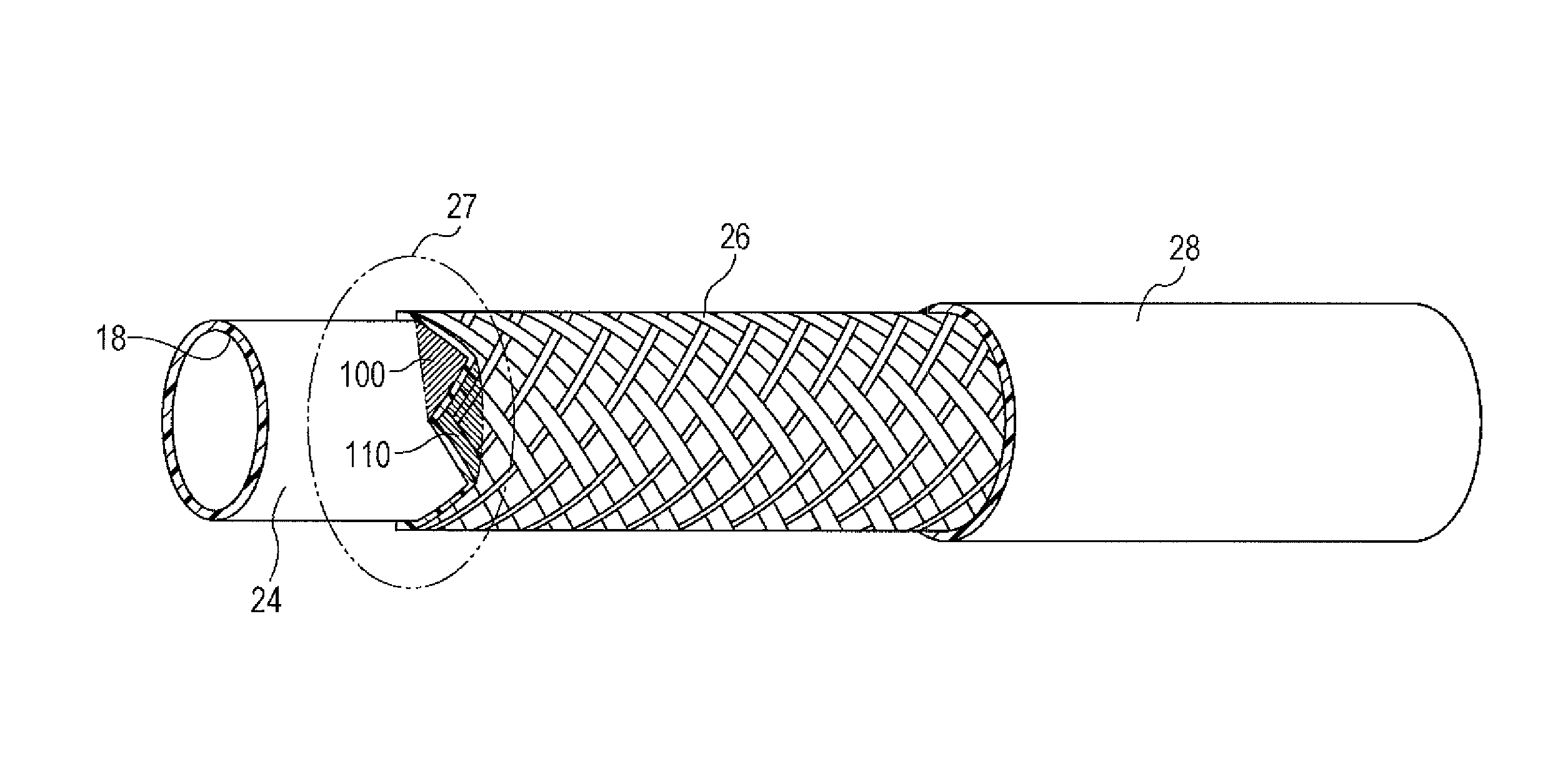

Catheter

A catheter includes an inner layer, a braid, an outer layer, and a distal tip. A recessed region having a first side and a second side is formed in a distal end portion of the braid, a length of the first side being longer than the sum of a wire width of a first wire and a distance between two adjacent first wires, a length of the second side being longer than the sum of a wire width of a second wire and a distance between two adjacent second wires. The distal tip is bonded to the inner layer in the recessed region. By providing the recessed region, the number of peaks formed in the distal end portion of the braid is made smaller than that in the existing case.

Owner:ASAHI INTECC CO LTD

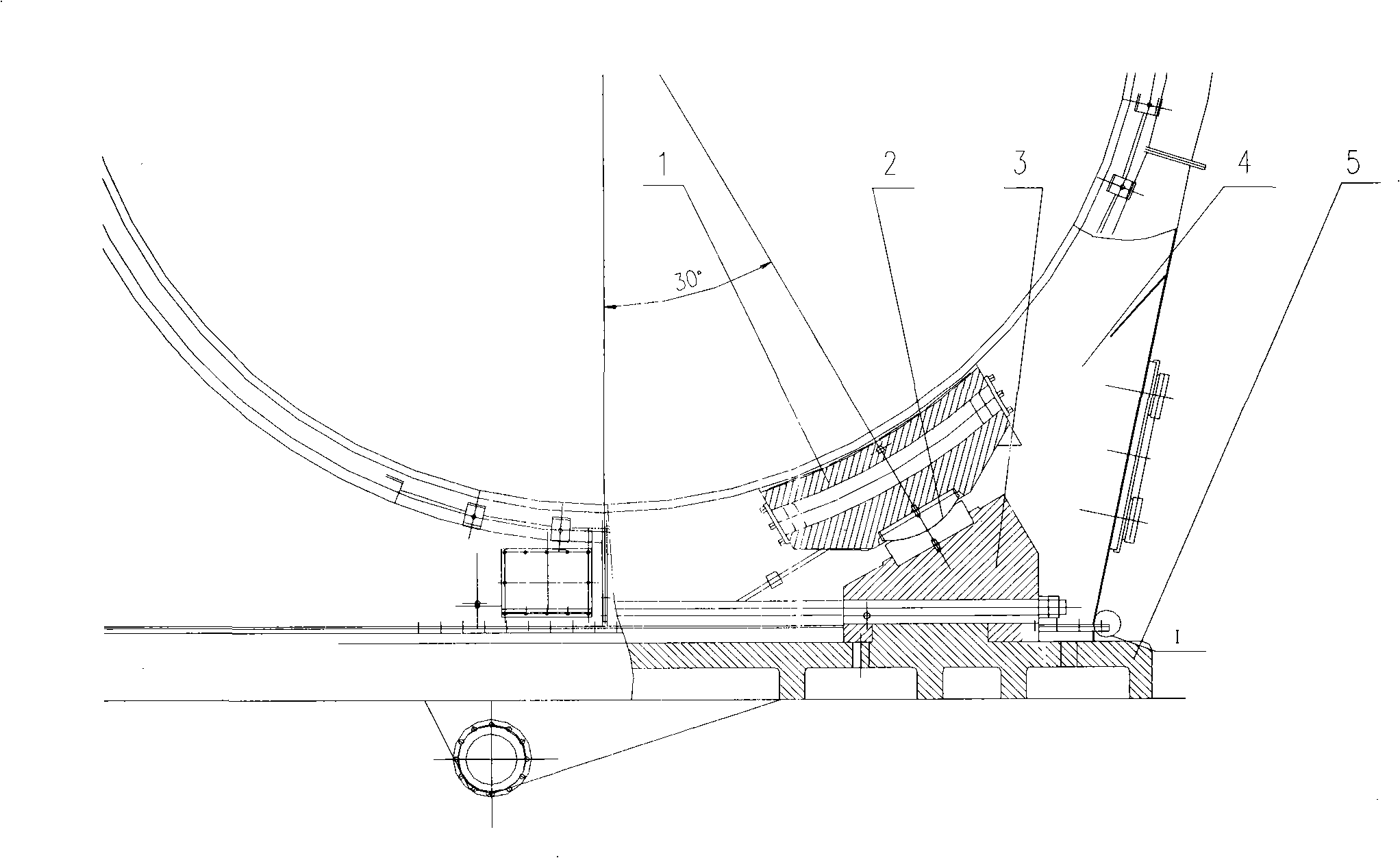

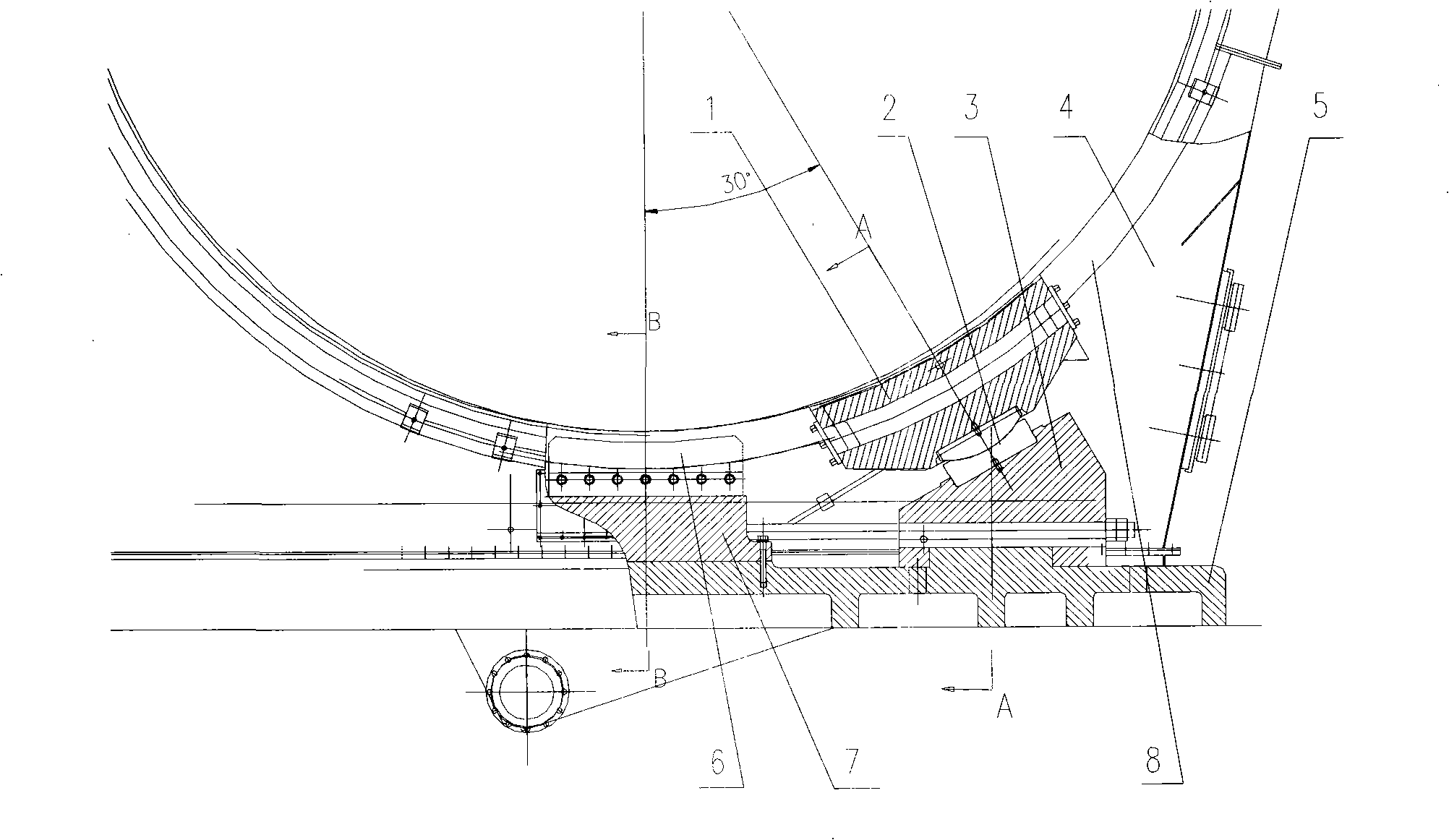

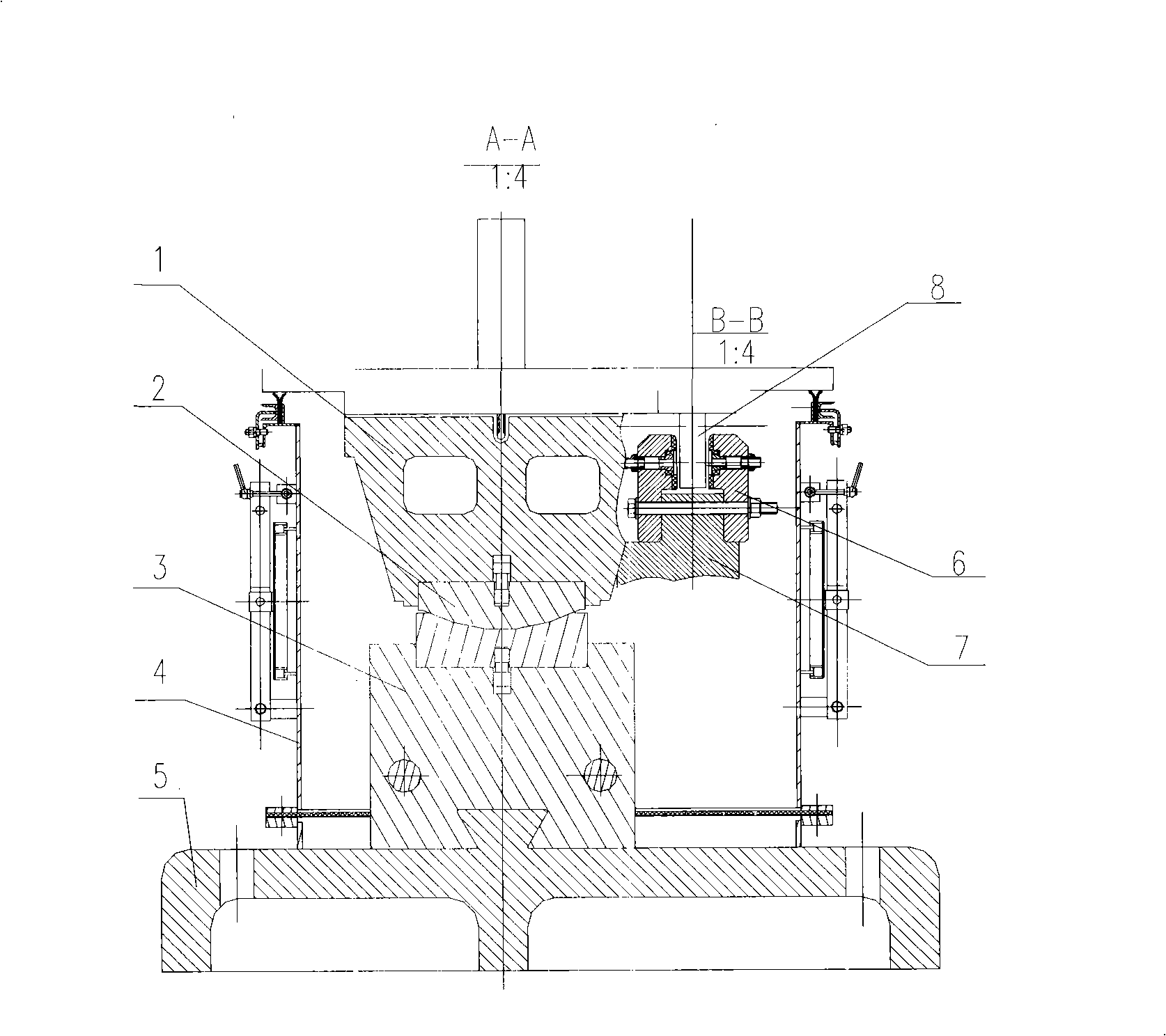

Design of pure static pressure sliding shoe structure for fixed end and free end in tube mill supporting device

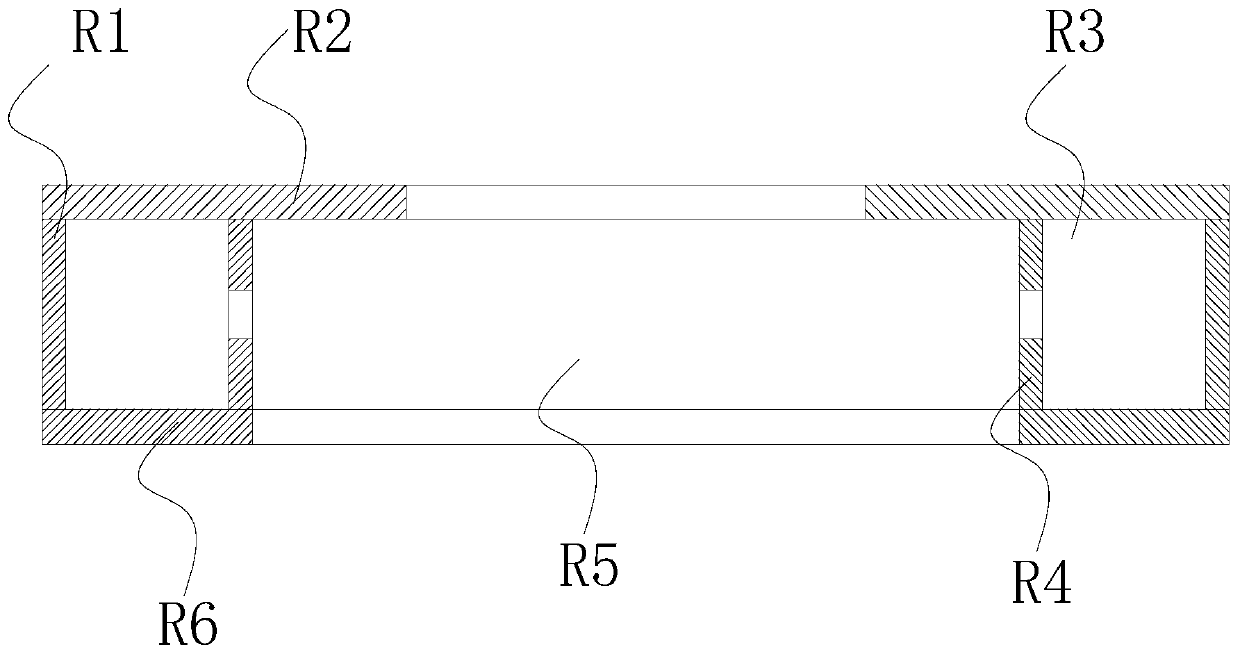

InactiveCN101323095AThe value range is sureGood thrustGrinding carriagesRevolution surface grinding machinesAxial thrustEngineering

The invention provides a design of a pure static pressure slide-shoe structure at a fixing end and a moving end of a supporting device of a tube mill. In the supporting device of the tube mill, the moving end, namely, a feeding end is designed to a radical pure static pressure slide-shoe structure which can move axially, the fixing end, namely, a discharging end is designed to a combined pure static pressure slide-shoe structure that can not only anti thrust axially but also can move radially, and in the combined pure static pressure slide-shoe structure, axial direction and radical direction are combined. In the design of the invention, the value range adopts optimized design, and is affirmed after being tested. The structure has the characteristics of good self-calibration property and strong on-load property. An axial thrust bearing at the fixing end has the advantages of simple structure, good anti-thrust property and long service life.

Owner:CITIC HEAVY INDUSTRIES CO LTD +1

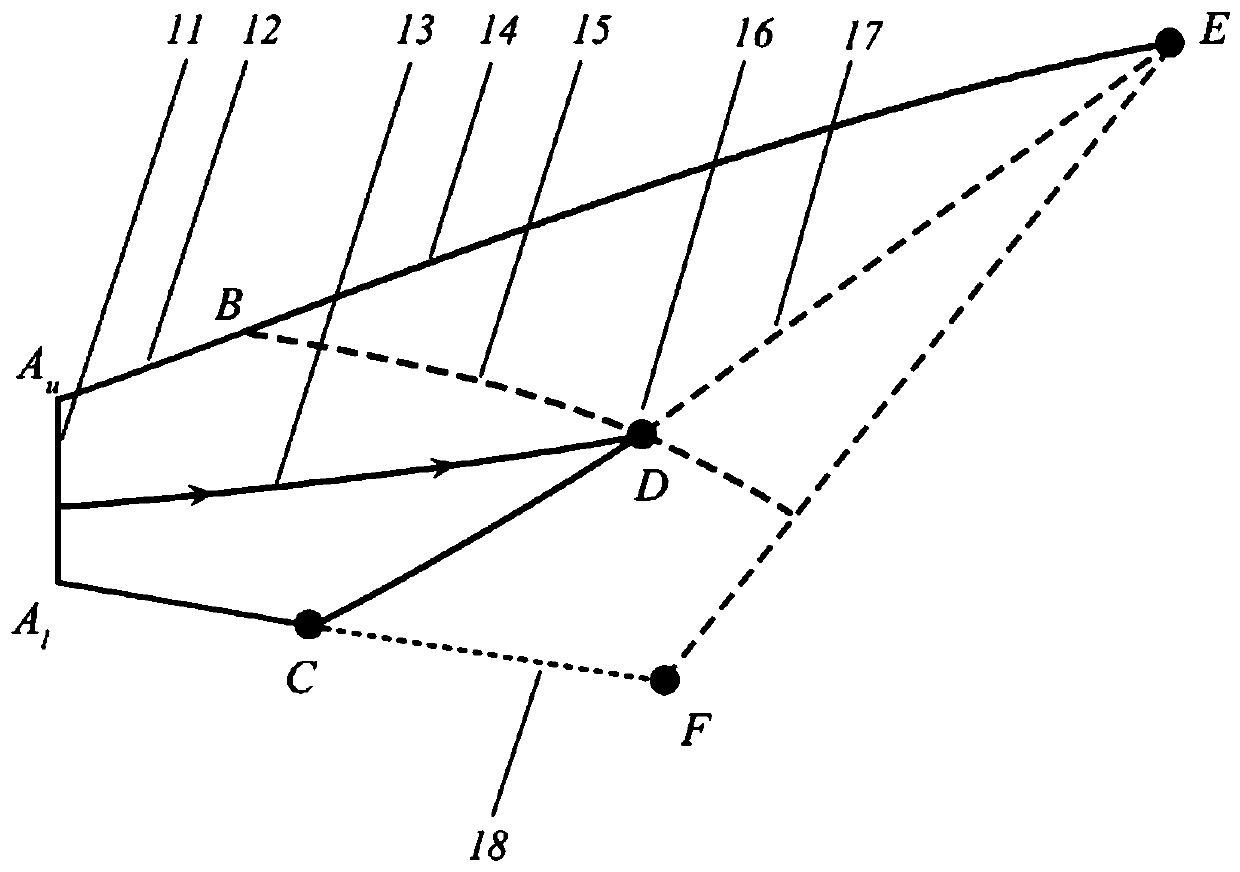

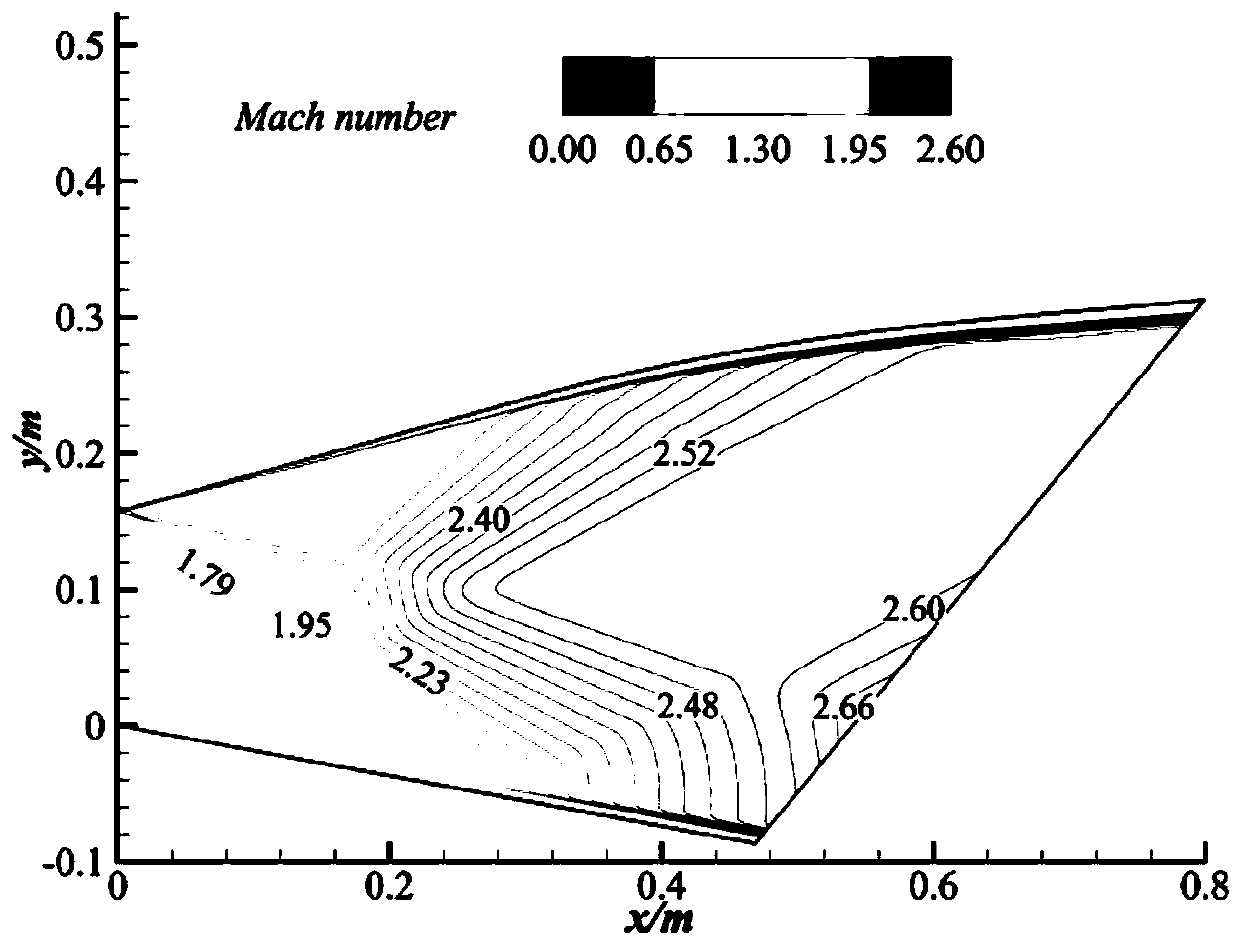

Supersonic thrust spray pipe reverse design method based on maximum thrust theory

InactiveCN110633522AImprove thrust performanceControl shapeSpecial data processing applicationsMethod of characteristicsEngineering

The invention discloses a supersonic thrust nozzle inverse design method based on a maximum thrust theory, which comprises the following steps of: presetting physical parameters of a core point, and further determining the physical parameters and a geometric position on a left-hand characteristic line passing through the core point; according to the nozzle inlet parameter distribution and the corepoint parameter, calculating by adopting a whirl characteristic line method and an iterative method to obtain an initial expansion section, and determining a nozzle inlet and expansion surface influence domain according to the inlet parameter and the initial expansion section; determining the last two characteristic lines emitted by the upper expansion surface and the lower expansion surface of the influence domain, and obtaining an intersection point which is a characteristic line intersection point; connecting the core point to the feature line intersection point; according to the law of conservation of flow, the inlet influence domain and the left-hand characteristic line passing through the core point, determining the upper wall surface profile of the thrust nozzle to be designed by adopting a spiral characteristic line method; and determining a lower wall surface profile to finish the design of the thrust nozzle. According to the invention, the performance is maximized under thecondition of meeting geometric and aerodynamic constraint conditions, and the fusion of the nozzle and the fuselage of the aircraft is better.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

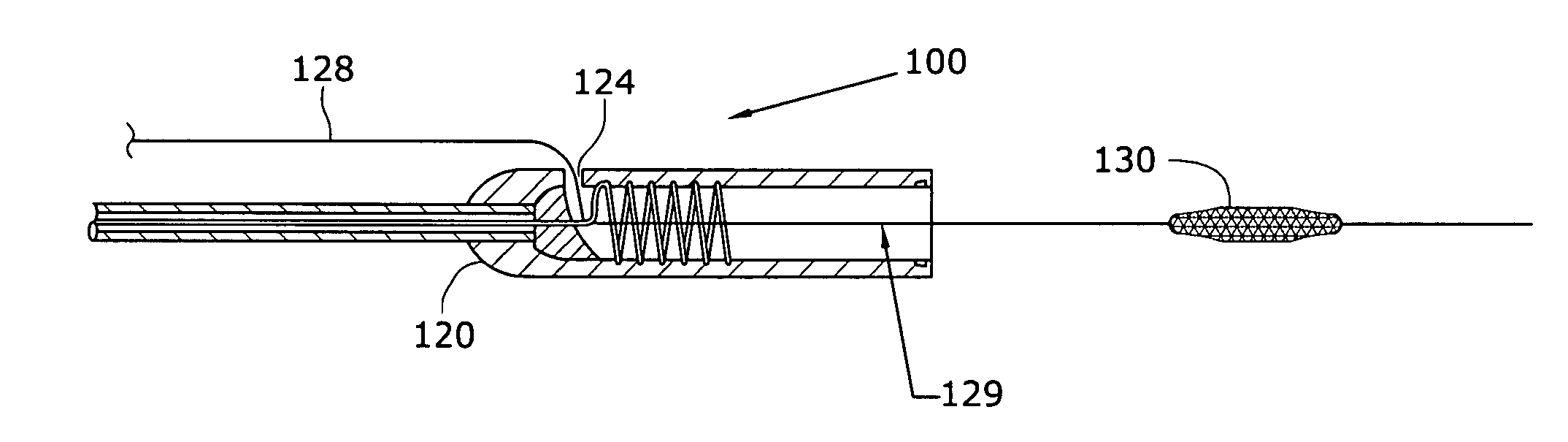

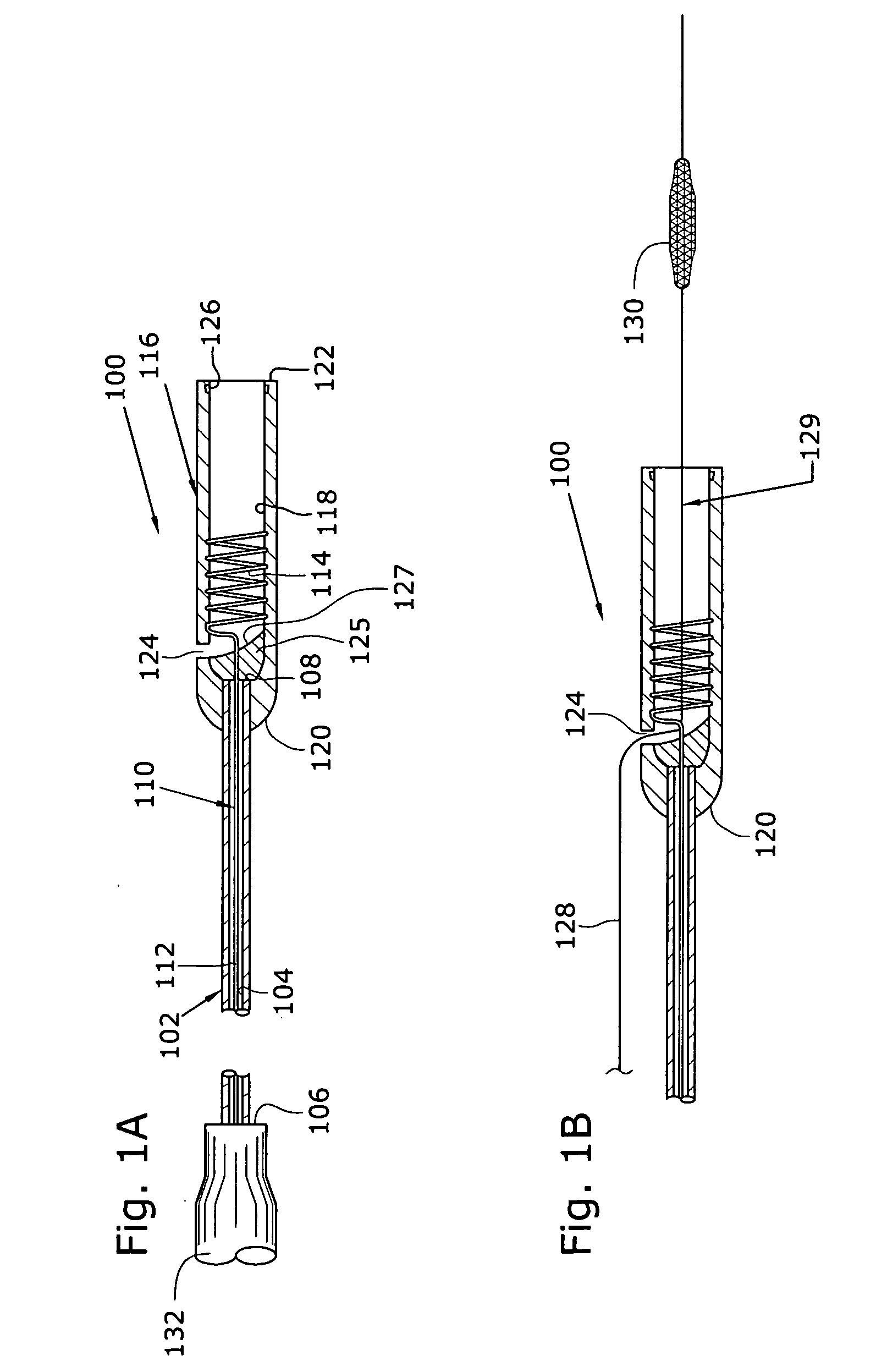

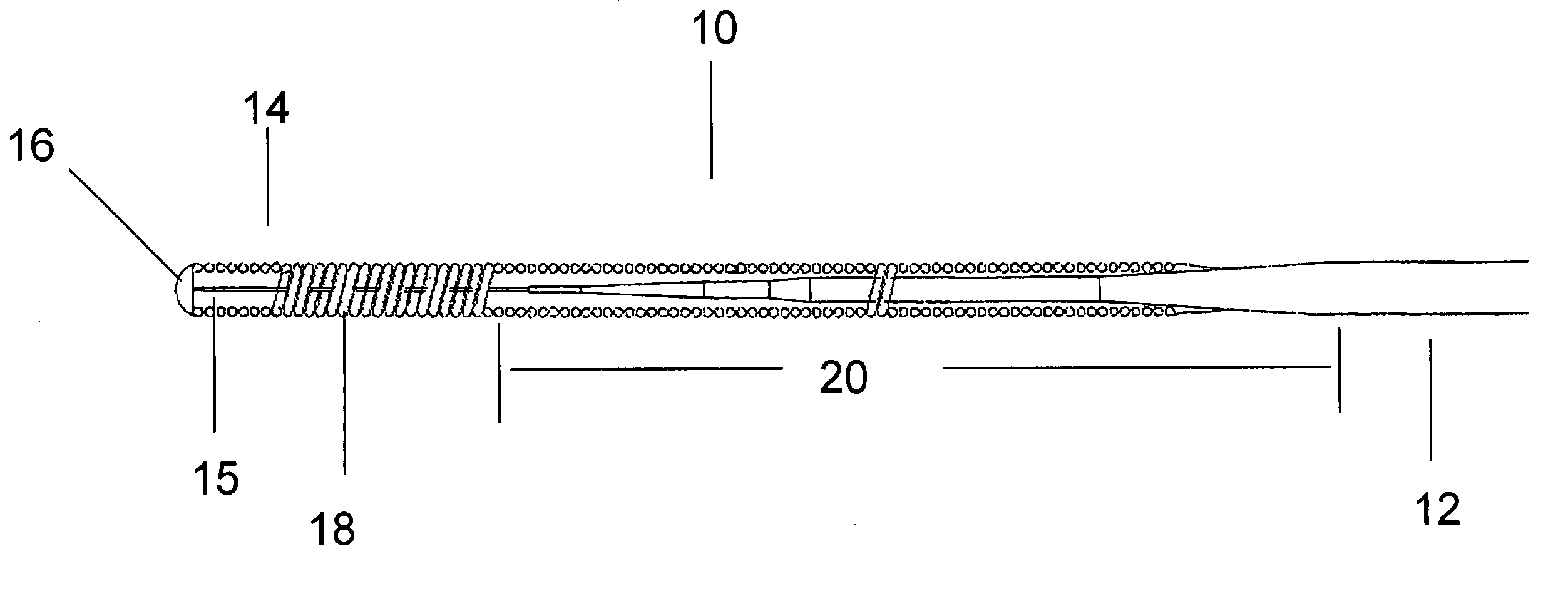

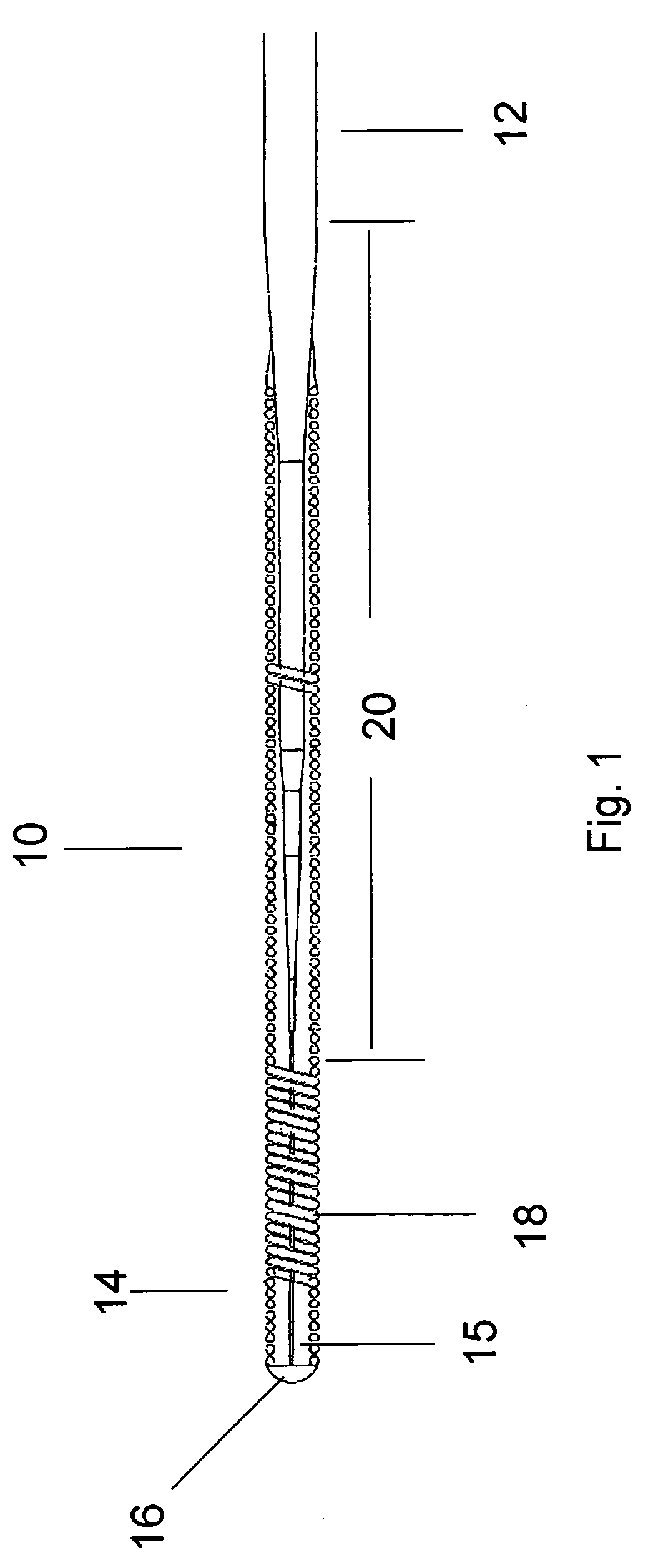

Single operator sheath catheter

A sheath catheter used to compress and / or retrieve a filter from a body lumen. The sheath catheter includes an elongate proximal shaft and a distal recovery sheath. The proximal shaft includes a central lumen that accommodates a shaft portion of a solid core wire to provide the catheter with better pushability. The solid core wire further includes a coiled portion that extends within the recovery sheath from a distal end of the proximal shaft. The coiled portion of the core wire provides a transition in flexibility from the stiffer proximal shaft to the more flexible recovery sheath. The recovery sheath further includes a sheath lumen that is sized to receive the filter therein.

Owner:MEDTRONIC VASCULAR INC

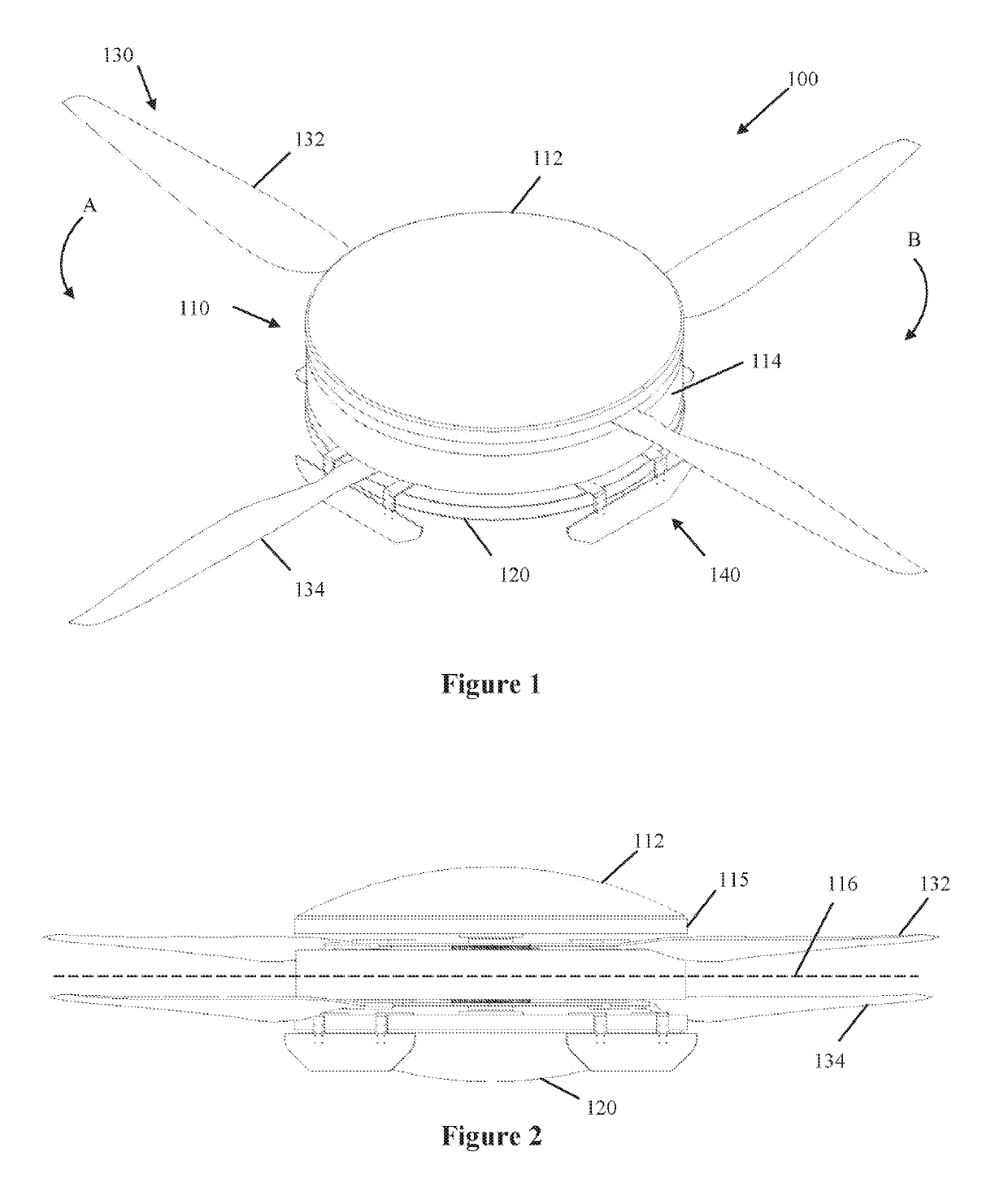

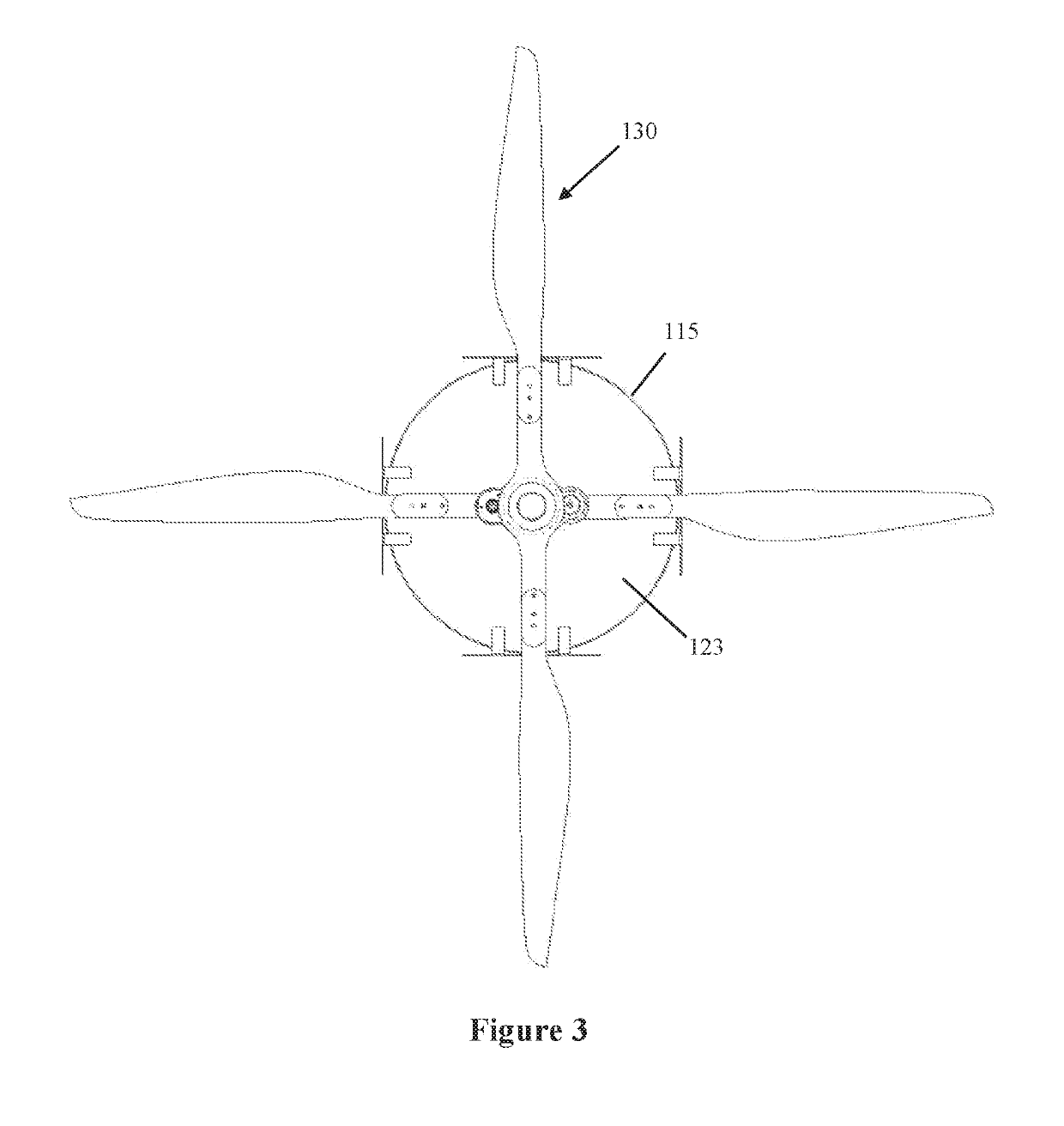

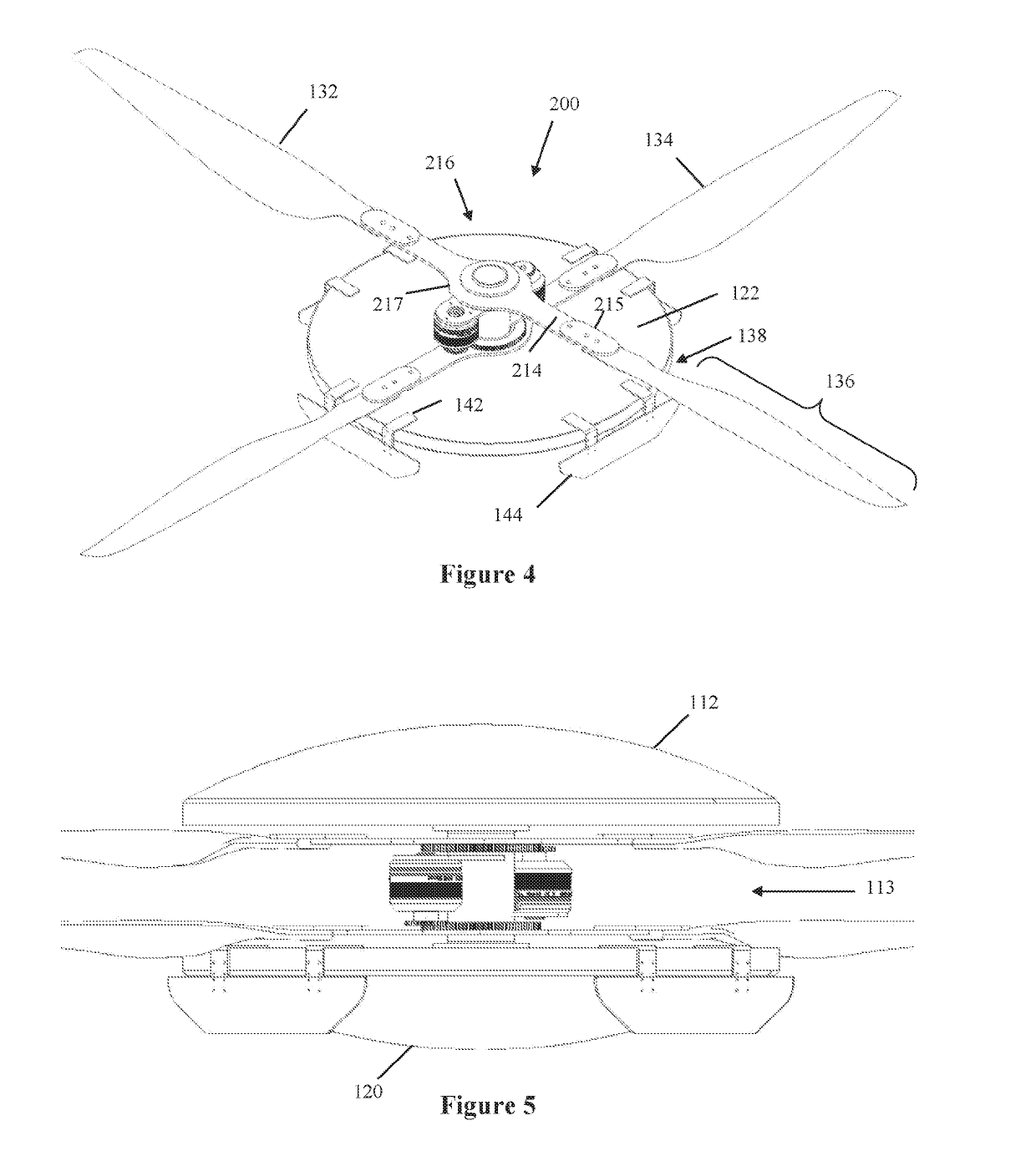

Manned and unmanned aircraft

ActiveUS20190193848A1Highly stable, maneuverable, and mechanically efficientEasy to liftUnmanned aerial vehiclesEnergy efficient board measuresJet aeroplaneCounter rotation

Owner:DRONEXUS AERO LLC

Titanium molybdenum alloy guidewire

InactiveUS20060089568A1High springbackHigh flexabilityGuide wiresDiagnostic recording/measuringNiti alloyTitanium

A guidewire for medical use such as in vascular and nonvascular systems. The guidewire made from a titanium molybdenum alloy wire with a composition of approximately 78% titanium 11.5% molybdenum 6% zinc and 4.5% tin by weight such that it is softer than stainless steel guidewires and stiffer than NiTi alloy guidewires. The distal end of the guidewire is of a smaller diameter and softer than the proximal end and fitted with a coil for springiness such that the distal end will bend when encountering curves in the body passageways. The distal tip may be heat treated for a gradient of softness with the distal tip being the softest. The distal end may also be tapered to provide an additional gradient of softness. A distal tip on the distal end of the guidewire protects the wall of the passageway from being punctured as the guidewire travels through the passageway. The resulting guidewire has properties between those of stainless steel guidewires and NiTi alloy guidewires for better torsion and stiffness characteristics.

Owner:MX MEDICAL +1

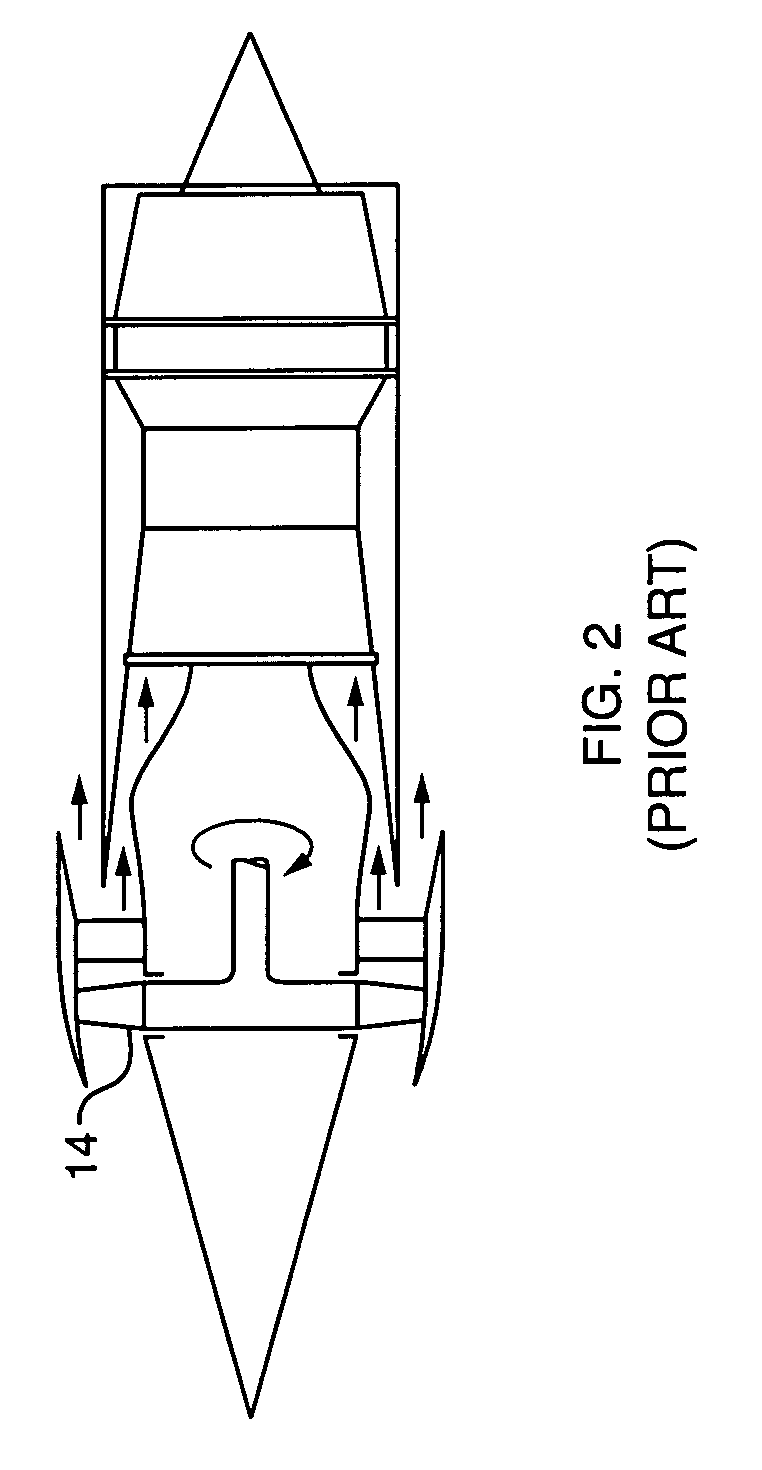

Pulse combustor performance improvement with airspeed

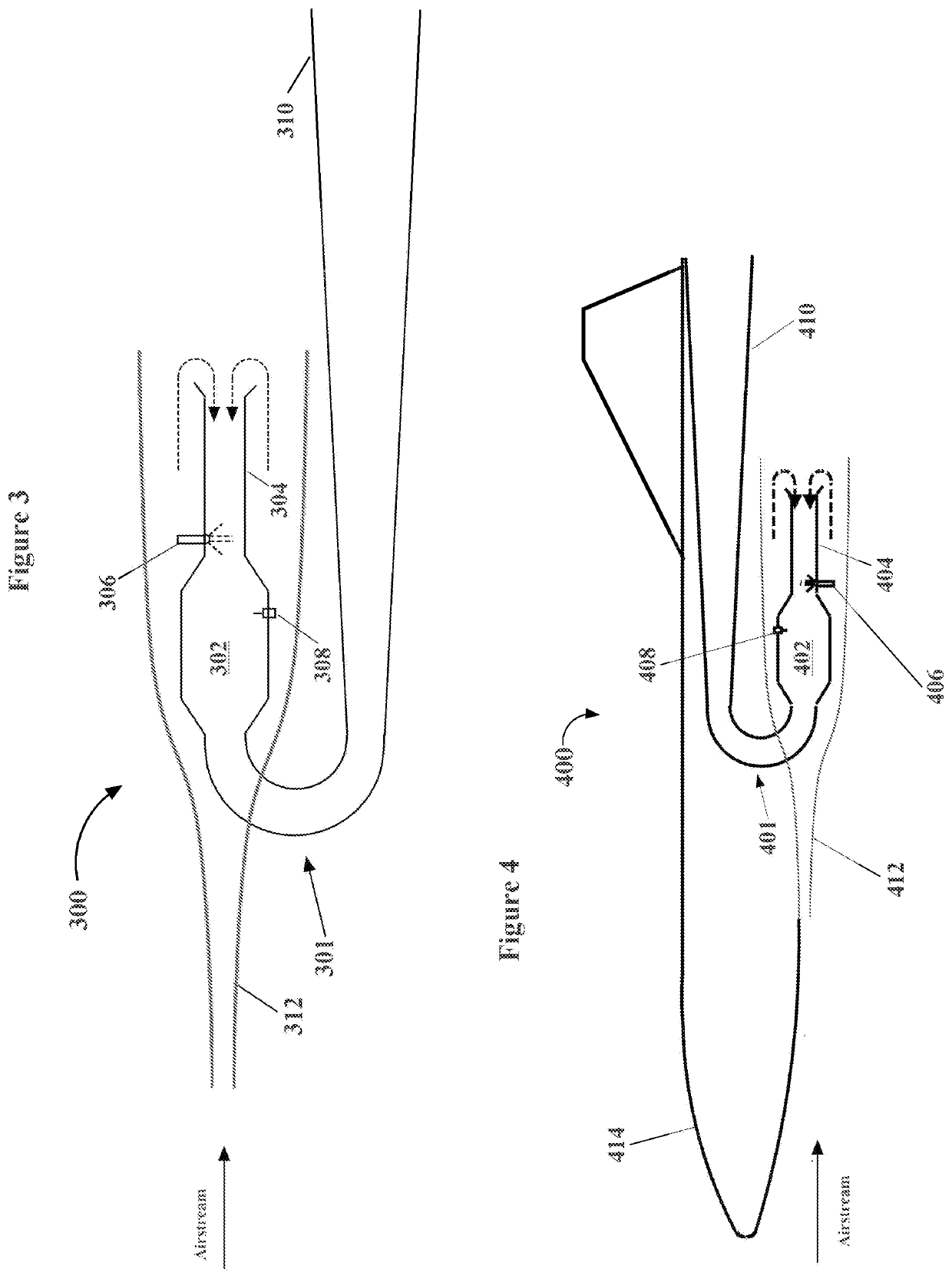

InactiveUS20200003158A1Easy to operateImprove powerPower plant cooling arrangmentsTurbine/propulsion fuel supply systemsJet engineAtmospheric air

A system and method is disclosed for improving the performance of pulsejet engines and of flight vehicles that incorporate pulsejet engines as a propulsion system. The system and method will decelerate the oncoming airstream to which a U-shaped pulsejet engine that is the propulsion system for a flight vehicle is exposed so that larger amounts of atmospheric air will be ingested into a rearward-facing inlet pipe for improved engine operation at low and high speeds / altitudes. The system and method provide for the recovery of the dynamic pressure of the incoming fresh airstream to raise the static pressure around the rearward facing inlet pipe to generate higher pressures and higher air density for improving the ingestion of air mass into the inlet pipe of the pulsejet engine thereby producing greater engine power and thrust.

Owner:NORTH AMERICAN WAVE ENGINE CORP

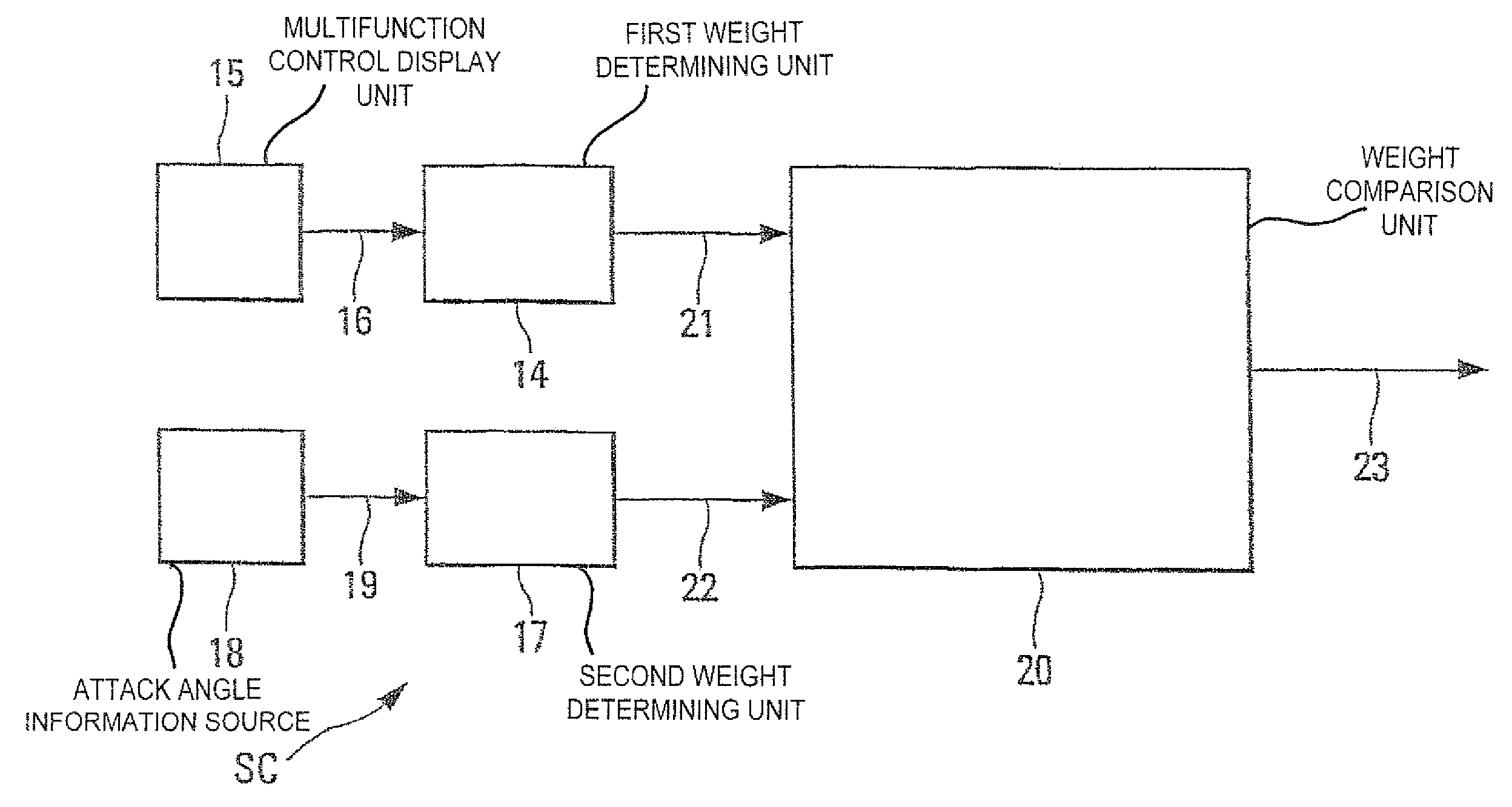

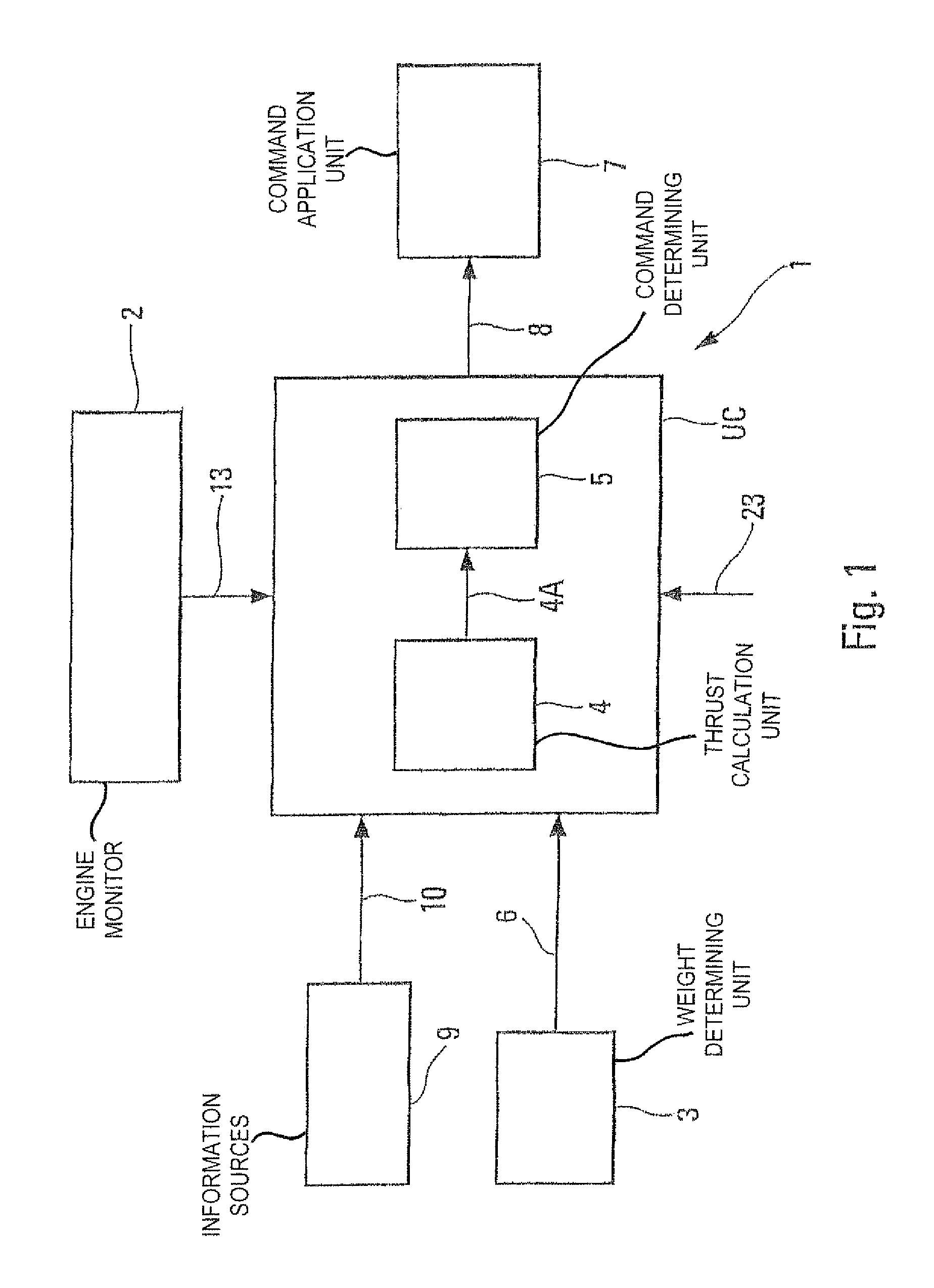

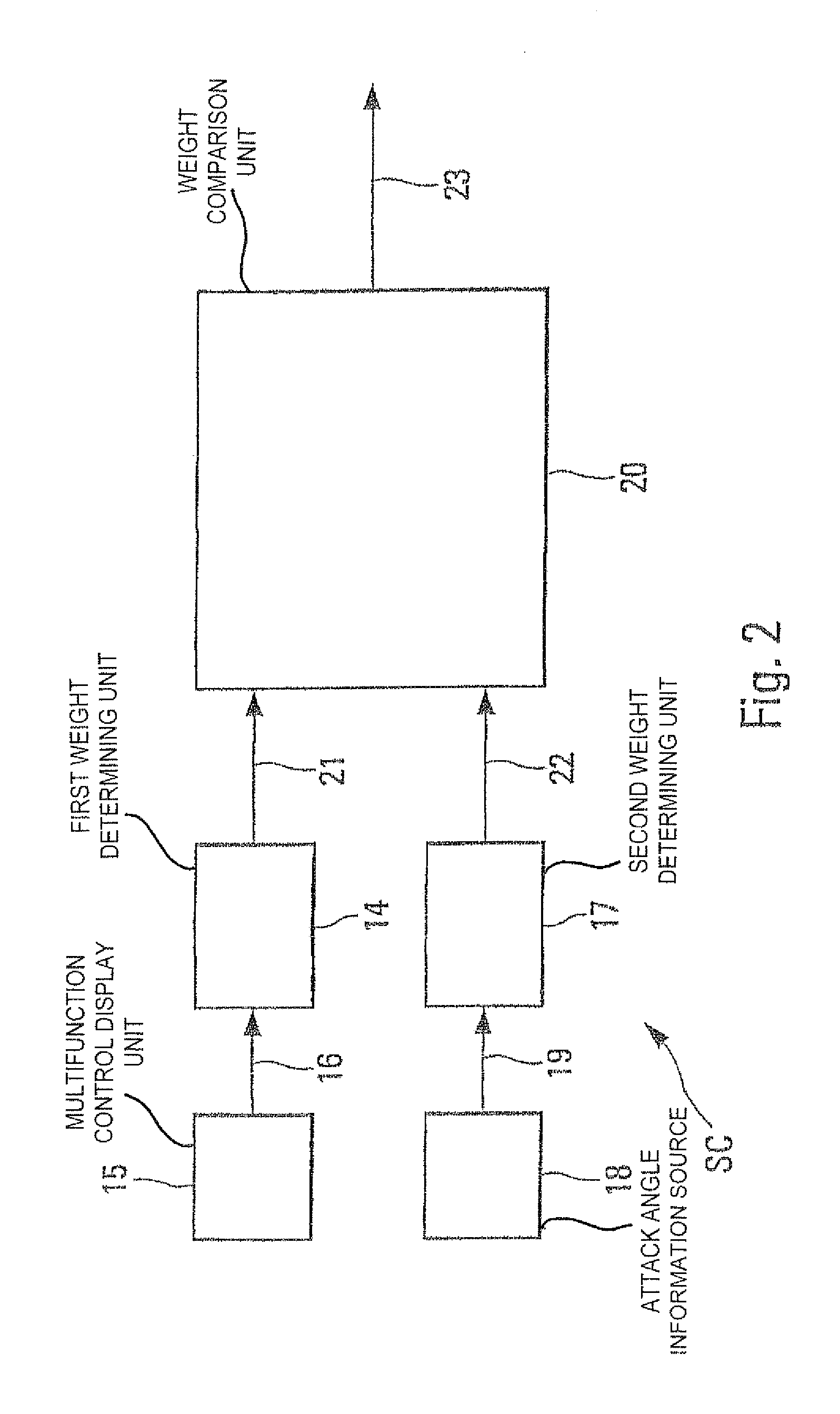

Method and device for controlling the thrust of a multi-engine aircraft

ActiveUS8359129B2Avoiding unusual flight attitudeReduce gradientAnalogue computers for vehiclesAnalogue computers for trafficAirplaneAerospace engineering

Owner:AIRBUS OPERATIONS (SAS)

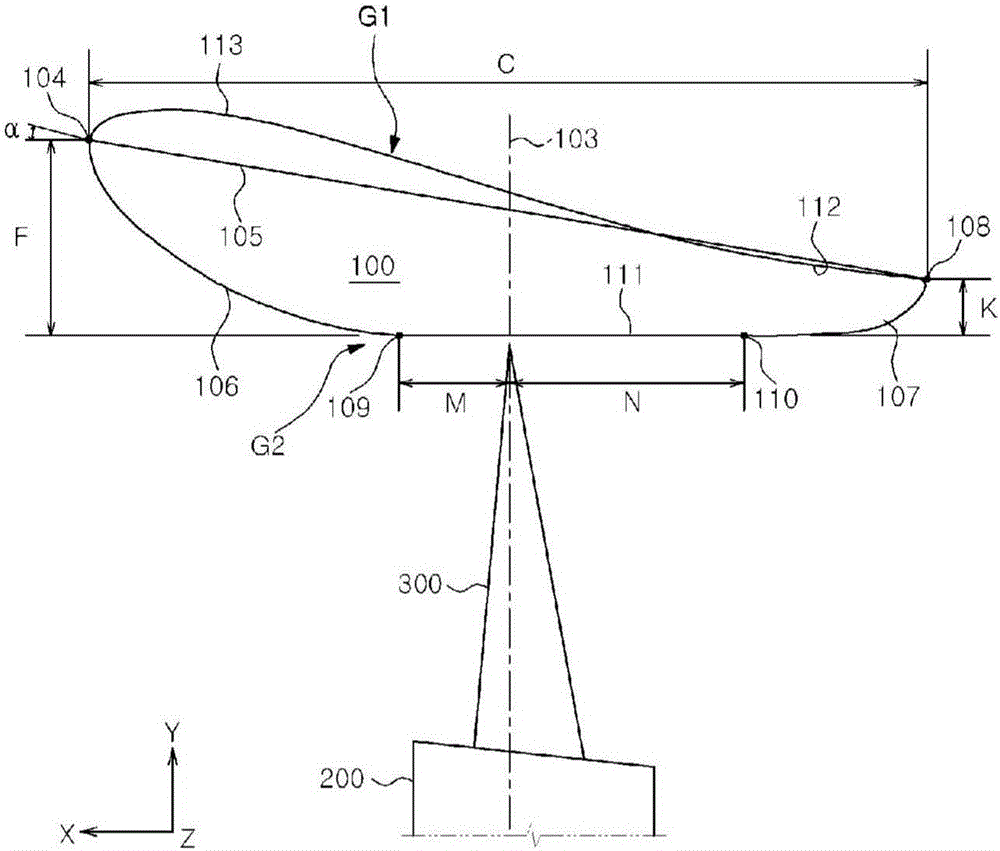

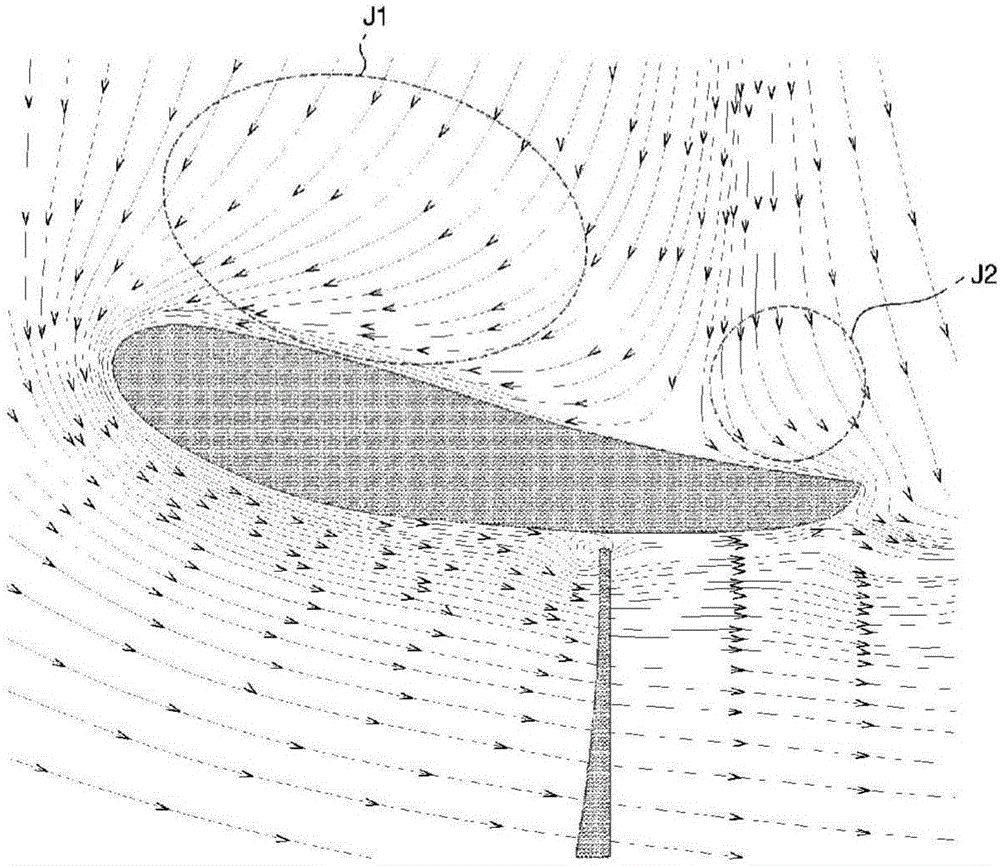

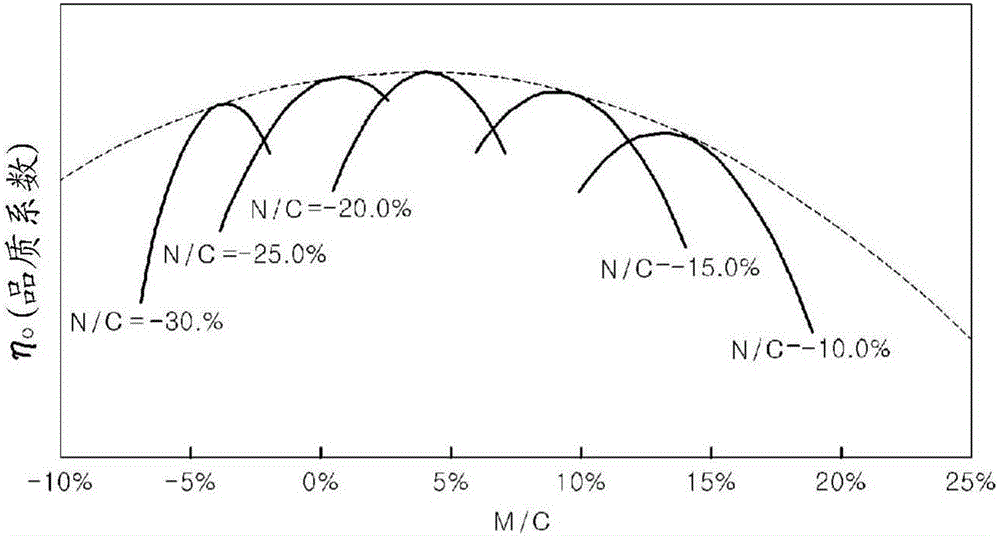

Propulsion device for ship

A propulsion device for a ship is introduced. The propulsion device for the ship comprises a duct having a nose corresponding to the front vertex of a hydrofoil cross-section and a tail corresponding to the rear vertex of the hydrofoil cross-section, wherein the shape of the duct cross-section comprises: an outer surface formed upward in a convex shape at the front end of the duct and formed downward in a concave shape at the rear end of the duct; an inner front part of the duct formed downward in a convex shape at the front end of the duct; an inner rear part of the duct formed downward in a convex shape at the rear end of the duct; and a parallel part for connecting the inner forward part and the inner backward part in parallel to each other.

Owner:SAMSUNG HEAVY IND CO LTD

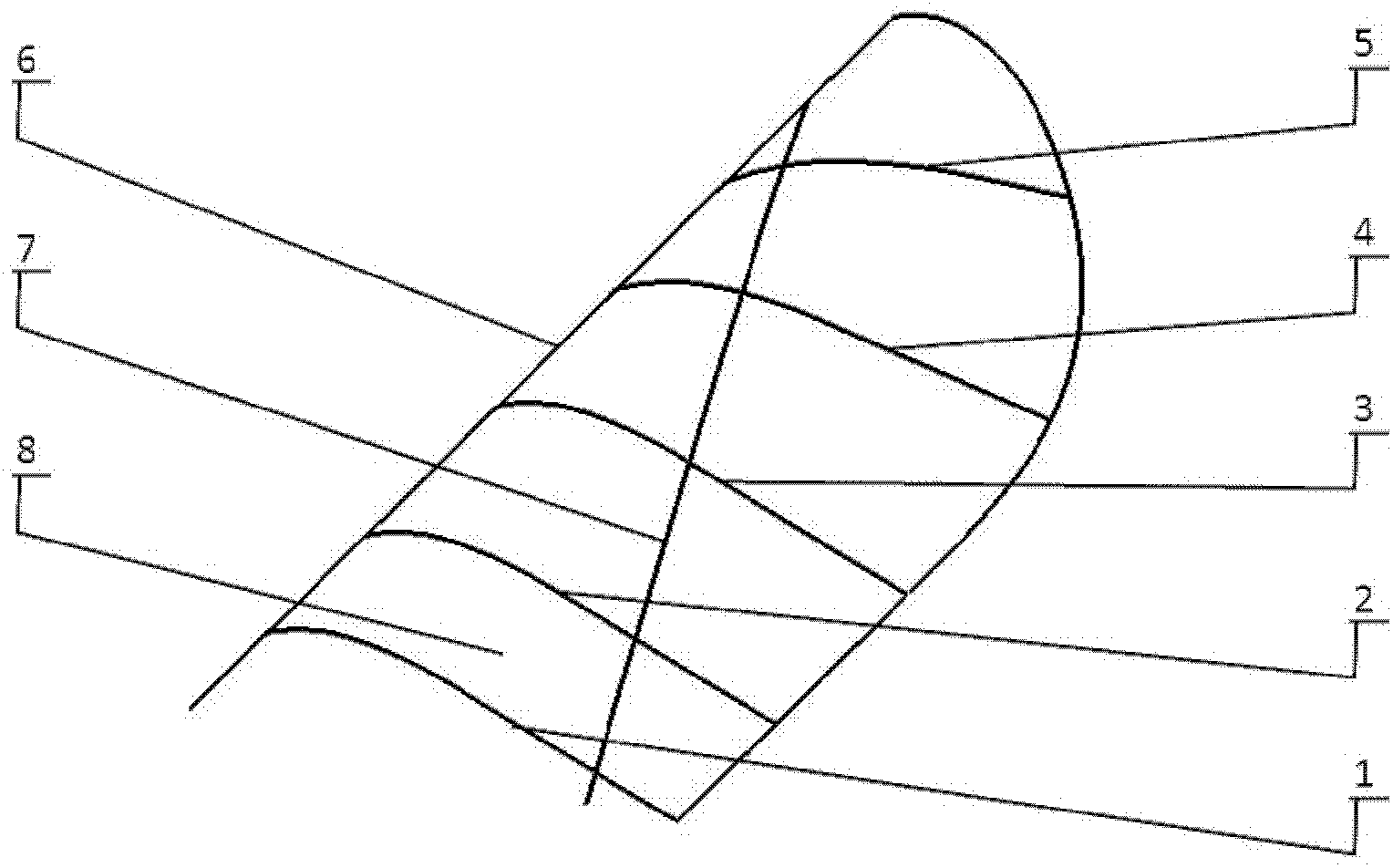

Wing of micro ornithopter

ActiveCN102501972AFlat stiffness distributionSmooth transition of stiffness distributionOrnithoptersAcute angleFront edge

The invention discloses a wing of a micro ornithopter. According to the present invention, a main beam is level and straight; the front edge points of five wing ribs are fixed on the main beam; the wing rib No.1, the wing rib No.2 and the wing rib No.3 are perpendicular to the main beam; the wing rib No.4 and the wing rib No.5 form acute angles with the tip part direction of the main beam; the chord lengths of the wing rib No.1, the wing rib No.2 and the wing rib No.3 are the same; the chord length of wing rib No.4 and the chord length of the wing rib No.5 are sequentially reduced, and are shorter than the chord length of the wing rib No.1; an assistant beam is an arc structure; the outer edge point of the assistant beam is fixed on the main beam between the end point of the tip part of the main beam and the rear edge point of the wing rib No.5, the root part of the assistant beam passes through the rear half part of the wing rib No.1, the assistant beam contacts the positions corresponding to the five wing ribs and is fixed with the positions corresponding to the five wing ribs; the main beam, the assistant beam and the wing ribs form a wing structure frame, and a skin is adhered above the frame to form a complete wing. With the present invention, the stiffness distribution of the whole wing flatly transits, the structure continuity is good, the good force loading property is provided, the structure is simple, and the wing of the present invention is convenient to manufacture.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Portable glass tank capping machine

ActiveCN111285307AFast and secure insertionShrinking is good forThreadless stopper insertionClosure stoppersHydraulic cylinderMechanical engineering

The invention discloses a portable glass tank capping machine. The structure of the portable glass tank capping machine comprises a wooden plug clamping and shrinking device, a hydraulic cylinder, ananti-skid handle, a supporting barrel, an inner connecting rod, an outer connecting rod and a glass tank clamping device, the outer top center of the supporting barrel is perpendicularly connected tothe anti-skid handle, the inner bottom of the supporting barrel is perpendicularly connected with the hydraulic cylinder, and the hydraulic cylinder is located over the wooden plug clamping and shrinking device. Compared with prior art, the portable glass tank capping machine has the beneficial effects that the novel portable glass tank capping machine is formed by combining the wooden plug clamping and shrinking device, the hydraulic cylinder, the anti-skid handle, the supporting barrel, the inner connecting rod, the outer connecting rod and the glass tank clamping device, the size is small,carrying is convenient, a glass tank is fixed through the suction cups, the wooden plug is clamped and shrunk in the mode that the wooden plug is clamped and shrunk, so that the diameter of the woodenplug is reduced, the wooden plug is pushed downwards through the hydraulic cylinder, the wooden plug can be conveniently, rapidly and stably plugged into a glass tank opening, the capping and plugging efficiency is greatly improved, capping and plugging are stable, and damage to the glass tank capping and plugging is effectively avoided.

Owner:平邑经济开发区投资发展有限公司

Thermal conductive adhesive spreading device for CPU hardware

PendingCN108580196AUniform thicknessReasonable thicknessLiquid surface applicatorsCoatingsThermal adhesiveEngineering

The invention discloses a thermal conductive adhesive spreading device for CPU hardware. The thermal conductive adhesive spreading device comprises a holding tank of which one end is connected to an extrusion mechanism, and the extrusion mechanism comprises an extrusion piston, a mounting barrel, a fixing plate and a driving device; the outer side of the extrusion piston is in sliding fit to the inner wall of the holding tank, and one side of the extrusion piston is fixed to the output end of the driving device fixed to the fixing plate; the fixing plate is fixed to the inner wall of the mounting barrel, and the outer side of one end of the mounting barrel is provided with external threads; and the end, close to the mounting barrel, of the holding tank is provided with internal threads, and the holding tank is movably connected to the mounting barrel through threads. According to the thermal conductive adhesive spreading device for the CPU hardware, thermal conductive adhesive can be spread on the surface of a CPU heat generation end, and the thickness of the thermal conductive adhesive is rational; the thicknesses of different areas are uniform, and hand fatigue caused by manual spreading by workers is avoided; and the thermal conductivity of the thermal conductive adhesive for a CPU is improved.

Owner:苏州柯谱瑞欣通信科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com