Patents

Literature

46results about How to "Guaranteed quiet effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

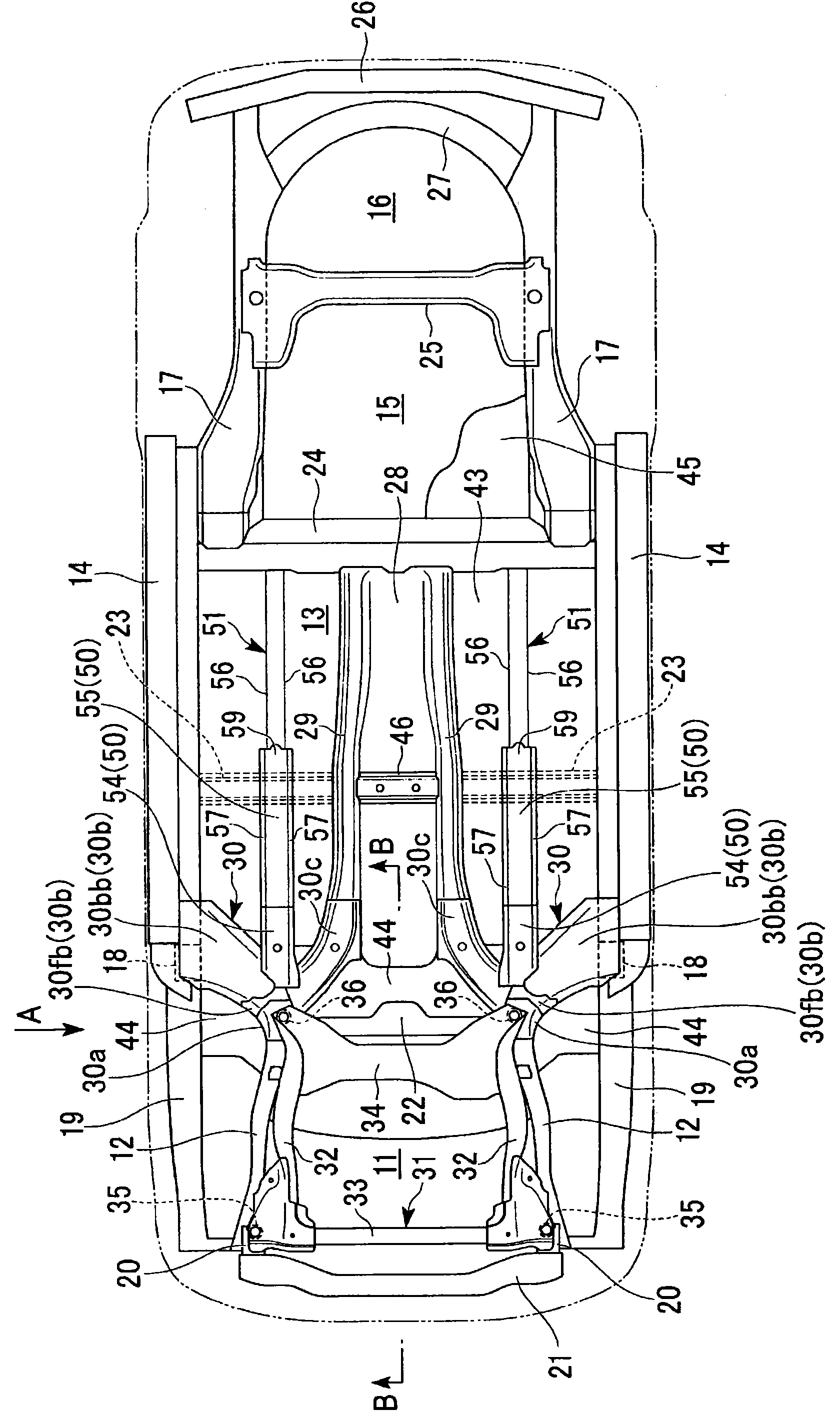

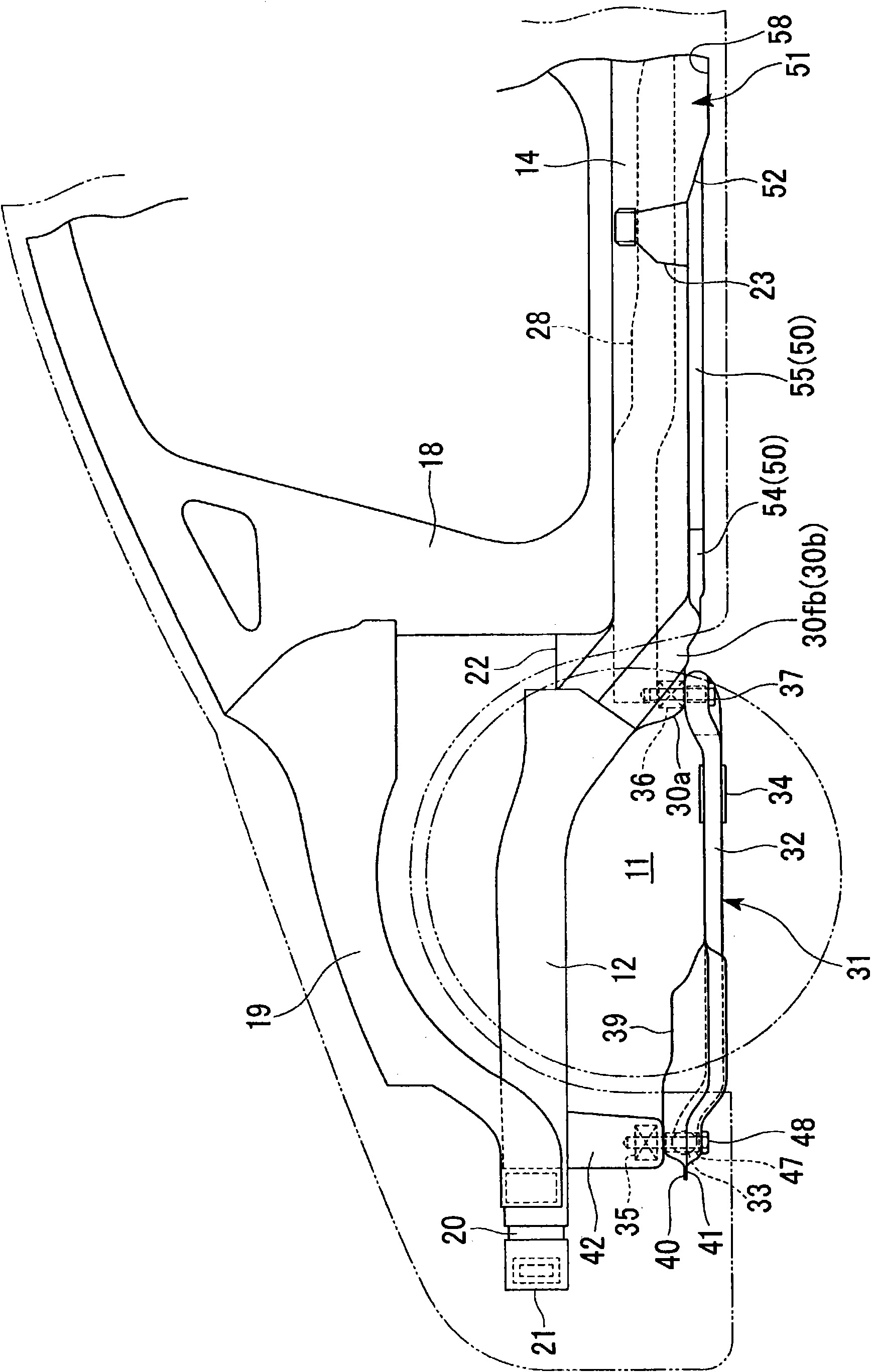

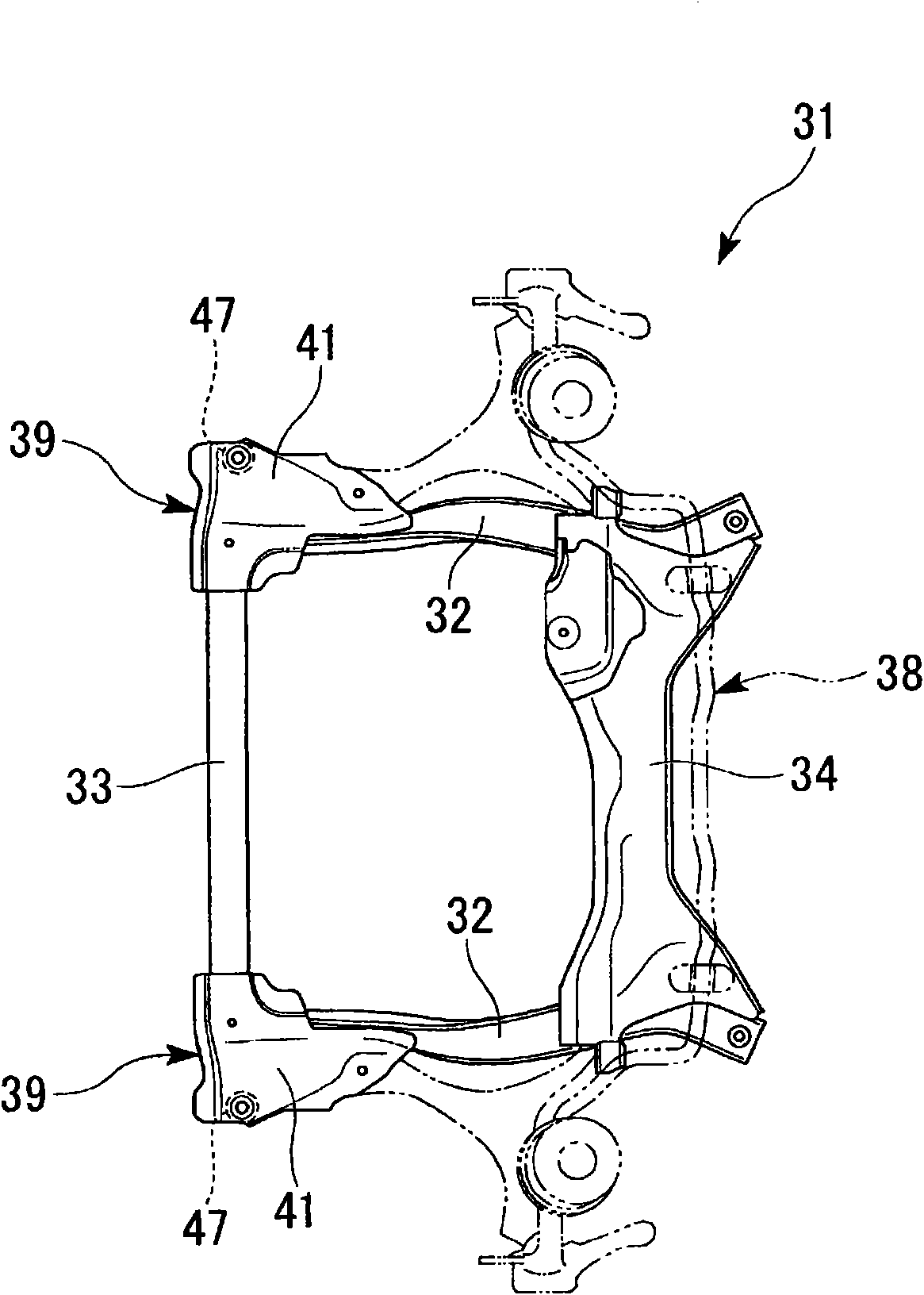

Vehicle body floor structure

ActiveCN102656080AImprove rigidityBig spaceUnderstructuresSuperstructure subunitsEngineeringMechanical engineering

Owner:HONDA MOTOR CO LTD

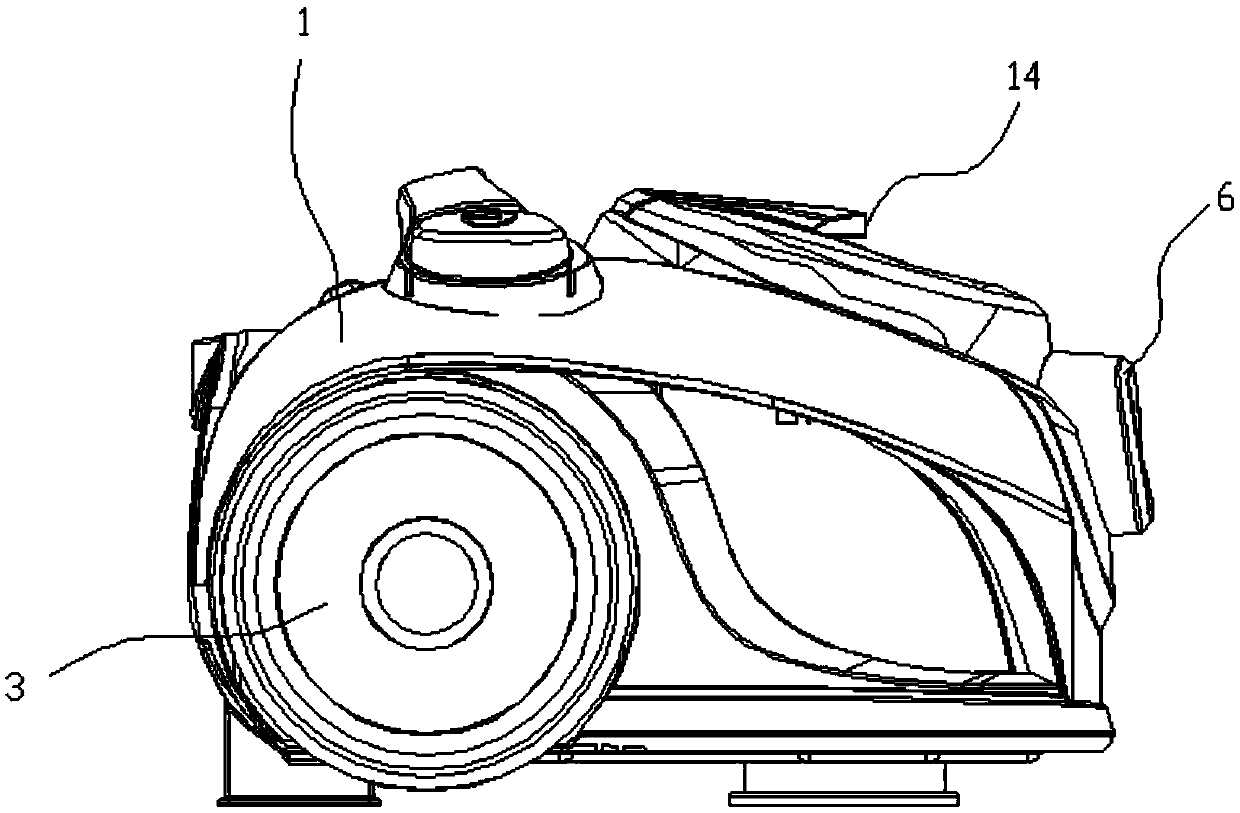

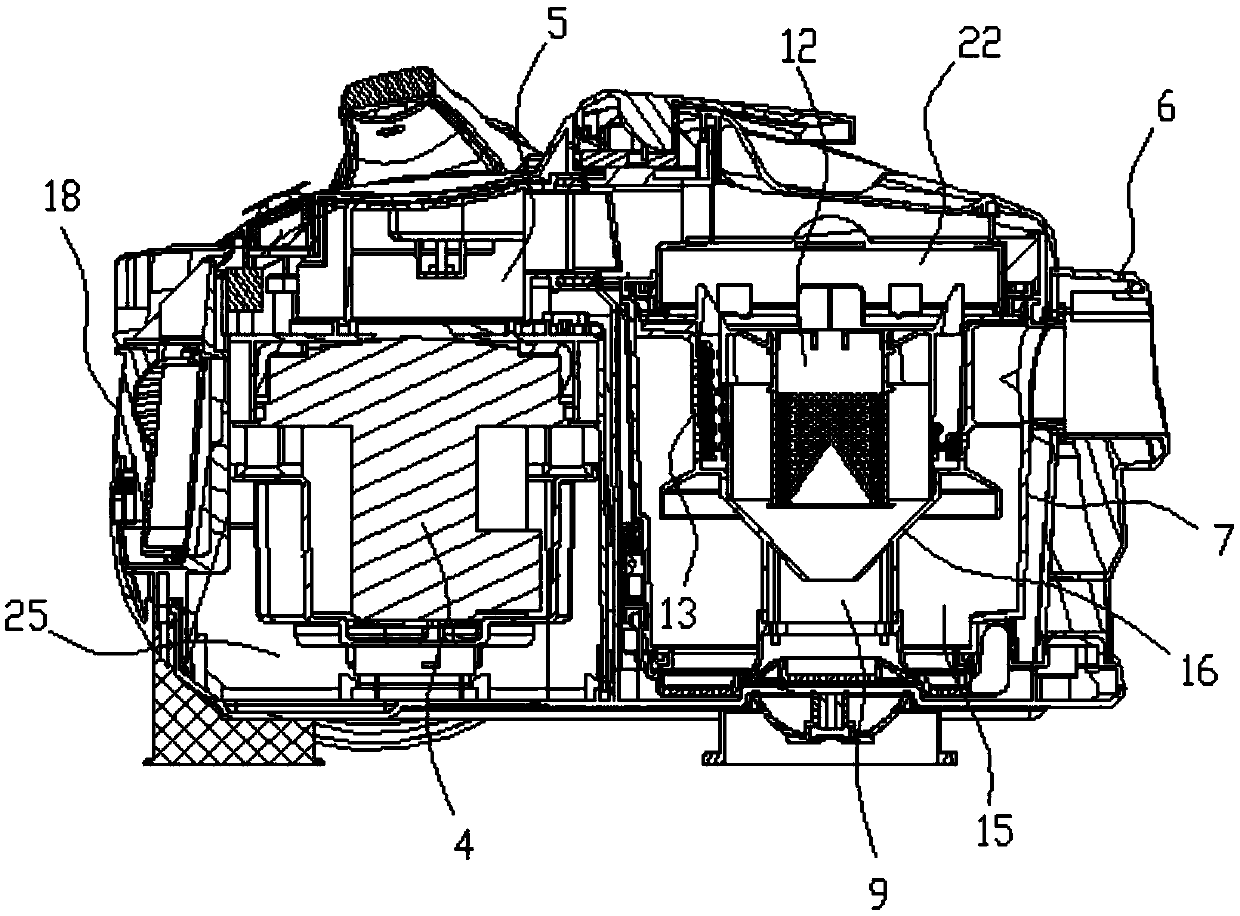

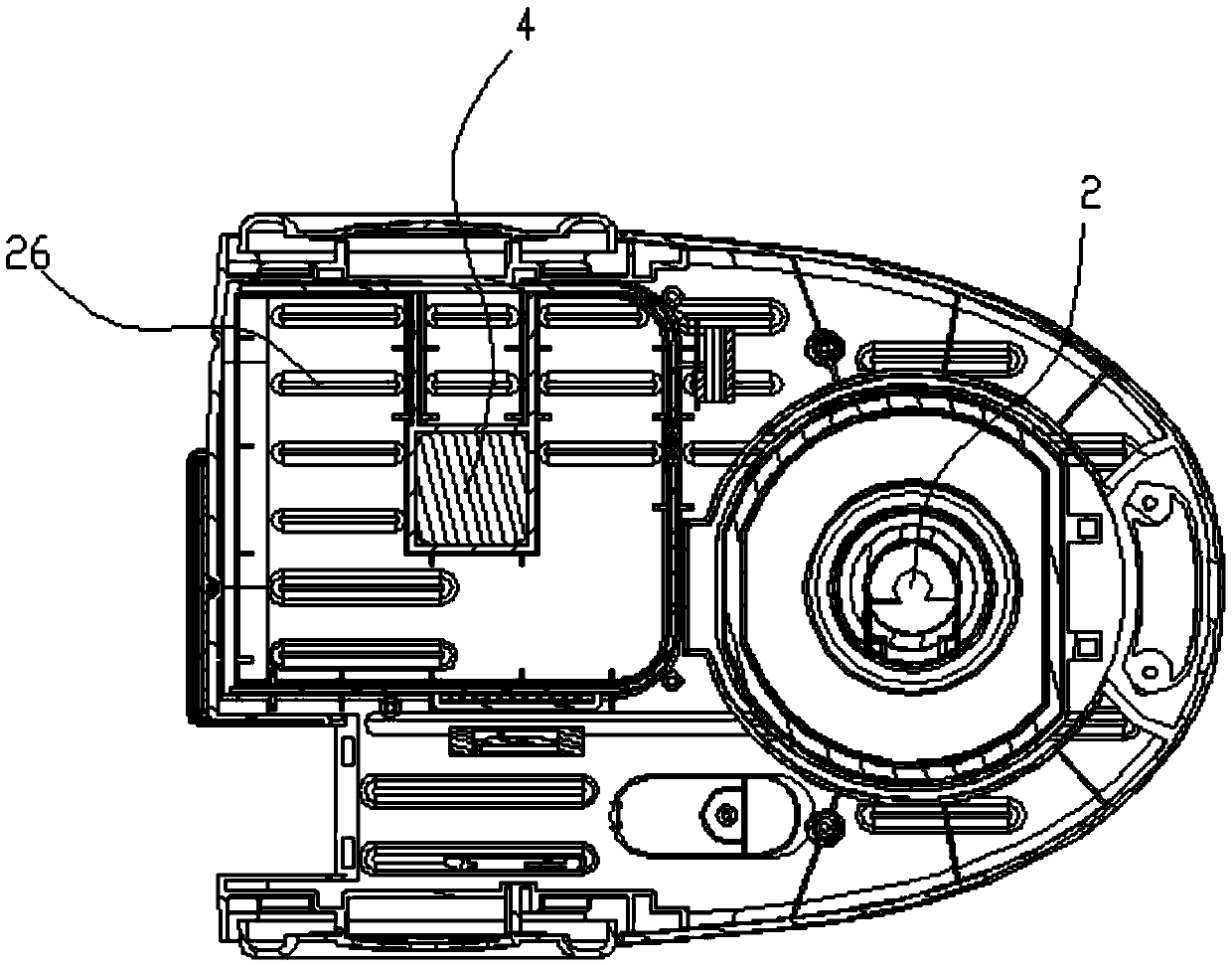

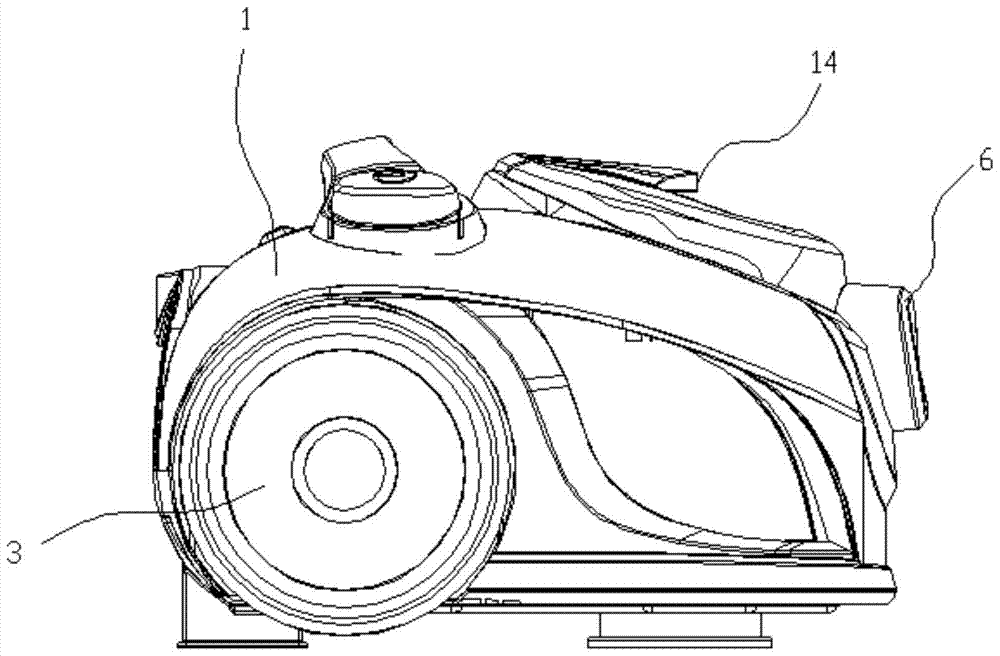

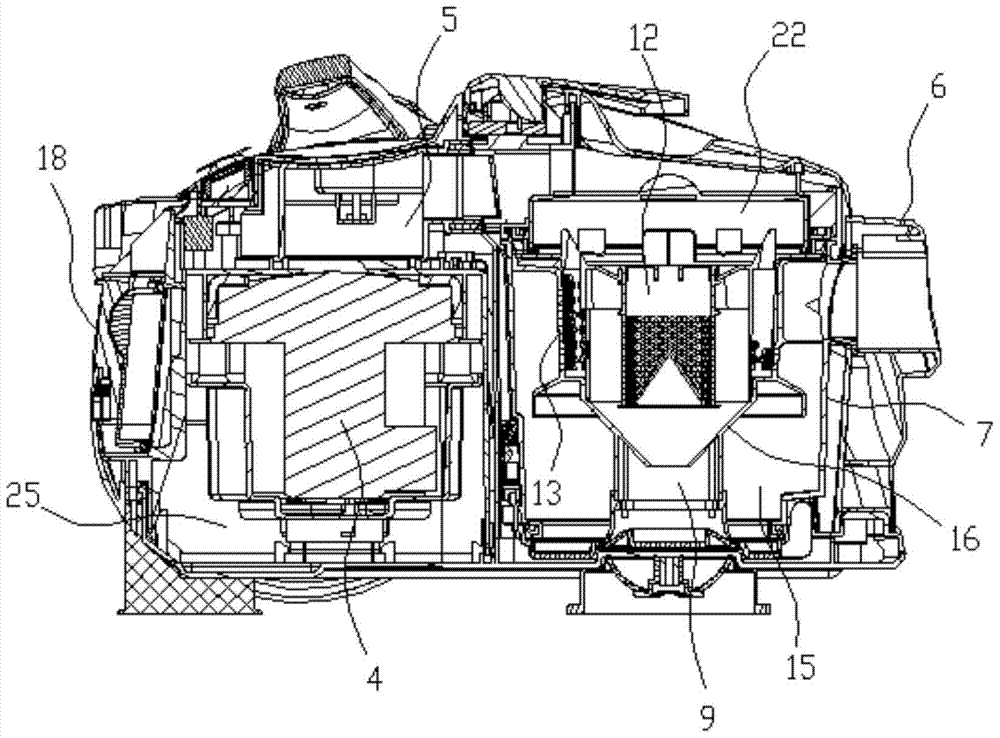

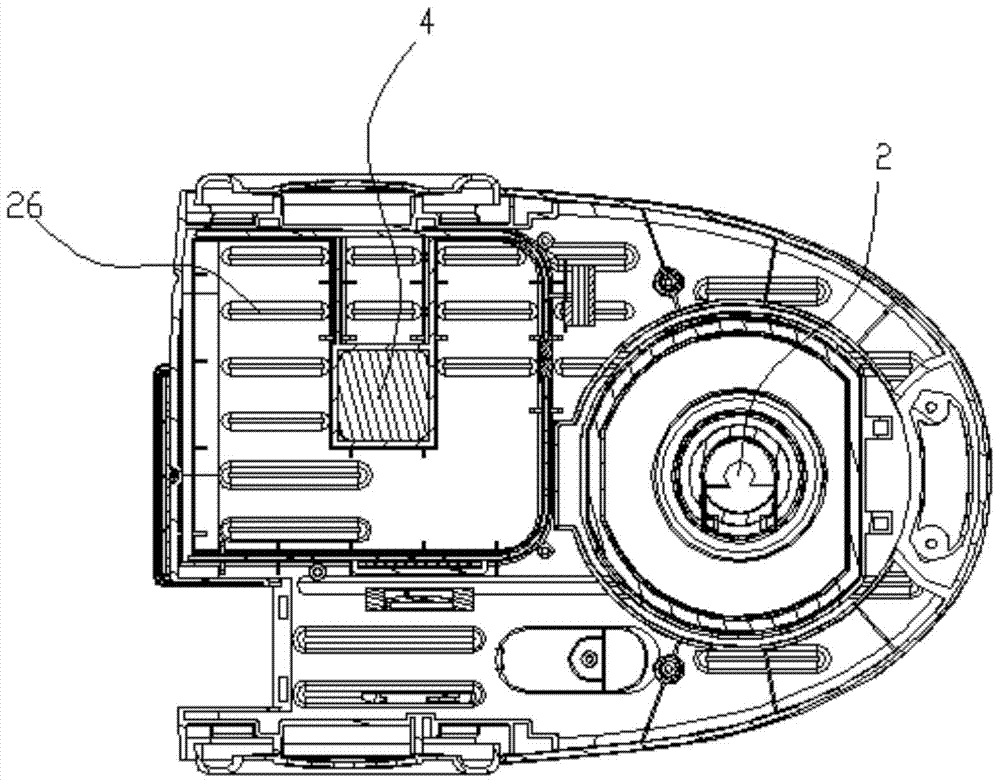

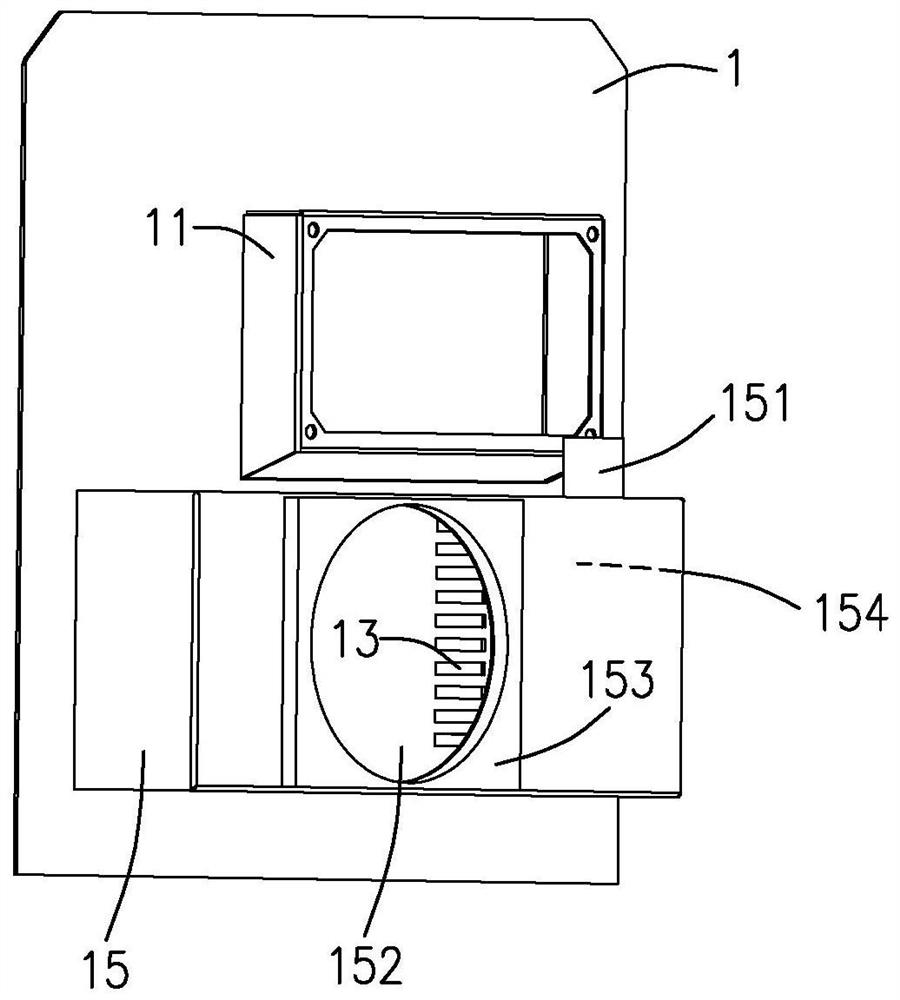

Vacuum cleaner structure

The invention discloses a vacuum cleaner structure which comprises a main machine shell, a dust suction mop, a universal wheel, a plurality of moving wheels and an induced draft motor. The main machine shell is provided with a dust cup component and a suction opening seat. The suction opening seat is connected with the dust suction mop through a dust suction pipe. The dust cup component comprises a dust cup, a cyclone cone and inner dust bin. The cyclone cone is provided with a straight wind inlet, a downwardly-spiral wind guide channel and a cyclone outlet which are sequentially communicated. The straight wind inlet is communicated with the suction opening seat. The cyclone cone is provided with a cone inner cylinder. The cone inner cylinder is provided with a vertical wind return channel communicated with the cyclone outlet. The cyclone outlet is communicated with the inlet of the vertical wind return channel and the inner dust bin. The outlet of the vertical wind return channel is communicated with the induced draft motor. The vacuum cleaner structure has the advantages that the wind inlet and outlet channels are reasonable in structure, and dust can be separated and collected by cyclone; the vacuum cleaner structure is high in dust suction ability and is provided with a multistage filter structure which is good in filter effect; noise during wind discharge can be reduced, and vibration and the noise can be reduced effectively to keep a good silent effect by a stability strengthening structure.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

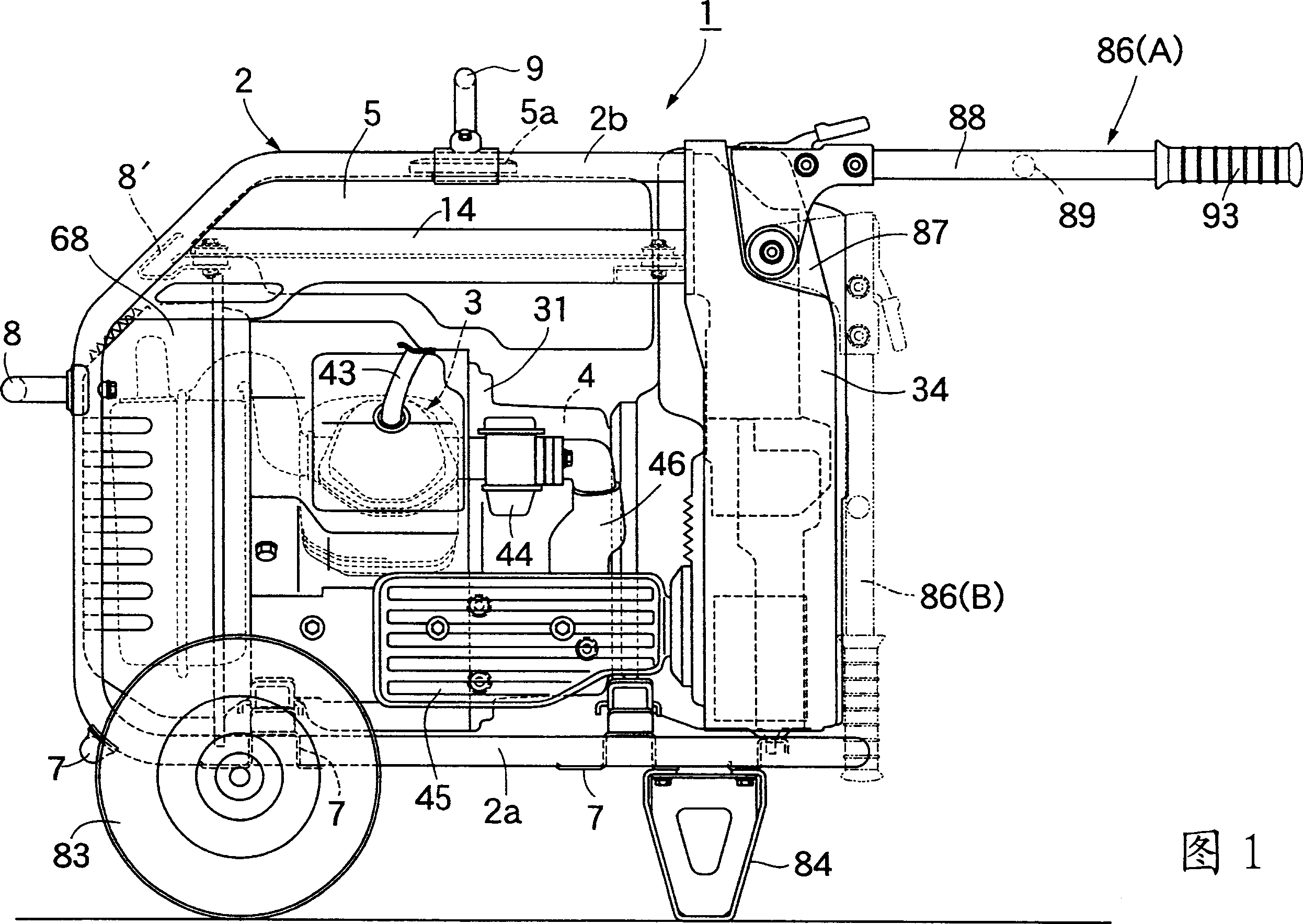

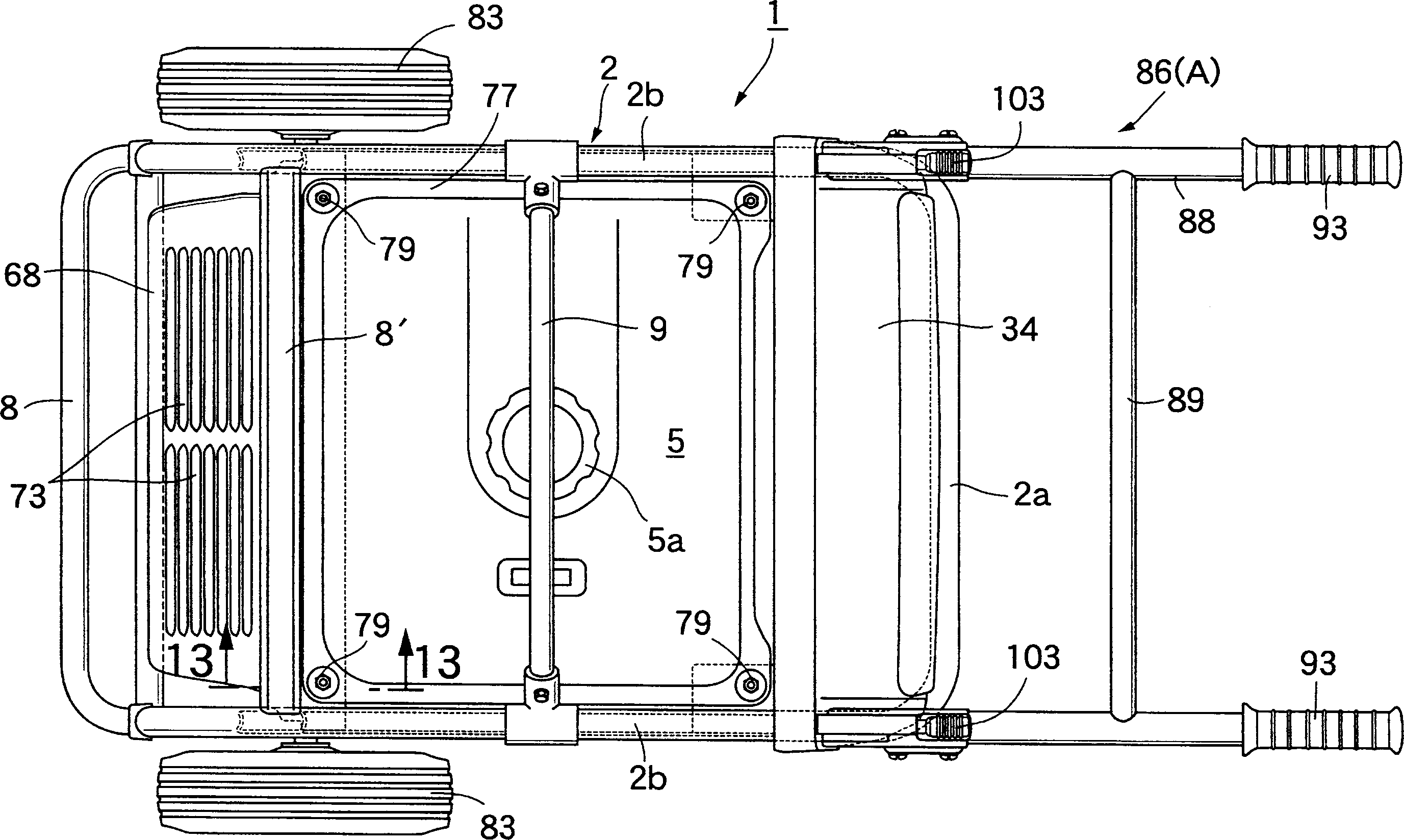

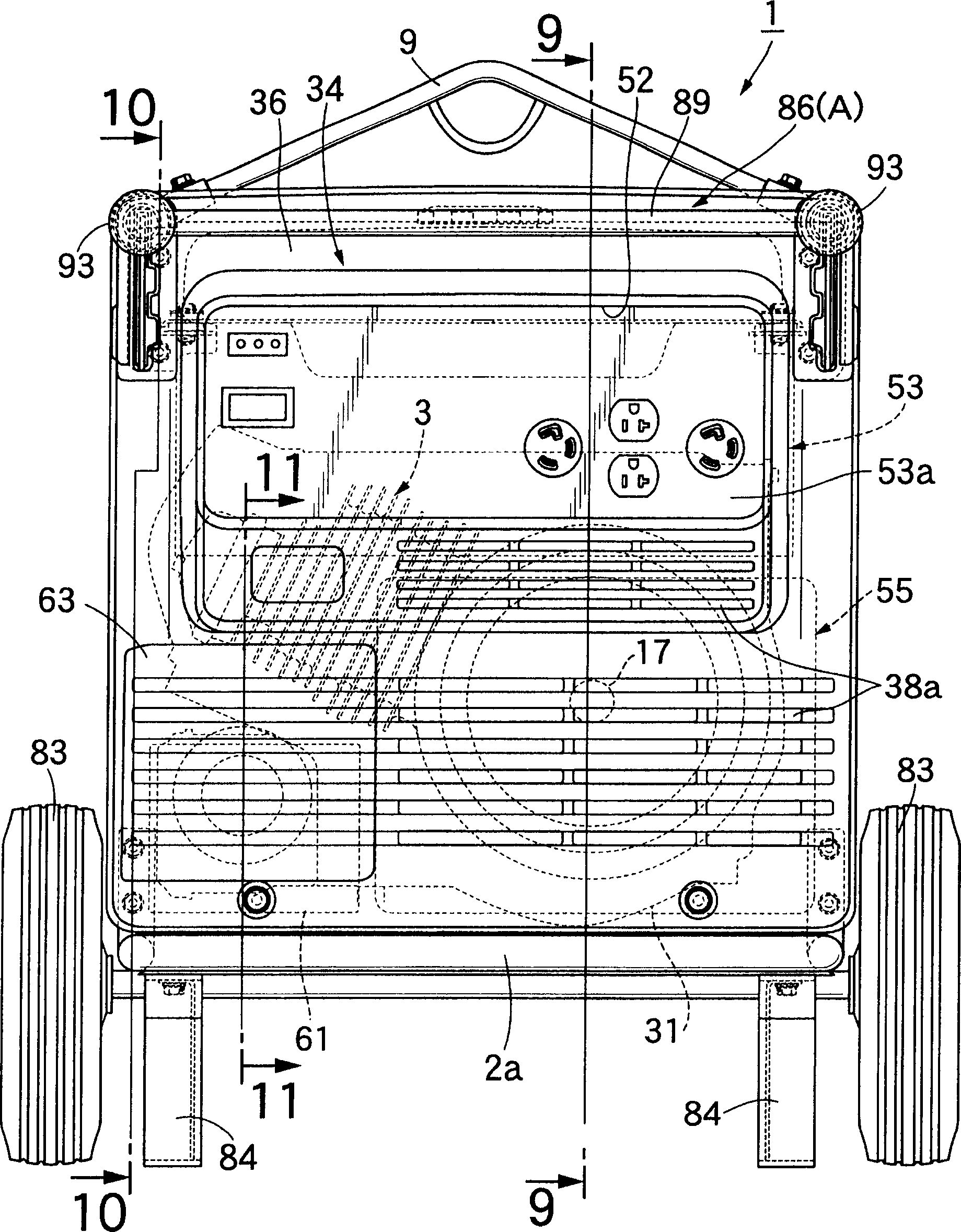

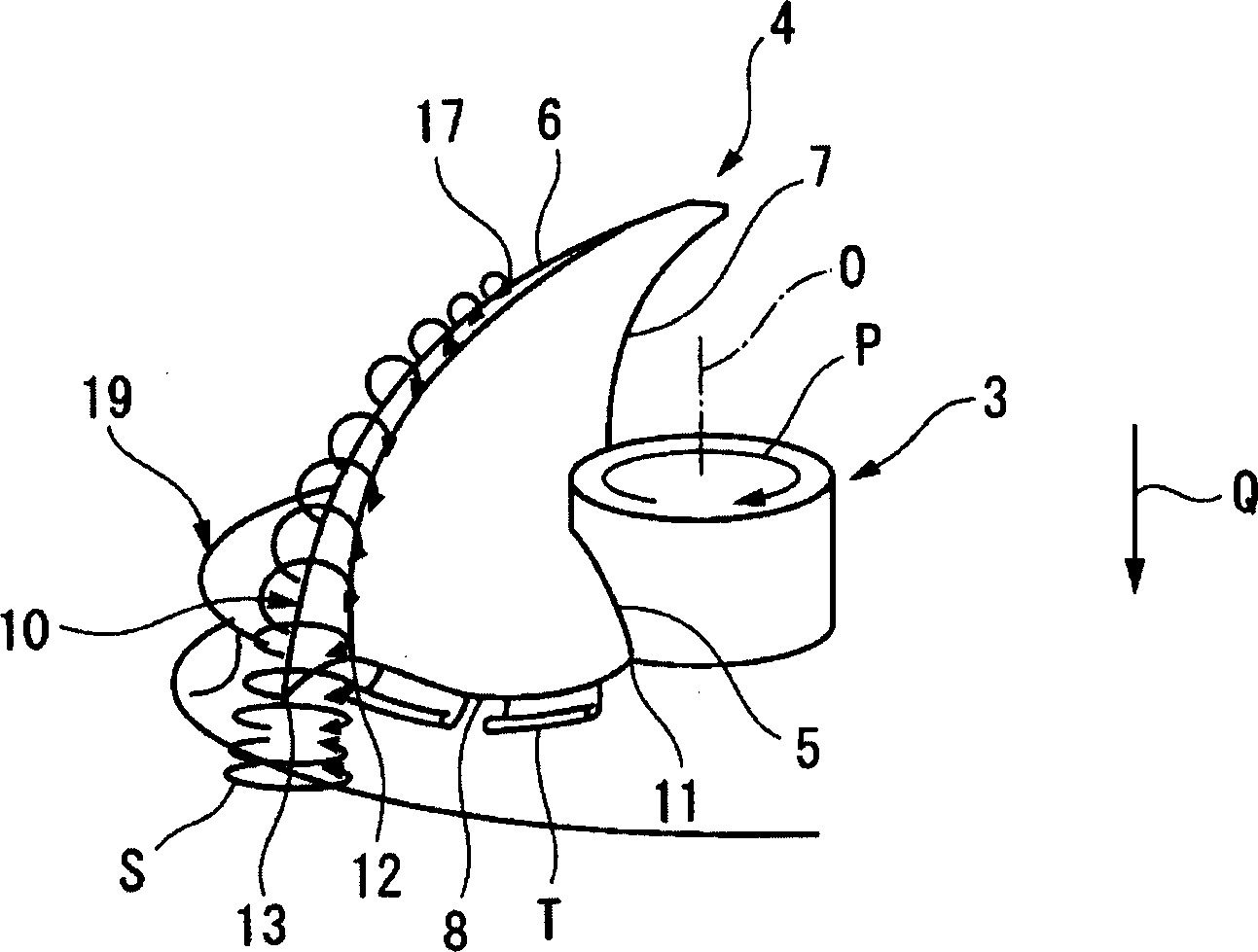

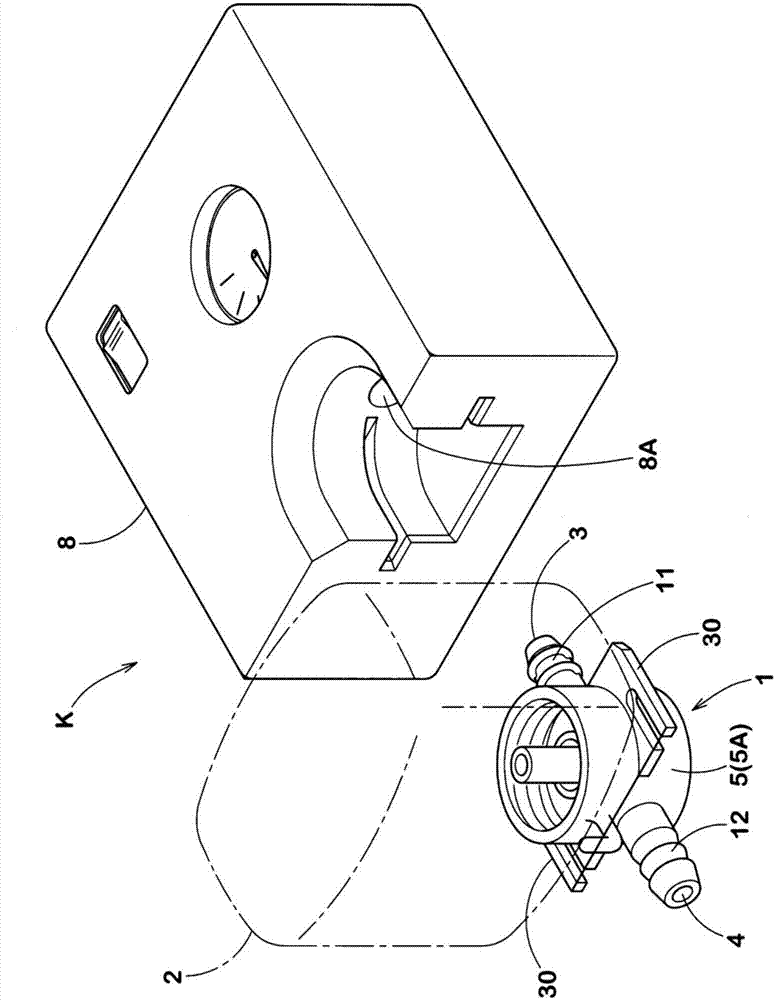

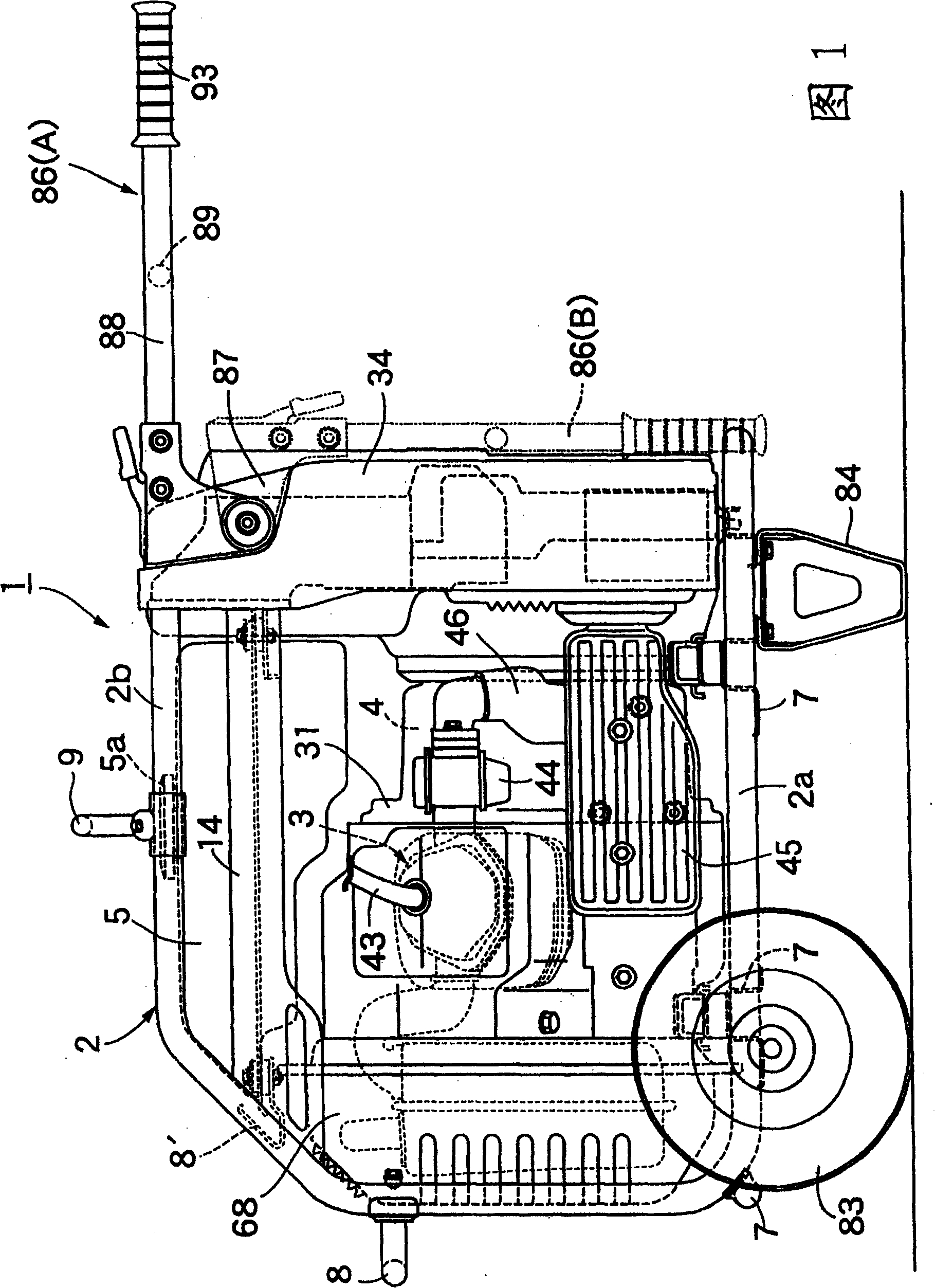

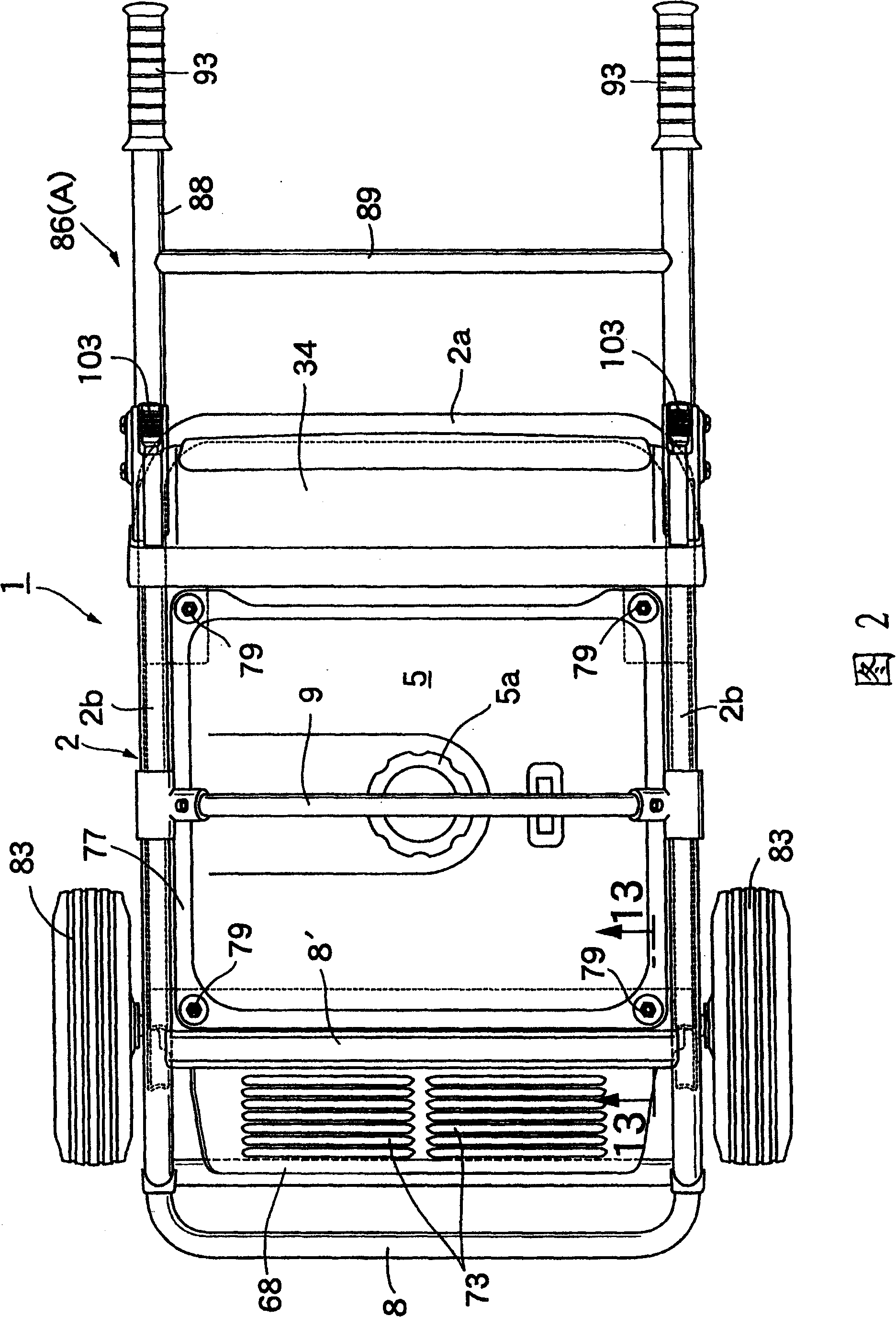

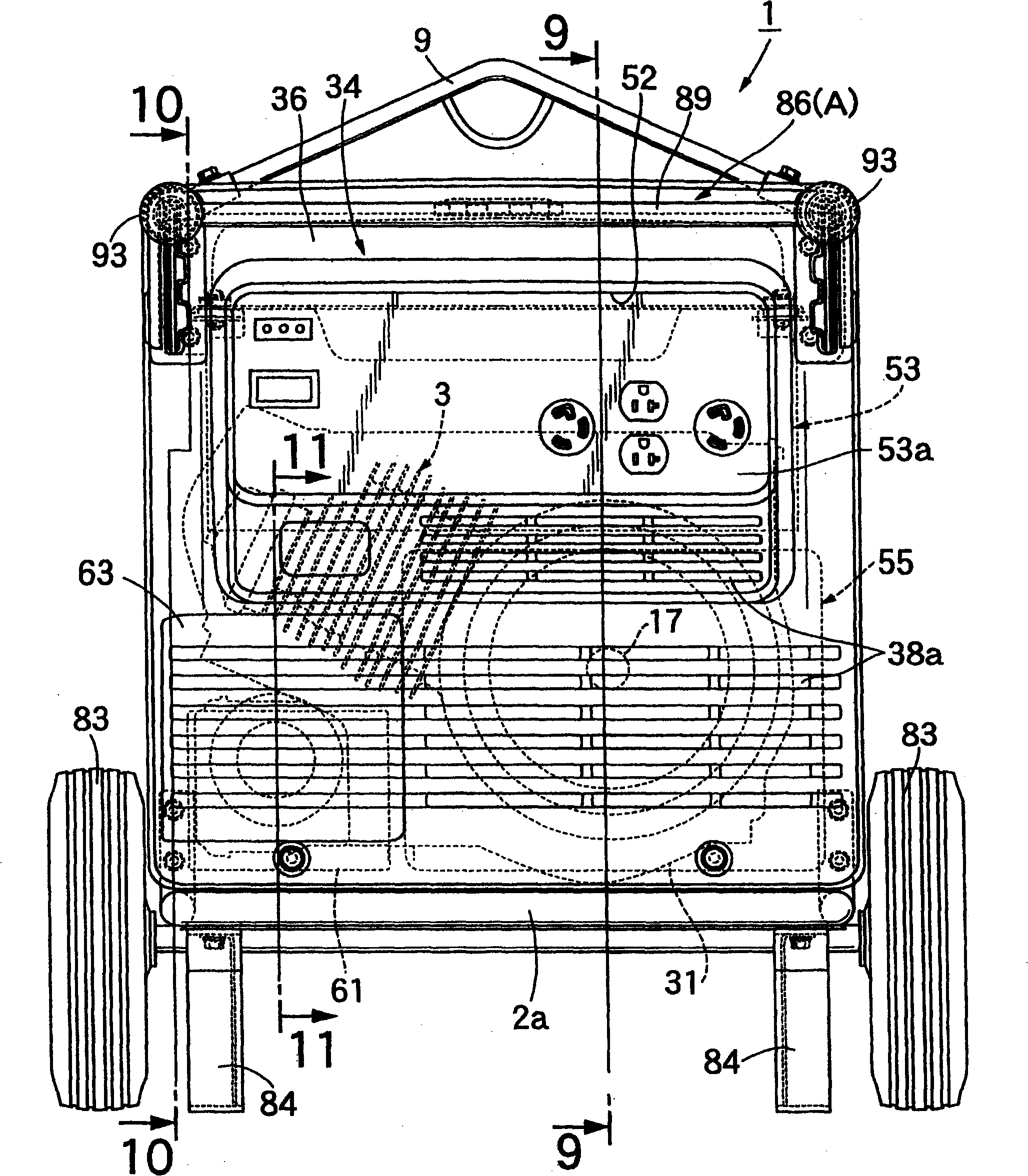

Engine-driven electric generator

InactiveCN1823216ASimple structureReduce weightEngine controllersMachines/enginesEngineeringElectric generator

An engine-driven generator is provided that is formed by supporting on a frame (2) an engine (3) and a generator (4) driven by the engine (3), wherein the frame is formed by integrally connecting via a cross member (7) lower side sections of a pair of left and right side frames (2b, 2b) formed by bending a steel pipe into a U-shape, a control box (34) housing and holding an electrical component (53, 55) is mounted on open end parts of the two side frames (2b, 2b) in order to reinforce the frame (2) by connecting the open end parts to each other, and an assembly of the engine (3) and generator (4) is resiliently supported on the cross member (7). The structure of the frame of the engine-driven generator can thereby be simplified, the frame can be reinforced by the control box that houses and supports the electrical component, and the frame can be made lightweight.

Owner:HONDA MOTOR CO LTD

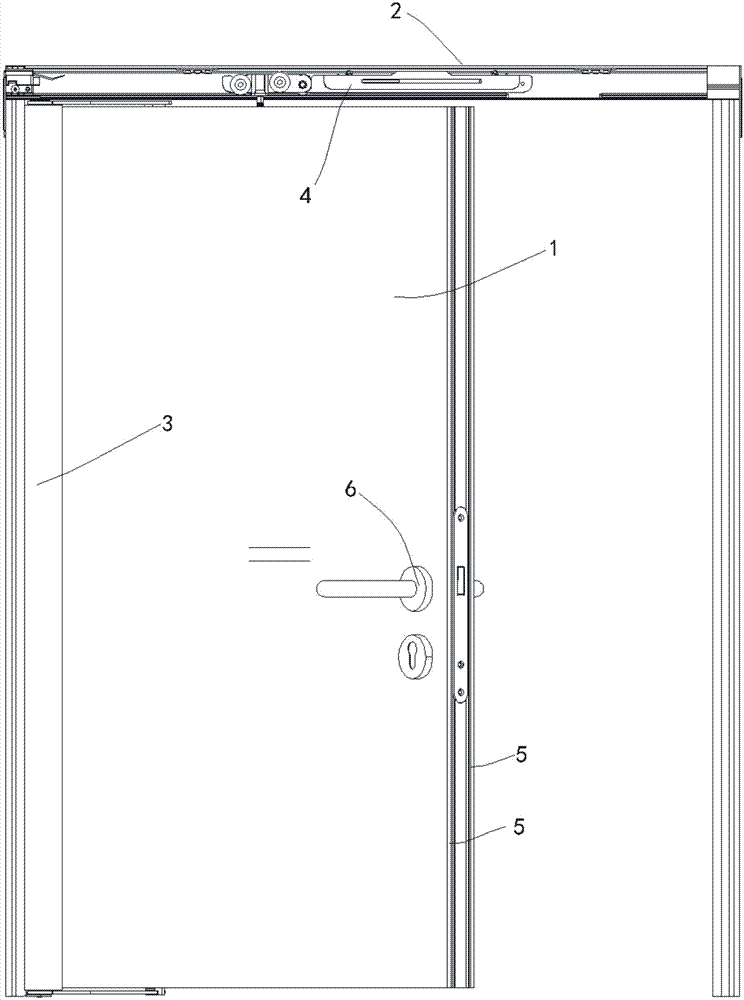

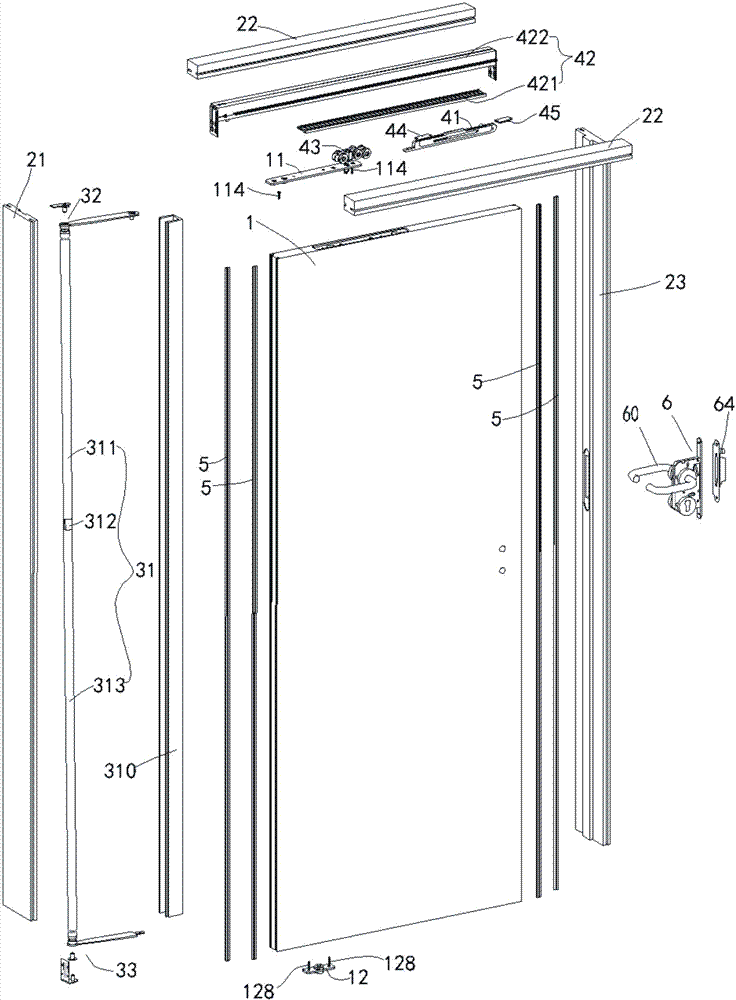

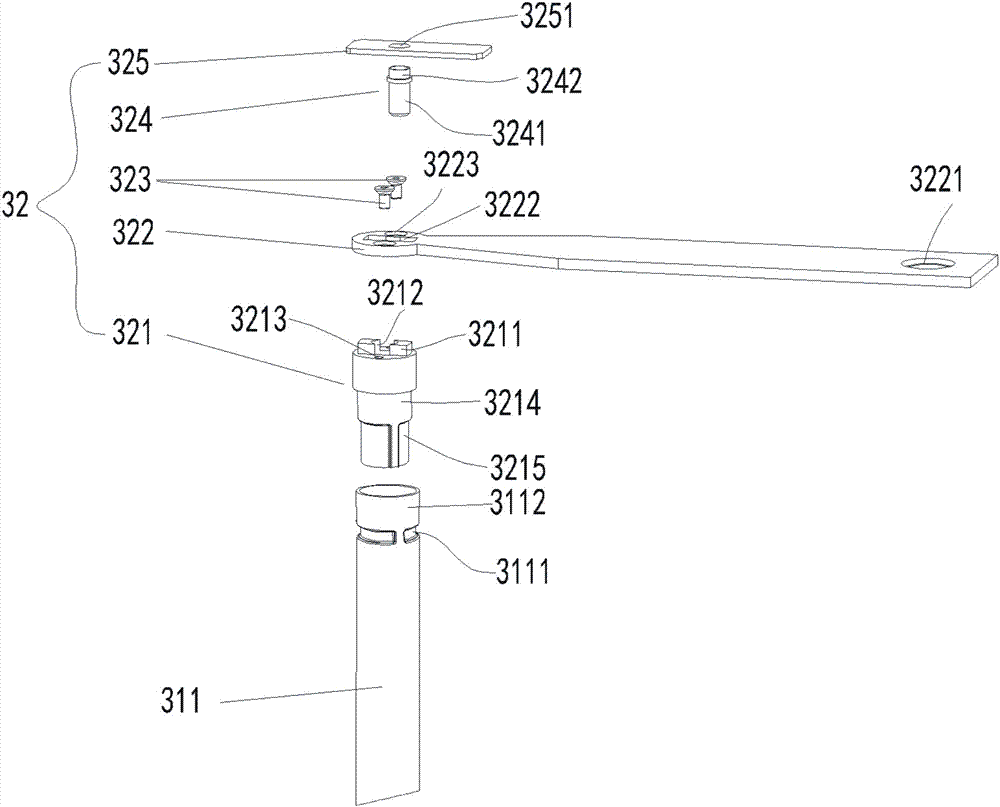

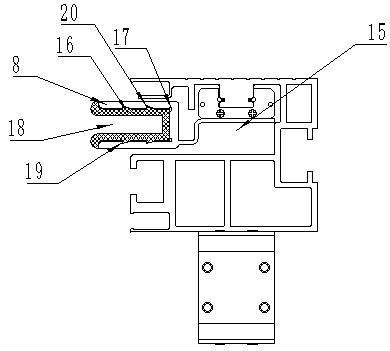

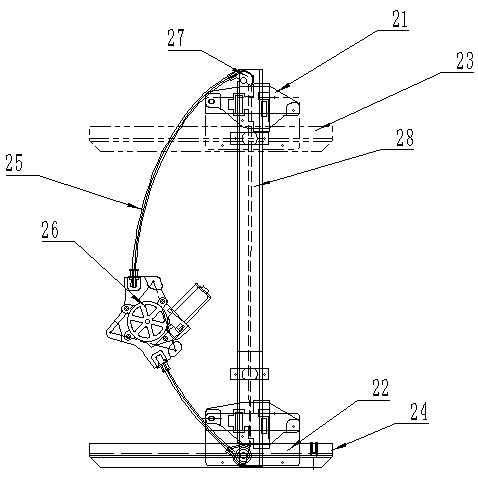

Noiseless vertical hinged lateral overturned door system

ActiveCN104328990AEliminate impact noiseReduce the impactWing arrangementsWing suspension devicesEngineeringPulley

The invention relates to a vertical hinged lateral overturned door system, and provides a noiseless vertical hinged lateral turned door system. An overturn mechanism is arranged between a door leaf and a rotating shaft vertical plate of a door frame, so that the door leaf is overturned laterally in the process of horizontally pushing a door, and a door-opening sweeping space is reduced; meanwhile, a buffer component is arranged in the overturn mechanism, and friction during rotation is reduced; damping pulley mechanism is arranged between a lintel horizontal plate and the door leaf, and collision between the door leaf and the door frame is eliminated in the door opening and door closing travels; side edges of the door leaf is provided with sealing strips to further reduce the collision between the door leaf and the door frame and achieve a soundproof effect; the locking end of the door leaf is provided with a noiseless lock body, and noise in the locking and unlocking process is avoided. According to the scheme, the noise generated in the door using process is comprehensively eliminated, and home and office environments are silenced.

Owner:GUANGDONG MINGMEN LOCKS IND

Film removing method and film removing device for coated glass

The invention relates to a film removing method and film removing device for coated glass. Particularly, scribing film removing is conduced on the coated glass by adopting laser, and the problem that chemical etching pollutes the environment is solved. Meanwhile, due to the fact that the working range of a high-speed galvanometer is limited, the film removing method comprises the steps that the whole piece of coated glass is divided into at least two film removing areas through cooperation of software and a CCD sensor, an image of one film removing area is acquired through the CCD sensor, even positioning points are set, and the software acquires the positioning points on a displacement path in real time; when film removing is conducted on the next film removing area, overlapped film removing is firstly conducted on the part, close to the junction of the two film removing areas, of the precious film removing area, a displacement path of overlapped film removing can be acquired according to the positioning points located on the displacement path in the area subjected to film removing, therefore, a film removing line is more coherent, splicing lines or splicing traces generated at the junction of the two film removing areas are eliminated, and the splicing problem of large-breadth coated glass etching is solved.

Owner:ZHEJIANG HOLY LASER TECH CO LTD

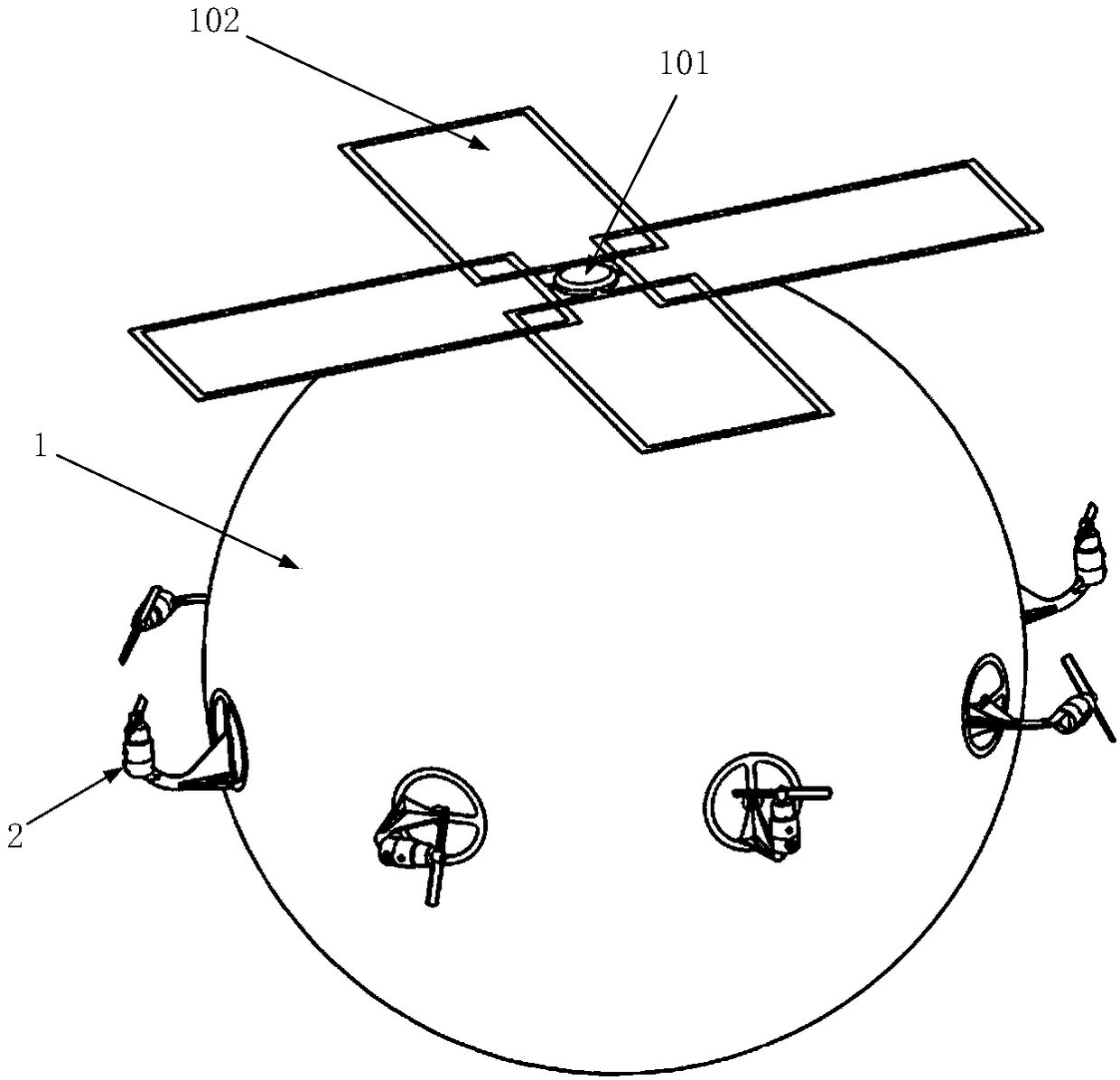

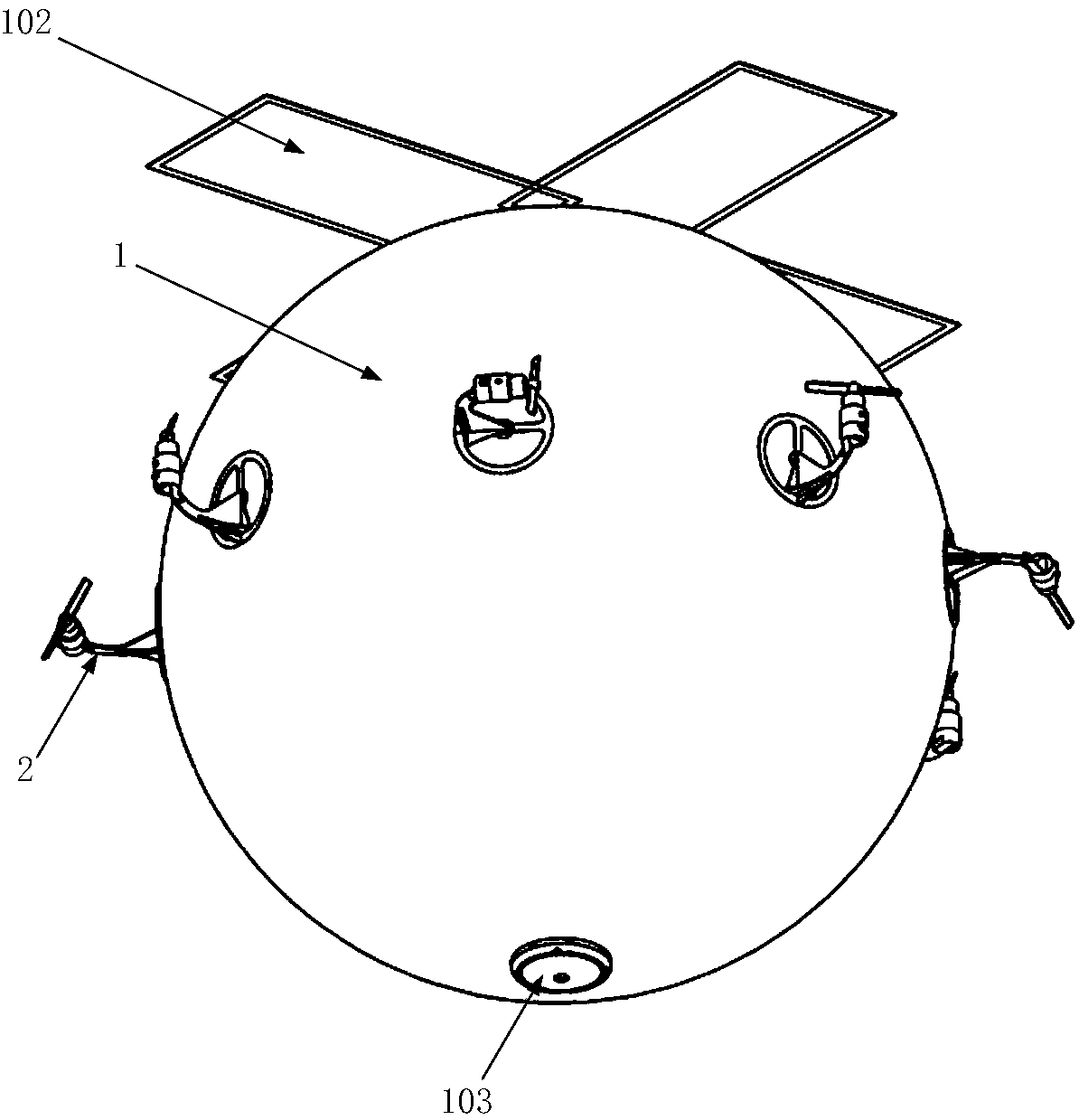

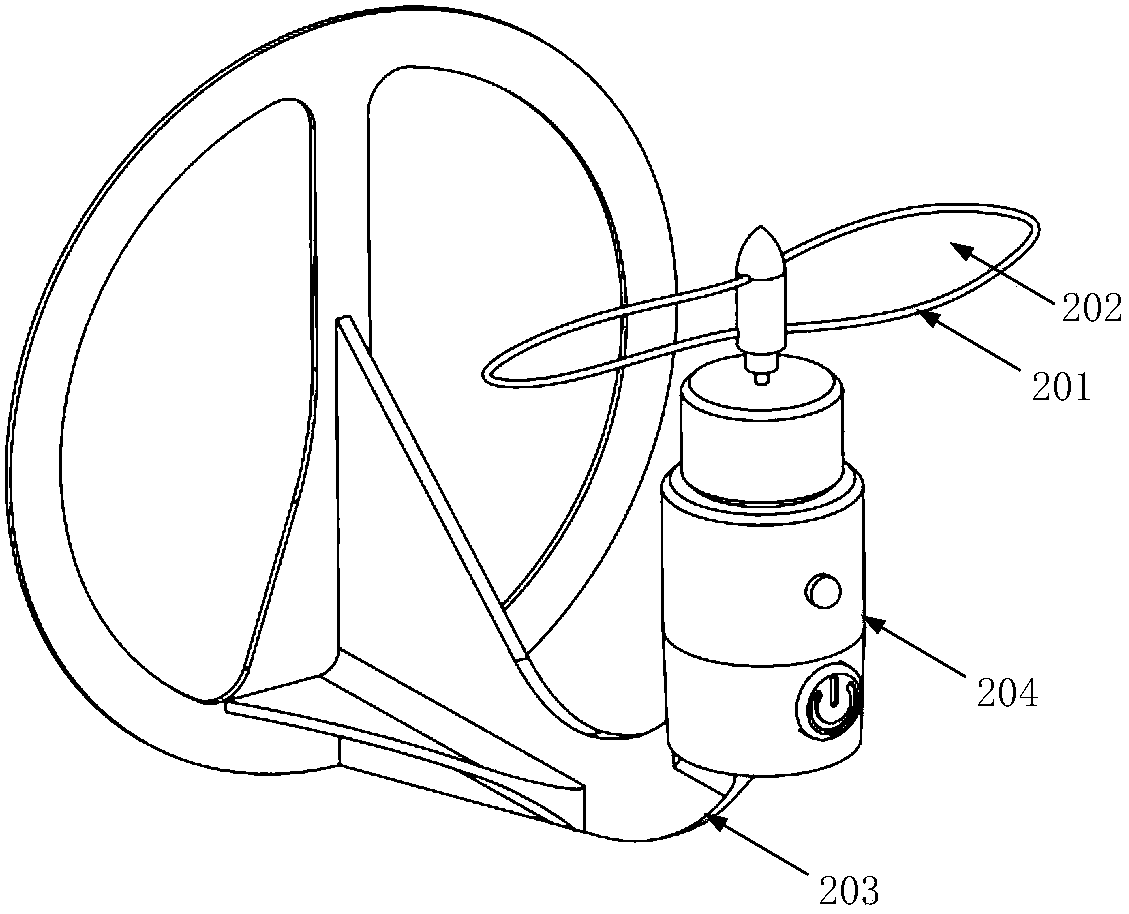

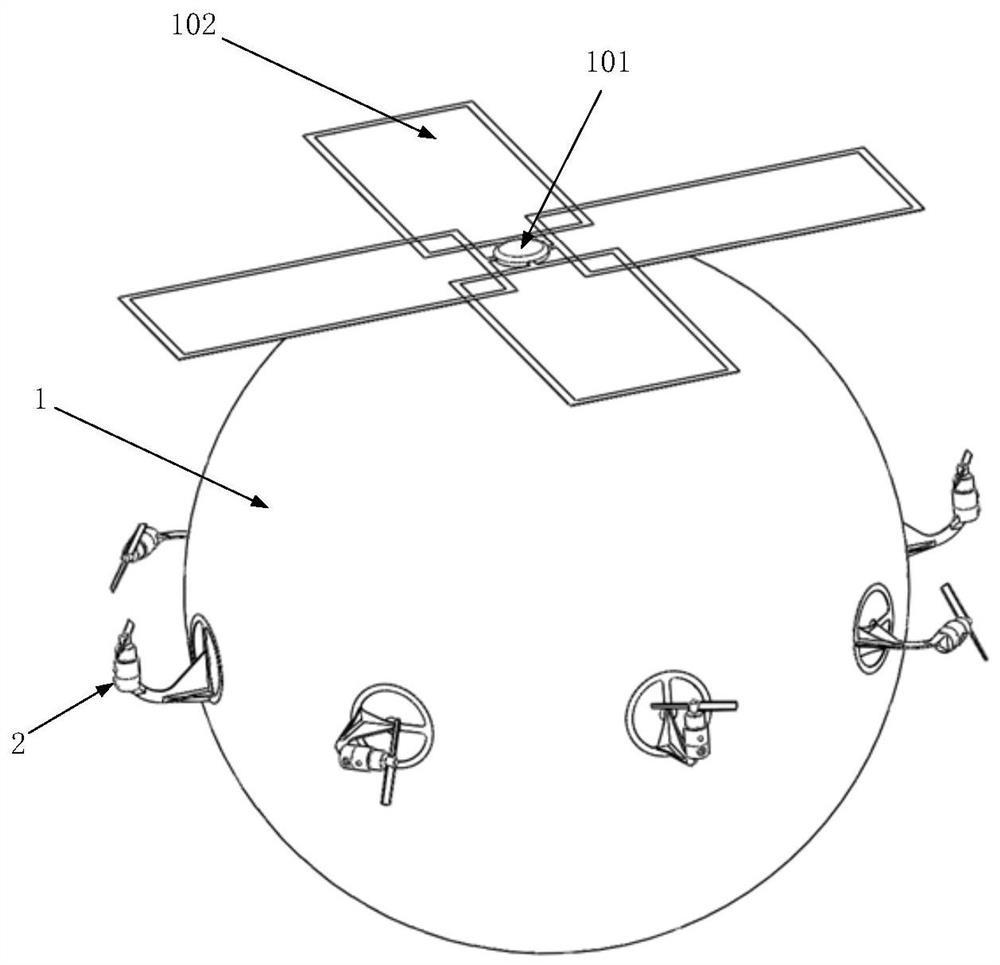

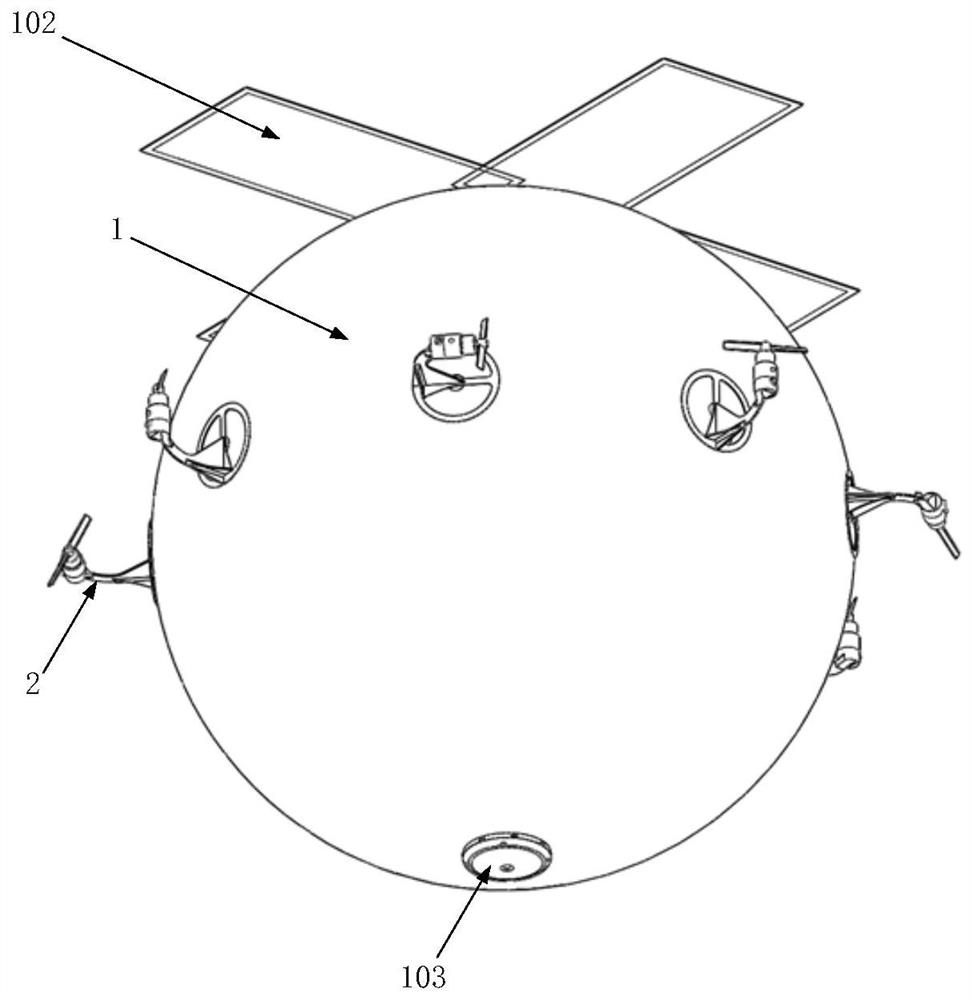

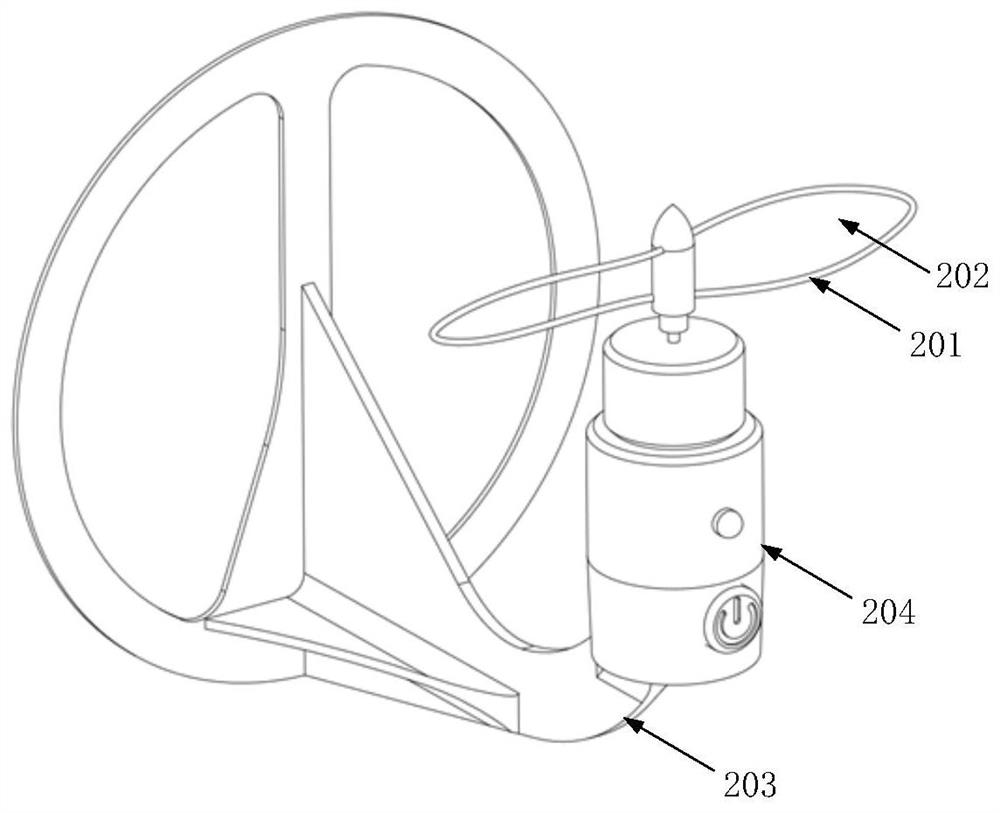

Rotor and inflatable airbag combined type floating aircraft with vectored thrust

ActiveCN108146608ASimple structureImprove securityRigid airshipsHybrid airshipsMaximum diameterAirbag

The invention discloses a rotor and inflatable airbag combined type floating aircraft with vectored thrust. The rotor and inflatable airbag combined type floating aircraft with vectored thrust comprises an aerostat and rotor power modules. Rotors in the rotor power modules are mounted on the round surface with maximum diameter at equal intervals in the circumferential direction by using 8-shaped frames and flexible film extended blades, which are molded by laser at one time; the rotors in the rotor power modules are arranged in horizontal and vertical layouts; and the rotors in the rotor powermodules can realize that the vector-propelled rotor modules regularly programs power output and can finish rapid motions, such as climbing, descending, hovering, spinning and so on, of the aircraft in each direction. A flexible film solar cell module is designed at the top end of an aerostat and a charging unit and a central control unit are designed at the bottom end of the aerostat. The rotor and inflatable airbag combined type floating aircraft with vectored thrust is mainly applied to near spaces, closed indoor spaces and semi-closed spaces, has the advantages, such as long flight duration, large ceiling, stable floating, low flight noise and so on, of the aerostat and also has the advantages, such as higher mobility and operating performance, of a multi-rotor unmanned aerial vehicle.

Owner:BEIHANG UNIV

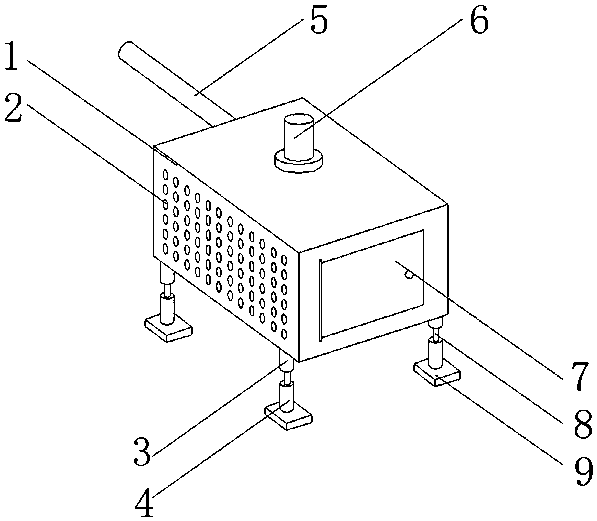

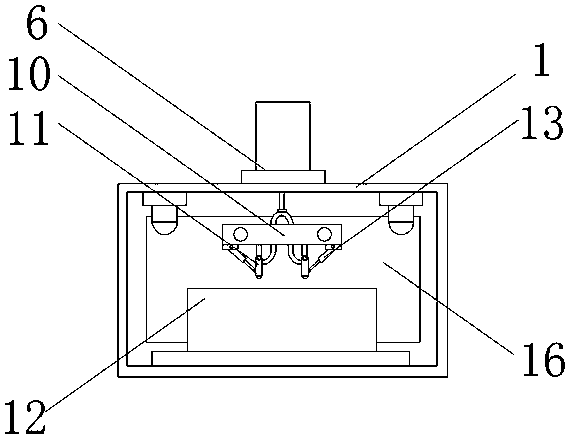

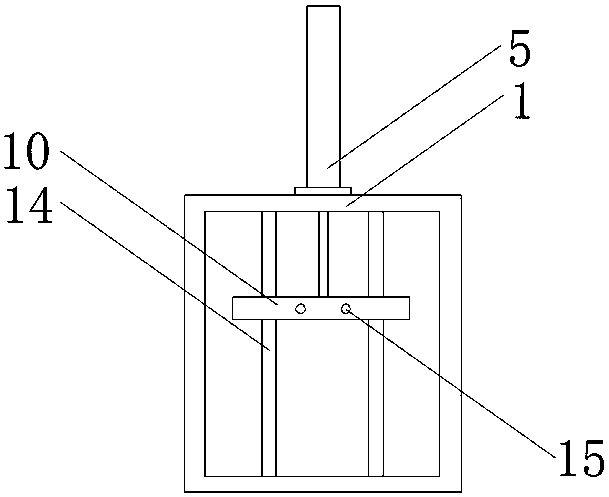

Double-cylinder ultra-low mute diesel generating set

InactiveCN107587938AAdequate heat dissipationGuaranteed quiet effectMachines/enginesEngine componentsEngineeringPiston rod

The invention discloses a double-cylinder ultra-low mute diesel generating set which comprises a protection case, wherein a cavity is formed inside the protection case; a damping device is arranged atthe lower end of the protection case; power generating equipment is arranged in the cavity; two lead screws are fixedly arranged on opposite side walls in the cavity; a moving block penetrates through the lead screws; an oil cylinder is fixed on one side of the protection case; the tail end of a piston rod of the cylinder penetrates through the protection case and is fixed on one side of the moving block; an air blower is fixedly arranged at the upper end of the protection case; the lower end of the air blower is connected with a connecting pipe; and two sides at the lower end of the moving block are rotationally connected with air cylinders.

Owner:盐城市双利电机有限公司

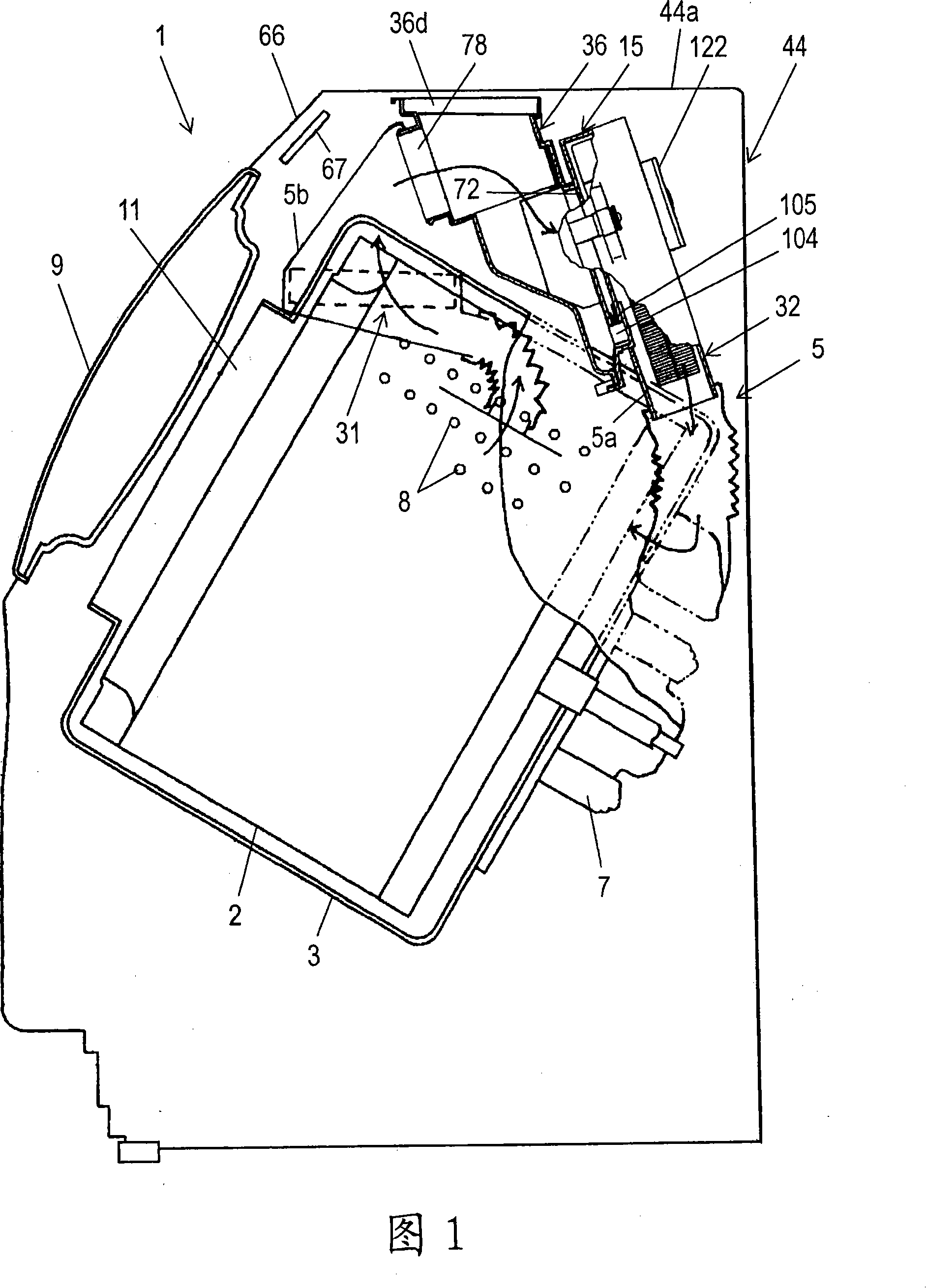

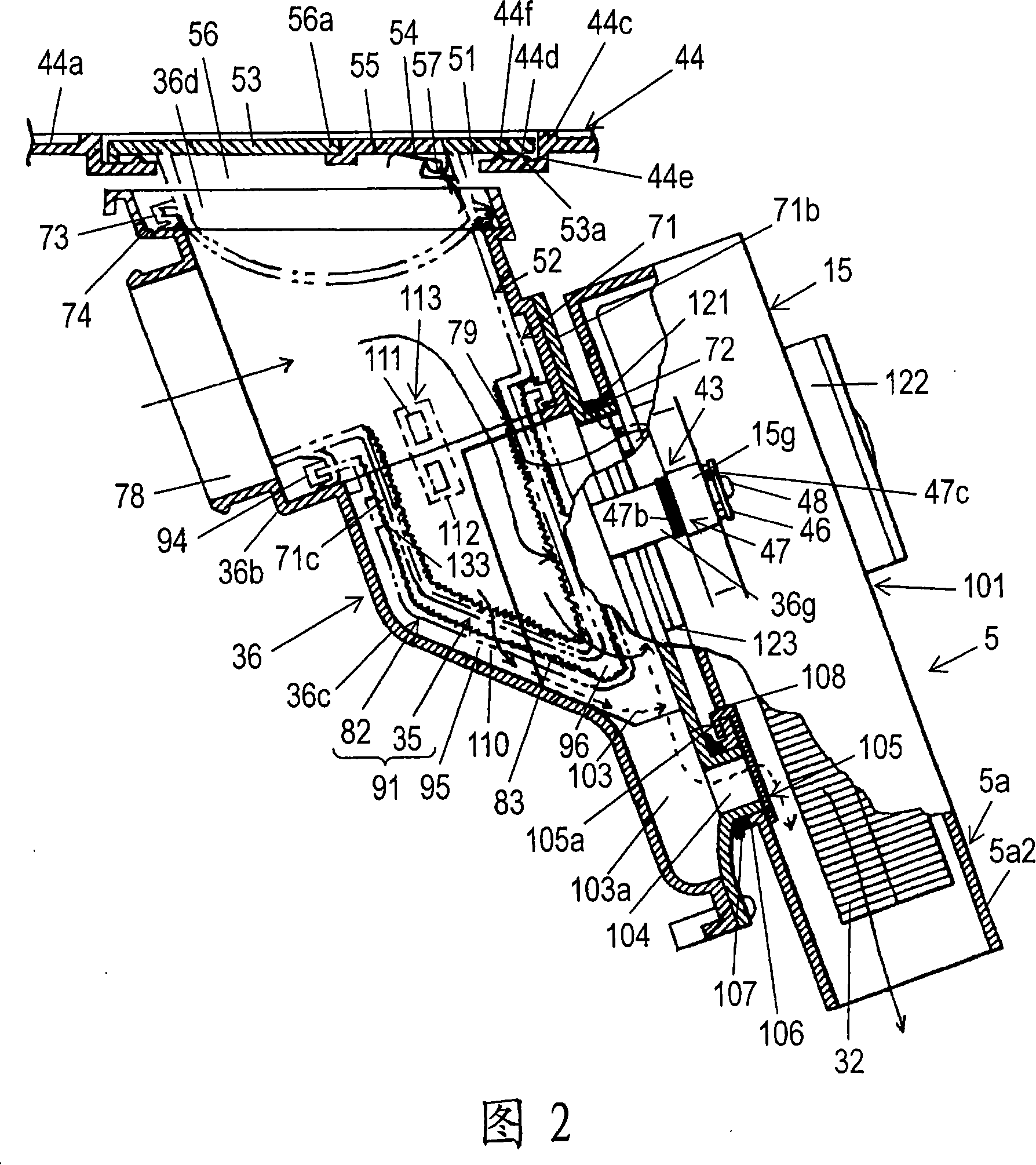

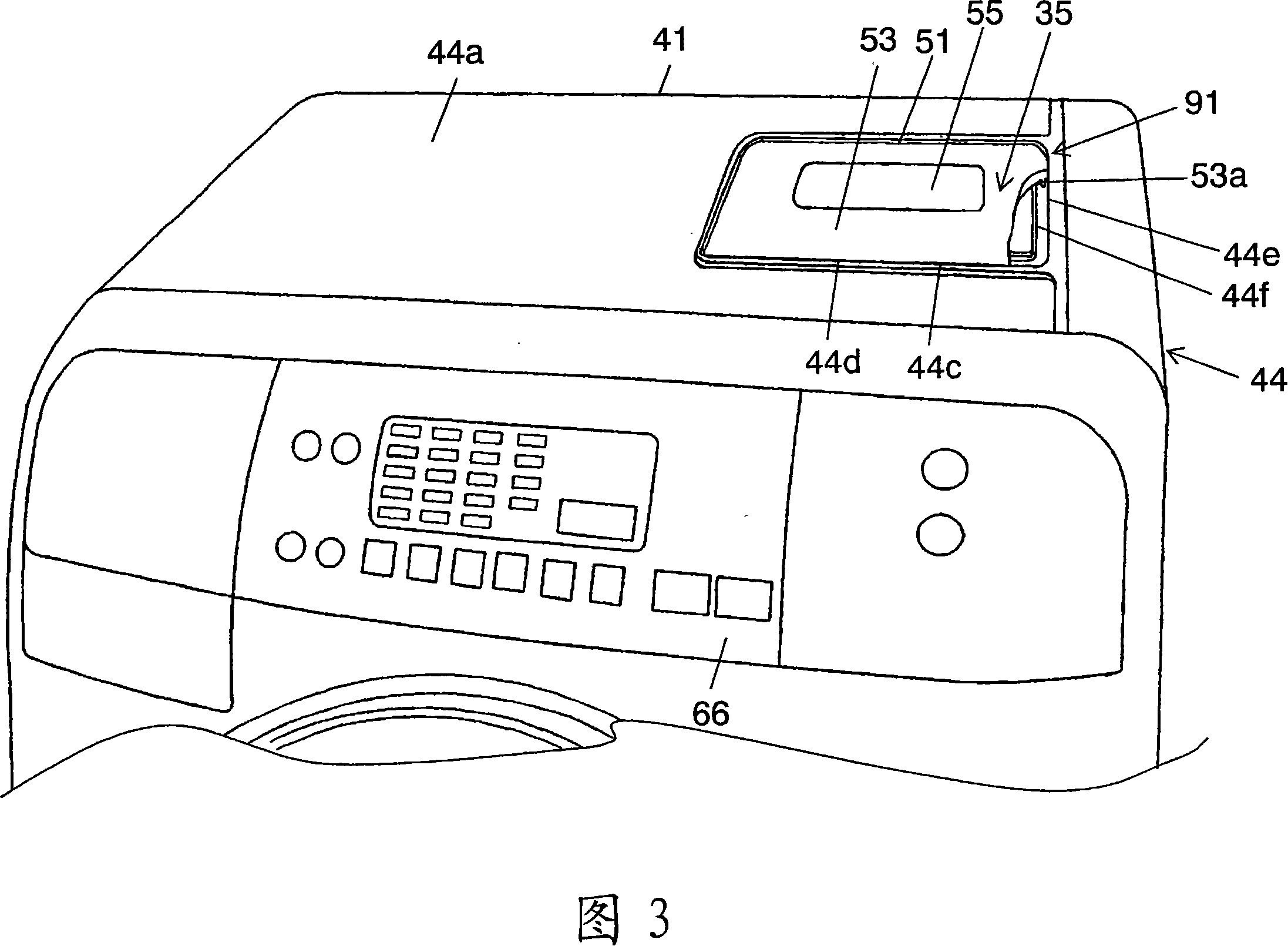

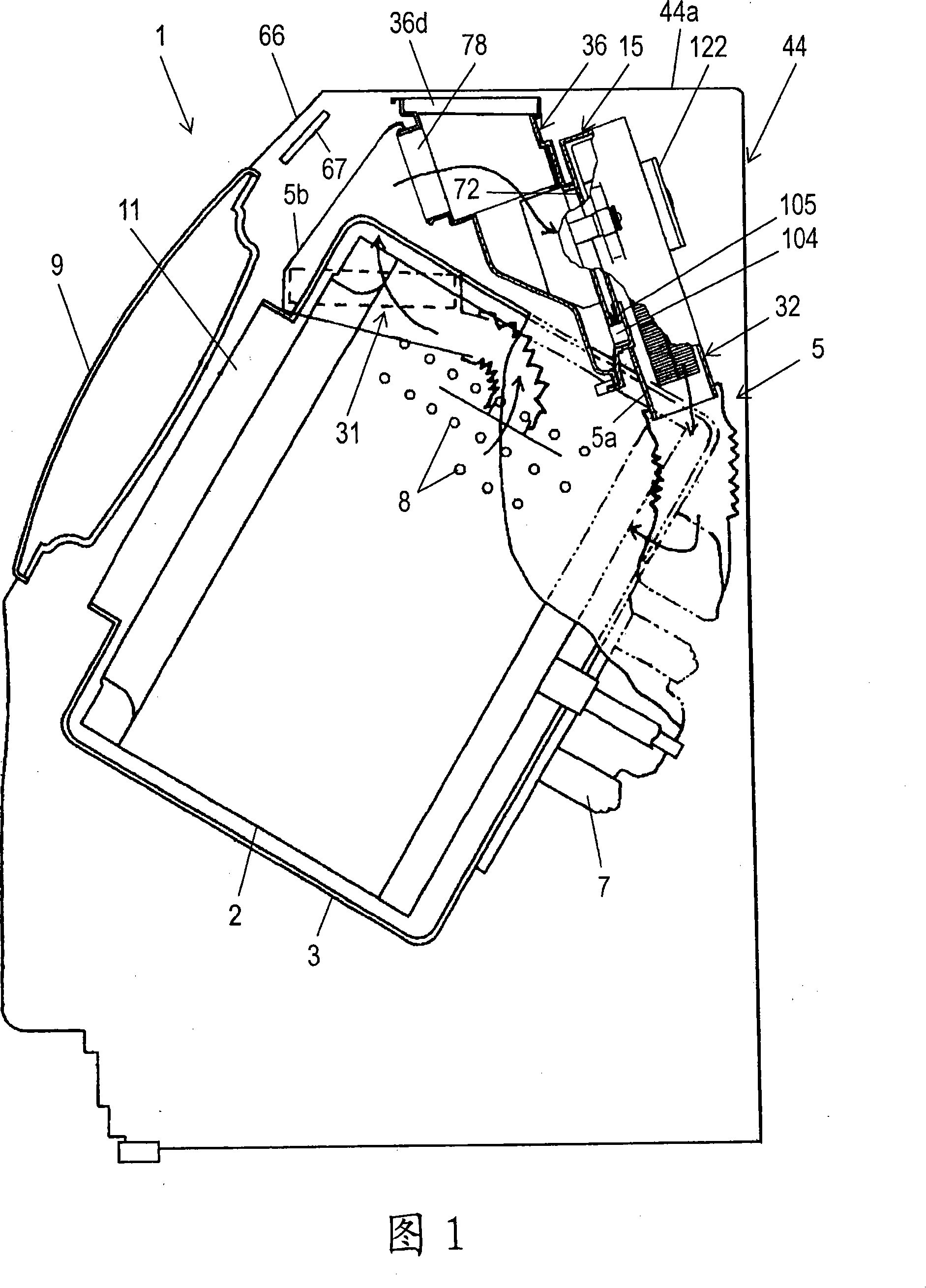

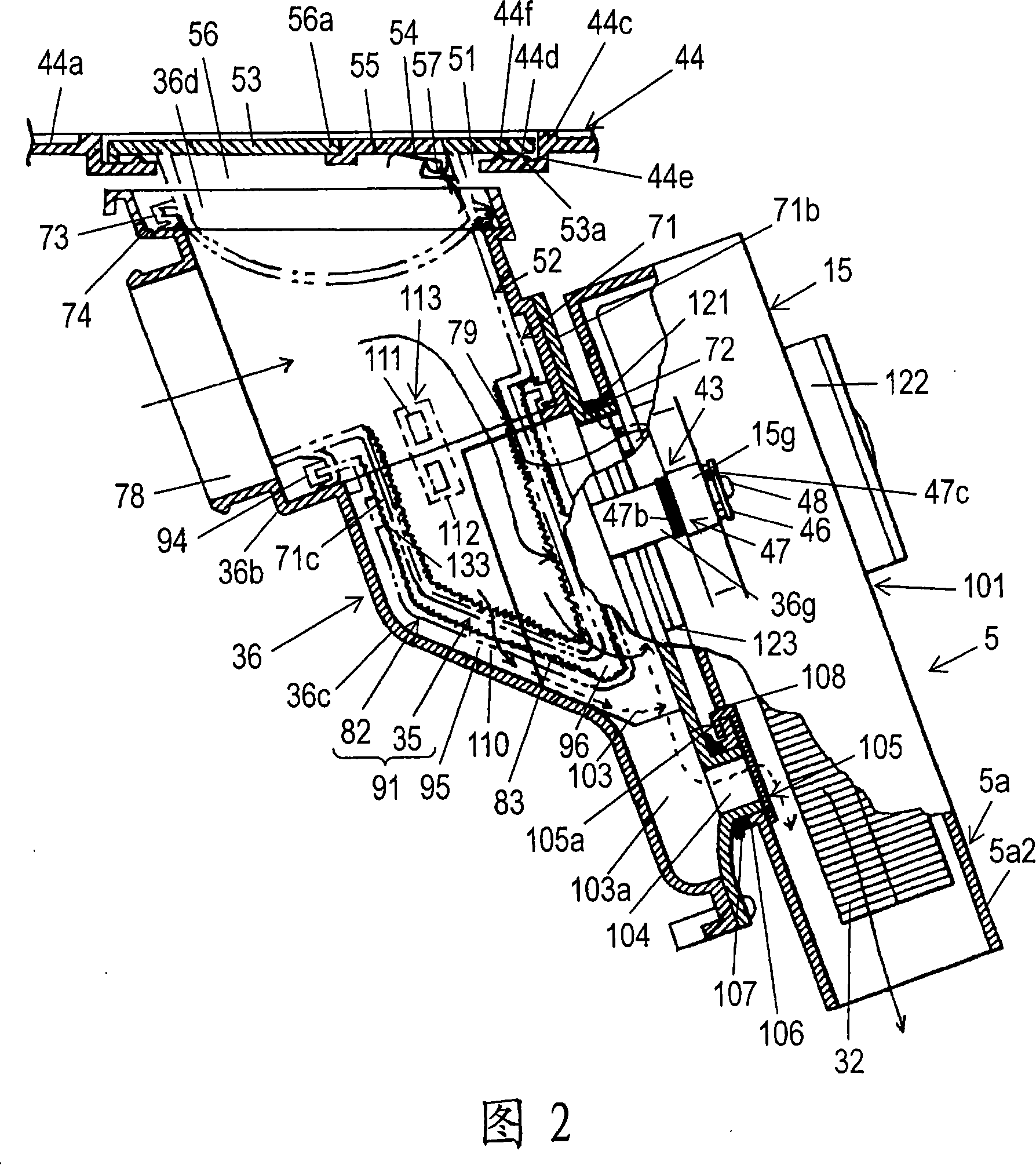

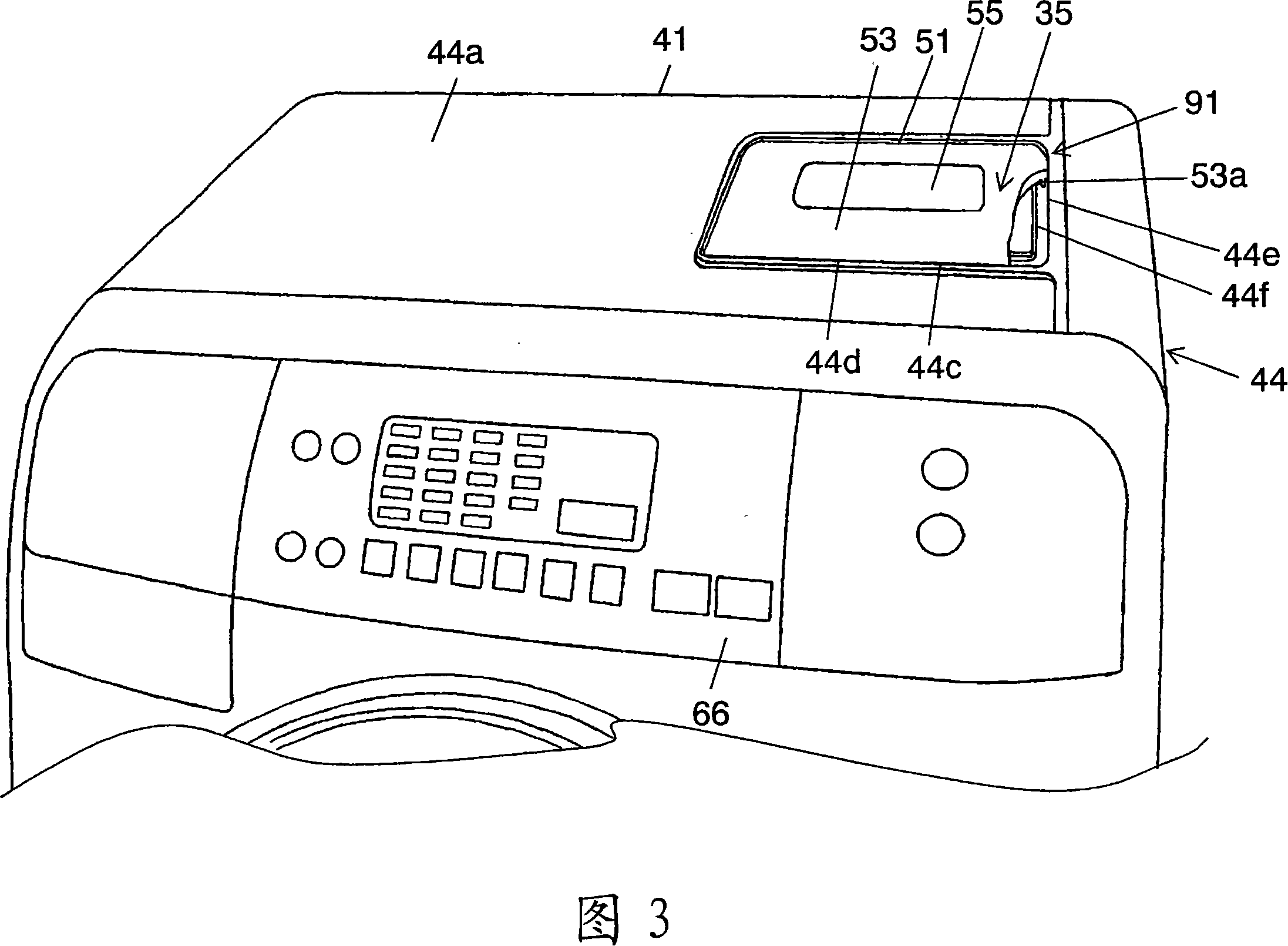

Roller washing and drying machine

ActiveCN101173443AEasy to drill intoReduce in quantityOther washing machinesWashing machine with receptaclesEngineeringMechanical engineering

The invention provides a roller type washing drier which is provided with a blast device. In order to ensure the air in the bucket through the cycle blast route with a filter chamber, a dehumidifying device and a heating device to realize the drying procedure of the washing, the blast device combines the air inlet side at the cycle air outlet side of the filter chamber by the manner of mutual shake-proof structure part, thereby realizing integration.

Owner:PANASONIC CORP

Seepage-preventing wood veneer structure for wall and installing method thereof

The invention discloses a seepage-preventing wood veneer structure for a wall and an installing method thereof. The wood veneer structure comprises a base plate, wherein the bottom surface of the baseplate is provided with a diversion groove, the end faces of the base plate are provided with water absorbing layers, the top face of the base plate is provided with a fixing plate, the end faces of the fixing plate are both provided with sliding grooves, clamping blocks are connected to the sliding grooves through springs, the surface of the fixing plate is provided with an isolating membrane anda sound absorbing layer, and the base plate is connected with a face plate through the fixing plate. The bottom surface of the face plate is provided with a fireproof buffer layer, and the inner sideface of the fireproof buffer layer is provided with a clamping groove. The installing method of the seepage-preventing wood veneer structure comprises the steps that the wall is flatted and dried, akeel support is installed, then the base plate is installed on the keel support, and finally the face plate is installed on the base plate. The seepage-preventing wood veneer structure has the advantages of being higher in installing efficiency, simple to change in a later period, better in dampproof capability and high in firmness.

Owner:湖州韵高木业有限公司

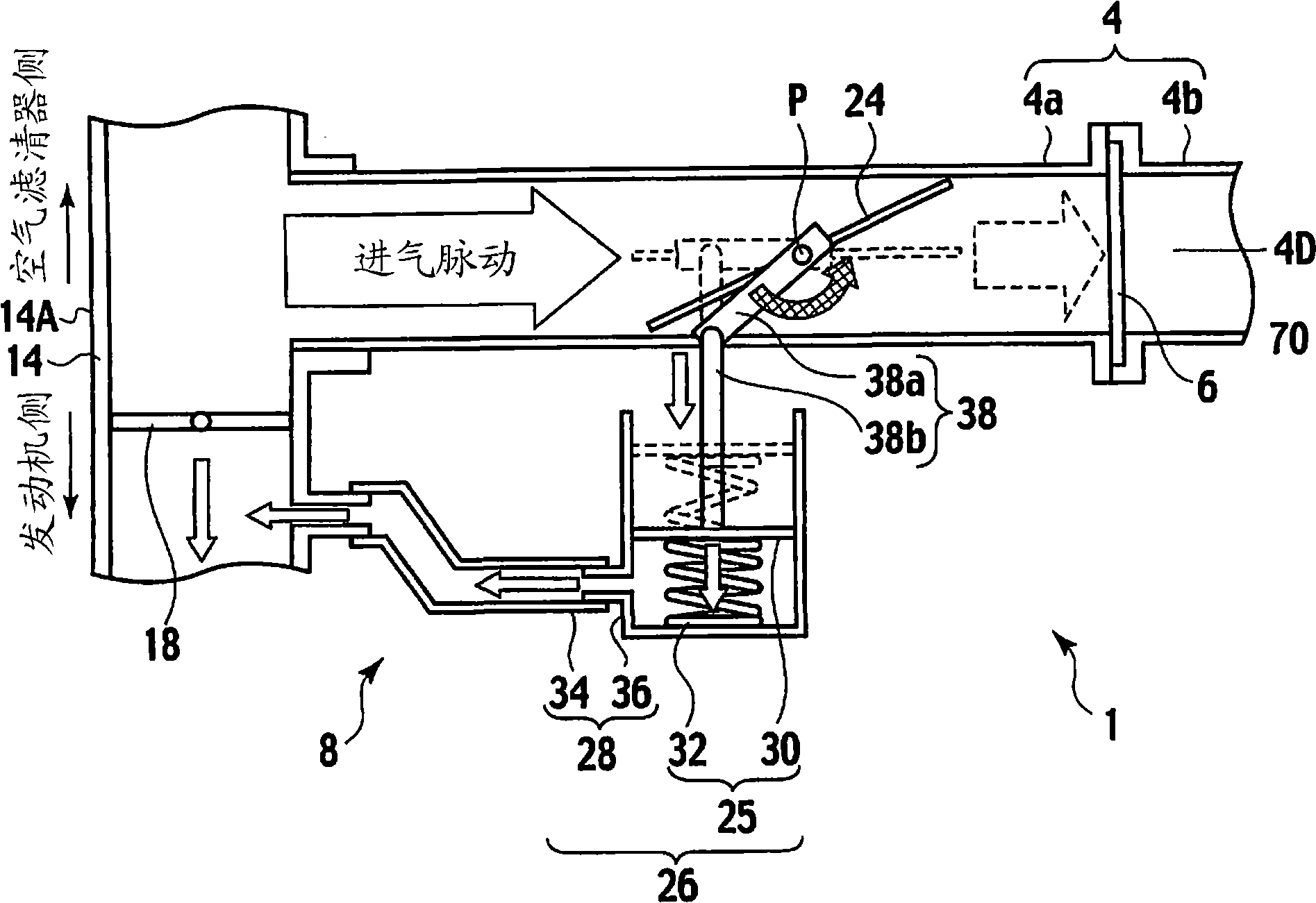

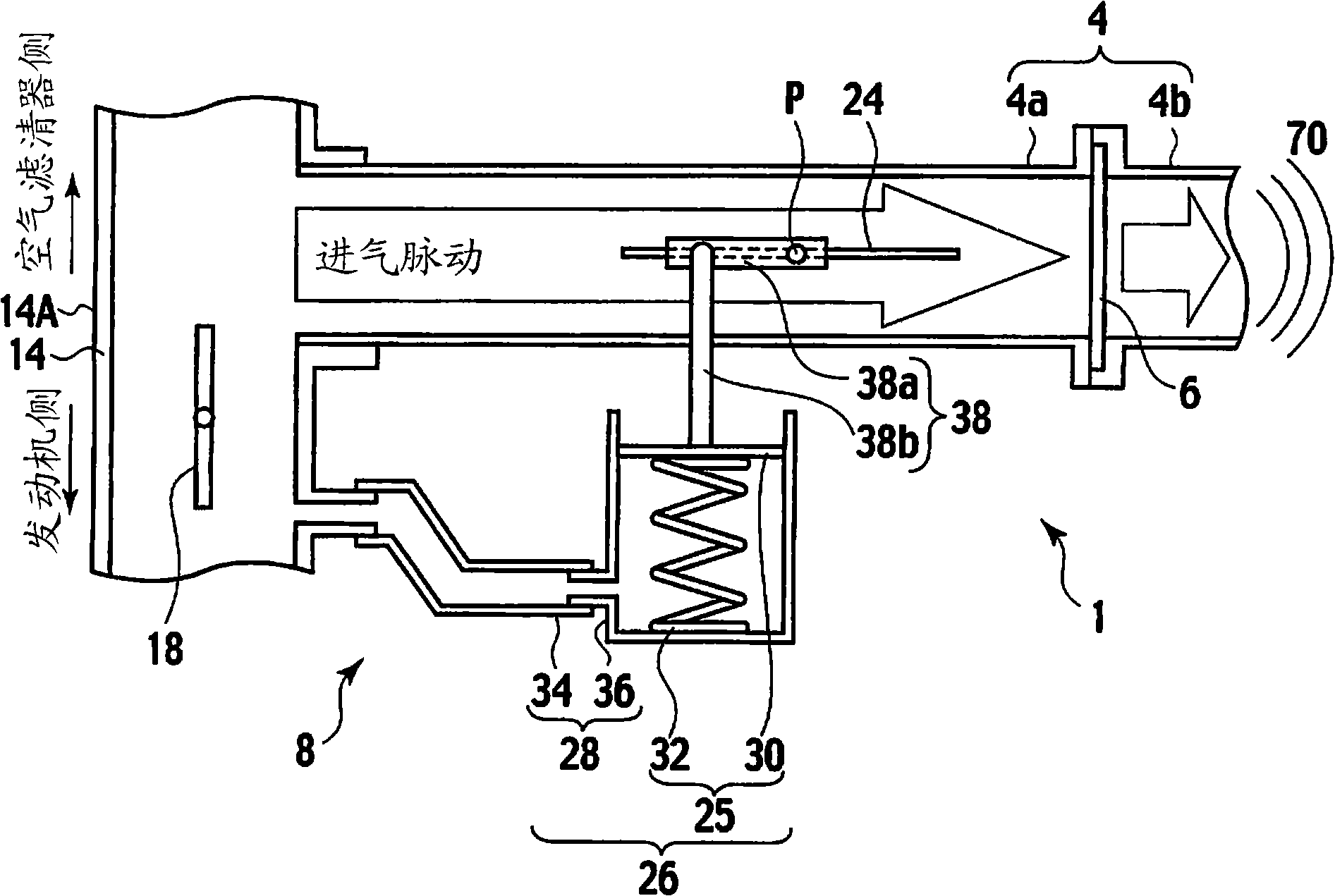

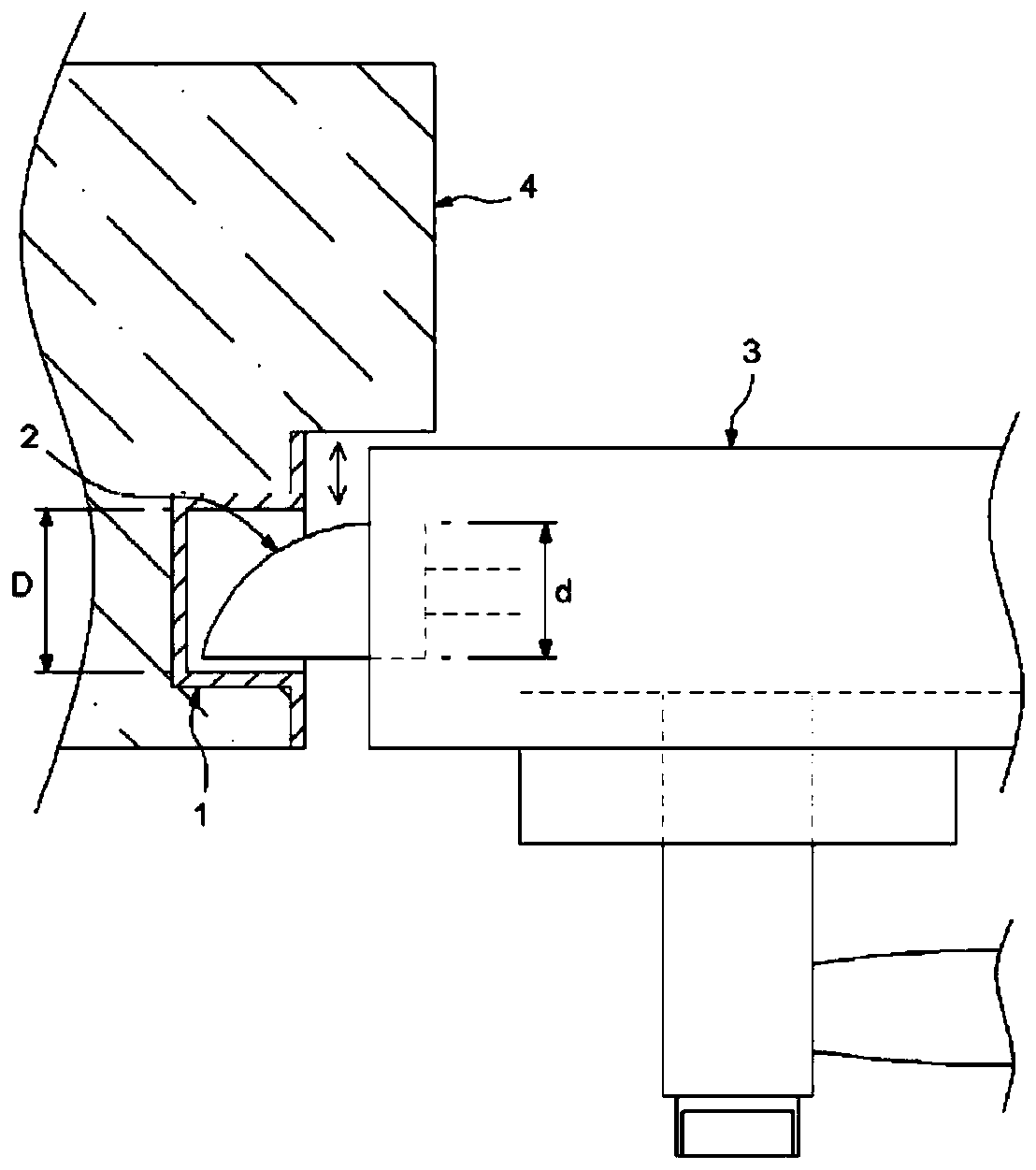

Intake air noise adjuster

InactiveCN101353995AReduce the effect of enlargementGuaranteed quiet effectIntake silencers for fuelEngineering

An intake air noise adjuster includes: a communicating conduit including: a first end communicating to an intake air passage to an engine, and a second end communicating to an external air; an elastic body configured to block the communicating conduit; and a flow channel area changer configured to change a flow channel area of the communicating conduit based on a change of an intake air negative pressure caused in the intake air passage.

Owner:NISSAN MOTOR CO LTD +1

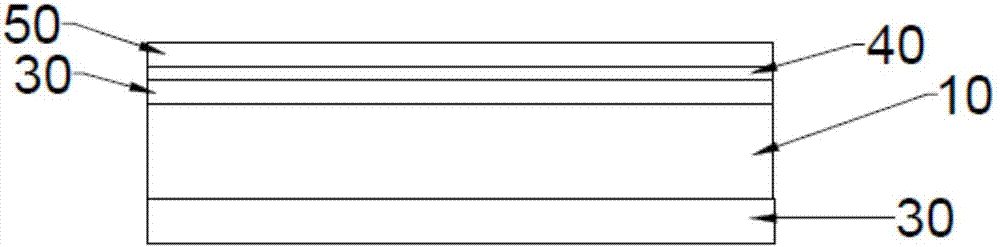

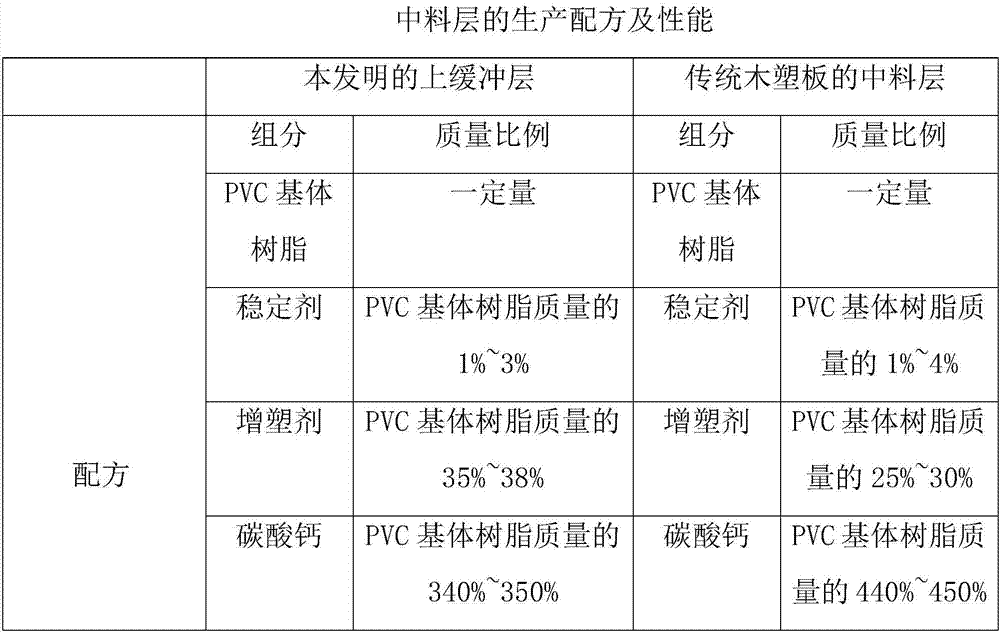

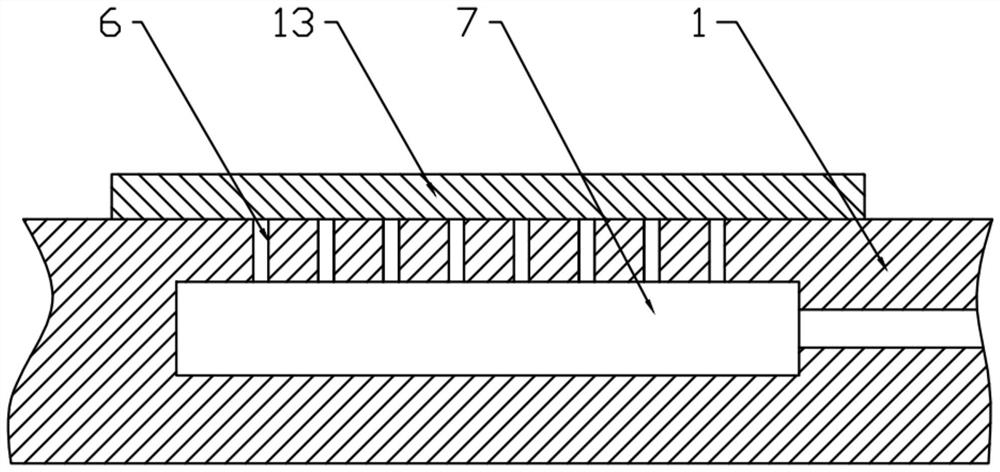

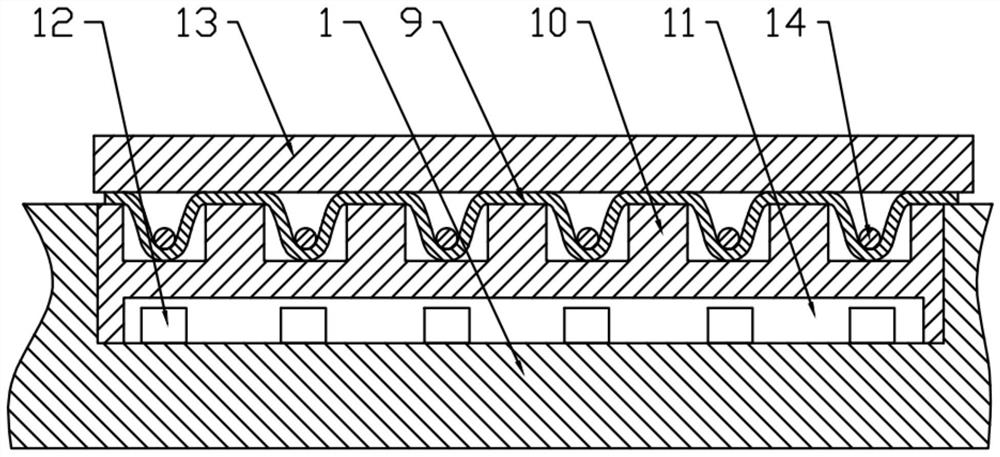

Soundproof wood-plastic floor

The invention provides a soundproof wood-plastic floor which comprises a wood-plastic base layer, an IXPE lower buffer layer arranged on the lower surface of the wood-plastic base layer, and an upper buffer layer connected to the upper surface of the wood-plastic base layer. The upper buffer layer can buffer impact force and vibration on the wood-plastic floor when people walk on the floor, and the lower buffer layer can secondarily buffer impact force and vibration generated to the ground when the wood-plastic floor is stressed. According to the wood-plastic floor, through the dual buffering effects and the sound absorption effect of the upper buffer layer and the lower buffer layer, noise generated by the floor when people walk on the floor is effectively lowered, and a good soundproof effect is achieved.

Owner:ZHEJIANG KINGDOM NEW MATERIAL GRP CO LTD

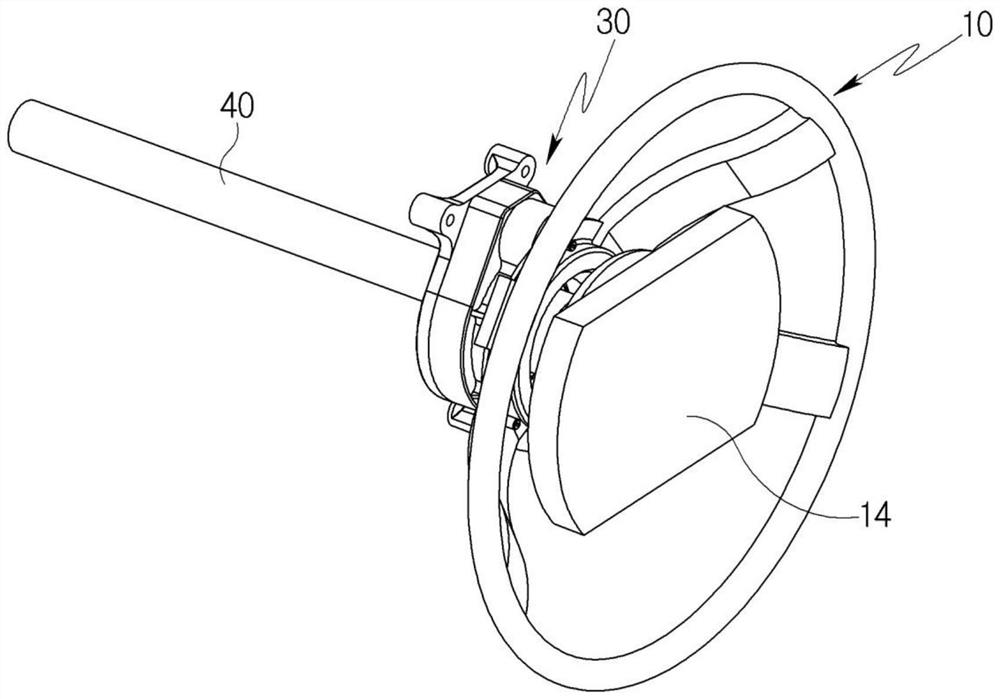

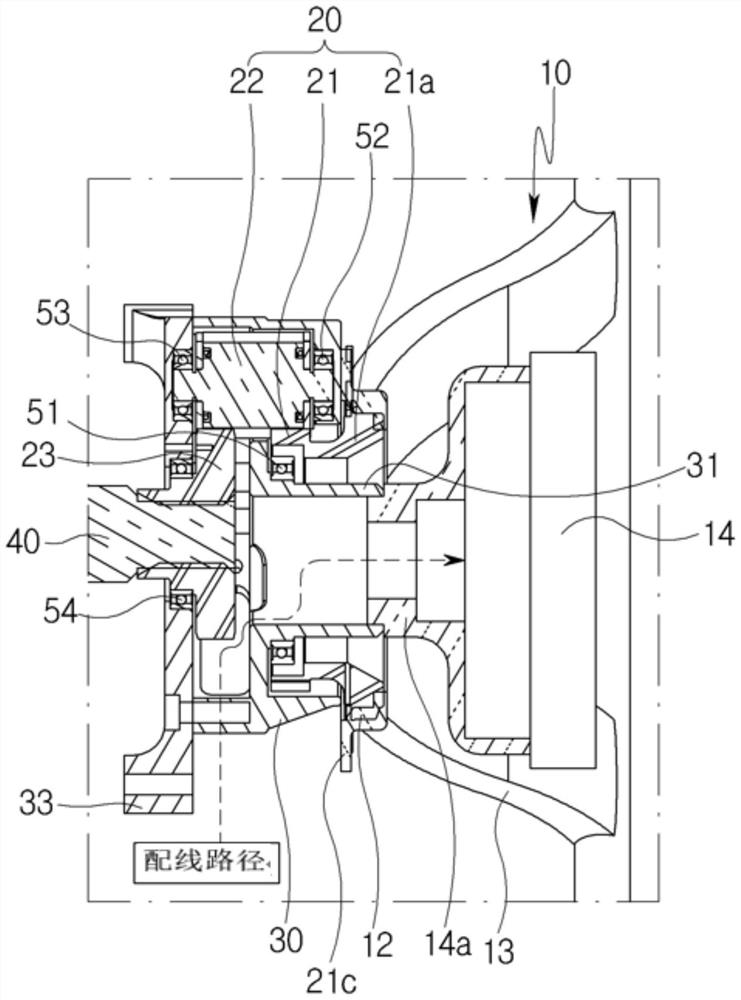

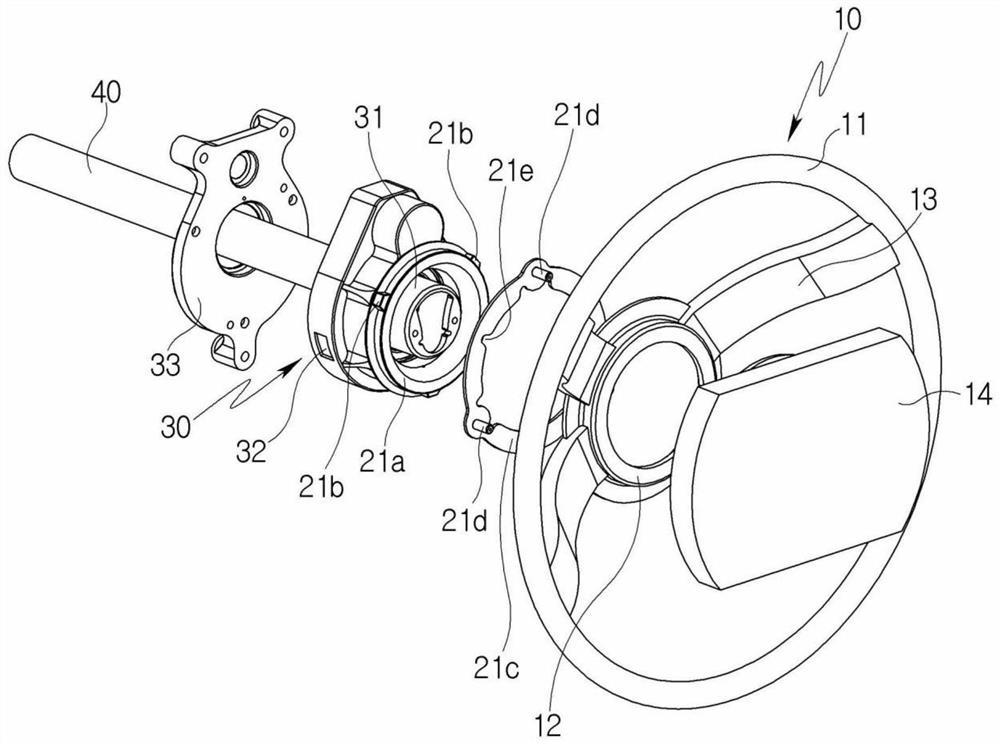

Vehicle steering apparatus having irrotational core part

ActiveCN112543726AEasy to useRemove distortionPedestrian/occupant safety arrangementVehicle sub-unit featuresSteering wheelSteering angle

Disclosed is a vehicle steering apparatus capable of facilitating the user's convenience by providing on a hub positioned at the center of a steering wheel an irrotational core part on which various electric modules are to be mounted so that it is possible to use the electric modules conveniently regardless of a steering angle. The vehicle steering apparatus comprises a housing fixed to a vehiclebody, a steering wheel rotatably mounted relative to the housing, a steering gear set installed to transmit rotation of the steering wheel to a steering shaft, and an irrotational core part fixed to the housing and allowing an outer wire harness to be wired thereto.

Owner:PYONG HWA VALEO

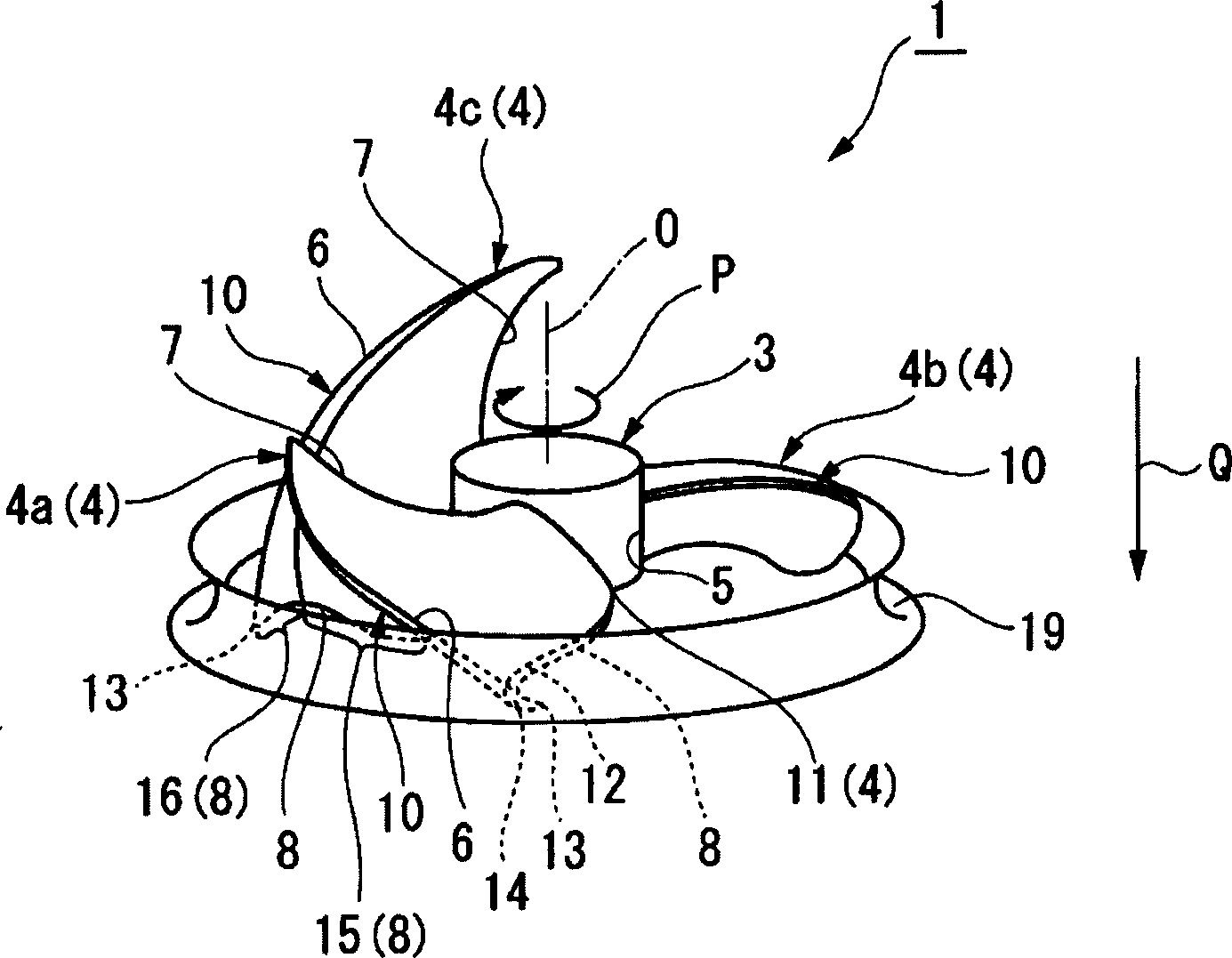

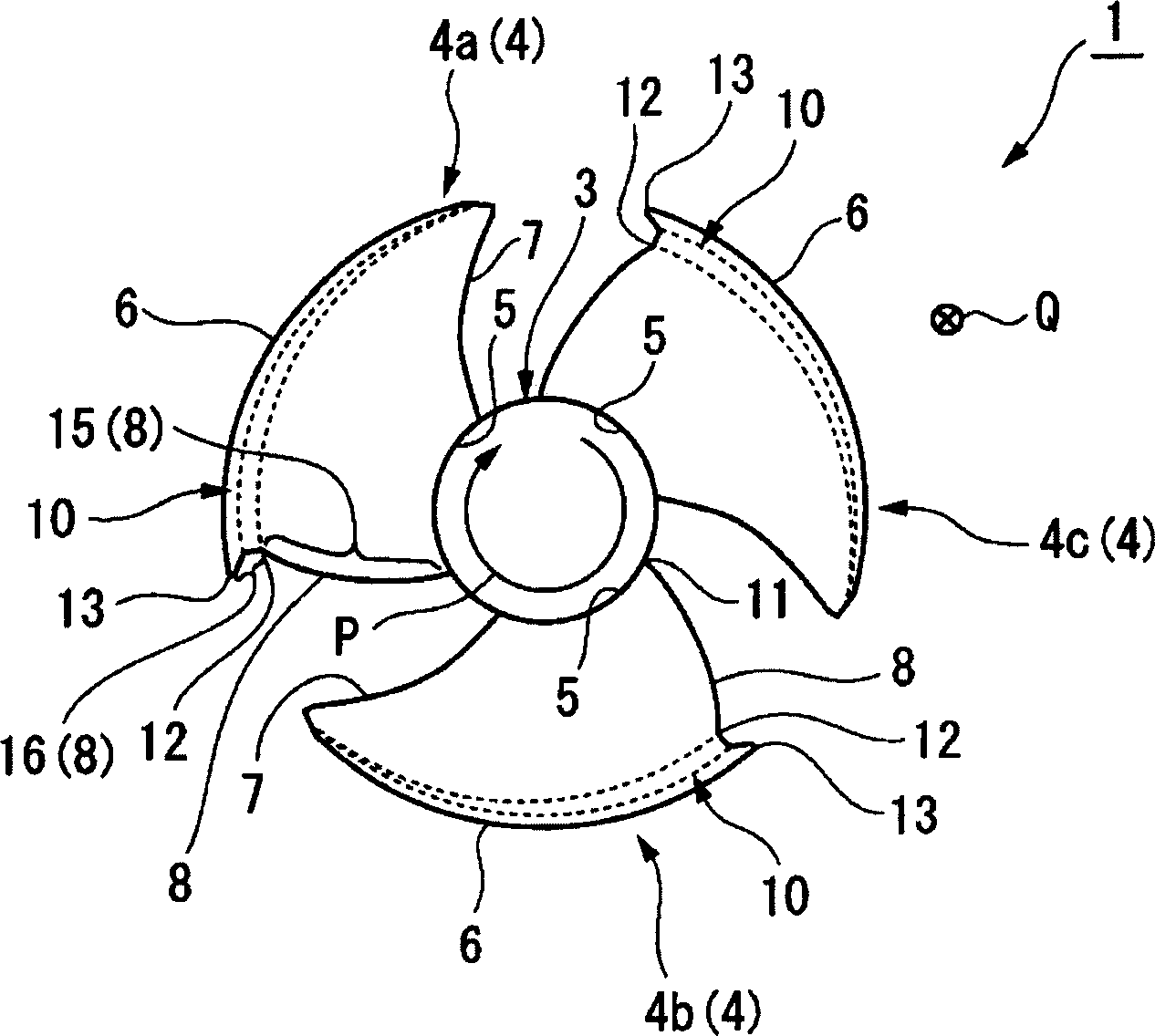

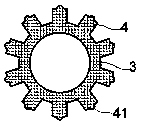

Spiral fan and air conditioner therewith

InactiveCN1712734AReduce eddy current noiseSuppression of useless work lossPump componentsOther chemical processesPropellerTrailing edge

PROBLEM TO BE SOLVED: To provide a propeller fan capable of increasing marketability by preventing noise caused by swirl and increasing performance by suppressing the loss of aerodynamic force and an air conditioner using the propeller fan. SOLUTION: This propeller fan 1 sends out a fluid from an upstream side to a downstream side by rotating a hub 3 to which at least one vane 4 is fitted in a prescribed direction. The outer peripheral part of the vane 4 comprises a curved part 10 curved so that at least a part near its trailing side faces a negative pressure side. The trailing line 8 of the vane 4 is formed in such a curve that advances in the rotating direction while drawing a gentle curve from the inner peripheral end to the outer peripheral side of the vane 4 when projected on a plane perpendicular to the rotating axis O of the hub 3 and retreats in the rotating direction so as to have an inflection point 12 on the slightly root side of the outer peripheral end 13 of the vane 4. COPYRIGHT: (C)2006,JPO&NCIPI

Owner:SAMSUNG ELECTRONICS CO LTD

A vacuum cleaner structure

The invention discloses a vacuum cleaner structure which comprises a main machine shell, a dust suction mop, a universal wheel, a plurality of moving wheels and an induced draft motor. The main machine shell is provided with a dust cup component and a suction opening seat. The suction opening seat is connected with the dust suction mop through a dust suction pipe. The dust cup component comprises a dust cup, a cyclone cone and inner dust bin. The cyclone cone is provided with a straight wind inlet, a downwardly-spiral wind guide channel and a cyclone outlet which are sequentially communicated. The straight wind inlet is communicated with the suction opening seat. The cyclone cone is provided with a cone inner cylinder. The cone inner cylinder is provided with a vertical wind return channel communicated with the cyclone outlet. The cyclone outlet is communicated with the inlet of the vertical wind return channel and the inner dust bin. The outlet of the vertical wind return channel is communicated with the induced draft motor. The vacuum cleaner structure has the advantages that the wind inlet and outlet channels are reasonable in structure, and dust can be separated and collected by cyclone; the vacuum cleaner structure is high in dust suction ability and is provided with a multistage filter structure which is good in filter effect; noise during wind discharge can be reduced, and vibration and the noise can be reduced effectively to keep a good silent effect by a stability strengthening structure.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

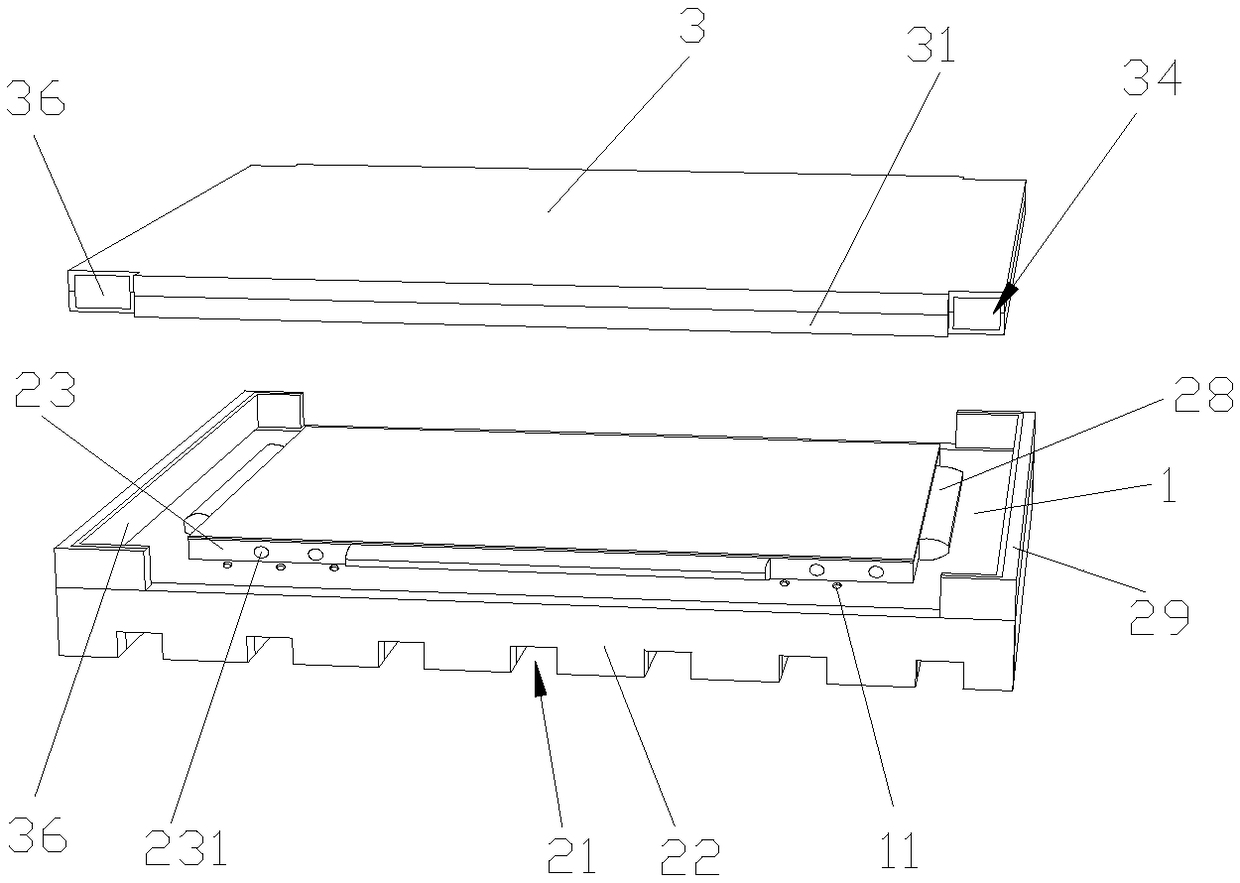

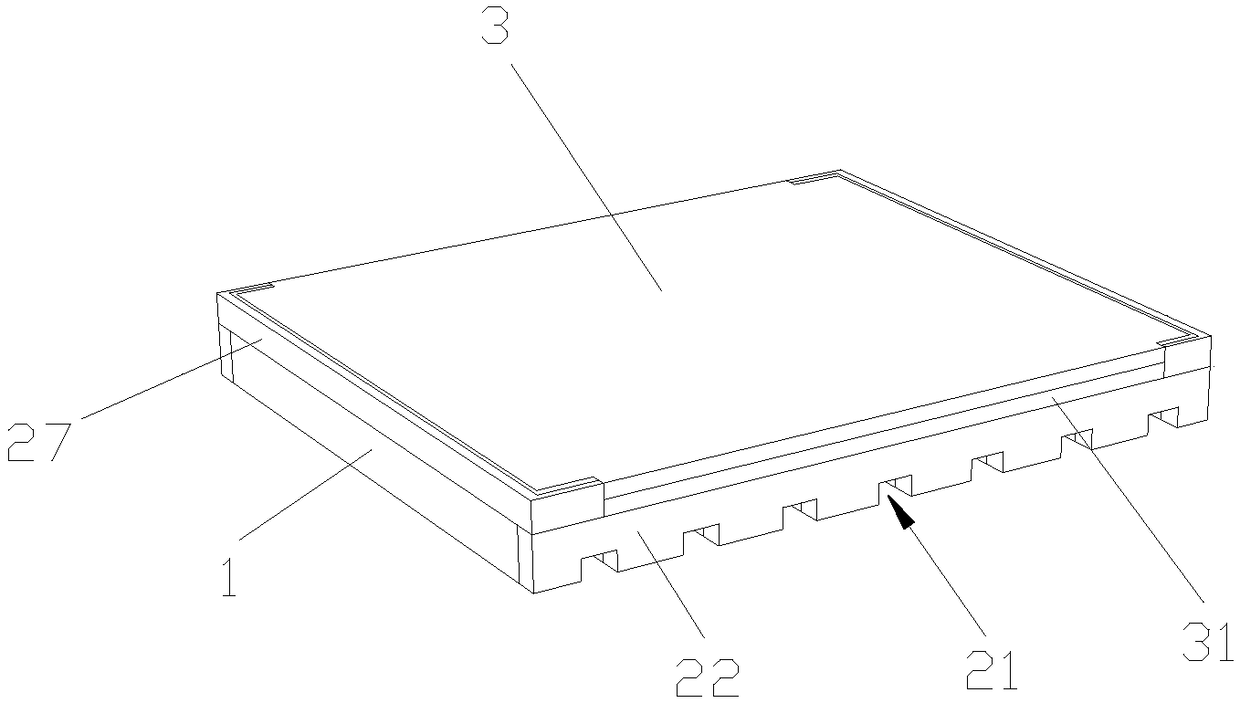

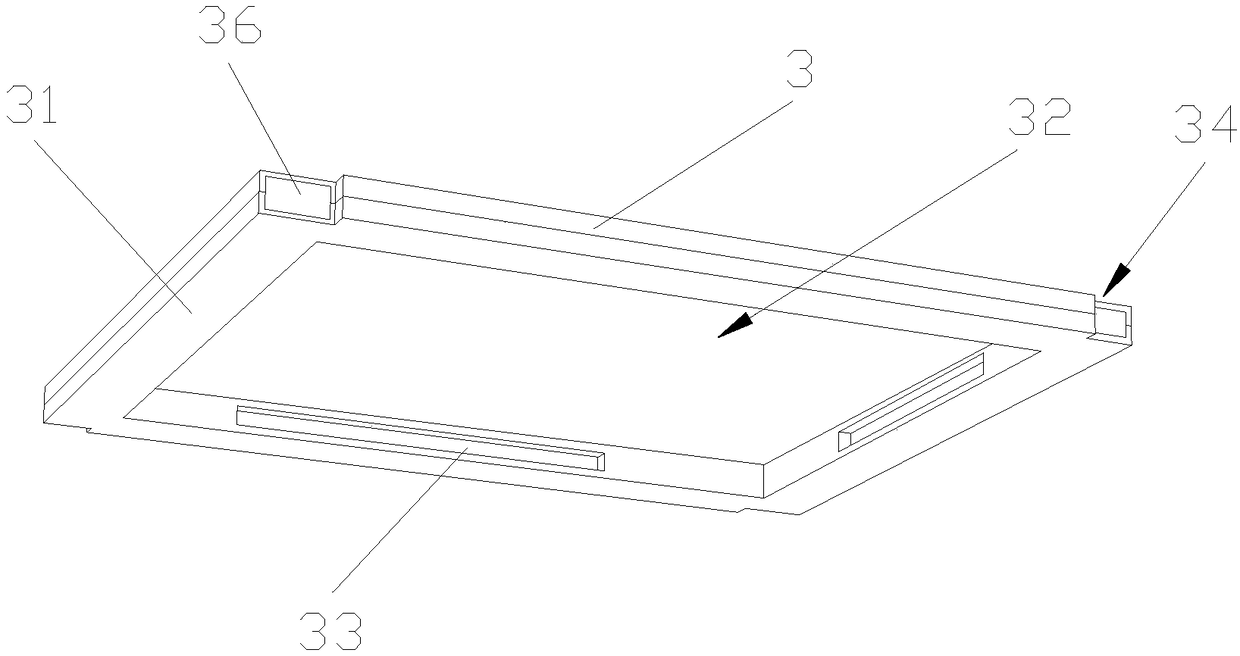

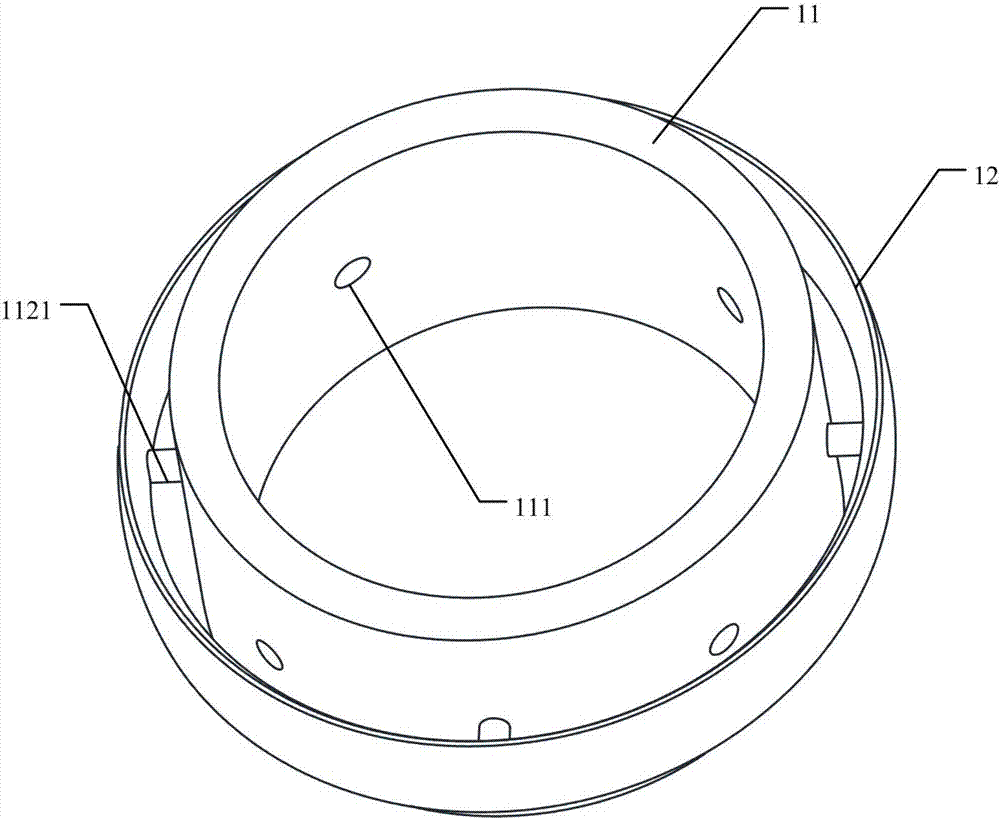

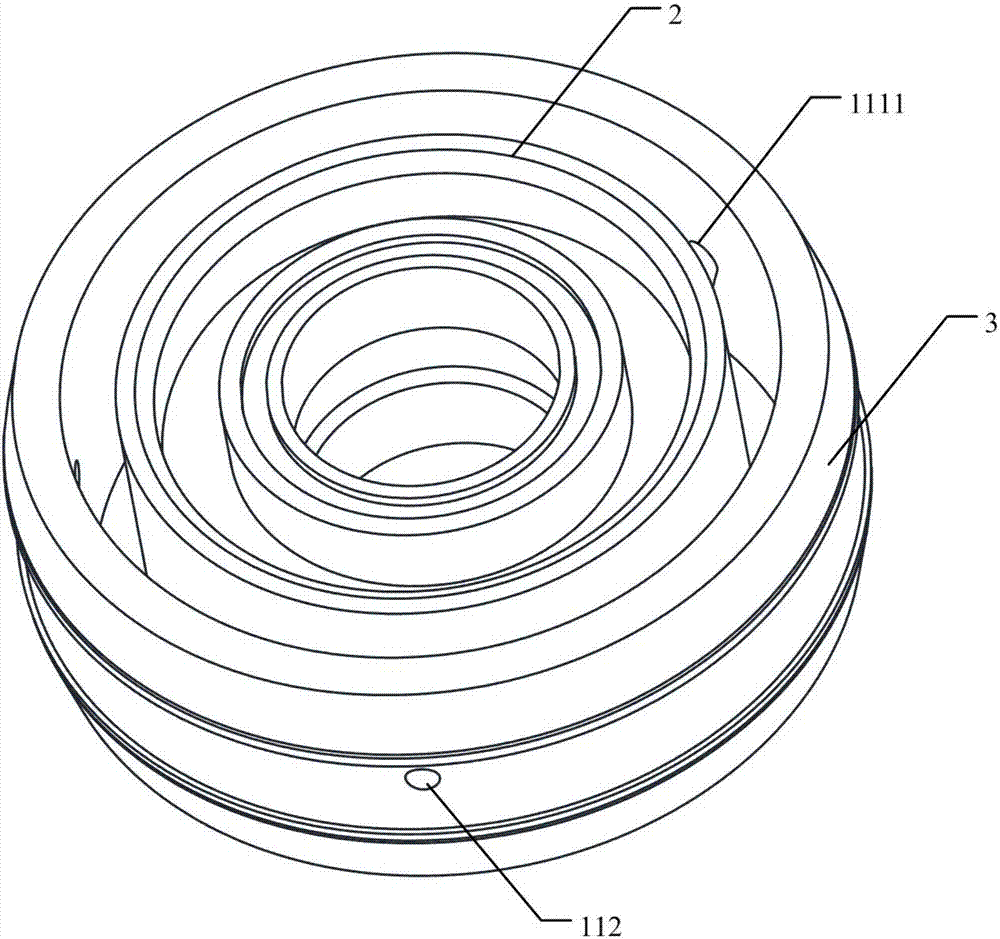

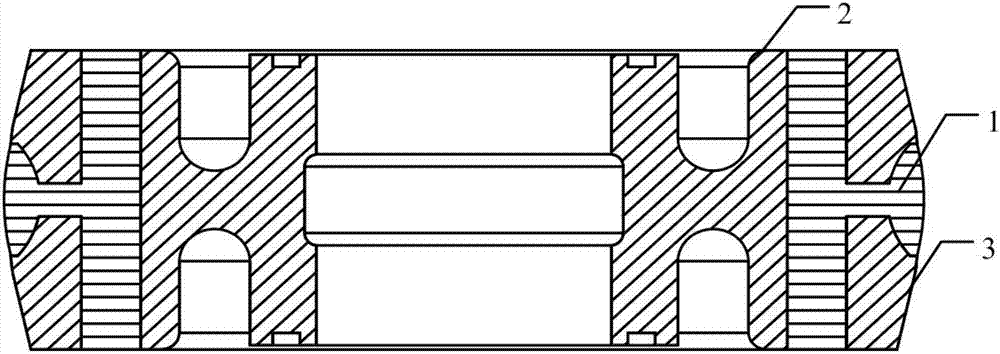

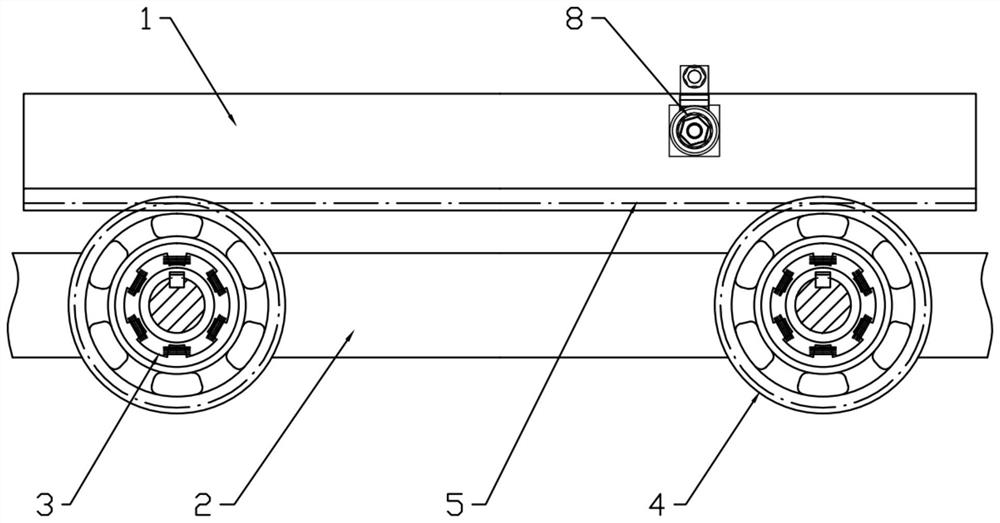

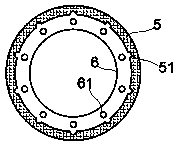

Sandwich bidirectional damping wheel

ActiveCN107984960AMeet the needs of heavy loadsAvoid separationHigh resiliency wheelsEngineeringHeavy load

The invention discloses a sandwich bidirectional damping wheel. The sandwich bidirectional damping wheel comprises a wheel core (1), an inner wheel wrapping part (2) and an outer wheel wrapping part (3), wherein the wheel core (1) comprises a support part (11) and a reinforcing part (12), and the support part (11) is of an annular cylinder structure; the inner wheel wrapping part (2) is embedded into the support part (11) in a matched manner, the outer wheel wrapping part (3) is located between the support part (11) and the reinforcing part (12), and the reinforcing part (12) is embedded intothe outer side of the outer wheel wrapping part (3) in a matched manner; the wheel core (1) is made of TRP, and the inner wheel wrapping part (2) and the outer wheel wrapping part (3) are made of PP.The sandwich bidirectional damping wheel has the advantages that the PP+TRP+PP structure is used, the PP and the TPR are located on the same wheel cambered surface, a damping effect and a silencing effect are guaranteed, support is enhanced, and heavy load requirements are satisfied.

Owner:ZHONGSHAN CASCOO METAL MACHINERY CO LTD

A composite aeroplane with rotor and inflatable airbag with vector thrust

ActiveCN108146608BSimple structureImprove securityRigid airshipsHybrid airshipsFlight vehicleClassical mechanics

The invention discloses a composite aeroplane with a rotor and an inflatable air bag with vector thrust, which includes an aerostat and a rotor power module. The rotor in the rotor power module is made of a 8-shaped frame formed by laser and a flexible film to form a blade, which is installed on the largest diameter circular surface of the aerostat at equal intervals in the circumferential direction. It is divided into horizontal and vertical layouts, which can realize vector The propelled rotor module is regularly programmed to output power, which can complete the rapid movement of the aircraft in all directions, including climbing, descending, hovering, and spinning. The top of the aerostat is designed with a flexible thin-film solar cell module, and the bottom is designed with a charging and central control unit. The invention is mainly used in adjacent spaces, enclosed indoor spaces and semi-enclosed spaces. It not only has the advantages of long battery life, large ceiling, stable floating and low flight noise of the aerostat, but also has the advantages of high maneuverability of the multi-rotor UAV. Excellent performance and handling performance.

Owner:BEIHANG UNIV

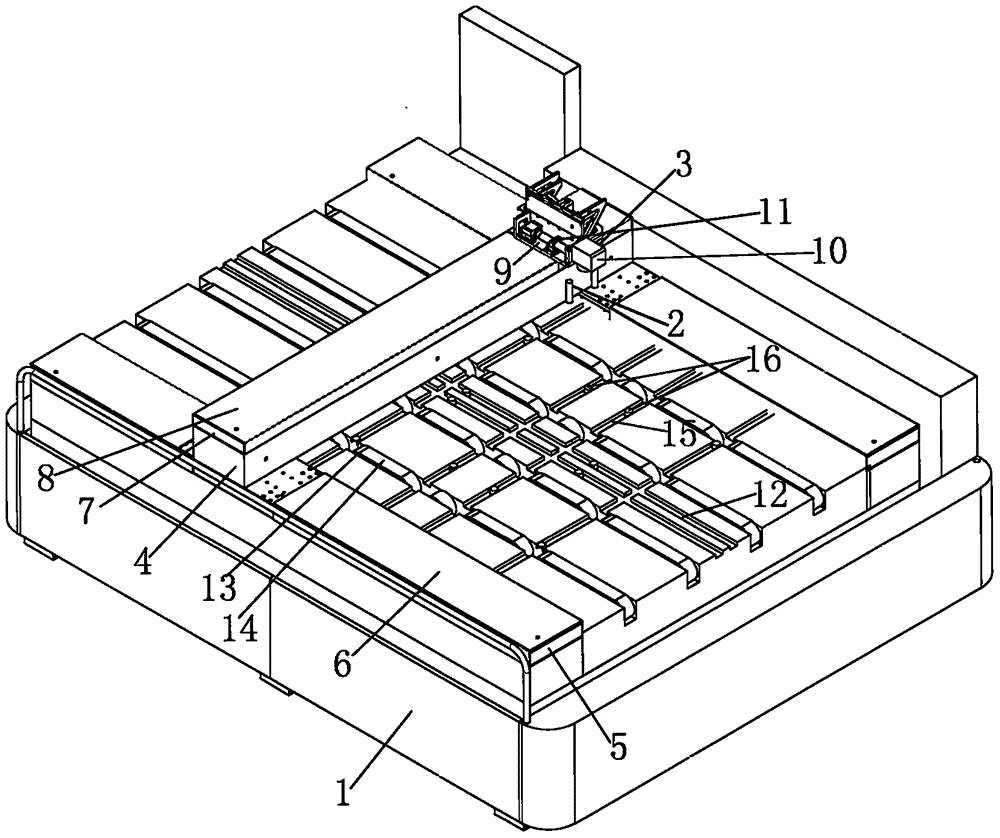

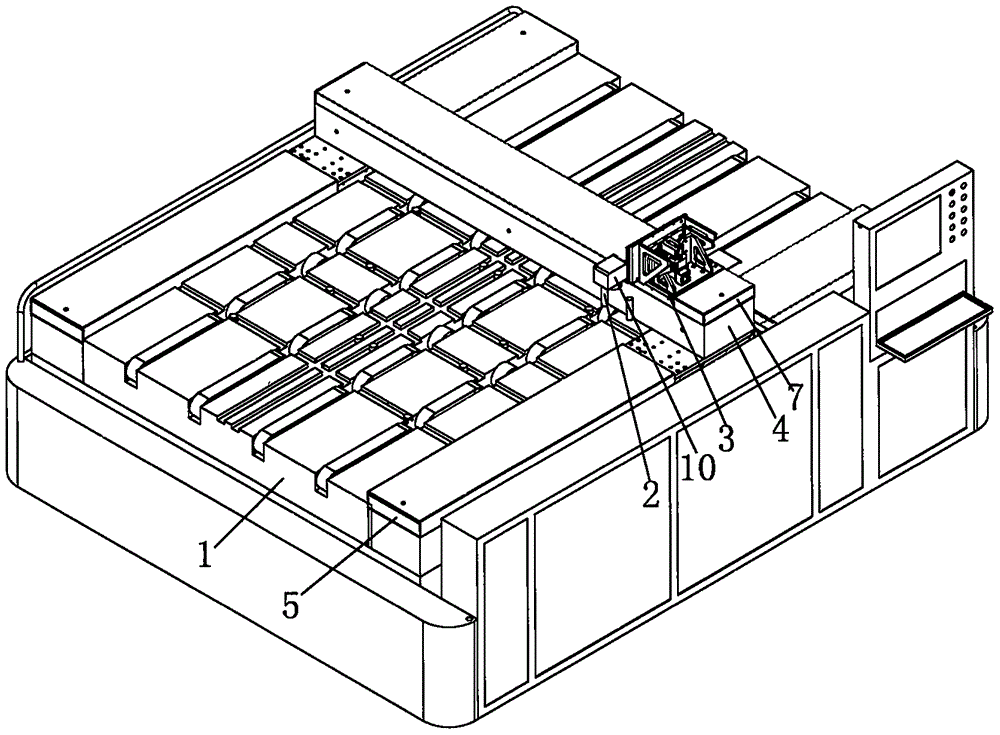

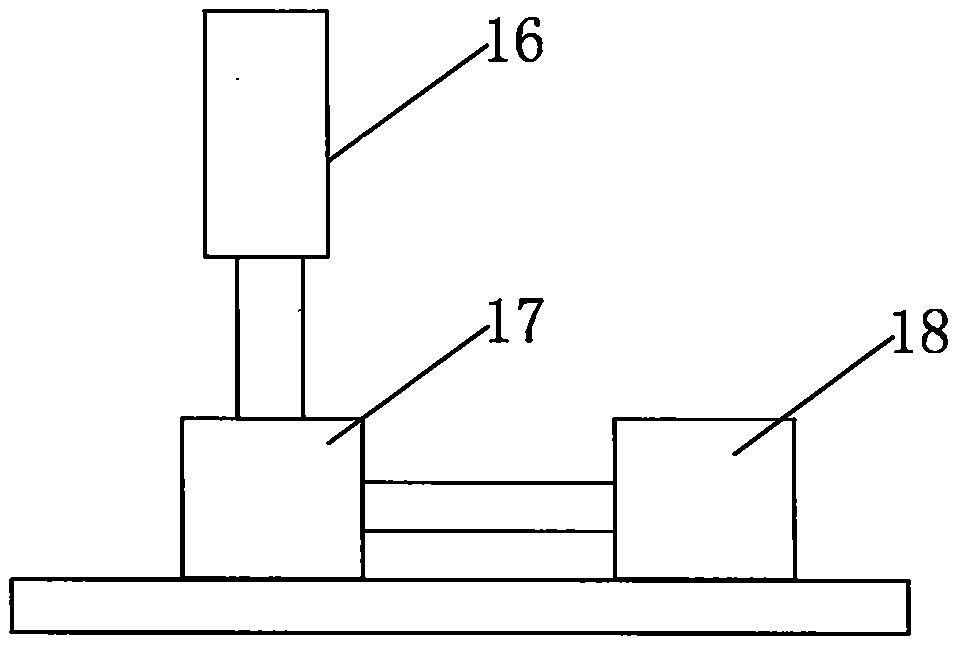

Material friction abnormal sound test bed with magnetic suspension type objective table

PendingCN112683777AAvoid direct contactDoes not affect transmissionUsing mechanical meansMaterial analysisGear wheelEngineering

The invention belongs to the technical field of friction abnormal sound experiment equipment, and particularly relates to a material friction abnormal sound test with a magnetic levitation type objective table; the test bed comprises an objective table, a rack and at least two magnetic levitation bearings, the objective table is arranged above the rack, the magnetic levitation bearings are arranged in parallel, mounting shafts penetrate through rotors of the magnetic levitation bearings, and the mounting shafts are mounted on the rack. A gear is coaxially and statically connected to an outer ring of the magnetic levitation bearing, and a rack is fixedly connected to the bottom face of the objective table and engaged with the gear. The objective of the invention is to solve the problem that an objective table cannot guarantee a mute effect during a material friction abnormal sound test.

Owner:CHINA AUTOMOTIVE ENG RES INST

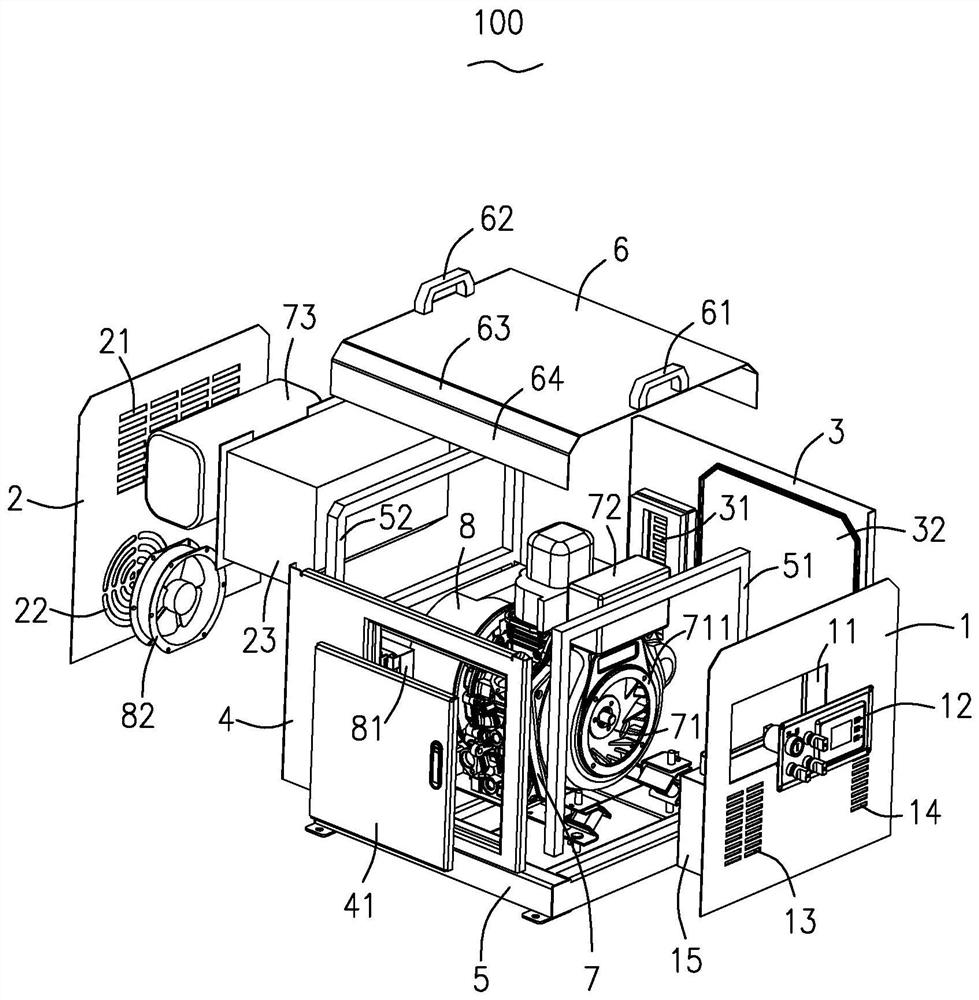

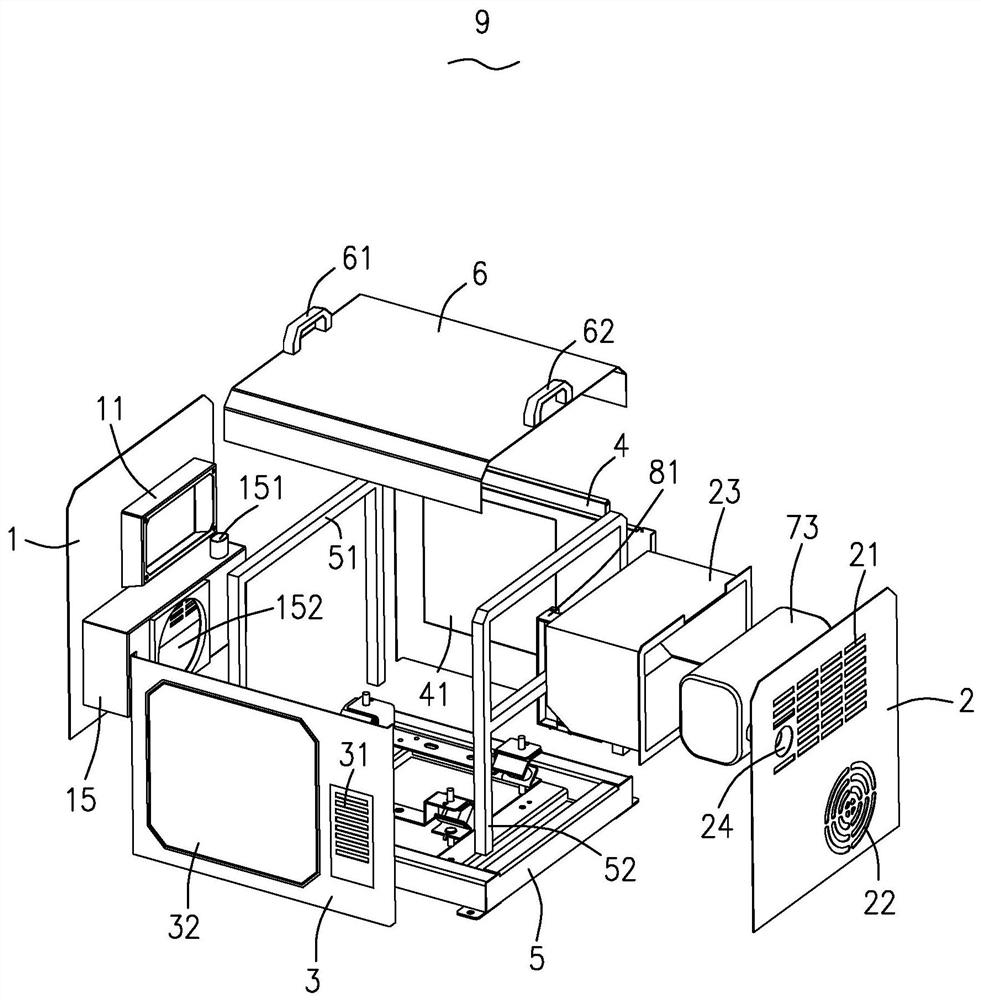

Generator set

PendingCN113027603AGuaranteed quiet effectGuaranteed cooling effectPump componentsEngine componentsCooling effectElectric generator

The invention provides a generator set. The generator set comprises an engine, a generator and a sound insulation box, wherein the engine comprises an air inlet fan; the generator is driven by the engine; the engine and the generator are both arranged in the sound insulation box, and the sound insulation box comprises a first side plate; a first air inlet is formed in the first side plate, an air inlet part is arranged on one side of the first side plate, an air inlet cavity is formed in the air inlet part, and the first air inlet communicates with the air inlet cavity; and a first exhaust hole is formed in the air inlet part, the first exhaust hole communicates with the air inlet cavity, and the first exhaust hole and the air inlet fan are coaxially arranged. By arranging the air inlet part on the sound insulation box of the generator set, outside air directly enters the air inlet fan of the engine through the air inlet cavity, and thus the mute effect, the cooling effect and the air inlet efficiency of the generator set are guaranteed.

Owner:JIANGSU CHANGFA AGRI EQUIP

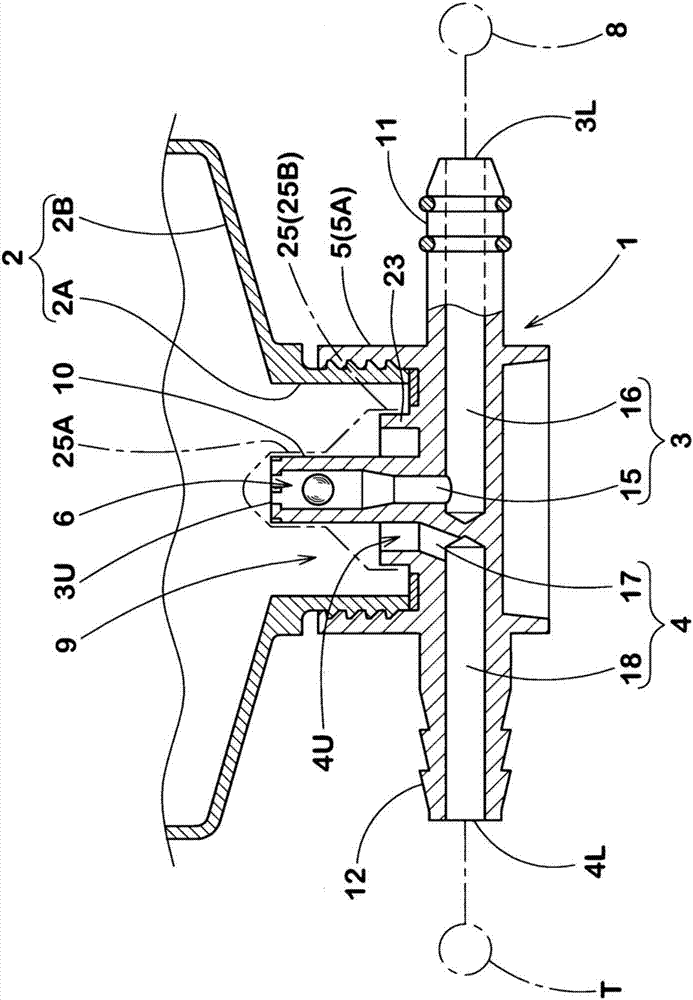

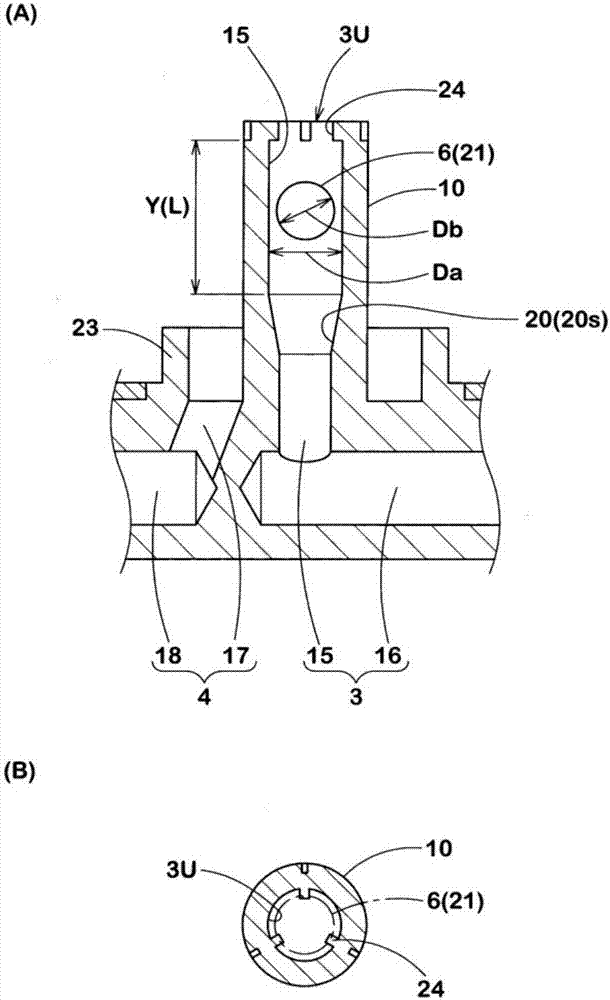

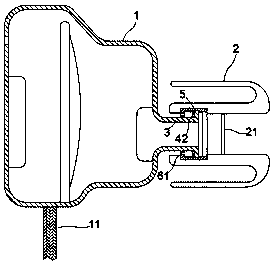

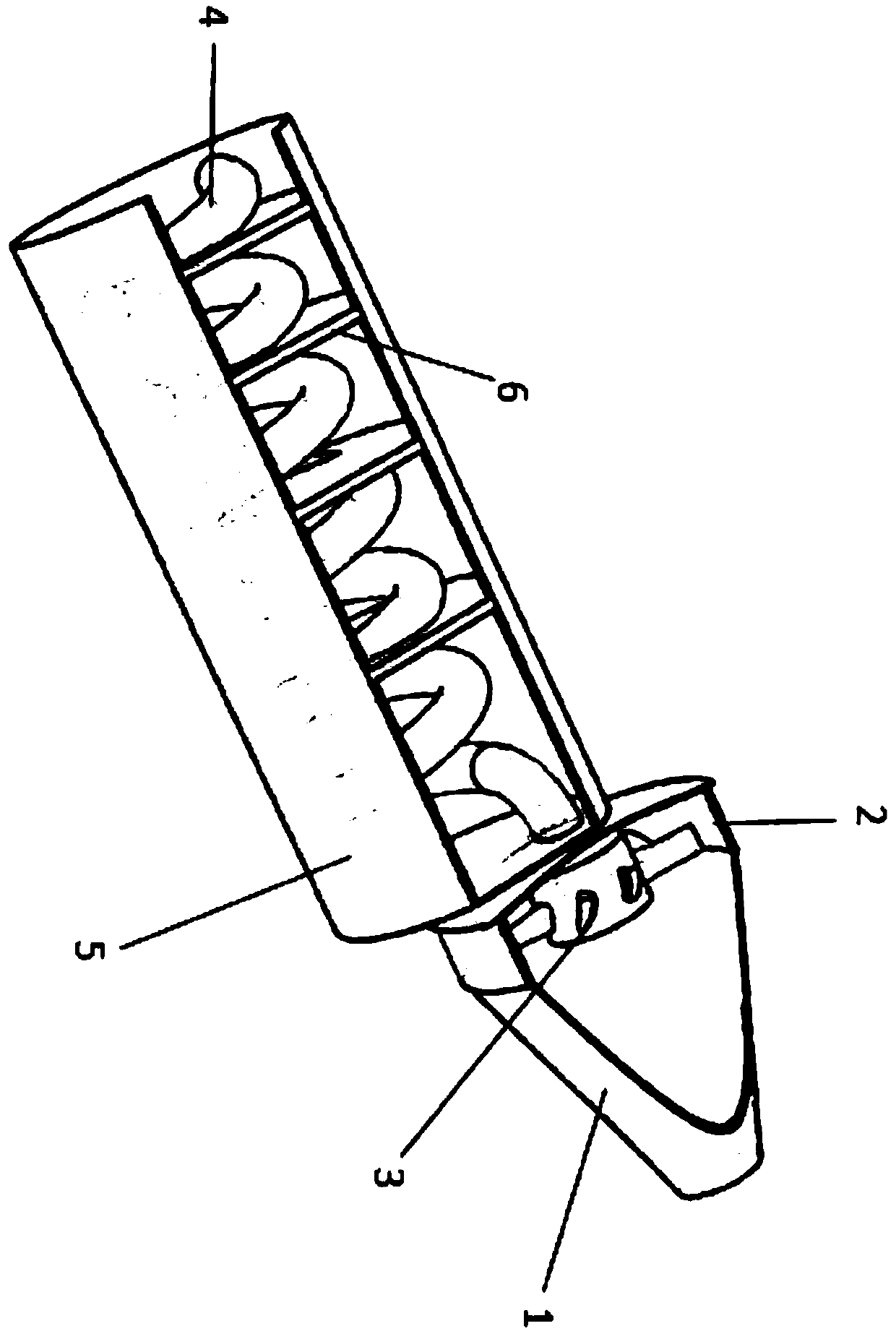

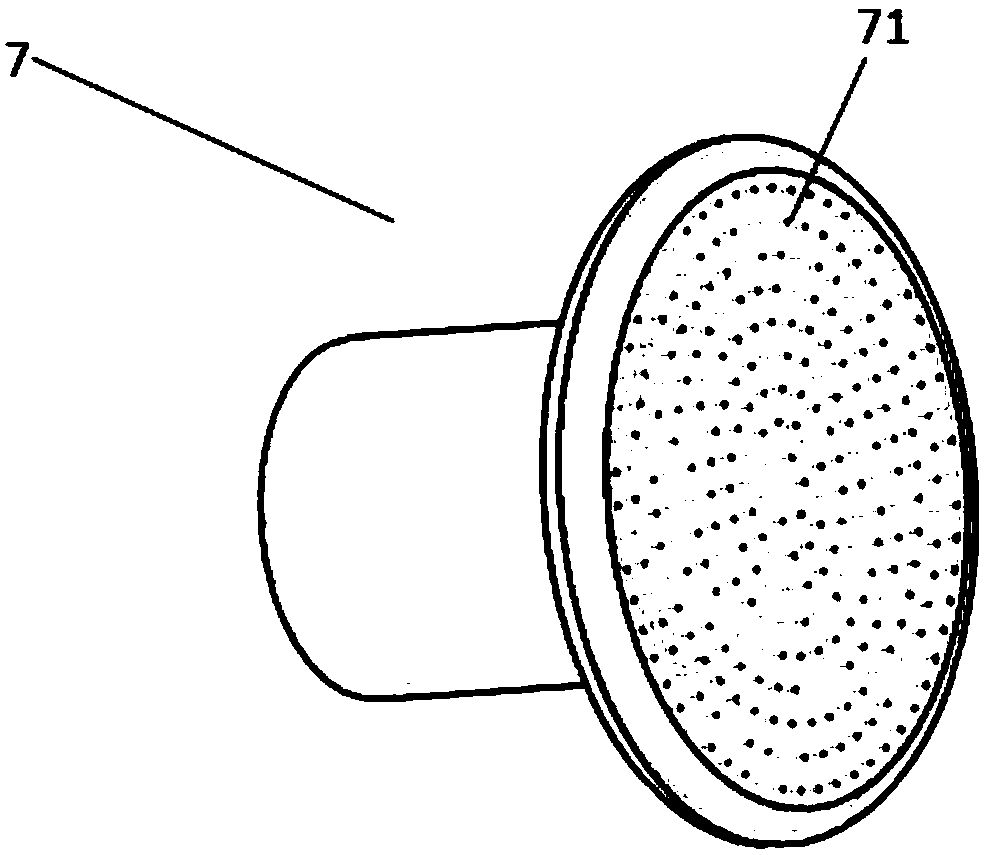

Cap Unit For Puncture Repair

[Problems] To suppress the occurrence of abnormal noise from a ball valve due to vibrations during the vehicle is traveling, while employing a simple structure. [Means for solving the problems] A check valve 6 for preventing a backflow of a puncture repair liquid from a bottle container 2 is disposed in a first flow path 3 for taking compressed air from a compressor 8 into a bottle container 2. The check valve is formed by a ball valve 21 disposed in a valve housing zone Y which is located in a vertical passage part 15 of the first flow path 3 and between an upper opening 3U and a valve seat portion 20. The ball valve 21 is formed from a rubber elastic body having a specific gravity of 1.1 or more, and a rebound resilience of 15% or less.

Owner:SUMITOMO RUBBER IND LTD

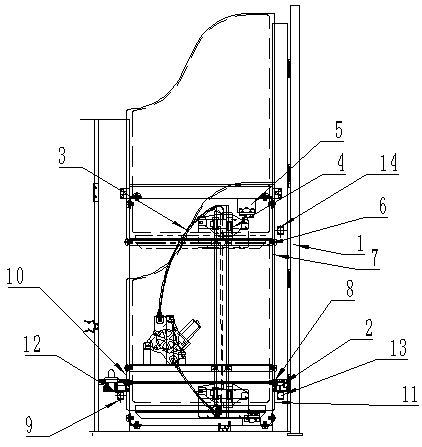

Bus electric lifting driver safety fence door

PendingCN110450751AProtect safe drivingEnsure lifting stabilityPedestrian/occupant safety arrangementDriver/operatorEngineering

The invention relates to a bus electric lifting driver safety fence door. The bus electric lifting driver safety fence door comprises a door frame, a fixing device, a motion conveying device, a bracket and a contact switch; the door frame is provided with a glass fixing profile and a glass fixing frame; the fixing device comprises a glass clamping strip; the glass plate fixing profile is fixedly connected with the glass fixing frame through the glass clamping strip; slide blocks are arranged on the motion conveying device, and are arranged at the front end and the back end of the door frame; the bracket is fixed on the door frame; and the contact switch is arranged on the door frame. Drivers can operate a button for one-key lifting; glass is lowered for conversation; during normal driving,one-key hoisting is achieved to protect safe driving of the drivers; the structure is skillful in design; the slide block type two side stable structures are adopted; and rails and profiles are designed as a whole, so that the installation is more convenient, the glass lifting stability and the silence effect are guaranteed, and the glass safety can be preferably guaranteed.

Owner:张家港保税区瑞天国际贸易有限公司

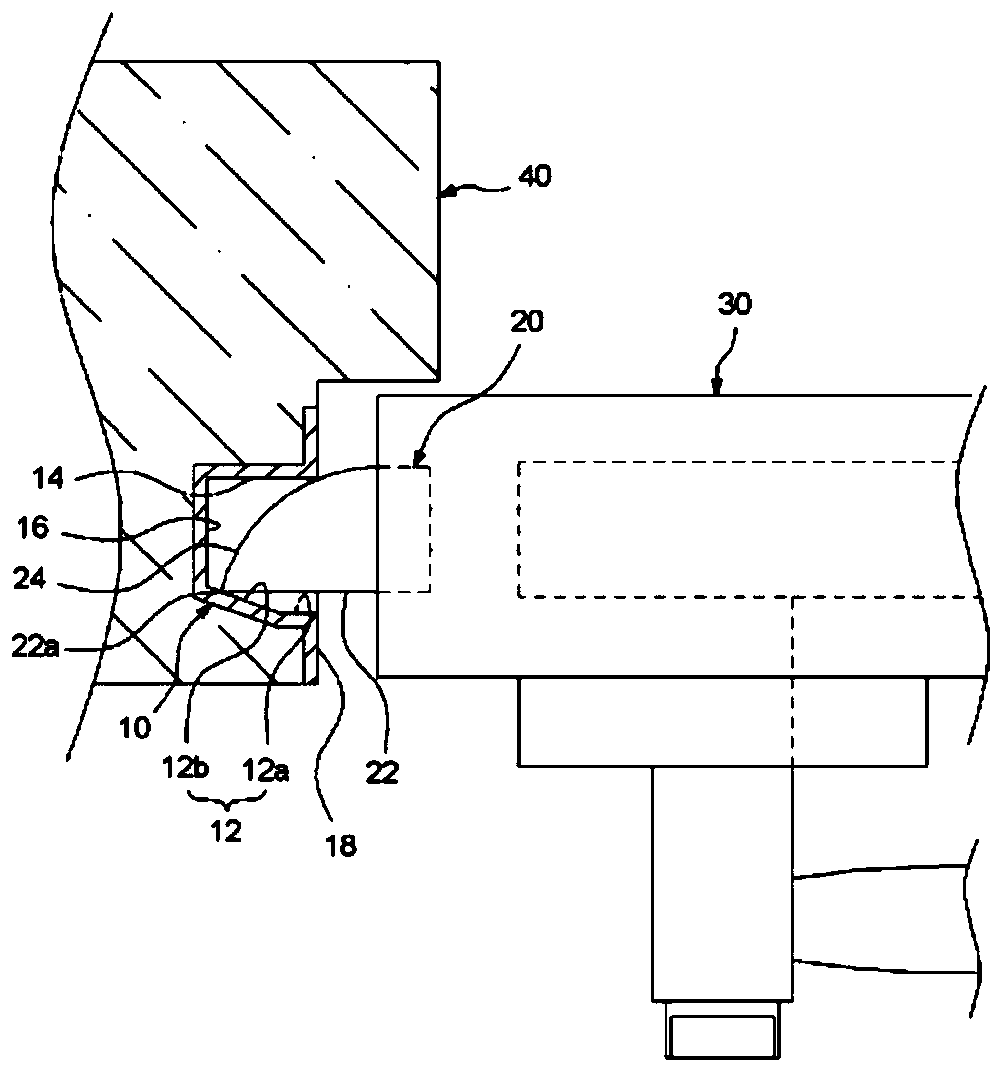

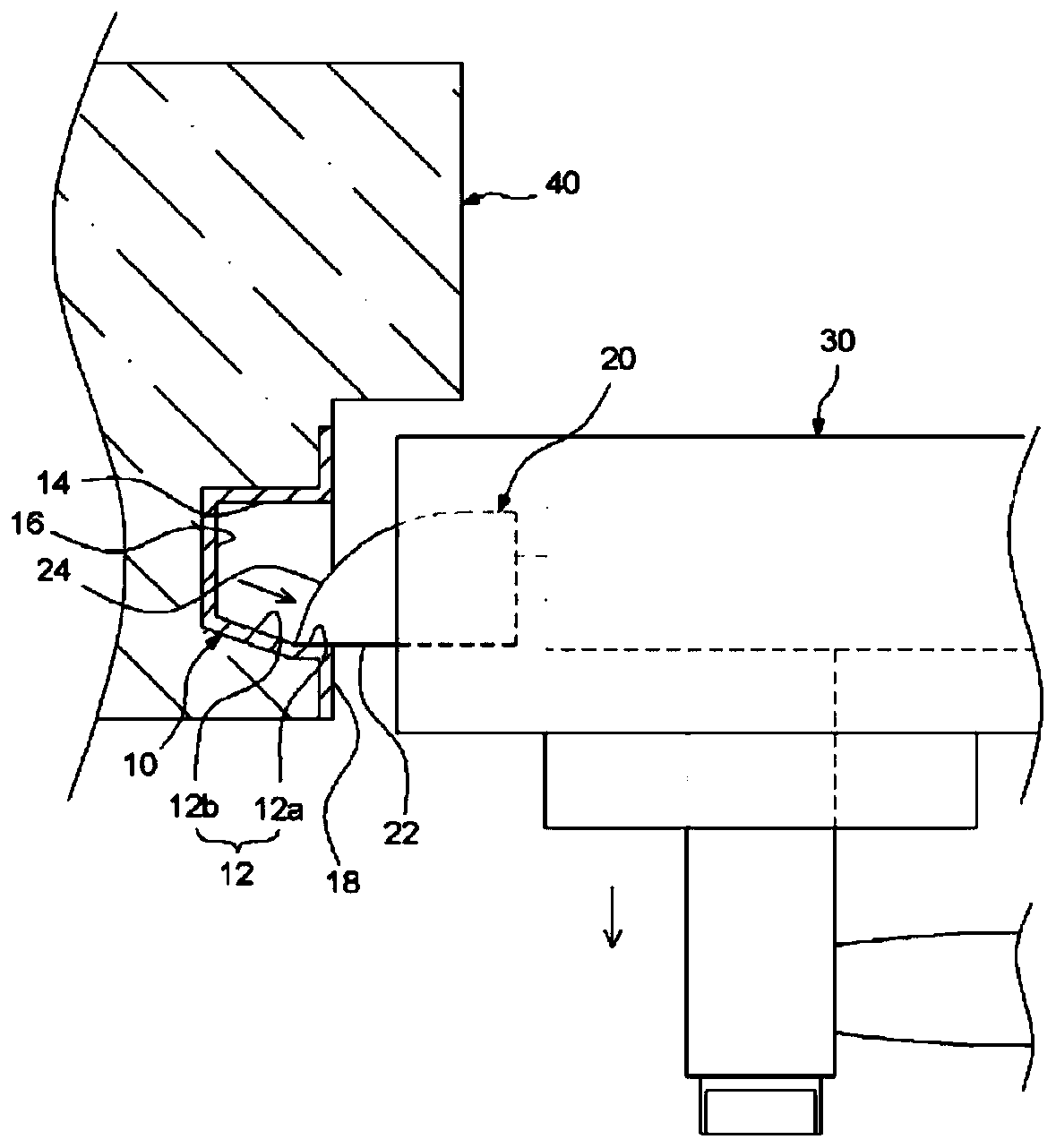

Door striker for preventing door movement

InactiveCN110352283AAvoid shakingGuaranteed quiet effectBuilding locksWing accessoriesAtmospheric pressureClose contact

The present invention improves the cross-sectional shape of a striker so that a latch can be maintained in close contact with a striker while the latch is fitted to the striker without back-and-forthclearance, in order to solve the problem of a conventional striker, in which a door is shaken to make noise due to application of various external forces including changes in indoor and outdoor air pressure while a latch installed on the door is caught by a door striker installed on a door frame. The present invention comprises: a latch assembly provided on a side surface of a door (30), which isconnected to and operated by a handle member; and a striker (10), to which a latch (20) of the latch assembly is fitted, installed on a door frame (40), wherein the striker (10) has a front latching protrusion (12) for latching a front surface (22) of the latch (20) and a rear latching protrusion (14) for latching a rear surface (24) of the latch (20), wherein the front latching protrusion (12) iscomposed of a right-angled surface (12a) of a front end thereof and an inclined surface (12b) the inside thereof.

Owner:宋成勉

Pressure elimination in-ear earphone

InactiveCN108429962AGuaranteed quiet effectPrevent incomingMicrophonesLoudspeakersMagnetic tension forceSound transmission class

The invention relates to a pressure elimination in-ear earphone. The pressure elimination in-ear earphone comprises a shell and a transmission line, a sound transmission head is arranged on an in-earend of the shell, and a sealing plug sleeve is detachably installed on the sound transmission head; the sound transmission head comprises a fixed cylinder, sealing plates are arranged on a round end of the fixed cylinder, and limiting slide ribs are arranged at free ends of the sealing plates; a pressure elimination cylinder is sleeved at the outside of the fixed cylinder, a limiting chute is engraved on the inner ring wall of the pressure elimination cylinder, and the bottom end of the pressure elimination cylinder is folded 90 degrees inward to form a sealing ring; pressure elimination holesmatched with the sealing plates are equidistantly formed in the sealing ring; and the sealing plates and the sealing ring are sucked through a magnetic force. The pressure elimination in-ear earphonehas a novel and unique structure, the ear pressure generated when the plug sleeve is inserted into the auditory meatus can be eliminated, meanwhile, the sealing property can be ensured after successful wearing, and the music experience is effectively improved.

Owner:钱娟娟

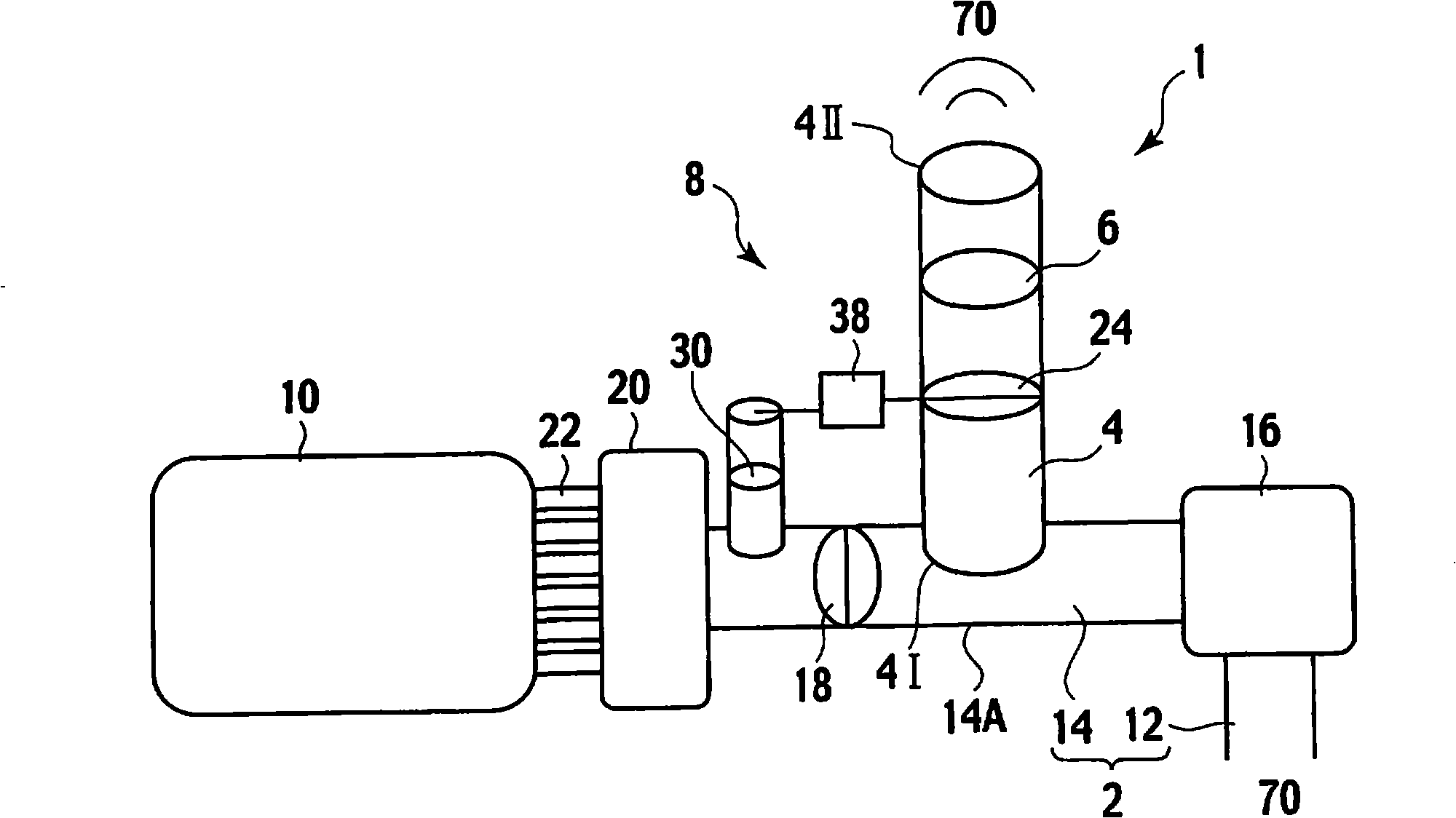

Engine-driven electric generator

InactiveCN100419232CSimple structureReduce weightEngine controllersMachines/enginesEngineeringElectric generator

An engine-driven generator is provided that is formed by supporting on a frame (2) an engine (3) and a generator (4) driven by the engine (3), wherein the frame is formed by integrally connecting via a cross member (7) lower side sections of a pair of left and right side frames (2b, 2b) formed by bending a steel pipe into a U-shape, a control box (34) housing and holding an electrical component (53, 55) is mounted on open end parts of the two side frames (2b, 2b) in order to reinforce the frame (2) by connecting the open end parts to each other, and an assembly of the engine (3) and generator (4) is resiliently supported on the cross member (7). The structure of the frame of the engine-driven generator can thereby be simplified, the frame can be reinforced by the control box that houses and supports the electrical component, and the frame can be made lightweight.

Owner:HONDA MOTOR CO LTD

Roller washing and drying machine

ActiveCN101173443BEasy to drill intoReduce in quantityOther washing machinesWashing machine with receptaclesMechanical engineering

The invention provides a roller type washing drier which is provided with a blast device. In order to ensure the air in the bucket through the cycle blast route with a filter chamber, a dehumidifying device and a heating device to realize the drying procedure of the washing, the blast device combines the air inlet side at the cycle air outlet side of the filter chamber by the manner of mutual shake-proof structure part, thereby realizing integration.

Owner:PANASONIC CORP

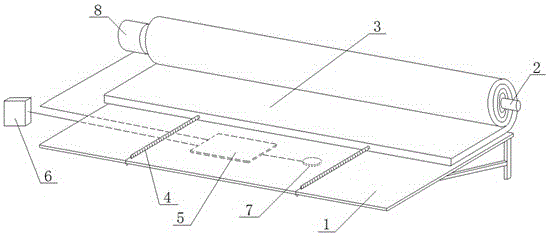

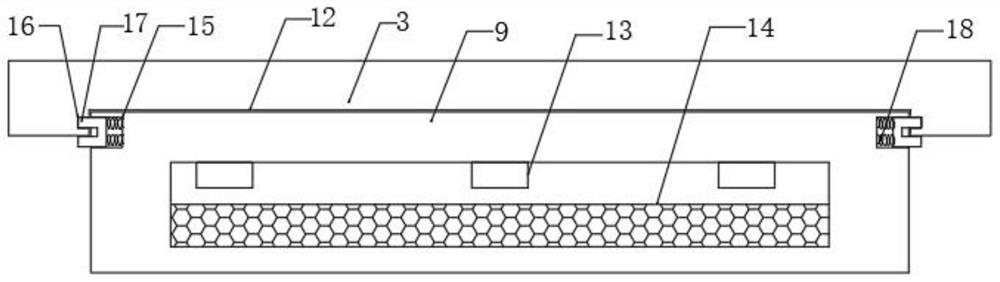

Intelligent electronic control mute canopy

InactiveCN105133799ASimple structureRealize electric controlSunshadesElectric machineClassical mechanics

The invention relates to an intelligent electronic control mute canopy. Aiming at improvement on the existing canopies, an intelligent electronic control structure is introduced to the design; whether raindrops fall to the upper surface of the canopy body (1) can be judged by using a vibration sensor (7) to detect the vibration condition of the canopy body (1); based on the judgment result, intelligent control is carried out on a sponge body (3) by a rotating motor (8) by virtue of a revolving shaft (2), so as to realize the mute effect of the canopy designed according to the invention and avoid influence on the work and rest of people; while the rotating motor (8) controls the sponge body (3) to wind the resolving shaft (2), in combination with tensile force released by springs (4) towards the release direction of the sponge body (3), drainage operation for the sponge body (3) can be realized by a layer-by-layer overlaying structure during a winding process of the sponge body (3), so that the dryness and cleanness of the sponge body (3) can be timely kept, and the reuse work efficiency of the sponge body (3) can be improved.

Owner:SUZHOU YIXINYUAN PHOTOELECTRIC TECH

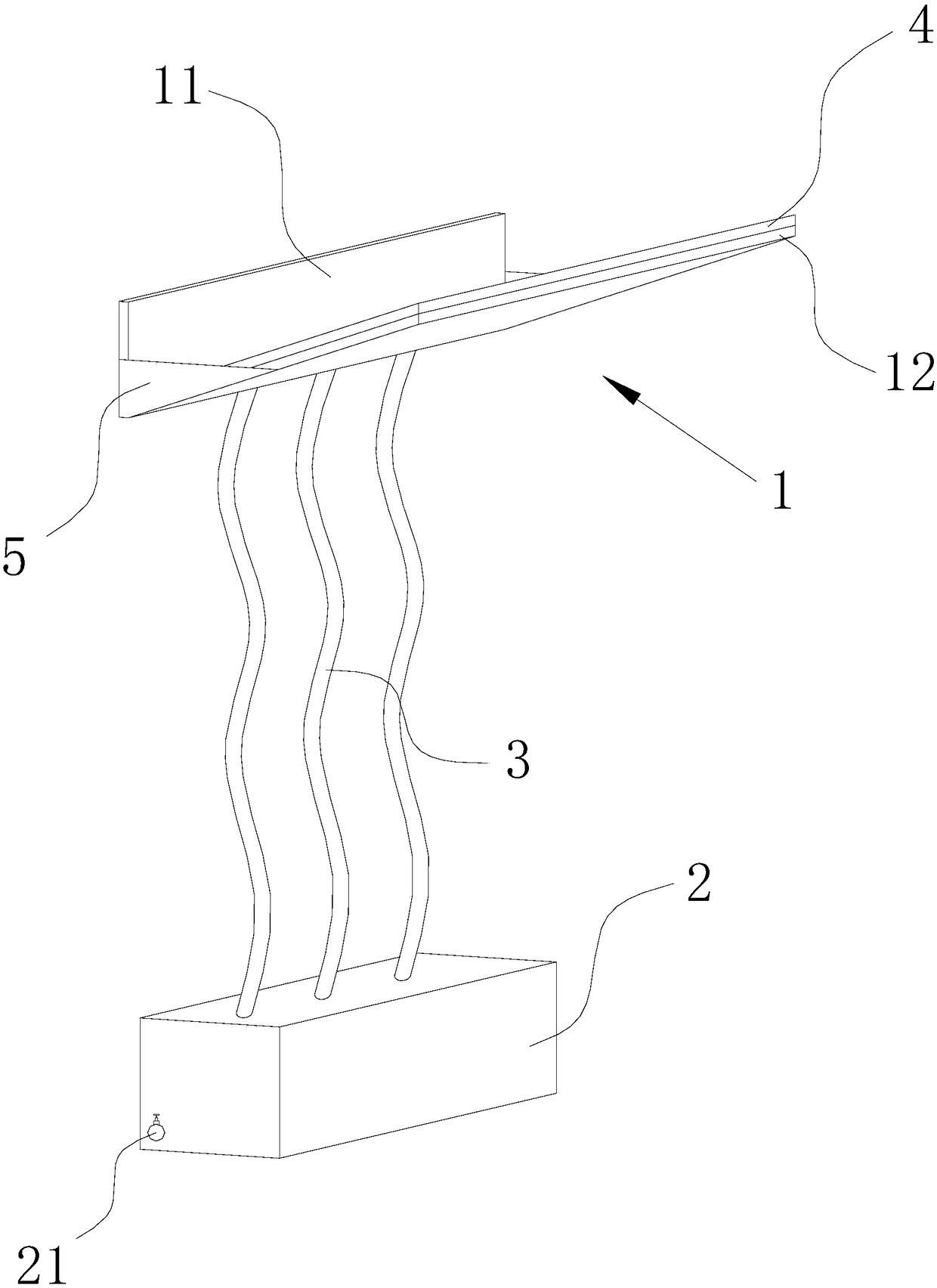

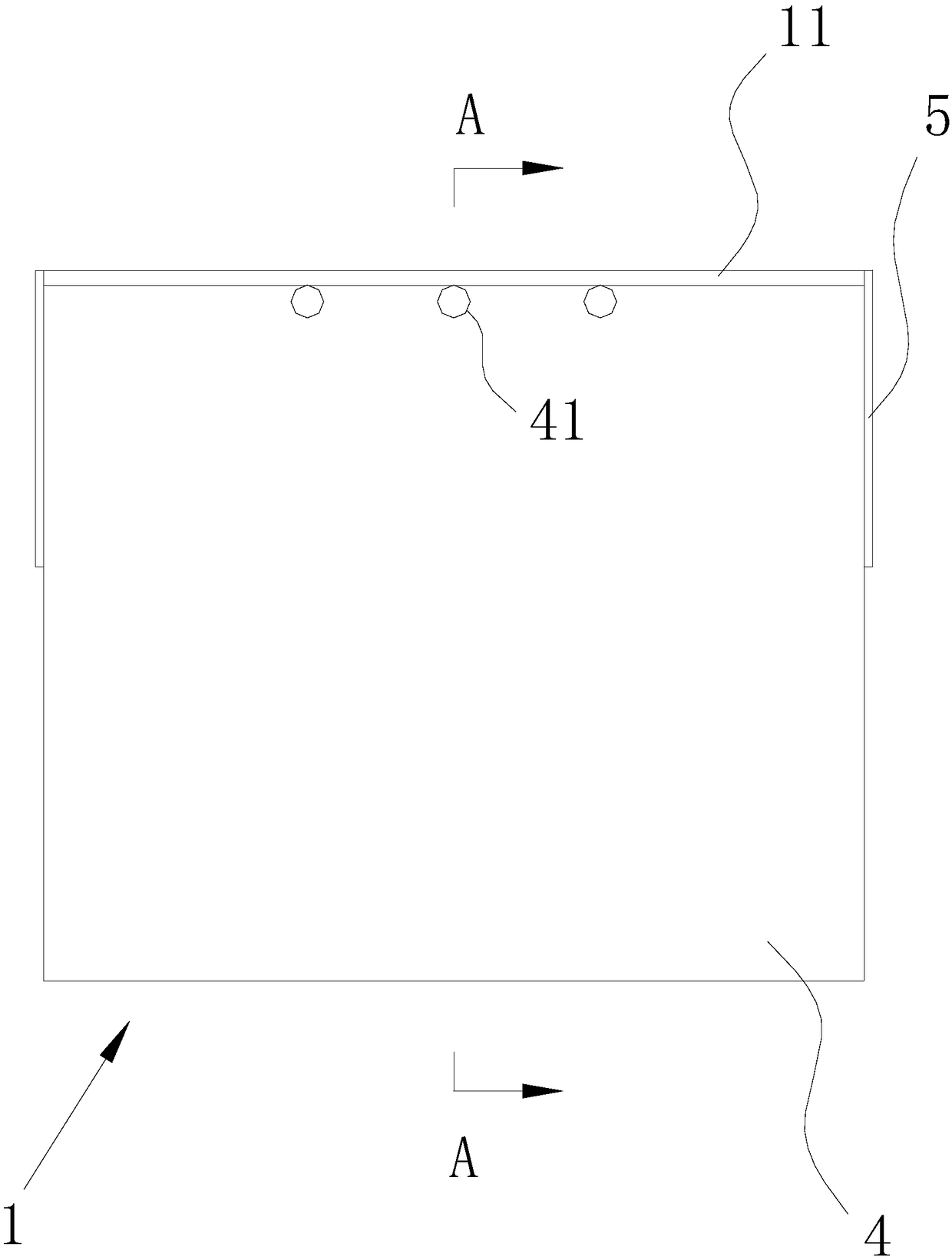

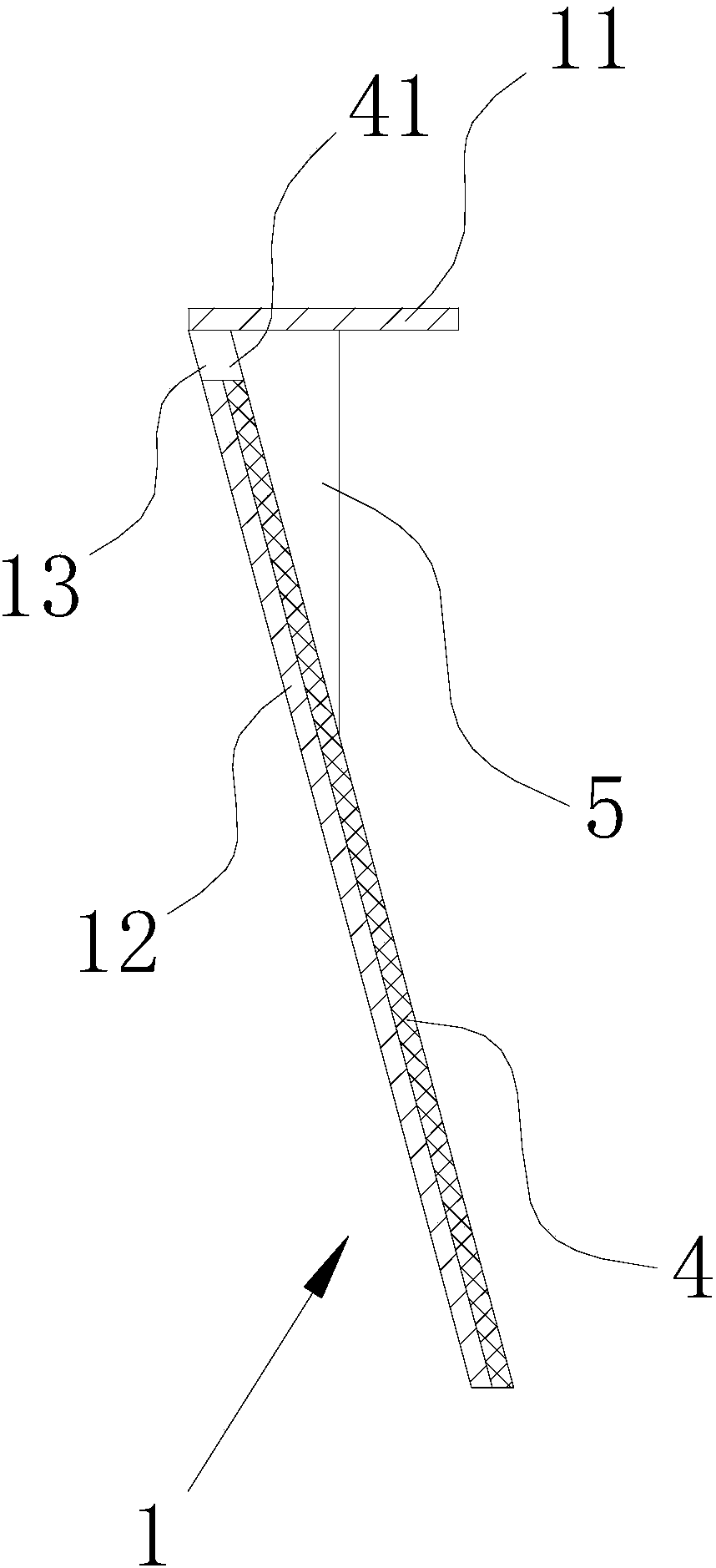

Silent rain shed with rainwater recycling function

PendingCN108316576AWill not affect the flowGuaranteed quiet effectSunshadesGeneral water supply conservationEngineeringDrain tube

The invention provides a silent rain shed with a rainwater recycling function. The rain shed comprises a body and a water collecting box which are arranged up and down, wherein the body comprises a fixing plate which is vertically arranged and has a left-and-right length direction as well as a rain baffle which is obliquely arranged and has a high front part and a lower rear part; the lower side of the fixing plate is connected with the rear side of the rain baffle; both the fixing plate and the rain baffle are rectangular and have the same length; the left and right sides of the rain baffle are respectively flush with the left and right sides of the fixing plate correspondingly; three perforated drainage holes which are in left-and-right alternative arrangement are formed in the rear sideof the rain baffle close to the fixing plate; the lower side of each drainage hole is communicated with the upper end of a drainage pipe; the lower end of each drainage pipe is communicated with thewater collecting box; the water collecting box is in a hollow cuboid shape; the lower side or left side or right side of the water collecting box is connected with a drainage valve; and a PVC wire loop cushion layer is arranged on the rain baffle and is provided with a through hole corresponding to each drainage hole. The rain shed provided by the invention has the advantages that the sound causedby impact of rainwater on the rain shed can be reduced, and the rainwater falling on the rain shed can be collected.

Owner:刘睿哲

Motor fan pump for vacuum cleaner

ActiveCN106949099BGrowth anechoic spaceTo achieve the purpose of noise reduction and shock absorptionPump componentsSuction cleanersAir pumpEngineering

The invention discloses a motor air pump for a dust collector. The motor air pump comprises an air inlet pipeline, a fan outer cover, a fan and an exhaust pipeline, wherein a first opening is formed in the top of the air inlet pipeline; a second opening is formed in the bottom of the air inlet pipeline; a third opening is formed in the bottom of the fan outer cover; the fan outputs air towards the third opening; a main body of the exhaust pipeline is of a spiral structure; a fully enclosing exhaust hood is arranged outside the exhaust pipeline; a first end of the exhaust hood is closed; a first end of the exhaust pipeline penetrates through the first end of the exhaust hood and is connected with a third opening of the fan outer cover in a closed mode; a second end of the exhaust hood is open; the internal space of the exhaust hood is divided into a plurality of closed buffer cavities through partition plates; a second end of the exhaust pipeline sequentially penetrates through the partition plates and is drawn out of a second end of the exhaust hood; and a plurality of evenly formed through holes are formed in the pipeline wall, in the exhaust hood, of the exhaust pipeline. The noise of the air pump of the dust collector can be effectively lowered.

Owner:苏州市海朋生活家电有限公司

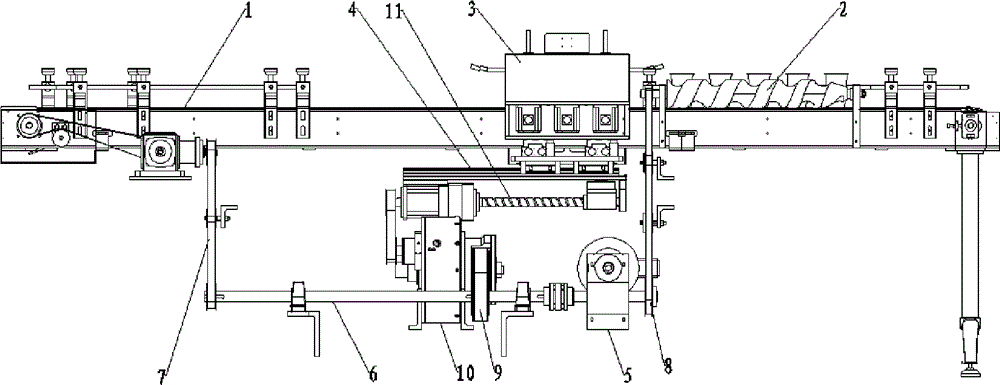

Mechanical type linear reciprocating synchronizing device

ActiveCN103129964BEnsuring Motion Synchronization AccuracyIncrease productivityConveyor partsProduction lineEngineering

The invention discloses a mechanical type linear reciprocating synchronizing device. A separation bolt can be rotationally located at one end of a conveying belt and is axially placed along the moving direction of the conveying belt, a mechanical arm can be located on a linear guide rail in a sliding mode, and the linear guide rail is fixed at one side of the width direction of the conveying belt. The mechanical type linear reciprocating synchronizing device is further provided with a motor, a main driving shaft, a first transmission device, a second transmission device, a third transmission device and a cam mechanism. Motive power of the motor is output to the main driving shaft, the first transmission device, the second transmission device and the third transmission device respectively enable motive power of the main driving shaft to be transmitted to a driving roller of the conveying belt, the separation bolt and the cam mechanism, and the cam mechanism drives the mechanism arm to slide along the linear guide rail. The mechanical type linear reciprocating synchronizing device is large in power, strong in rigidity, and accurate in synchronism. During high-speed movement, the whole device can keep a mute effect, avoids shock and impact caused by heavy load and the high-speed movement, responds quickly, and improves production efficiency of a production line.

Owner:KUSN FASTEC MACHINERY

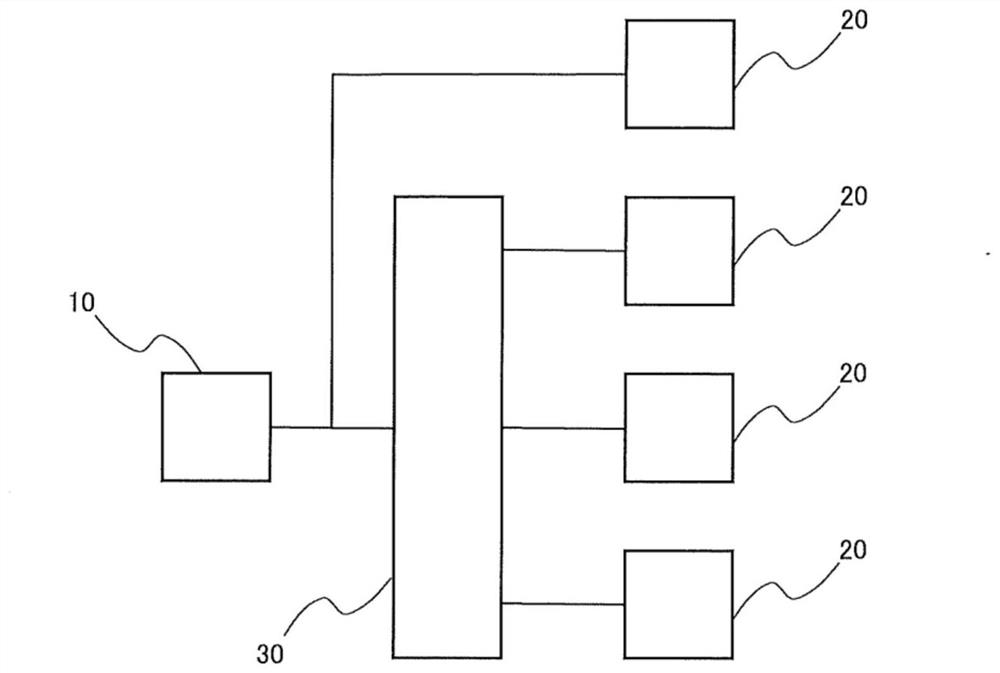

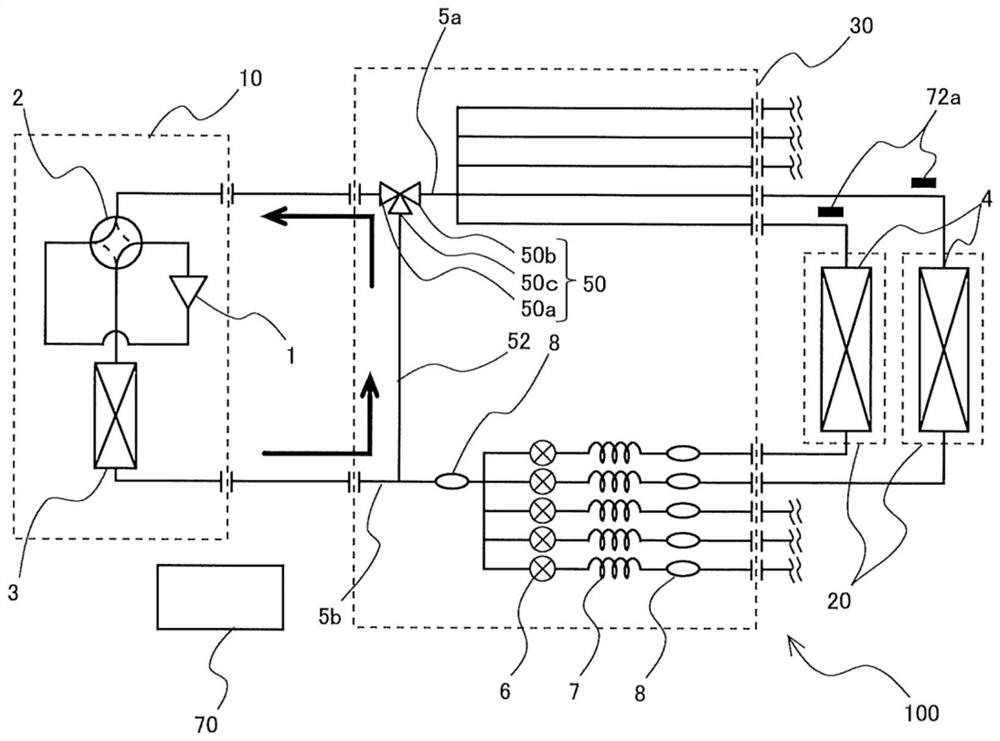

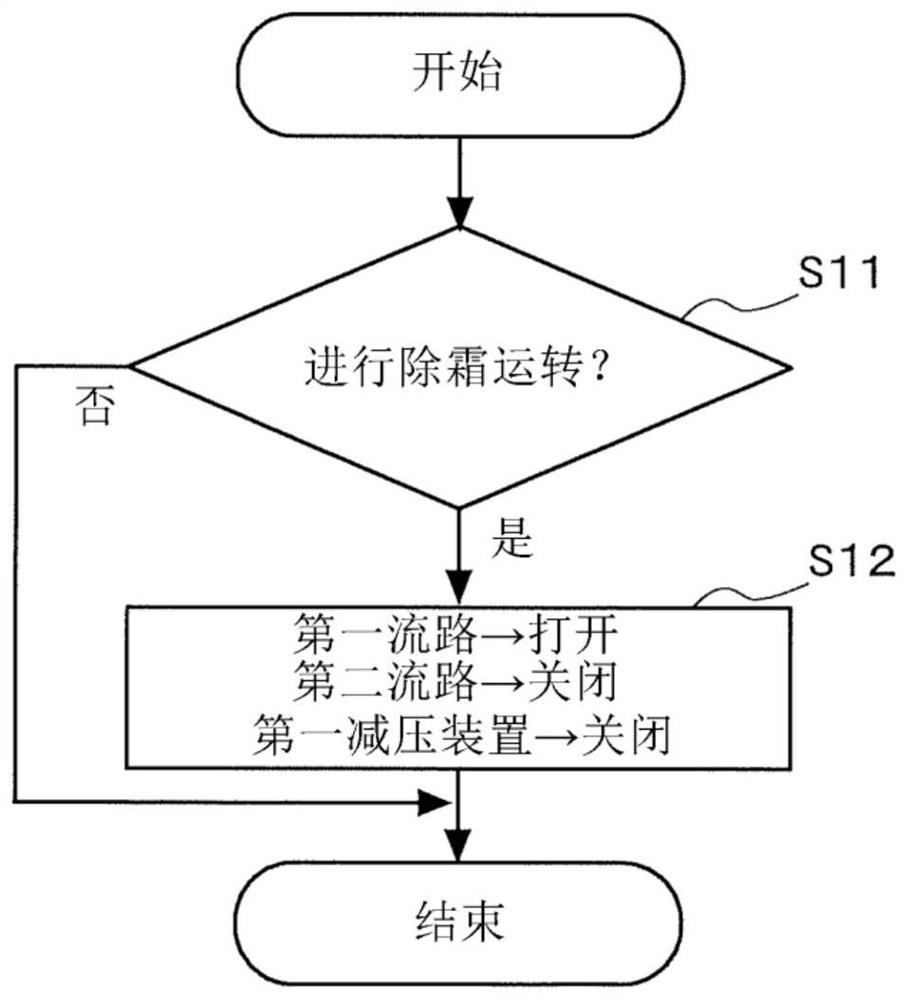

Air conditioning device

PendingCN114008393AGuaranteed quiet effectSuppress noiseMechanical apparatusSpace heating and ventilation safety systemsEngineeringAir conditioning

This air conditioning device comprises a relay that has a first decompression device. The relay has a flow path switching valve that is provided to first refrigerant piping connected between a compressor and a load-side heat exchanger, and bypass piping that is connected to the flow path switching valve at one end, and at the other end is connected to second refrigerant piping connected between the first decompression device and a heat source-side heat exchanger. The flow path switching valve has, as internal flow paths, a first flow path communicating the first refrigerant piping and the bypass piping, and a second flow path communicating the compressor and the load-side heat exchanger via the first refrigerant piping, and switches the internal flow paths such that one internal flow path among the first flow path and the second flow path is open while the other internal flow path is closed.

Owner:MITSUBISHI ELECTRIC CORP

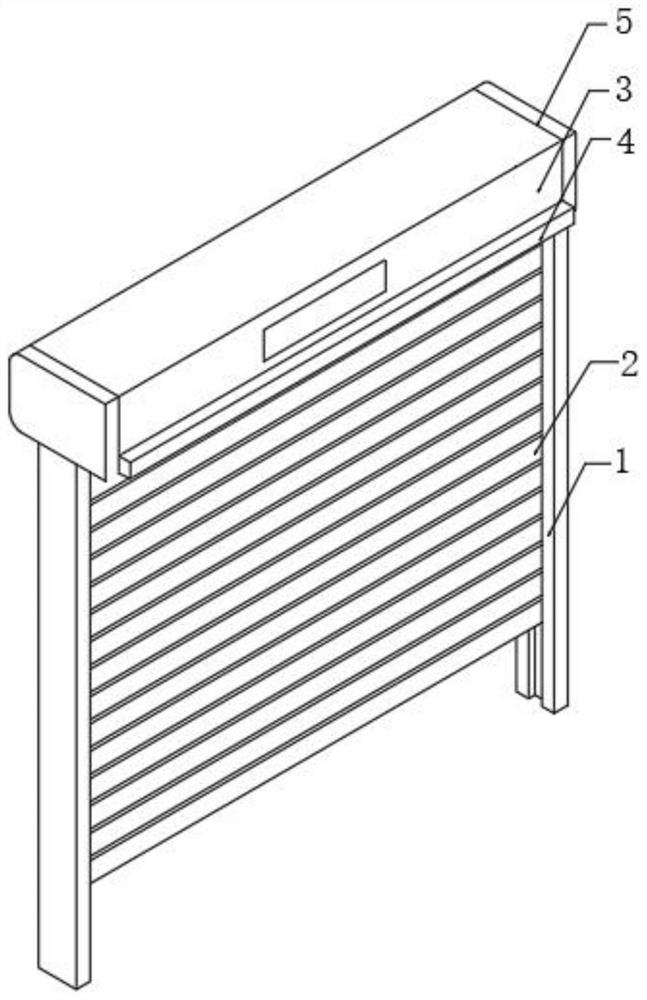

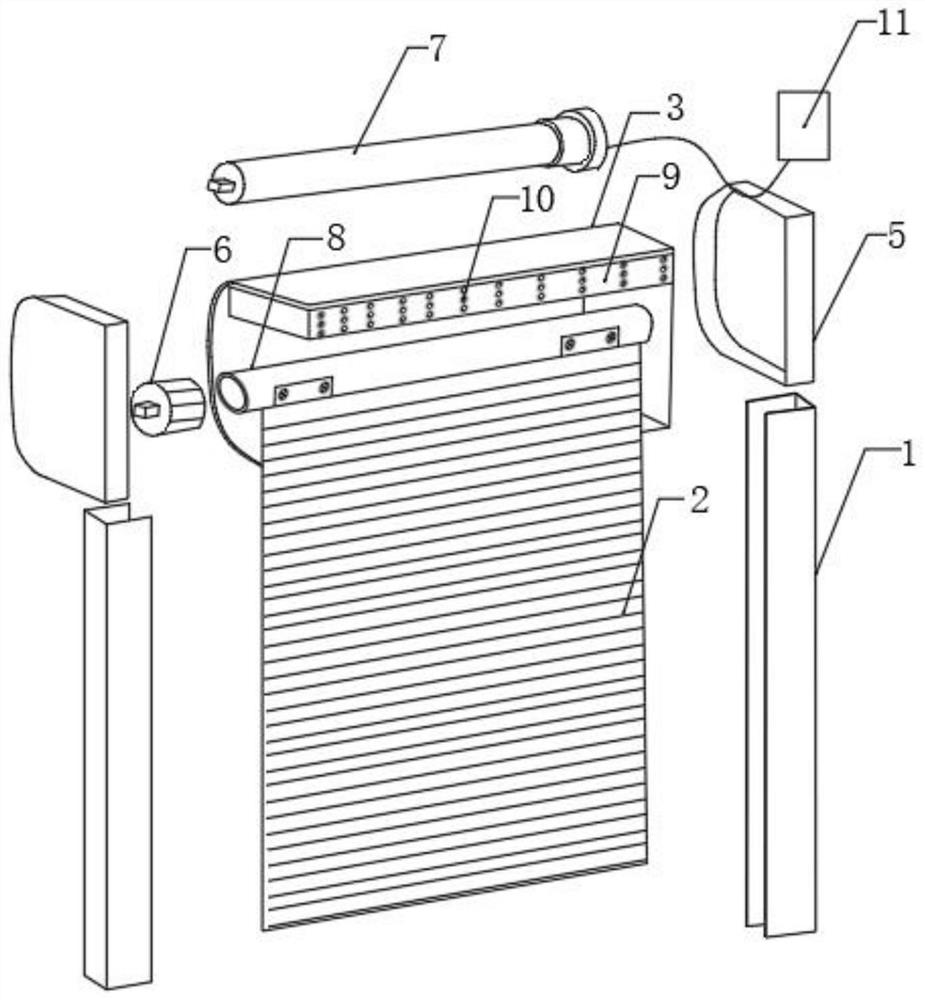

Environment-friendly roller shutter

ActiveCN112282618AGuaranteed quiet effectAbsorb noise pollutionShutters/ movable grillesCleaning using toolsSteel tubeElectric machinery

The invention discloses an environment-friendly roller shutter which comprises two vertical rods, a protective cover is fixedly installed at the top ends of the two vertical rods, a through groove isformed in the middle of the bottom end of the protective cover, tail inserting parts are fixedly installed on the two sides of the inner wall of the protective cover, a steel pipe shaft is connected between the two tail inserting parts in a penetrating mode, a roller shutter body is connected to the surface of the steel pipe shaft in a winding mode, the bottom end of the roller shutter body is connected with the through groove in an inserting manner, and the two sides of the roller shutter body are connected with limiting grooves formed in one sides of the corresponding vertical rods in an embedded mode. By means of sound absorption holes formed in the outer wall of a fixed box and silencers and sound absorption cotton installed in the fixed box, noise pollution generated in the winding and unwinding process of a tubular motor and the roller shutter body is conveniently and effectively absorbed, the mute performance of the roller shutter in the using process is guaranteed, noise pollution is avoided, the roller shutter body is composed of a plurality of shutter pieces, the plurality of shutter pieces are embedded in connecting grooves through connecting pieces, stretching and retracting of T-shaped columns are controlled through second limiting springs, the shutter pieces are convenient to assemble and disassemble, and the damaged shutter pieces are convenient to replace.

Owner:南京市淑先科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com