Electrode structure and electrode fixing structure for plasma thruster

A plasma and electrode structure technology, applied in the field of electric propulsion, can solve the problems of reducing the discharge current, increasing the resistance of the main discharge circuit, affecting the electromagnetic acceleration effect and thrust effect of the pulse plasma thruster, so as to reduce local loss and improve thrust effect, the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

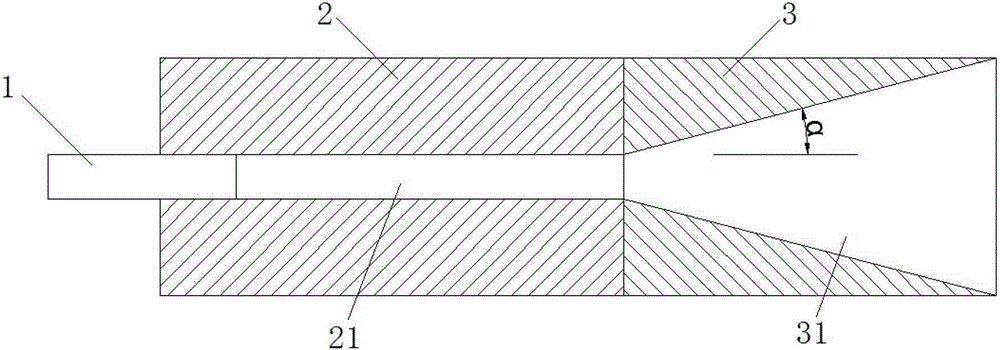

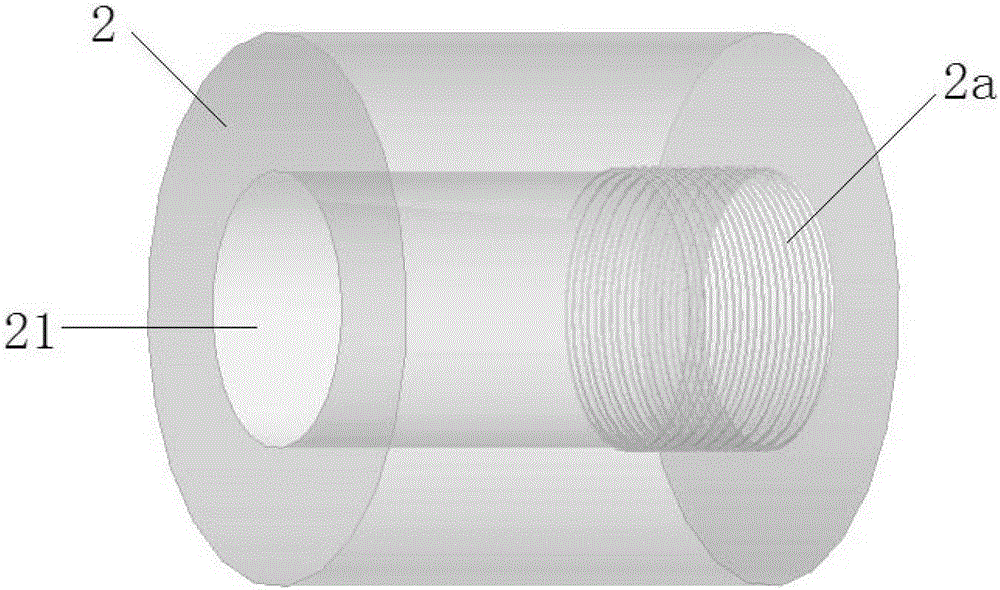

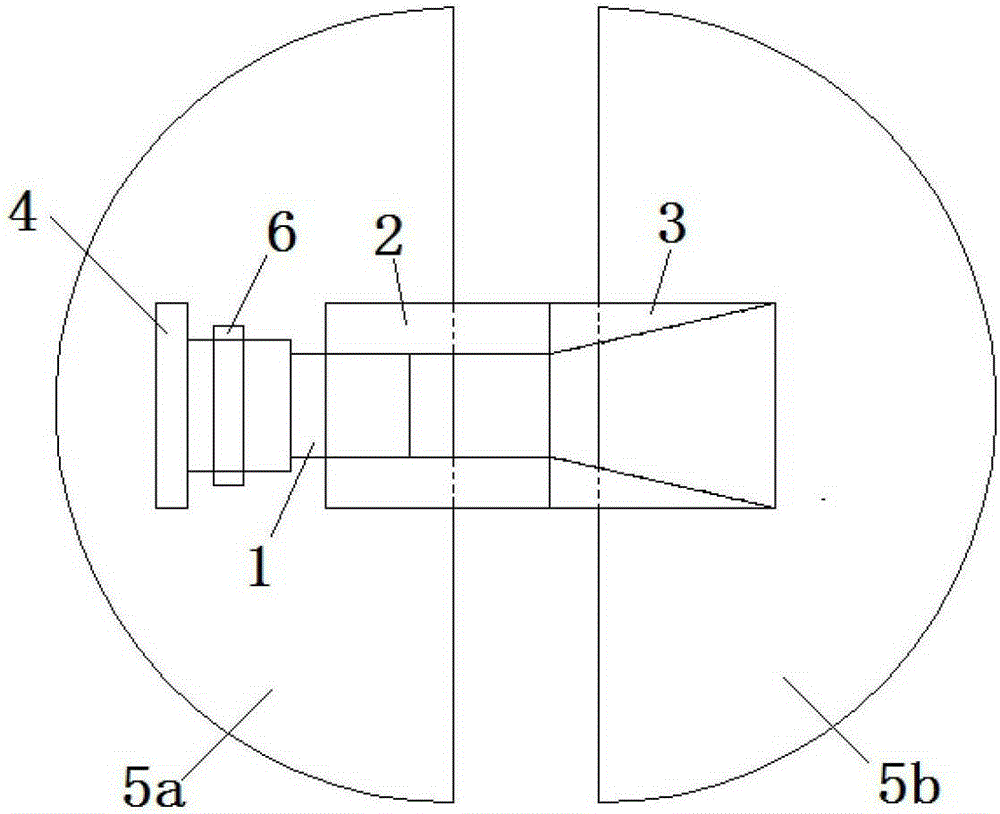

[0028] figure 1 It is a schematic diagram of the electrode structure of the present invention. In this embodiment, it includes: a cylindrical cathode 1, a cylindrical insulator 2, and an anode 3, wherein the cylindrical cathode 1 has a diameter of 5 mm and a length of 10 mm. The material of the cathode can be lead or Aluminum and other metals. One end of the cylindrical cathode 1 is inserted into the interior of the cylindrical insulator 2 with a through hole 21 and is in close contact with it, and the distance from the cylindrical cathode 1 into the interior of the cylindrical insulator 2 is adjustable, but the cylindrical cathode 1 should be ensured The contact position between the front end surface and the inner through hole 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com