Supersonic thrust spray pipe reverse design method based on maximum thrust theory

A technology of maximum thrust and design method, applied in computing, electrical digital data processing, special data processing applications, etc., can solve the problems of increasing design complexity, unable to optimize nozzle performance, etc. The effect of enhancing overall stability, excellent aerodynamic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

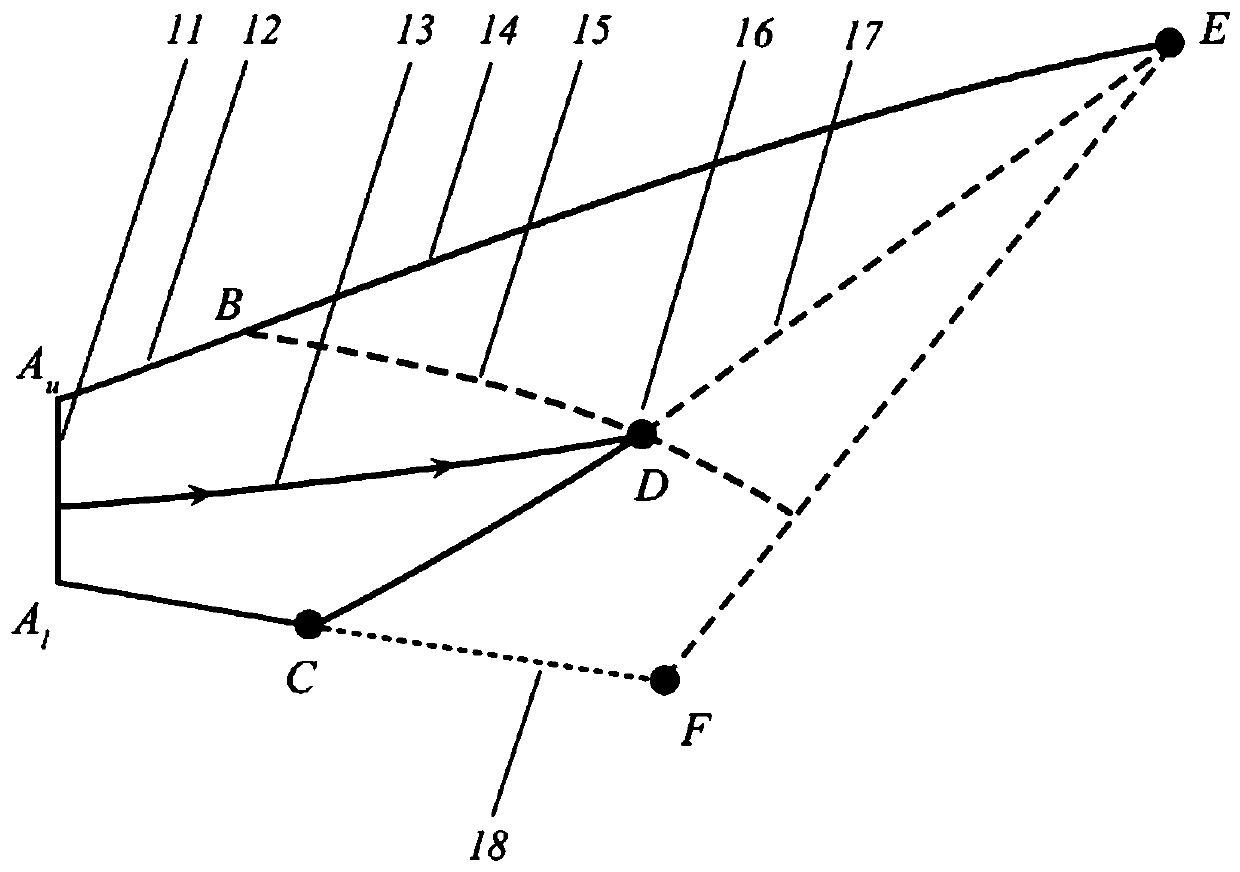

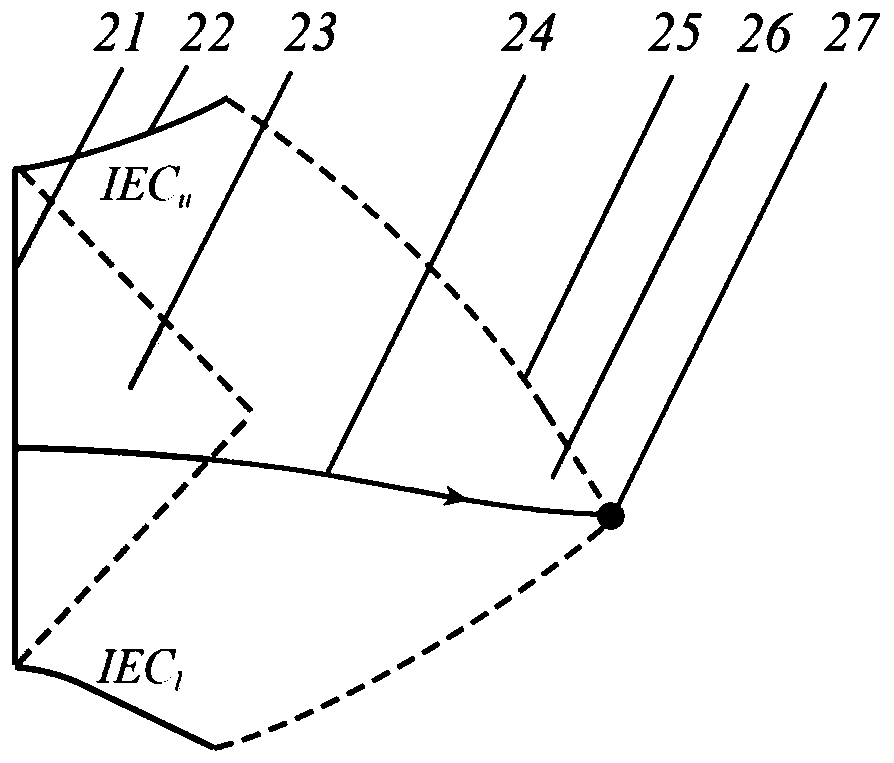

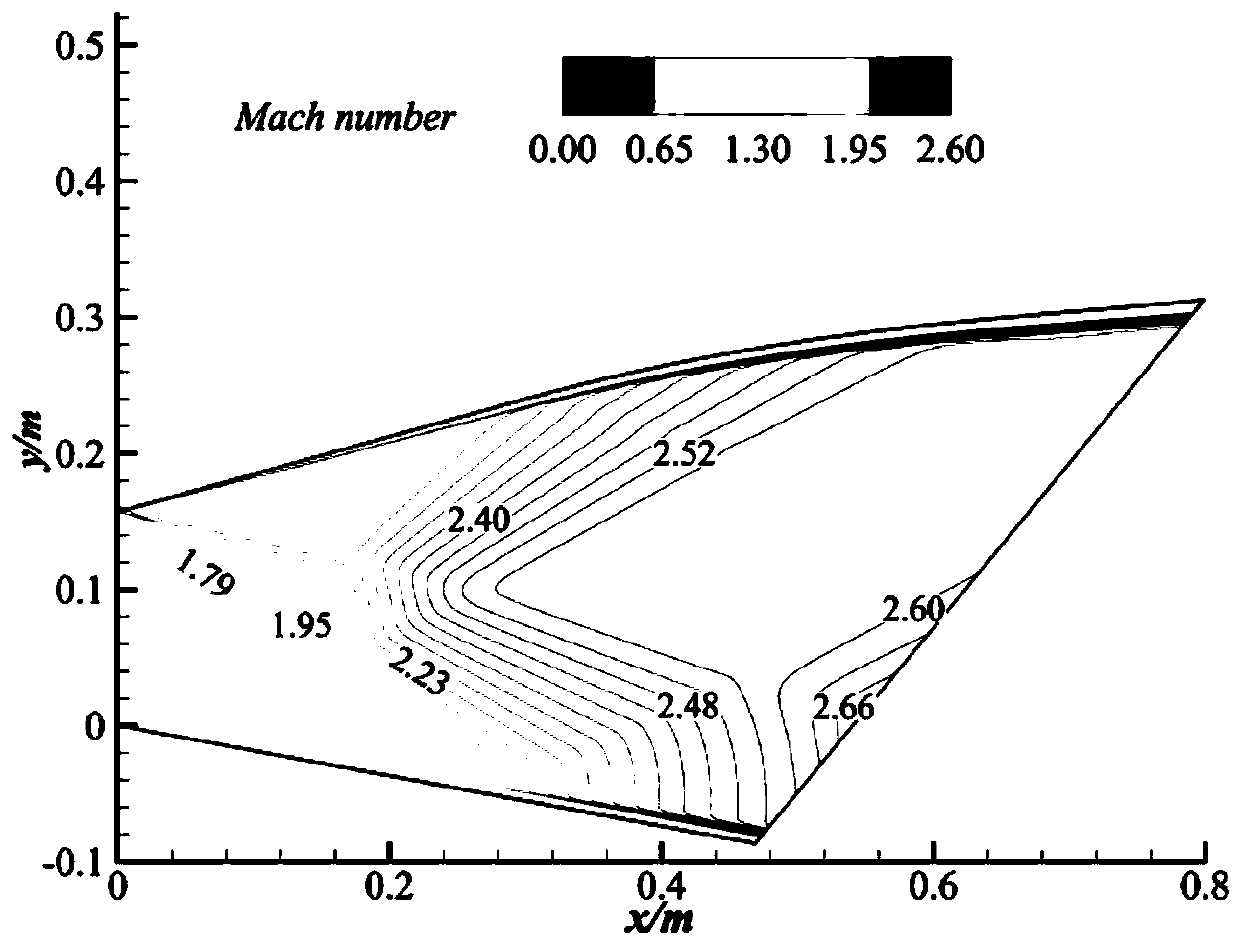

[0045] combine figure 1 As shown, the present invention discloses a supersonic thrust nozzle reverse design method based on the maximum thrust theory, comprising the following steps:

[0046] Step 1, preset the physical parameters of the core point required in the maximum thrust nozzle design method, and determine the physical parameters and geometric positions on the left characteristic line passing through the core point in combination with the preset flow ratio;

[0047] Step 2: According to the nozzle inlet parameter distribution and the core point parameters, the initial expansion section is calculated by the swirl characteristic line method and the iterative method, and the influence domain of the inlet and the expansion surface is determined according to the inlet parameters and the initial expansion section;

[0048] Step 3: Determine the last two characterist...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com