Foaming agent, preparation method thereof, and preparation method of aluminum foam

A technology of foaming agent and aluminum melt, which is applied in the preparation of foamed aluminum, the foaming agent for preparing small-pore foamed aluminum and its preparation field, to achieve the effects of reducing the degree of agglomeration, promoting nucleation, and reducing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

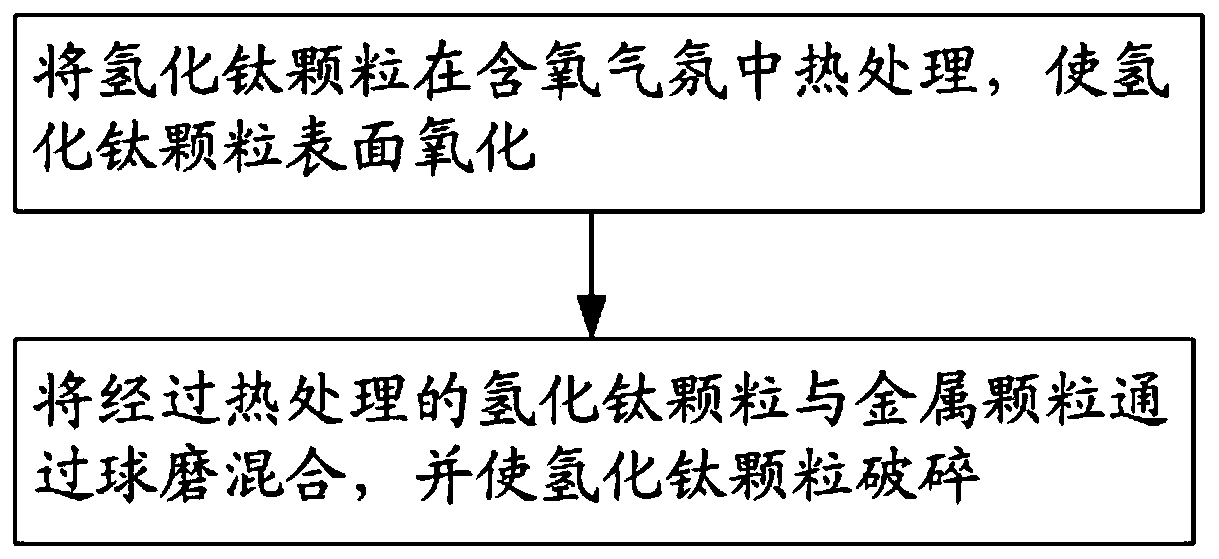

[0013] see figure 1 , the invention provides a kind of preparation method of whipping agent, comprising:

[0014] S1, heat-treating the titanium hydride particles in an oxygen-containing atmosphere to oxidize the surface of the titanium hydride particles; and

[0015] S2, mixing the heat-treated titanium hydride particles and metal particles through ball milling, and breaking the titanium hydride particles.

[0016] The titanium hydride is used as a gas source for the foaming process. The particle size of the titanium hydride particles is preferably less than 150 mesh, more preferably -150 mesh to -400 mesh. In the step S1, the heat treatment temperature is preferably 400°C to 500°C, and the heat treatment time is preferably 1 hour to 8 hours. The oxygen-containing atmosphere is preferably air. Heating the titanium hydride particles in an oxygen-containing atmosphere can form a dense oxide film on the surface of the particles, that is, a titanium dioxide film, thereby dela...

Embodiment 1

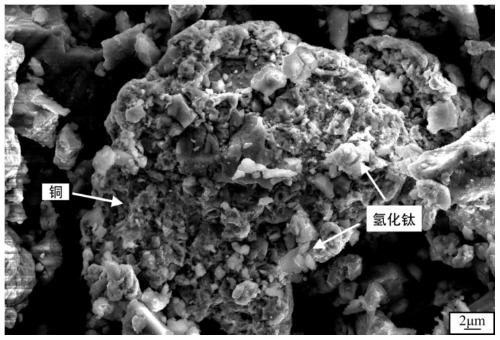

[0027] Preparation of foaming agent: Use titanium hydride powder with a particle size of -300 mesh and copper powder with a particle size of -200 mesh as raw materials, first place titanium hydride in air at 500 ° C for 2 hours, and then combine with copper powder according to the following process Parameters for ball milling and mixing: the mass ratio of pretreated titanium hydride to copper powder is 1:1, the mass ratio of balls to materials is 3:1, the speed of the ball mill is 250r / min, and the milling time is 4h. After ball milling, composite particles with broken pretreated titanium hydride discretely distributed on the copper powder matrix are formed in the composite powder. The microscopic appearance of the scanning electron microscope is as follows: figure 2 shown. When this composite powder is used as a foaming agent, it can significantly refine the pore size.

Embodiment 2

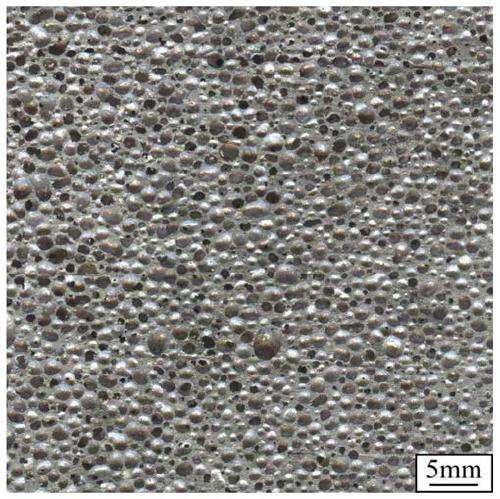

[0029]Preparation of aluminum foam with small pore size: the foamed aluminum with small pore size was prepared by using the foaming agent in Example 1. First heat and melt the aluminum ingot in a stainless steel crucible brushed with zinc oxide paint, then adjust the melt temperature to 680°C, add 3wt.% calcium metal particles and stir for 10 minutes to increase the viscosity. After the increase, adjust the melt temperature to At 660°C, add 1wt.% foaming agent and stir for 3 minutes to disperse. After the dispersion is completed, heat-preserve and foam for 5 minutes. After the foaming process is fully carried out, take out the crucible and place it in the air to cool naturally to room temperature. An average pore size of 1mm can be prepared. Small pore aluminum foam with uniform pore structure, such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com