Patents

Literature

32results about How to "Quick vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

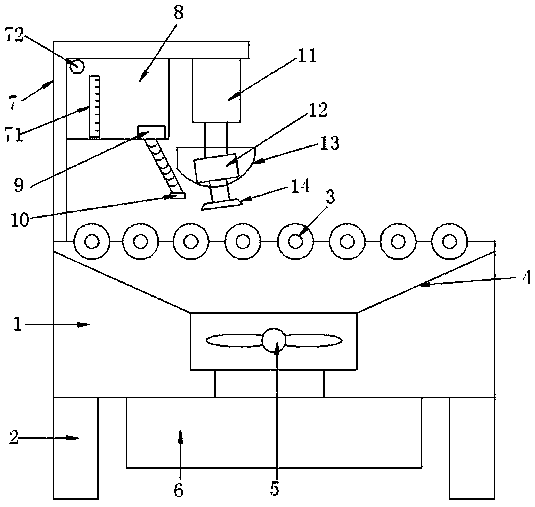

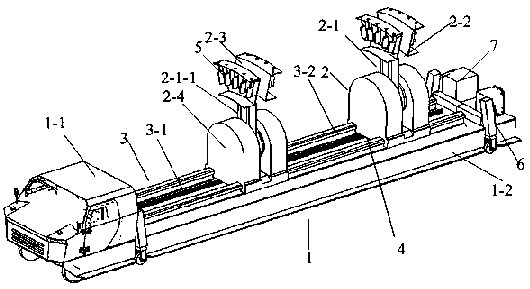

Grinding device for high-speed steel

InactiveCN108081046AImprove grinding efficiencyEasy to useGrinding drivesGrinding feedersDrive motorAgricultural engineering

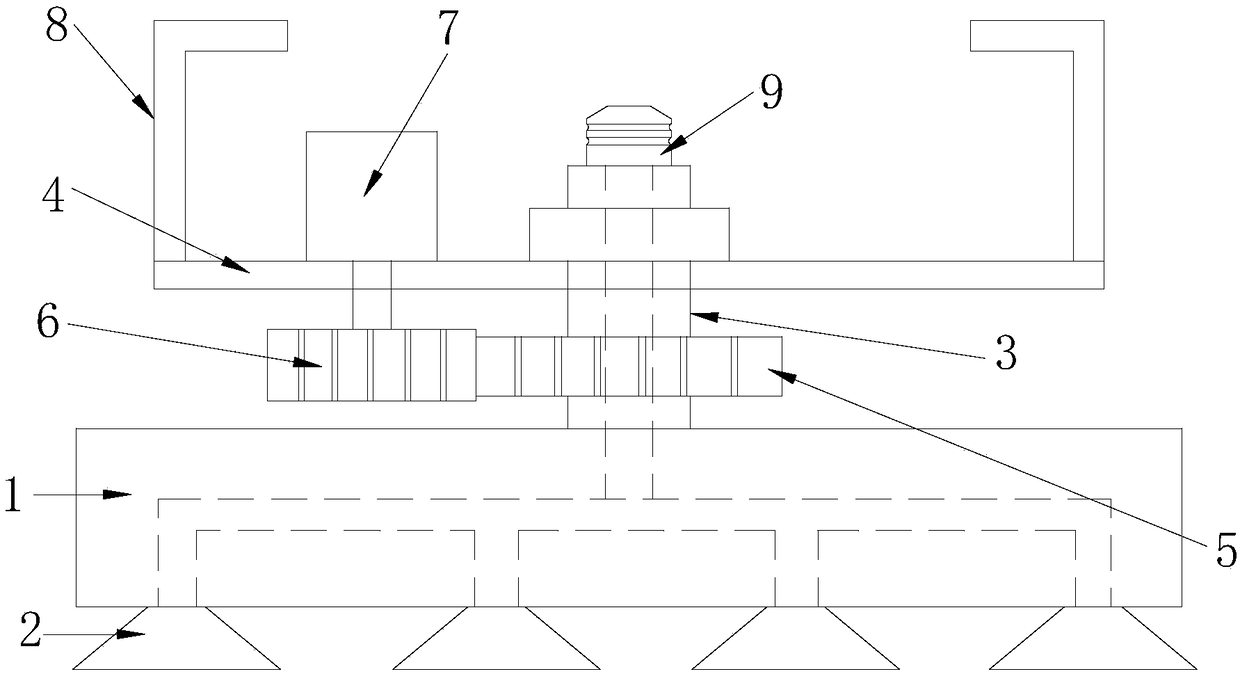

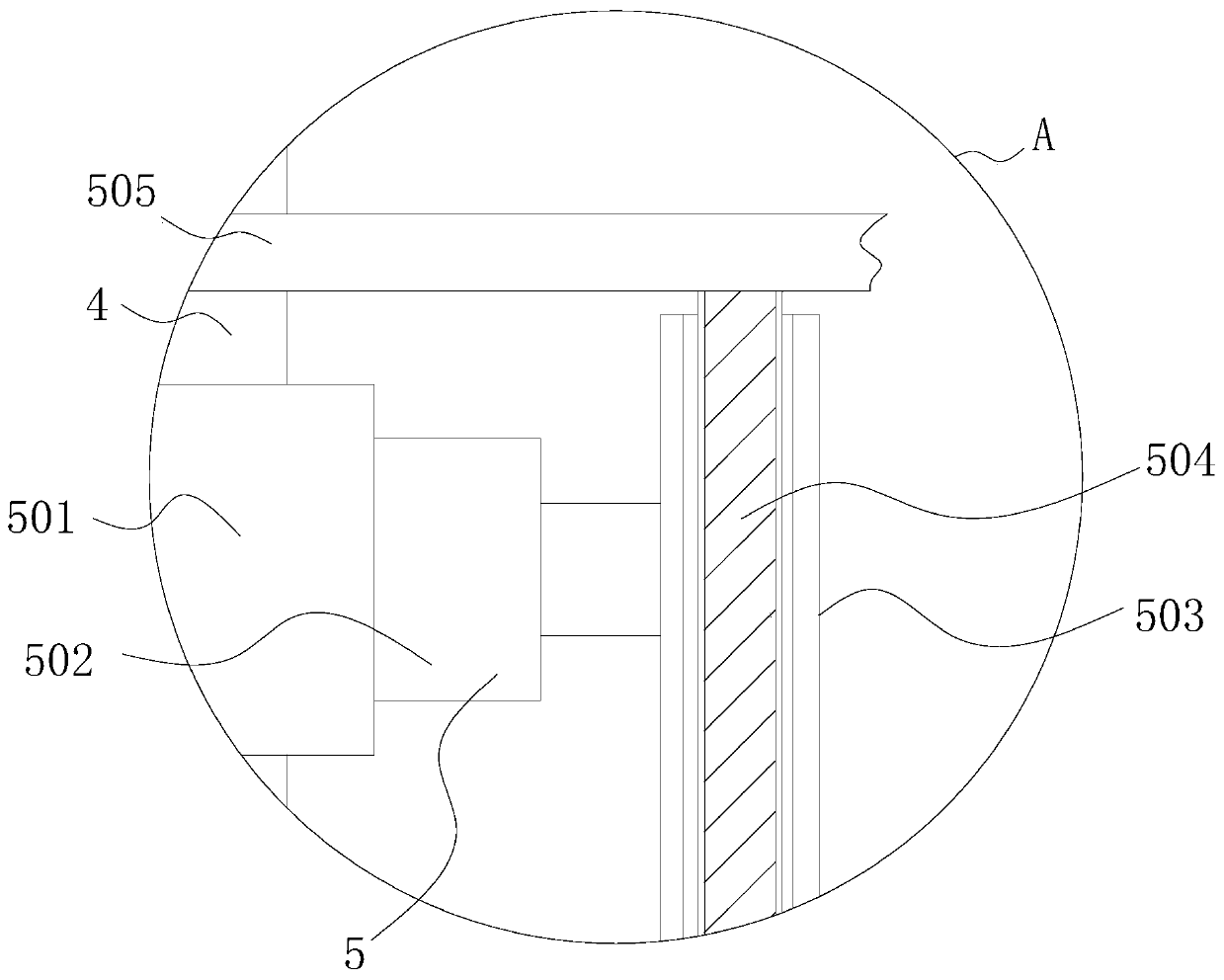

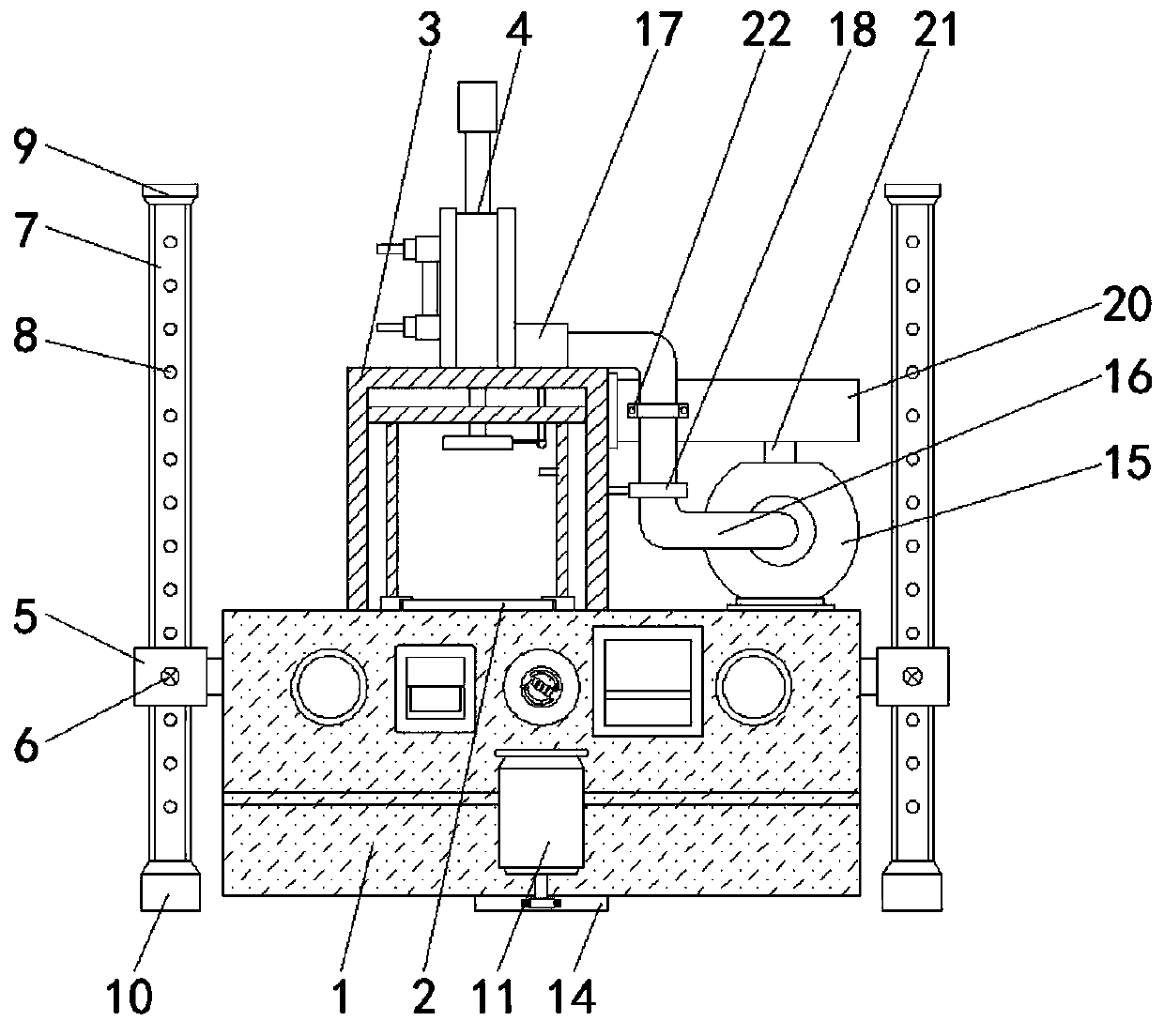

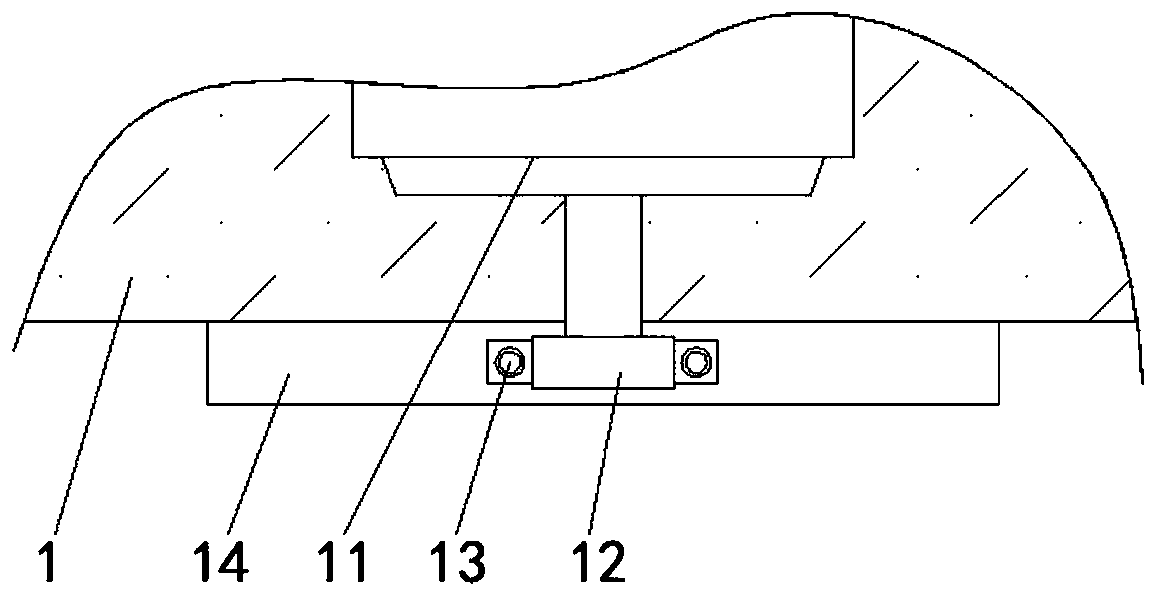

The invention discloses a grinding device for high-speed steel, and relates to the technical field of equipment for high-speed steel. According to the technical scheme, the bottom of a machine frame is provided with supporting legs, a rotating roller conveying mechanism is arranged on the upper surface of the machine frame, the lower end of the rotating roller conveying mechanism is provided witha dust collection cover, a dust suction fan is arranged at the bottom of the dust collection cover, and the bottom of the dust suction fan is connected with a collection box through a dust suction pipe; a mounting frame is arranged at the left upper end of the machine frame, a water tank is arranged on the inner side of the mounting frame, a suction pump is arranged inside the water tank, and thesuction pump is connected with a spray head through a water pipe; and an adjustor is arranged at the front end of the machine frame, a driving motor is installed on an adjusting rod of the adjuster, agrinding cutter is installed on a rotating shaft of the driving motor, and a dust cover is arranged on the outer surface of the driving motor. According to the device, the rapid spray type grinding can be realized conveniently, so that the grinding efficiency is improved, the use is convenient, the operation is simple and convenient, the rapid dust collection can be realized, and the environmentcan be effectively protected.

Owner:TIANGONG AIHE SPECIAL STEEL

Glass cutting machine based on laser guide cutting

The invention discloses a glass cutting machine based on laser guide cutting, which comprises a laser guide cutting device, a cooler, a cutting knife body and a dust exhaust apparatus which are sequentially suspended on the bracket in parallel along the cutting motion direction, wherein the laser guide cutting device emits a laser beam on the glass surface to be cut to form a guide cutting groove; the cooler comprises a first air nozzle which is arranged on the first supporting plate bottom surface and faced with the guide cutting groove; the first air nozzle inputs cooling gas via a gas input pipe; the cutting knife body comprises a cutting rack connected with the bracket, and a cutting knife wheel connected to the bottom of the cutting rack through a wheel pin; the dust exhaust apparatus comprises a first dust exhaust head which is arranged on a second supporting plate bottom surface and faced with the cutting knife wheel; and the vacuum pull of the first dust exhaust head is supplied by an electric exhaust blower through a dust exhaust hose. The glass cutting machine implements laser guide cutting and guide cutting groove quick cooling, enhances the cutting precision and reduces the horizontal cracks and glass chippings. The glass cutting machine can perform quickly dust exhausting on the glass chippings so as to prevent the glass chippings from being attached to the glass surface, thereby reducing the pollution.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

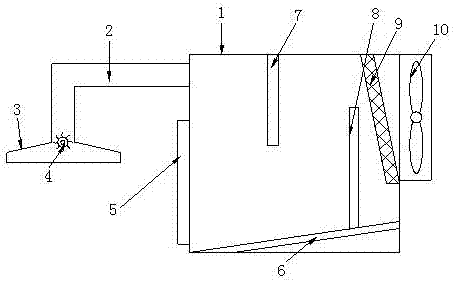

Dust suction device capable of rapidly collecting dust

The invention discloses a dust suction device capable of rapidly collecting dust and relates to the technical field of automatic equipment. A dust inlet pipe is connected to a dust inlet of a dust collecting box, a dust inlet head is mounted at the lower end of the dust inlet pipe, a smashing cutter roller is arranged on the inner side of the connecting position of the dust inlet pipe and the dust inlet head, a dust collecting plate is arranged at the inner bottom of the dust collecting box in an inclined manner, the dust collecting plate is arranged in a left-low and right-high manner, a dust outlet brake plate is arranged at the left end of the dust collecting plate, and is connected to the dust collecting box in a clamped manner, a lower baffle is mounted on the rear side of the dust collecting plate, an upper baffle is arranged on the inner front side of the dust collecting box, an adsorption opening is formed in the upper rear side of the dust collecting box, a filter net is mounted on the adsorption opening in an inclined manner, and a dust suction draught fan is arranged on the adsorption opening. Rapid dust suction and smashing can be conveniently achieved, the dust suction efficiency can be improved, use is convenient, operation is easy and convenient, and the efficiency is high.

Owner:SUZHOU SAISHUOLA STAINLESS STEEL PROD CO LTD

High stability robot sucking disc device

The invention discloses a high stability robot sucking disc device, and relates to the technical field of robot tools. A rotating shaft is installed at the upper end of a disc body, a sucker is installed at the bottom of the disc body, the sucker is connected with an air hole groove inside the disc body, the air hole groove communicates with a hollow hole inside the rotating shaft, a connecting joint is installed at the upper end of the rotating shaft and communicates with the hollow hole, the rotating shaft is installed on an installing plate through a bearing block, fixing supports are installed at the two ends of the installing plate, a first gear is installed at the middle portion of the rotating shaft and is meshed with a second gear, the second gear is installed on a rotating shaft of a driving motor, and the driving motor is installed on the installing plate. When the high stability robot sucking disc device is used, quick vacuum type adsorption and rotation can be achieved, andthe high stability robot sucking disc device is high in stability, easy and convenient to operate and high in efficiency.

Owner:SUZHOU LONGQI AUTOMATION TECH CO LTD

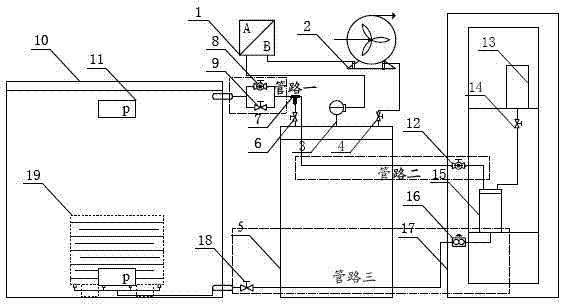

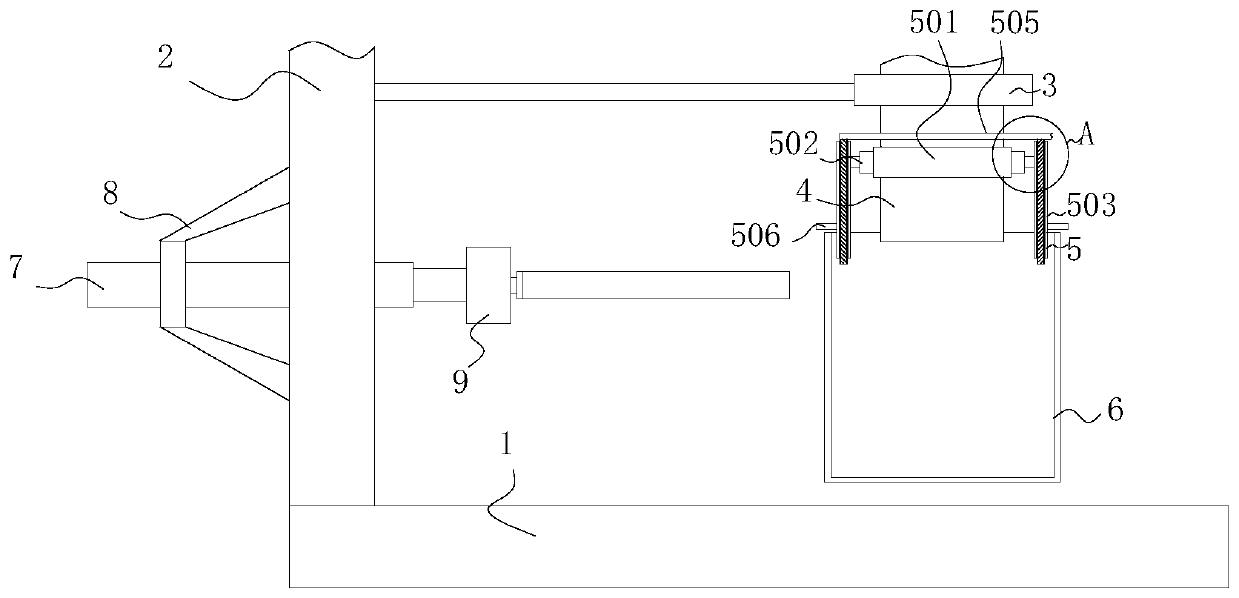

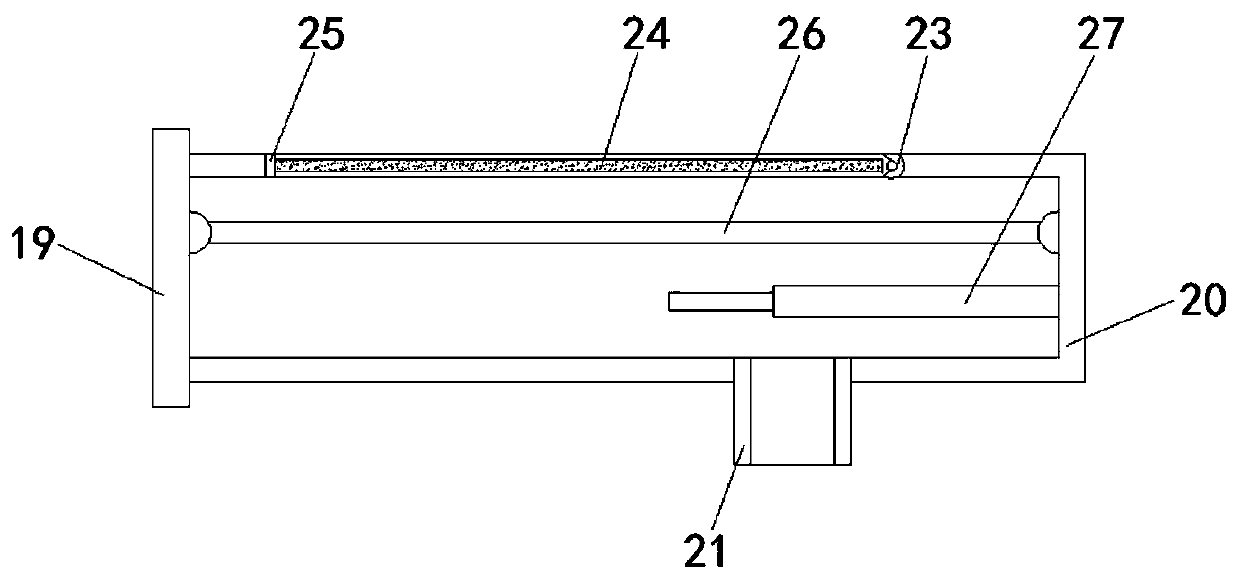

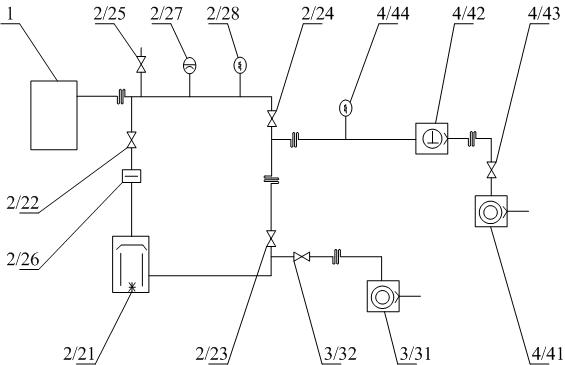

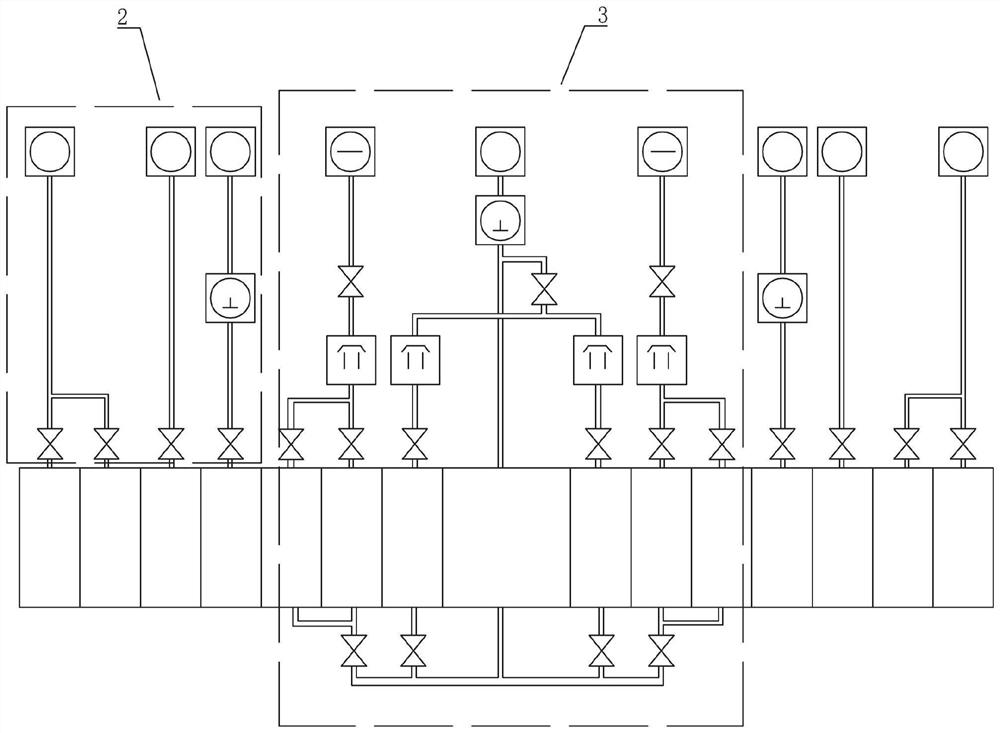

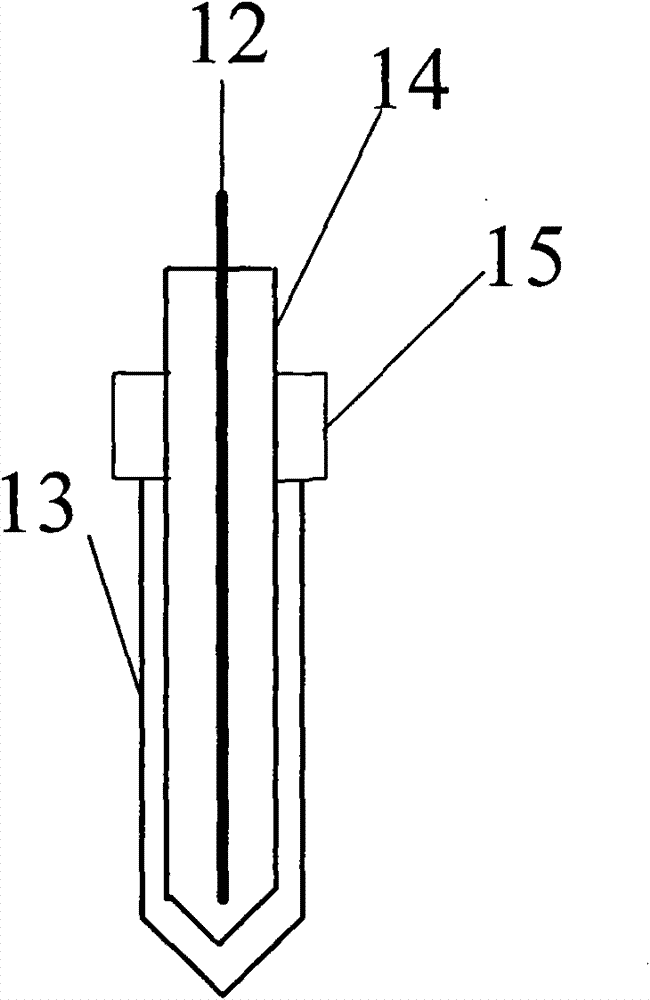

Evacuating device of temperature thermocouple casing of photovoltaic polycrystalline silicon ingot casting furnace

InactiveCN101942697AQuick vacuumFind quicklyPolycrystalline material growthSingle crystal growth detailsTemperature controlMetallurgy

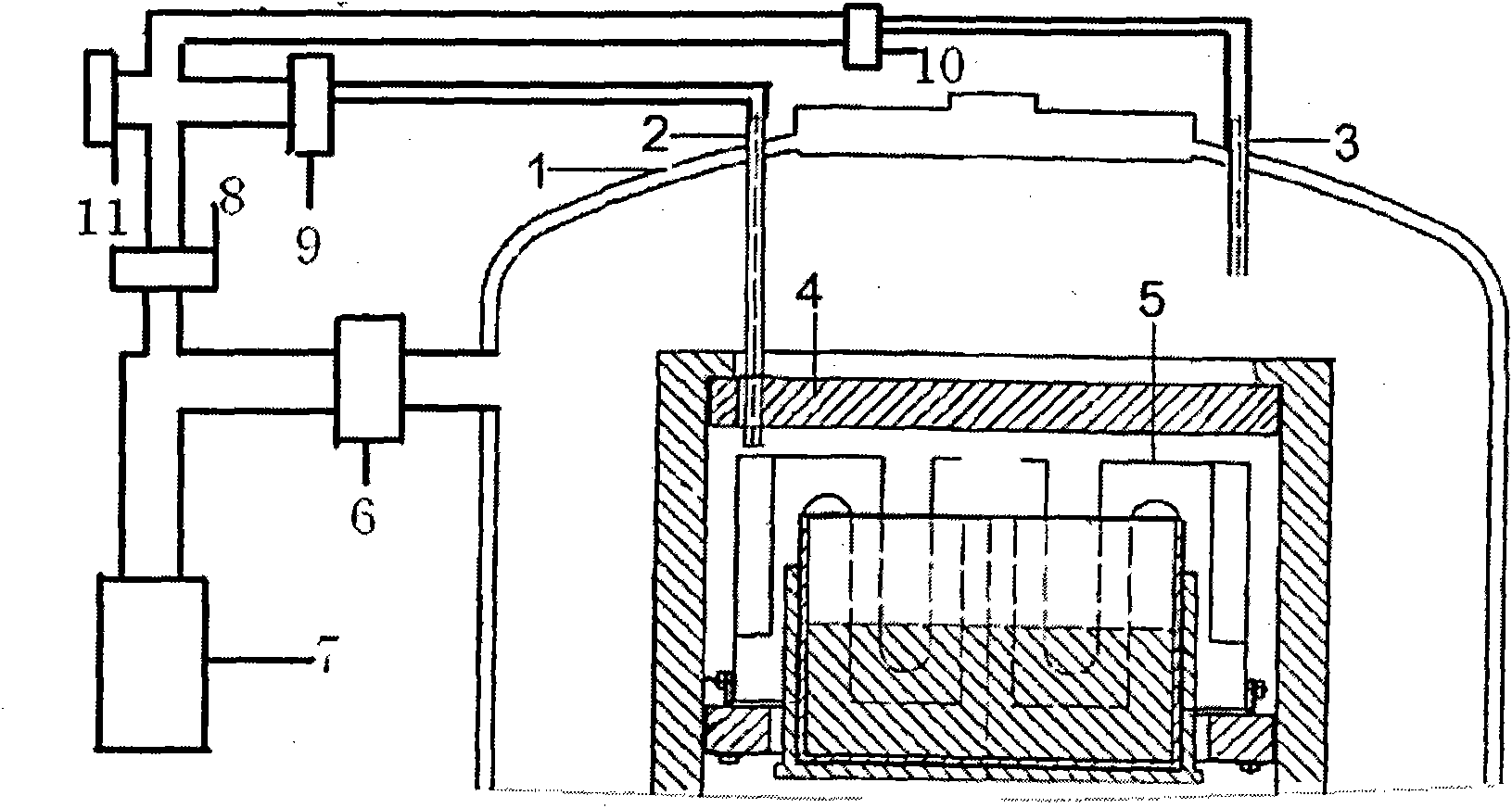

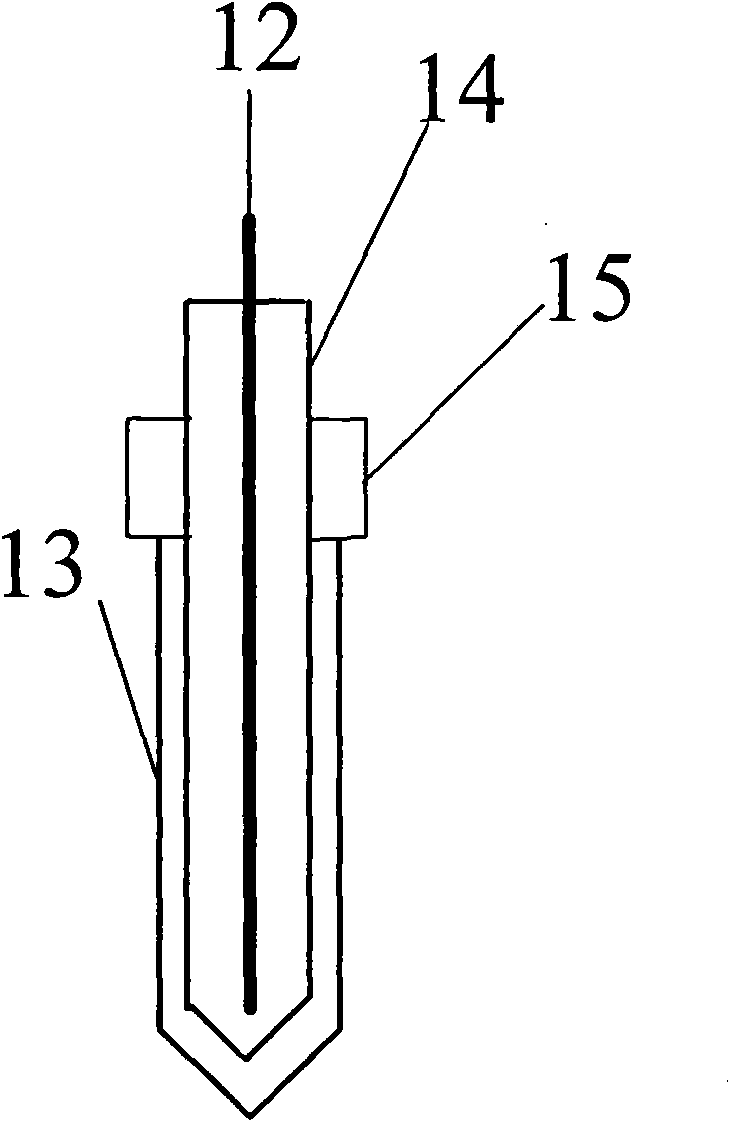

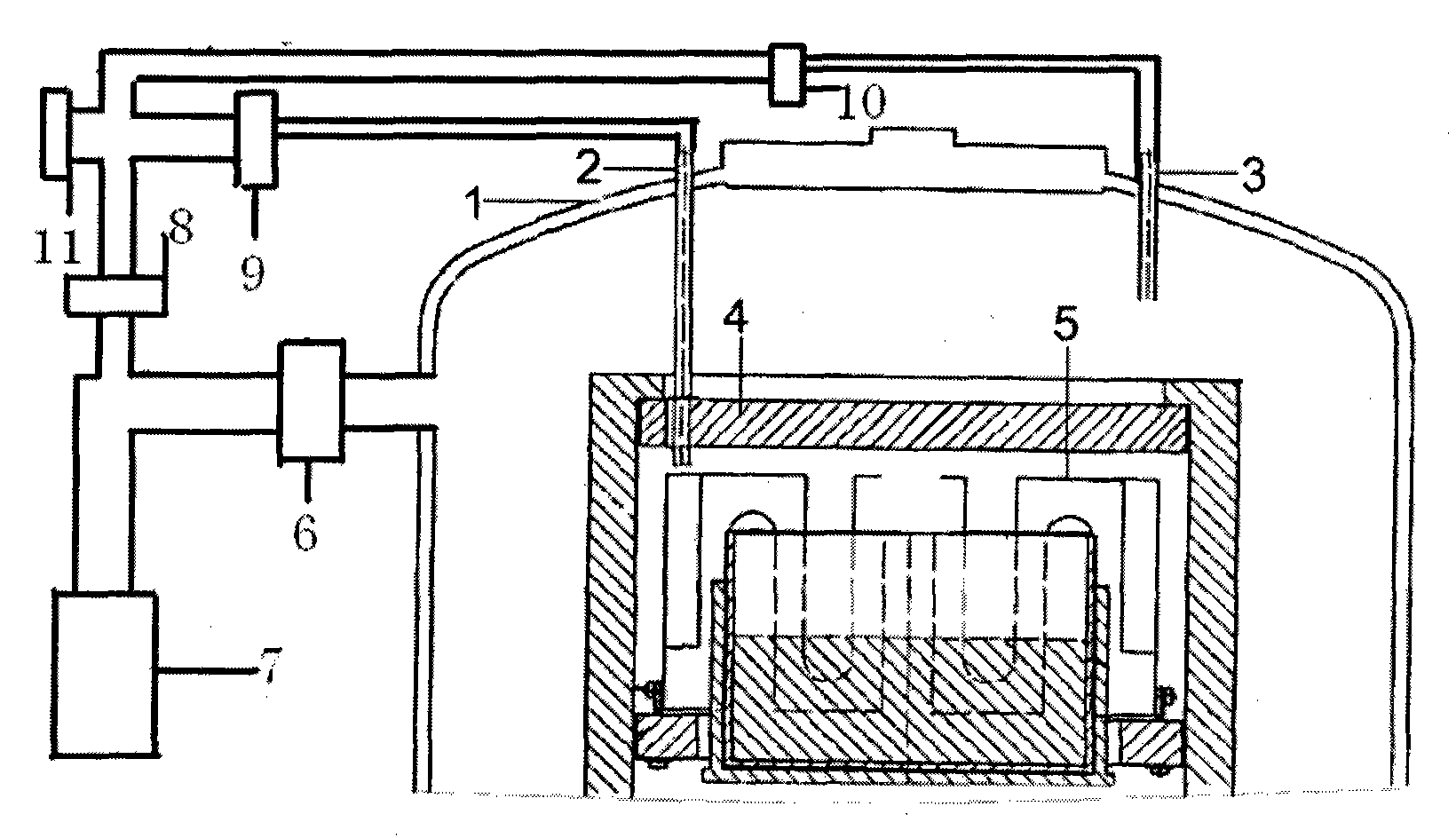

The invention relates to an evacuating device of a temperature thermocouple casing of a photovoltaic polycrystalline silicon ingot casting furnace, belonging to the technical field of evacuating automation of the photovoltaic polycrystalline silicon ingot casting furnace and comprising a temperature-controlling temperature thermocouple casing, an over-temperature protection temperature thermocouple casing, a vacuum pump set, a casing evacuating valve, a temperature-controlling temperature thermocouple hand-operated valve, an over-temperature protection temperature thermocouple hand-operated valve, an evacuating valve and a vent valve, wherein the temperature-controlling temperature thermocouple casing, the over-temperature protection temperature thermocouple casing and the vacuum pump set are communicated by utilizing the casing evacuating valve through a vacuum pipeline; a photovoltaic polycrystalline silicon ingot casting furnace cavity is communicated with the vacuum pump set by utilizing the evacuating valve through the vacuum pipeline; the vent valve is connected on the vacuum pipeline; the top of the furnace body is fixed on the upper end of the temperature-controlling temperature thermocouple casing, and the lower end of the temperature-controlling temperature thermocouple casing is inserted into a heat insulation cover of a heater through a heat insulation board; and the over-temperature protection temperature thermocouple casing is fixed on the furnace body and inserted into the furnace cavity. The invention can ensure that the evacuating speed of the integral equipment is enhanced; leak points can be quickly found; the ingot casting period is shortened; and the ingot casting quality is enhanced.

Owner:TSINGHUA UNIV +2

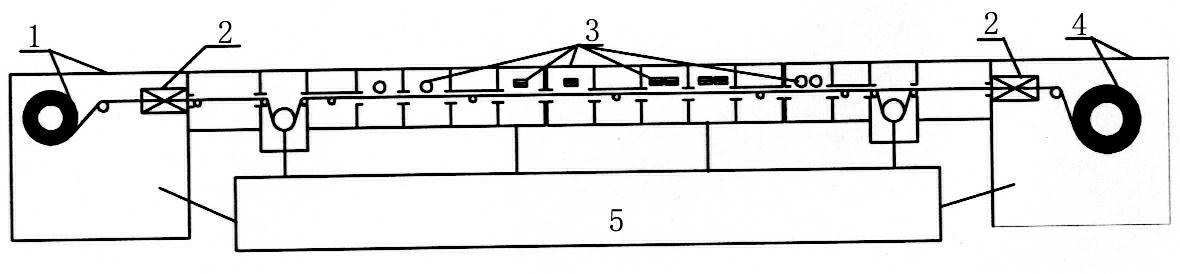

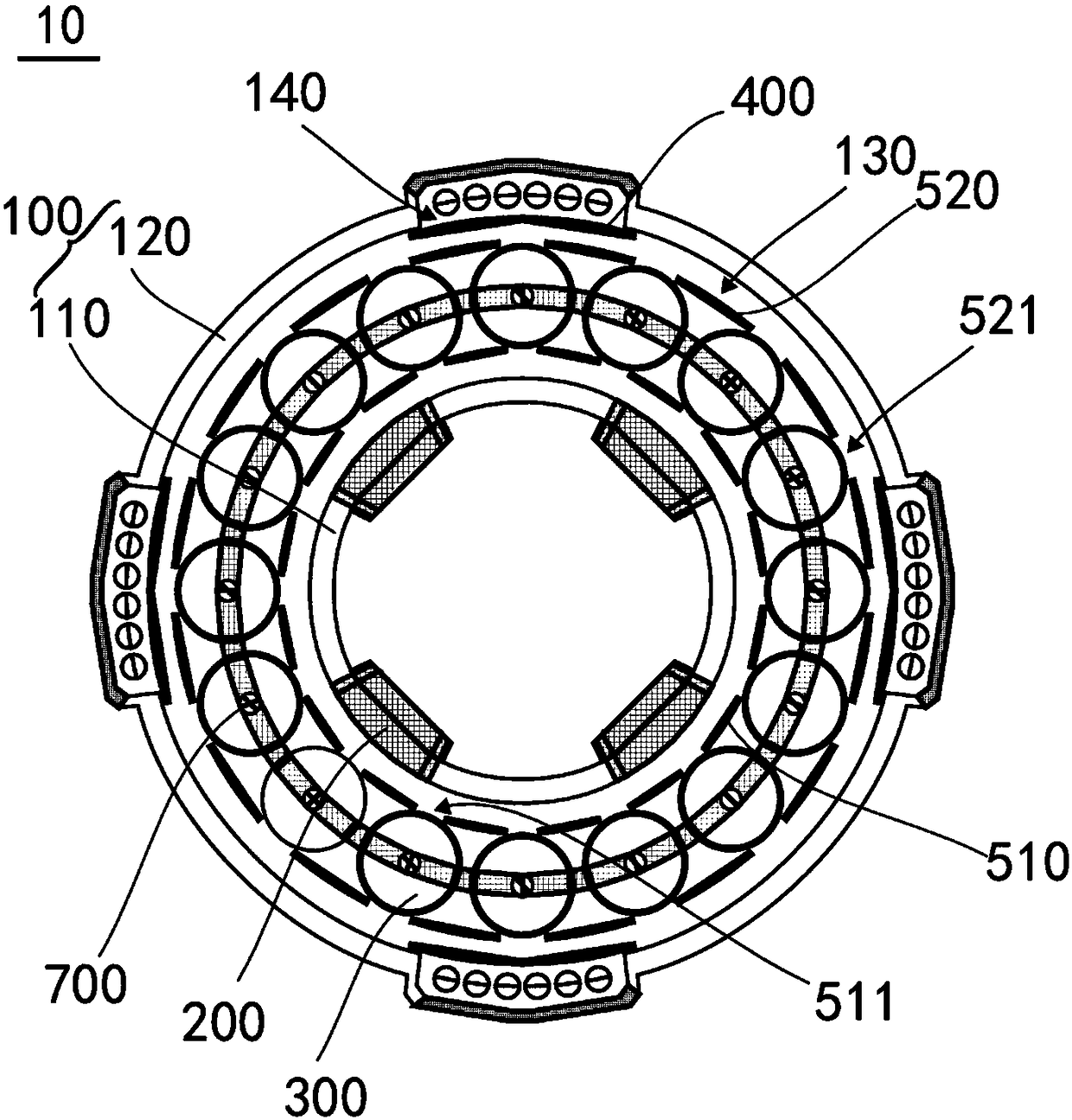

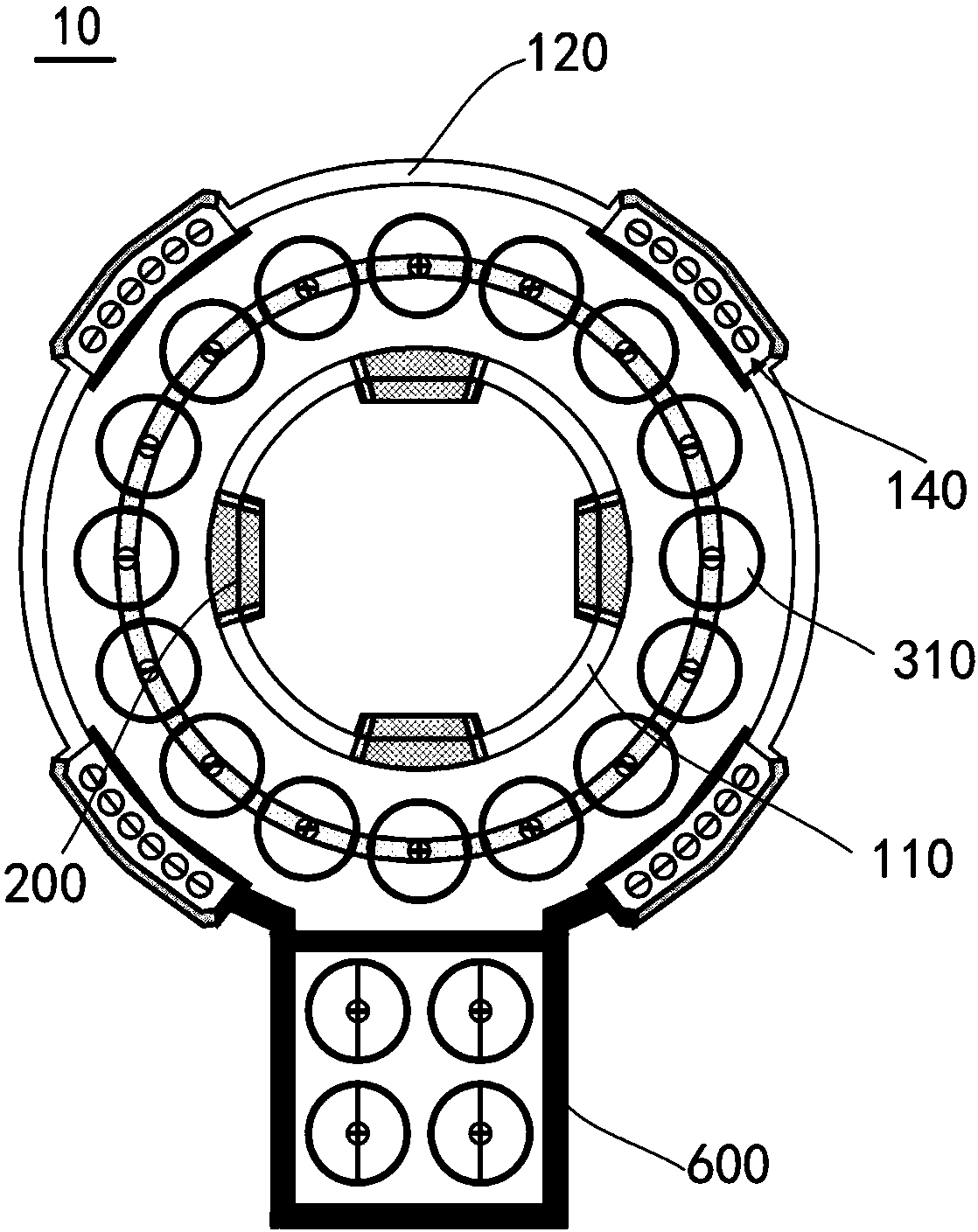

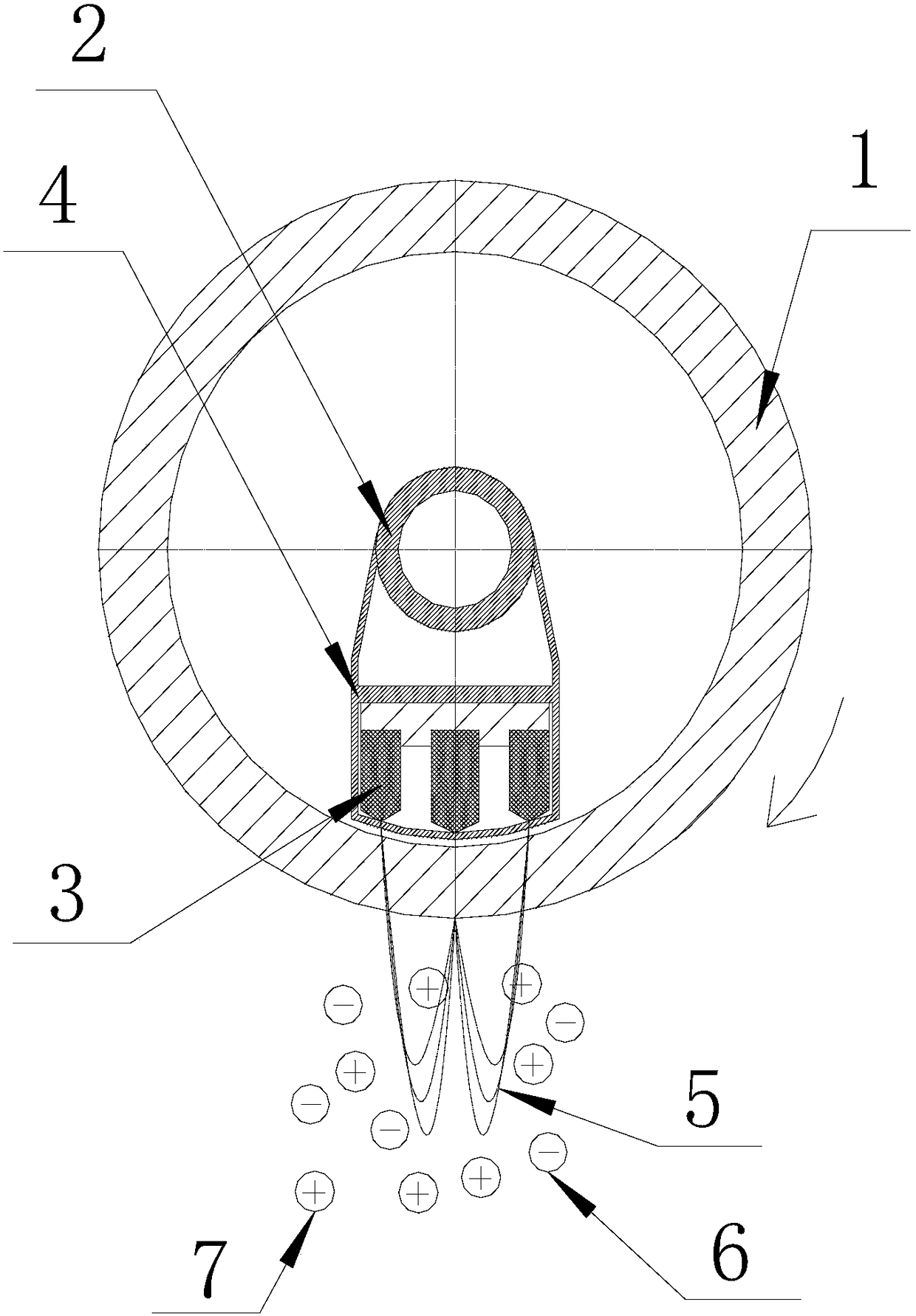

Rotary magnetron target and horizontal magnetron sputtering coating equipment

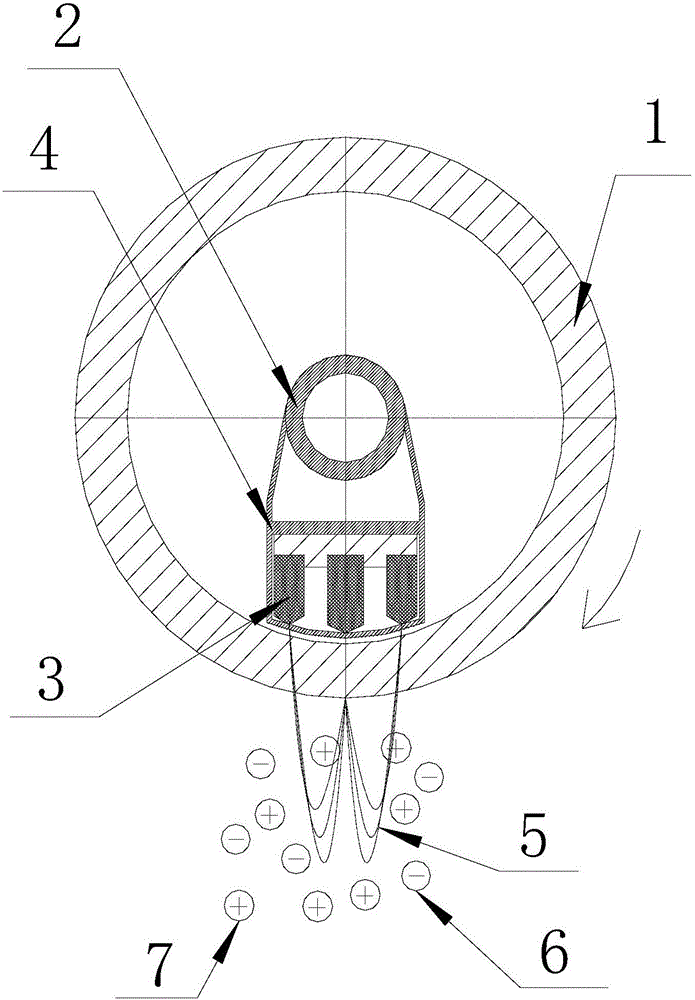

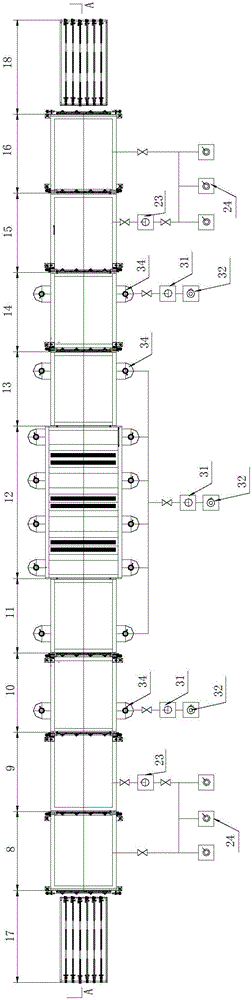

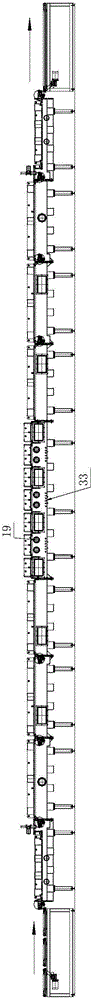

ActiveCN105908146AIncrease distribution densityIncrease the number of particlesVacuum evaporation coatingSputtering coatingSputteringMaterials science

The invention discloses a rotary magnetron target and horizontal magnetron sputtering coating equipment. The rotary magnetron target comprises a target, a magnetic core and a magnet, wherein the magnetic core is arranged at the middle part of the target, at least one magnet is arranged at the periphery of the magnetic core, and one end facing the target, of the magnet, is conical. The horizontal magnetron sputtering coating equipment comprises a front pre-pumping chamber, a front rough-pumping chamber, a front fine-pumping chamber, a front buffering chamber, a coating chamber, a rear buffering chamber, a rear fine-pumping chamber, a rear rough-pumping chamber and a rear pre-pumping chamber which are sequentially connected, wherein one or more coating chambers are provided, and one rotary magnetron target is arranged in each coating chamber, and located above a workpiece. According to the rotary magnetron target, the tail end of the magnet is designed to be a tip, thus the distribution density of magnetic force lines on the surface of the target is enhanced, and the number of the sputtered target particles can be increased, and then the coating efficiency of the surface of the workpiece is increased. The rotary magnetron target is applied to the horizontal magnetron sputtering coating equipment, thus the coating efficiency of the workpiece can be effectively increased, and the production cycle of a whole process line is shortened, and then the production efficiency is increased.

Owner:ZHAOQING KERUN VACUUM EQUIP

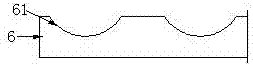

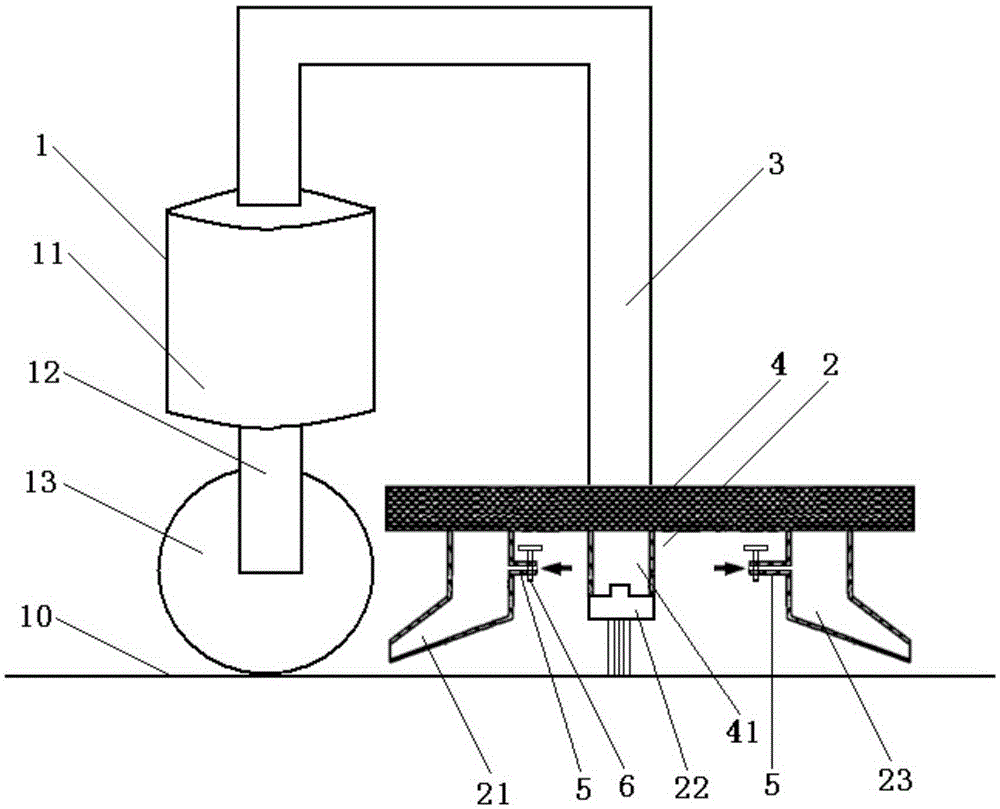

Glass cutting device

InactiveCN105236720AQuick vacuumReduce pollutionGlass severing apparatusMechanical engineeringEngineering

The invention discloses a glass cutting device, which includes a cutter knife body, a dust sucking device arranged in parallel therewith, and a bracket which connects the cutter knife body to the dust sucking device. The cutter knife body, the bracket and the dust sucking device are arranged in a cutting moving direction successively. The cutter knife body comprises: a cutting frame connected to one end of the bracket and a cutter knife wheel connected to the bottom of the cutting frame through a wheel pin. The dust sucking device includes a support board which is connected to the other end of the bracket, and a first dust sucking head which is disposed on the bottom surface of the support board and towards the cutter knife wheel. The first dust sucking head is connected to an external electric exhaust fan having a dust collection box through a dust suction soft pipe, wherein the electric exhaust fan is used for providing vacuum sucking force. The glass cutting device is compact in structure, is convenient to detach, is easy to produce, is safe and reliable and is strong in practicability. The glass cutting device can suck glass chips generated from the cutter knife wheel quickly and prevent the glass chips from being attached to surface of glass, thereby reducing pollution, and further can reduce the environment pollution in a dustless workshop due to the glass chips.

Owner:SUZHOU KAIDE MICRO ELECTRONICS CO LTD

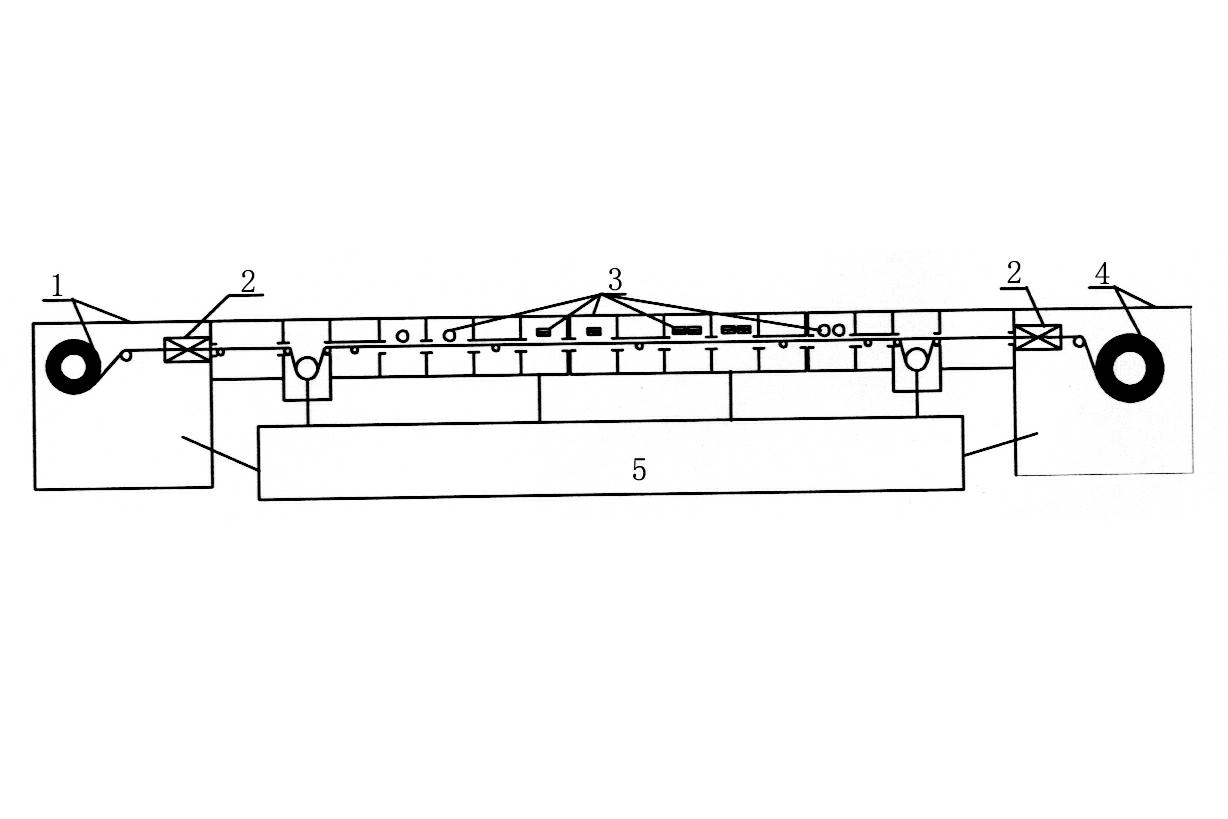

Roll-to-roll continuous vacuum coating production machine

InactiveCN102618839ALow costIncrease productivityVacuum evaporation coatingSputtering coatingManufacturing engineeringIndustrial engineering

The invention provides a roll-to-roll continuous vacuum coating production machine. The production machine is characterized by comprising a vacuum unrolling chamber, a production line main body and a vacuum rolling chamber, wherein the vacuum unrolling chamber is connected with the production line main body; the production line main body is connected with the vacuum rolling chamber; and a vacuum isolation valve is arranged between the vacuum unrolling chamber and the production line main body, and a vacuum isolation valve is arranged between the production line main body and the vacuum rolling chamber. The production machine well overcomes the defects of the prior art, greatly improves the production efficiency, enlarges the yield, reduces the cost, and is favorable for popularization and application.

Owner:WEIHAI JINBO NEW ENERGY TECH

Tunnel-type sputtering film-plating machine

PendingCN108425093ASmall duty cycleLarge amountVacuum evaporation coatingSputtering coatingRadio frequencyEngineering

The invention discloses a tunnel-type sputtering film-plating machine. The tunnel-type sputtering film-plating machine comprises a film plating cylinder, a radio-frequency ion source, a film plating hanger, and a hanger driving device; the film plating cylinder comprises an inner cylinder and an outer cylinder; a film plating chamber is formed between the inner cylinder and the outer cylinder; thetwo ends of the inner cylinder and the two ends of the outer cylinder are correspondingly connected in a sealed manner, so that the film plating chamber is sealed; the internal wall of the outer cylinder facing the film plating chamber, or the external wall of the inner cylinder facing the film plating chamber are provided with a plurality of film plating target grooves; the radio-frequency ion source is connected with the internal wall of the outer cylinder facing the film plating chamber, or the external wall of the inner cylinder facing the film plating chamber; the film plating hanger isdesigned to be annular, and is arranged in the film plating chamber; the inner cylinder is sleeved with the film plating hanger; the film plating hanger is connected with a plurality of hanging rods;the hanging rods are arranged in an annular manner in parallel; and the hanger driving device is connected with the film plating hanger, and is used for driving the film plating hanger to rotate. Thetunnel-type sputtering film-plating machine is capable of increasing production power and efficiency effectively.

Owner:VITALNK IND SHENZHEN +1

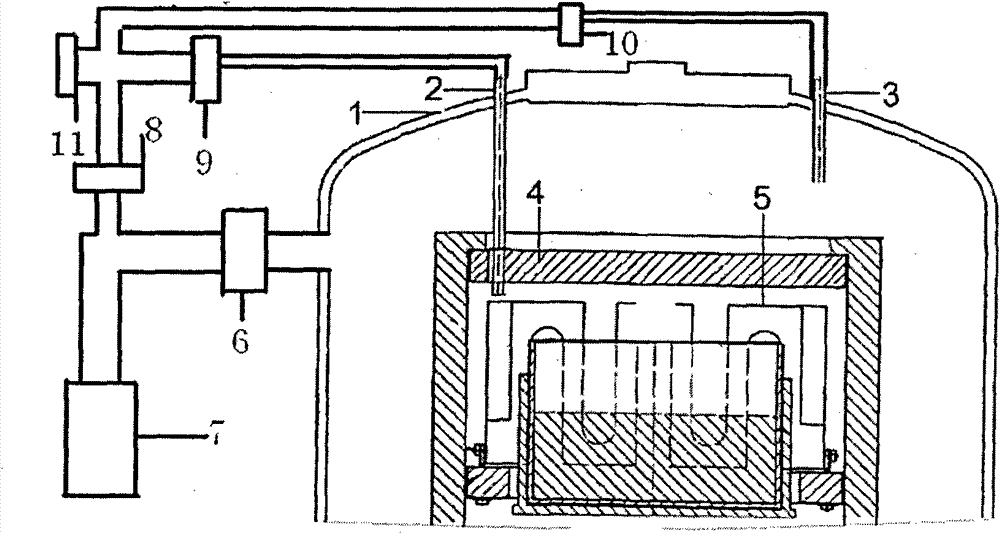

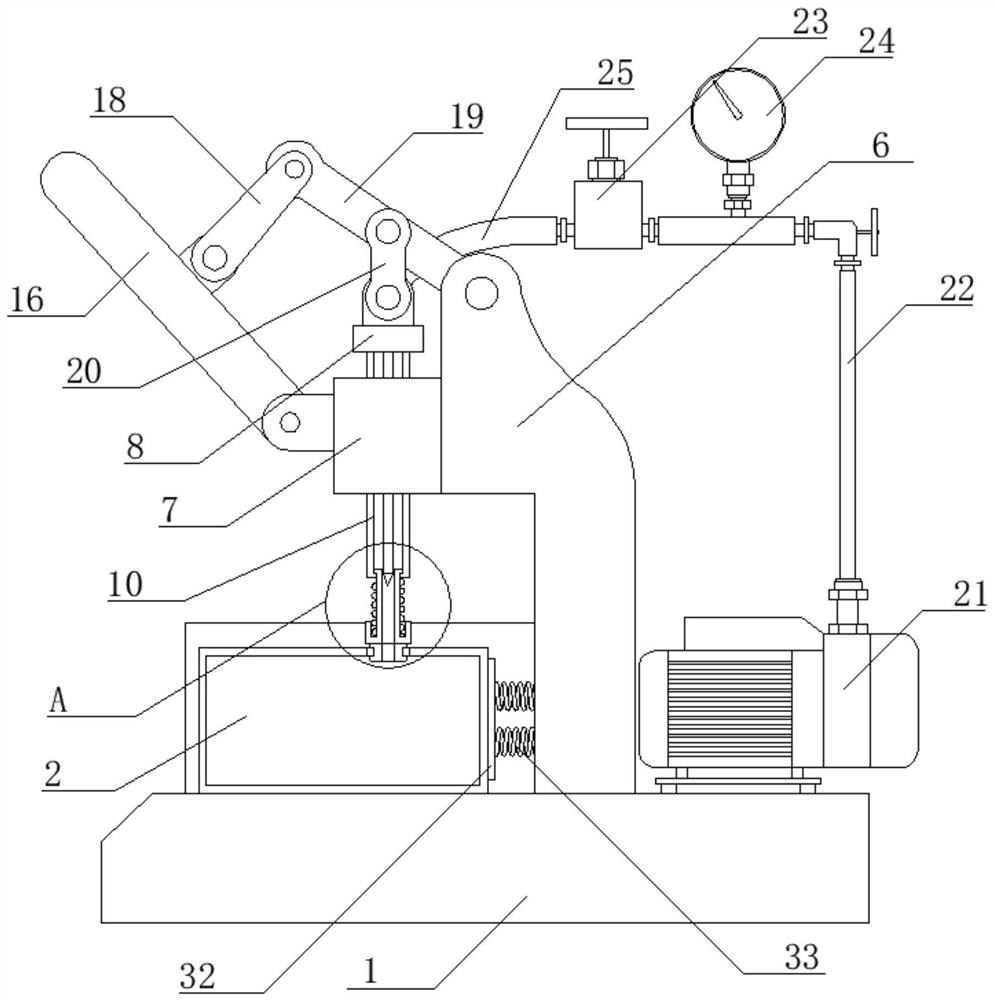

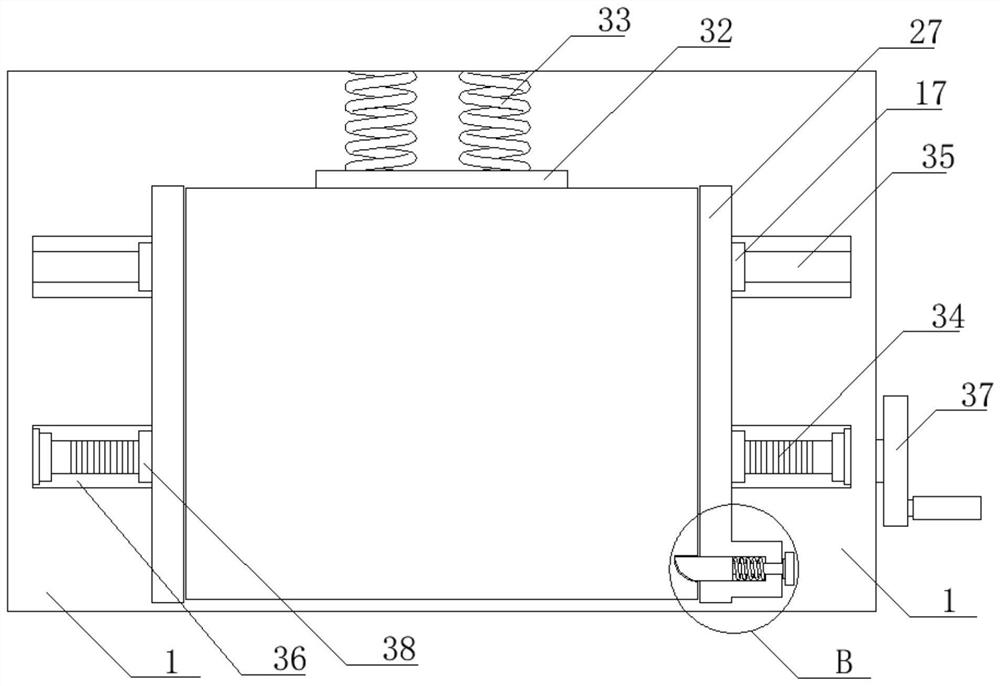

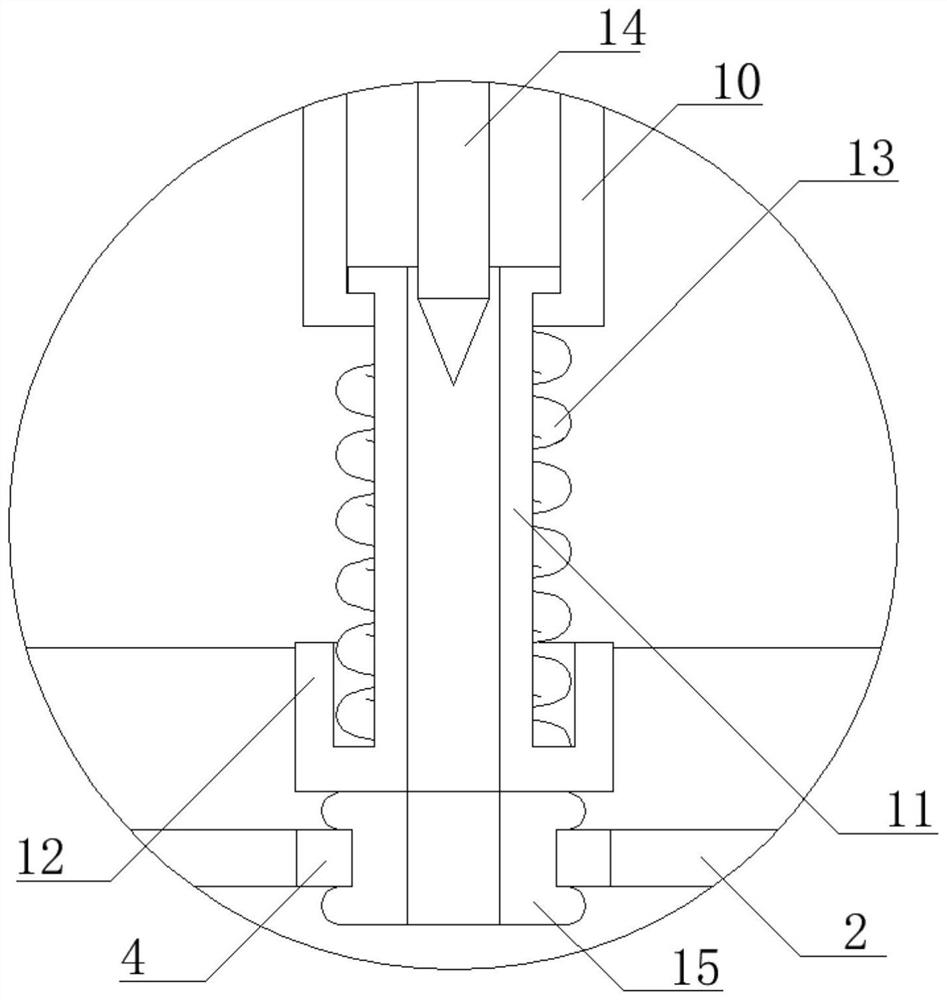

Vacuum saturation device for soil engineering centrifugal model test

The invention relates to a vacuum saturation device for a soil engineering centrifugal model test, and the device provided by the invention comprises a vacuum pump used for supplying power to the whole device, wherein one end of the vacuum pump is connected to a power control cabinet while the other end of the vacuum pump is connected to a water vapor separating jar which is used as the energy storage of the whole device; the water vapor separating jar is connected to the power control cabinet through an electric contact vacuum pressure gage; the vacuum pump is turned off and turned on in real time according to the higher and lower limit values of pressure preset by the electric contact vacuum pressure gage; a three-way valve is arranged on the top of the water vapor separating jar; a first vapor outlet of the three-way valve is connected to a saturation box for supplying a saturation space through a first pipeline; the saturation box is separated from the whole device; a second vapor outlet of the three-way valve is connected to an oil supply jar of a saturation system through a second pipeline; and the bottom of the oil supply jar is connected to a model box in the saturation box through a third pipeline. The vacuum saturation device is not limited by the volume of a saturation object, the saturation speed is controllable, and the saturation quality is ensured.

Owner:ZHEJIANG UNIV

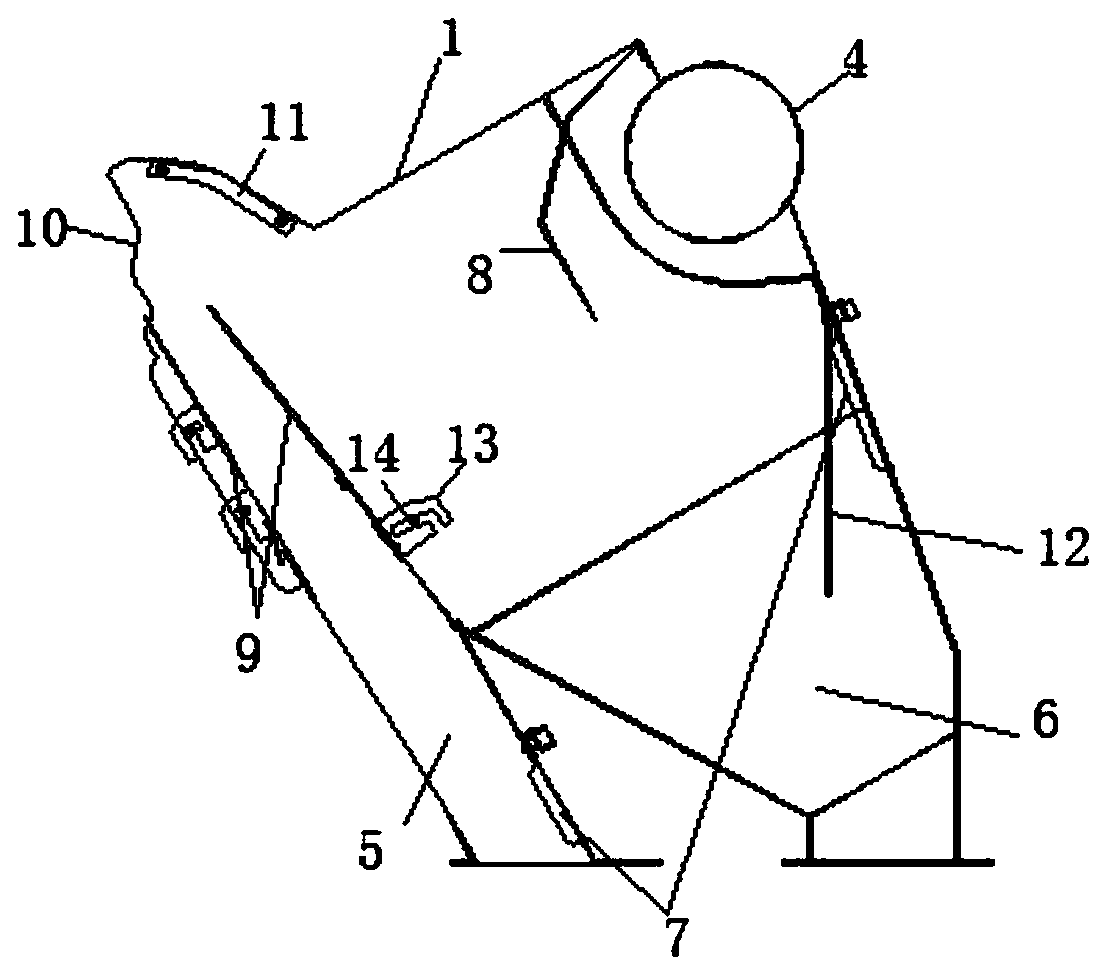

Tunnel drilling equipment by adopting gas drive

PendingCN111594204AReduce horizontal sizeEasy to transportTunnelsControl engineeringElectric machinery

The invention provides tunnel drilling equipment by adopting gas drive. A second motor and a first rotary platform are installed on a drilling supporting seat; a rotary device is installed at the bottom of the drilling supporting seat, and the rotary device can drive the drilling supporting seat to rotate; the rotary device is installed on a transmission mechanism, the transmission mechanism is connected with a first motor, and the rotary device is driven to move along a guide rail under the action of a controller controlling the first motor; the output end of the second motor is connected with the first rotary platform, the second motor drives a telescopic arm of the first rotary platform to swing at a first preset angle in the perpendicular direction of the length direction of the guiderail, and the first rotary platform is a swinging structure provided with the telescopic arm; a second rotary platform is installed at the output end of the telescopic arm; and a drill jig is connected to the output end of the second rotary platform, and the drill jig drives an impact drill on the drill jig to perform feeding motion through a pneumatic driving mechanism. Therefore, the tunnel drilling equipment by adopting the gas drive can improve the drilling efficiency.

Owner:ZHONGBEI UNIV

Multifunctional blackboard eraser

The invention relates to a multifunctional blackboard eraser which comprises a brush and a fixing support. The brush is connected with the fixing support, the fixing support is positioned inside the brush body, an engine is arranged inside the brush body, a vortex type fan blade and a fan blade are respectively connected with two sides of the engine through rotating shafts, a filter is arranged on the brush body and connected with the brush body through the fixing support, the vortex type fan blade is connected with the fixing support, dust boards are arranged on the brush body in the positions close to the two sides of the brush, a battery box and a switch are arranged inside the brush body, and the switch is respectively connected with the battery box and the engine through wires. Because the structure is adopted, the engine can drive the brush and the fan blades to rotate only by powering on the switch, thereby achieving the effect of quickly cleaning the blackboard and collecting the dust.

Owner:赵臣

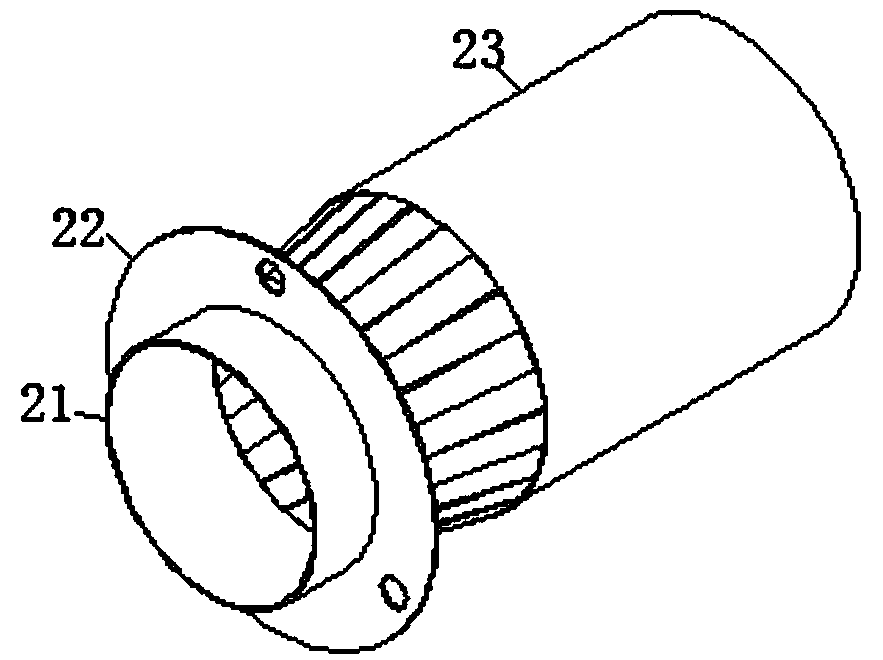

Finished product packaging equipment for marinated chicken foot making

InactiveCN110143314AReduce processing costsReduce labor costsPackaging by pressurising/gasifyingWrapper twisting/gatheringEngineeringHydraulic cylinder

The invention relates to the technical field of marinated chicken foot making, and discloses finished product packaging equipment for marinated chicken foot making. The finished product packaging equipment comprises a bottom plate. The side face of the top of the bottom plate is welded to the bottom of a fixing plate, the side face of the fixing plate is welded to a connecting frame, the connecting frame is fixedly connected to the outer surface of a guide pipe, a positioning and air exhausting part is connected to the guide pipe, a packaging bag is connected to the outer surface of the positioning and air exhausting part, the bottom of the guide pipe is inserted into an inner cavity of the packaging bag, one end of a hydraulic cylinder penetrates through the side face of the fixing plateto be fixedly connected with the fixing plate, and the side, close to the packaging bag, of the hydraulic cylinder is fixedly connected with an edge sealing part. The packaging bag is positioned through the positioning and air exhausting part, the packaging bag is conveniently filled through the guide pipe, air in the packaging bag can be exhausted through the positioning and air exhausting part between filling and edge sealing, the packaging bag is edge-sealed through the edge sealing part, and the purpose that marinated chicken feet are filled, vacuumized and edge-sealed simultaneously through the equipment is achieved.

Owner:安徽乐川食品有限公司

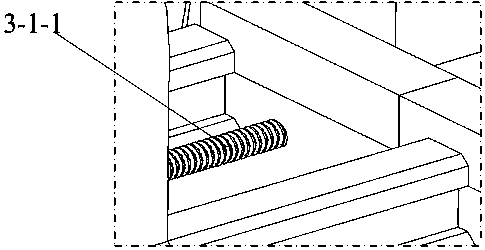

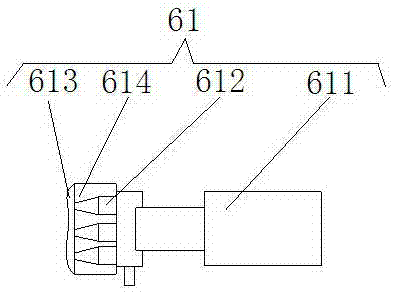

Adjustable jig used for electronic product casing machining

The invention relates to the technical field of electronic products and discloses an adjustable jig used for electronic product casing machining. The jig comprises a jig base. A fixing seat is arranged at the top of the jig base. The top of the jig base is fixedly connected with a base frame. A cylinder mechanism is arranged at the top of the base frame. The left and right sides of the jig base are fixedly connected with fixing barrels correspondingly. The front faces of the fixing barrels are in threaded connection with set screws. Supporting columns are inserted into the fixing barrels correspondingly. Threaded holes are formed in the front faces of the supporting columns correspondingly. The supporting columns are fixed to the corresponding fixing barrels through the threaded holes andthe set screws. The tops of the supporting columns are fixedly connected with top blocks correspondingly. The bottoms of the supporting columns are fixedly connected with bottom blocks correspondingly. The exterior of the jig base is fixedly connected with an electric push rod. By means of the adjustable jig used for electronic product casing machining, the purposes that adjusting is convenient and dust can be removed fast are achieved.

Owner:陕西安易信息科技有限公司

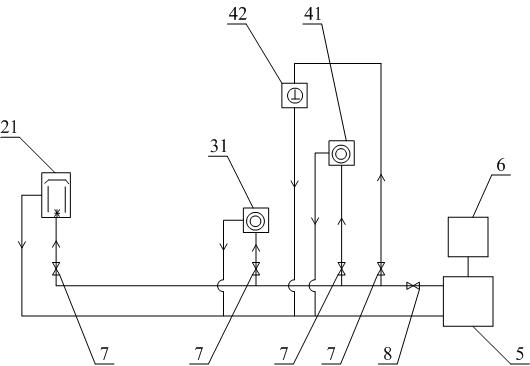

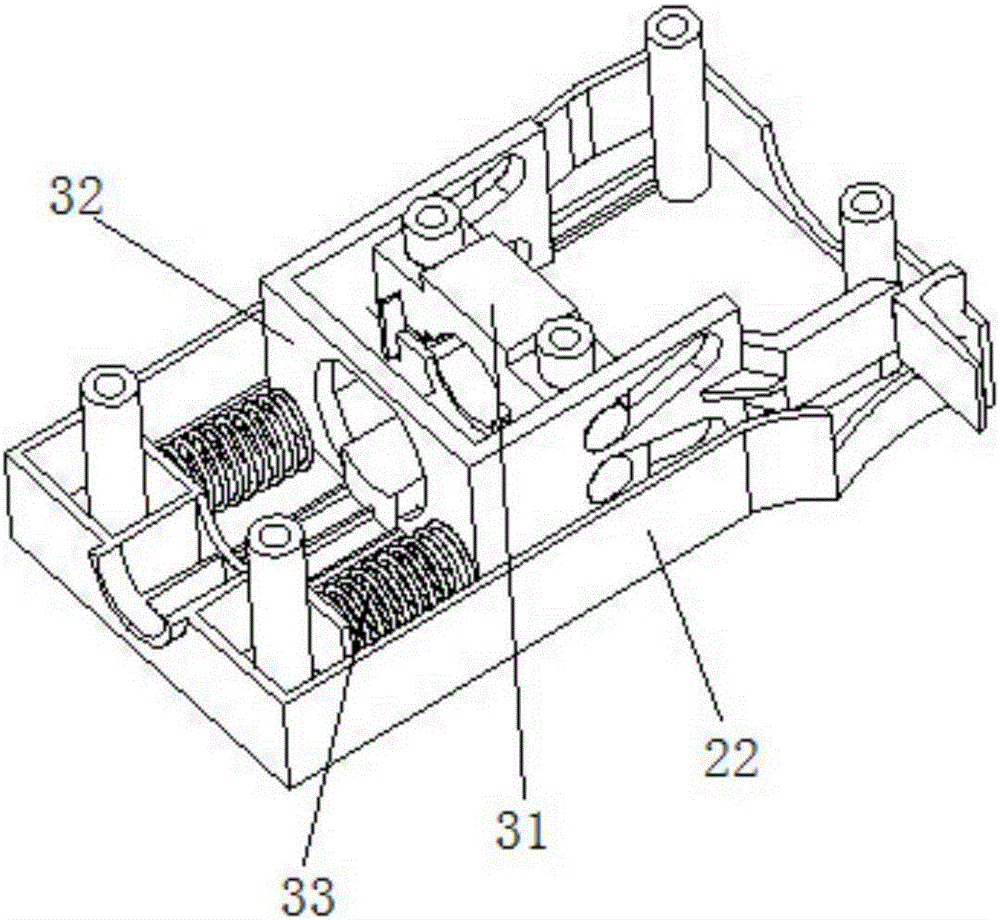

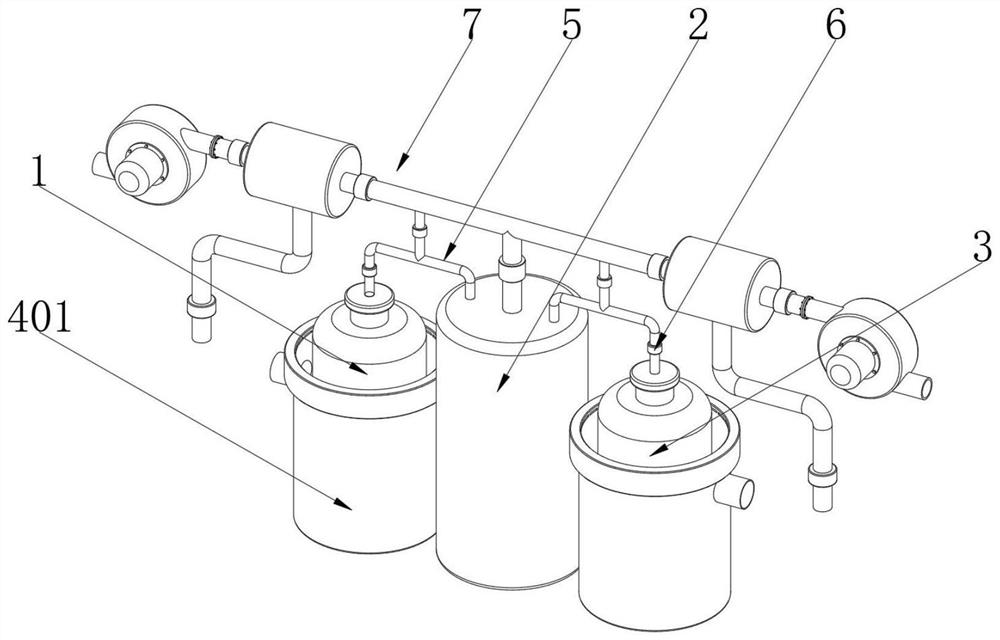

Rapid vacuumizing system and control method and device thereof

InactiveCN111946602AQuick vacuumFlexible vacuumPump controlPump installationsVacuum pumpingThermodynamics

The invention discloses a rapid vacuumizing system and a control method and device thereof. The rapid vacuumizing system comprises a vacuum pumping system and a water circulation system. The vacuum pumping system comprises a pumped container, a high vacuum air path, a low vacuum air path and a middle vacuum air path. A high vacuum pump of the high vacuum air path, a first low vacuum pump of the low vacuum air path, a second low vacuum pump of the middle vacuum air path and a middle vacuum pump jointly form the rapid vacuumizing system. According to the technical scheme provided by the invention, the vacuum container is rapidly vacuumized through the high vacuum air path, the low vacuum air path and the middle vacuum air path, and vacuum containers with different levels of vacuum requirements are rapidly vacuumized, so that rapid and flexible vacuumizing with low, medium and high vacuum degree requirements is realized. The control operation is stable, the vacuum degree requirement of the vacuum container is effectively met, the heat insulation effect of the vacuum container is guaranteed, and the material loss in the vacuum container is reduced.

Owner:BAOWU CLEAN ENERGY EZHOU CO LTD

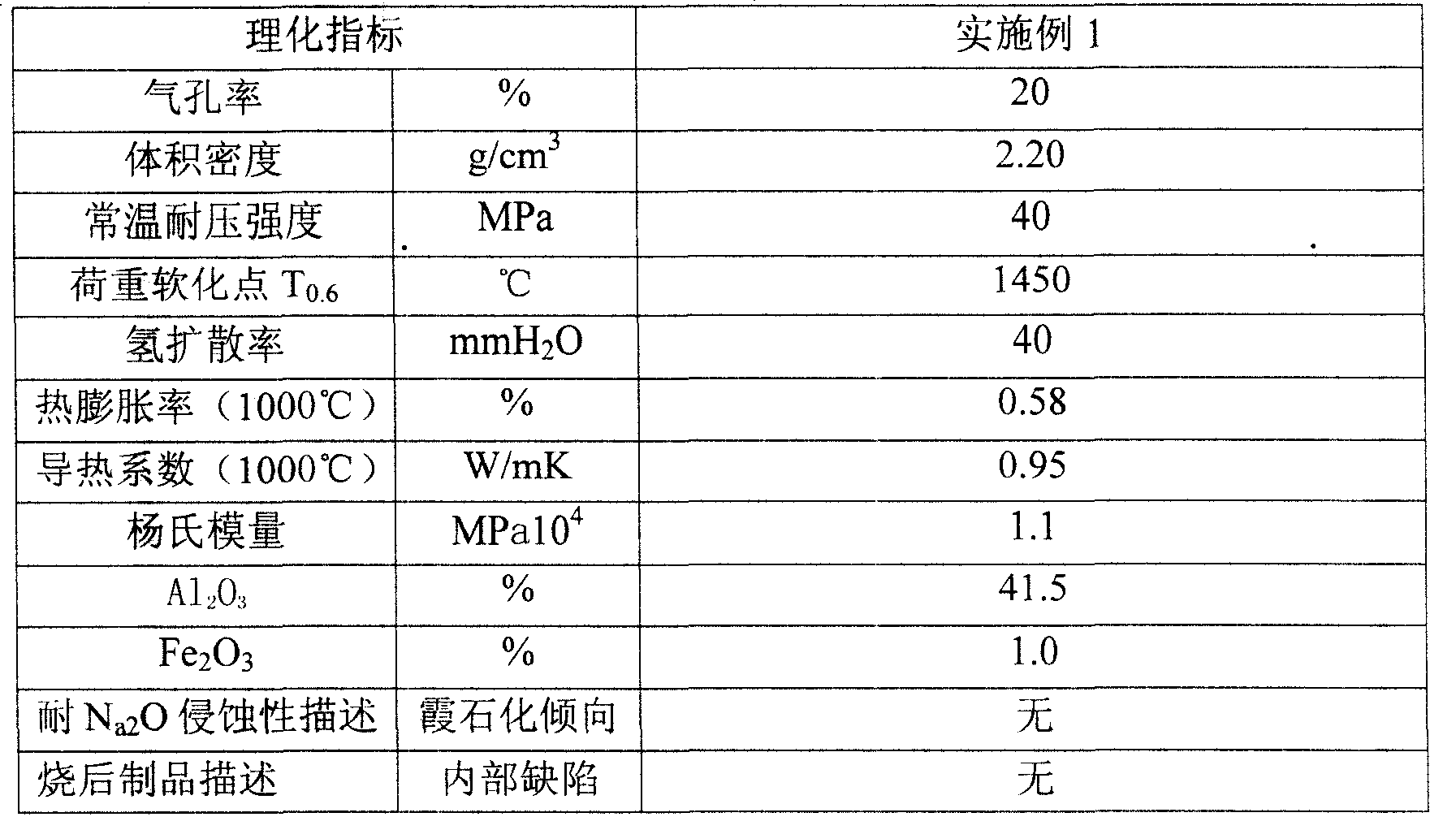

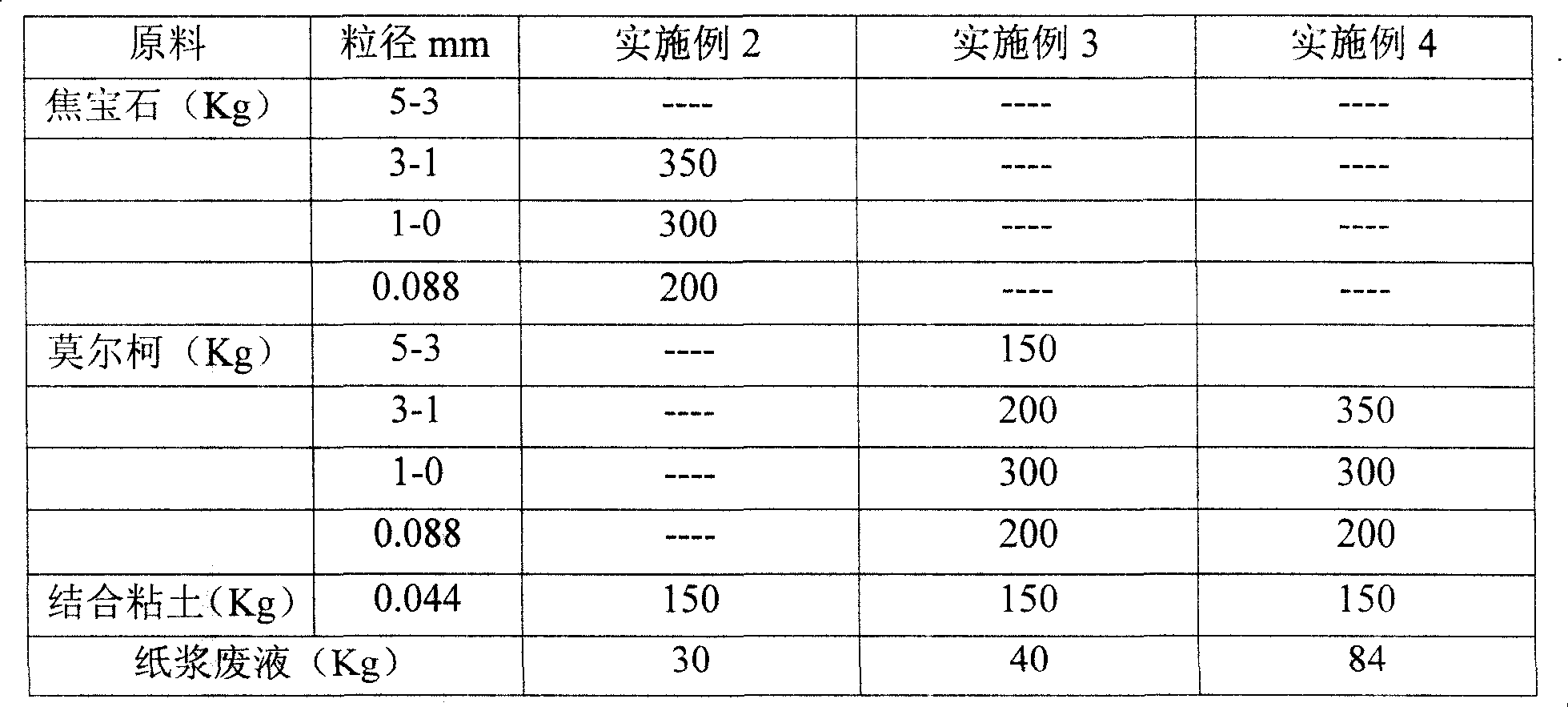

Manufacture method of tin slot bottom brick

InactiveCN1927557AImprove high temperature strengthResistant to Na <sub>2<好</sub> Ceramic shaping apparatusSold ingredients supply apparatusBrickRefractory

A method for making tin bottom brick, is belongs to fireproof material technology areas. It includes batching, mixing, vibration and compression for molding, conservation and drying, heat treating and rubbing. It is characterized by after the mixed pug are poured into the model, vacuumpumping first then vibration and compression for molding. There are 3%-5%(weight percentages)paper pulp barren liquor in blending. The invention adopts the method of vacuumpumping first and then vibration and compression to solving the problems that the residual air leads to lamination crack when producing thicker brick.

Owner:ZIBO GT INDAL CERAMICS

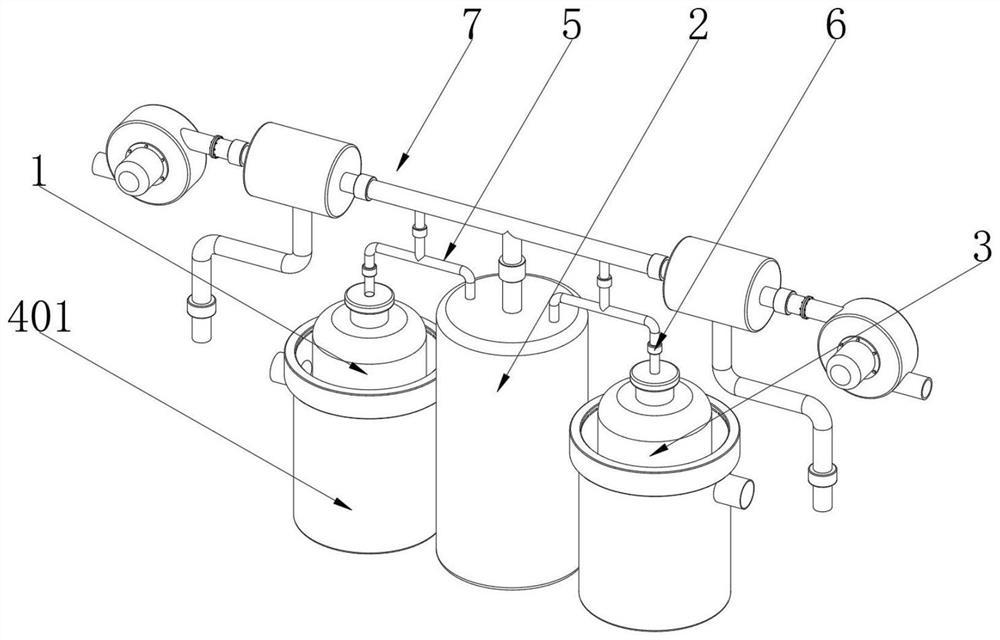

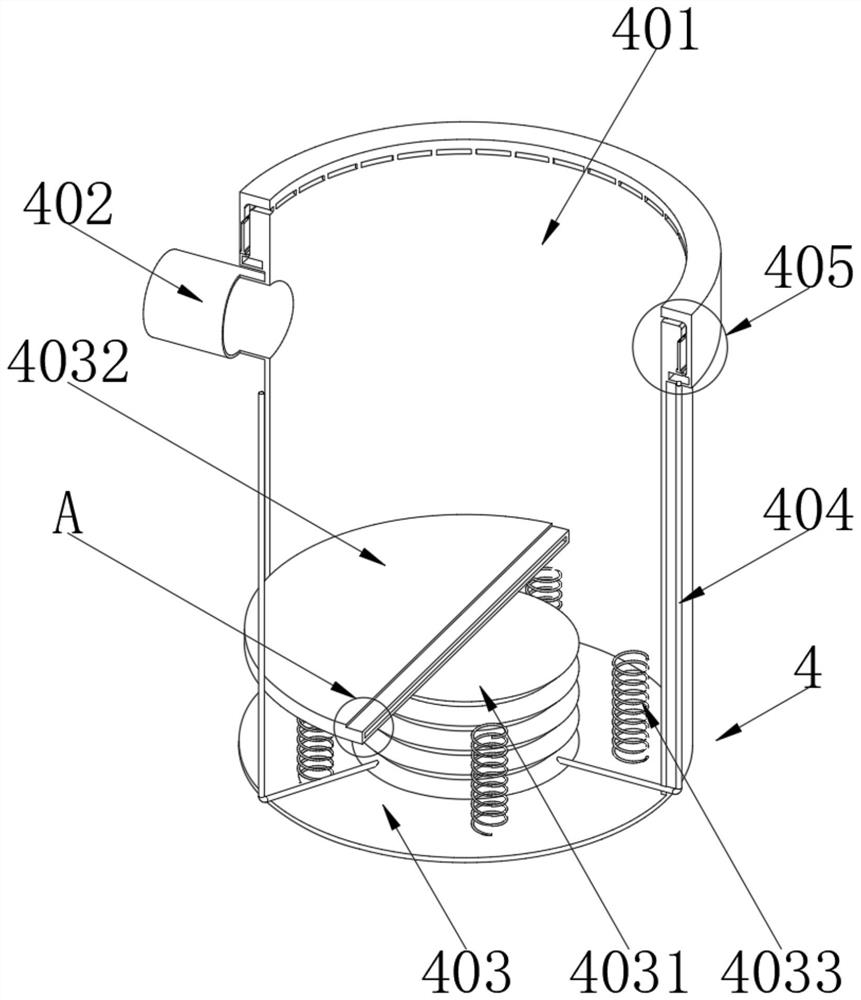

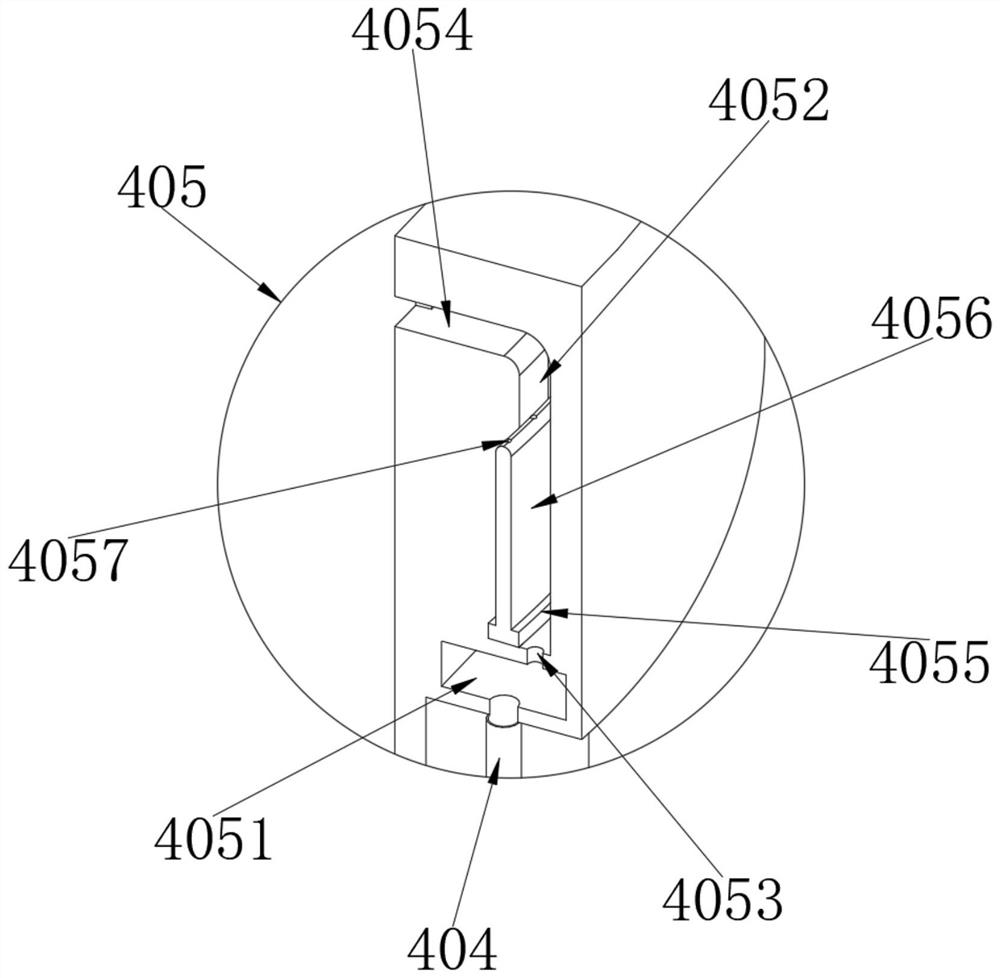

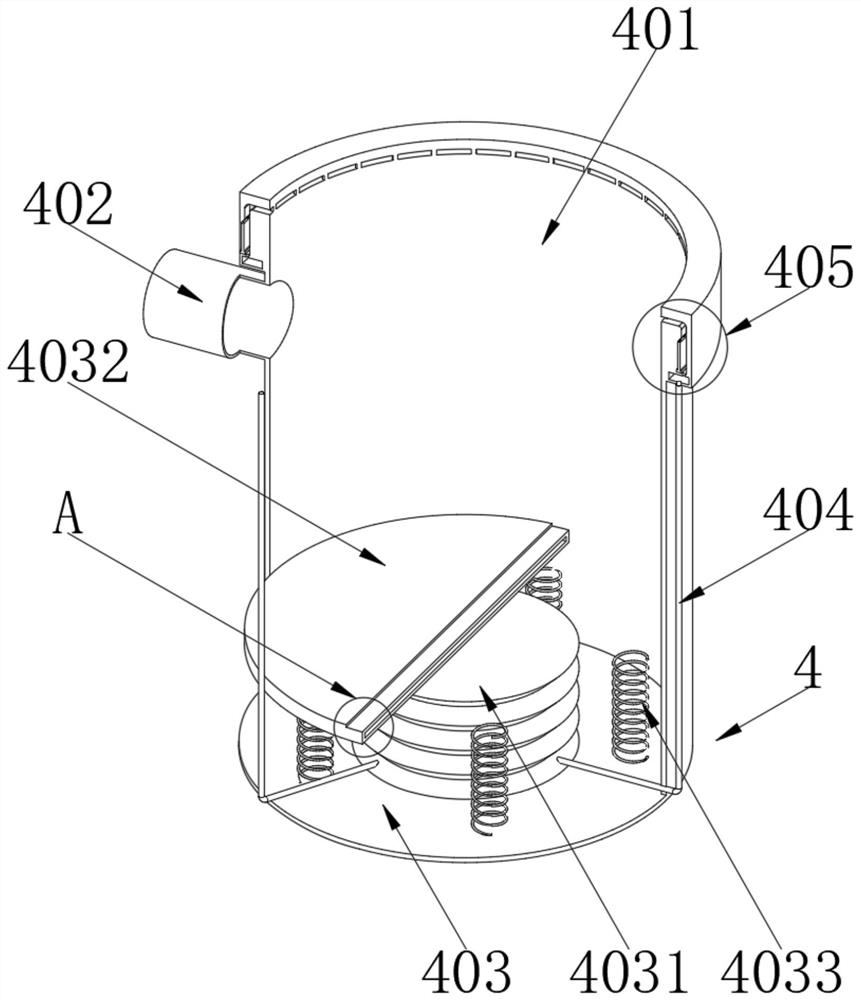

Liquefied gas grading purification device

ActiveCN113041641APlace stableConducive to liquefactionNon-rotating vibration suppressionVapor condensationProcess engineeringRefrigeration

The invention discloses a liquefied gas graded purification device, and belongs to the technical field of gas purification. The device comprises a purification tank, wherein a raw material tank is arranged on one side of the purification tank, a liquefaction tank is arranged on the other side of the purification tank, the raw material tank and the liquefaction tank are both cooled through a cooling device, the raw material tank is connected with the purification tank through a first connecting pipe, the liquidation tank is connected with the purification tank through a first connecting pipe, the top ends of the raw material tank, and the purification tank and the liquidation tank are all provided with vacuumizing devices. According to the invention, the placed raw material tank and liquidation tank can extrude a supporting corrugated pipe, so that extruded gas is conveyed into a communicating cavity through a gas conveying hose; a sealing plate is pushed by gas to slide in a containing groove and a limiting groove, and slides out of the limiting groove under the pushing action of the gas so as to seal a gap between a cooling barrel and the raw material tank and a gap between the cooling barrel and the liquidation tank, so that the refrigeration effect of liquid nitrogen is better, and the liquefying and purifying effects of the gas are better.

Owner:无锡恒大电子科技有限公司

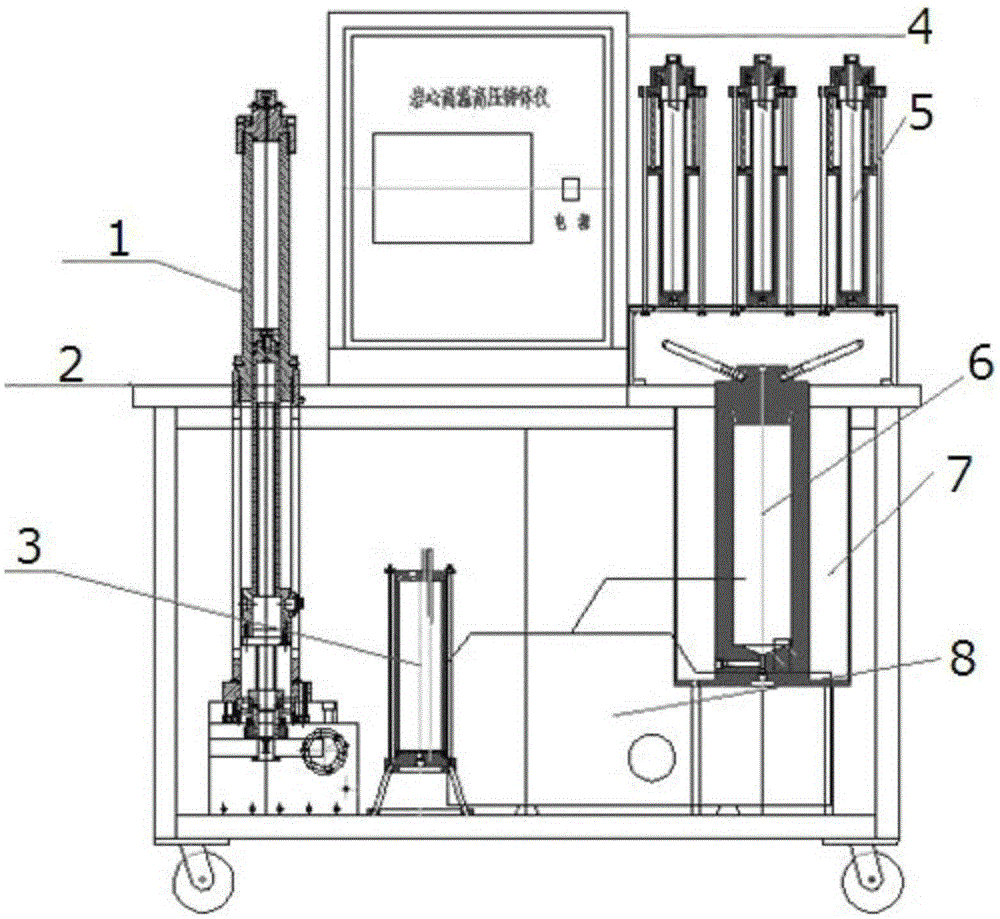

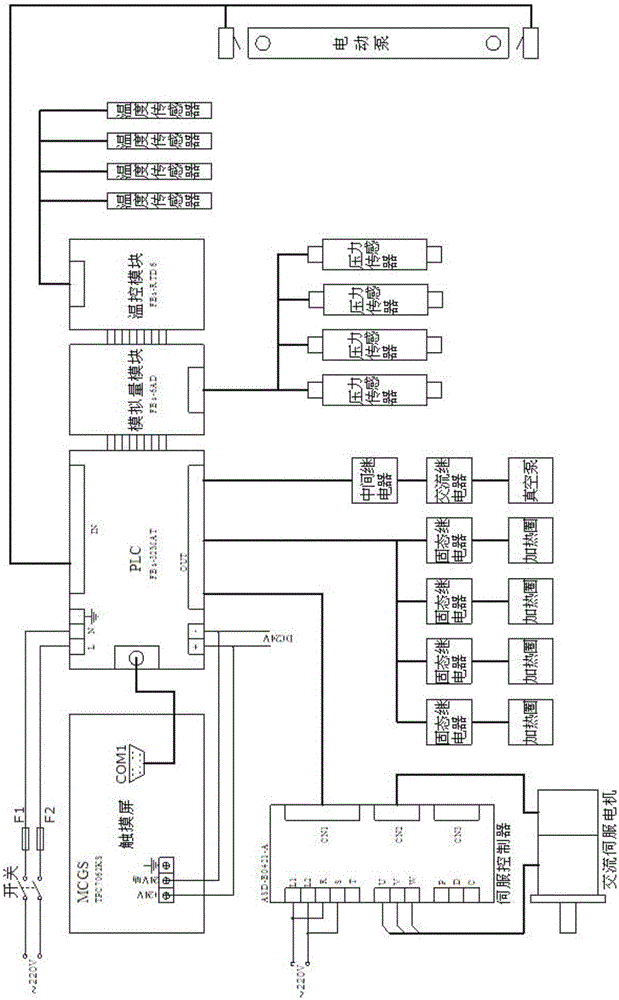

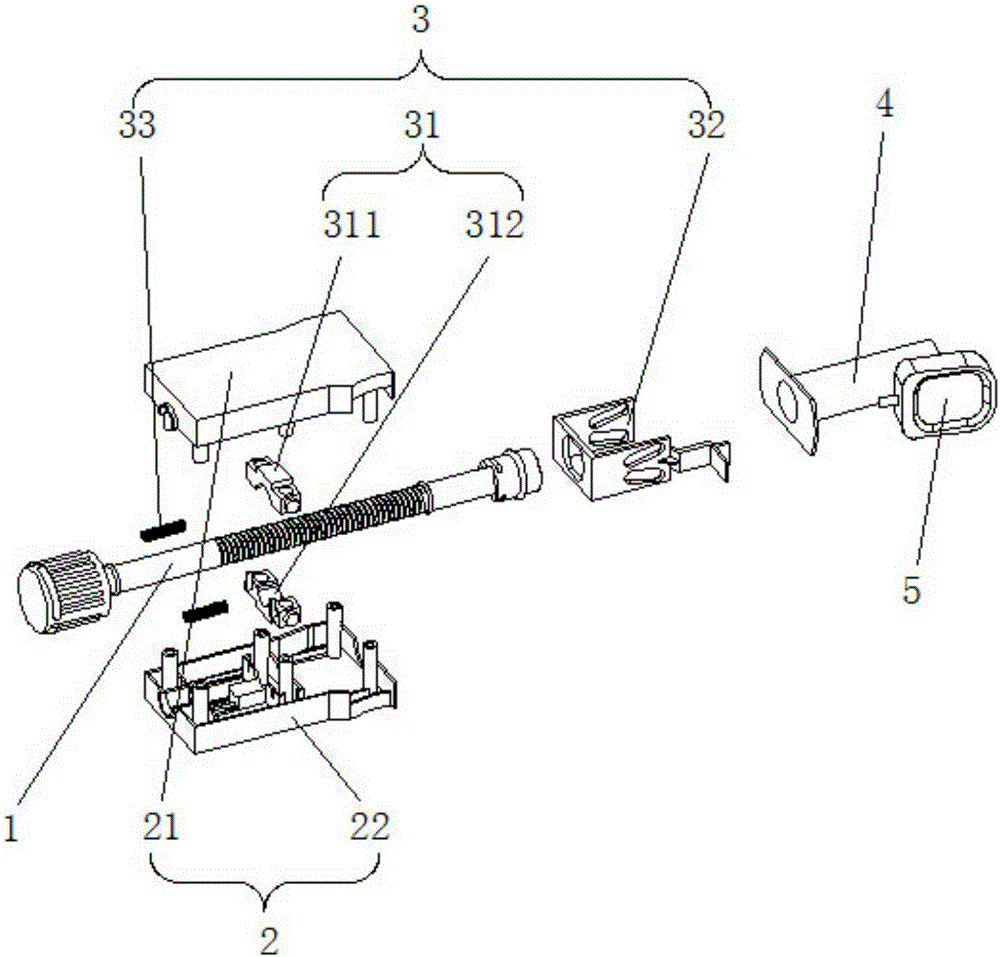

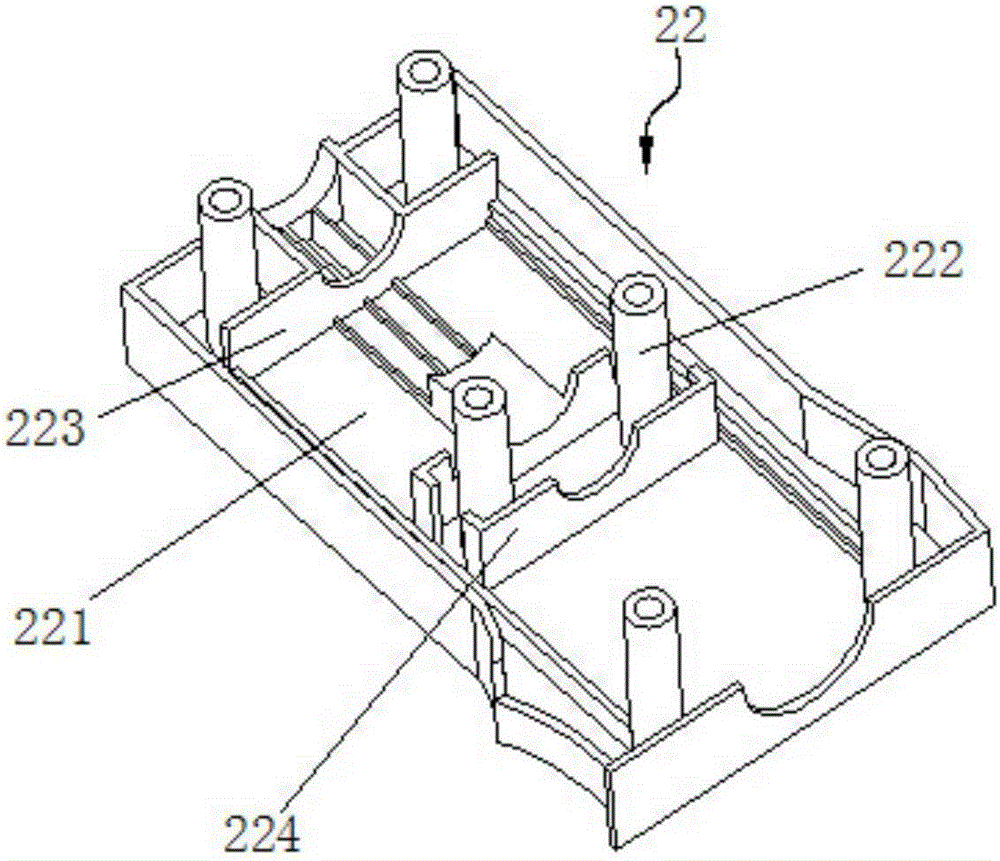

Core high temperature and high pressure casting instrument

ActiveCN104020303BEasy to take outImprove efficiencyPreparing sample for investigationProgramme control in sequence/logic controllersEngineeringHigh pressure

The invention relates to a core high-temperature and high-pressure casting machine which comprises a displacement pump, a rock sample container, a sample container, a vacuum pump and a PLC (Programmable Logic Controller) control system, wherein the PLC control system comprises a PLC, a touch screen, a motor controller and an analog quantity module; the touch screen, the motor controller and the analog quantity module are connected by the PLC; the analog quantity module is connected with a pressure sensor and a temperature control module which is connected with a temperature sensor; the PLC is in control connection with a heating ring and the vacuum pump; the pressure sensor is connected with the displacement pump which is driven by a motor controlled by the motor controller; the temperature sensor and the heating ring are arranged on the circumferential outer wall of the rock sample container. The core high-temperature and high-pressure casting machine can be used for overcoming the defects of low working efficiency, low ultimate pressure and the like of a traditional casting machine and has the advantages of easiness in operation, strong practicability, high efficiency, high injection pressure, rapidity in vacuumization and the like, and the whole flow is intelligentized by using the core high-temperature and high-pressure casting machine.

Owner:CHINA PETROLEUM & CHEM CORP +1

Medical pressurizing device

InactiveCN105233395AExquisite structure designStable structureSurgeryDilatorsDisplay deviceBiomedical engineering

The invention relates to a medical pressurizing device. The medical pressurizing device comprises a piston device, a holding shell, a self-lock release device and a tube, wherein the piston device comprises a pushing rod and a piston head; the self-lock release device is arranged in the holding shell; the piston head is connected to the front end of the pushing rod; the front end of the pushing rod penetrates into the holding shell and the self-lock release device in the holding shell and stretches into the tube; the piston head is in tight fit with the inner wall of the tube; the tube is fixedly connected to the holding shell; the pushing rod is matched with the self-lock release device; a testing connecting end communicated with the inner side of the tube is arranged on the tube; a digital pressure display device is fixedly arranged on the testing connecting end. The medical pressurizing device has the beneficial effects that the design is smart, the structure is exquisite, the operation is convenient and rapid, the adjustment is visual, the control is precise, and the rapid decompression can be achieved.

Owner:江苏爱芮斯医疗科技有限责任公司

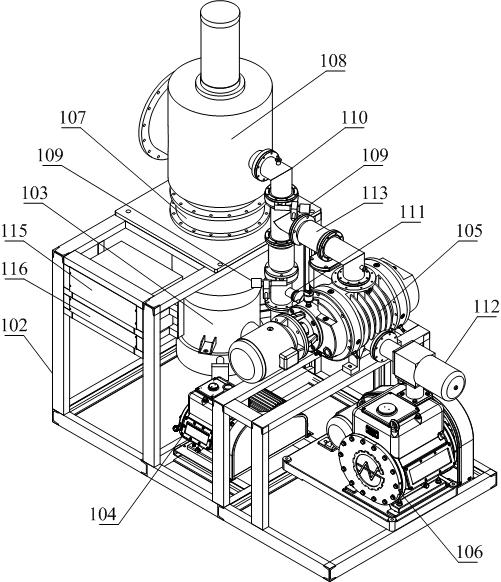

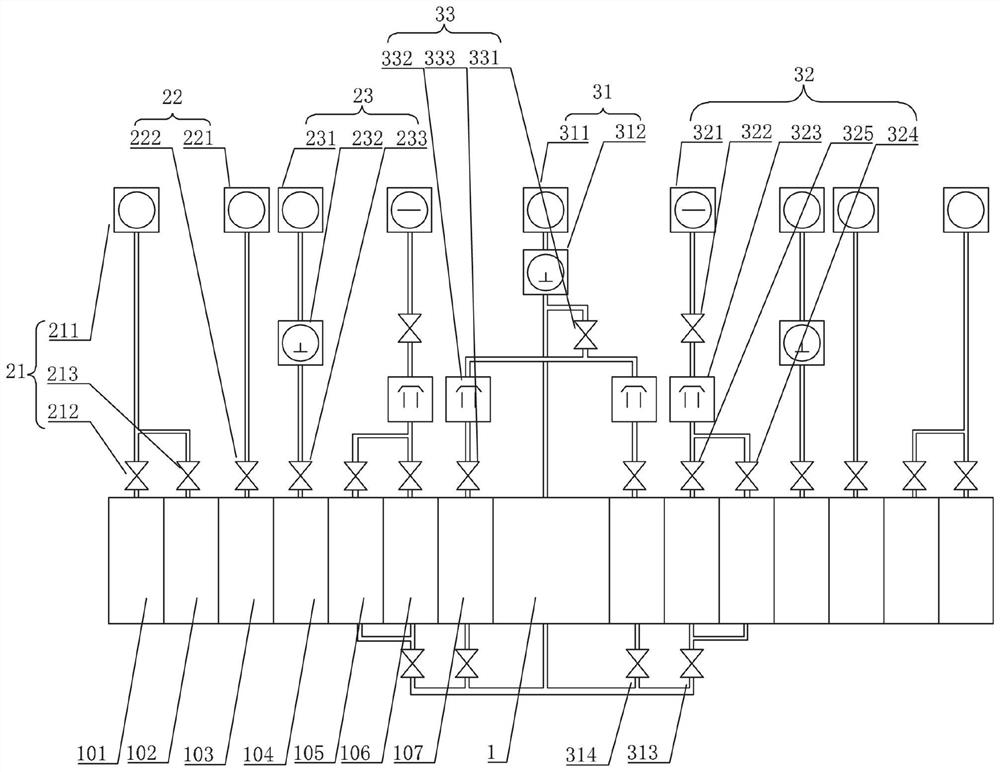

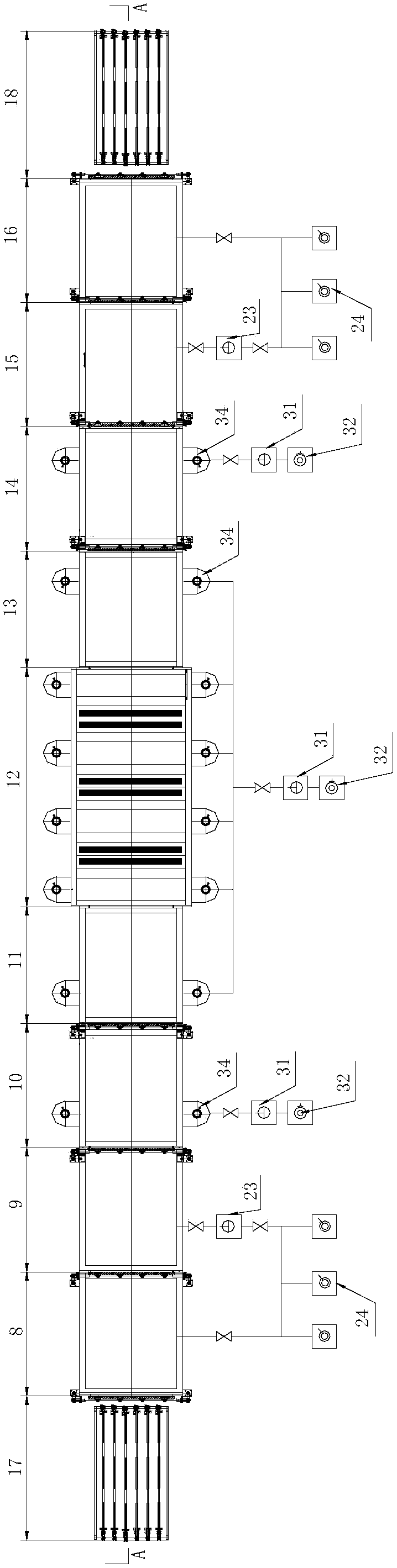

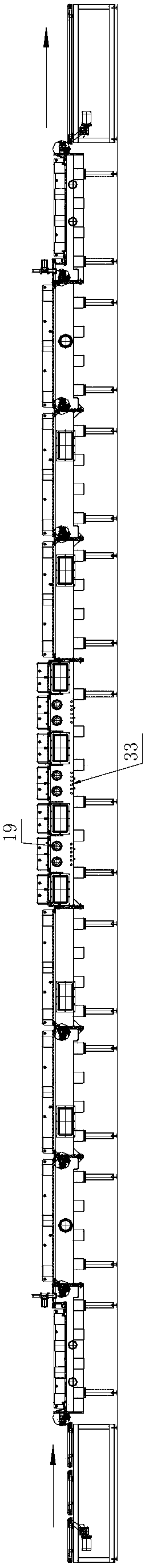

Vacuum-pumping control system and control method for roll-to-roll coating machine

PendingCN114525490AQuick vacuumStable vacuumVacuum evaporation coatingSputtering coatingControl systemPumping vacuum

The invention relates to the field of vacuum coating, and discloses a vacuum-pumping control system of a roll-to-roll coating machine, which comprises a controller, and two primary vacuum-pumping units and a deep vacuum-pumping unit which are connected with the controller, the two primary vacuumizing units respectively act on a first chamber, a second chamber, a third chamber and a fourth chamber on one side of the coating chamber, and the deep vacuumizing unit acts on a fifth chamber, a sixth chamber and a seventh chamber on the two sides of the coating chamber. According to the vacuum coating machine, rapid vacuumizing of the vacuum coating machine can be achieved, and the vacuum degree in the coating chamber meets the working requirement; in addition, the vacuum degree in the multiple transition cavities can be gradually increased from the two sides to the middle, the requirement and pressure for a vacuum pump are reduced, the requirement and pressure for sealing structures on the two sides are reduced, and energy consumption is reduced; and meanwhile, the high vacuum degree of the coating chamber is maintained through the high vacuum degree of the chambers on the two sides, so that the high vacuum degree in the coating chamber is more stable, and the coating quality and efficiency are improved.

Owner:CHONGQING 2D MATERIALS INST OF CHINA

Evacuating device of temperature thermocouple casing of photovoltaic polycrystalline silicon ingot casting furnace

InactiveCN101942697BQuick vacuumFind quicklyPolycrystalline material growthSingle crystal growth detailsTemperature controlExhaust valve

The invention relates to an evacuating device of a temperature thermocouple casing of a photovoltaic polycrystalline silicon ingot casting furnace, belonging to the technical field of evacuating automation of the photovoltaic polycrystalline silicon ingot casting furnace and comprising a temperature-controlling temperature thermocouple casing, an over-temperature protection temperature thermocouple casing, a vacuum pump set, a casing evacuating valve, a temperature-controlling temperature thermocouple hand-operated valve, an over-temperature protection temperature thermocouple hand-operated valve, an evacuating valve and a vent valve, wherein the temperature-controlling temperature thermocouple casing, the over-temperature protection temperature thermocouple casing and the vacuum pump setare communicated by utilizing the casing evacuating valve through a vacuum pipeline; a photovoltaic polycrystalline silicon ingot casting furnace cavity is communicated with the vacuum pump set by utilizing the evacuating valve through the vacuum pipeline; the vent valve is connected on the vacuum pipeline; the top of the furnace body is fixed on the upper end of the temperature-controlling temperature thermocouple casing, and the lower end of the temperature-controlling temperature thermocouple casing is inserted into a heat insulation cover of a heater through a heat insulation board; and the over-temperature protection temperature thermocouple casing is fixed on the furnace body and inserted into the furnace cavity. The invention can ensure that the evacuating speed of the integral equipment is enhanced; leak points can be quickly found; the ingot casting period is shortened; and the ingot casting quality is enhanced.

Owner:TSINGHUA UNIV +2

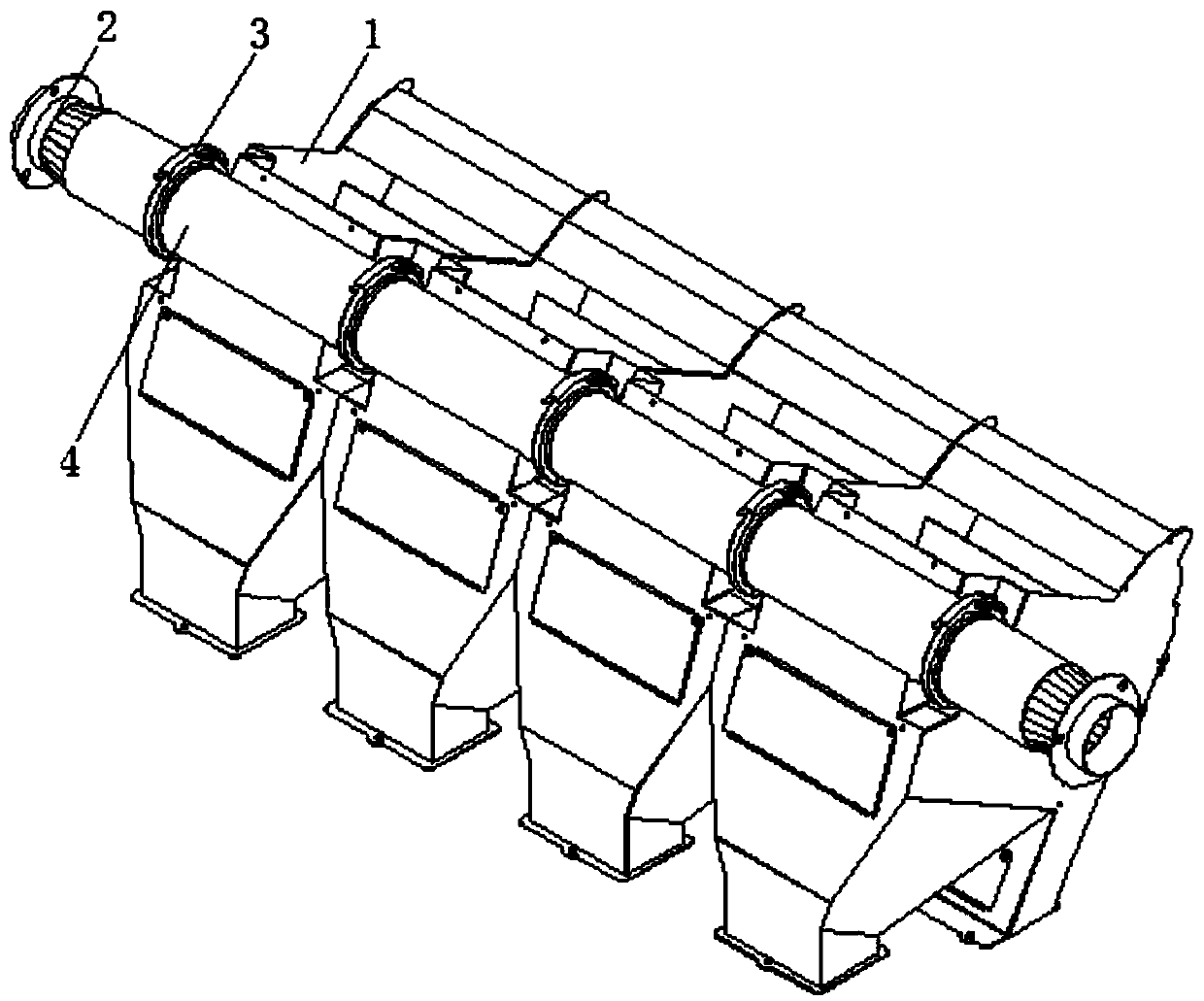

Rotary magnetron target and horizontal magnetron sputtering coating equipment

ActiveCN105908146BIncrease distribution densityIncrease the number of particlesVacuum evaporation coatingSputtering coatingSputteringMaterials science

The invention discloses a rotary magnetron target and horizontal magnetron sputtering coating equipment. The rotary magnetron target comprises a target, a magnetic core and a magnet, wherein the magnetic core is arranged at the middle part of the target, at least one magnet is arranged at the periphery of the magnetic core, and one end facing the target, of the magnet, is conical. The horizontal magnetron sputtering coating equipment comprises a front pre-pumping chamber, a front rough-pumping chamber, a front fine-pumping chamber, a front buffering chamber, a coating chamber, a rear buffering chamber, a rear fine-pumping chamber, a rear rough-pumping chamber and a rear pre-pumping chamber which are sequentially connected, wherein one or more coating chambers are provided, and one rotary magnetron target is arranged in each coating chamber, and located above a workpiece. According to the rotary magnetron target, the tail end of the magnet is designed to be a tip, thus the distribution density of magnetic force lines on the surface of the target is enhanced, and the number of the sputtered target particles can be increased, and then the coating efficiency of the surface of the workpiece is increased. The rotary magnetron target is applied to the horizontal magnetron sputtering coating equipment, thus the coating efficiency of the workpiece can be effectively increased, and the production cycle of a whole process line is shortened, and then the production efficiency is increased.

Owner:ZHAOQING KERUN VACUUM EQUIP

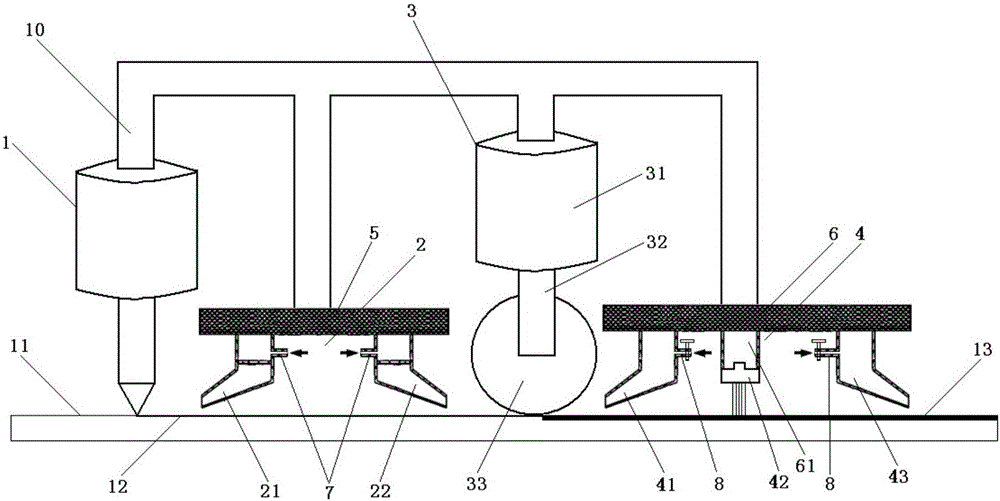

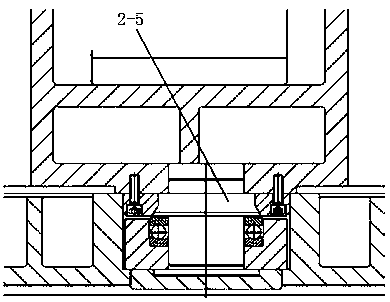

Vacuumizing and filling device and method for medical instrument

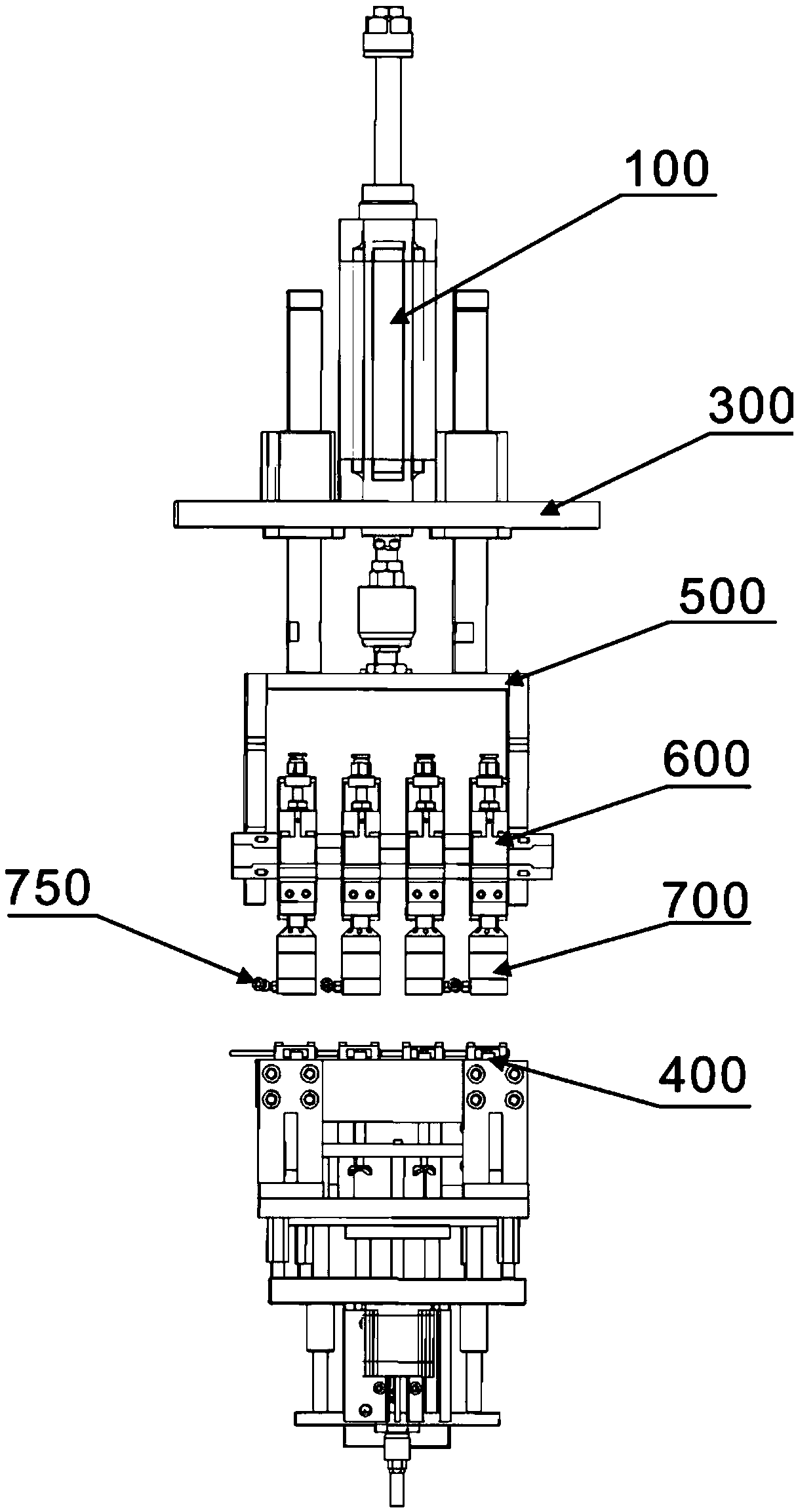

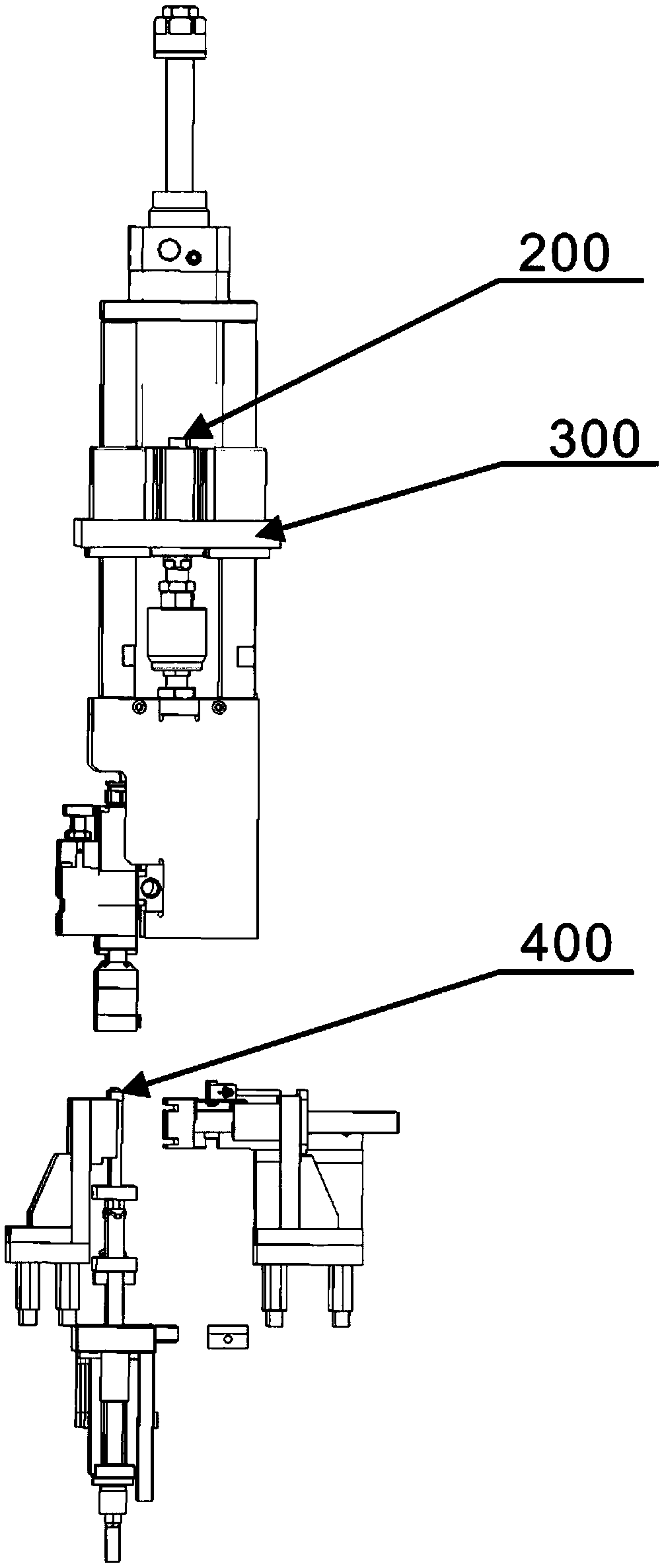

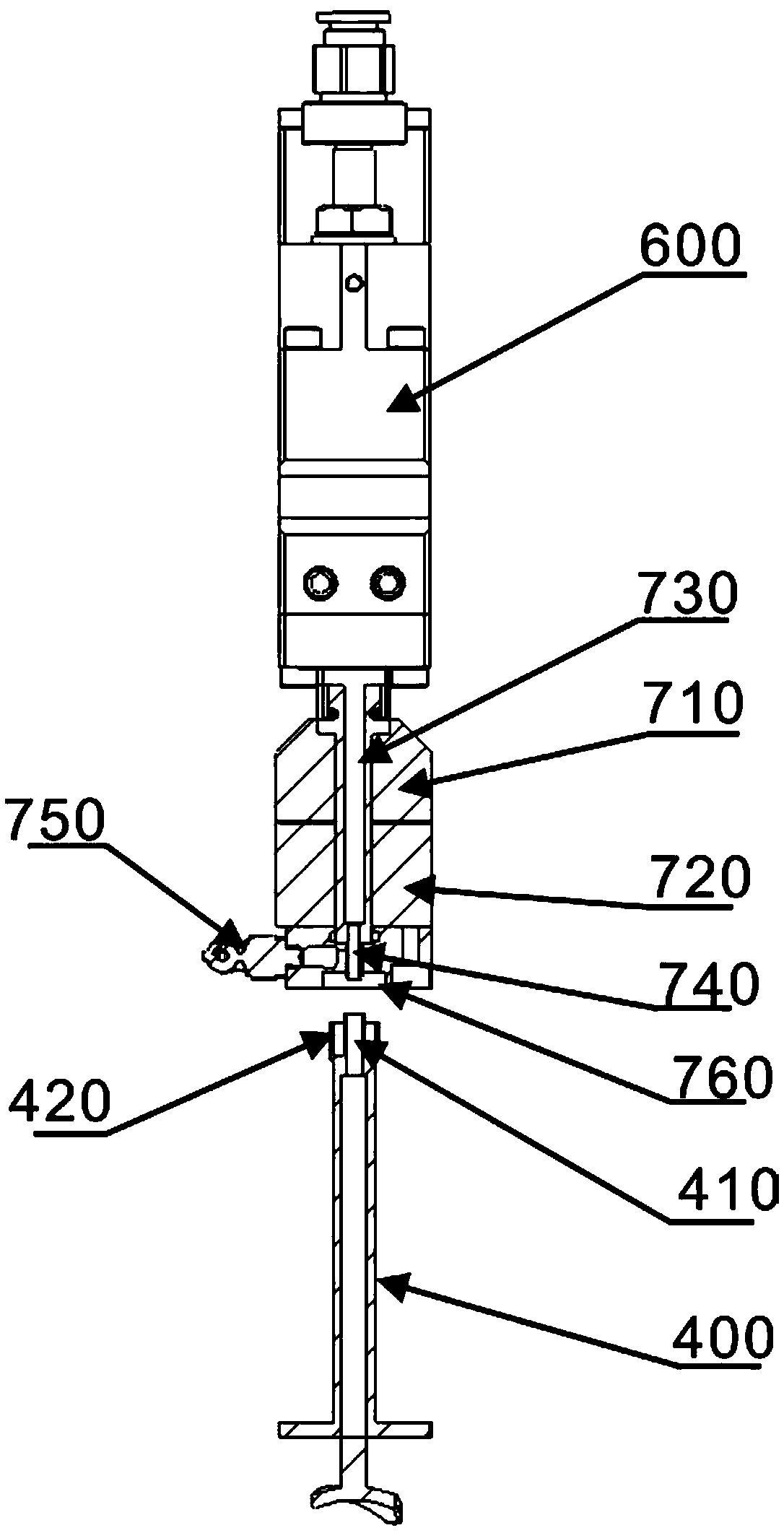

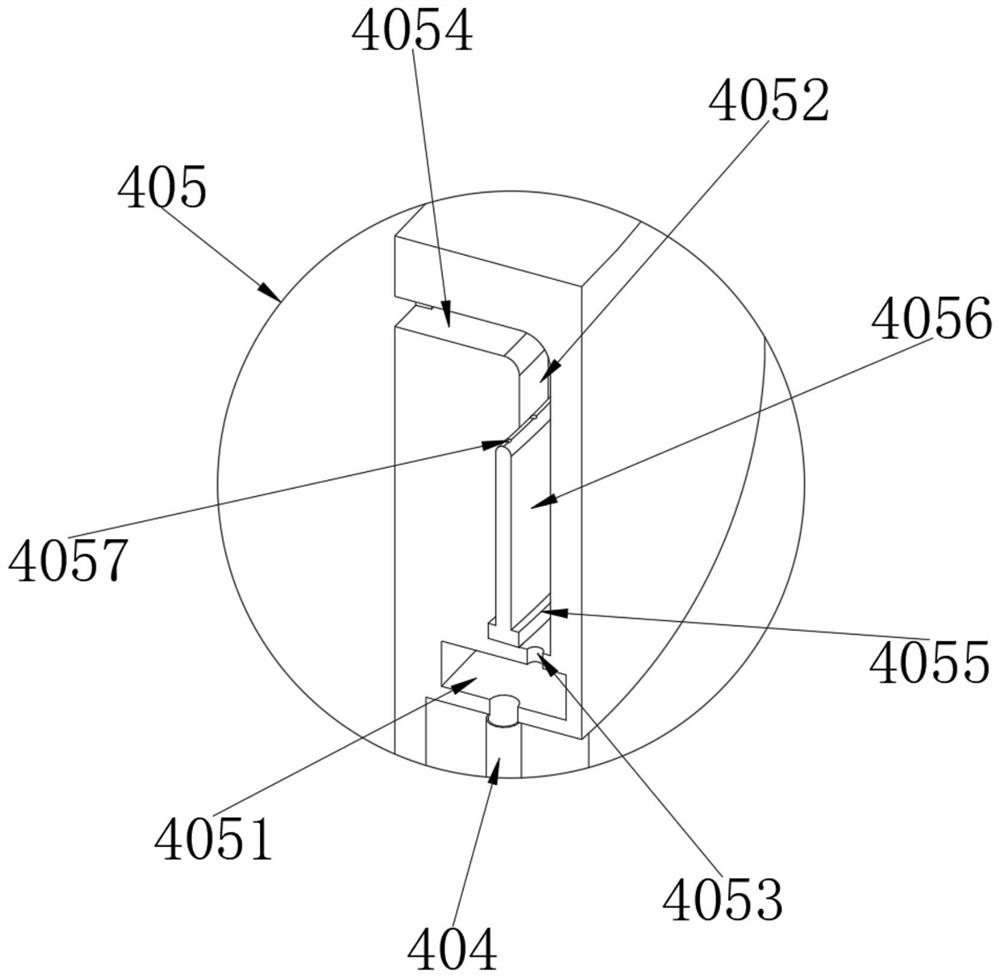

PendingCN109436423ASolve the problem of vacuumingQuick vacuumPackaging by pressurising/gasifyingEngineeringMachining

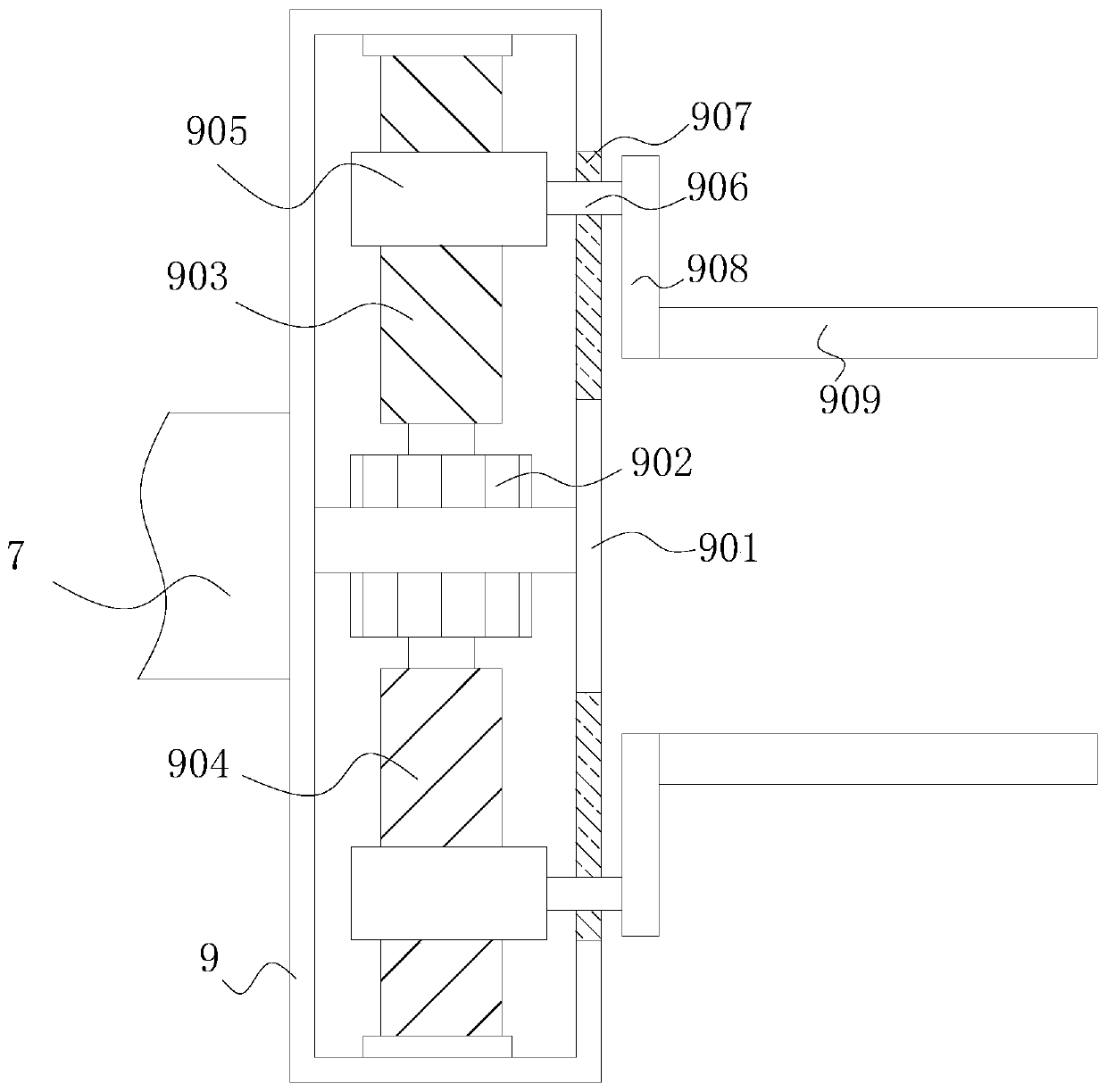

The invention provides a vacuumizing and filling device and method for a medical instrument. The vacuumizing and filling device for the medical instrument comprises a vertical air cylinder, a connection plate, a limiting air cylinder, a support, filling assemblies and seal pieces. The vertical air cylinder and the limiting air cylinder are installed on the connection plate. The limiting air cylinder is used for limiting the lifting procedure of the vertical air cylinder. An output shaft of the vertical air cylinder is connected with the support. The support is provided with the multiple filling assemblies. The seal pieces are fixedly connected with the lower sides of the filling assemblies. The vertical air cylinder conducts ascending and descending movement so as to drive the filling assemblies and the seal pieces to conduct ascending and descending movement. The seal pieces are connected to syringe bodies in sealed and sleeved manner so as to conduct vacuumizing on the syringe bodies. The filling assemblies are used for filling medicine into the vacuumized syringe bodies. The vacuumizing and filling device for the medical instrument guarantees that in the medicine filling processof the syringe bodies, no air is leaked, the structure is small and exquisite, the technology is simplified, and machining is convenient; and after the structure of the vacuumizing and filling devicefor the medical instrument is magnified, the vacuumizing and filling device for the medical instrument is also suitable for large-sized medical instruments, and market popularization is easy.

Owner:普叶顿(上海)自动化科技有限公司

Manufacture method of tin slot bottom brick

InactiveCN1927557BSolve the problem of splittingUniform structureCeramic shaping apparatusSold ingredients supply apparatusLiquid wasteBrick

A method for making tin bottom brick, is belongs to fireproof material technology areas. It includes batching, mixing, vibration and compression for molding, conservation and drying, heat treating and rubbing. It is characterized by after the mixed pug are poured into the model, vacuumpumping first then vibration and compression for molding. There are 3%-5%(weight percentages)paper pulp barren liquor in blending. The invention adopts the method of vacuumpumping first and then vibration and compression to solving the problems that the residual air leads to lamination crack when producing thicker brick.

Owner:ZIBO GT INDAL CERAMICS

Brake clamp for automobile

The invention discloses a brake caliper for automobiles, which comprises a casing, one side of the casing is fixedly connected with a brake cylinder, a storage slot is provided on the back of the casing, and a storage slot corresponding to the storage slot is provided on the front of the casing. Adapted observation window, the interior of the housing is provided with a brake device, and a dust removal device is fixedly installed on the inner wall of the housing below the brake device. The end of the dust removal device away from the inner wall of the housing is exposed in the observation window. The dust removal device includes a dust removal head, and the dust removal head is fixedly connected with the dust collection box through a dust delivery pipe fixedly connected at the bottom thereof, and the dust collection box is fixedly installed on the top of the air pump and connected with the inner impeller chamber of the air pump Pass. The invention makes the contact surface between the brake disc and the brake pad cleaner by setting the dust removal device, reduces the dust on the brake pad, reduces the influence of dust and mud on the brake caliper, and makes the use effect of the brake caliper better.

Owner:天津春斌科技有限公司

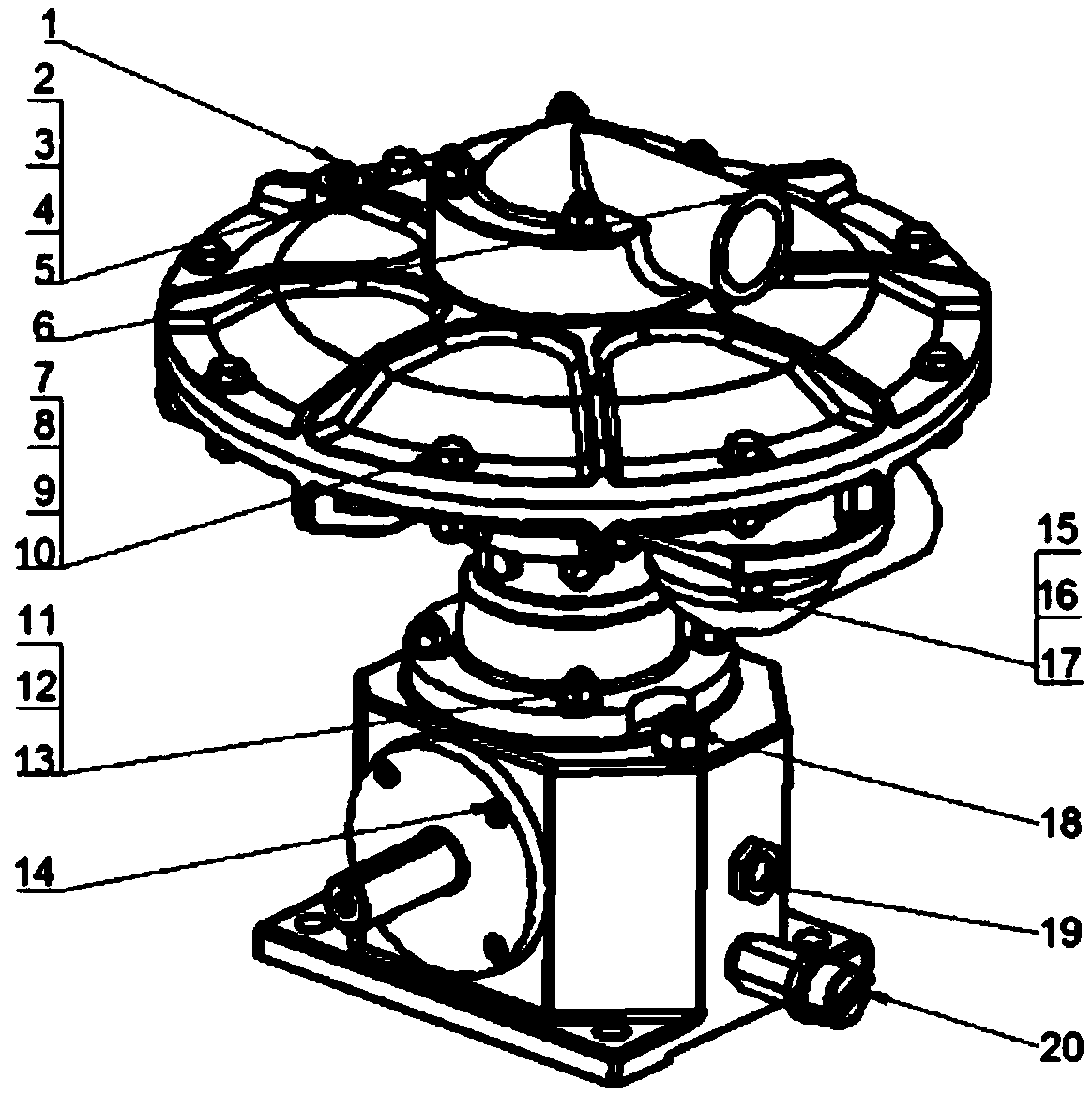

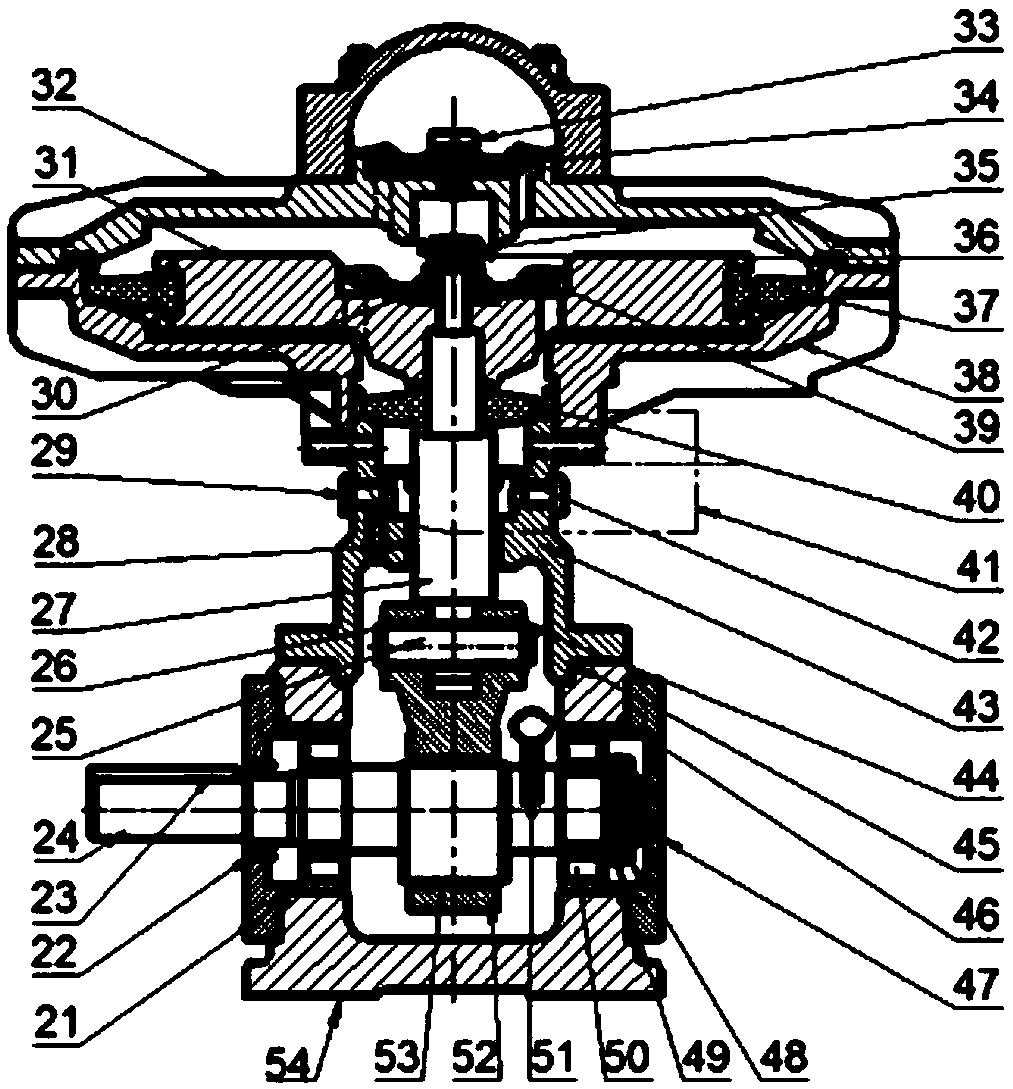

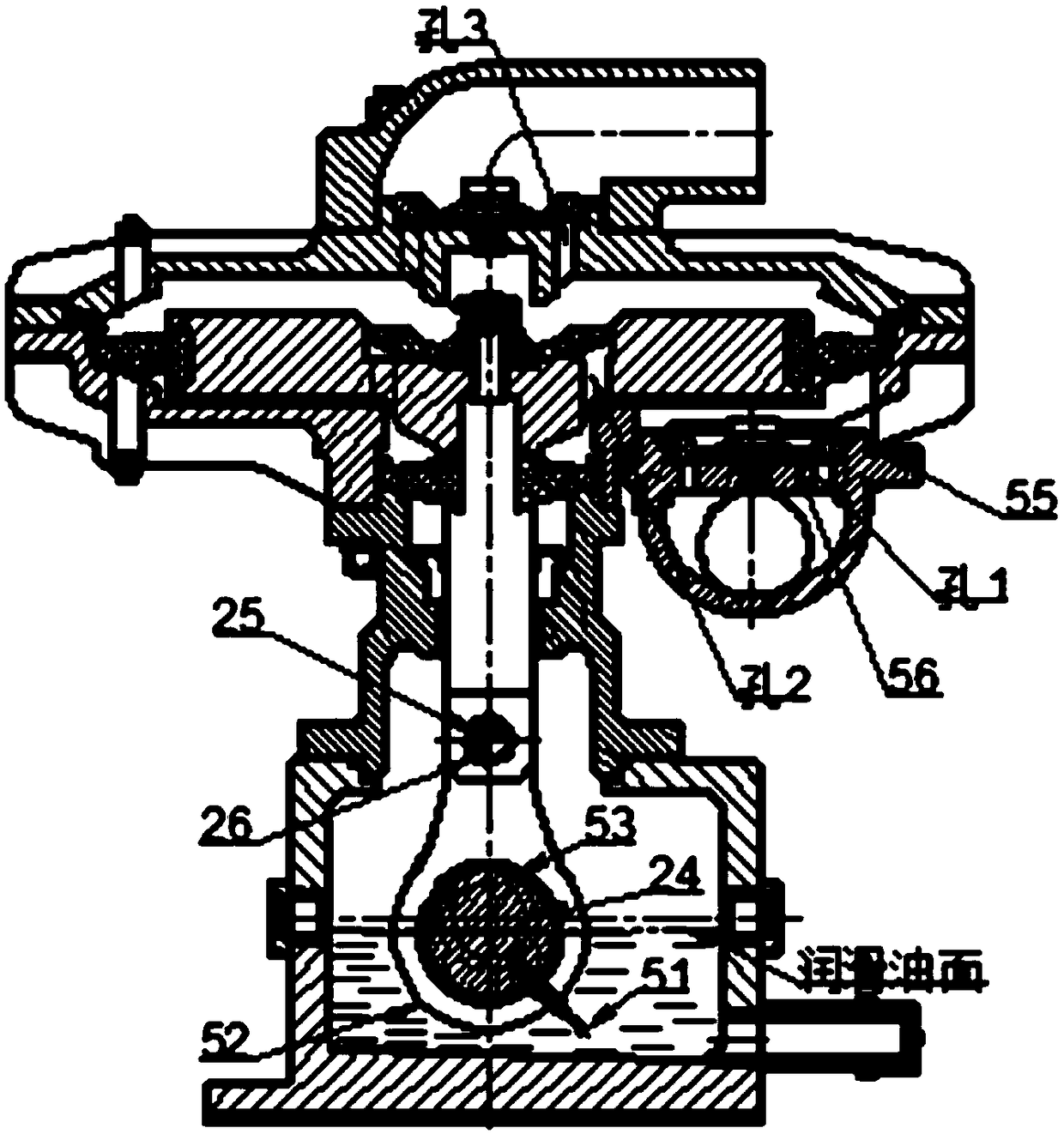

Parasitical auxiliary self-priming vacuum pump

PendingCN108612656ALight in massStrong vacuuming abilityFlexible member pumpsPriming pumpAtmospheric airEngineering

The invention discloses a parasitical auxiliary self-priming vacuum pump which comprises a flow passage component and a power component. A sealed chamber of the flow passage component is composed of aneck seal, an upper cover, a lower cover, an outlet check pad and an inlet check pad. A diaphragm is arranged in the sealed chamber, and a diaphragm check pad is arranged in the middle of the upper surface of the diaphragm. A diaphragm shaft sequentially penetrates the diaphragm check pad, the diaphragm and the neck seal from top to bottom, and the lower end of the diaphragm shaft stretches intoa crankshaft box of the power component and is fixedly connected with a crankshaft. The crankshaft in the crankshaft box drives a diaphragm sheet to continuously and vertically move through the diaphragm shaft, the diaphragm sheet and the three check pads cooperate, and air is extracted to a lower chamber of a sealed cavity from a pump cavity of a water pump, then pressed to an upper chamber to move in one way and finally exhausted to the atmosphere to assist in self priming of the water pump. According to the vacuum pump, the secondary self-priming work efficiency of a dry mounted centrifugalpump can be improved, and production and rescue losses caused by long-time preparation of a primer pump can be reduced; and meanwhile potential safety hazards of manpower can be avoided, and the labor intensity can be reduced.

Owner:AMOS FLUID TECH CO LTD

Pphotovoltaic junction box simulation waterproof and dustproof grade testing device

ActiveCN113074884ARealize non-destructive testingQuick vacuumMeasurement of fluid loss/gain ratePhotovoltaic energy generationStructural engineeringPumping vacuum

The invention discloses a photovoltaic junction box simulation waterproof and dustproof grade testing device which comprises a base and a junction box, an air hole is formed in the top of the junction box, an elastic sealing ring is fixedly connected in the air hole, a sealing layer is fixedly connected to the bottom end of the elastic sealing ring, and a support is fixedly connected to the upper end of the base. The upper end of the support is fixedly connected with a fixed sliding barrel, a telescopic connecting barrel is slidably connected in the fixed sliding barrel, the top end of the telescopic connecting barrel is connected with a downward pressing mechanism through a connecting base, the downward pressing mechanism is connected with the support and the fixed sliding barrel, and the upper end of the telescopic connecting barrel is further connected with a vacuumizing assembly. A lead screw adjusting assembly is arranged on the surface of the base, the lead screw adjusting assembly is connected with two oppositely-arranged fixing plates, a fixing assembly is arranged on the front portion of one fixing plate, and a fixing groove matched with the fixing assembly is formed in the surface of one side wall of the junction box. The junction box is provided with the air hole, and the junction box can be vacuumized through the vacuumizing assembly, so that nondestructive testing of the junction box is realized.

Owner:青岛酒店管理职业技术学院

Integrated dust suction discharge hopper assembly

PendingCN109622554AEasy to cleanReduce cloggingDirt cleaningSortingSuction equipmentWaste management

The invention discloses an integrated dust suction discharge hopper assembly which comprises discharge hoppers, dust suction pipes and connectors. The discharge hopper assembly is composed of the multiple discharge hoppers, the dust suction pipes are welded to the multiple discharge hoppers correspondingly, the multiple dust suction pipes are fixed through horizontal clamps to form a dust suctionpipeline, the connectors are arranged on the two sides of the dust suction pipeline and connected with dust suction equipment, the dust suction pipes are provided with dust suction holes, wind shieldsmatched with the dust suction holes are arranged in the discharge hoppers, one side of each discharge hopper is provided with a feed inlet, a qualified product cavity and an unqualified product cavity are arranged in each discharge hopper, each qualified product cavity is arranged on the side close to the feed inlet, each unqualified product cavity is arranged as a large cavity and internally provided with a first baffle, one side of each feed inlet is provided with a second baffle, and the two sides of each second baffle are movably fixed to the corresponding discharge hopper through bolts.The dust suction pipes and the discharge hoppers are integrated and fixed through the horizontal clamps, disassembling is convenient so as to remove dust in the dust suction pipes, and blockage is reduced.

Owner:BULLER YIJIE FEATURES SELECTED MACHINERY HEFEI

A liquefied gas classification purification device

ActiveCN113041641BPlace stableConducive to liquefactionNon-rotating vibration suppressionVapor condensationCooling effectGas passing

The invention discloses a classification and purification device for liquefied gas, which belongs to the technical field of gas purification and comprises a purification tank. A raw material tank is arranged on one side of the purification tank, and a liquefaction tank is arranged on the other side of the purification tank. The raw material tank and the The temperature of the liquefaction tank is lowered by the cooling device, and the raw material tank and the purification tank and between the liquefaction tank and the purification tank are connected by the first connecting pipe. The device, the placed raw material tank and liquefaction tank can squeeze the supporting bellows, so that the extruded gas is transported to the inside of the communication cavity through the gas delivery hose, and the gas pushes the sealing plate to slide inside the storage groove and the limit groove. The sealing plate slides out of the limit groove under the push of the gas, and seals the gap between the cooling barrel, the raw material tank and the liquefaction tank, so that the cooling effect of liquid nitrogen is better, and the effect of liquefaction and purification of gas is improved. better.

Owner:无锡恒大电子科技有限公司

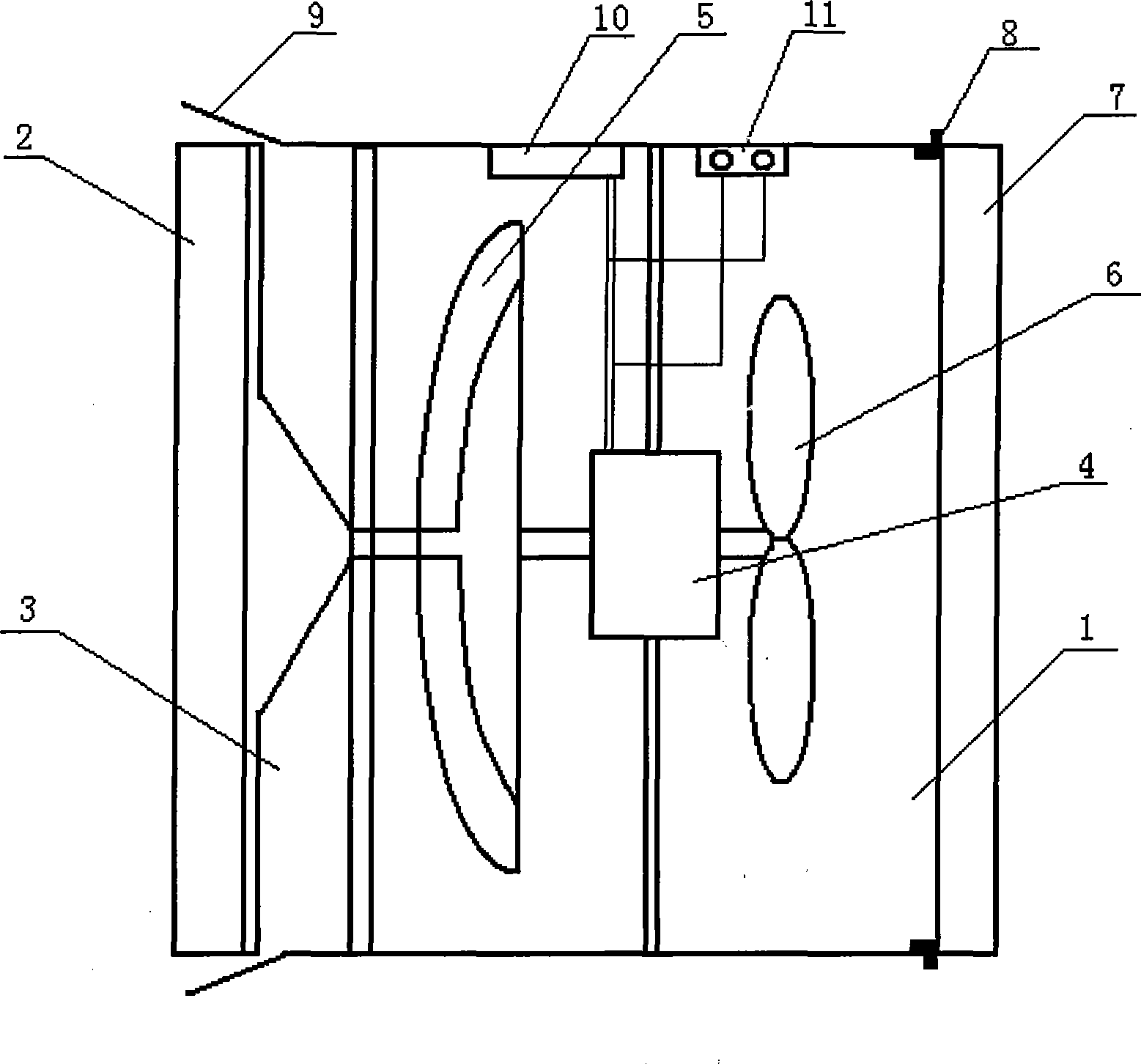

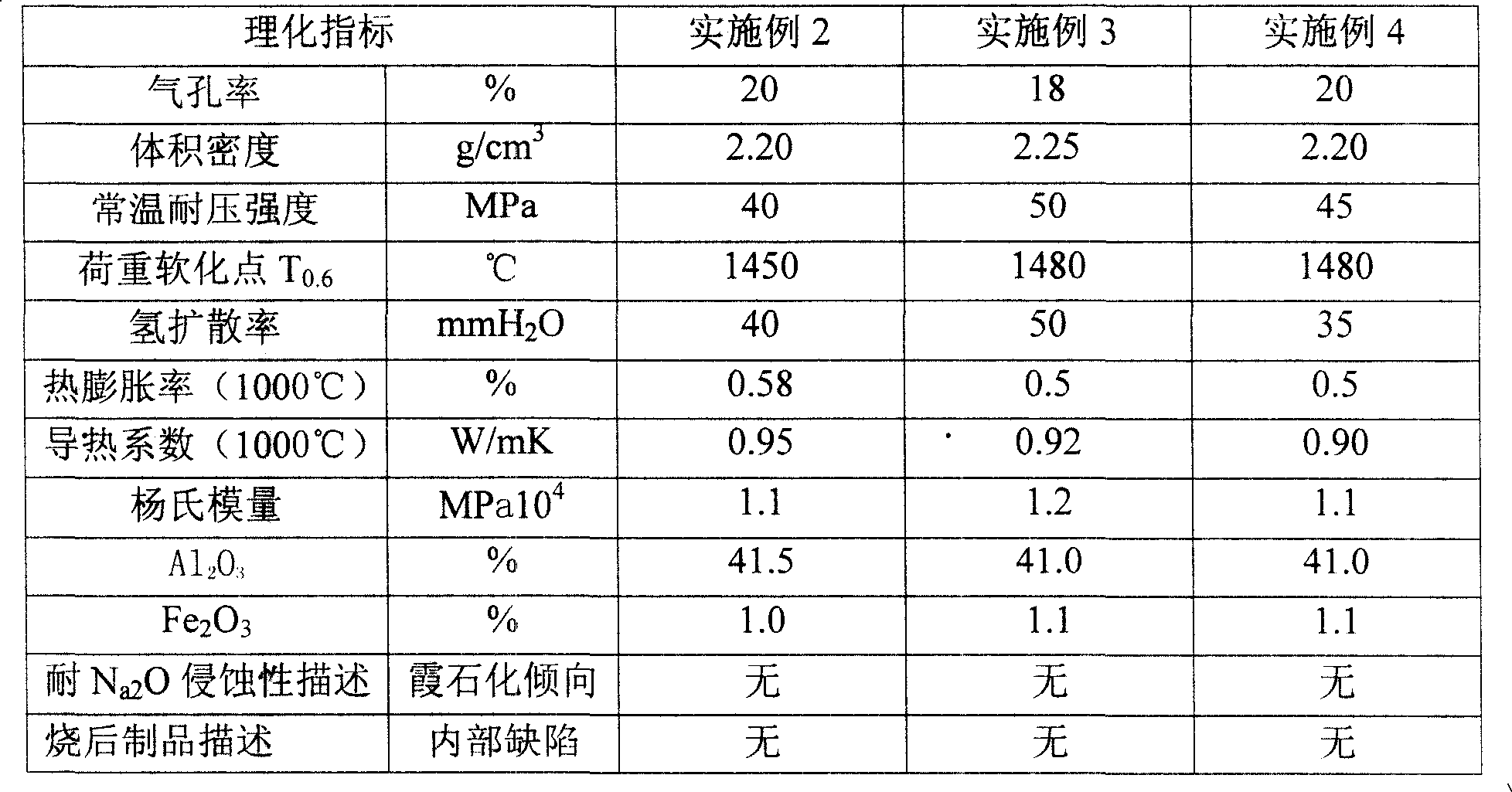

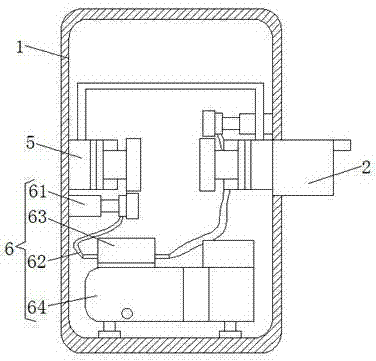

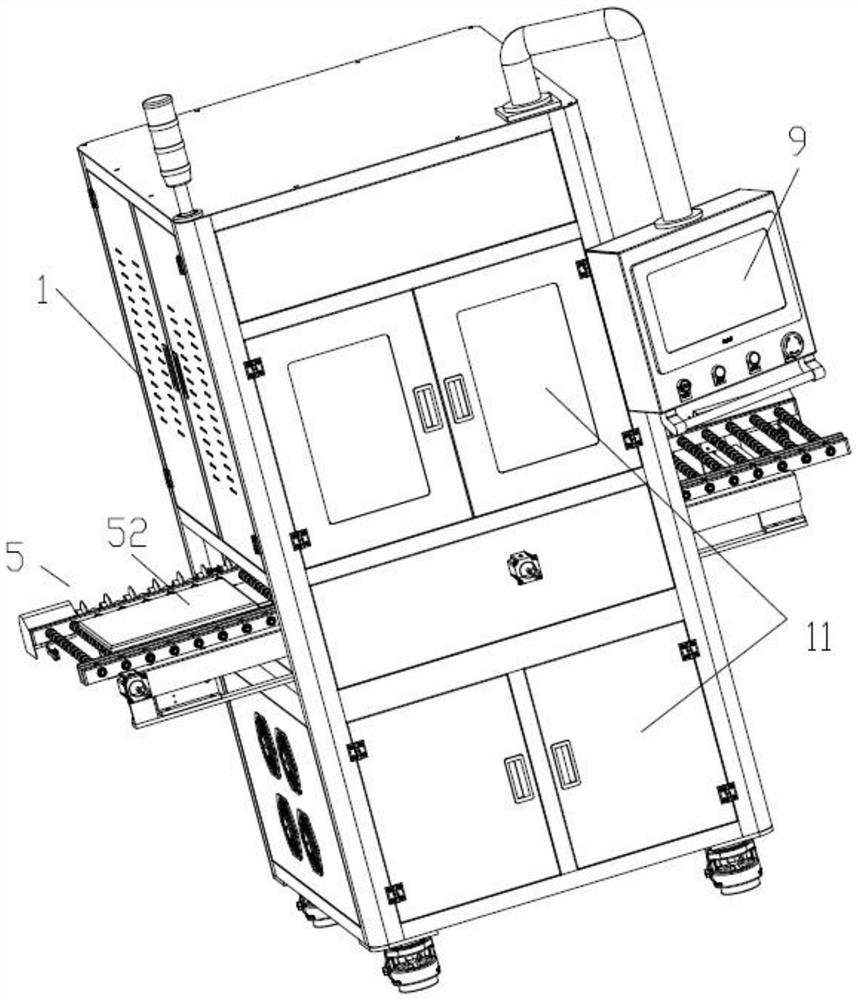

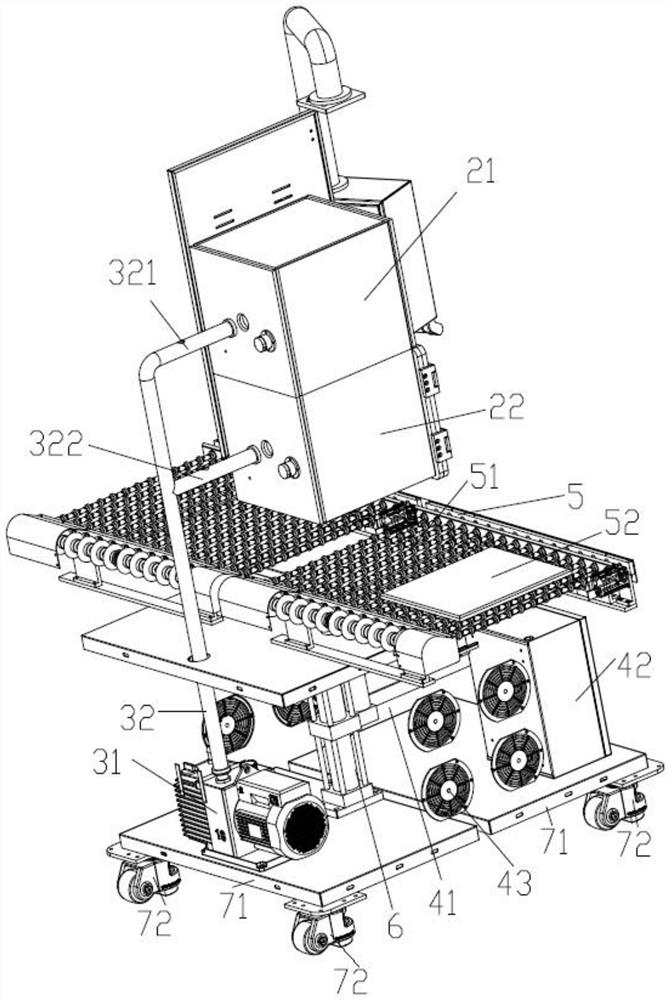

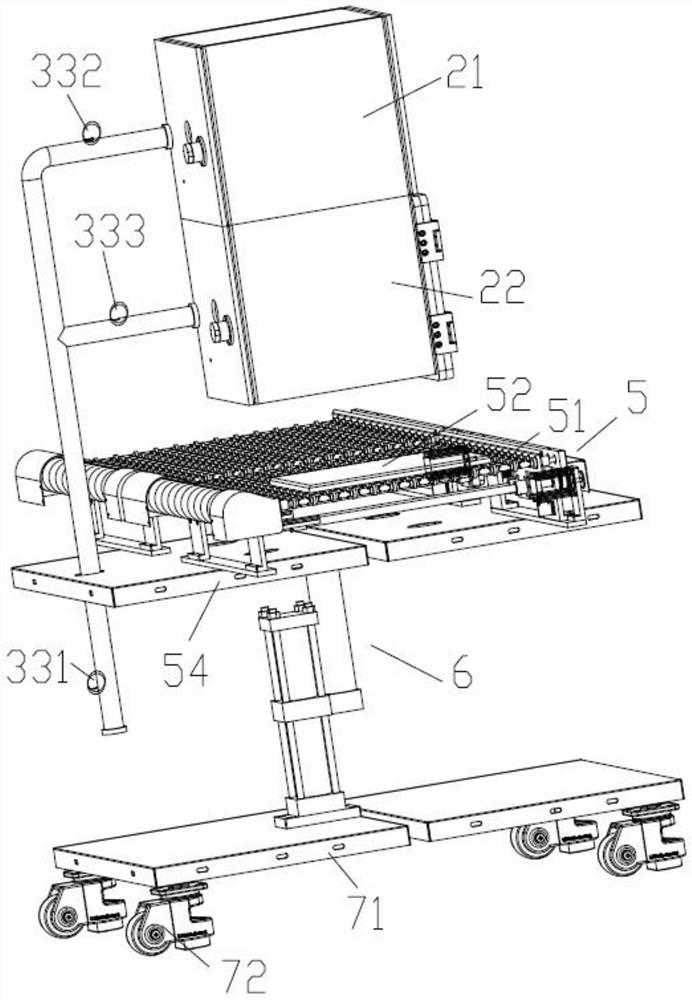

Vacuum plasma machine capable of rapidly vacuumizing on line

PendingCN113118139AShorten the timeImprove work efficiencyCleaning processes and apparatusEngineeringPumping vacuum

The invention relates to the technical field of plasma machine structures, and particularly discloses a vacuum plasma machine capable of rapidly vacuumizing on line. The vacuum plasma machine comprises an outer machine frame, and an inner cavity is formed in the outer machine frame; a negative pressure storage bin and a plasma vacuum bin arranged on the lower side face of the negative pressure storage bin are arranged in the inner cavity; a vacuum pump device is further arranged in the inner cavity and connected with a vacuum check loop pipe; the vacuum check loop pipe is connected with a first branch pipe and a second branch pipe; the negative pressure storage bin communicates with the vacuum check loop pipe through the first branch pipe, the plasma vacuum bin communicates with the vacuum check loop pipe through the second branch pipe, and the first branch pipe communicates with the second branch pipe; the vacuum plasma machine further comprises a moving table, and a conveying belt is arranged on the moving table. and a workpiece table is further arranged on the conveying belt. According to the vacuum plasma machine, the vacuumizing time can be greatly shortened, and the working efficiency is greatly improved.

Owner:中山市普雷斯等离子科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com