Liquefied gas grading purification device

A technology of liquefied gas and liquefaction tanks, which is applied in the field of liquefied gas classification and purification devices, can solve problems affecting the service life of vacuum pumps, start and stop of vacuum pumps, instability of raw material tanks and liquefaction tanks, etc., and achieve good liquefaction and purification effects, pumping The vacuum process is rapid and the cooling effect is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

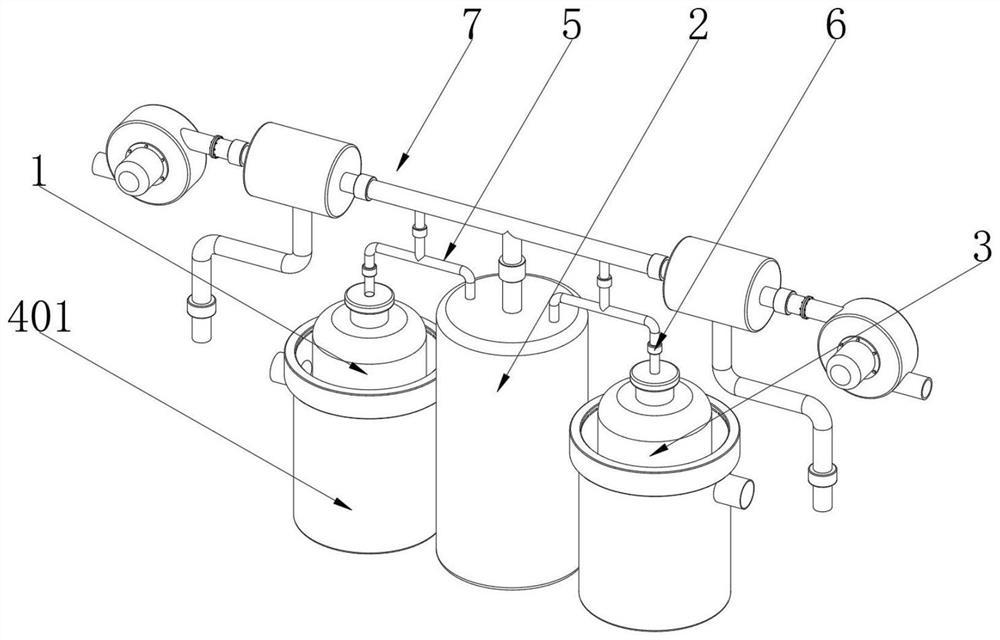

[0038] Example: such as Figure 1~6 As shown, a liquefied gas classification purification device, the purification device includes a raw material tank 1, a purification tank 2, a liquefaction tank 3, a cooling device 4, a first connecting pipe 5, a first electromagnetic valve 6 and a vacuum device 7;

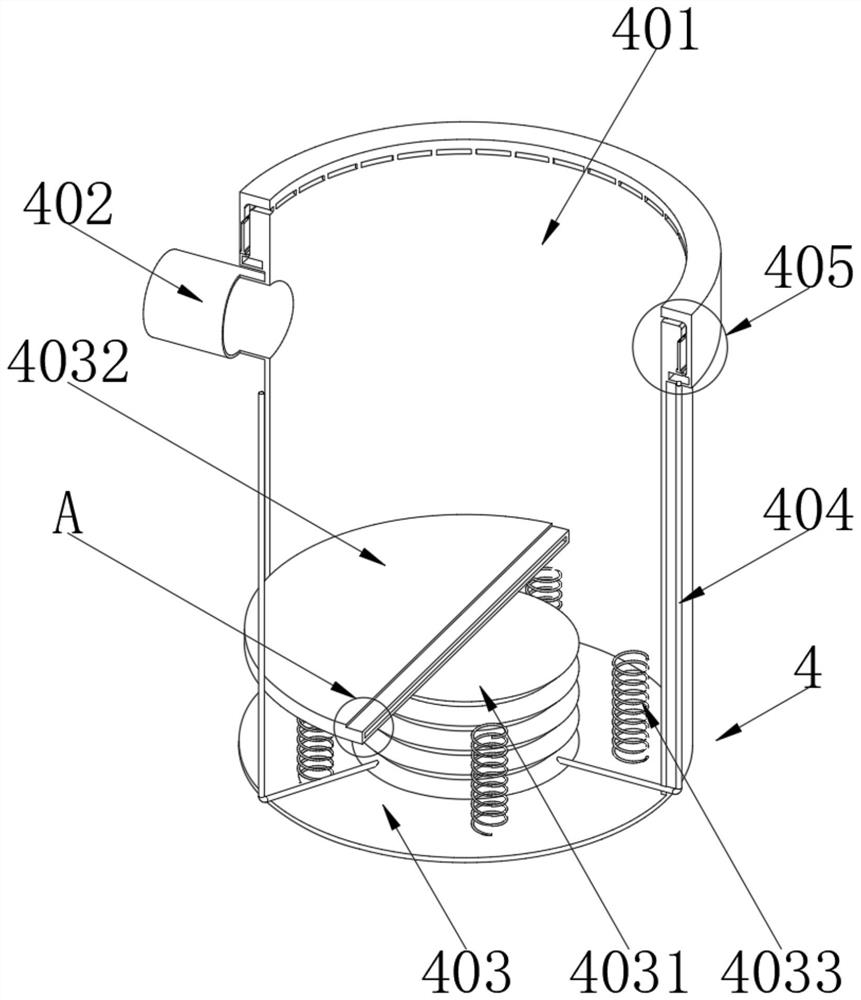

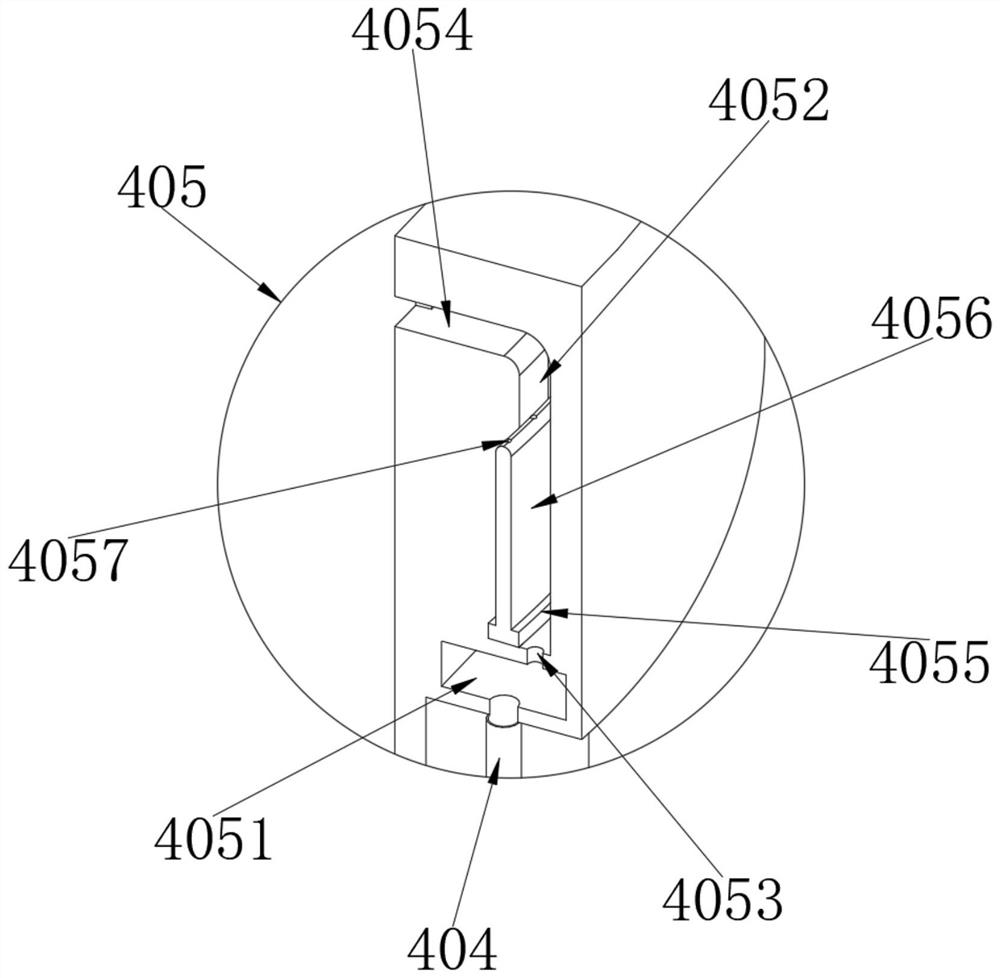

[0039] One side of the purification tank 2 is provided with a raw material tank 1, and the other side of the purification tank 2 is provided with a liquefaction tank 3. The purification tank 2 is used to purify the gas inside the raw material tank 1, remove impurity gases, and liquefy the purified gas Stored in the liquefaction tank 3, both the raw material tank 1 and the liquefaction tank 3 are cooled by the cooling device 4, and the cooling device 4 is used to cool the raw material tank 1 in order to remove impurity gases, so that impurities with high boiling points can be vaporized, and then removed For impurity gas, the cooling device 4 is used to lower the temperature of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com