Jet vacuum-pumping rapid water diversion device

A jet device and vacuum pumping technology, applied in the mechanical field, can solve the problems of affecting the sealing effect, heavy bottom valve, failure of the bottom valve, etc., and achieve the effect of light weight and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

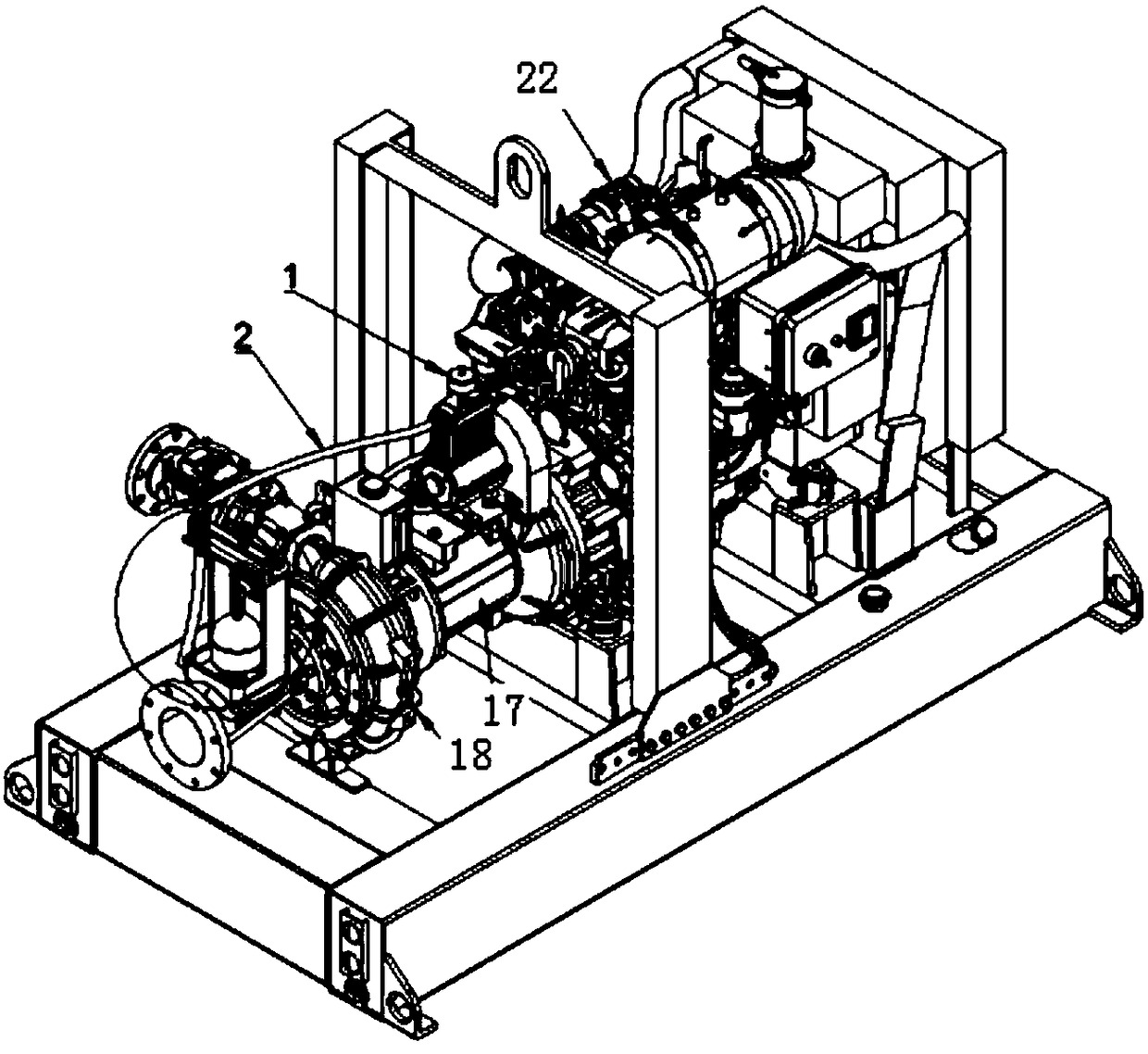

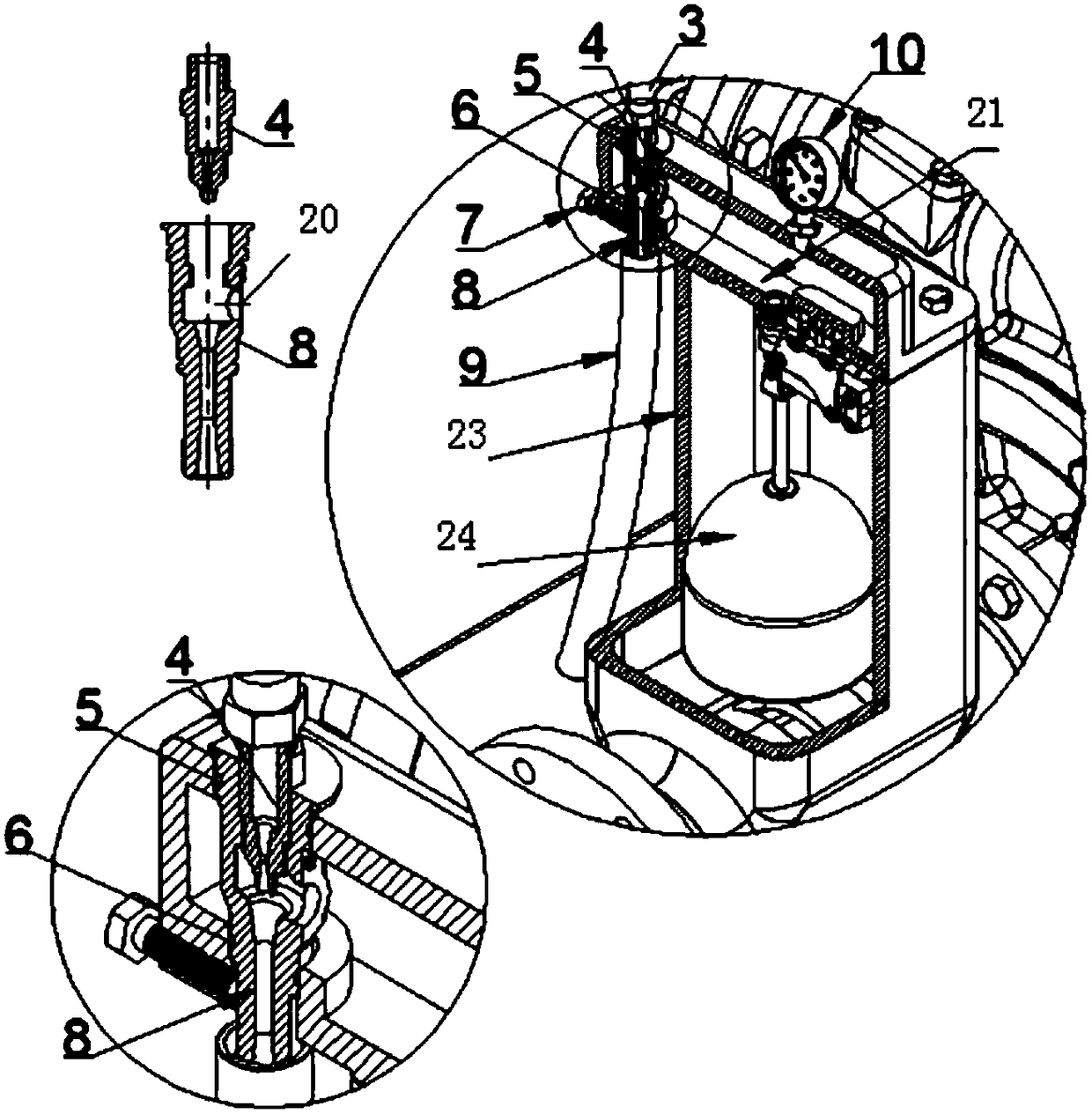

[0020] Embodiment 1: Referring to the accompanying drawings, the supporting air compressor 1 is directly installed on the suspension 17 of the centrifugal pump 18, and is connected to the shaft drive of the centrifugal pump through a belt. The air compressor 1 can also be installed on the diesel engine 16, and the intake pipe 2 It is a high-temperature-resistant and high-pressure-resistant air pipe, which is used to connect the exhaust port of the air compressor 1 and the jet device. The 90° elbow 3 is used for the conversion connection between the intake pipe 2 and the throat pipe 4 of the jet pump device. The bolt 5 withstands the jet The jet tube 6 of the device is fixed in the suction chamber 23 of the centrifugal pump 12, the inlet of the jet tube 6 communicates with the pump chamber of the centrifugal pump, and the jet tube 6 passes through the suction chamber and is sealed by O-rings 5 and 6. The float switch 24 in the suction chamber is used to automatically close the...

Embodiment 2

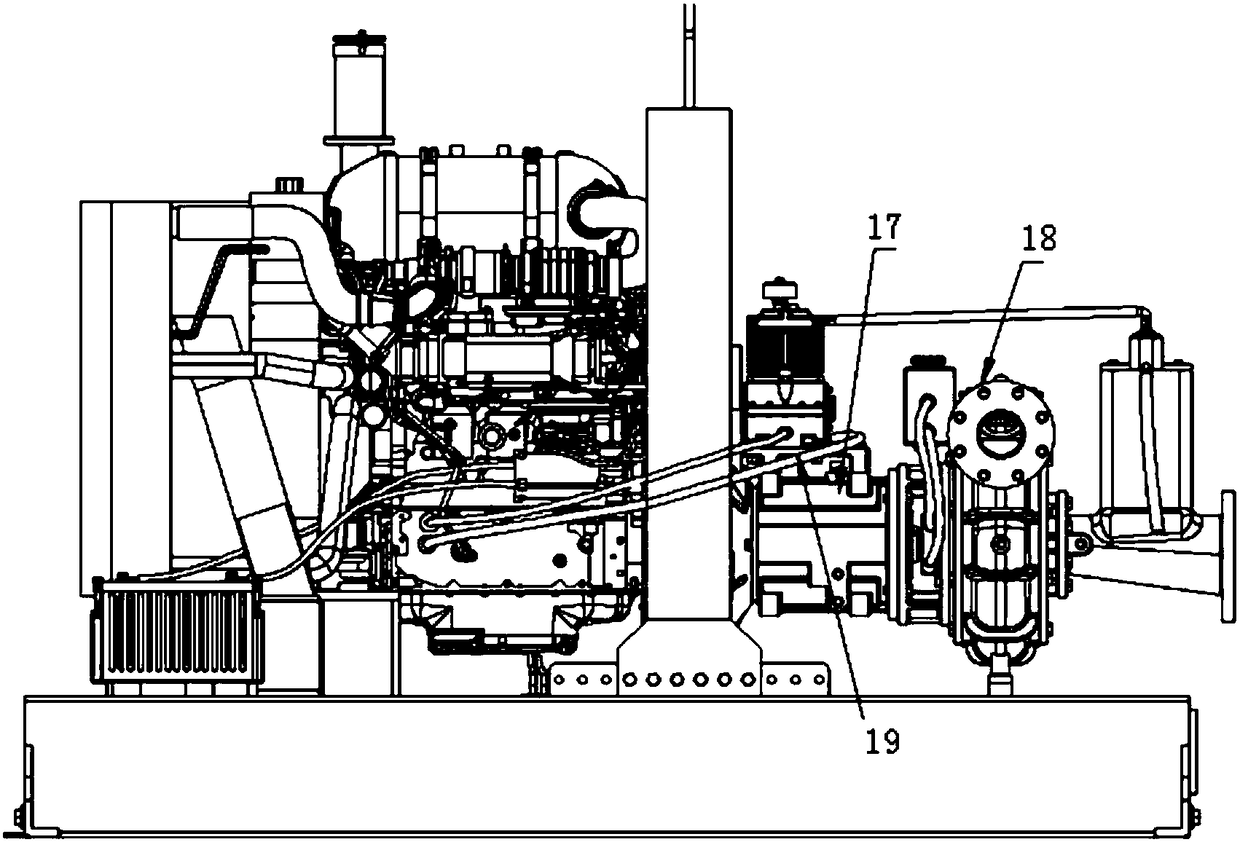

[0026] Embodiment 2: The supporting air compressor 1 is directly installed on the suspension 17 of the centrifugal pump 18, and is connected to the pump shaft drive of the centrifugal pump by a belt. The air compressor 1 can also be installed on the diesel engine 22. The high-pressure resistant air pipe is used to connect the exhaust port of the air compressor 1 and the throat pipe 15 of the jet device, the throat pipe 15 is connected with the injection pipe 16 by threads, and the inlet 20 of the injection pipe 16 is connected to the 90° elbow 14, The three-way pipe 13, the ball valve 11 and the outer wire directly 12 until the inlet pipe of the centrifugal pump communicates with the pump chamber, the vacuum pressure gauge 10 is connected to the other interface of the three-way 13, and the exhaust hose 9 is connected to the end of the jet pipe 16 for Diversion and noise reduction of exhaust gas.

[0027] The principle of embodiment 2, such as Figure 4 , 5 , 6;

[0028] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com