Roller washing and drying machine

A washing-drying machine and drum-type technology, which is applied to other washing machines, household dryers, washing machines with containers, etc., can solve the problems of affecting the circulation air supply path, being easily affected, etc., so as to improve the efficiency of the heat exchange area, The effect of reducing the number of processing parts and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

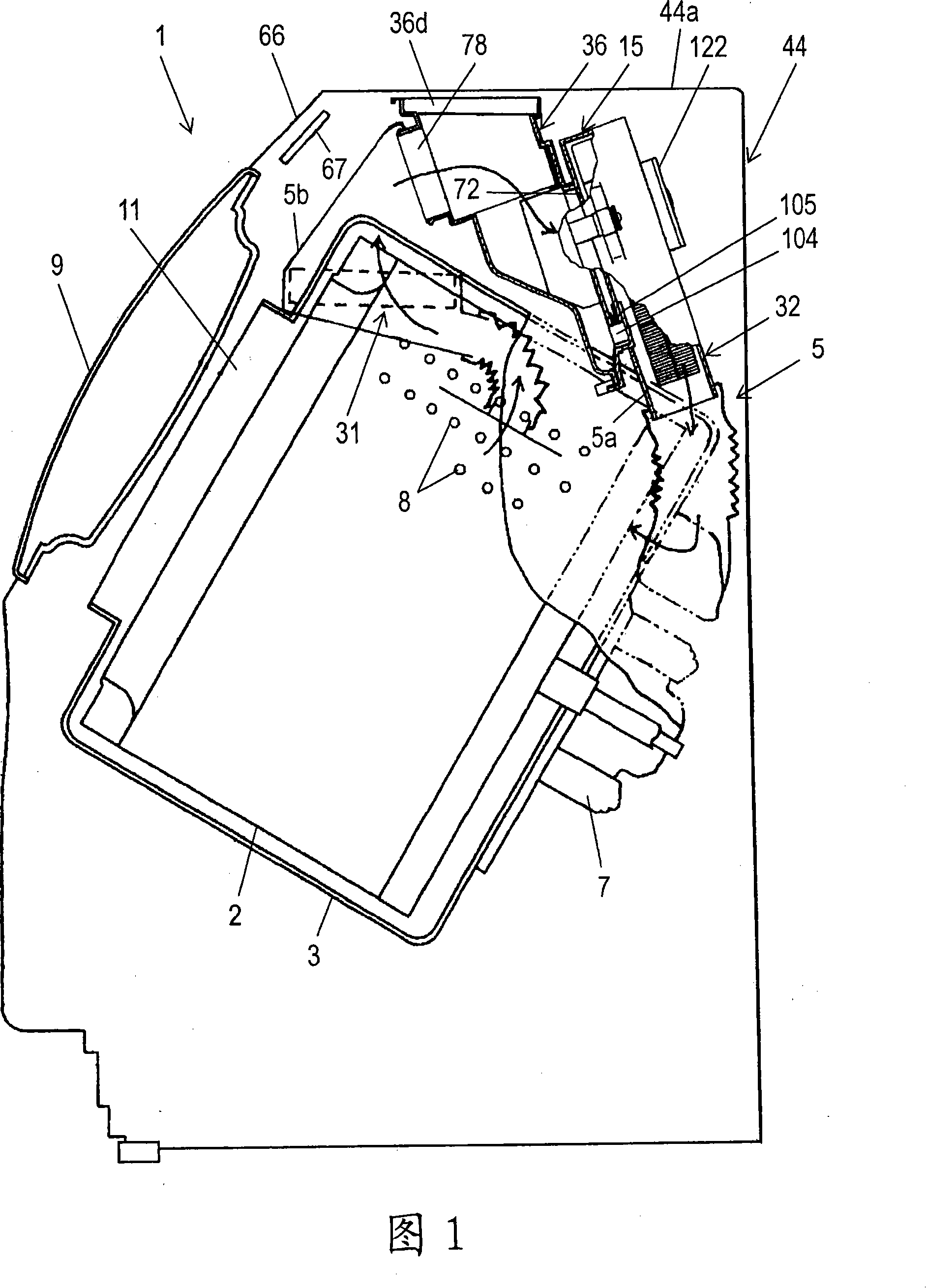

[0030] Fig. 1 is a cross-sectional view showing the configuration of main parts of a drum-type washer-dryer according to an embodiment of the present invention. In FIG. 1 , in the drum-type washer-dryer 1 , the bucket 3 is placed in a suspended state in the main body 44 of the washer-dryer through a suspension structure not shown in the figure. It is a cylindrical rotary drum 2 whose axis direction is inclined downward from the front side to the back side. The front side of the bucket 3 is formed with the clothes inlet and outlet 11 communicated with the opening end of the rotary drum 2, and the door 9 can be opened and closed to close the opening portion provided on the upward slope formed on the front side of the main body 44 of the washing and drying machine. By opening the door 9, laundry can be taken out and put into the rotary drum 2 through the clothes inlet and outlet 11 described above. Since the door 9 is arranged on the upward slope, the operation of taking out and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com