Portable glass tank capping machine

A glass jar and capping machine technology, applied in the directions of bottle/container cap, bottle filling, screwless stopper, etc. Tightness, easy fixation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

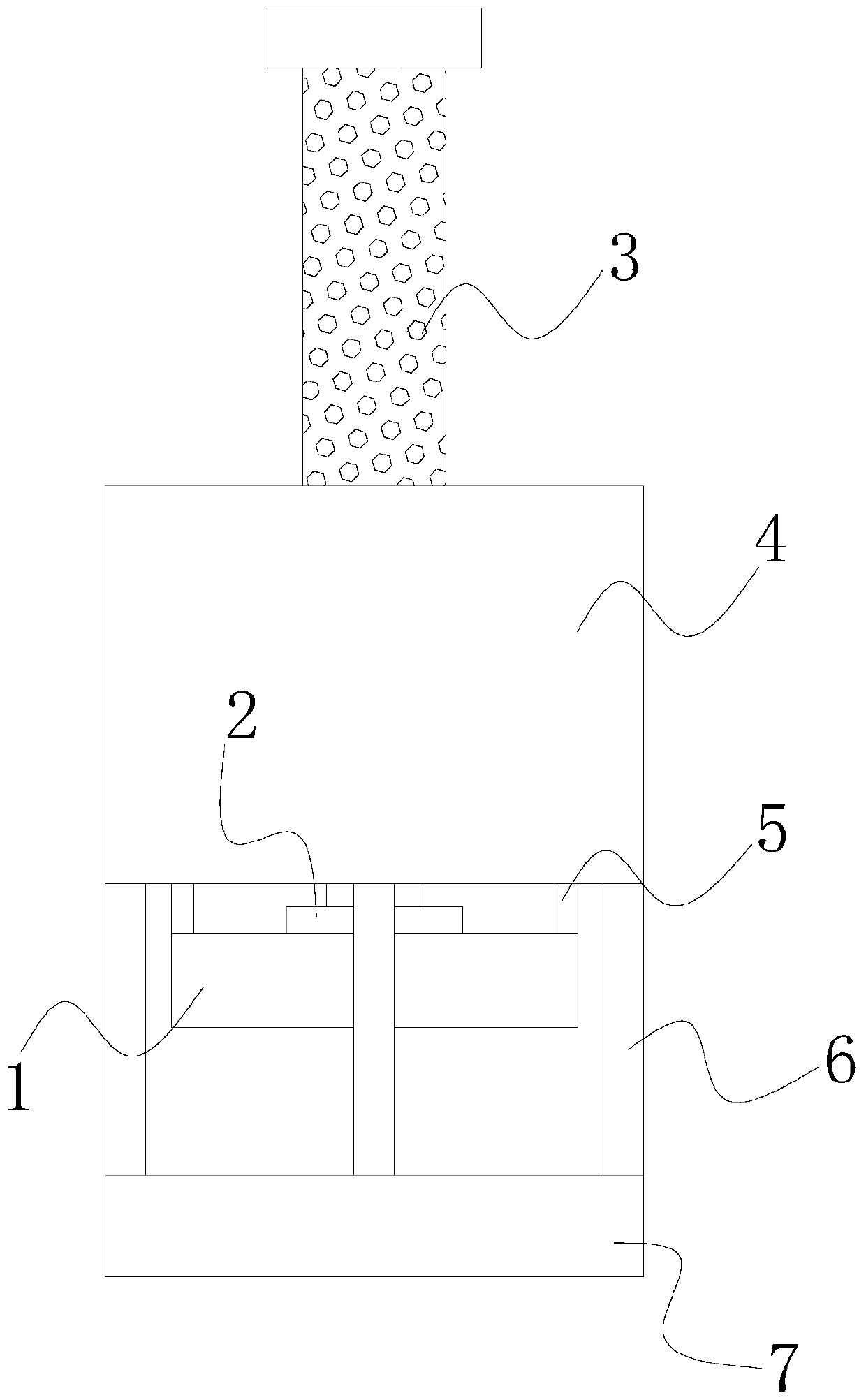

[0038] see figure 1 , the present invention provides a technical solution for a portable glass jar capping machine: its structure includes a cork clamping device 1, a hydraulic cylinder 2, an anti-skid handle 3, a support cylinder 4, an inner connecting rod 5, an outer connecting rod 6, a glass jar clamp Tightening device 7, the outer top center of the support tube 4 is vertically connected to the anti-slip handle 3, and the inner bottom is vertically connected to the hydraulic cylinder 2, the hydraulic cylinder 2 is located directly above the cork clamping device 1, and the cork clamping The four positive directions of the device 1 are connected with the support cylinder 4 through the inner connecting rod 5, and the glass jar clamping device 7 is arranged in parallel below the cork clamping device 1, and the glass jar clamping device 7 passes through four Equidistantly arranged outer connecting rods 6 are connected to the support cylinder 4;

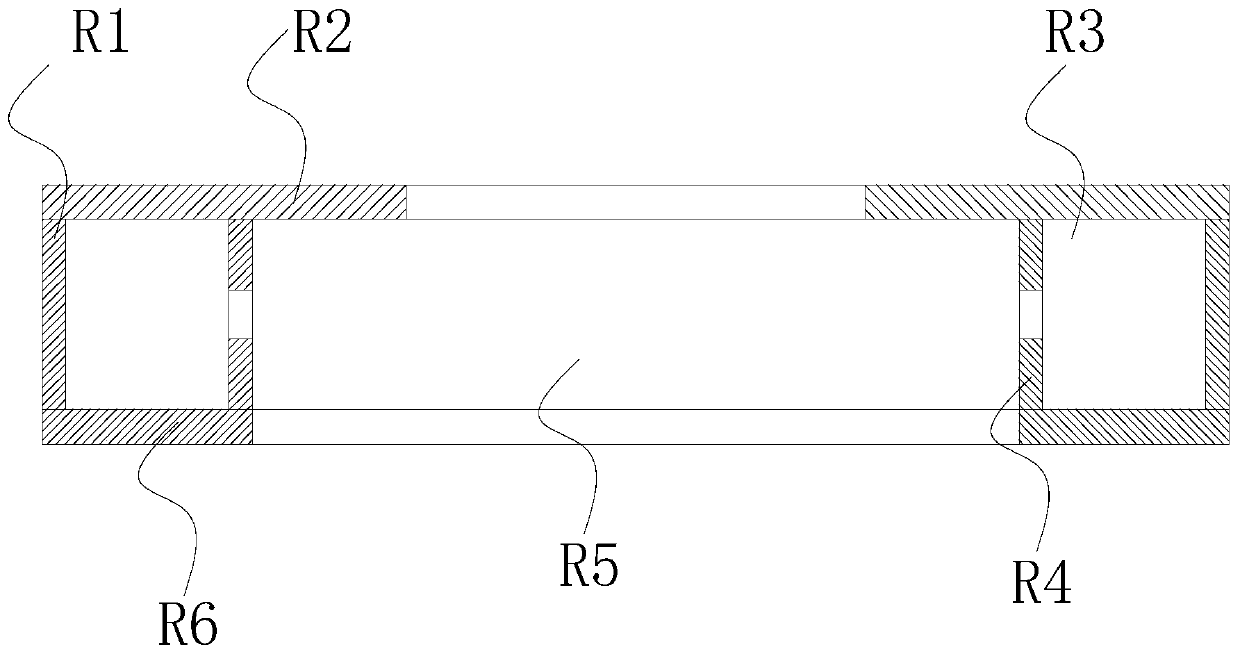

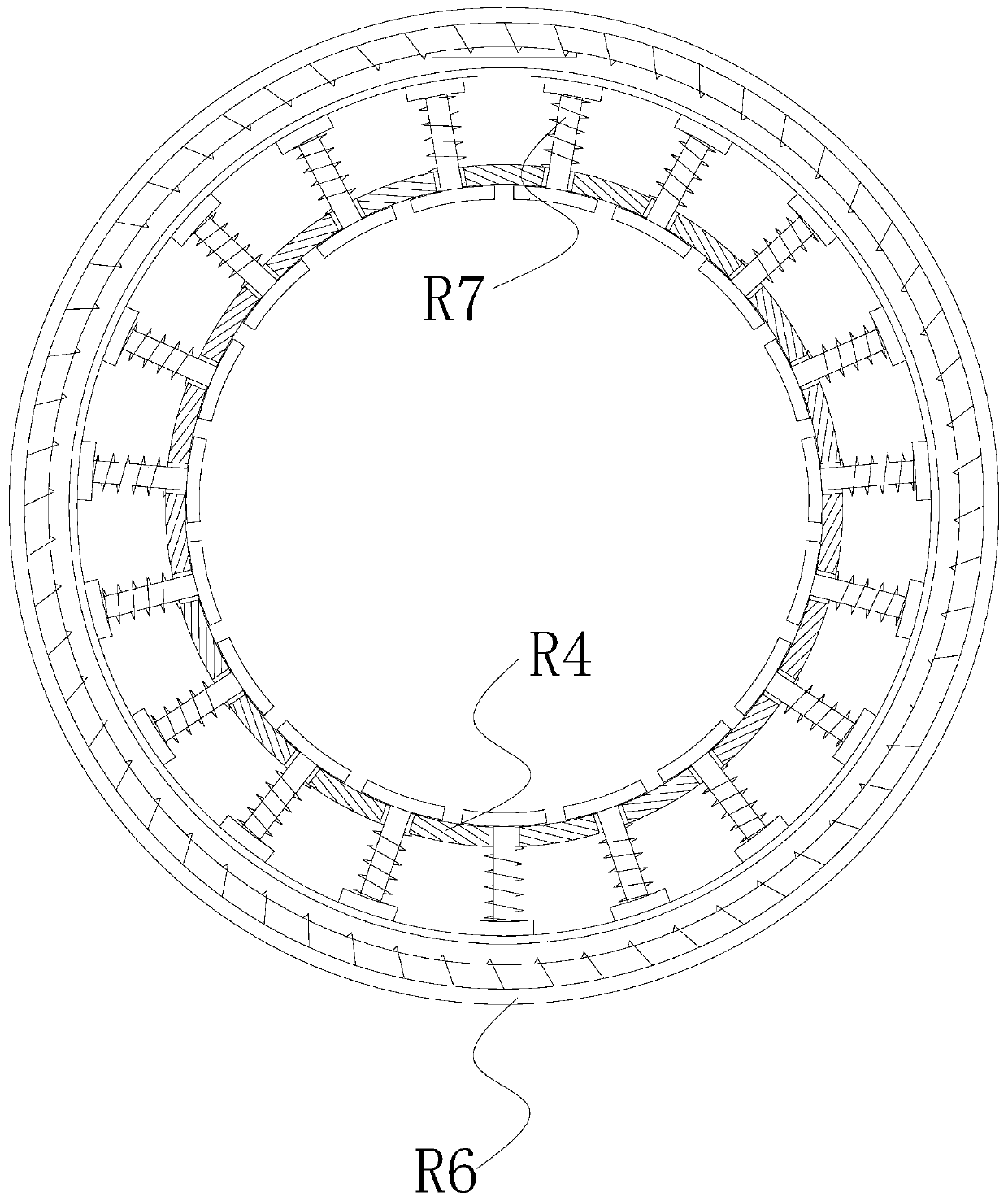

[0039] see Figure 2-3 The co...

Embodiment 2

[0045] see figure 1 , the present invention provides a technical solution for a portable glass jar capping machine: its structure includes a cork clamping device 1, a hydraulic cylinder 2, an anti-skid handle 3, a support cylinder 4, an inner connecting rod 5, an outer connecting rod 6, a glass jar clamp Tightening device 7, the outer top center of the support tube 4 is vertically connected to the anti-slip handle 3, and the inner bottom is vertically connected to the hydraulic cylinder 2, the hydraulic cylinder 2 is located directly above the cork clamping device 1, and the cork clamping The four positive directions of the device 1 are connected with the support cylinder 4 through the inner connecting rod 5, and the glass jar clamping device 7 is arranged in parallel below the cork clamping device 1, and the glass jar clamping device 7 passes through four Equidistantly arranged outer connecting rods 6 are connected to the support cylinder 4, and the aluminum ring R1 is arran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com