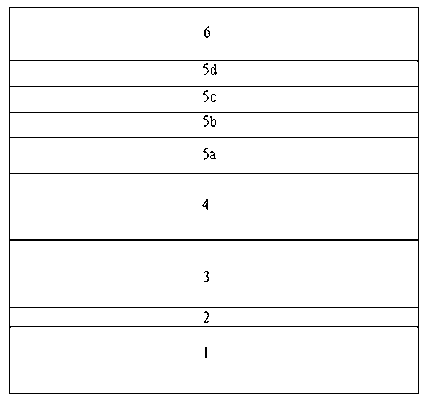

Patents

Literature

57results about How to "Reduce stress difference" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

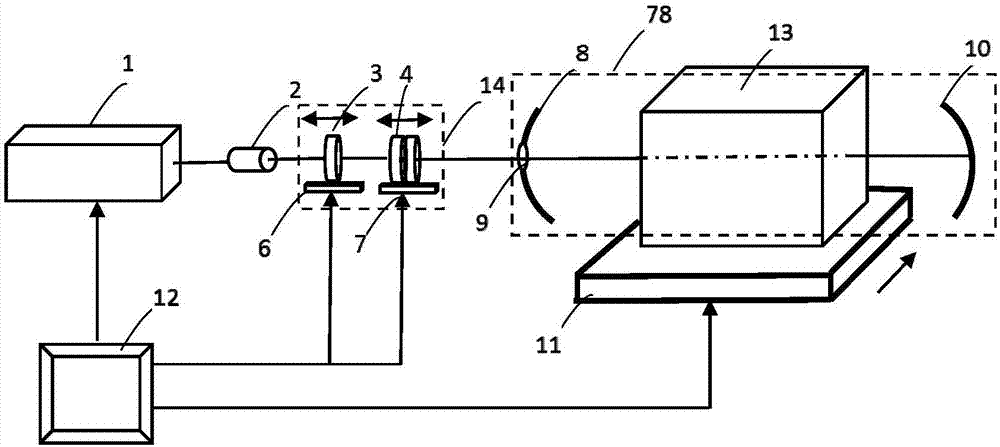

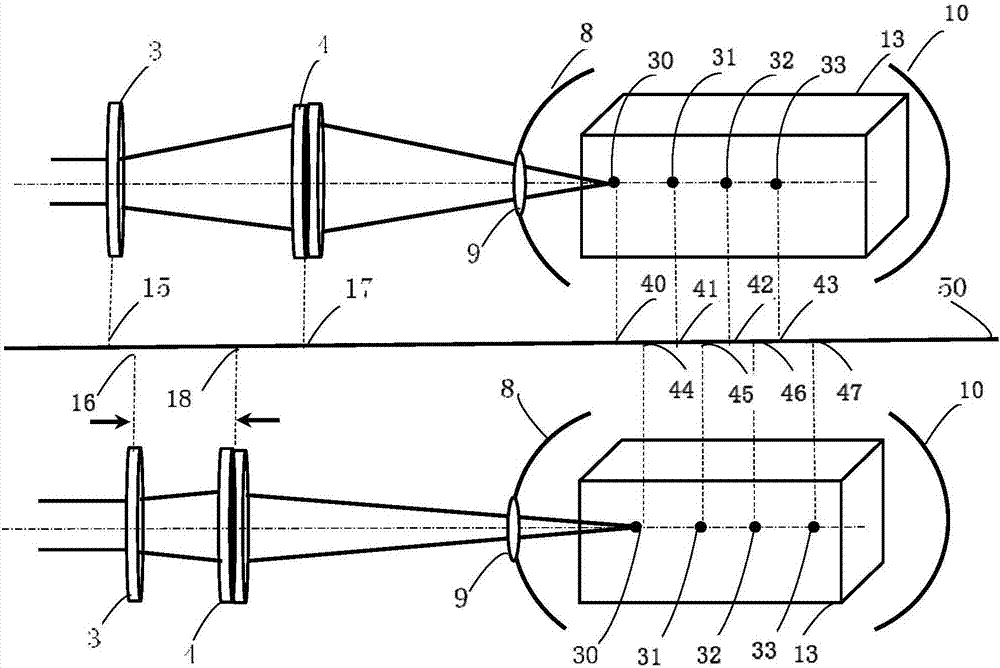

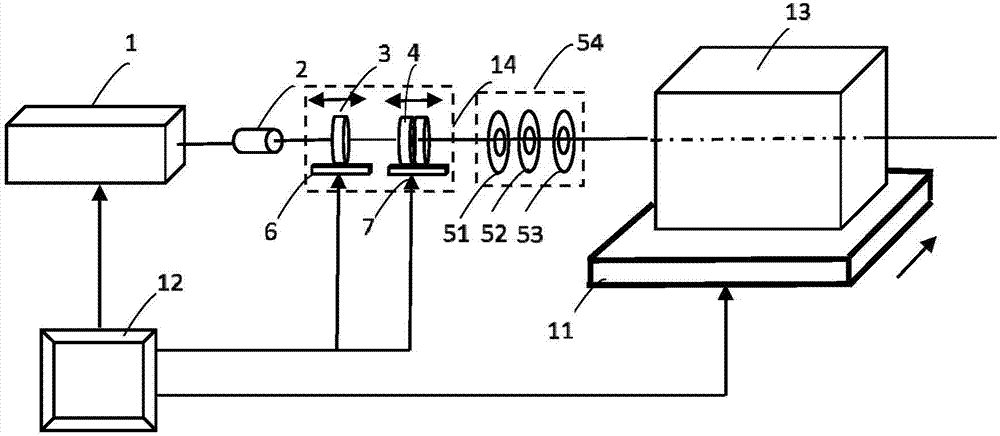

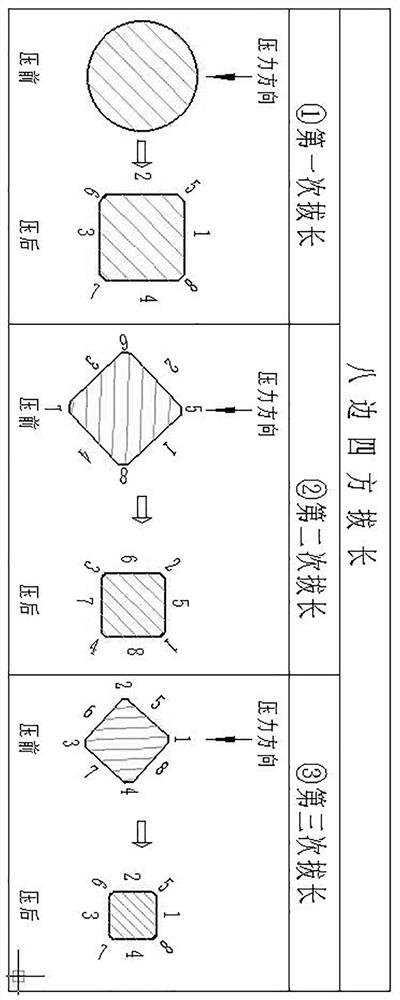

Laser multi-focus dynamic machining method and system

PendingCN107243690AReduce lossesIncrease profitLaser beam welding apparatusOptical axisOptoelectronics

The invention discloses a laser multi-focus dynamic machining method and system, and belongs to the technical field of laser machining application. The method includes the steps that multiple same-optical-axis focus points incoming into a to-be-machined object do back and forth movement at set frequency along the direction of the optical axis, and therefore each laser focus does linear back and forth movement in the thickness direction of the to-be-machined object, and therefore the static point heating manner is converted into linear dynamic heating manner. The invention further provides a device for achieving the above method. A multi-focus derivative system or multi-focusing-lens set is adopted for enabling lasers to form multiple laser focuses in the to-be-machined transparent material. By means of the method, high quality and high efficiency cutting separation of the thicker transparent fragile material can be achieved. The device is relatively simple in structure and easy to control.

Owner:HUAZHONG UNIV OF SCI & TECH

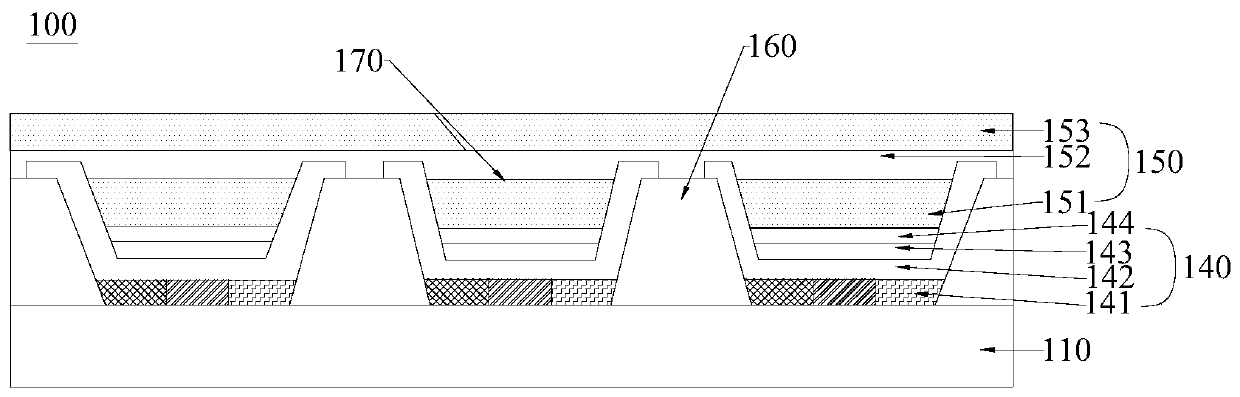

MQW (multiple quantum well)-growth applied GaN (gallium nitride)-based green-light LED (light emitting diode) epitaxial structure

InactiveCN103178176AReduce stress differenceReduced polarizing electric fieldSemiconductor devicesElectron holeGallium nitride

The invention discloses an MQW (multiple quantum well)-growth applied GaN (gallium nitride)-based green-light LED (light emitting diode) epitaxial structure, and relates to the technical field of LED epitaxial production, in particular to growth technology of GaN-based green-light LEDs. The MQW-growth applied GaN-based green-light LED epitaxial structure comprises a GaN nucleating layer, a non-mixed GaN layer, a n-type GaN layer, an InGaN (indium gallium nitride) / GaN MQW active layer and a p-type GaN layer which are sequentially grown on a substrate. The InGaN / GaN MQW active layer comprises a GaN barrier layer, an InGaN quantum well layer and a temperature-changing GaN transition layer. A buffering layer shallow well with low In components is grown between the GaN barrier layer and the InGaN quantum well layer of the InGaN / GaN MQW active layer. Stress between a quantum well and a barrier is greatly reduced, and stress difference between the quantum well and the barrier is relieved, so that a polarization electric field in the quantum well is greatly reduced. By the buffering layer shallow well between the barrier and the quantum well, the polarization electric field is reduced, spatial segregation of an electron-hole wave function is relieved, and effective radiative recombination can be improved.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

GaN-based green light LED (light-emitting diode) epitaxial structure and manufacturing method thereof

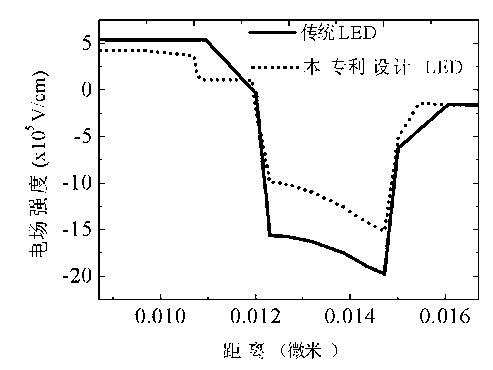

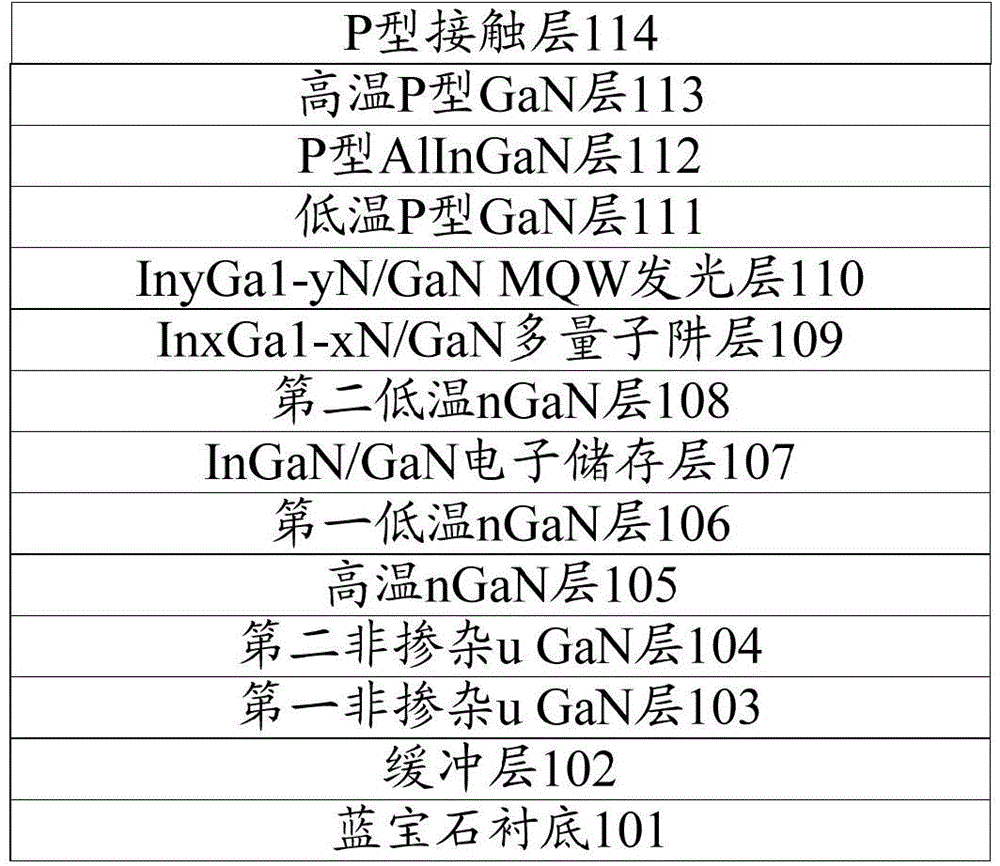

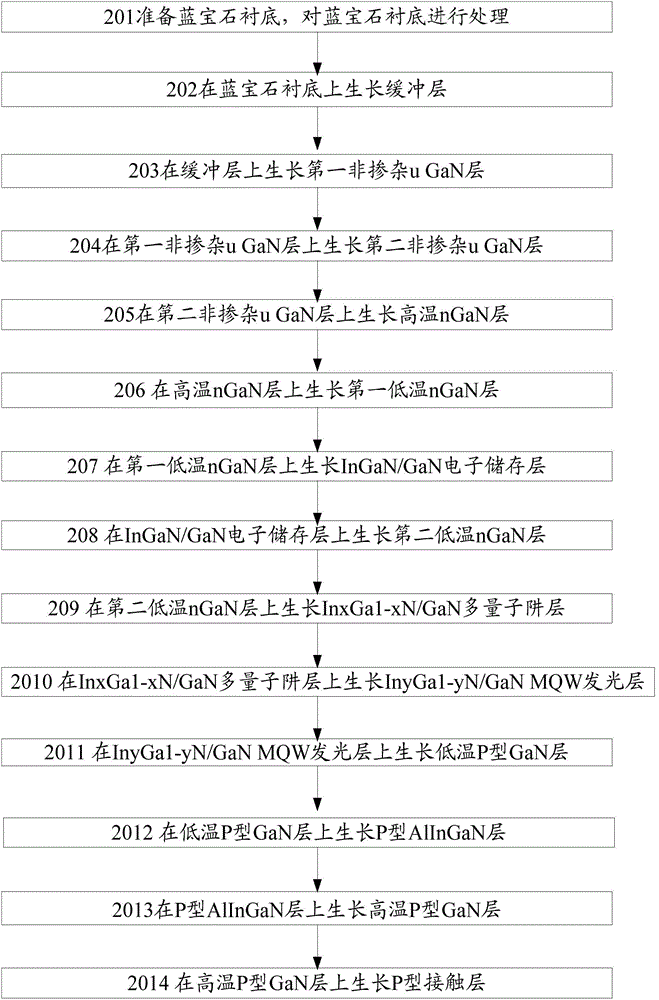

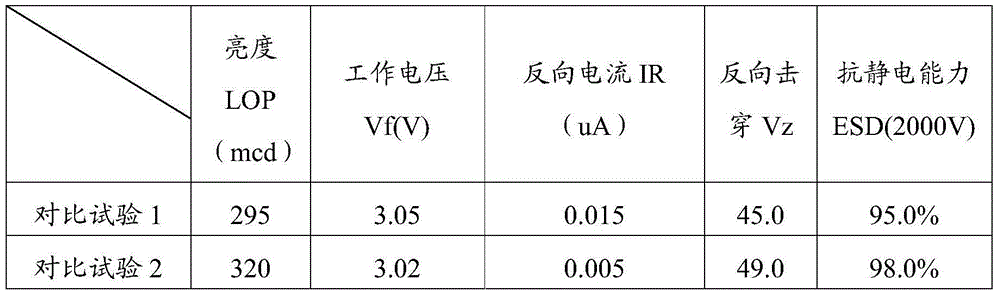

ActiveCN104409591AImprove the internal quantum effectImprove luminous efficiencySemiconductor devicesMultiple quantumLattice mismatch

The invention discloses GaN-based green light LED (light-emitting diode) epitaxial structure. The GaN-based green light LED epitaxial structure comprises a sapphire substrate, a buffer layer, a first undoped u GaN layer, a second undoped u GaN layer, a high-temperature nGaN layer, a first low-temperature nGaN layer, an InGaN / GaN electronic storage layer, a second low-temperature nGaN layer, an InxGal-xN / GaN multiple-quantum well layer, an InyGal-yN / GaNMQW luminescent layer, a low-temperature P type GaN layer, a P type AlInGaN layer, a high temperature P type GaN layer and a P type contact layer from bottom to top in sequence. The invention further provides a manufacturing method of the GaN-based green light LED epitaxial structure. The GaN-based green light LED epitaxial structure can be used for solving the problems of greatened lattice mismatch, strengthened polarization effect and poor crystal quality in the MQW structure of the GaN-based light emitting diode, improving the internal quantum efficiency of the internal quantum well and obviously improving the luminous efficiency of the LED apparatus.

Owner:XIANGNENG HUALEI OPTOELECTRONICS

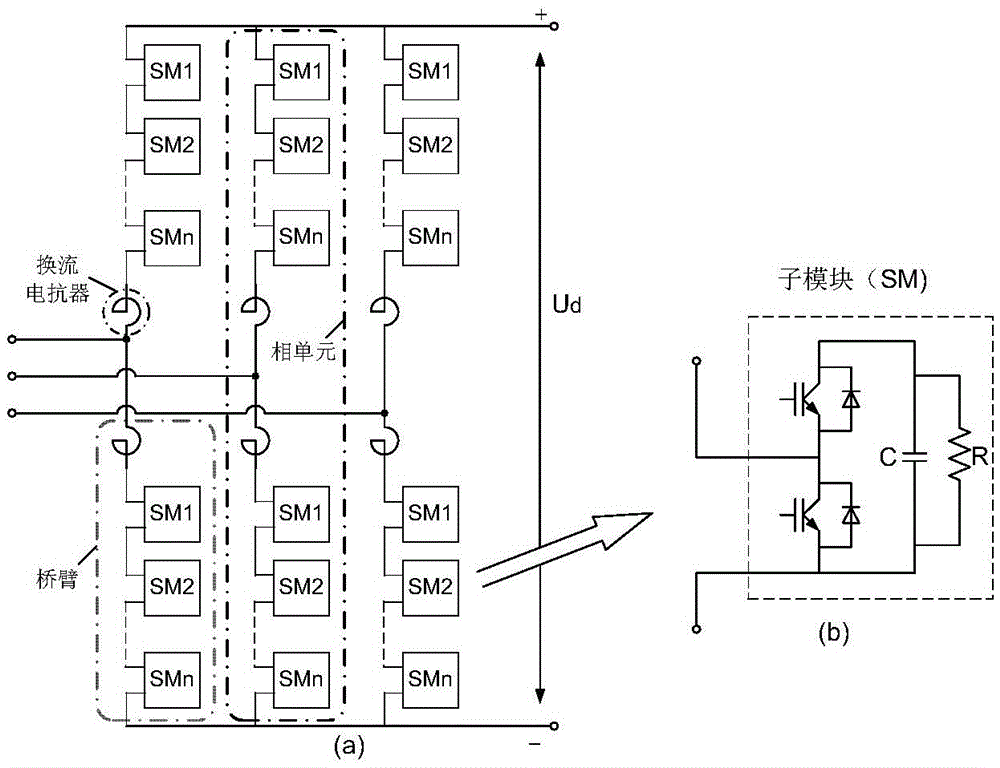

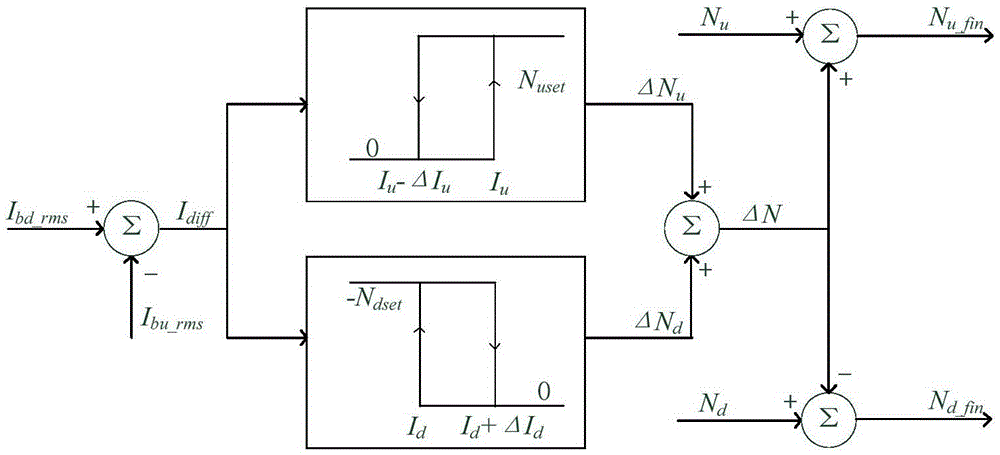

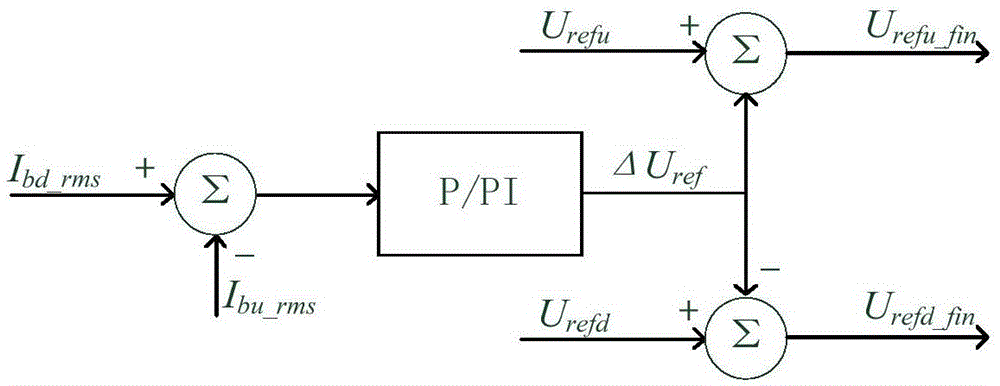

Control Method of Bridge Arm Current in Modular Multilevel Converter

ActiveCN103812377BReduce or even suppress asymmetryReduce stress differenceConversion with reversalPower flowComputer module

Owner:NR ELECTRIC CO LTD +3

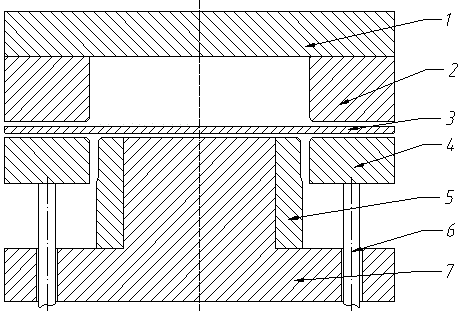

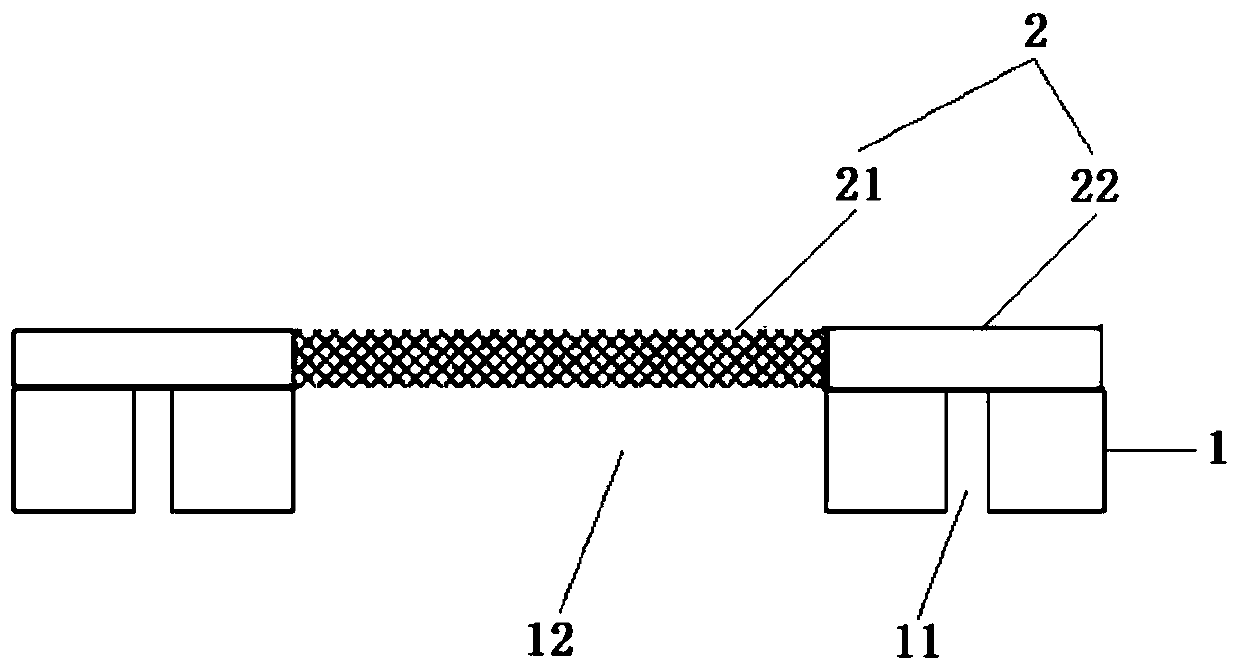

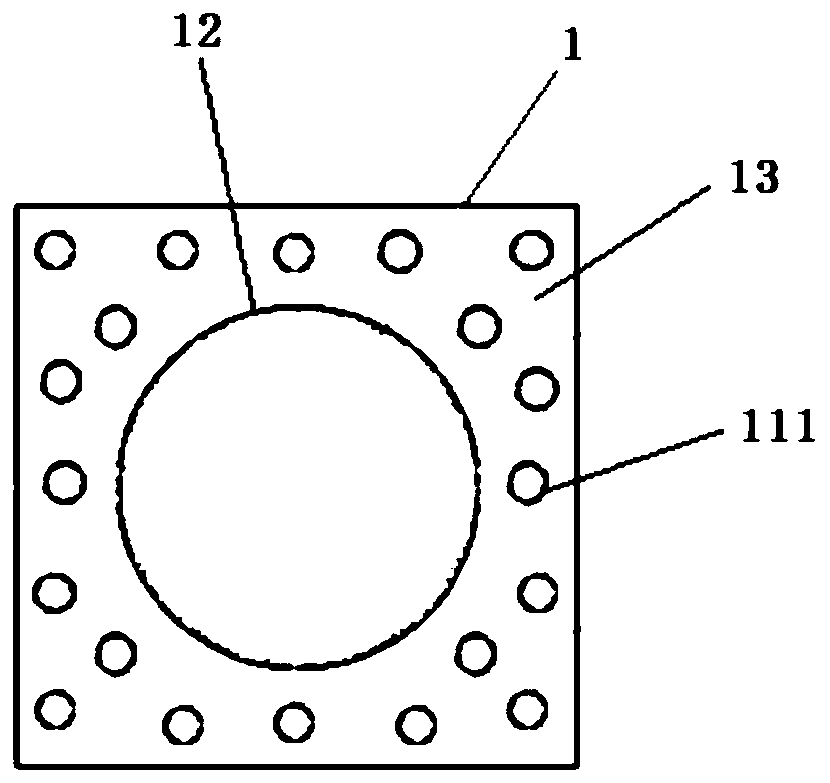

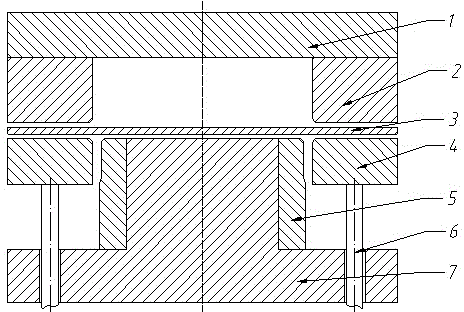

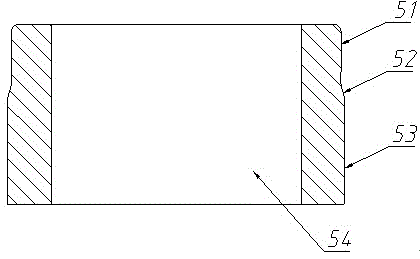

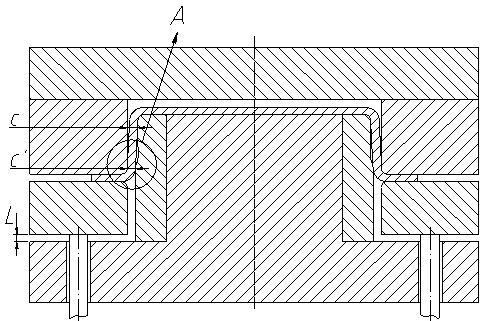

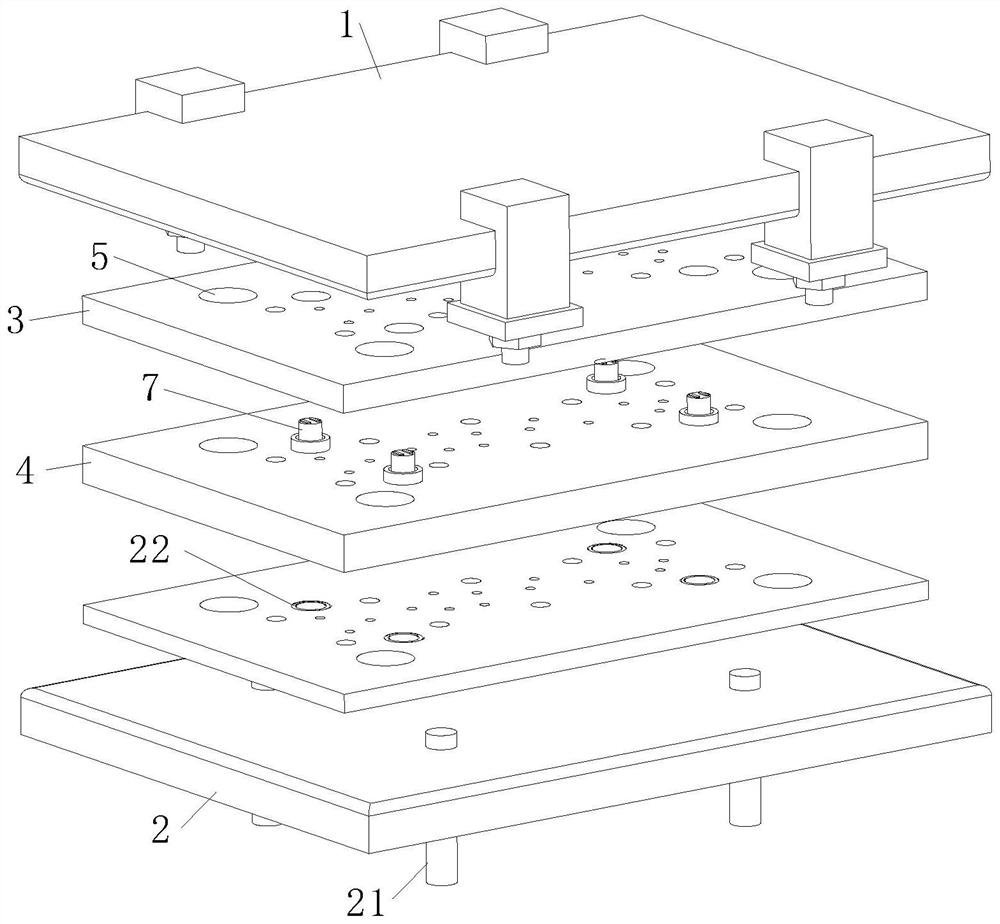

Stamping part side wall curled rebounding control stamping device

ActiveCN103949544AIncrease flow resistanceReduce stress differenceShaping toolsEngineeringStamping process

The invention discloses a stamping part side wall curled rebounding control stamping device which comprises an upper die base, a concave die, a blank holder, a convex die and a lower die base from top to bottom, wherein the blank holder is in driving connection with a holder-on rod; the convex die is matched with the concave die; the upper die base is fixedly connected with the concave die and moves synchronously with the concave die; the convex die is fixedly connected with the lower die base; the convex die comprises a first stamping part and a second stamping part from top to bottom; the first stamping part and the second stamping part are in smooth transition by virtue of a transition curve part; a clearance between the outer contour of the side wall of the first stamping part and the side wall of the concave die is 1.2-1.6 times of the thickness of a to-be-stamped plate; a clearance between the outer contour of the side wall of the second stamping part and the side wall of the concave die 2 is 0.8-0.9 times of the thickness of the to-be-stamped plate; the projection length of the transition curve part in the stamping direction is 2-3 times of the thickness of the to-be-stamped plate. According to the stamping part side wall curled rebounding control stamping device, the die clearance is changed during a stamping process, so that the stress difference between inner and outer layers of a material is decreased, side wall curled rebounding of parts is effectively controlled, and the formation precision and quality of the parts are improved.

Owner:SOUTH CHINA UNIV OF TECH

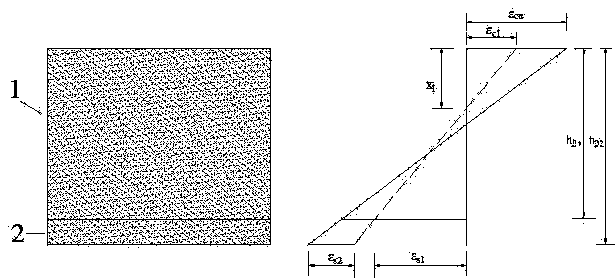

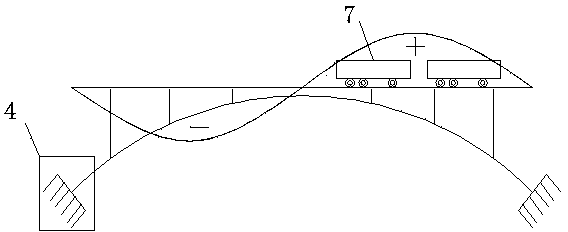

Comprehensive structure prestress reinforcing method on basis of influence line theory

ActiveCN104389275AReduce stress differenceNovel ideaBuilding repairsBridge erection/assemblyStress distributionInfluence line

The invention discloses a comprehensive structure prestress reinforcing method on the basis of the influence line theory. The comprehensive structure prestress reinforcing method includes steps of analyzing by means of the influence line theory in the structural mechanics, temporarily adjusting (loading or deloading) the internal force within a certain area in an influence line to change the state of the internal force or the stress within a section to be reinforced; reinforcing the section to be reinforced; finally, stopping temporary adjustment of the internal force to actively adjust the stress distribution of the reinforced combined section after the strength of the reinforcing layer is achieved and new and used materials are effectively combined, so that the 'stress difference' of the reinforced new and used materials stays reasonable and perfect reinforcing effect is realized. The comprehensive structure prestress reinforcing method is novel in concept and utilizes the influence line theory skillfully to temporarily adjust the internal force of the section to be reinforced before reinforcing, so that the reinforced concrete is prepressed or pretensioned (structural prestress), the stress difference of new and used concrete is reduced and stress performance of the reinforced combined section is improved.

Owner:邢兵 +2

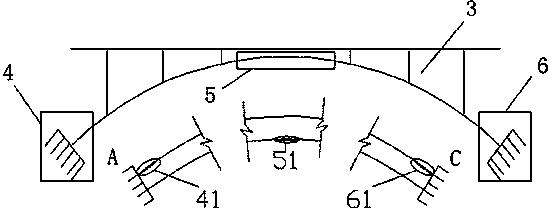

Air cooling device for tempered glass

ActiveCN108298802AExtend the motion pathReduce contact areaGlass tempering apparatusCooling effectExhaust pipe

The invention provides an air cooling device for tempered glass and relates to the field of glass cooling. The air cooling device comprises drive rollers, upper air grids located above the drive rollers and lower air grids located below the drive rollers, wherein an air baffle for preventing air from blowing downwards is arranged below each drive roller and arranged between adjacent lower air grids, a longitudinal exhaust pipe is fixed at the upper end of the air baffle and fixed on the side surface of the corresponding lower air grid, and two ends of the exhaust pipe are open; multiple vertically transverse partitions are arranged on each air baffle longitudinally, so that multiple cooling units which are only open at upper ends are formed by the partitions with the lower air grids, the exhaust pipes and the air baffles; each exhaust pipe is provided with an air inlet in the corresponding cooling unit, and the lower air grids blow glass for cooling; air cushions are formed by air accumulation in each cooling unit, air in the cooling units can be discharged from the exhaust pipes through the air inlets instead of blowing to two sides along the two lower air grids, so that the longitudinal cooling effect on the glass is uniform, and stress difference caused by non-uniform cooling is reduced.

Owner:广东天锐节能环保玻璃有限公司

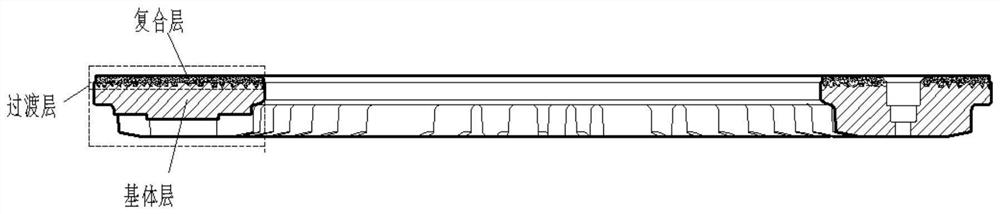

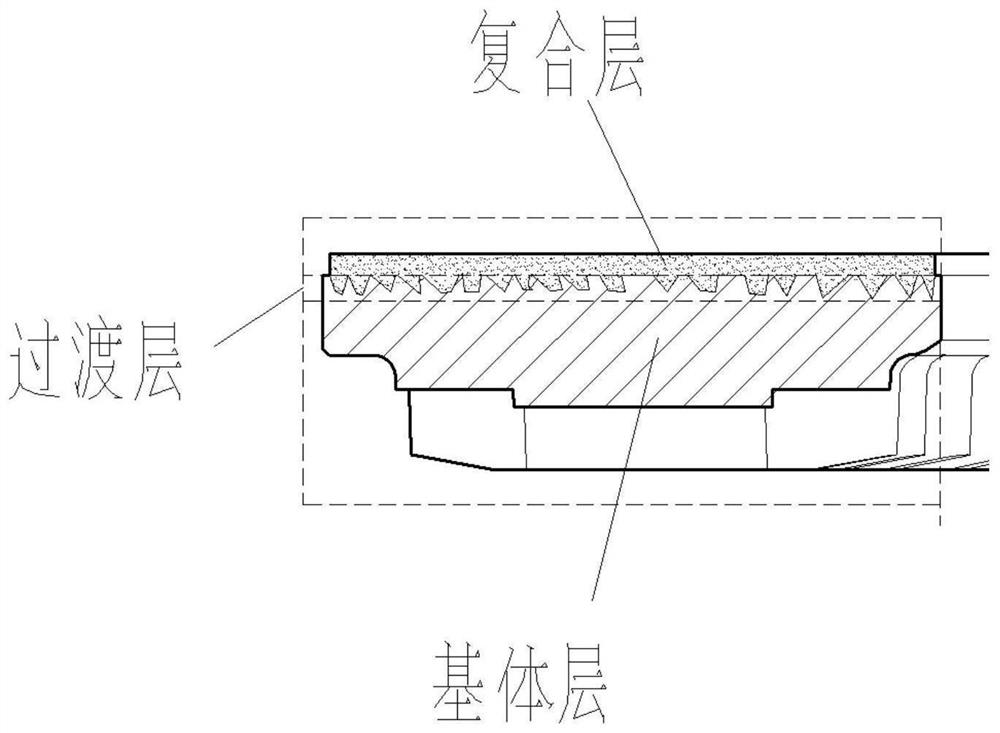

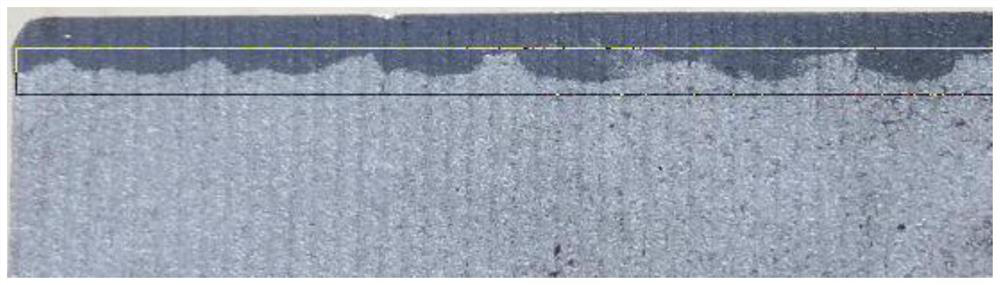

Composite material brake disc

ActiveCN112413012AReduce temperature riseIncrease the volume fraction of reinforcing particlesBraking discsFoundry mouldsUltimate tensile strengthWear resistance

The invention provides a composite material brake disc. The composite material brake disc comprises a base body layer playing a role in bearing and a composite layer providing friction braking force,the base body layer and the composite layer are combined with each other in a metallurgical bonding mode, a transition layer is generated at the interface where the base body layer and the composite layer are combined with each other, and a reinforcing structure for connecting the base body layer and the composite layer is formed in the transition layer. According to the composite material brake disc, on one hand, the volume fraction of reinforced particles of the composite layer is increased, the abrasion resistance is improved, ceramic particles are prevented from being added into the base body layer, the strength and the elongation of the base body layer are improved, the failure risk is reduced, the heat conduction capacity of the base body layer is improved, heat generated by the friction layer is transferred into air, and the overall temperature rise of the brake disc is reduced; and on the other hand, compared with the prior art that an aluminum alloy base body layer and an abrasion-resisting layer are connected in a mechanical bonding mode, the composite material brake disc generates the transition layer between the base body layer and the composite layer in the metallurgical bonding mode, the bonding force between the base body layer and the composite layer is improved, and the risk of failure such as cracking between the composite layer and the base body layer in thecold and hot fatigue process is reduced.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

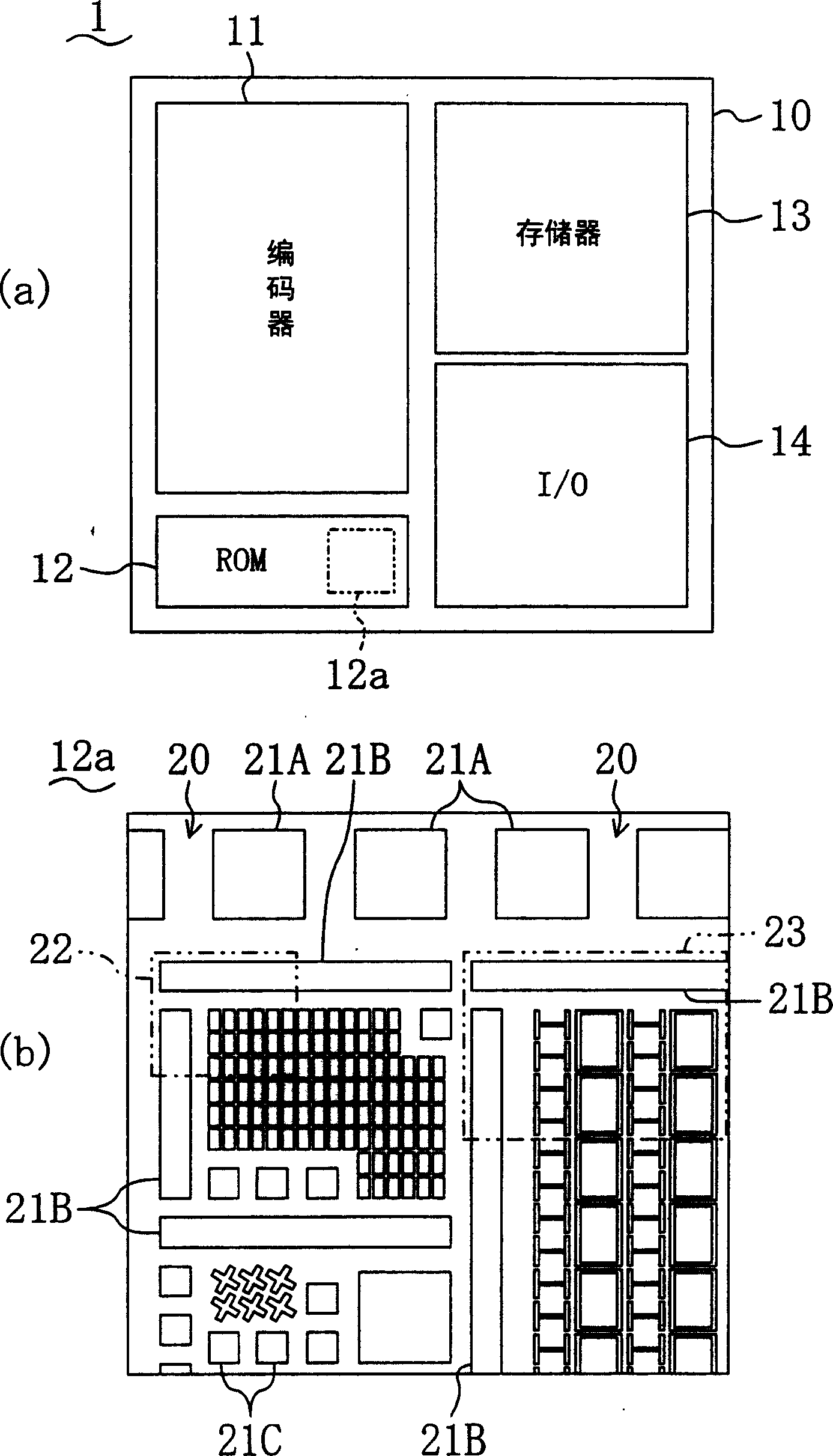

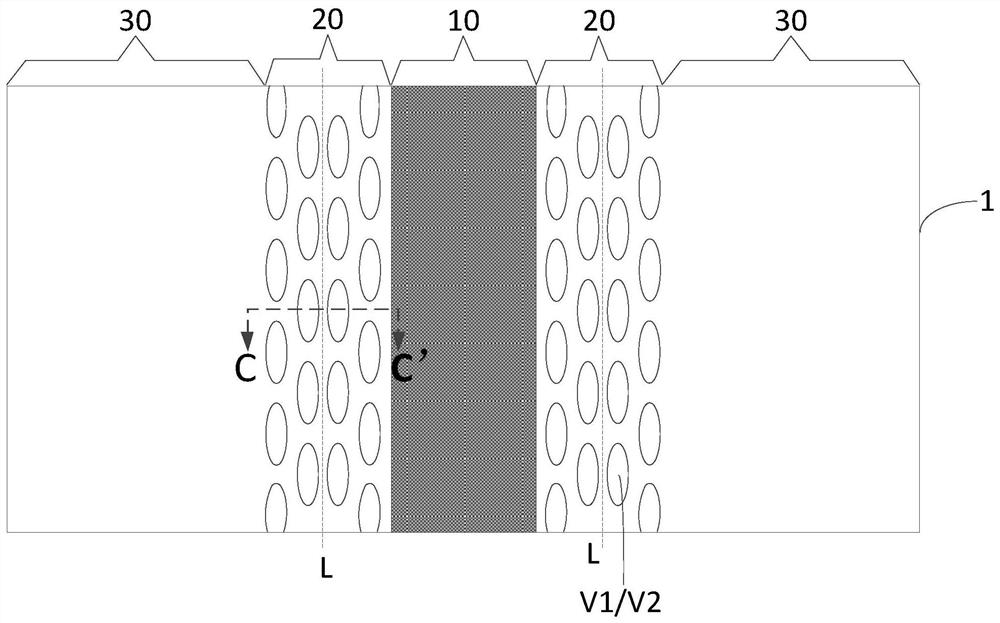

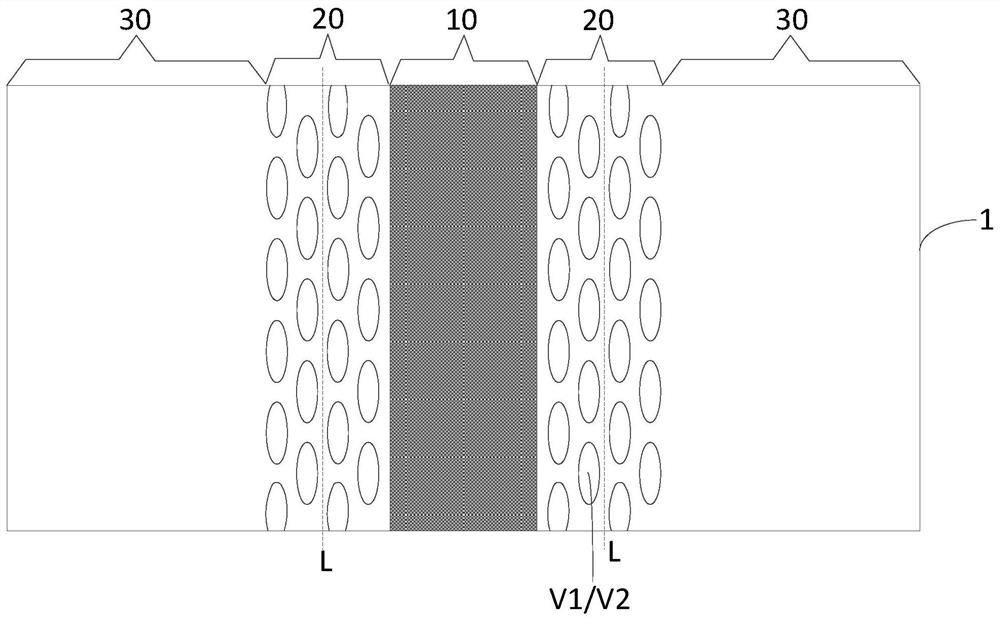

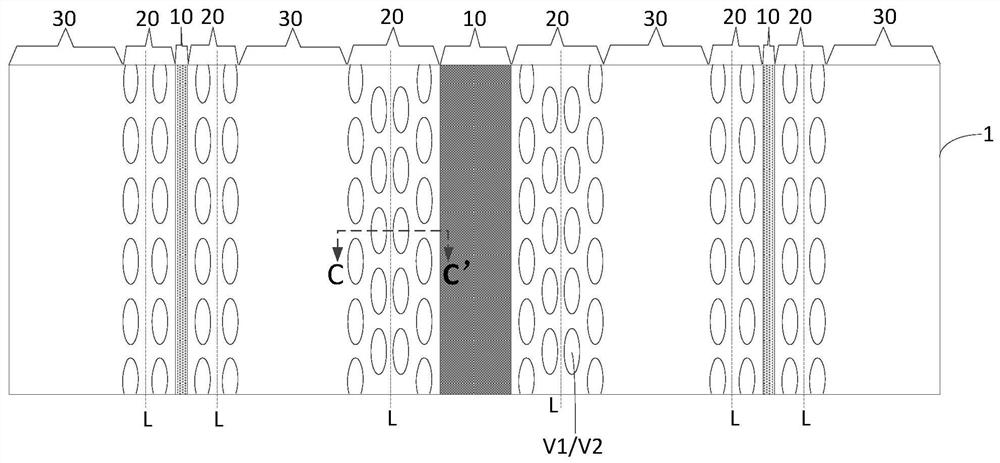

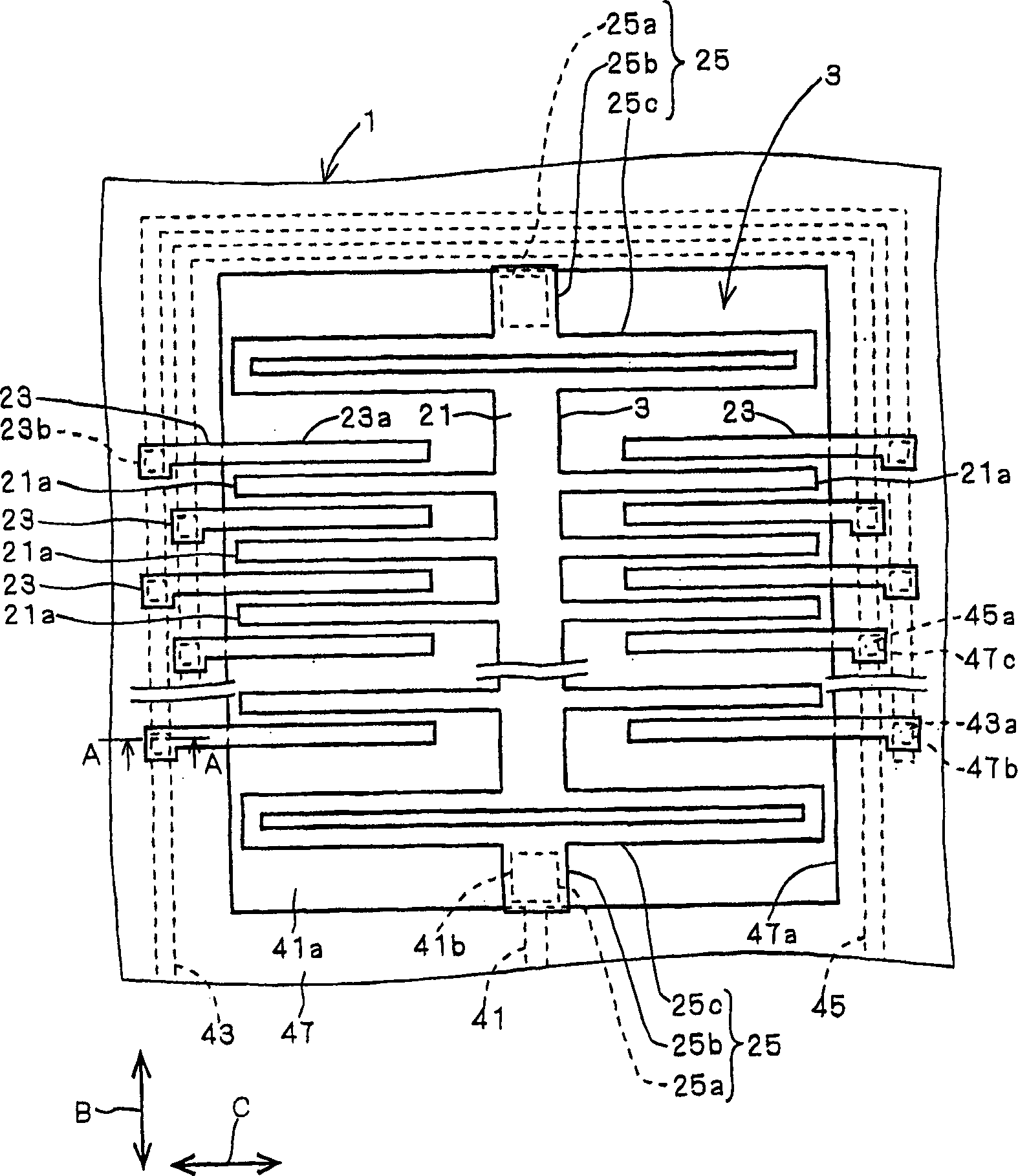

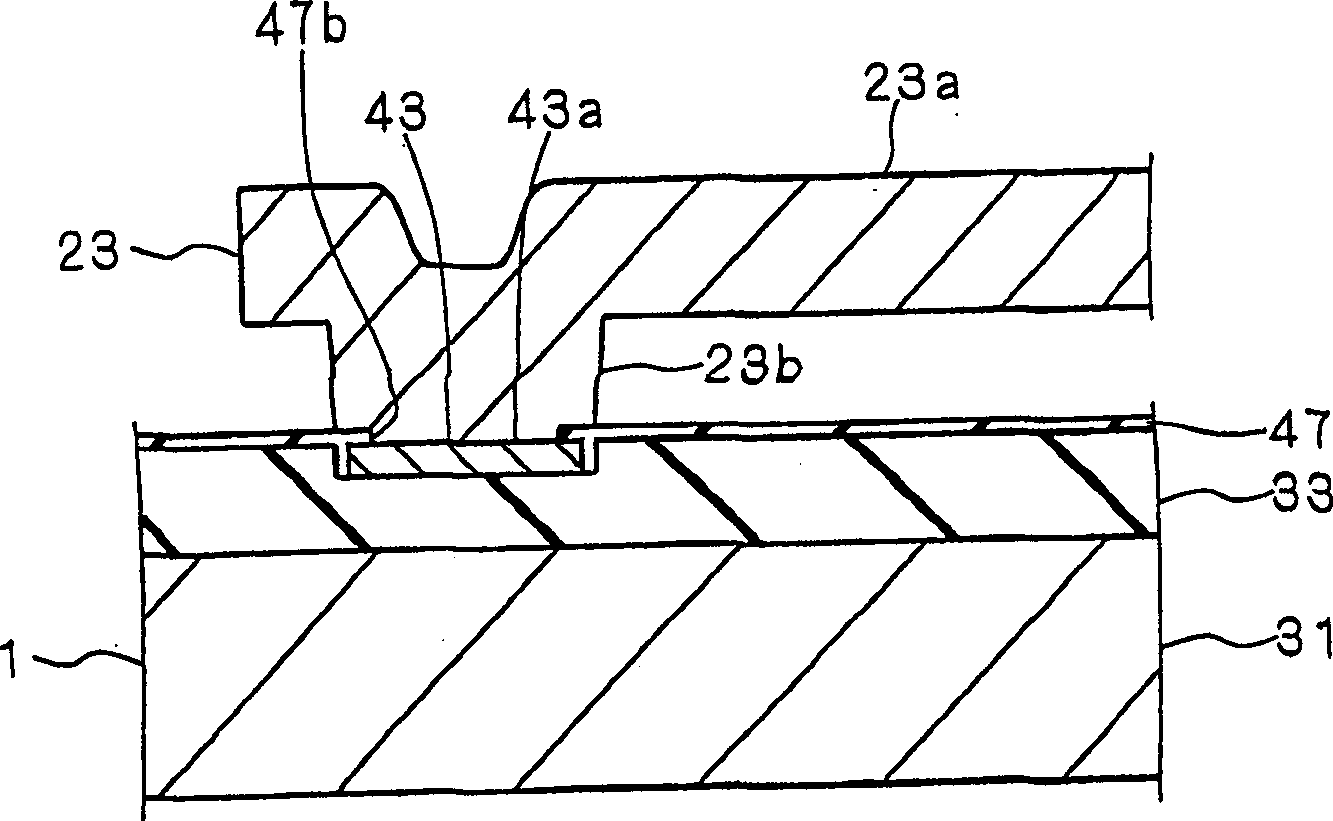

Semiconductor integrated circuit device

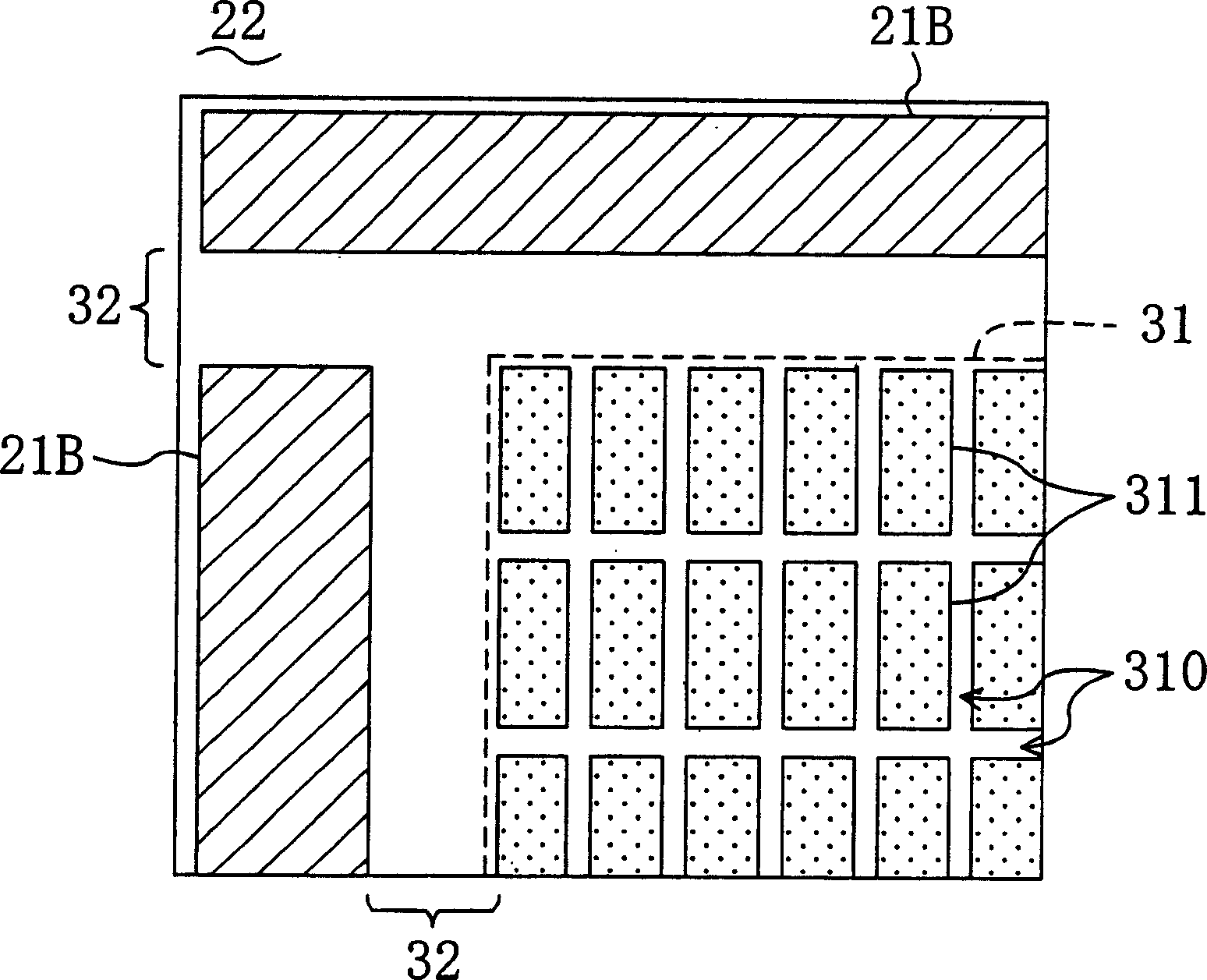

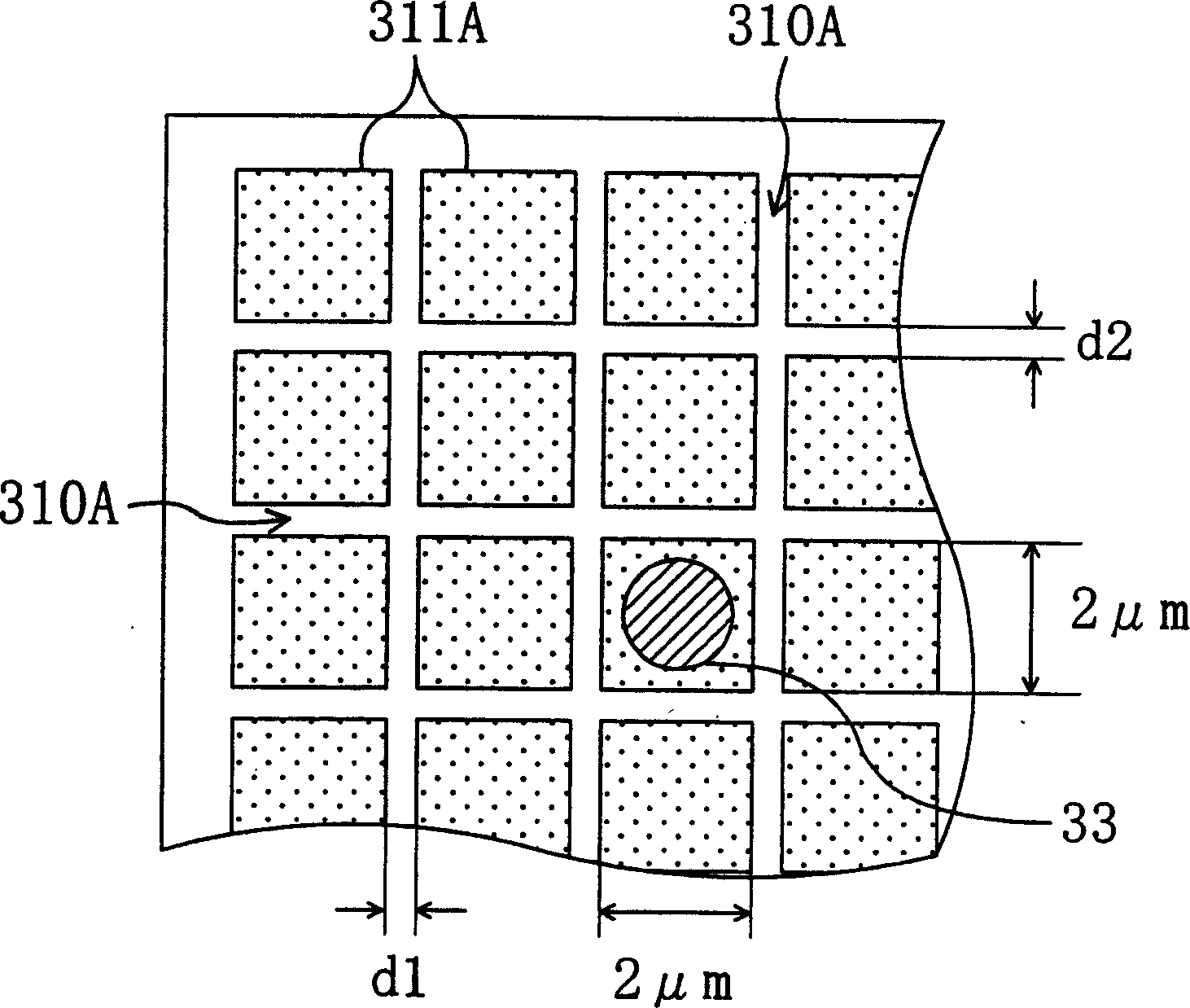

ActiveCN1574278AReduce stress differencePrevent changes in operating characteristicsTransistorSolid-state devicesEngineeringPeripheral

To reduce and moreover prevent change in the operation characteristic of semiconductor elements due to difference in stress generated at the end and the center by reducing difference of stress at the end and center of the active region of a device. A semiconductor element formed in the active region (311) included in a first element forming area (31a) (stress varying region 101) in a peripheral circuit forming area (31) is not electrically driven but only a semiconductor element in a second element forming area (31b) (stress stable region 102) is driven electrically. Therefore, the second element forming area (31b) in the peripheral circuit forming area (31) is isolated from the STI region (32) at the external side of element, and thereby is not easily influenced by a compressed stress.

Owner:PANNOVA SEMIC

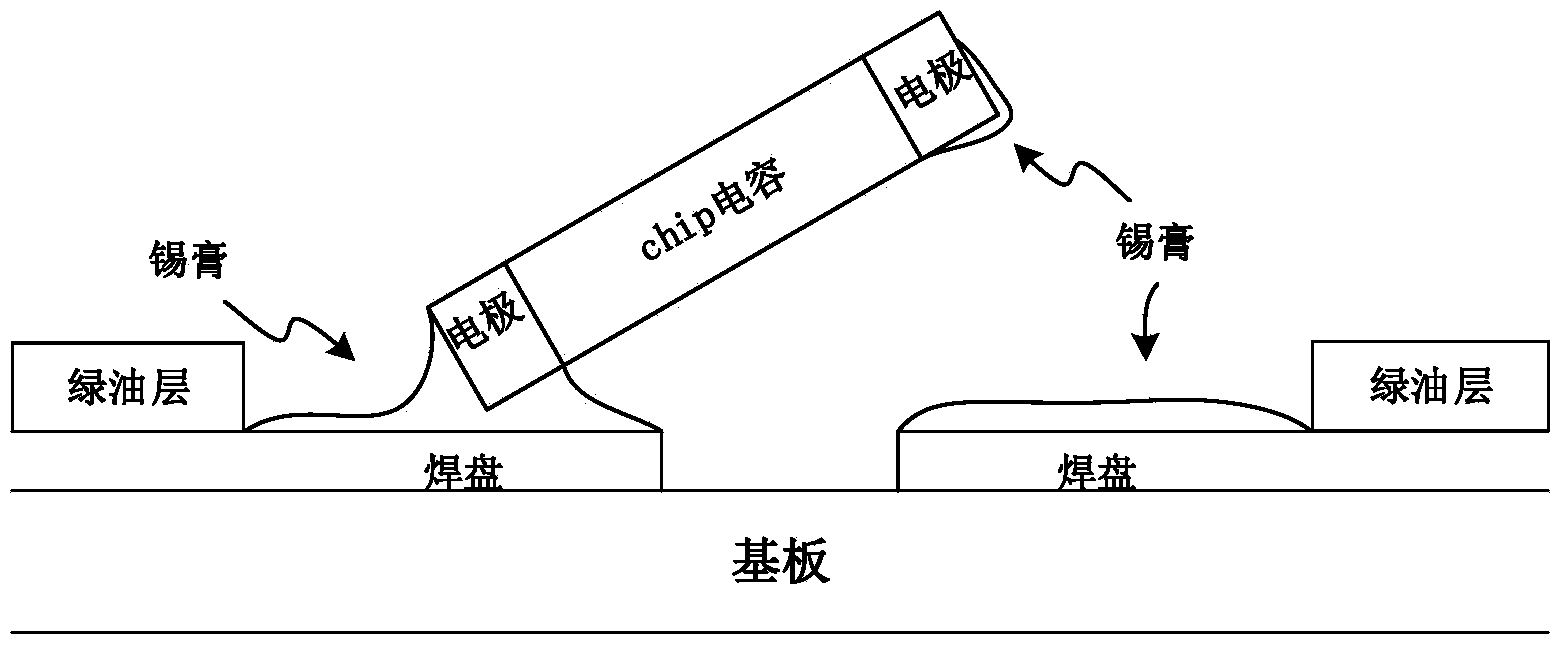

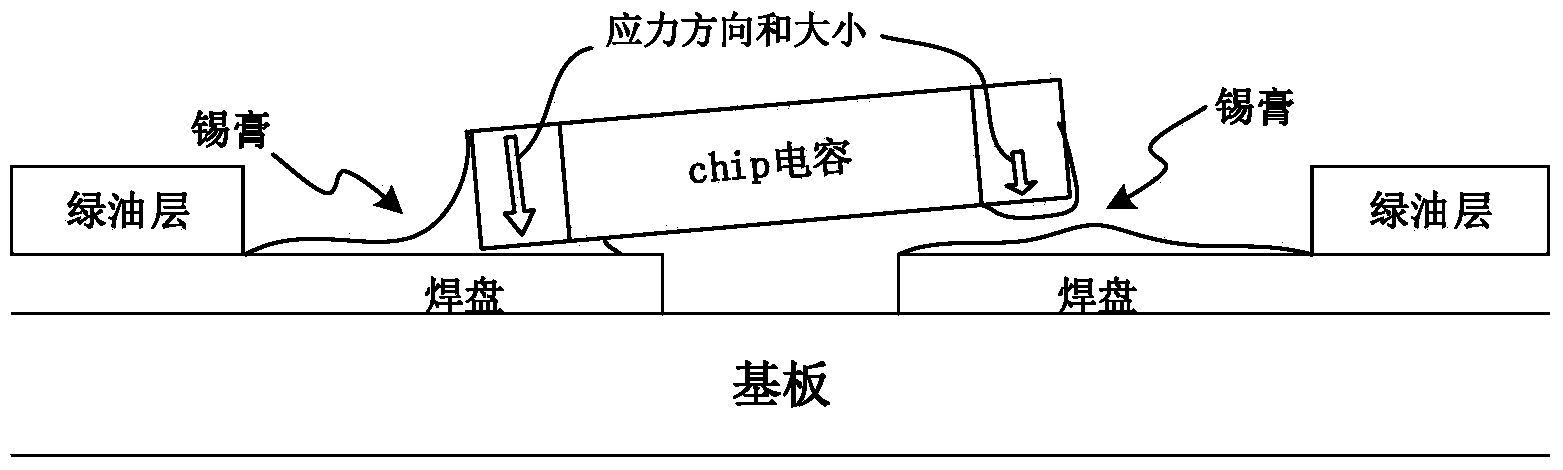

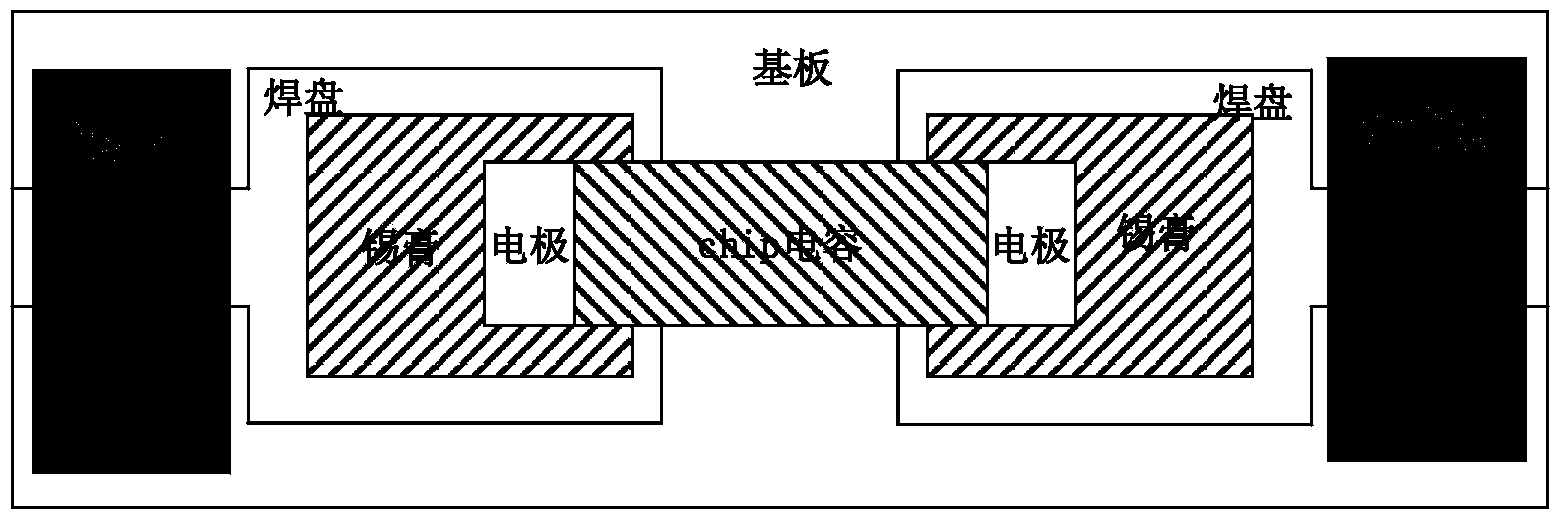

Bonding pad structure of SMT component, installation method and circuit board

InactiveCN104144563AReduce stress differenceAvoid bad monumentsPrinted circuit assemblingElectrical connection printed elementsResistEngineering

The invention provides a bonding pad structure of an SMT component, an installation method and a circuit board. The bonding pad structure comprises at least two bonding pads arranged on the surface of a substrate, the SMT component comprises a body, a first electrode and a second electrode, the first electrode and the second electrode are arranged at the two opposite ends of the body, each bonding pad is provided with a solder resist area used for limiting flowing of liquid tin, and the first electrode and the second electrode are welded to the two bonding pads respectively and are at least partially opposite to the solder resist areas respectively. According to the bonding pad structure of the SMT component and the installation method, the bonding pads are provided with the solder resist areas, the flowing direction of tin paste which becomes liquid after being melted is limited through the solder resist areas, the liquid tin moves towards the bonding pads or the electrodes and is attached to the bonding pads or the electrodes, and accordingly the amount of the liquid tin attached to the two opposite electrodes of the SMT component is almost the same, stress difference produced by attachment of the liquid tin between the two opposite electrodes is little and poor tombstoning phenomena are avoided.

Owner:GUANGDONG MIDEA GRP WUHU REFRIGERATING EQUIP CO LTD

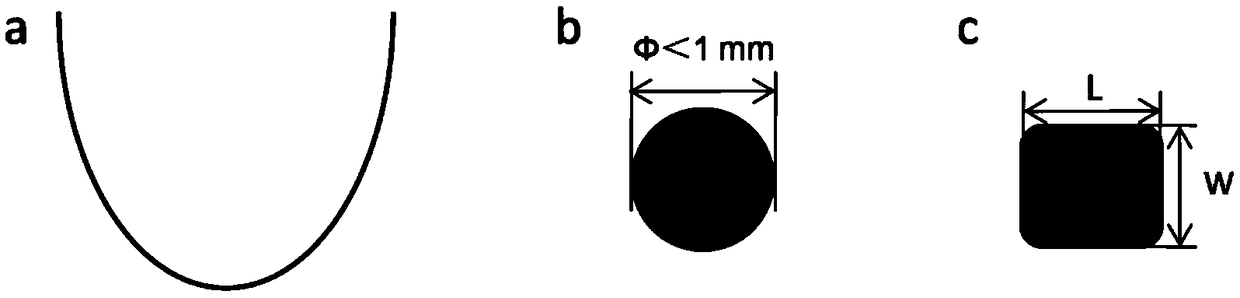

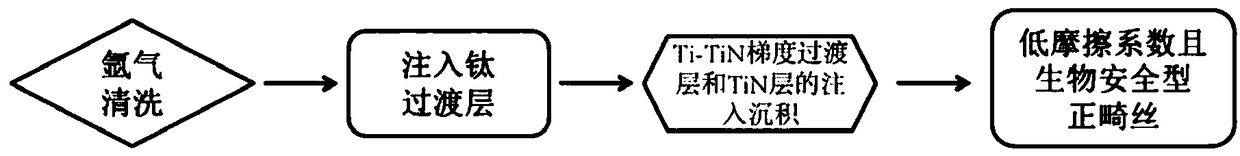

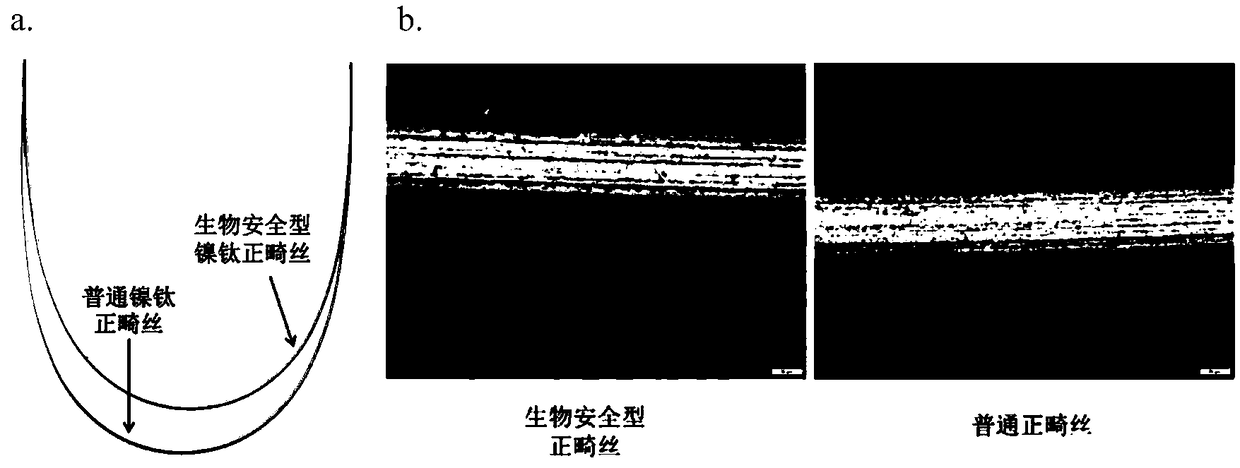

Nickel-titanium alloy medical equipment with surface coating and coating preparation method

ActiveCN108690967AShorten the timeLoss of phase transition temperatureArch wiresVacuum evaporation coatingMedical equipmentTitanium nitride

The invention discloses a method for preparing a surface coating of nickel-titanium alloy medical equipment. The method comprises the following steps that (1) impulse negative bias is loaded, and titanium ions are injected, so that a titanium transition layer is formed; and (2) under the condition that impulse negative bias and titanium injection are kept, nitrogen is pumped in with flow being instep increase from 0 to 20 sccm, a titanium-titanium nitride gradient transition layer is formed, and finally a pure titanium nitride layer is formed. The invention further discloses the nickel-titanium alloy medical equipment with the surface coating. The surface coating comprises the titanium transition layer, the titanium-titanium nitride gradient transition layer and the pure titanium nitridelayer from inside to outside; and content of titanium nitride is evenly increased in a gradient mode in the titanium-titanium nitride gradient transition layer.

Owner:CHINA MOREFOUND TECH LTD SHENZHEN

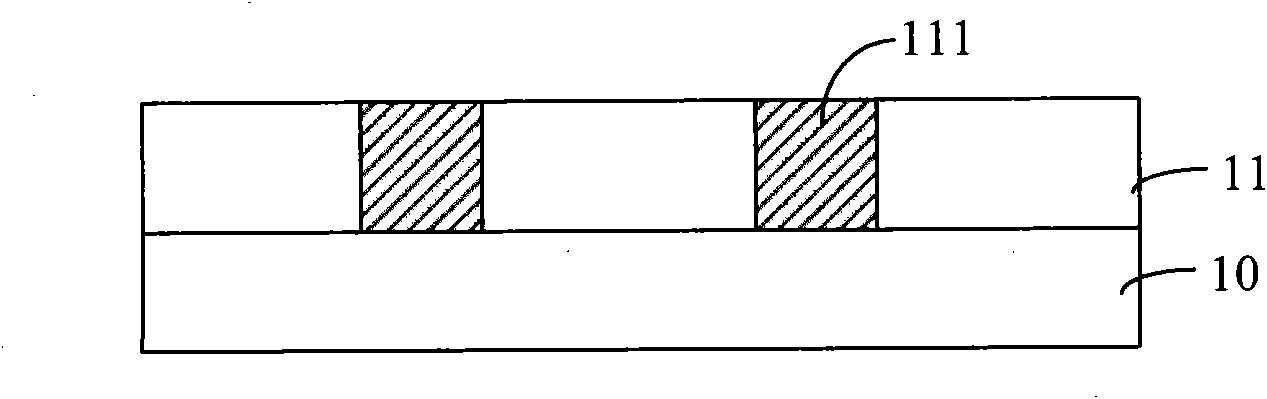

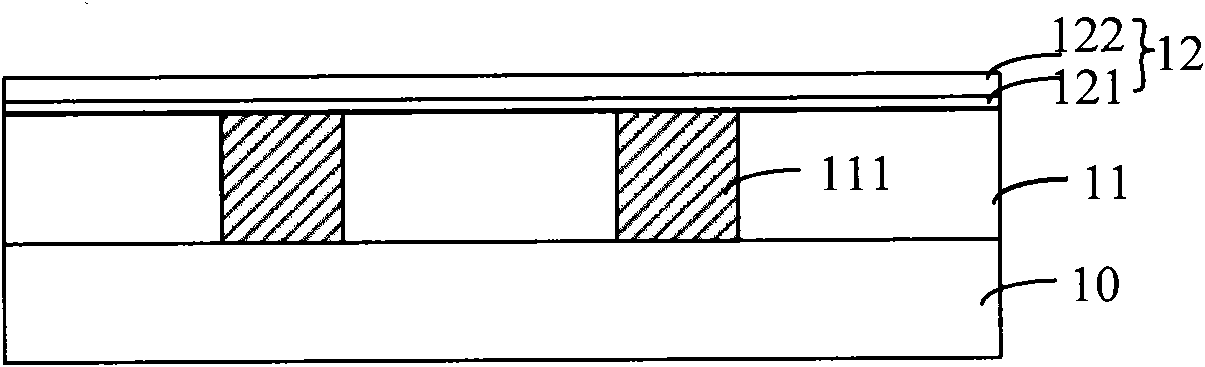

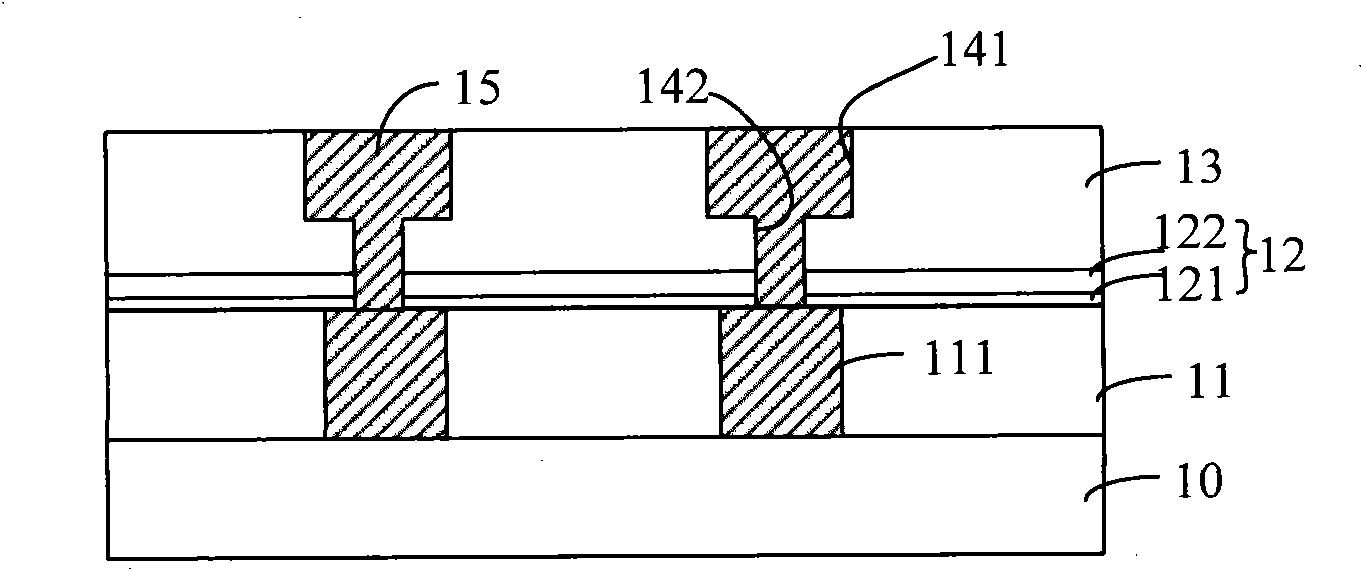

Method for forming dual damascene structure and semiconductor device

ActiveCN102468218AReduce stress differenceImprove adhesionSemiconductor/solid-state device detailsSolid-state devicesInterconnectionDielectric layer

A method for forming a dual damascene structure and a semiconductor device are disclosed. The method comprises the following steps: providing a substrate, wherein a first dielectric layer and a nitrating silicon carbide layer are successively formed on the substrate; forming a stress buffer layer on the nitrating silicon carbide layer; forming a second dielectric layer on the stress buffer layer, wherein a dielectric constant of the second dielectric layer is less than 3.5; etching the second dielectric layer, the stress buffer layer and the nitrating silicon carbide layer so as to form an interconnection groove and an interconnection through hole; filling metal in the interconnection groove and an interconnection through hole so as to form the dual damascene structure. By using the method and the device of the invention, the second dielectric layer and the nitrating silicon carbide layer can not generate spalling.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP

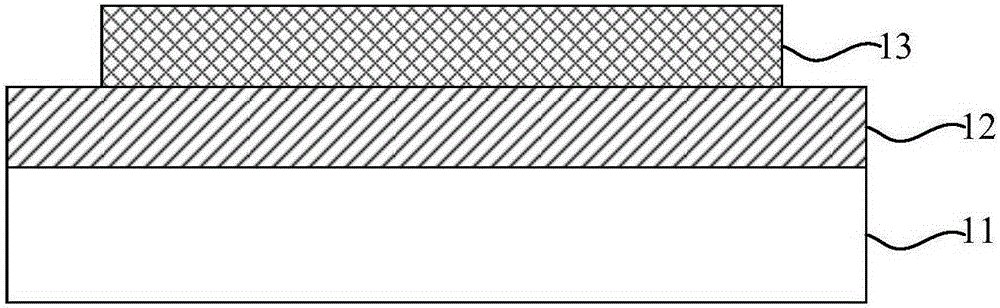

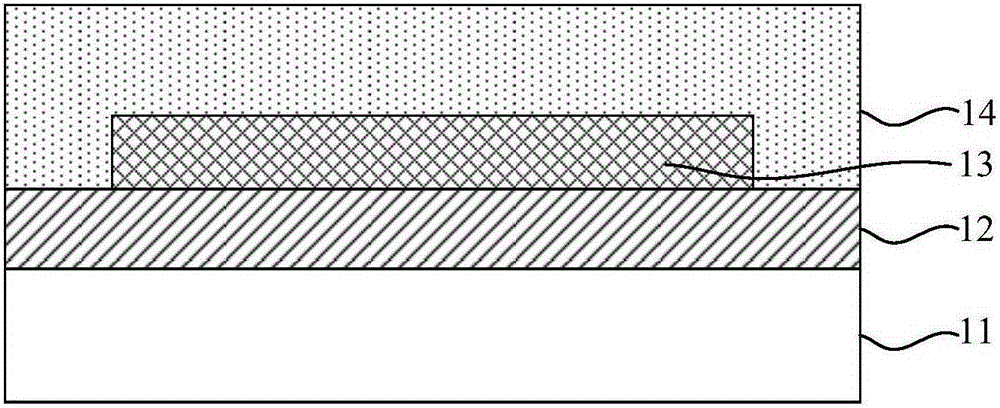

Semiconductor device and preparation method thereof

ActiveCN106548941AImprove yieldImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectrical conductorDielectric layer

The invention discloses a semiconductor device and a preparation method thereof. The preparation method comprises the following steps: providing a semiconductor substrate; forming a dielectric layer and a stress buffer layer on the semiconductor substrate in turn; etching the dielectric layer and the stress buffer layer; depositing a first metal layer; etching the first metal layer, and then carrying out an annealing process; and preparing a passivation layer on the first metal layer to form a semiconductor device. The stress coefficient of the stress buffer layer is between the stress coefficient of the first metal layer and the stress coefficient of the dielectric layer. It is observed that the stress buffer layer is arranged between the first metal layer and the dielectric layer. As the stress coefficient of the stress buffer layer is between the stress coefficient of the first metal layer and the stress coefficient of the dielectric layer, the stress buffer layer can effectively buffer the stress difference produced between the first metal layer and the dielectric layer in the annealing process. Therefore, defects such as metal loss caused by annealing can be avoided effectively, and the yield and performance of the semiconductor device are improved.

Owner:FOUNDER MICROELECTRONICS INT

Casting process of anti-heat-crack vermicular graphite cast iron brake disc

InactiveCN109306430AEliminate internal stressUniform coolingFoundry mouldsFoundry coresHeat resistanceGraphite

The invention provides a casting process of an anti-heat-crack vermicular graphite cast iron brake disc, and relates to the technical field of vermicular graphite cast iron machining. The casting process of the anti-heat-crack vermicular graphite cast iron brake disc mainly comprises the steps of high-temperature heat melting, purification detection, remelting, vermicular inoculation, sand box preheating, rapid casting, staged cooling, cleaning and polishing, and the like. By adoption of the casting process of the anti-heat-crack vermicular graphite cast iron brake disc, the defects of the prior art are overcome, and the wear resistance and corrosion resistance of traditional vermicular graphite cast iron are effectively ensured; and in addition, heat cracks of the brake disc are effectively prevented, the stability of the brake disc is improved, and the brake disc have efficient heat resistance and fatigue resistance.

Owner:ANHUI DATIAN CASTING

Supporting plate and display device

ActiveCN113793554AReduce weightReduce rigidityIdentification meansPhotovoltaic energy generationStress concentrationDisplay device

The embodiment of the invention discloses a supporting plate and a display device. The supporting plate is characterized in that a plurality of through holes are formed in a first region (namely a bending region), and a plurality of first grooves which are distributed in a first surface of a supporting plate body at intervals and a plurality of second grooves which are distributed in a second surface of the supporting plate body at intervals are formed in the transition region; and a stress difference between the first region and the second region(the supporting region) can be reduced so that stress generated during bending is distributed more uniformly, the problem of stress concentration at the junction of the bending region and the supporting region in the prior art can be effectively solved, cracks are prevented from being generated at the joint of the bendingregion and the supporting region, and the supporting piece is effectively prevented from being broken. According to the scheme, the weight of the supporting plate can be reduced, the rigidity of the supporting plate is reduced, the bending capacity of the supporting plate is improved, and therefore the reliability of the supporting plate is improved.

Owner:BOE TECH GRP CO LTD +1

Depth detection device for water conservancy and hydropower

InactiveCN113819975AControl lifting speedImprove conversionMachines/enginesLevel indicatorsGear wheelElectric machine

The invention belongs to the technical field of detection devices and particularly relates to a depth detection device for water conservancy and hydropower. The device comprises a main body, wherein supporting blocks for supporting a roller are arranged at an upper end of the main body, the supporting blocks are connected through rotating shafts, and the rotating shafts of the supporting blocks are sleeved with the roller for sleeving a rope; connecting blocks for limiting and sliding the T-shaped sliding rod are arranged at two ends of the supporting block, the roller is connected with a speed regulating box through a rope, a motor is arranged at the speed regulating box and drives a rack mechanism to rotate through a main shaft, and the rack mechanism drives a first transmission gear mechanism to rotate through a second transmission gear mechanism; the first transmission gear mechanism drives the third gear mechanism to rotate through a connecting shaft, and the rotating speed of the third gear mechanism is controlled through the motor, so the lifting speed of the rope is controlled, stress difference caused by uneven speed is reduced, conversion of the extending distance of the rope is effectively improved, and detection precision is improved.

Owner:ECONOMIC RES INST OF STATE GRID GANSU ELECTRIC POWER

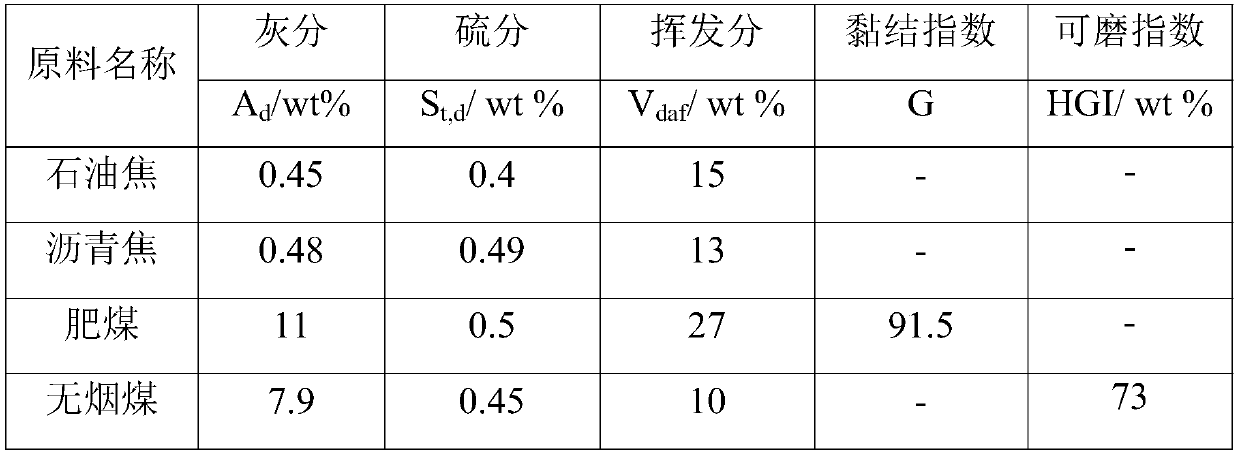

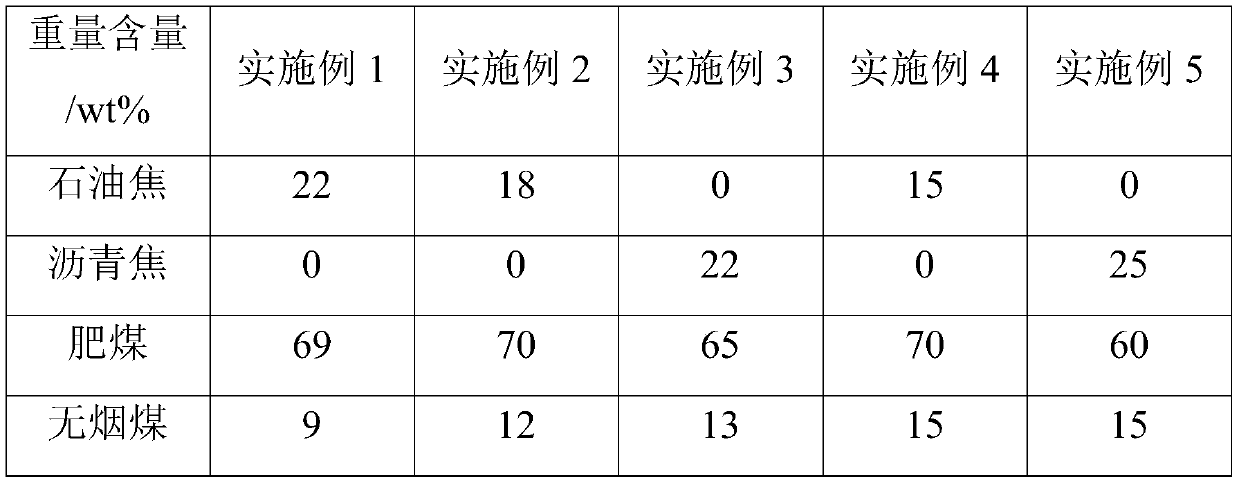

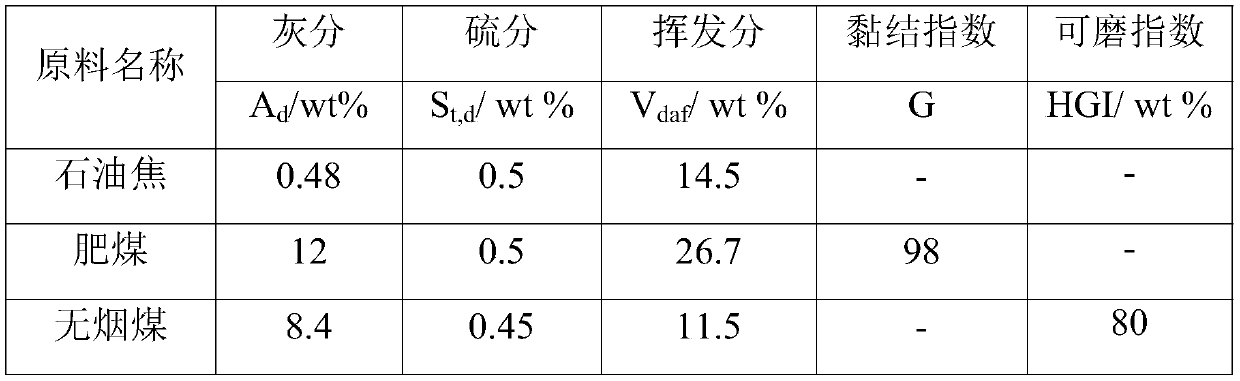

Formed coke and preparation method and application thereof

ActiveCN111575034AReduce stress differenceHigh heat intensitySpecial form destructive distillationBriquetteCoal chemical industry

The invention relates to the field of coal chemical industry, in particular to formed coke and a preparation method and application thereof. The preparation method of the formed coke comprises the following steps: (1) pressing mixed coal obtained by mixing raw materials to obtain formed coal; based on the total weight of the raw materials, the raw materials comprise 15-25 wt% of coke powder, 60-70wt% of fat coal and 5-15 wt% of anthracite; and (2) putting the formed coal into a coke oven at room temperature, heating the coke oven from room temperature to 1000-1200 DEG C at a rate of 6-10 DEGC / h, and carrying out destructive distillation at 1000-1200 DEG C for 380-480 h to obtain the formed coke. The formed coke obtained in the invention has the advantages of few internal cracks, large lumpiness, high thermal strength and low ash content so that the formed coke has a wide application prospect.

Owner:山西沁新能源集团股份有限公司

Dustproof structure, microphone packaging structure and electronic equipment

PendingCN111131985AAlleviate stress differenceAvoid wrinklesElectrostatic transducer microphonesMicrophoneMesh grid

Owner:WEIFANG GOERTEK MICROELECTRONICS CO LTD

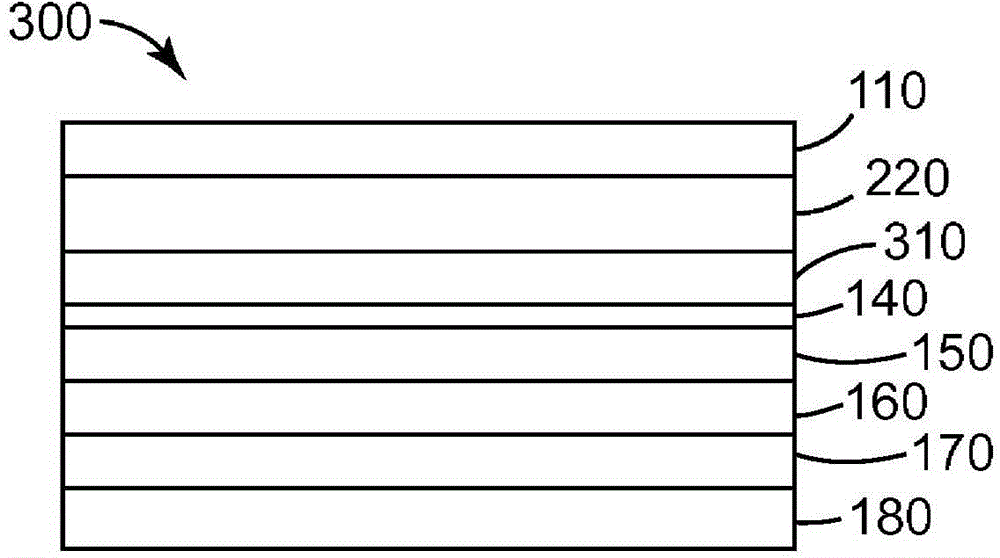

Durable solar mirror films

ActiveCN104470713AAdditional stress increasesExtend your lifeSolar heating energyMirrorsSpecular reflectionReflective layer

The present disclosure generally relates to durable solar mirror films, methods of making durable solar mirror films, and constructions including durable solar mirror films. In one embodiment, the present disclosure relates to a solar mirror film comprising: a multilayer optical film layer including having a coefficient of hygroscopic expansion of less than about 30 ppm per percent relative humidity; and a reflective layer having a coefficient of hygroscopic expansion.

Owner:3M INNOVATIVE PROPERTIES CO

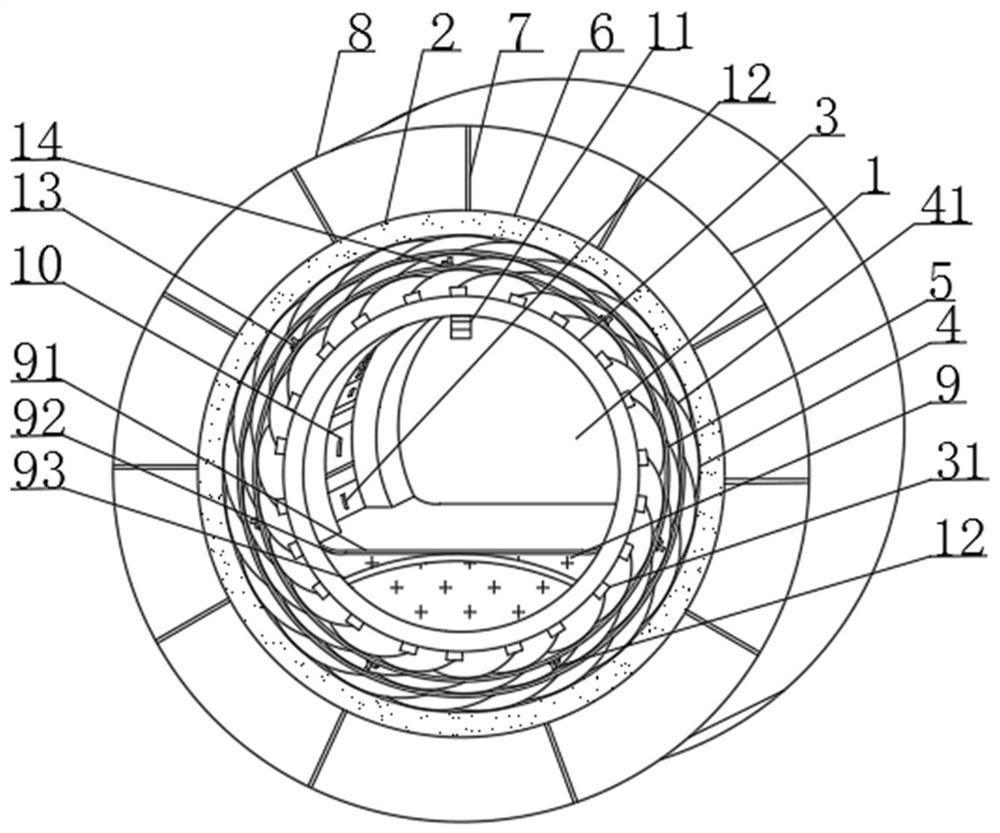

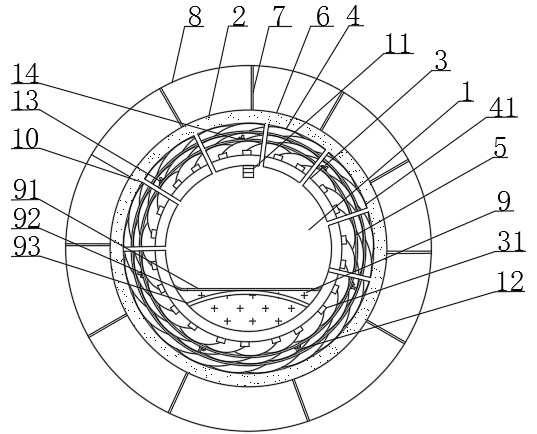

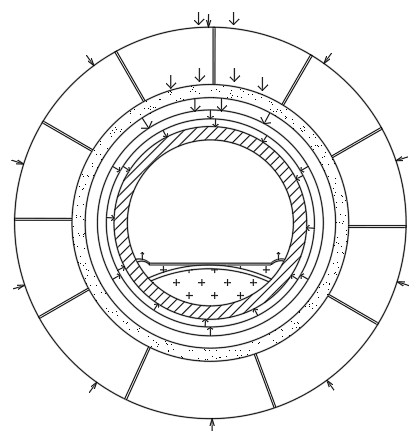

Rock burst pressure relief and danger relief method

ActiveCN113530566AIncrease internal stressReduce stress differenceMining devicesUnderground chambersSupporting systemEnergy absorption

The invention belongs to the technical field of coal mine underground roadway support, and particularly relates to a rock burst pressure relief and danger relief method. The method comprises a roadway bifurcation section, wherein an abdicating energy absorption support mechanism is arranged inside the roadway bifurcation section; a shallow surface surrounding rock anchor net support ring is built on the outer wall of the abdicating energy absorption support mechanism; the abdicating energy absorption support mechanism comprises an O-shaped steel shed frame, pressure decomposition pressure relief layers and pressure division toughness tubes; the pressure decomposition pressure relief layers and the pressure division toughness tubes are respectively provided with a plurality of layers and are distributed at intervals; the pressure decomposition pressure relief layer consists of a plurality of arc-shaped buffer pressure division steel plates in fish scale-shaped distribution; the impact energy abdicating absorption is realized through the arranged abdicating energy absorption support mechanism; the rock burst destructiveness is weakened; meanwhile, the arranged arc-shaped buffer pressure division steel plates are matched with the pressure division toughness tubes for dispersing the pressure to the whole O-shaped steel shed frame; the O-shaped steel shed frame is sufficiently utilized; and the whole support system collapse due to local instability of the support system is avoided.

Owner:HUAIBEI PINGYUAN SOFTROCK SUPPORTING ENG TECH

Display backboard, manufacturing method thereof and display device

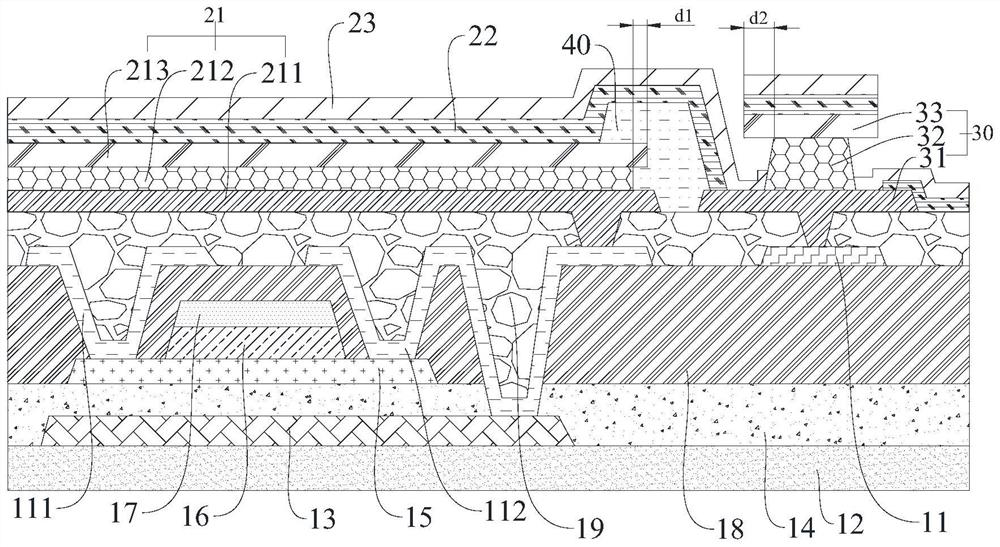

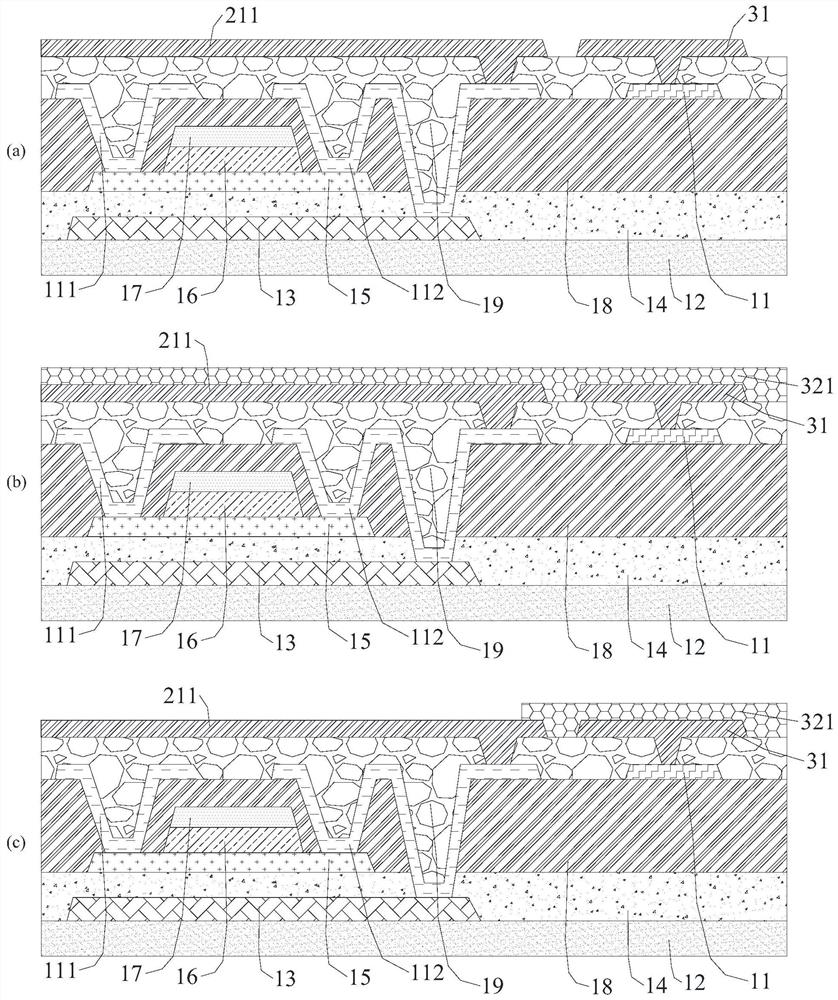

PendingCN114709244ASolve the problem of large pressure dropImprove stabilitySolid-state devicesSemiconductor/solid-state device manufacturingDisplay devicePhysics

The invention provides a display backboard, a manufacturing method thereof and a display device. In the display backboard, a light-emitting structure comprises a first electrode layer, a light-emitting layer and a second electrode layer, at least part of the light-emitting structure is located in an opening of a pixel definition layer, and the first electrode layer is arranged close to a substrate; the isolation structure is located on the side, away from the opening, of the pixel definition layer; one part of the second electrode layer extends to the side surface, close to the pixel definition layer, of the isolation structure from the opening of the pixel definition layer along the pixel definition layer through a gap between the pixel definition layer and the isolation structure, and the second electrode layer is electrically connected to the isolation structure; the light-emitting layer is not connected at the gap between the pixel definition layer and the isolation structure; in the direction perpendicular to the substrate, the height of the isolation structure is larger than that of the first electrode layer. The thickness of the first electrode layer is small, the problem that a metal film layer of the reflection first electrode layer swells or falls off can be smoothly solved, and then the display effect and the product yield of the product are remarkably improved.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

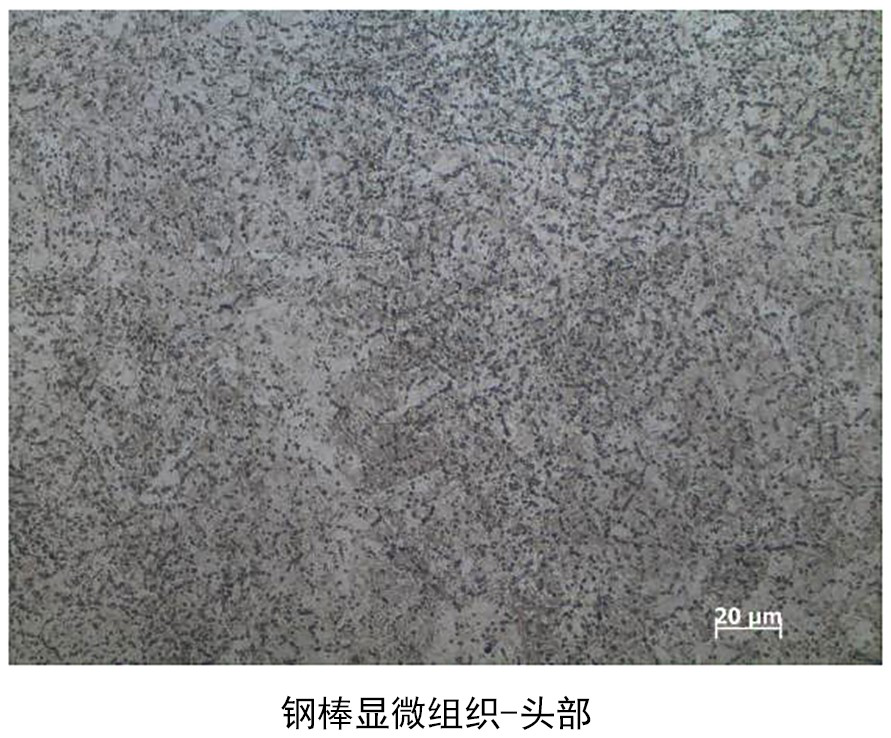

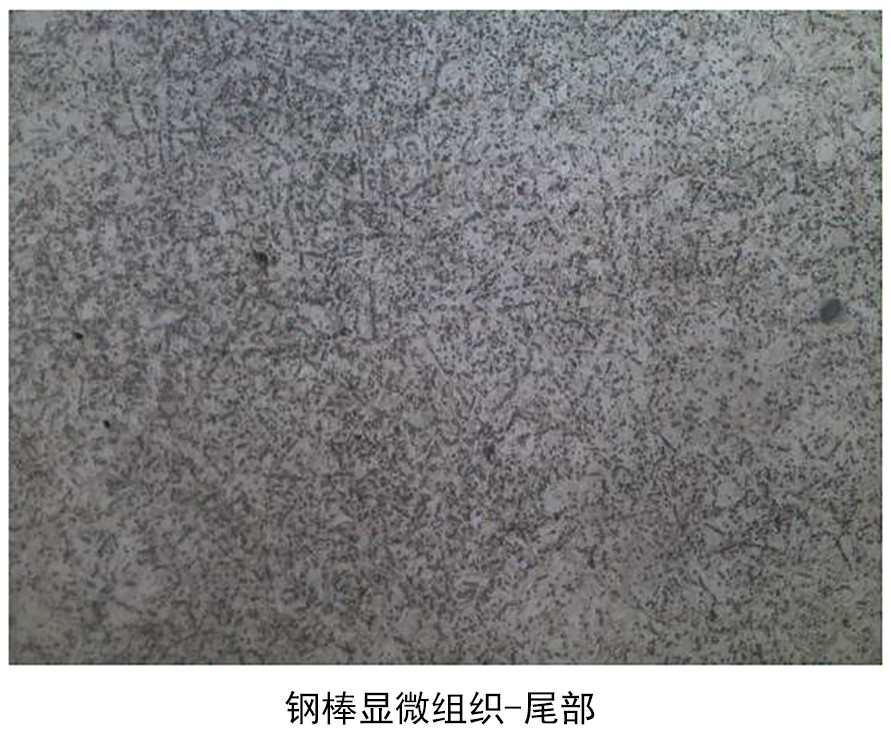

Forging production process of 30Cr15MoN high-nitrogen martensitic stainless steel bar

ActiveCN112496216AAvoid plastic dropUniform tissueMetal-working apparatusTemperature controlMartensitic stainless steel

The invention belongs to the technical field of metal pressure machining processes, and particularly discloses a forging production process of a 30Cr15MoN high-nitrogen martensitic stainless steel bar, which comprises the steps of electroslag remelting, heating, forging preparation, forging and red annealing. According to the method, the problems that 30Cr15MoN steel in an existing forging processis prone to cracking and uneven in structure are effectively solved by combining the optimized forging mode that drawing is directly conducted without upsetting and an eight-edge four-method is adopted for drawing with strict temperature control, meanwhile, the forging heating number is reduced, and the production efficiency is improved; The steel bar forged through the method is excellent in performance in all aspects and can meet the material requirements of high-precision sharp-end projects.

Owner:DEQING TIANMA BEARING CO LTD

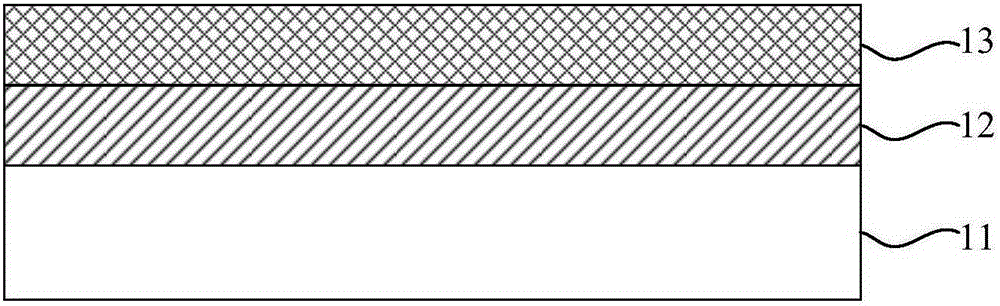

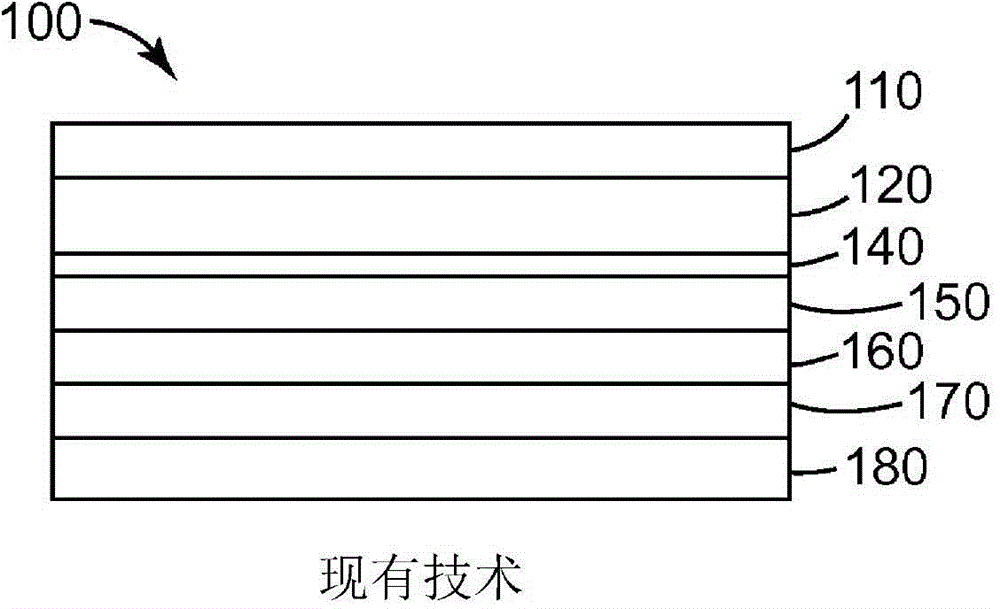

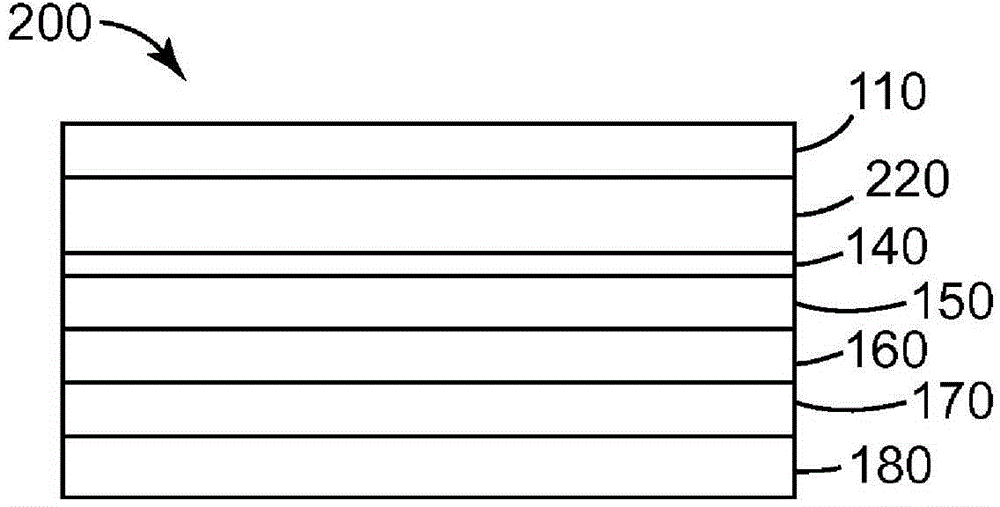

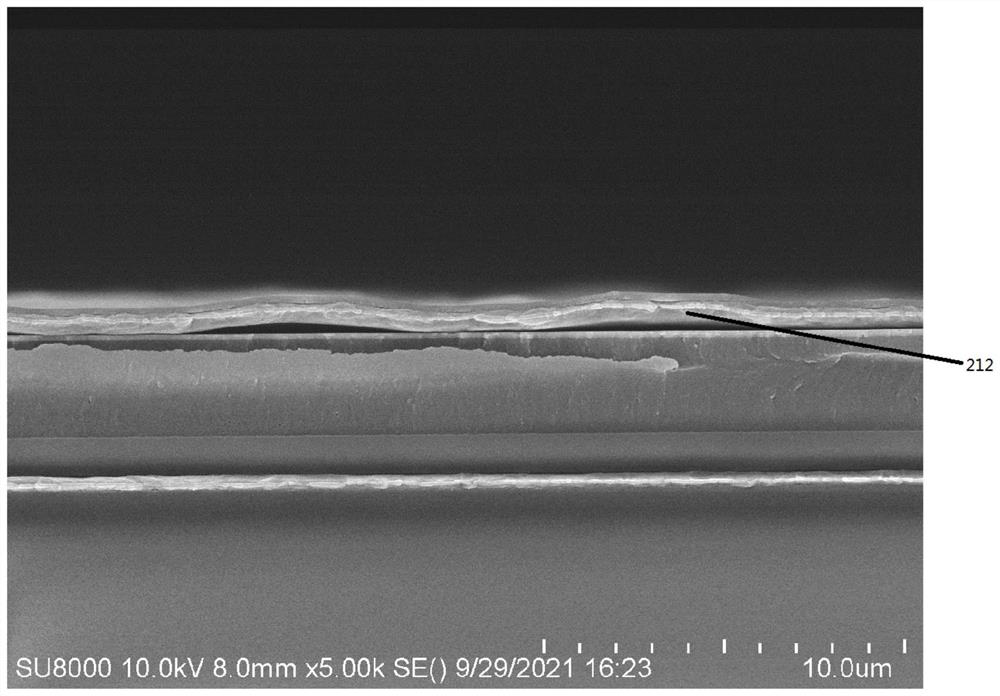

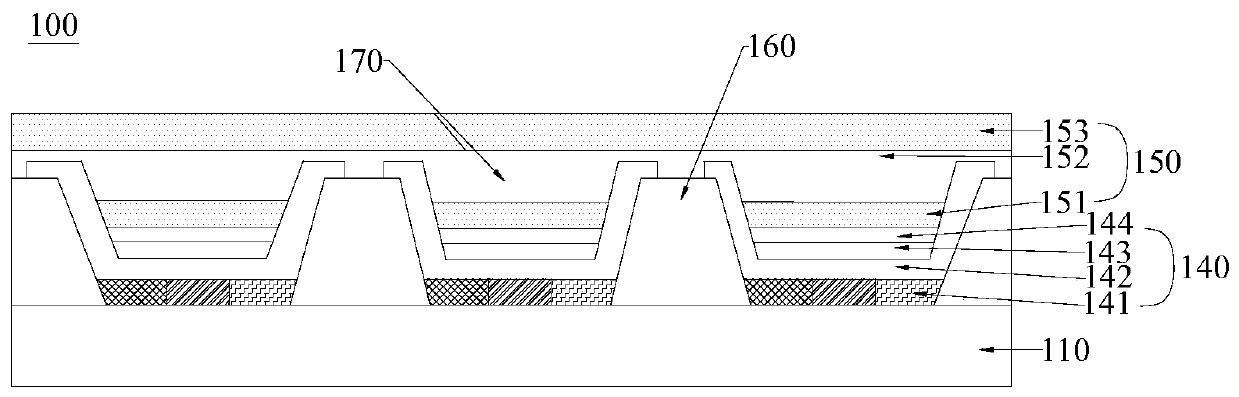

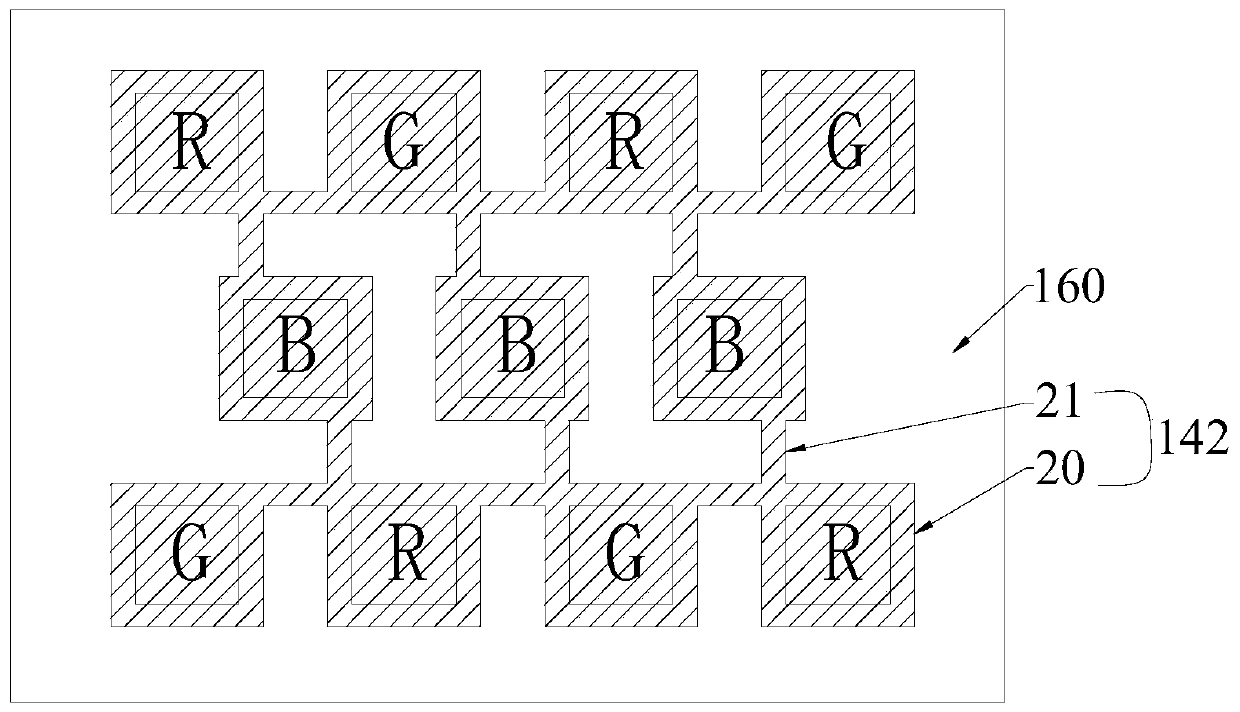

Flexible display panel and preparation method thereof, and flexible display device

ActiveCN110581226AReduce stress differenceImprove adhesionFinal product manufactureSolid-state devicesOrganic electroluminescenceFlexible display

The invention discloses a flexible display panel and a preparation method thereof, and a flexible display device. The display panel includes a flexible substrate, a pixel definition layer which is arranged on the flexible substrate and is provided with a plurality of openings internally provided with light emitting structure layers, and a film packaging layer, wherein the film packaging layer comprises a first inorganic packaging layer and a first organic packaging layer which are arranged in a stacked manner, the first inorganic packaging layer is located above the light emitting structure layers in the openings of the pixel definition layer, and the first organic packaging layer covers the pixel definition layer and the first inorganic packaging layer and is in direct contact with an upper surface of the pixel definition layer. The display panel is advantaged in that the stress between an organic electroluminescent device layer and the film packaging layer can be improved, so a problem that the film layers are easy to separate when the flexible display panel is bent is solved.

Owner:YUNGU GUAN TECH CO LTD

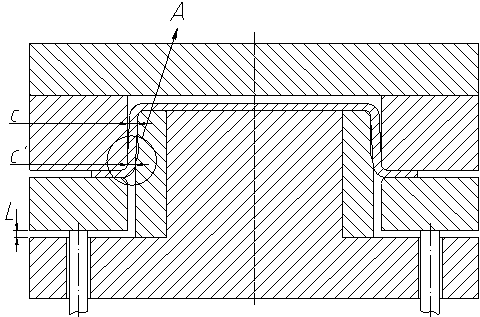

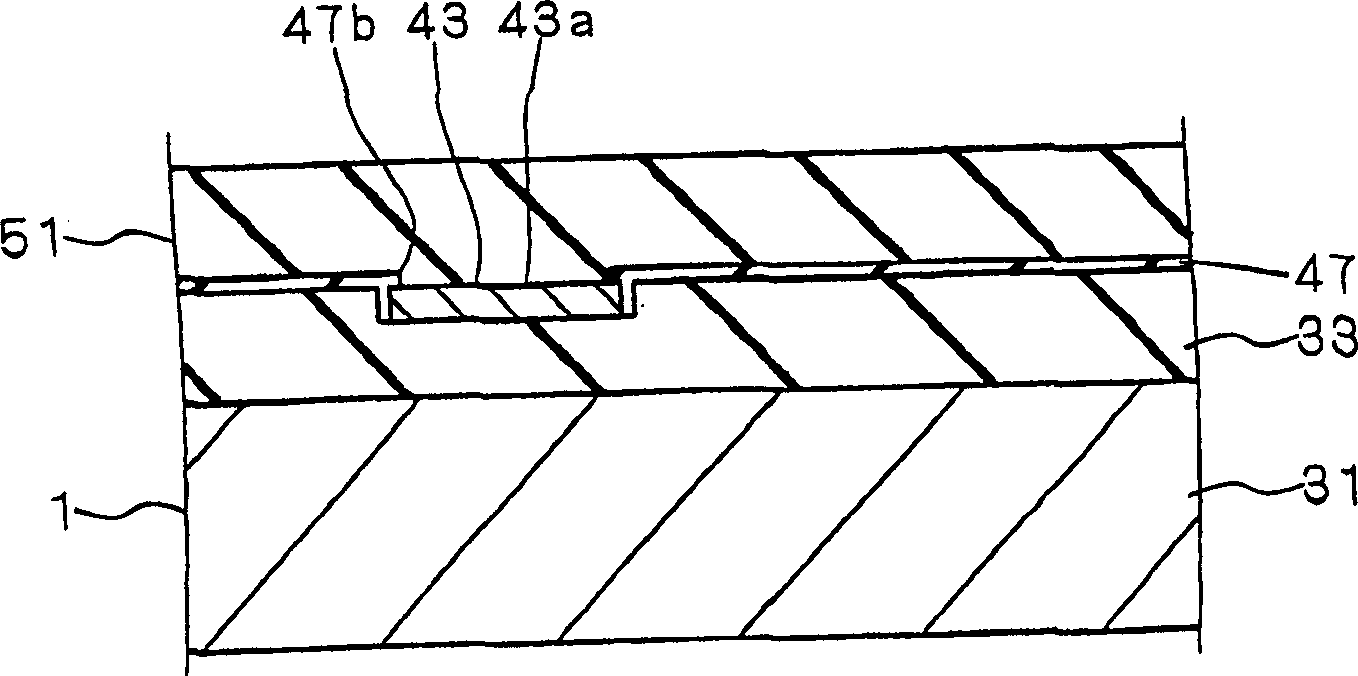

Method for manufacturing thin-film structure

InactiveCN1462482AImprove softeningReduce stress differenceAcceleration measurement using interia forcesSemiconductor/solid-state device manufacturingSemiconductorFilm structure

The present invention relates to a manufacturing method of a thin-film structural body which is formed by using a semiconductor processing technique, and an object thereof is to provide a manufacturing method of a thin-film structural body, capable of reducing a stress difference exerted between a sacrifice film and a substrate upon thermal shrinkage.In order to achieve this object, a sacrifice film (51), which is formed on a substrate (1), is formed by using a PSG film in which the concentration of phosphorus is set to a value which is greater than 3 mol %, and also smaller than 4 mol %. After a thin-film layer (53) has been formed thereon and after the thin-film layer (53) has been patterned, the sacrifice film (51) is removed by an etching process.

Owner:MITSUBISHI ELECTRIC CORP

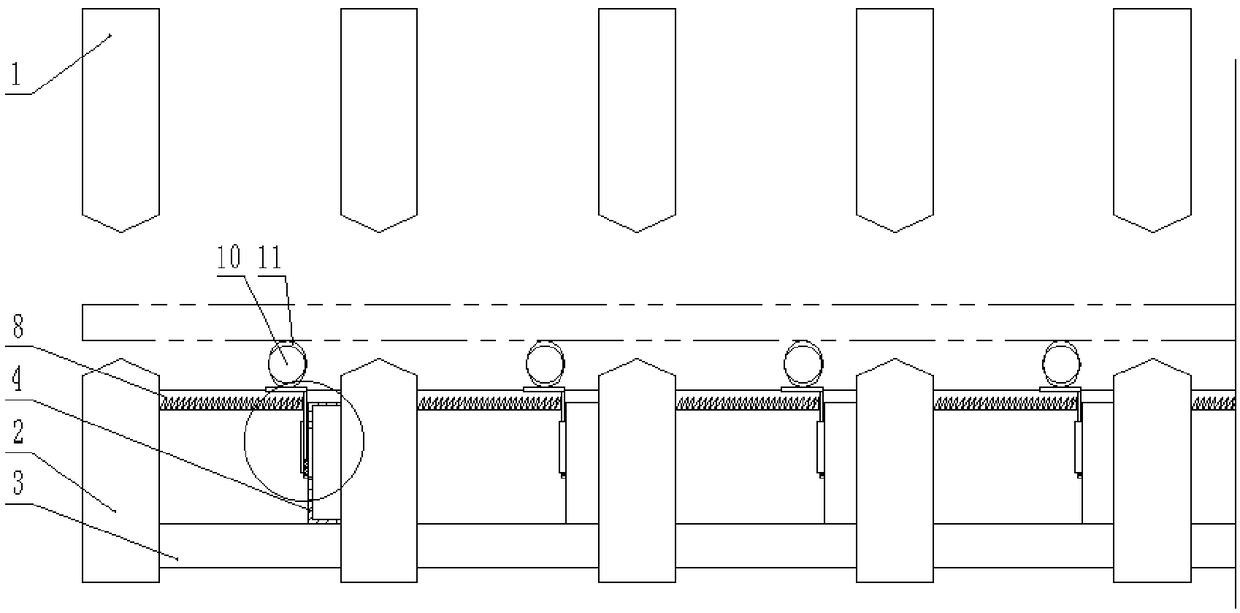

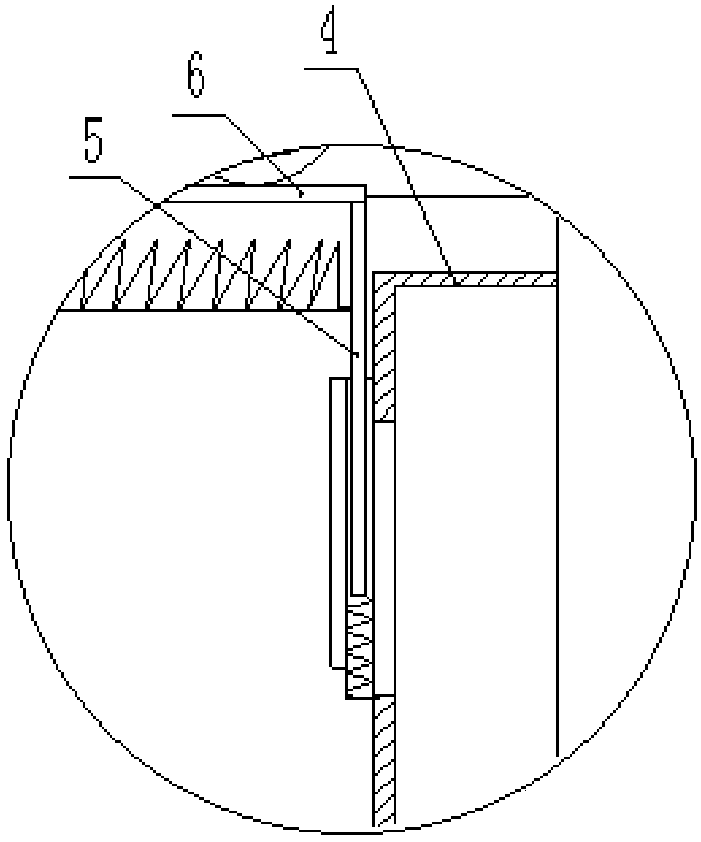

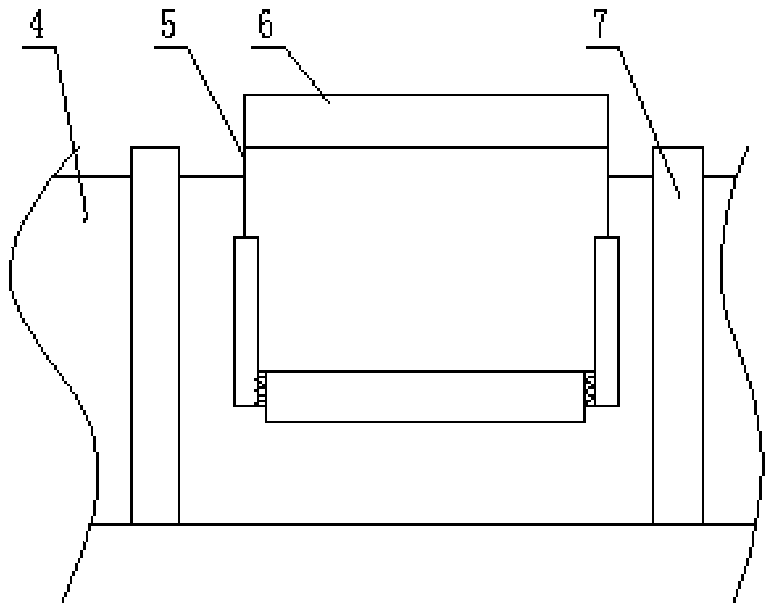

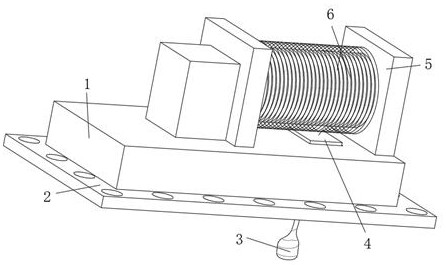

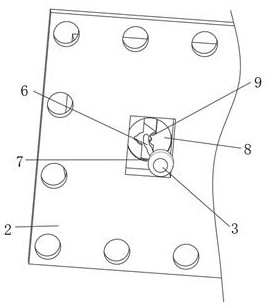

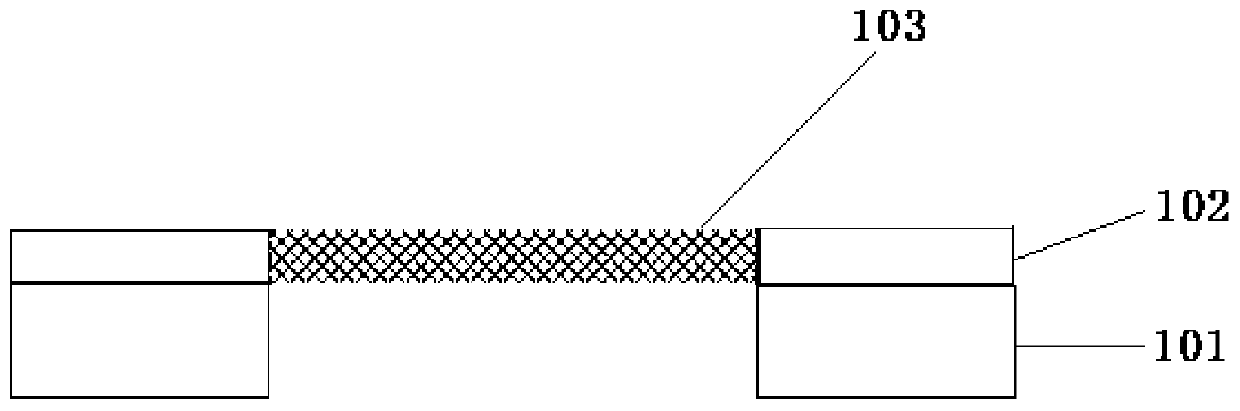

A stamping device for controlling the curling and rebounding of the side wall of a stamping part

The invention discloses a stamping part side wall curled rebounding control stamping device which comprises an upper die base, a concave die, a blank holder, a convex die and a lower die base from top to bottom, wherein the blank holder is in driving connection with a holder-on rod; the convex die is matched with the concave die; the upper die base is fixedly connected with the concave die and moves synchronously with the concave die; the convex die is fixedly connected with the lower die base; the convex die comprises a first stamping part and a second stamping part from top to bottom; the first stamping part and the second stamping part are in smooth transition by virtue of a transition curve part; a clearance between the outer contour of the side wall of the first stamping part and the side wall of the concave die is 1.2-1.6 times of the thickness of a to-be-stamped plate; a clearance between the outer contour of the side wall of the second stamping part and the side wall of the concave die 2 is 0.8-0.9 times of the thickness of the to-be-stamped plate; the projection length of the transition curve part in the stamping direction is 2-3 times of the thickness of the to-be-stamped plate. According to the stamping part side wall curled rebounding control stamping device, the die clearance is changed during a stamping process, so that the stress difference between inner and outer layers of a material is decreased, side wall curled rebounding of parts is effectively controlled, and the formation precision and quality of the parts are improved.

Owner:SOUTH CHINA UNIV OF TECH

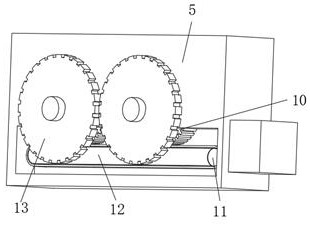

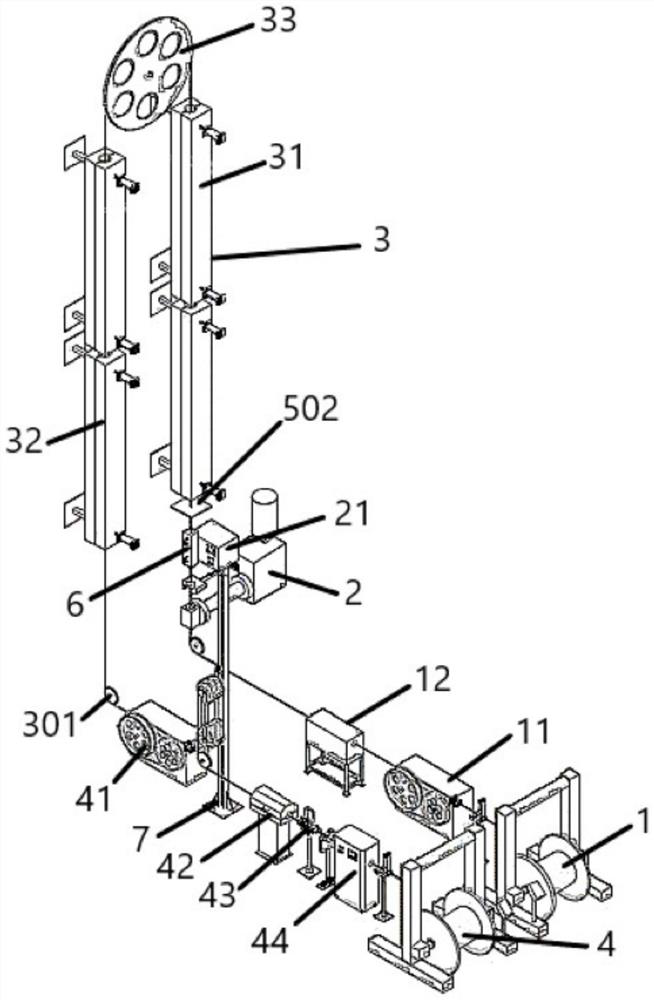

Vertical production line of cable for new energy electric vehicle

ActiveCN112309647AQuality improvementReduce stressDomestic articlesInsulating conductors/cablesProduction lineElectrical conductor

Disclosed is a vertical production line of cables for new energy electric vehicles. The vertical production line comprises a pay-off reel, a first traction machine, an extruder, a vulcanizing device,a second traction machine and a take-up reel which are installed in sequence, the vulcanizing device comprises an ascending vulcanizing section, a descending vulcanizing section and a reversing wheel,the ascending vulcanizing section and the descending vulcanizing section each comprise at least two vulcanizing pipes, each vulcanization pipe further comprises two vulcanization pipe units, and a preheater is installed between the ascending vulcanizing section and the extruder. According to the invention, the vulcanizing device is divided into the vertically arranged ascending vulcanizing section and descending vulcanizing section, so that rubber on a conductor does not generate an eccentric effect on the conductor under the action of gravity, the ascending vulcanizing section or descendingvulcanizing section is divided into a plurality of vulcanizing pipes arranged at intervals, the heating temperature of different vulcanizing pipes is controlled, and adjustment is carried out according to different vulcanization states of different parts, so that the overall vulcanization quality and vulcanization efficiency of cables are improved, and the forming quality of the cables is improved.

Owner:WUXI XINHONGYE WIRE & CABLE

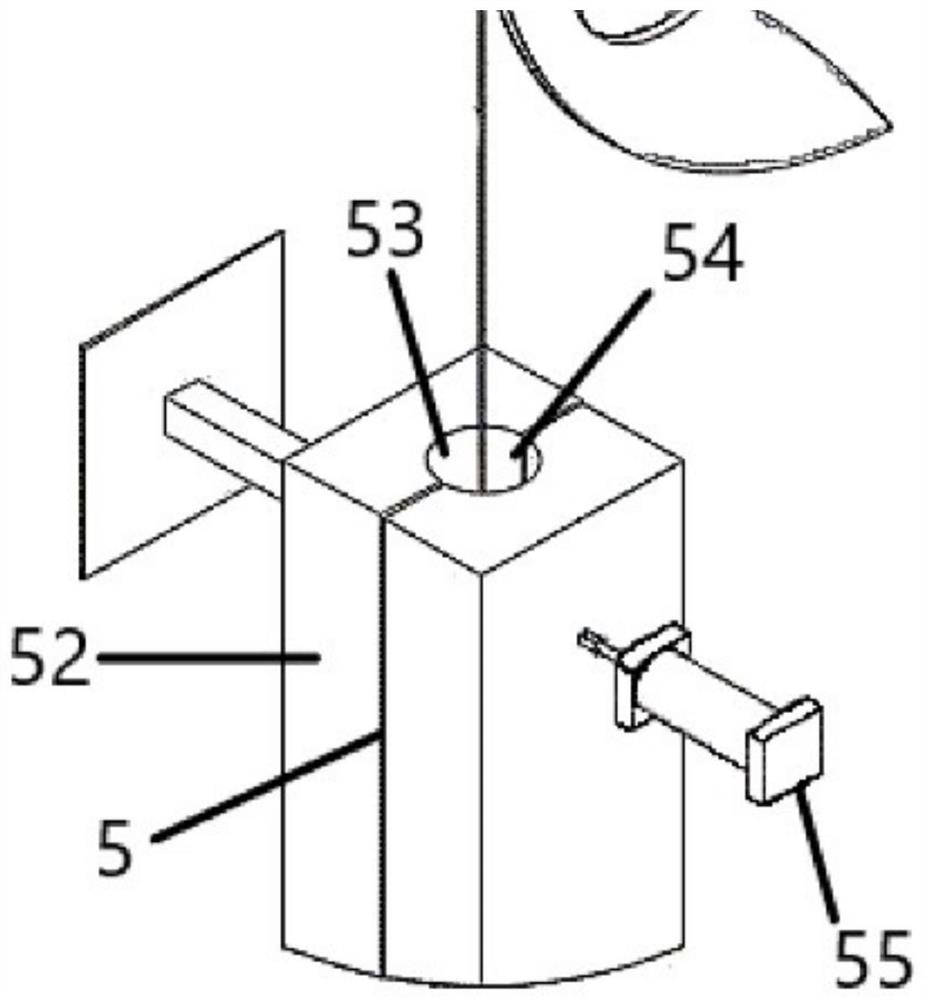

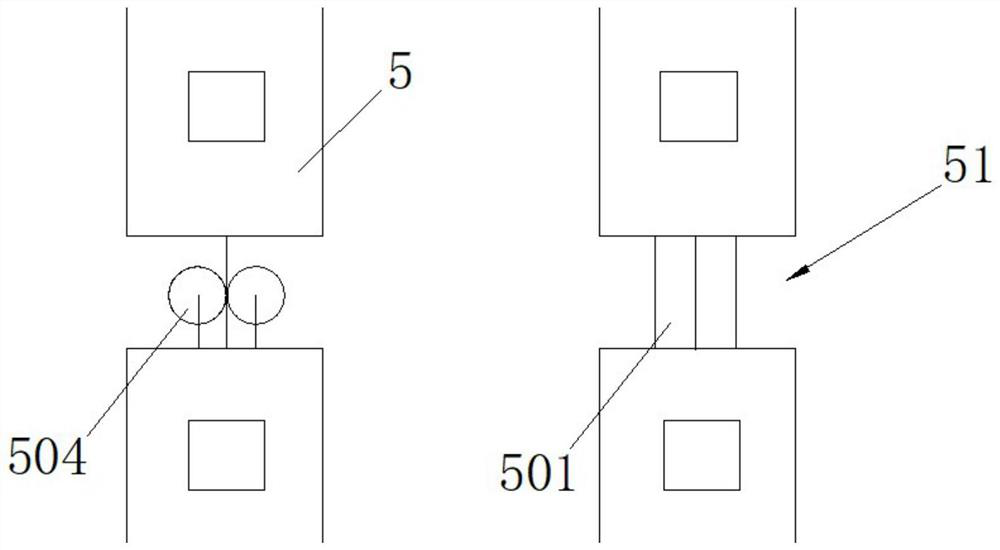

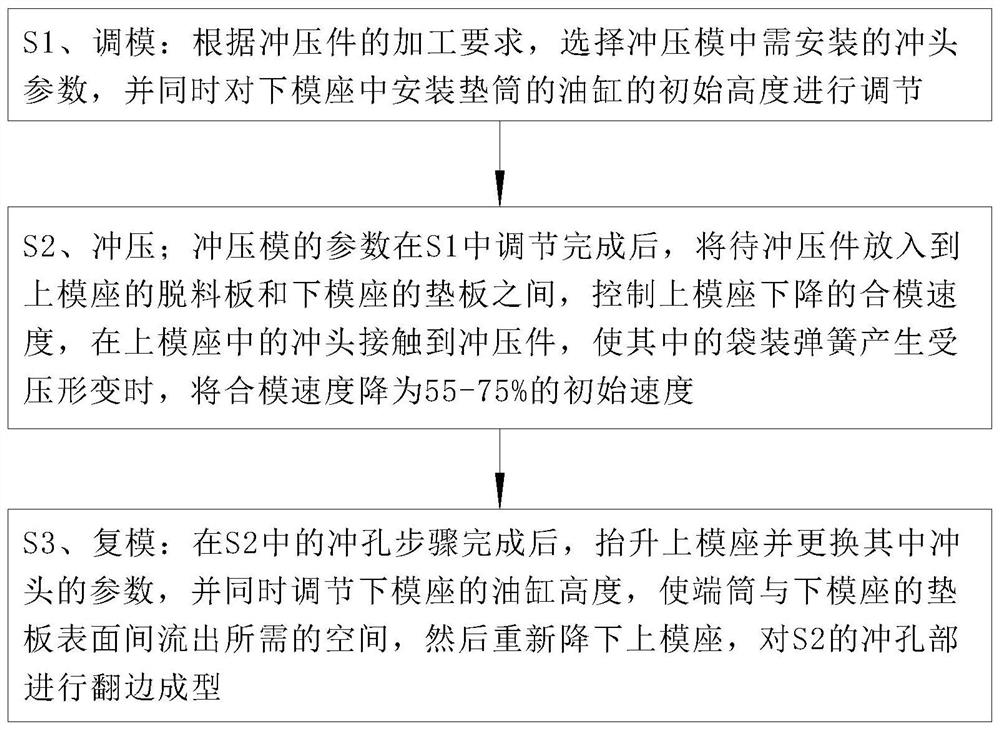

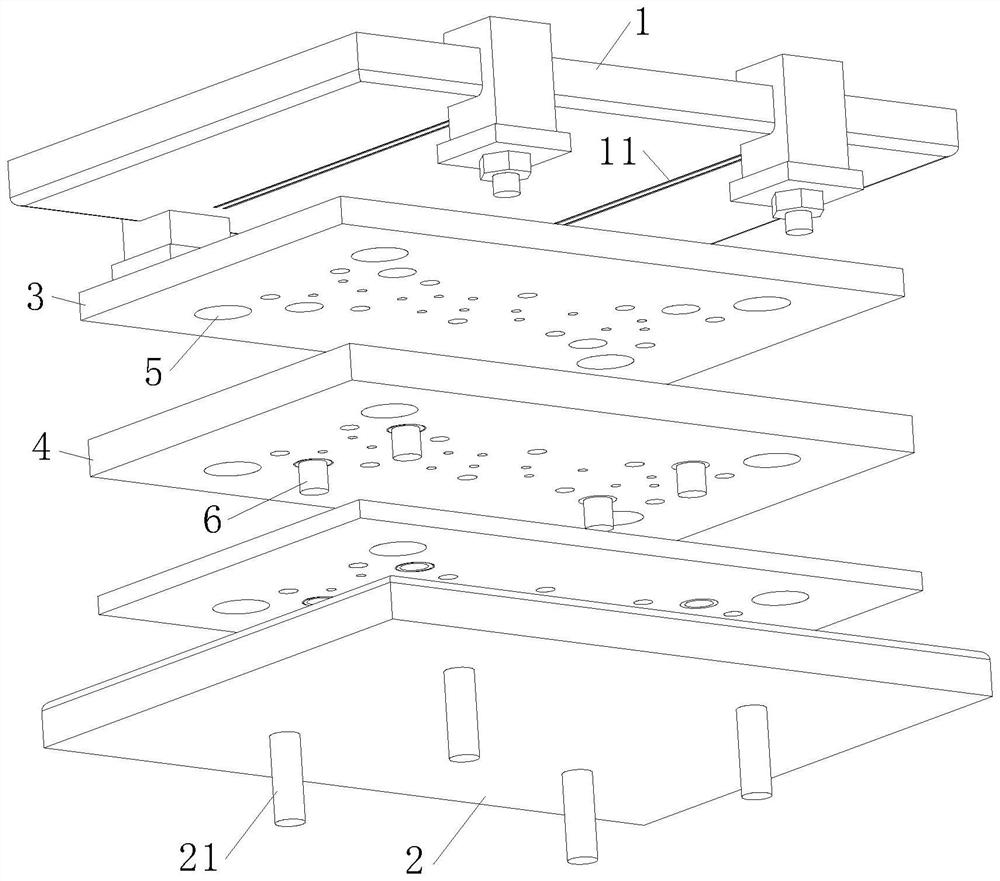

Manufacturing method of stamping formed part, and stamping formed part

PendingCN113399553AEasy to adjust insert parametersReduce stress differenceShaping toolsStamping processIndustrial engineering

The invention relates to the technical field of stamping, in particular to a manufacturing method of a stamping formed part, and the stamping formed part. The manufacturing method comprises the steps of die adjusting, stamping and die copying, and a used stamping die comprises an upper die holder, a lower die holder and a controller; due to the fact that the deformation condition of a board in the forming process is complex and is changed with contact between the board and a die surface, main stress parameters in the board surface of each part of a blank are further dynamically changed, and consequently drawing defects generated in the stamping process are difficult to prejudge; and the quality of a formed part is affected. Therefore, a quick connector is arranged and used for fixedly connecting an insert; insert parameters for stamping the formed part are easy to adjust, and stress difference of the insert acting on different parts of the formed part in the stamping process is adjusted by the aid of a bagged spring mounted at the tail end of the insert; the stress difference borne by drawing of the formed part is reduced through the deformation quantity of the bagged spring; and the surface quality of the formed part is maintained, and therefore the manufacturing quality of the stamping formed part is improved.

Owner:殷胜男

Enhanced free-spraying profile without scratches and preparation method of enhanced free-spraying profile

InactiveCN105482304AGood jointReduce stress differenceSynthetic resin layered productsCyclopenteneAntioxidant

The invention relates to an enhanced free-spraying profile without scratches. The profile is prepared by adopting a first mixture as an inner layer, and the second mixture as an outer layer through performing coextrusion molding; the first mixture is prepared from 100 parts of PVC (polyvinyl chloride), 20 to 30 parts of activated calcium carbonate, 5 to 10 parts of glass fibre, 2 to 4 parts of stabilizer, 0.1 to 2 parts of antioxidant, 5 to 10 parts of zinc stearate, 1 to 5 parts of mica powder, 2 to 5 parts of PE (polyethylene), 0.5 to 2 parts of tungsten oxytetrachloride, 4 to 8 parts of 2-pentene, 4 to 8 parts of cyclopentene and 2 to 10 parts of PMMA (polymethyl methacrylate); the second mixture is prepared from100 parts of PMMA, 20 to 30 parts of activated calcium carbonate, 1 to 4 parts of light stabilizer, 2 to 5 parts of PE, 0 to 4 parts of PVC and 15 to 30 parts of toner. According to the enhanced free-spraying profile without scratches and the preparation method of the enhanced free-spraying profile, the formula of the mixture of the PVC inlayer and the PMMA outer layer is improved, and the strength of the co-extruded profile PVE inner layer is improved, so that the whole strength of a final product is improved.

Owner:黄石市三利塑业模具有限公司

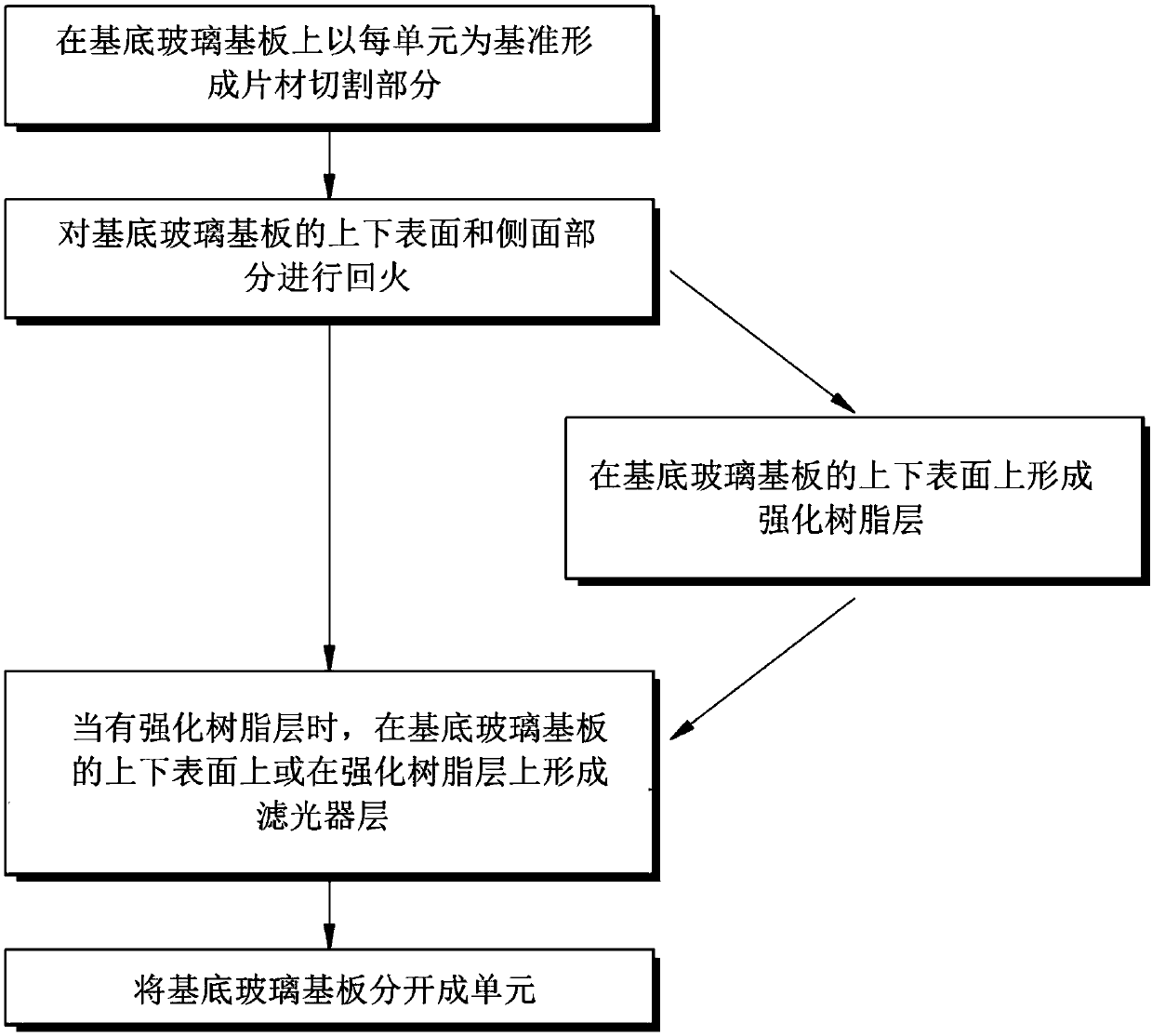

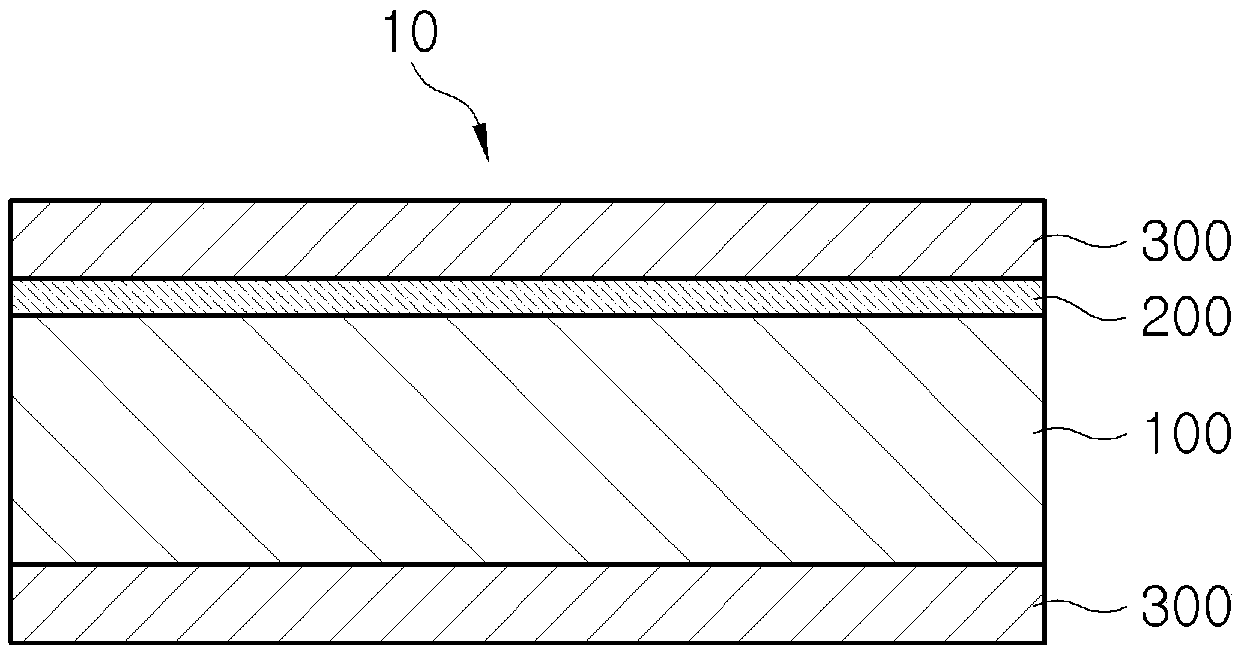

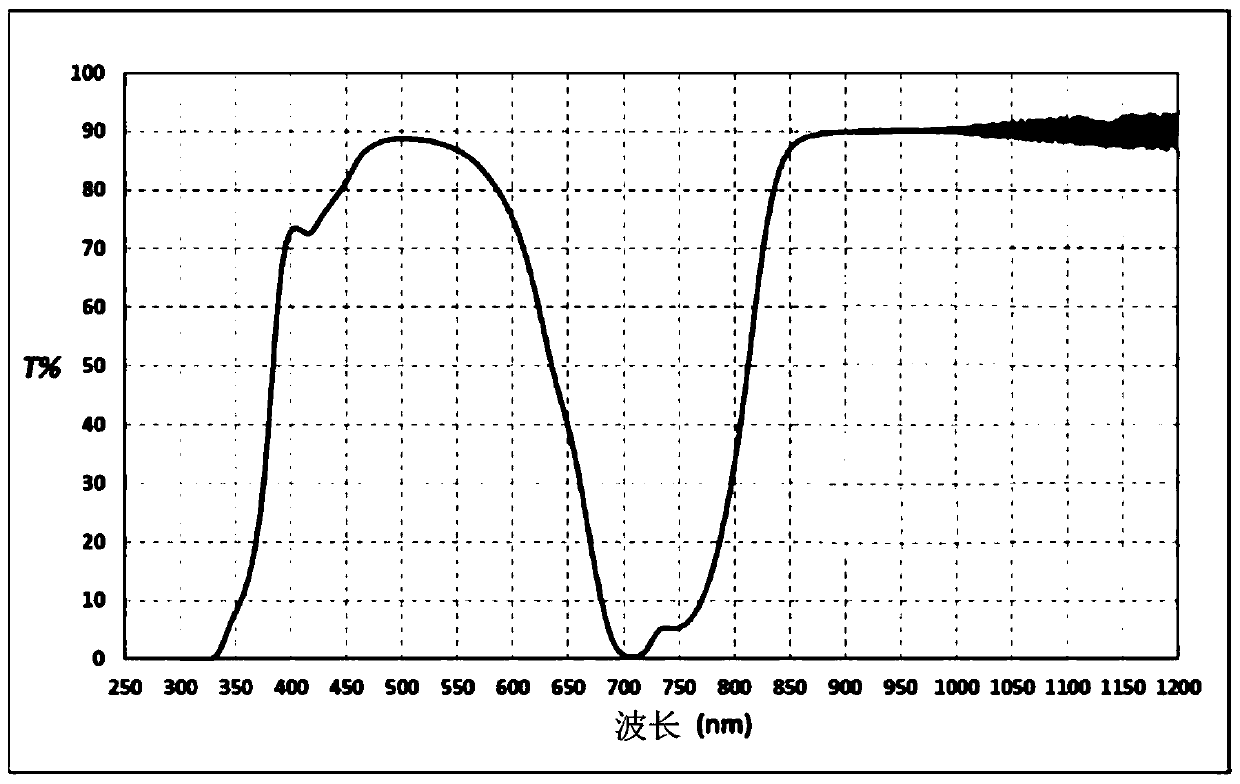

Optical filter and manufacturing method of optical filter

InactiveCN109581560AEasy to handleEasy to processOptical filtersGlass severing apparatusOptical filterSheet material

The present invention discloses an optical filter and a manufacturing method thereof. The optical filter includes a reinforced glass substrate and optical filter layers formed on each of the upper andlower sides of the reinforced glass substrate. The manufacturing method of the optical filter comprises the steps of: forming a sheet cutting portion on a disc glass substrate on a cell-by-cell basis; reinforcing the disc glass substrate so that the upper and lower portions of the disc glass substrate as well as the side portion through the sheet cutting portion can be reinforced; forming opticalfilter layers on the upper and lower sides of the disc glass substrate, respectively; and forming a cell-unit optical filter by separating the disc glass substrate on a cell-by-cell basis, wherein each unit serves as an optical filter based on the unit.

Owner:UTI INC

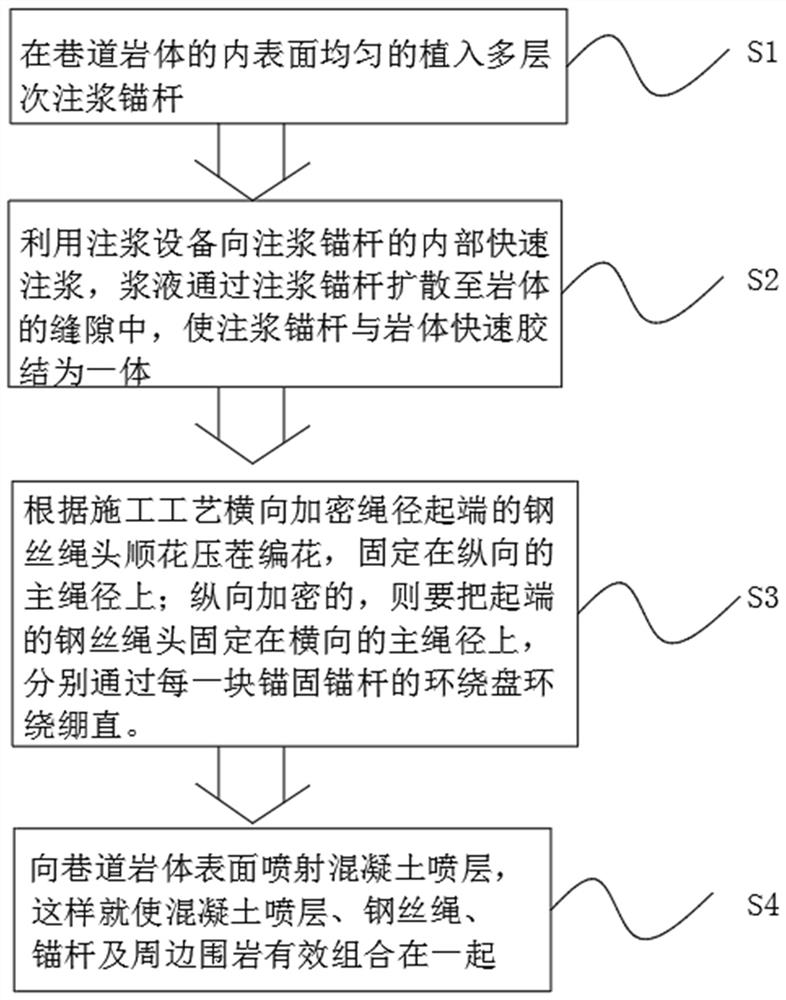

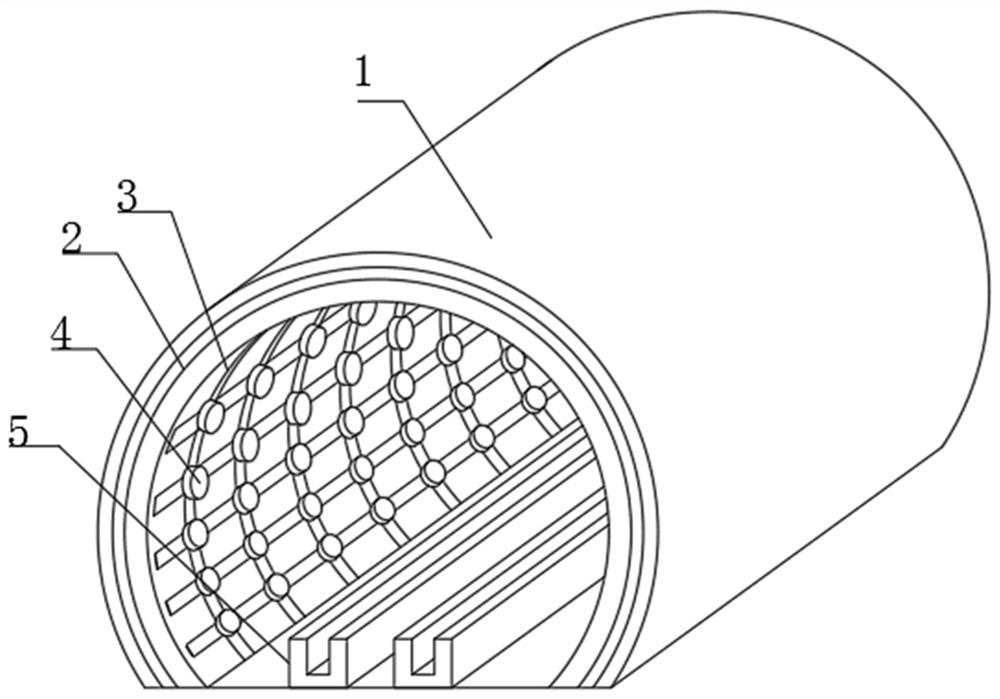

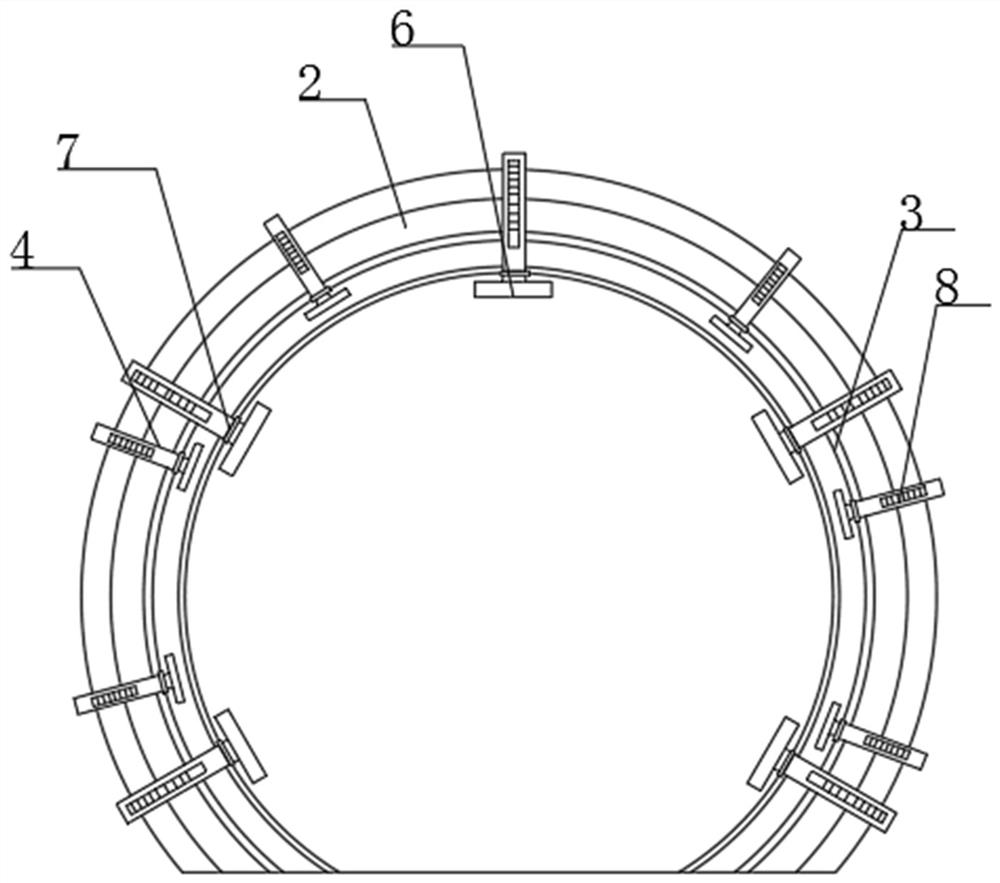

A Supporting Equipment Aiming at the Ejection Problem of Anchor Rod and Cable Cover Plate

ActiveCN112832836BIncrease initial support resistanceReduce stress differenceUnderground chambersTunnel liningRock boltInternal stress

The invention discloses a support method and support equipment aiming at the ejection of anchor bolt and anchor cable cover plate. According to different surrounding rock conditions, the key parameters of grouting are scientifically selected, and the grouting equipment is used to inject grouting bolts. Internal rapid grouting, the grout diffuses into the cracks of the rock mass through the grouting bolt, and grouts into the surrounding rock body of the roadway, so that the grout diffuses, compacts and condenses in the cracks in the rock mass, and breaks the loose parts within the reach The surrounding rock is cemented into a whole, and the grout under pressure is retained in the surrounding rock body of the roadway to increase the initial support resistance of the surrounding rock, form a slurry cemented reinforced arch, and construct the superficial part of the surrounding rock to have a certain internal stress The ring body of the surrounding rock makes the connection between the multi-layer anchor rod and the multi-layer spray layer more firm, forms multiple protection circles inside the surrounding rock, and at the same time makes the grouting anchor rod and the rock mass quickly cemented together to reduce the depth The stress difference of the surrounding rock, thereby preventing the dangerous situation of ejection of the bolt and the anchor cable.

Owner:HUAIBEI PINGYUAN SOFTROCK SUPPORTING ENG TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com