Prefabricated reinforced concrete simply-supported girder bridge deck pavement and maintenance structure and construction method

A reinforced concrete and simply supported girder bridge technology, applied in bridges, bridge parts, bridge construction, etc., can solve problems such as skid resistance, poor driving comfort, difficult to guarantee service life, strong reflection and easy to dazzle, etc., to achieve outstanding performance, The effect of low engineering cost and low requirements for construction environmental conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

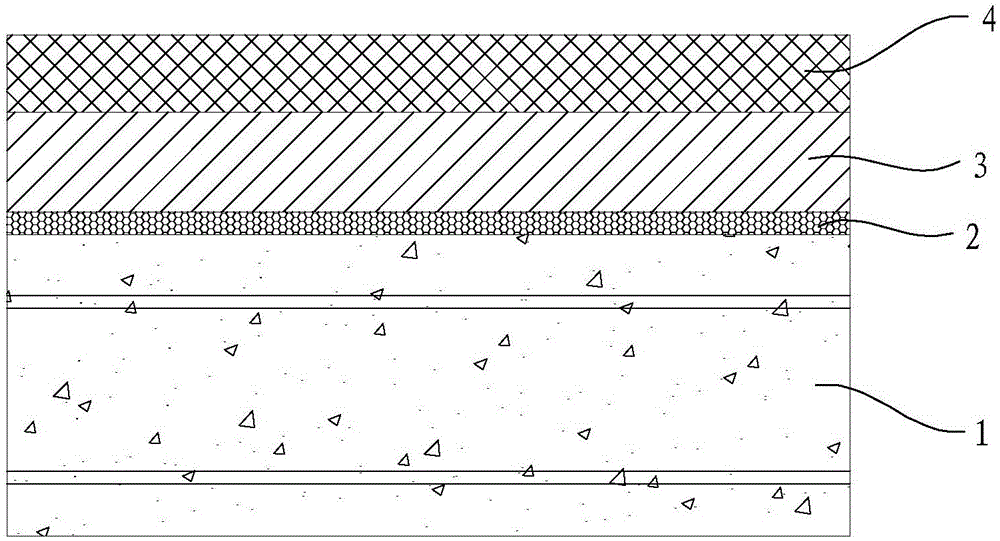

[0029] Such as figure 1 As shown, the prefabricated reinforced concrete simply supported bridge deck pavement maintenance structure in this embodiment includes a cement concrete pavement layer 1 , a bonded waterproof layer 2 , a colloidal concrete pavement layer 3 and an anti-skid layer 4 . Among them, the cement concrete pavement layer 1 is equipped with single-layer or double-layer steel bars to improve the composite stress performance and overall rigidity of the pavement layer. The cement concrete pavement layer 1 is made of C50 steel fiber concrete with a thickness of 15-18cm. The bonded waterproof layer 2 is coated on the cement concrete pavement layer 1 with an ester binder as the primer, and the colloidal concrete pavement layer 3 is made by mixing curing agent, polyurethane and aggregate, and the colloidal concrete pavement layer The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com