Glass cutting machine based on laser guide cutting

A laser cutting and cutting machine technology, applied in glass cutting devices, glass manufacturing equipment, manufacturing tools, etc., can solve problems such as environmental pollution in dust-free workshops, glass surface scratches or pollution, and affect the quality of glass edges. Effects of preventing cutting slippage, reducing horizontal cracks, and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Below in conjunction with accompanying drawing of description, the present invention will be further described.

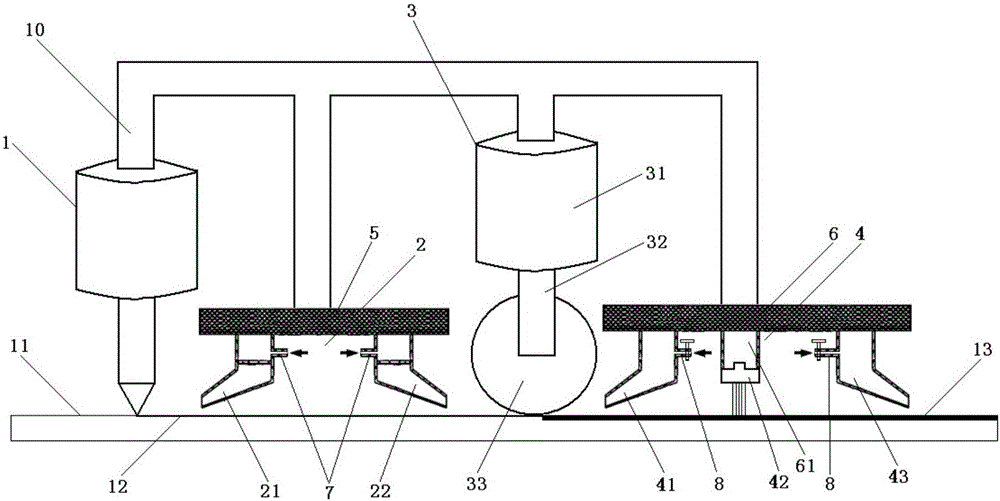

[0020] Such as figure 1 The shown glass cutting machine based on laser cutting includes a laser cutting device 1, a cooling device 2, a cutter body 3 and a dust suction device 4 suspended side by side on a support 10 along the cutting movement direction. The device 2 is suspended on the bracket 10 between the laser cutting device 1 and the cutter body 3 by being installed on the first support plate 5 , and the dust suction device 4 is suspended on the bracket 10 by being installed on the second support plate 6 .

[0021] The laser cutting device 1 emits a laser beam on the glass surface 11 to be cut to form a cutting groove 12 on the glass surface 11 .

[0022] The cooling device 2 includes a first air nozzle 21 disposed on the bottom surface of the first support plate 5 and facing the guide groove 12 ; the first air nozzle 21 is supplied with cooling gas t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com