Core high temperature and high pressure casting instrument

A high-temperature, high-pressure, casting instrument technology, which is applied in the direction of program control and material analysis in instruments, sequence/logic controllers, etc., can solve problems such as instability, low work efficiency, and poor practicability, and achieve strong practicability and abstraction. The effect of fast vacuum and high perfusion pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

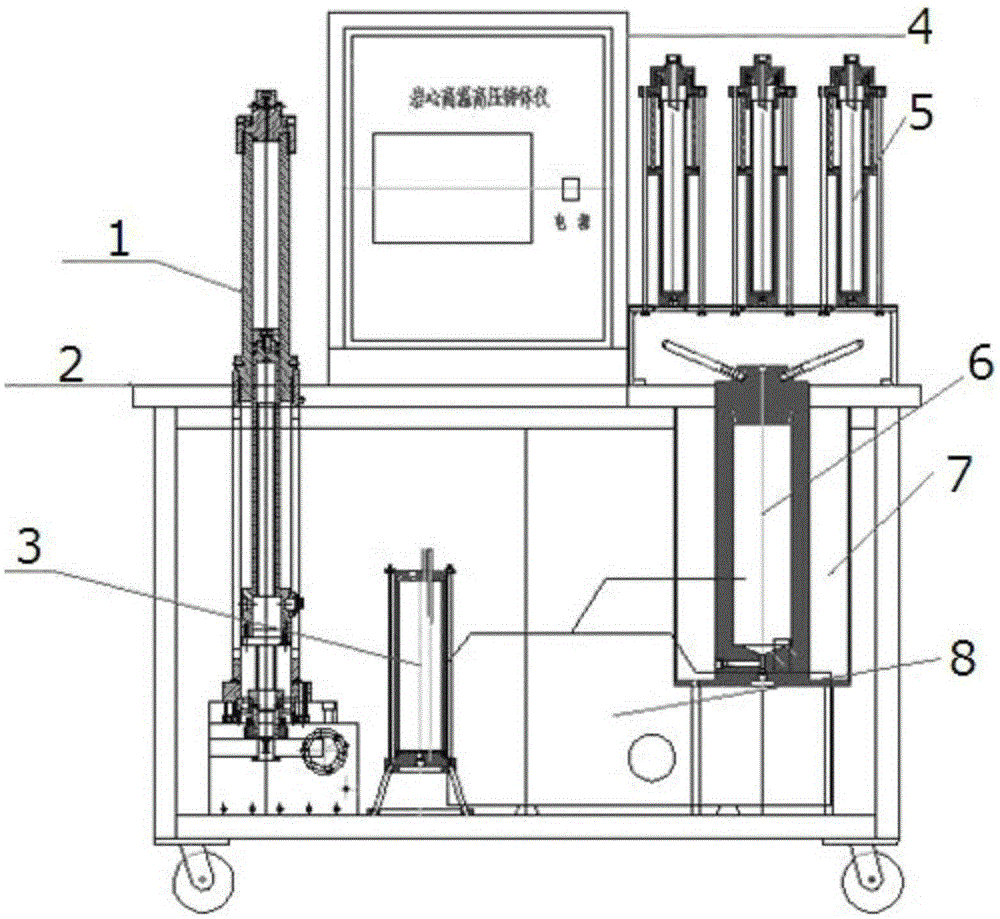

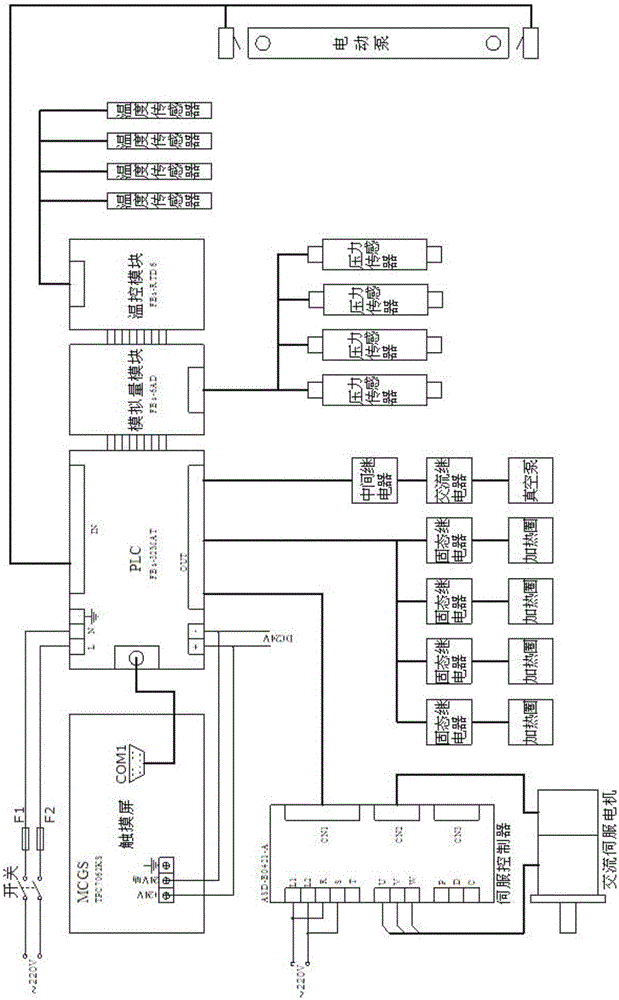

[0017] Such as figure 1 , 2 The shown core high temperature and high pressure casting instrument includes a high pressure displacement system, a vacuum system, a core chamber system and a PLC control system.

[0018] (1) High-pressure displacement system: used to provide power source for pressurizing the rock sample container, mainly driven by a high-power motor to complete the displacement pump 1, the ultimate pressure is 80MPa, and the high-power motor is controlled by a motor controller, the motor controller Controlled by PLC output. The displacement pump completes the two processes of entering the pump and withdrawing the pump. The pump enters to pressurize, and the pump withdraws to reduce the pressure. It is connected to the pressure sensor. When the pressure is too high or too low, it can automatically complete the depressurization or pressurization, and always maintain the pressure change ± 0.05MPa.

[0019] (2) Vacuum system: British Edward RV12 vacuum pump 8 is ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com