Patents

Literature

33results about How to "Increase the number of particles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

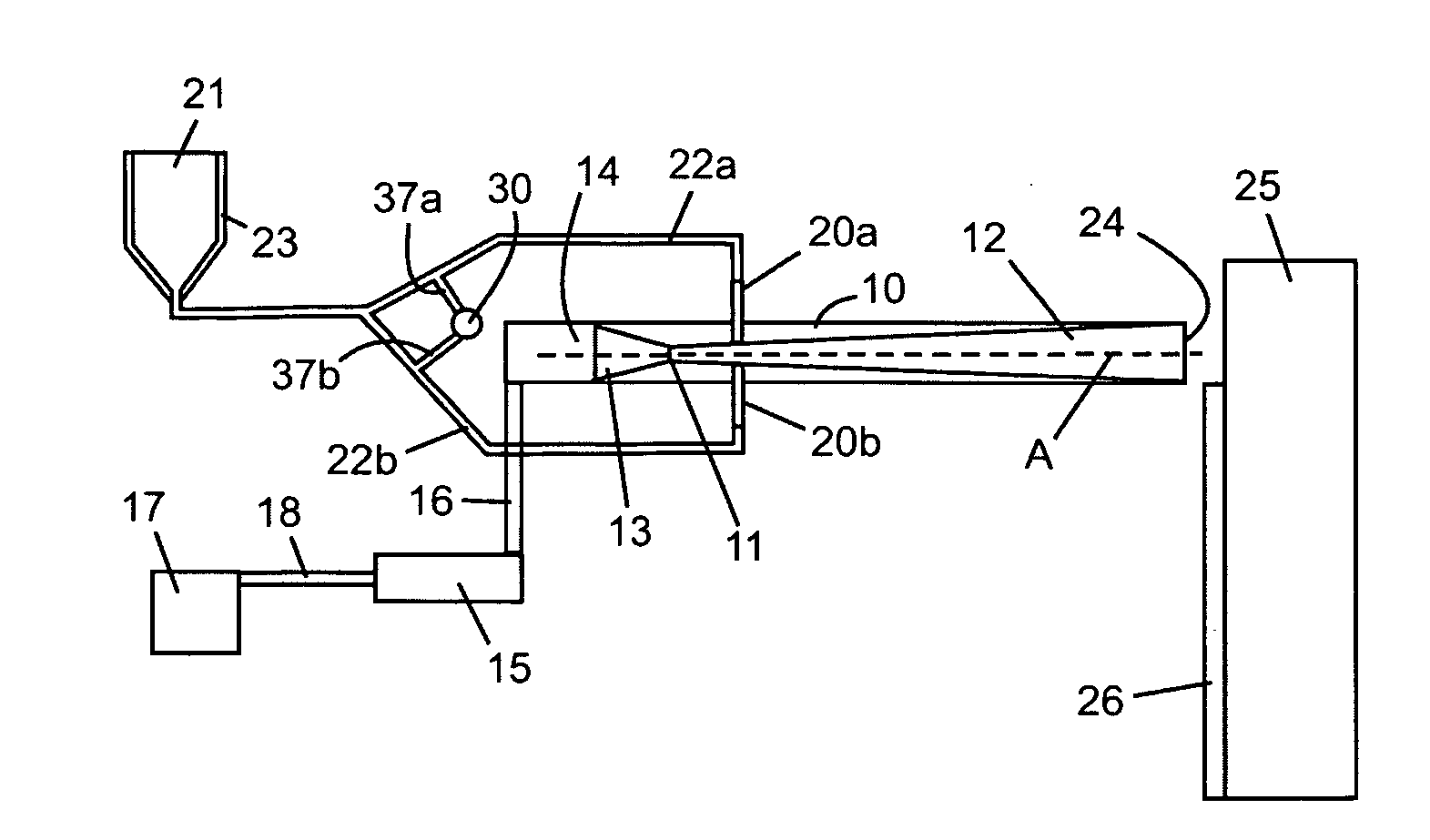

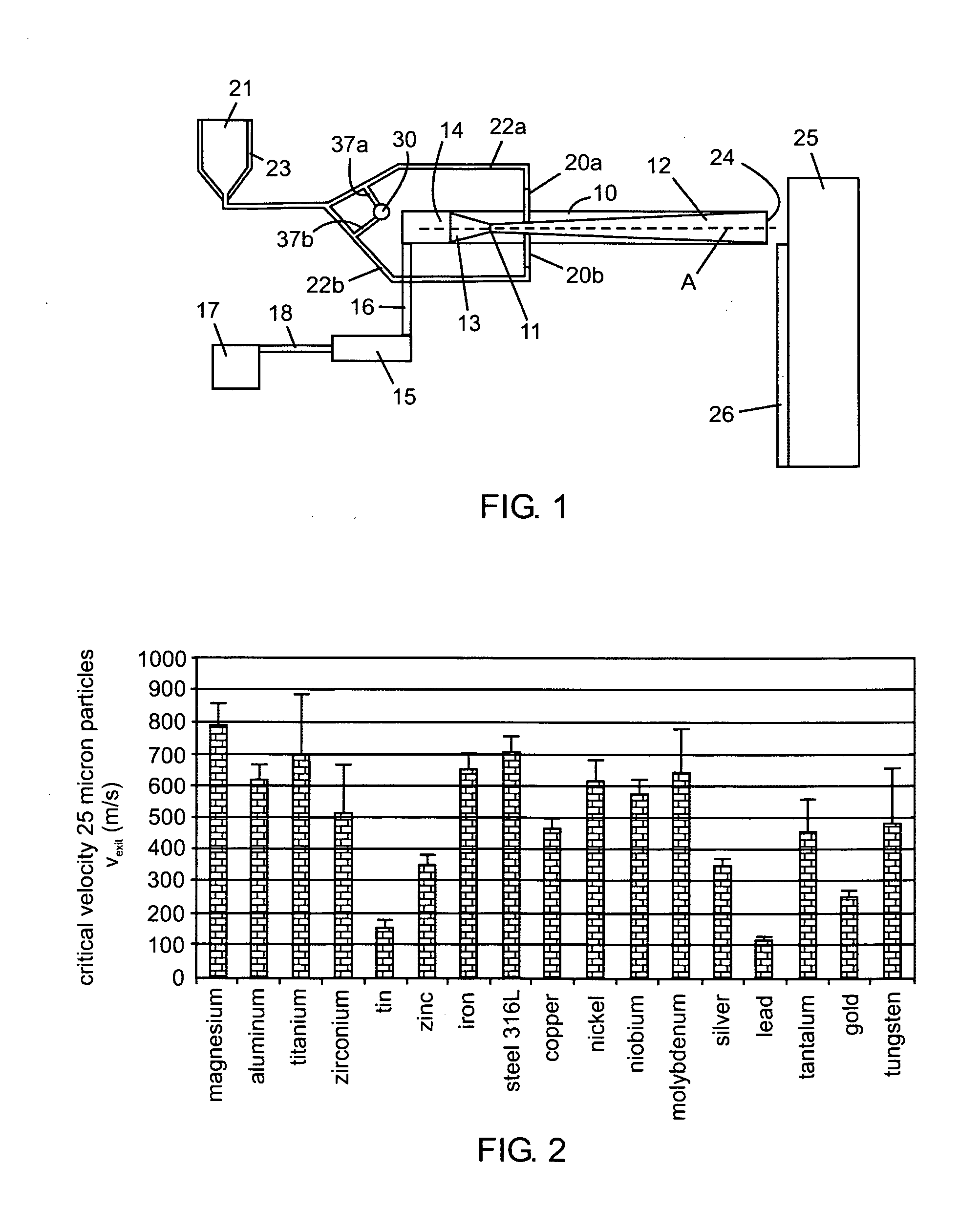

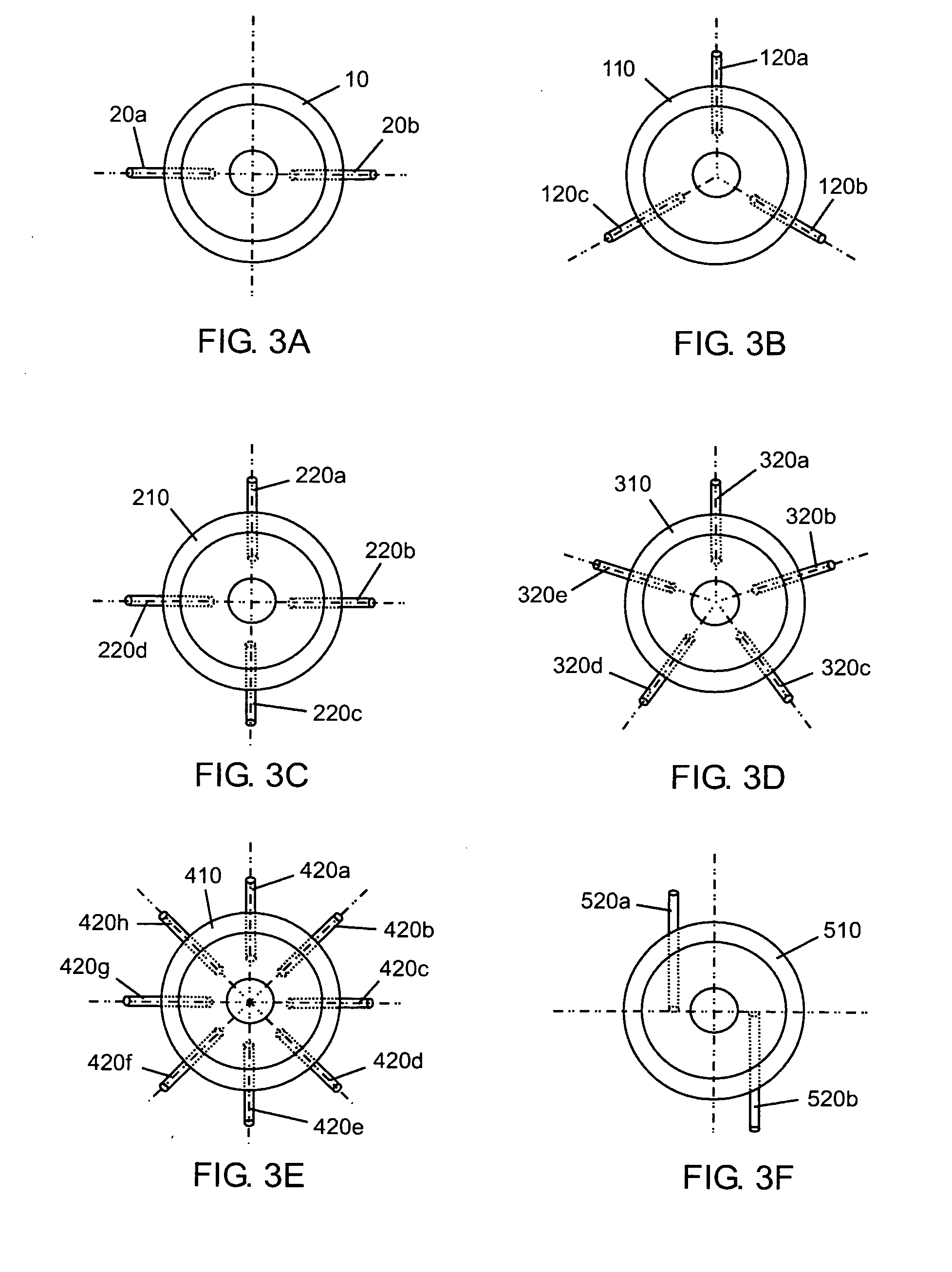

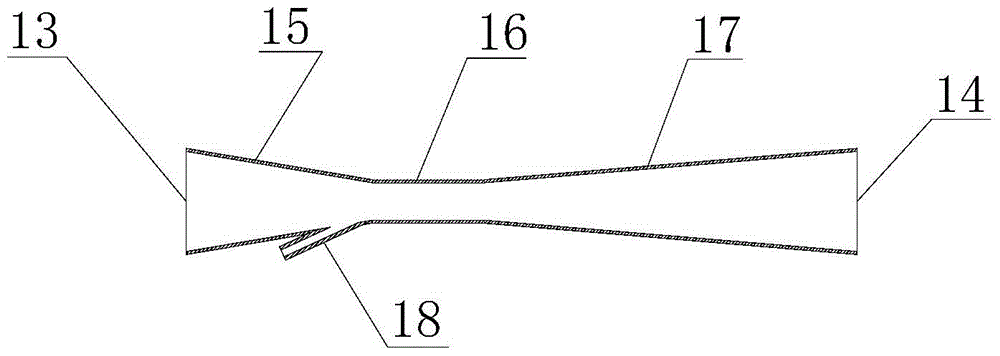

Cold gas dynamic spray apparatus, system and method

ActiveUS20100151124A1Large operating rangeEasy to clogLiquid surface applicatorsMolten spray coatingInjection pressureSpray nozzle

A system for cold gas dynamic spraying of particulate material has a de Laval nozzle and two or more radial particle inlets located between the throat and the outlet of the nozzle, the two or more particle inlets arranged symmetrically around a linear flow path of the nozzle. Blocking of the inlets is reduced by controlling pressure of particle carrier gas to provide a stable particulate material injection pressure before and during introduction of working gas into the nozzle, and / or by clearing the particle inlets of residual particles after a spraying process. Such a system and associated method combines benefits of both downstream and upstream cold gas spray systems. Further, a nozzle for spraying particulate material having a cross-sectional shape that is narrower in a middle section compared to edge sections provides coatings with superior cross-sectional profiles.

Owner:NAT RES COUNCIL OF CANADA

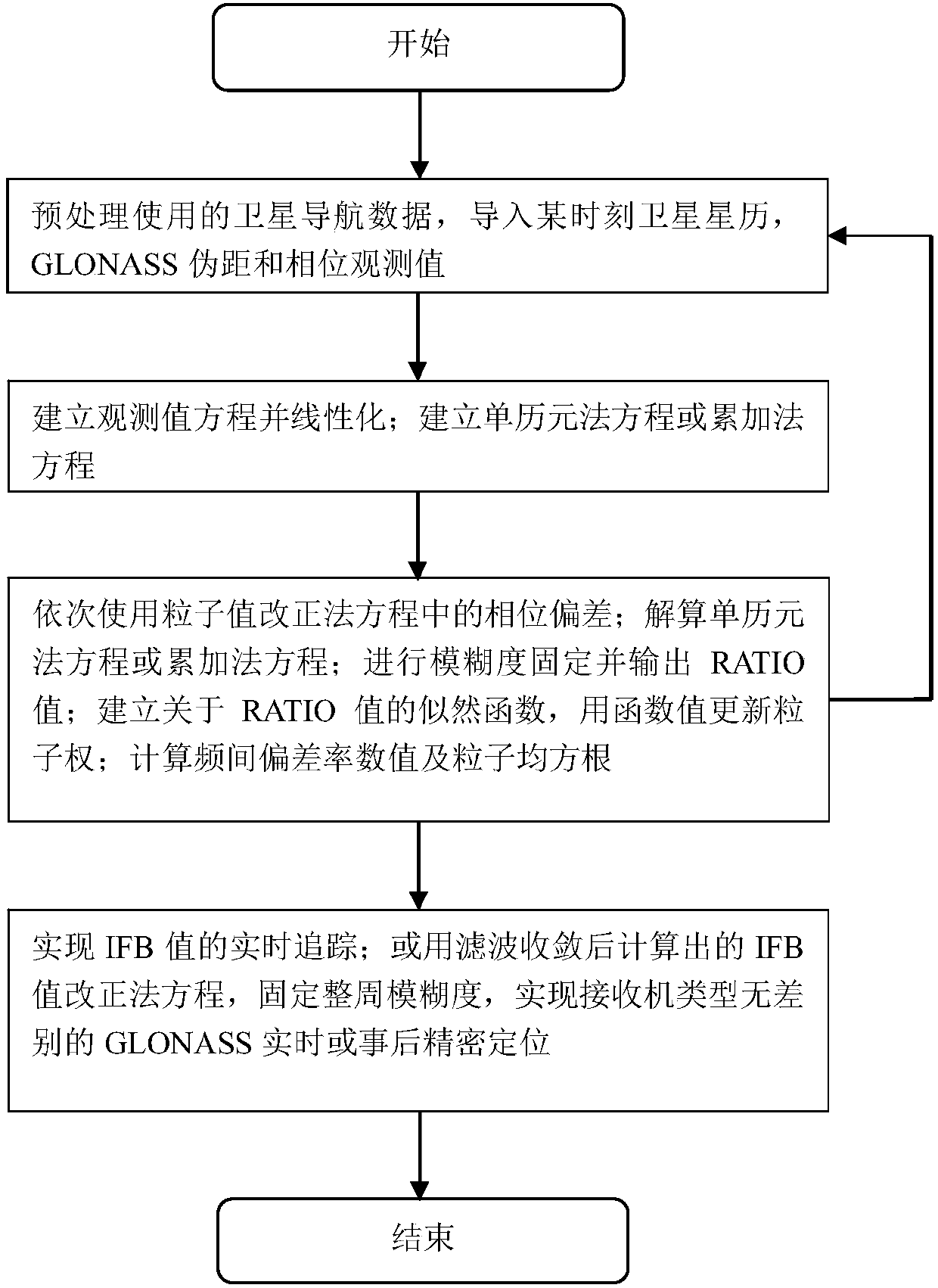

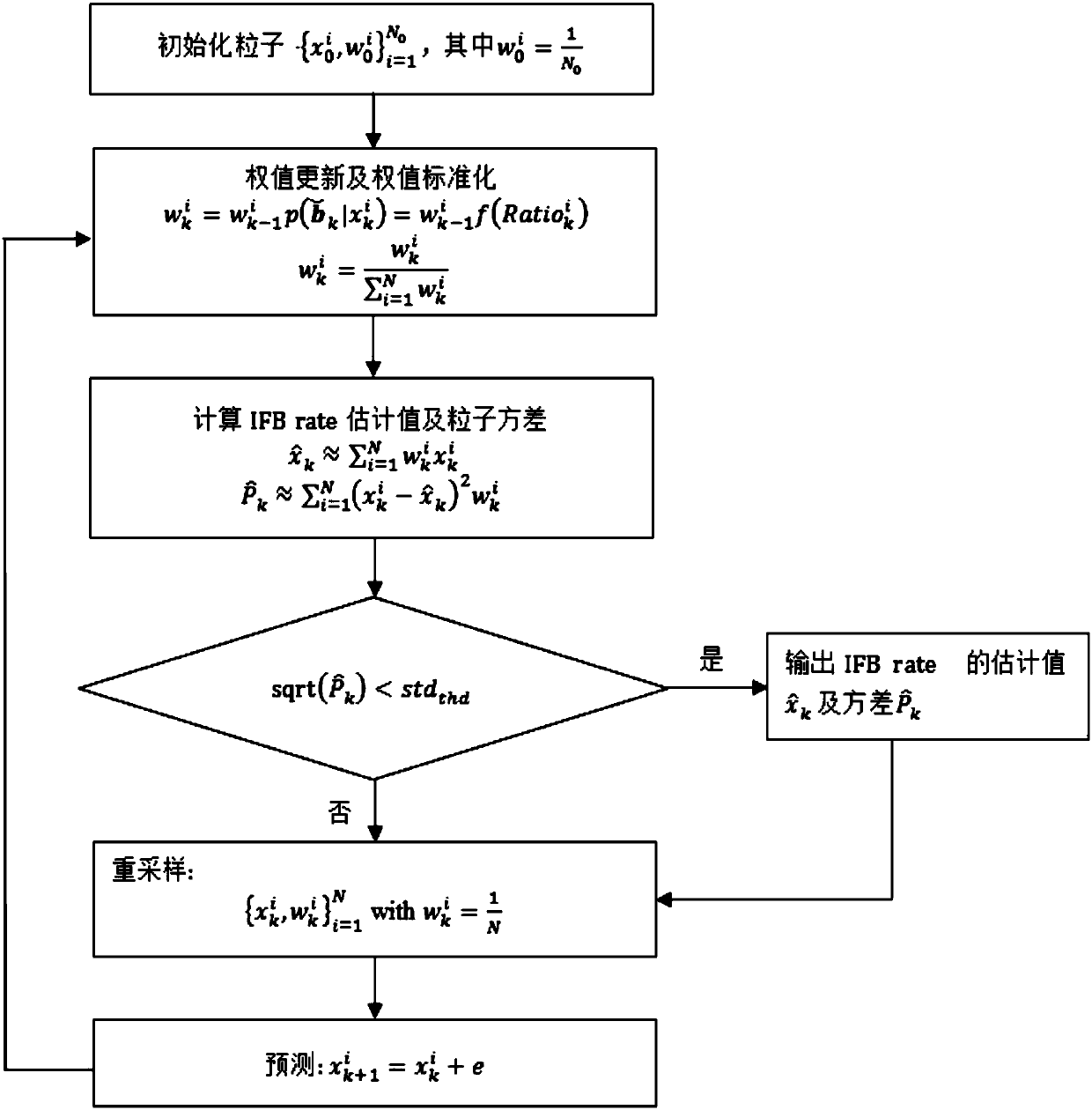

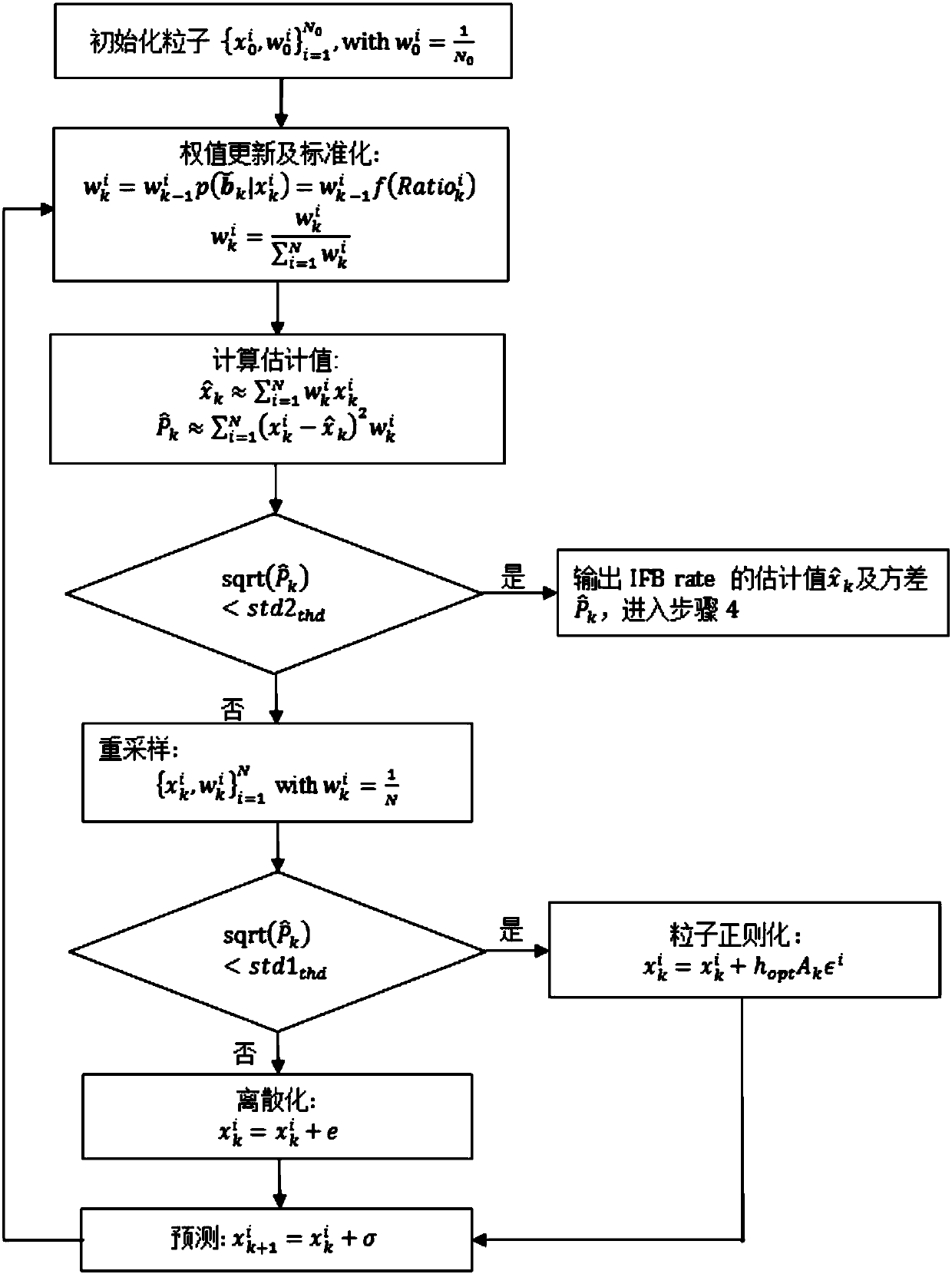

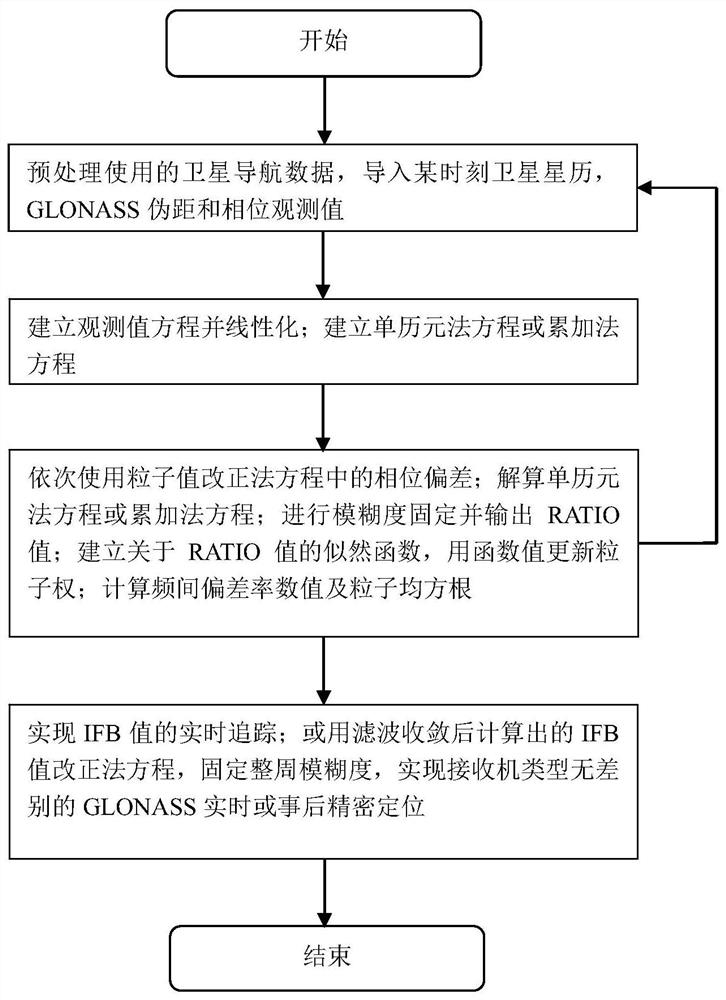

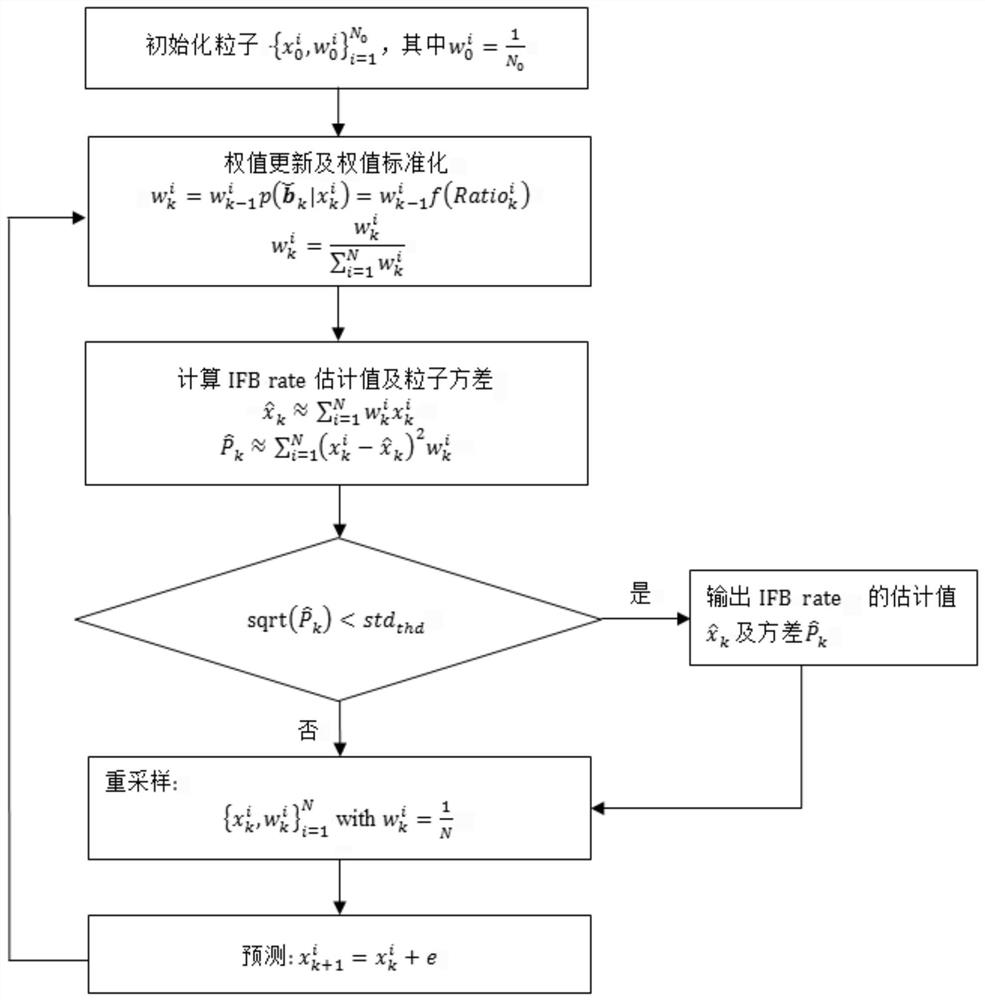

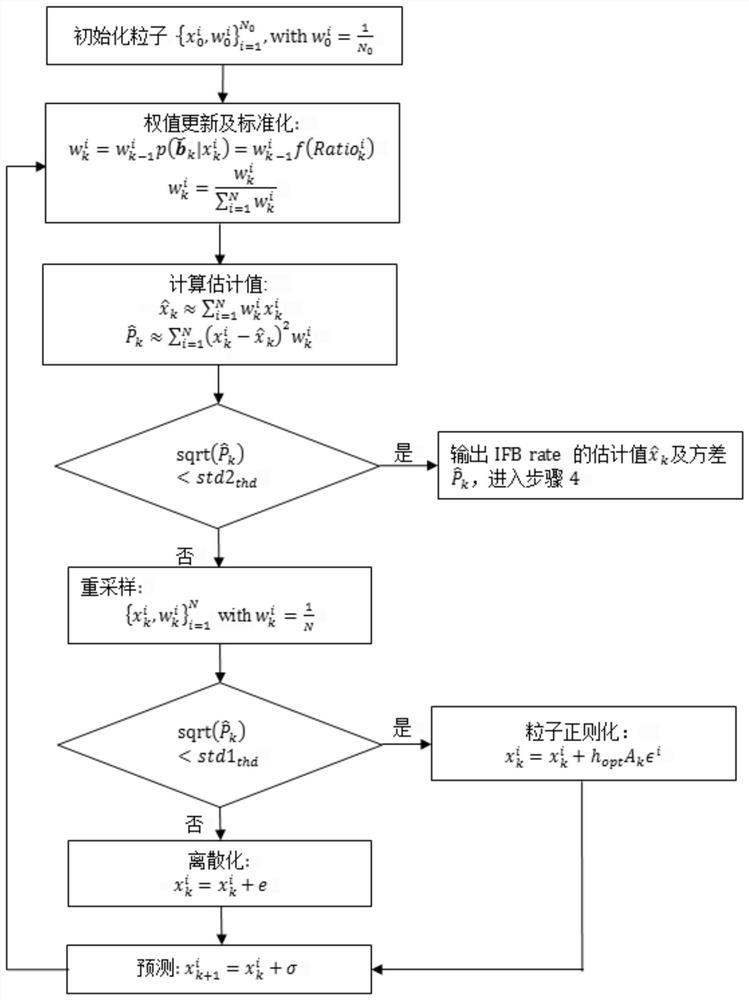

GLONASS phase inter-frequency bias real-time tracking and precise estimation method based on particle filtering

ActiveCN107678050ARealize precise positioningAchieve real-time trackingSatellite radio beaconingDouble differenceMean square

The invention discloses a GLONASS phase inter-frequency bias real-time tracking and precise estimation method based on particle filtering. The method comprises the following steps that step 1: data preprocessing: the satellite ephemeris and the pseudo range observation value and the phase observation value of the current ephemeris cloud are imported; step 2: a double difference pseudo range and carrier phase observation equation is established, and a single epoch normal equation or a previous epoch accumulation normal equation is obtained after linearization; step 3: the phase bias in the normal equation is corrected according to the particle value to solve the normal equation; and the particle filtering weight is updated, and the value of the phase inter-frequency bias rate and the particle mean square root are calculated; and step 4: the steps 1-3 are repeated to perform real-time tracking or precise estimation of the value of the phase inter-frequency bias rate; and phase inter-frequency bias correction is performed through the value of the phase inter-frequency bias rate after filtering convergence, and the integer ambiguity is fixed so as to realize precise estimation. Real-time tracking of the inter-frequency bias and GLONASS precise positioning without receiver type difference can be efficiently realized.

Owner:SOUTHWEST JIAOTONG UNIV

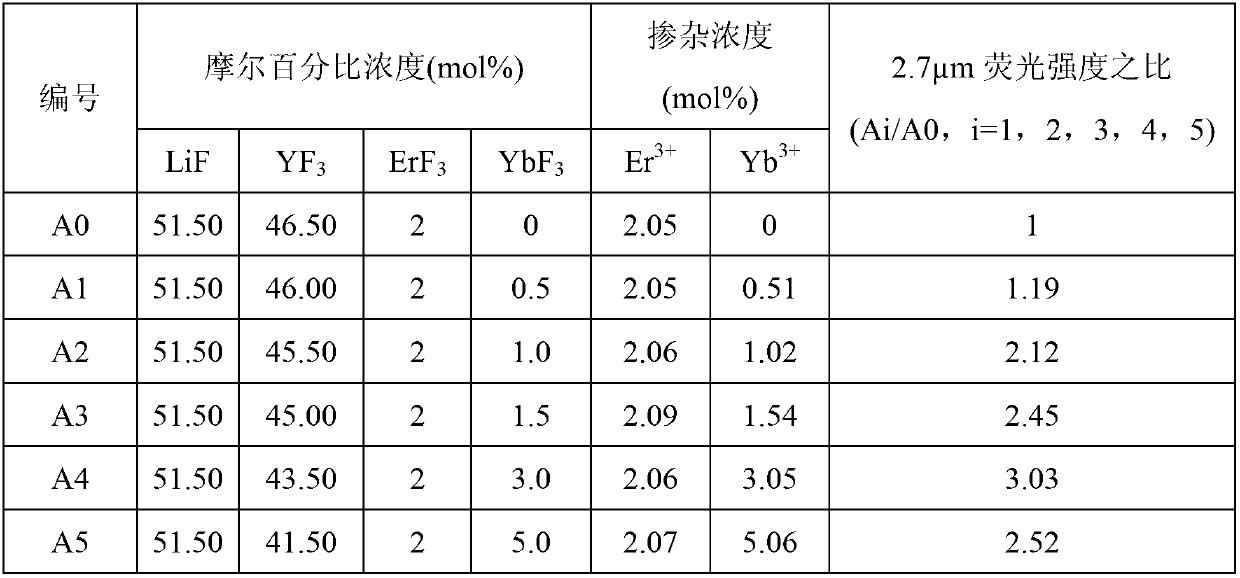

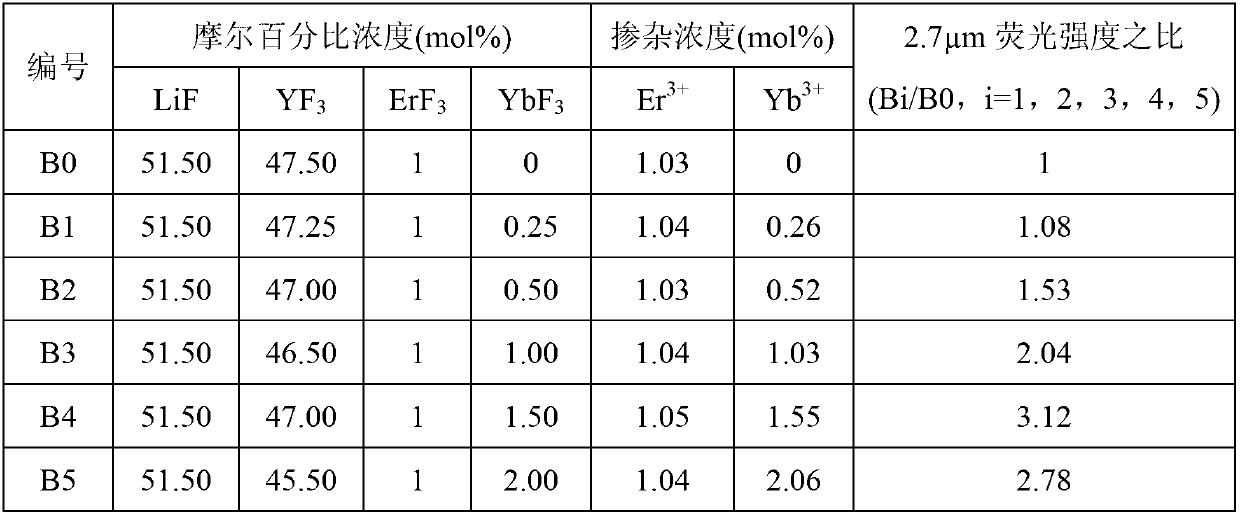

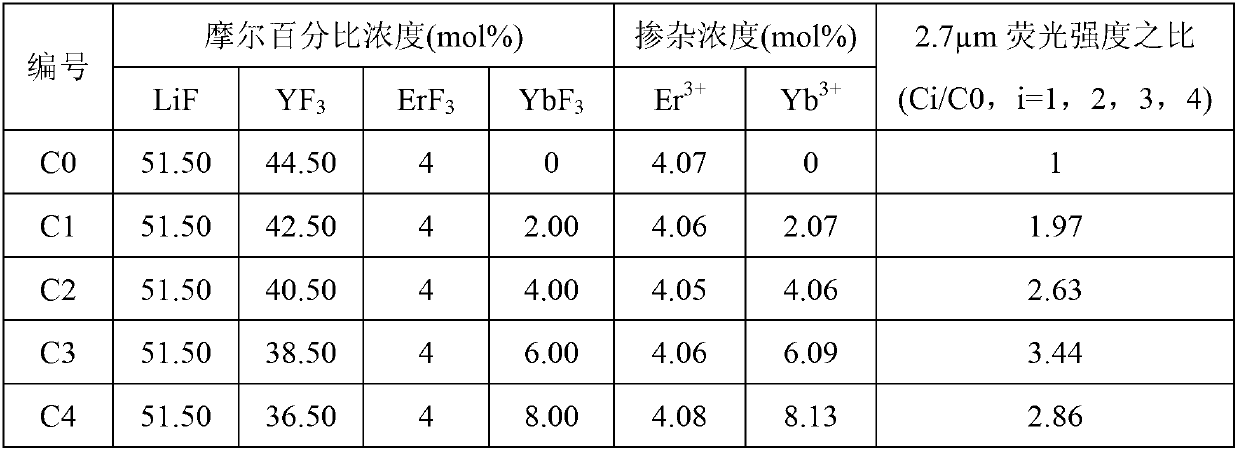

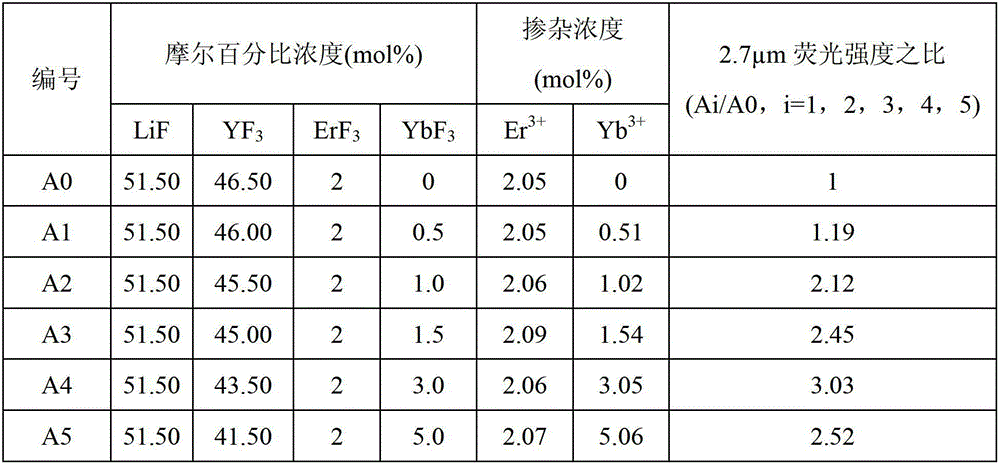

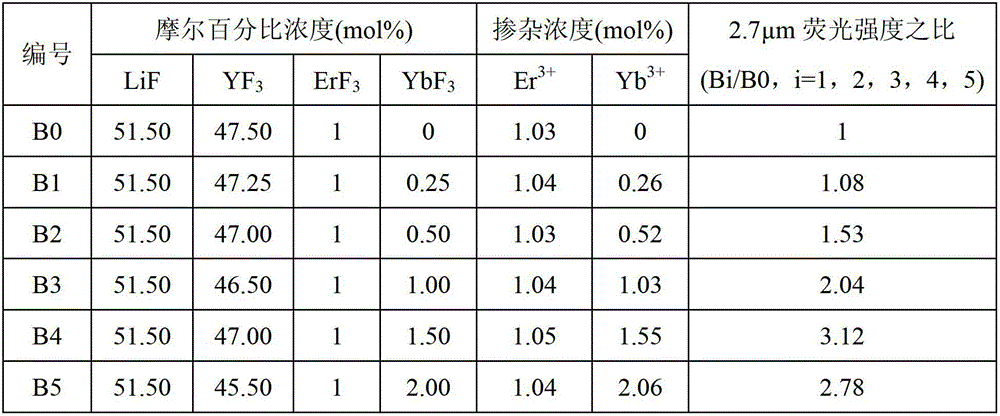

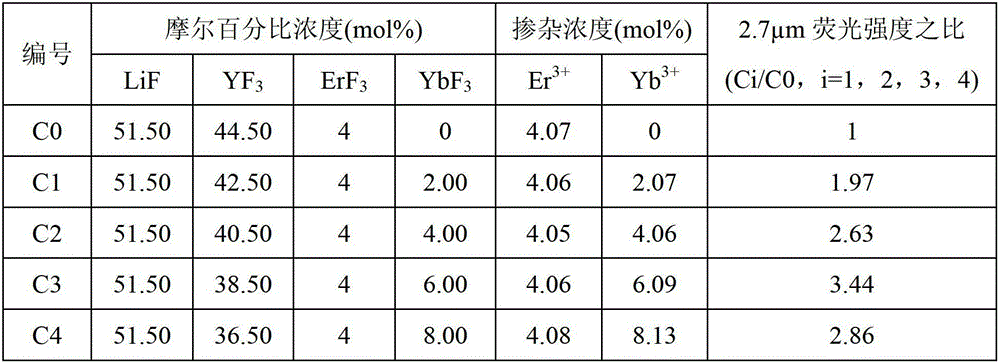

Er<3+>/Yb<3+> co-doped yttrium lithium fluoride monocrystal and preparation method thereof

InactiveCN102978701AHigh phonon energyPhonon energy low highPolycrystalline material growthFrom frozen solutionsWater vaporOxygen

The invention discloses an Er<3+> / Yb<3+> co-doped yttrium lithium fluoride monocrystal and a preparation method thereof. The yttrium lithium fluoride monocrystal is a rare earth ion Er<3+> / Yb<3+> co-doped monocrystal; the molecular formula is LiY(1-x-y)ErxYbyF4, wherein x is greater than or equal to 0.008 and less than or equal to 0.085, and y is greater than or equal to 0.002 and less than or equal to 0.170; the segregation coefficients of Yb<3+> and Er<3+> in the yttrium lithium fluoride are about 1, and efficient intermediate infrared laser of 2.7 microns can be output; and the yttrium lithium fluoride monocrystal has high transmittance of intermediate infrared laser, has better thermal, mechanical and chemical stabilities than those of glass state materials and has the characteristics of low phonon energy, high optical transmittance of wavebands with width of 300-5500nm, less color center forming amount, low thermal lens effect and the like, thereby being more easily processed and more suitably used in laser devices. In the preparation method disclosed by the invention, a sealing crucible falling technology is used, so that the operation is simple; the raw material is fluorated at high temperature in a sealed water-free and oxygen-free environment, so that the crystal is isolated from air and water vapor during the growth; and therefore, the high-quality Er<3+> / Yb<3+> co-doped LiYF4 monocrystal containing little OH<-> ion and oxide is obtained.

Owner:NINGBO UNIV

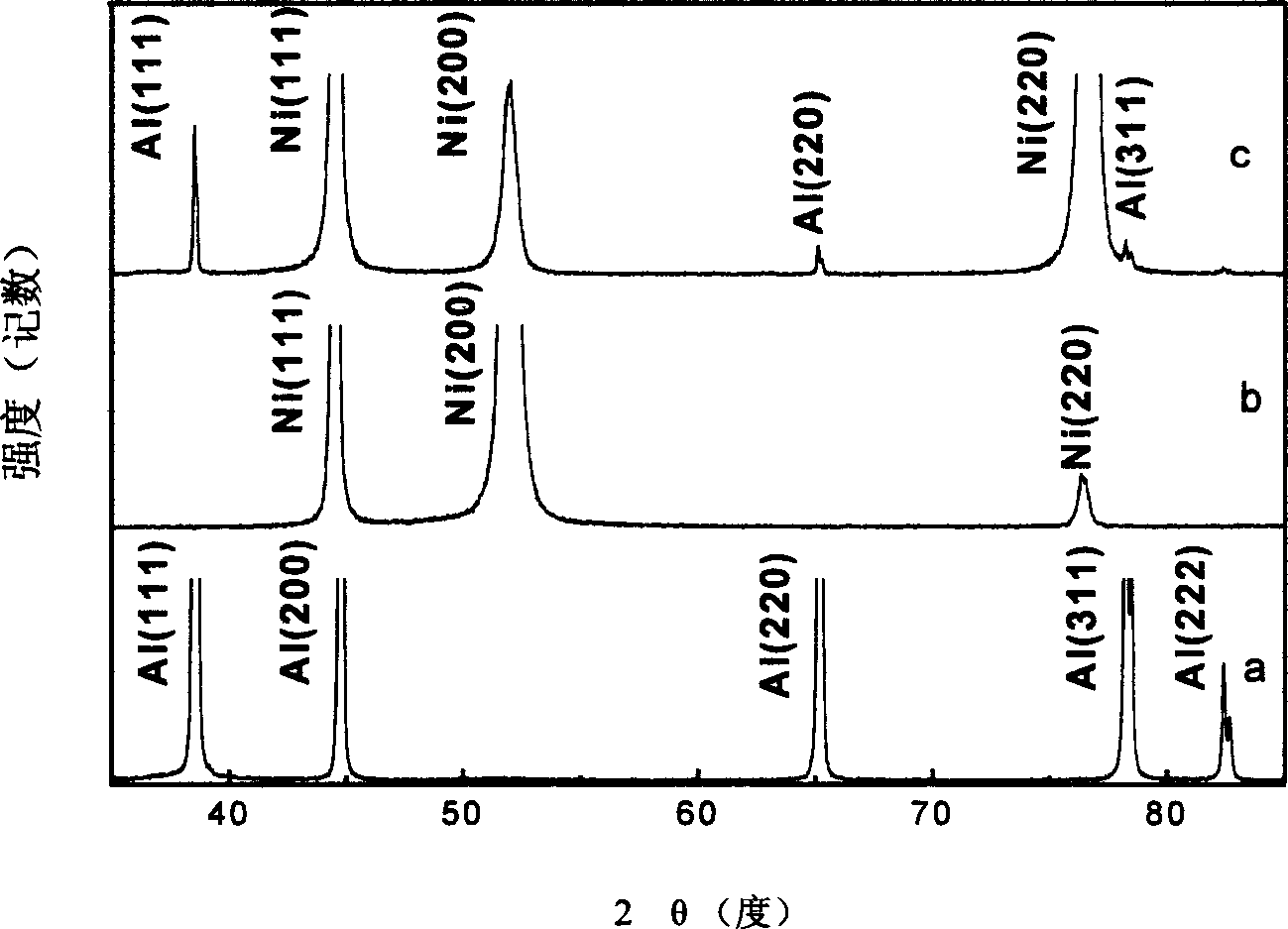

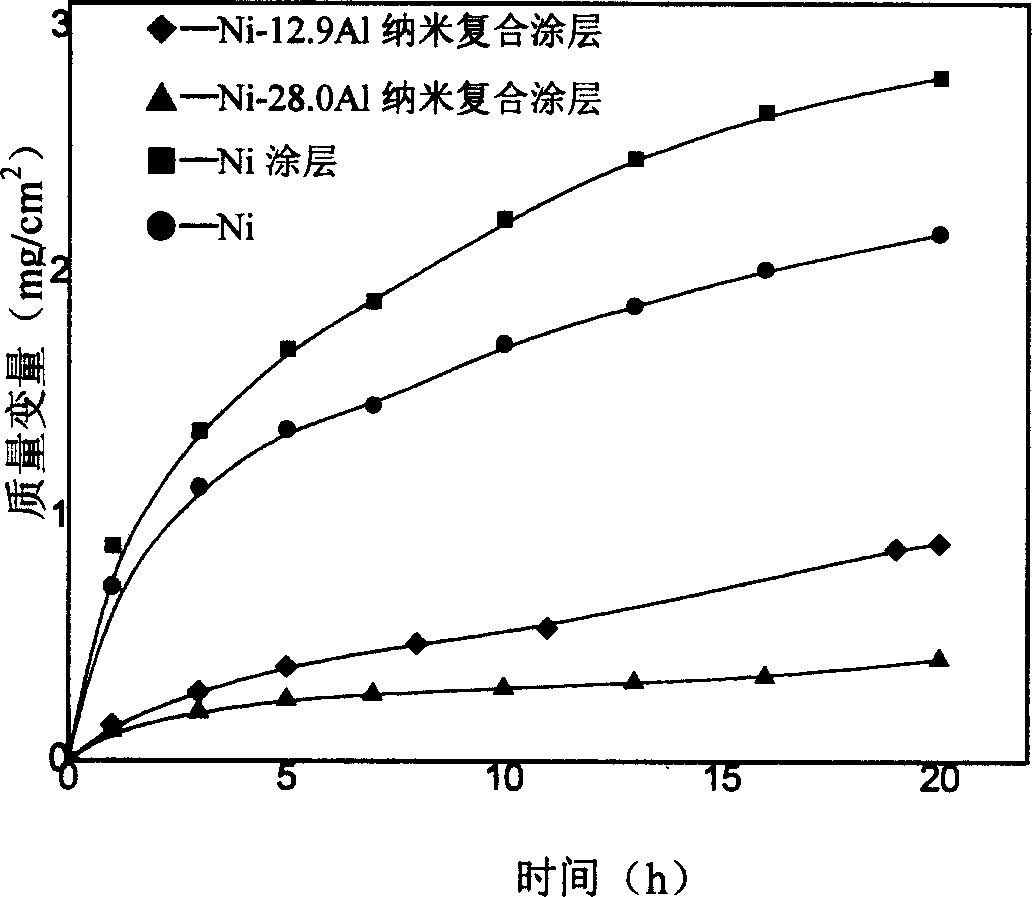

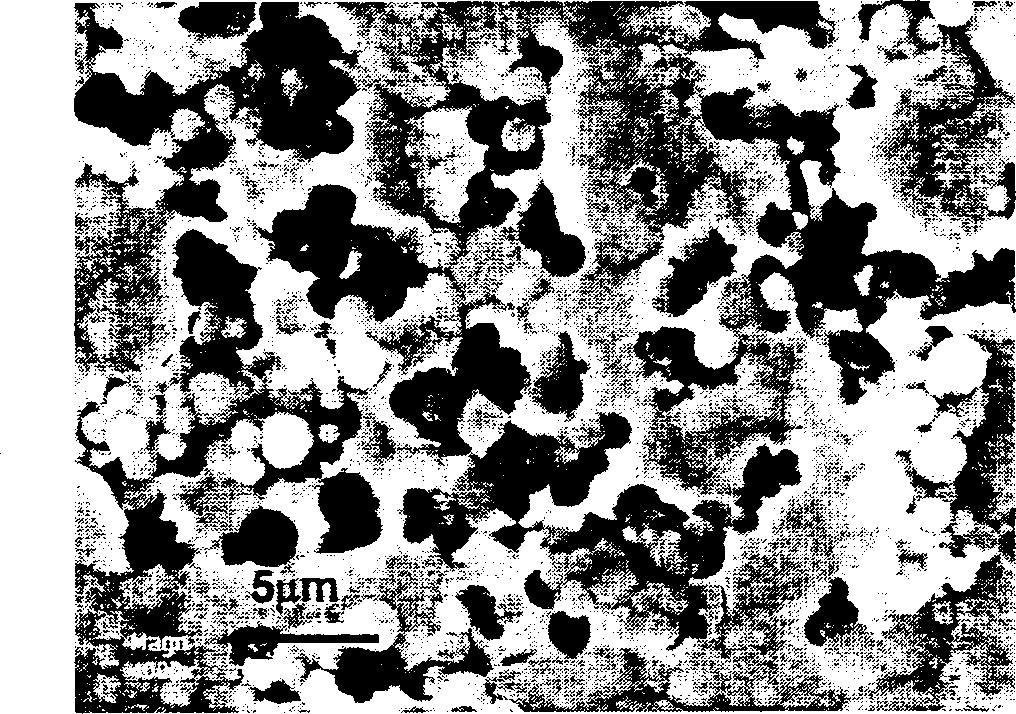

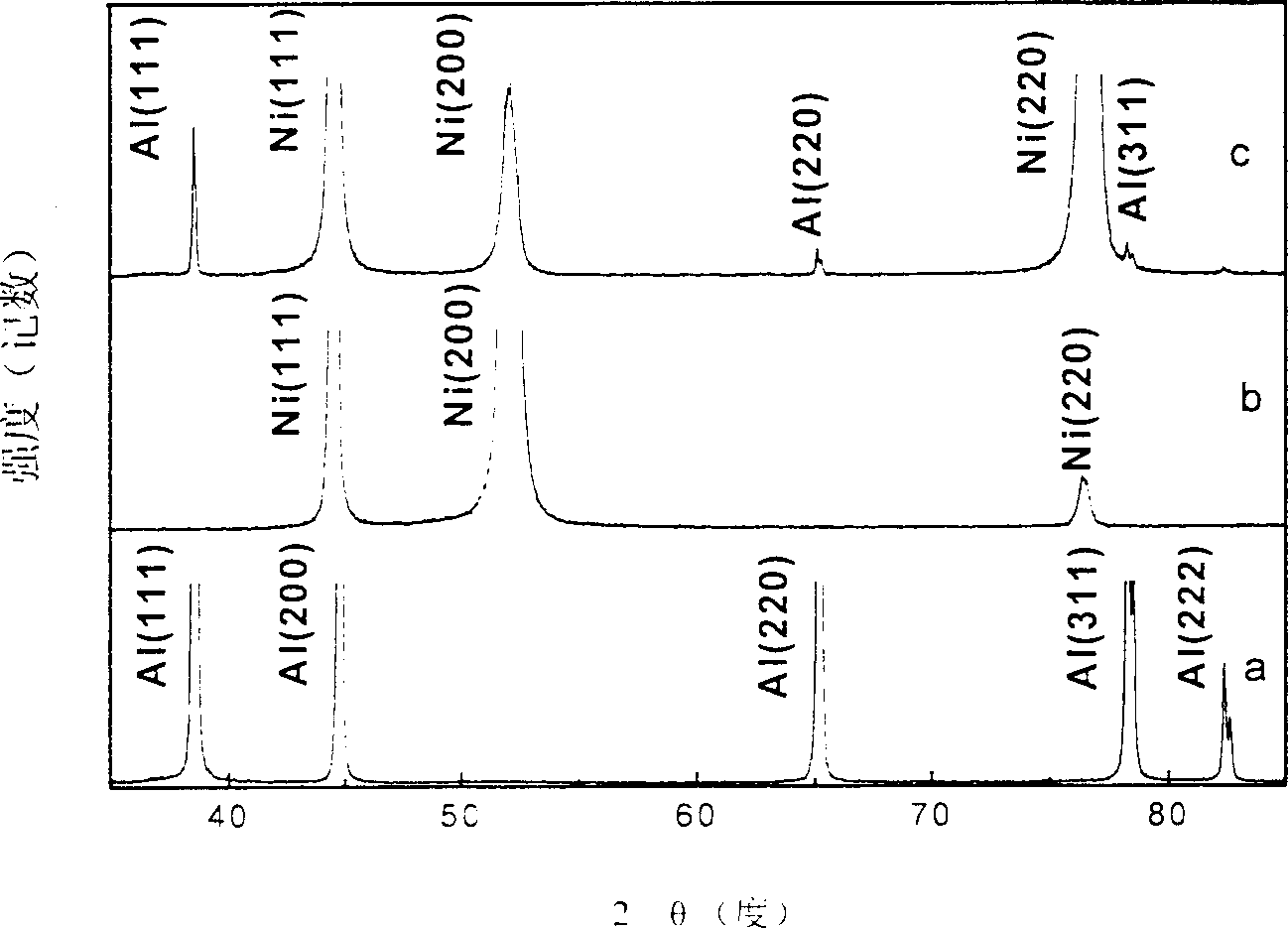

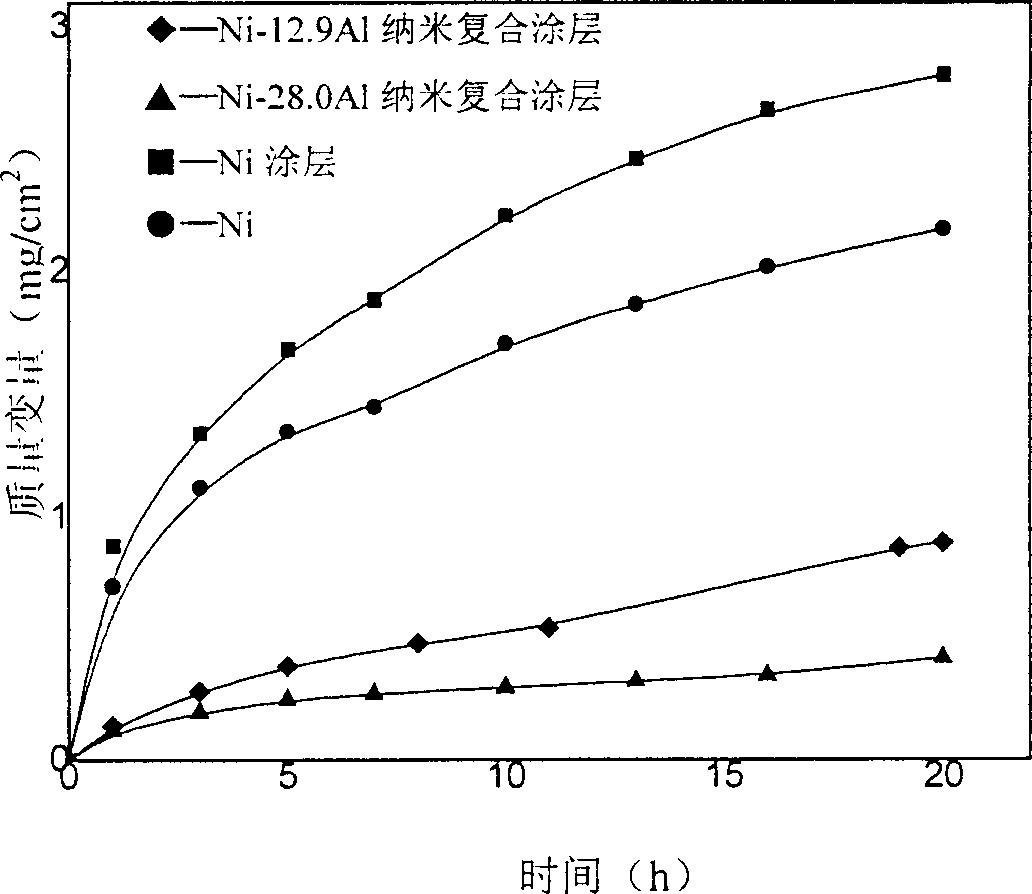

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1576398AIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

The thermally grown Al2O3 film type M-Al nano composite coating consists of nano crystal M coating and nano metal Al grains dispersed in the coating, where M is Ni, Fe or Co. The Al content is 9.8-35 wt%, and M is the rest. The nano composite Ni-Al, Fe-Al or Co-Al coating is prepared through composite electroplating process to deposit metal M and Al coating on to the base material of Ni, Fe or Co, carbon steel or alloy steel. The present invention has the features of simple technological process, low cost, high and controllable compounded amount, compact coating, no need of vacuum diffusion treatment of the nano composite coating, direct thermally growth of protecting Al2O3 film, etc.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Particle drawing method

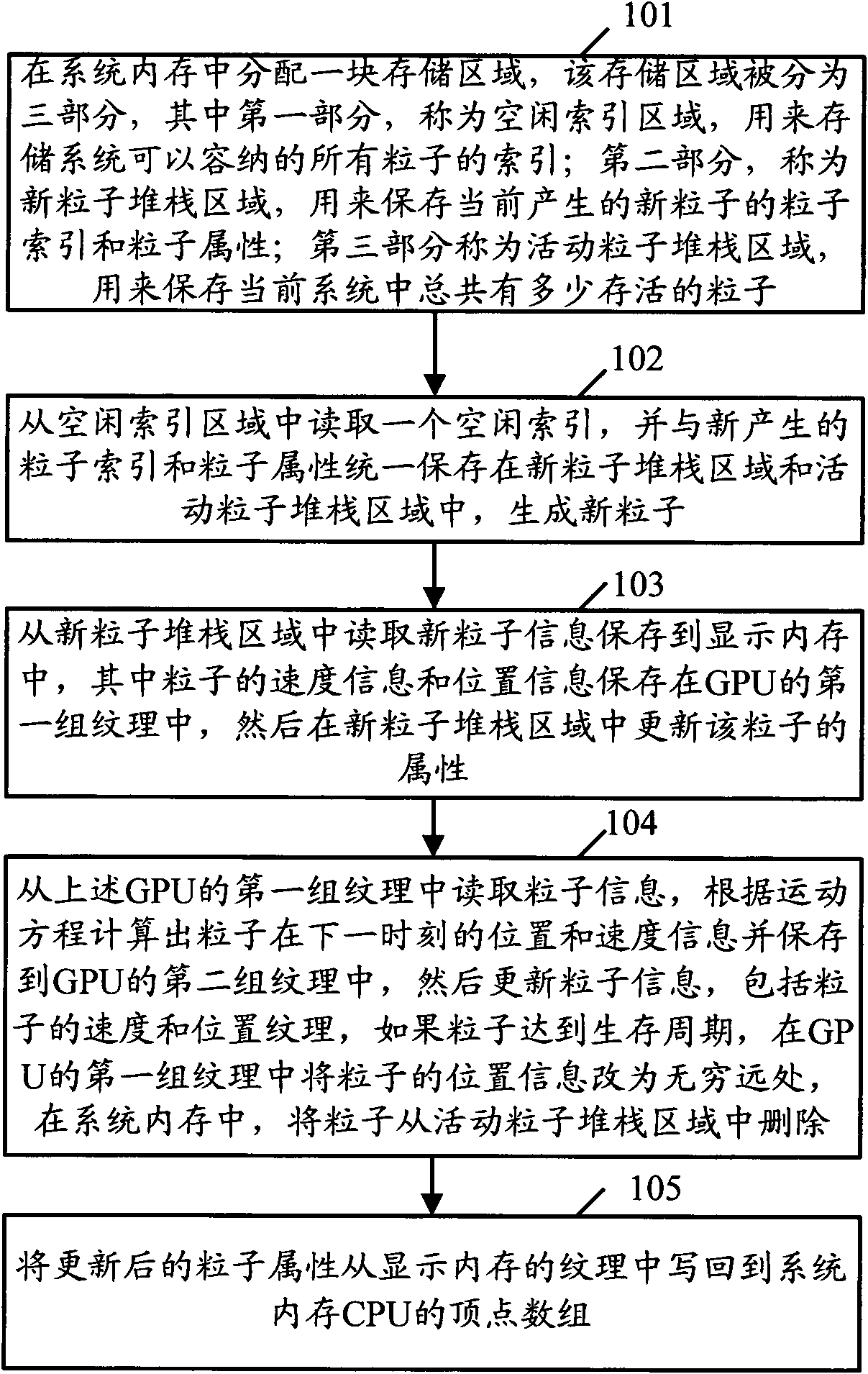

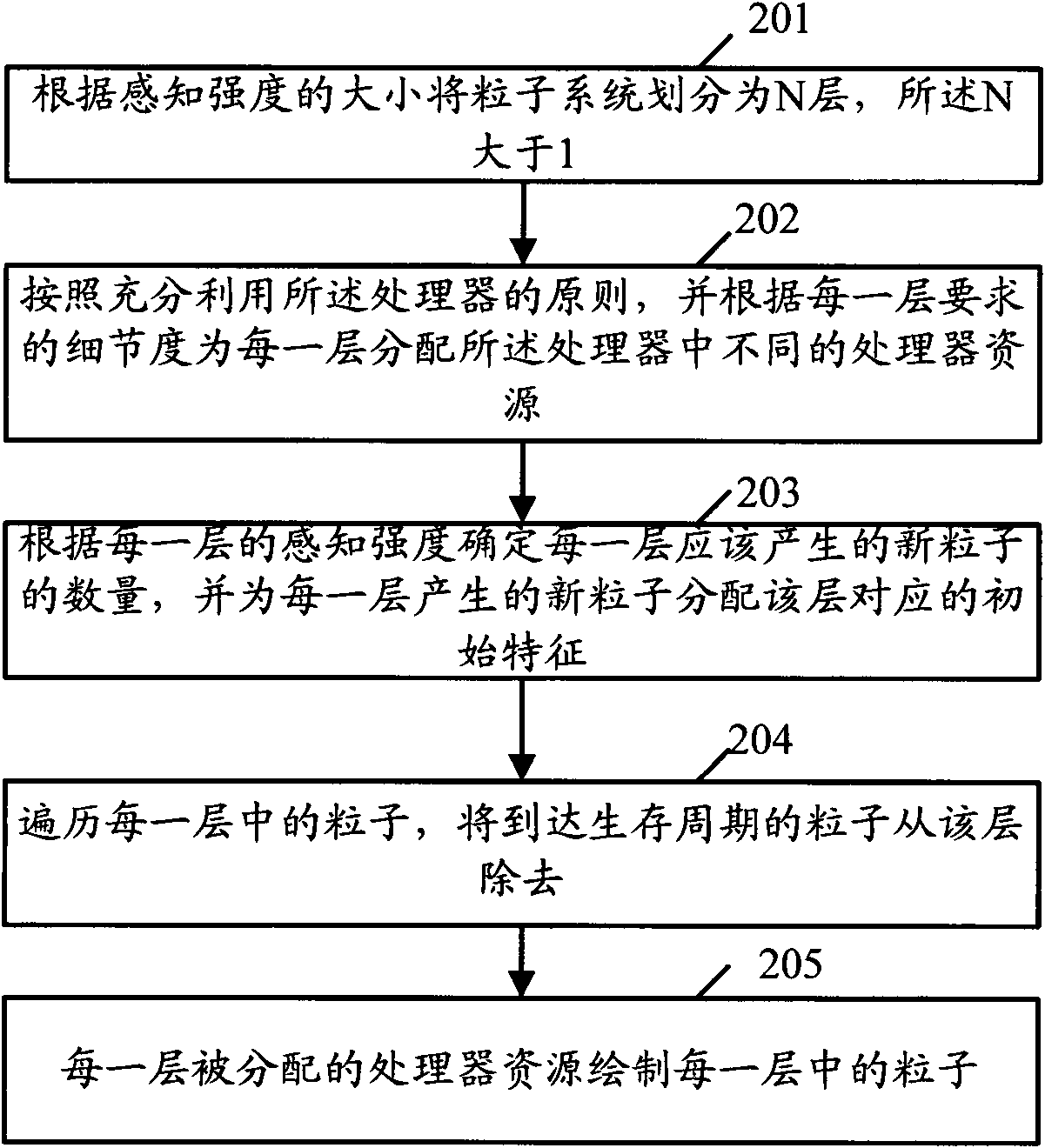

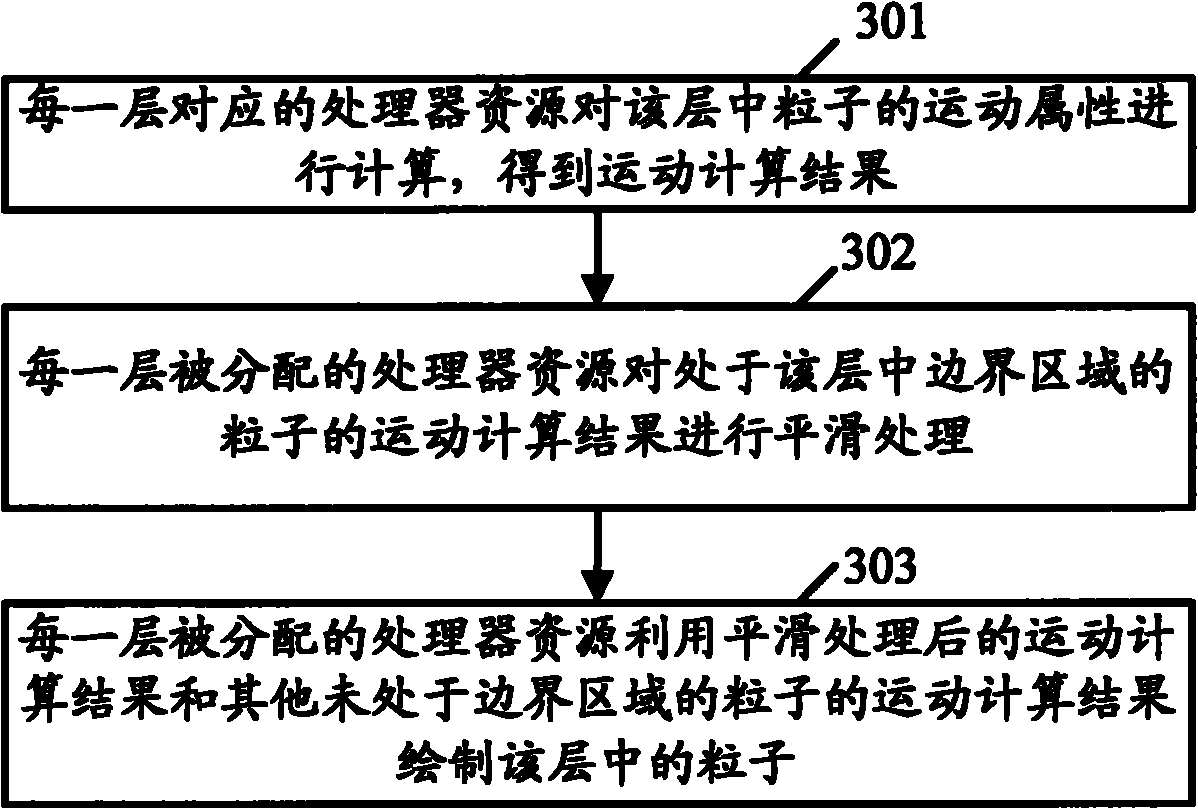

InactiveCN102426692AIncrease profitDraw realProcessor architectures/configurationUltimate tensile strengthComputer science

The invention provides a particle drawing method, which is applied to equipment provided with a processor comprising at least two cores. The method comprises the following steps of: according to sensing intensity, dividing a particle system into N layers, wherein N is more than 1; according to a principle of fully utilizing the processor, distributing different processor resources in the processor for each layer according to the detail degree required by each layer; according to the sensing intensity of each layer, determining the amount of new particles which need to be generated in each layer; distributing an initial characteristic corresponding to the layer for new particles generated on each layer; traversing particles in each layer, and removing particles which reach the life cycle from the layer; and drawing the particles in the layer by distributed processor resource of each layer.

Owner:BEIJING PIXEL SOFTWARE TECH

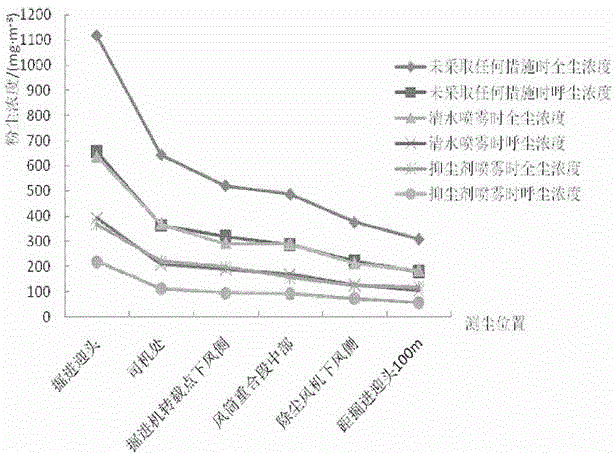

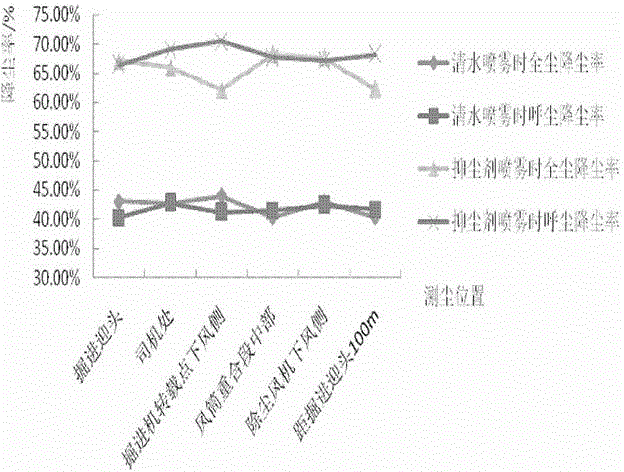

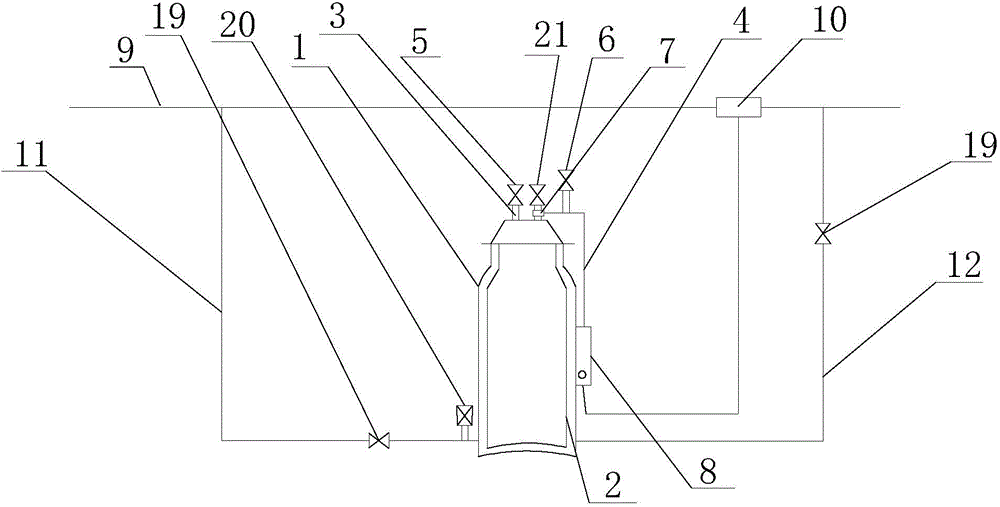

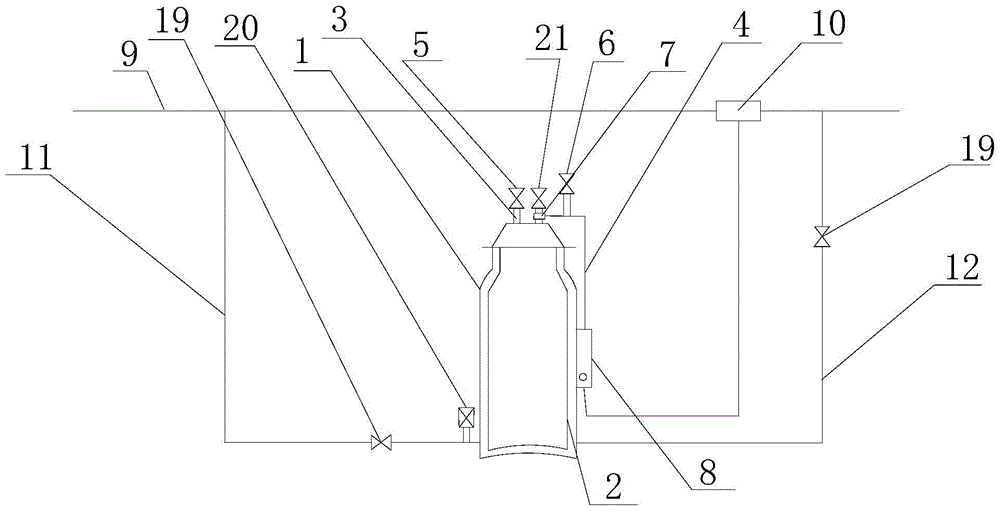

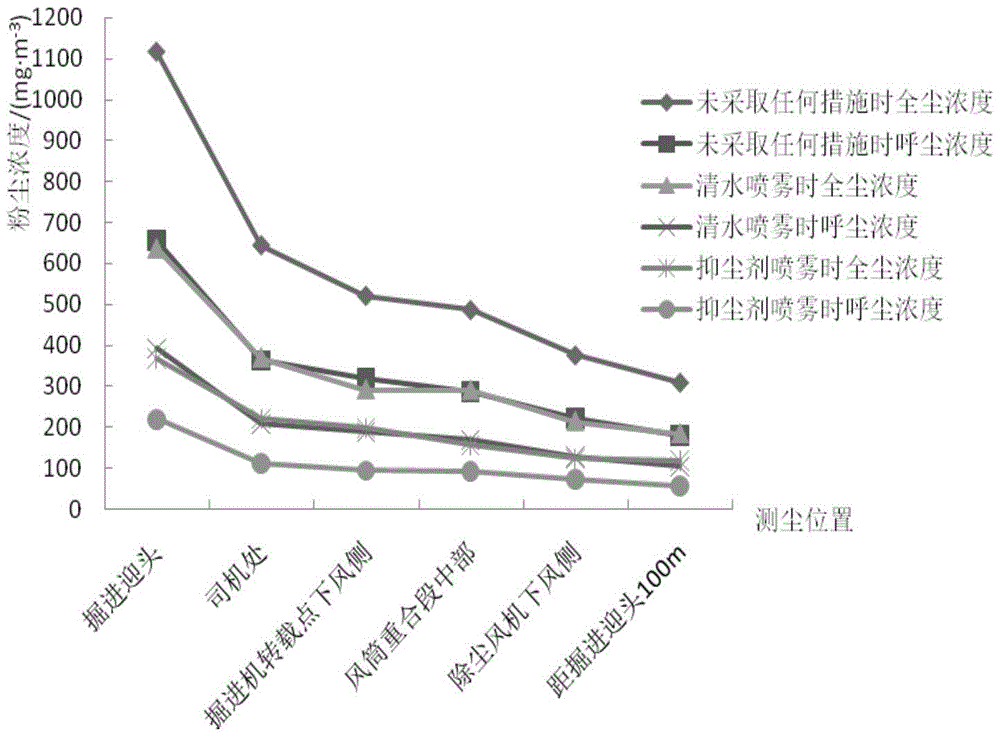

Rock dust polymerization and moisture-preservation inhibitor for coal mines and adding device thereof

ActiveCN104533507AImprove wettabilityReduce surface tensionOther chemical processesDust removalBetaineEvaporation

The invention discloses a rock dust polymerization and moisture-preservation inhibitor for coal mines and an adding device thereof. The rock dust polymerization and moisture-preservation inhibitor comprises the following components in percentage by weight: 0.05%-0.07% of cocamidopropyl betaine, 0.05%-0.07% of magnesium chloride, 0.05%-0.07% of sodium fatty alcohol polyoxyethylene ether carboxylate and the balance being water. The invention further provides an automatic adding device of the rock dust polymerization and moisture-preservation inhibitor for the coal mines. The cocamidopropyl betaine and the sodium fatty alcohol polyoxyethylene ether carboxylate have good wettability; after cocamidopropyl betaine and the sodium fatty alcohol polyoxyethylene ether carboxylate are compounded, the surface tension of water can be greatly reduced and the contact possibility of fog drops and dust particles is promoted; the magnesium chloride has a good moisture preservation performance so that the moisture preservation content of the captured dust particles is greatly enhanced, and a secondary dust raising phenomenon caused by water evaporation is prevented.

Owner:SHANDONG UNIV OF SCI & TECH

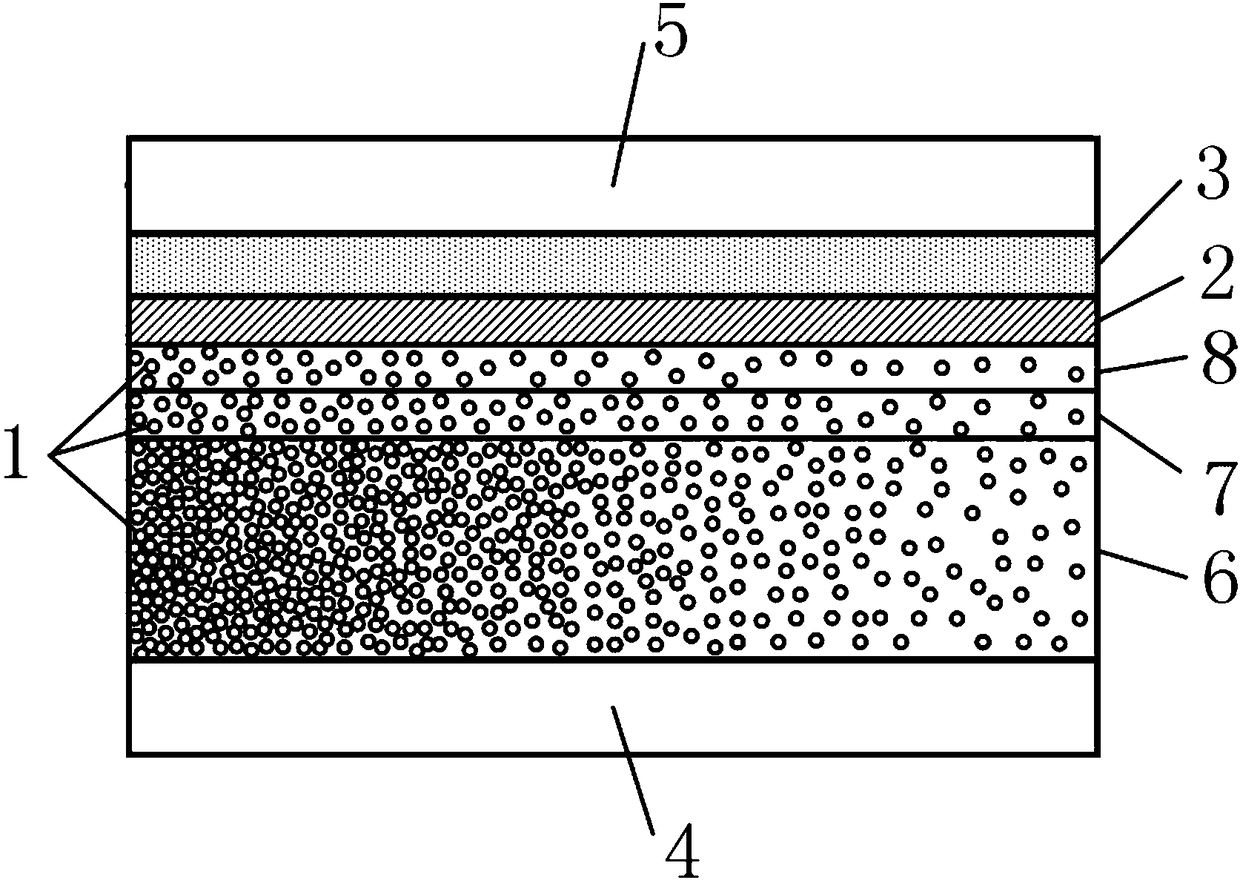

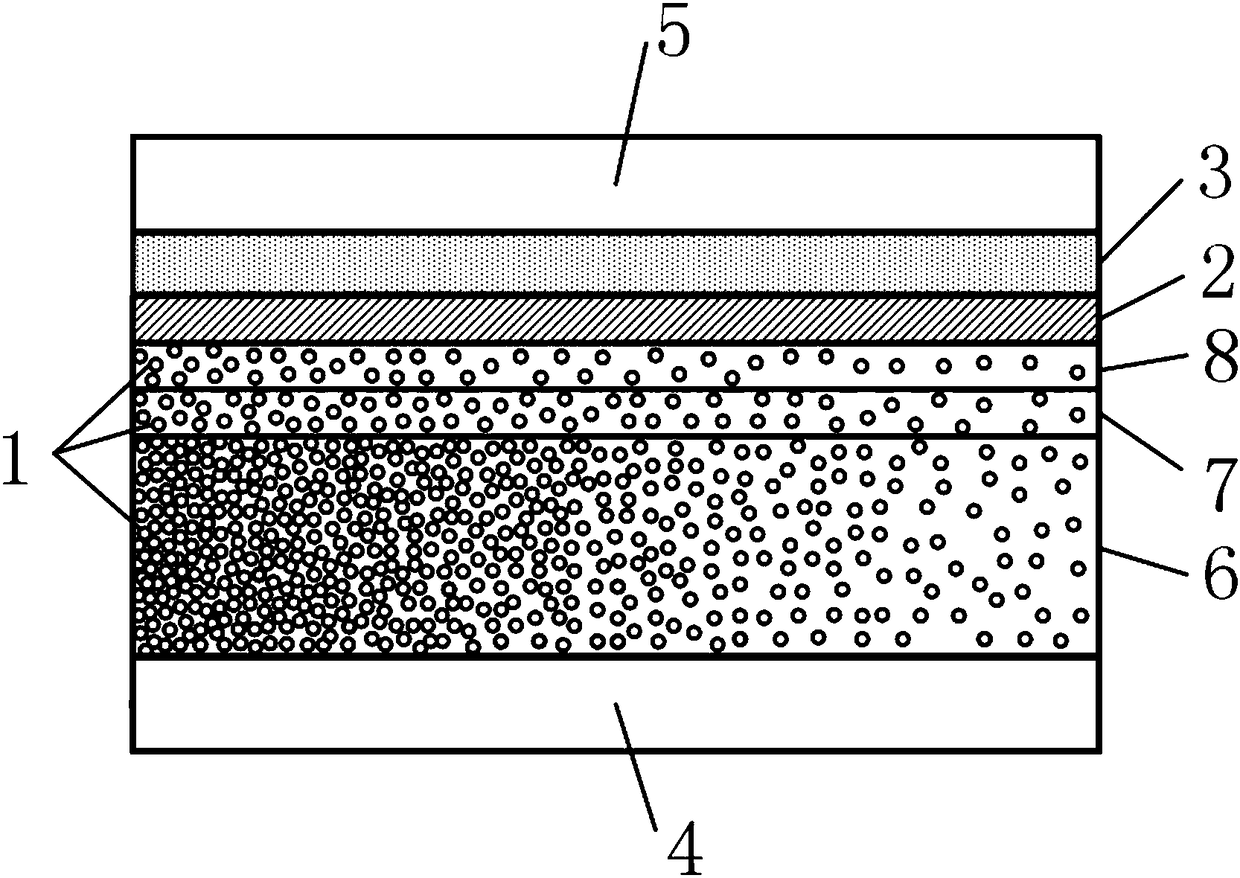

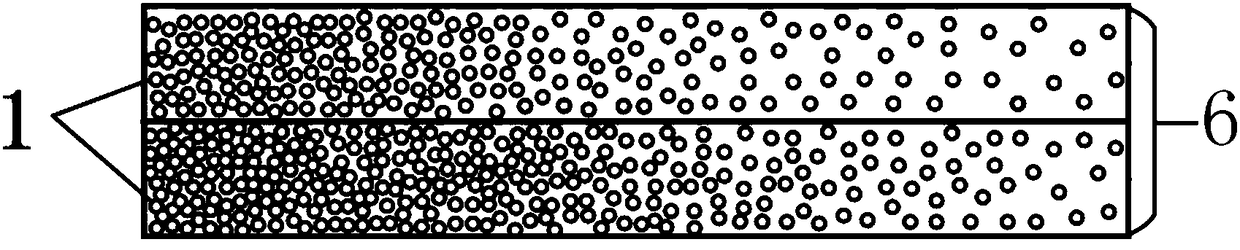

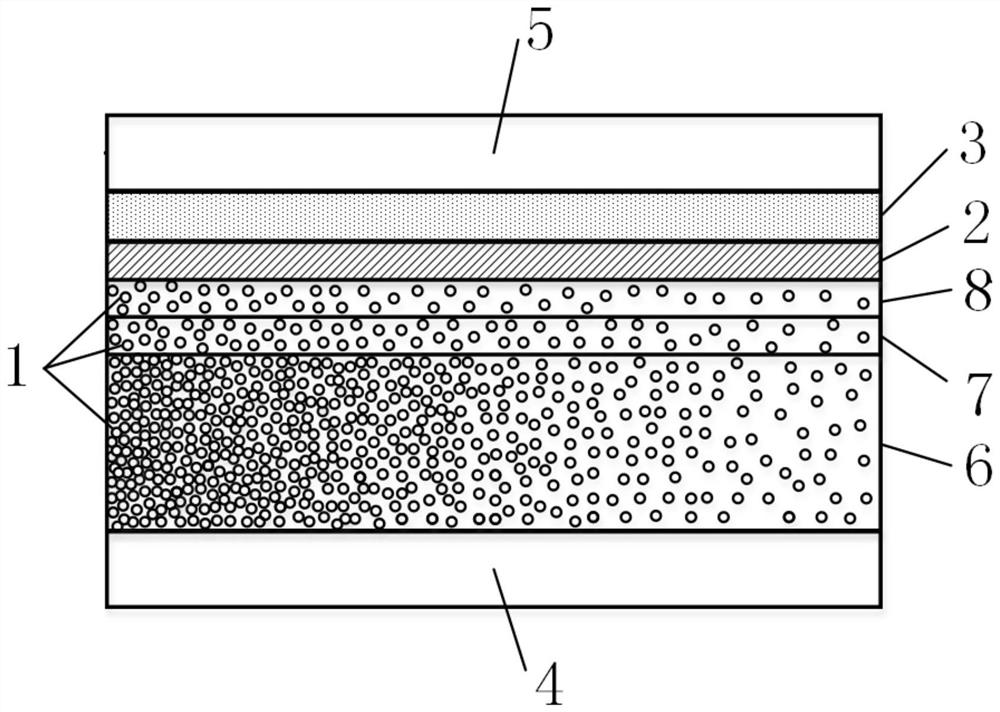

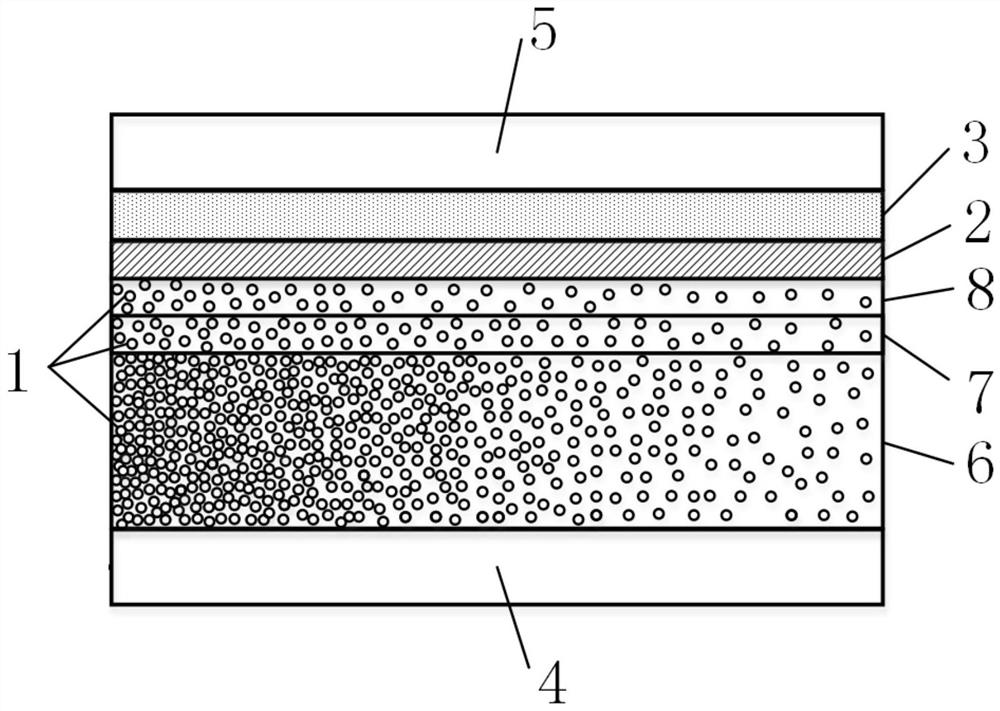

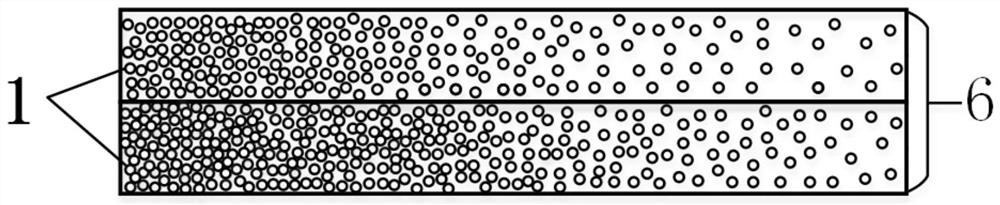

Solid oxide fuel cell gradient porosity anode and solid oxide fuel cell

ActiveCN108598493AHigh strength propertiesImprove performanceCell electrodesFuel cellsPorosityFuel cells

The invention discloses a solid oxide fuel cell gradient porosity anode and a solid oxide fuel cell. The solid oxide fuel cell gradient porosity anode comprises an anode function layer, an anode transition layer and an anode support layer which are connected in sequence from top to bottom. The opening porosity of the anode transition layer is greater than or equal to the opening porosity of the anode function layer. The opening porosity of the anode transition layer is smaller than or equal to the opening porosity of the anode support layer. The opening porosity of the anode function layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual decrease along a horizontal direction, or the opening porosity of the anodefunction layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual increase. The anode is characterized by relatively low activation polarization, concentration polarization and ohm polarization loss. The fuel cell is characterized by high output electrical property and high intensity.

Owner:XI AN JIAOTONG UNIV

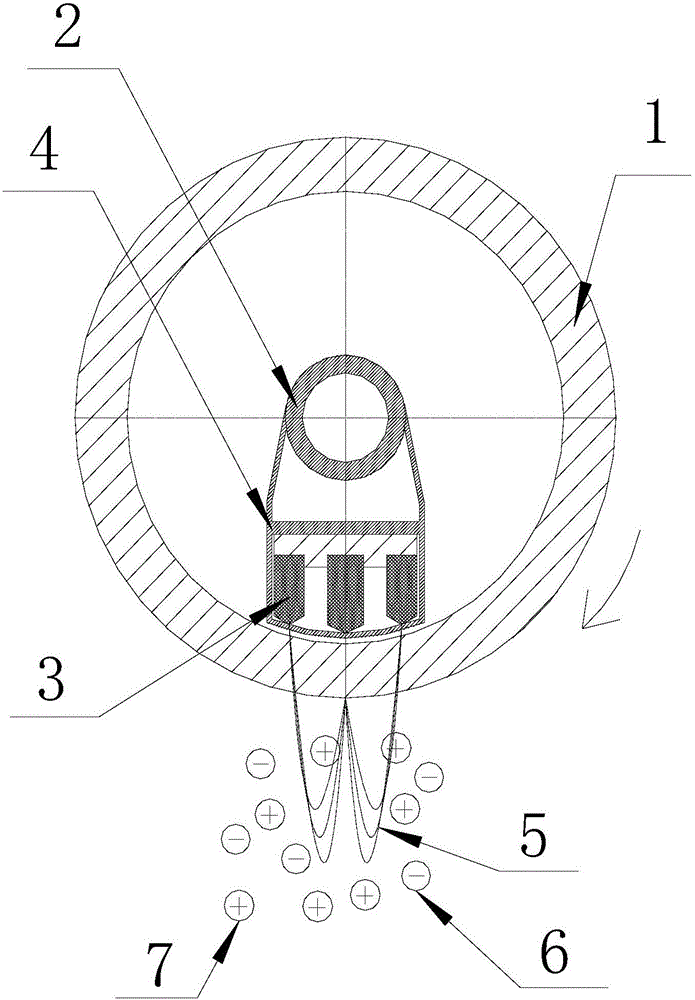

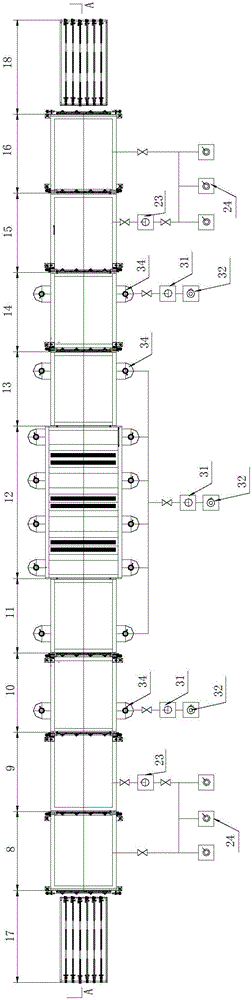

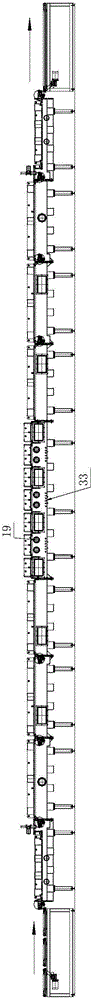

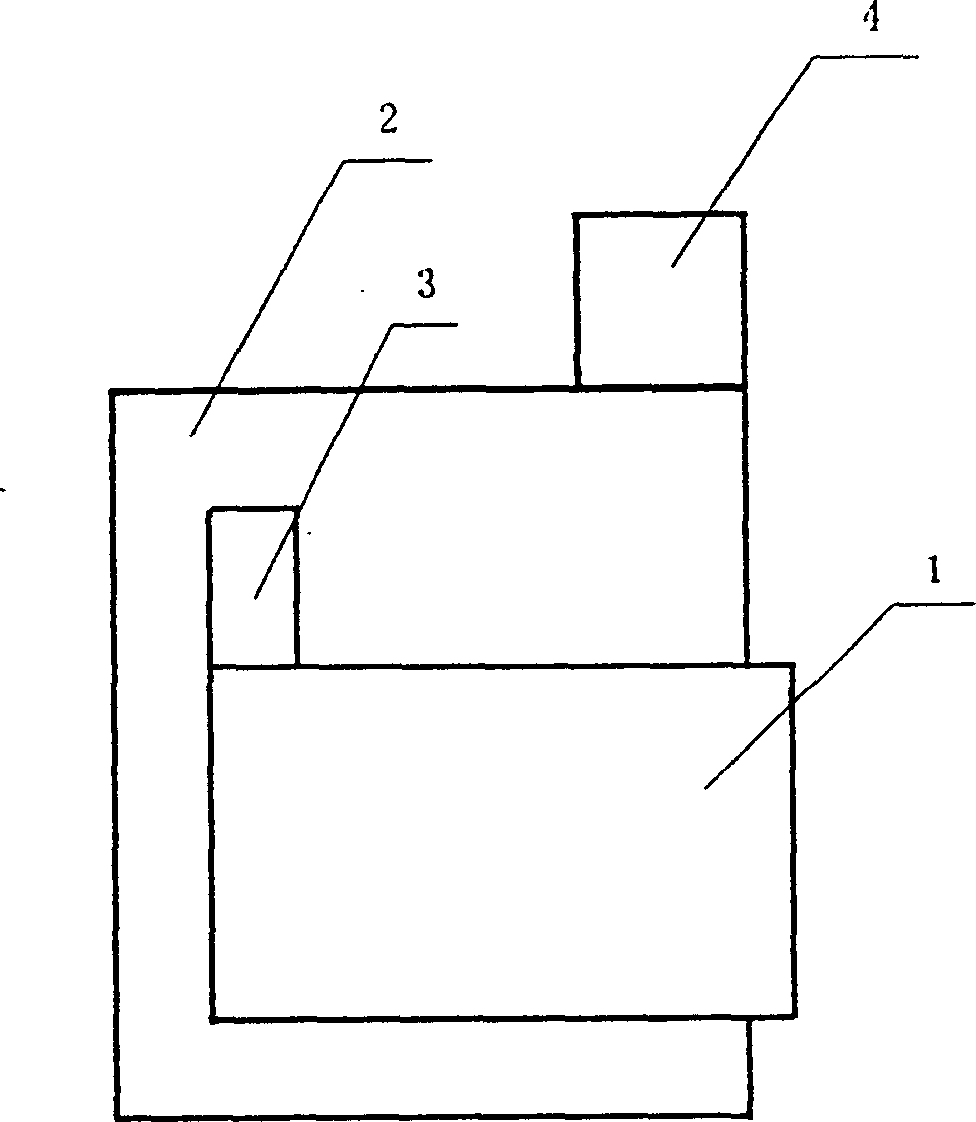

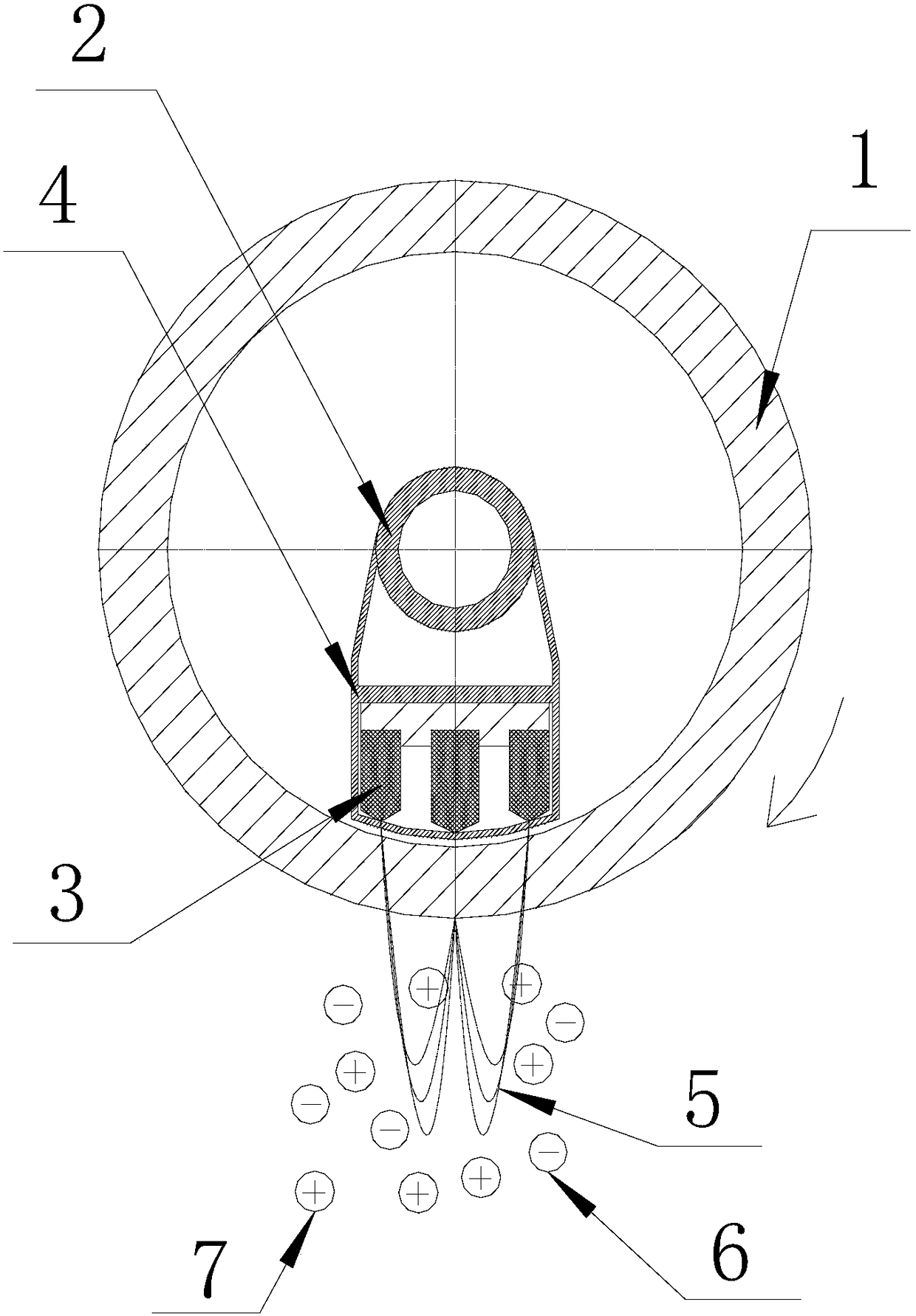

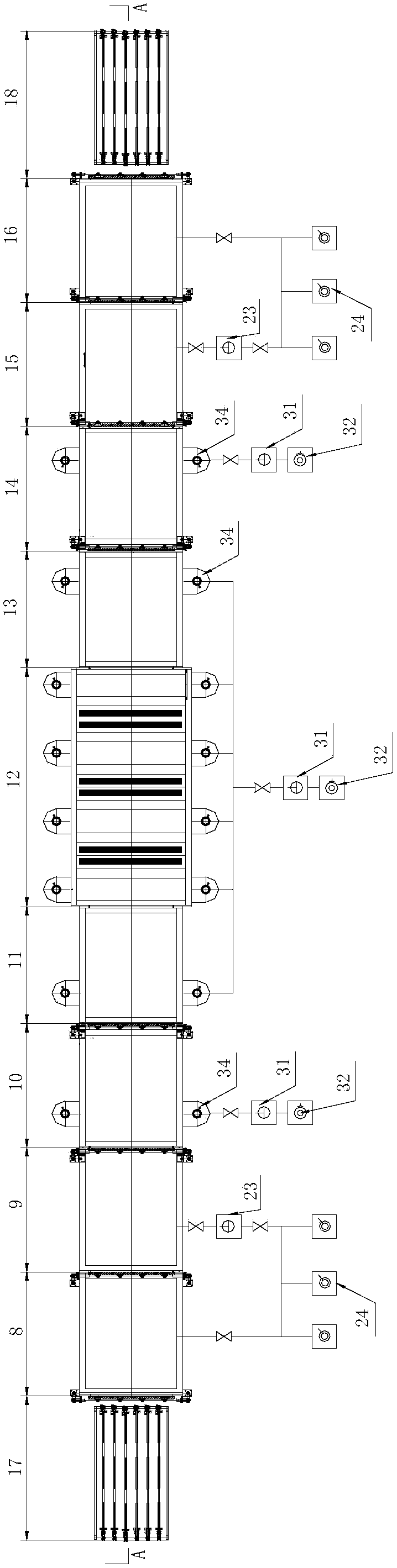

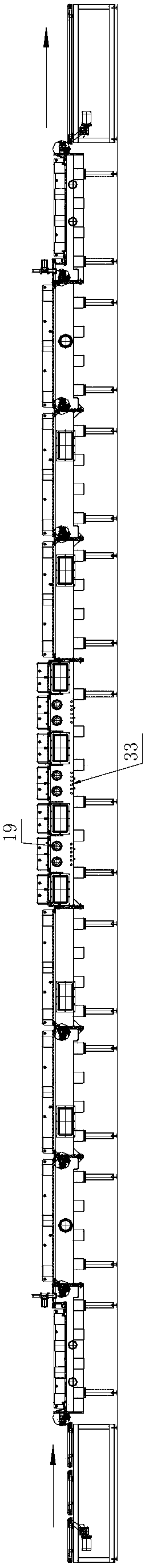

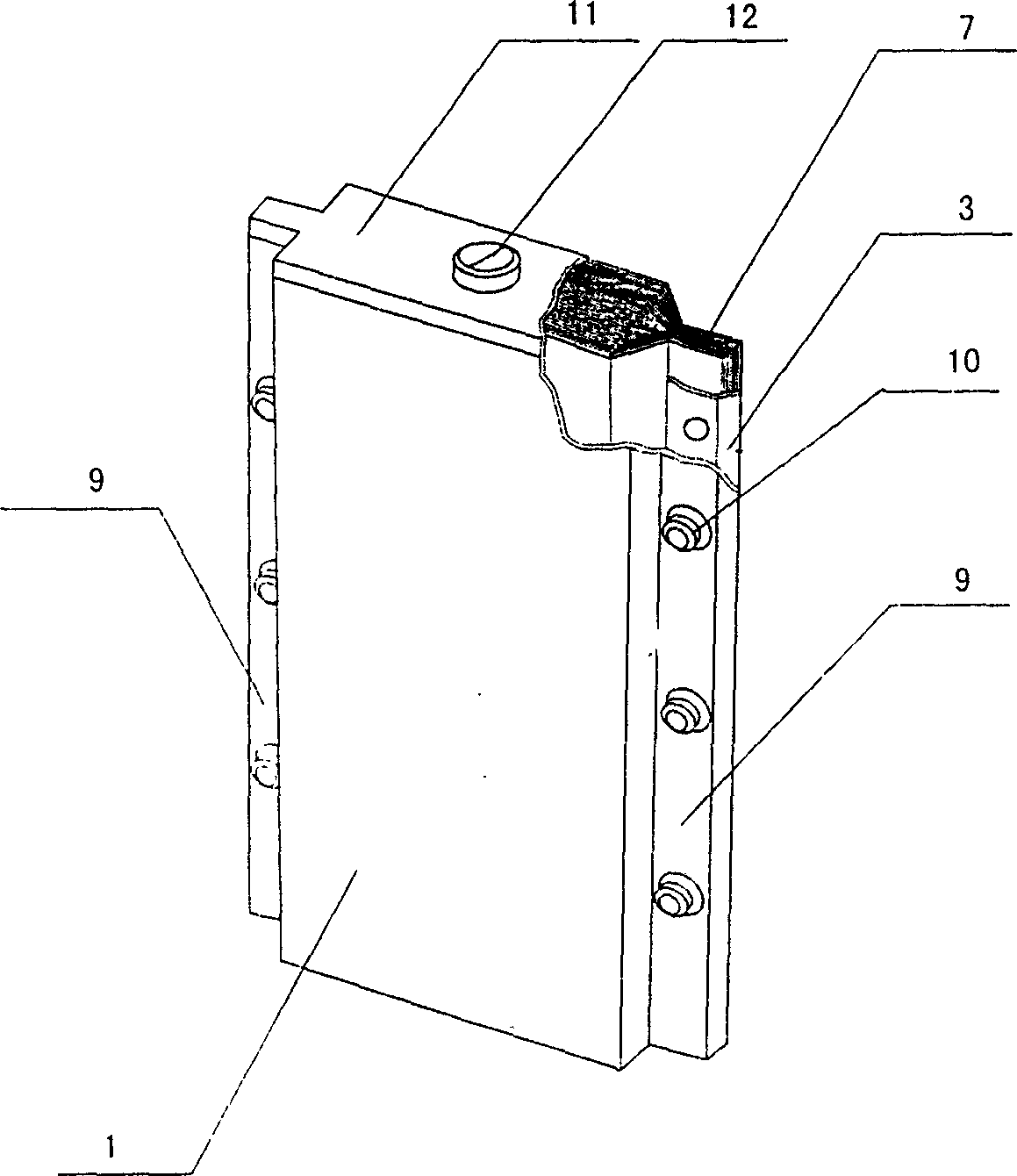

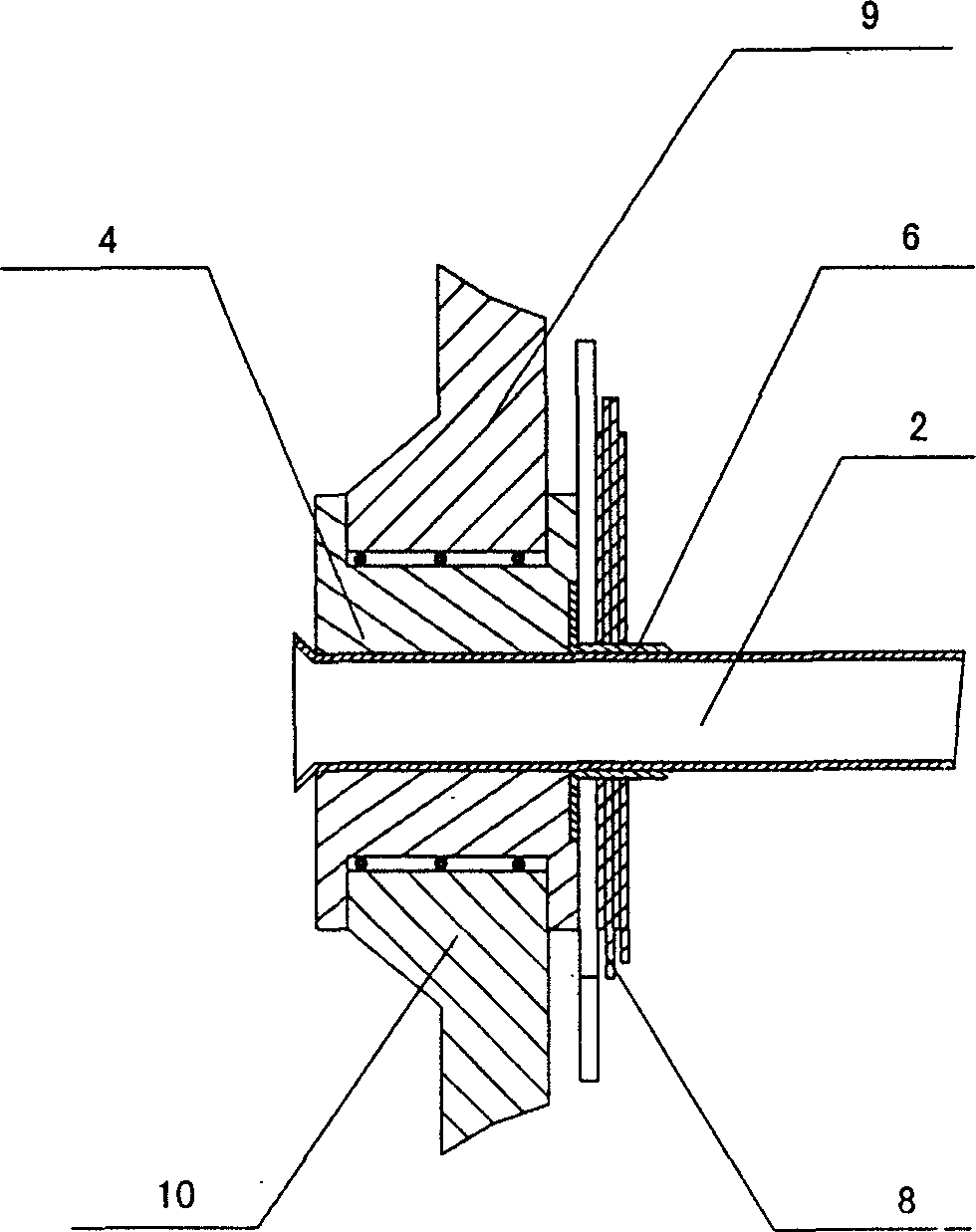

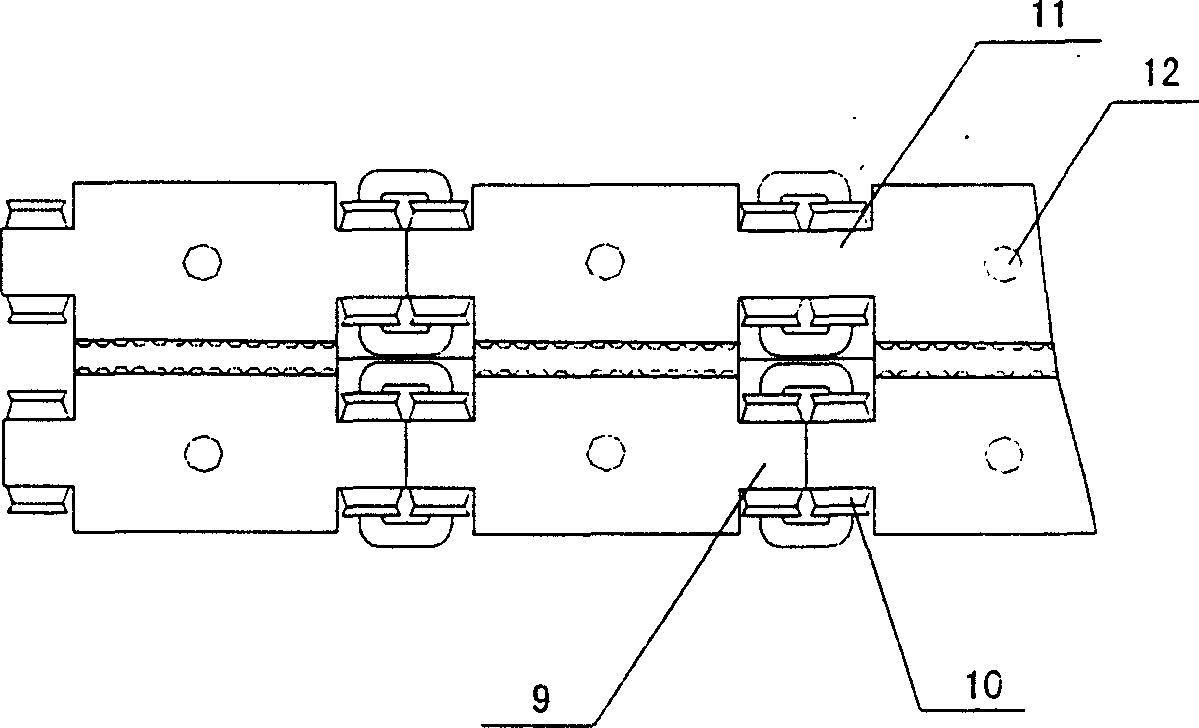

Rotary magnetron target and horizontal magnetron sputtering coating equipment

ActiveCN105908146AIncrease distribution densityIncrease the number of particlesVacuum evaporation coatingSputtering coatingSputteringMaterials science

The invention discloses a rotary magnetron target and horizontal magnetron sputtering coating equipment. The rotary magnetron target comprises a target, a magnetic core and a magnet, wherein the magnetic core is arranged at the middle part of the target, at least one magnet is arranged at the periphery of the magnetic core, and one end facing the target, of the magnet, is conical. The horizontal magnetron sputtering coating equipment comprises a front pre-pumping chamber, a front rough-pumping chamber, a front fine-pumping chamber, a front buffering chamber, a coating chamber, a rear buffering chamber, a rear fine-pumping chamber, a rear rough-pumping chamber and a rear pre-pumping chamber which are sequentially connected, wherein one or more coating chambers are provided, and one rotary magnetron target is arranged in each coating chamber, and located above a workpiece. According to the rotary magnetron target, the tail end of the magnet is designed to be a tip, thus the distribution density of magnetic force lines on the surface of the target is enhanced, and the number of the sputtered target particles can be increased, and then the coating efficiency of the surface of the workpiece is increased. The rotary magnetron target is applied to the horizontal magnetron sputtering coating equipment, thus the coating efficiency of the workpiece can be effectively increased, and the production cycle of a whole process line is shortened, and then the production efficiency is increased.

Owner:ZHAOQING KERUN VACUUM EQUIP

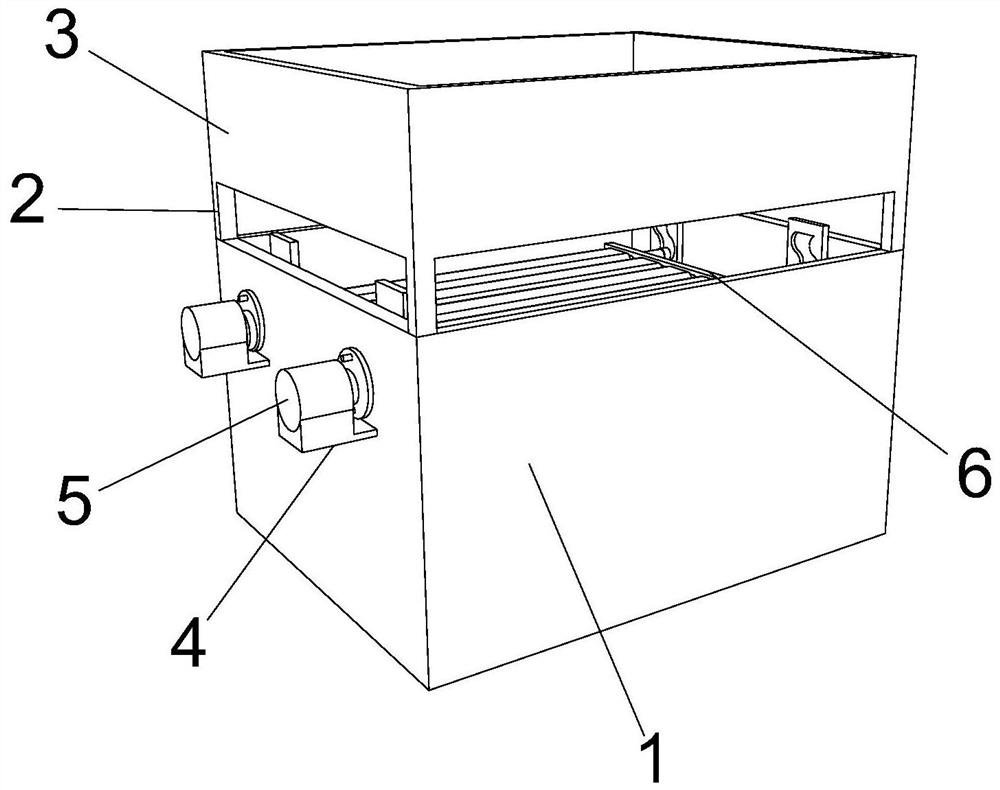

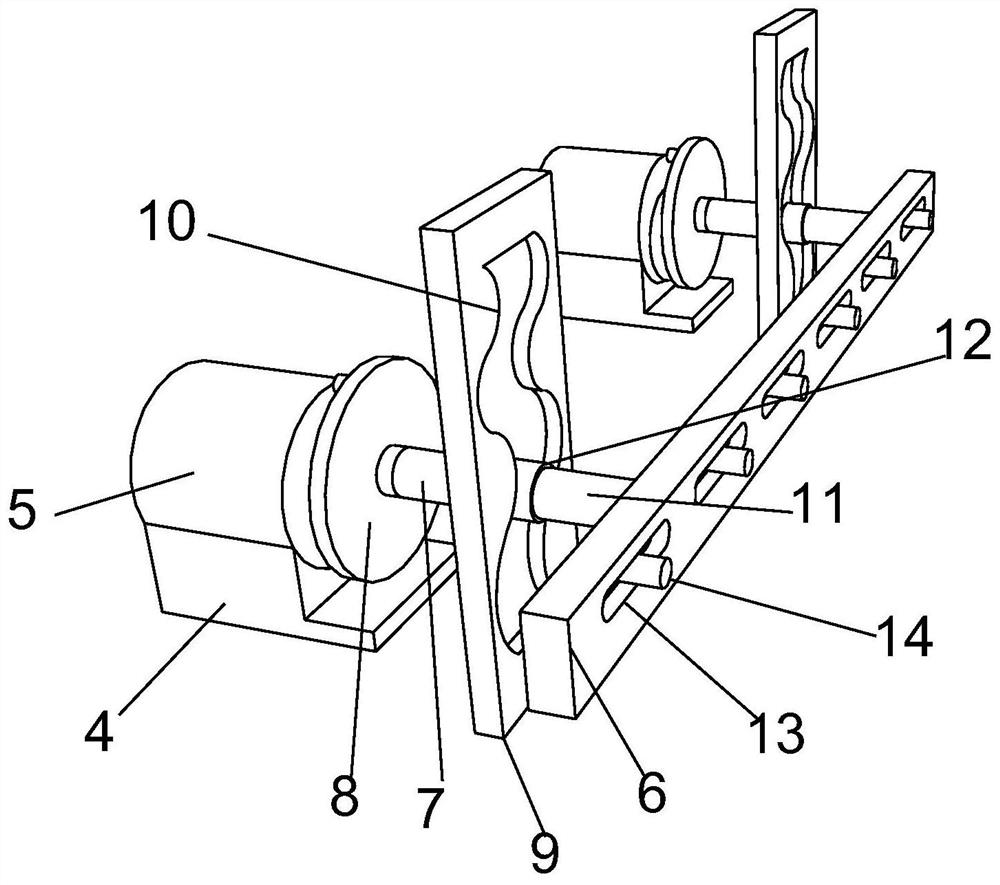

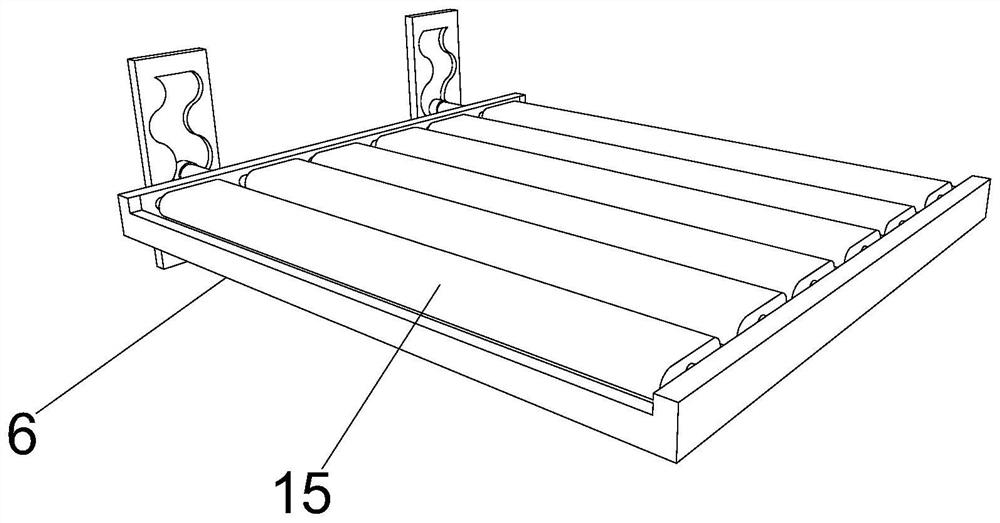

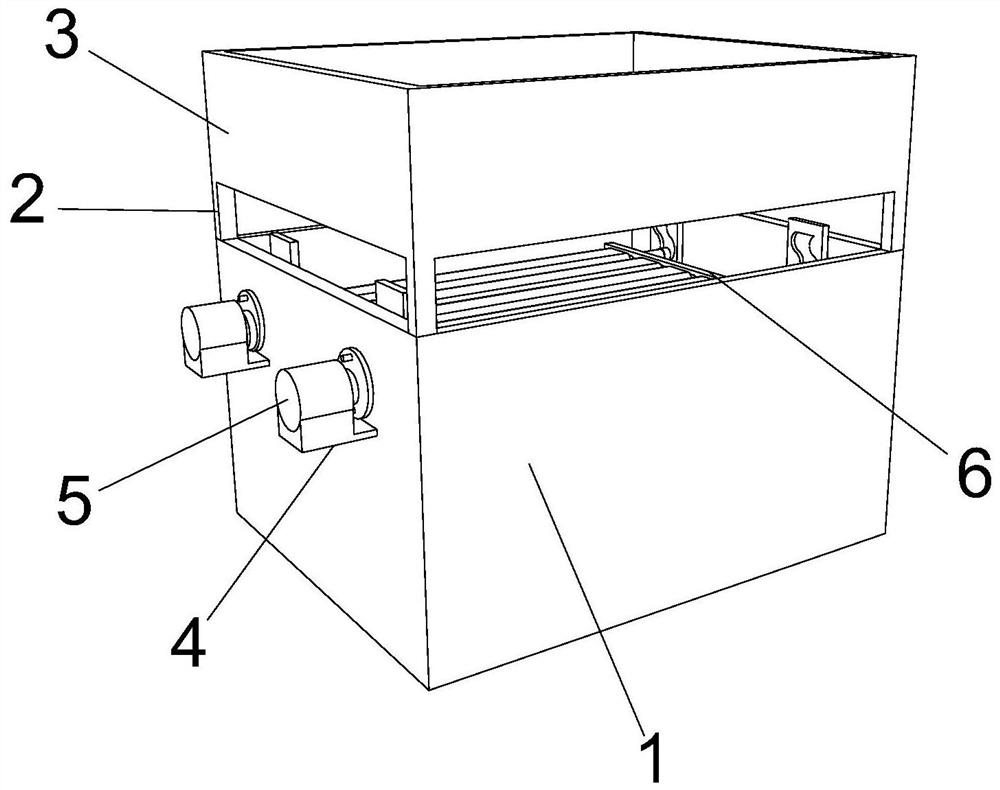

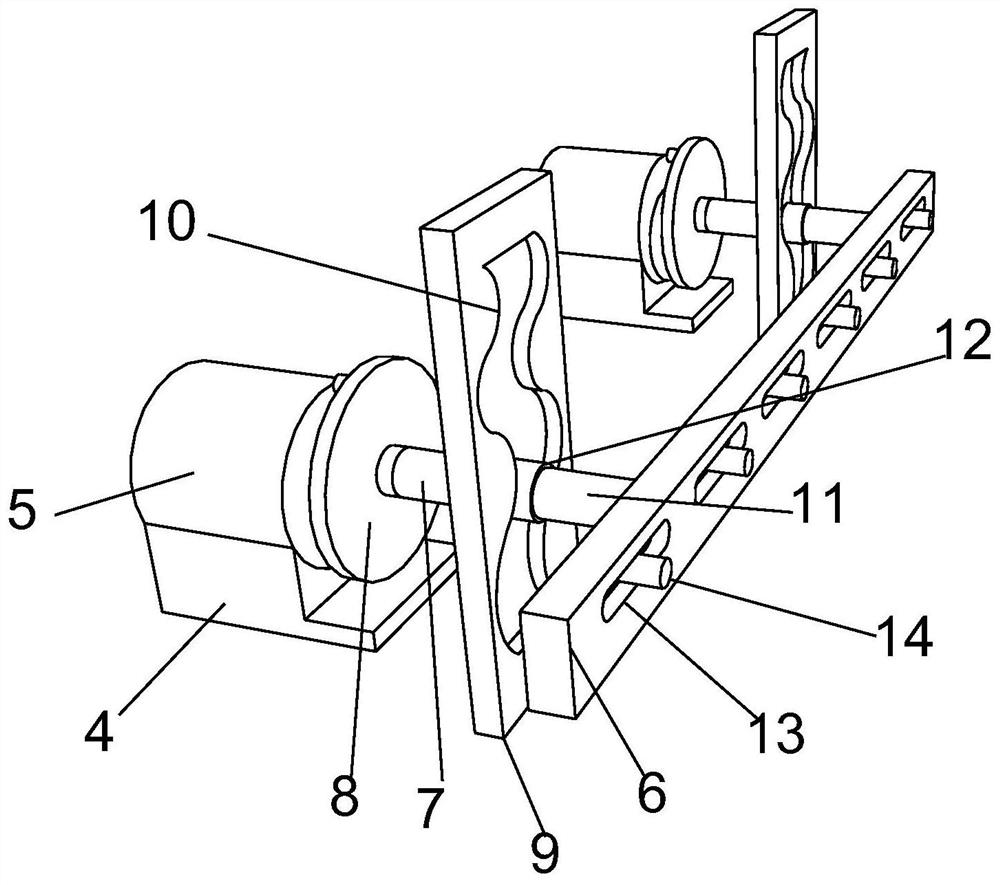

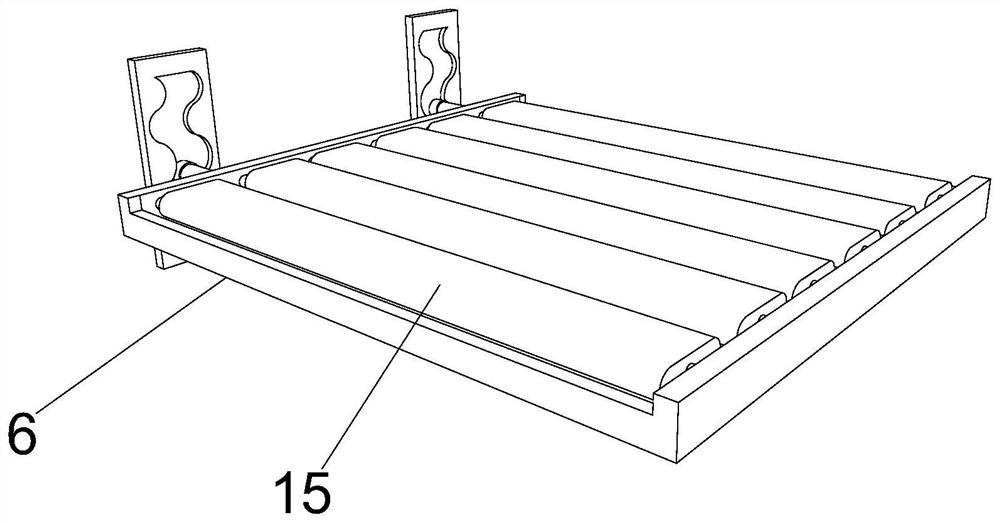

Glucosamine hydrochloride production hydrolysis device

ActiveCN112090373ATiled flatIncrease contact areaSugar derivativesSugar derivatives preparationEngineeringGlucosamine Hydrochloride

The invention relates to the technical field of glucosamine hydrochloride production, and discloses a glucosamine hydrochloride production hydrolysis device. The device comprises a hydrolysis box, theupper end of the hydrolysis box is hollow, the four corners of the upper end of the hydrolysis box are vertically upward fixedly provided with support rods, the support rods are rectangular long rods, the upper ends of the four groups of support rods are fixedly provided with a storage box, a row of material leaking grooves are transversely formed in the lower end of the interior of the storage box, the material leaking grooves are rectangular grooves and vertically penetrate through the inner wall of the bottom of the storage box, overturning plates are movably installed in the material leaking grooves through rotating shafts, the overturning plates are rectangular plates, and the overturning plates can freely overturn in the material leaking grooves through the rotating shafts. According to the invention, by arranging a hydrolysis bearing plate, hydrochloride can be flatly laid in the hydrolysis bearing plate after falling into the hydrolysis bearing plate, and then the hydrolysis bearing plate moves downwards to be in contact with water, so that the hydrochloride is in more uniform contact with a hydrolysis solution, and the hydrolysis speed of the hydrochloride is increased.

Owner:SHANDONG RUNDE BIOTECH CO LTD

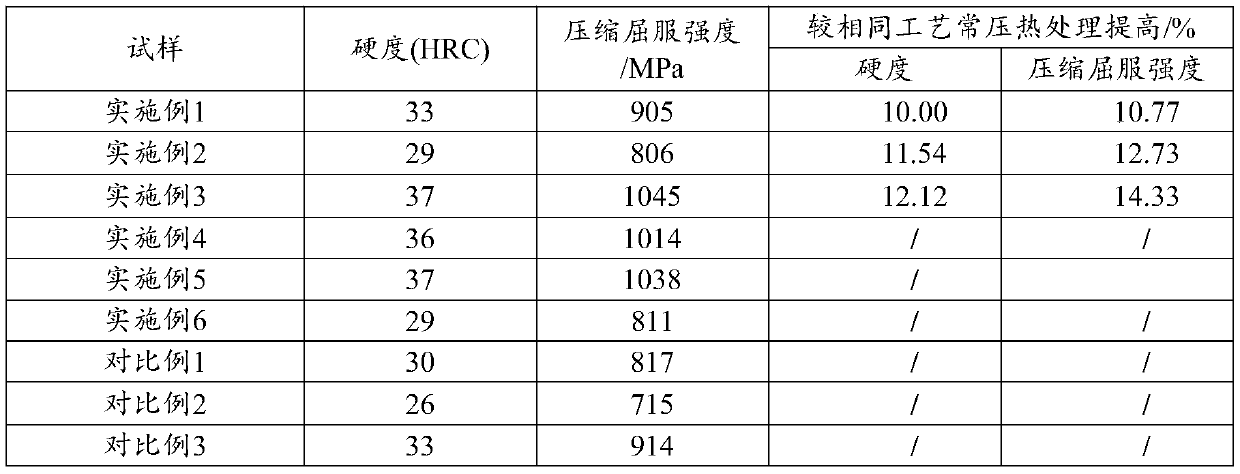

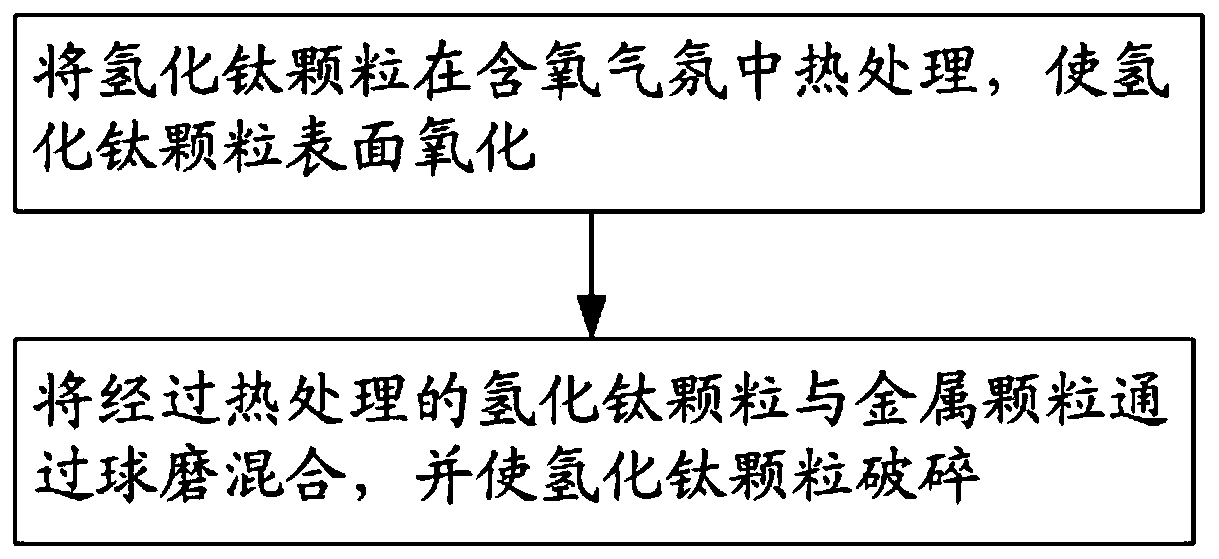

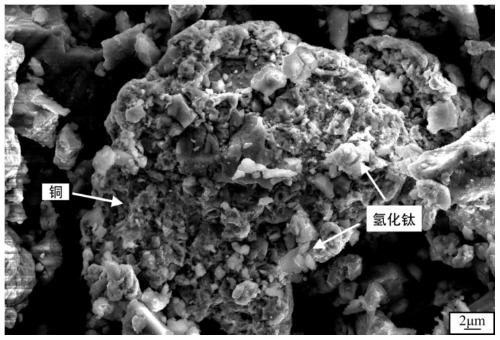

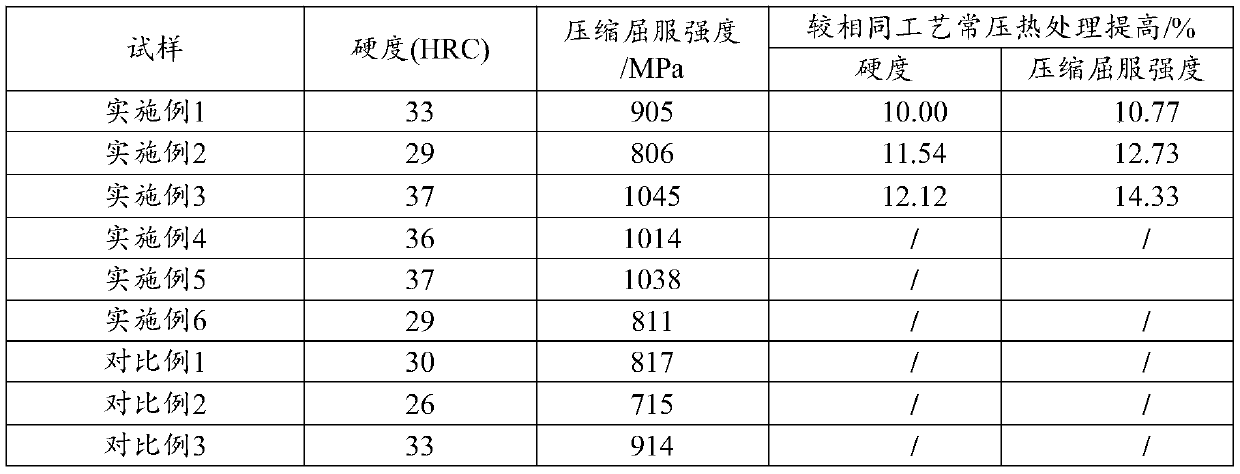

Hot working method for improving mechanical properties of medium carbon steel

The invention provides a hot working method for improving mechanical properties of medium carbon steel, and relates to the technical field of metal material science. The hot working method comprises the step: the medium carbon steel is sequentially subjected to high-temperature and high-pressure heat treatment and low-temperature and high-pressure heat treatment. The medium carbon steel is subjected to high-temperature and high-pressure heat treatment to obtain a fine martensite structure with the high dislocation density, dislocation provides more positions for precipitation of carbide in thesubsequent low-temperature and high-pressure heat treatment process, and the number of precipitated carbide particles is increased; and through low-temperature and high-pressure heat treatment, the diffusion coefficient of atoms is decreased under the high pressure effect, thus the number of the precipitated carbide particles is large, the precipitated carbide particles are not prone to growing up and thus are finer and more dispersed, the dispersion enhancement effect is enhanced, and the hardness and strength of the medium carbon steel are increased. Compared with the same process normal-pressure heat treatment, the hardness value and compression yield strength of the medium carbon steel treated through the hot working method are increased by 10.00-12.12% and 10.77-14.33% correspondingly.

Owner:本溪聚赢新材料科技有限公司

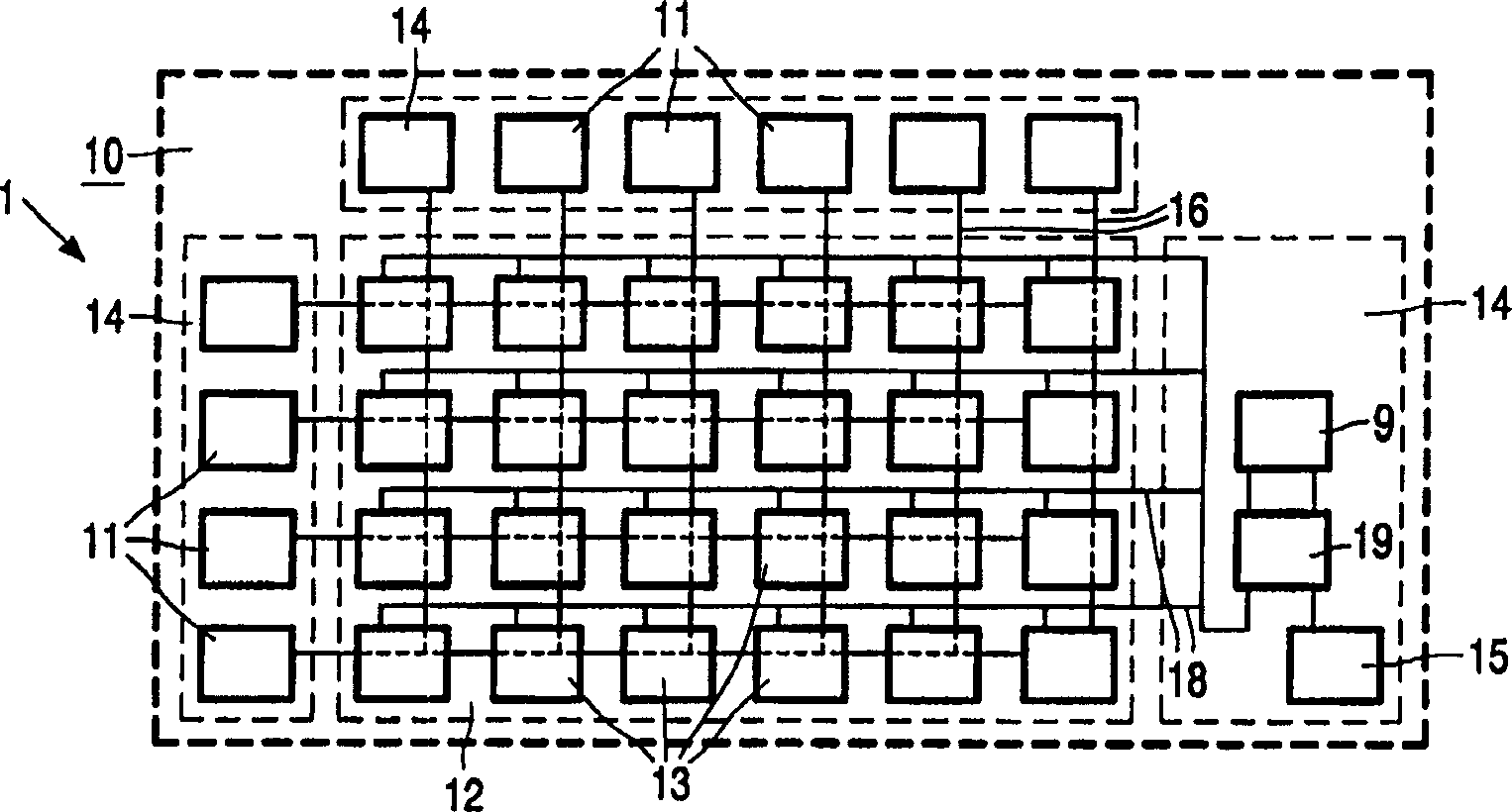

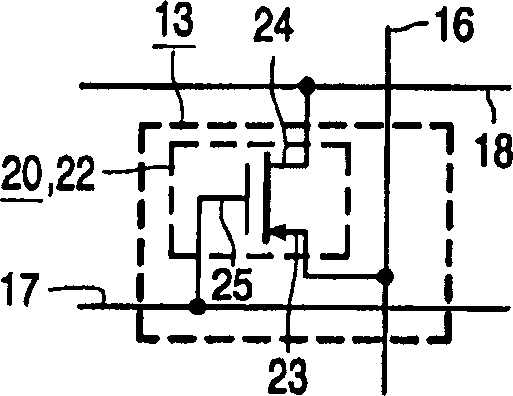

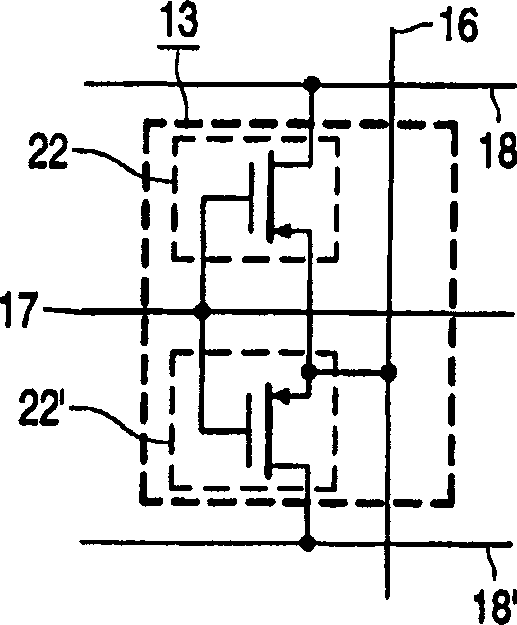

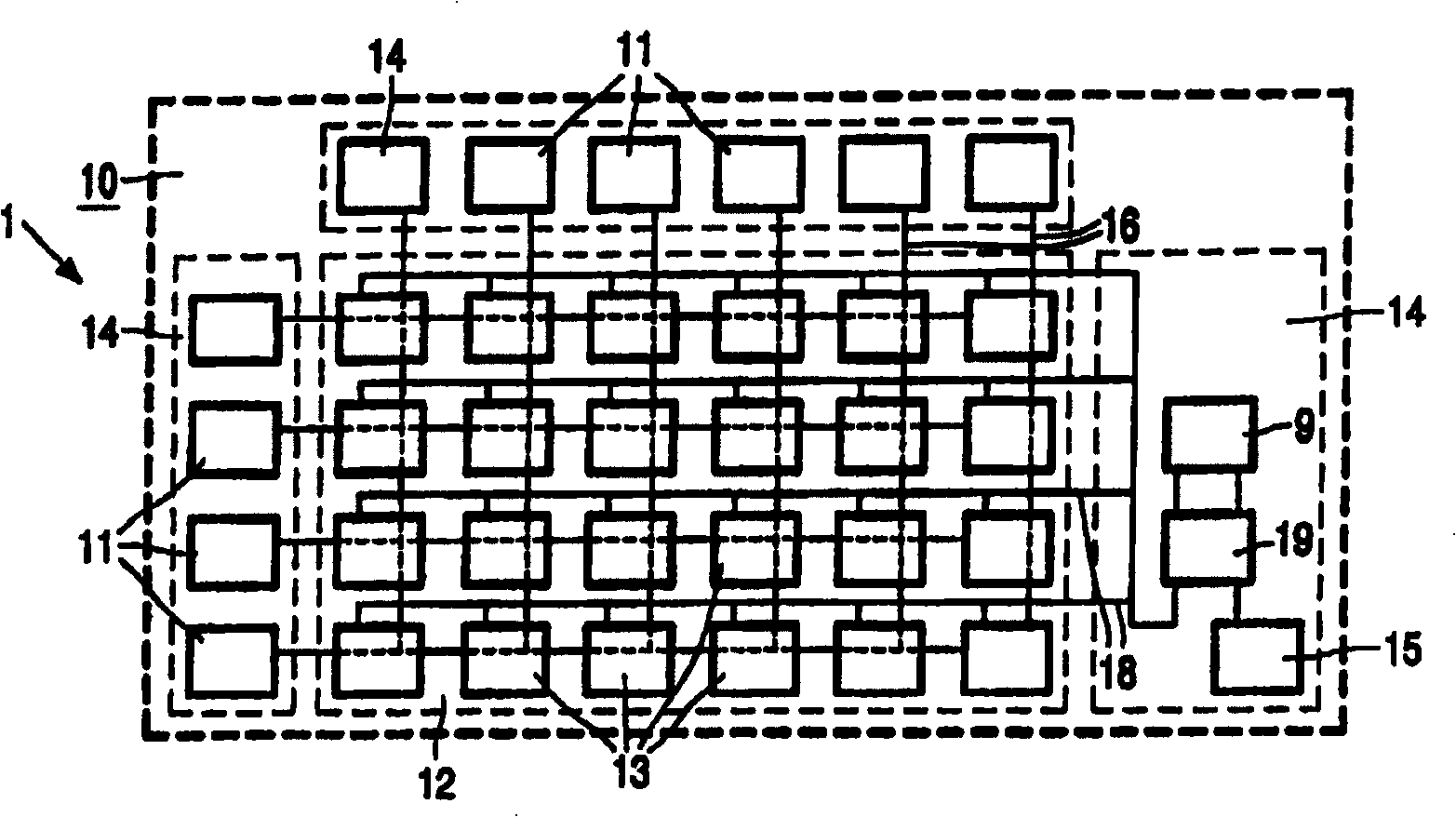

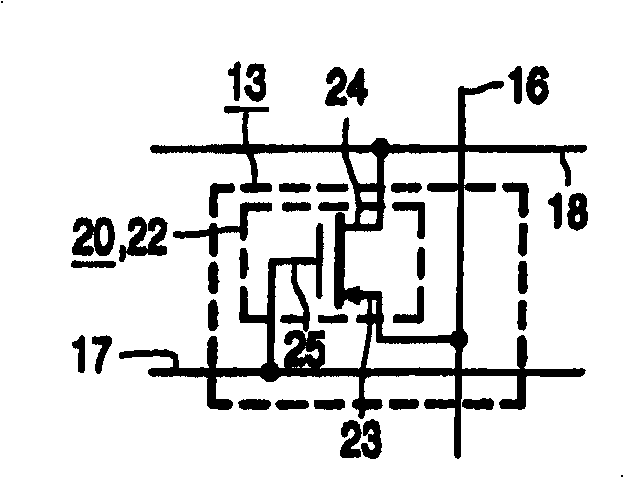

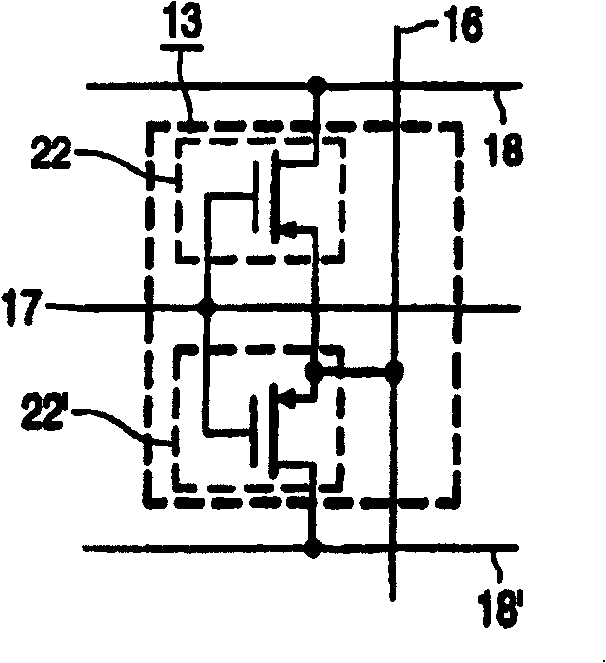

Integrated circuit and method of manufacturing same

InactiveCN1675768AReduces the chance of arbitrary changesVary the threshold voltageSemiconductor/solid-state device detailsSolid-state devicesTheoretical computer scienceIntegrated circuit

The integrated circuit (1) according to the invention comprises a set of cells (10), each of the cells (11, 13, 15, 19) comprises an electrical device (20) with a device parameter whose parameter value is a function of random parametric variations. The set of cells (10) comprises a first subset (12) of identification cells (13) with first random parametric variations, and a second subset (14) of cells (11, 15,19), which are able to generate an identification code by measuring the random differences between the parameter values of the identification cells (13). According to the invention the cells (11, 15, 19) of the second subset (14) have second random parametric variations, which are smaller than the first random parametric variations, thereby making the generation of the identification code relatively easy.

Owner:NXP BV

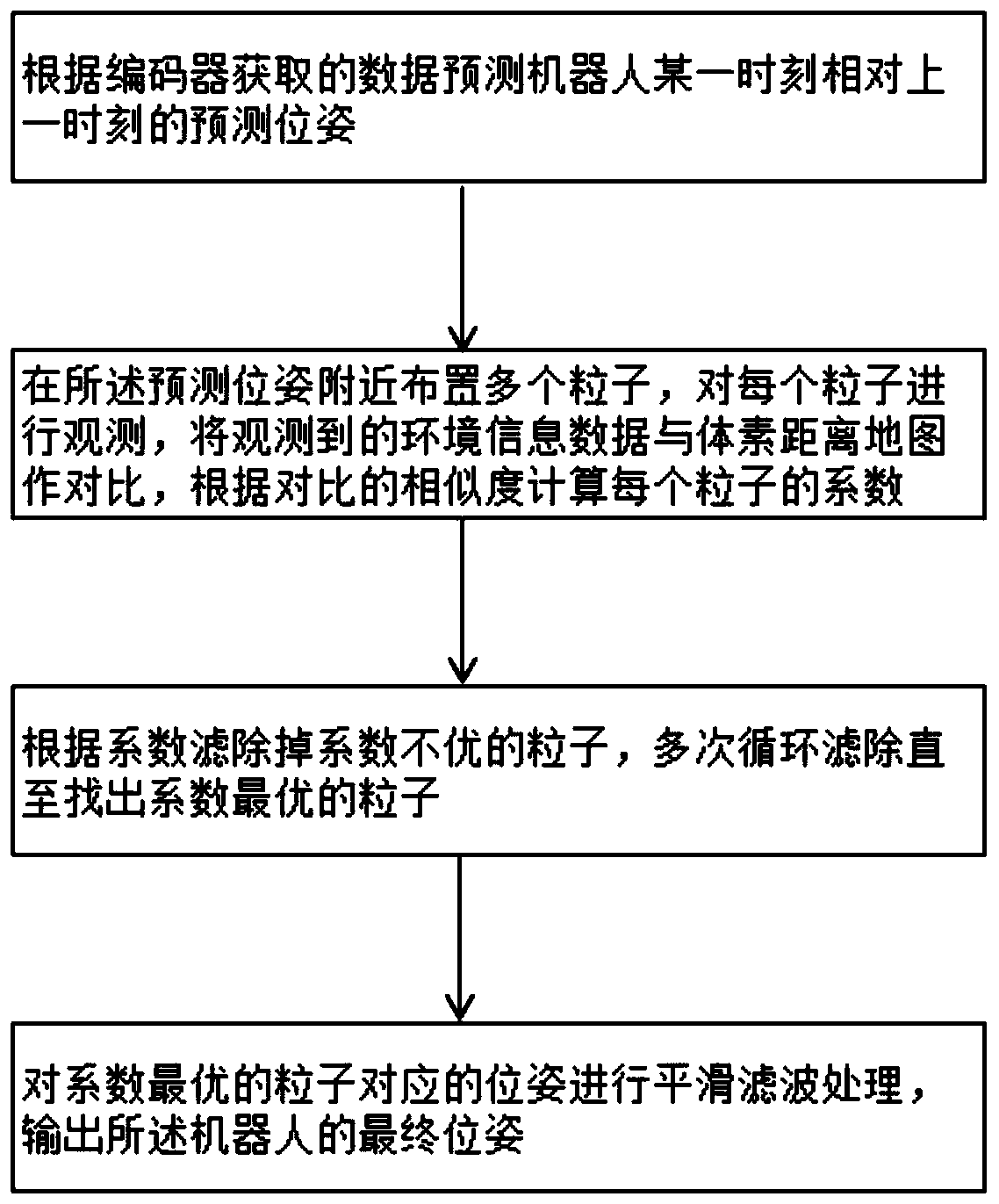

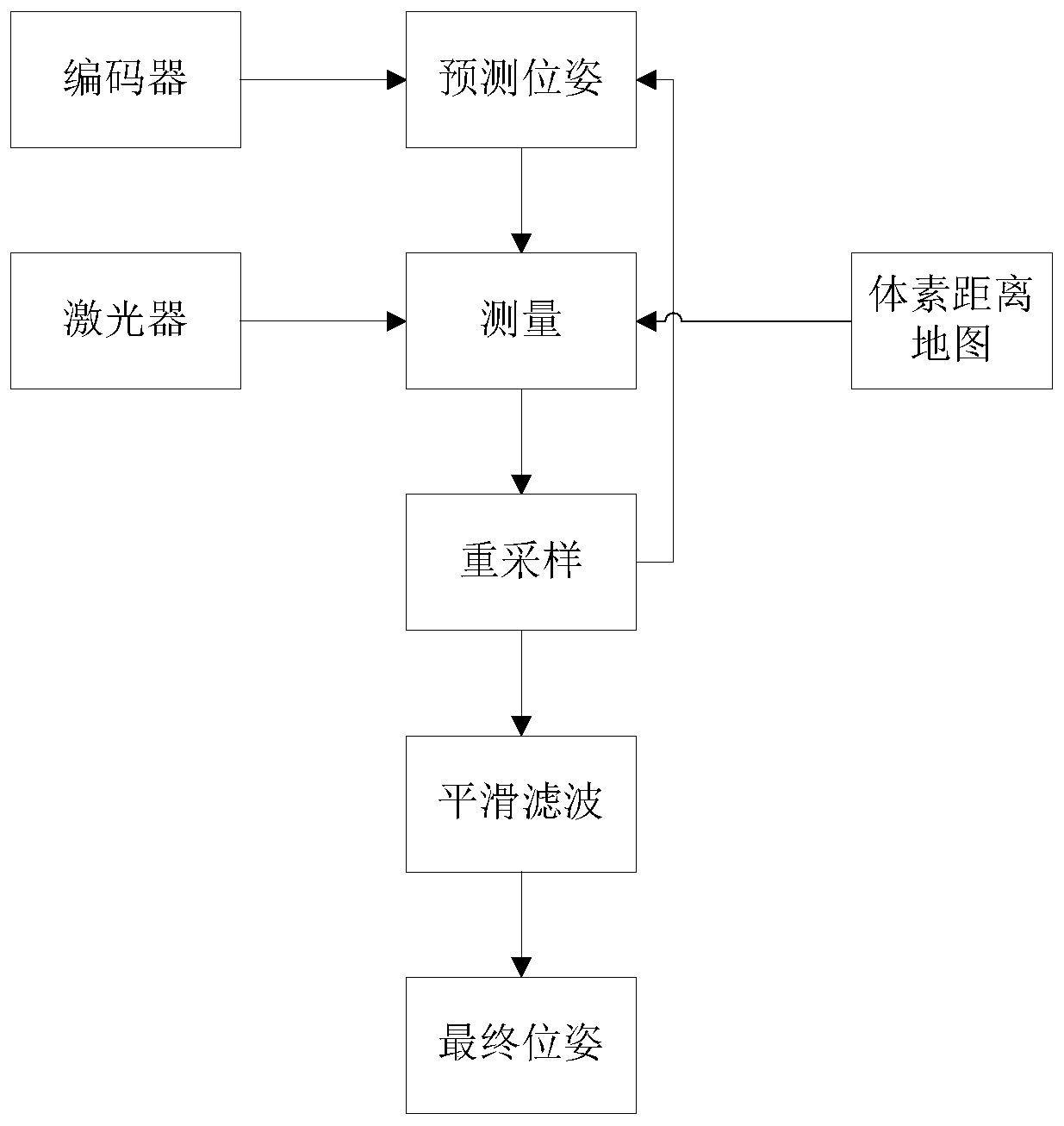

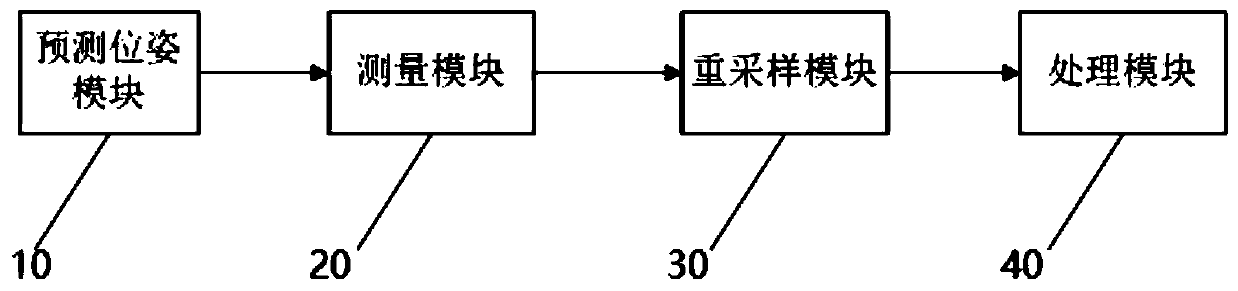

Three-dimensional laser positioning method and system

PendingCN111076724AEasy to filterIncrease the number of particlesNavigational calculation instrumentsVoxelComputational physics

The invention relates to a three-dimensional laser positioning method and system. The method comprises the following steps: predicting a predicted pose of a robot at a certain moment relative to a previous moment according to data acquired by an encoder; arranging a plurality of particles near the predicted pose, observing each particle, comparing the observed environment information data with a voxel distance map, and calculating the coefficient of each particle according to the similarity of comparison; filtering particles with low coefficients according to the coefficients, and carrying outcircular filtering for multiple times until the particle with the optimal coefficient is found out; and carrying out smooth filtering processing on the pose corresponding to the particle with the optimal coefficient, and outputting the final pose of the robot. According to the method, the query speed can be increased, and the positioning precision can be improved.

Owner:SUZHOU AGV ROBOT CO LTD

Preparation method of cement decorated hanging plate

The invention discloses a preparation method of a cement decorated hanging plate. The method comprises the following steps of mixing and stirring ferrous chloride, ferric chloride, copper chloride, sodium citrate, polyvinyl alcohol and distilled water, transferring the mixture into a reaction kettle for reaction, and performing centrifugal separation to obtain CuFeO2 nano-cube water dispersion; adding silver nitrate into the CuFeO2 nano-cube water dispersion, stirring the mixture for reaction, and performing centrifugal separation to obtain silver-plated CuFeO2 nano-cube; stirring the silver-plated CuFeO2 nano-cube with sodium bentonite to obtain an antibacterial agent; adding polycarboxylate water reducer into slag and steel slag separately, adding water into the two mixtures and performing wet grinding, and then mixing the two mixtures to obtain a mixture; adding cement clinker, ceramsite and triethanolamine into the mixture and the antibacterial agent, adding water into the mixtureand the antibacterial agent, and mixing and stirring the mixture and the antibacterial agent to obtain decorated hanging plate slurry; and pouring the decorated hanging plate slurry into a template paved with a transfer printing film with a specific pattern, keeping standing, tearing down the transfer printing film, and carrying out high-pressure washing on the surface until a pattern is displayedto obtain the cement decorated hanging plate. The cement decorated hanging plate has the advantages of no toxicity, no smell, no cracking, and no biological parasitism; the plate has various patterns, appearance is attractive, weight is light, and hardness is high; and the plate is not prone to breakage, easy to carry and wide in application field.

Owner:HUBEI UNIV OF TECH

A kind of er3+/yb3+ co-doped yttrium lithium fluoride single crystal and its preparation method

InactiveCN102978701BLow phonon energyLess color centersPolycrystalline material growthFrom frozen solutionsWater vaporSingle crystal

The invention discloses an Er<3+> / Yb<3+> co-doped yttrium lithium fluoride monocrystal and a preparation method thereof. The yttrium lithium fluoride monocrystal is a rare earth ion Er<3+> / Yb<3+> co-doped monocrystal; the molecular formula is LiY(1-x-y)ErxYbyF4, wherein x is greater than or equal to 0.008 and less than or equal to 0.085, and y is greater than or equal to 0.002 and less than or equal to 0.170; the segregation coefficients of Yb<3+> and Er<3+> in the yttrium lithium fluoride are about 1, and efficient intermediate infrared laser of 2.7 microns can be output; and the yttrium lithium fluoride monocrystal has high transmittance of intermediate infrared laser, has better thermal, mechanical and chemical stabilities than those of glass state materials and has the characteristics of low phonon energy, high optical transmittance of wavebands with width of 300-5500nm, less color center forming amount, low thermal lens effect and the like, thereby being more easily processed and more suitably used in laser devices. In the preparation method disclosed by the invention, a sealing crucible falling technology is used, so that the operation is simple; the raw material is fluorated at high temperature in a sealed water-free and oxygen-free environment, so that the crystal is isolated from air and water vapor during the growth; and therefore, the high-quality Er<3+> / Yb<3+> co-doped LiYF4 monocrystal containing little OH<-> ion and oxide is obtained.

Owner:NINGBO UNIV

Gradient porosity anode for solid oxide fuel cell and fuel cell

ActiveCN108598493BHigh strength propertiesImprove performanceCell electrodesFuel cellsFuel cellsConcentration polarization

The invention discloses a solid oxide fuel cell gradient porosity anode and a solid oxide fuel cell. The solid oxide fuel cell gradient porosity anode comprises an anode function layer, an anode transition layer and an anode support layer which are connected in sequence from top to bottom. The opening porosity of the anode transition layer is greater than or equal to the opening porosity of the anode function layer. The opening porosity of the anode transition layer is smaller than or equal to the opening porosity of the anode support layer. The opening porosity of the anode function layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual decrease along a horizontal direction, or the opening porosity of the anodefunction layer, the opening porosity of the anode transition layer and the opening porosity of the anode support layer are in gradient gradual increase. The anode is characterized by relatively low activation polarization, concentration polarization and ohm polarization loss. The fuel cell is characterized by high output electrical property and high intensity.

Owner:XI AN JIAOTONG UNIV

Preparation method and application of novel adsorptive iron salt compound flocculant

InactiveCN107117696AImprove adsorption capacityFast adsorption rateWater treatment parameter controlWater/sewage treatment by flocculation/precipitationActivated carbonIron salts

The invention provides a preparation method and an application of a novel adsorptive iron salt compound flocculant. The method comprises the following steps: (1) mixing activated carbon powder and poly-ferric sulfate powder at a mass ratio of (1-0.3):1; (2) adding into a stirrer, grinding, and mixing to obtain mixed powder; and (3) compounding the mixed powder and polyacrylamide at a mass ratio of 99:1, grinding, and mixing to obtain the novel adsorptive iron salt compound flocculant. The novel flocculant of the invention is prepared from poly-ferric sulfate flocculant, activated carbon and polyacrylamide as the raw materials, in which the poly-ferric sulfate flocculant can remove the dispersed impurities and macromolecular organic matters in water (which cannot be well adsorbed by powdered activated carbon), and the powdered activated carbon can remove micromolecular organic matters that are hardly removed by coagulation, so that the treatment capacities for removing organic matters of the poly-ferric sulfate flocculant and the powdered activated carbon are both further improved.

Owner:太原市淼洁环保技术有限公司

Adding device for coal mine rock dust co-polymerization moisture inhibitor

ActiveCN104533507BImprove wettabilityReduce surface tensionOther chemical processesDust removalBetaineMining engineering

The invention discloses a rock dust polymerization and moisture-preservation inhibitor for coal mines and an adding device thereof. The rock dust polymerization and moisture-preservation inhibitor comprises the following components in percentage by weight: 0.05%-0.07% of cocamidopropyl betaine, 0.05%-0.07% of magnesium chloride, 0.05%-0.07% of sodium fatty alcohol polyoxyethylene ether carboxylate and the balance being water. The invention further provides an automatic adding device of the rock dust polymerization and moisture-preservation inhibitor for the coal mines. The cocamidopropyl betaine and the sodium fatty alcohol polyoxyethylene ether carboxylate have good wettability; after cocamidopropyl betaine and the sodium fatty alcohol polyoxyethylene ether carboxylate are compounded, the surface tension of water can be greatly reduced and the contact possibility of fog drops and dust particles is promoted; the magnesium chloride has a good moisture preservation performance so that the moisture preservation content of the captured dust particles is greatly enhanced, and a secondary dust raising phenomenon caused by water evaporation is prevented.

Owner:SHANDONG UNIV OF SCI & TECH

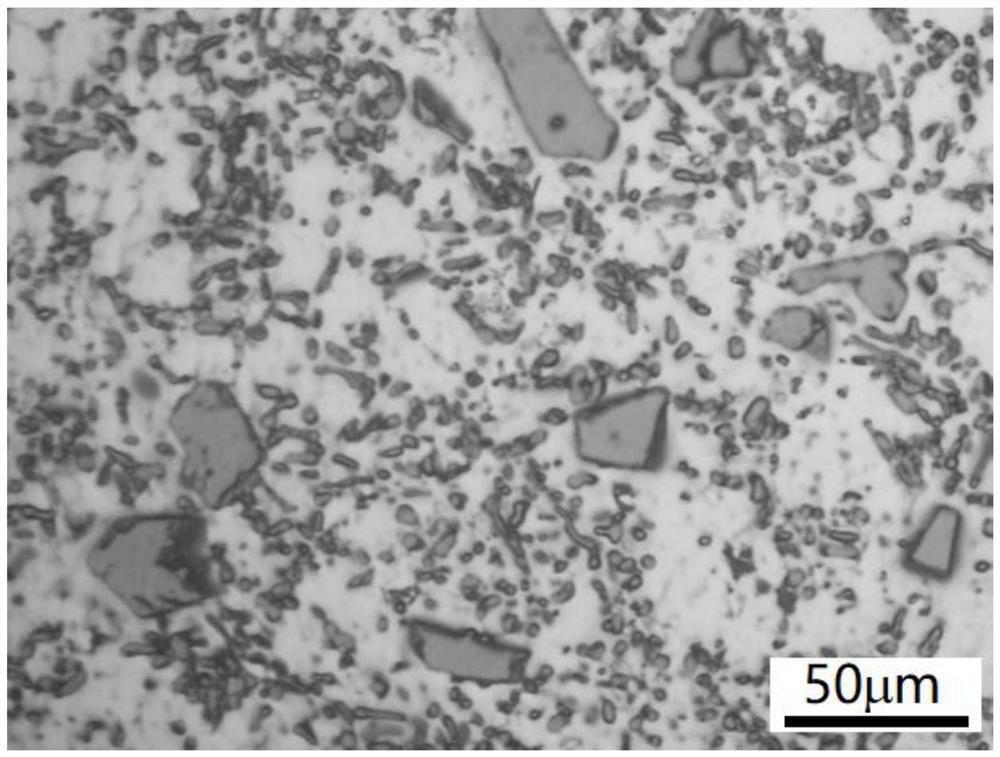

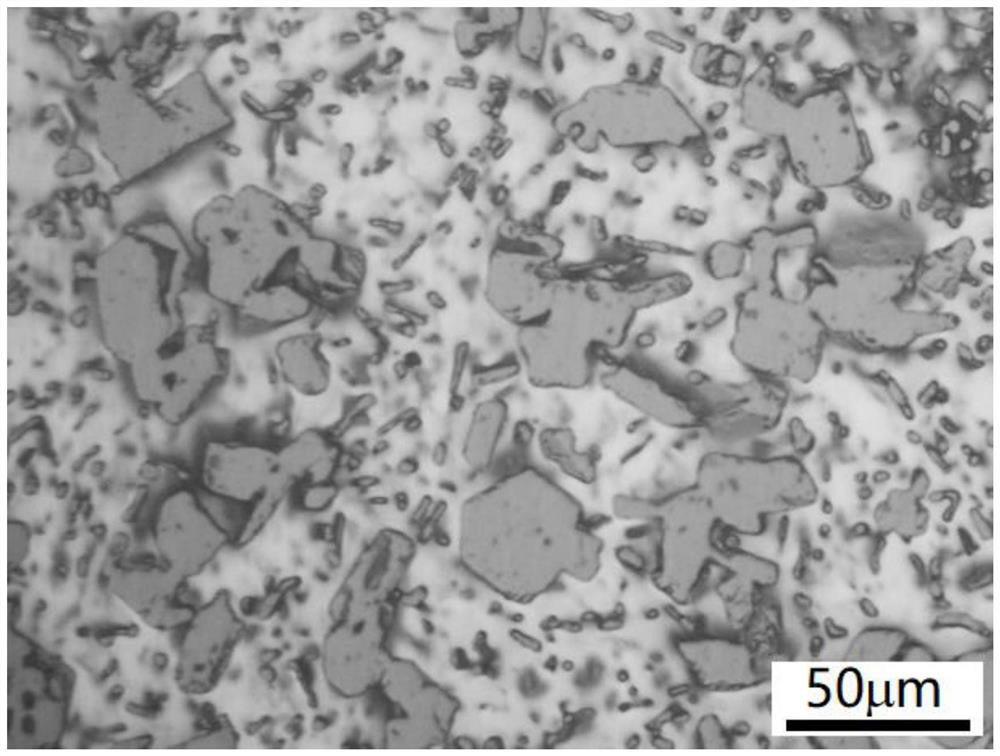

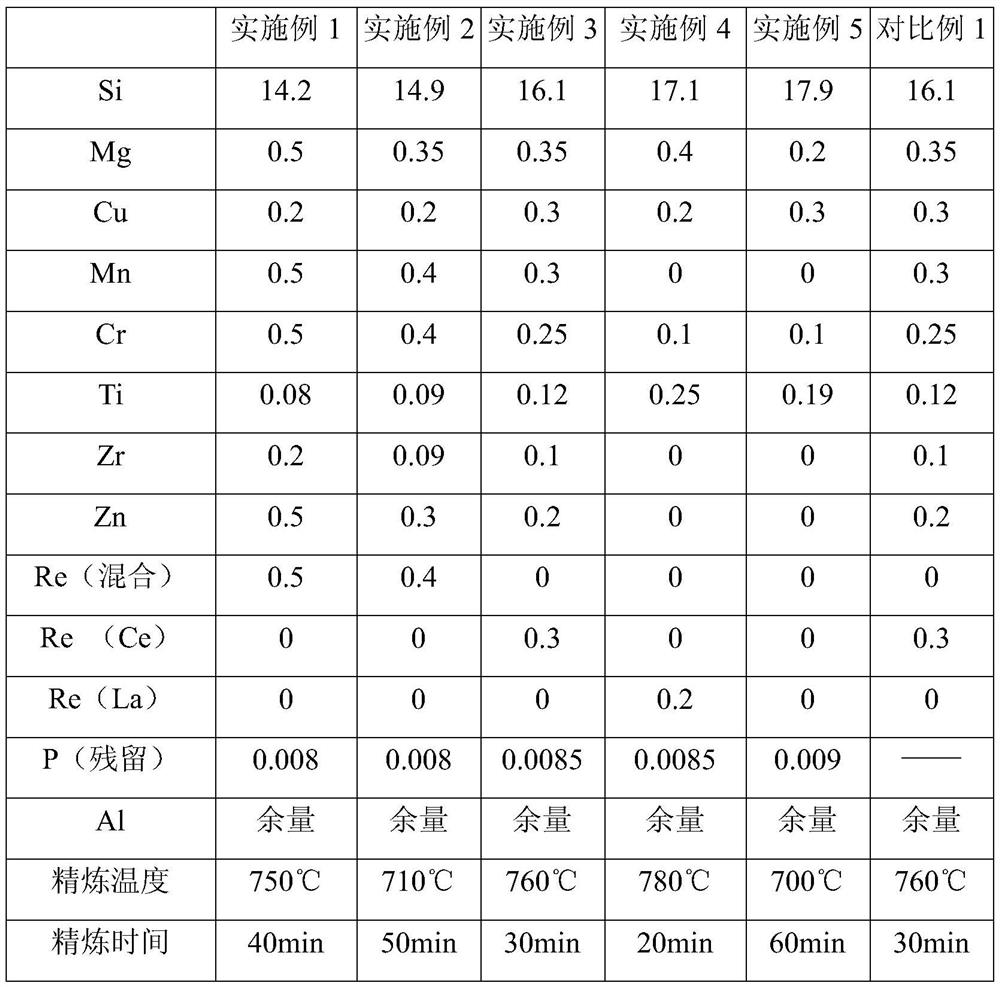

A kind of high elastic modulus and high plasticity aluminum-silicon casting alloy and its preparation method and application

ActiveCN113699418BHigh modulus of elasticityImprove plasticityProcess efficiency improvementSiliconPlastic property

The invention discloses a high elastic modulus and high plasticity aluminum-silicon casting alloy, a preparation method and application, and belongs to the field of casting aluminum alloys. The high elastic modulus and high plasticity aluminum-silicon casting alloy includes components and their mass percentages as follows: Si is 14-18%, Cu is 0-0.4%, Mg is 0.2-0.5%, and Mn is 0-0.5% , Cr is 0.1-0.5%, Zr is 0-0.25%, Zn is 0-0.5%, Ti is 0.05-0.25%, Re is 0-0.5%, and the balance is Al and inevitable impurities. The high elastic modulus and high plasticity aluminum-silicon casting alloy utilizes P to effectively transform primary Si, and has the characteristics of light weight, good casting performance, high elastic modulus and high elongation, and high tensile strength strength. The high elastic modulus and high plasticity aluminum-silicon cast alloy can be applied to automobile parts with special requirements for elastic modulus and plasticity.

Owner:SHANGHAI WANTAI AUTO PARTS +1

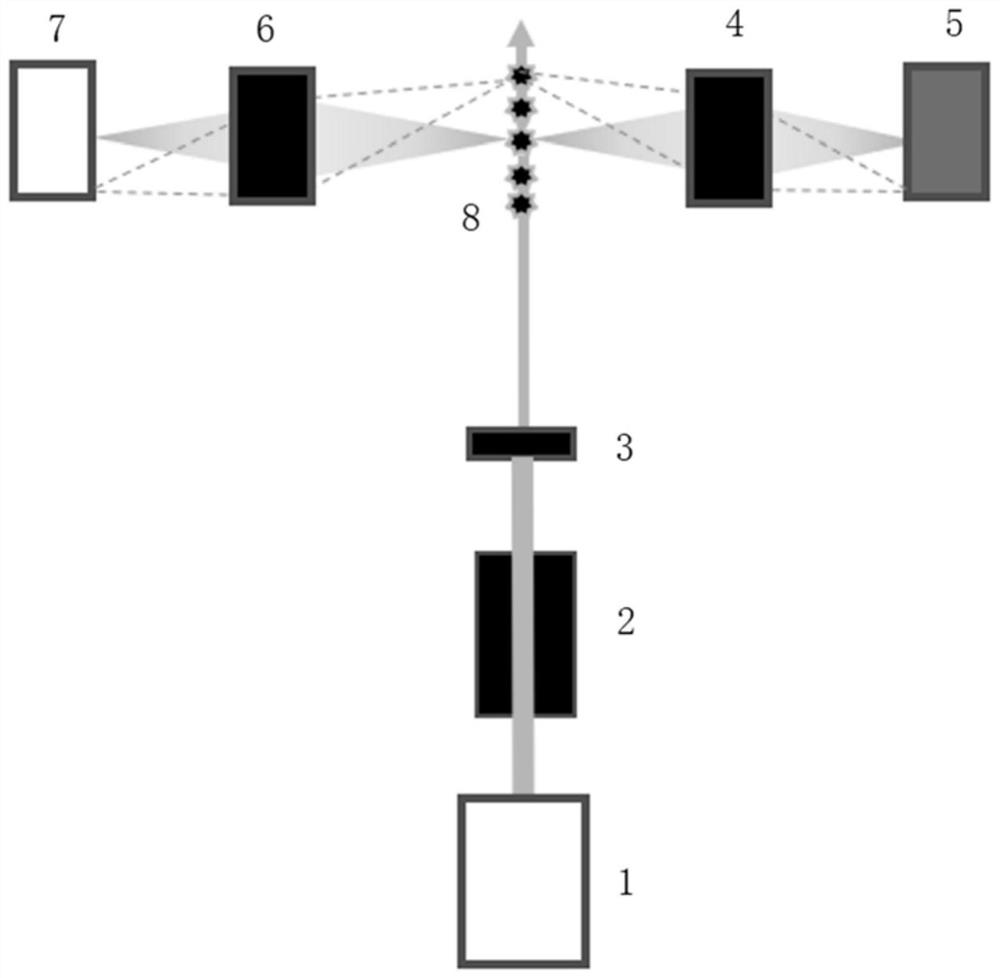

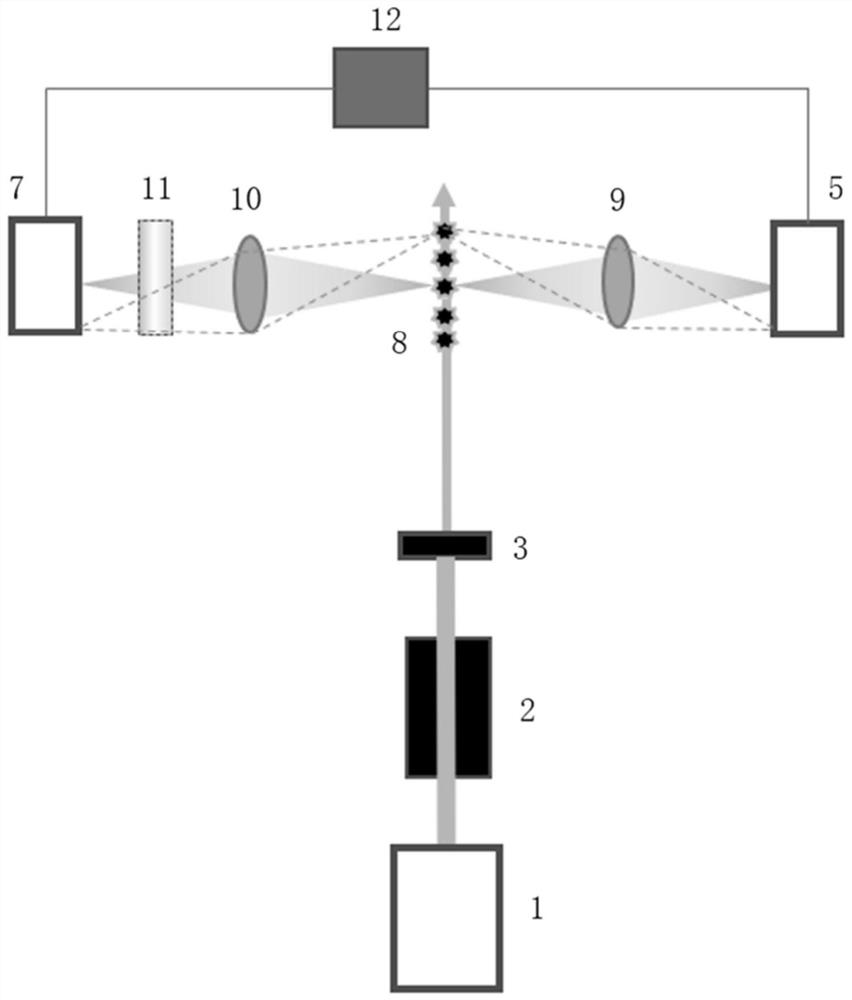

A Suspended Particle Flux Measurement Device Using Synchronous Polarization and Fluorescence

ActiveCN111366510BQuick identificationImprove accuracyWater resource assessmentParticle suspension analysisSuspended particlesParticulates

A suspended particle flux measurement device using synchronous polarization and fluorescence, including a light source, a polarizer, an illumination optical system, a first receiving optical system, a second receiving optical system, a polarization imaging system, a fluorescence camera, and an image processing terminal, the light source The emitted light passes through the polarizer to generate incident polarized light, which is converted into a sheet light source through the illumination optical system, and illuminates multiple suspended particles in a liquid section. The first and second receiving optical systems are set at two symmetrical scattering angles , receive the scattered light of the suspended particles and send them to the polarization imaging system and the fluorescence camera respectively, so that each suspended particle forms a polarization image point and a fluorescence image point on the polarization imaging system and the fluorescence camera respectively, realizing multiple For the measurement of the flux of suspended particulate matter, the polarization-fluorescence synchronous measurement data of each suspended particulate matter is used to determine the type information of the suspended particulate matter. The device can quickly and high-throughput identify suspended particulate matter in water.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Integrated circuit and method of manufacturing same

InactiveCN100438014CReduces the chance of arbitrary changesVary the threshold voltageSemiconductor/solid-state device detailsSolid-state devicesTheoretical computer scienceIntegrated circuit

The integrated circuit (1) according to the invention comprises a set of cells (10), each of the cells (11, 13, 15, 19) comprises an electrical device (20) with a device parameter whose parameter value is a function of random parametric variations. The set of cells (10) comprises a first subset (12) of identification cells (13) with first random parametric variations, and a second subset (14) of cells (11, 15,19), which are able to generate an identification code by measuring the random differences between the parameter values of the identification cells (13). According to the invention the cells (11, 15, 19) of the second subset (14) have second random parametric variations, which are smaller than the first random parametric variations, thereby making the generation of the identification code relatively easy.

Owner:NXP BV

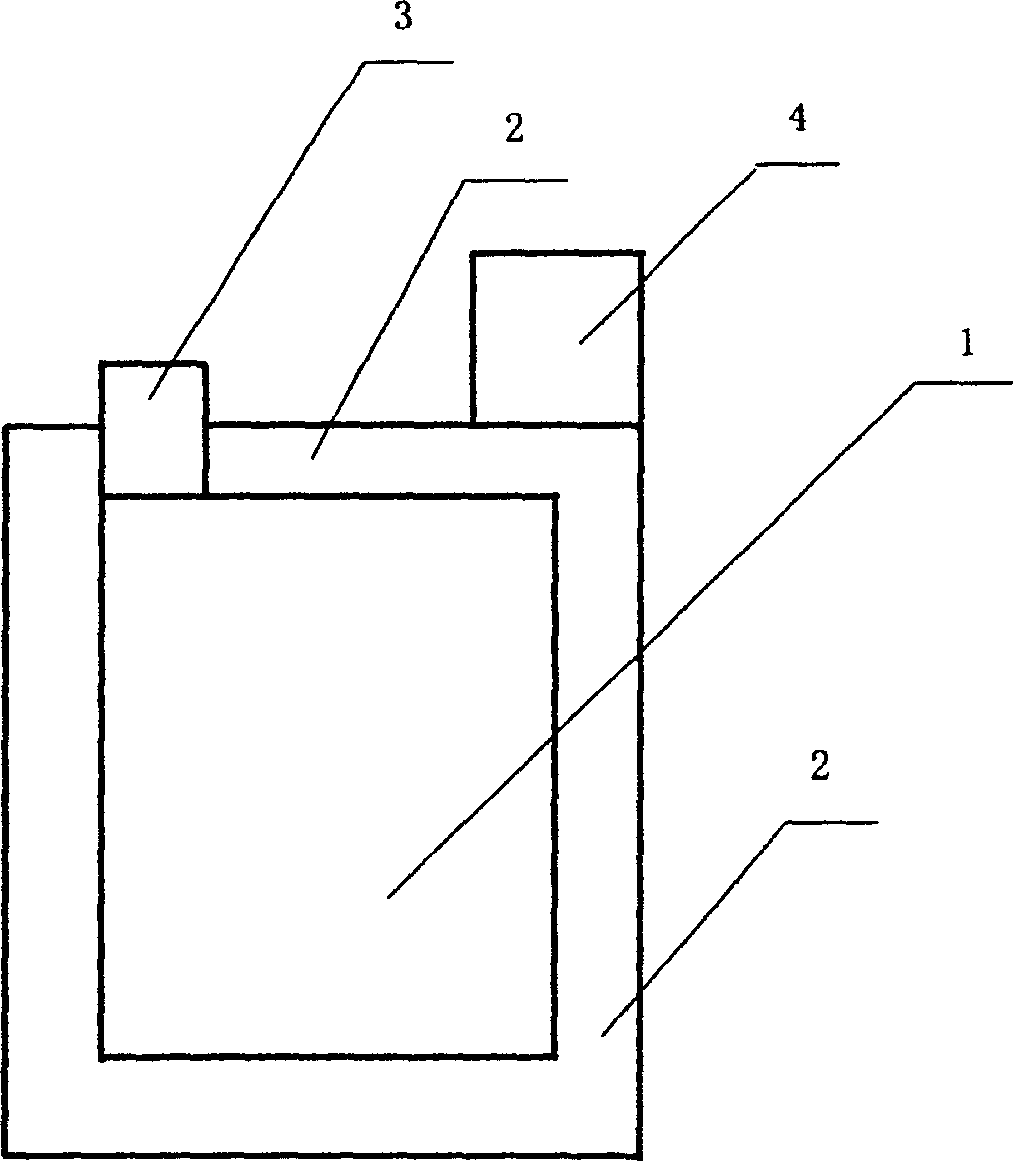

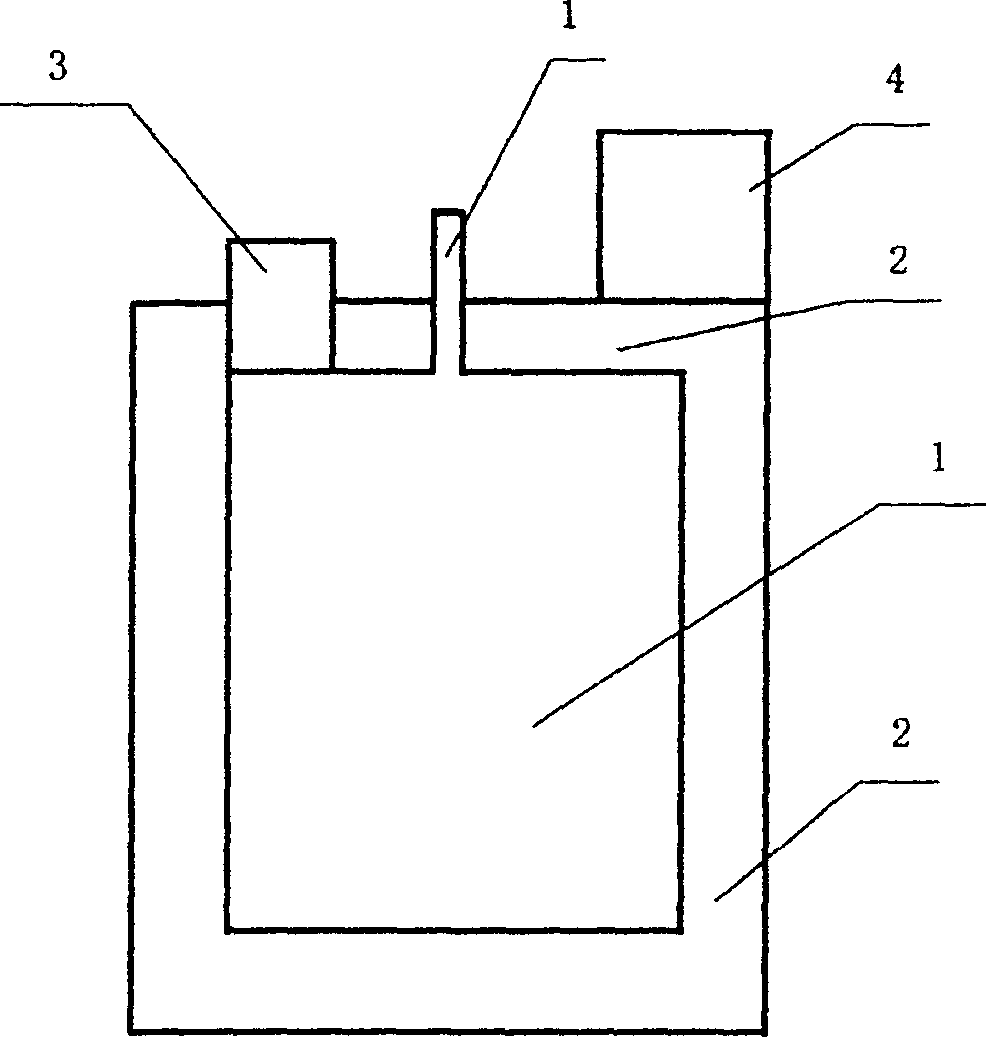

Alkaline accumulator

InactiveCN1243386CIncrease the number of particlesImprove composite effectAlkaline accumulatorsAlkaline accumulator electrodesInternal pressureEngineering

The invention relates to an alkaline accumulator. It includes positive pole, negative pole, insulator and shell. Area of the negative pole is larger than the area of the positive pole. Upper end of the negative pole is higher than the height of upper end of the positive pole. The relationship of areas between positive pole and negative pole is described by the formula: S(+)=aS(-) where a=0-1.0. The invented alkaline accumulator can lower internal pressure of battery, raise use rate of active material in pole and reduce incidence rate of battery short circuit.

Owner:CHUNLAN GROUP CORP

Real-time tracking and precise estimation method of glonass phase-frequency deviation based on particle filter

ActiveCN107678050BRealize precise positioningAchieve real-time trackingSatellite radio beaconingCarrier signalData pre-processing

The invention discloses a method for real-time tracking and precise estimation of GLONASS phase-frequency deviation based on particle filtering, comprising the following steps: Step 1: data preprocessing, importing satellite ephemeris, pseudo-range observation value and phase observation value of current historical cloud ; Step 2: Establish double-difference pseudorange and carrier phase observation equations, and obtain the single epoch method equation or the previous epoch accumulation method equation after linearization; Step 3: Correct the phase deviation in the method equation according to the particle value, and solve the algorithm equation ; Update the weight of the particle filter, calculate the value of the phase-frequency deviation rate and the root mean square of the particle; Step 4: Repeat step 1-3, real-time tracking or precise estimation of the value of the phase-frequency deviation rate; after the filter converges, pass the phase frequency The value of the inter-frequency deviation rate is corrected for the phase-frequency deviation, and the ambiguity of the whole cycle is fixed to realize precise estimation; the invention can efficiently realize the real-time tracking of the inter-frequency deviation and GLONASS precise positioning with no difference in the receiver type.

Owner:SOUTHWEST JIAOTONG UNIV

Hydrolysis unit for glucosamine hydrochloride production

ActiveCN112090373BIncrease the rate of hydrolysisEven contactSugar derivativesSugar derivatives preparationCrystallographyEngineering

The invention relates to the technical field of glucosamine hydrochloride production, and discloses a hydrolysis device for the production of glucosamine hydrochloride, including a hydrolysis box, the upper end of the hydrolysis box is hollowed out, and the four corners of the upper end of the hydrolysis box are vertically fixed and installed with supports The support rods are rectangular long rods, and the upper ends of the four sets of support rods are fixed with storage boxes. The inner lower end of the storage boxes is provided with a row of leakage grooves horizontally. The leakage grooves are rectangular grooves and the leakage grooves run through the bottom of the storage box up and down. The inner wall and the inside of the leakage trough are movably equipped with a turning plate through a rotating shaft. The turning plate is a rectangular plate and the turning plate can be freely turned inside the leakage trough through a rotating shaft. In the present invention, the hydrolysis bearing plate is set so that the hydrochloride can be spread on the inside of the hydrolysis bearing plate after falling into the interior of the hydrolysis bearing plate, and then the hydrolysis bearing plate moves downward to contact with water, so that the hydrochloride is in contact with the hydrolysis solution More uniform, increasing the rate of hydrolysis of hydrochloride.

Owner:SHANDONG RUNDE BIOTECH CO LTD

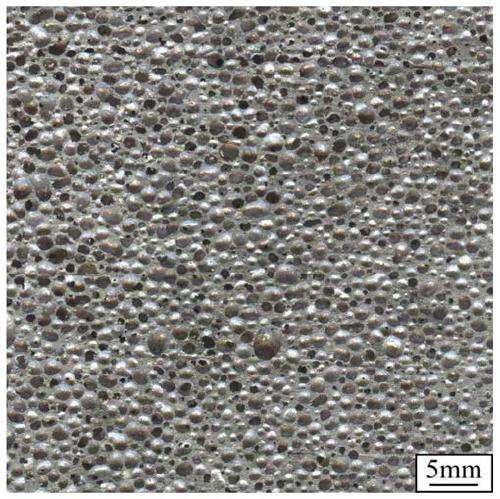

Foaming agent, preparation method thereof, and preparation method of aluminum foam

Owner:TSINGHUA UNIV

A thermal processing method for improving the mechanical properties of medium carbon steel

The invention provides a hot working method for improving mechanical properties of medium carbon steel, and relates to the technical field of metal material science. The hot working method comprises the step: the medium carbon steel is sequentially subjected to high-temperature and high-pressure heat treatment and low-temperature and high-pressure heat treatment. The medium carbon steel is subjected to high-temperature and high-pressure heat treatment to obtain a fine martensite structure with the high dislocation density, dislocation provides more positions for precipitation of carbide in thesubsequent low-temperature and high-pressure heat treatment process, and the number of precipitated carbide particles is increased; and through low-temperature and high-pressure heat treatment, the diffusion coefficient of atoms is decreased under the high pressure effect, thus the number of the precipitated carbide particles is large, the precipitated carbide particles are not prone to growing up and thus are finer and more dispersed, the dispersion enhancement effect is enhanced, and the hardness and strength of the medium carbon steel are increased. Compared with the same process normal-pressure heat treatment, the hardness value and compression yield strength of the medium carbon steel treated through the hot working method are increased by 10.00-12.12% and 10.77-14.33% correspondingly.

Owner:本溪聚赢新材料科技有限公司

Rotary magnetron target and horizontal magnetron sputtering coating equipment

ActiveCN105908146BIncrease distribution densityIncrease the number of particlesVacuum evaporation coatingSputtering coatingSputteringMaterials science

The invention discloses a rotary magnetron target and horizontal magnetron sputtering coating equipment. The rotary magnetron target comprises a target, a magnetic core and a magnet, wherein the magnetic core is arranged at the middle part of the target, at least one magnet is arranged at the periphery of the magnetic core, and one end facing the target, of the magnet, is conical. The horizontal magnetron sputtering coating equipment comprises a front pre-pumping chamber, a front rough-pumping chamber, a front fine-pumping chamber, a front buffering chamber, a coating chamber, a rear buffering chamber, a rear fine-pumping chamber, a rear rough-pumping chamber and a rear pre-pumping chamber which are sequentially connected, wherein one or more coating chambers are provided, and one rotary magnetron target is arranged in each coating chamber, and located above a workpiece. According to the rotary magnetron target, the tail end of the magnet is designed to be a tip, thus the distribution density of magnetic force lines on the surface of the target is enhanced, and the number of the sputtered target particles can be increased, and then the coating efficiency of the surface of the workpiece is increased. The rotary magnetron target is applied to the horizontal magnetron sputtering coating equipment, thus the coating efficiency of the workpiece can be effectively increased, and the production cycle of a whole process line is shortened, and then the production efficiency is increased.

Owner:ZHAOQING KERUN VACUUM EQUIP

Polypropylene composite material and preparation method thereof

The invention relates to a preparation method of a polypropylene composite material. The polypropylene composite material is prepared from 55-90 parts by mass of polypropylene, 3-5 parts by mass of modified sepiolite, 1-2 parts by mass of modified nano TiO2 and a processing aid, the sepiolite is subjected to surface treatment by a hydrochloric acid solution, and the preparation process comprises the following steps: soaking the sepiolite, removing scum, filtering, carrying out acid treatment, filtering, drying, firing at 500 DEG C, cooling and modifying the sepiolite; the preparation method comprises the following steps: carrying out surface treatment on nano TiO2 by using methyl methacrylate, stirring TiO2, deionized water and sodium dodecyl sulfate, heating to a certain temperature, dropwise adding a certain amount of methyl methacrylate after stirring, and after the reaction is finished, carrying out reduced pressure filtration, drying to a constant amount, and grinding into particles to obtain modified nano TiO2; the composite material is prepared by the following steps: drying polypropylene, modified sepiolite and modified nano TiO2, mixing in a mixer according to a certain proportion, extruding and granulating, and carrying out injection molding.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

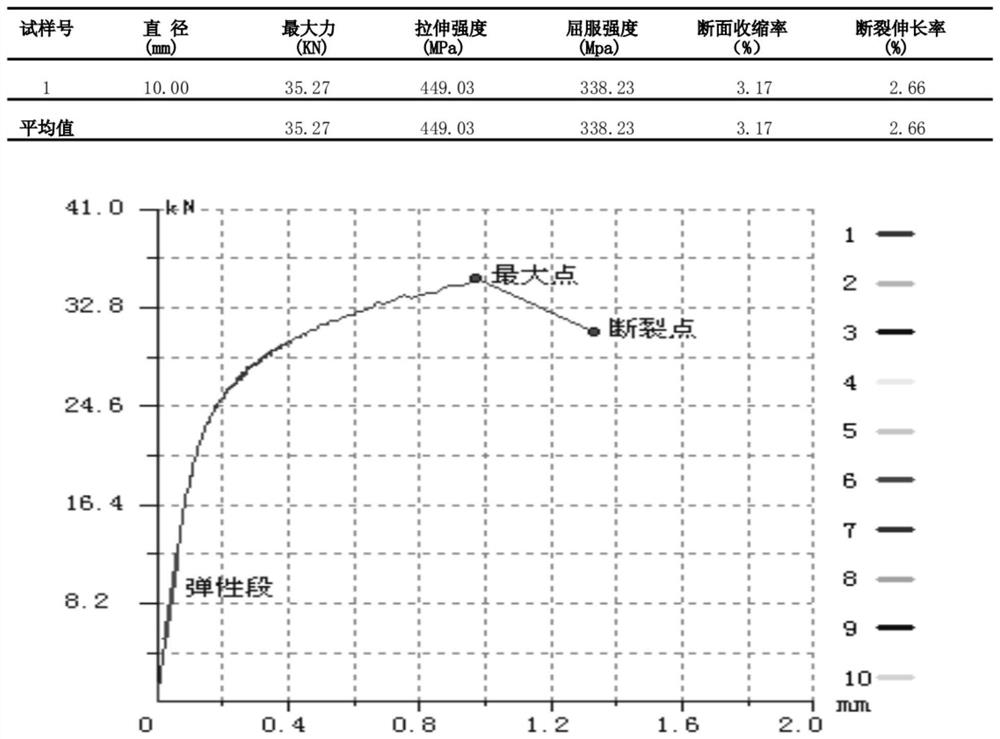

A kind of high elongation rut400 vermicular graphite cast iron and its production process

ActiveCN111187973BHigh tensile strengthHigh elongationProcess efficiency improvementFerrosiliconGraphite

A kind of high-elongation RuT400 vermicular graphite cast iron and its production process, using pig iron, scrap steel, nickel, ferrosilicon, recarburizer, or pig iron, recycled material, scrap steel, recarburizer as raw materials, put it into an intermediate frequency furnace for smelting , get qualified molten iron, add recarburizer and take it out of the furnace; carry out baking operation on the spheroidizing treatment bag, fill in vermicularizing agent, inoculant and iron filings to keep warm, pour molten iron into the vermicularizing treatment bag, when the vermicularizing treatment bag When the amount of molten iron poured into the medium accounts for 2 / 3 of the total mass of molten iron, add an inoculant for secondary inoculation, and continue to pour in the remaining molten iron; flow inoculant to obtain vermicular graphite cast iron. The advantages are: simple process and easy operation. The obtained vermicular graphite cast iron has a tensile strength of more than 400MPa, a yield strength of more than 300MPa, and a breaking elongation of more than 2.5%. Its elongation at break is more than 2.5 times that required by the national standard RuT400A.

Owner:锦州捷通铁路机械股份有限公司

Alkaline battery

InactiveCN1180503CHigh energySolve internal pressure sealingFinal product manufactureAlkaline accumulators manufactureInternal resistanceBiochemical engineering

Owner:CHUNLAN GROUP CORP

Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

InactiveCN1266316CIncrease the number of nucleiDiffusion fastElectrolytic coatingsGrown filmNanoparticle

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com