Patents

Literature

88results about How to "Improve lattice matching" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

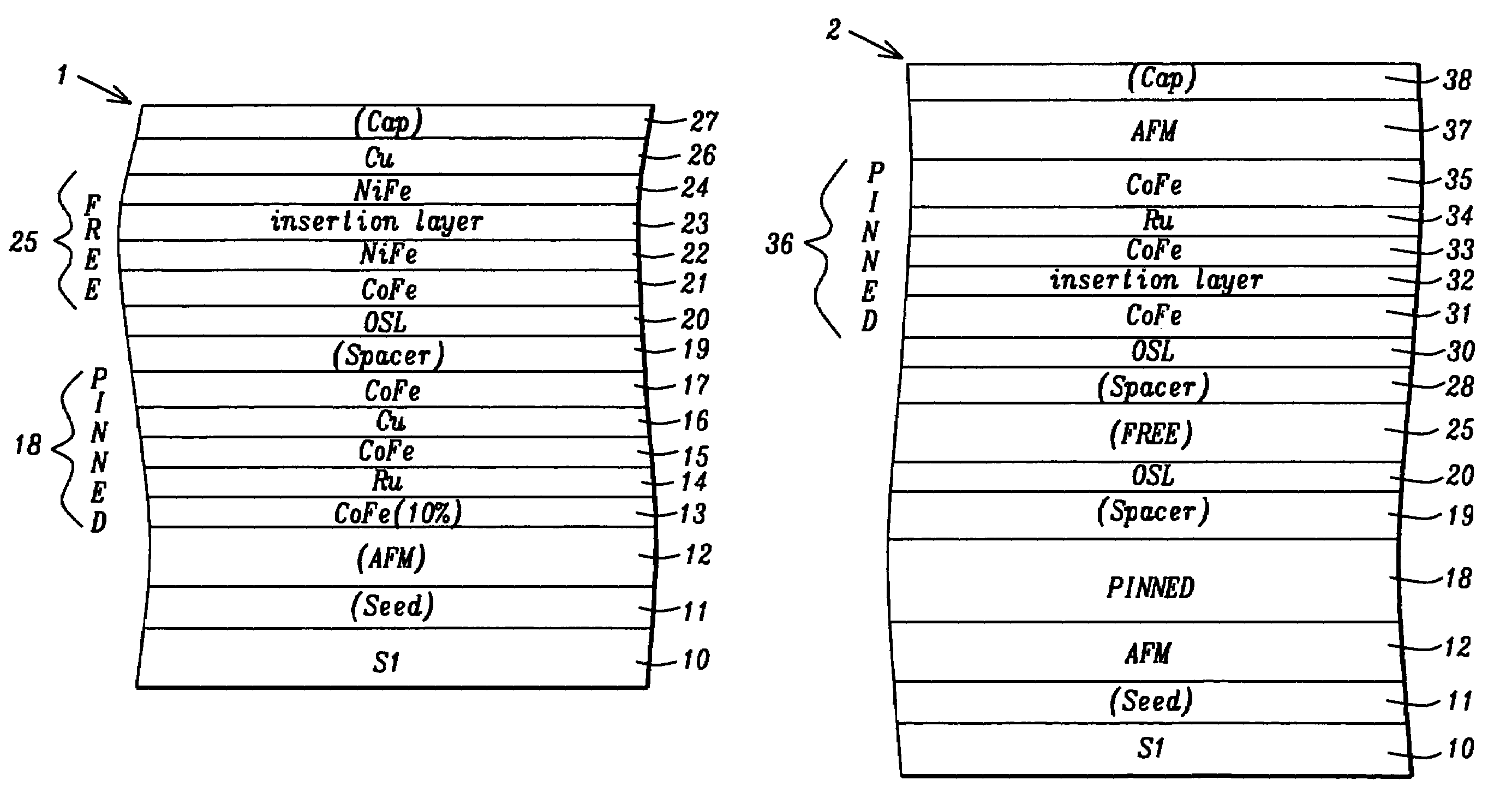

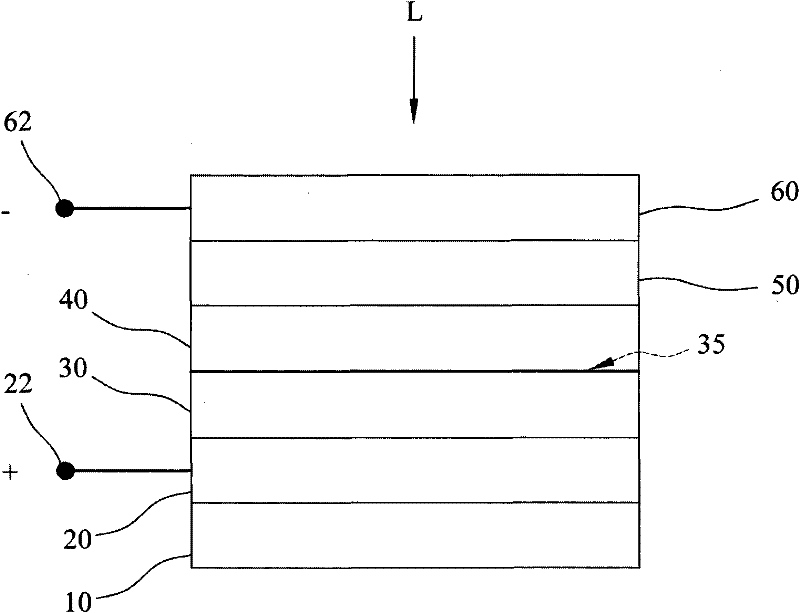

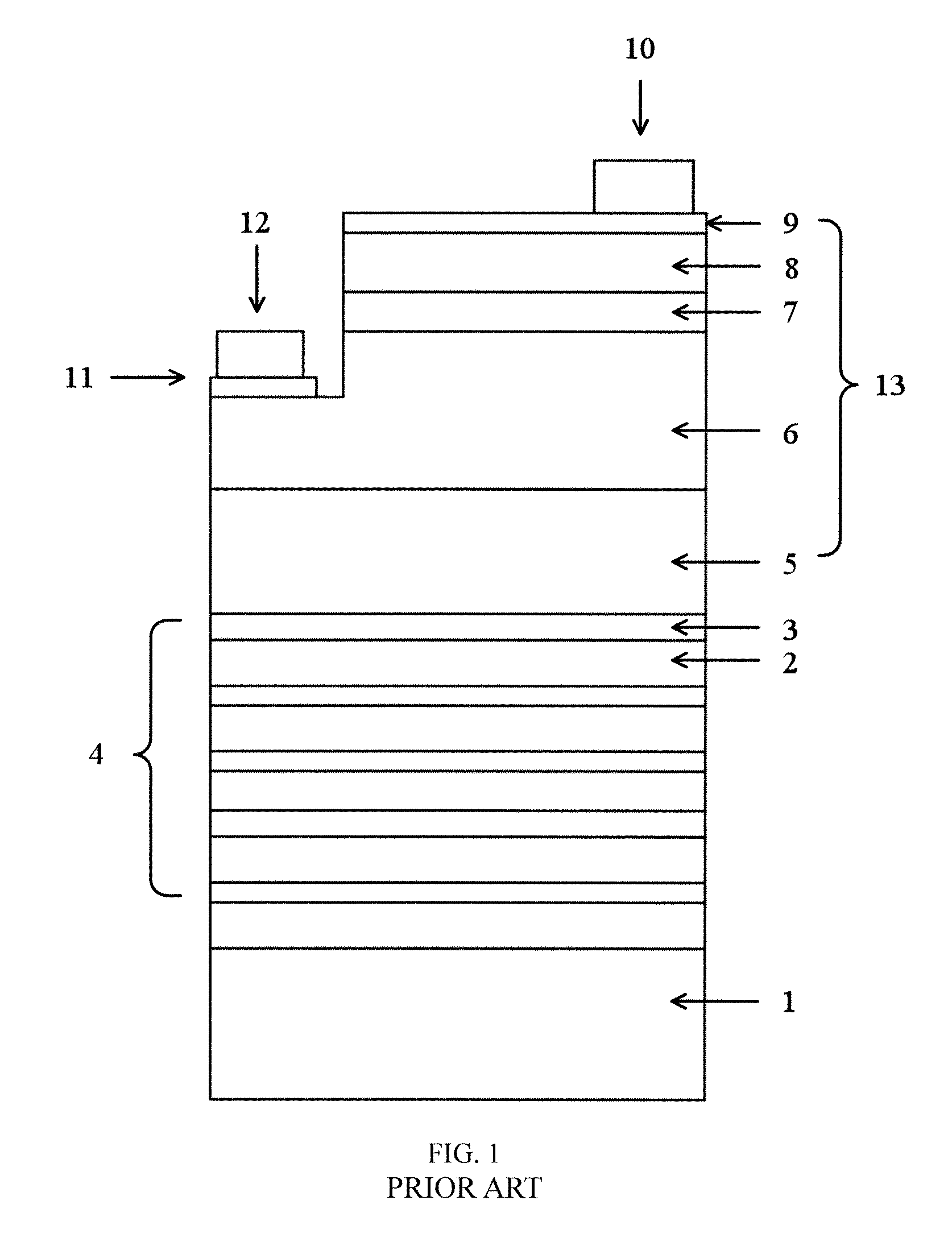

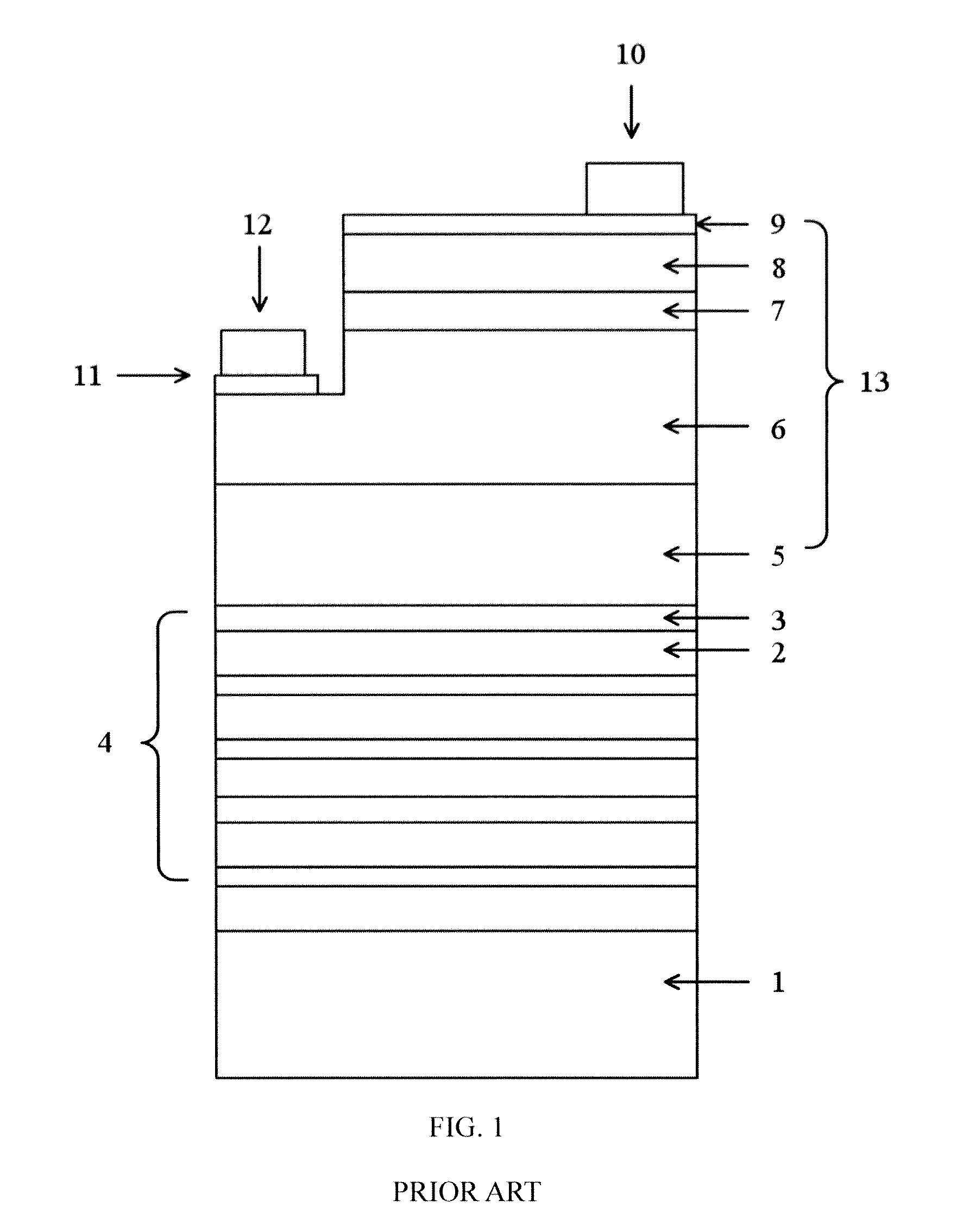

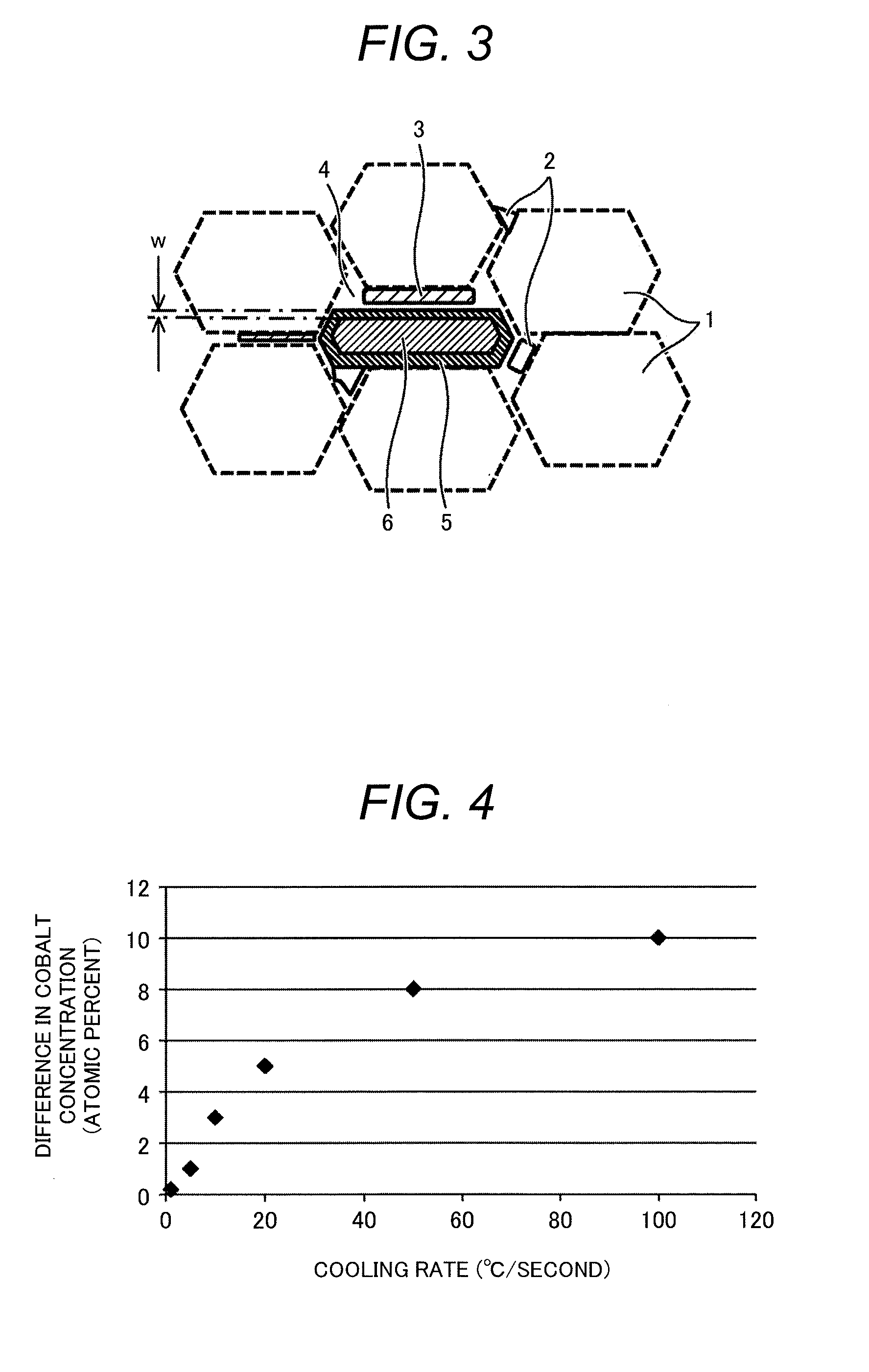

Process and structure to fabricate CPP spin valve heads for ultra-high recording density

InactiveUS7256971B2Raise the ratioIncrease resistanceNanostructure applicationNanomagnetismDopantElectrical resistance and conductance

A CPP-GMR spin value sensor structure with an improved MR ratio and increased resistance is disclosed. All layers except certain pinned layers, copper spacers, and a Ta capping layer are oxygen doped by adding a partial O2 pressure to the Ar sputtering gas during deposition. Oxygen doped CoFe free and pinned layers are made slightly thicker to offset a small decrease in magnetic moment caused by the oxygen dopant. Incorporating oxygen in the MnPt AFM layer enhances the exchange bias strength. An insertion layer such as a nano-oxide layer is included in one or more of the free, pinned, and spacer layers to increase interfacial scattering. The thickness of all layers except the copper spacer may be increased to enhance bulk scattering. A CPP-GMR single or dual spin valve of the present invention has up to a threefold increase in resistance and a 2 to 3% increase in MR ratio.

Owner:HEADWAY TECH INC

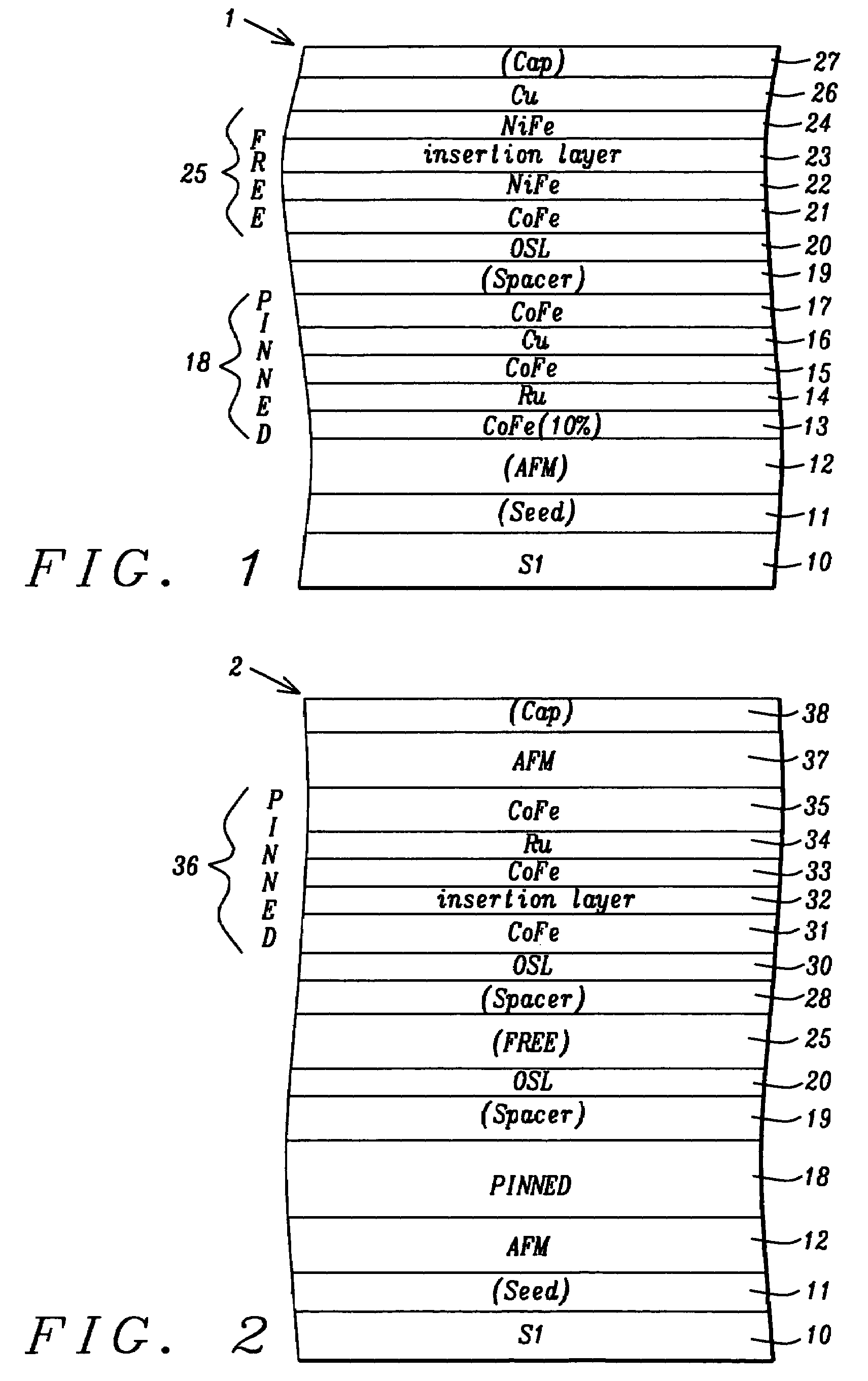

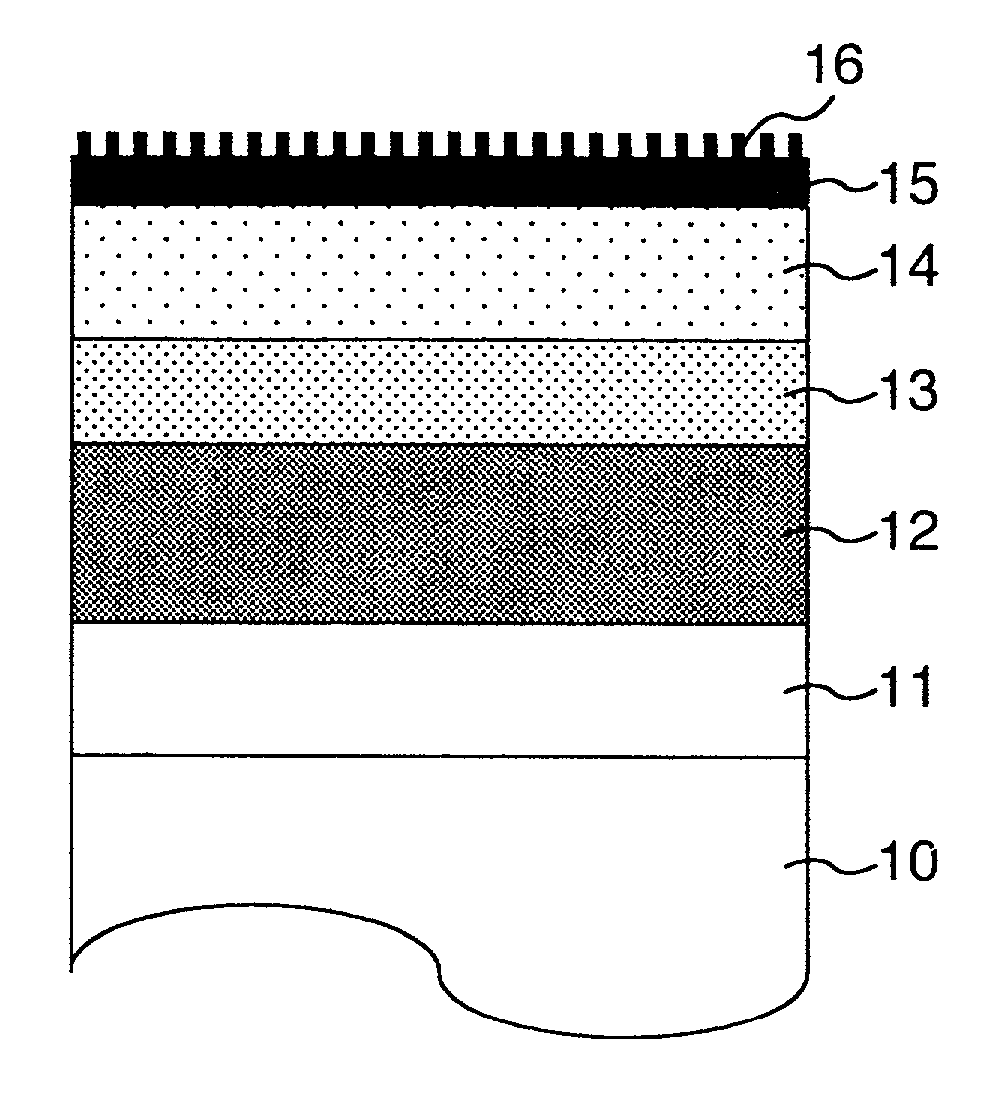

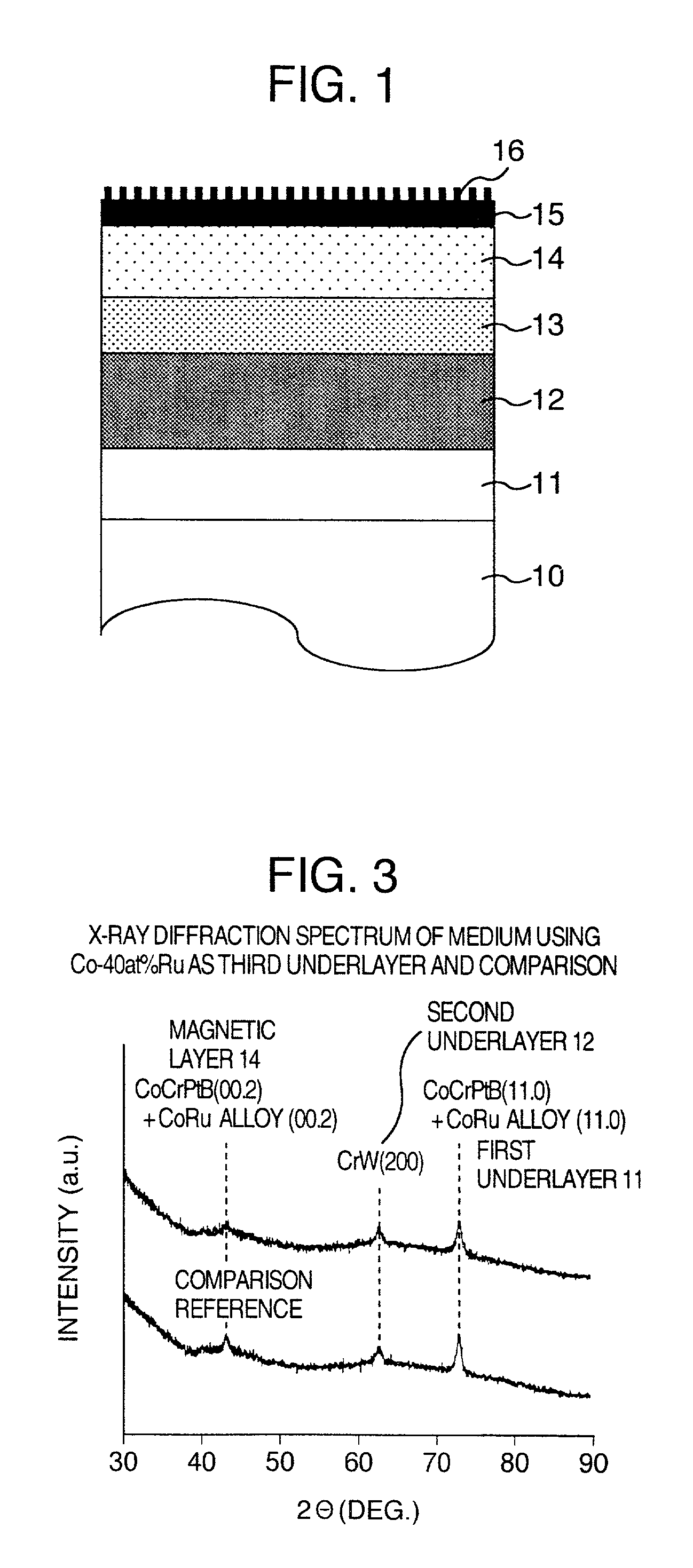

Magnetic recording medium and magnetic recording apparatus

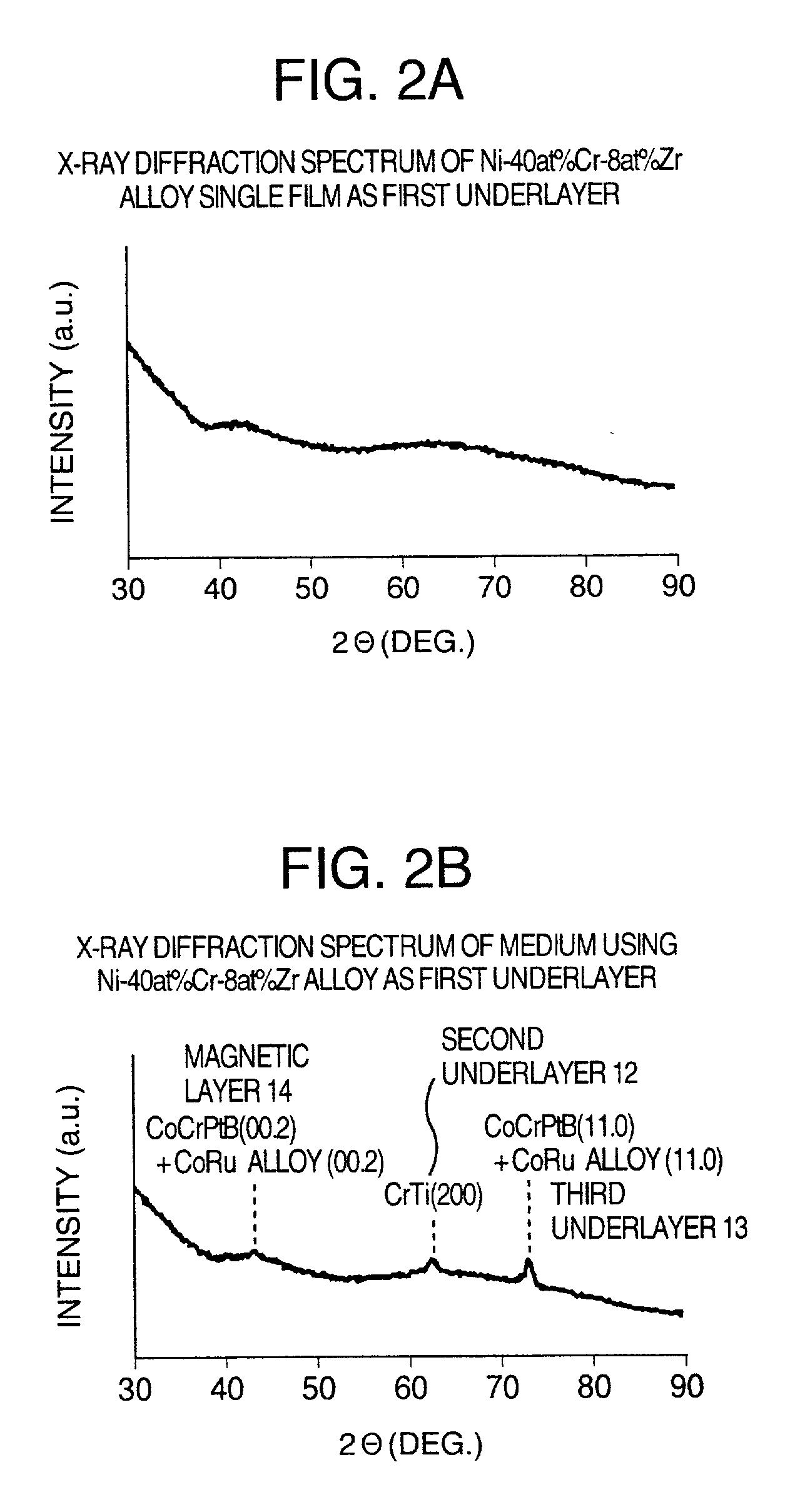

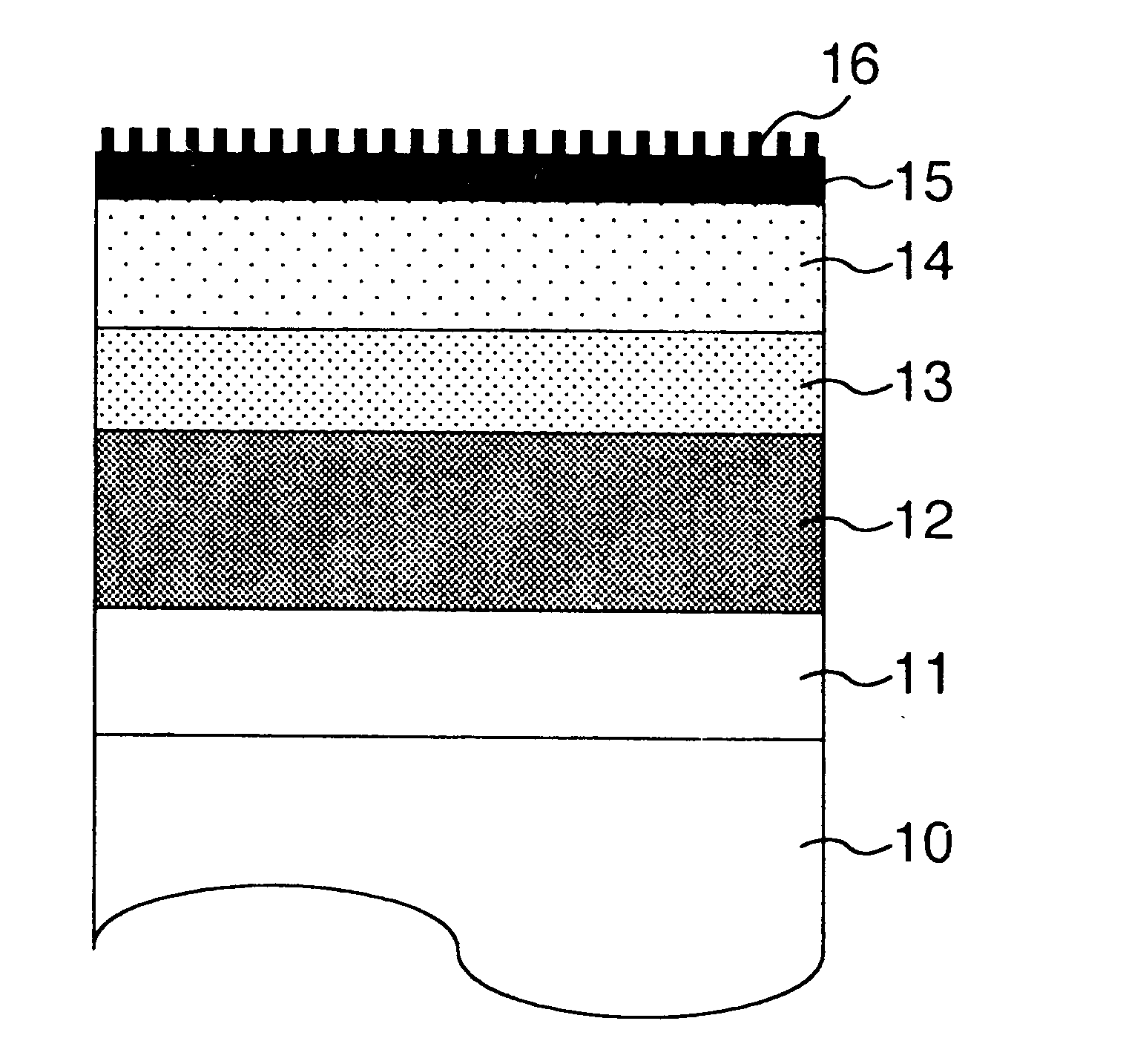

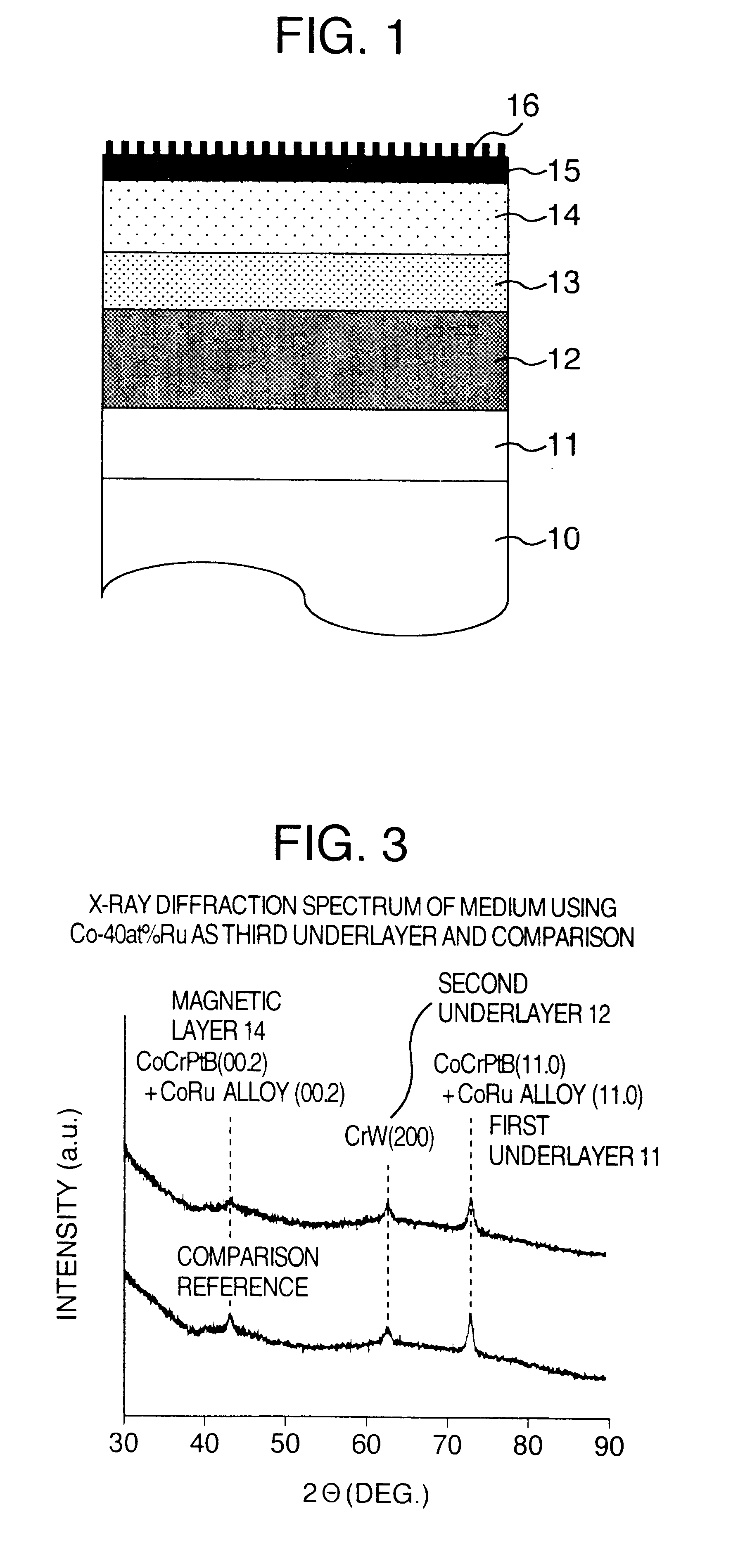

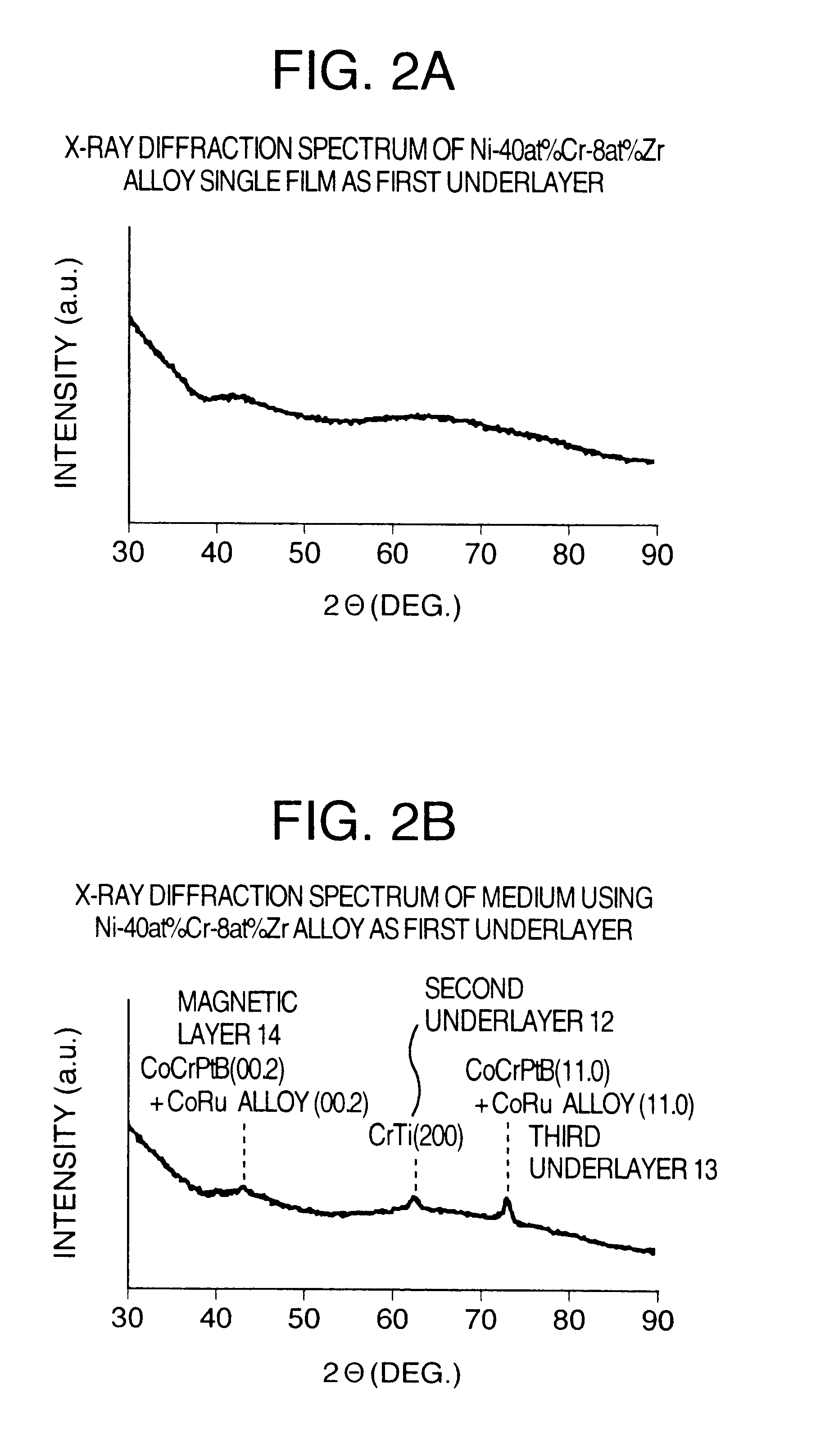

InactiveUS20020064691A1Improve lattice matchingEnhance coercivityBase layers for recording layersRecord information storageCrystal structureOptoelectronics

The longitudinal magnetic recording medium includes a non-magnetic substrate, a first underlayer having at least one of an amorphous structure and a fine crystal structure formed on the non-magnetic substrate, a second underlayer having a body-centered cubic structure formed on the first underlayer, a third underlayer having a hexagonal closed packed structure formed on the second underlayer, and a magnetic layer having the hexagonal closed packed structure formed on the third underlayer, wherein the third underlayer is composed of an alloy containing Co and Ru.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

Magnetic recording medium and magnetic recording apparatus

InactiveUS6623874B2Improve lattice matchingEnhance coercivityBase layers for recording layersRecord information storageCrystal structureOptoelectronics

The longitudinal magnetic recording medium includes a non-magnetic substrate, a first underlayer having at least one of an amorphous structure and a fine crystal structure formed on the non-magnetic substrate, a second underlayer having a body-centered cubic structure formed on the first underlayer, a third underlayer having a hexagonal closed packed structure formed on the second underlayer, and a magnetic layer having the hexagonal closed packed structure formed on the third underlayer, wherein the third underlayer is composed of an alloy containing Co and Ru.

Owner:HITACHI GLOBAL STORAGE TECH JAPAN LTD

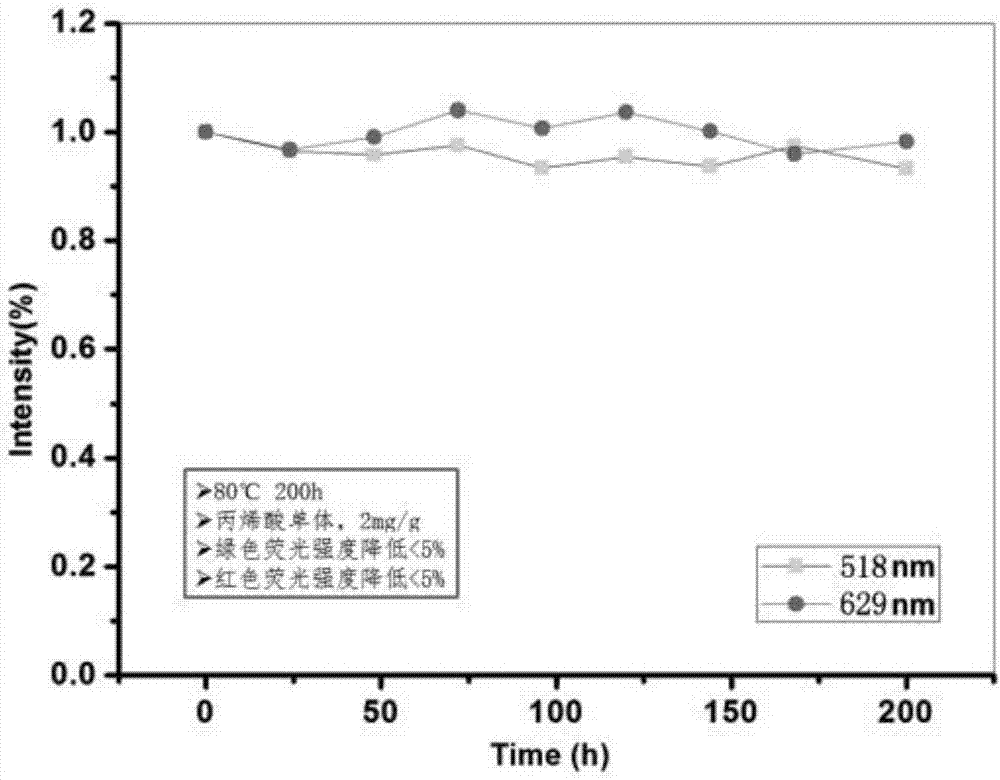

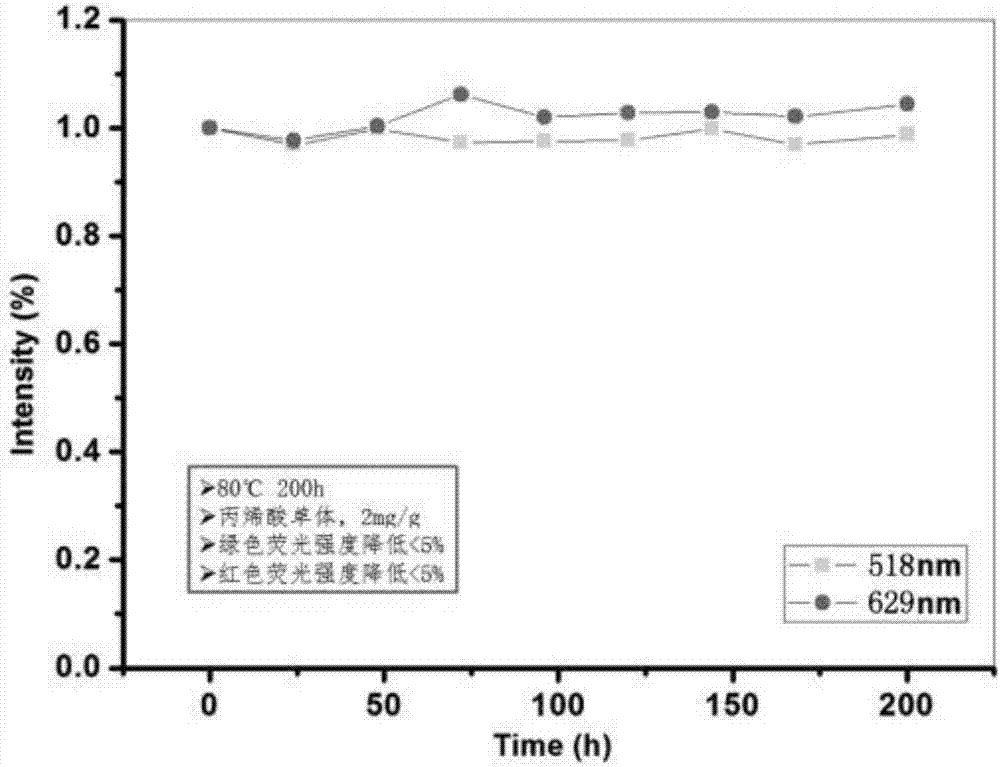

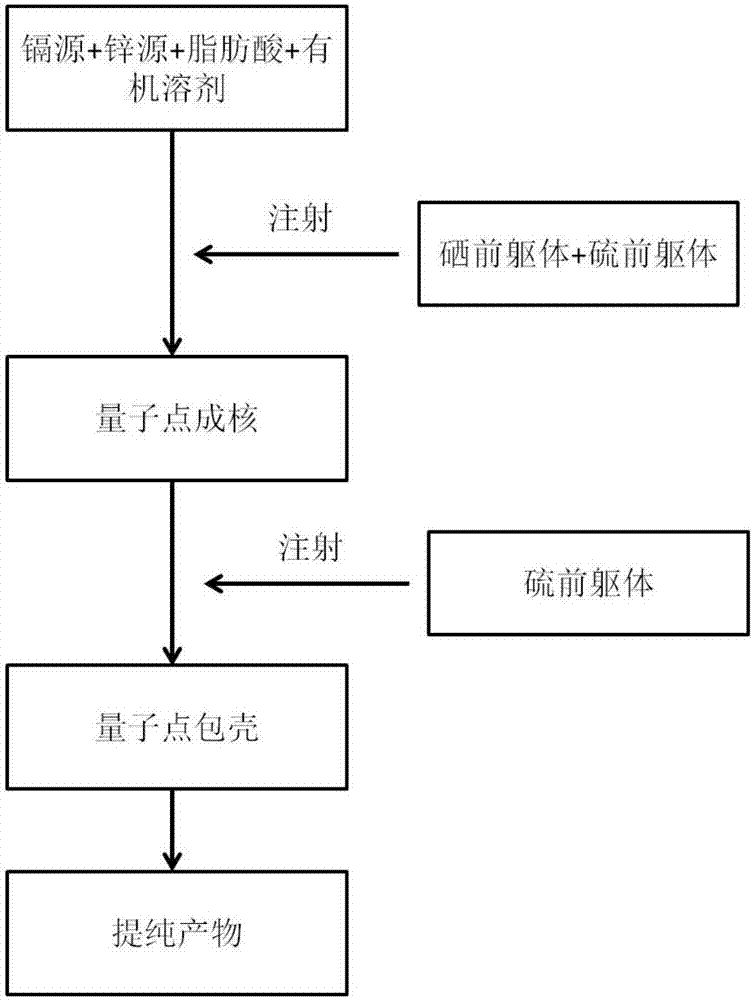

Preparing method for CdSe/CdZnSeS/ZnS core-shell quantum dots

ActiveCN107090291AImprove lattice matchingImprove photostabilityLuminescent compositionsQuantum yieldSynthesis methods

The invention provides a preparing method for CdSe / CdZnSeS / ZnS core-shell quantum dots. The preparing method is simple in synthesis method, short in synthesis time and high in quantum efficiency and stability, and is characterized by including the following steps that (1) zinc sources, cadmium sources, an organic solvent and organic ligand are mixed and stirred to be even, then the mixture is heated to be at the temperature of 260 DEG C to 320 DEG C, and protection gas is introduced into the whole reaction process; (2) in the stirring state, a selenium precursor and a sulfur precursor which are mixed to be even are rapidly injected; (3) after the precursors in the step (2) are completely injected, timing is started, and in 0 s to 30 s, the sulfur precursor is injected again; (4) at the temperature of 260 DEG C to 300 DEG C, the mixture is reacted for 1 min to 60 min. The preparing method for the CdSe / CdZnSeS / ZnS core-shell quantum dots has the advantages that CdZnSeS serves as a medium and is connected with a core CdSe and a shell CdS, the lattice matching performance between the cores and the shell layers of the quantum dots is high, the light stability and the heat stability between the cores and the shell layers of the quantum dots are quite high, and the yield of quantum can be 80% or above. The preparing method is simple in synthesis step, easy to operate and capable of facilitating large-scale production.

Owner:TIANJIN NAMEI NAMI TECH CO LTD

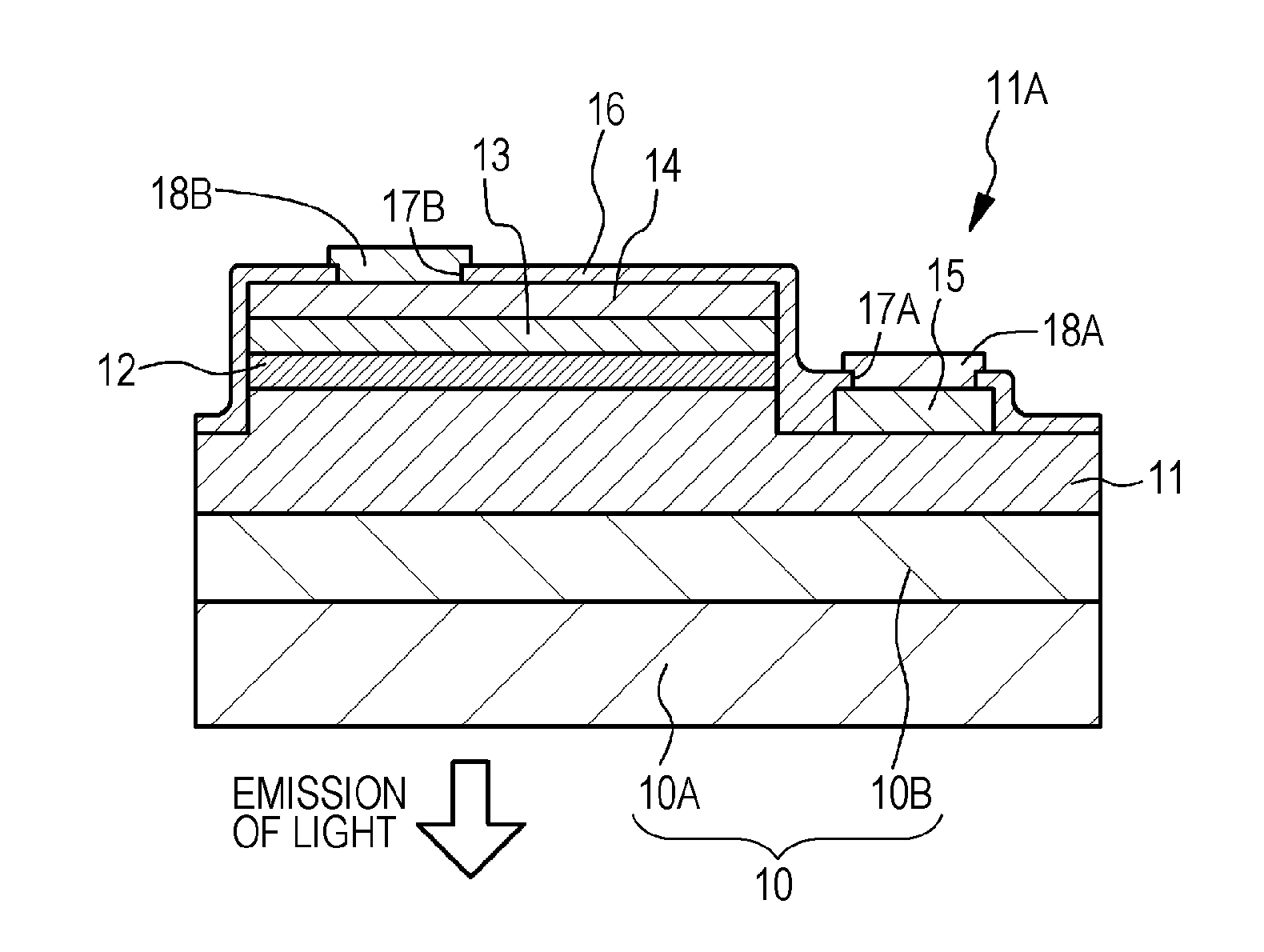

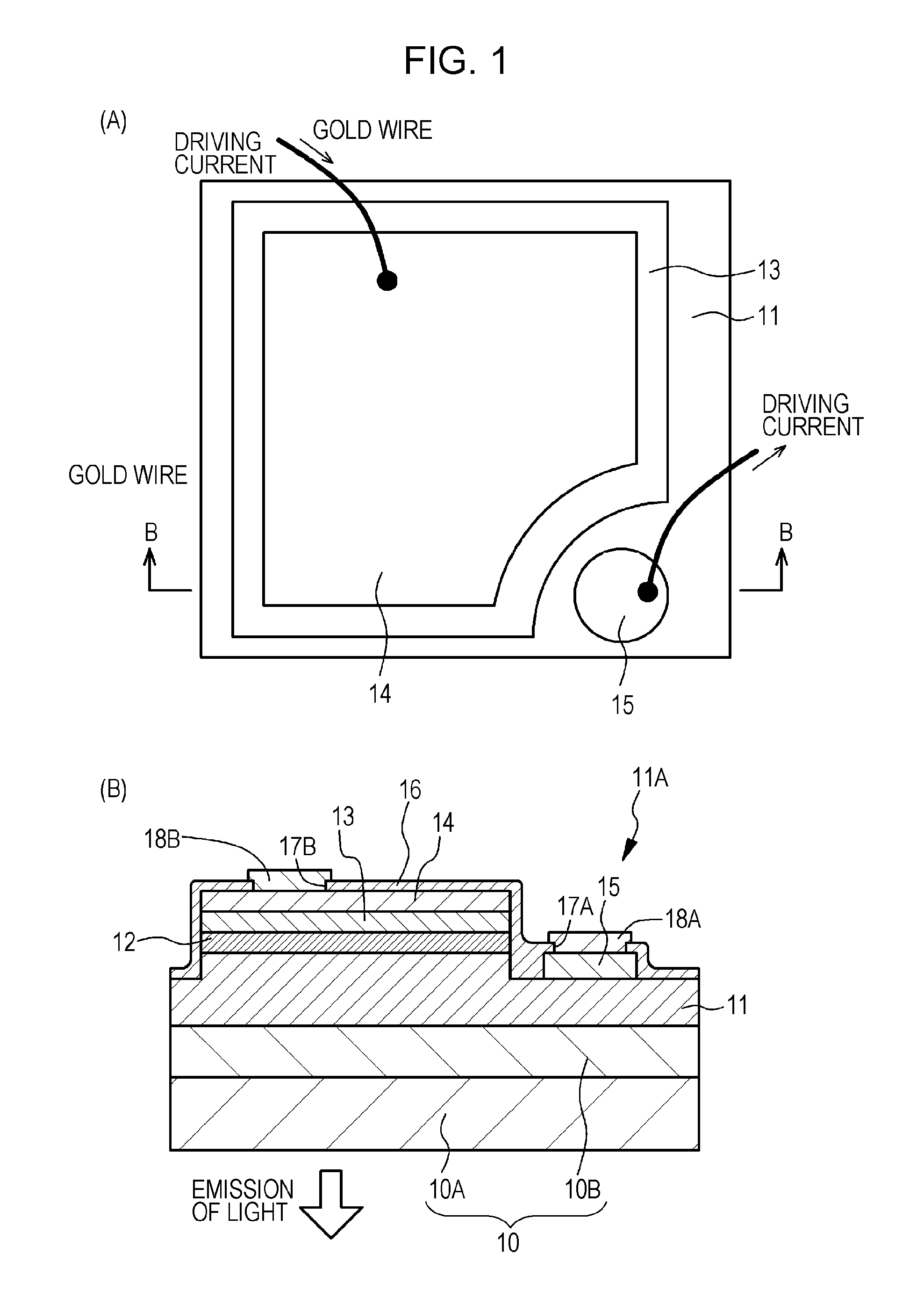

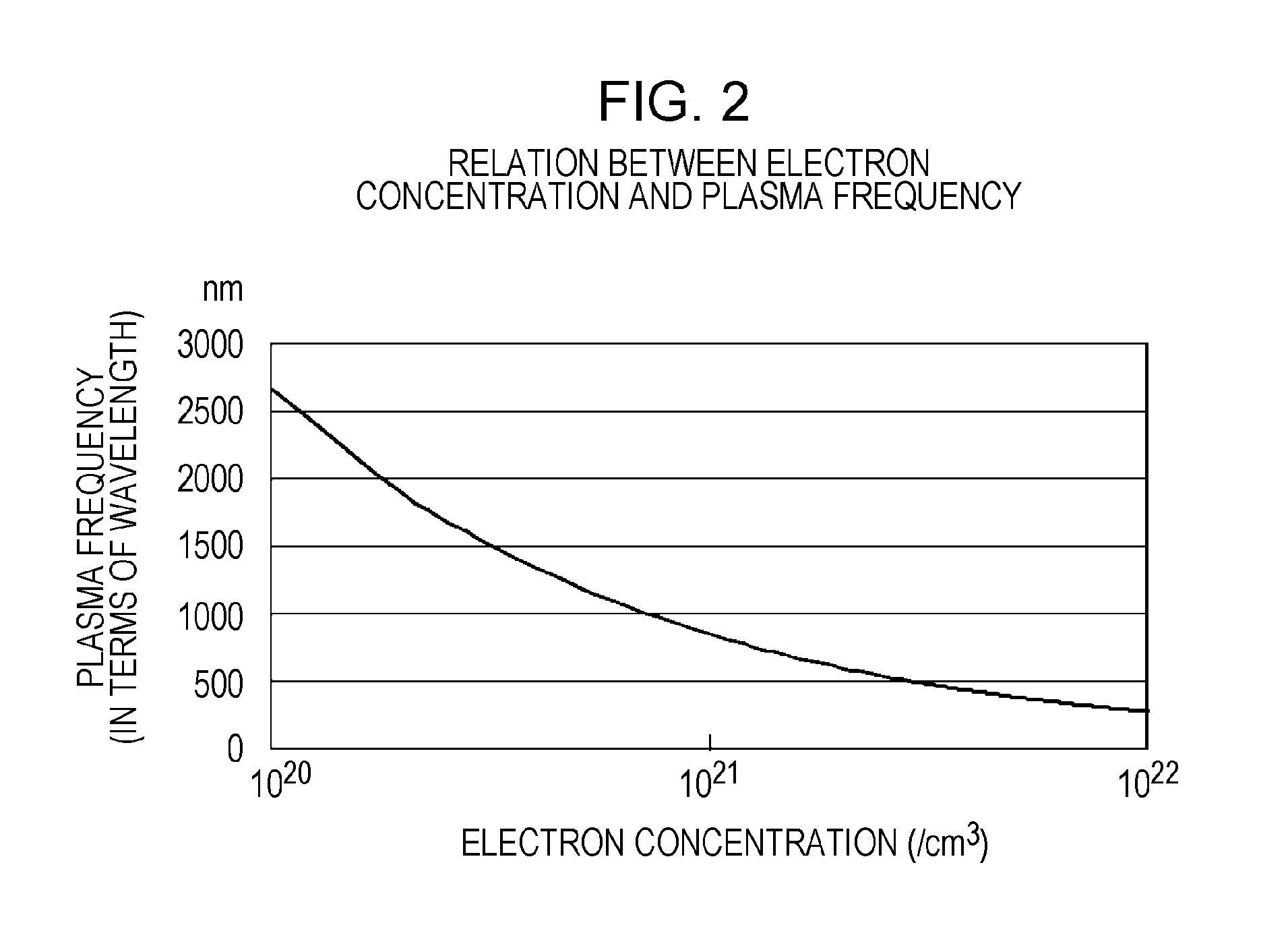

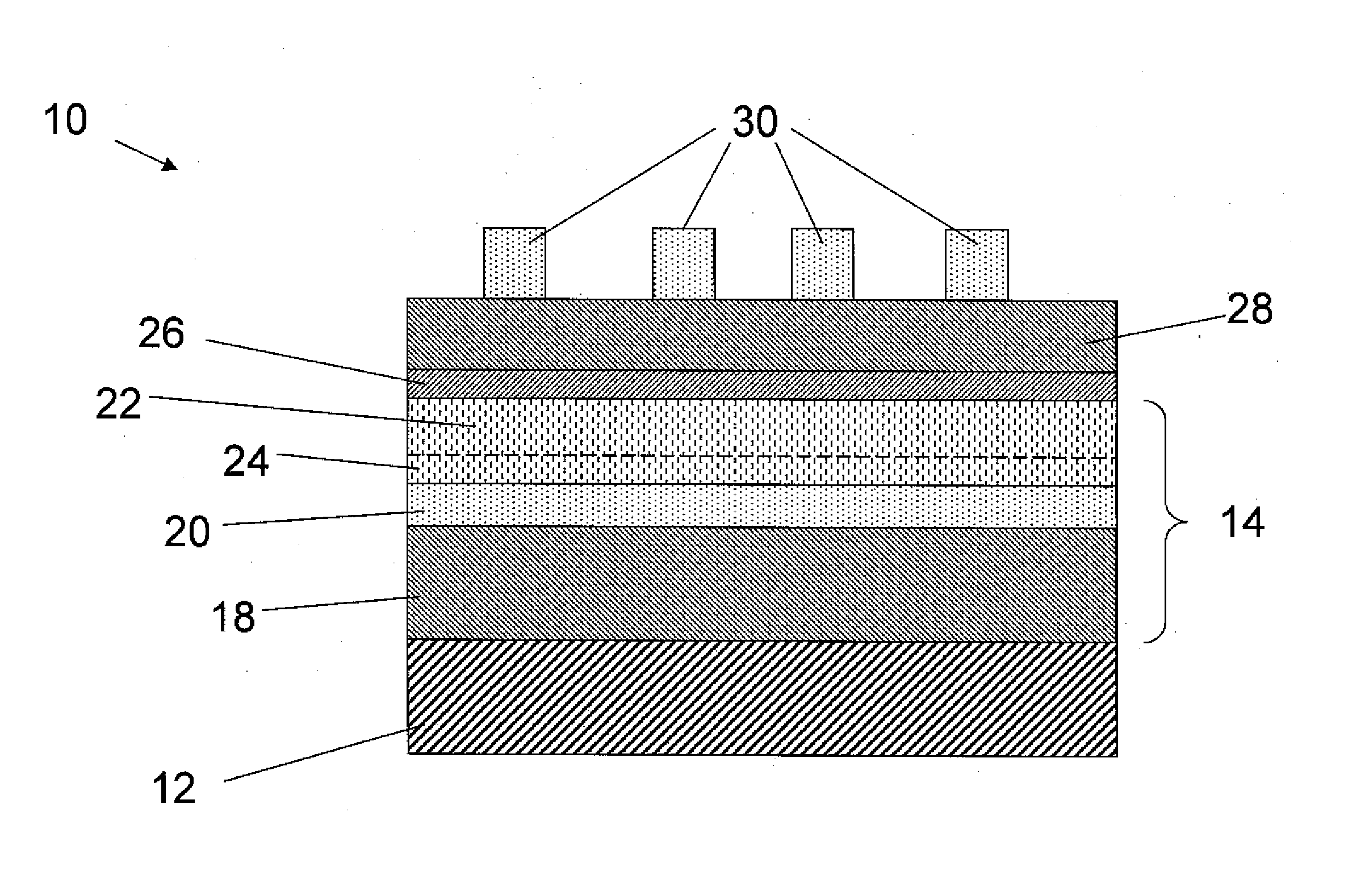

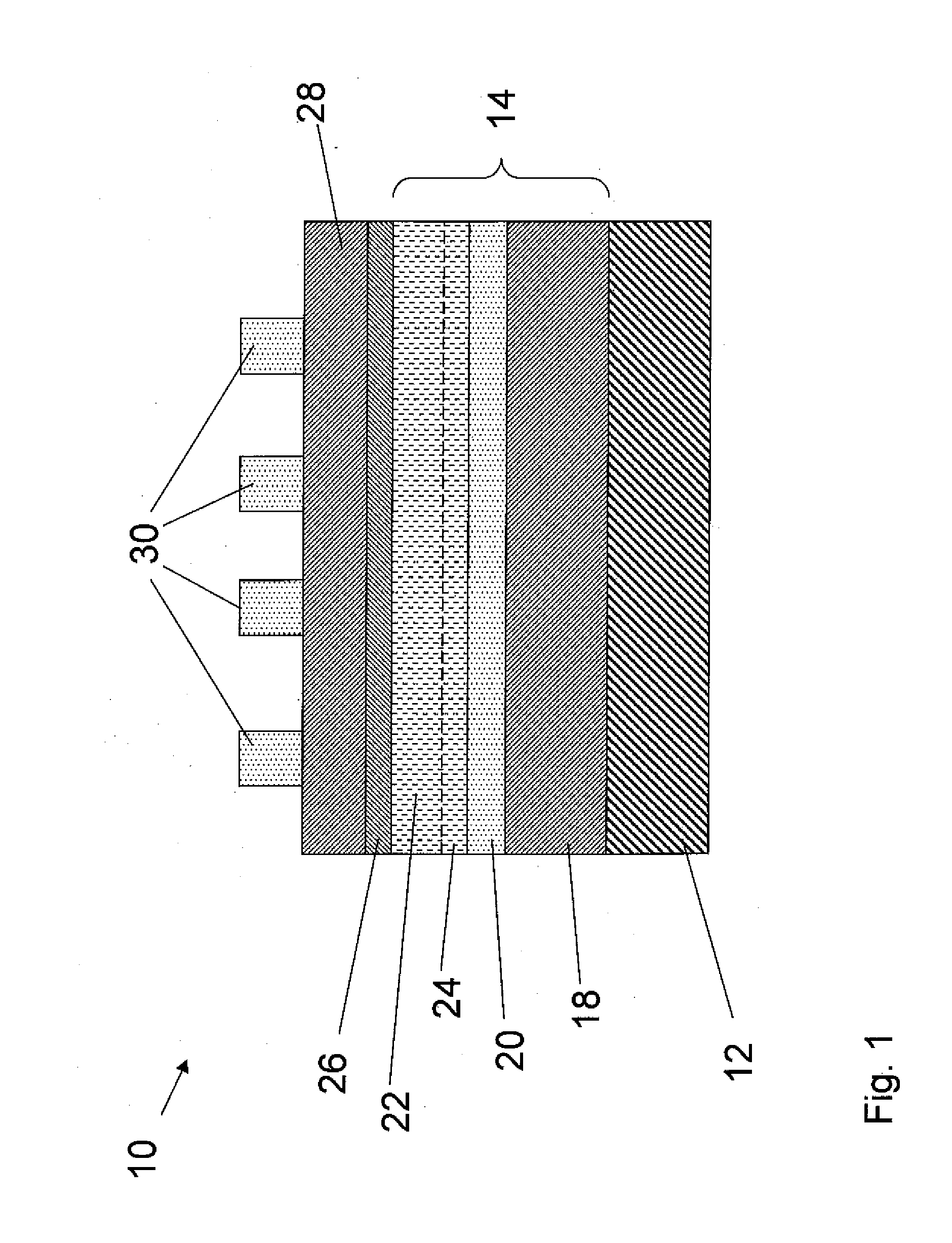

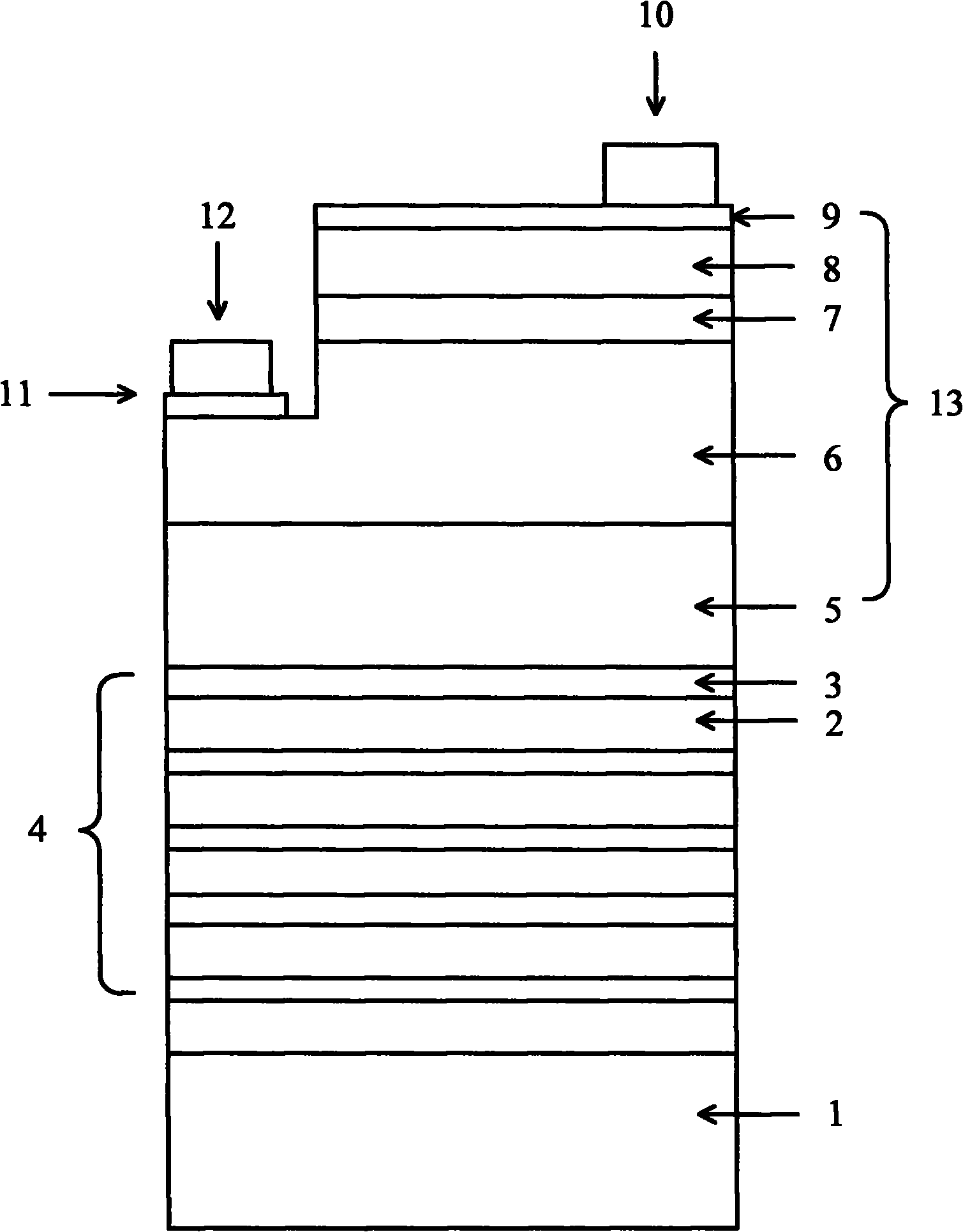

Semiconductor light-emitting device and method for manufacturing the same

InactiveUS20110012146A1Increase electron densityHighly achievedSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringActive layer

There is provided a light-emitting device including a second electrode which exhibits a stable behavior in a process for manufacturing a light-emitting device or during an operation of a light-emitting device. A light-emitting device includes a first compound semiconductor layer 11 with an n-type conductivity type, an active layer 12 formed on the first compound semiconductor layer 11 and composed of a compound semiconductor, a second compound semiconductor layer 13 with a p-type conductivity type formed on the active layer 12, a first electrode 15 electrically connected to the first compound semiconductor layer 11, and a second electrode 14 formed on the second compound semiconductor layer 13, wherein the second electrode 14 is composed of a titanium oxide, has an electron concentration of 4×1021 / cm3 or more, and reflects light emitted from the active layer.

Owner:SONY CORP

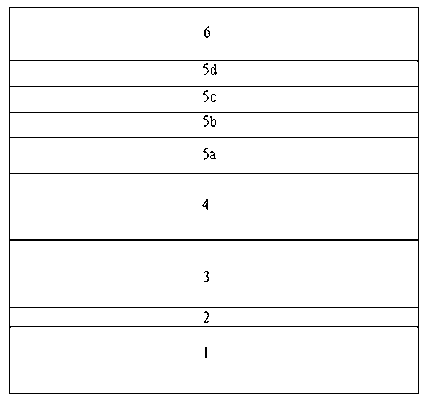

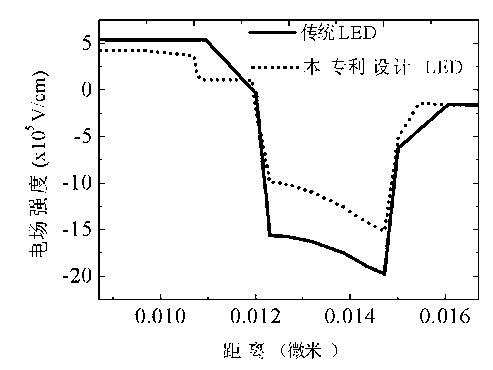

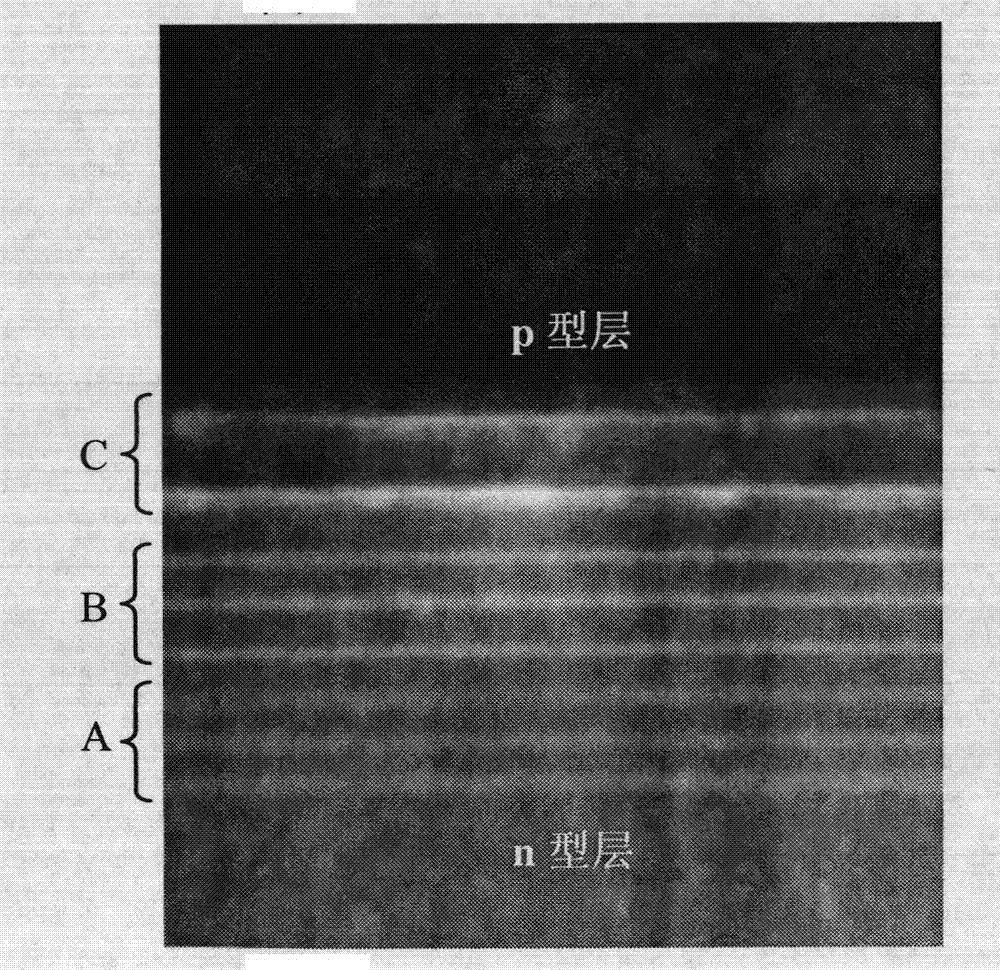

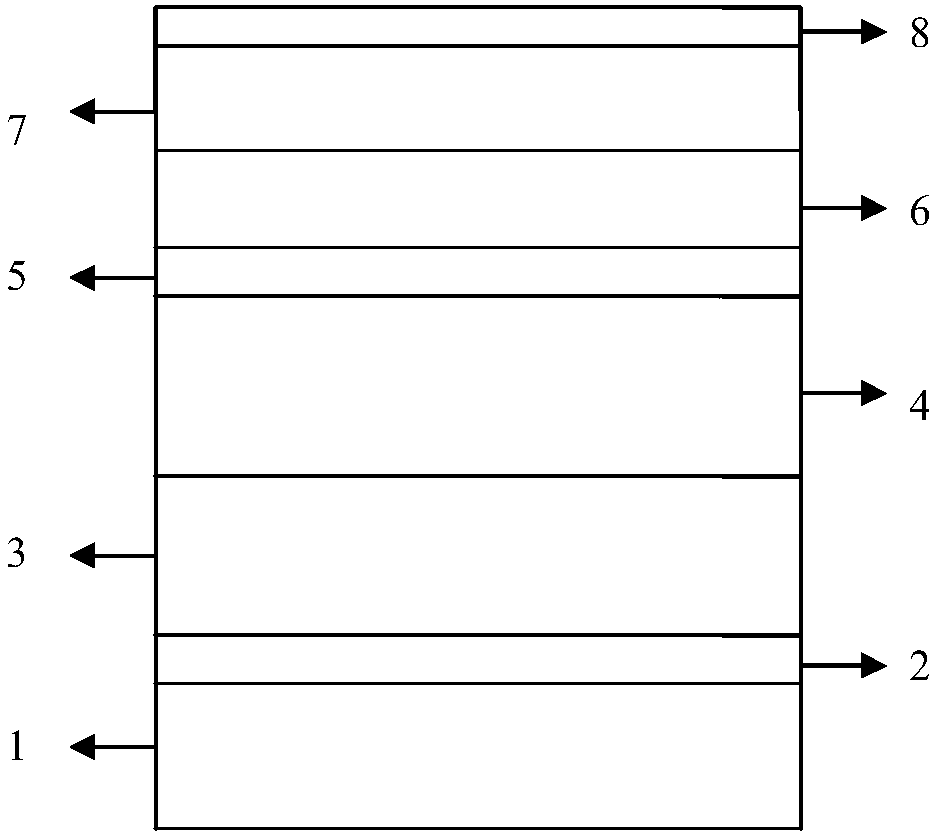

MQW (multiple quantum well)-growth applied GaN (gallium nitride)-based green-light LED (light emitting diode) epitaxial structure

InactiveCN103178176AReduce stress differenceReduced polarizing electric fieldSemiconductor devicesElectron holeGallium nitride

The invention discloses an MQW (multiple quantum well)-growth applied GaN (gallium nitride)-based green-light LED (light emitting diode) epitaxial structure, and relates to the technical field of LED epitaxial production, in particular to growth technology of GaN-based green-light LEDs. The MQW-growth applied GaN-based green-light LED epitaxial structure comprises a GaN nucleating layer, a non-mixed GaN layer, a n-type GaN layer, an InGaN (indium gallium nitride) / GaN MQW active layer and a p-type GaN layer which are sequentially grown on a substrate. The InGaN / GaN MQW active layer comprises a GaN barrier layer, an InGaN quantum well layer and a temperature-changing GaN transition layer. A buffering layer shallow well with low In components is grown between the GaN barrier layer and the InGaN quantum well layer of the InGaN / GaN MQW active layer. Stress between a quantum well and a barrier is greatly reduced, and stress difference between the quantum well and the barrier is relieved, so that a polarization electric field in the quantum well is greatly reduced. By the buffering layer shallow well between the barrier and the quantum well, the polarization electric field is reduced, spatial segregation of an electron-hole wave function is relieved, and effective radiative recombination can be improved.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

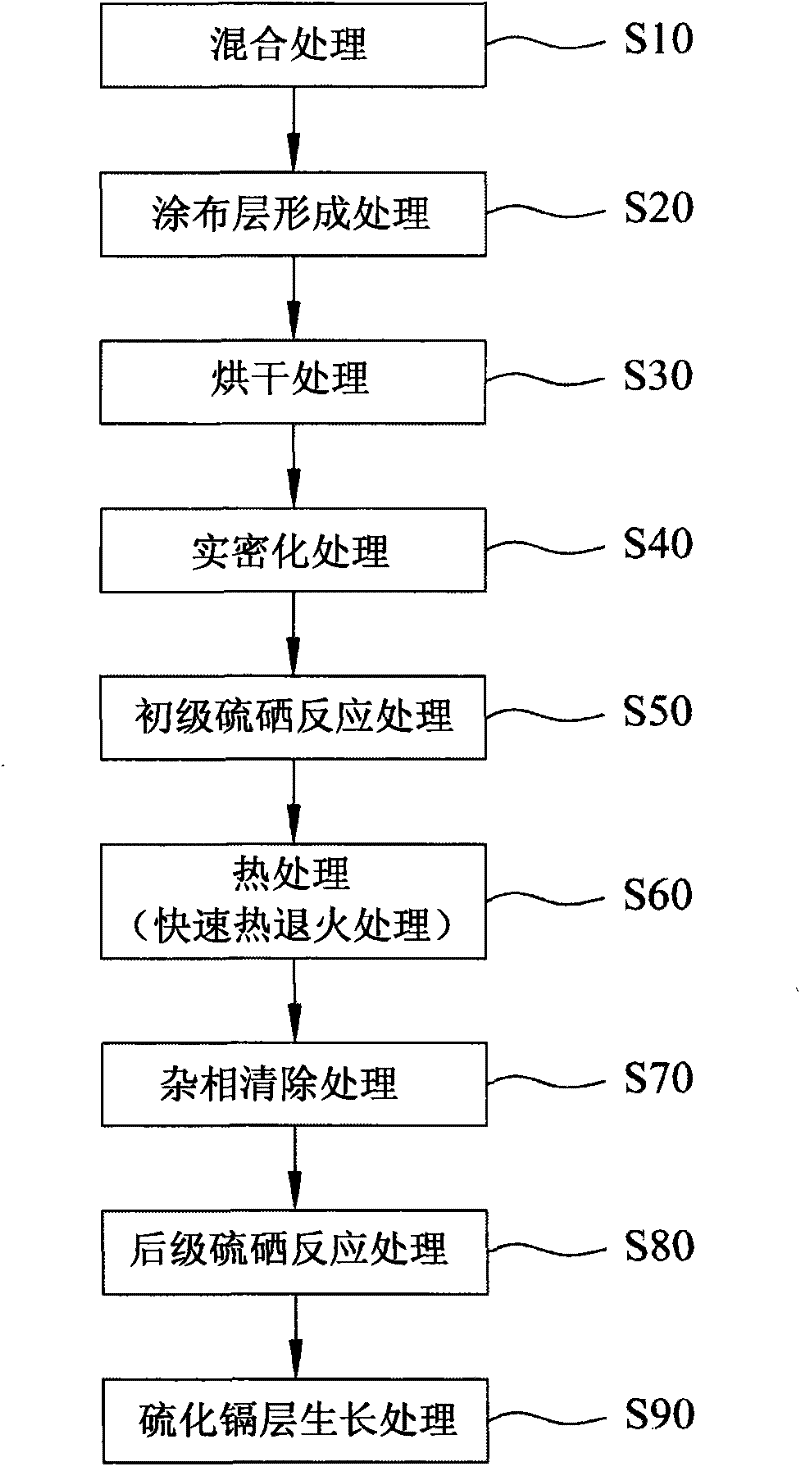

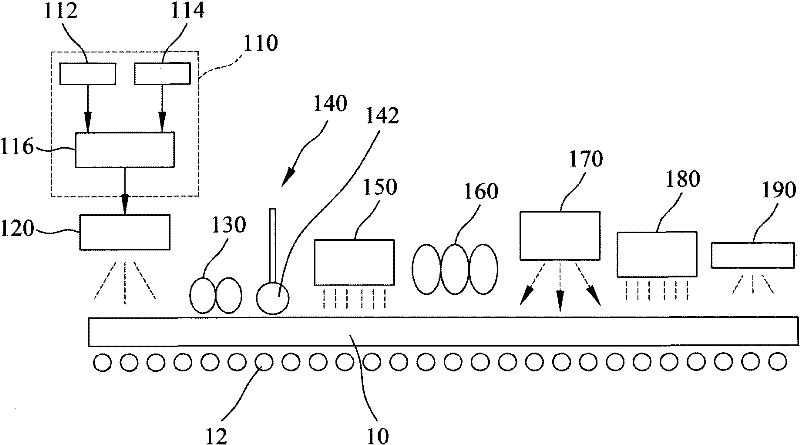

Method and system for forming Cu-In-Ga-S-Se absorption layer and cadmium sulfide buffer layer in antivacuum way

InactiveCN102130202AQuality improvementReduce in quantityFinal product manufactureSemiconductor devicesWater bathsPotassium cyanide

The invention discloses a method and system for forming a Cu-In-Ga-S-Se absorption layer and a cadmium sulfide buffer layer in an antivacuum way. The method comprises the steps of: in specific to a substrate with a back electrode layer under antivacuum, forming a coating layer from mixed slurry on the back electrode layer, primarily drying, compacting the coating layer by using a compacting device, carrying out primary S-Se reaction treatment to form a primary Cu-In-Ga-S-Se layer, thermally treating to improve the lattice matching of the primary Cu-In-Ga-S-Se layer, carrying out miscellaneous-phase removal treatment by using potassium cyanide or bromides to remove miscellaneous-phase cuprous selenide and copper sulphide, carrying out post-stage S-Se reaction treatment to generate a needed post-stage Cu-In-Ga-S-Se absorption layer, and finally, forming a cadmium sulfide buffer layer on the Cu-In-Ga-S-Se absorption layer by using a chemical-tank water bath method.

Owner:JENN FENG NEW ENERY CO LTD

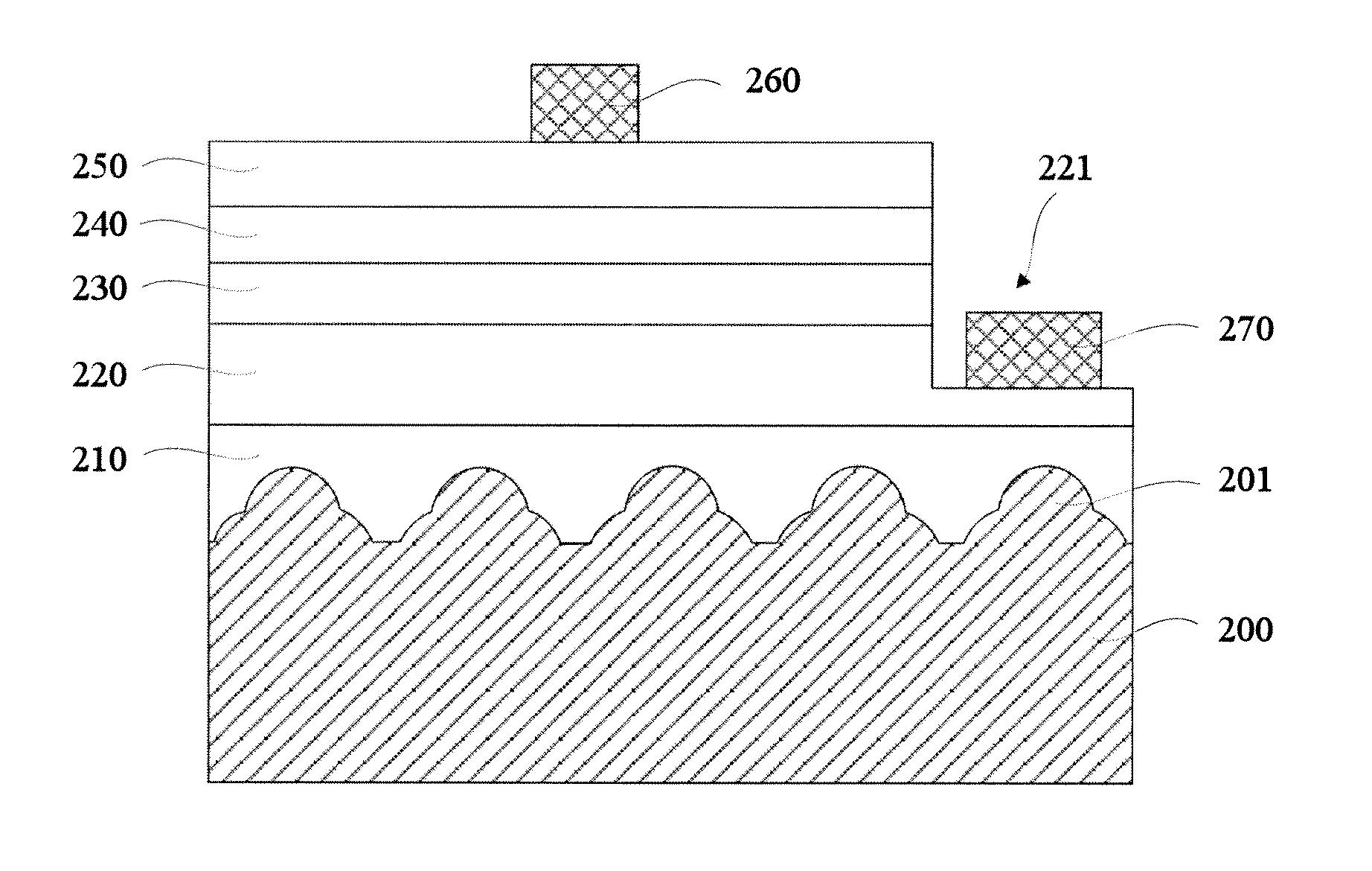

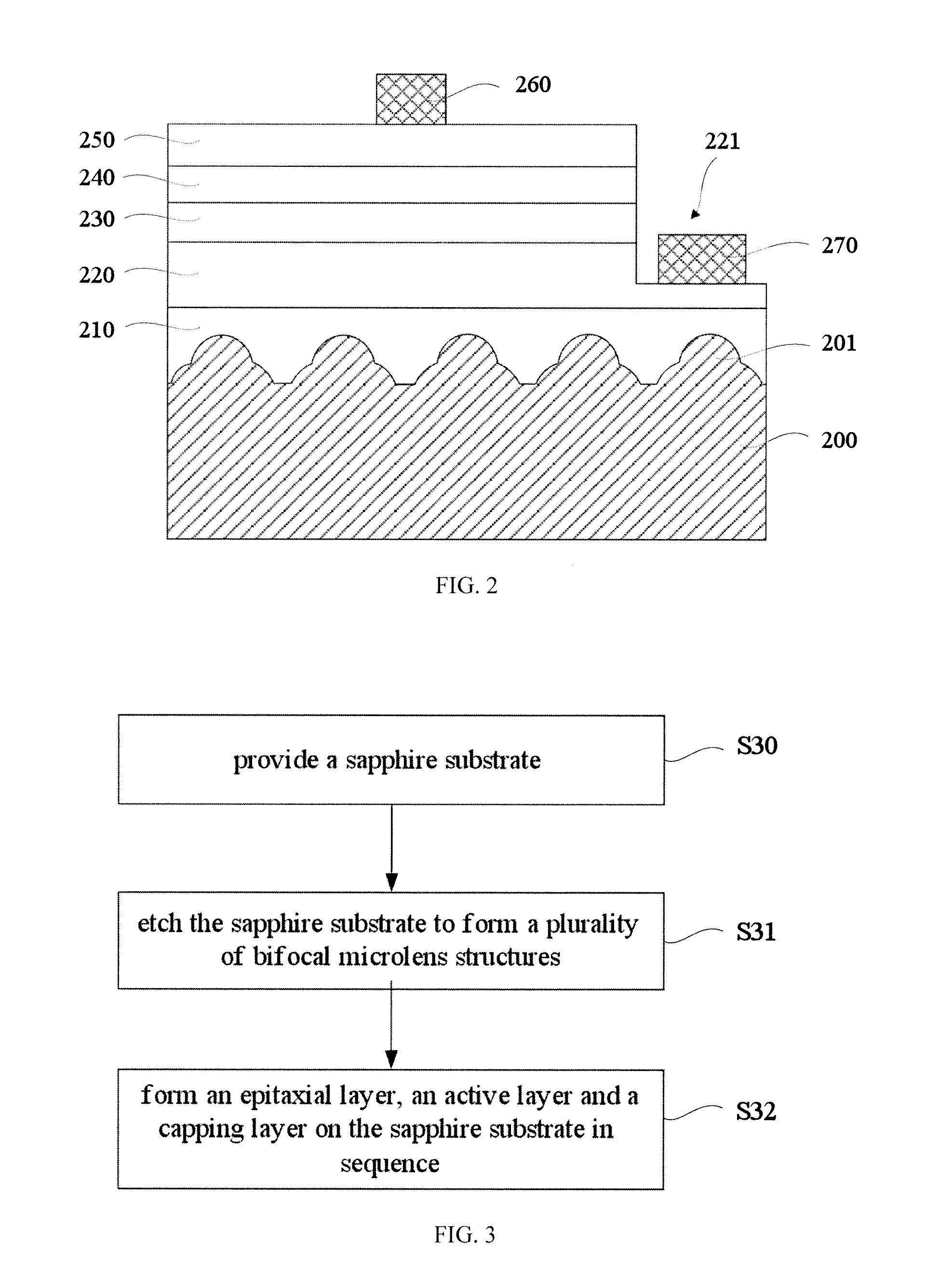

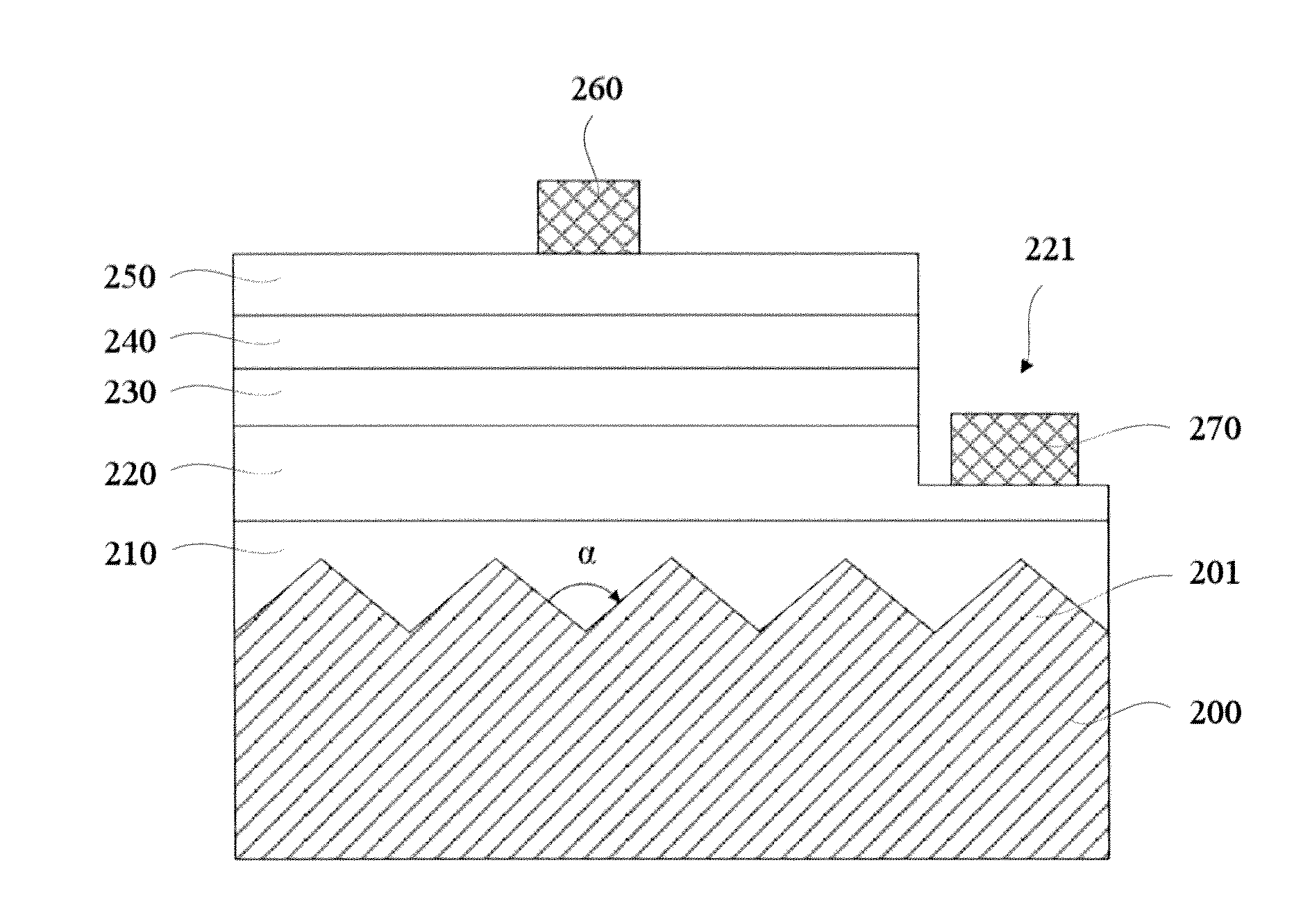

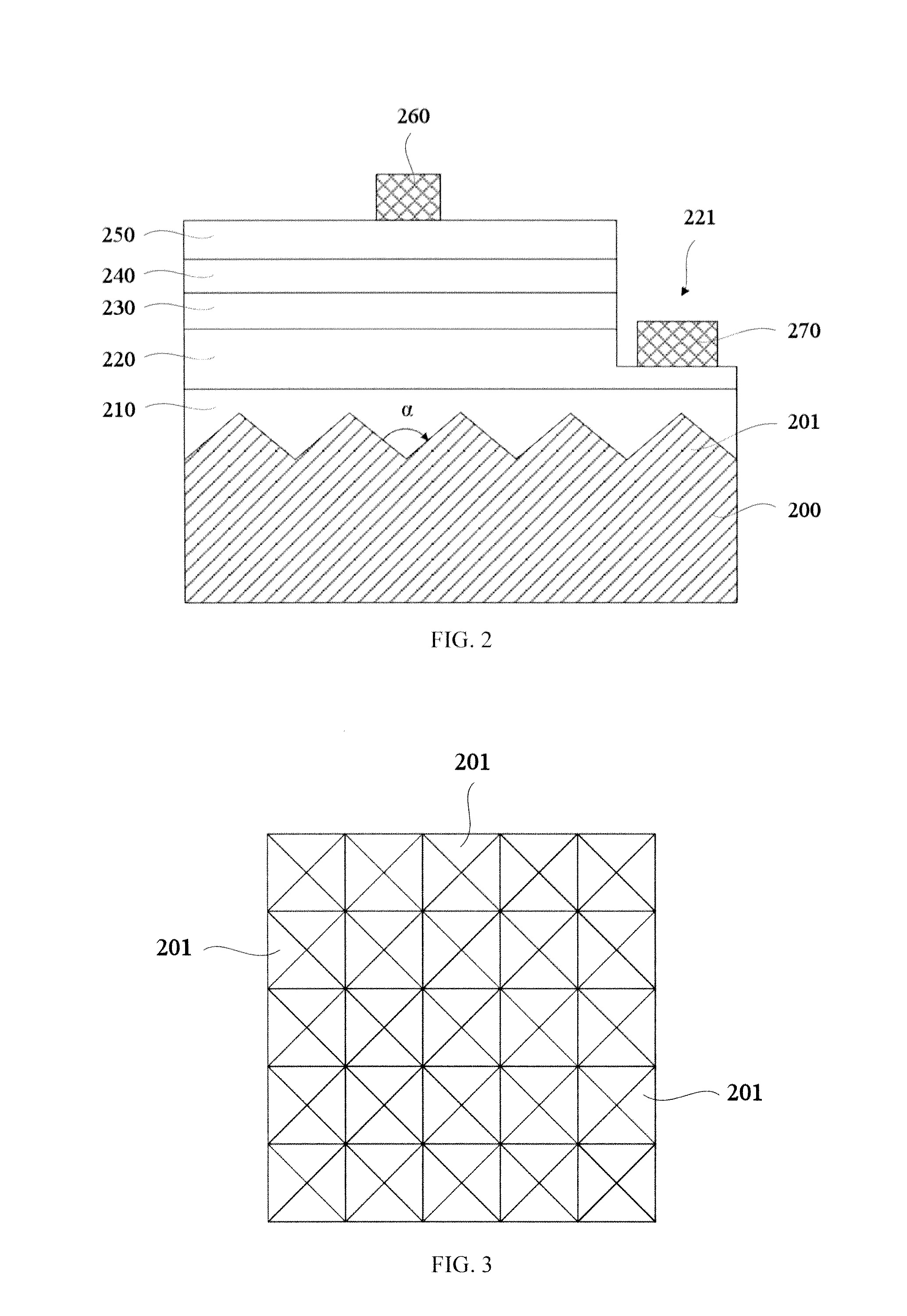

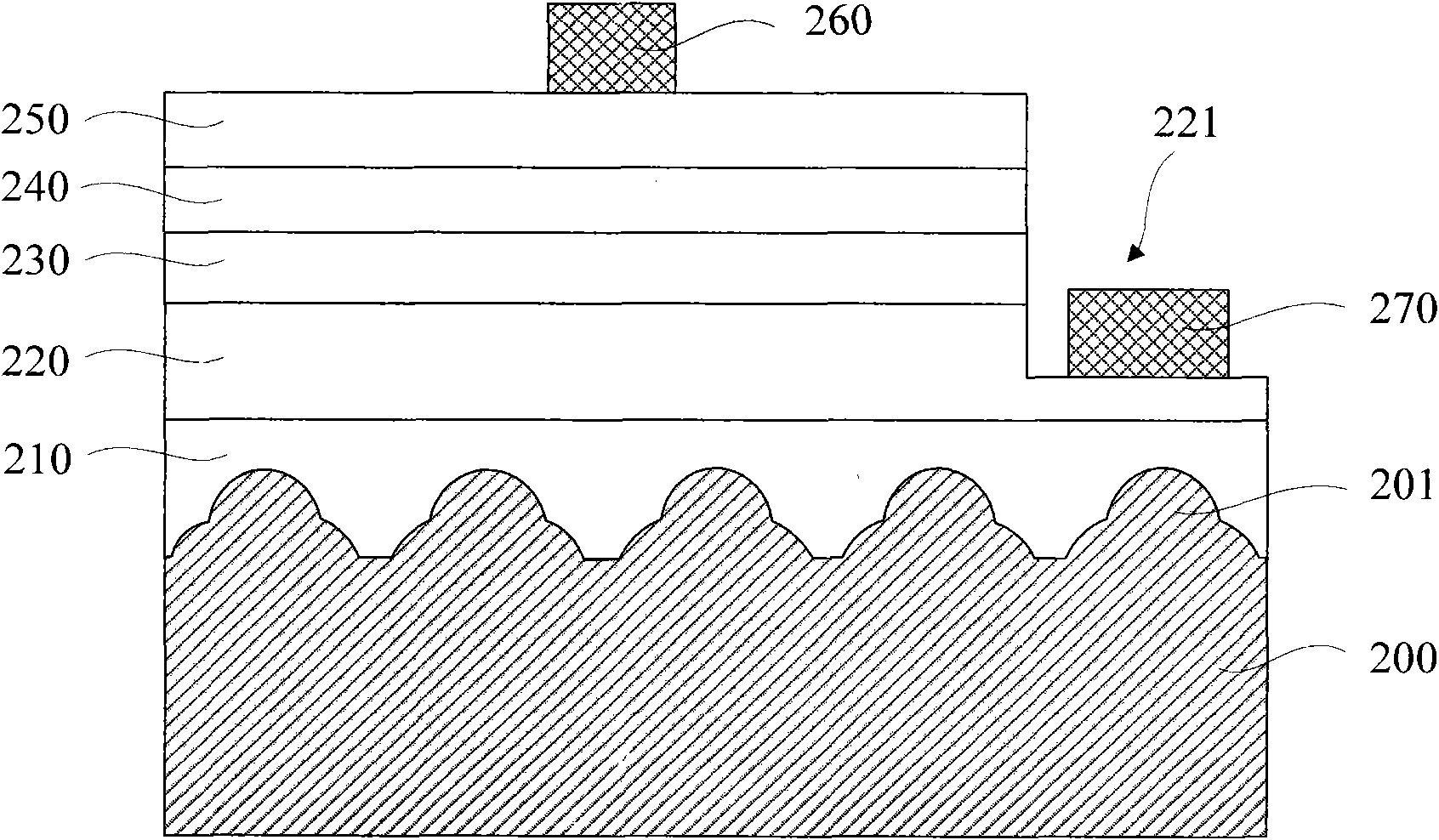

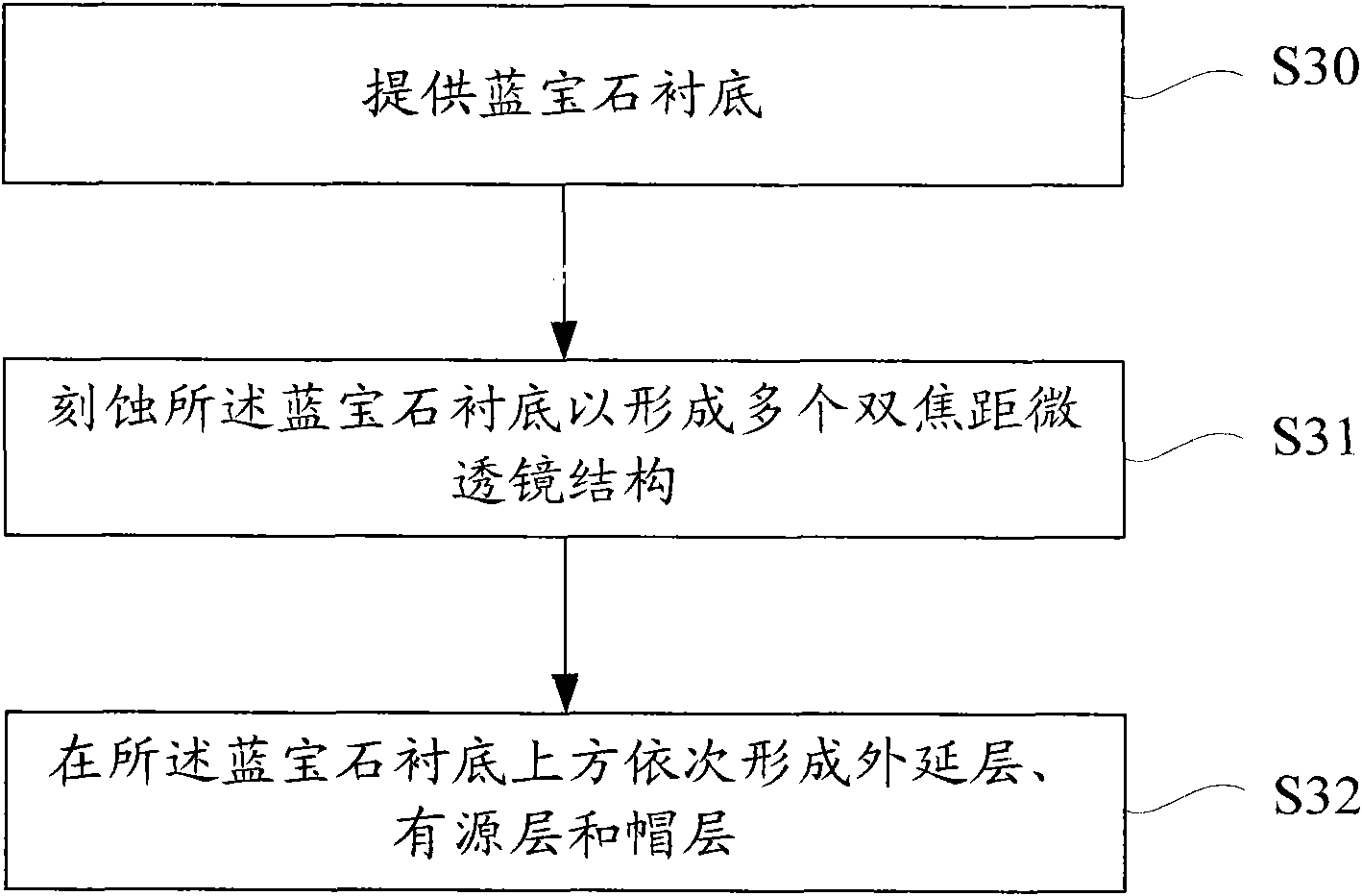

Light emitting diode and fabrication method thereof

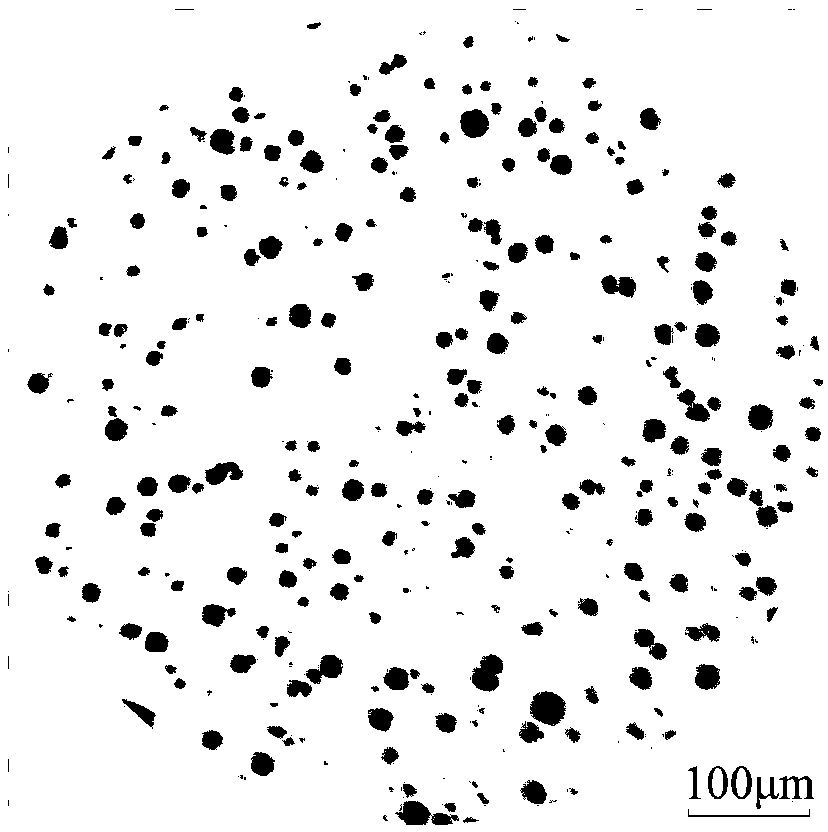

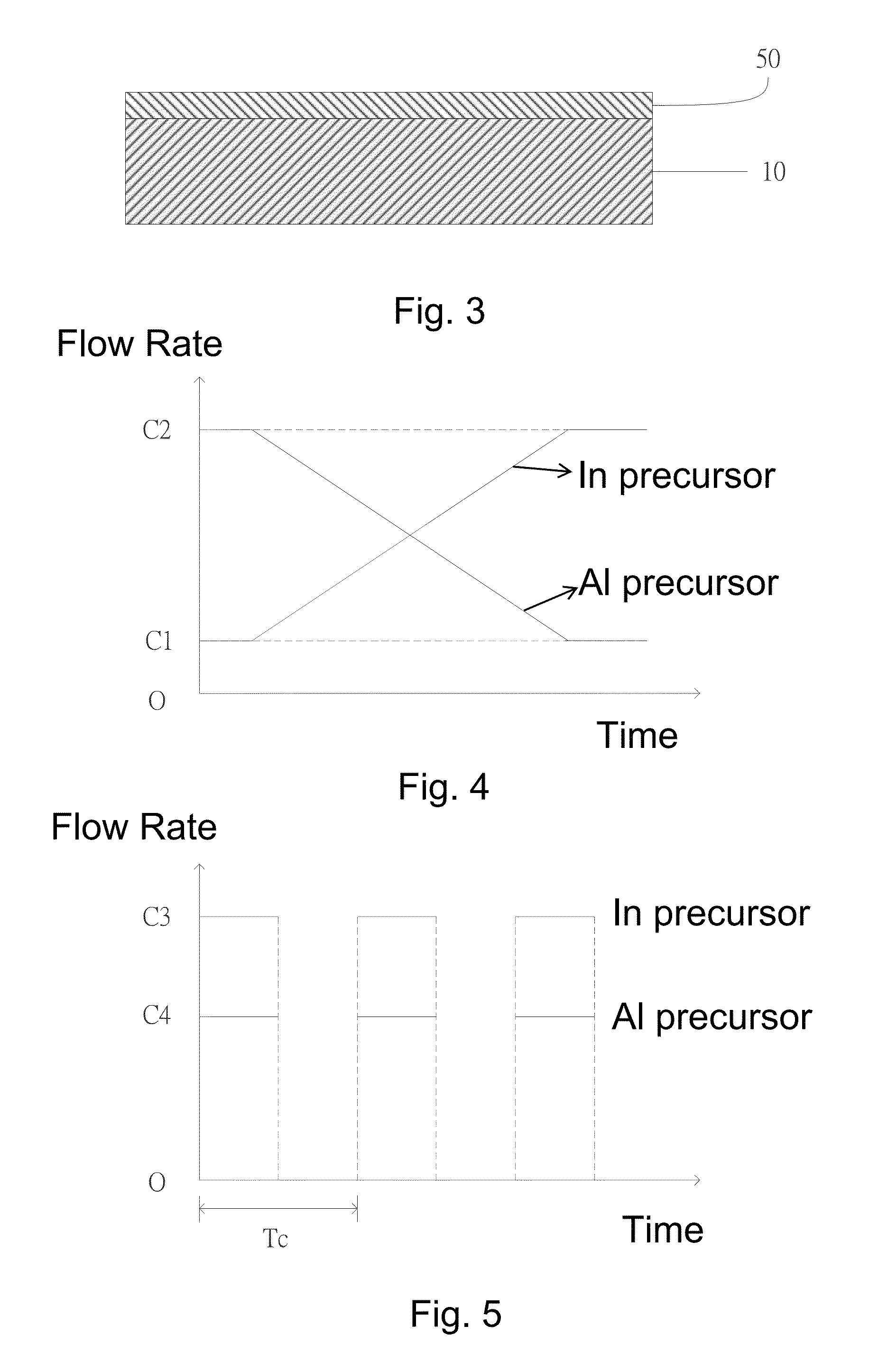

InactiveUS20130214246A1Low light extraction efficiencyLight extraction efficiency can be improvedSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum efficiencyCrystallographic defect

An LED and its fabrication method are disclosed. The LED includes: a sapphire substrate (200); an epitaxial layer (220), an active layer (230) and a capping layer (240) arranged on the sapphire substrate (200) in sequence; wherein a plurality of bifocal microlens structures (201) are formed on the surface of the sapphire substrate (200) close to the epitaxial layer (220). The bifocal microlens structures (201) can increase the light reflected by the sapphire substrate (200), raising the external quantum efficiency of the LED, thus increasing the light utilization rate of the LED. Furthermore, the bifocal microlens structures (201) can improve the lattice matching between the sapphire substrate (200) and other films, reducing the crystal defects in the film formed on the sapphire substrate (200) and increasing the internal quantum efficiency of the LED.

Owner:XIAN SHENGUANG ANRUI PHOTOELECTRIC TECH

Method of making photovoltaic devices with reduced conduction band offset between pnictide absorber films and emitter films

InactiveUS20160071994A1Reduces conduction bandQuality improvementSemiconductor/solid-state device manufacturingPhotovoltaic energy generationEngineeringAlloy

The principles of the present invention are used to reduce the conduction band offset between chalcogenide emitter and pnictide absorber films. Alternatively stated, the present invention provides strategies to more closely match the electron affinity characteristics between the absorber and emitter components. The resultant photovoltaic devices have the potential to have higher efficiency and higher open circuit voltage. The resistance of the resultant junctions would be lower with reduced current leakage. In illustrative modes of practice, the present invention incorporates one or more tuning agents into the emitter layer in order to adjust the electron affinity characteristics, thereby reducing the conduction band offset between the emitter and the absorber. In the case of an n-type emitter such as ZnS or a tertiary compound such as zinc sulfide selenide (optionally doped with Al) or the like, an exemplary tuning agent is Mg when the absorber is a p-type pnictide material such as zinc phosphide or an alloy of zinc phosphide incorporating at least one additional metal in addition to Zn and optionally at least one non-metal in addition to phosphorus. Consequently, photovolotaic devices incorporating such films would demonstrate improved electronic performance.

Owner:CALIFORNIA INST OF TECH +1

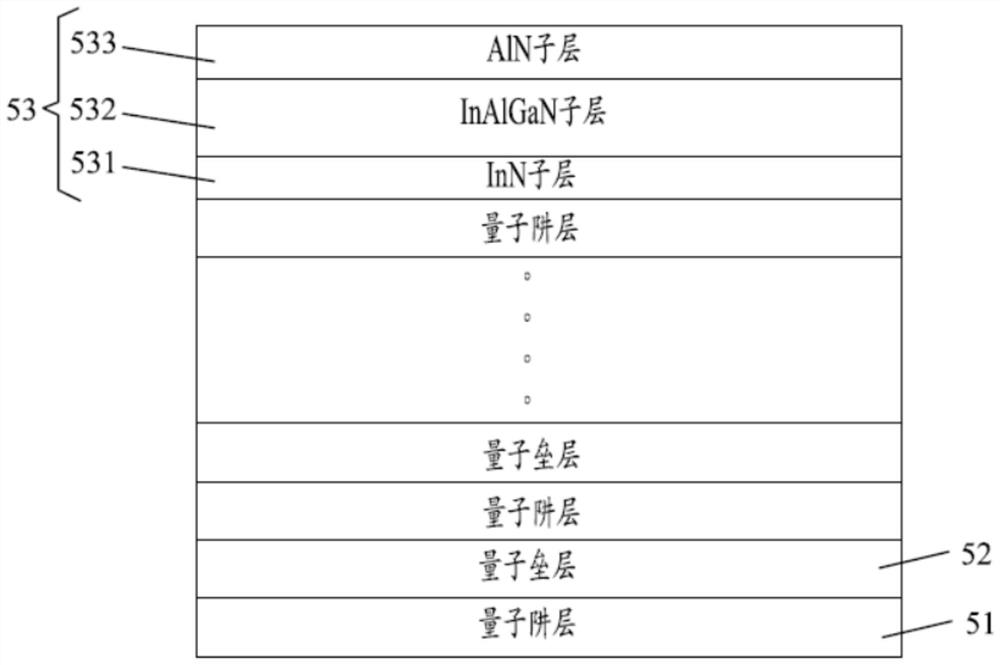

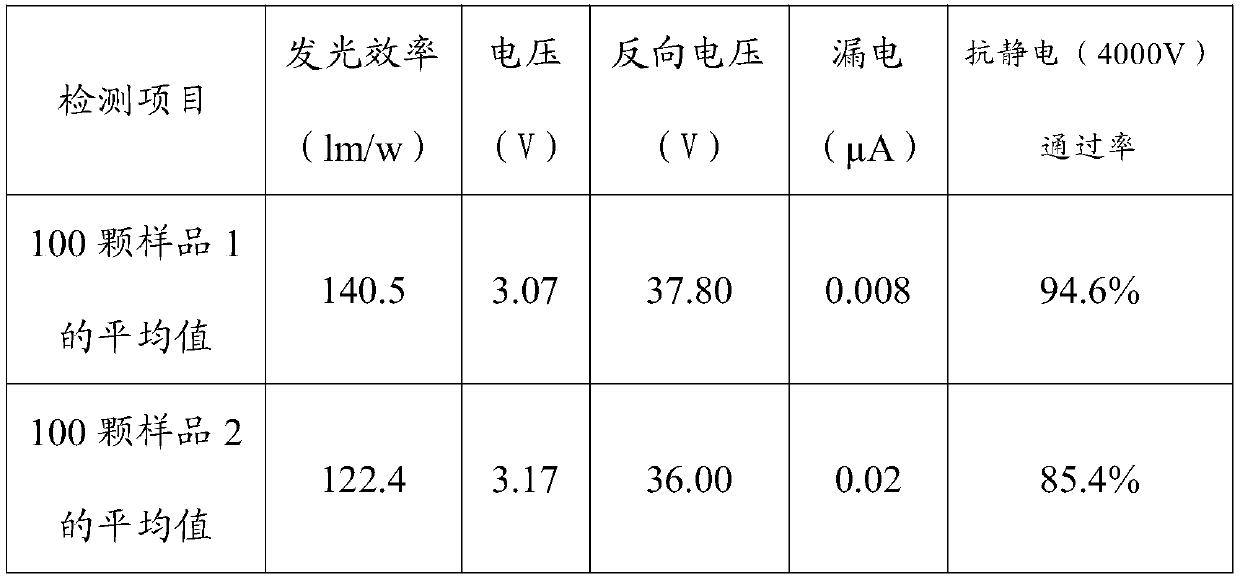

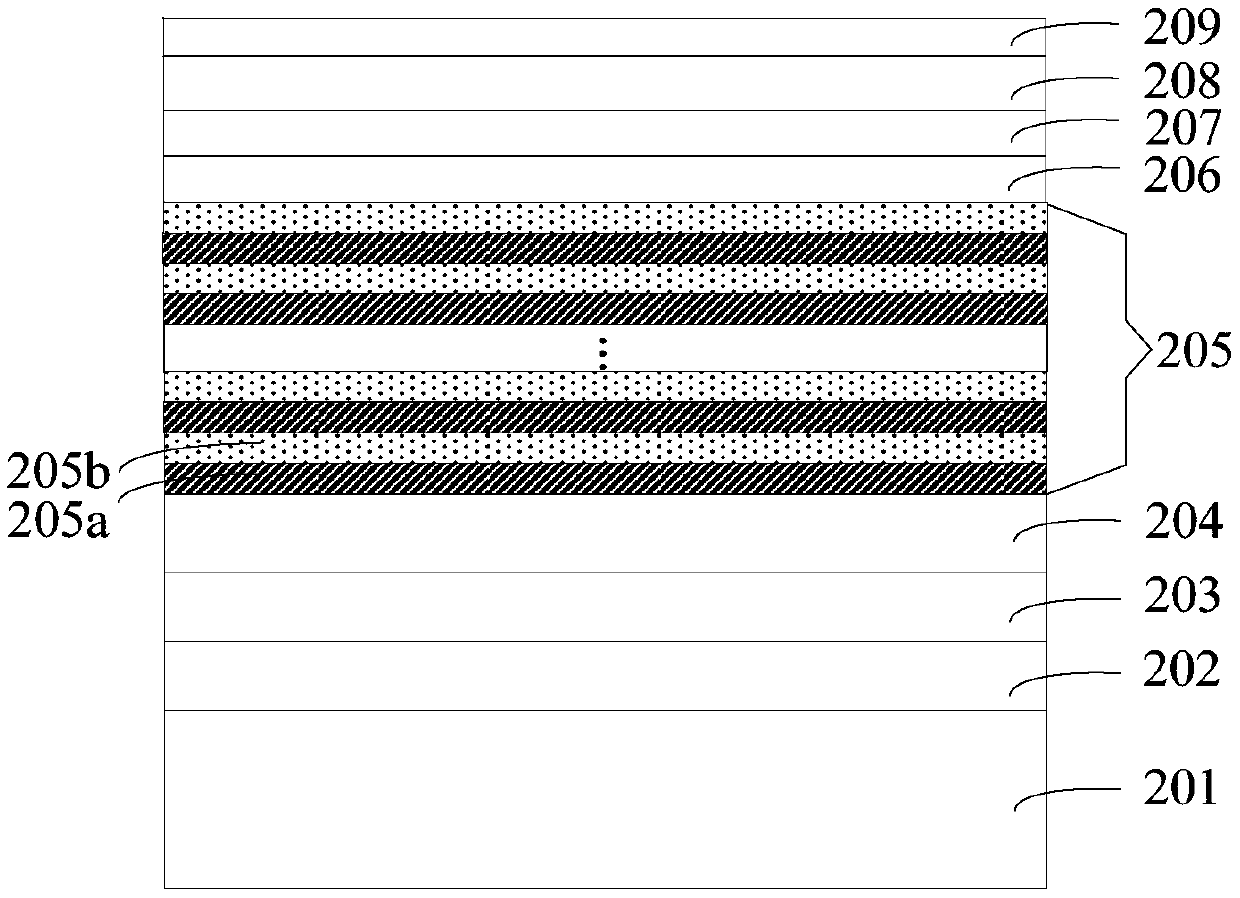

GaN-based light-emitting diode epitaxial wafer, preparation method thereof and light-emitting diode

PendingCN114725257AQuality improvementAvoid decompositionPolycrystalline material growthFrom chemically reactive gasesValence bandElectron hole

The invention provides a GaN-based light-emitting diode epitaxial wafer and a preparation method thereof, and a light-emitting diode, the GaN-based light-emitting diode epitaxial wafer comprises a multi-quantum well layer, and the multi-quantum well layer is a periodic structure formed by alternately growing quantum well layers and quantum barrier layers; wherein the last growing quantum barrier layer is a composite quantum barrier layer, the composite quantum barrier layer comprises an InN sub-layer, an InAlGaN sub-layer and an AlN sub-layer which grow in sequence, the In component of the InAlGaN sub-layer is gradually reduced in the epitaxial growth direction, and the Al component of the InAlGaN sub-layer is gradually increased in the epitaxial growth direction. The last quantum barrier is specially designed, so that lattice matching and energy level gradual transition of the quantum well layer and the P layer are improved, barrier peaks formed by valence bands of the quantum well and the electron blocking layer are effectively reduced, hole injection is facilitated, meanwhile, the effect of a part of the electron blocking layer is achieved, electron overflow is reduced, and the performance of the device is improved. The light-emitting efficiency of the light-emitting diode is improved, and the antistatic capability of the light-emitting diode is improved.

Owner:JIANGXI ZHAO CHI SEMICON CO LTD

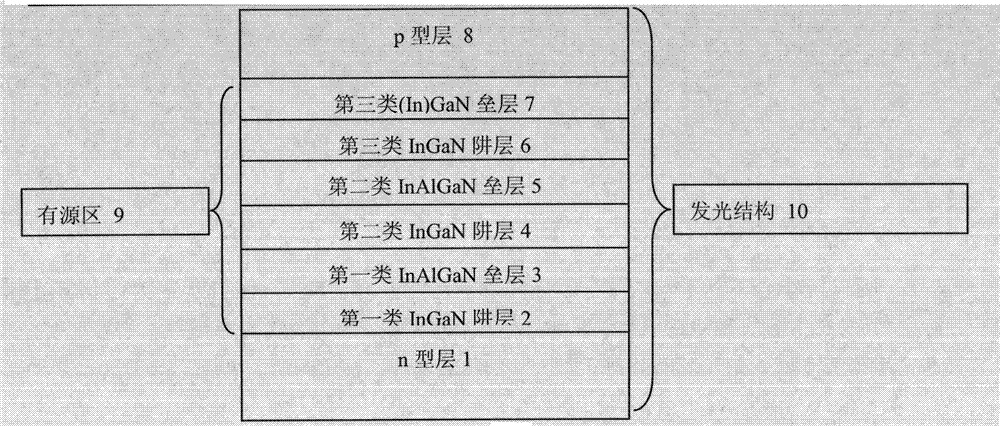

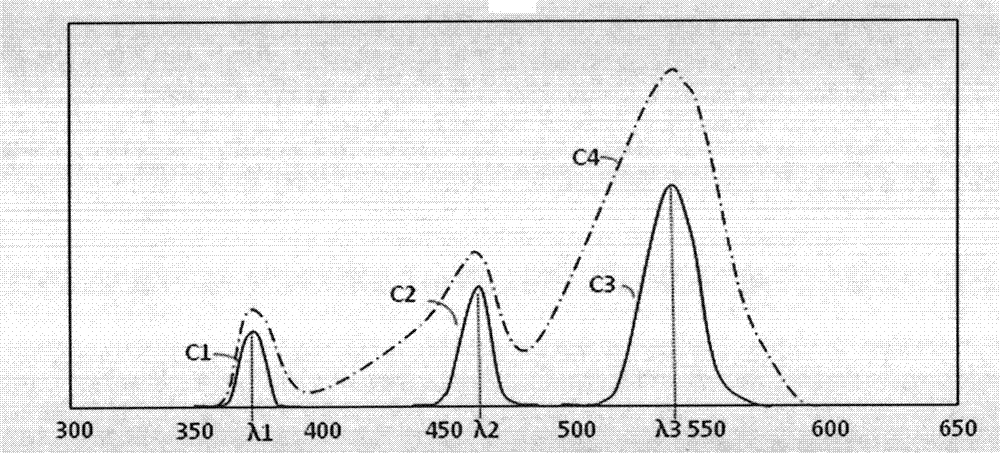

Light-emitting diode (LED) lighting structure

ActiveCN103117342AIncrease widthImprove compound efficiencySemiconductor devicesQuantum wellEffect light

The invention provides a light-emitting diode (LED) lighting structure. The LED lighting structure comprises a p type doped region, a n-type doped region and a lighting active region, wherein the p-type doped region is used for injecting into a hole, the n-type doped region is located on the bottom and used for injecting electrons and the lighting active region is located on the n-type doped region. The LED lighting structure is characterized in that the lighting active region comprises at least one InGaN trap layer and at least one InAlGaN barrier layer of a first type quantum well, at least one InGaN trap layer and at least one InAlGaN barrier layer of a second type quantum well and at least one InGaN trap layer and at least one InAlGaN barrier layer of a third type quantum well.

Owner:广东昭信集团股份有限公司

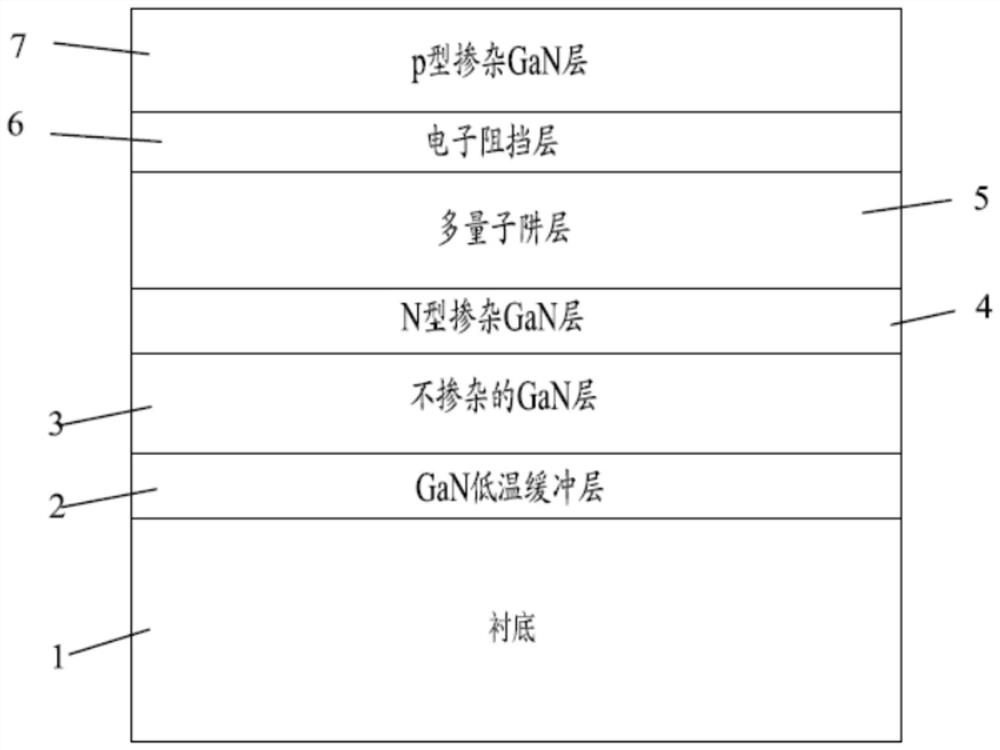

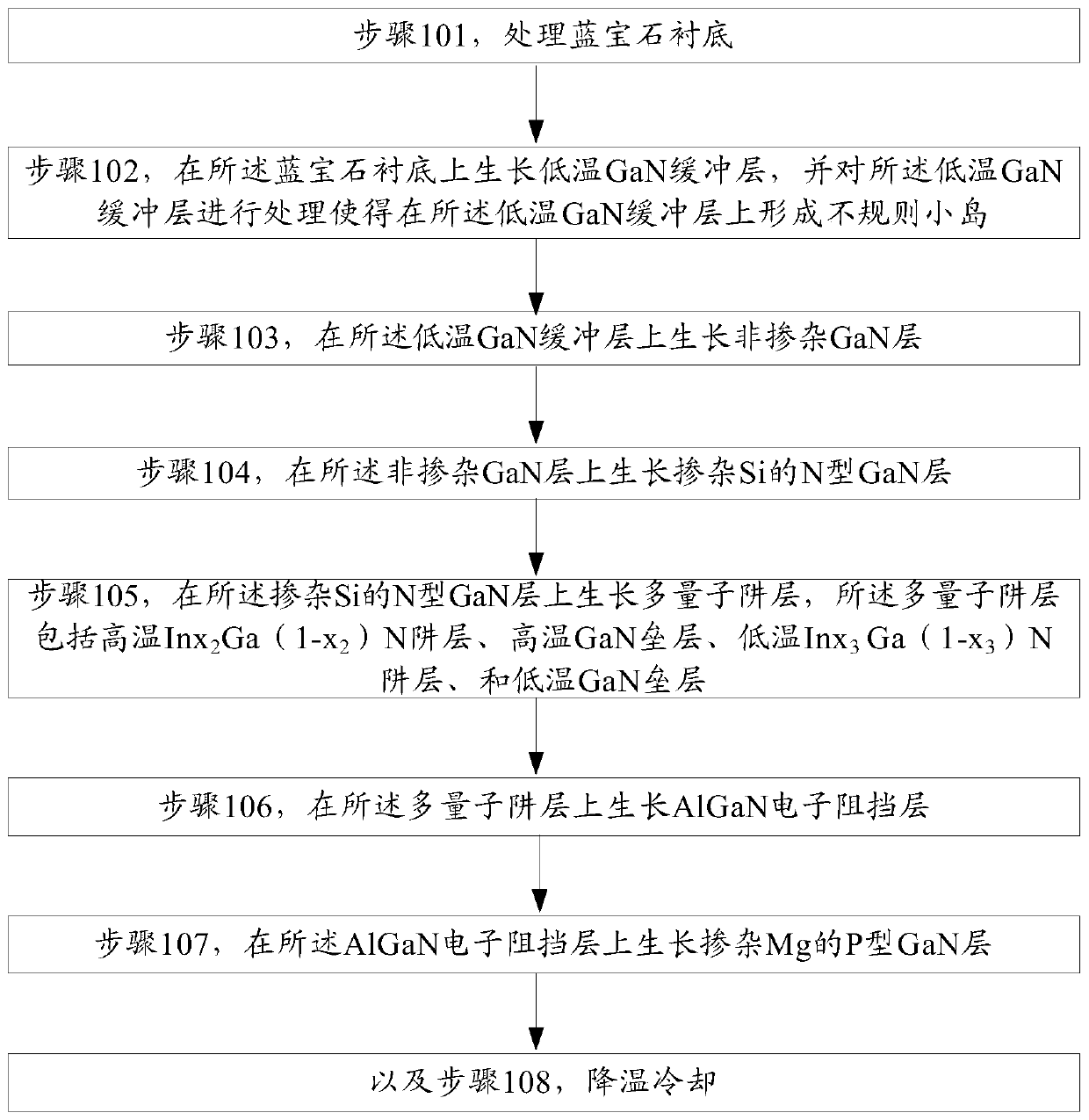

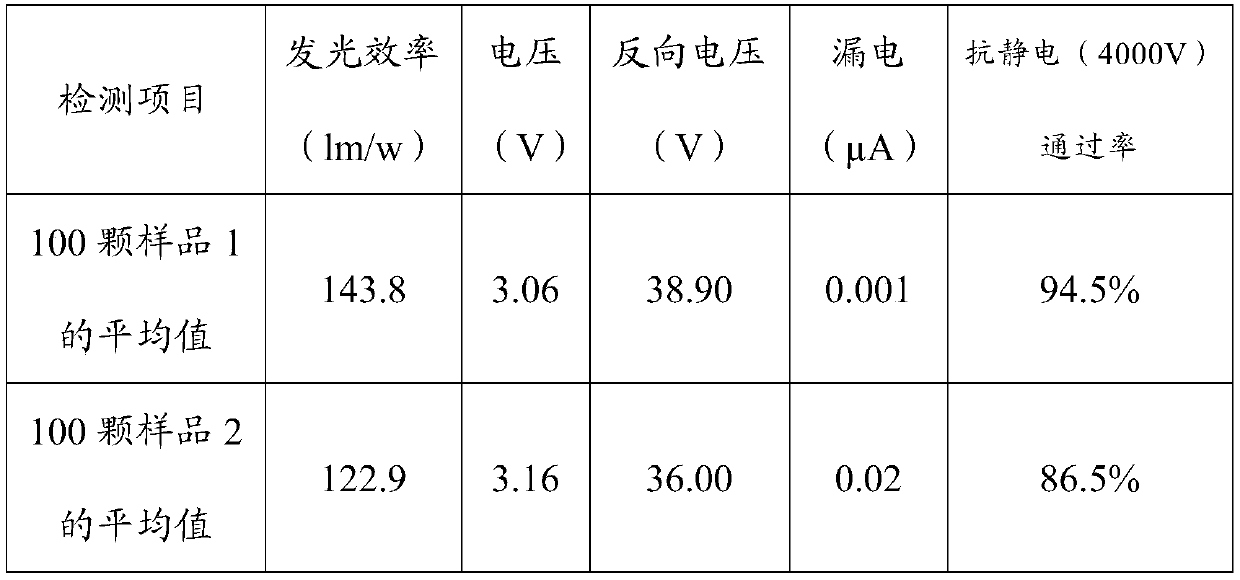

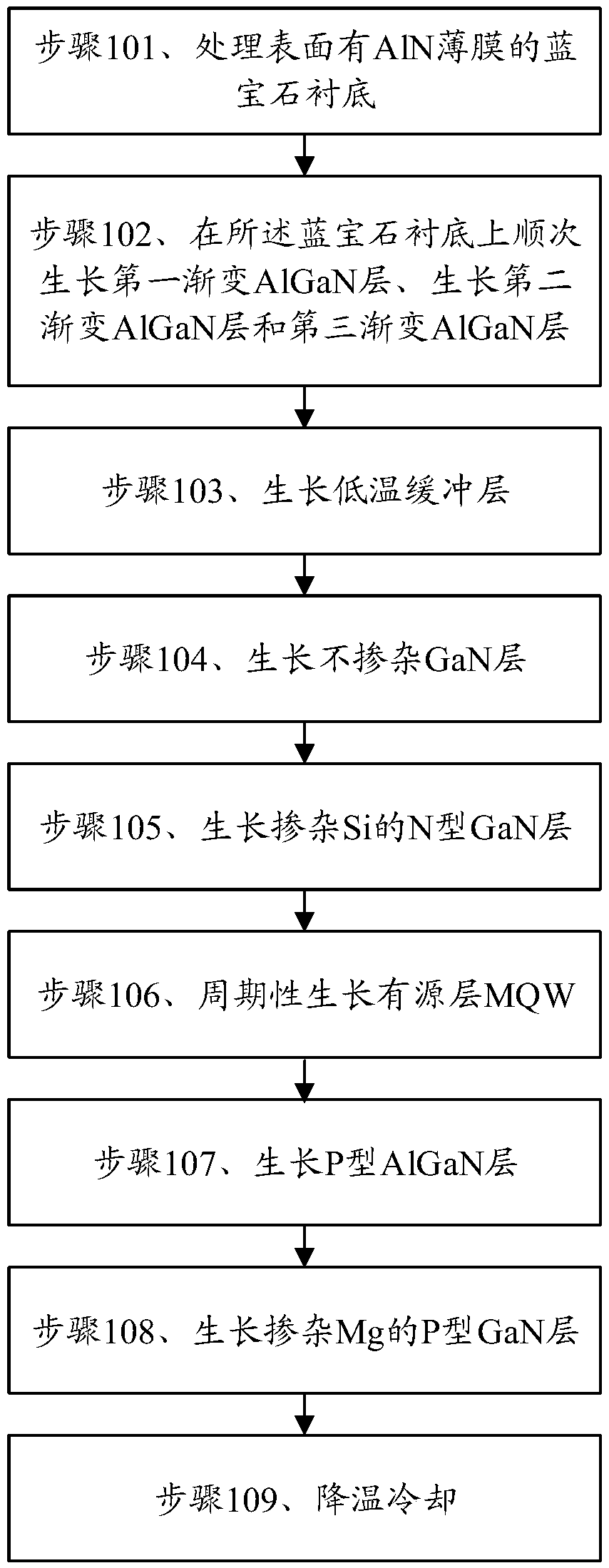

LED epitaxial structure growth method

ActiveCN109860345AIncrease brightnessImprove leakageSemiconductor devicesQuantum wellOptoelectronics

The invention discloses an LED epitaxial structure growth method. The method comprises steps: a sapphire substrate is processed; a low-temperature GaN buffer layer grows on the sapphire substrate, thelow-temperature GaN buffer layer is processed, and an irregular island is formed on the low-temperature GaN buffer layer; an undoped GaN layer grows on the low-temperature GaN buffer layer; a Si-doped N-type GaN layer grows on the undoped GaN layer; a multi-quantum well layer grows on the Si-doped N-type GaN layer; an AlGaN electron blocking layer grows on the multi-quantum well layer; a Mg-dopedP-type GaN layer grows on the AlGaN electron blocking layer; and temperature reduction and cooling are carried out. According to the growth method disclosed in the invention, the light emitting efficiency of the LED can be effectively enhanced, warpage of the epitaxial wafer can be reduced, the qualified rate of the GaN epitaxial wafer is improved, the surface of the epitaxial layer becomes flat,and the appearance is better.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

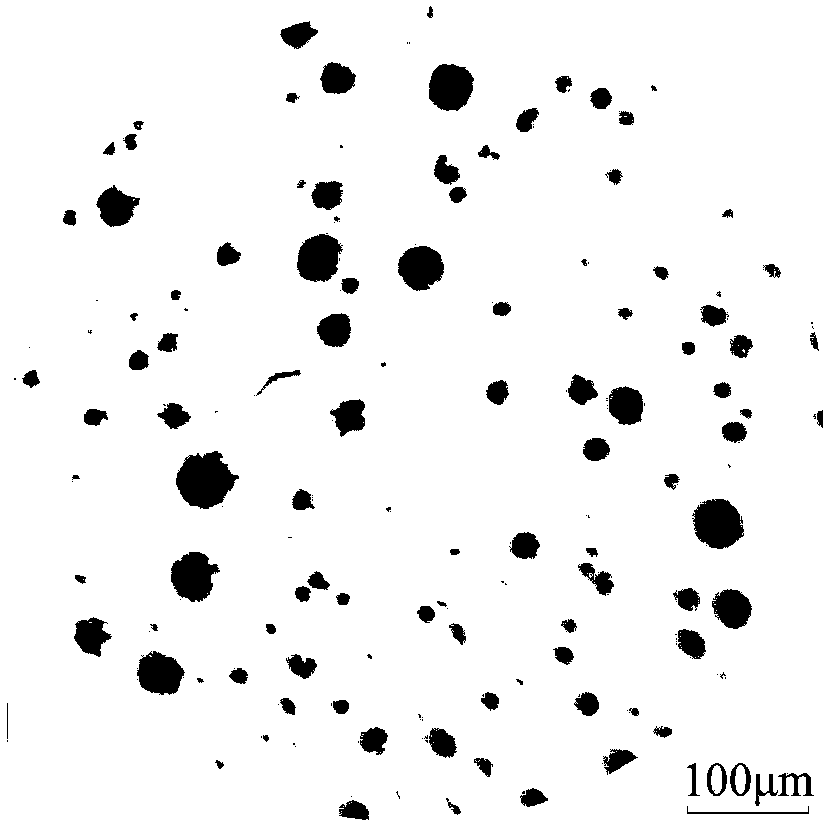

Light emitting diode and fabrication method thereof

InactiveUS20130193406A1Low light extraction efficiencyLight extraction efficiency can be improvedSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum efficiencyCrystallographic defect

The present invention discloses an LED and its fabrication method. The LED comprises: a sapphire substrate; an epitaxial layer, an active layer and a capping layer arranged on the sapphire substrate in sequence; wherein a plurality of cone-shaped structures are formed on the surface of the sapphire substrate close to the epitaxial layer. The cone-shaped structures can increase the light reflected by the sapphire substrate, raising the external quantum efficiency of the LED, thus increasing the light utilization rate of the LED. Furthermore, the formation of a plurality of cone-shaped structures can improve the lattice matching between the sapphire substrate and other films, reducing the crystal defects in the film formed on the sapphire substrate, increasing the internal quantum efficiency of the LED.

Owner:ENRAYTEK OPTOELECTRONICS

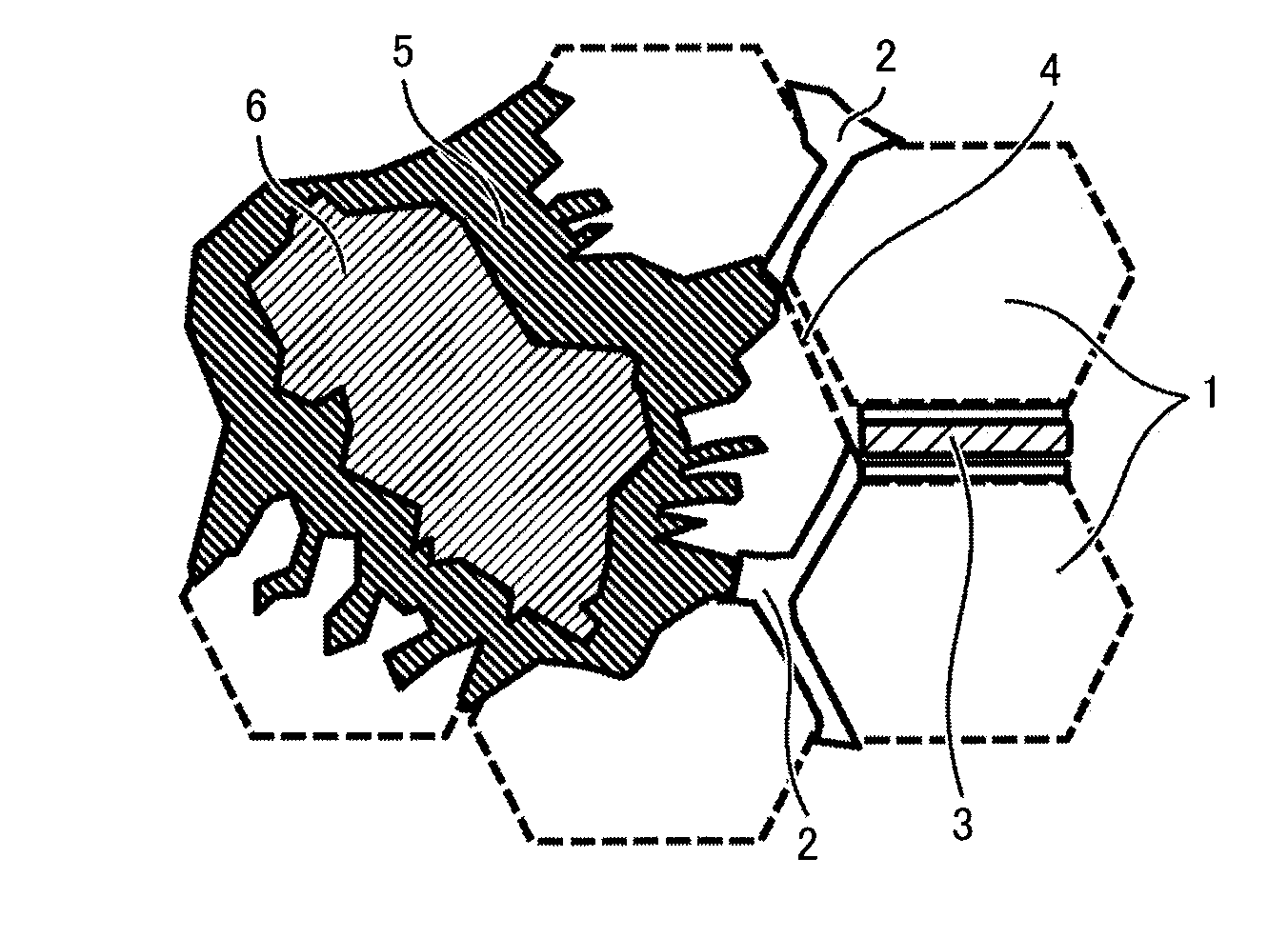

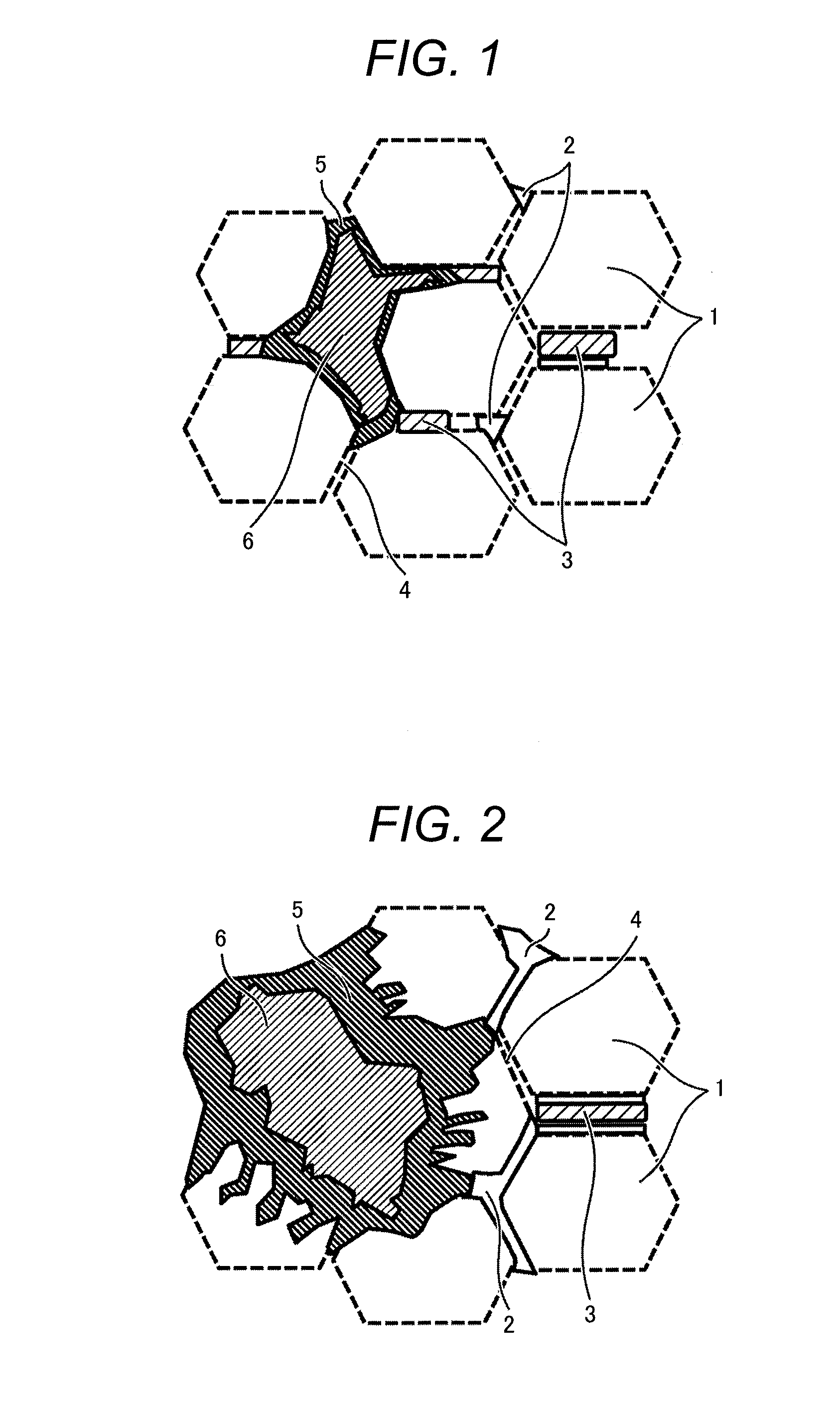

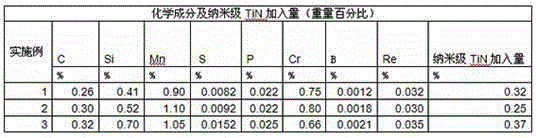

Sintered Magnet

InactiveUS20130069746A1High Remanent Flux DensityHigh energyPermanent magnetsInorganic material magnetismRare-earth elementSintered magnets

Disclosed is a sintered magnet which is a rare-earth magnet using a less amount of a rare-earth element but having a higher maximum energy product and a higher coercivity. The sintered magnet includes a NdFeB crystal; and an FeCo crystal adjacent to the NdFeB crystal through the medium of a grain boundary. The FeCo crystal includes a core and a periphery and has a cobalt concentration decreasing from the core to the periphery. The FeCo crystal has a difference in cobalt concentration of 2 atomic percent or more between the core and the periphery. In the NdFeB crystal, cobalt and a heavy rare-earth element are unevenly distributed and enriched in the vicinity of the grain boundary.

Owner:HITACHI LTD

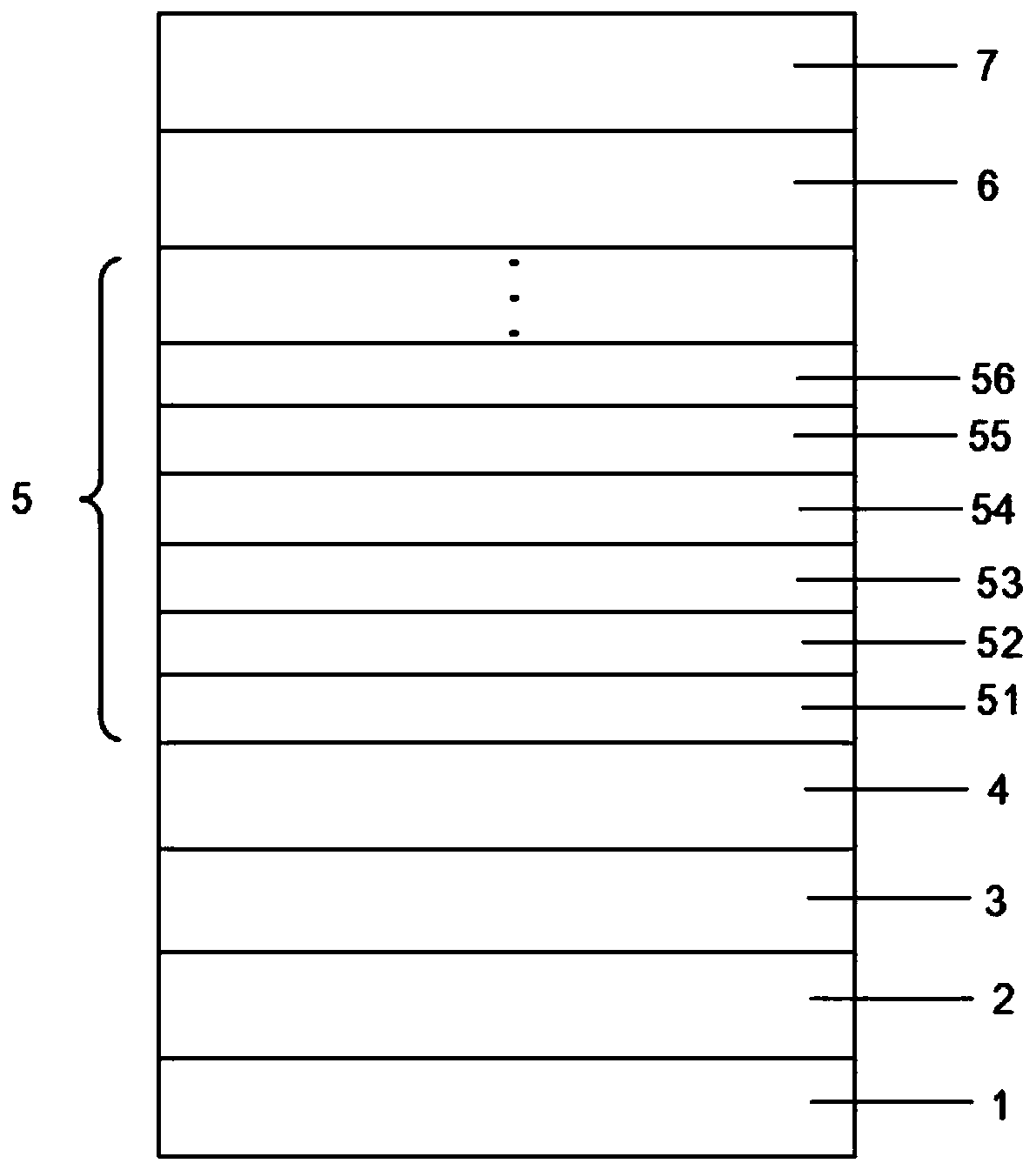

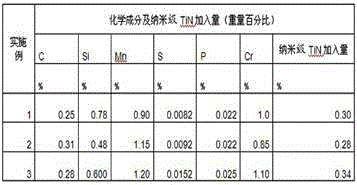

Steel for bucket teeth of construction machinery and preparation method of bucket teeth

ActiveCN104651729AImprove hardenabilityImprove mechanical propertiesFurnace typesHeat treatment furnacesTinImpact toughness

The invention discloses steel for bucket teeth of construction machinery and a preparation method of the bucket teeth, and relates to the technical field of mechanism manufacturing. The steel for the bucket teeth is prepared from the following substances in percentage by weight: 0.25 to 0.33% of C, 0.30 to 0.80% of Si, 0.80 to 1.20% of Mn, 0.60 to 1.0% of Cr, 0.030 to 0.036% of Re, 0.0005 to 0.0035% of B, 0.20 to 0.40% of nanometer TiN, not greater than 0.030% of S, and not greater than 0.030% of P. With the adoption of the method, the problems of poor impact toughness, easy breaking, small service life, and high production cost which is caused by lots of added precious metals Mo and Ni can be solved.

Owner:柳州市友军机械配件铸造有限公司

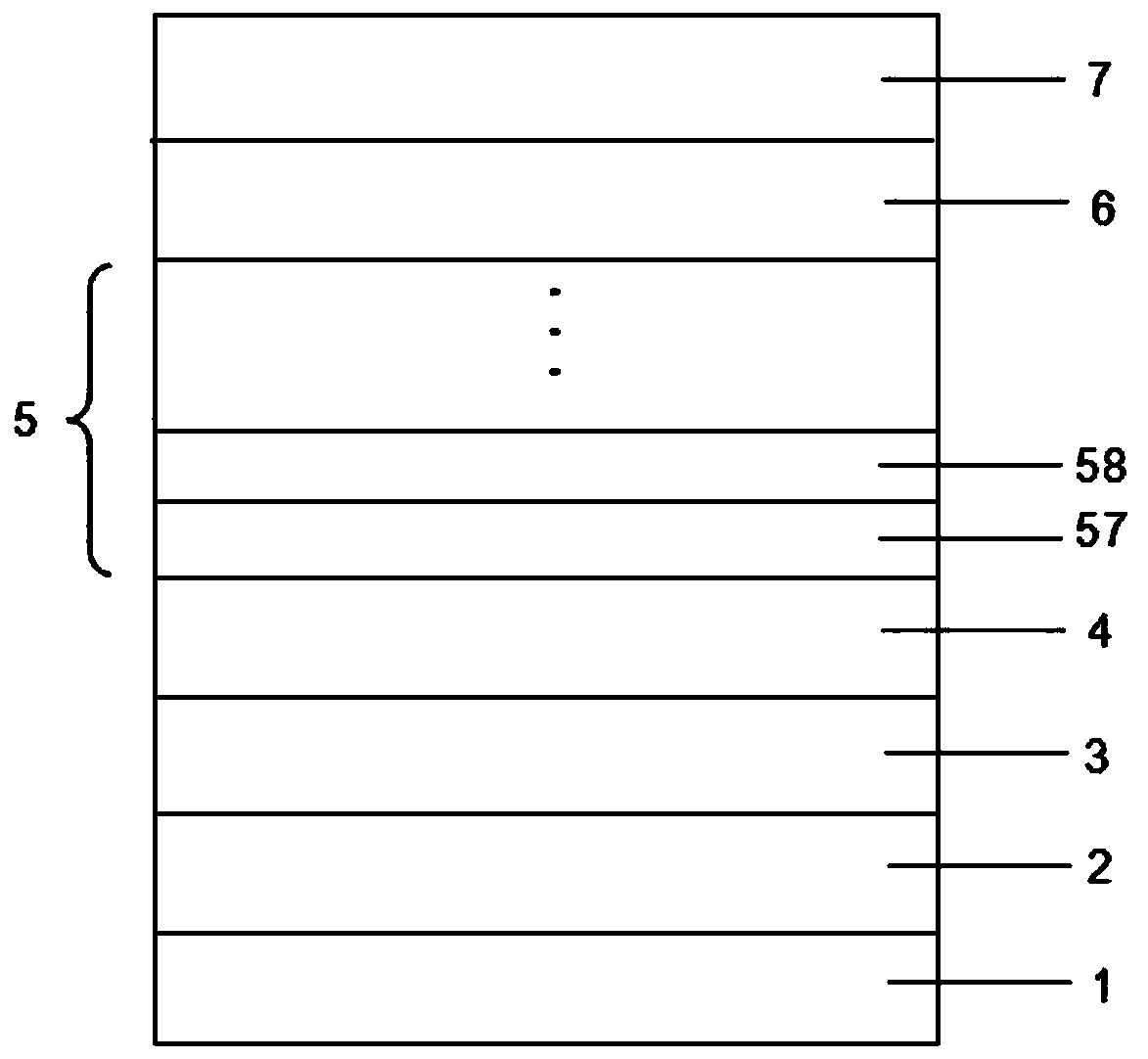

Growth method of LED epitaxial structure

ActiveCN110629197AImprove luminous efficiencyLower forward voltageChemical vapor deposition coatingSemiconductor devicesQuantum wellLuminescence

The invention discloses a growth method of an LED epitaxial structure. The method comprises the successive steps of treating a substrate, growing a low-temperature buffer layer GaN, growing a doping-free GaN layer, growing a Si-doped N-type GaN layer, growing a multi-quantum well layer, growing a AlGaN electronic blocking layer, growing a Mg-doped P-typed GaN layer and performing cooling. The process of growing the multi-quantum well layer comprises the successive steps of growing a high-temperature InGaN well layer, growing a low-temperature GaN base layer, growing a high-Al-component gradualchange AlN layer, growing a Si-doped low-temperature InGaN well layer, growing a high-temperature GaN base layer and growing a low-Al-component gradual change AlN layer. According to the method, theproblems are solved that for an existing LED epitaxial growth method, the growth quality of the quantum well is low, and the radiation recombination efficiency of the quantum well is low. The luminescence efficiency of an LED is improved accordingly, warping of an epitaxial slice is reduced, and forward voltage of the LED is lowered.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

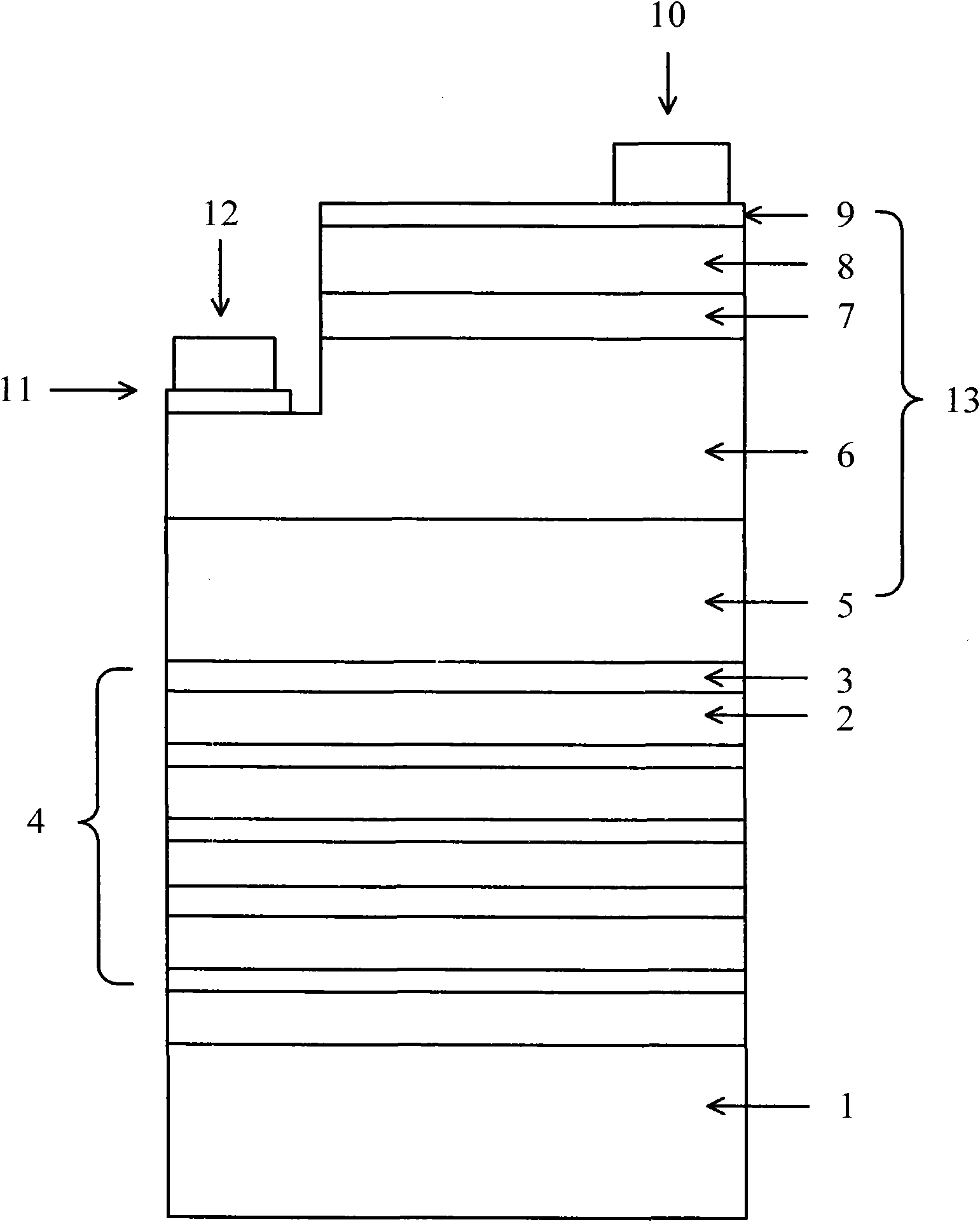

LED (light-emitting diode) and manufacturing method thereof

InactiveCN102024898AImprove external quantum efficiencyImprove light utilizationSemiconductor/solid-state device manufacturingSemiconductor devicesQuantum efficiencyCrystallographic defect

The invention discloses an LED (light-emitting diode) and a manufacturing method thereof, wherein the LED comprises a sapphire substrate, an epitaxial layer, an active layer and a cap layer, which are sequentially positioned above the sapphire substrate, wherein, a plurality of bifocal lenticule structures are arranged on the surface of the sapphire substrate, which is near to the epitaxial layer. The bifocal lenticule structures can increase the reflection of light of the sapphire substrate, improve external quantum efficiency of the LED, and further improve light utilization ratio of the LED; moreover, as a plurality of bifocal lenticule structures are formed, lattice matching degree between the sapphire substrate and other membranous layers can be improved, the crystal defect of the membranous layers formed on the sapphire substrate is reduced, and internal quantum efficiency of the LED is improved.

Owner:XIAN SHENGUANG ANRUI PHOTOELECTRIC TECH

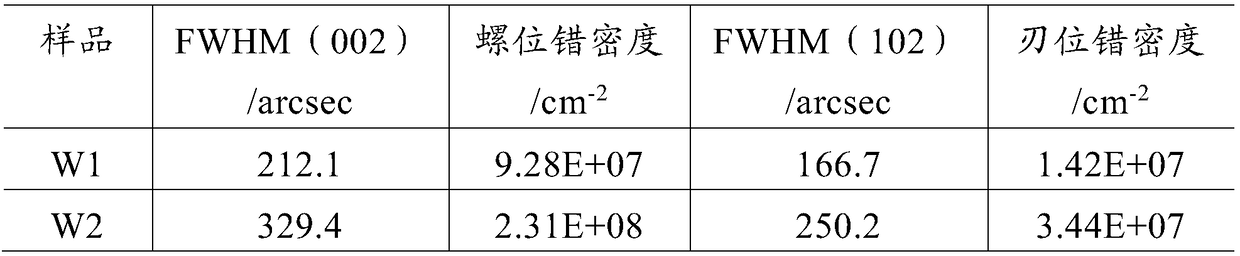

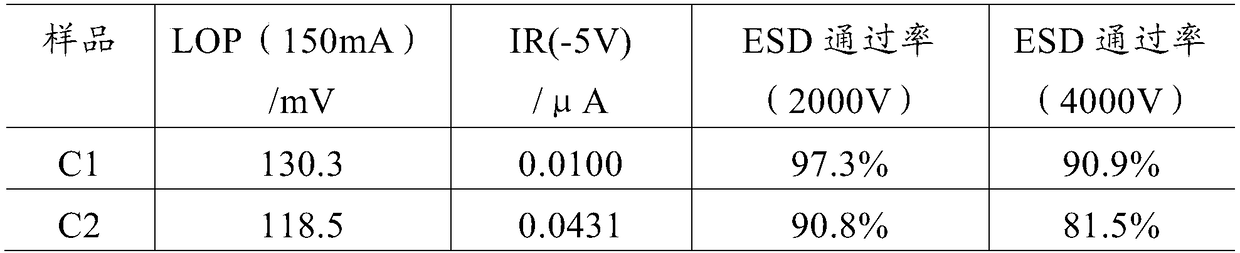

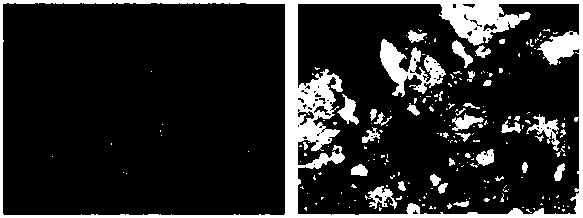

LED epitaxial wafer growth method

ActiveCN109300854AEvenly filledImprove uniformitySemiconductor/solid-state device manufacturingSemiconductor devicesOptoelectronicsActive layer

The present invention discloses an LED epitaxial wafer growth method. The method comprises the steps of: arranging a sapphire substrate of an AlN film at a processing surface, growing a first gradualchange AlGaN layer, a second gradual change AlGaN layer and a third gradual change AlGaN layer in order on the sapphire substrate, growing a low-temperature buffer layer, an un-doped GaN layer and a Si-doped N-type GaN layer, periodically growing an active layer MQW, growing a P-type AlGaN layer, growing a Mg-doped P-type GaN layer, and performing cooling. The first gradual change AlGaN layer, thesecond gradual change AlGaN layer and the third gradual change AlGaN layer are grown to reduce the dislocation density, improve the crystalline quality, reduce the warping of an epitaxial wafer, improve the percent of pass of the GaN epitaxial wafer and improve the LED luminous efficiency. The gradual change AlGaN layers are subjected to annealing processing to allow the whole surface of the epitaxial wafer to be smoother, allow the surface hexagonal defects and the hollow pits to be fewer and allow the whole appearance to be better.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

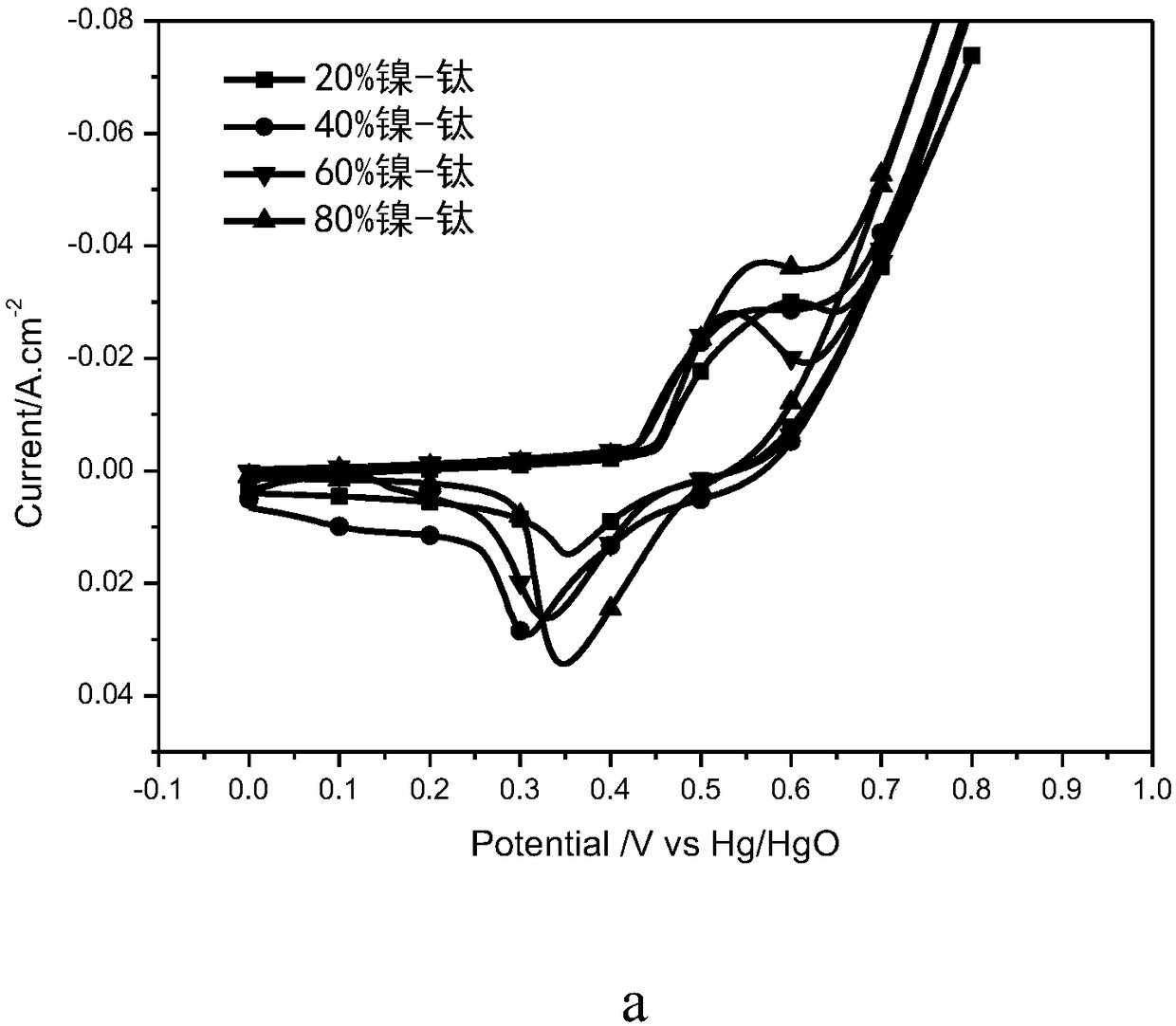

Preparation method of porous titanium-substrate-loaded nickel oxide (nickel hydroxide) electrode with electroconductive ceramic interface

InactiveCN108281291AImprove corrosion resistancePorosityHybrid capacitor electrodesHybrid/EDL manufactureCathodic polarizationContact resistance

The invention discloses a preparation method of a porous titanium-substrate-loaded nickel oxide (nickel hydroxide) electrode with an electroconductive ceramic interface. The preparation method includes (1), ball-milling and mixing metal titanium hydride powder and nickel powder to obtain a metal powder mixture;(2), putting a certain amount of the metal powder mixture into a steel die, and performing pressurization to obtain a metal pressed blank; (3), putting the metal pressed blank into a tubular furnace, and controlling sintering atmosphere and temperature time to obtain the porous titanium-substrate-loaded nickel oxide electrode with the electroconductive ceramic interface; (4), washing the surface of the electrode by dilute acid and deionized water; (5), in nickel nitrate, depositing acertain amount of nickel hydroxide on the surface of the electrode according to a cathodic polarization method to obtain the porous titanium-substrate-loaded nickel hydroxide electrode with the electroconductive ceramic interface. The preparation method has the advantages that the porous electroconductive ceramic interface TinO2n-1-Ti*NiOy generated during high-temperature hypoxic sintering is utilized, contact resistance between active substances and a substrate is reduced, and contact strength between the active substances and the substrate is improved.

Owner:陈军

Alloy steel for bucket teeth and preparation method of bucket teeth

The invention discloses alloy steel for bucket teeth and a preparation method of the bucket teeth, and relates to the field of mechanical manufacturing. The alloy steel for the bucket teeth comprises the chemical components in percentage by weight: 0.25-0.33 percent of C, 0.30-0.80 percent of Si, 0.85-1.25 percent of Mn, 0.70-1.10 percent of Cr, 0.20-0.35 percent of nanoscale TiN, less than or equal to 0.030 percent of p and less than or equal to 0.030 percent of S. The method comprises the following steps: smelting and casting the materials to obtain castings; and performing heat treatment to obtain the bucket teeth. When the alloy steel is smelted, Ca-Si alloys are added while preliminary deoxidizing is carried out by using ferromanganese and silicon iron at the same time, the nanoscale TiN is added during modification treatment; the bucket teeth castings are subjected to high-temperature solid solution spheroidizing annealing. According to the alloy steel and the preparation method, the problems of high material cost of the bucket teeth, poor impact toughness, easiness for breakage and short service life are solved.

Owner:柳州市友军机械配件铸造有限公司

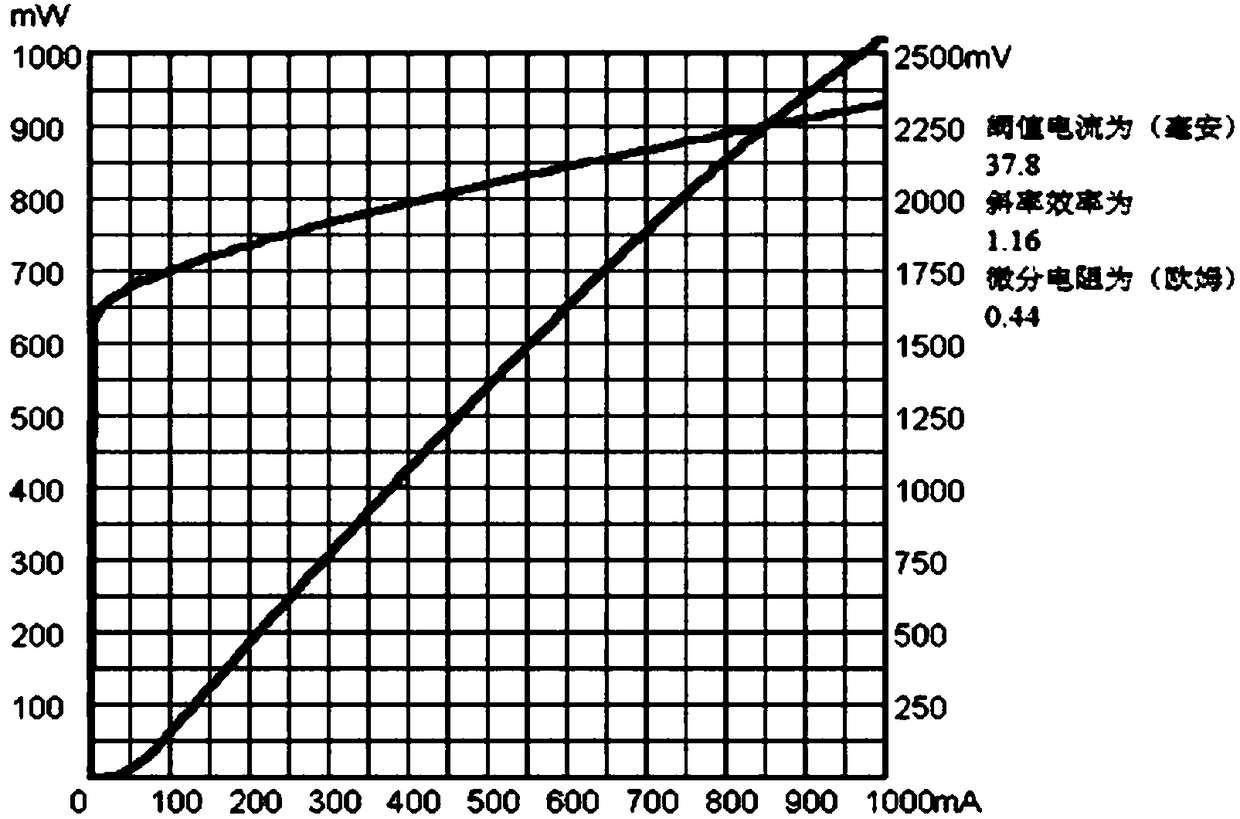

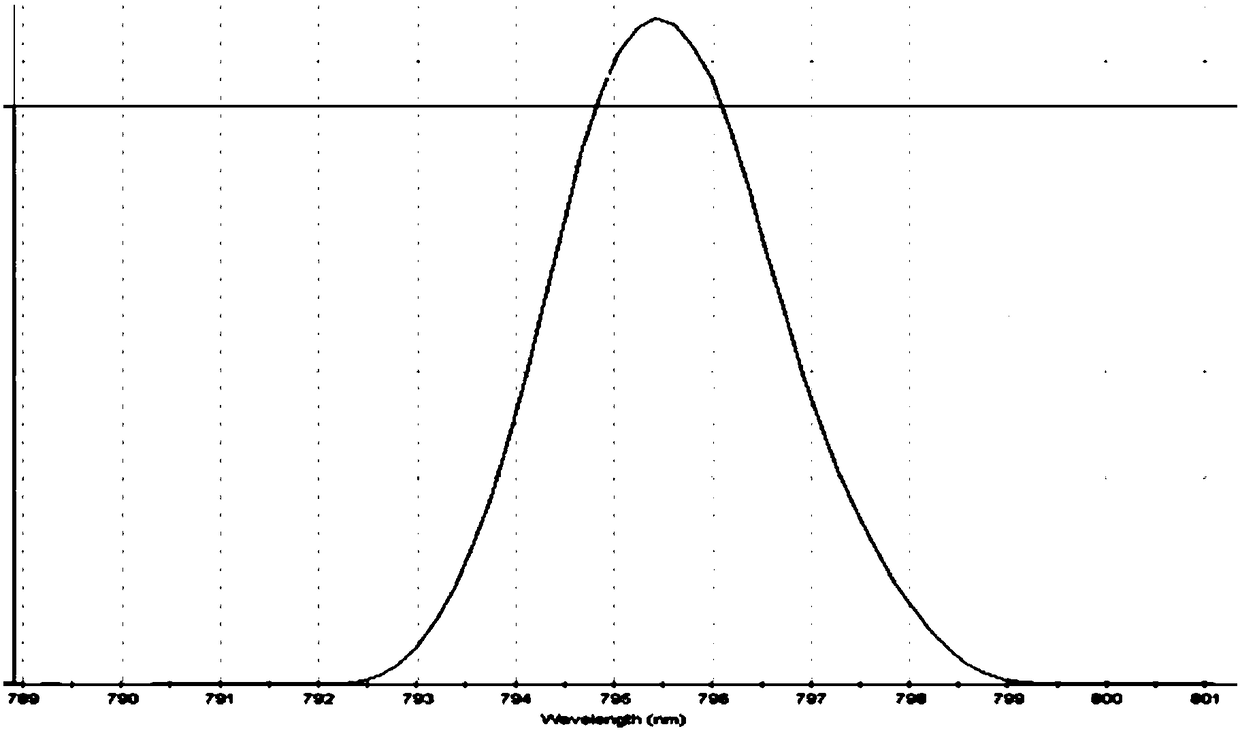

795nm quantum well laser based on AlGaAs/GaInP active region

ActiveCN108346973AReduce the difficulty of growingImprove lattice matchingLaser detailsLaser active region structureElectric fieldAluminium

The present invention provides a 795nm quantum well laser based on an AlGaAs / GaInP active region. The epitaxial structure comprises a substrate, a buffer layer, an N-type lower limit layer, a lower waveguide layer, a quantum well layer, an upper waveguide layer, and P-type upper limit layer and an ohmic contact layer from the bottom to the top. The upper waveguide layer and the lower waveguide layer are made of an aluminum-free material gallium indium phosphate, the quantum well layer is made of an aluminum gallium arsenide material, and a wide waveguide semi-aluminum-free active region is formed by the waveguide layers and the quantum well layer. According to the 795nm quantum well laser, the special requirements of a pump laser with the application of a small and simplified self-doubledlaser crystal can be satisfied, at the same time, the influence of the roughness of a growth interface and an episodic field at a cavity surface on the service and reliability of the laser can be reduced effectively by an optimized laser structure.

Owner:Shandong Huaguang Optoelectronics Co. Ltd.

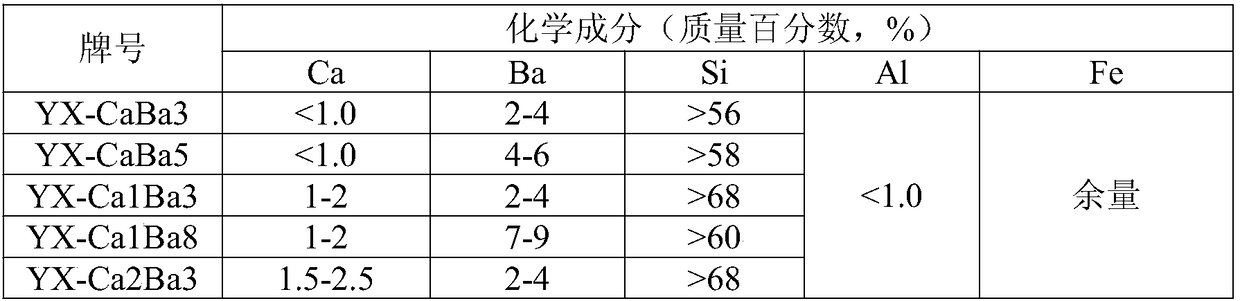

Modified inoculation core-spun yarn and preparation method thereof

The invention belongs to the technical field of material chemistry and specifically relates to a modified inoculation core-spun yarn and a preparation method thereof. The modified inoculation core-spun yarn is prepared from the following raw materials in percentage by mass: 60-90% of inoculation core-spun yarn, 10-20% of micron silicon carbide and 2-10% of nano silicon carbide. The modified inoculation core-spun yarn provided by the invention can increase the nucleation quantity, optimize the nodulizing process and improve the mechanical property of the casting.

Owner:HEFEI KAIER NANOMETER ENERGY & TECH

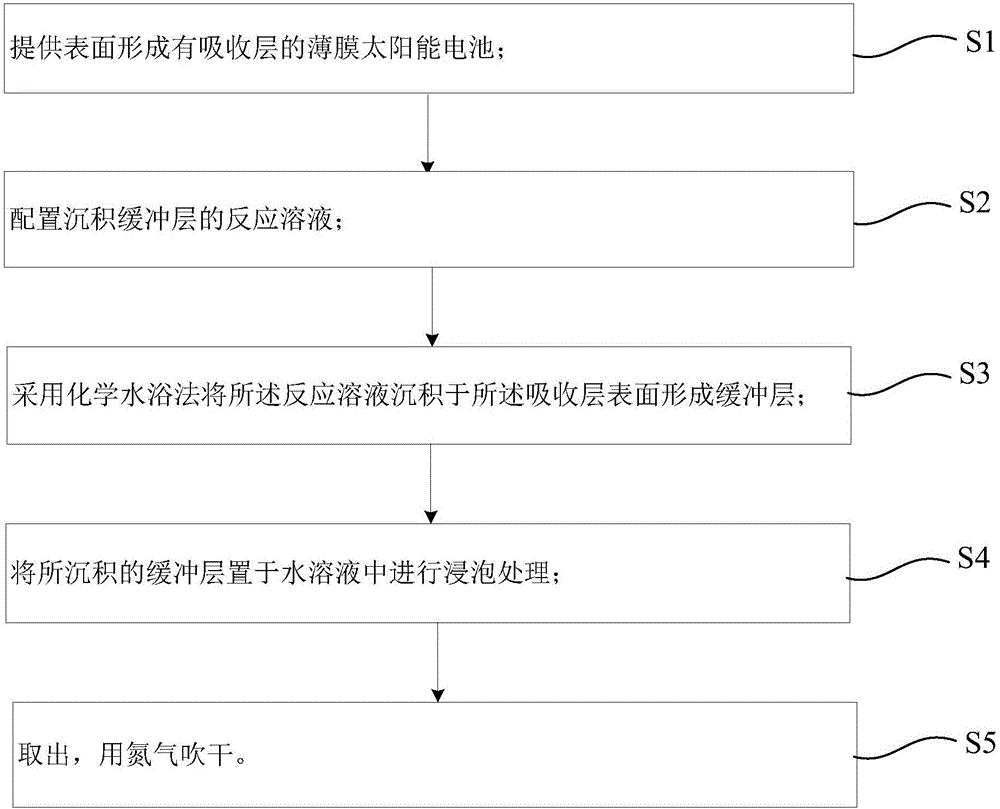

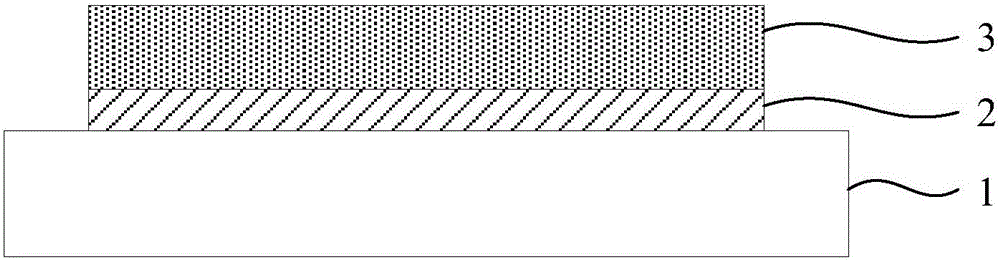

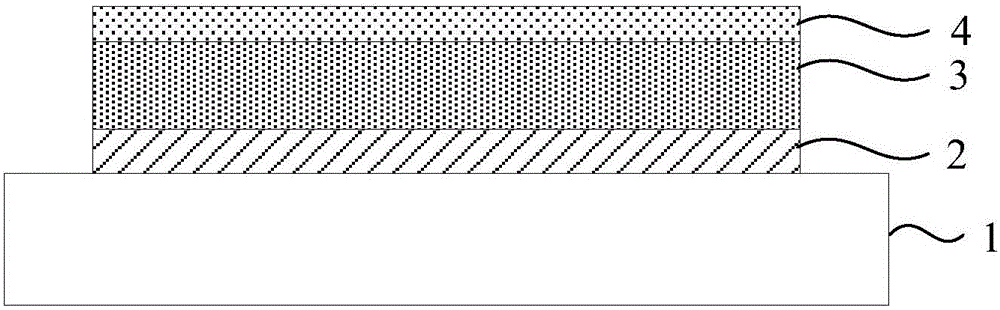

Film solar cell buffer layer postprocessing technology

InactiveCN105914262AIncrease short circuit current densityImprove conversion efficiency absolute valueFinal product manufacturePhotovoltaic energy generationChemical bath depositionThin film solar cell

The invention provides a film solar cell buffer layer postprocessing technology. The technology comprises the following steps of providing a film solar cell whose surface is provided with an absorbed layer; configuring a reaction liquid; using a chemical bath deposition method to deposit the reaction liquid on an absorbed layer surface so as to form a buffer layer; and then placing the buffer layer in a water solution so as to carry out soaking processing; and finally taking out and using nitrogen to carry out drying. By using the buffer layer postprocessing technology, buffer layer surface flatness can be improved; buffer layer surface floccules can be reduced; a contact area with an upper layer window layer and lattice matching are increased; recombination of a carrier in a buffer layer / a window layer interface is reduced; a short-circuit current density of the film solar cell can increase 1.0-2.0mA / cm<2>; and a cell conversion efficiency absolute value can increase 1-3%. Because ammonia water, isopropanol, ammonium acetate and the like which are used for soaking treatment are conventional reagents and can be recycled, technological cost is low, equipment is simple and reliable and operation is safe, and the technology is suitable for industrial production.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

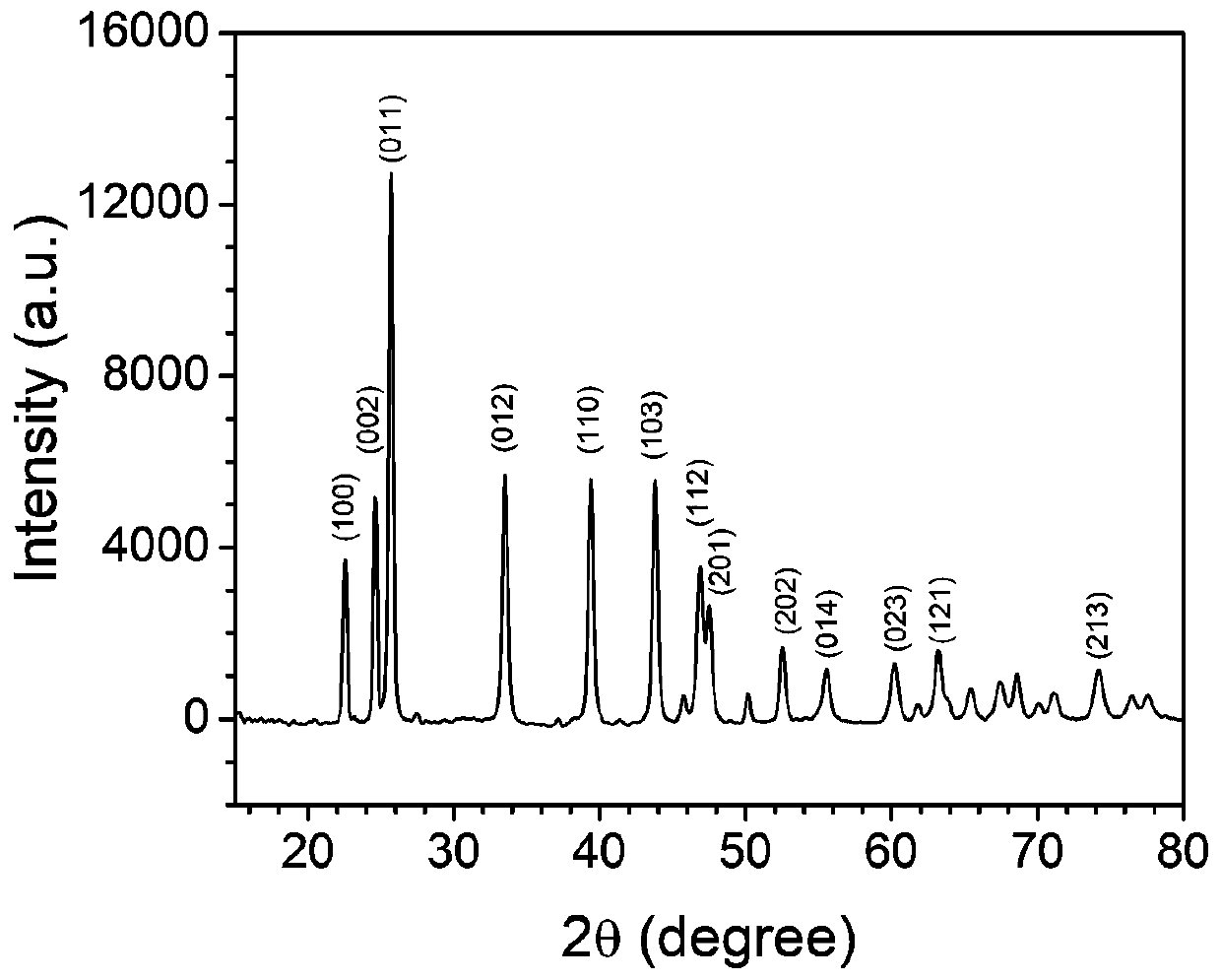

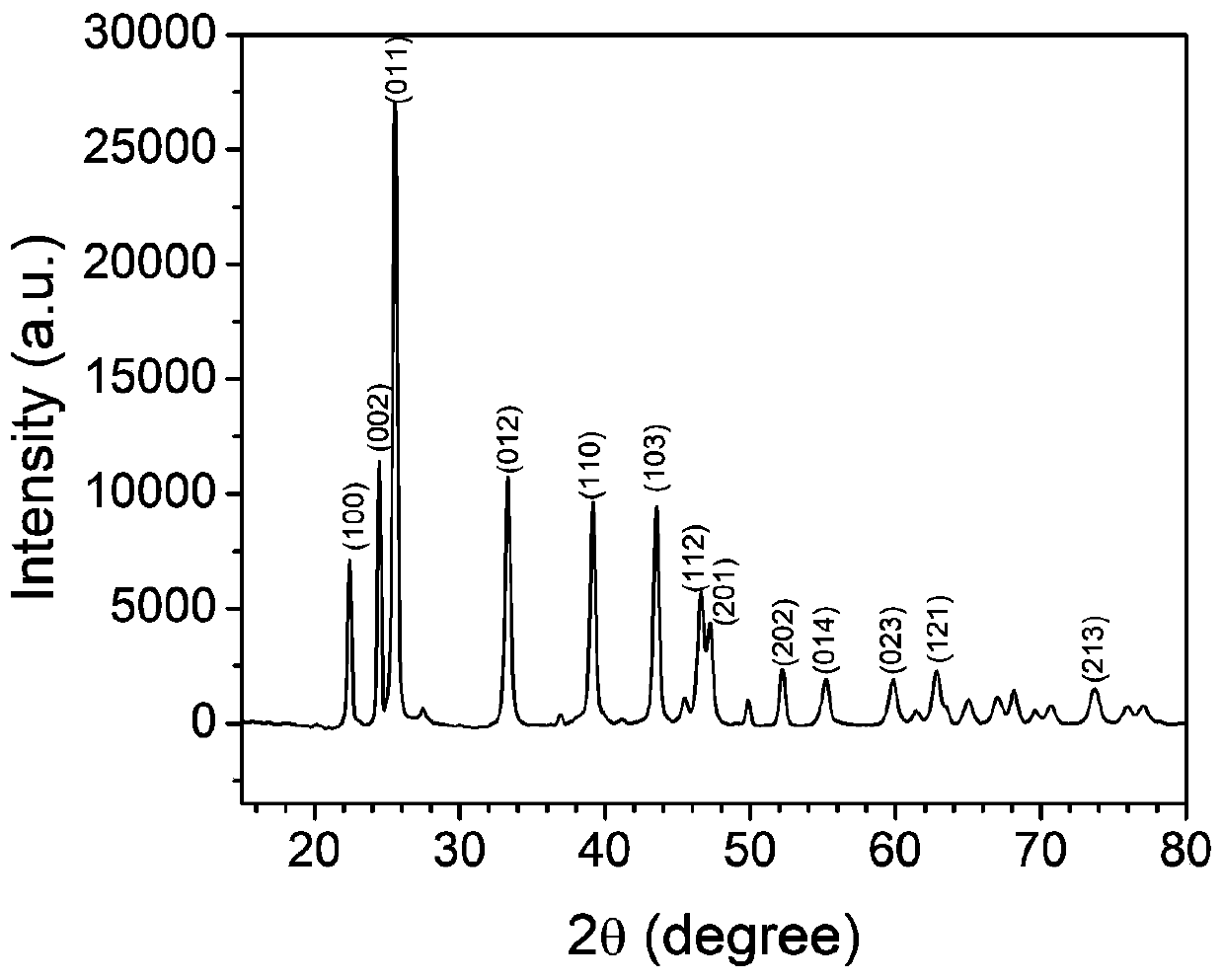

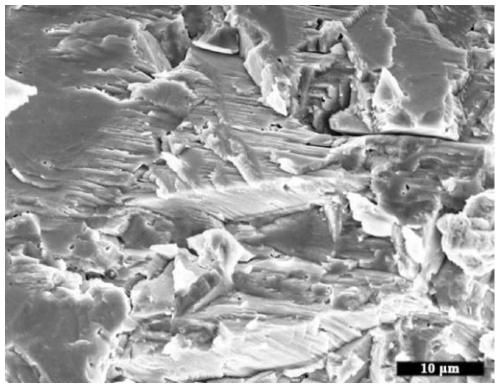

Thermoelectric thin film with chemical composition of Mg3.2Bi1.5Sb0.5 and preparation method thereof

ActiveCN111349902ALow thermal conductivityIncreased ZT valueVacuum evaporation coatingSputtering coatingSputteringChemical composition

The invention provides a thermoelectric thin film with a chemical composition of Mg3.2Bi1.5Sb0.5 and a preparation method thereof, and belongs to the technical field of thermoelectric materials. The thermoelectric thin film is prepared by means of vacuum magnetron sputtering, and the obtained thermoelectric thin film has a two-dimensional spatial structure and is low in thermal conductivity; and meanwhile, the thin film structure can form a quantum confinement effect, thereby increasing the power factor of materials. According to the thermoelectric thin film with the chemical composition of Mg3.2Bi1.5Sb0.5, a c-axis oriented LaAlO3 single crystal is used as a substrate of vacuum magnetron sputtering, the c-axis oriented LaAlO3 single crystal has a very high lattice matching degree with Mg3.2Bi1.5Sb0.5, the preferential growth of the thermoelectric thin film in the c-axis direction can be induced, and finally, the carrier mobility of the thermoelectric thin film is greatly increased andthe thermoelectric performance of the thermoelectric thin film is further greatly increased. A Mg3.2Bi1.5Sb0.5 alloy target is prepared by ball milling and then hot pressing, the obtained alloy target is not prone to cracking in the magnetron sputtering process, and the deposited thin film is uniform in composition.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

Green quantum dots, preparation method therefor and application of green quantum dots

ActiveCN110819348AGood monodispersityImprove optical qualityMaterial nanotechnologySolid-state devicesQuantum dotParticle physics

The invention discloses green quantum dots, a preparation method therefor and an application of the green quantum dots. The green quantum dots have CdSe / ZnSeXS1-X / ZnS structures and comprise CdSe cores, ZnSeXS1-X shells and ZnS shells, wherein peripheries of the CdSe cores are coated with the ZnSeXS1-X shells, X is greater than 0 and is not greater than 1, and peripheries of the ZnSeXS1-X shells are coated with the ZnS shells. The green quantum dots have the characteristics of quantum efficiency higher than 90%, half-peak breadth between 20nm and 26nm, monodispersity and the like; and QLED devices based on the green quantum dots have the advantages of high external quantum efficiency, long device lifetime and the like.

Owner:NANJING TECH CORP LTD

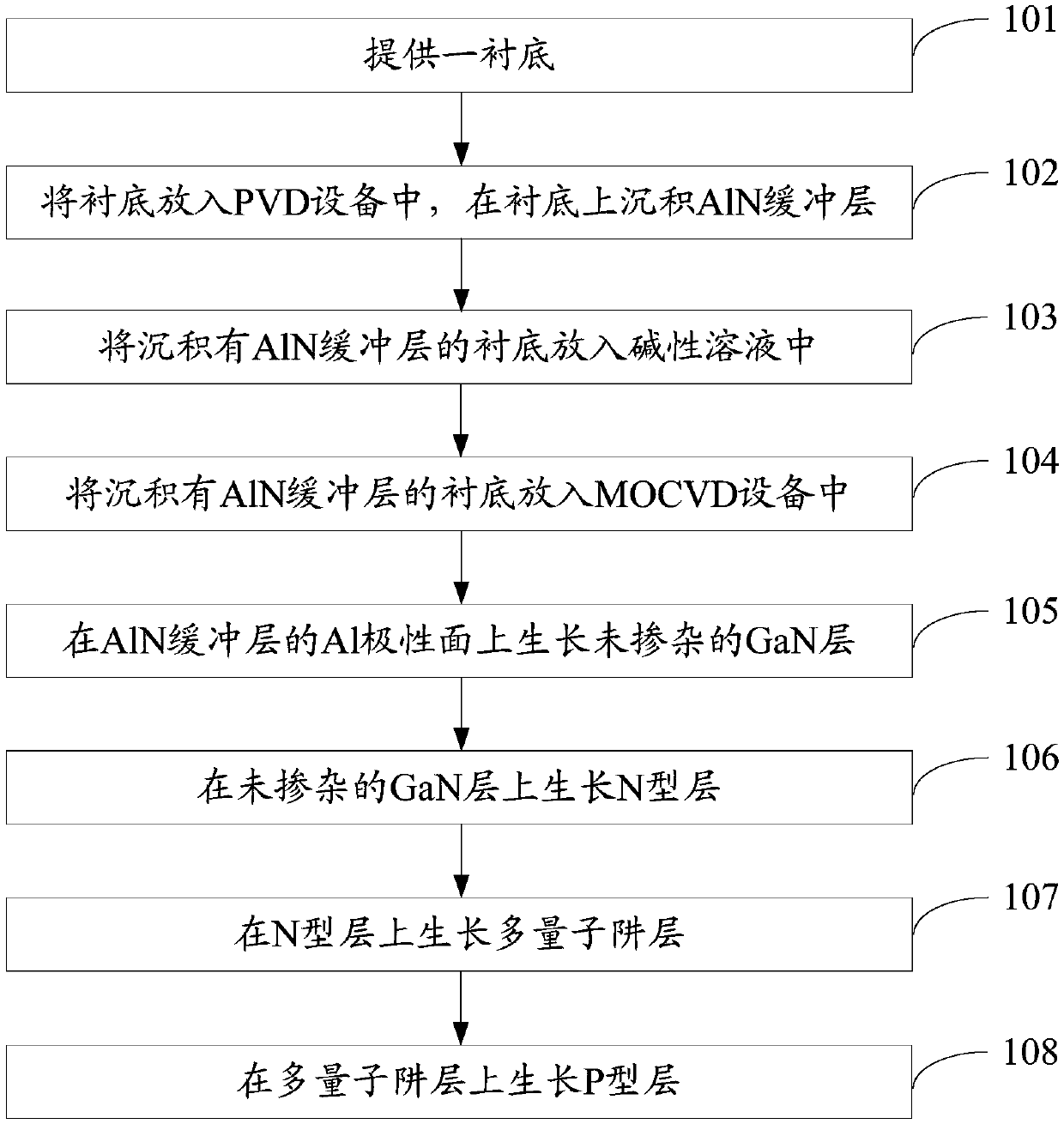

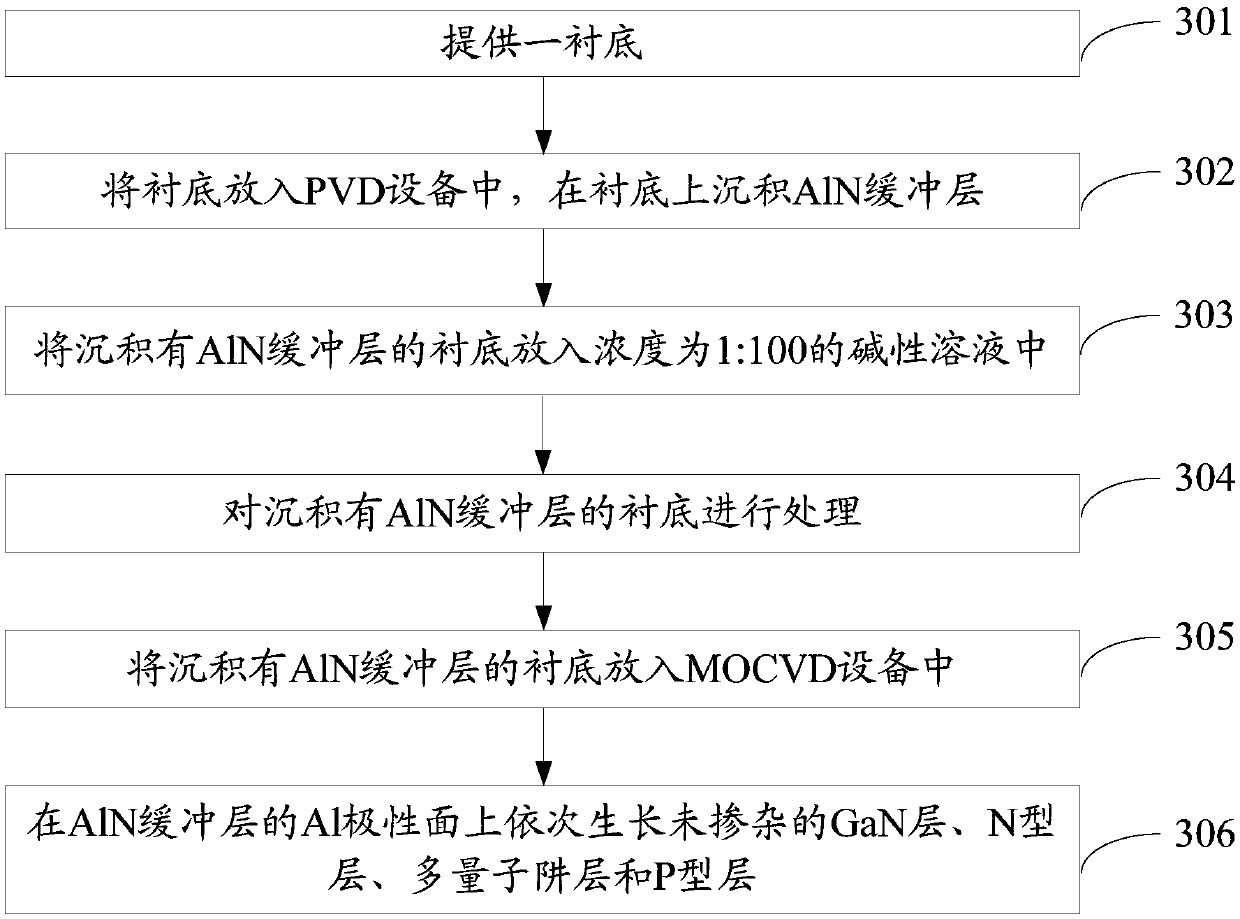

Manufacturing method of light-emitting diode epitaxial wafer

ActiveCN109686820AImprove lattice matchingReduce stressSemiconductor devicesQuantum wellSemiconductor

The invention discloses a manufacturing method of a light-emitting diode epitaxial wafer, and belongs to the technical field of semiconductors. The manufacturing method comprises the following steps:providing a substrate; putting the substrate into PVD equipment, and depositing an AlN buffer layer on the substrate; putting the substrate deposited with the AlN buffer layer into an alkaline solution, and reacting the alkaline solution with the AlN buffer layer to ensure that the surface of the AlN buffer layer is an Al polar surface; putting the substrate deposited with the AlN buffer layer into MOCVD equipment, and sequentially growing an undoped GaN layer, an N-type layer, a multi-quantum well layer and a P-type layer on the Al polar surface of the AlN buffer layer. When the surface of the AlN buffer layer is an Al polar surface, the lattice matching degree between the AlN buffer layer and the undoped GaN layer is higher. Therefore, the manufacturing method can improve the lattice matching degree between the AlN buffer layer and the GaN layer, thereby improving the crystal quality of the grown light-emitting diode epitaxial wafer and further improving the luminous efficiency of the LED.

Owner:HC SEMITEK ZHEJIANG CO LTD

Halide-coated halogen perovskite quantum dots and preparation method thereof

ActiveCN112680215AImprove photostabilitySize limitMaterial nanotechnologyNanoopticsQuantum efficiencyHalogen

The invention relates to a halide-coated halogen perovskite quantum dot and a preparation method thereof. The method is characterized in that the preparation method comprises the following steps: mixing a halogen perovskite quantum dot with halide, uniformly grinding, and calcining in a protective atmosphere at 400-1,000 DEG C for 0.5-100 hours to obtain the halide-coated halogen perovskite quantum dot, wherein the halide further comprises metal elements and / or non-metal elements, the non-metal elements are one or more of oxygen elements, sulfur elements and nitrogen elements, and the metal elements comprise one or more of Cu, Fe, Co, Ni, Zn, Hg, Ca, Mg, Sr, Ba, Pb, Sn, Al, Co, Ce, Bi, Sb, Ag, Rh, Zr, Na, K, Cs and Sb. According to the method, the outer surface of the perovskite quantum dot is coated with halide, so that the luminous quantum efficiency of the perovskite quantum dot can be improved, and the light stability of the perovskite quantum dot is improved.

Owner:JIANGSU UNIV OF TECH

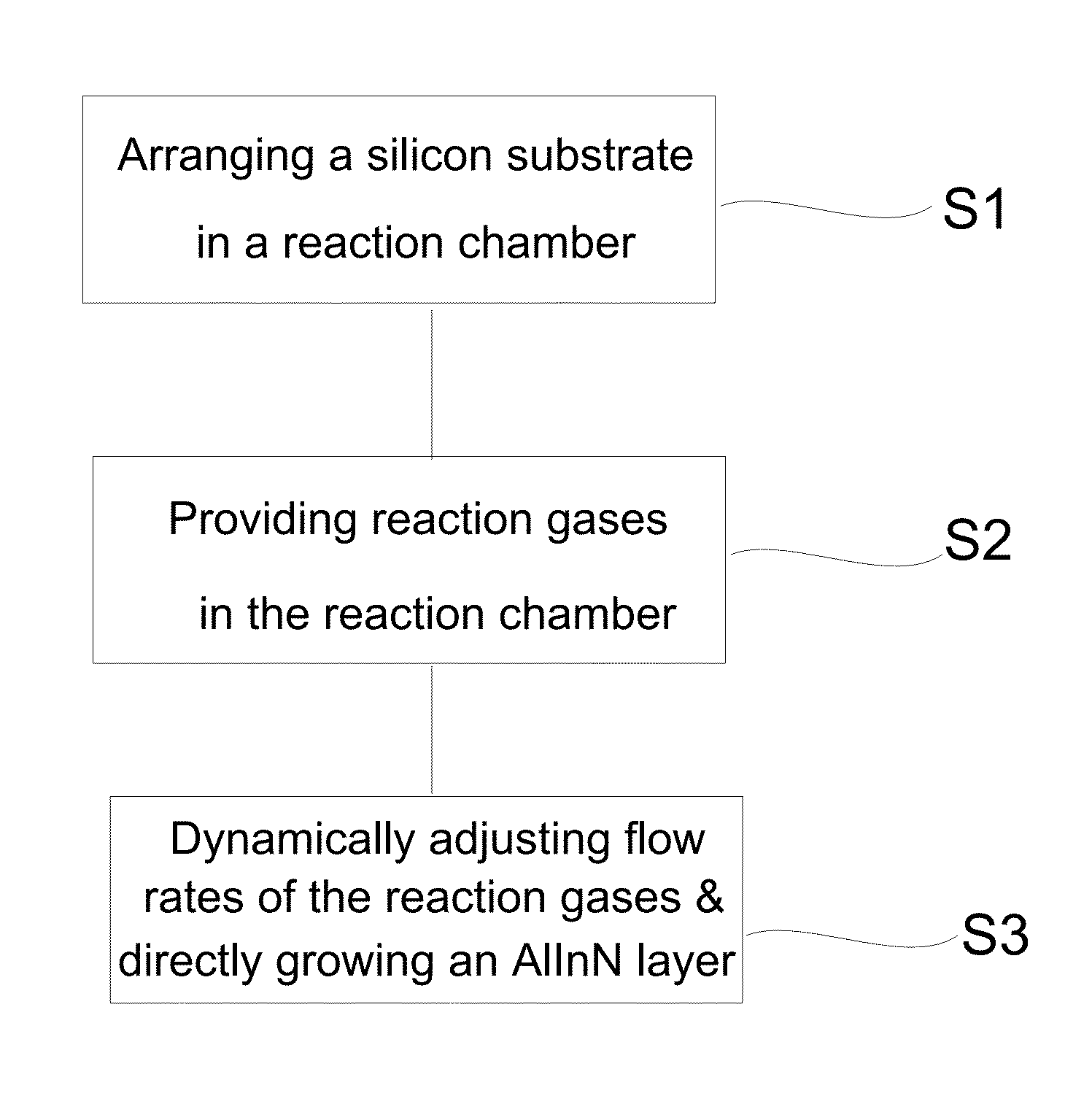

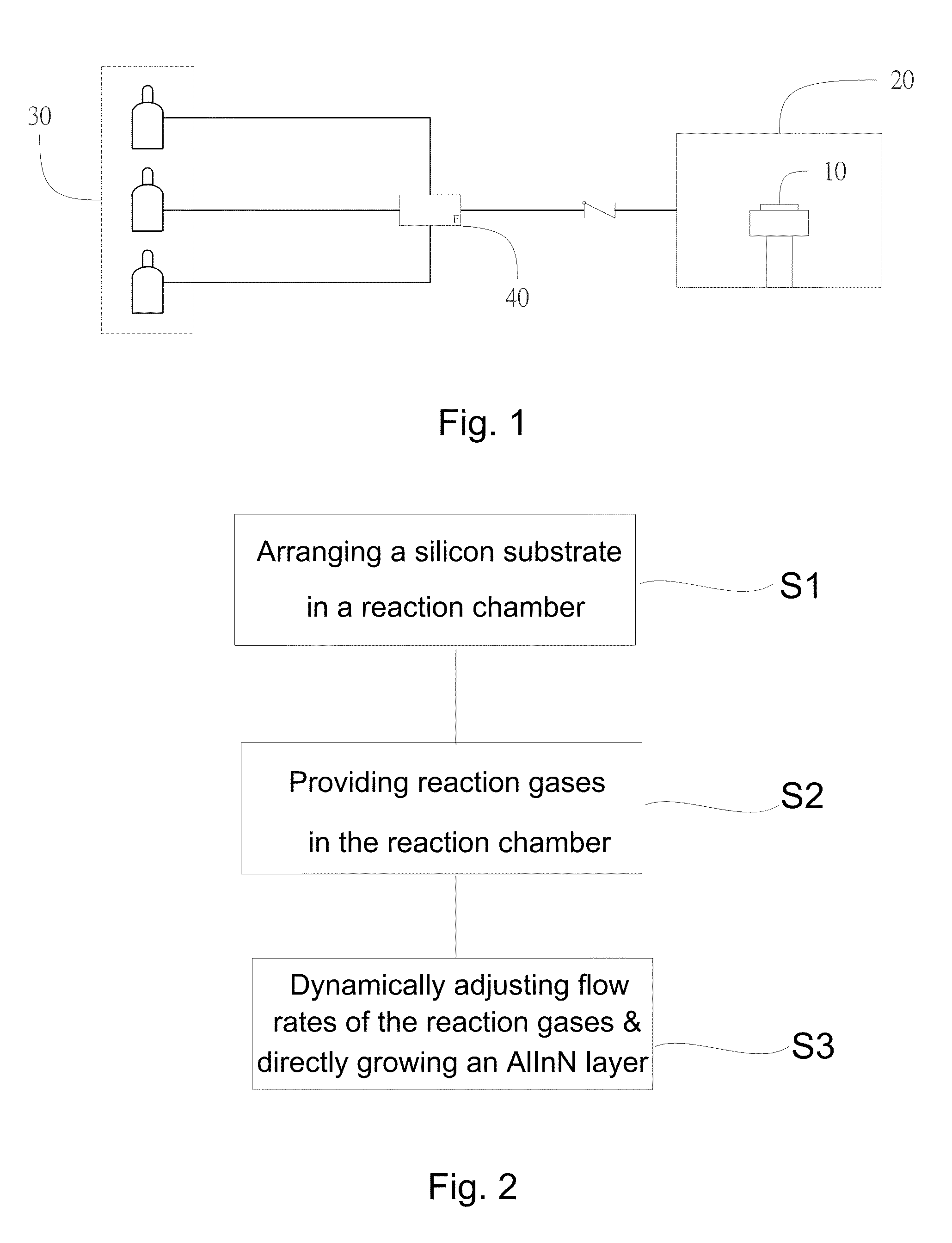

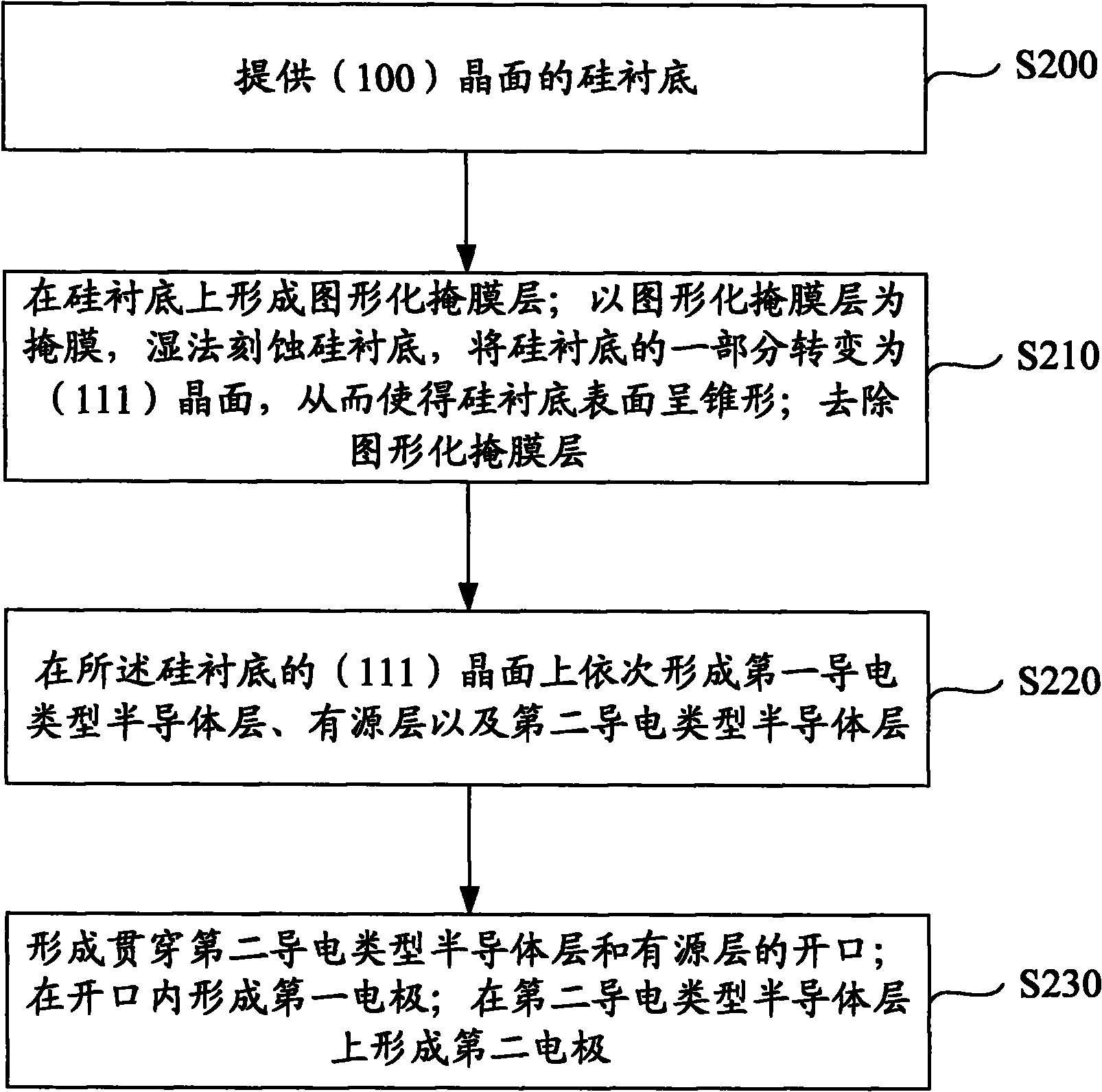

Method for growing aluminum indium nitride films on silicon substrate

ActiveUS20150235837A1Improve lattice matchingReduce residual stressSemiconductor/solid-state device manufacturingSemiconductor devicesIndiumAluminium

A method for growing aluminum indium nitride (AlInN) films on silicon substrates comprises several steps: firstly, arranging a silicon substrate in a reaction chamber; secondly, providing multiple reaction gases in the reaction chamber, wherein the reaction gases include aluminum precursors, indium precursors and nitrogen-containing gases; finally, dynamically adjusting flow rates of the reaction gases and directly growing an AlInN layer on the silicon substrate via a crystal growth process. By directly forming an AlInN layer on the silicon substrate, lattice matching is increased, residual thermal stress is reduced and film quality is improved. In addition, fabrication process is simplified and thus cost is reduced.

Owner:NAT CHIAO TUNG UNIV

Light emitting diode (LED) and manufacturing method thereof

InactiveCN102163662AIncrease reflectionImprove external quantum efficiencySemiconductor devicesActive layerLight-emitting diode

The invention discloses a light emitting diode (LED) and a manufacturing method thereof. The method comprises the following steps of: providing a silicon substrate with a (100) crystal plane; taking a graphical mask layer as a mask, performing wet etching on the silicon substrate, and converting a part of the silicon substrate into a (111) crystal plane so as to make the surface of the silicon substrate conical; forming a first conductive semiconductor layer, an active layer and a second conductive semiconductor layer in turn on the (111) crystal plane of the silicon substrate; forming an opening which passes through the second conductive semiconductor layer and the active layer; forming a first electrode in the opening; and forming a second electrode on the second conductive semiconductor layer. The invention can improve the light utilization rate of the LED.

Owner:ENRAYTEK OPTOELECTRONICS

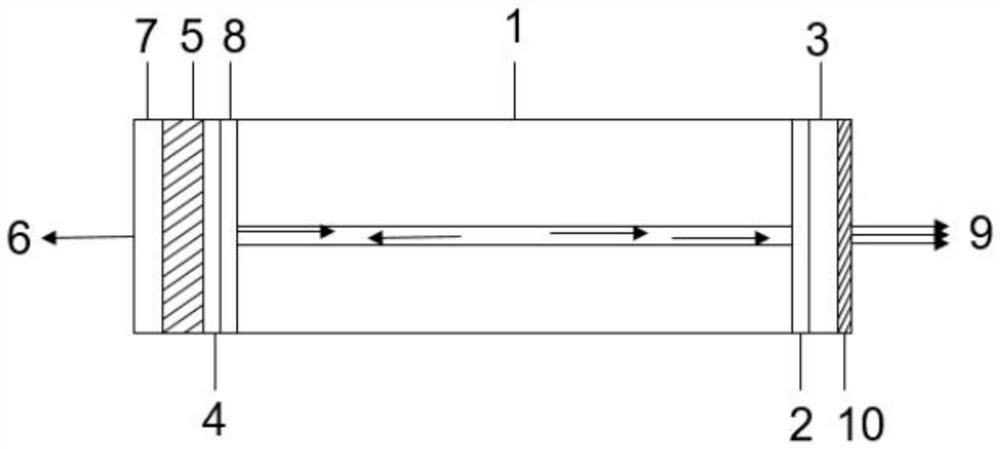

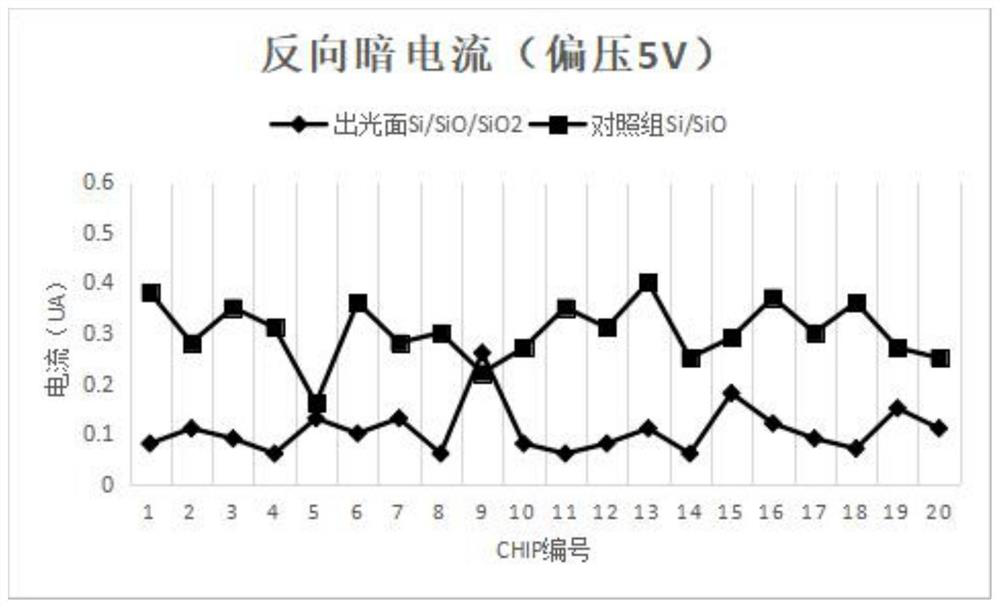

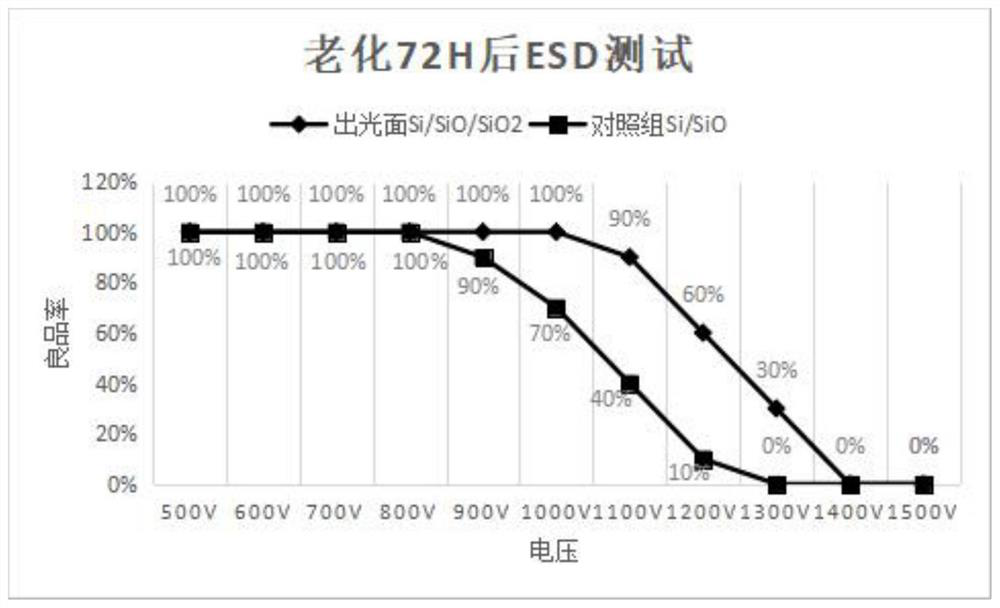

Communication laser semiconductor chip and manufacturing method thereof

ActiveCN113422289AImprove lattice matchingHigh interface state densityLaser detailsSemiconductor lasersLattice mismatchWafer

The invention relates to the technical field of communication chip semiconductors, and provides a manufacturing method of a communication laser semiconductor chip. The method comprises the following steps of: S1, performing stripping and clamping on a wafer of which the end surface is to be coated to obtain a Bar strip, and processing the Bar strip; S2, sequentially coating the light emitting cavity surface of the to-be-plated Bar strip after treatment with three layers of high-transmittance film systems, wherein the three layers of high-transmittance film systems are respectively a first Si film, a first SiO film and a first SiO2: H film; and S3, after film coating of the light emitting cavity surface is completed, sequentially coating the backlight cavity surface of the Bar strip to be coated with four layers of high-reflection film systems, wherein the four layers of high-reflection film systems are a second SIO film, a second Si film, a second SiO2: H film and a third Si film respectively. The invention also provides the communication laser semiconductor chip. The chip is manufactured by the manufacturing method of the communication laser semiconductor chip. The end face film system adopts a pure Si multi-layer film, so that the lattice matching degree between film layers can be effectively improved, and the influence of excitons, defects and lattice vibration caused by high lattice mismatch ratio on the light absorption coefficient is reduced.

Owner:湖北光安伦芯片有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com