Soundproof wood-plastic floor

A wood-plastic floor and mute technology, which is applied in the field of wood-plastic floor, can solve the problem of loud noise on the floor, and achieve the effect of reducing noise and good mute effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be clearly and completely described below through specific embodiments in conjunction with the accompanying drawings.

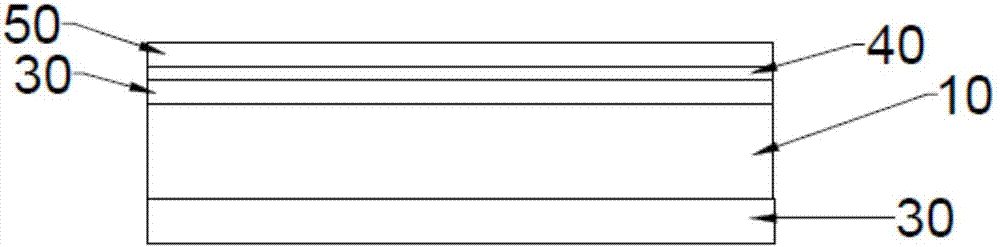

[0033] Such as figure 1 As shown, a wood-plastic floor 1 provided by the present invention is illustrated. The wood-plastic floor 1 includes a wood-plastic base layer 10 , an upper buffer layer 20 and a lower buffer layer 30 .

[0034] The wood-plastic base layer 10 is a layered structure made of wood-plastic materials, and serves as the main supporting structure of the wood-plastic floor 1 . The thickness range of the wood-plastic base layer 10 is preferably 3.0mm-5.0mm.

[0035] The lower buffer layer 30 is arranged on the back side of the wood-plastic base layer 10, that is to say, in the state of use, the lower buffer layer 30 is positioned below the wood-plastic base layer 10 and contacts the ground, and the lower buffer layer 30 is bonded to the wood-plastic base layer 10 of the lower surfa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com