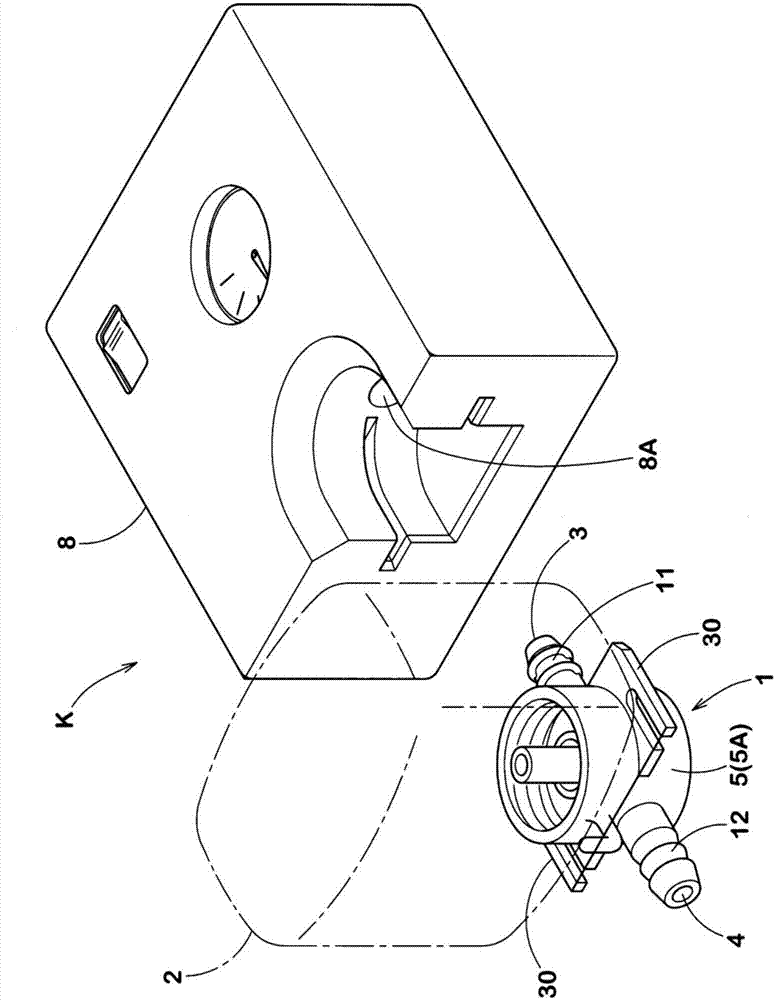

Cap Unit For Puncture Repair

A technology for repairing air leaks and compressing air, which is applied in vehicle maintenance/repair, applications, household appliances, etc. It can solve the problems of passenger discomfort, abnormal noise, etc., and achieve the effect of ensuring quiet performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

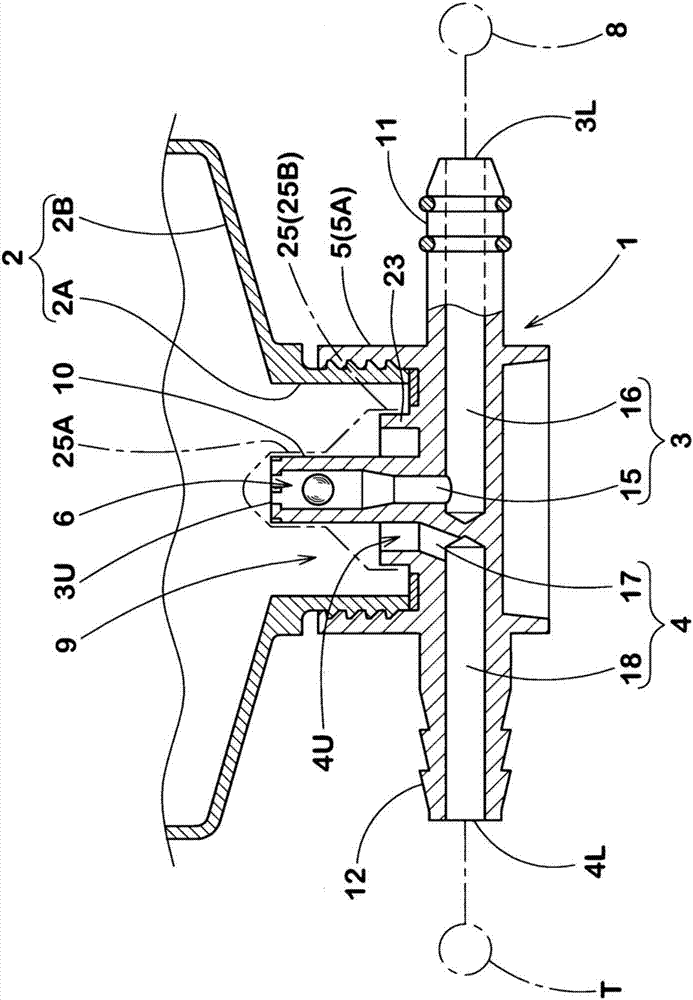

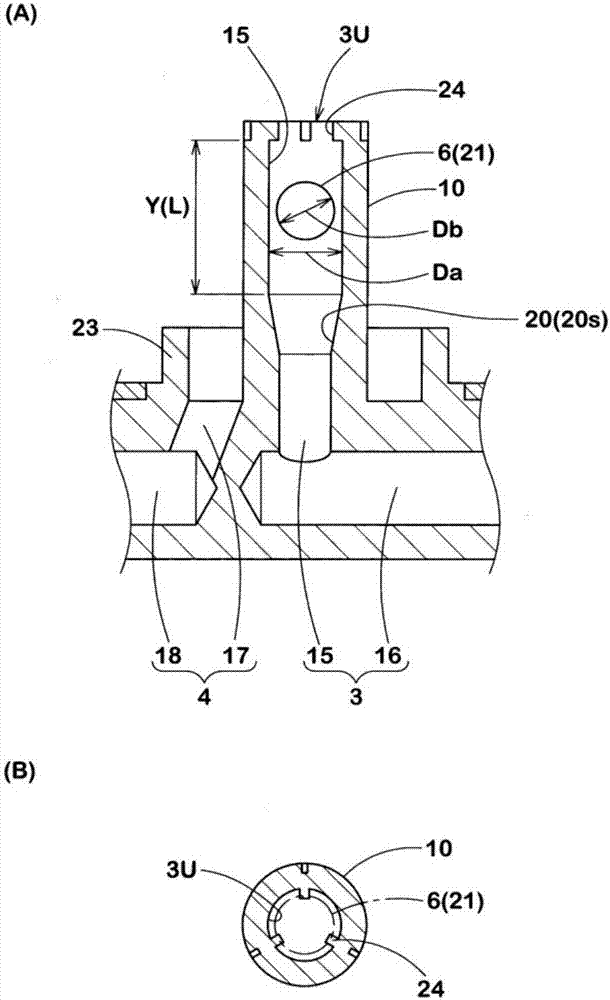

[0046] In order to confirm the effect of the present invention, a trial production was carried out according to the specifications in Table 1. figure 2 Cover unit of the configuration shown. In addition, the injection and boosting time of each cover unit, whether there is a reverse flow of air leakage repair fluid, and whether there is abnormal noise from the ball valve are tested. The specific gravity, rebound elastic modulus, and low-temperature embrittlement temperature of the ball valve are changed by changing the material of the rubber elastic body.

[0047] (1) Injection boost time:

[0048] The time required to inject 400 cc of blow-by repair fluid into a tire (195 / 65R15) using a shared compressor and raise the internal pressure of the tire pressure gauge from 0 to 250 kPa was measured. The ambient temperature is -30°C.

[0049] (2) Whether there is backflow of air leakage repair fluid:

[0050] The cover unit was taken out after the blow-by repair fluid injection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com