Patents

Literature

77results about How to "Reasonable thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

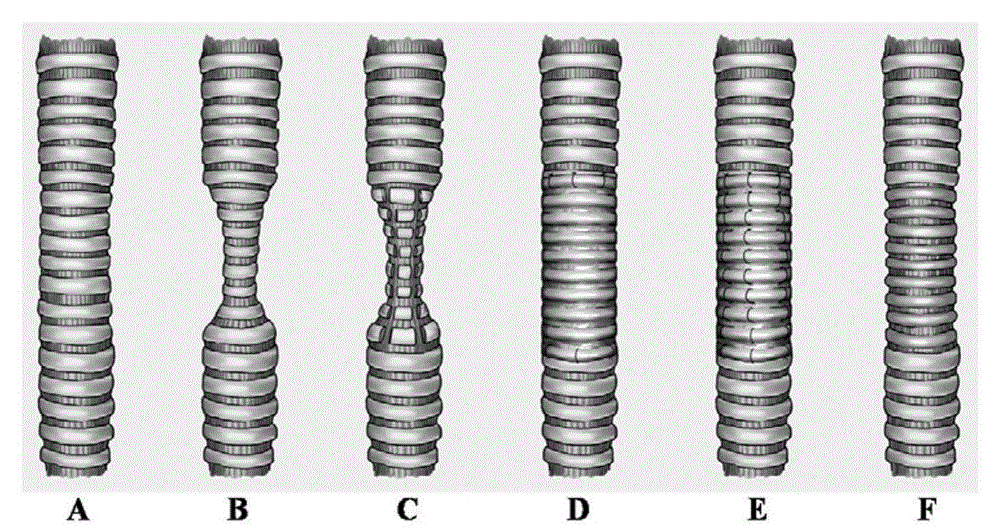

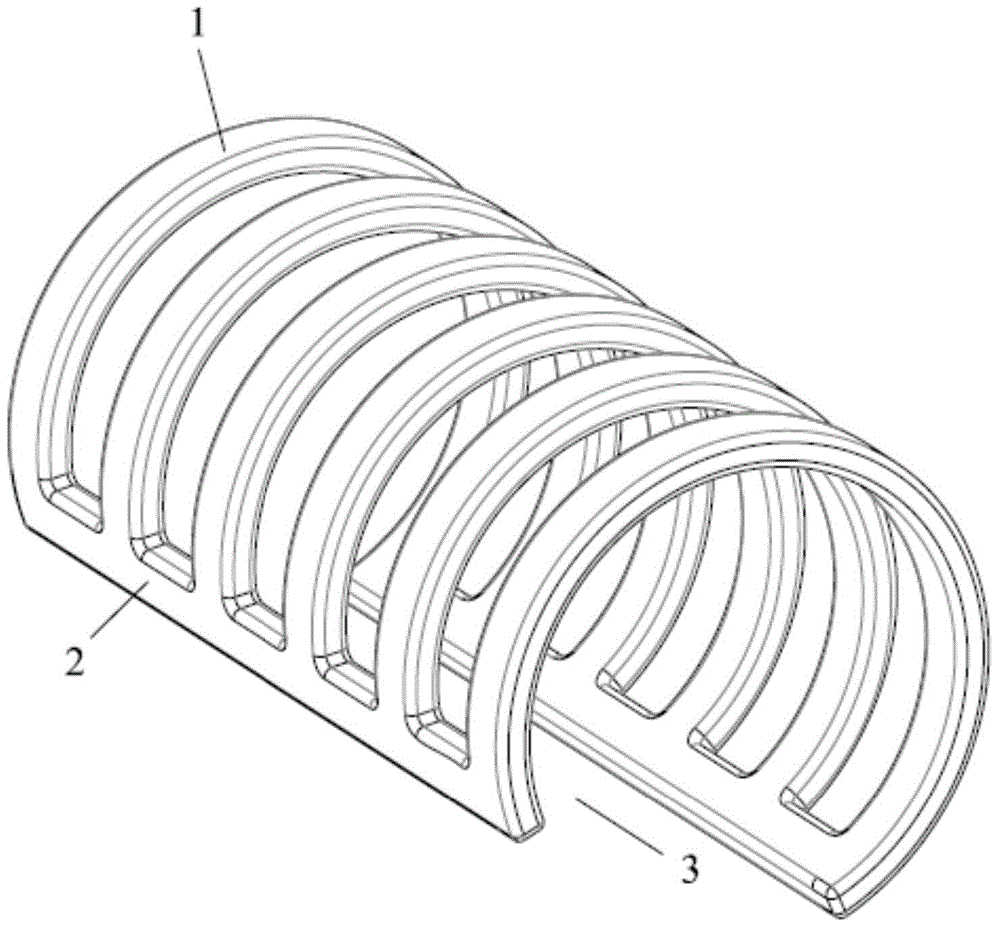

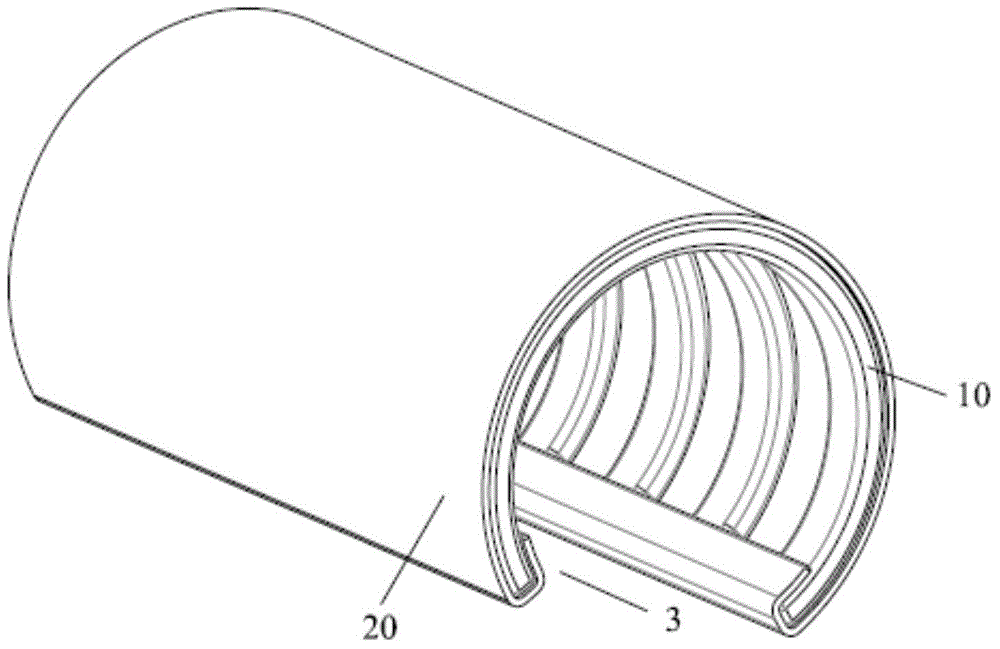

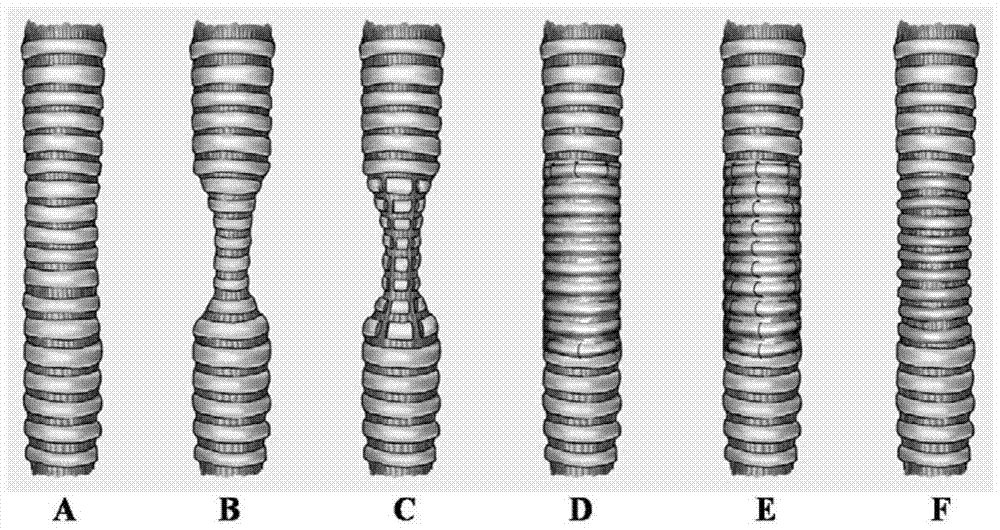

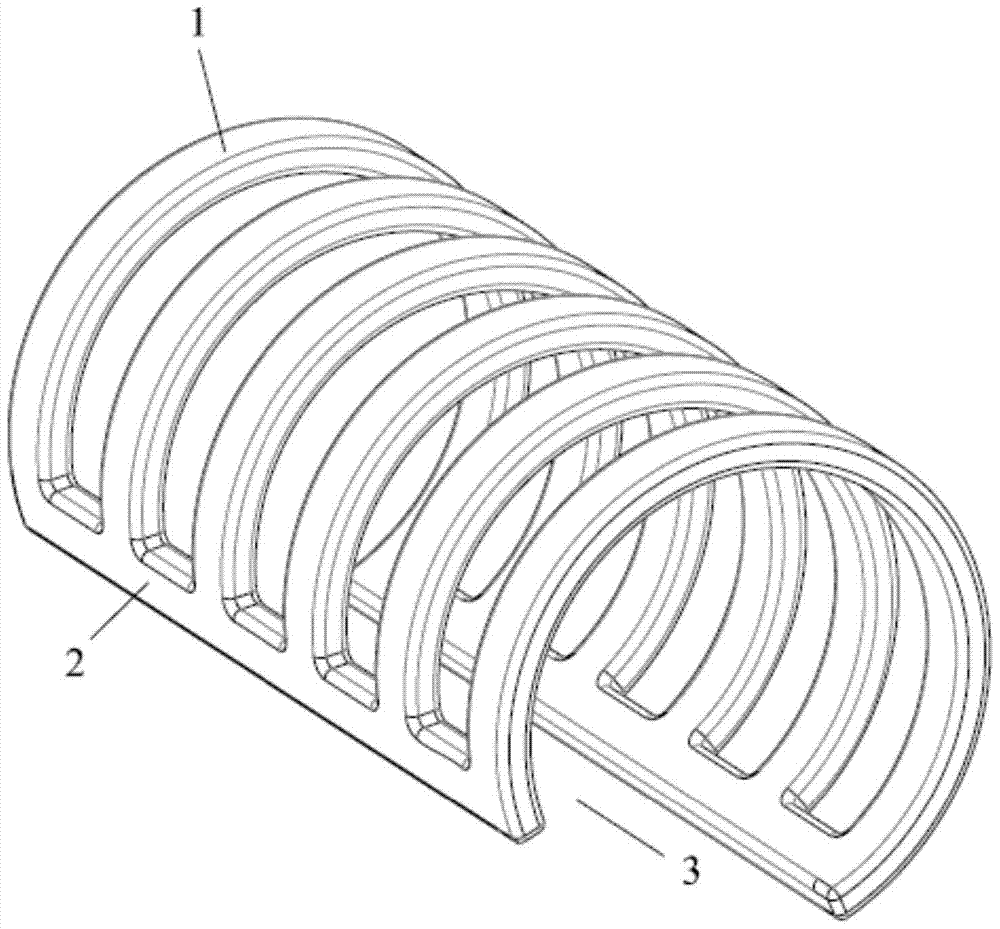

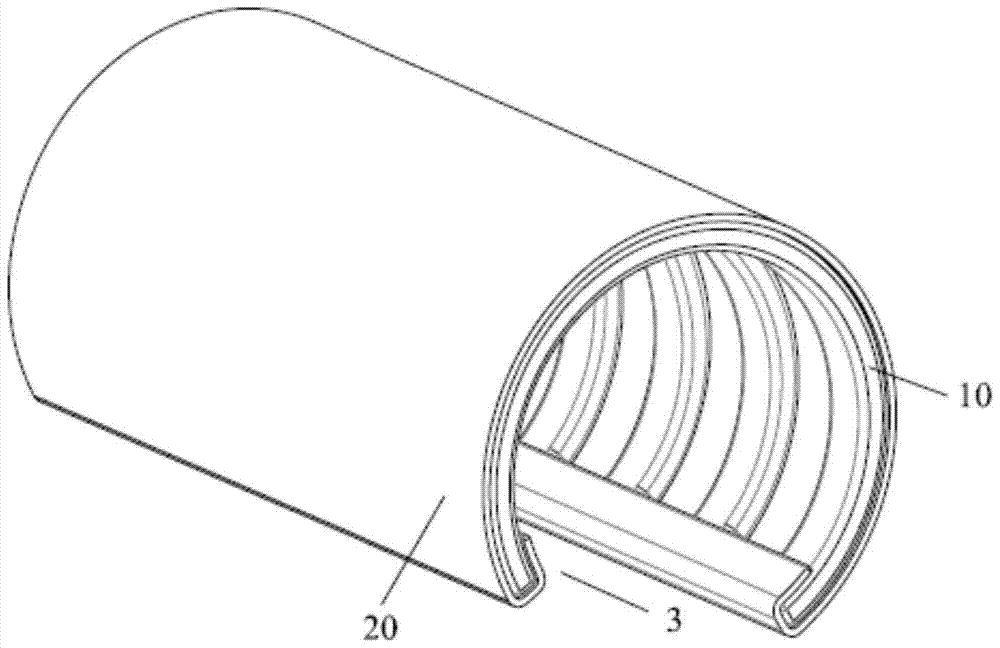

Tracheal stent and application thereof

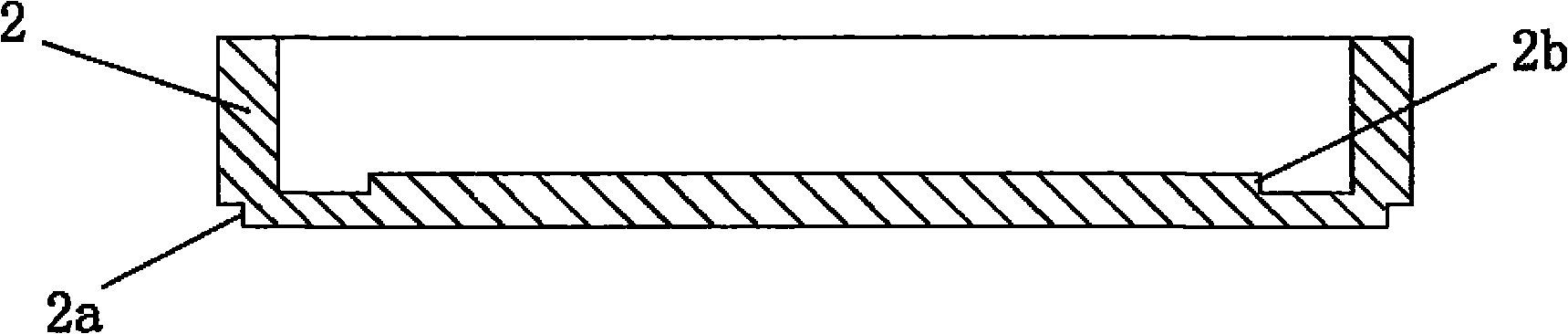

InactiveCN105055060ANarrow repairWon't breakStentsTubular organ implantsInsertion stentMembrane complex

The invention relates to a tracheal stent and application thereof. The tracheal stent comprises supporting rings and a supporting connecting rod, wherein the various supporting rings are of C-shaped structures and are serially connected by virtue of the supporting connecting rod, so that the various supporting rings are integrally fixed with the supporting connecting rod. The invention further provides a tissue engineering trachea, and the tissue engineering trachea is prepared by winding a chondrocyte-gelatin / polycaprolactone electrospun membrane complex on the outer surface of the tracheal stent. The tracheal stent or the tissue engineering trachea disclosed by the invention can be used for repairing tracheal stenosis by virtue of a tracheal external support suspension method, and a new C-shaped cartilaginous ring is formed after the implantation of the tracheal stent or the tissue engineering trachea, so as to guarantee growth potential finally.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

Double fluorescent polyester viscose wool elastic gabardine spinning yarns, lining prepared thereby and preparation method thereof

InactiveCN101397703AImproved shade perceptionHigh strengthDyeing processWoven fabricsEngineeringMaterials processing

The invention relates to a bi-fluorescent polyester-viscose wool elastic gabardine spinning yarn which is characterized in that the spinning yarn is formed by the steps of adopting 150D cationic polyester low stretch yarns and 32S polyester-viscose wool three in one blended yarns to carry out air cladding to 40D urethane elastic fibers by a networking threading machine and then twisting; the polyester-viscose wool three in one blended yarns comprise the following components according to weight ratio of blending: 14 percent to 16 percent of bright triangular polyester, 65 percent to 71 percent of viscose staple fibers and 16 percent to 18 percent of wool. The invention also discloses a fabric spun by the yarn, and a preparation method of the fabric. Compared with the prior art, the invention has the advantages of adopting the material processing method of air-cladding polyester filament yarns, the viscose staple fibers and urethane elastic fiber, making full use of the respective features of the polyester filament yarns and the viscose staple fibers, namely, different shrinking performances and coloring properties, so as to greatly improve the color light feeling, the strength and the curly and fluffy feeling of the yarn, thereby causing the fabric to have a remarkably full and smooth style; added with Lycra effect of the urethane elastic fibers, finished products have moderate elasticity and better wrinkle resistance and the fabric is reasonable in thickness and draping property.

Owner:ZHEJIANG ZHINK GROUP +1

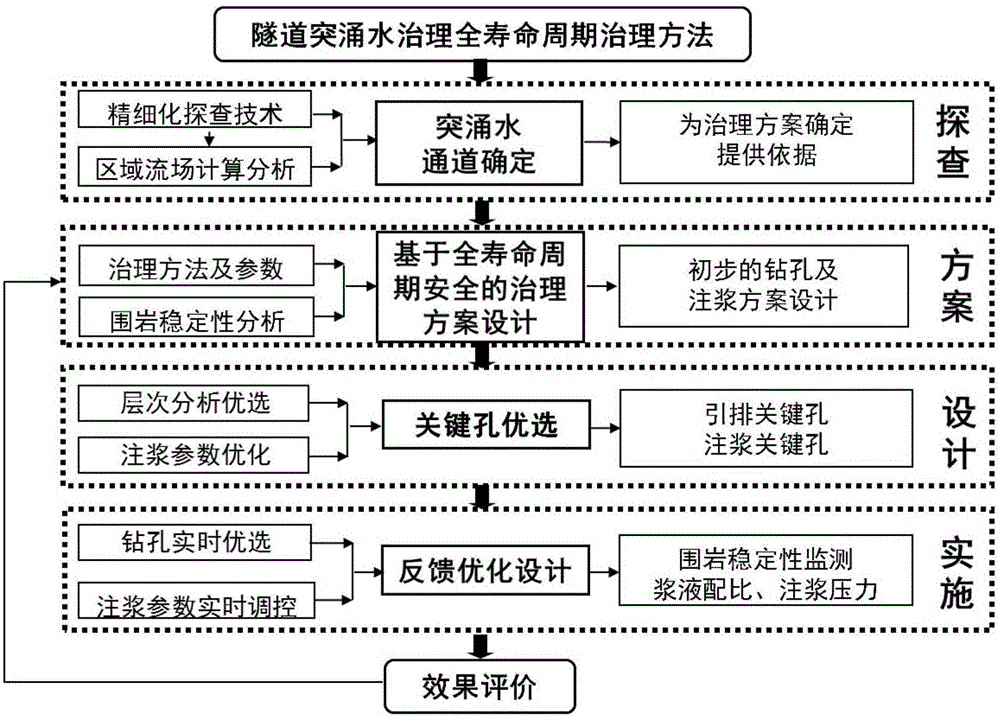

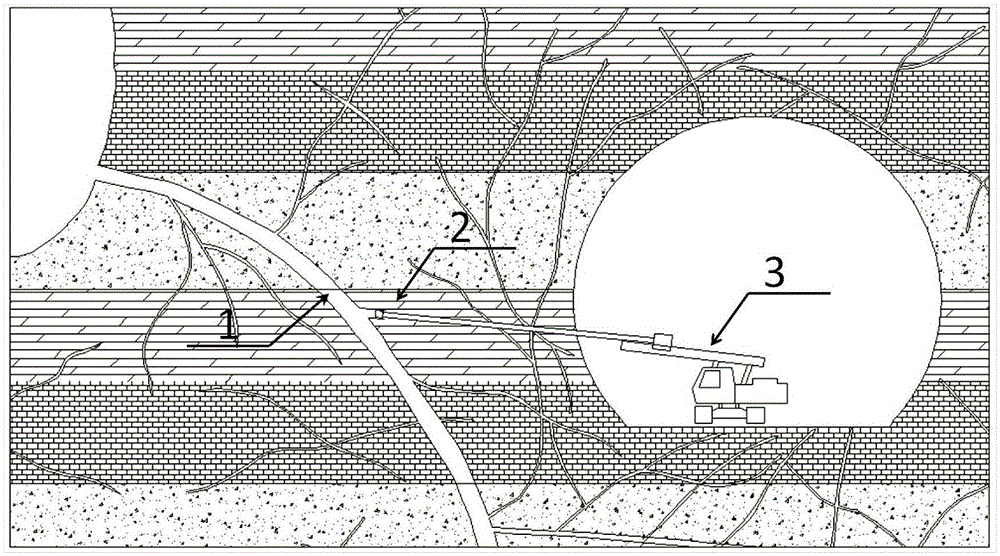

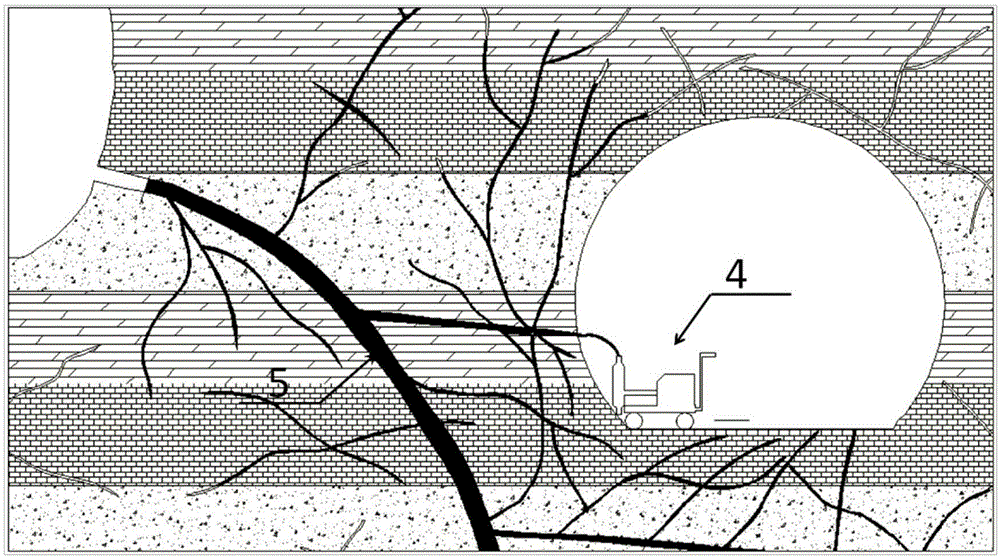

Life-cycle treatment method of water inrush in tunnel

ActiveCN105041345AImprove targetingImprove effectivenessUnderground chambersTunnel liningWall rockTunnel construction

The invention discloses a life-cycle treatment method of water inrush in a tunnel. The method comprises the steps that three-dimensional morphologic features of a water conductive structure of a water inrush zone in the tunnel are obtained by combining geological data, excavation data, detection results of comprehensive geophysical detection and numerical calculation results; grouting sealing water inrush is taken into account, surrounding rock physical mechanical parameters are improved simultaneously, design of a treatment scheme is conducted on the water inrush zone in the tunnel, and design of a keyhole and a drainage keyhole is conducted according to a water inrush main controlling structure; the stability of the tunnel in the construction period and the safety in the operation period are guaranteed by conducting numerical simulation on the tunnel section which is reinforced according to the design scheme; grouting construction is conducted according to the design scheme, a monitoring device is buried during the construction process, and feedback optimal design is implemented; inspection is conducted on the treatment effect of the grouting reinforcement section in the tunnel, and the excavation time is determined. According to the life-cycle treatment method of the water inrush in the tunnel, it is guaranteed that the surrounding rock in the tunnel construction period is stale and water inrush of the tunnel does not occur in the operation period, the chronic problem that nine of the ten tunnels leak is completely eradicated, and the effective treatment of the water inrush in the tunnel and the environmental protection are achieved.

Owner:SHANDONG UNIV

Crystallizer protective slag for effectively controlling carbon steel cracks in compact strip production (CSP)

The invention discloses crystallizer protective slag for effectively controlling carbon steel cracks in a compact strip production (CSP). The crystallizer protective slag comprises the following chemical components in percentage by mass: 35 to 38 percent of CaO, 28 to 31 percent of SiO2, 1 to 3 percent of Al2O3, 1 to 2 percent of MgO, 0.5 to 1.5 percent of Fe2O3, 10 to 11.5 percent of F, 9 to 11.5 percent of Na2O, 1.5 to 3.5 percent of MnO, 5 to 8 percent of fixed carbon, and the balance of inevitable trace elements. Through the crystallizer protective slag for controlling the carbon steel cracks in the CSP, the alkalinity is improved by 0.04 to 0.09, the alkalinity is controlled to be 1.20 to 1.25, the constraint that the alkalinity cannot be more than 1.16 in the field is broken, the viscosity is controlled to be 0.08 to 0.09Pa.S, and the melting point is from 1,155 to 1,185 DEG C; capabilities of dissolving and absorbing inclusions are improved, and heat transfer is retarded by reducing a vitreous body, so that an aim of reducing longitudinal cracks is fulfilled; and by adjusting the proportioned carbon and controlling the thickness of a liquid slag layer, bonding steel leakage caused by high crystallization temperature and deteriorated lubricating performance due to over high alkalinity of the protective slag is relieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

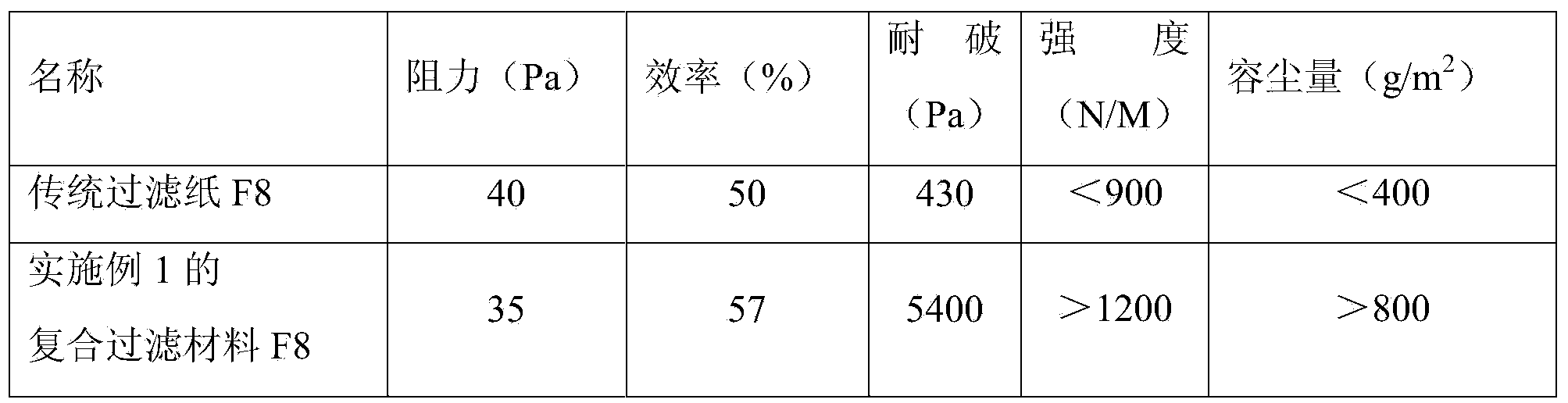

Air filtration glass fiber cotton composite material of series F5-F9 and manufacturing method thereof

ActiveCN103657258AHigh porosityGood coarse and medium filter effectLaminationLamination apparatusAir filtrationGlass fiber

The invention discloses an air filtration glass fiber cotton composite material of series F5-F9. The air filtration glass fiber cotton composite material comprises non-woven cloth and a glass fiber cotton layer combined on the surface of the non-woven cloth through an adhesive material, wherein the non-woven cloth is 0.05-0.1mm thick; the glass fiber cotton layer is 0.25-1.5 mm thick and consists of glass fiber cotton with the diameter of 0.75-1.25 microns; the adhesive material is acrylic resin. A method for preparing the composite material comprises the steps of mixing and smelting proper amount of zinc oxide, borax, white sand, potash feldspar powder, pure alkaline, calcite, potassium carbonate and barium carbonate, performing primary fiber forming and then dragging the fibers through high-temperature and high-speed air flow to obtain the glass fiber cotton; dispersing the glass fiber cotton on the surface of the non-woven cloth, spraying glue, and drying to obtain the product. The air filtration glass fiber cotton composite material disclosed by the invention is high in intensity and high in filtration performance and has wide application prospects; due to the preparation method, the performance of the air filtration glass fiber cotton composite material can be further guaranteed.

Owner:CHONGQING ZAISHENG TECH CORP

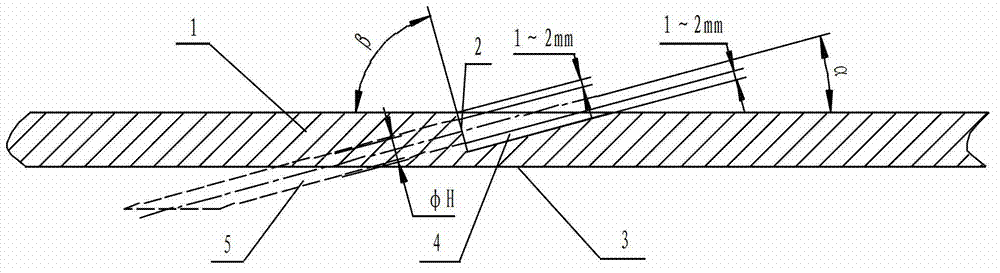

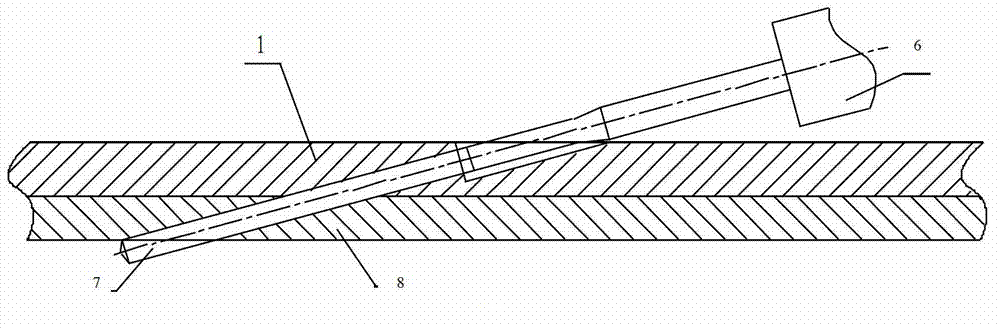

Method for processing deep minipore with large gradient on difficult-to-process material

The invention provides a method for processing a deep minipore with large gradient on a difficult-to-process material. The method comprises the following steps of: adding and fixing a cutting force balancing guide plate with reasonable thickness, excellent cutting performance and good locating cooperation and firm adhesion with a workpiece on the workpiece, milling an inclined plane vertical to the central axis of the hole on the guide plate through a large diameter milling tool, and converting deep inclined minipore processing into common minipore processing to solve the problems of large gradient of the difficult-to-process material, chip breaking, chip discharge, chip removal, cutter back-off, cutter vibration and cutter striking in the deep minipore cutting processing and the problem that the surface roughness and the length dimension of an entrance cannot meet the demand in direct processing, and the method provides reliable technical support for integral surface processing and anti-fatigue manufacturing and provides guarantee for improving the service life and safety of the parts.

Owner:AECC AVIATION POWER CO LTD

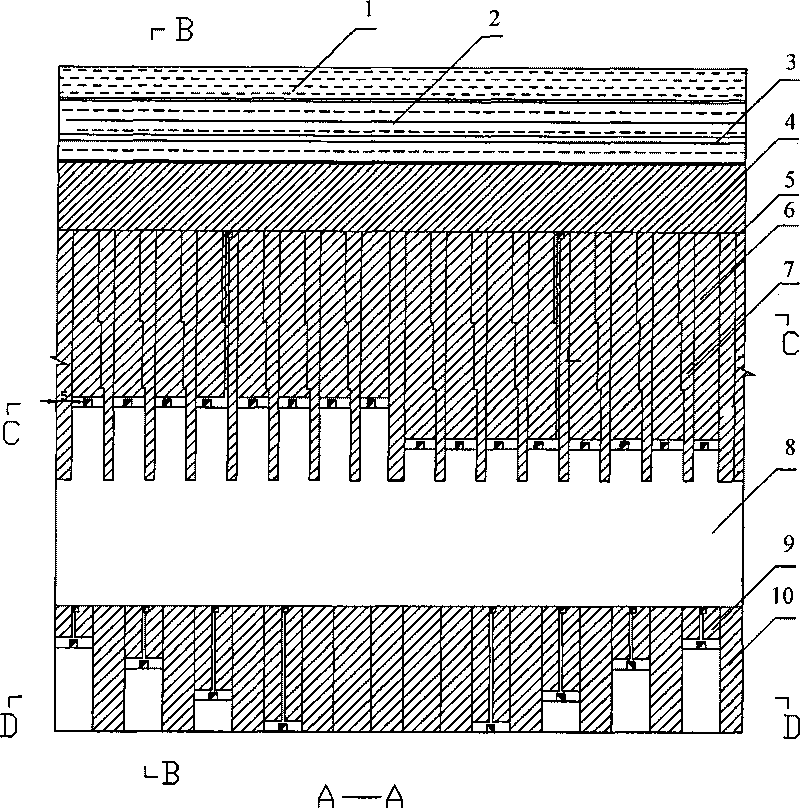

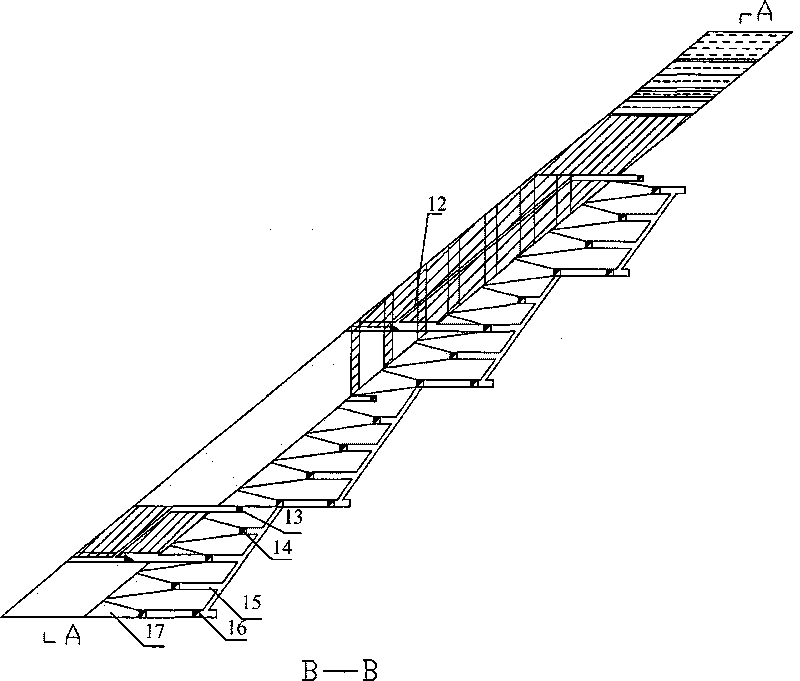

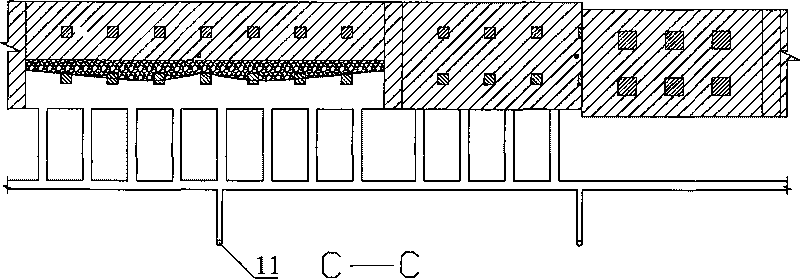

Middle-waisted bidirectional filling and mining method under canopy guard in thick and great metal mine in sea bed

InactiveCN101761340ASmall amount of deformationImprove mining safetyMineral miningMaterial fill-upOcean bottomFilling materials

The invention discloses a middle-waisted bidirectional filling and mining method under canopy guard in a thick and great metal mine in sea bed, which is characterized in that a safety isolating layer is preserved between an ore body and the sea bed; the ore body is divided into an upper part and a lower part at the middle waist in the altitude direction; the altitude from the middle waist position to the sea bed sea mud is 100-150m; stoping is carried out from the middle waist position of the ore body, wherein the upper part adopts upstroke mining and the lower part adopts downstroke mining; a rock trackless quasi-upward slicing cemented method with a regular post pillar is adopted in the upstroke mining method; a rock trackless quasi-ordinary slicing cemented method is adopted in the downstroke mining; the gob in the stope is filled with filling materials. The invention is characterized by having high safety of mining, little loss of resources, high degree of mechanism, low labor intensity, great production capacity, short stoping time, low mining settlement and the like.

Owner:CENT SOUTH UNIV +1

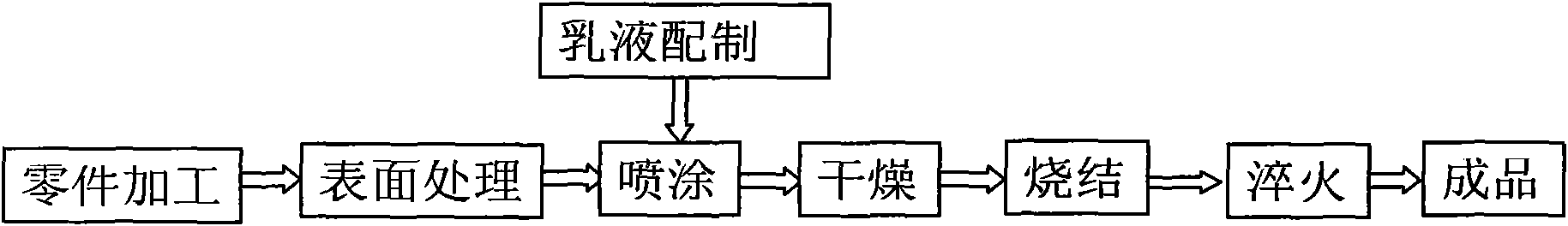

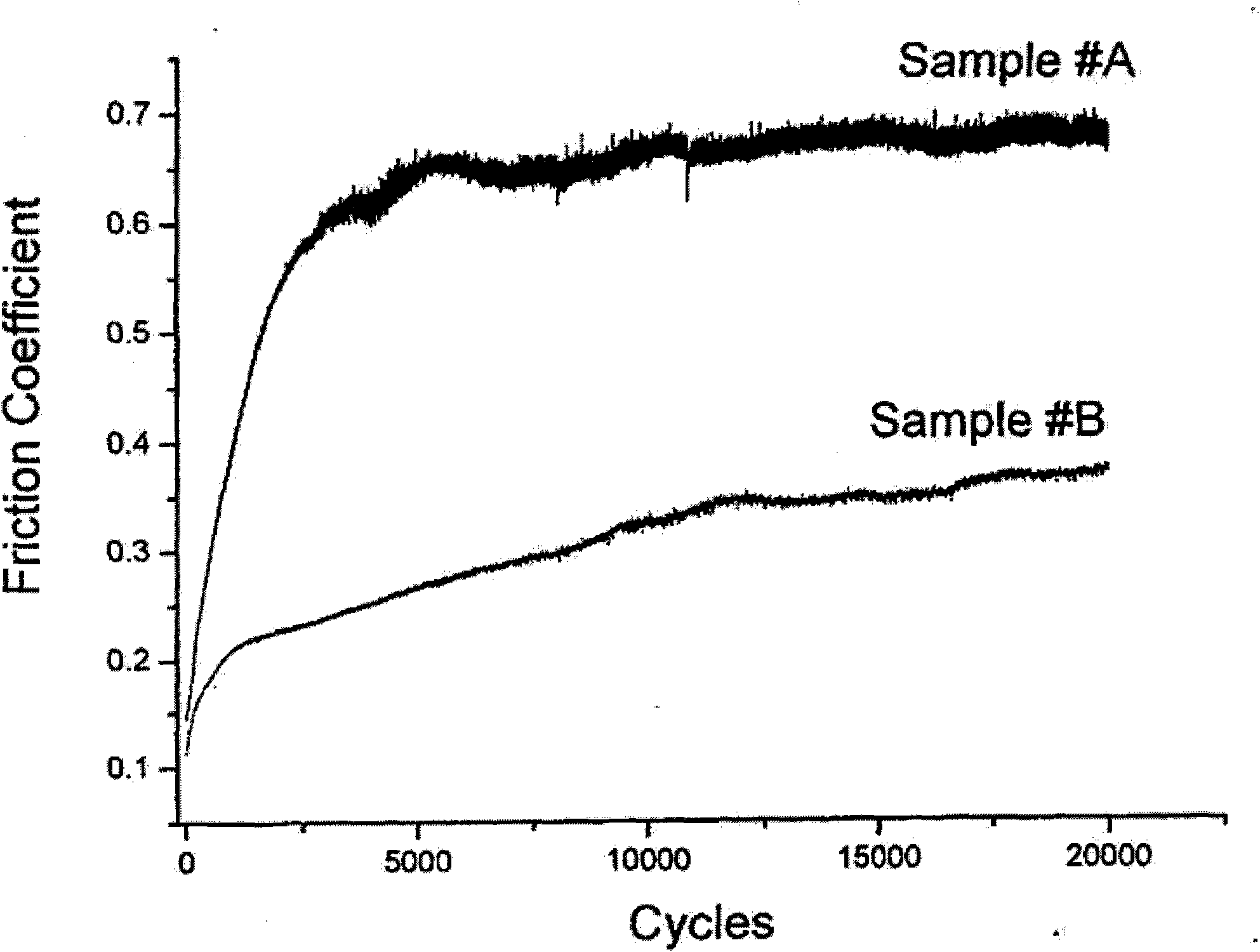

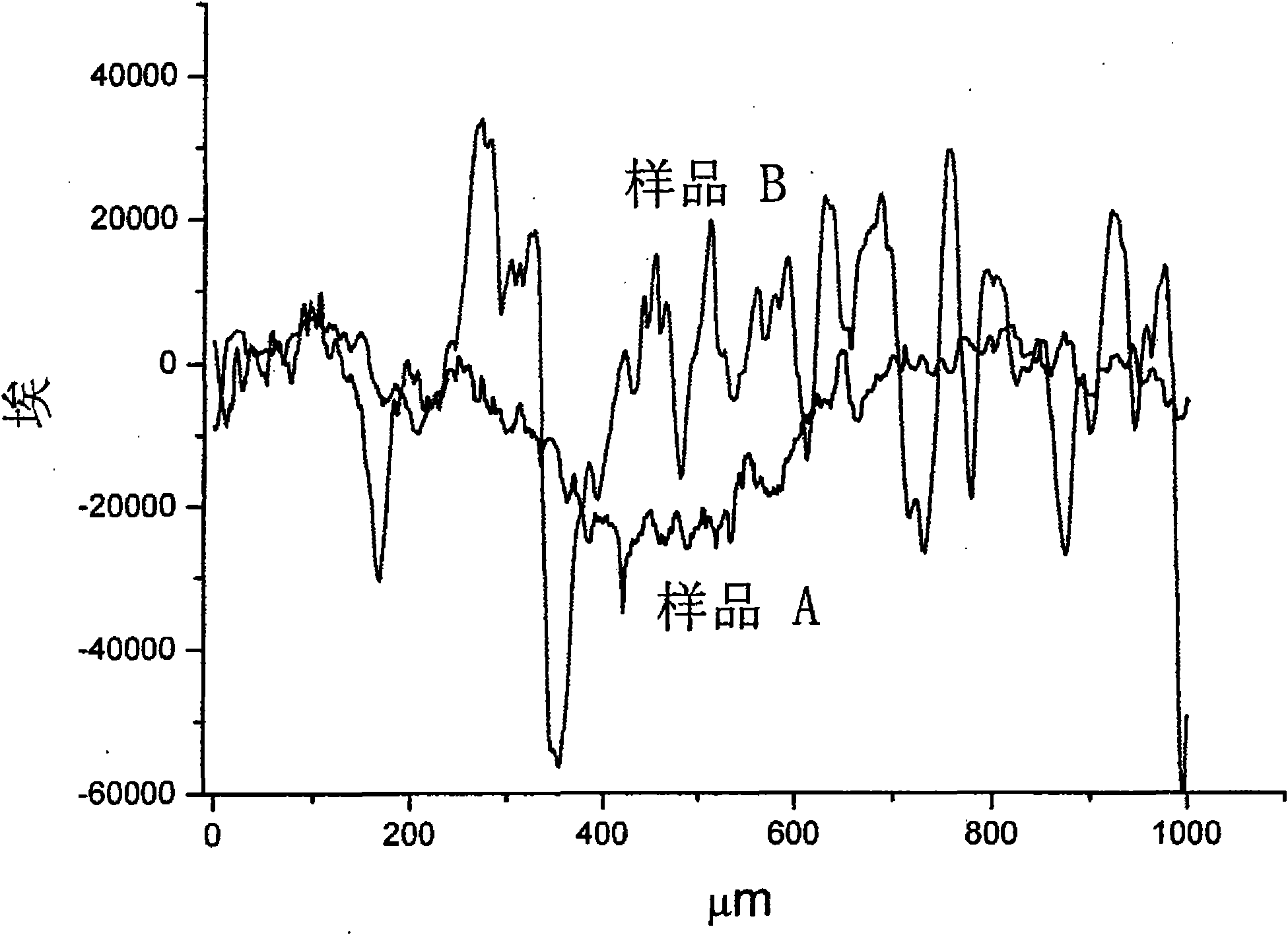

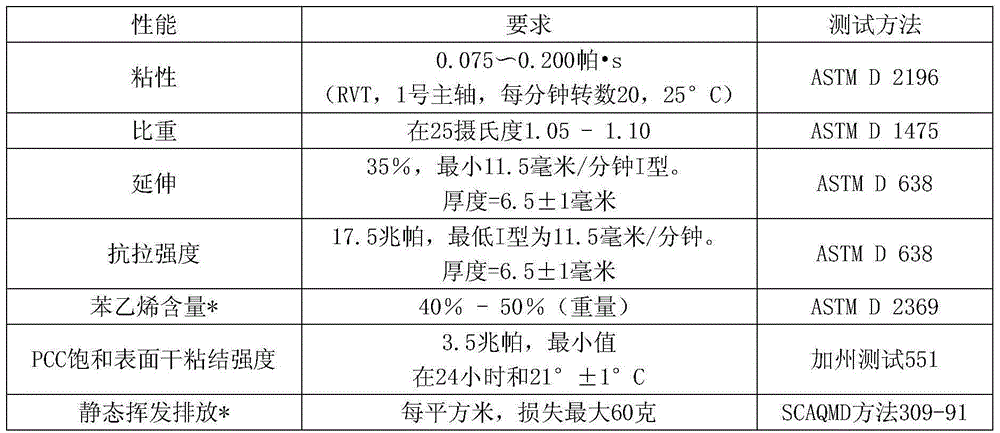

Abrasion-resistant and friction-reducing emulsion and preparation method for spraying same on surface of soft metal

InactiveCN101831222AExtended service lifeReasonable thicknessPretreated surfacesSpecial surfacesPhosphoric acidAlloy

The invention discloses abrasion-resistant and friction-reducing emulsion. The abrasion-resistant and friction-reducing emulsion comprises 50 to 69 parts of polytetrafluoroethylene emulsion, 2.0 to 5.9 parts of chromium oxide, 2.5 to 5.4 parts of phosphoric acid, 0.2 to 0.4 part of lauryl sodium sulfate, 0.5 to 3.0 parts of abrasion-resistant additive and 20 to 40 parts of distilled water. The invention also relates to a preparation method for spraying the abrasion-resistant and friction-reducing emulsion on the surface of a soft metal. The method comprises the following steps of: preparing the abrasion-resistant and friction-reducing emulsion with the components; treating the surface of soft metal matrix; spraying the emulsion on the surface of the soft metal; drying the soft metal; sintering the soft metal; and quenching the soft metal. When the abrasion-resistant and friction-reducing emulsion of the technical scheme of the invention is coated on the surface of the soft metal, the friction coefficient can be reduced by 20 percent, and the abrasion amount ratio of the soft metal to the basis material is less than or equal to 0.5. The abrasion-resistant and friction-reducing emulsion can be widely used for surface treatment of the soft metal such as copper, aluminum and alloy thereof and the like at a friction and abrasion part of a gear pump side plate, a bearing bush, a bearing block hole, a cylinder barrel and the like, and has novel structure and originality.

Owner:LUZHOU GUOBANG MACHINERY

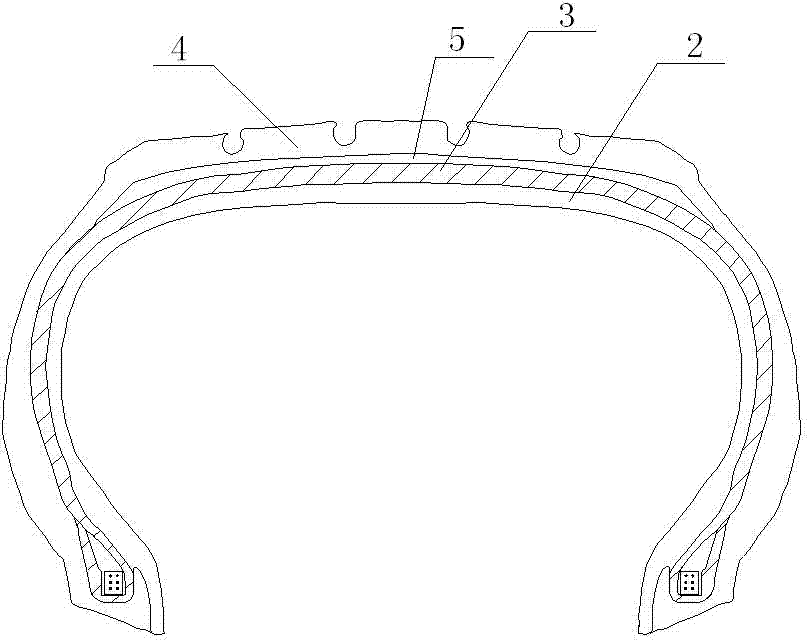

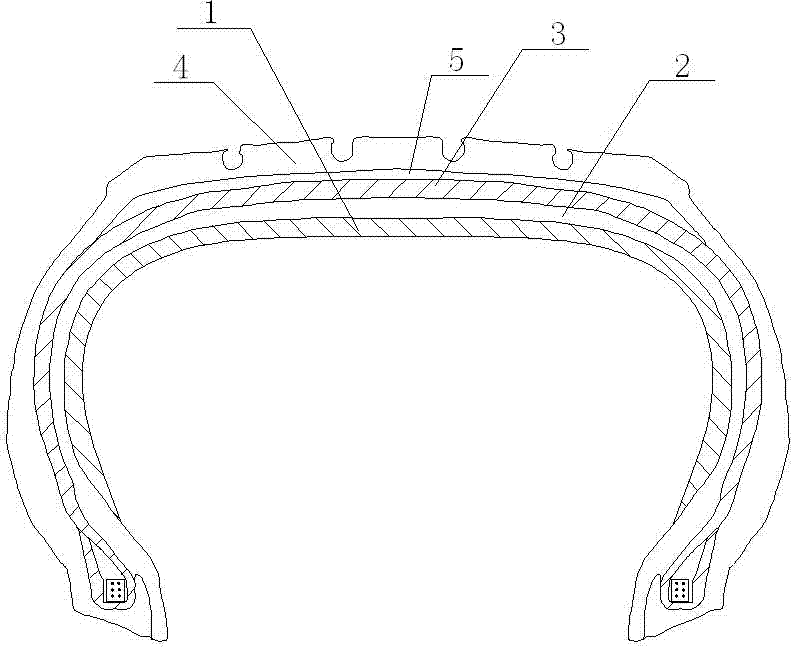

Preparation method of safe anti-puncturing tyre

InactiveCN103496302AStrong initial adhesionIncrease stickinessPneumatic tyre reinforcementsAdhesiveMolding machine

The invention relates to a preparation method of a safe anti-puncturing tyre. The safe anti-puncturing tyre is sequentially provided with a self-sealing layer, an air-tight layer, a curtain cloth layer, a belted layer and a tread from inside to outside. The preparation method comprises the following steps: (1) extruding the tread by using an extruding machine; (2) spraying and molding an adhesive to form the self-sealing layer; (3) respectively pressing the air-tight layer and the curtain cloth layer by a calendering machine; (4) molding the belted layer; and (5) fitting the self-sealing layer, the air-tight layer, the curtain cloth layer, the belted layer and the tread on a molding machine and integrally molding and fitting to obtain the safe anti-puncturing tyre. The tyre prepared by the preparation method provided by the invention is simple in structure and reasonable in design and has the characteristics of high production efficiency, low cost, good tyre anti-puncturing effect, high safety performance and the like.

Owner:杭州绿奇科技有限公司

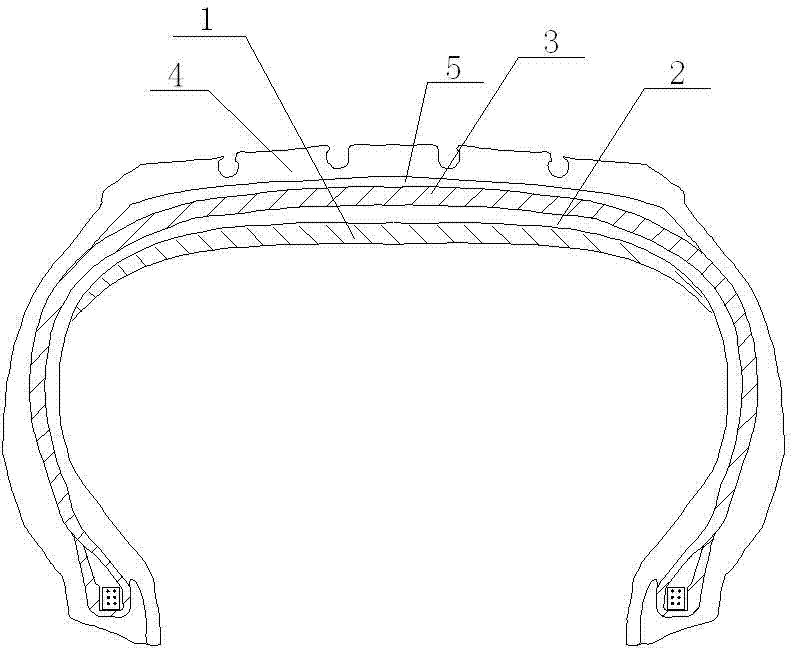

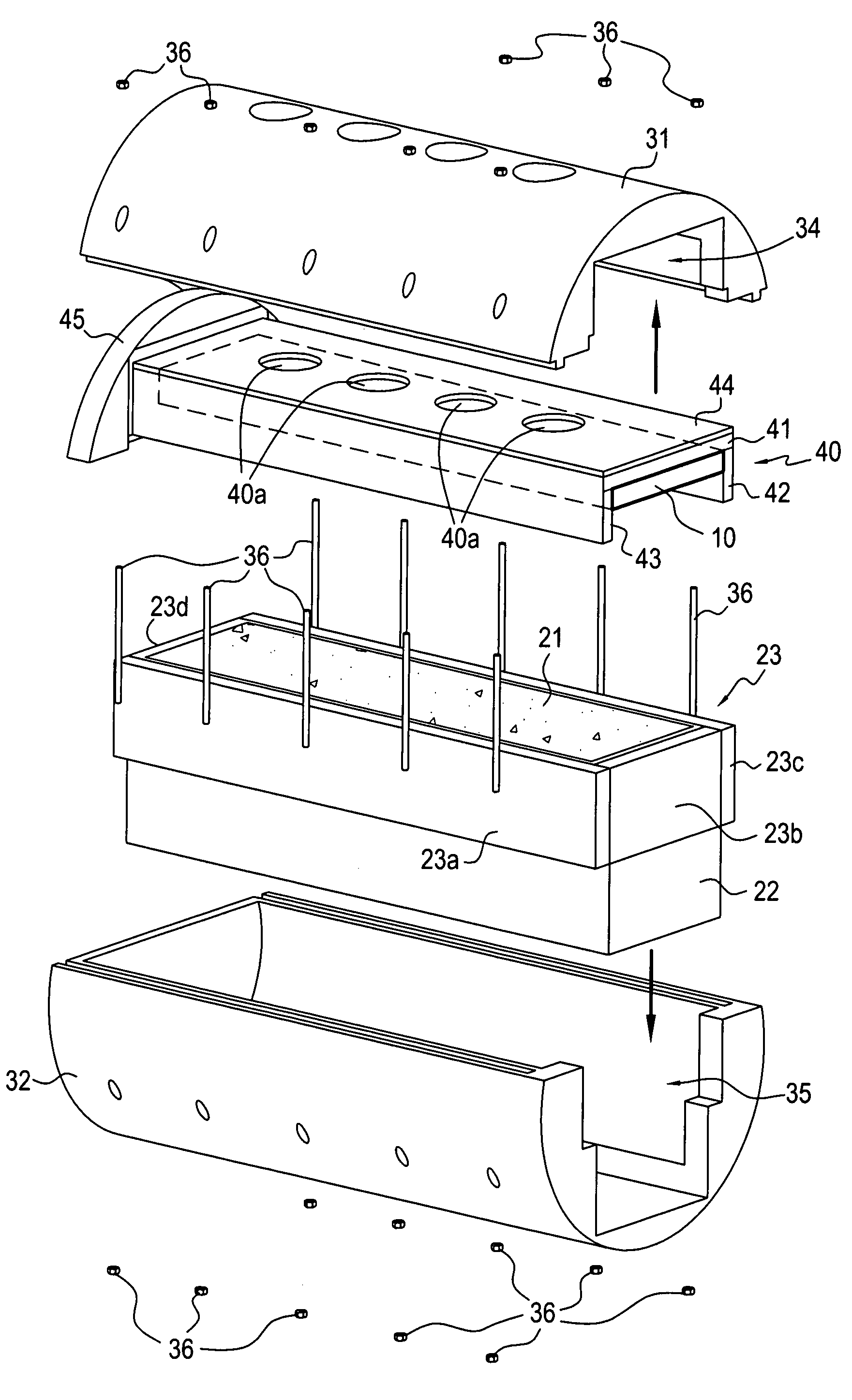

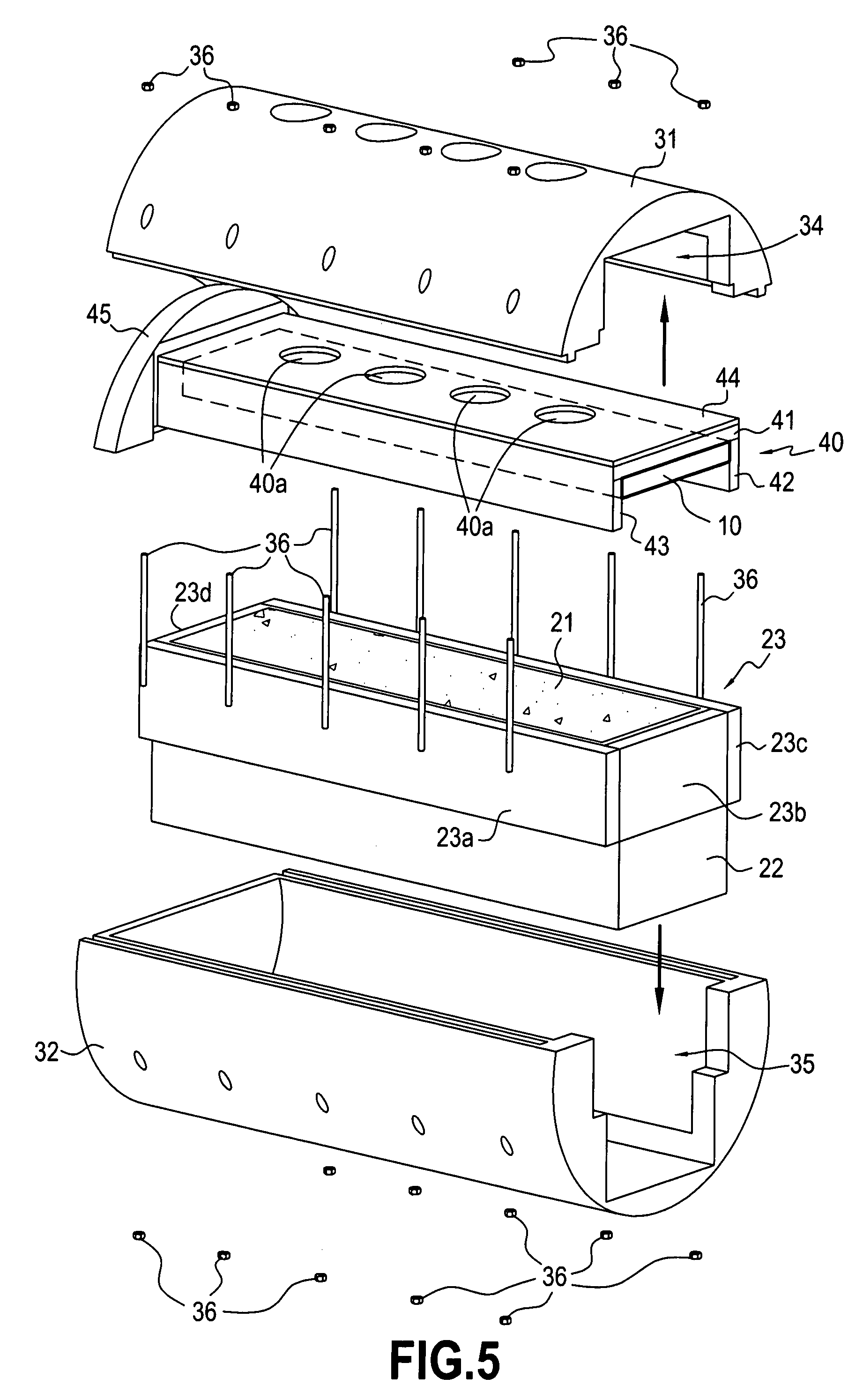

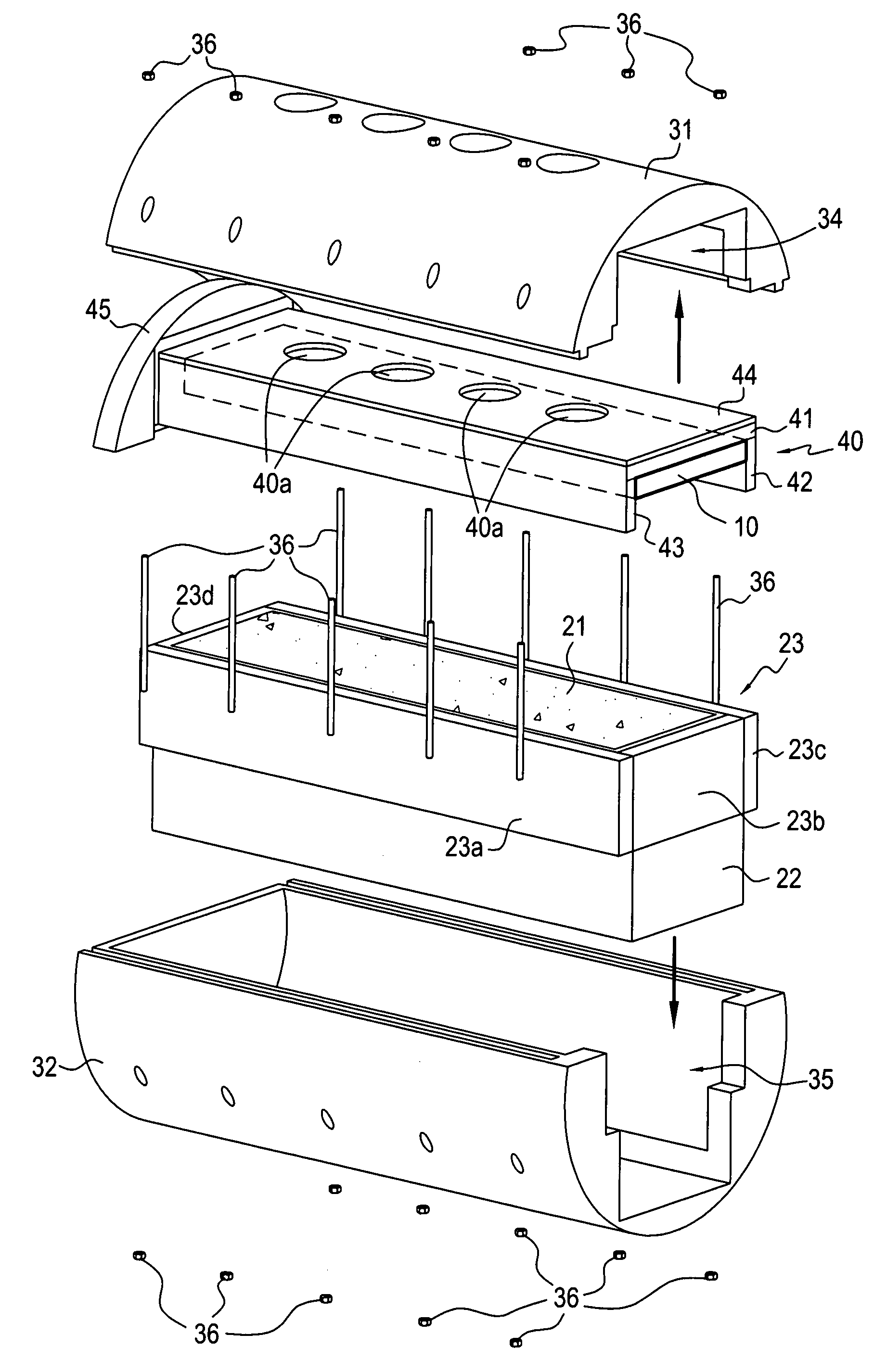

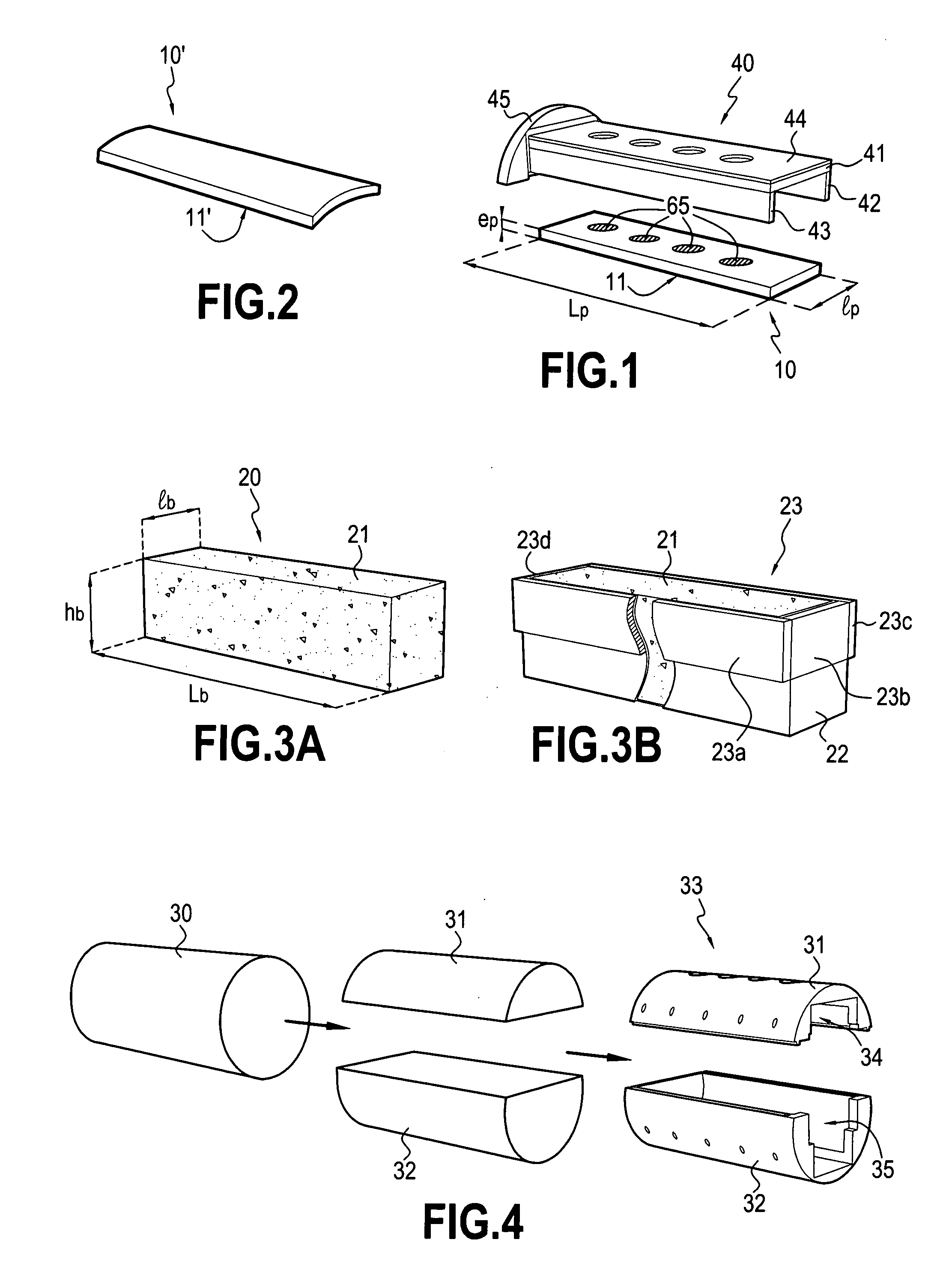

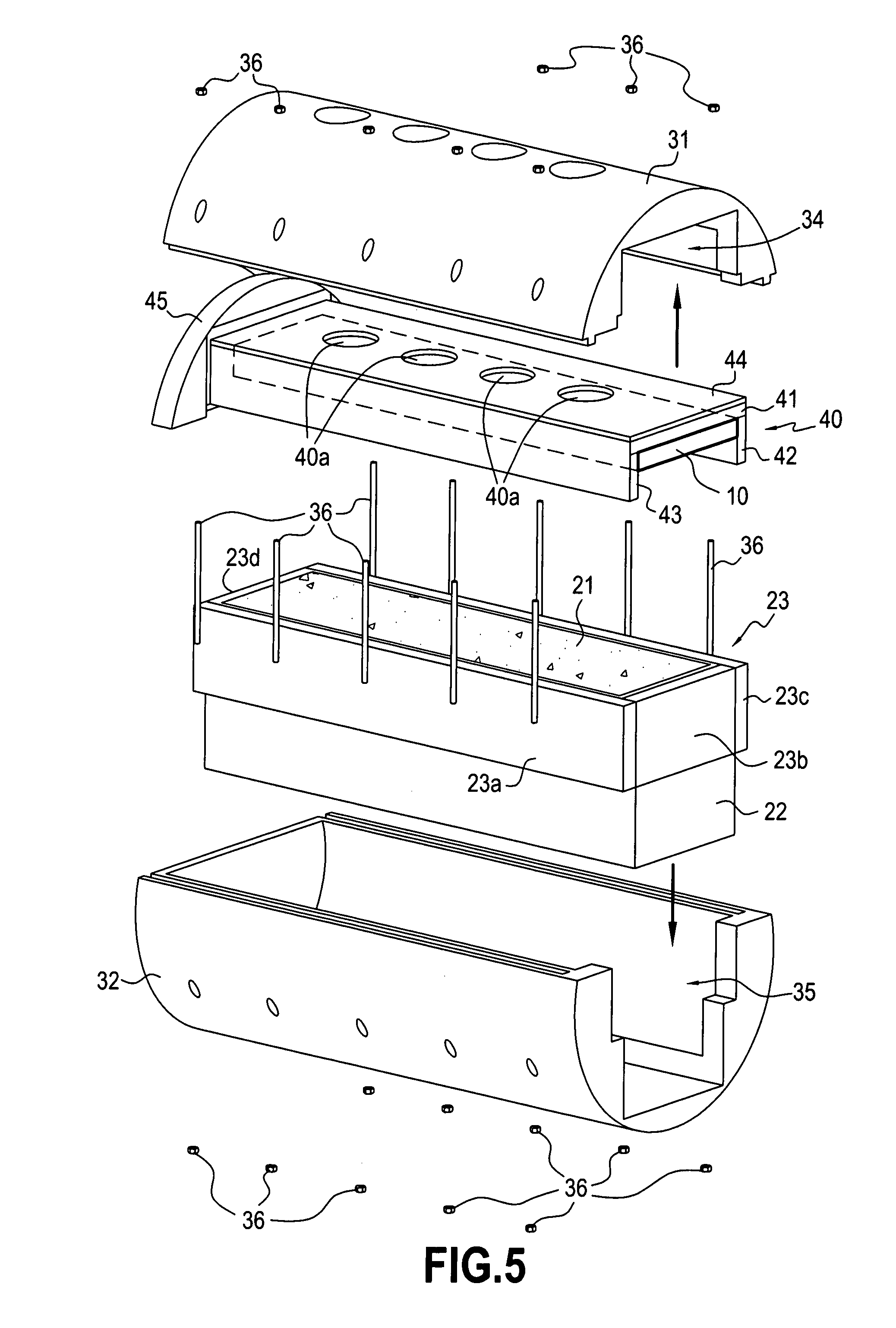

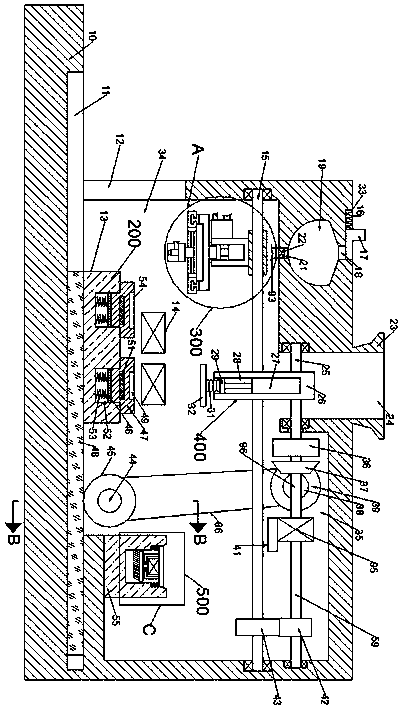

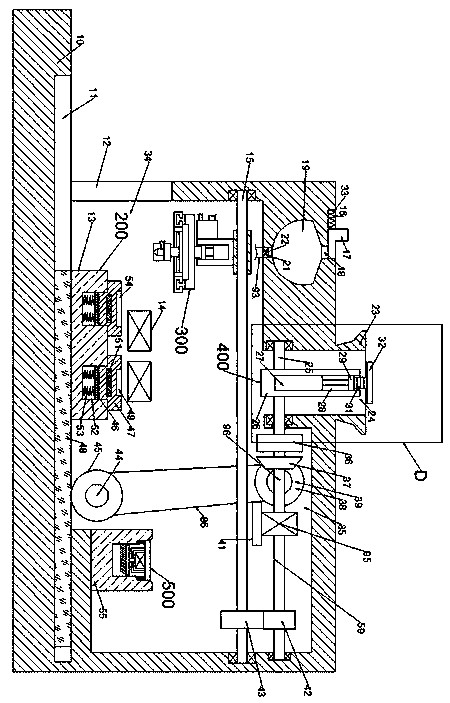

Thermal erosion test device and method for testing thermal protection materials of solid propellant thrusters

ActiveUS7628534B2Accurate representationSave levelThermometer detailsEngine manufactureCombustion chamberCorrosion testing

The invention relates to a thermal erosion test device for testing thermal protection materials for use in a solid propellant thruster. The device comprises a support for holding a plate made of the thermal protection material for testing so that its faces a face of a block of solid propellant, the space between the plate and the face of the propellant block defining a combustion chamber of substantially rectangular shape, said chamber extending along said plate and opening out into a nozzle.

Owner:ARIANEGRP SAS +1

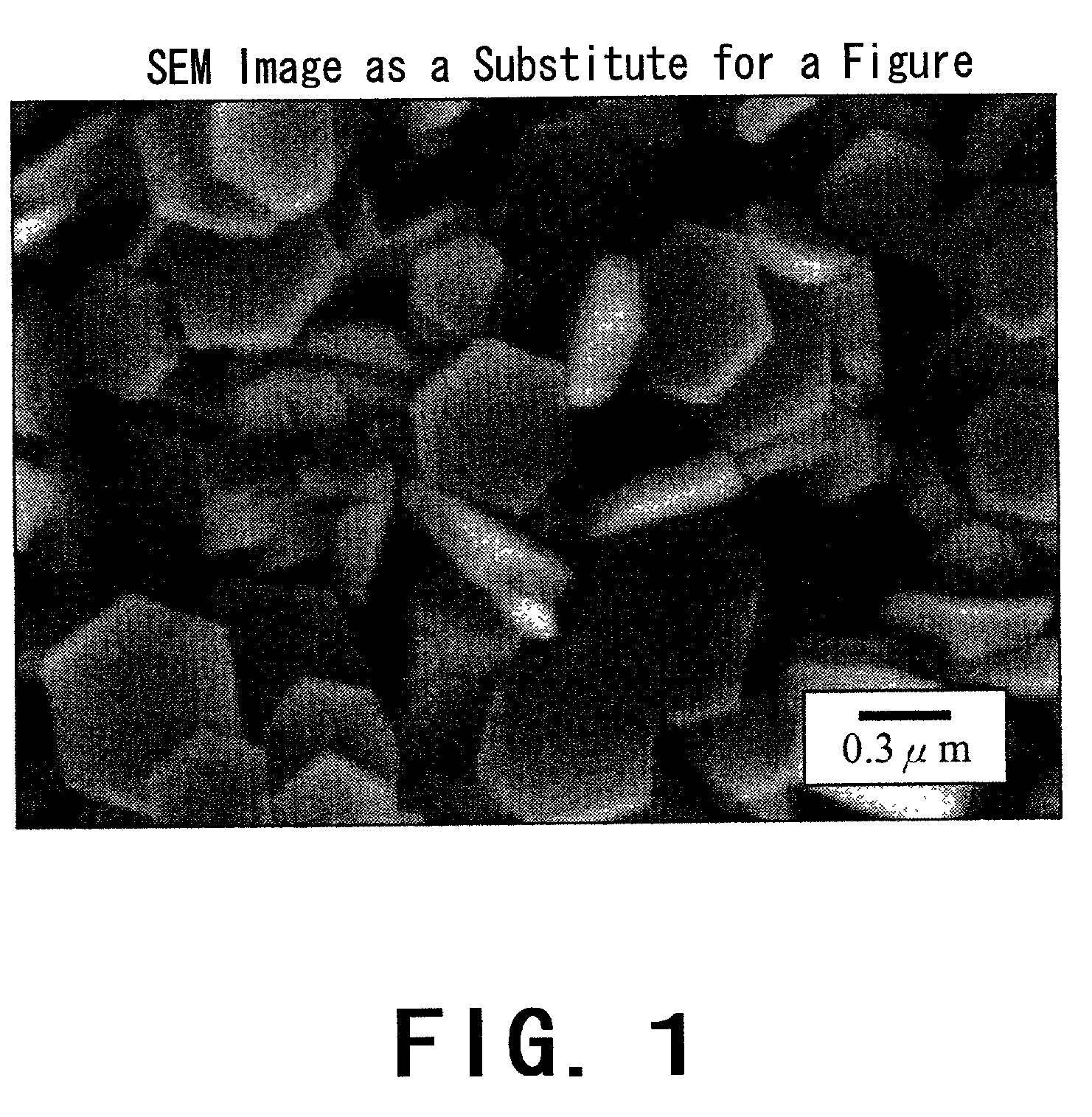

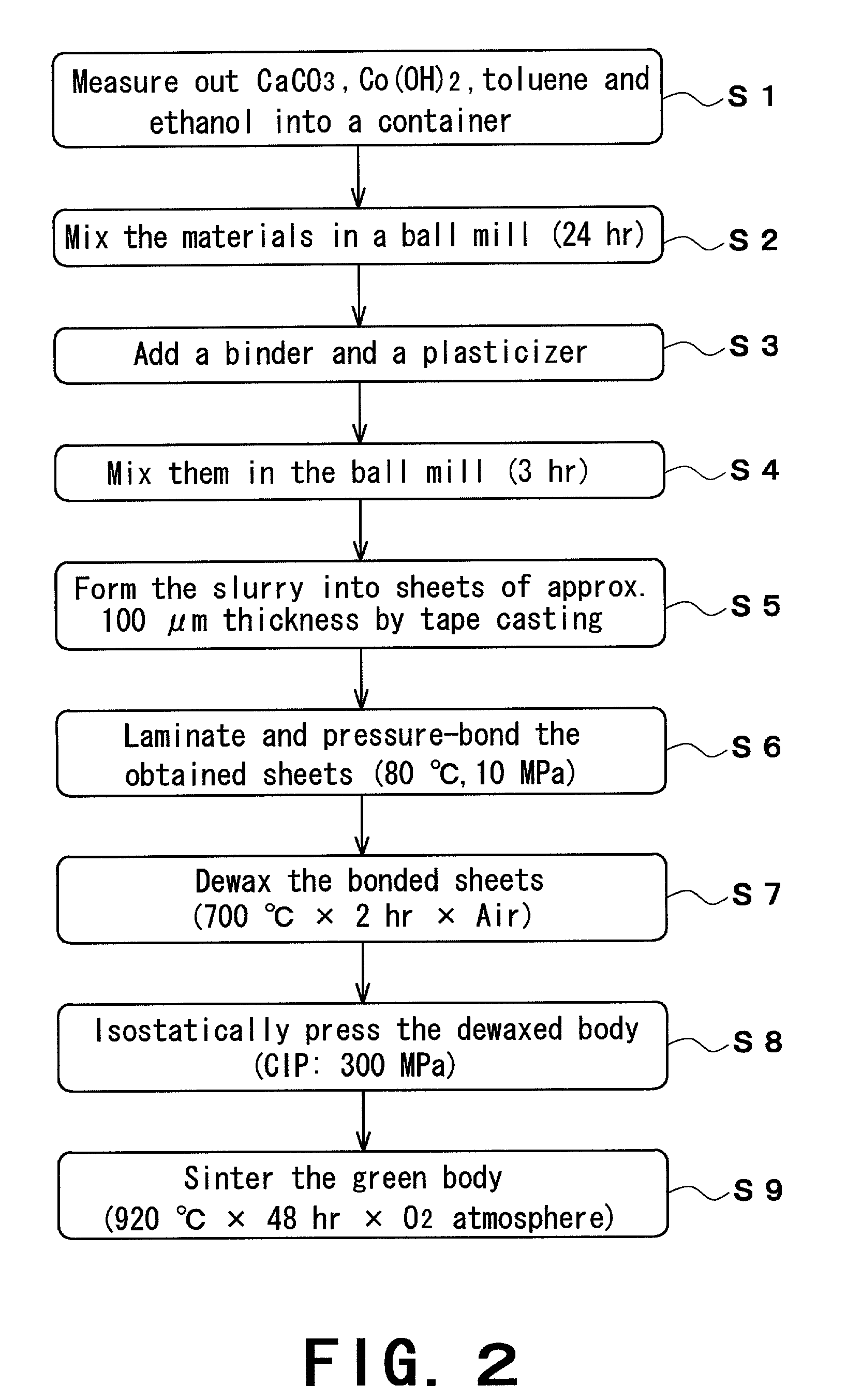

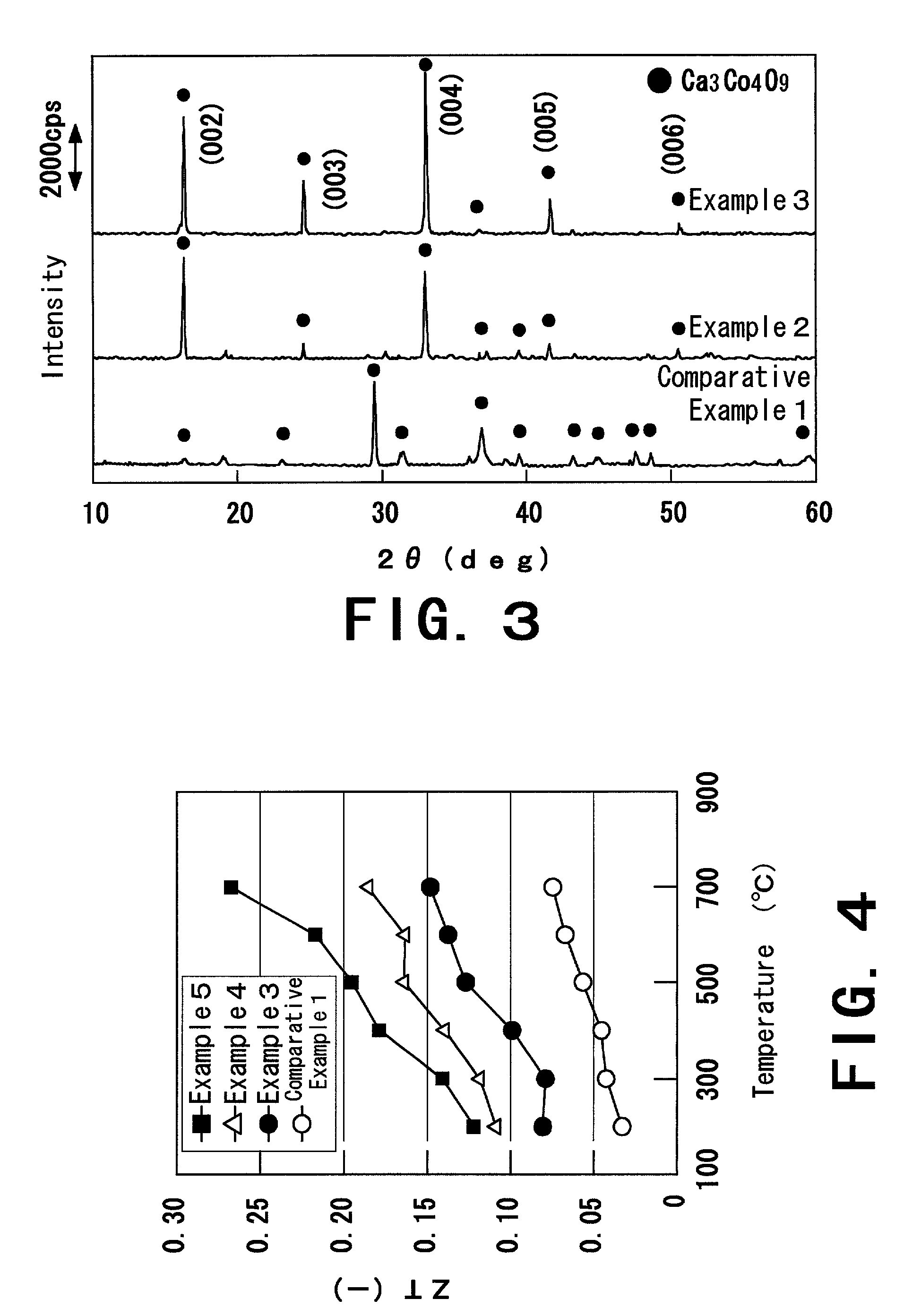

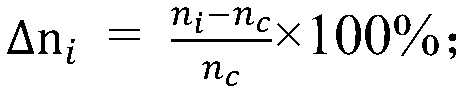

Grain oriented ceramics and a production process thereof, a platelike powder for producing the grain oriented ceramics, and a thermoelectric conversion element

InactiveUS20030013596A1Improve conductivityReasonable thicknessConductive materialRare earth metal compoundsAlkaline earth metalShell molding

Grain oriented ceramics constituted of a polycrystalline body of a layered cobaltite in which a {001}plane of each grain constituting the polycrystalline body has an average orientation degree of 50% or more by the Lotgering's method. In this case, the layered cobaltite is preferably a layered calcium cobaltite expressed by the following general formula: {(Ca1-xAx)2CoO3+alpha} (CoO2+beta)y (where A represents one or more elements selected among an alkali metal, an alkaline earth metal and Bi, 0 <=x<=0.3, 0.5 <=y <=2.0, and 0.85 <={3+alpha+(2+beta)y} / (3+2y) <=1.15). Such grain oriented ceramics are obtained by molding a mixture of the first powder constituted of a Co(OH)2 platelike powder and the second powder constituted of CaCO3 and the like such that a developed plane of the platelike powder is oriented, and by heating the green body at a predetermined temperature.

Owner:TOYOTA CENT RES & DEV LAB INC

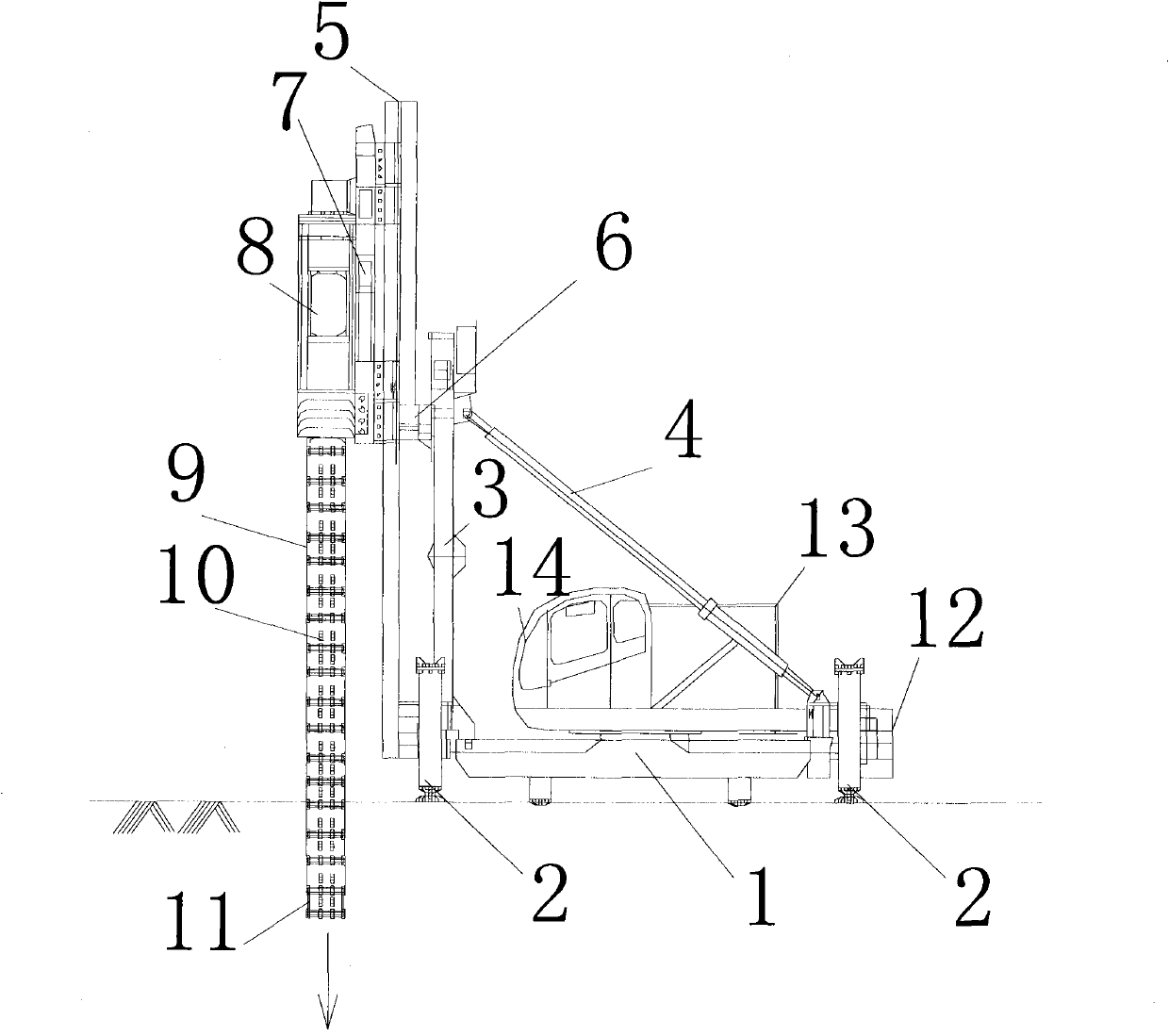

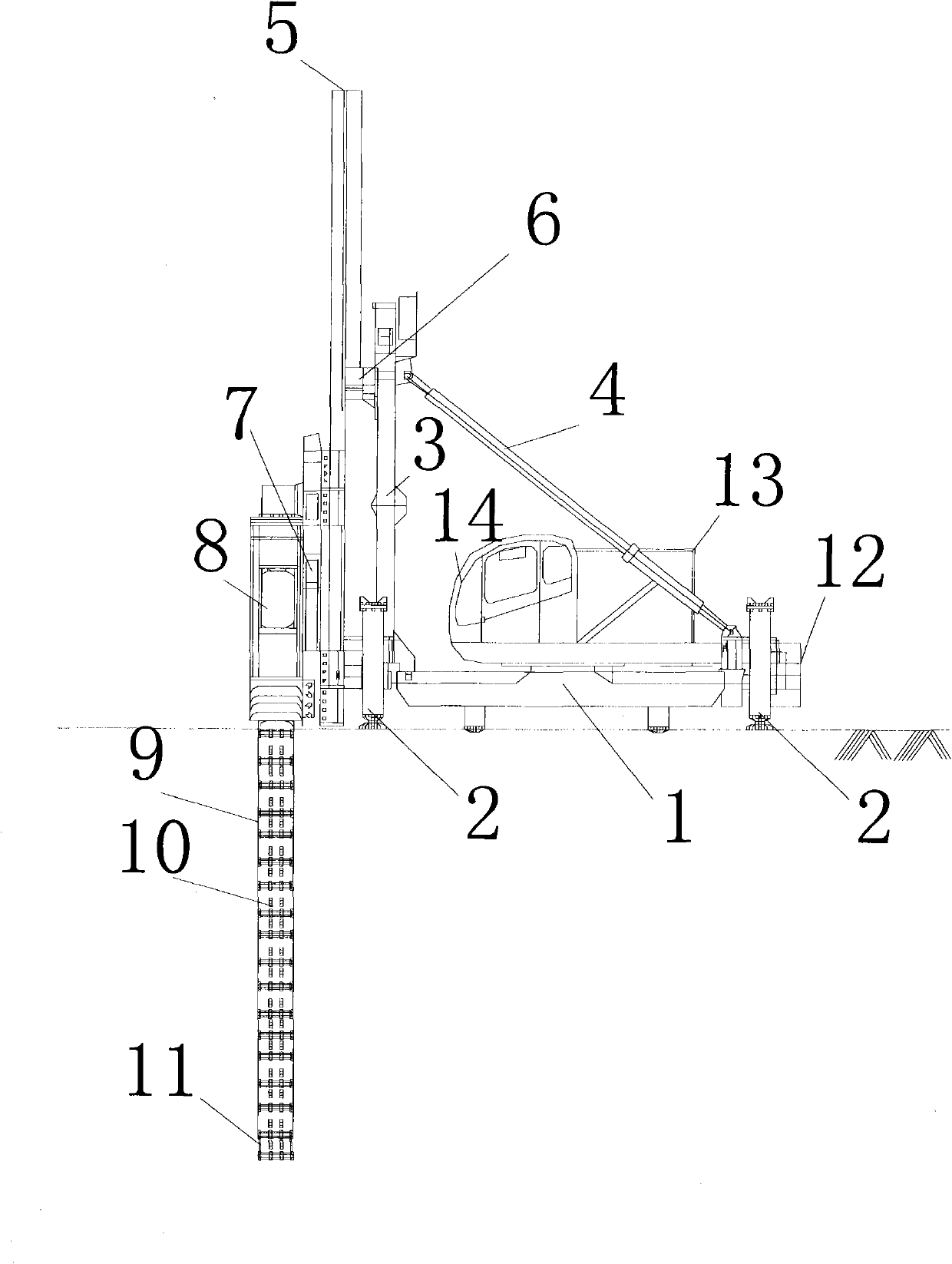

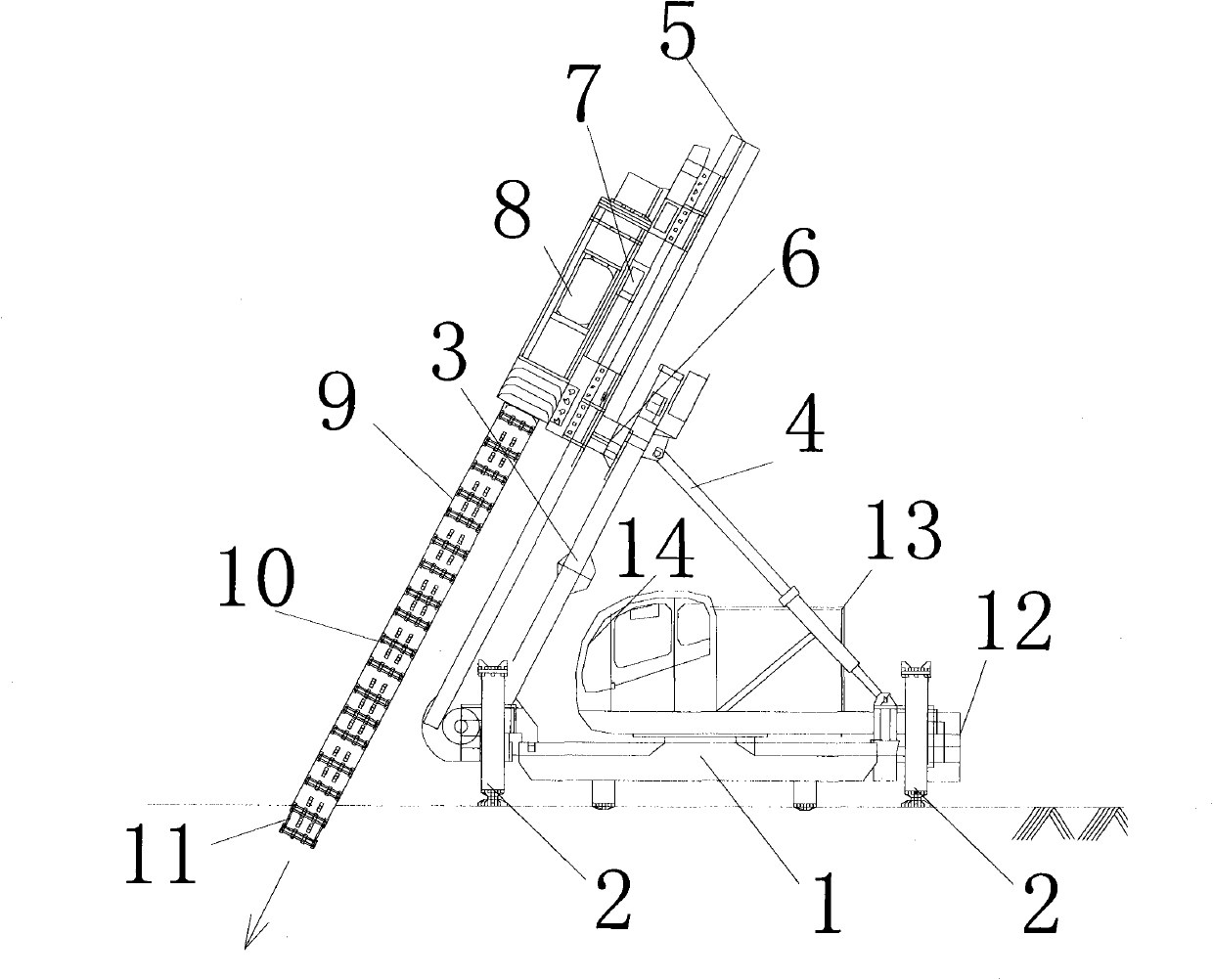

Continuous wall forming machine of underground cement soil impermeable wall

InactiveCN102021920AUniform textureTowards precisionSoil-shifting machines/dredgersAgricultural engineeringKnife blades

The invention relates to a continuous wall forming machine of an underground cement soil impermeable wall. A machine chassis and a hydraulic support form a walking travel mechanism, a frame and an oblique adjusting rod are arranged on the machine chassis, the frame is adjusted to be in a perpendicular or oblique position through the oblique adjusting rod, and a vertical guide rod and a horizontal drive cylinder are arranged on the frame. A cutter drive mechanism and a cutter combination box are connected with a cutter combination chain and a cutter head, and move up and down along the vertical guide rod through a vertical drive cylinder. The cutter combination chain surrounding the two sides of the cutter combination box moves around a position between the cutter drive mechanism and the cutter head. Soil layers are cut and agitated by blades fixed on the cutter combination chain. A non-fence impermeable wall having excellent impermeable effect is really built through the machine, and the continuous impermeable wall has the advantages of uniform texture, accurate advance direction, better impermeable effect and simple technology. The continuous wall forming machine can be used for digging downwards, cutting soil layers and building the cement soil wall in one step.

Owner:陶为

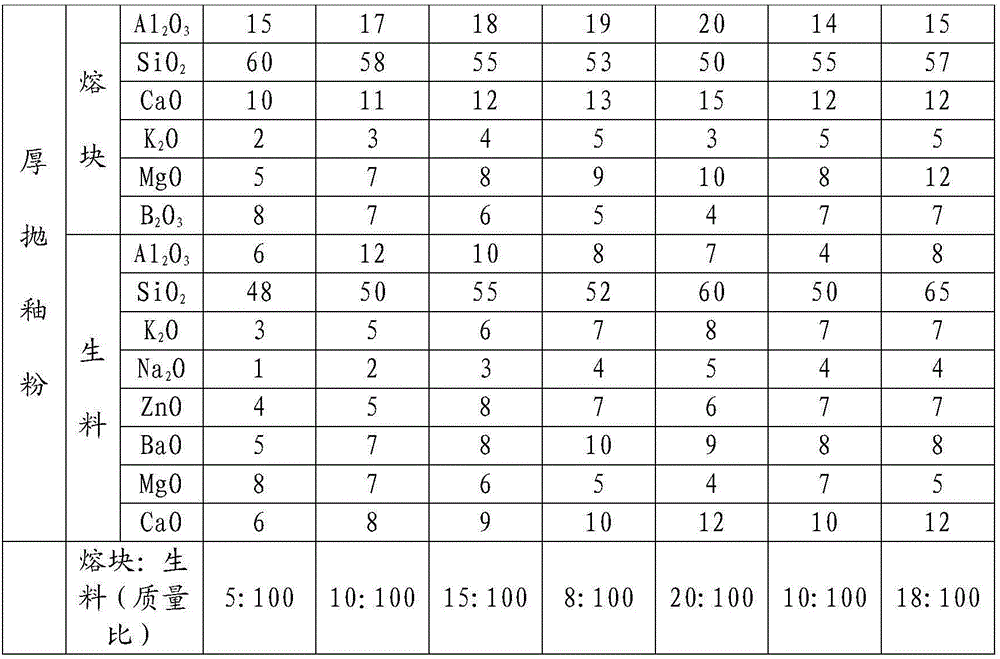

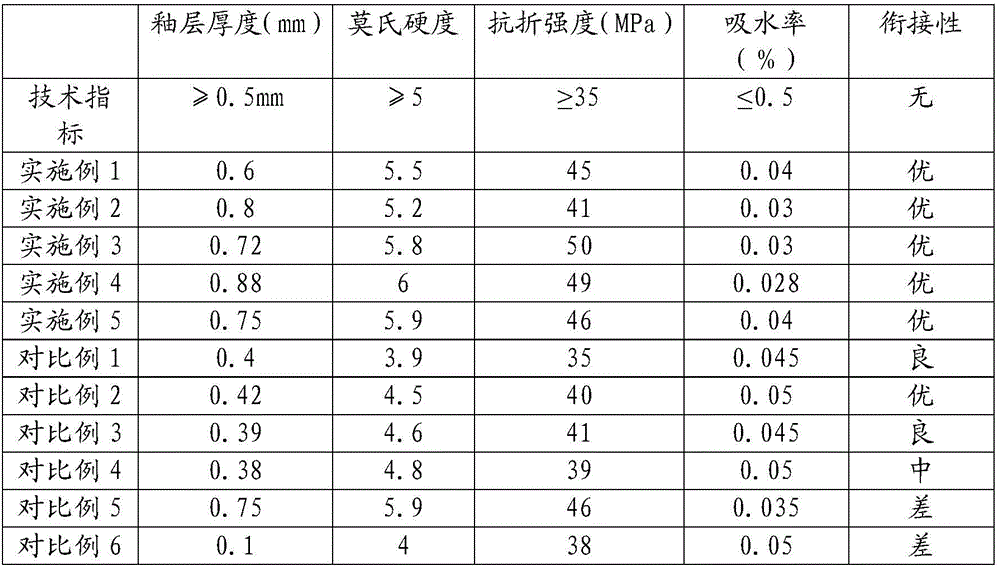

Background wall brick preparing method and background wall preparing method

ActiveCN106007800AGood melting performanceReduce high temperature viscosityCovering/liningsInkjet printingHardness

The invention provides a background wall brick preparing method. The background wall brick preparing method comprises the following steps: 1, forming a green body and drying the green body to obtain the dry green body; 2, applying ground coat enamel on the surface of the dry green body to obtain a first green brick; 3, inkjet printing the ground coat enamel of the first green brick to obtain a second green brick; 4, drying the second green brick to obtain a third green brick; 5, applying cover glaze on the inkjet-printed side of the third green brick to obtain a fourth green brick; 6, drying the fourth green brick to obtain a fifth green brick; 7, roasting the fifth green brick at high temperature to obtain a sixth green brick; 8, polishing the sixth green brick to obtain the background wall brick. The background wall brick is large in moh hardness and breaking strength and low in water absorption. The invention further provides a background wall preparing method, and the background wall is good in link and attractive and elegant in appearance.

Owner:HEYUAN DONGYUAN EAGLE CERAMICS CO LTD +2

Thermal erosion test device and method for testing thermal protection materials of solid propellant thrusters

ActiveUS20080192799A1Accurate representationSave levelThermometer detailsEngine manufactureCombustion chamberEngineering

The invention relates to a thermal erosion test device for testing thermal protection materials for use in a solid propellant thruster. The device comprises a support for holding a plate made of the thermal protection material for testing so that its faces a face of a block of solid propellant, the space between the plate and the face of the propellant block defining a combustion chamber of substantially rectangular shape, said chamber extending along said plate and opening out into a nozzle.

Owner:ARIANEGRP SAS +1

Production method of heating type hollow spherical-shape continuous casting protecting slag

The invention relates to a method for producing heat-radiate hollow ball casting protective slag. Wherein, it uses grammite, graphite, fluor, blast-furnace cement and ash whose particles are smaller than 20mm, to be mixed and put into furnace to be fused and sintered; feeds the fused material into Raymond machine to be grinded into the powder smaller than 74 mum; feeds powder into ball grinder, adds graphite carbon, adhesive and water, to be grinded into particles smaller than 45 mum; mixing into slurry; in the drying tower, uses high-pressure pump and atomizing nozzle to prepare slurry into final product. The invention can control the fusion speed, with stable arc shapes of liquid slag layer and casting blank. And the inventive casting blank has high quality.

Owner:彭绍权

Large-size low-loss optical fiber preform and manufacturing method thereof

ActiveCN109553295AIncrease deposition rateReasonable thicknessGlass making apparatusFiberUltrasound attenuation

The invention relates to a large-size low-loss optical fiber preform and a manufacturing method thereof. The manufacturing method comprises the following steps: preparing an optical fiber core rod byusing a VAD process, wherein the optical fiber core rod comprises a core layer and an inner cladding layer from interior to exterior; depositing a barrier layer loose body at the outer part of the optical fiber core rod by a OVD process, and then conducting sintering treatment, so as to obtain a synthesized core rod; and combining the synthesized core rod and a continuous fusion sleeve by a RIC process, so as to form the large-size low-loss optical fiber preform. The prepared large-size low-loss optical fiber preform has a diameter up to 205 mm, the fiber length of a single preform can reach 3200 km, the attenuation of an obtained optical fiber at 1310 nm is 0.316 dB / km or less, the attenuation coefficient at 1383 nm is 0.278 dB / km or less, the attenuation coefficient at a wavelength of 1550 nm is 0.174 dB / km or less, the mode field diameter at a wavelength of 1310 nm is 8.9-9.3 [mu]m, and the optical cable cut-off wavelength of the optical fiber is 1270 nm or less.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD +1

Tube-type glass bottle bottom firing process and bottle bottom firing device thereof

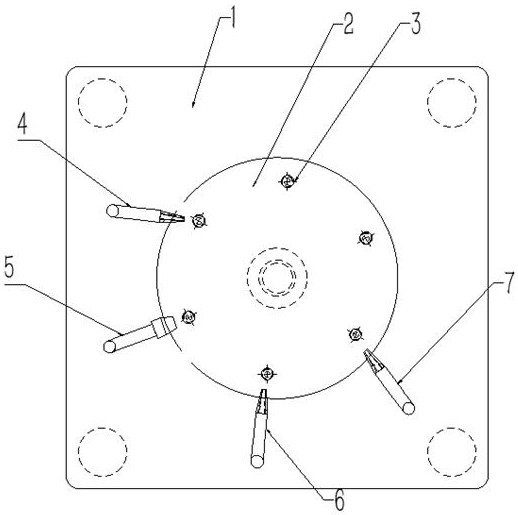

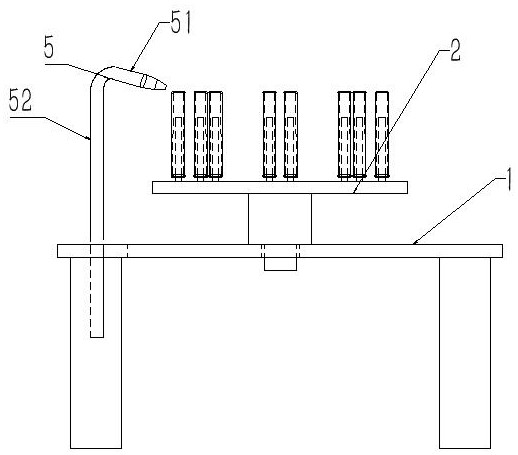

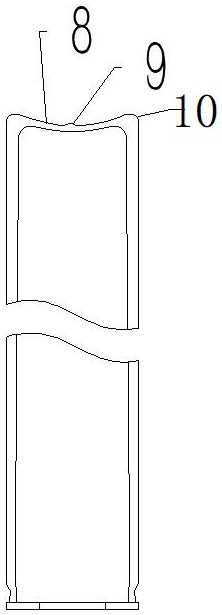

ActiveCN111606556AReasonable thicknessImprove smoothnessGlass reforming apparatusGlass severing apparatusEngineeringHeat conservation

The invention relates to a tube-type glass bottle bottom firing process and a bottle bottom firing device thereof. The tube-type glass bottle bottom firing process comprises the following steps: (1) performing bottom cutting; (2) preparing a bottom; (3) molding and polishing the bottle bottom; (4) heat preservation and annealing; (5) naturally cooling; and (6) cooling and unloading bottles. In thestep (2), the fire power of flame is reduced, the flame obliquely faces a glass bottle from top to bottom to fire the bottle bottom and blows to the center of the bottle bottom from a shoulder peak formed by connecting the bottle body and the bottle bottom, so that a fillet structure is formed at the shoulder peak connecting the bottle body and the bottle bottom, and a concave arc surface is formed from the inner edge of the shoulder peak to the center of the bottle bottom. Therefore, contact between the bottle bottom and the surface of an object is avoided, and damage caused by collision ofthe contact surface is effectively reduced.

Owner:淅川县恒运制瓶有限公司

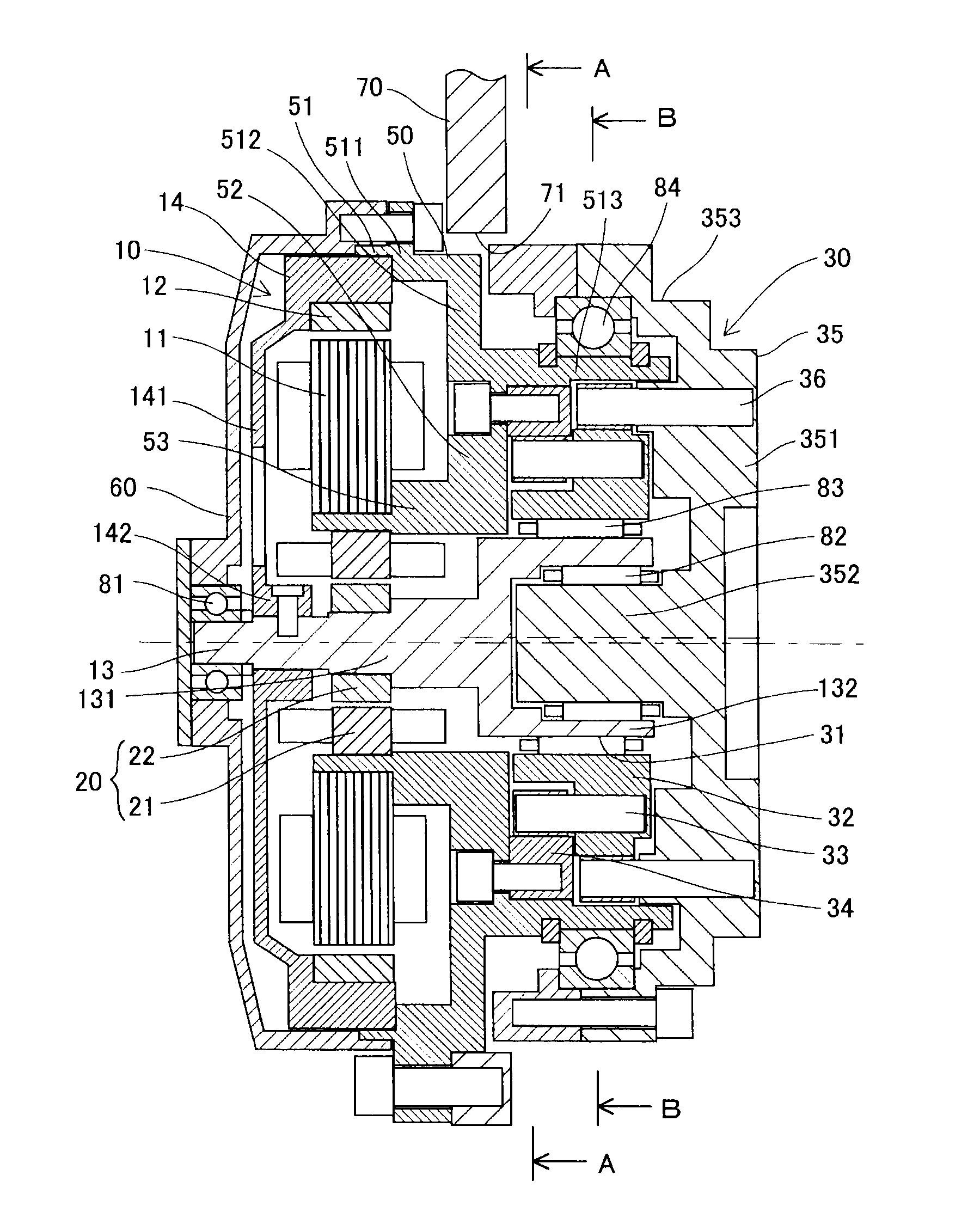

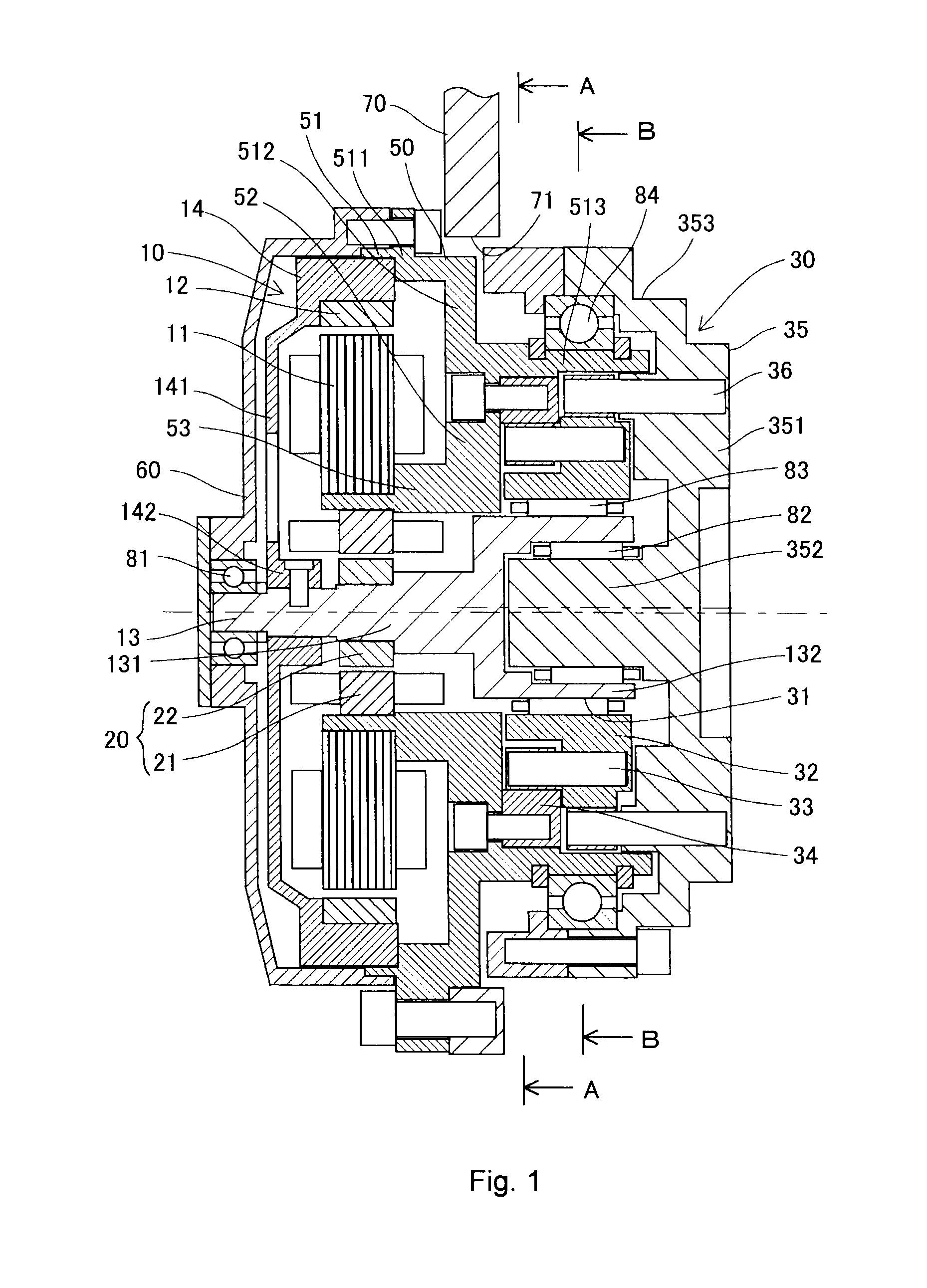

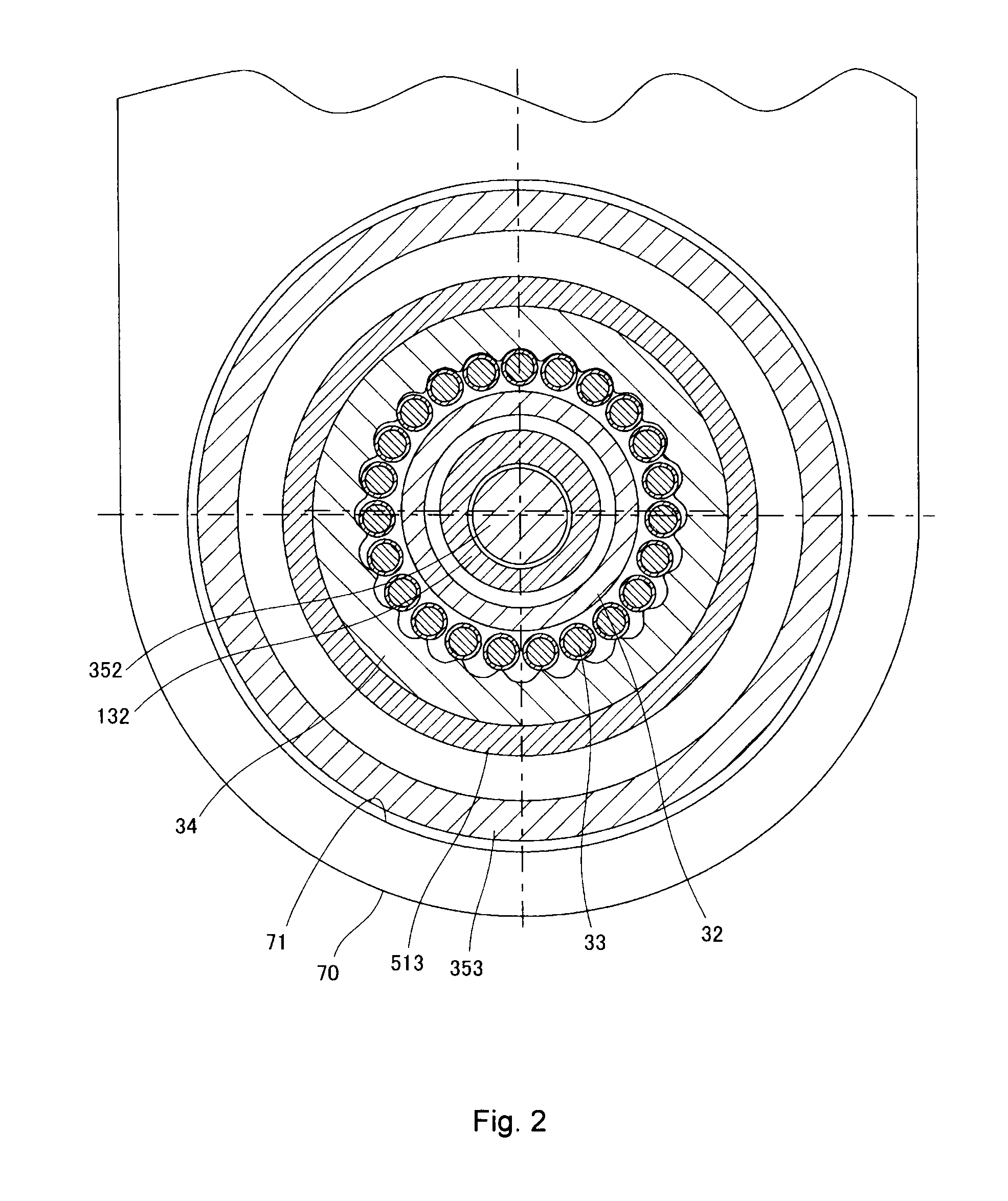

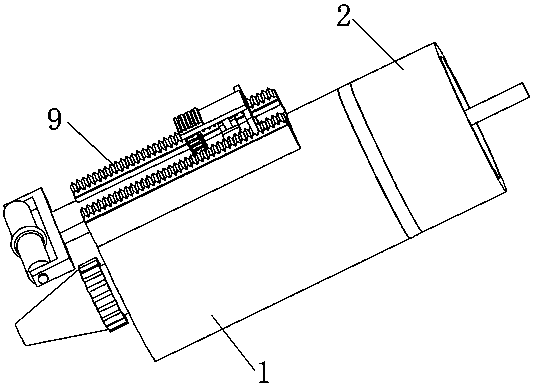

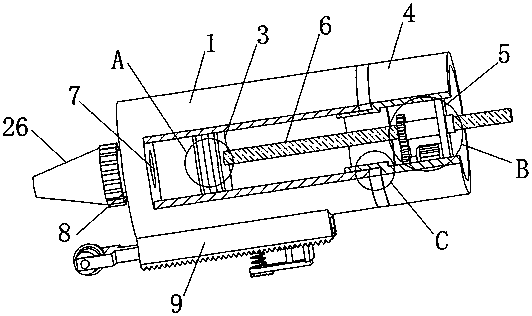

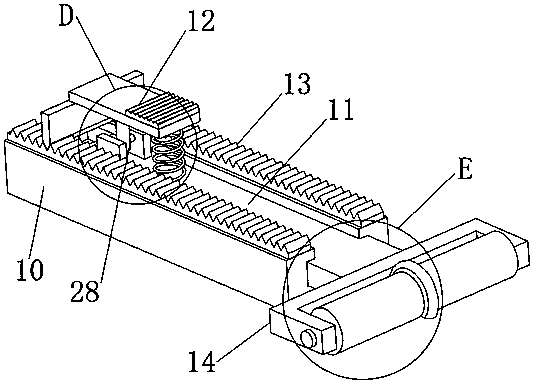

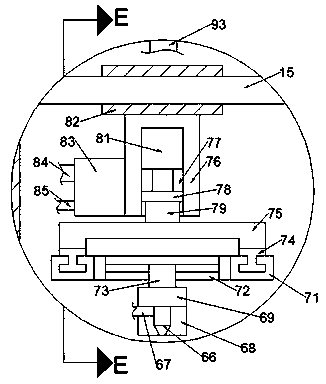

Electric rotary actuator

InactiveUS20110221293A1Improve cooling effectReduce axial sizeMechanical energy handlingCooling/ventillation arrangementInterior spaceReducer

A housing is provided with a partition wall portion that partitions an inner space of the housing into an electric motor accommodating space and a speed reducer accommodating space. The partition wall portion fixes a gear that constitutes a speed reducer. In addition, the partition wall portion has a housing boss portion, and an inner stator is fixed to the housing boss portion. Thus, heat generated by the inner stator is dissipated to the outside through the housing boss portion and the partition wall portion.

Owner:JTEKT CORP

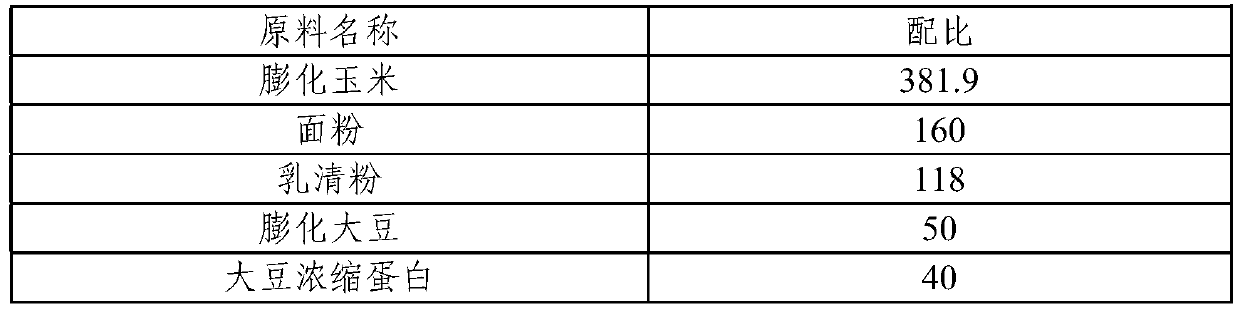

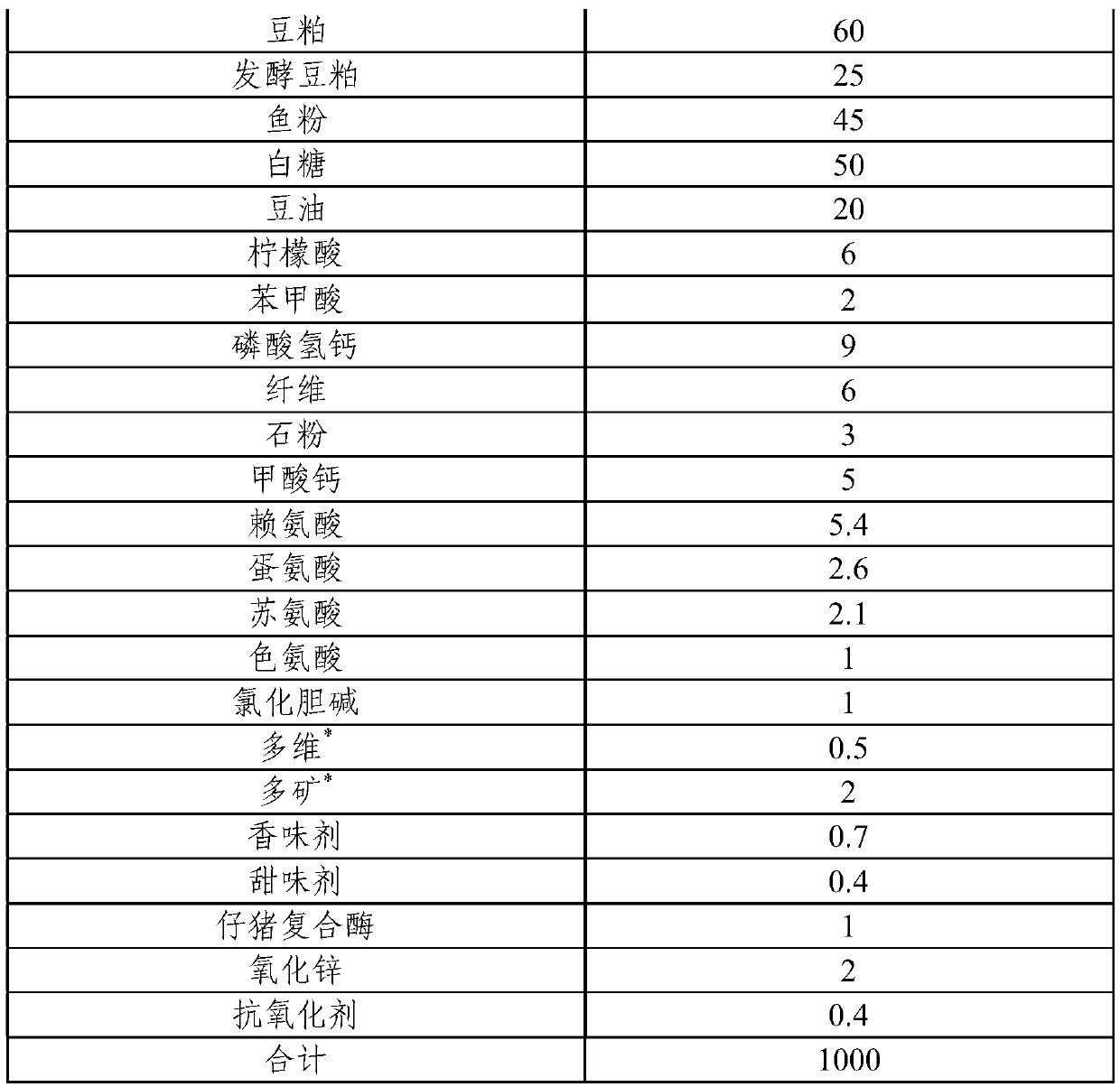

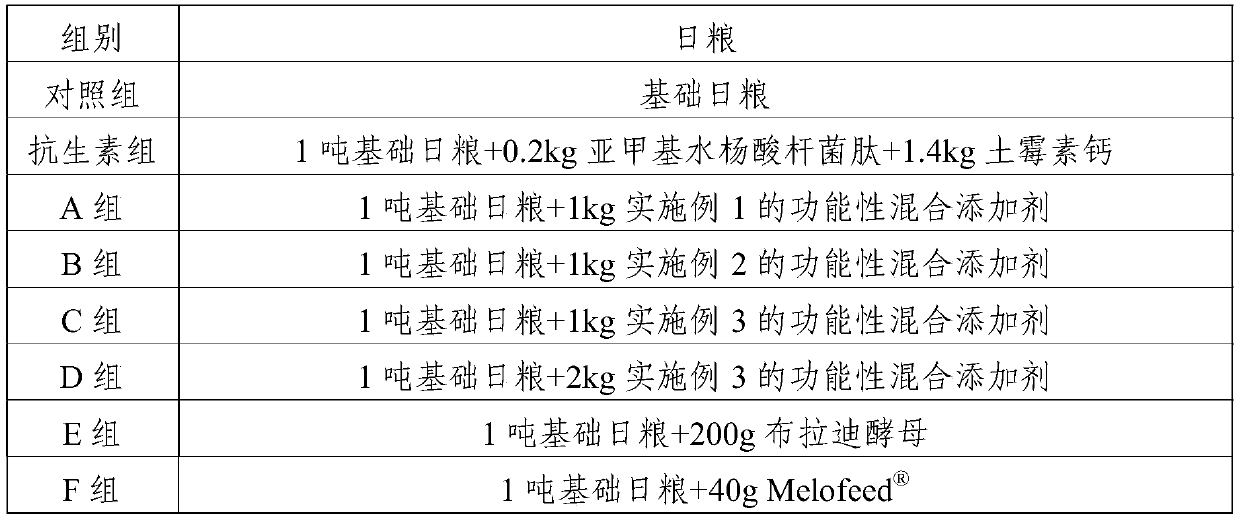

Functional mixed additive and application thereof

ActiveCN110326708APromote growth and developmentMorphological integrityFood processingDigestive systemBiotechnologyWeaning

The invention provides a functional mixed additive and application thereof. The functional mixed additive comprises Brady yeast, and the functional mixed additive can obviously improve piglet diarrhea, promote piglet growth and improve piglet survival rate. Under the condition of weaning or other stress of piglets, feed added with the functional mixed additive can effectively protect intestinal tracts, promote the integrity of epithelial cell morphology and structure, good growth of microvilli, tight epithelial connection and reasonable thickness of a mucus layer, improve the digestion and absorption of energy and nutrients of the piglets, and further promote the growth and development of the piglets. The functional mixed additive can effectively replace antibiotics, and the problems of influence of the antibiotics on ecological environment and drug resistance are solved.

Owner:凯恩格生物科技(宜昌)有限公司

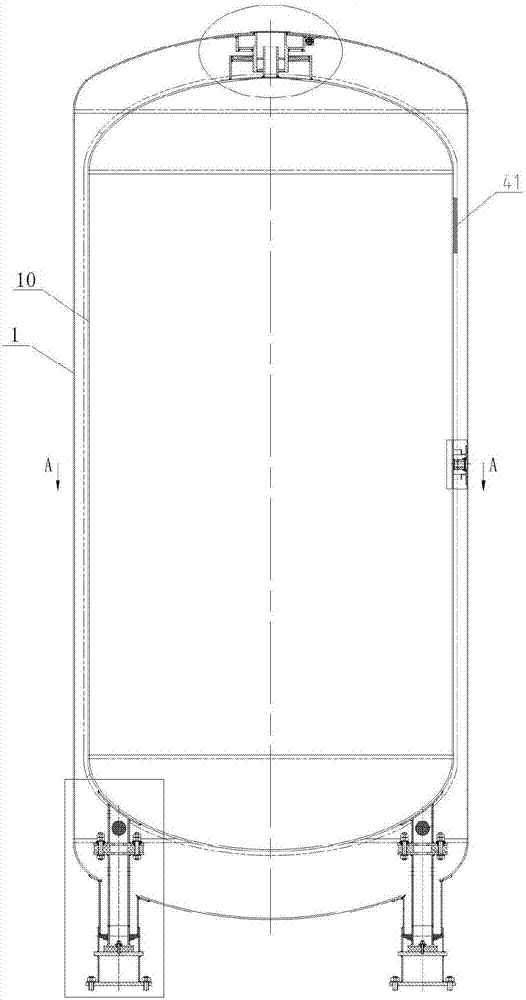

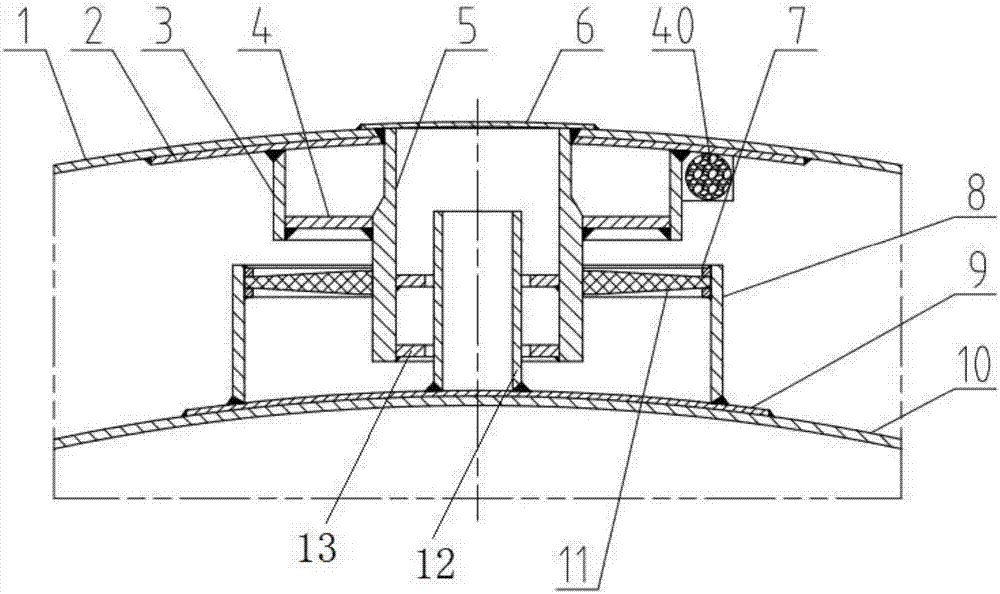

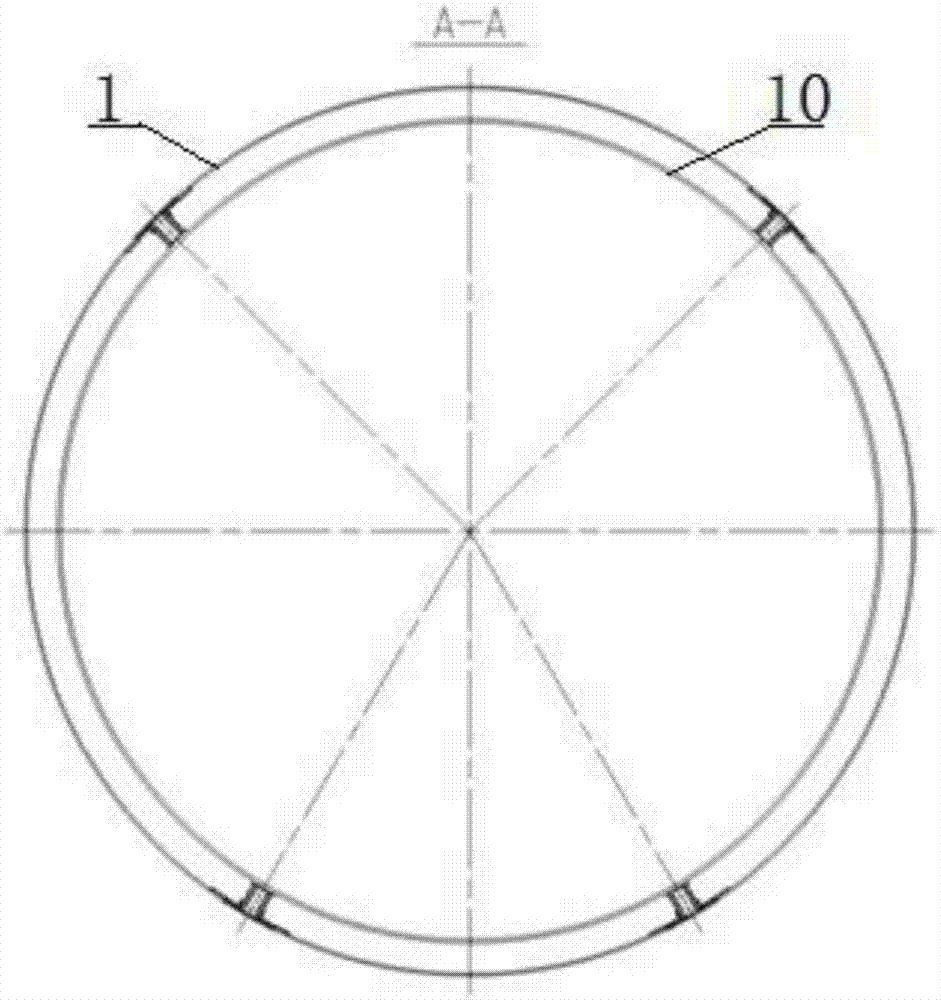

Vertical low-temperature container

ActiveCN107339600AMeet the requirements of transportation conditionsMeet the requirements of working state stabilityVessel wallsContainer filling methodsEngineeringMechanical engineering

The invention relates to a vertical low-temperature container. The technical problem that in the prior art, when a vertical low-temperature container stores a medium with the temperature reaching -196 DEG C or lower, the heat insulating property of a supporting structure of the vertical low-temperature container is severely decreased is mainly solved. The vertical low-temperature container comprises a liner and a shell. An end socket axial support is arranged between the outer side of the top of the liner and the inner side of the top of the shell. A steel pipe glass steel support is arranged between the outer side of the bottom of the liner and the outer side of the bottom of the shell. According to the technical scheme, the problem is well solved, and the vertical low-temperature container can be used for storing the low-temperature medium with the temperature being -196 DEG C or lower.

Owner:ZHANGJIAGANG FURUI HYDROGEN ENERGY EQUIP CO LTD

Thermal conductive adhesive spreading device for CPU hardware

PendingCN108580196AUniform thicknessReasonable thicknessLiquid surface applicatorsCoatingsThermal adhesiveEngineering

The invention discloses a thermal conductive adhesive spreading device for CPU hardware. The thermal conductive adhesive spreading device comprises a holding tank of which one end is connected to an extrusion mechanism, and the extrusion mechanism comprises an extrusion piston, a mounting barrel, a fixing plate and a driving device; the outer side of the extrusion piston is in sliding fit to the inner wall of the holding tank, and one side of the extrusion piston is fixed to the output end of the driving device fixed to the fixing plate; the fixing plate is fixed to the inner wall of the mounting barrel, and the outer side of one end of the mounting barrel is provided with external threads; and the end, close to the mounting barrel, of the holding tank is provided with internal threads, and the holding tank is movably connected to the mounting barrel through threads. According to the thermal conductive adhesive spreading device for the CPU hardware, thermal conductive adhesive can be spread on the surface of a CPU heat generation end, and the thickness of the thermal conductive adhesive is rational; the thicknesses of different areas are uniform, and hand fatigue caused by manual spreading by workers is avoided; and the thermal conductivity of the thermal conductive adhesive for a CPU is improved.

Owner:苏州柯谱瑞欣通信科技有限公司

A kind of trachea support and its application

The invention relates to a trachea support and its application. The trachea stent is provided with support rings and support links, each of the support rings is C-shaped, and each support ring is connected in series by support links, so that each support ring and support links are fixed into one. The present invention also provides a tissue engineered trachea, which is made by wrapping the chondrocyte-gelatin / polycaprolactone electrospun membrane composite on the outside of the trachea stent. Using the tracheal stent or tissue engineered trachea of the present invention, the tracheal stenosis can be repaired by the extratracheal support suspension method, and a new C-shaped cartilage ring can be formed after implantation, finally making it have the potential to grow.

Owner:SHANGHAI CHILDRENS MEDICAL CENT AFFILIATED TO SHANGHAI JIAOTONG UNIV SCHOOL OF MEDICINE

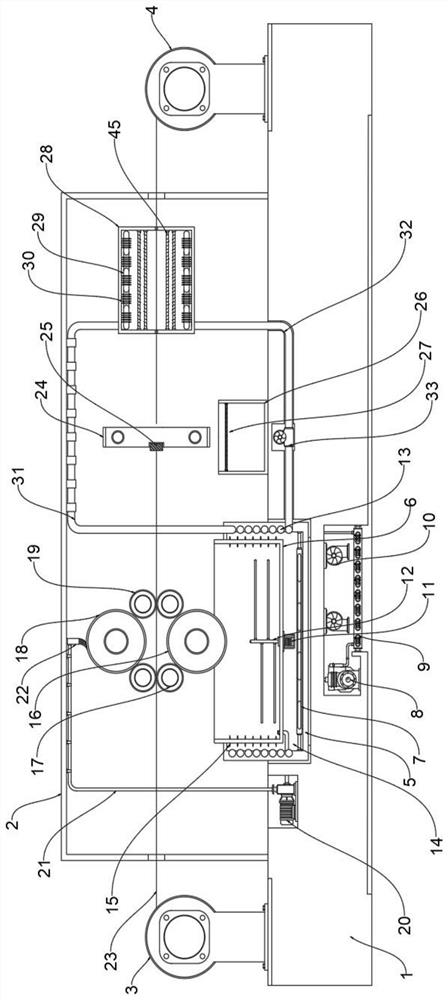

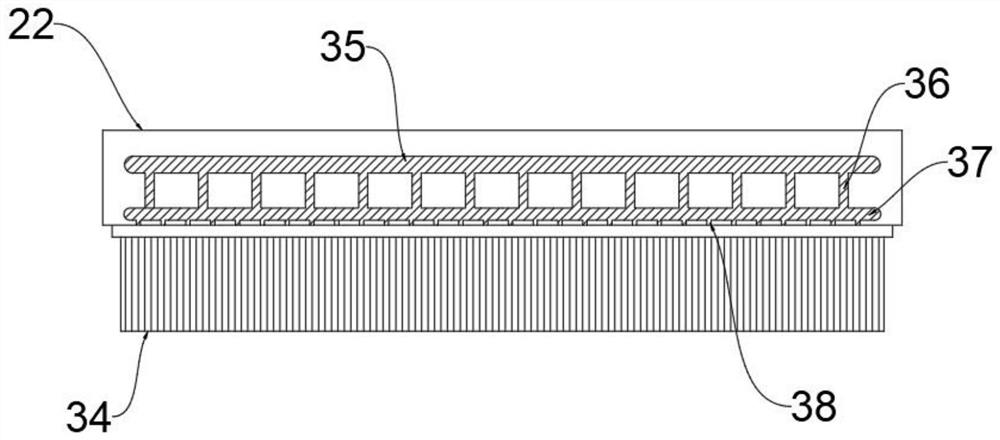

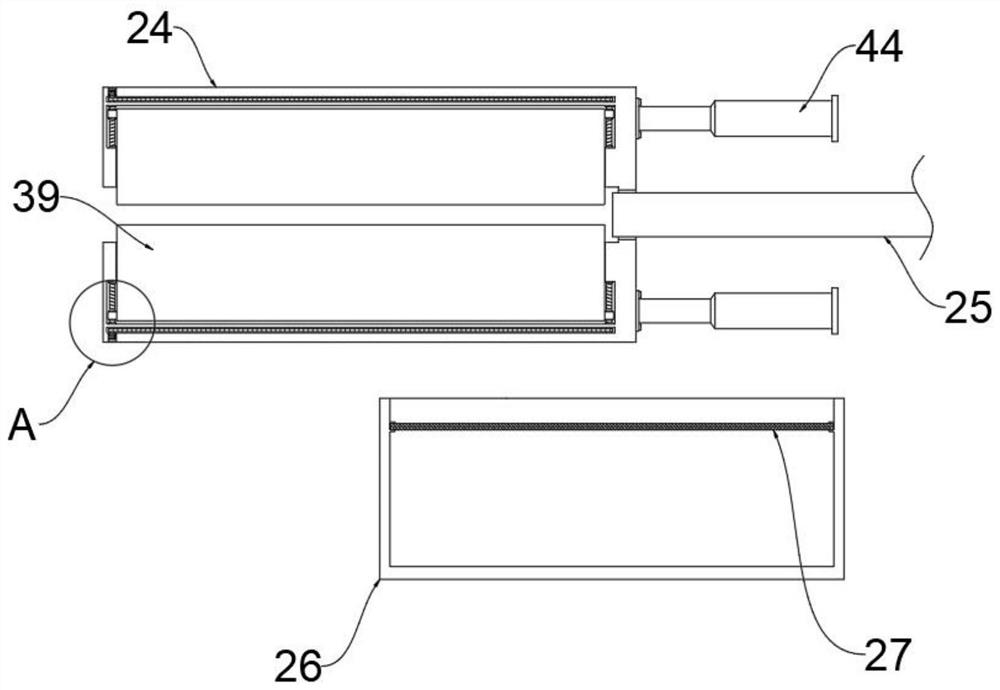

AI chip heat dissipation detection equipment based on different silicone grease smearing modes

ActiveCN111599725AExcellent wayExcellent thicknessSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingEngineeringSilicone grease

The invention discloses AI chip heat dissipation detection equipment based on different silicone grease smearing modes, which comprises a working box, wherein a working cavity is formed in the workingbox, and a slot block inlet is formed in a leftward opening in the left side of the working cavity. According to the invention, a chip and a radiator are placed in a main chip groove by using an adding mechanism, and a smearing mechanism can smear silicone grease with different modes or thicknesses on the upper end surface of the chip. In addition, the equipment is further provided with a wipingmechanism, that is, the smeared silicone grease can be wiped clean, and the upper end surface of the chip can be re-smeared, so that the heat dissipation performance of the chip under the condition ofanother smearing shape or thickness can be tested again, and the optimal silicone grease smearing mode or thickness can be obtained finally. The reasonable silicone grease smearing mode and thicknesscan be obtained, and the problems of insufficient heat dissipation capacity, oil seepage and the like caused by excessive or insufficient silicone grease smearing are solved.

Owner:北京旺达世嘉科技发展有限公司

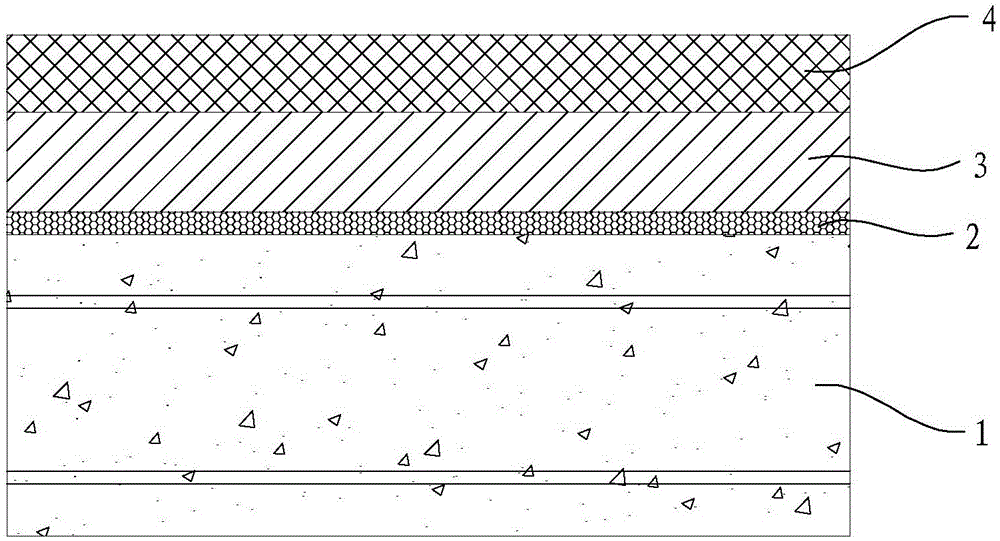

Prefabricated reinforced concrete simply-supported girder bridge deck pavement and maintenance structure and construction method

ActiveCN105113420AReasonable thicknessIncreasing the thicknessBridge structural detailsBridge erection/assemblyAdhesiveBridge deck

The invention discloses a prefabricated reinforced concrete simply-supported girder bridge deck pavement and maintenance structure. The structure comprises a cement concrete pavement layer with single-layer reinforcing steel bars or double-layer reinforcing steel bars, and the cement concrete pavement layer is coated with a bond waterproof layer with ester adhesives as primer, and a colloidal concrete pavement layer formed by blending a curing agent, polyurethane and aggregate is laid on the bond waterproof layer; and an anti-sliding layer is arranged on the colloidal concrete pavement layer. The invention further discloses a construction method of the prefabricated reinforced concrete simply-supported girder bridge deck pavement and maintenance structure. Compared with the prior art, the structure has the beneficial effects that a novel material is adopted, the thicknesses of all structural layers are more reasonable, the performance of the structural layers is more prominent, the bonding strength between the upper pavement layer and the lower pavement layer is good, construction is convenient, and the maintenance cost is low.

Owner:NINGBO ROABY TECH INDAL GROUP

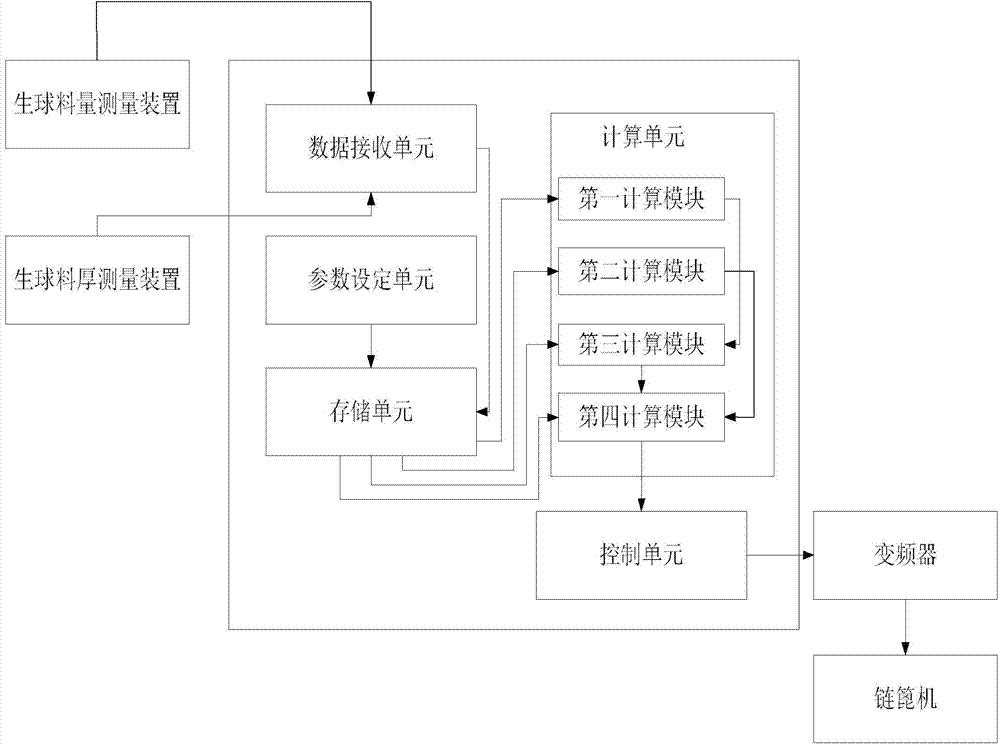

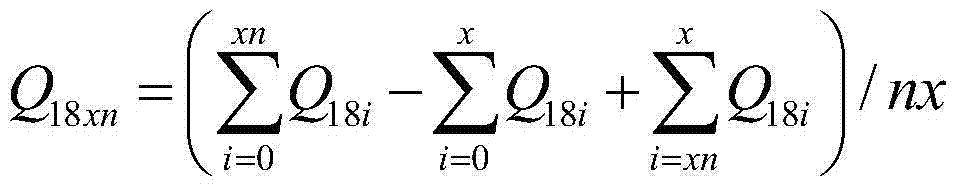

Machine speed control system of chain grate

The invention relates to the technical field of automatic control, in particular to a machine speed control system of a chain grate. The machine speed control system of the chain grate comprises a green ball material amount measuring device, a green ball material thickness measuring device, a frequency converter and a control device, wherein the green ball material amount measuring device, the frequency converter and the green ball material thickness measuring device are respectively connected with the control device, the green ball material thickness measuring device measures at least three green ball material thickness measuring values instantaneously, and the frequency converter is connected with the chain grate through a driving motor. The machine speed control system of the chain grate can achieve control over the machine speed of the chain grate, enables the thickness of a material layer on the chain grate to be reasonable, prevents the phenomena of burning loss of grate bed equipment and resource waste of a wind short circuit, guarantees the quality of ball drying, and prevents the problems of ring forming, ball breaking and caking inside a kiln, red material generation of an annular cooler and the like.

Owner:SHOUGANG CORPORATION

Preparation method of drainage agent for refining in three phases

ActiveCN100581683CReasonable particle size compositionImprove liquidityMelt-holding vesselsGranularityRefractory

The invention relates to a flow guiding agent used for a three-step refining and a preparation method thereof. The flow guiding agent mainly consists of the components with the following weight percentages: 23 to 35 percent of Cr2O3, 13 to 45 percent of SiO2 and 3 to 15 percent of Zr2O3. The forming of the granularity of the flow guiding agent is reasonable and the flowing capability is good; the refractory degree is not less than 1780 DEG C and agglomeration can be resisted; the capability of steel liquid penetration resisting is strong and the specific gravity is high; a proper thickness of an agglomeration layer can be formed and the self-opening rate of a steel bundle can be effectively enhanced; the component composing is reasonable and impurities brought into a casting-start process can be avoided. The invention is suitable for the manufacturing of high clean steels.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

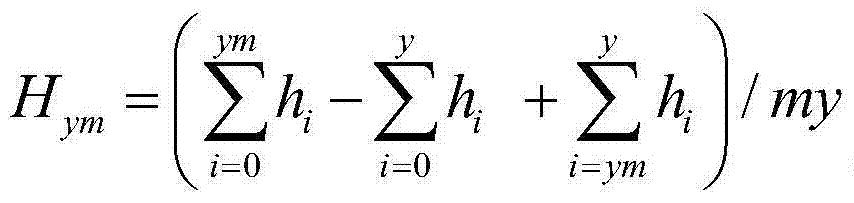

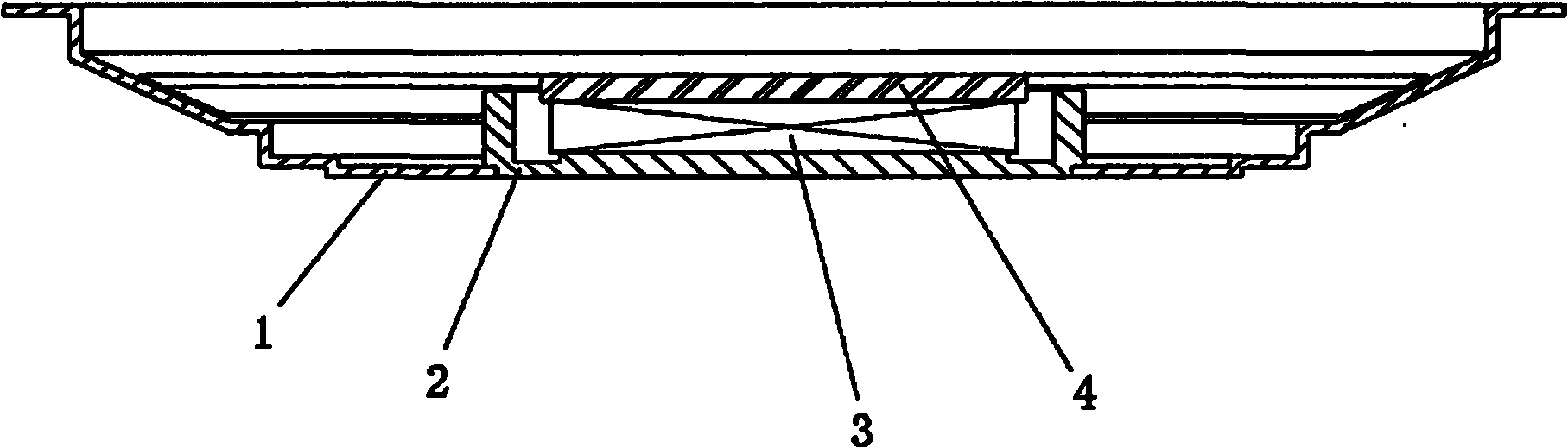

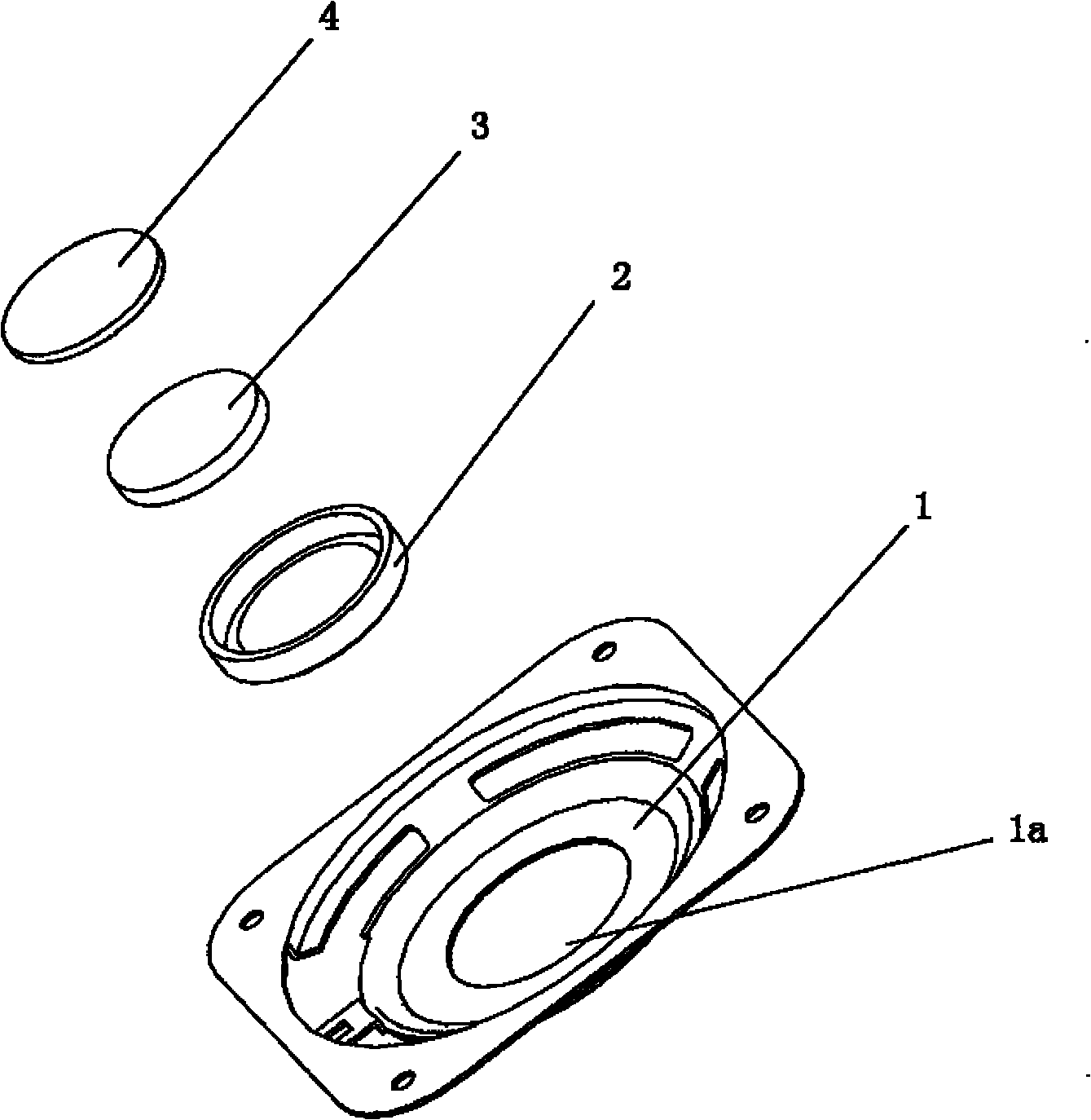

Thin type speaker magnetic circuit

InactiveCN101867857ALower the altitudeImprove reliabilityElectrical transducersMagnetic polesLoudspeaker

The invention relates to a thin type speaker magnetic circuit. According to the technical scheme provided by the invention, the thin type speaker magnetic circuit comprises a basin frame, a U-shaped magnetic yoke, a magnet and a magnetic pole core, wherein the magnet and the magnetic core are arranged inside the U-shaped magnetic yoke, the lower surface of the magnet is tightly combined with the inner surface of the bottom of the U-shaped magnetic yoke, the upper surface of the magnet is tightly combined with the magnetic pole core, and a certain magnetic gap is reserved between the outer walls of the magnet and the magnetic pole core and the inner wall of the U-shaped magnetic yoke. The thin type speaker magnetic circuit is characterized in that a center hole is arranged on the center of the bottom of the basin frame, the U-shaped magnetic yoke is arranged in the center hole, and the bottom surface of the U-shaped magnetic yoke and the bottom surface of the basin frame are positioned on the same plane. The invention has skillful and reasonable structure and effectively reduces the total height of the speaker magnetic circuit without reducing the magnetic flux and the BL value, and overlarge heat energy cannot be caused by cutting magnetic lines of force by a voice coil in an alternating magnetic field so as to ensure the acoustic performance and the reliability of the speaker product.

Owner:WUXI JIEFU ELECTROACOUSTIC

Gluing device for protective film production

ActiveCN112974114AEnsure the uniformity of glue coatingImprove overall flexibilityPretreated surfacesCoatingsEngineeringProduction quality

The invention discloses a gluing device for protective film production, relates to the technical field of protective film production, and aims to solve the problem that the production quality of a protective film is affected due to a relatively single internal gluing structure of an existing gluing device. A shell is fixedly arranged at the upper end of a base, a protective film is arranged between an unwinding roller and a winding roller, a temperature adjusting box is arranged in the middle of the upper end of the base, a heat exchange cavity is formed in the temperature adjusting box, a condenser is fixedly arranged at the bottom of the heat exchange cavity, a glue storage box is arranged at the upper end of the condenser, a first heat exchange pipe is fixedly arranged on the inner wall of the temperature adjusting box, first glue delivery rollers are installed on the two sides of the upper end of a first glue suction roller, a second glue suction roller is installed above the position between second glue delivery rollers, a gluing mechanism is installed at the upper end of the second glue suction roller, a trowelling mechanism is installed in the middle of the interior of the shell, and a drying device is installed on one side of the trowelling mechanism.

Owner:东莞市金恒晟新材料科技有限公司

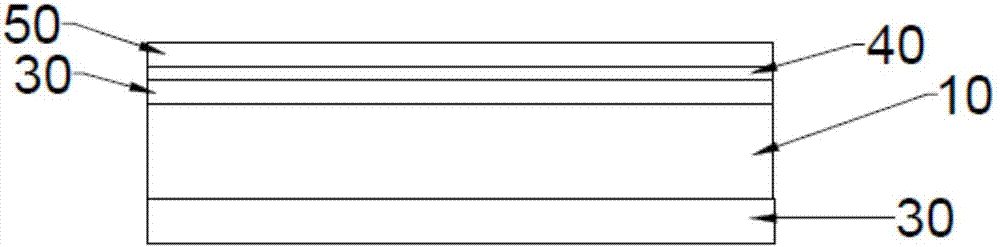

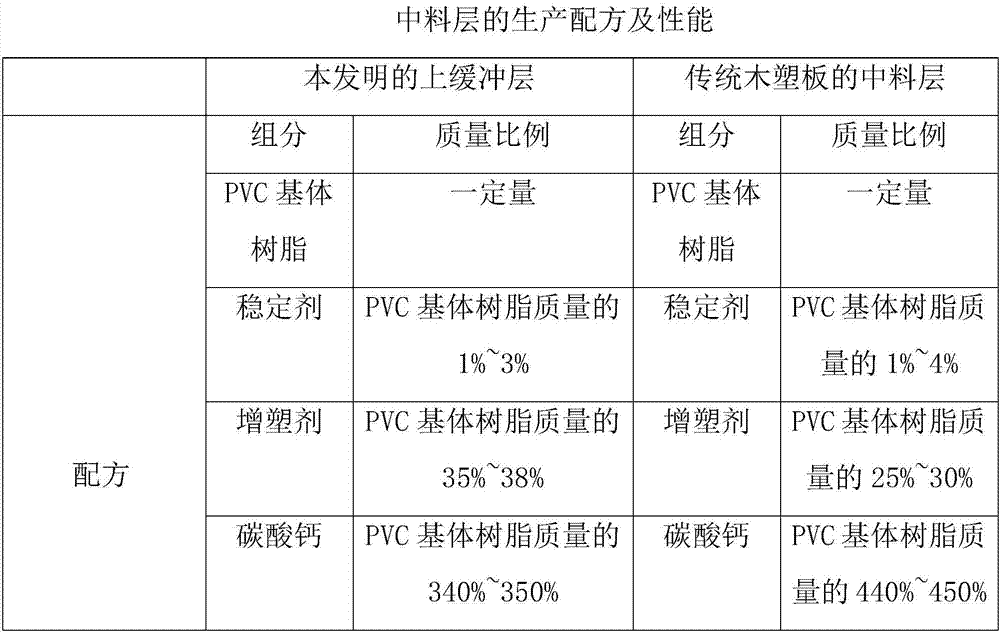

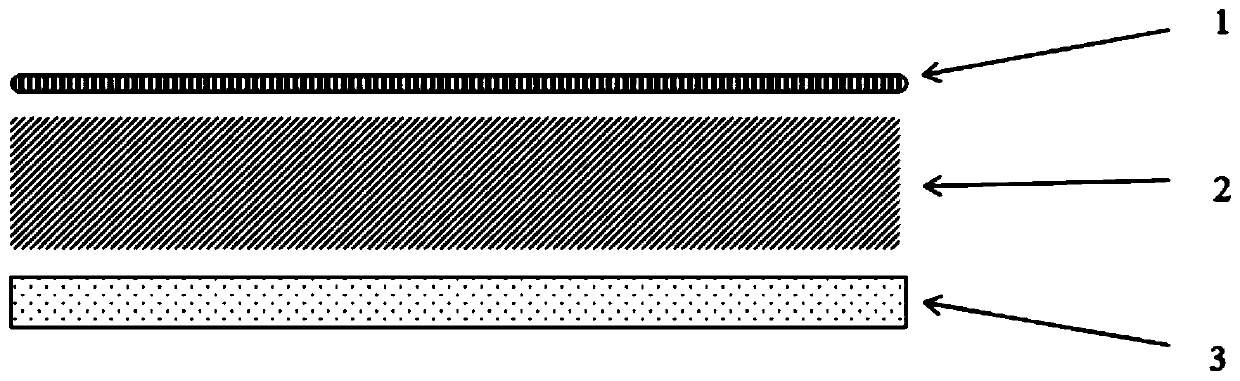

Soundproof wood-plastic floor

The invention provides a soundproof wood-plastic floor which comprises a wood-plastic base layer, an IXPE lower buffer layer arranged on the lower surface of the wood-plastic base layer, and an upper buffer layer connected to the upper surface of the wood-plastic base layer. The upper buffer layer can buffer impact force and vibration on the wood-plastic floor when people walk on the floor, and the lower buffer layer can secondarily buffer impact force and vibration generated to the ground when the wood-plastic floor is stressed. According to the wood-plastic floor, through the dual buffering effects and the sound absorption effect of the upper buffer layer and the lower buffer layer, noise generated by the floor when people walk on the floor is effectively lowered, and a good soundproof effect is achieved.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

Antibacterial anti-inflammatory and biomedical dressing for promoting wound healing and preparation method of dressing

InactiveCN111249515APromote healingPrevent impregnationAbsorbent padsBandagesPolyurethane membraneNonwoven fabric

The invention discloses an antibacterial anti-inflammatory and biomedical dressing for promoting wound healing and a preparation method of the dressing, and belongs to the technical field of medical supplies. The dressing uses a curcumin-containing calcium alginate fiber nonwoven fabric as a skin close layer, the curcumin-containing calcium alginate fiber nonwoven fabric can provide an ideal antibacterial environment for wound healing, promote wound healing, and relieve wound pain; the dressing uses a chitosan fiber non-woven fabric as a middle layer, and the chitosan fiber non-woven fabric has the effects of diminishing inflammation, promoting blood coagulation and inhibiting scars while absorbing exudates; the dressing uses a polyurethane film as an isolation layer, and the polyurethanefilm can achieve the effects of preventing dust, water, air leakage and pollution; and the biomedical dressing prepared by compounding the curcumin-containing calcium alginate fiber nonwoven fabric, the chitosan fiber non-woven fabric and the polyurethane film has complementary and synergistic effects, and the advantages of realizing antibacterial and bacteriostatic properties, a good anti-inflammatory effect and anti-adhesion performance, promoting rapid wound healing and having good biocompatibility. The medical hemostatic dressing provided by the invention has no side effects on human bodies and no any irritation to skin, is safe to use, environmentally friendly and pollution-free, and has wide application prospects in the field of biomedical materials.

Owner:XI'AN POLYTECHNIC UNIVERSITY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com