Thermal growth AL2O3 film type M A1 nano composite plating and producing process and application

A nanocomposite and thermal growth technology, applied in coatings, electrolytic coatings, etc., can solve the problems of not much improvement in oxidation performance, uneven distribution of Al particles, and insufficient composite content, so as to improve oxidation resistance and improve The effect of the number of nucleation and the compactness of the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

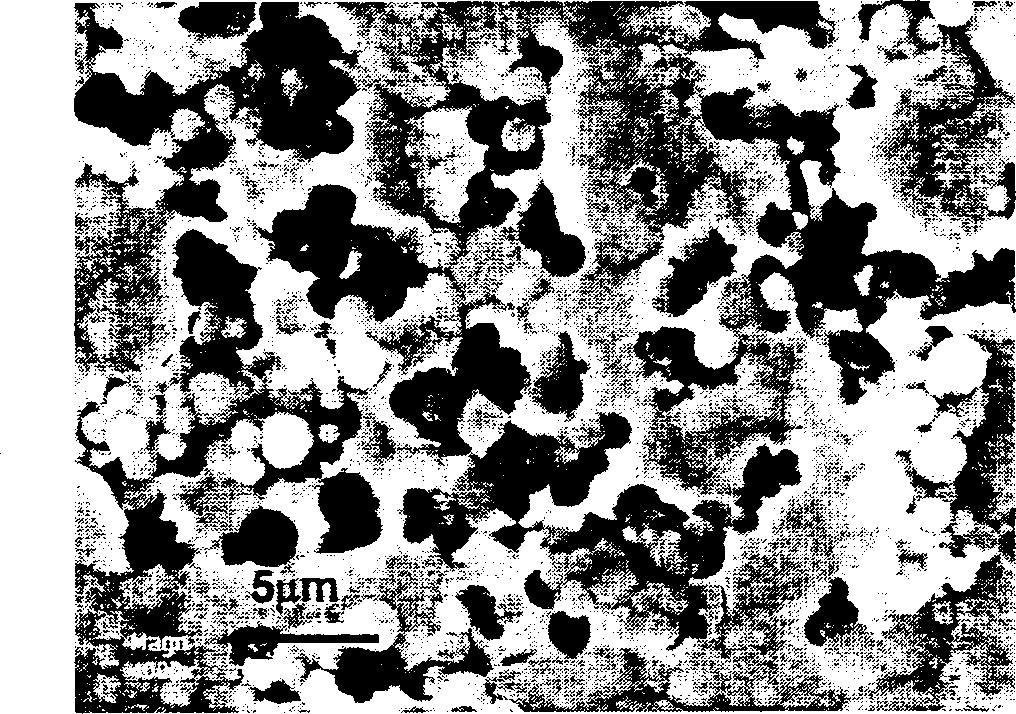

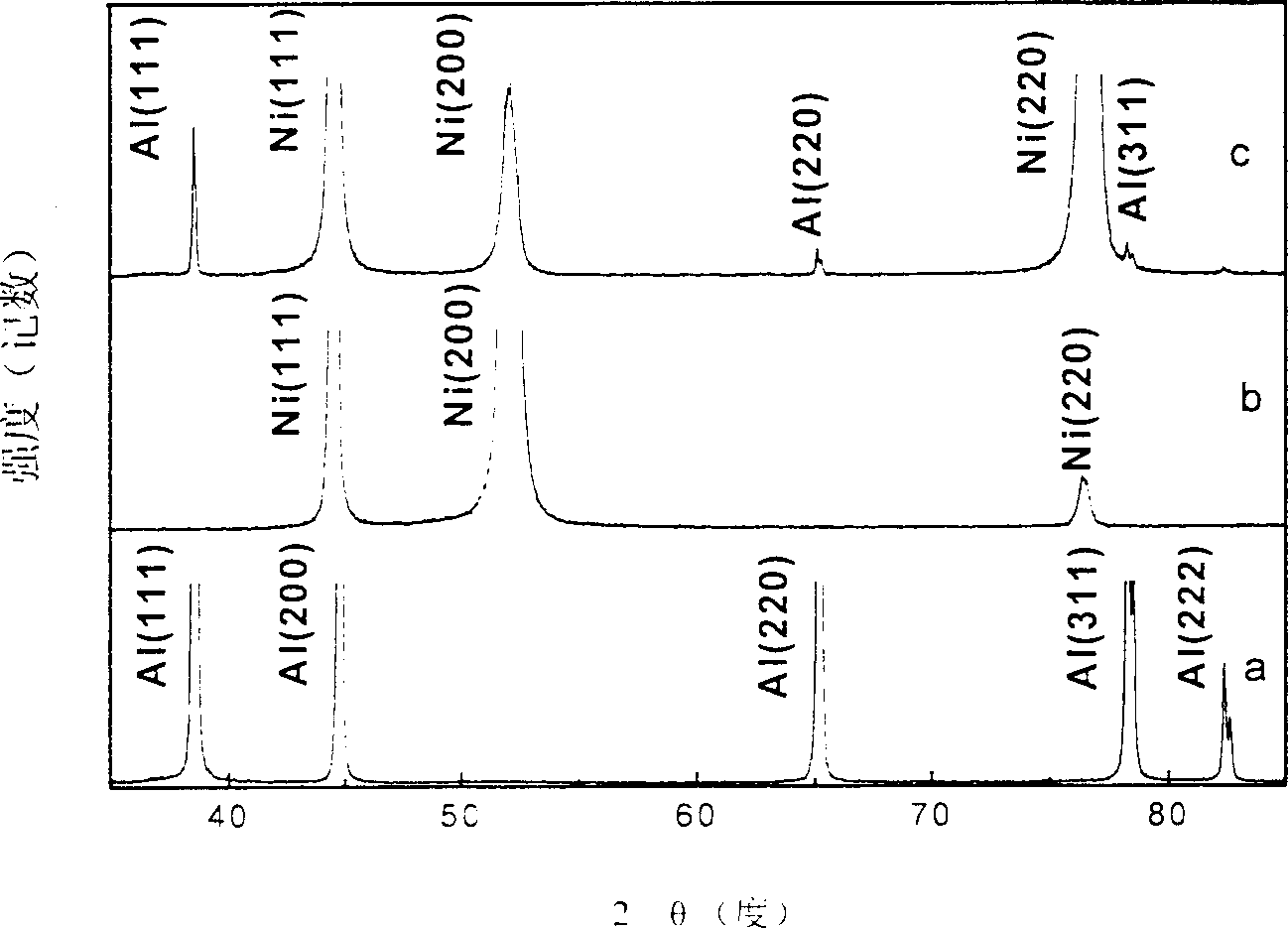

[0047] The composition of the M-Al nanocomposite coating of the present invention is a combination of nanocrystalline M-based coating and second-phase Al nanoparticles dispersedly distributed, that is, M-Al, wherein M can be Ni, Fe or Co; Deposition (i.e. composite electroplating) technology is used to prepare Ni-Al, Fe-Al or Co-Al nanocomposite coatings; the plating solution is the commonly used above-mentioned sulfate system (MSO 4 ), the Al powder is nano-sized. In this embodiment, the preparation and results of the Ni-Al nanocomposite coating will be described in detail. The average particle size of the nano-Cr powder used is 40 and 75 nm, respectively.

[0048] Its flow process that present embodiment prepares Ni-Al nanocomposite coating is:

[0049] The base metal is Ni (Fe, Co, carbon steel or low alloy steel can also be used as the base material) - the surface is ground to 800# water sandpaper - the surface is ultrasonically cleaned - co-electrodeposition is carried o...

Embodiment 2

[0058] Example 2 (oxidation performance at 950°C)

[0059] Whether the nanocomposite coating of the present invention has superior high temperature oxidation resistance depends on whether the nanocomposite coating can thermally grow continuous protective Al 2 o 3 Oxide film.

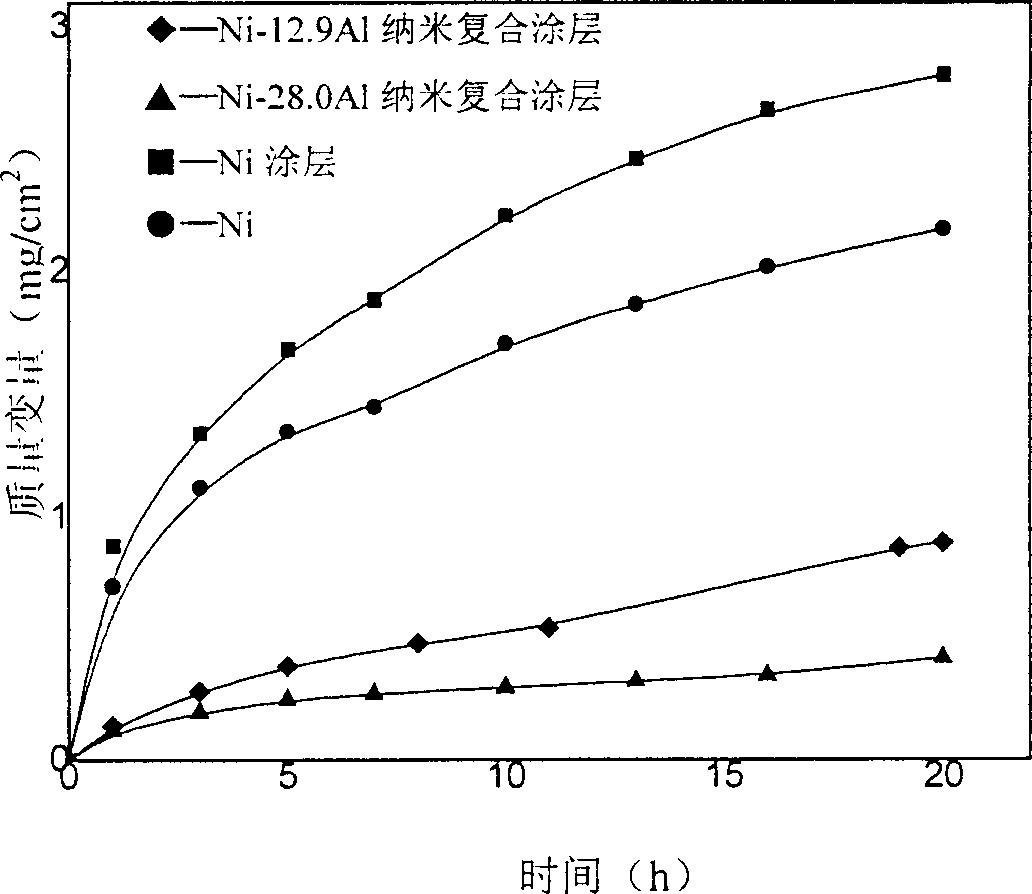

[0060] The temperature used in this embodiment is in the range of 950-1050°C. When the Al composite amount in the nanocomposite coating exceeds a critical value, the nanocomposite coating can thermally grow protective Al 2 o 3 membrane. Thermally grown Al 2 o 3 The minimum content (or critical content) required by the film is related to the nanometer size of the added Al powder. The smaller the particle size, the lower the critical content. For example, when the average size used in the embodiment is respectively 40 and 75nm, the minimum content of Al is respectively 9.8 and 12.9% by mass percentage at 950°C, the maximum content is 35%, and the balance is M; with the increase of oxidation temperat...

Embodiment 3

[0063] Example 3 (oxidation resistance at 1050°C)

[0064] As mentioned before, as long as the compounded Al content exceeds the critical content, the nanocomposite coating can grow continuous protective Al 2 o 3 oxide layer, and the higher the Al content, the formation of continuous Al 2 o 3 The shorter the time required for the oxide layer, that is, the better the protection performance. This example mainly introduces the oxidation of Ni-28Al nanocomposite coating with an average particle size of 75nm at 1050°C.

[0065] The oxidation experiment was carried out in a laboratory environment at a temperature of 1050°C for 20 hours. Figure 7 It is the oxidation weight gain of the substrate Ni, the single Ni coating, and the Ni-28Al nanocomposite coating at 20 h. The oxidation parabolic constants calculated for the three samples are 2.5×10 -11 , 6.4×10 -10 , 5.5×10 -12 g 2 / cm 4 ·s. Oxidation rate of Ni-28Al and Al 2 o 3 The thermal growth rate is comparable. Accor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com