Antibacterial anti-inflammatory and biomedical dressing for promoting wound healing and preparation method of dressing

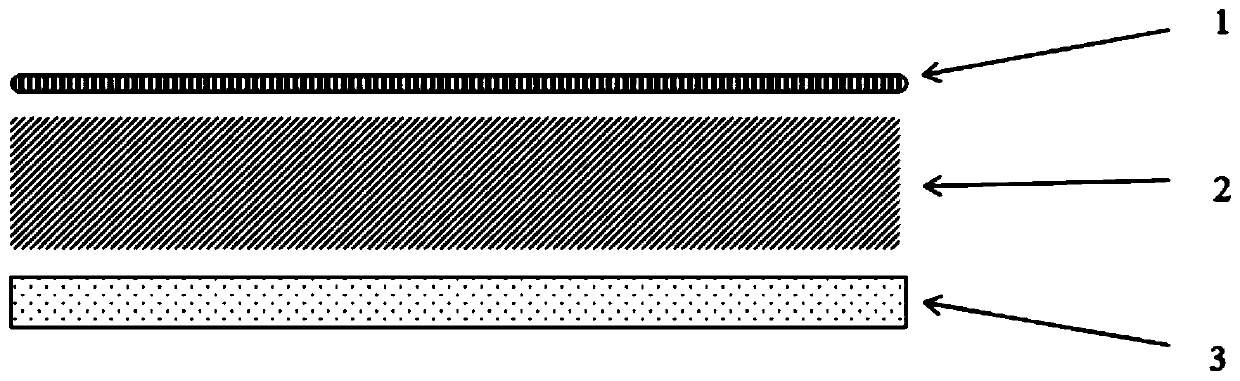

A wound healing and biomedical technology, applied in the field of medical supplies, can solve the problems of ineffective prevention of wound infection, poor binding fastness of antibacterial agents, and slow wound healing speed, so as to block the penetration of bacteria and viruses, promote wound healing, The effect of avoiding secondary trauma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Weigh 10 g of sodium alginate with a molecular weight of 80,000 and add it to 400 mL of deionized water, stir and dissolve to obtain a sodium alginate solution with a mass concentration of 2.5%; add 0.3 g of curcumin extract to the sodium alginate solution, stir After uniformity, the spinning dope is left to defoam. The prepared spinning solution is added to the coagulation bath and drawing bath of 2% and 5% calcium chloride by mass percentage respectively, and then conventional wet spinning is carried out at a temperature of 20°C, and the resulting as-spun fibers are 1.5 times The post-drawing process is followed by water washing at 20°C and heat treatment at 40°C to obtain drug-containing antibacterial and anti-inflammatory calcium alginate fibers. Send the prepared fibers into the opening machine, the opening time is 3min, and feed the carding machine through the cotton feeding system to be carded into a fiber web. The main cylinder speed of the carding machine is co...

Embodiment 2

[0040] Weigh 10 g of sodium alginate with a molecular weight of 100,000 and add it to 323 mL of deionized water, stir and dissolve to obtain a sodium alginate solution with a mass concentration of 3%; add 0.4 g of curcumin extract to the sodium alginate solution, stir After uniformity, the spinning dope is left to defoam. The prepared spinning solution is added to the coagulation bath and drawing bath of 2% and 5% calcium chloride by mass percentage respectively, and then conventional wet spinning is carried out at a temperature of 40°C, and the resulting as-spun fibers are 1.7 times The post-drawing process is followed by water washing at 40°C and heat treatment at 60°C to obtain drug-containing antibacterial and anti-inflammatory calcium alginate fibers. Send the prepared fibers into the opening machine, the opening time is 4min, and feed the carding machine through the cotton feeding system to be carded into a fiber web. The main cylinder speed of the carding machine is con...

Embodiment 3

[0044] Weigh 10 g of sodium alginate with a molecular weight of 120,000 and add it to 286 mL of deionized water, stir and dissolve to obtain a sodium alginate solution with a mass concentration of 3.5%; add 0.5 g of curcumin extract to the sodium alginate solution, stir After uniformity, the spinning dope is left to defoam. The prepared spinning solution is added to the coagulation bath and drawing bath of 2% and 5% calcium chloride by mass percentage respectively, and then conventional wet spinning is carried out at a temperature of 55°C, and the resulting as-spun fibers are 2 times The post-drawing process is followed by water washing at 55°C and heat treatment at 80°C to obtain drug-containing antibacterial and anti-inflammatory calcium alginate fibers. Send the prepared fibers into the opening machine, the opening time is 5min, and feed the carding machine through the cotton feeding system to be carded into a fiber web. The main cylinder speed of the carding machine is con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com