Patents

Literature

41results about How to "Strong vacuuming ability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

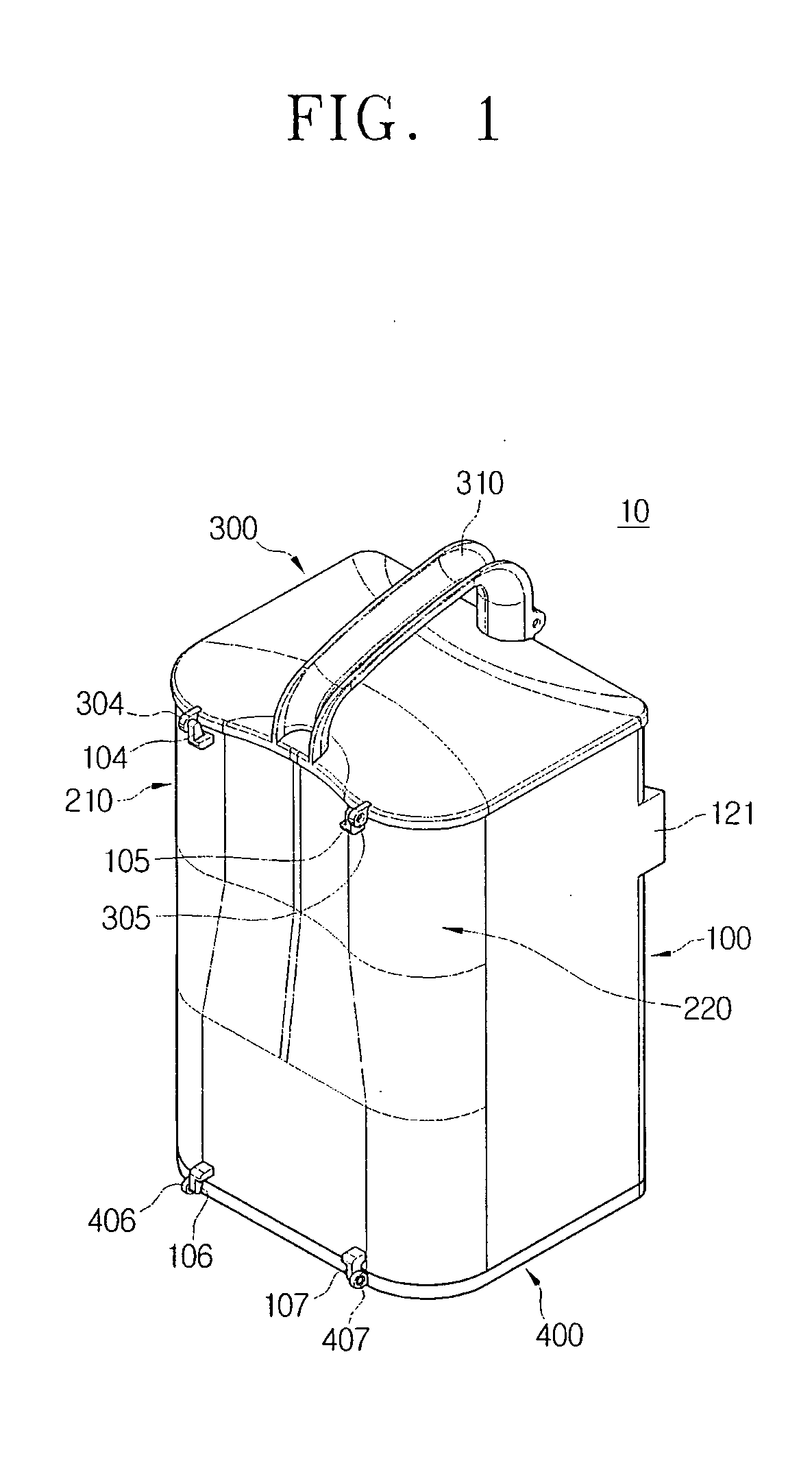

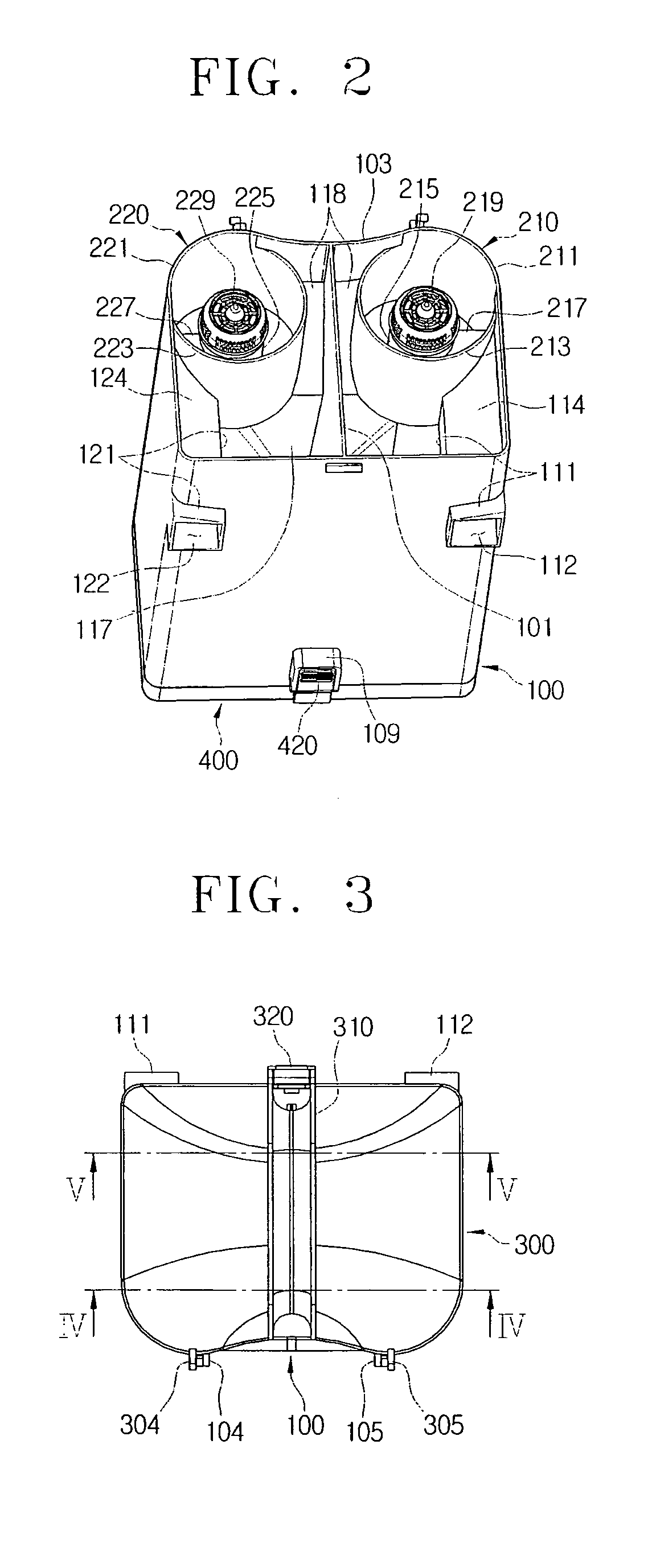

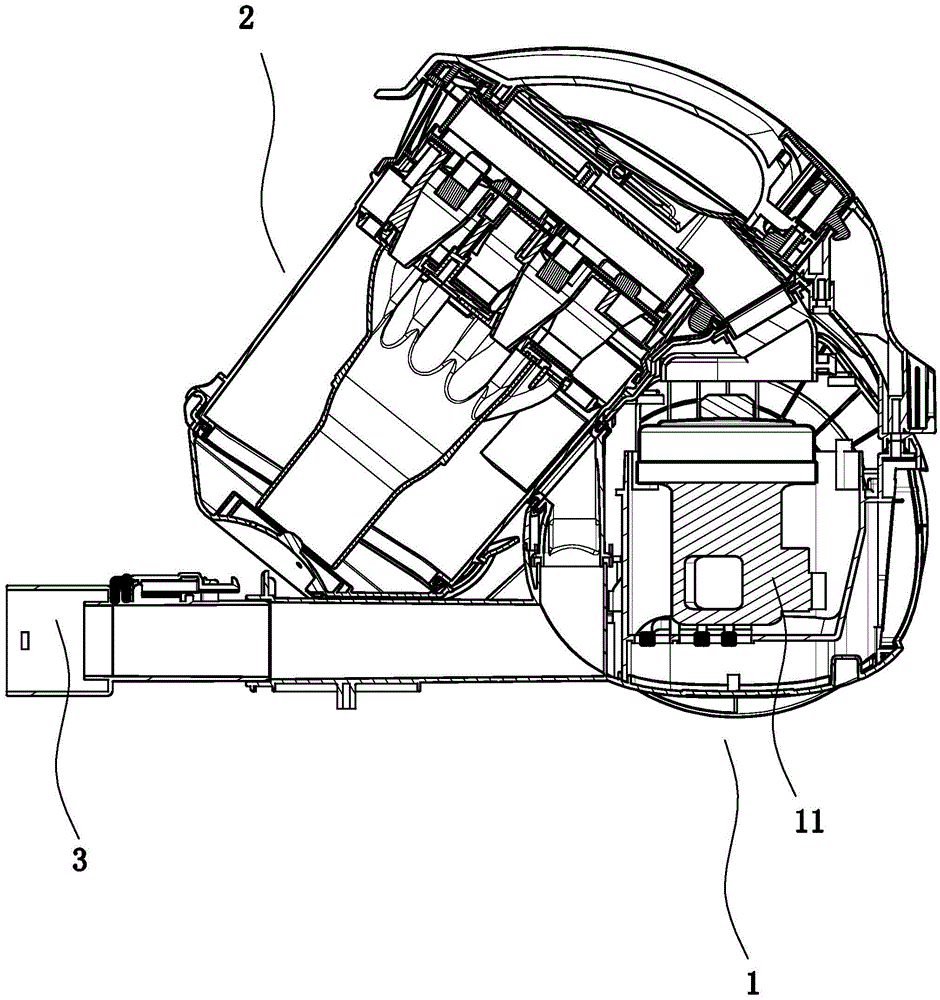

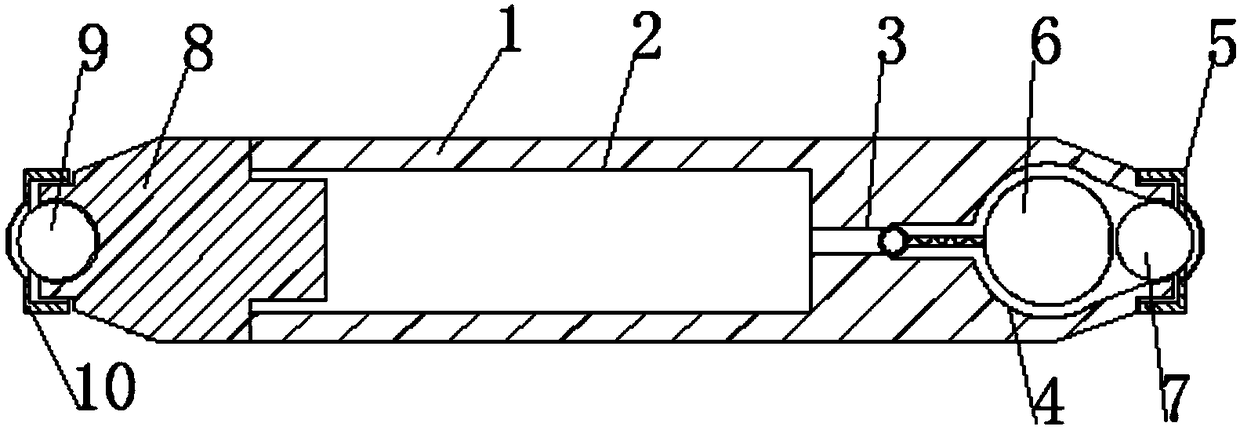

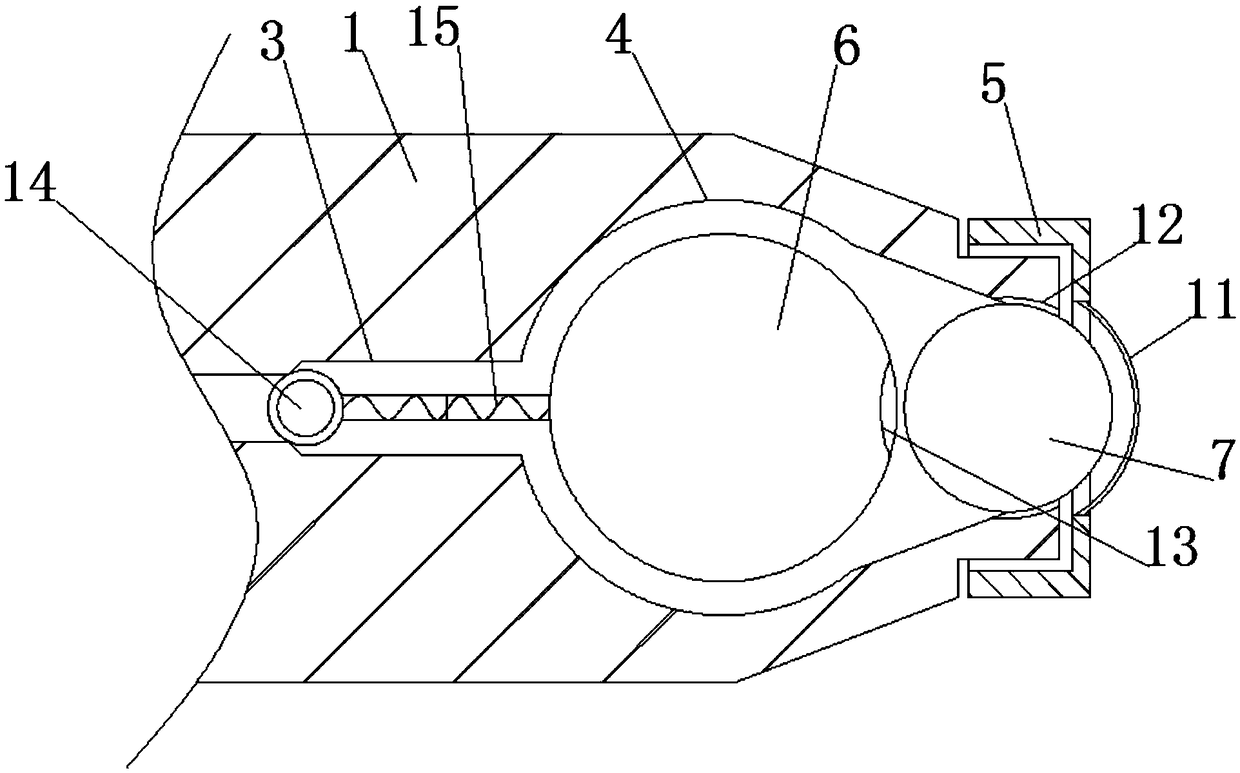

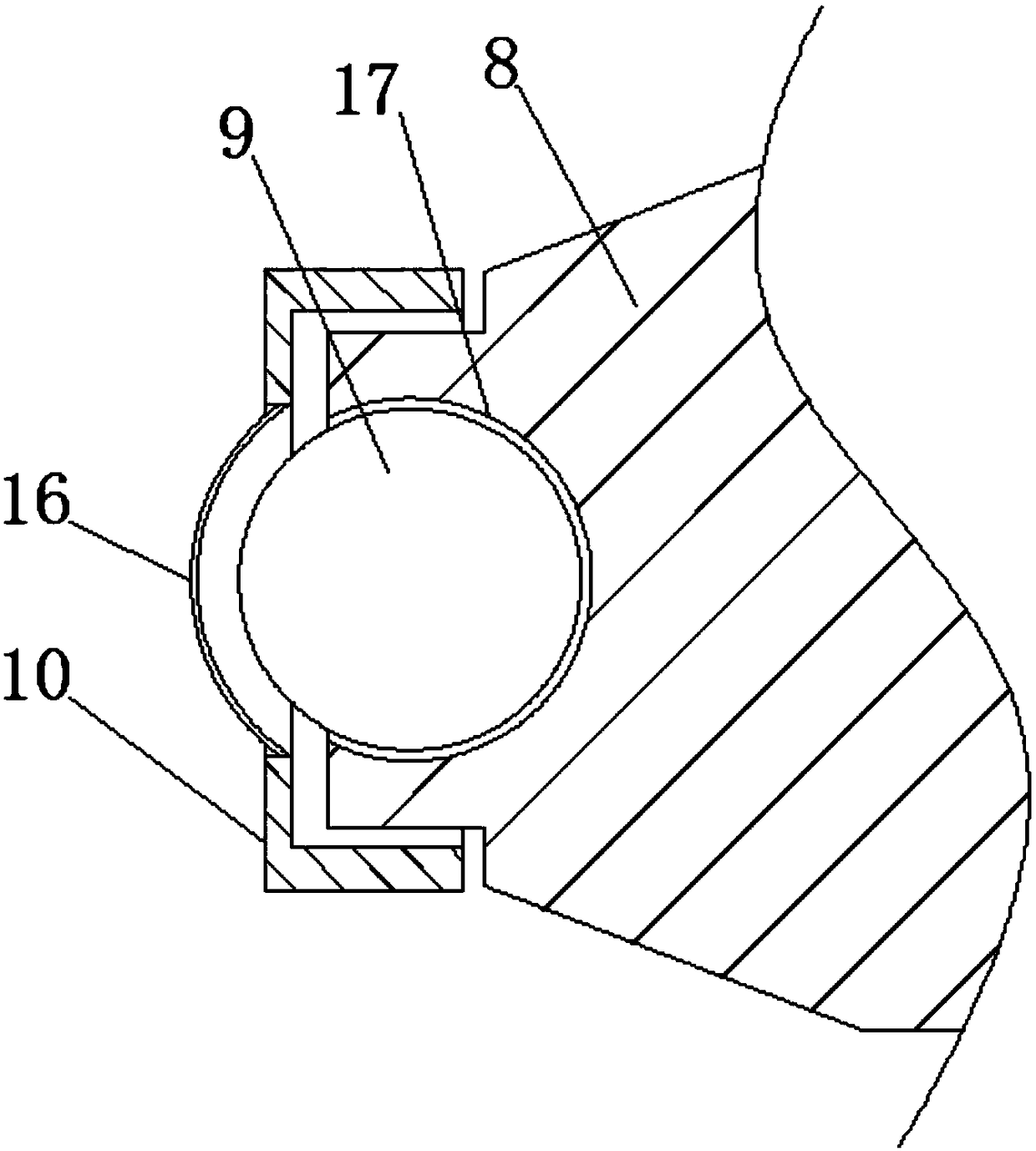

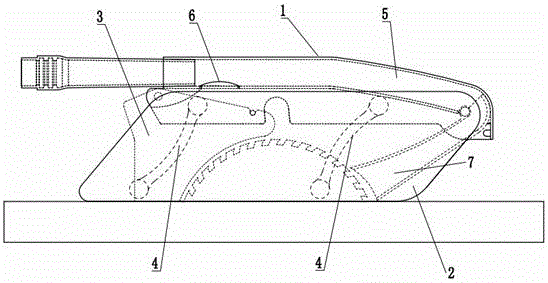

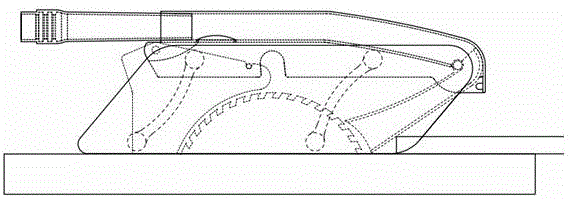

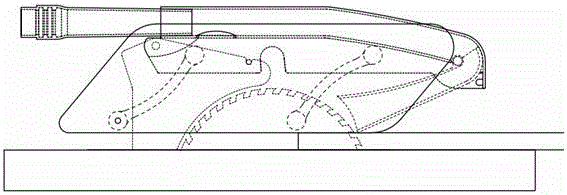

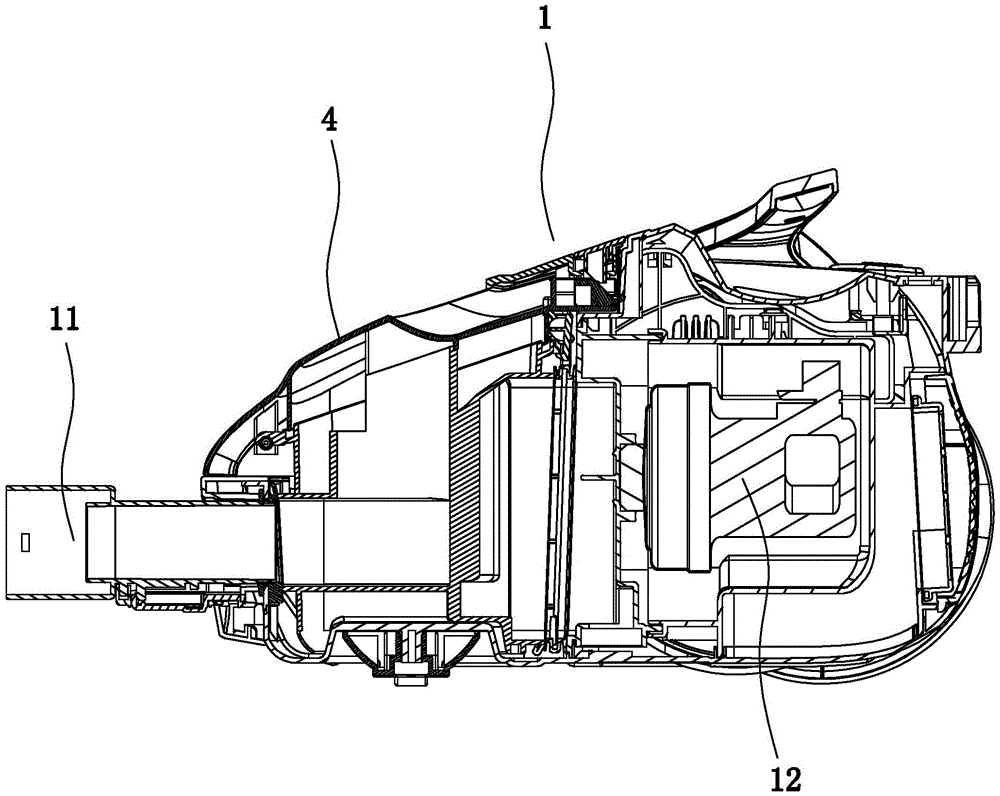

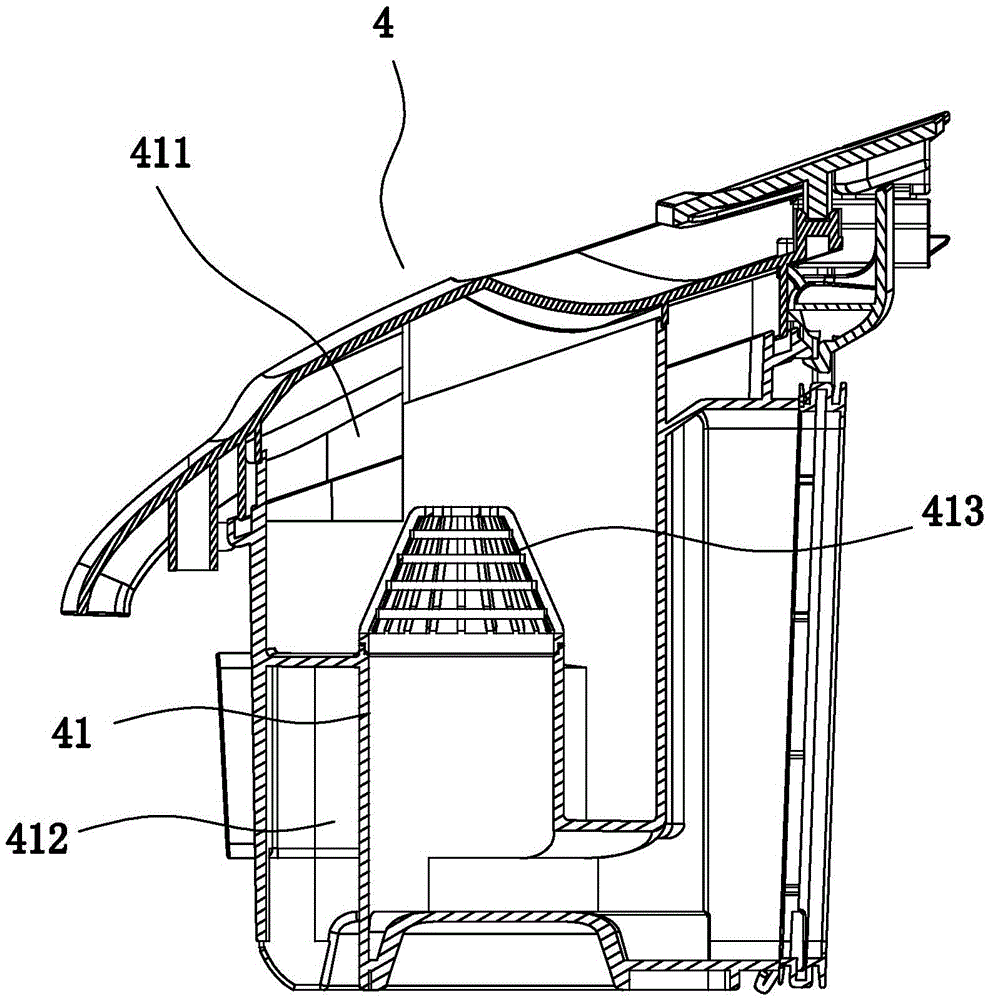

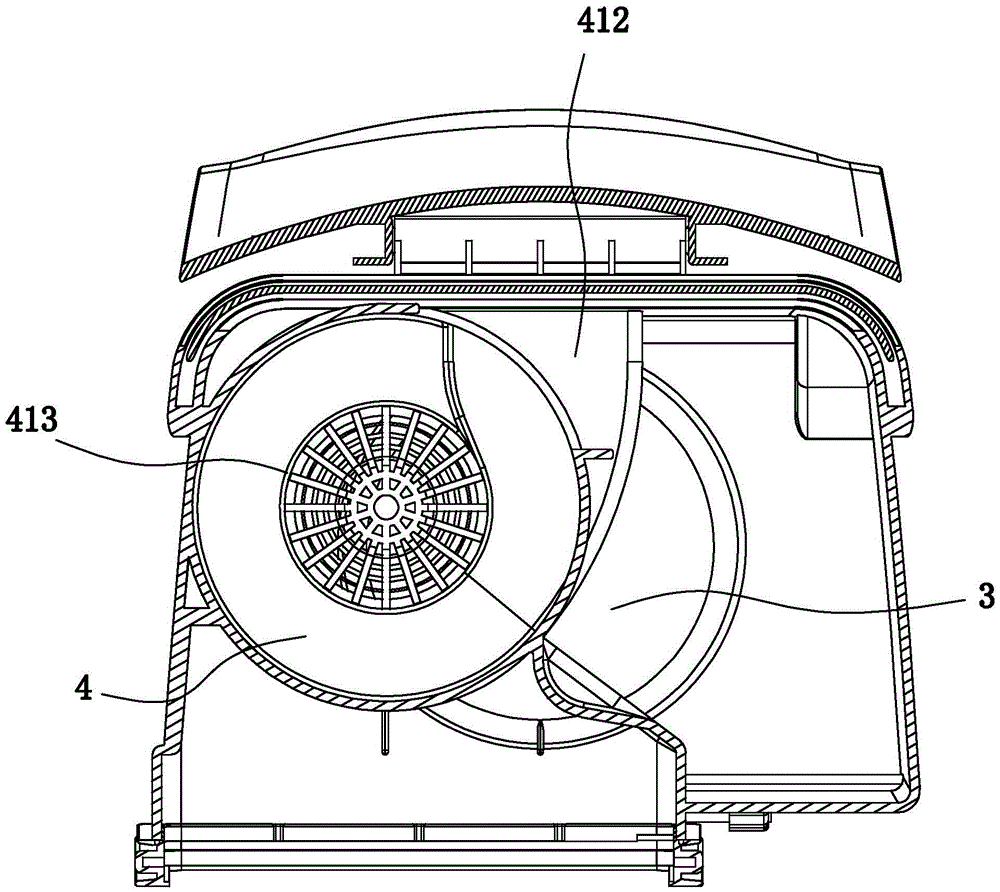

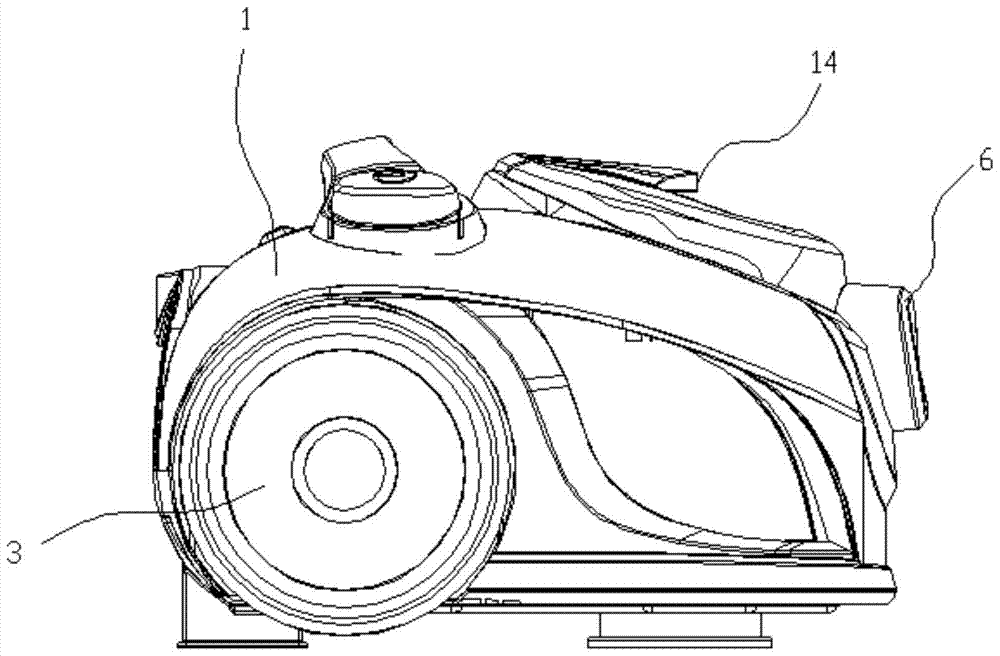

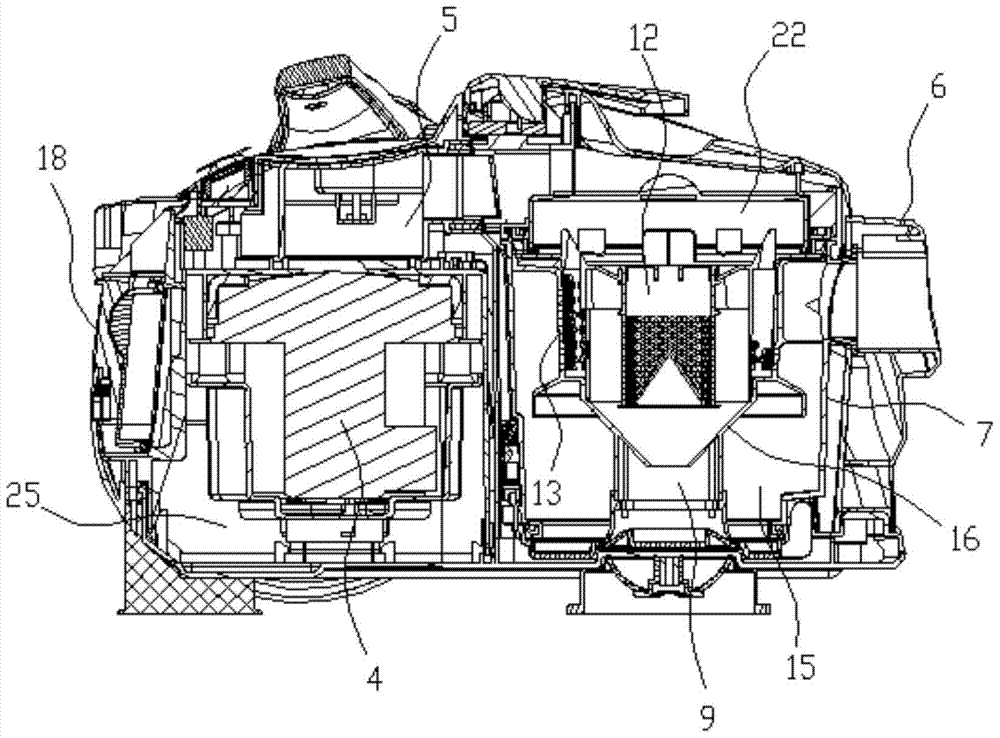

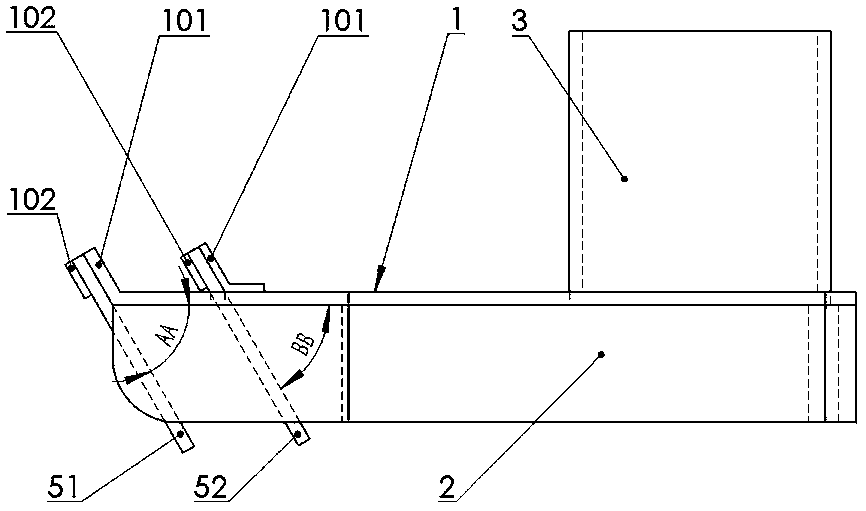

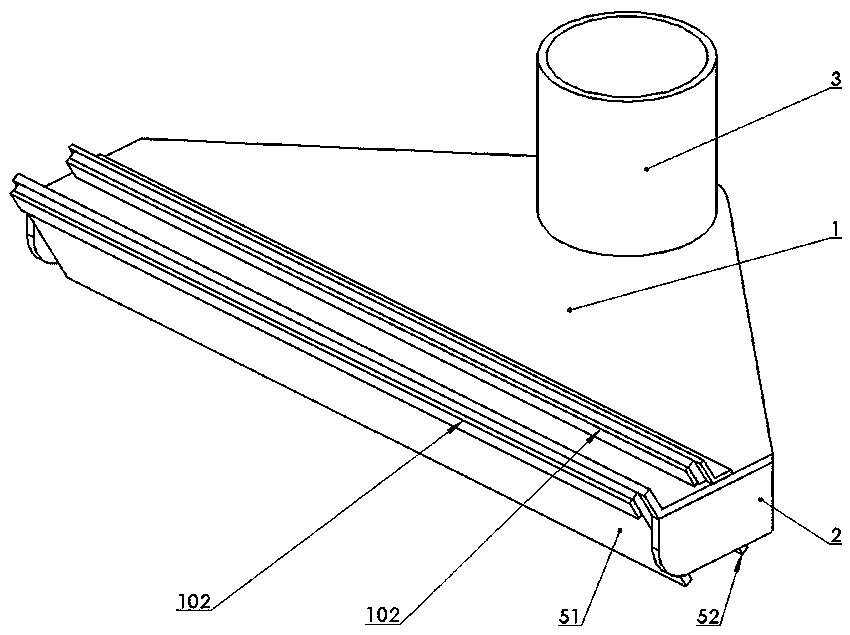

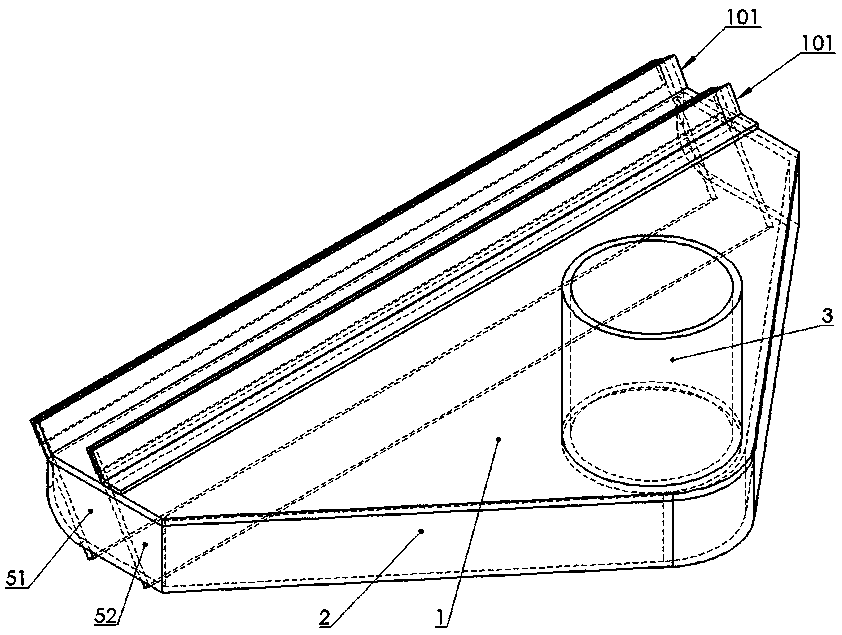

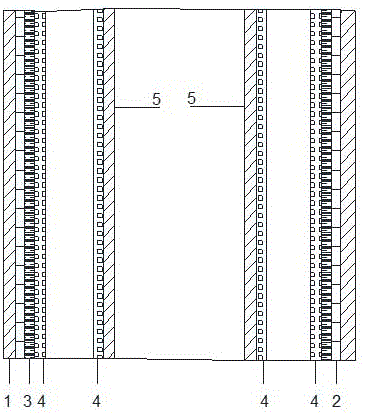

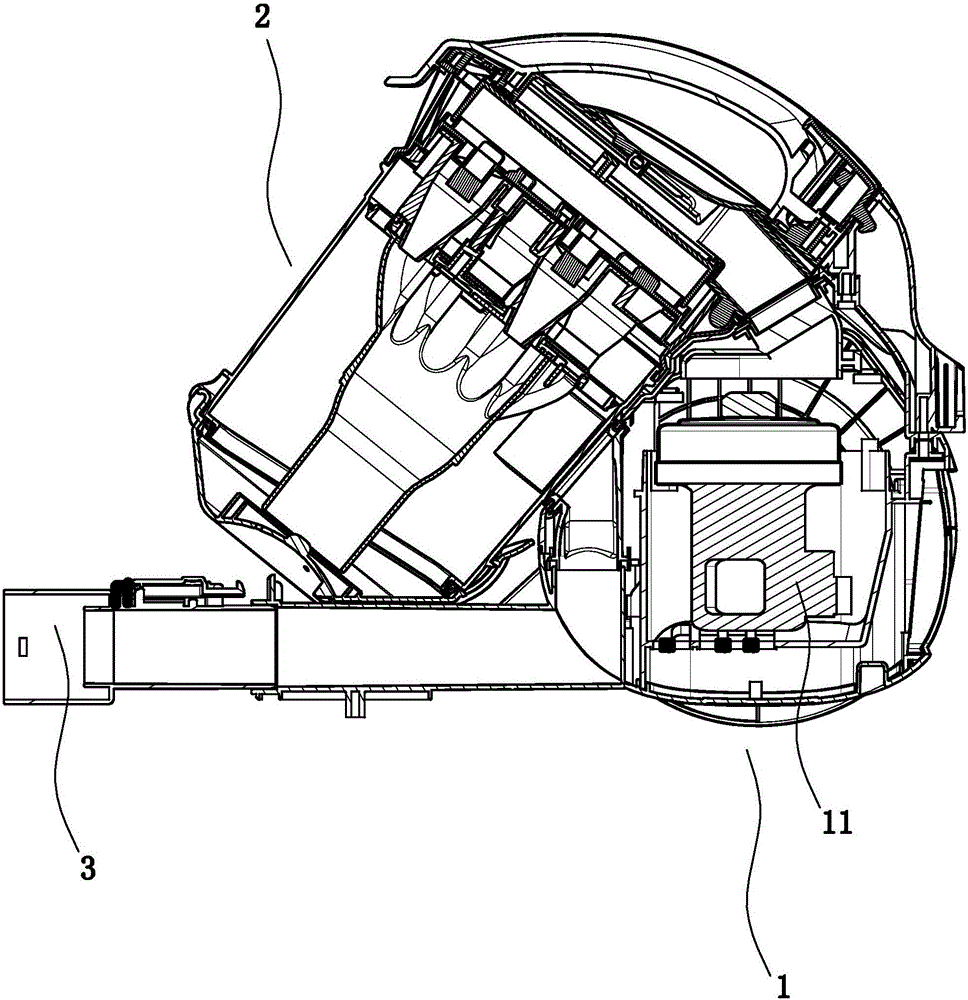

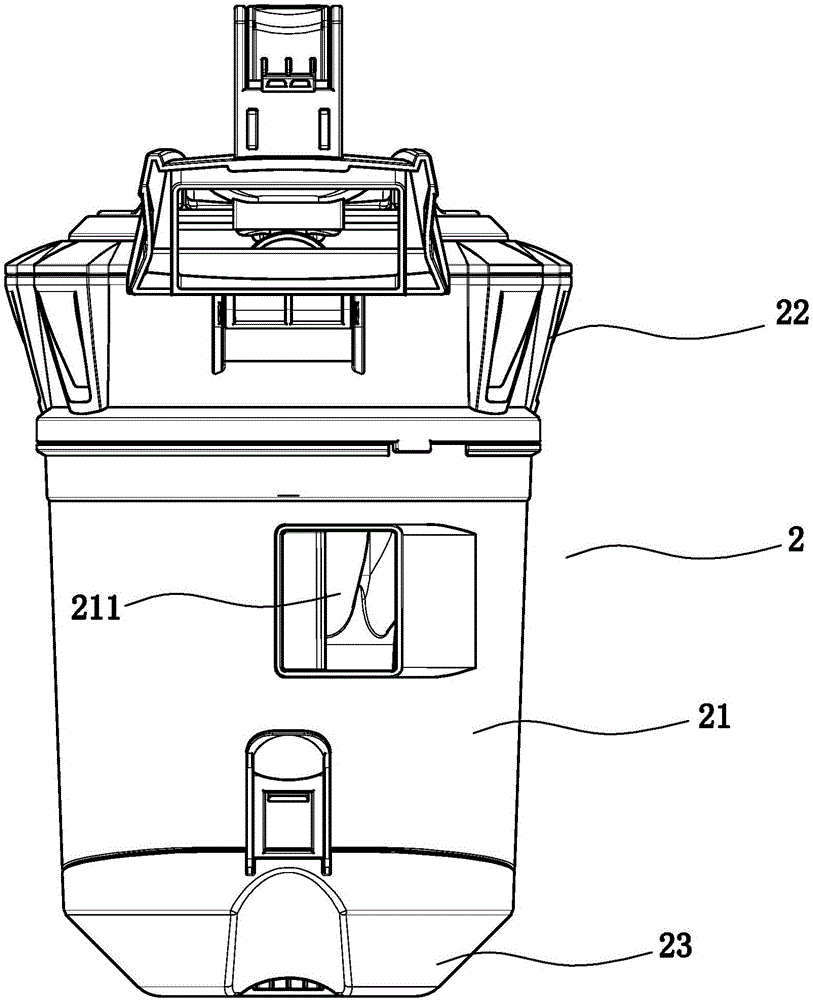

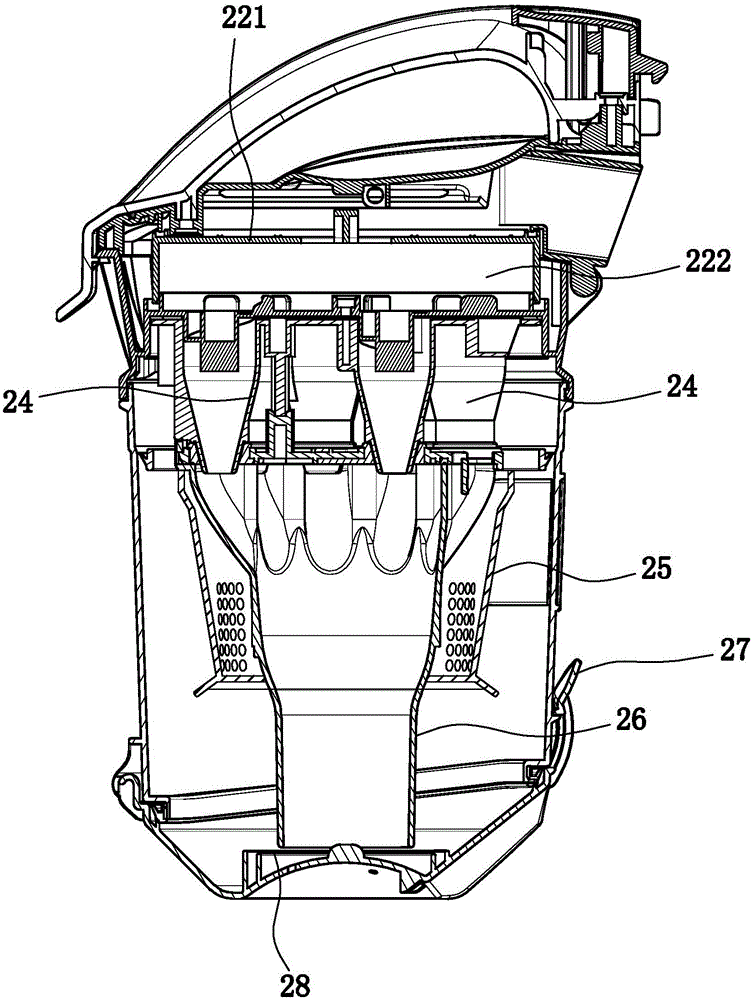

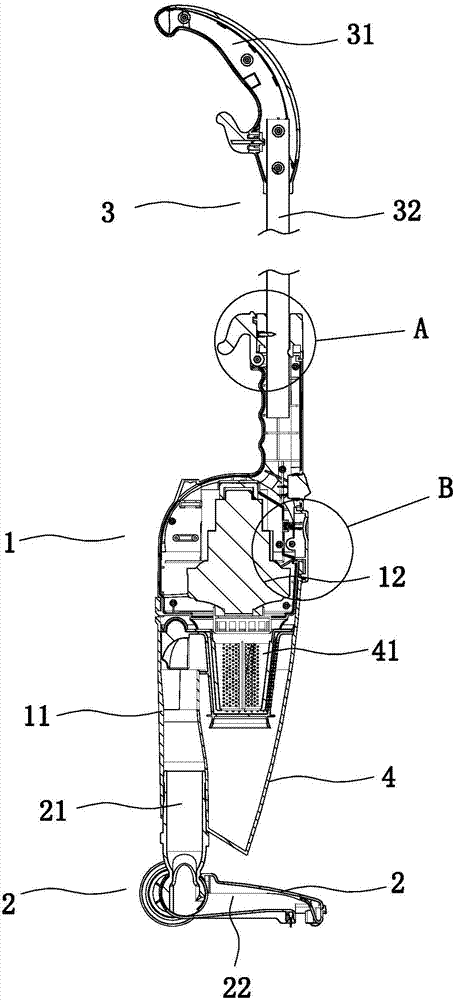

Cyclone dust-collecting apparatus for vacuum cleaner

InactiveUS7879121B2Strong vacuuming abilitySmall sizeCleaning filter meansCombination devicesEngineeringMechanical engineering

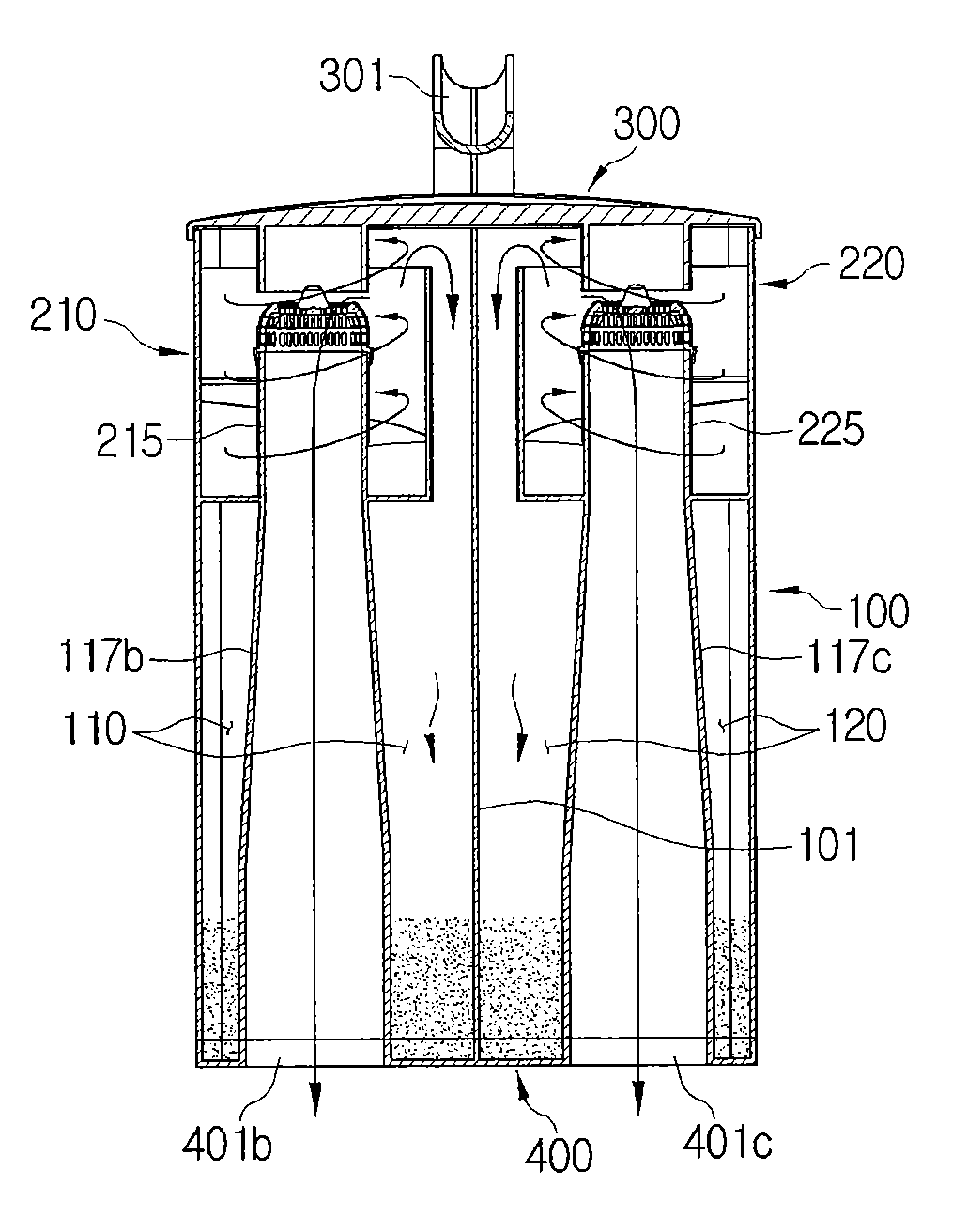

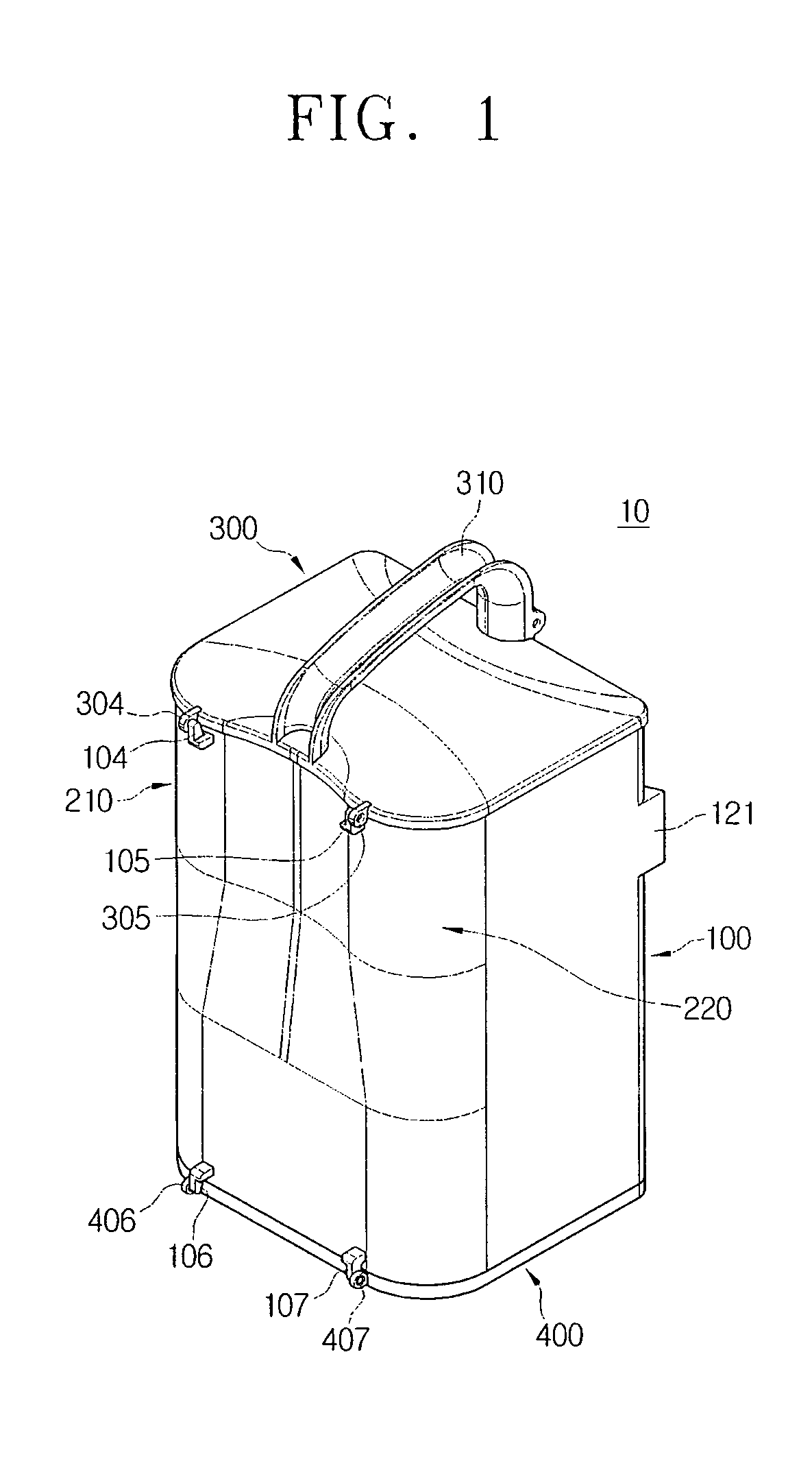

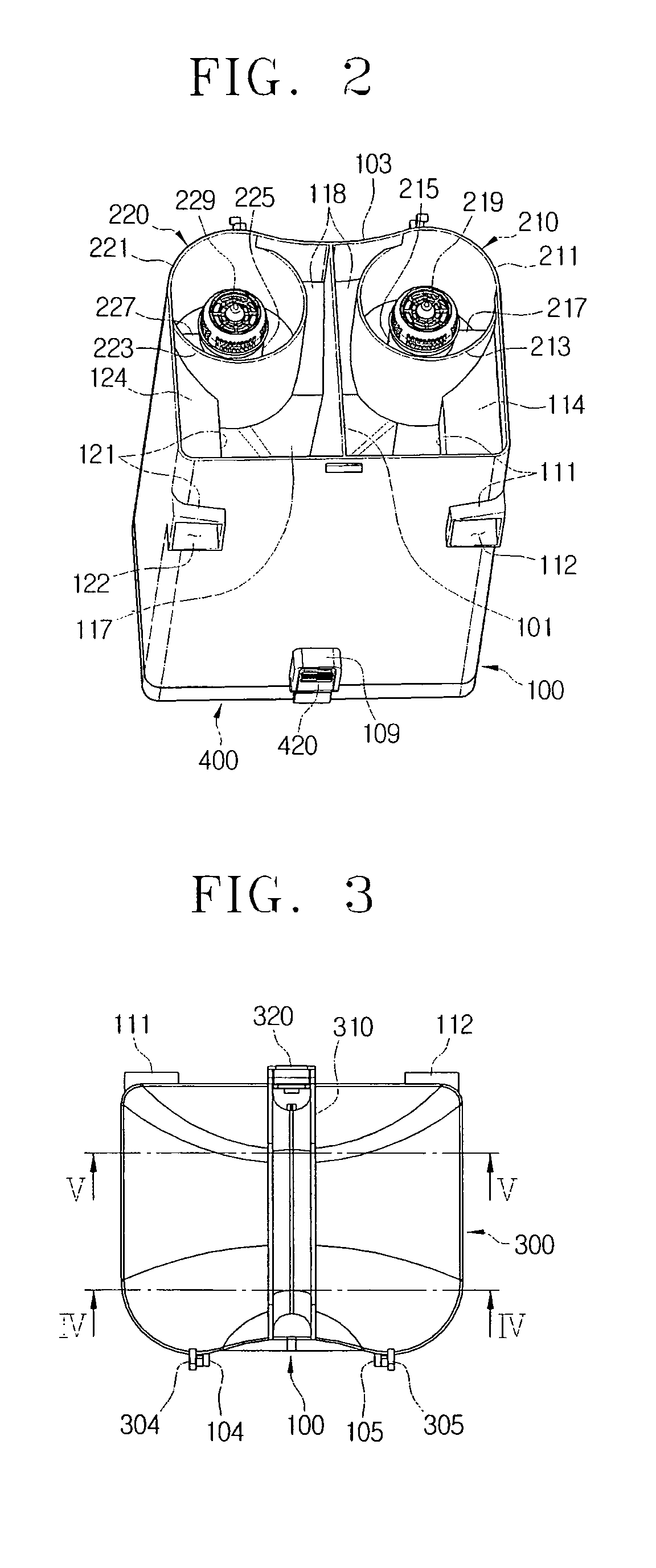

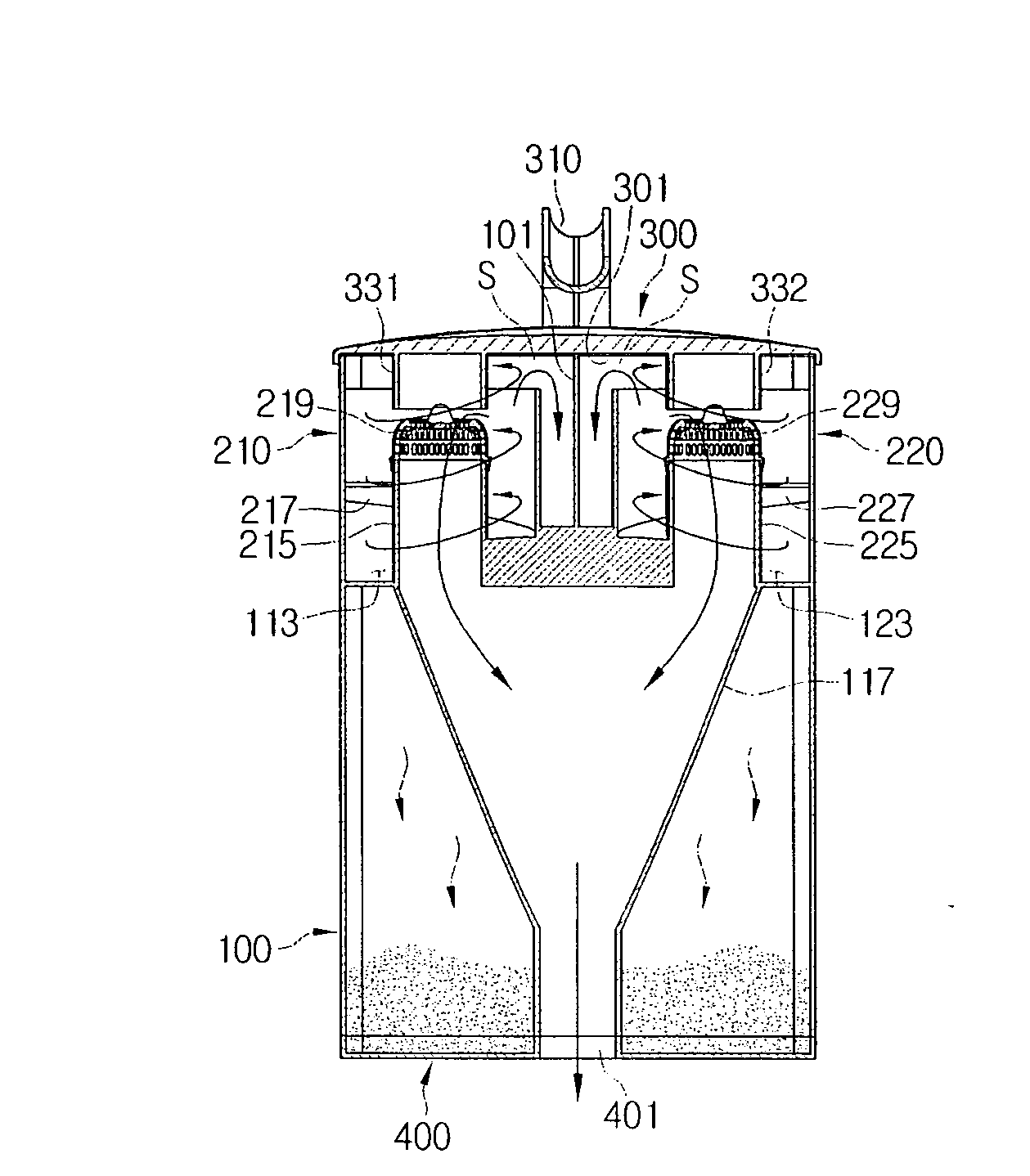

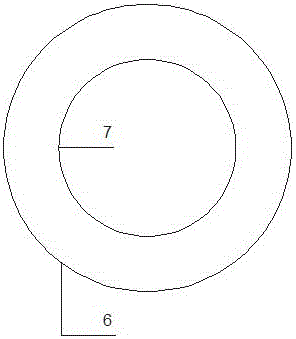

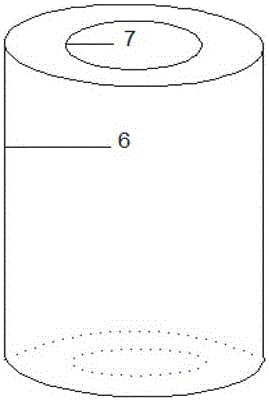

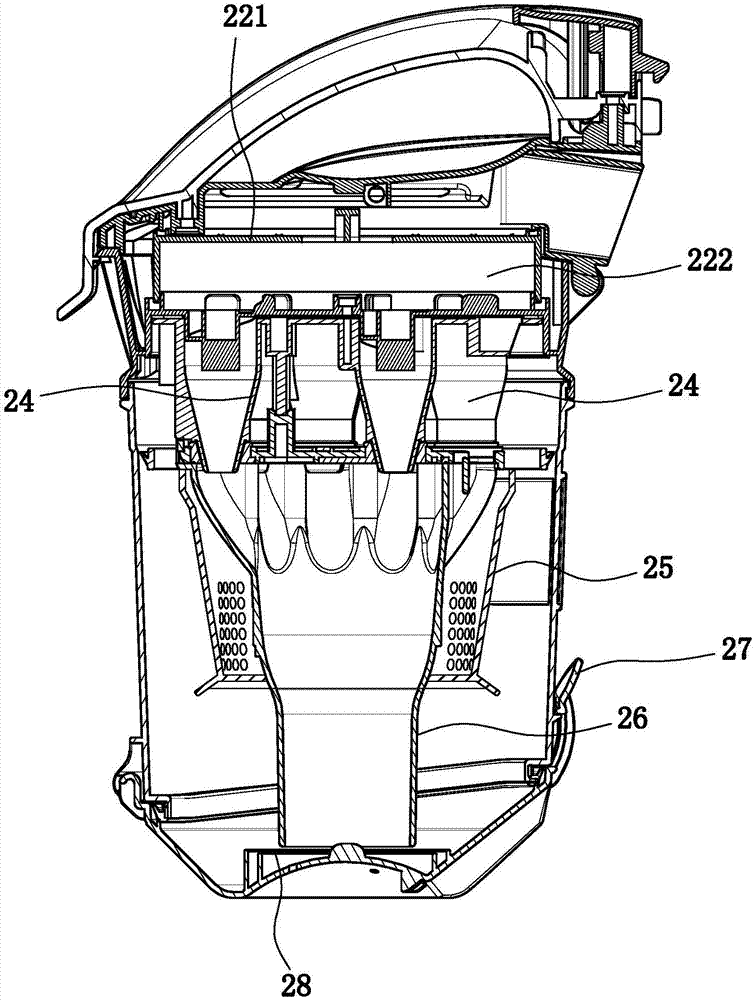

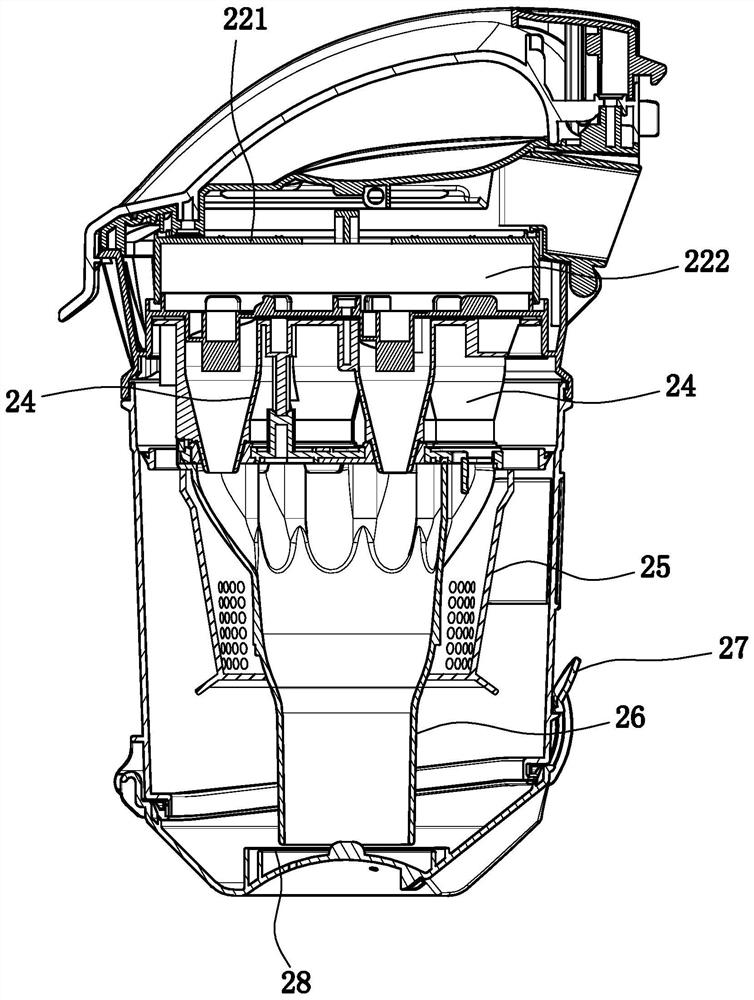

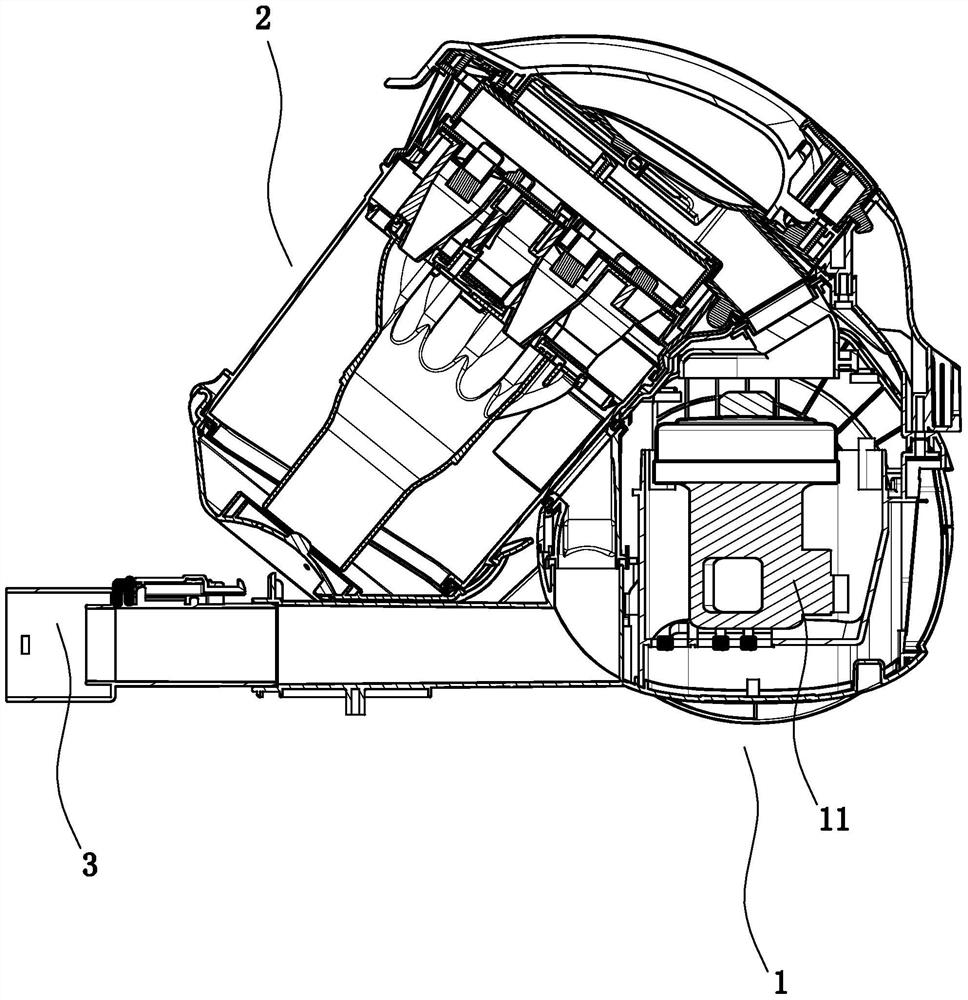

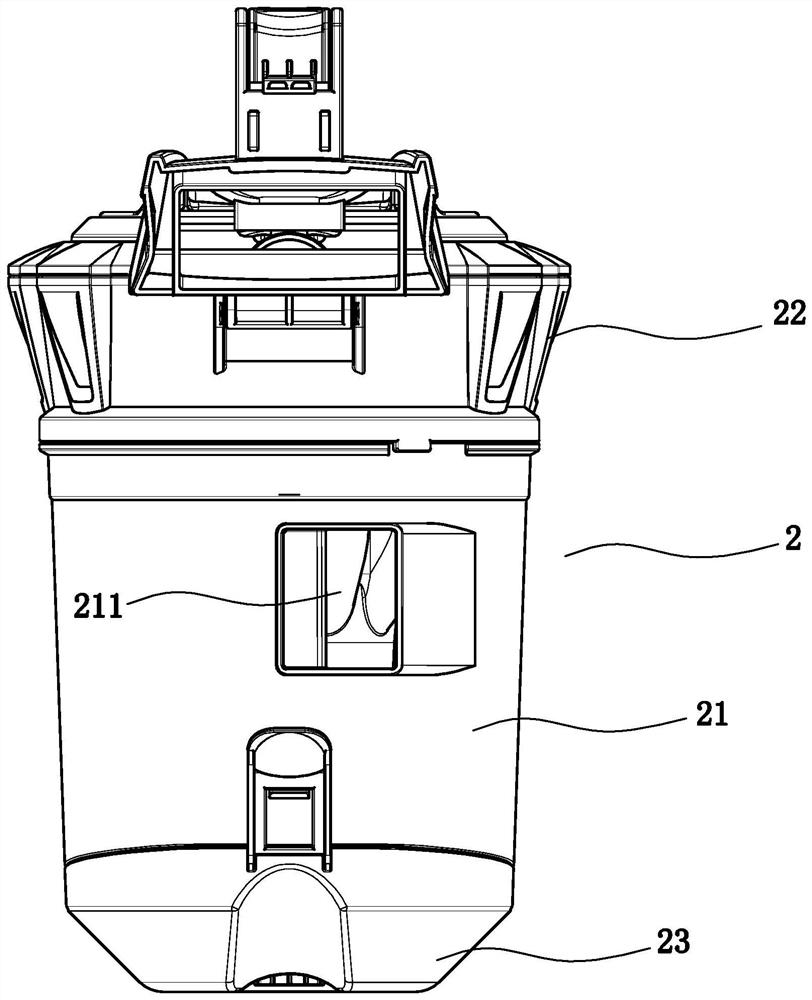

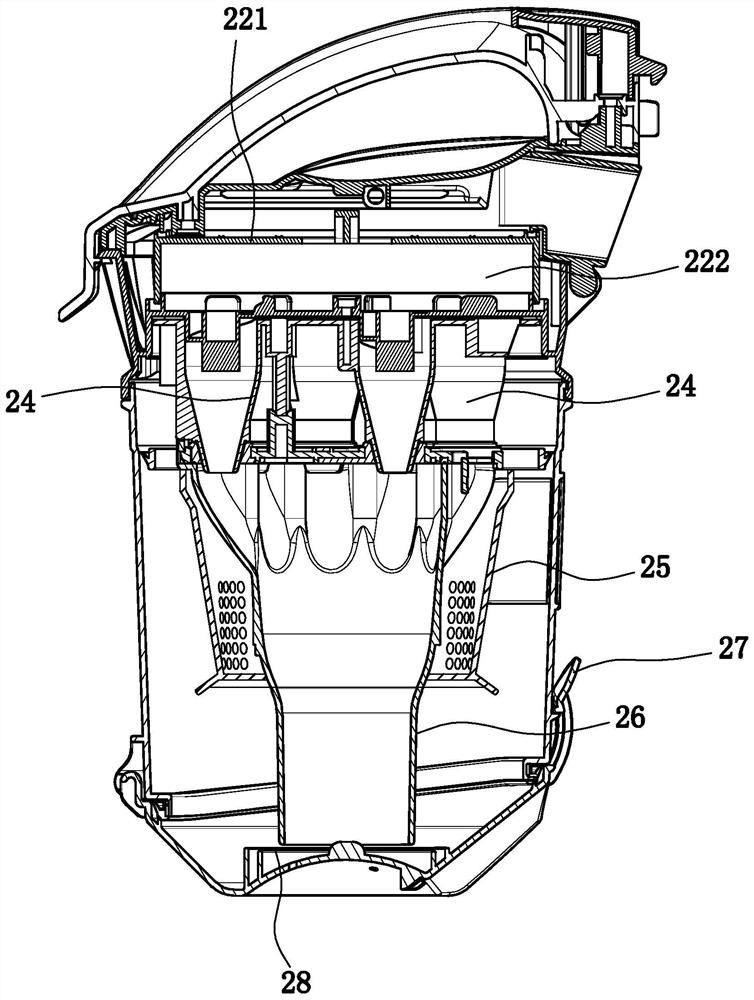

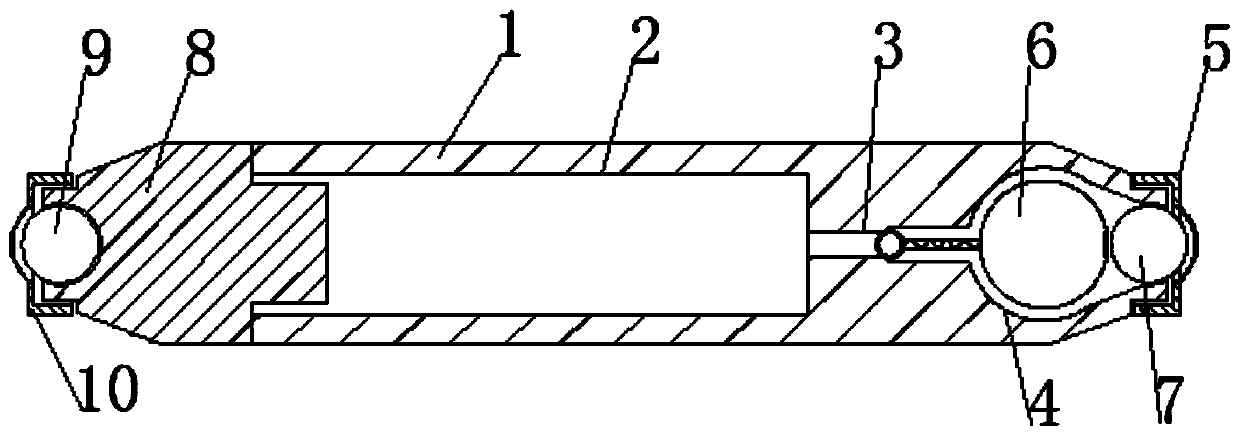

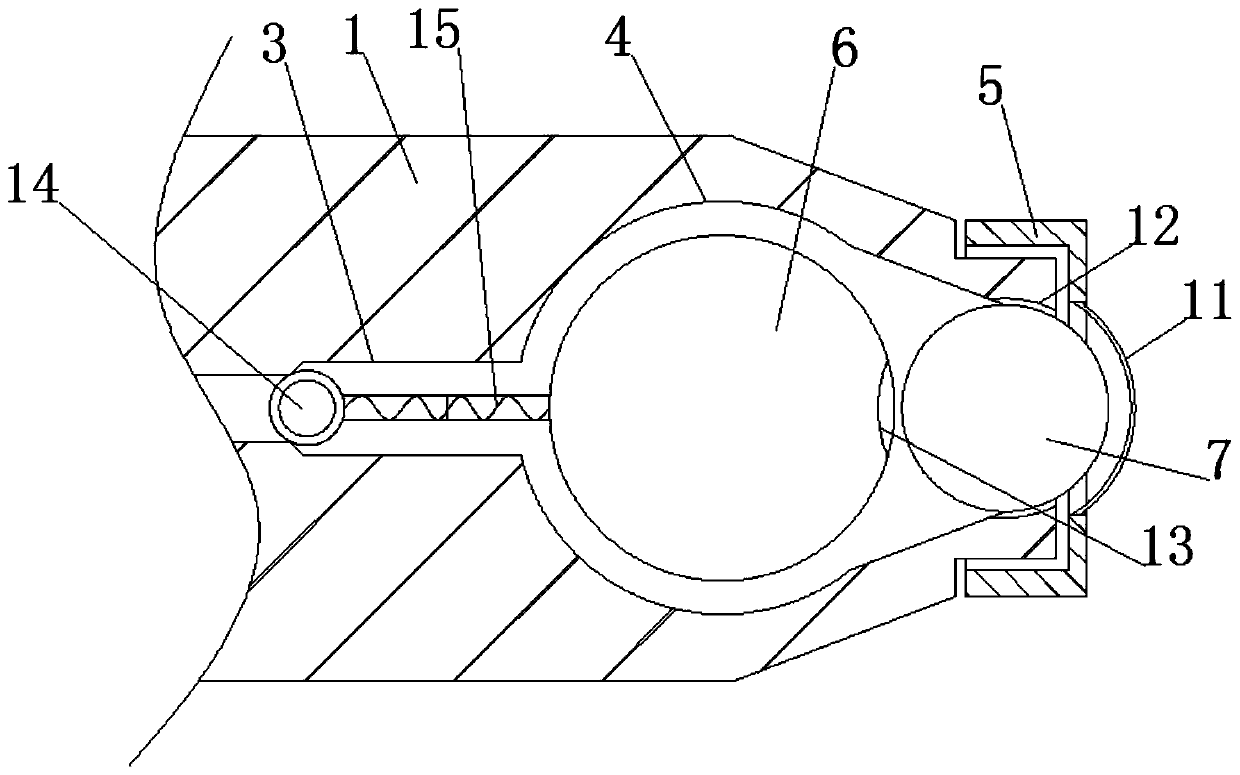

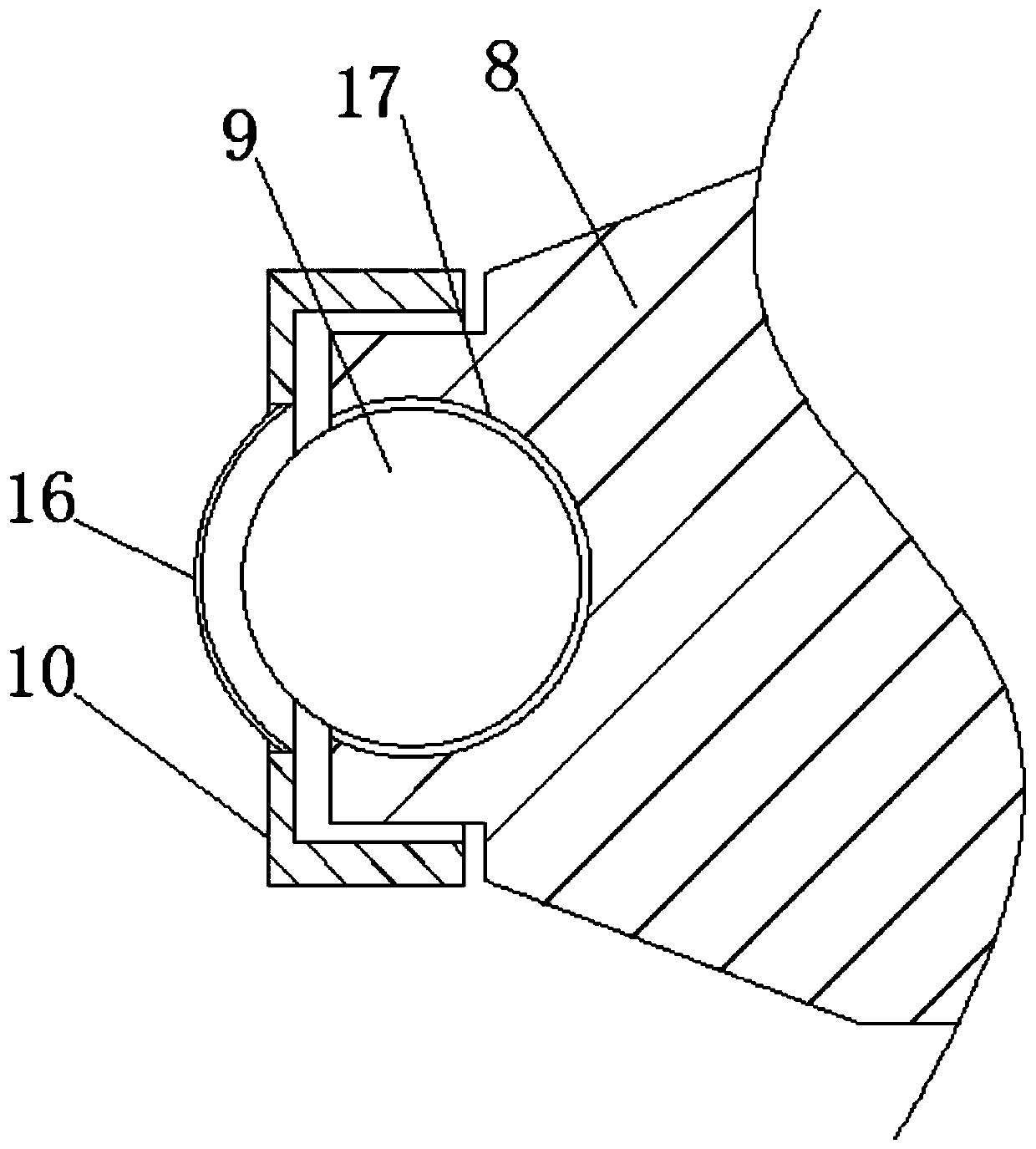

A cyclone dust-collecting apparatus is provided. The dust-collecting apparatus is detachably mounted in a main cleaner body of a vacuum cleaner and disposed on a suction flow path extending from a suction port body to a suction source. The dust-collecting apparatus includes a body having an opened lower portion; at least one cyclone unit disposed to one side in the body to separate dust from air flowing into the body and discharge air from which the dust has been separated; and a bottom cover to open or close the lower portion of the body. The body has an inflow pipe penetrating the body from a rear portion of the body and connected to the cyclone unit and the inflow pipe has an inclined top surface.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

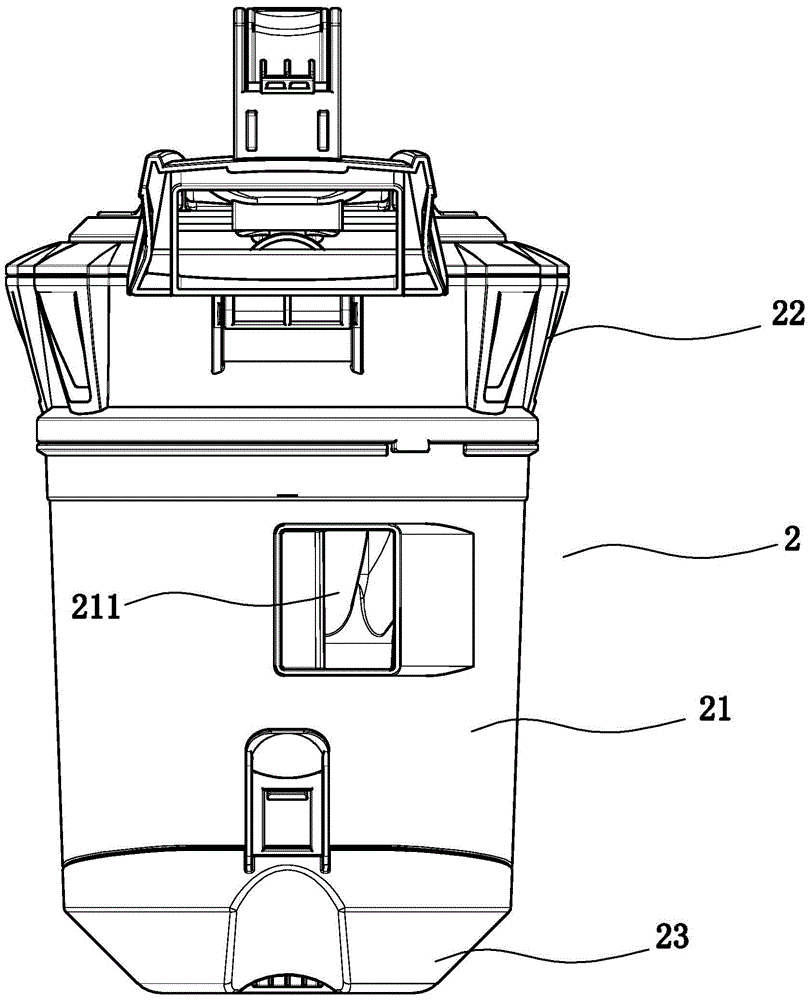

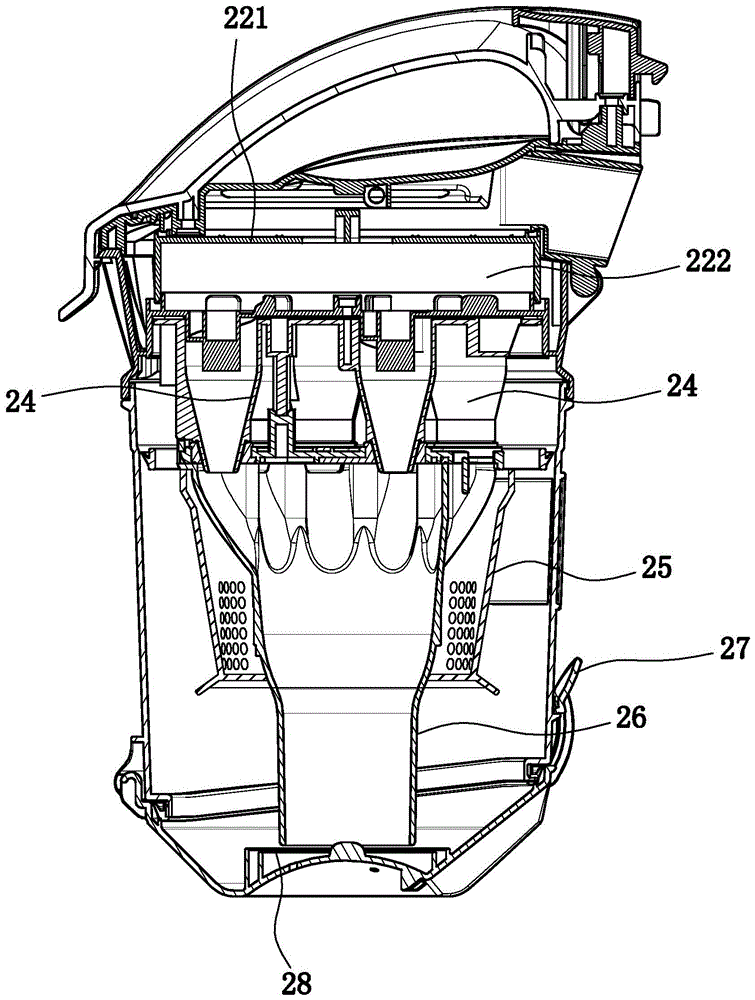

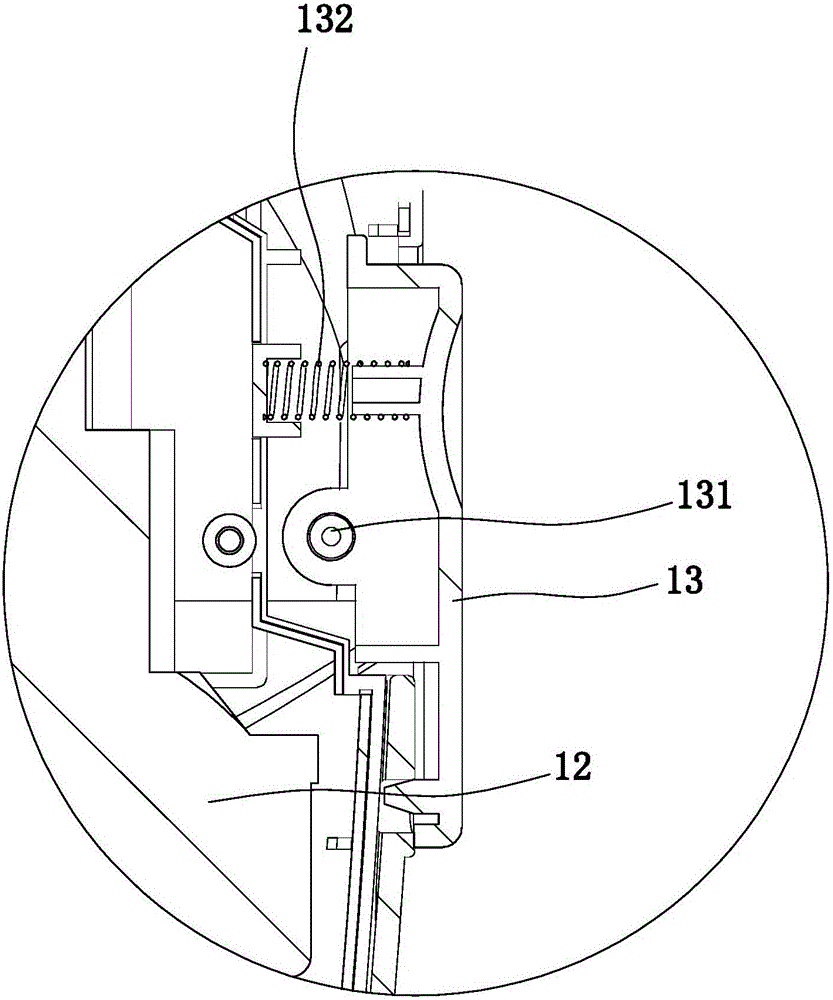

Cyclone dust-collecting apparatus for vacuum cleaner

InactiveUS20090205299A1Increase dust collection capacitySmall sizeCleaning filter meansCombination devicesMechanical engineeringVacuum cleaner

A cyclone dust-collecting apparatus is provided. The dust-collecting apparatus is detachably mounted in a main cleaner body of a vacuum cleaner and disposed on a suction flow path extending from a suction port body to a suction source. The dust-collecting apparatus includes a body having an opened lower portion; at least one cyclone unit disposed to one side in the body to separate dust from air flowing into the body and discharge air from which the dust has been separated; and a bottom cover to open or close the lower portion of the body. The body has an inflow pipe penetrating the body from a rear portion of the body and connected to the cyclone unit and the inflow pipe has an inclined top surface.

Owner:SAMSUNG GWANGJU ELECTRONICS CO LTD

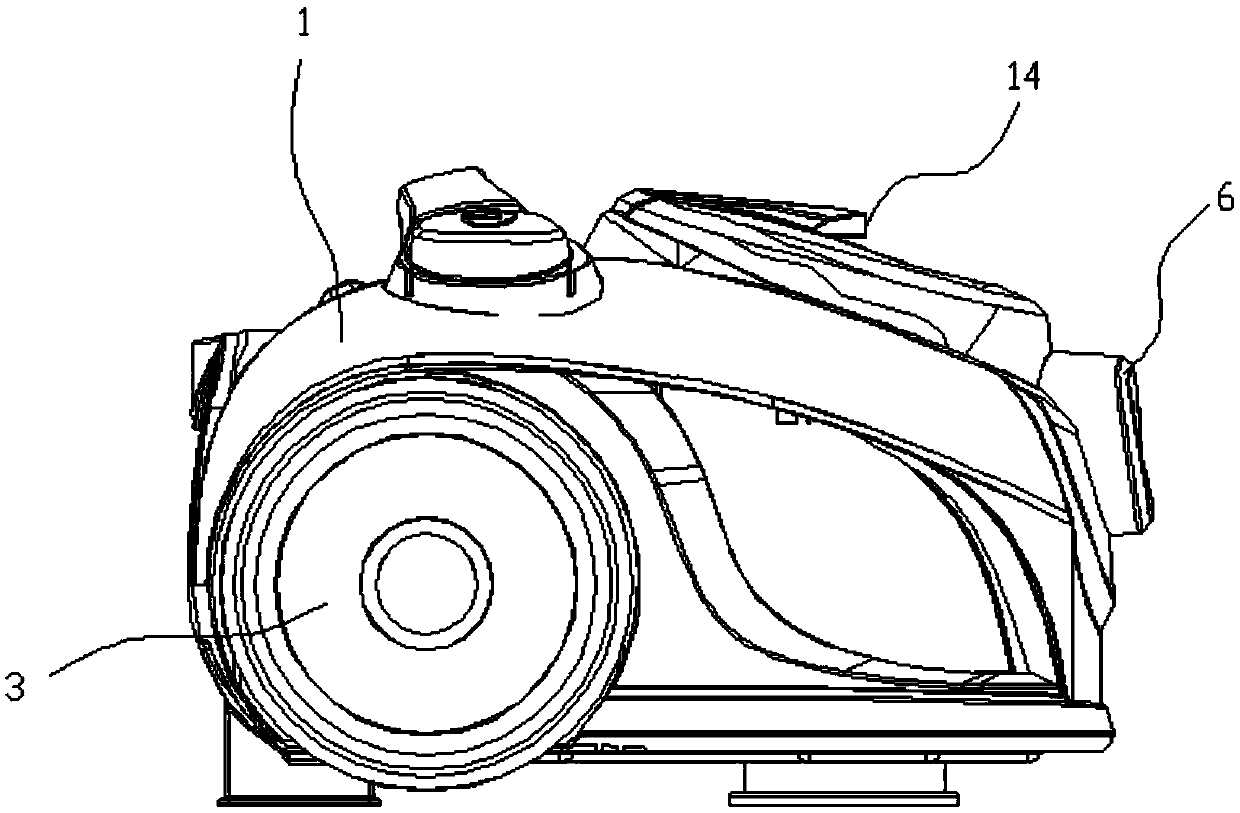

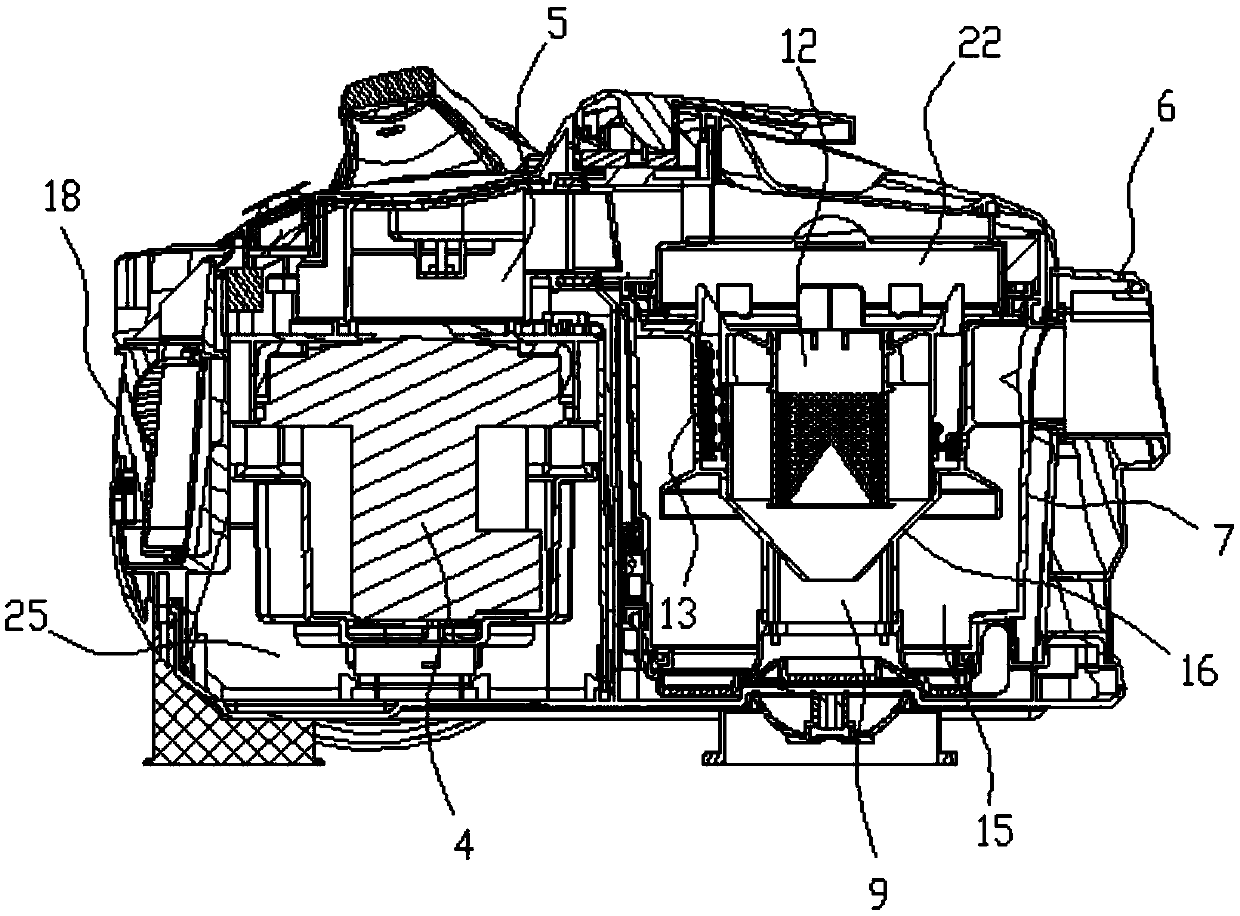

Vacuum cleaner structure

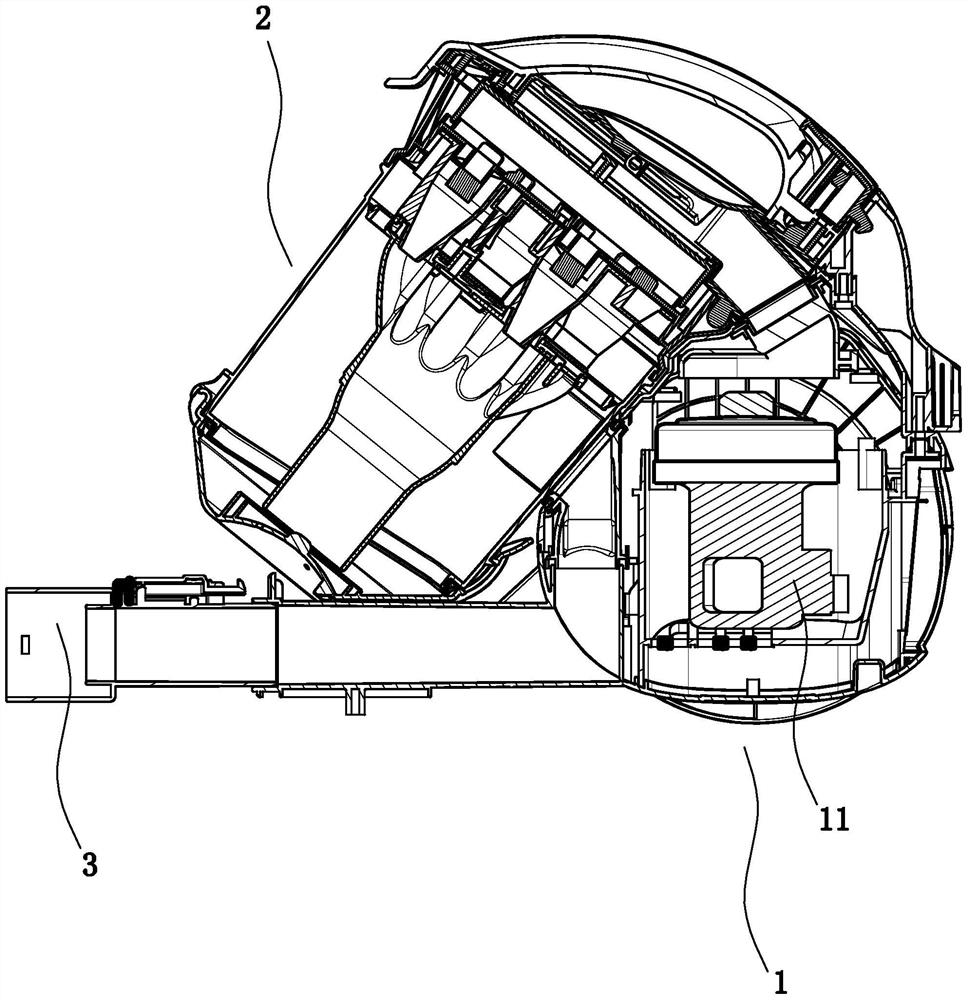

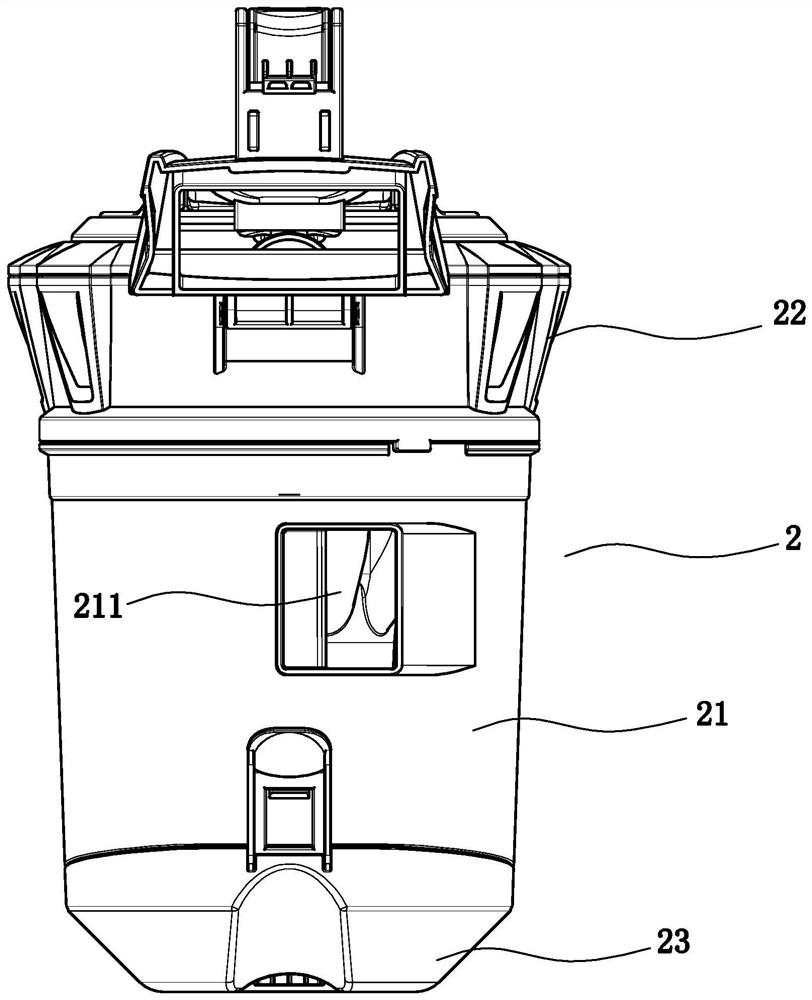

The invention discloses a vacuum cleaner structure which comprises a main machine shell, a dust suction mop, a universal wheel, a plurality of moving wheels and an induced draft motor. The main machine shell is provided with a dust cup component and a suction opening seat. The suction opening seat is connected with the dust suction mop through a dust suction pipe. The dust cup component comprises a dust cup, a cyclone cone and inner dust bin. The cyclone cone is provided with a straight wind inlet, a downwardly-spiral wind guide channel and a cyclone outlet which are sequentially communicated. The straight wind inlet is communicated with the suction opening seat. The cyclone cone is provided with a cone inner cylinder. The cone inner cylinder is provided with a vertical wind return channel communicated with the cyclone outlet. The cyclone outlet is communicated with the inlet of the vertical wind return channel and the inner dust bin. The outlet of the vertical wind return channel is communicated with the induced draft motor. The vacuum cleaner structure has the advantages that the wind inlet and outlet channels are reasonable in structure, and dust can be separated and collected by cyclone; the vacuum cleaner structure is high in dust suction ability and is provided with a multistage filter structure which is good in filter effect; noise during wind discharge can be reduced, and vibration and the noise can be reduced effectively to keep a good silent effect by a stability strengthening structure.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

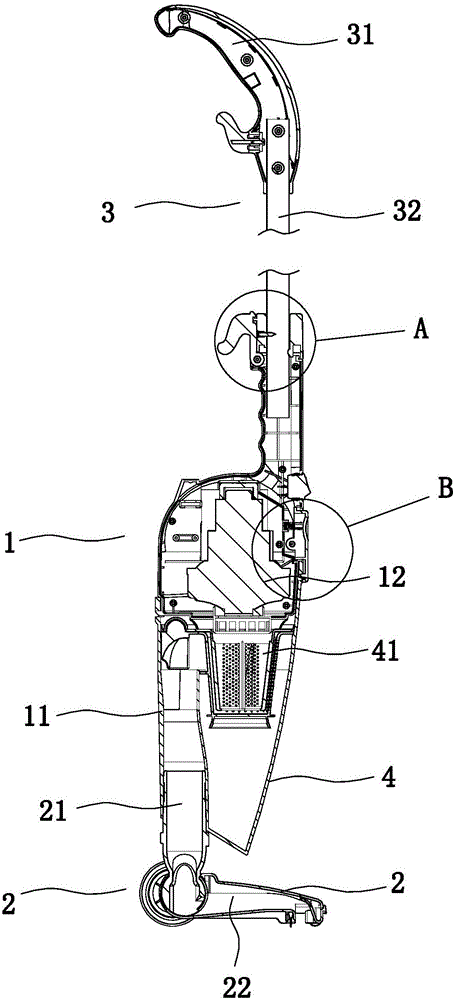

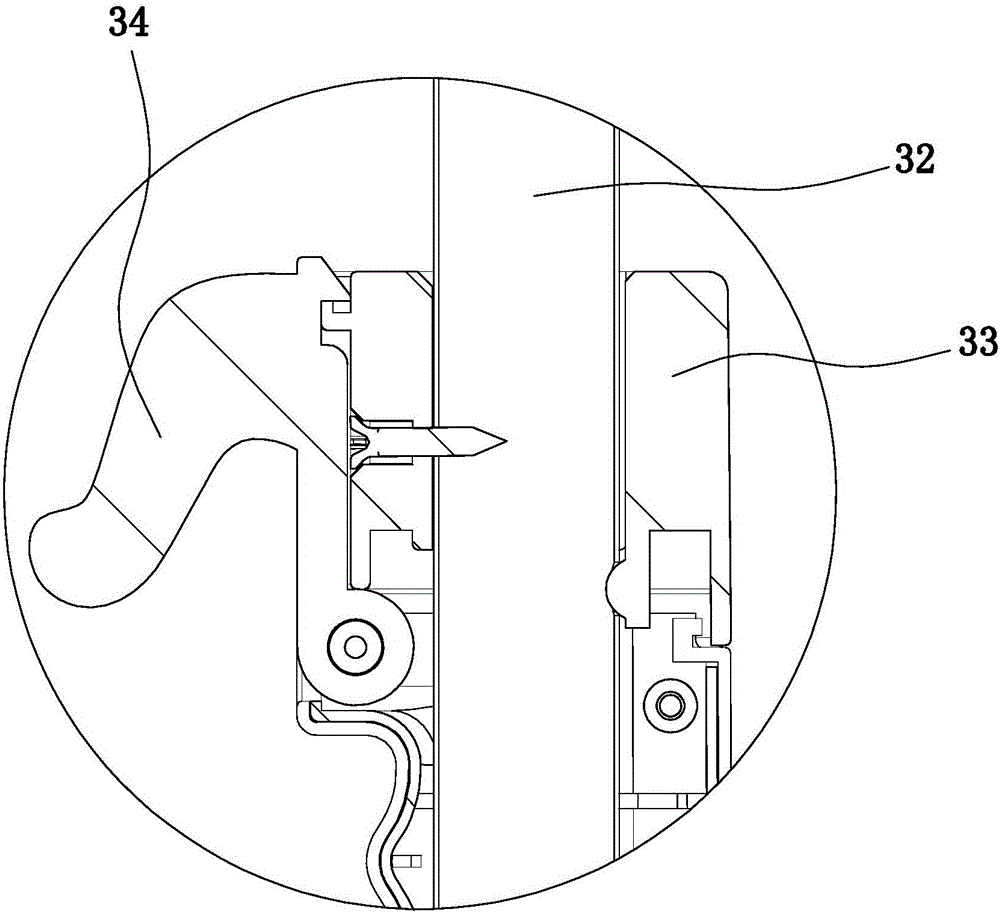

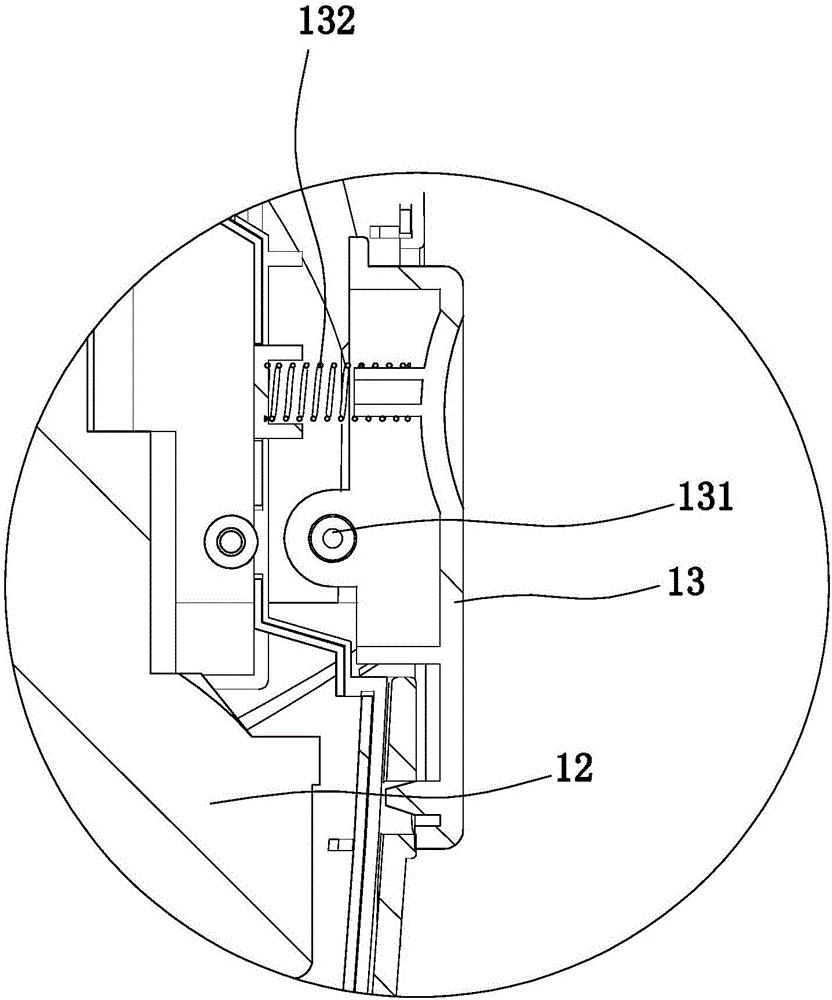

Portable cyclone dust collector

The invention discloses a portable cyclone dust collector which comprises a main machine body and a dust collecting mop; a handle, a dust cup, a machine body air inlet pipe and an air suction motor are arranged on the main machine body; the dust collecting mop comprises a mop substrate and an inserting pipe; the lower end of the inserting pipe is communicated with a mop internal air flue, and the upper end of the inserting pipe is clamped and communicated with the machine body air inlet pipe; a filter screen cartridge is arranged in the dust cup; a tangential air inlet and an upper-end air exhaust port are formed in the dust cup; a plurality of filtering holes are formed in the filter screen cartridge; the tangential air inlet is communicated with the machine body air inlet pipe; the upper-end air exhaust port is communicated with the air inlet end of the air suction motor; the air outlet end of the air suction motor is communicated with an external air exhaust port formed in the main machine body. The portable cyclone dust collector disclosed by the invention has the benefits that the handheld operation can be performed, and the cleaning process is quick and labor-saving; as the structure of the air flue is reasonable, the separation and the collection of dust can be effectively completed; the dust suction capacity is strong, and the filtering effect is good, so that and the cleanness of air exhaust can be guaranteed.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

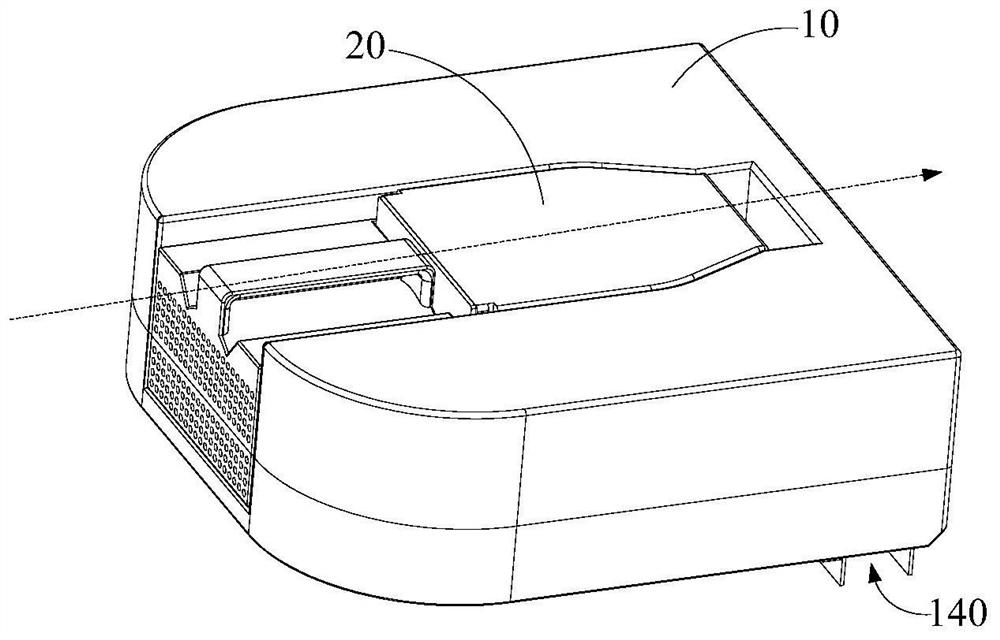

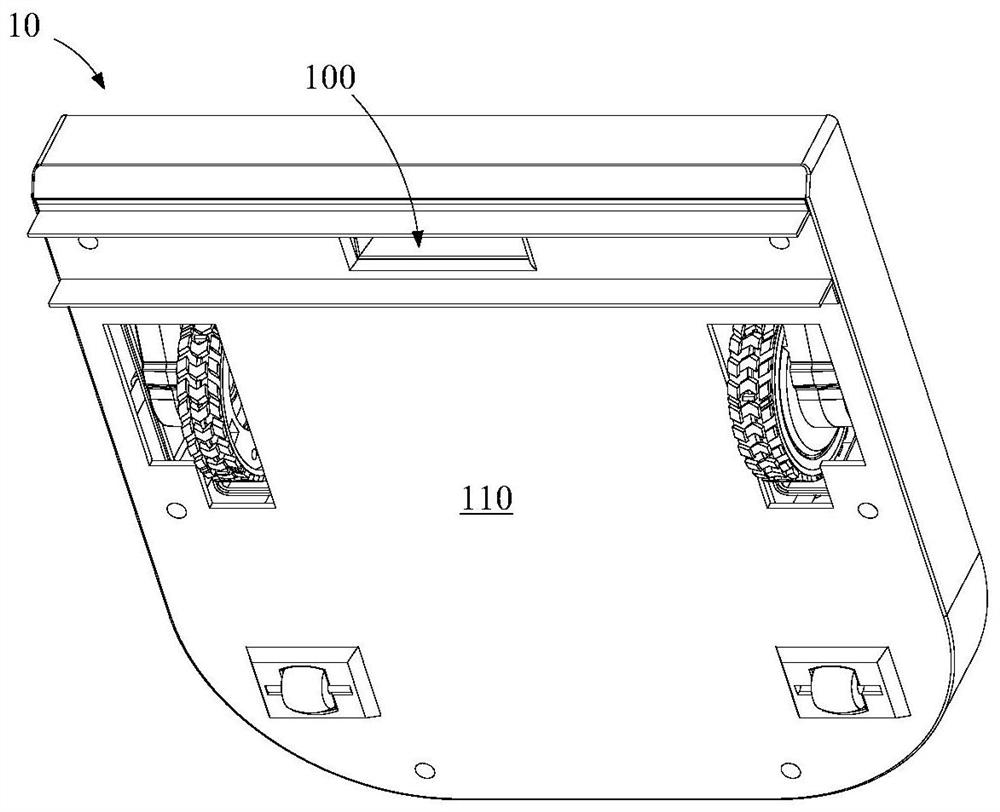

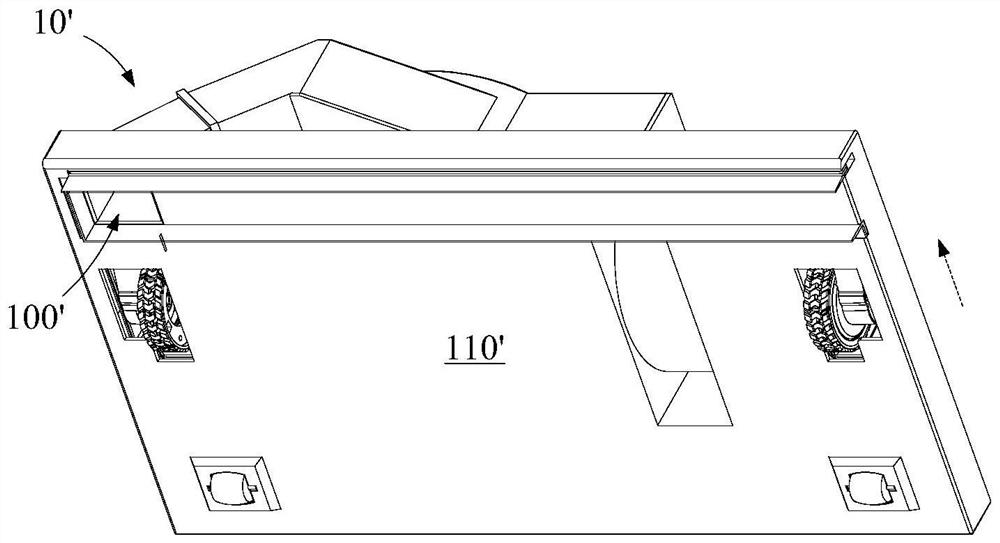

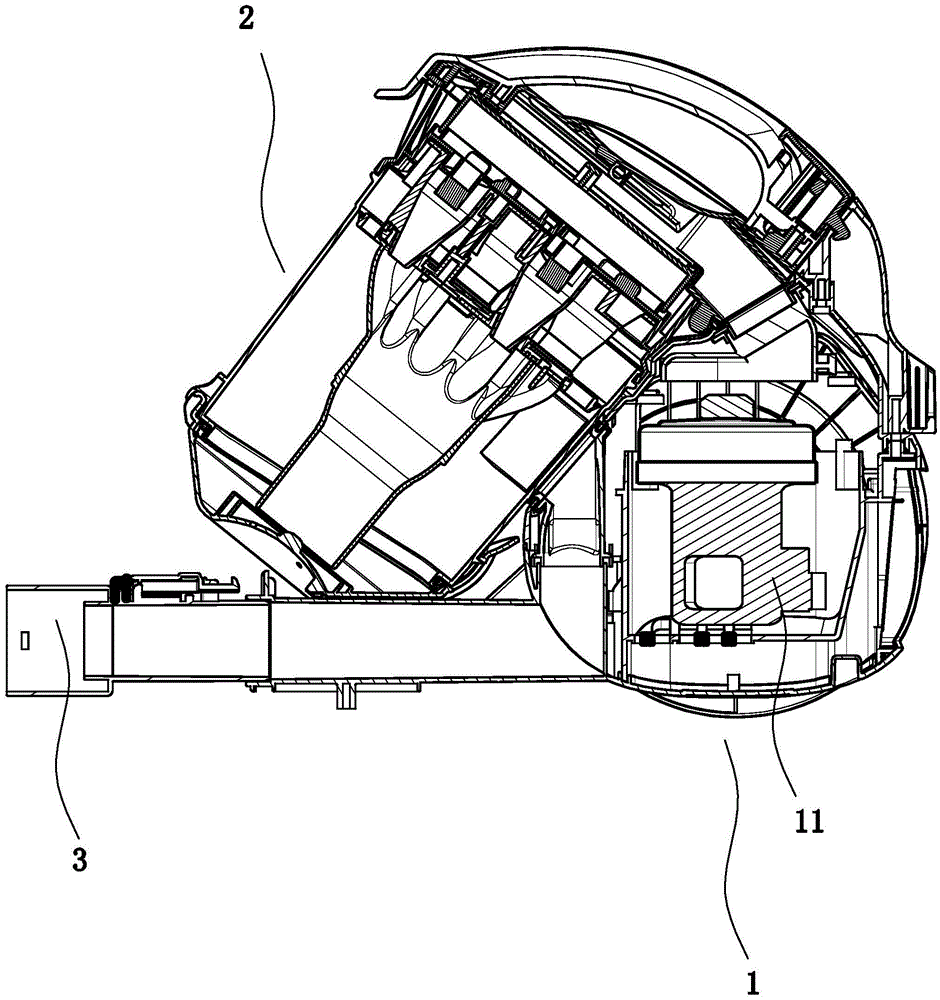

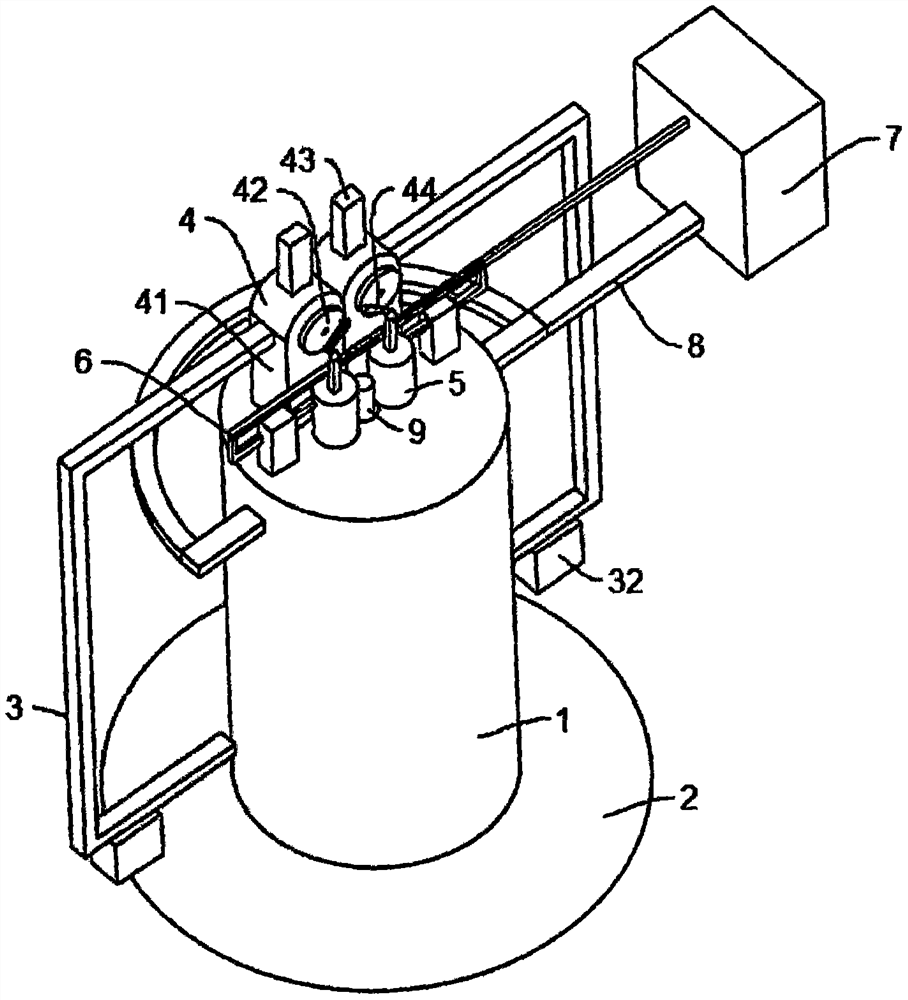

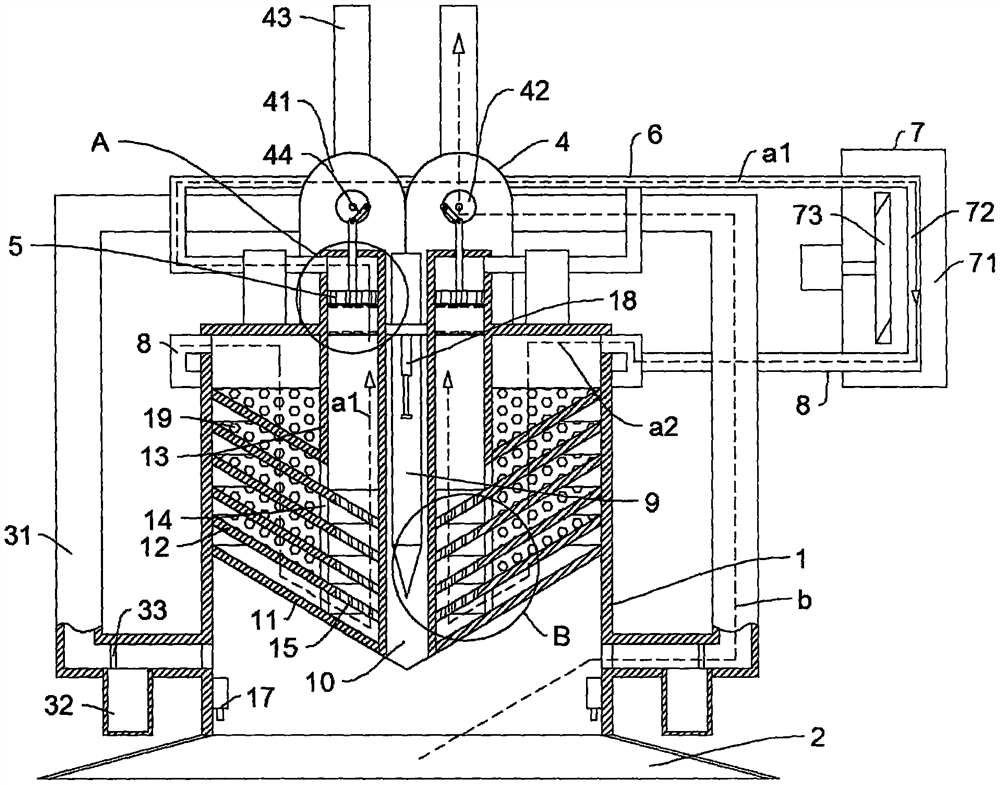

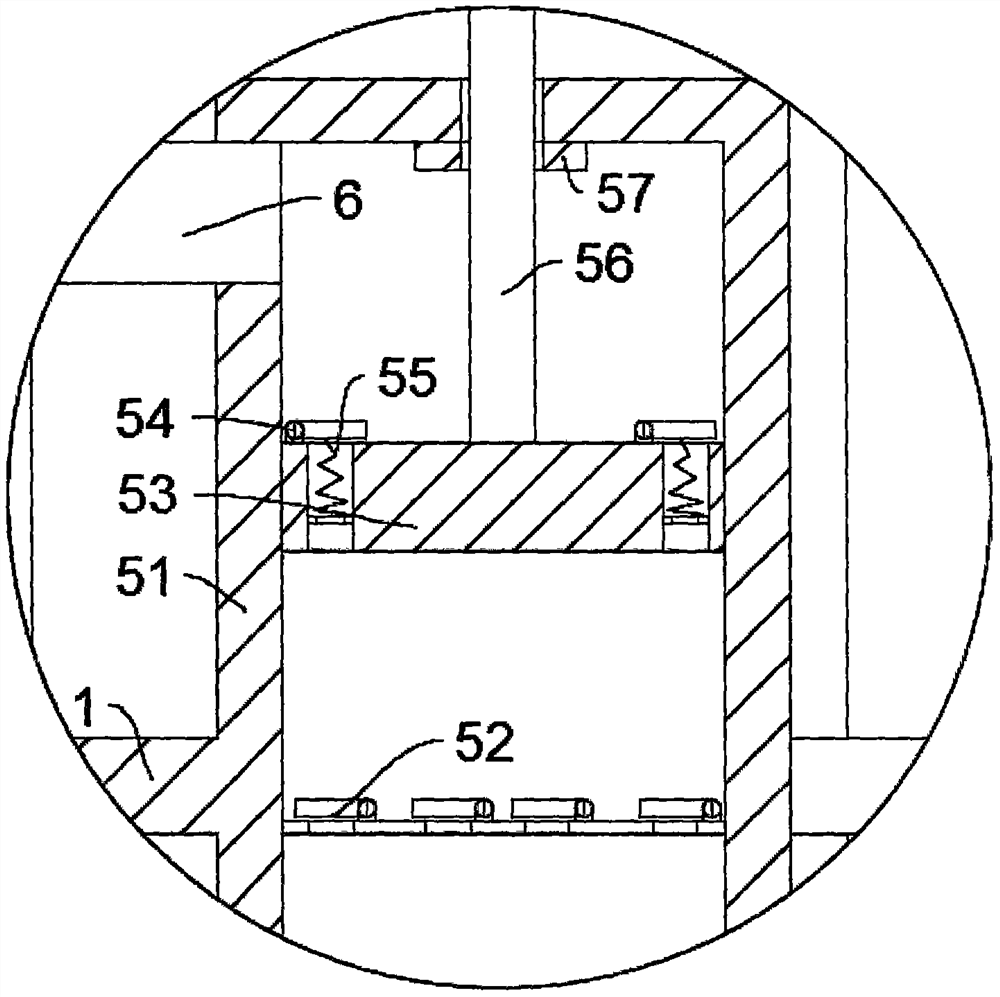

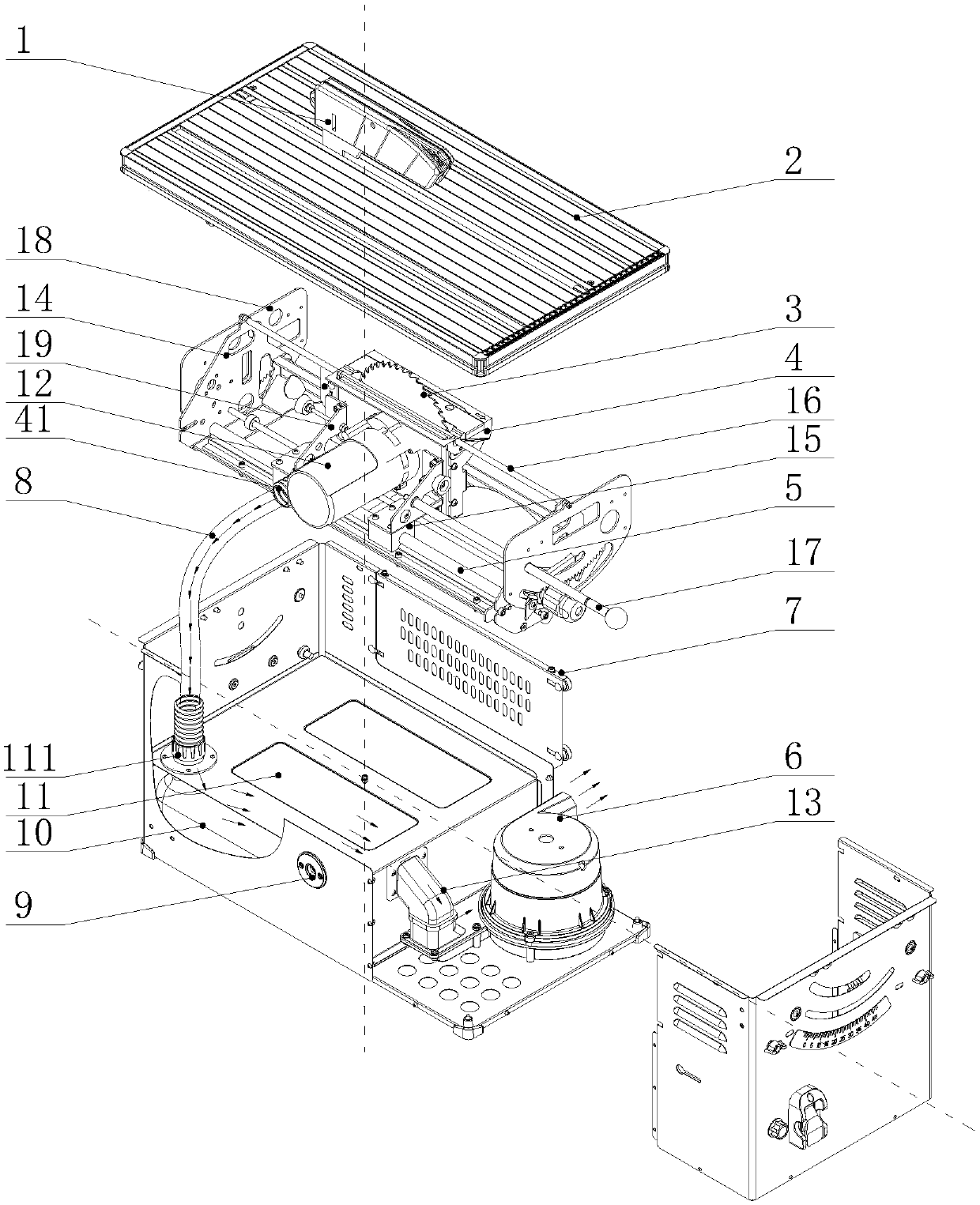

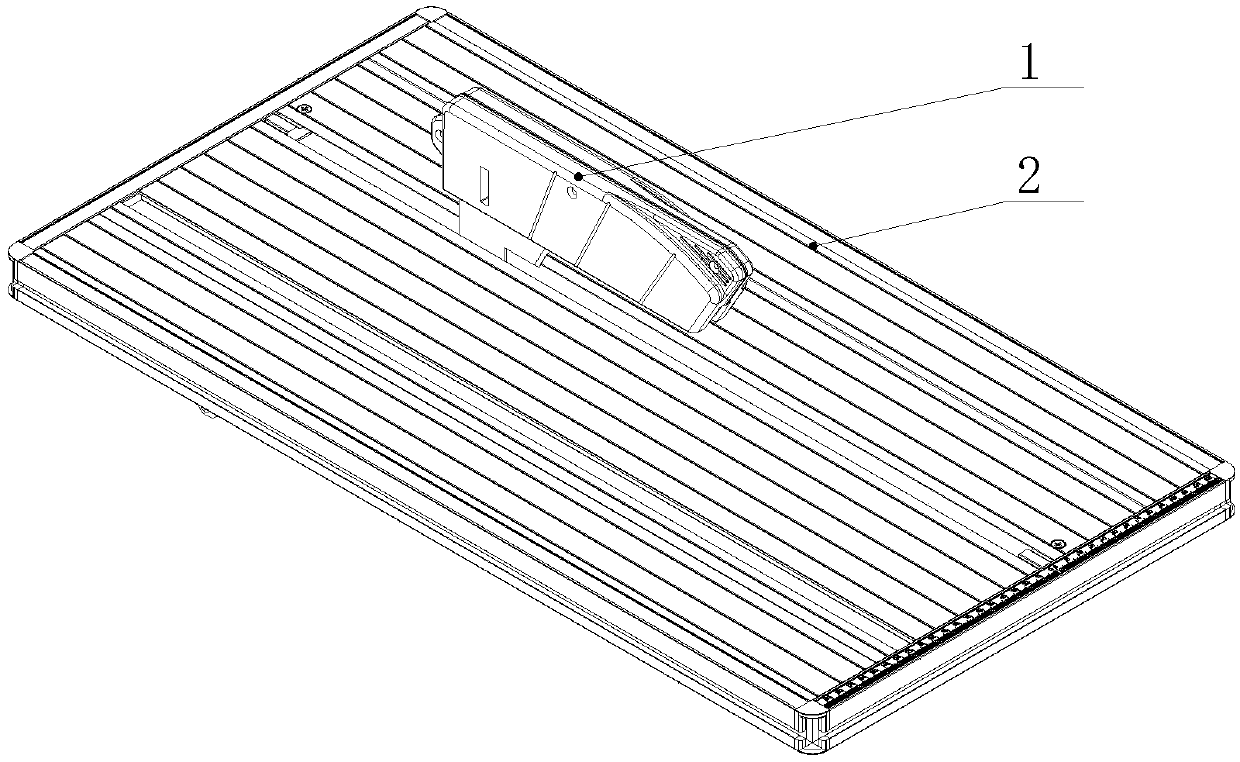

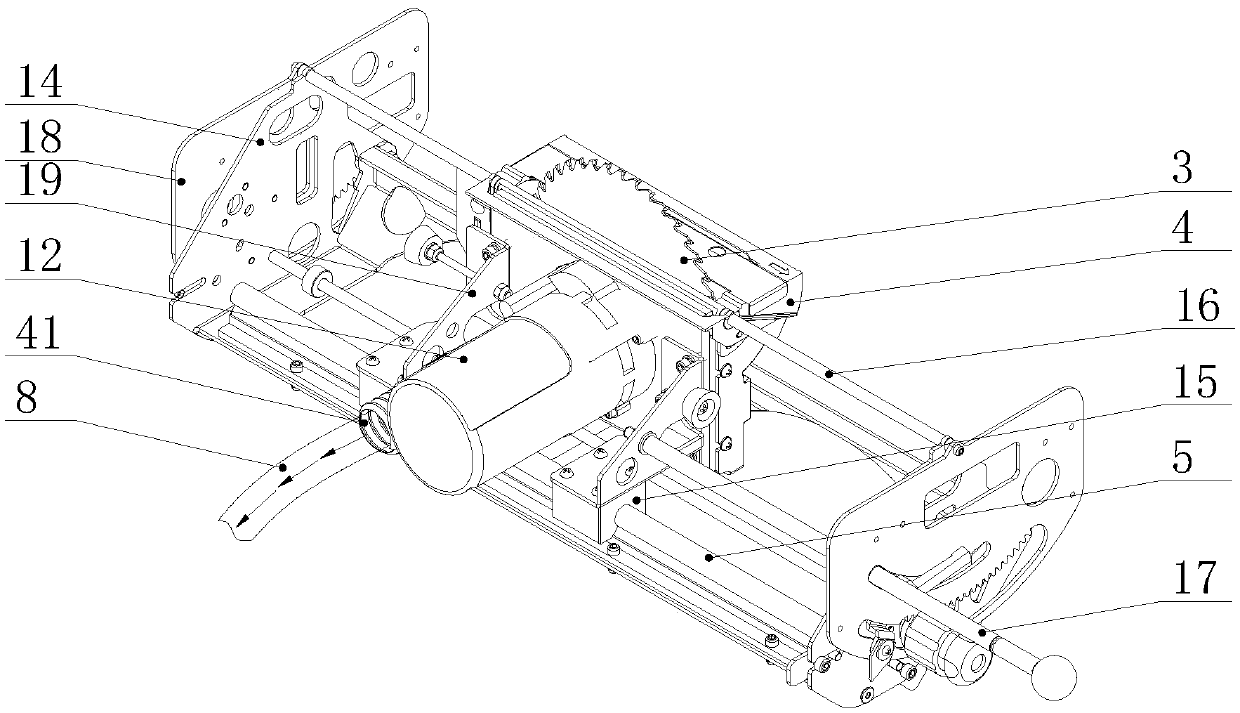

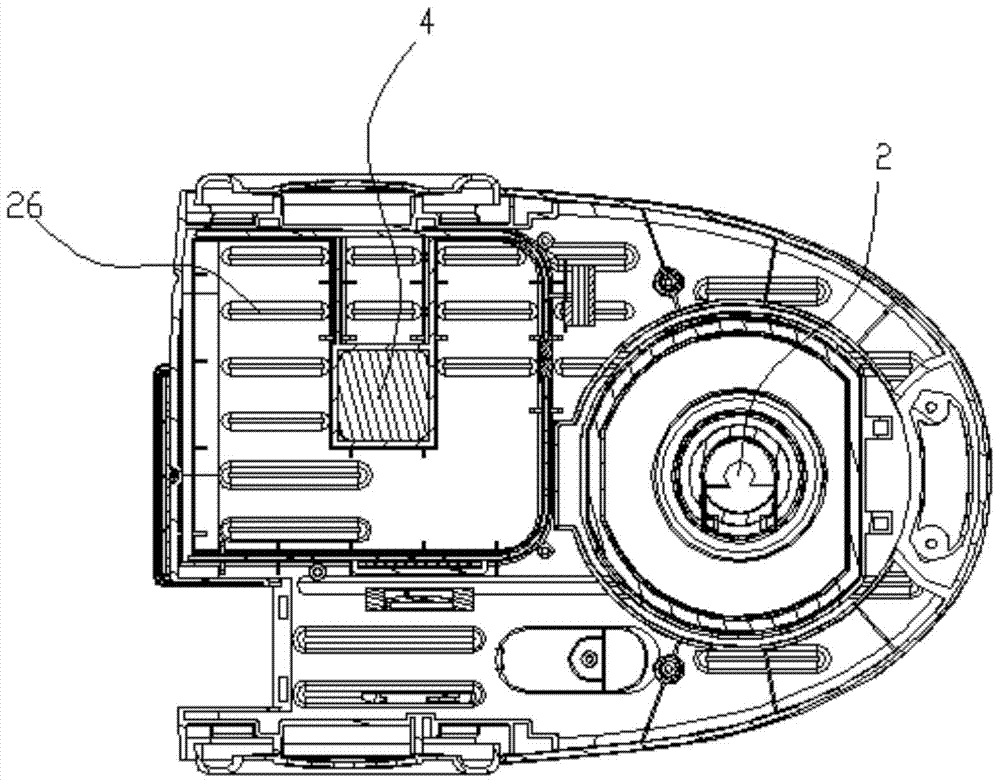

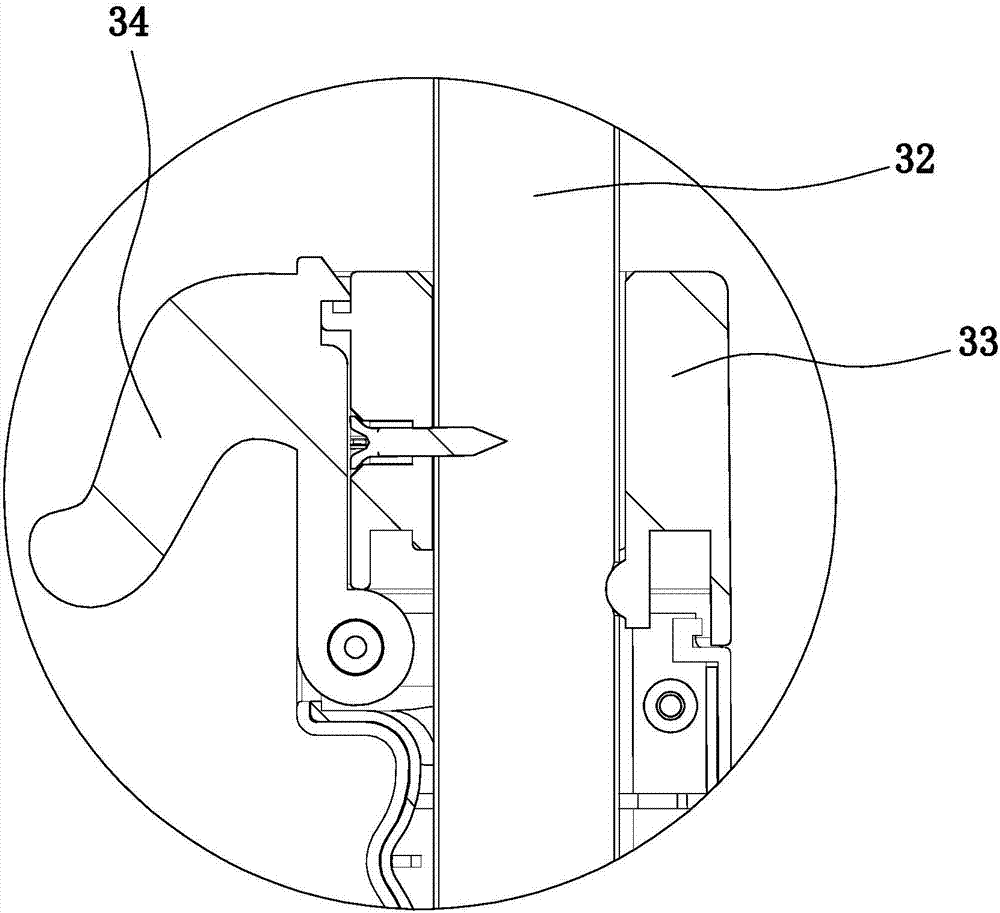

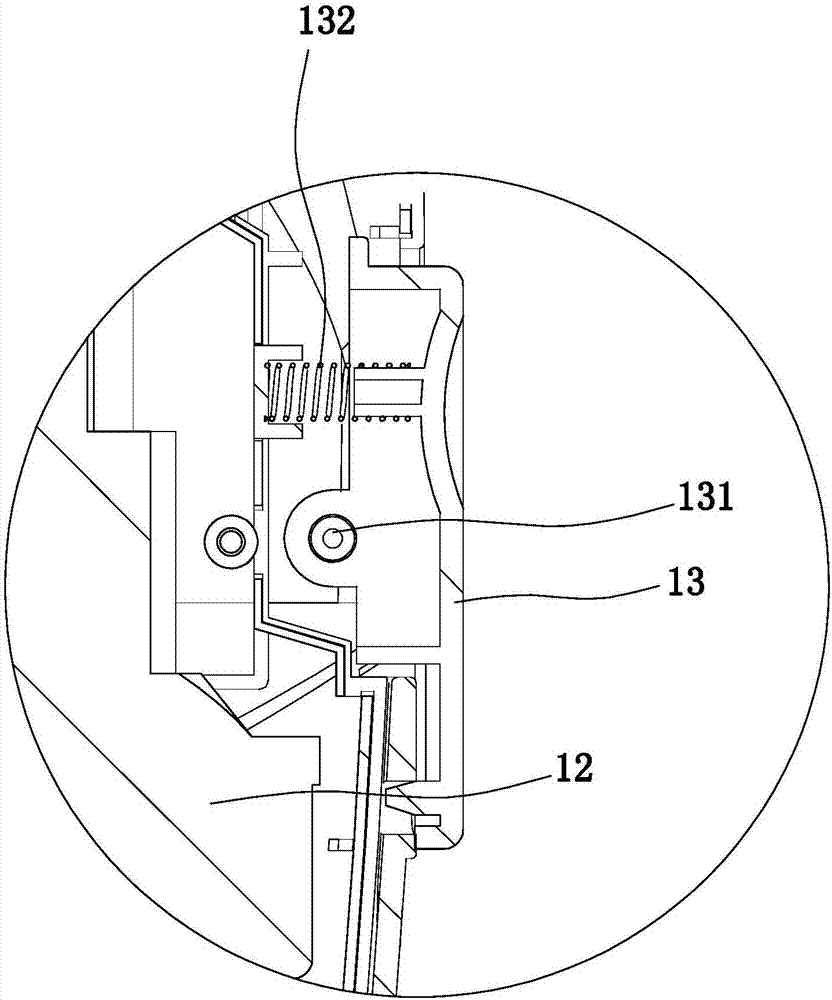

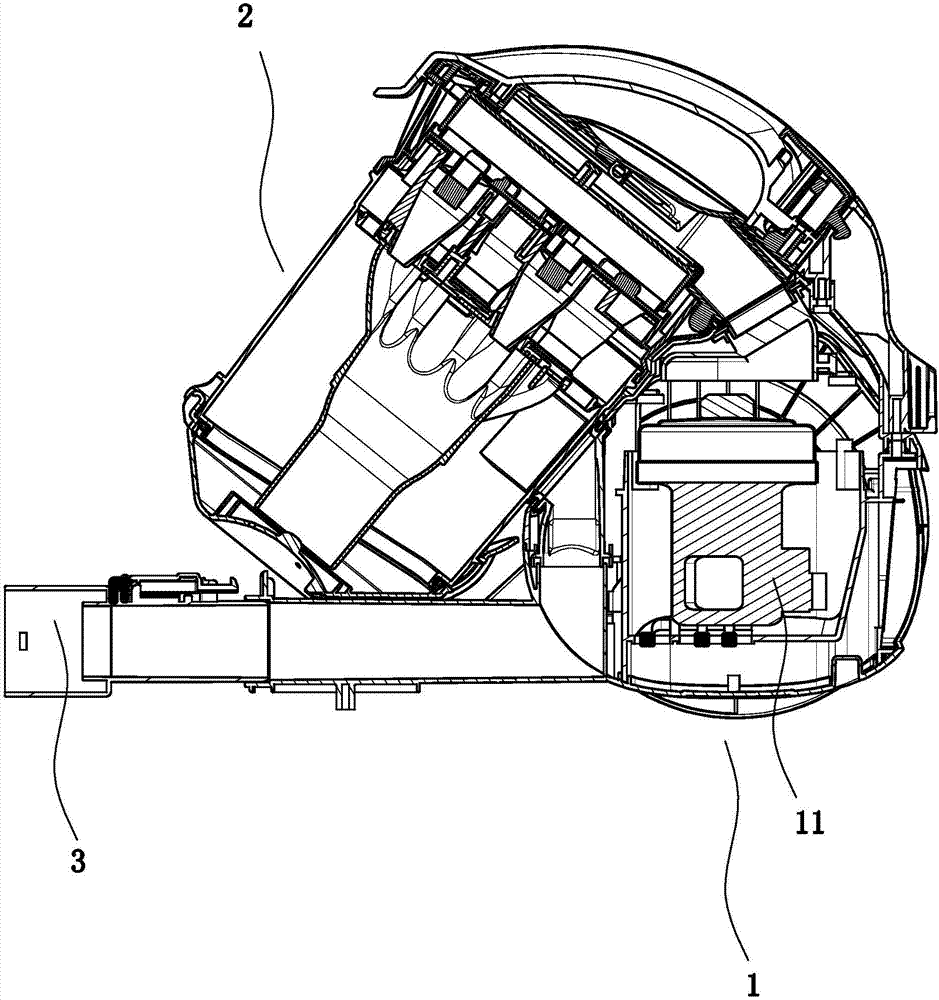

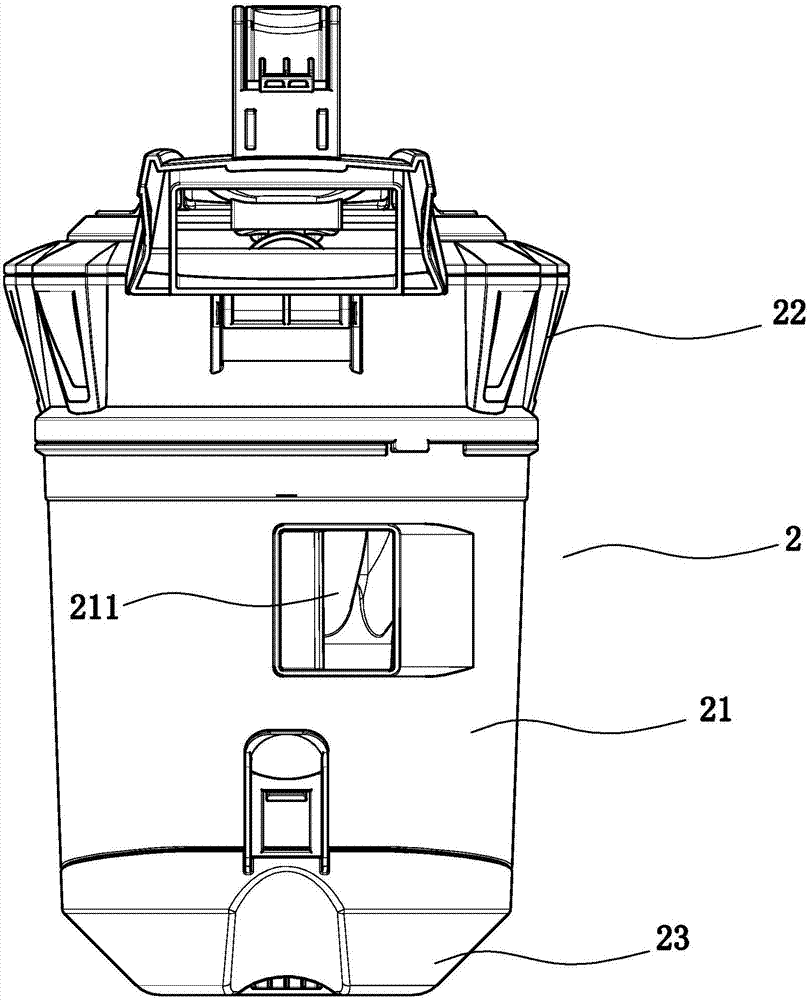

Autonomous cleaner

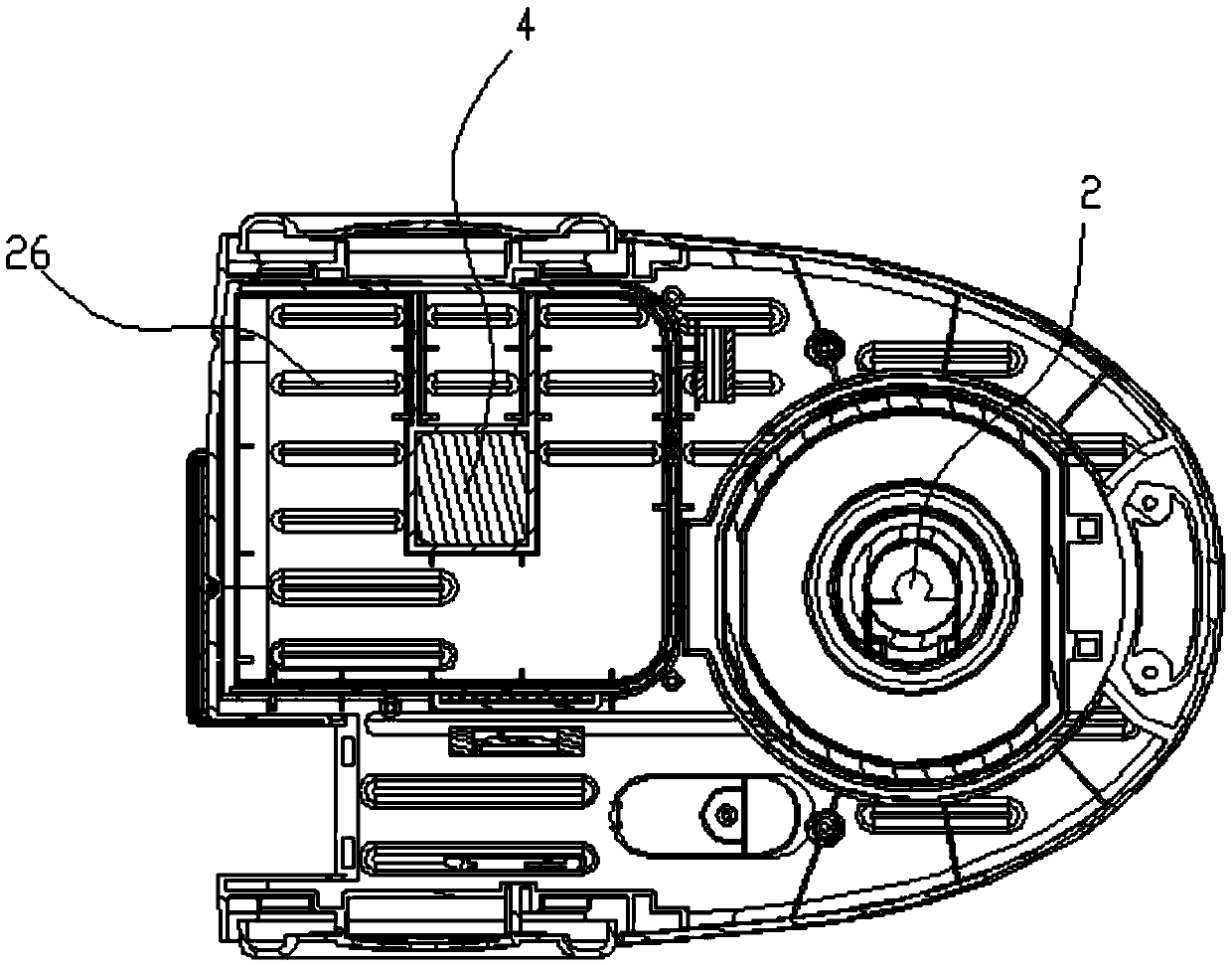

PendingCN111714027AReduce lossStrong vacuuming abilityCarpet cleanersFloor cleanersDrive wheelControl system

The invention discloses an automatic cleaner which comprises: a body which comprises an assembly space and a dust collection opening located in the bottom face and facing a to-be-cleaned face; a powersystem which comprises driving wheels which are arranged on the two opposite sides of the body and used for driving the body to move; a control system which is arranged on the body and used for controlling the driving wheels; a dust collection assembly which is arranged in the assembly space, whereinan air inlet channel of the dust collection assembly communicates with the dust collection openingand is used for collecting dust under the action of negative pressure; and a moving dust collection channel which is arranged on the peripheral side of the dust suction port and used for conducting scraping and sweeping dust collection in the first state and forming a dust suction channel communicating with the dust suction port in the second state. According to the automatic cleaner, the first state and the second state are set, scraping and sweeping dust collection or dust collection is conducted through switching of the first state and the second state of the moving dust collection channel, the dust collection capacity is high, the cleaning efficiency is high, and meanwhile energy losses are reduced.

Owner:ANKOBOT (SHENZHEN) SMART TECH CO LTD +1

Cyclone separation type dust collector

ActiveCN105640435AReasonable structureEfficient separationSuction filtersSuction nozzlesCycloneCyclonic separation

The invention discloses a cyclone separation type dust collector. The cyclone separation type dust collector comprises a main machine body, an air draft motor, a dust cup body and a suction port seat. The dust cup body comprises a cup body, a cup cover and a cup bottom. A cup body air inlet is formed in the cup body, multiple flow division cyclone conical barrels are arranged in the dust cup body, tangential air inflow branch pipes are arranged on the flow division cyclone conical barrels, openings are formed in the upper ends and the lower ends of the flow division cyclone conical barrels, and the openings in the upper ends are larger than the openings in the lower ends. The openings in the upper ends of the flow division cyclone conical barrels are communicated with the air inflow end of the air draft motor through a middle air duct, and the air outflow end of the air draft motor is communicated with an outer exhaust port in the main machine body. A filter rack is arranged in a cover air duct, and an air inflow sponge is arranged on the filter rack. The cyclone separation type dust collector has the advantages that the air ducts are reasonable in structure, and dust can be effectively separated and collected; the dust suction capacity is high, the filtering effect is good, and the cleanliness of exhausted air can be guaranteed; the mop anti-collision protection function is achieved, efficient cleaning capacity for wall foots and other dead corners is achieved, and functions are complete; overall stability is good, and noise is low.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

Silicon carbide surface modifying method

InactiveCN1417265AHigh grafting rateNot easy to fall offPigment treatment with non-polymer organic compoundsOrganic solventOrganic matter

The silicon carbide surface modifying process via organic matter grafting copolymerization includes purifying acrylamide, compounding water solution of acrylamide, dissolving acrosslinking agent, regulating pH value, dipping silicon carbide after being processed with organic solvent in the mixed solution, taking out the dipped silicon carbide, grafting and copolymerizing in oven at controlled temperature, hydrolyzing and stoving to obtain modified silicon carbide material with water absorbing and dust adsorbing surface and with relatively long effective period.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

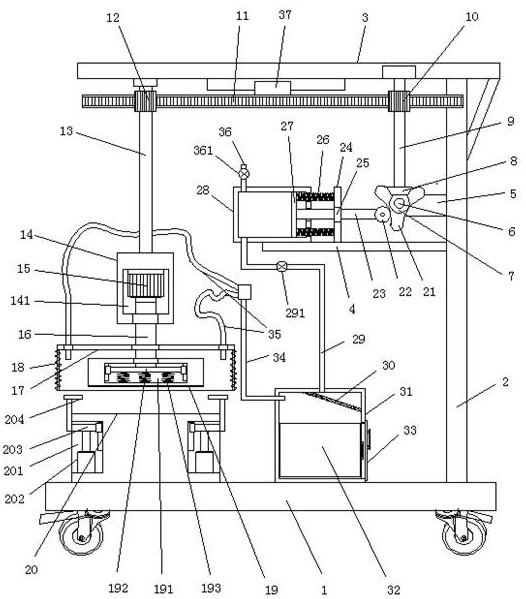

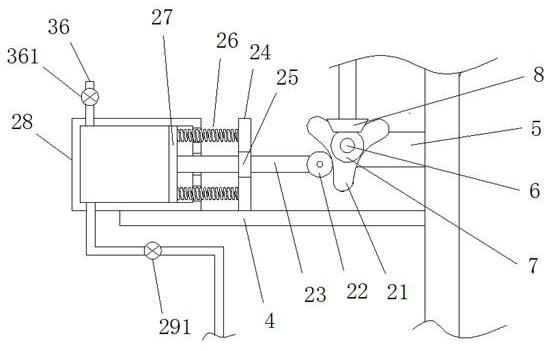

Rapid grinding device for building aluminum plate

InactiveCN113070755AEasy to polishVacuum collection in timeGrinding carriagesGrinding drivesConstruction engineeringStructural engineering

The invention discloses a rapid grinding device for a building aluminum plate. The rapid grinding device comprises a base, a vertical frame is fixedly arranged at the right end of the top of the base, a top plate is fixedly arranged at the top of the vertical frame, and a transverse frame fixed to the left side of the vertical frame and a fixing frame located above the transverse frame are further arranged between the base and the top plate. According to the rapid grinding device for the building aluminum plate, through mechanical operation, the aluminum plate can be conveniently ground, the trouble of manual grinding in the past is avoided, and the grinding efficiency is improved; and meanwhile, dust generated in the grinding process can be timely collected, the defect that subsequent grinding is affected due to the fact that the dust cannot be timely collected and falls on the surface of the aluminum plate in the past is overcome, a dust collection structure and a grinding structure are tightly combined, the structure is compact, the dust collection capacity is high, and the potential safety hazard to the human body caused by too much dust generated in the grinding process is greatly reduced; and meanwhile, a buffering function is achieved in the grinding process, and the service life of a grinding wheel is greatly guaranteed.

Owner:张宝玉

Metal anticorrosive paint preparation and coating method thereof

ActiveCN109046888AReduce wasteReduce laborEdge grinding machinesPortable grinding machinesCurrent limitingAgricultural engineering

The invention discloses metal anticorrosive paint preparation and a coating method thereof, and belongs to the field of anticorrosive paint. According to the metal anticorrosive paint preparation andthe coating method thereof, a coating repair device is provided; a storage groove is formed in the inner end of the coating repair device; anticorrosive paint is arranged at the inner end of the storage groove; a rear cover covers the groove mouth of the storage groove; a polishing mechanism is arranged at the left end of the rear cover; a one-way discharging groove, a gourd-shaped groove and a spacing groove are formed in the inner end of the coating repair device; the one-way discharging groove, the gourd-shaped groove and the spacing grooves are located at the right side of the storage groove; the storage groove, the one-way discharging groove, the gourd-shaped groove and the spacing grooves are cut through in sequence from left to right; a one-way flow mechanism is arranged at the inner end of the one-way discharging groove; the right end of the one-way flow mechanism is fixedly connected with a current limiting ball; and the current limiting ball is located at the inner side of the gourd-shaped groove. According to the metal anticorrosive paint preparation and the coating method thereof, the effect of repairing the areas, without anticorrosive paint, on the surfaces of parts can be realized, the waste of anticorrosive materials can be decreased, the repair operation is simple and convenient, and the labor capacity of the spray workers can be reduced.

Owner:FUJIAN HONGGUAN ROADS & BRIDGE ANTI CORROSIVE TECH

Dust collection and suction device for woodworking circular saw machine

InactiveCN106078952AAvoid obstructionImprove stabilityCircular sawsBark-zones/chip/dust/waste removalArchitectural engineeringCircular saw

The invention discloses a dust collection and suction device for a woodworking circular saw machine. The dust collection and suction device comprises a pipeline shield, two parallel dust boards and a locating plate; the pipeline shield is of a groove body structure, traction connecting rods are arranged at the two sides of the pipeline shield, one ends of the traction connecting rods are hinged to a groove wall, and the other ends of the traction connecting rods are hinged to the dust boards; a dust suction pipeline is arranged inside the pipeline shield; and the locating plate is hinged to the pipeline shield. Compared with the prior art, the dust collection and suction device for the woodworking circular saw machine has the advantages that dust in two dust concentration areas of a saw blade is absorbed by a pipe mouth and a middle-section dust suction port of the dust suction pipeline, so that the dust suction effect is better, and the pipe mouth of the dust suction pipeline is designed to follow a cutting chip port of the saw blade, can adapt to cutting chips of timber of different thicknesses or saw blades of different specifications and can change accordingly along with the position change of the cutting chip port.

Owner:HARVEY INDS

Multi-air-flue cyclone dust collector

The invention discloses a multi-air-flue cyclone dust collector which comprises a main dust collector body, a suction motor, a dust cup body and a suction port base. The dust cup body comprises a main cup body, a cup lid and a cup bottom. A cup body air inlet is formed in the main cup body. A plurality of flow division cyclone conical cylinders are arranged inside the dust cup body. Tangent air inlet branch pipes are arranged on the flow division cyclone conical cylinders. Openings are formed in the upper and lower ends of the flow division cyclone conical cylinders, and the opening in the upper end of each flow division cyclone conical cylinder is larger than the opening in the lower end of the flow division cyclone conical cylinder. The opening in the upper end of each flow division cyclone conical cylinder is communicated with the air inlet end of the suction motor through a middle air flue. The air outlet end of the suction motor is communicated with an outer exhaust port in the main dust collector body. A filter frame body is arranged in a lid air flue. An air inlet sponge is arranged on the filter frame body. The multi-air-flue cyclone dust collector has the advantages that the air flue is reasonable in structure, and dust separation and collection can be sufficiently completed; the dust suction capacity is high, the filtering effect is good, and the exhaust cleanness can be ensured; the mop anti-collision protection function is achieved, the efficient cleaning capacity for the foot of a wall and other dead corners is achieved, and comprehensive functions are achieved; the overall stability is good, and noise is small.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

Portable cyclone dust collection device

ActiveCN105982608AEfficient separationEfficient collectionSuction filtersExhaust-air diffusionLow noiseCyclone

The invention discloses a portable cyclone dust collection device. The device comprises a main machine body and a dust collection mop, wherein a handle, a dust cup, a machine body air inlet pipe and an air draft motor are arranged on the main machine body; the dust collection mop comprises a mop basal body and an inserting connecting pipe; the lower end of the inserting connecting pipe is communicated with an air channel in the mop and the upper end of the inserting connecting pipe is clamped and communicated with the machine body air inlet pipe; a filter screen cylinder is arranged in the dust cup; a tangential air inlet and an upper end air outlet are formed in the dust cup; a plurality of filter holes are formed in the filter screen cylinder; the tangential air inlet is communicated with the machine body air inlet pipe; the upper end air outlet is communicated with the air inlet end of the air draft motor; the air outlet end of the air draft motor is communicated with an external air outlet formed in the main machine body. The portable cyclone dust collection device has the beneficial effects that the device can be operated in hand, is fast and labor-saving in the cleaning process, has a reasonable air channel structure, has strong dust collection capacity and good filtering effects and can guarantee the cleanliness of the exhaust air; with an electric power storage structure, the device can work without electric wires; all the structures have stronger cooling, heat dissipation and shock resistance capacities; the device has good global stability and low noise.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

Numerical control laser cutting control system for power battery pole piece

InactiveCN113059286AIncrease vaporization rateIncrease temperatureLaser beam welding apparatusNumerical controlPower battery

The invention relates to the field of numerical control laser cutting control equipment, in particular to a numerical control laser cutting control system for a power battery pole piece. The system comprises a cylindrical sleeve and further comprises a conical dust hood, dust collection pipelines, a pneumatic piston cylinder, a steam pipe, a liquid pipe and a high-pressure laser gun, wherein the conical dust hood is connected to the bottom of the cylindrical sleeve; the dust collection pipelines are symmetrically connected to the outer side of the lower half section of the cylindrical sleeve, and the dust collection pipelines are connected with an air blowing structure; the pneumatic piston cylinder is connected to the coaxial position of the air blowing structure; the steam pipe is connected to the pneumatic piston cylinder, and the steam pipe is connected with air-cooling and water-cooling equipment; the liquid pipe is connected to the air-cooling and water-cooling equipment; and the high-pressure laser gun is installed at the center position of the cylindrical sleeve, and a heat dissipation structure is arranged inside the cylindrical sleeve. According to the device, real-time cooling in the laser cutting process can be achieved, the suction-force-variable smoke dust absorption effect is achieved, kinetic energy generated by vaporization of a cooling agent is converted to provide mechanical energy for dust collection, heat emitted by laser is effectively utilized, energy is saved, and laser distance measurement is automatically adjusted, so that the system is convenient and practical.

Owner:JINAN G WEIKE SCI & TECH

Self-dust-collecting dust collector

ActiveCN105686753AEfficient cleaning abilityReasonable structureSuction nozzlesCyclonic separationPulp and paper industry

The invention discloses a self-dust-collecting dust collector which comprises a main machine body and a dust collection mop. A side dust cup, a cyclone separation cylinder and a machine body air inlet pipe are installed on the main machine body. A motor cavity is formed in the main machine body, an air suction motor is arranged in the motor cavity, a vertical rotation-assisting inner cylinder is arranged in the cyclone separation cylinder, the upper end and the lower end of the rotation-assisting inner cylinder are provided with openings, the side wall of the cyclone separation cylinder is provided with a transversely cut air inlet and a side dust discharge opening, the side dust discharge opening is communicated with the side dust cup, the side dust discharge opening is higher than the transversely cut air inlet, the upper end of the rotation-assisting inner cylinder is higher than the transversely cut air inlet, the opening in the upper end of the rotation-assisting inner cylinder is communicated with the cyclone separation cylinder, the opening of the lower end of the rotation-assisting inner cylinder is communicated with the air inlet end of the air suction motor, the transversely cut air inlet is communicated with the machine body air inlet pipe, and the air outlet end of the air suction motor is communicated with an external exhaust port in the main machine body. The dust collector has the advantages that the functions of dust collection, separation and air exhaust can be effectively completed, the dust collection capacity is high, dust can be automatically isolated and compressed, and discharge cleanliness is guaranteed.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

Pulling rod type bench saw with dust collection function

ActiveCN109605491AAdjustable tilt angle increasesMeet processing needsCircular sawsBark-zones/chip/dust/waste removalMechanical engineering

The invention discloses a pulling rod type bench saw with a dust collection function. The pulling rod type bench saw with the dust collection function comprises a workbench, a saw frame, a pulling rod, a saw blade and a motor used for driving the saw blade; the workbench is installed on the top of the saw frame and provided with a saw groove, and the upper portion of the saw blade penetrates through the saw groove and extends to the upper side of the workbench; a closed box is arranged on the portion, located at the saw groove, of the lower side of the workbench and arranged at the periphery of the lower portion of the saw blade, and a rotation shaft is arranged on the upper portion of the closed box and can rotate relative to the saw frame; a sliding mechanism is arranged on the closed box and drives the closed box to slide in the direction of being parallel to the rotation shaft through the pulling rod; the sliding mechanism, the closed box, the saw blade, the motor and the rotationshaft can synchronously rotate; and a dust collection mechanism is arranged on the saw frame and communicates with the closed box. According to the pulling rod type bench saw with the dust collectionfunction, the rotation shaft and the closed box are arranged, the closed box, the saw blade, the motor and the rotation shaft can synchronously rotate, therefore, the inclination angle of the adjustable saw blade is increased, and the dust collection effect is improved.

Owner:QINGDAO CHENBA IND & TRADE CO LTD

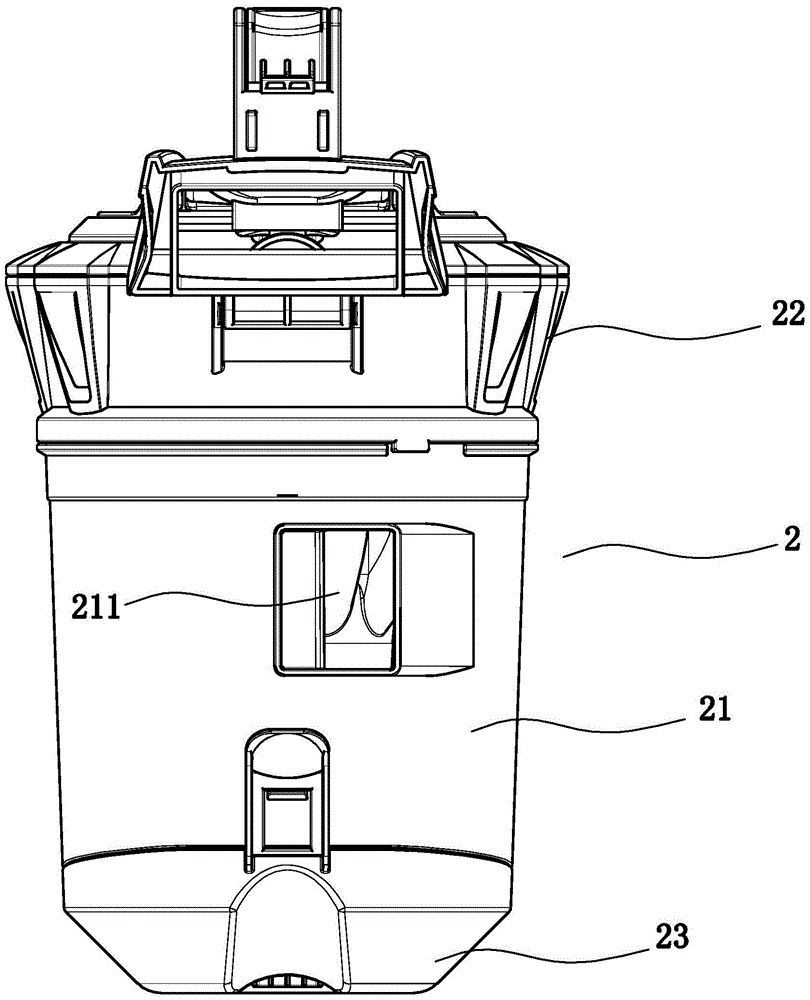

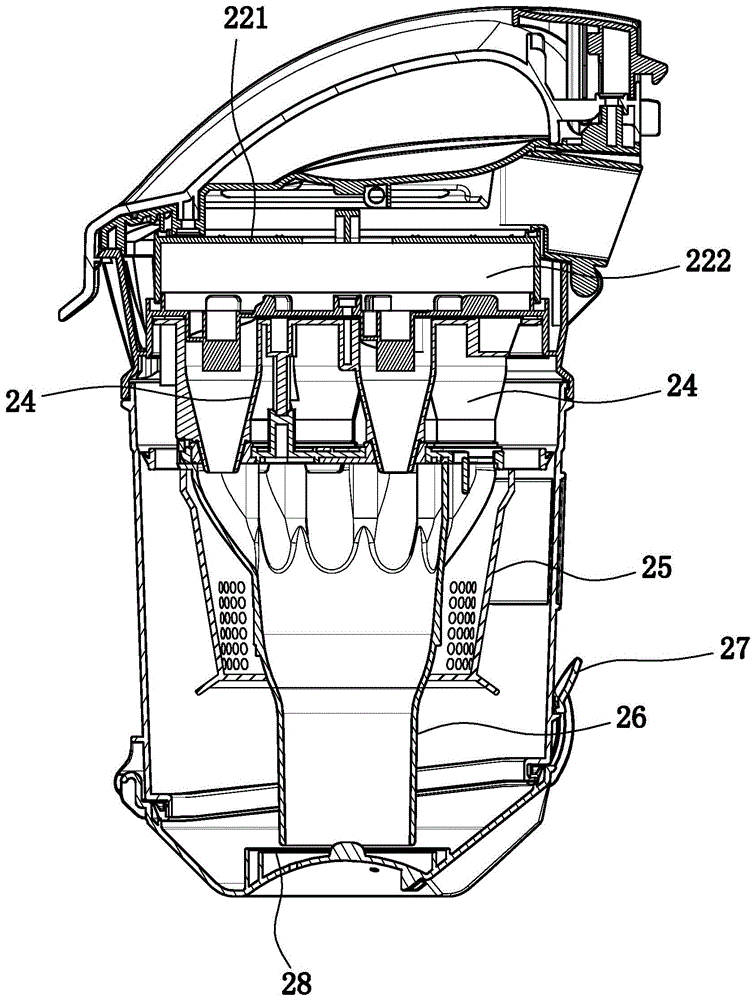

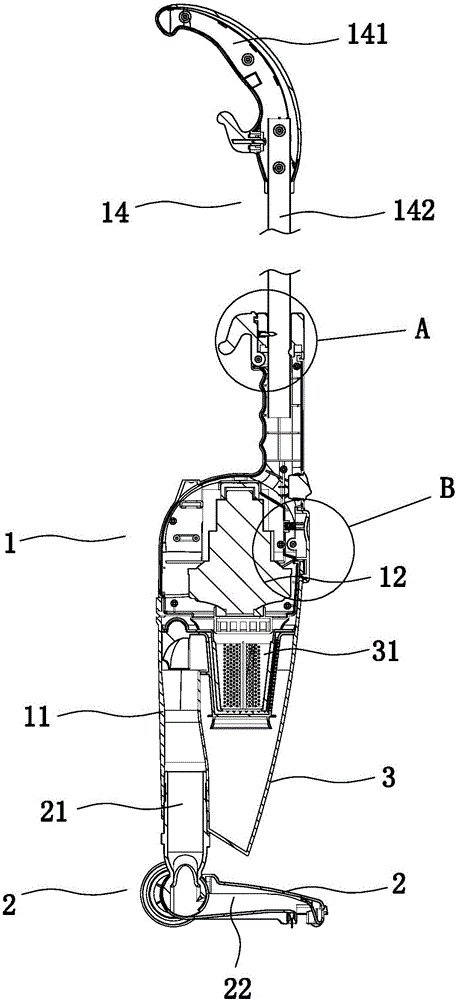

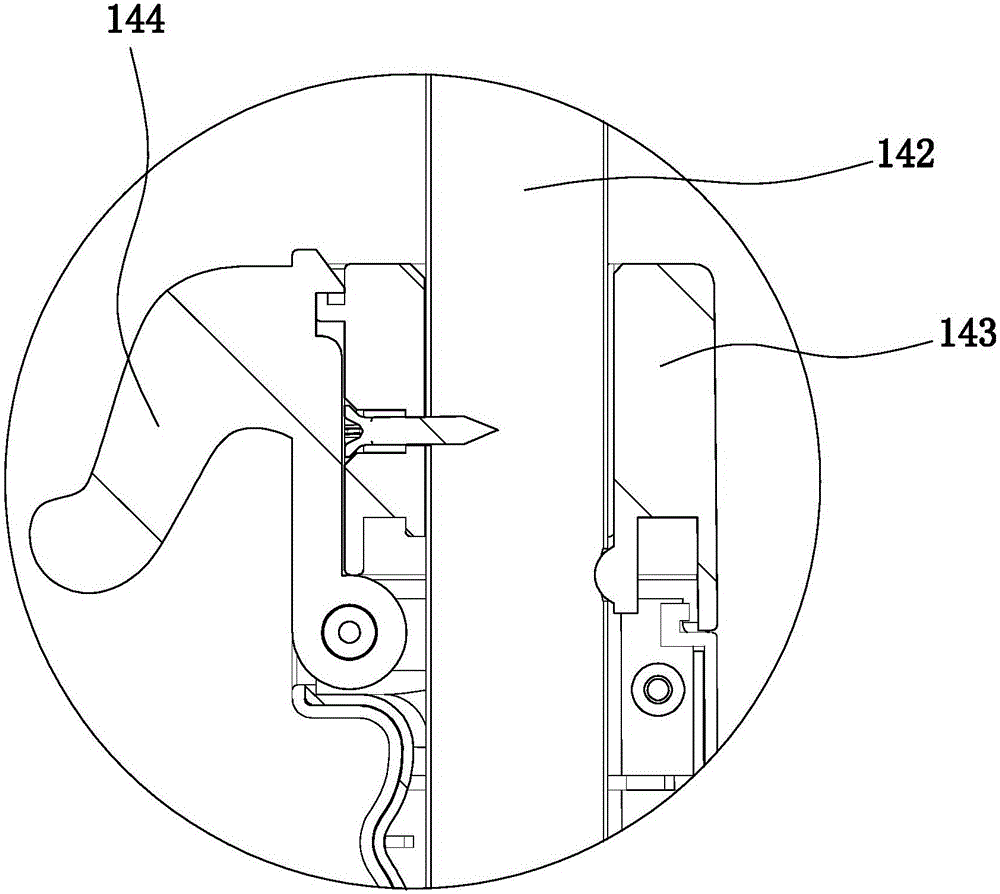

A vacuum cleaner structure

The invention discloses a vacuum cleaner structure which comprises a main machine shell, a dust suction mop, a universal wheel, a plurality of moving wheels and an induced draft motor. The main machine shell is provided with a dust cup component and a suction opening seat. The suction opening seat is connected with the dust suction mop through a dust suction pipe. The dust cup component comprises a dust cup, a cyclone cone and inner dust bin. The cyclone cone is provided with a straight wind inlet, a downwardly-spiral wind guide channel and a cyclone outlet which are sequentially communicated. The straight wind inlet is communicated with the suction opening seat. The cyclone cone is provided with a cone inner cylinder. The cone inner cylinder is provided with a vertical wind return channel communicated with the cyclone outlet. The cyclone outlet is communicated with the inlet of the vertical wind return channel and the inner dust bin. The outlet of the vertical wind return channel is communicated with the induced draft motor. The vacuum cleaner structure has the advantages that the wind inlet and outlet channels are reasonable in structure, and dust can be separated and collected by cyclone; the vacuum cleaner structure is high in dust suction ability and is provided with a multistage filter structure which is good in filter effect; noise during wind discharge can be reduced, and vibration and the noise can be reduced effectively to keep a good silent effect by a stability strengthening structure.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

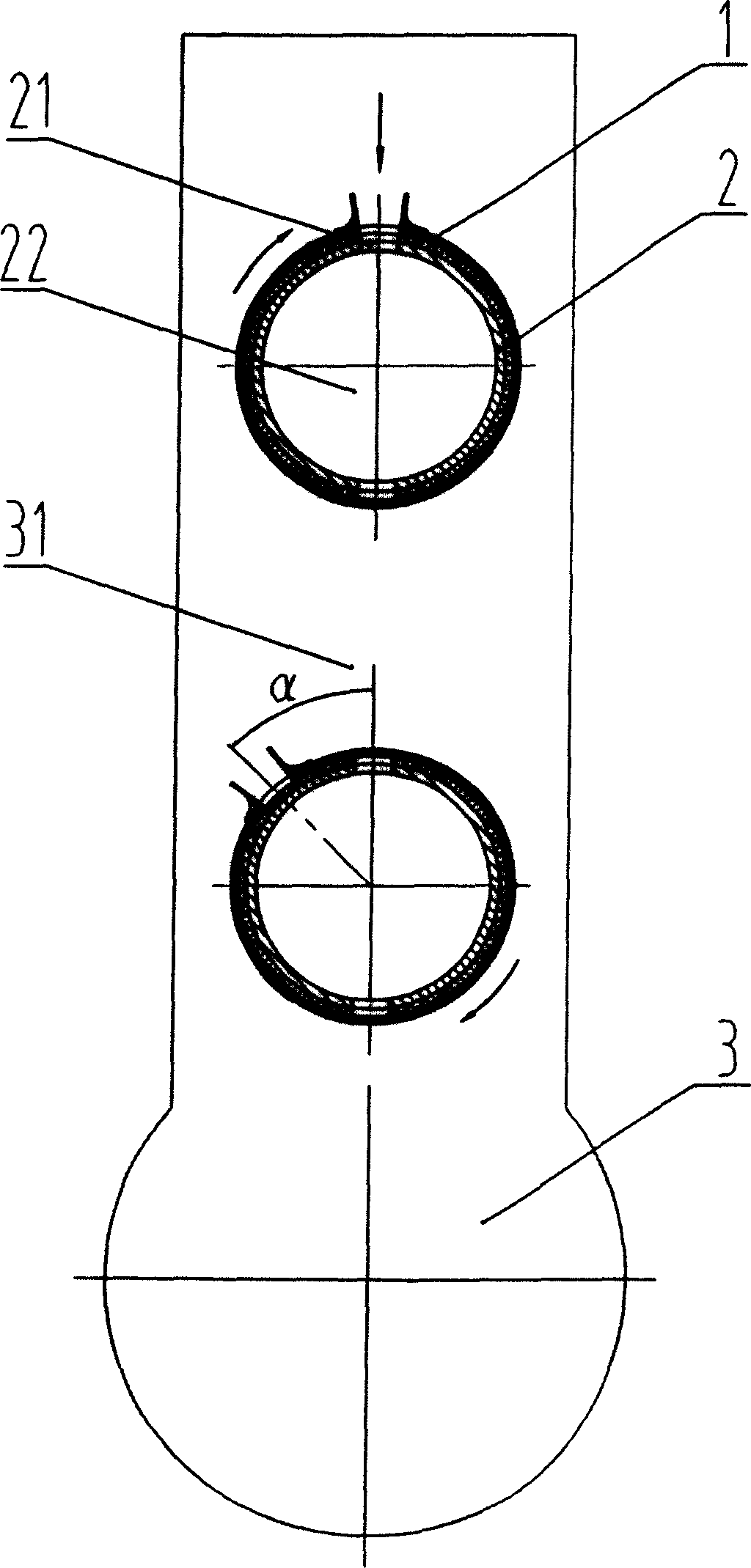

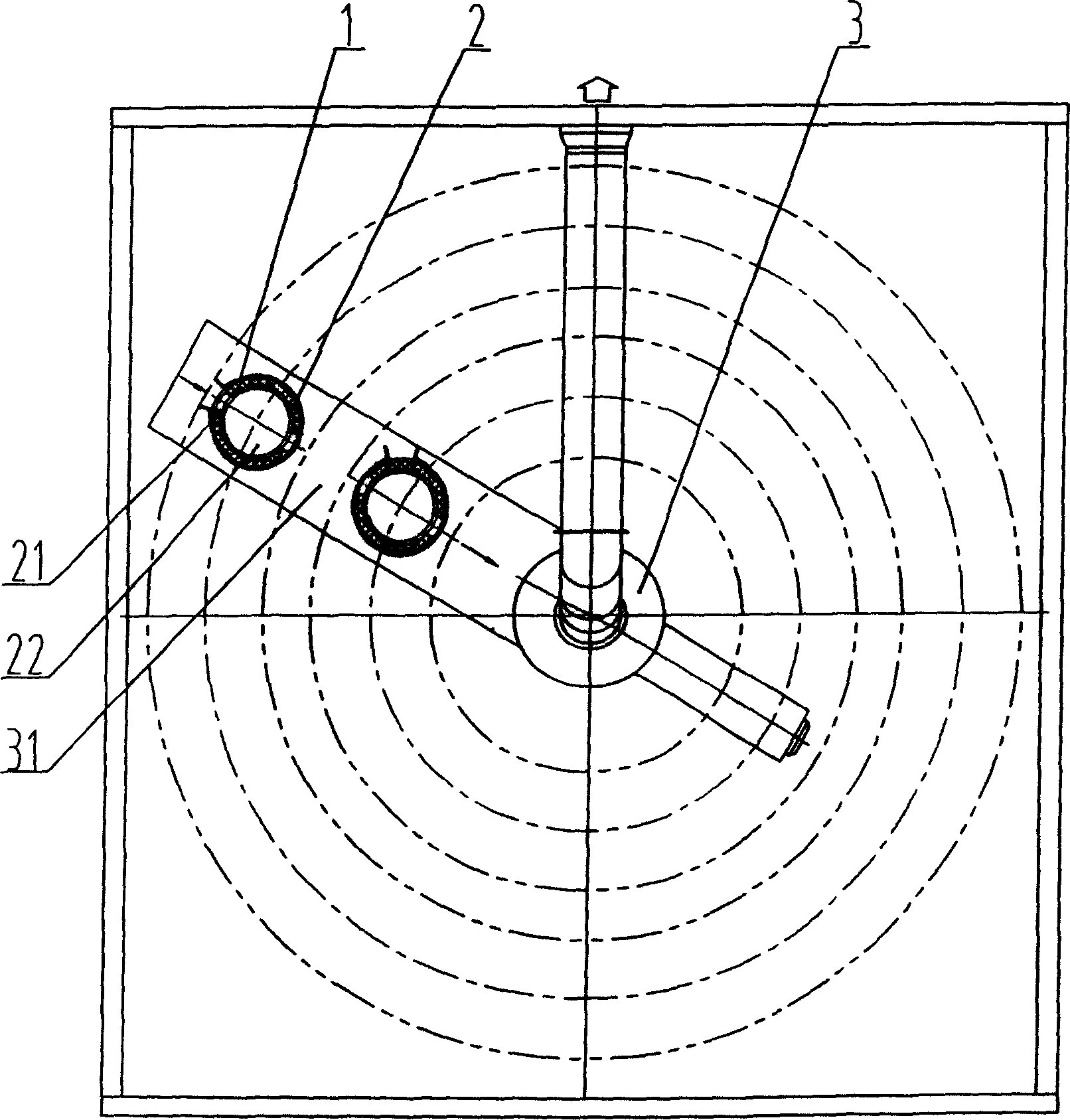

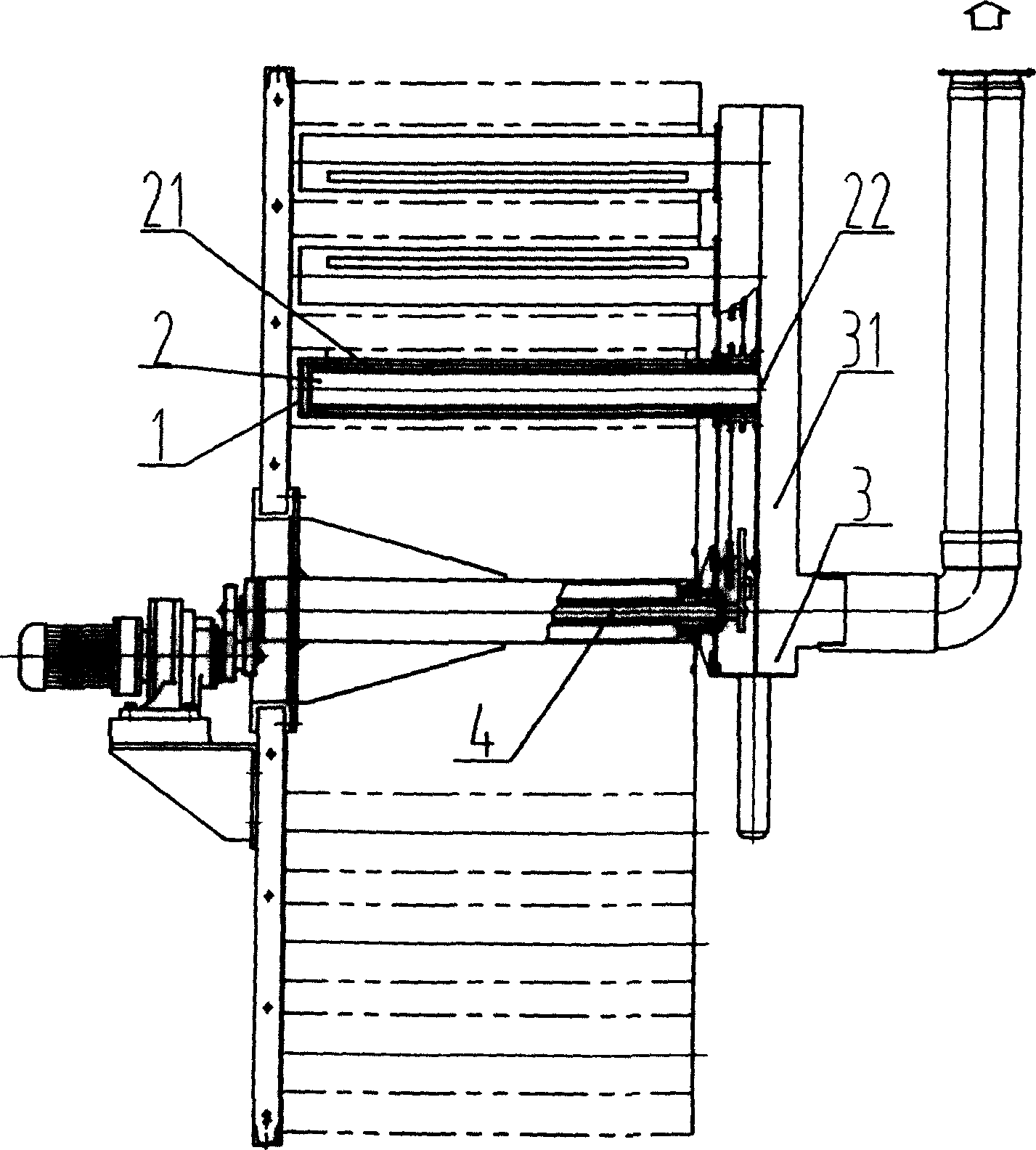

Rotational dust suction mechanism for dust filter

InactiveCN1673428AReduce power usageSolve the fundamental problem of friction damageDispersed particle filtrationTextiles and paperEngineeringDust collector

The present invention relates to dust sucking mechanism for dust collector, and is especially one kind alternate dust sucking mechanism for dust collector used in texture industry. The dust sucking mechanism includes switched suction nozzles, concentric sucking pipes with air inlet and air outlet inside the switched suction nozzles separately, switching unit connected to the switched suction nozzles and sucking cavity connected to the suction nozzles and the sucking pipes. The switching unit makes one of the suction nozzles communicated with the sucking cavity in turn. The present invention has the advantages of simple structure, high stability and reliability, concentrated sucking point, low power consumption, etc.

Owner:江阴永康机电有限公司

A suction nozzle for a road sweep and a road sweeper

PendingCN108951504AEasy to overcome resistanceLow bending stiffnessRoad cleaningRoad sweeperSoft materials

A suction nozzle for a road sweep and a road sweeper are disclosed. The suction nozzle comprises an upper cover plate, a front baffle plate, a side rear baffle plate, a suction pipe, and the upper cover plate, the front baffle plate and the side rear baffle plate together form a suction nozzle cavity with an open lower end, and the front baffle plate is a thin plate of two or more layers of soft material. -The invention can realize that the garbage enters the suction nozzle cavity more easily, the air inlet quantity of the front baffle plate is smaller and more stable, the air inlet quantity of the side back baffle plate is larger, and the transverse wind force in the suction nozzle cavity is greater. At that same fan speed and power, the suction nozzle has stronger comprehensive dust absorption capacity; Or, on the premise of the same combined suction nozzle suction, the fan speed and power are lower, and the sweeper fuel consumption and noise are reduced.

Owner:邓东

Organic matter high-voltage electric field double-pole catalytic degradation device for air purifier

InactiveCN105903344ASingle structureStrong vacuuming abilityGas treatmentDispersed particle separationBiochemical engineeringAir pollutants

The invention discloses an organic matter high-voltage electric field double-pole catalytic degradation device for an air purifier. The catalytic degradation device comprises an inner sleeve and an outer sleeve, the inner sleeve is arranged inside the outer sleeve, the inner sleeve comprises a positive plate and a catalytic layer which is attached to the first surface of the positive plate, the outer sleeve comprises an insulating supporting layer, a conducting layer, an insulating layer and a catalytic layer, the conducting layer is attached to the first surface of the insulating supporting layer, the insulating layer is attached to the surface of the conducting layer, the catalytic layer is attached to the surface of the insulating layer, and the the first surface of the positive plate is opposite to the first surface of the insulating supporting layer; by means of the double-pole catalytic layer, contact between the catalytic layers and air pollutants is more sufficient on the basis of a dust collecting electrode, and the pollutants in the air can be removed more easily to obtain clean air.

Owner:江苏乐居乐家网络科技有限公司

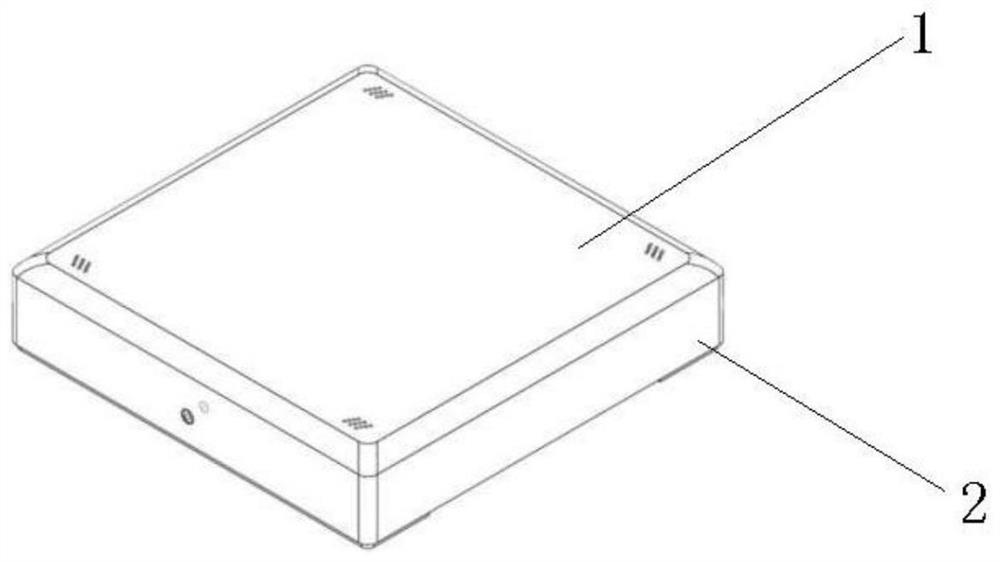

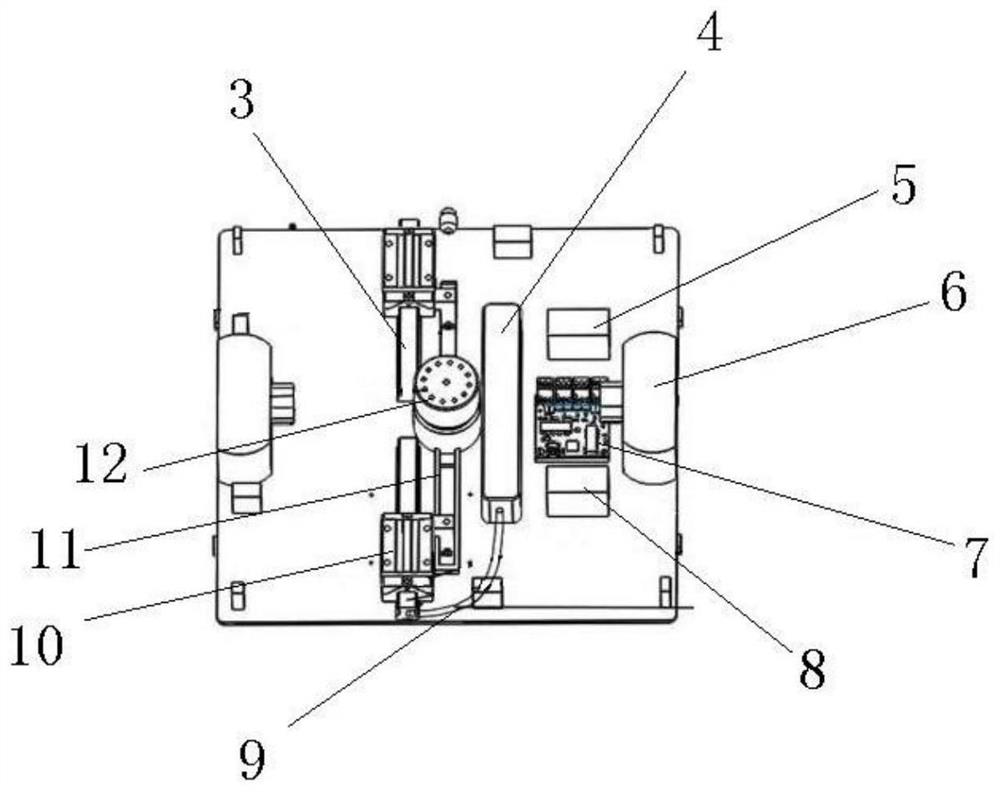

Glass cleaning robot with scraping module capable of doing autonomous reciprocating motion

InactiveCN113100656AImprove work efficiencyImprove cleanlinessCarpet cleanersFloor cleanersReciprocating motionElectric machinery

The invention discloses a glass cleaning robot with a scraping module capable of doing autonomous reciprocating motion, and belongs to the field of glass cleaning robots. The robot is in a cube shape, the cube is provided with an upper cover plate and a lower box body, a fan is arranged in the center of the bottom face of the lower box body, metal rails are arranged on the two sides of the fan, a cleaning head is arranged on the metal rails, the side face of the cleaning head is connected with a connecting rod, the bottom of the cleaning head is connected with a cleaning strip, and the bottom of the cleaning strip is arranged on the bottom face of the outer side of the lower box body, a water mist generator is arranged in the cleaning strip and connected with a water tank in the lower box body through a hose, a PLC is arranged on one side of the water tank, a motor a and a motor b are arranged on the two sides of the PLC, the motor b controls the cleaning head to move, and the motor a is connected with two driving belts arranged on the bottom face of the lower box body; rag is also arranged on the outer bottom surface of the lower box body. The device is good in wiping effect, high in working efficiency and convenient to operate.

Owner:DALIAN UNIV

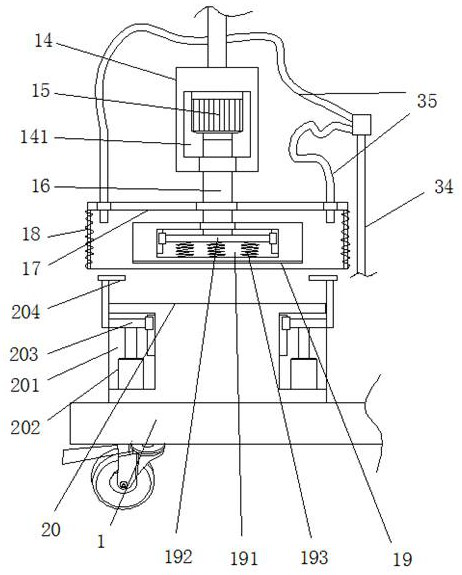

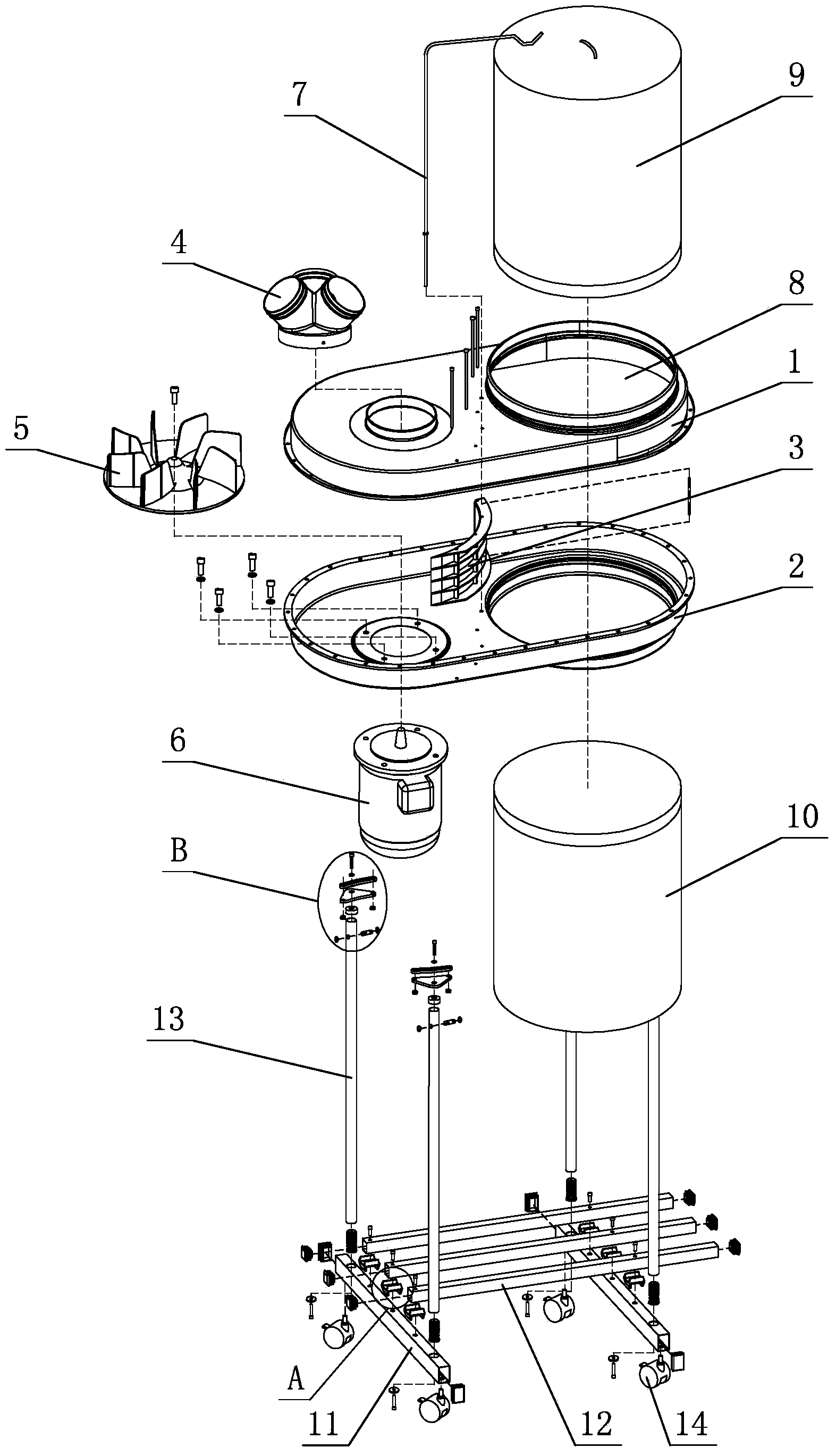

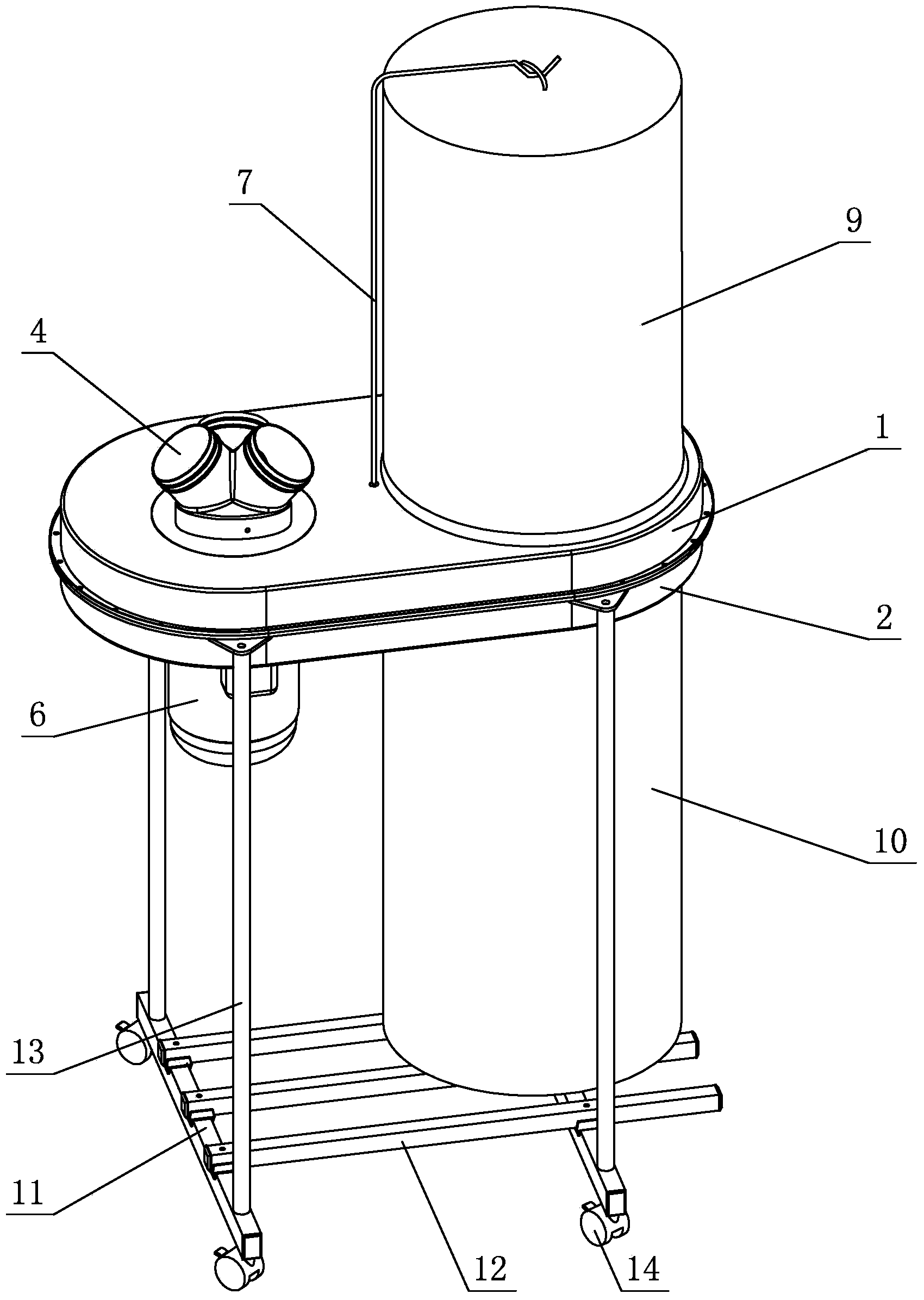

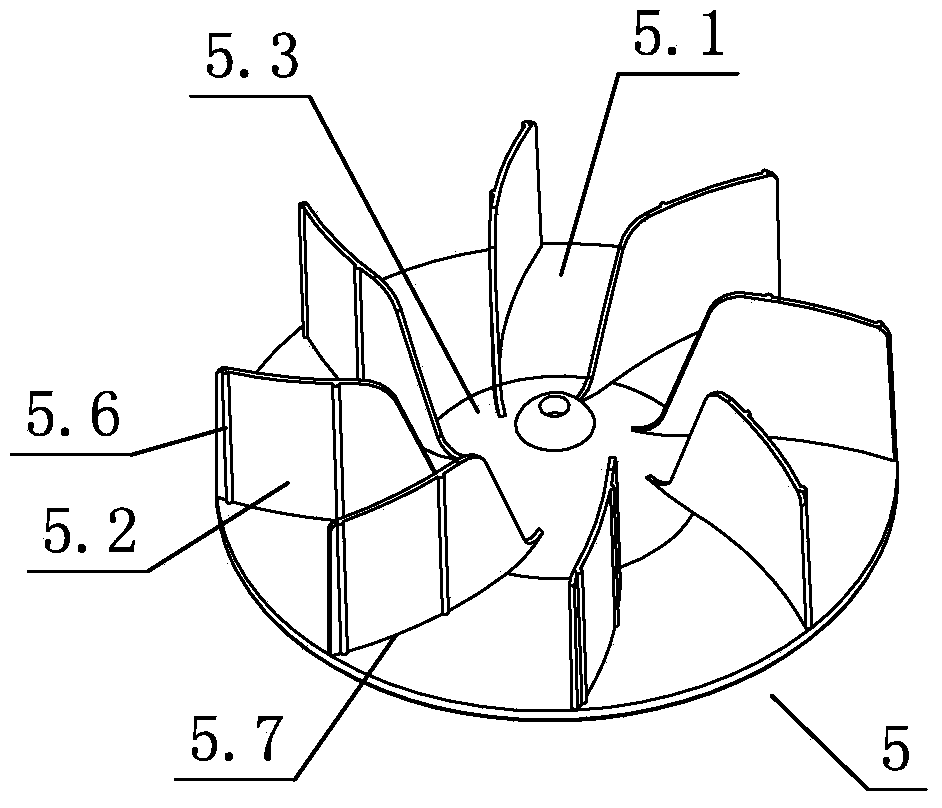

Wood-working machine dust collector and packing foam thereof

ActiveCN103624848AFlexible useEasy to useBark-zones/chip/dust/waste removalContainers to prevent mechanical damageEngineeringCentrifugal force

The invention discloses a wood-working machine dust collector. The wood-working machine dust collector comprises a bracket component, an upper cover body and a lower cover body, wherein the bracket component is provided with a universal mobile wheel; the upper cover body and the lower cover body are arranged above the bracket component; a blade is rotationally arranged between the upper cover body and the lower cover body through a driving device; an air inlet of the blade is connected with a dust absorbing head and an air outlet of the blade is connected with more than one group of filtering bag component; a volute flow guiding device is arranged between the filtering bag component and the blade. Due to the fact that the blade is rotationally arranged between the upper cover body and the lower cover body, the air inlet of the blade is connected with the dust absorbing head, the air outlet of the blade is connected with more than one group of filtering bag component, and the volute flow guiding device is arranged between the filtering bag component and the blade, after being absorbed from the air inlet of the blade, dust is conveyed into the filtering bag component through the air outlet to be filtered; due to the fact that air enters the volute flow guiding device tangentially, the volute flow guiding device has a very high centrifugal dust-absorbing effect and a good dust-absorbing effect. The wood-working machine dust collector can also move at any time through the universal mobile wheel, so that the wood-working machine dust collector is convenient to use; more than two wood-working machine dust collectors can be conveyed by one set of packing foam, so that the practicability is strong.

Owner:FOSHAN HAOYANG WOODWORK MACHINERY MFR

Flow-splitting multi-air-channel dust collecting device

ActiveCN106037585AReasonable structureEfficient separationSuction filtersElectricityShock resistance

The invention discloses a flow-splitting multi-air-channel dust collecting device. The flow-splitting multi-air-channel dust collecting device comprises a main machine body, an air sucking motor, a dust cup and a suction hole base, wherein the dust cup comprises a cup body, a cup cover and a cup bottom, the cup body is provided with a cup air inlet, the interior of the dust cup is provided with a plurality of flow-splitting cyclone conical barrels, tangential air inlet branch pipes are arranged on the flow-splitting cyclone conical barrels, the upper end and the lower end of each barrel are open, the opening in the upper end is larger than the opening in the lower end, the openings in the upper ends of the flow-splitting cyclone conical barrels communicate with the air inlet end of the air sucking motor through middle air channels, the air outlet end of the air sucking motor communicates with an external air exhaust hole in the main machine body, filtering racks are arranged in cover air channels, and air inlet sponge is arranged on the filtering racks. The flow-splitting multi-air-channel dust collecting device has the beneficial effects that the air channels are reasonable in structure, and the separation and collection of dust can be effectively completed; the dust collecting capacity is strong, the filtering effect is good, and the air exhaust cleanliness can be guaranteed; an electricity storage structure is available, therefore, the progressive flow-splitting dust collecting device can work without an electric wire, and in addition, the structures are strong in cooling and heat dissipating capacities and shock resistance; the integral stability is good, and the noise is small.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

A portable cyclone vacuum cleaner

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

A multi-channel cyclone vacuum cleaner

The invention discloses a multi-air-flue cyclone dust collector which comprises a main dust collector body, a suction motor, a dust cup body and a suction port base. The dust cup body comprises a main cup body, a cup lid and a cup bottom. A cup body air inlet is formed in the main cup body. A plurality of flow division cyclone conical cylinders are arranged inside the dust cup body. Tangent air inlet branch pipes are arranged on the flow division cyclone conical cylinders. Openings are formed in the upper and lower ends of the flow division cyclone conical cylinders, and the opening in the upper end of each flow division cyclone conical cylinder is larger than the opening in the lower end of the flow division cyclone conical cylinder. The opening in the upper end of each flow division cyclone conical cylinder is communicated with the air inlet end of the suction motor through a middle air flue. The air outlet end of the suction motor is communicated with an outer exhaust port in the main dust collector body. A filter frame body is arranged in a lid air flue. An air inlet sponge is arranged on the filter frame body. The multi-air-flue cyclone dust collector has the advantages that the air flue is reasonable in structure, and dust separation and collection can be sufficiently completed; the dust suction capacity is high, the filtering effect is good, and the exhaust cleanness can be ensured; the mop anti-collision protection function is achieved, the efficient cleaning capacity for the foot of a wall and other dead corners is achieved, and comprehensive functions are achieved; the overall stability is good, and noise is small.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

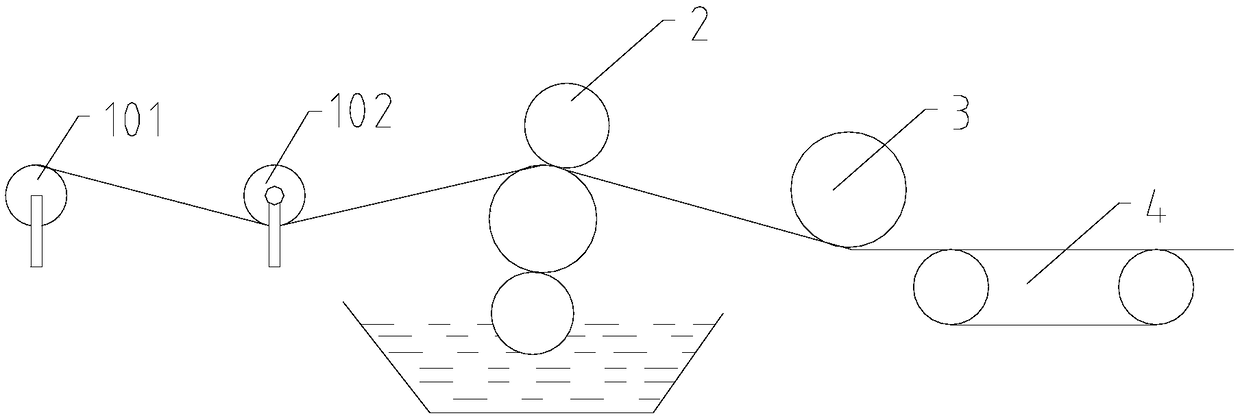

Web press

The invention provides a web press. The web press comprises a web feeding unit, a printing unit and a wed discharging unit which are sequentially arranged on a main frame, wherein the web feeding unitcomprises a web feeding roller and a tension roller which are mounted on the main frame, and webs on the web feeding roller are connected to the tension roller for being conveyed to the printing unitvia the tension rollers; the tension roller is used for conveying the webs to the printing unit and comprises an outer roller tube which is provided with suction holes and a vacuumizing pipe; both sides of the outer roller tube are provided with molecular vacuum pumps, the rotating blades of the molecular vacuum pumps are fixed onto the outer roller tube, and the fixed blades of the molecular vacuum pumps are arranged on a fixing shaft coaxial to the outer roller tube; the printing unit comprises a printing roller for printing the webs; the web discharging unit is used for collecting the websfrom the printing unit and conveying the webs out to a web discharging conveying belt. The web press can avoid skidding of the webs and ensure the web printing quality.

Owner:安徽瀚洋纸品印刷有限公司

A split-type cyclone vacuum cleaner

ActiveCN105996905BReasonable structureEfficient separationSuction filtersThermodynamicsElectric machine

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

A split-flow multi-air duct dust collection device

ActiveCN106037585BReasonable structureEfficient separationSuction filtersElectric machineryEngineering

The invention discloses a flow-splitting multi-air-channel dust collecting device. The flow-splitting multi-air-channel dust collecting device comprises a main machine body, an air sucking motor, a dust cup and a suction hole base, wherein the dust cup comprises a cup body, a cup cover and a cup bottom, the cup body is provided with a cup air inlet, the interior of the dust cup is provided with a plurality of flow-splitting cyclone conical barrels, tangential air inlet branch pipes are arranged on the flow-splitting cyclone conical barrels, the upper end and the lower end of each barrel are open, the opening in the upper end is larger than the opening in the lower end, the openings in the upper ends of the flow-splitting cyclone conical barrels communicate with the air inlet end of the air sucking motor through middle air channels, the air outlet end of the air sucking motor communicates with an external air exhaust hole in the main machine body, filtering racks are arranged in cover air channels, and air inlet sponge is arranged on the filtering racks. The flow-splitting multi-air-channel dust collecting device has the beneficial effects that the air channels are reasonable in structure, and the separation and collection of dust can be effectively completed; the dust collecting capacity is strong, the filtering effect is good, and the air exhaust cleanliness can be guaranteed; an electricity storage structure is available, therefore, the progressive flow-splitting dust collecting device can work without an electric wire, and in addition, the structures are strong in cooling and heat dissipating capacities and shock resistance; the integral stability is good, and the noise is small.

Owner:NINGBO HAIJI ELECTRIC APPLIANCE

A metal anti-corrosion paint application equipment and application method thereof

ActiveCN109046888BReduce wasteReduce laborEdge grinding machinesPortable grinding machinesPolishingCoating

The invention discloses metal anticorrosive paint preparation and a coating method thereof, and belongs to the field of anticorrosive paint. According to the metal anticorrosive paint preparation andthe coating method thereof, a coating repair device is provided; a storage groove is formed in the inner end of the coating repair device; anticorrosive paint is arranged at the inner end of the storage groove; a rear cover covers the groove mouth of the storage groove; a polishing mechanism is arranged at the left end of the rear cover; a one-way discharging groove, a gourd-shaped groove and a spacing groove are formed in the inner end of the coating repair device; the one-way discharging groove, the gourd-shaped groove and the spacing grooves are located at the right side of the storage groove; the storage groove, the one-way discharging groove, the gourd-shaped groove and the spacing grooves are cut through in sequence from left to right; a one-way flow mechanism is arranged at the inner end of the one-way discharging groove; the right end of the one-way flow mechanism is fixedly connected with a current limiting ball; and the current limiting ball is located at the inner side of the gourd-shaped groove. According to the metal anticorrosive paint preparation and the coating method thereof, the effect of repairing the areas, without anticorrosive paint, on the surfaces of parts can be realized, the waste of anticorrosive materials can be decreased, the repair operation is simple and convenient, and the labor capacity of the spray workers can be reduced.

Owner:FUJIAN HONGGUAN ROADS & BRIDGE ANTI CORROSIVE TECH

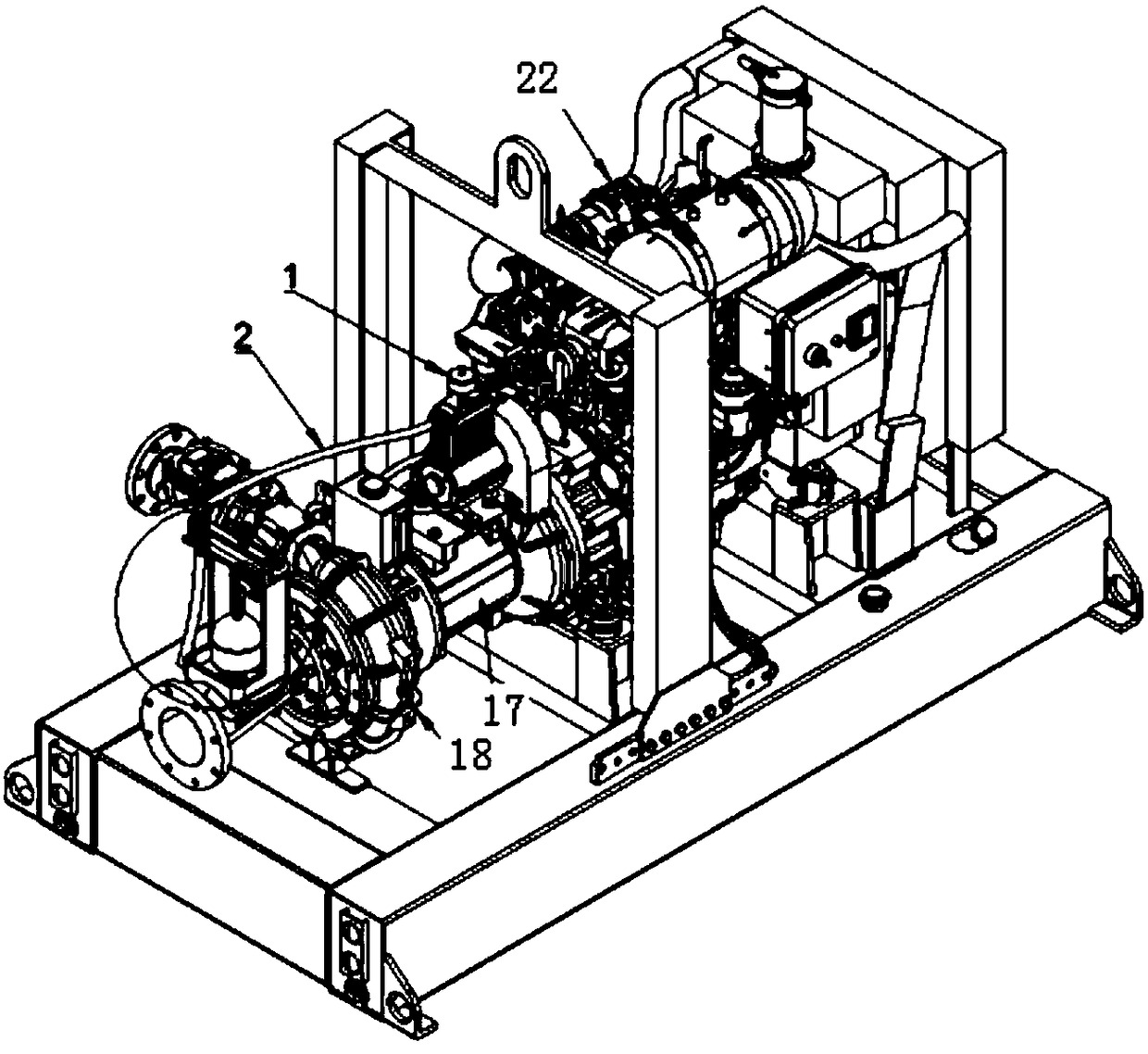

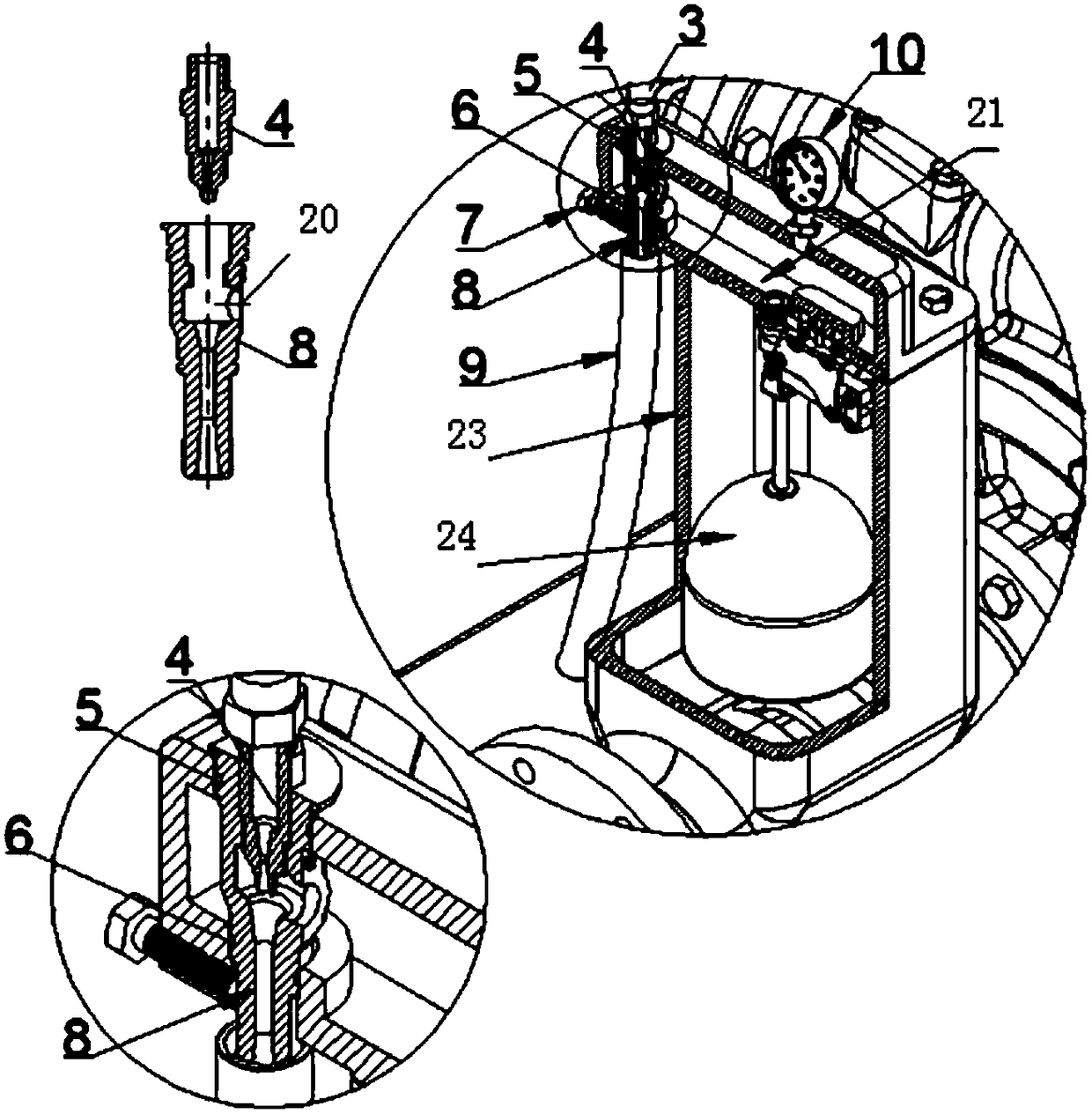

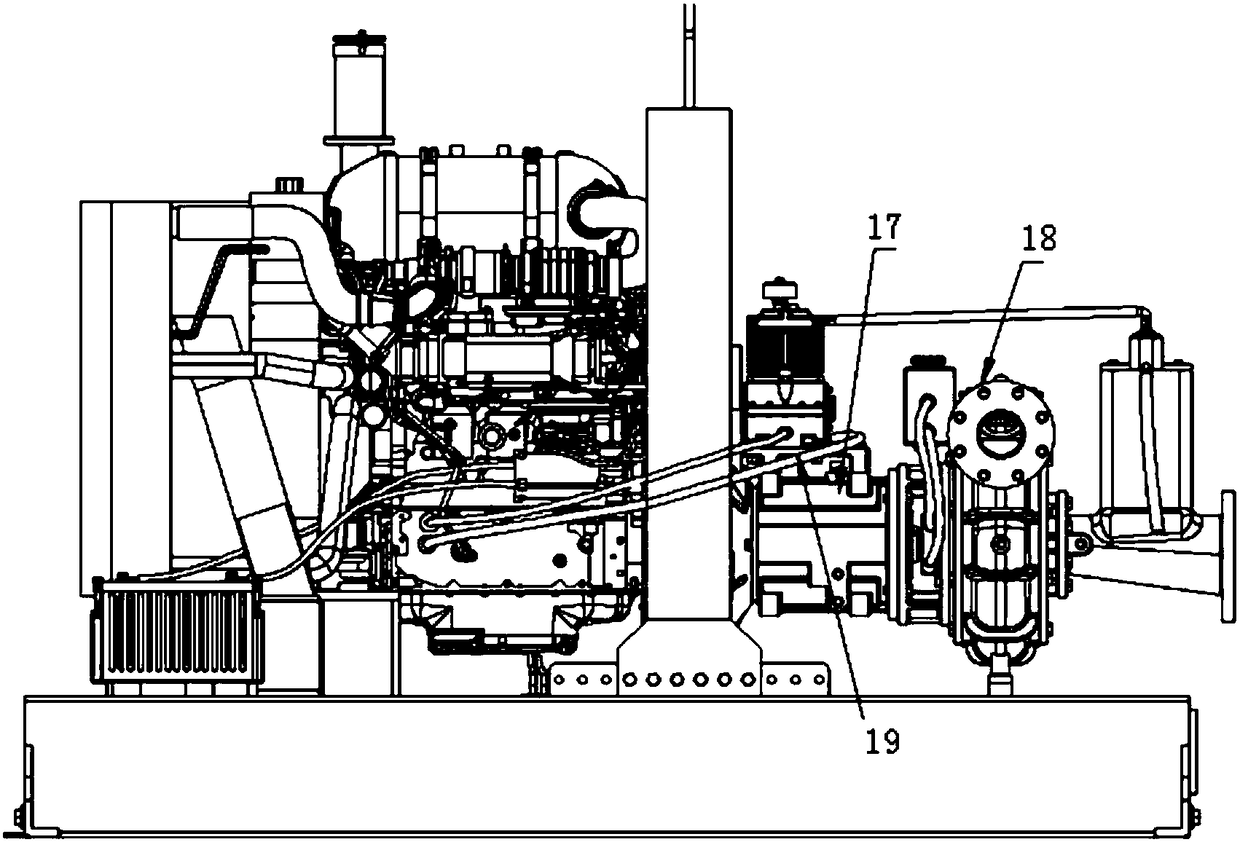

Jet vacuum-pumping rapid water diversion device

PendingCN108518345AReduce volumeReduce weightPriming pumpNon-positive displacement fluid enginesEmergency rescueAir compressor

The invention discloses a jet vacuum-pumping rapid water diversion device comprising a diesel engine, an air compressor, a jet device, connecting pipes and other pipes, a ball valve, a floating ball switch and a vacuum pressure gauge. The water diversion device is characterized in that the jet device comprises a jet pipe and a Venturi pipe, and the air compressor is installed on the diesel engineon a supporting seat or a supporting centrifugal pump; an exhaust port of the air compressor is connected to an air inlet pipe of which the end is connected to the Venturi pipe, and the Venturi pipe is in screw joint with the jet pipe of which the side wall is provided with a jet pipe inlet; the jet pipe inlet communicates with a chamber of the supporting centrifugal pump, and the bottom of the Venturi pipe is connected to an exhaust hose; and the air compressor is driven by the diesel engine. According to the water diversion device, the time for the centrifugal pump ready to start can be shortened greatly, and the secondary self-priming working efficiency is improved; the production loss caused by long-time shutdown is decreased, and the labor cost is reduced; especially, the emergency rescue work can be quickly started, and the disaster loss is reduced; and meanwhile, artificial potential safety hazards can be avoided effectively, and the labor intensity is reduced.

Owner:AMOS FLUID TECH CO LTD

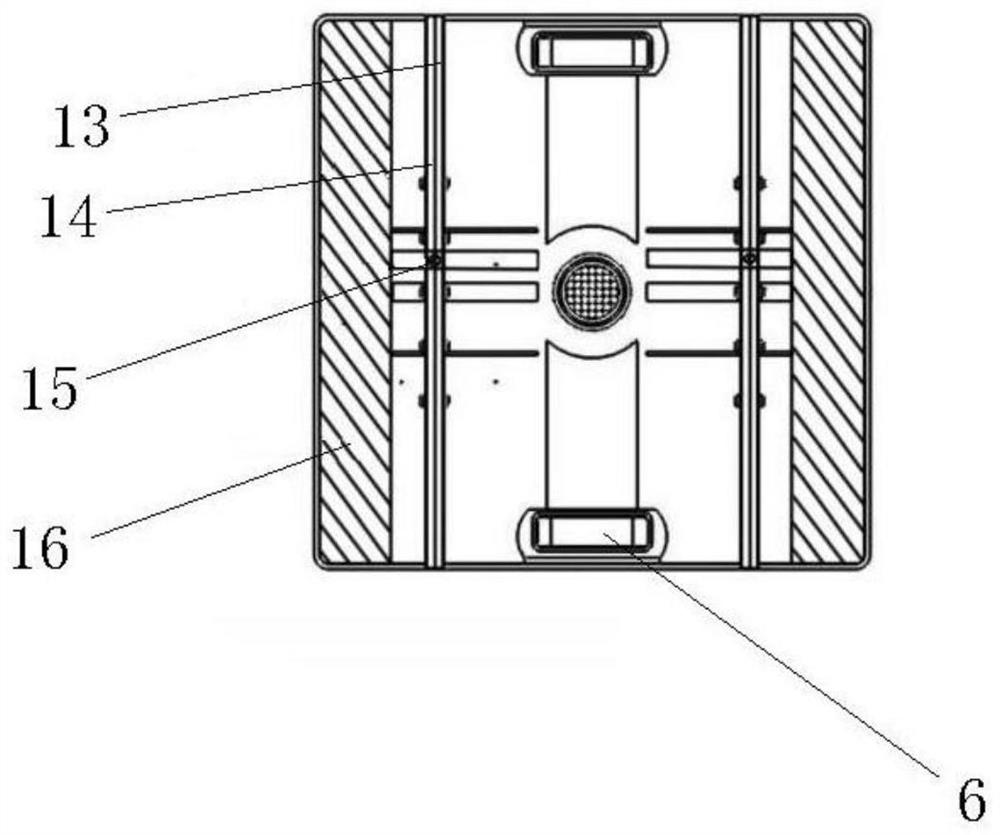

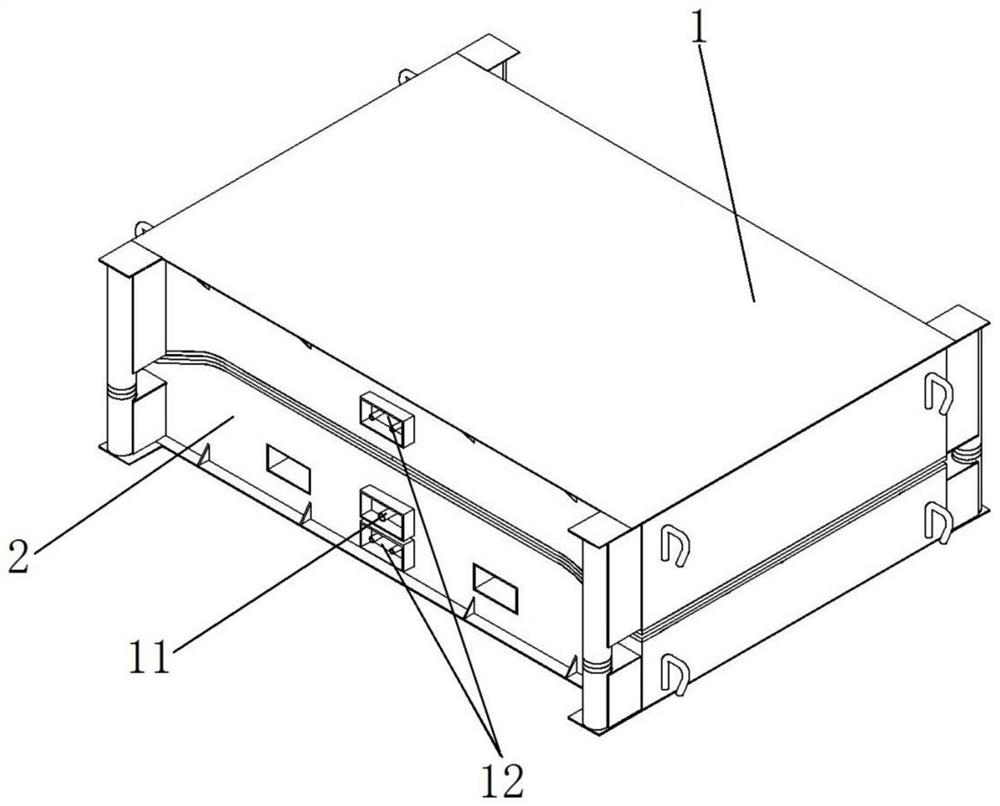

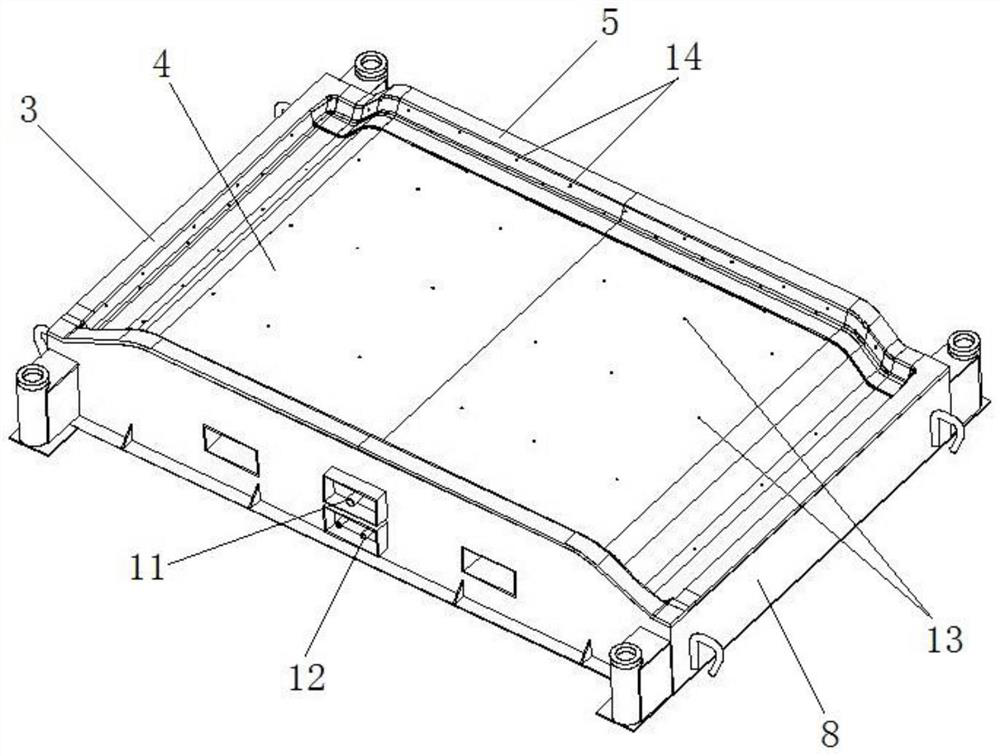

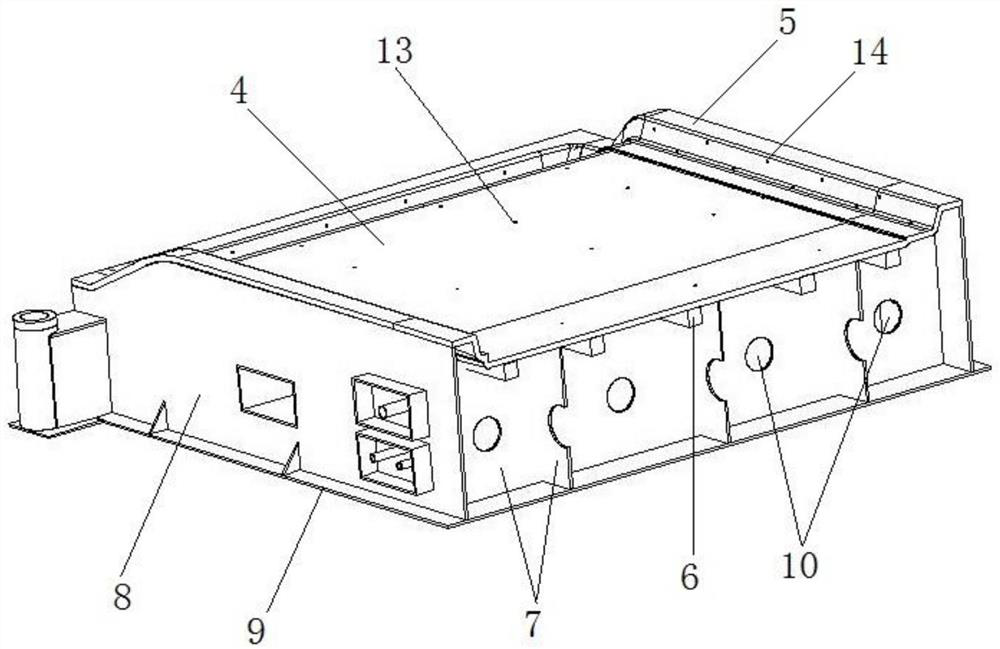

Lower die of vacuum automatic coating die and vacuum automatic coating die

The invention belongs to the field of mold forming, and particularly relates to a lower mold of a vacuum automatic coating mold and the vacuum automatic coating mold, the lower mold of the vacuum automatic coating mold comprises a forming face used for forming a product and a sealing structure located on the periphery of the forming face, and the sealing structure is provided with a sealing face used for being matched with a corresponding upper mold to achieve sealing of a mold cavity. The forming surface is provided with a forming surface vacuumizing hole, so that the surface skin can be attached to the forming surface through vacuumizing, the sealing surface is provided with a sealing surface vacuumizing hole, so that the edge part of the surface skin can be sucked on the sealing surface through vacuumizing sealing, and by adopting the scheme, the edge part of the surface skin can be sucked on the sealing surface of the lower mold efficiently and conveniently at low cost; therefore, the skin can be reliably sucked on the forming surface through the forming surface vacuumizing holes.

Owner:郑州豫诚模具有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com