Vertical production line of cable for new energy electric vehicle

A technology for electric vehicles and cables, used in cable/conductor manufacturing, insulation of conductors/cables, circuits, etc., can solve the problems of cable jitter, self-weight overhang, poor cable forming quality, etc., to reduce stress and improve processing. Efficiency and the effect of reducing the defective rate of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

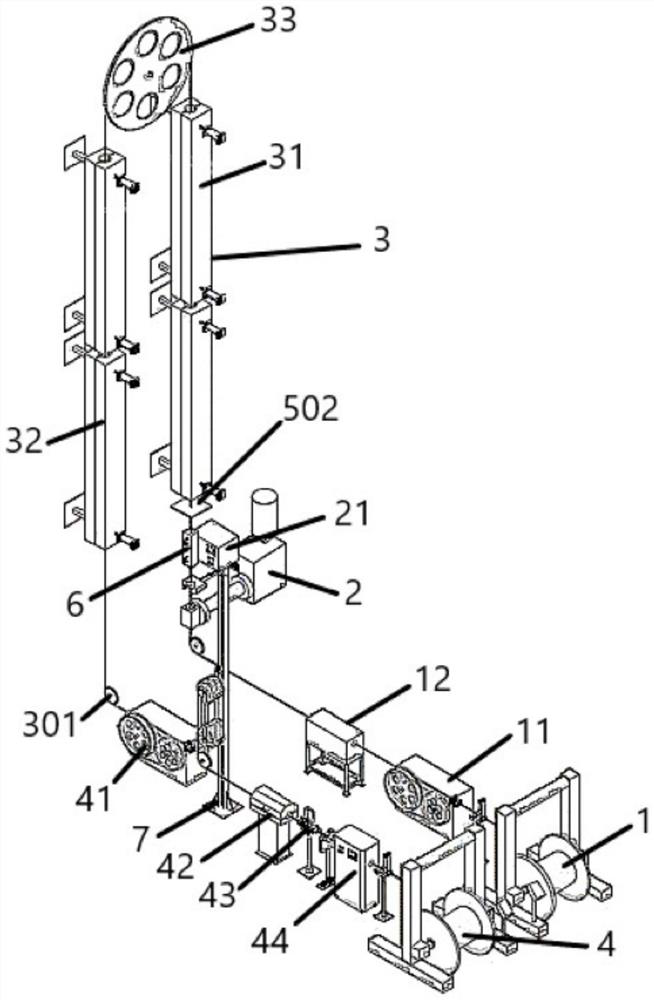

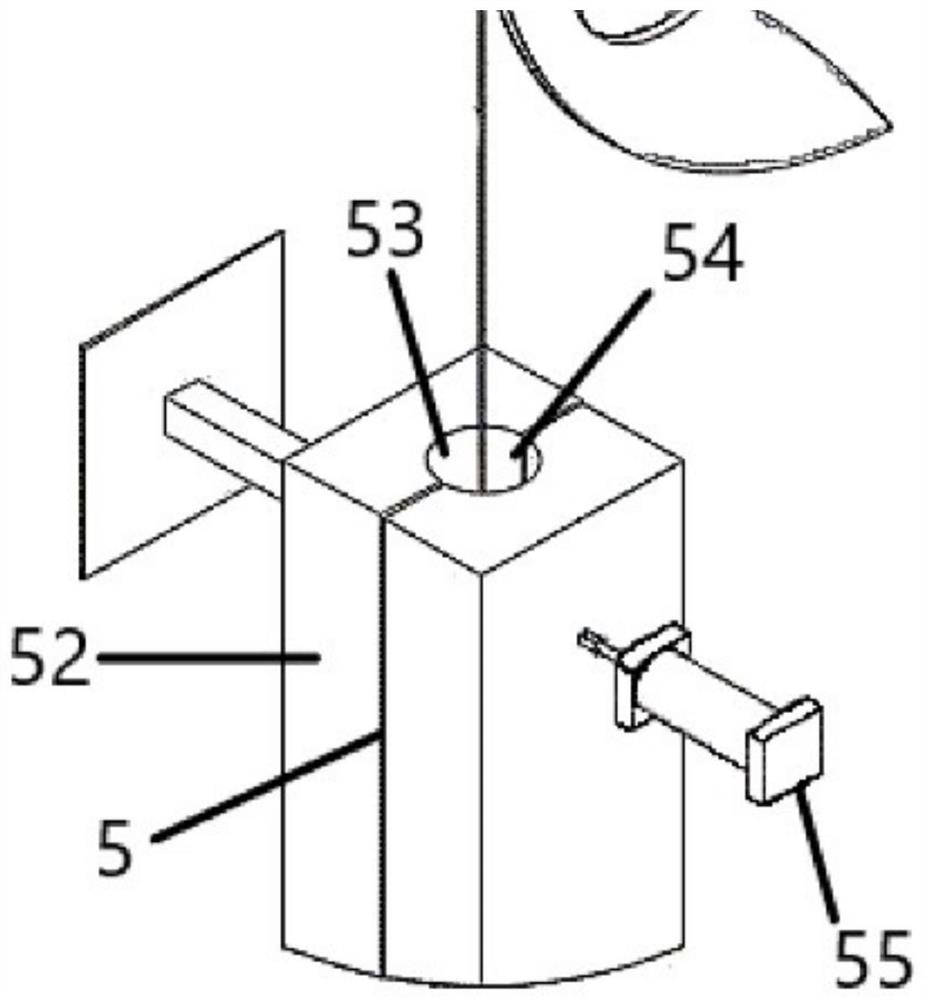

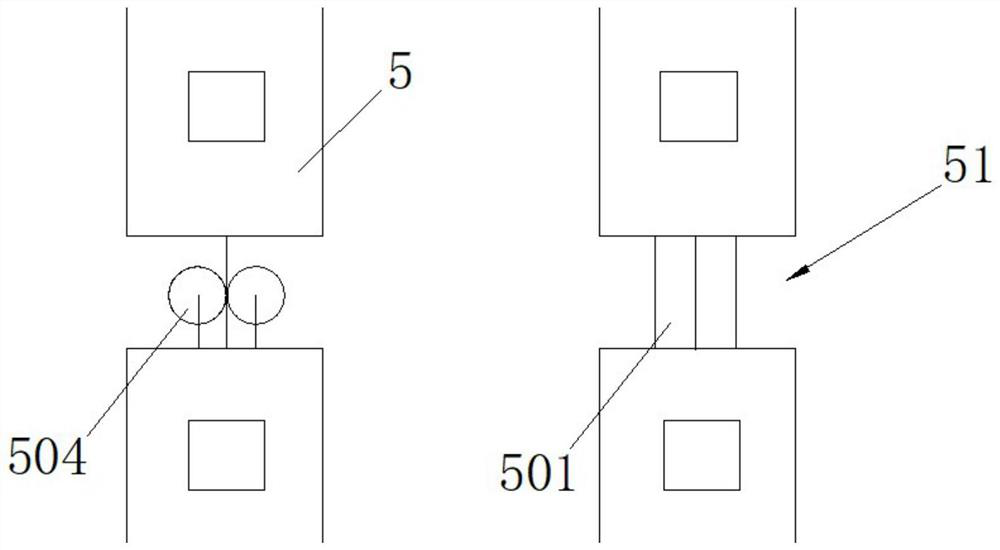

[0030] Embodiment 1: A kind of vertical production line of new energy electric vehicle cable, refer to the attached Figure 1-6 , including a pay-off reel 1, a first tractor 11, an oven 12, an extruder 2, a vulcanization device 3, a second traction machine 41 and a take-up reel 4 installed in sequence, and the vulcanization device 3 includes an upward vulcanization section 31, Down vulcanization section 32 and reversing wheel 33, the up vulcanization section 31 and down vulcanization section 32 are arranged side by side and vertically, the reversing wheel 33 is located above the up vulcanization section 31 and down vulcanization section 32, and the cable passes through this The shortest distance between the parallel segments of the up vulcanization section 31 and the down vulcanization section 32 is the first length, the diameter of the reversing wheel 33 is the same as the first length, and the pay-off reel 1 and the take-up reel 4 are installed side by side on On the ground ...

Embodiment 2

[0036] Embodiment 2: A kind of vertical production line of new energy electric vehicle cable, refer to the attached Figure 1-6 , including a pay-off reel 1, a first tractor 11, an oven 12, an extruder 2, a vulcanization device 3, a second traction machine 41 and a take-up reel 4 installed in sequence, and the vulcanization device 3 includes an upward vulcanization section 31, Down vulcanization section 32 and reversing wheel 33, the up vulcanization section 31 and down vulcanization section 32 are arranged side by side and vertically, the reversing wheel 33 is located above the up vulcanization section 31 and down vulcanization section 32, and the cable passes through this The shortest distance between the parallel segments of the up vulcanization section 31 and the down vulcanization section 32 is the first length, the diameter of the reversing wheel 33 is the same as the first length, and the pay-off reel 1 and the take-up reel 4 are installed side by side on On the ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com