Patents

Literature

226results about How to "Line optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

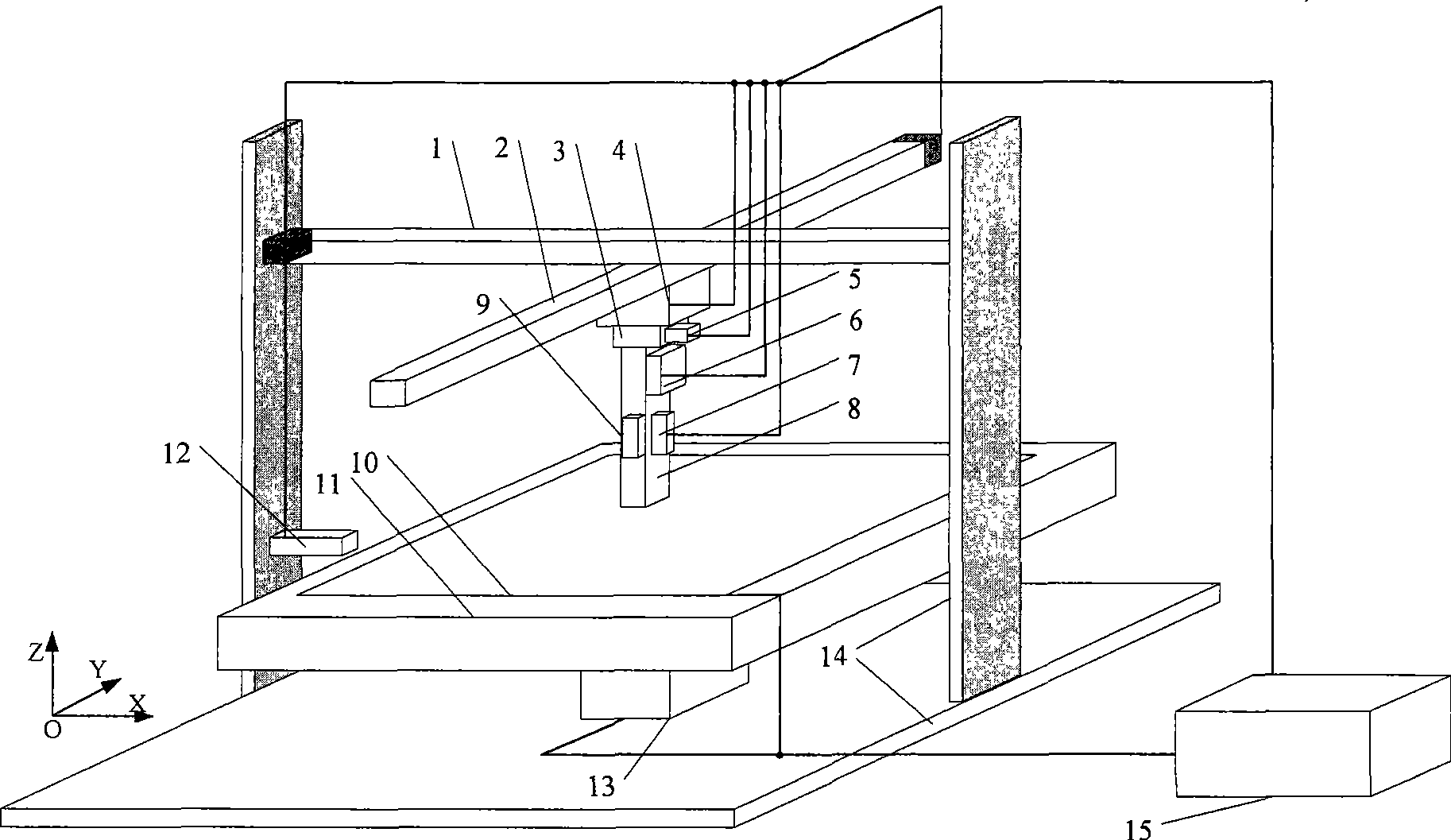

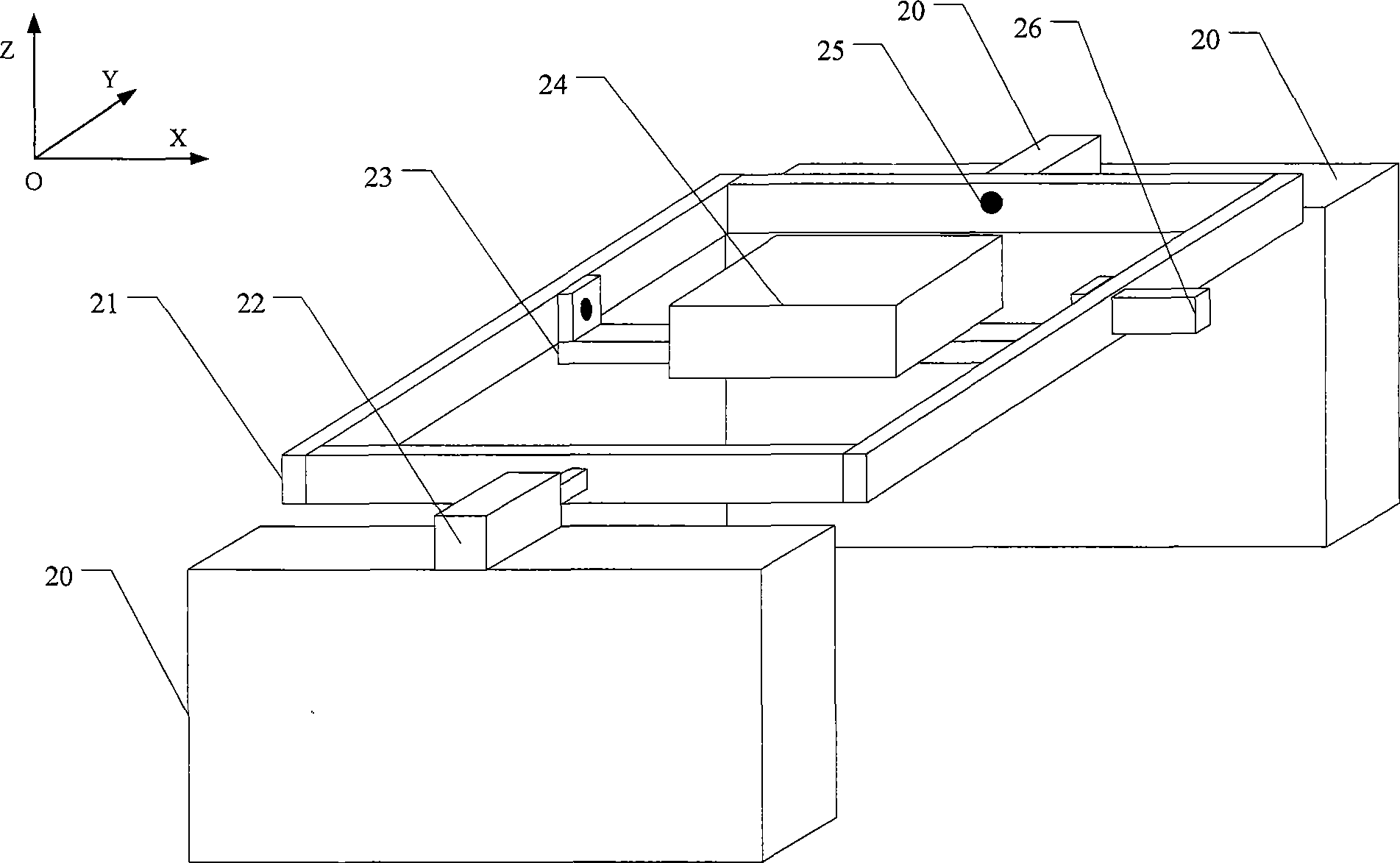

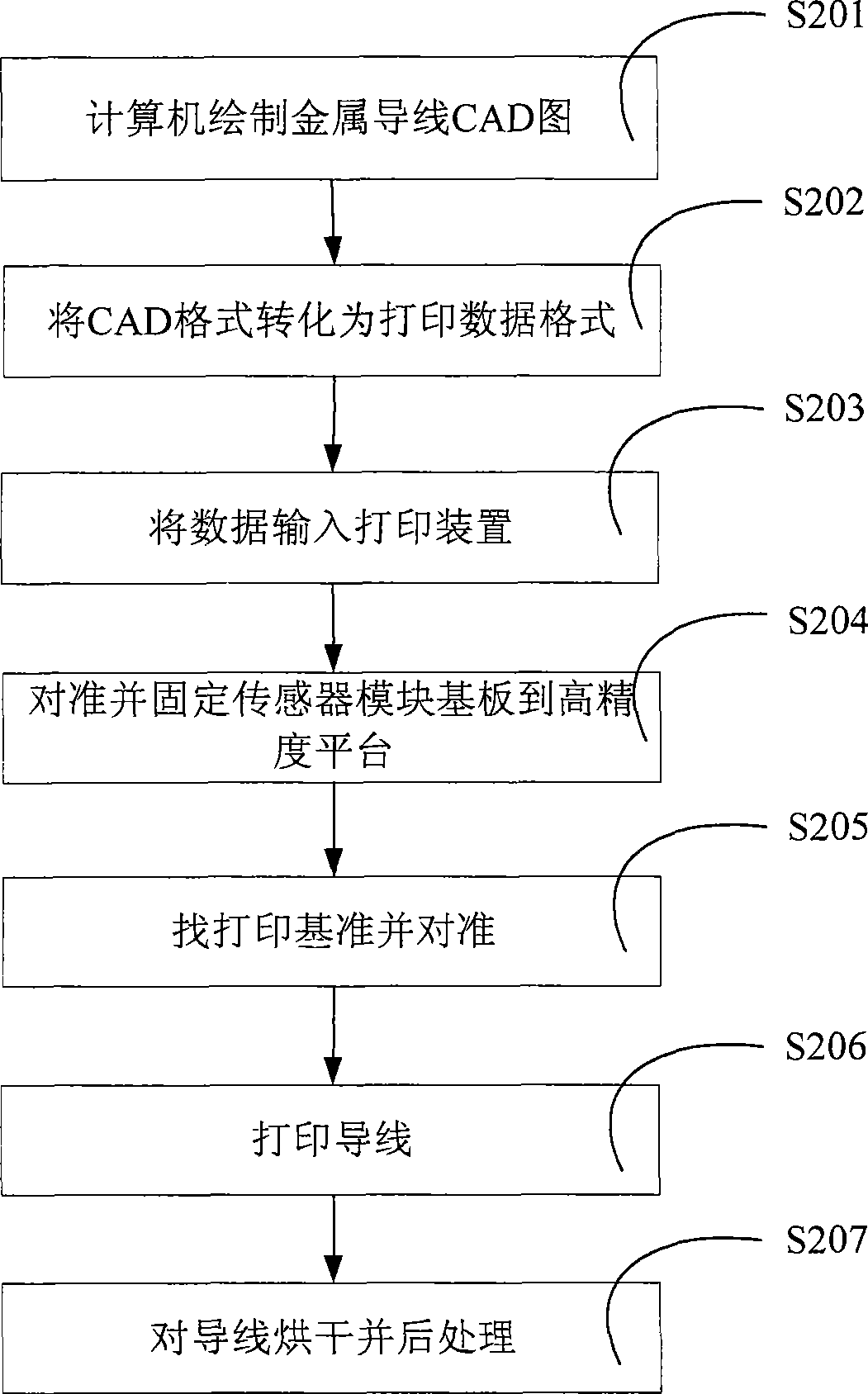

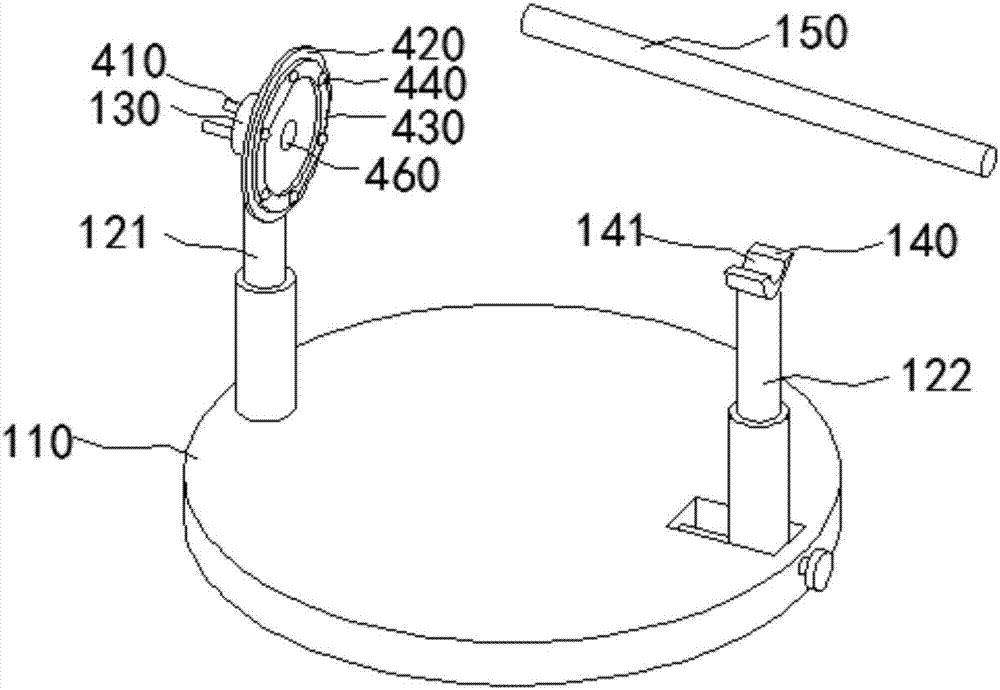

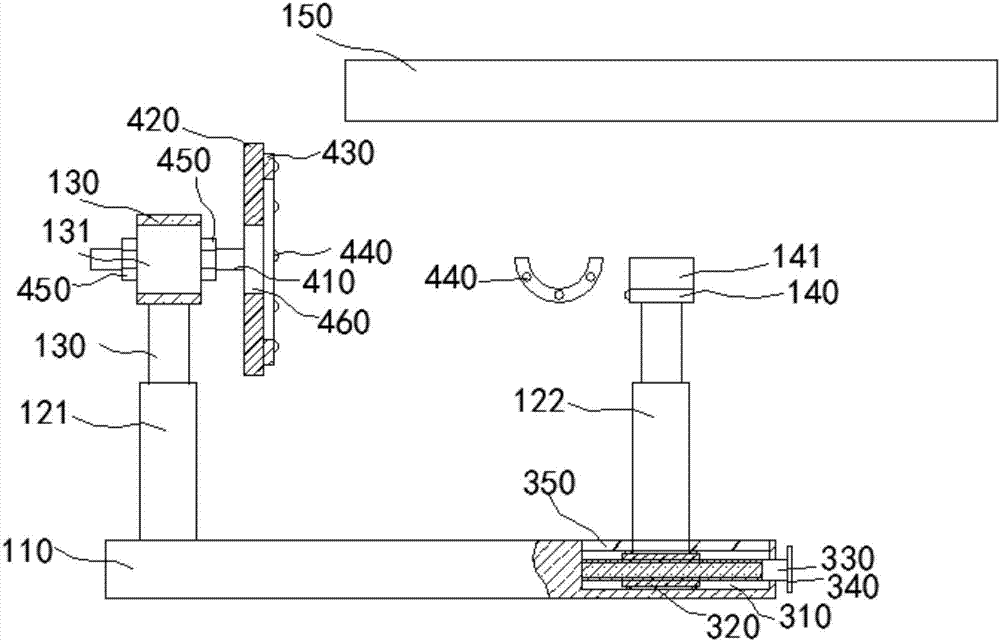

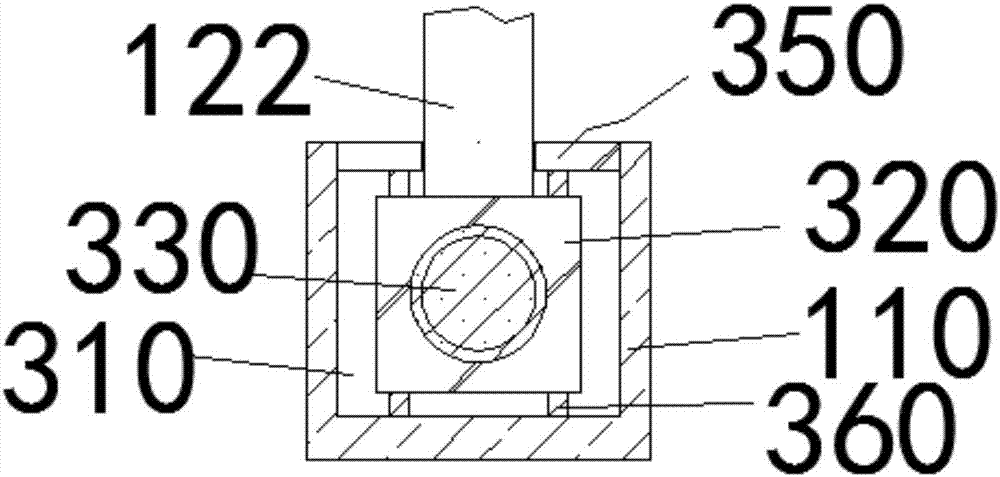

Printing device and printing method for integrating electronic components

ActiveCN101462414AImprove efficiencyIncreased processing flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingHead movementsComputer module

The invention relates to a printing device, which can perform precise conductive pattern printing on a step shaped substrate, and comprises a platform module, a printing module, and a head movement module, wherein at least one of the platform module and the head movement module is provided with a rotating movement unit, and the rotating movement unit can drive a platform or a head to rotate around an X axis and a Y axis respectively, thereby ensuring that the head aligns a step surface which has an angle a with an X-Y plane to print; and the angle a is an angle which is more than 0 degree and is less than or equal to 90 degrees. A main innovation point is that the printing device can continuously print on the step shaped substrate; and the rotating movement unit is arranged on the printing device, or a step of real-time rotating printing of the head is added in a printing method, or the printing is respectively performed in a horizontal plane and a step plane, so as to solve the continuous problem of physical property of a metal conducting wire printed on the surface of the step shaped substrate, and ensure that the printed metal wire is not interrupted and has good electrical conductivity.

Owner:CARERAY DIGITAL MEDICAL TECH CO LTD

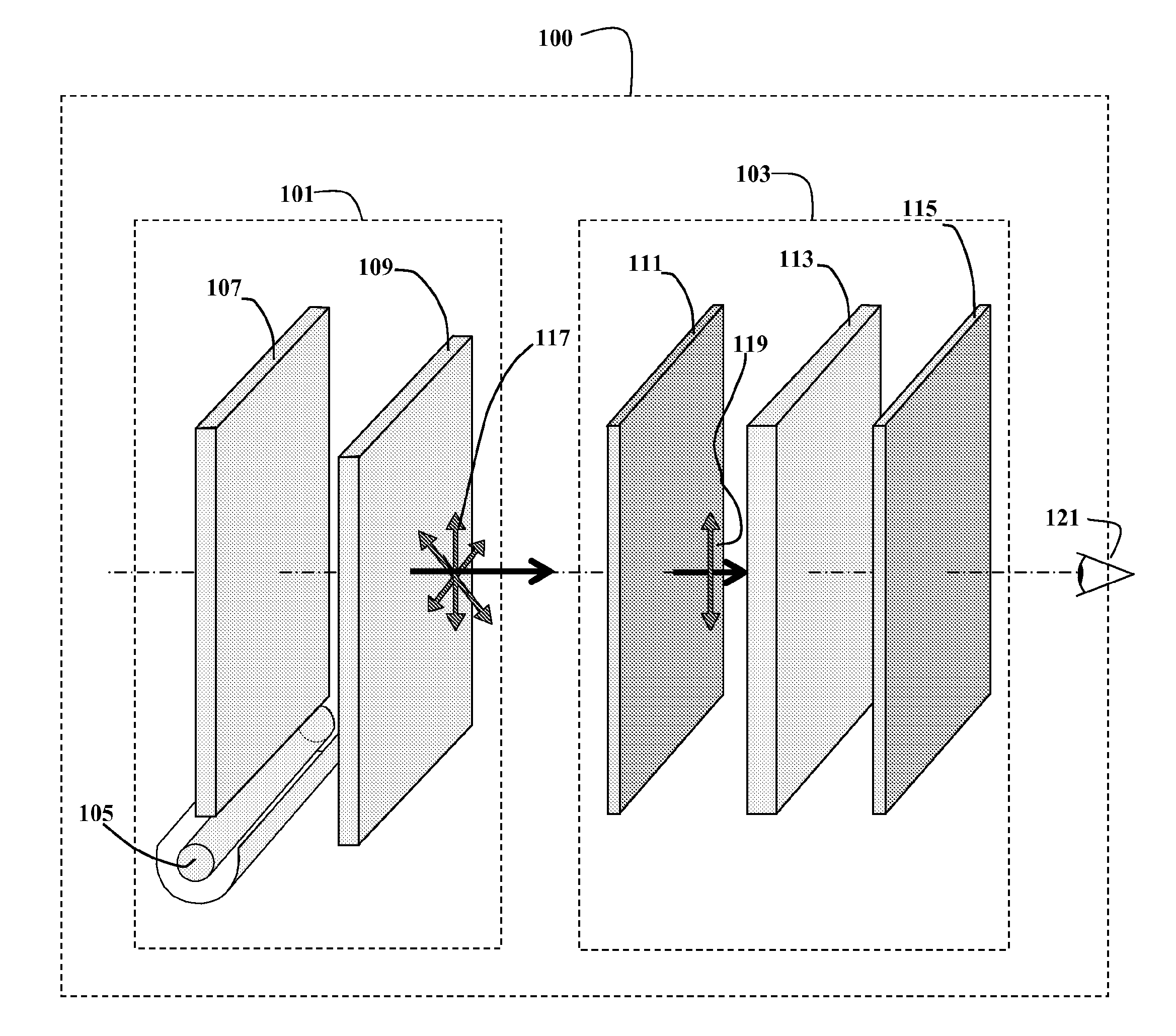

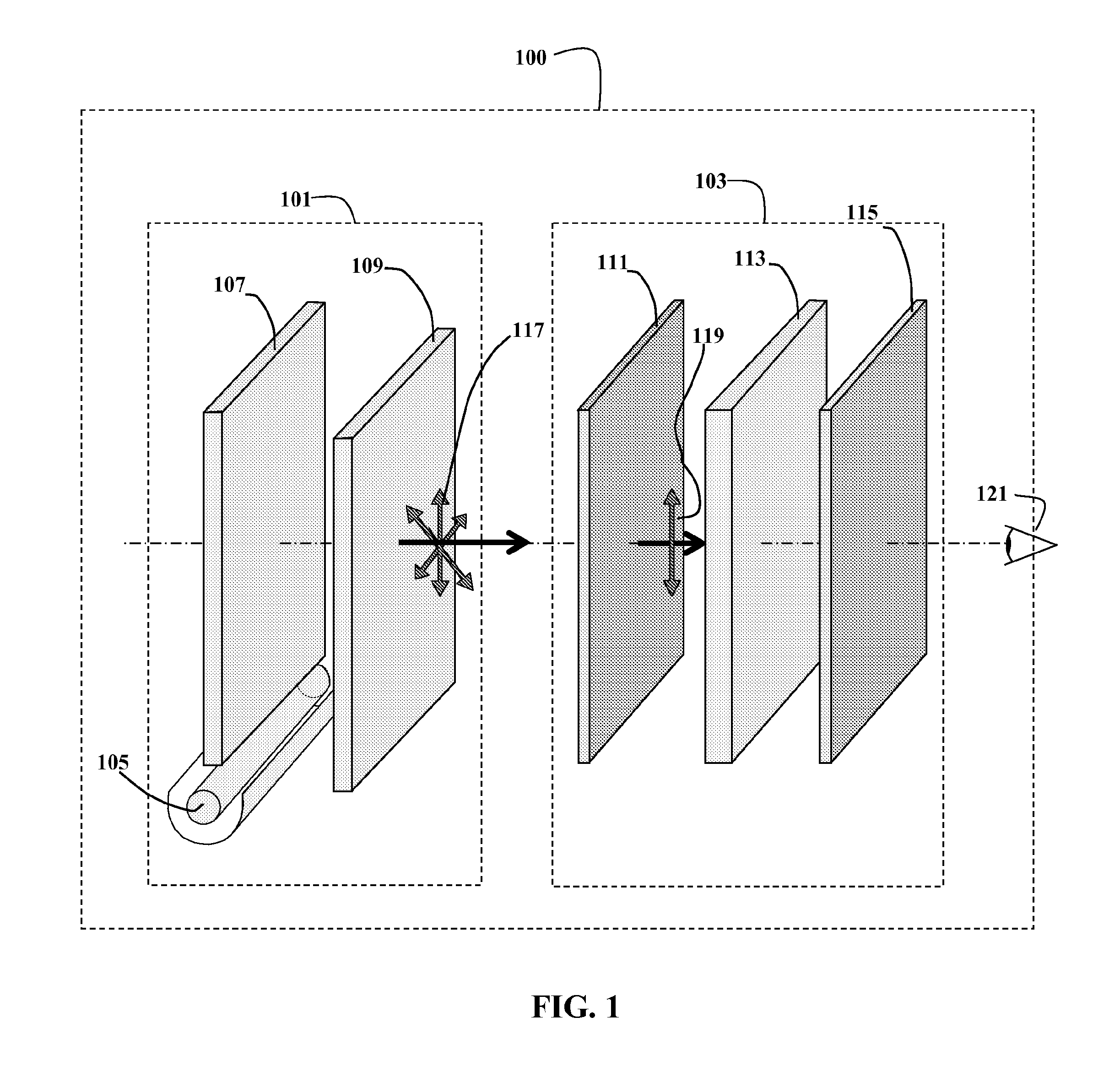

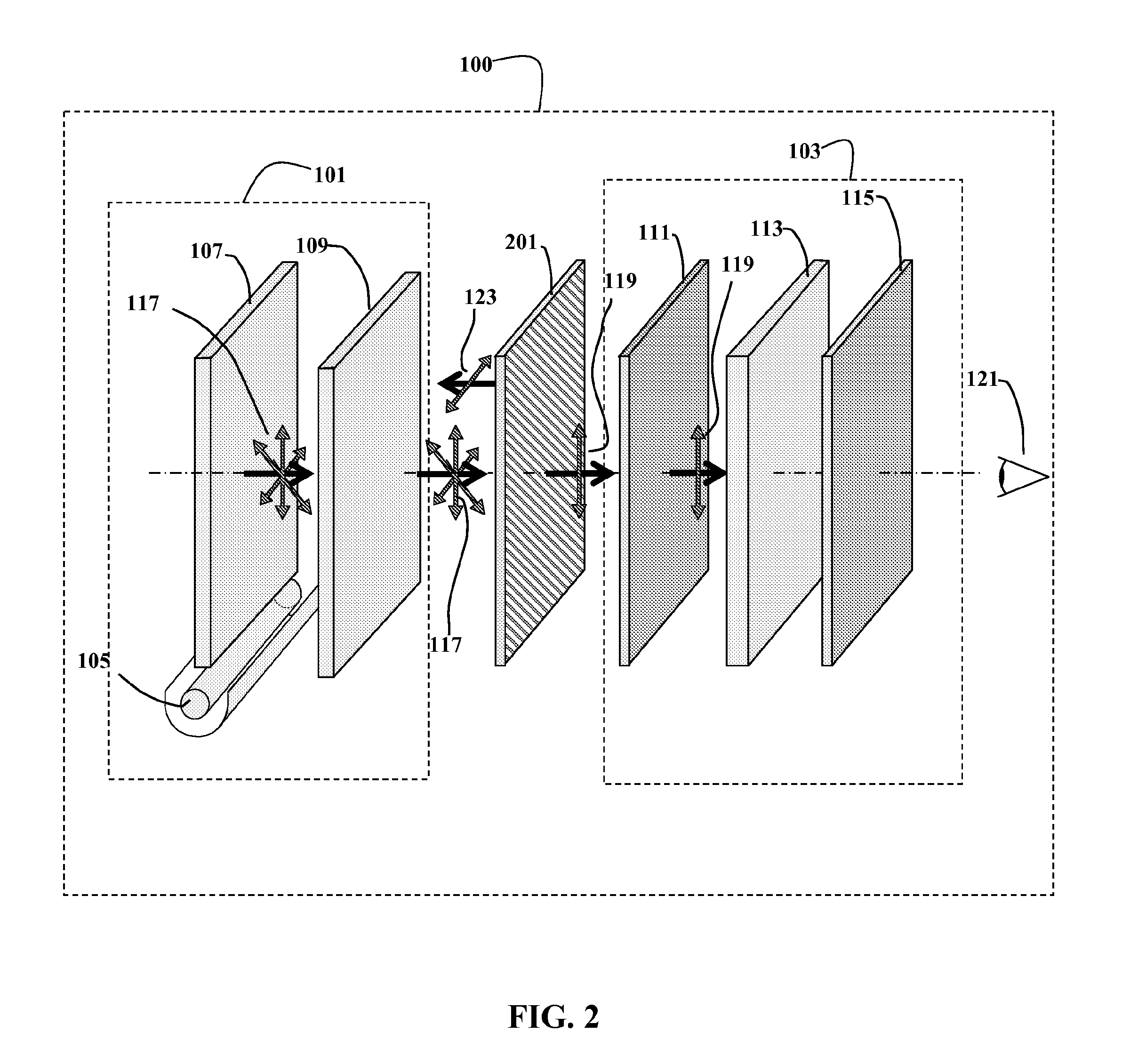

NanoEmbossed shapes and fabrication methods of wire grid polarizers

InactiveUS20100134719A1High contrast ratioHigh transmissionVacuum evaporation coatingSputtering coatingLiquid-crystal displayWire grid

A wire grid polarizer may be formed by embossing a substrate surface with a mold having a plurality of grooves to form raised ridges; and depositing a metal line profile onto the ridges through one or more baffles oriented at an oblique angle to the normal of the substrate. The metal line profile is characterized by a cross-sectional width that tapers such that the metal line profile is wider proximate a vertex of the ridges than proximate a base of the ridges. A wire grid polarizer may comprise a substrate with a plurality of raised ridges and a plurality of metal lines on the raised ridges. The metal lines are characterized by cross-sectional metal line profiles having triangular shapes with a tip down configuration. Such a wire grid polarizer may be used in a liquid crystal display.

Owner:AGOURA TECH

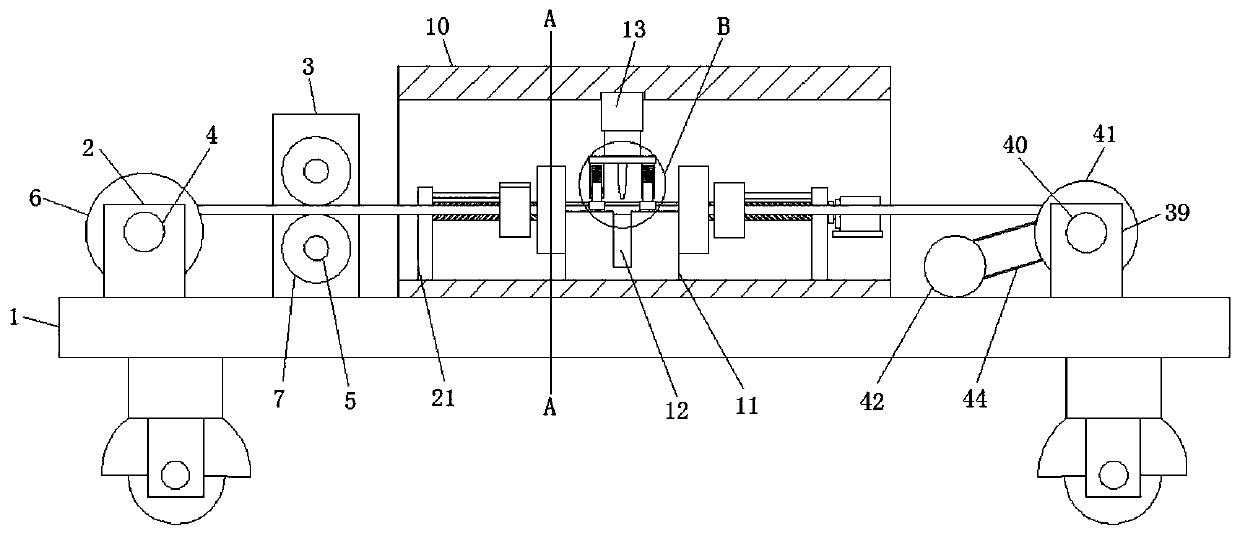

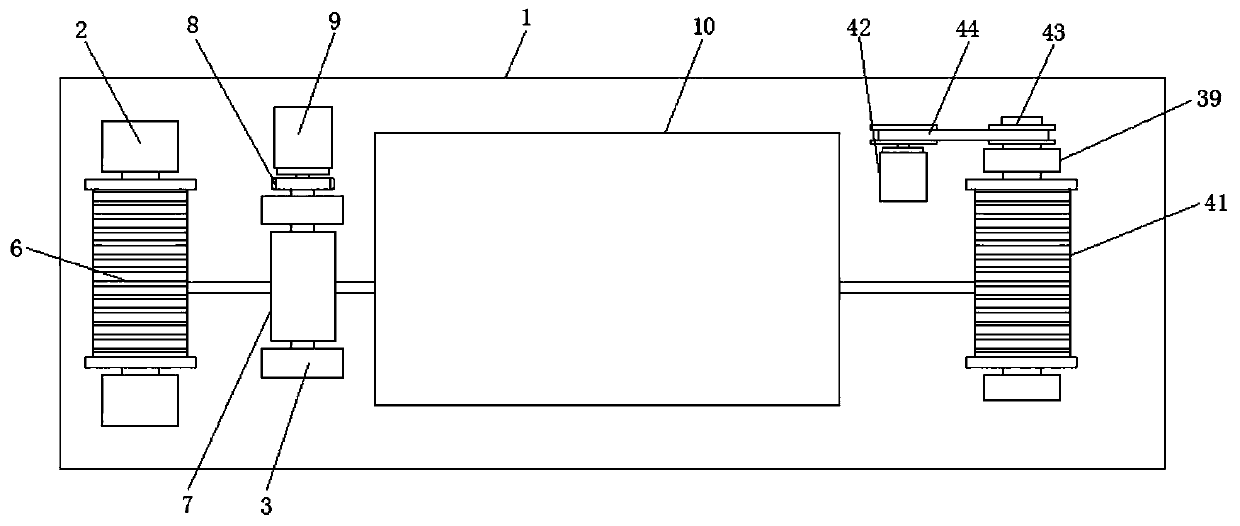

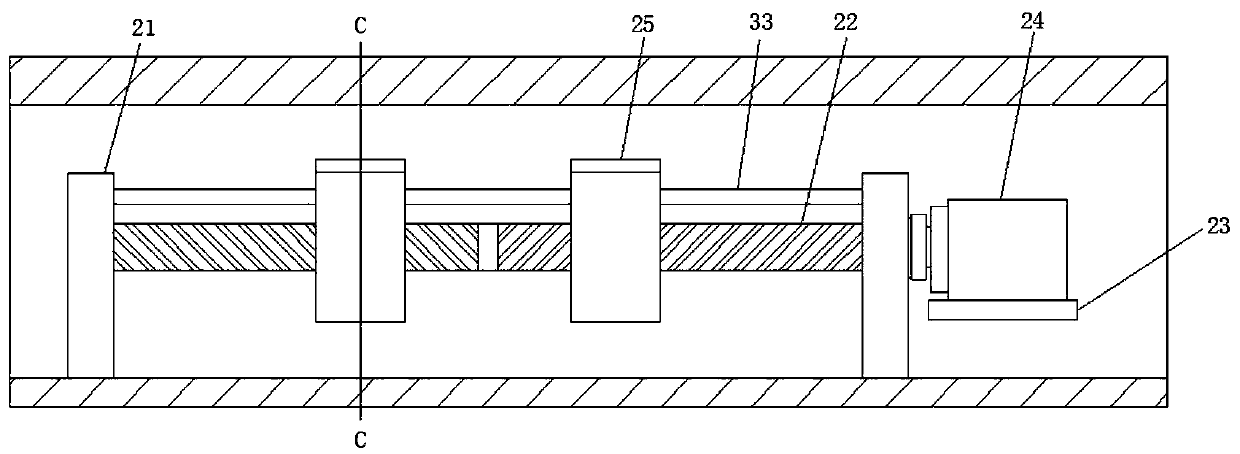

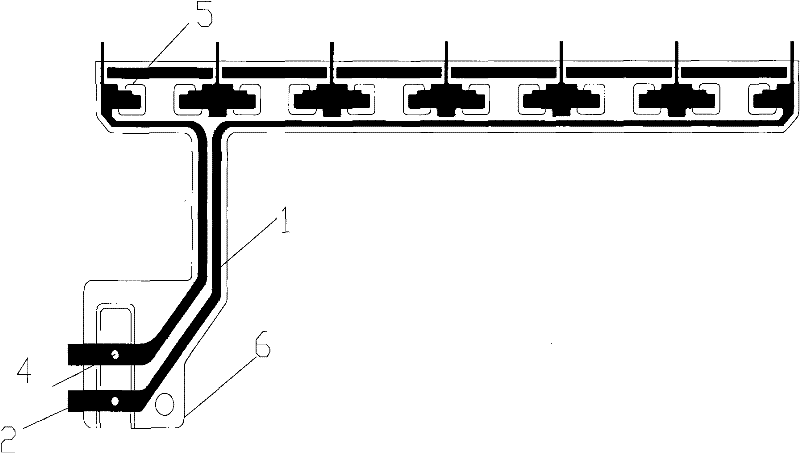

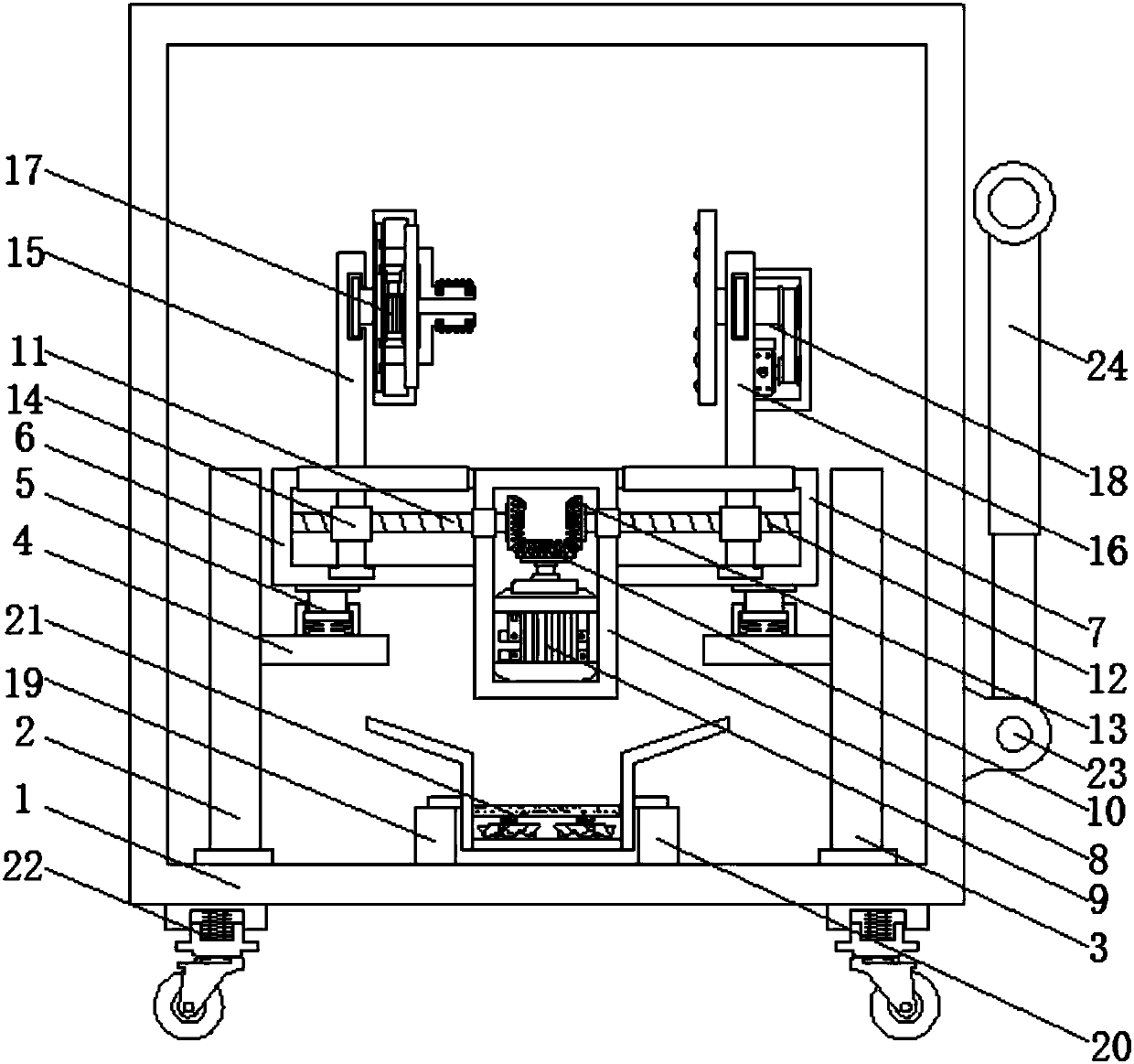

Cable laying and installation cutting and peeling equipment

InactiveCN110265933ALine optimizationConveying works wellApparatus for removing/armouring cablesApparatus for laying cablesBiochemical engineering

The invention discloses cable laying and installation cutting and peeling equipment, which comprises a work bench. The four corners of the lower end surface of the work bench are respectively and fixedly connected with a supporting leg through a screw; the lower end of each supporting leg is equipped with a universal wheel; one side of the upper end surface of the work bench is fixedly connected with support bases 1 and support bases 2 through screws; the support bases 2 are located at the side, close to the center of the work bench, of the support bases 1; the number of the support bases 1 and the number of the support bases 2 are two; a fixation shaft 1 is rotatably connected between the two support bases 1 through a rolling bearing and fixation shafts 2 are rotatably connected between the two support bases 2 through rolling bearings; the rod body outer walls of the fixation shaft 1 and the fixation shafts 2 are fixedly connected with a pay-off roller and a conveying roller through screws respectively; the two fixation shafts 2 are symmetrically arranged at the upper and lower ends of the support base 2; the back sides of the two fixation shafts 2 pass through the support bases 2 and are rotatably connected through a gear set; and the back end of the rear support base 2 is provided with a servo motor 1.

Owner:ANHUI TIANMING CABLE

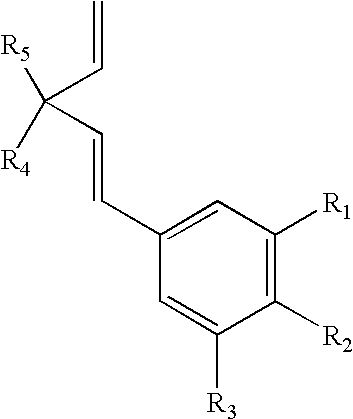

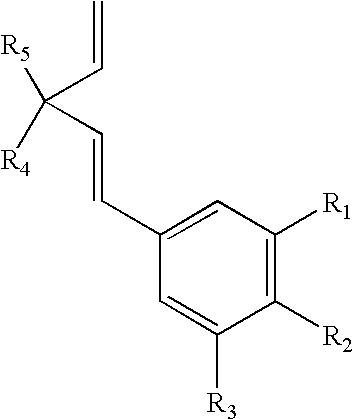

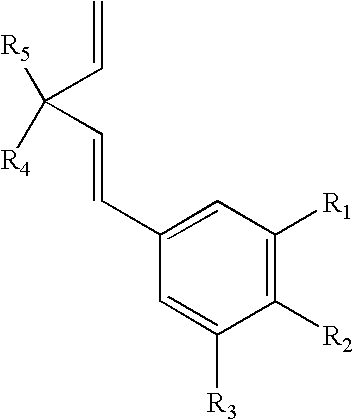

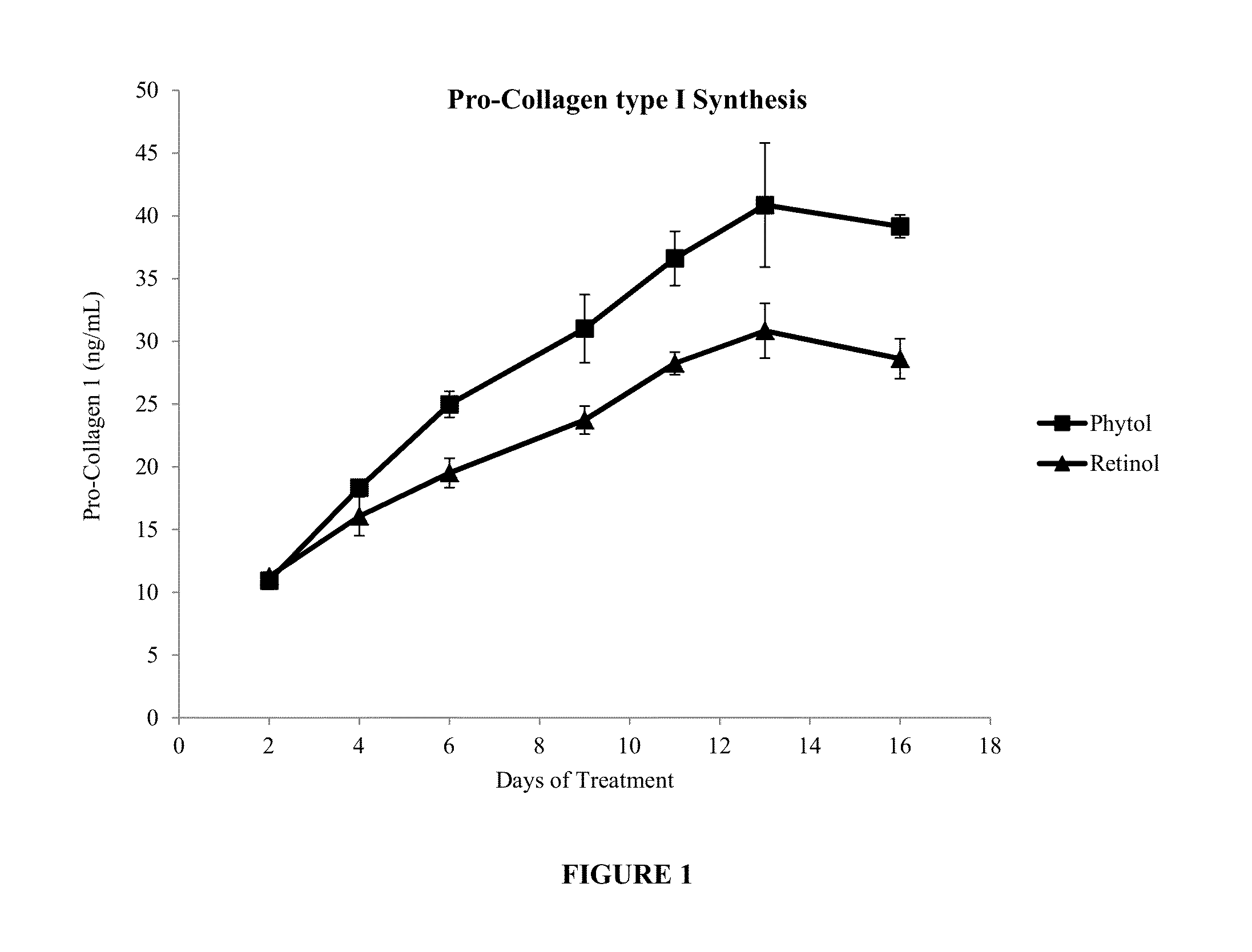

Skin appearance through gene manipulation

ActiveUS20090036545A1Ameliorating and reducing and reversing adverse consequencePreventing and slowing down adverse consequenceCosmetic preparationsBiocideWrinkle skinFine line

The present invention relates to a method for treating, preventing and improving the condition and / or aesthetic appearance of aging skin, particularly, treating, preventing, ameliorating, reducing and / or eliminating fine lines and / or wrinkles of skin, through meroterpene induced gene manipulation.

Owner:SYTHEON

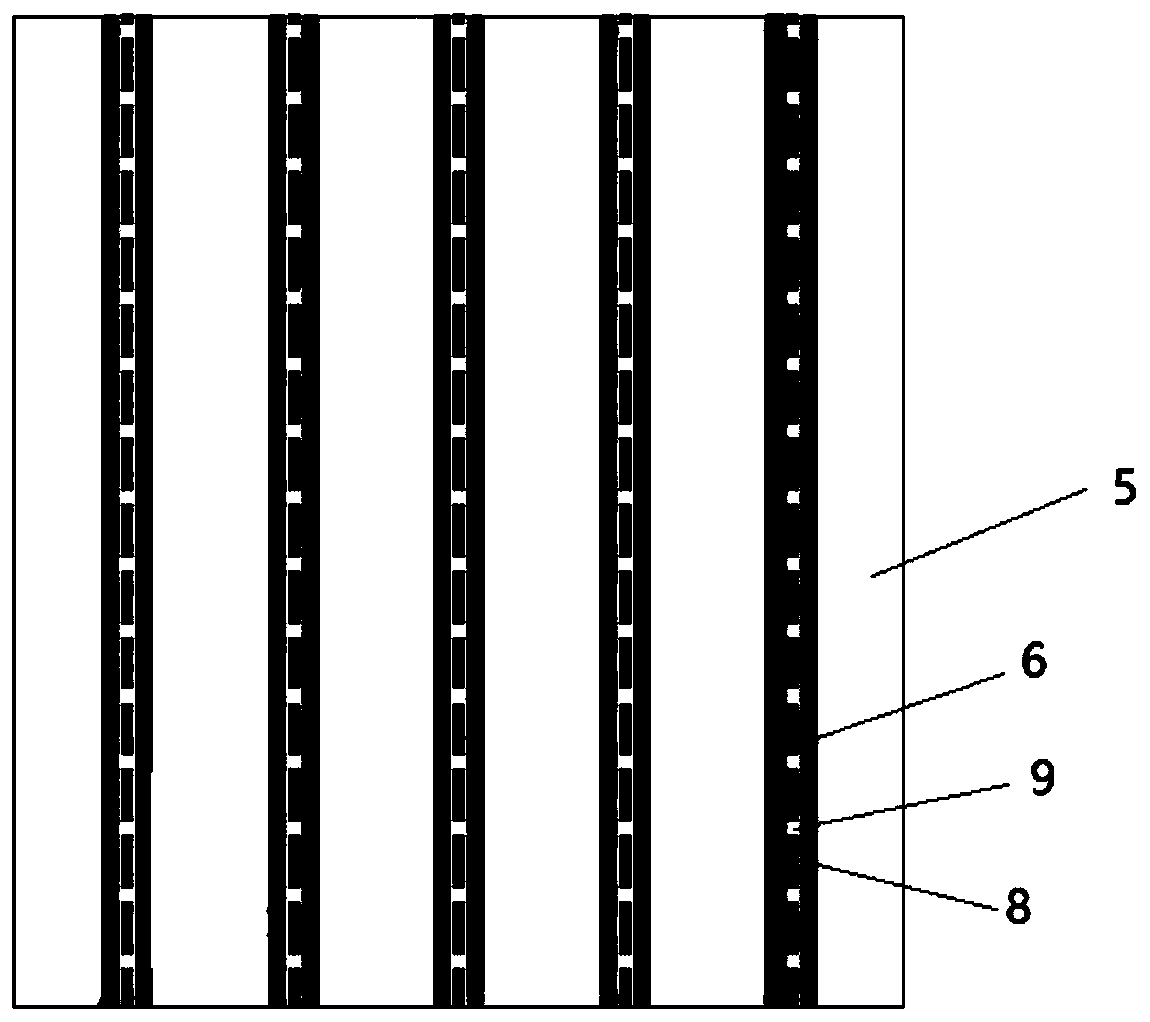

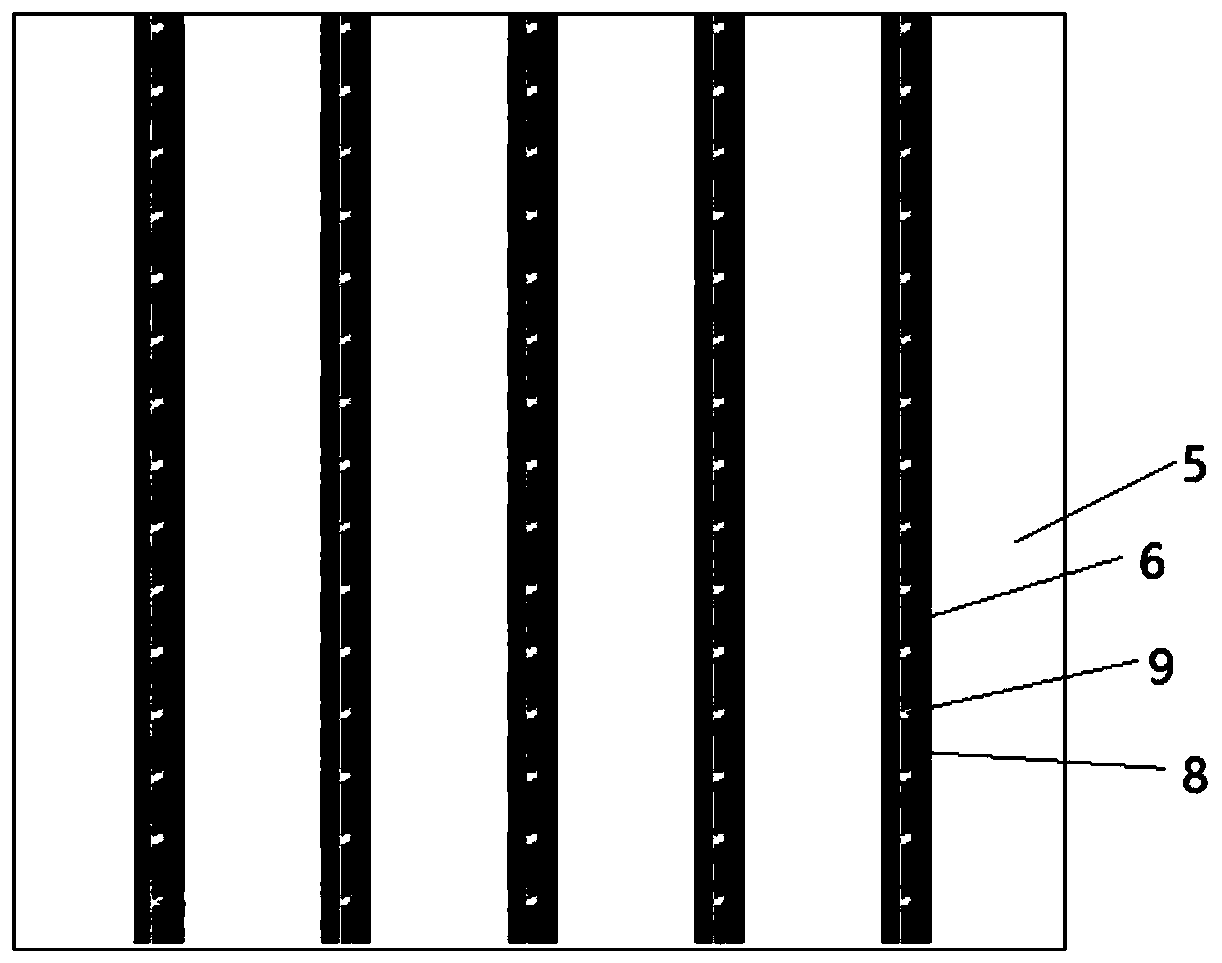

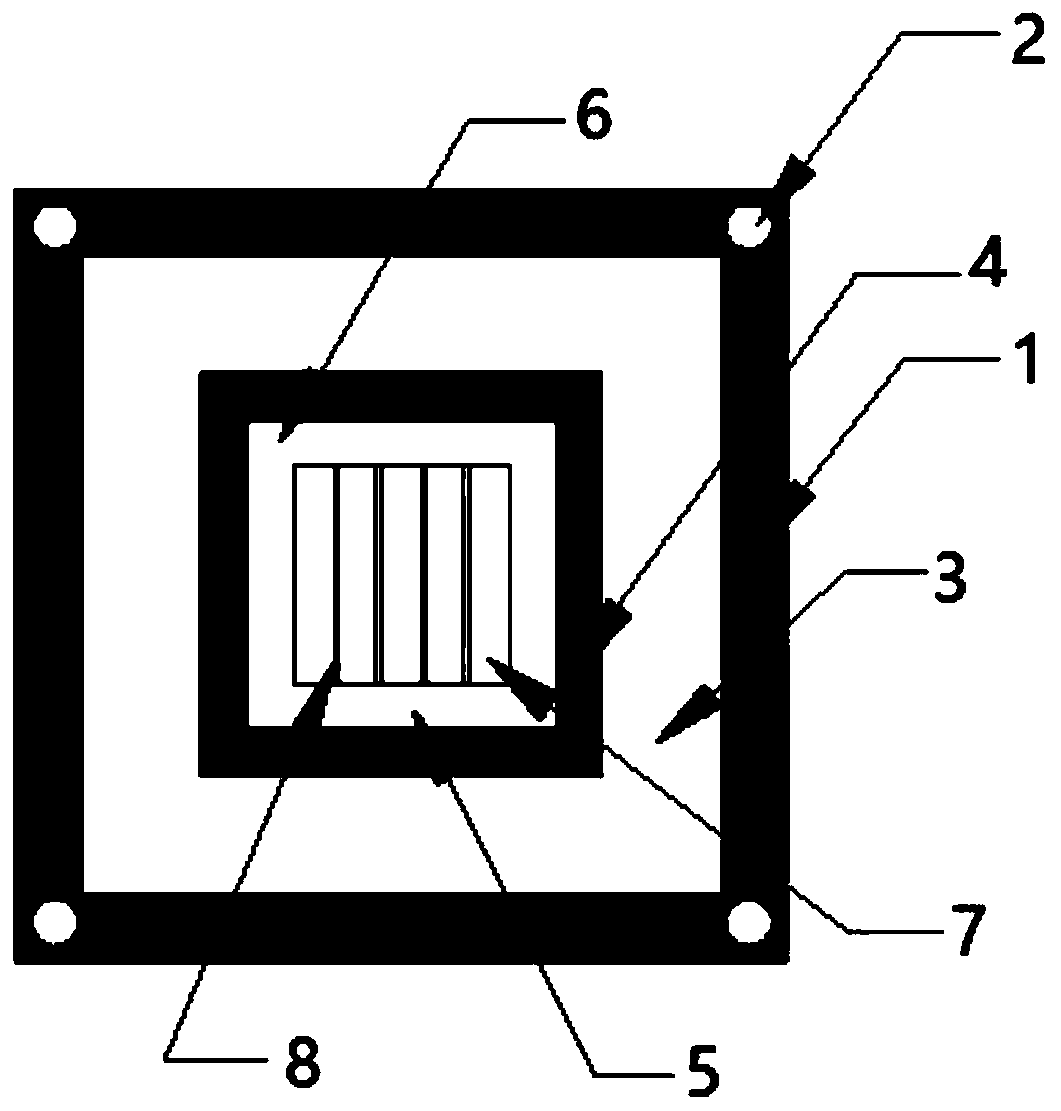

Manufacturing method of metal alloy composite screen plate

InactiveCN110039883ALow elongationGood dimensional stabilityPlate printingFoil printingDouble supportPuncture resistance

The invention discloses a manufacturing method of a metal alloy composite screen plate. The manufacturing method comprises the following specific steps of 1) carrying out net pulling compounding; 2) manufacturing an alloy sheet pattern outer contour; 3) preparing a film layer; 4) coating an adhesive layer; 5) coating a film; 6) drying; 7) laser; 8) cleaning; and 9) detecting and packaging. In thisway, according to the manufacturing method of the metal alloy composite screen plate, a metal alloy sheet is adopted to replace traditional mesh cloth, and the manufacturing method has low elongationrate, better dimensional stability, printing resistance, puncture resistance, double supports of the metal alloy sheet and the film layer are adopted, the service life of the bonding strength far beyond a silk-screen and the film layer can be improved by 30% or above, and under the action of a high-molecular adhesive, the adhesion force of the high-molecular composite layer is extremely high, theplate making yield is greatly improved, the production cost is saved, the printing is good, the line type is good, and the efficiency of a battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

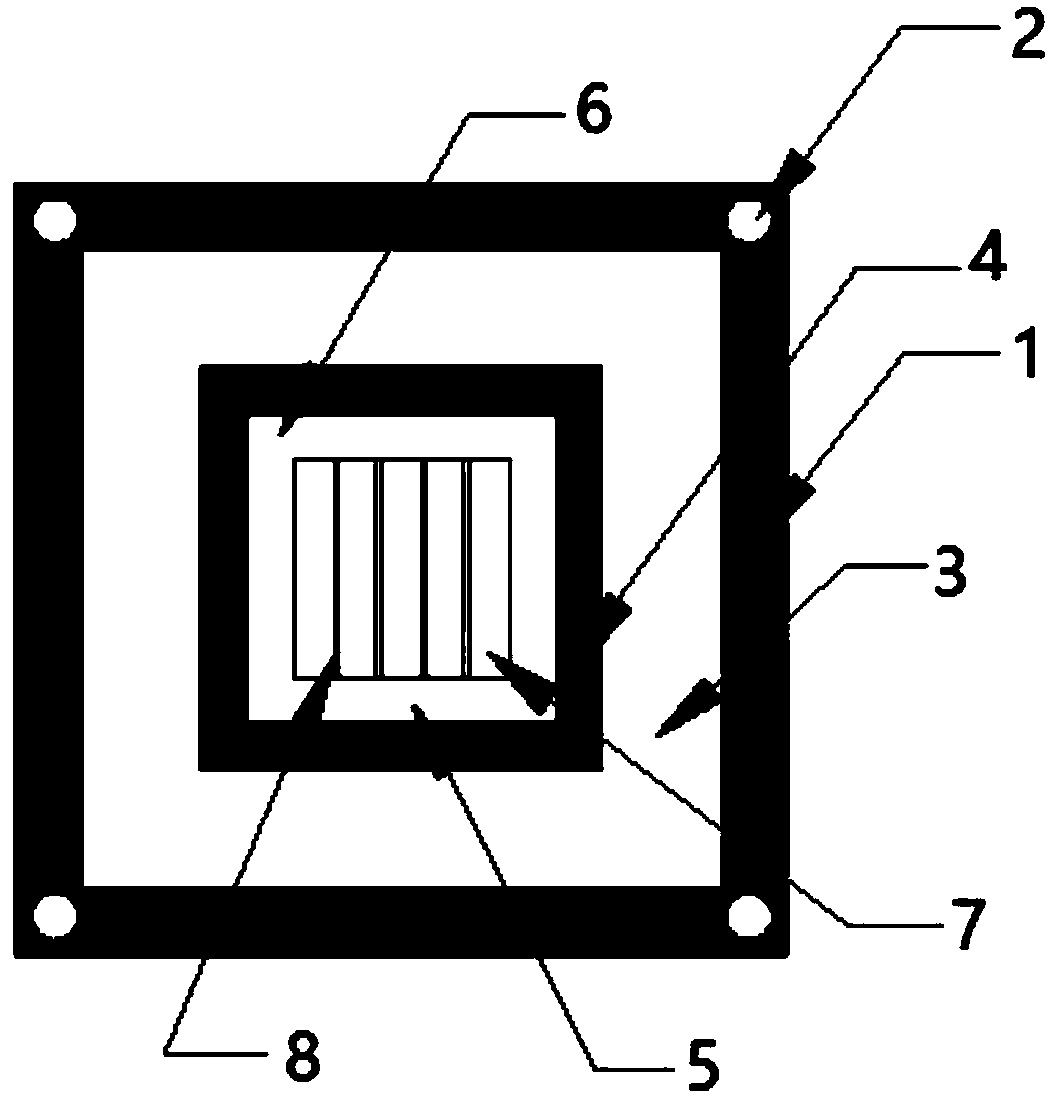

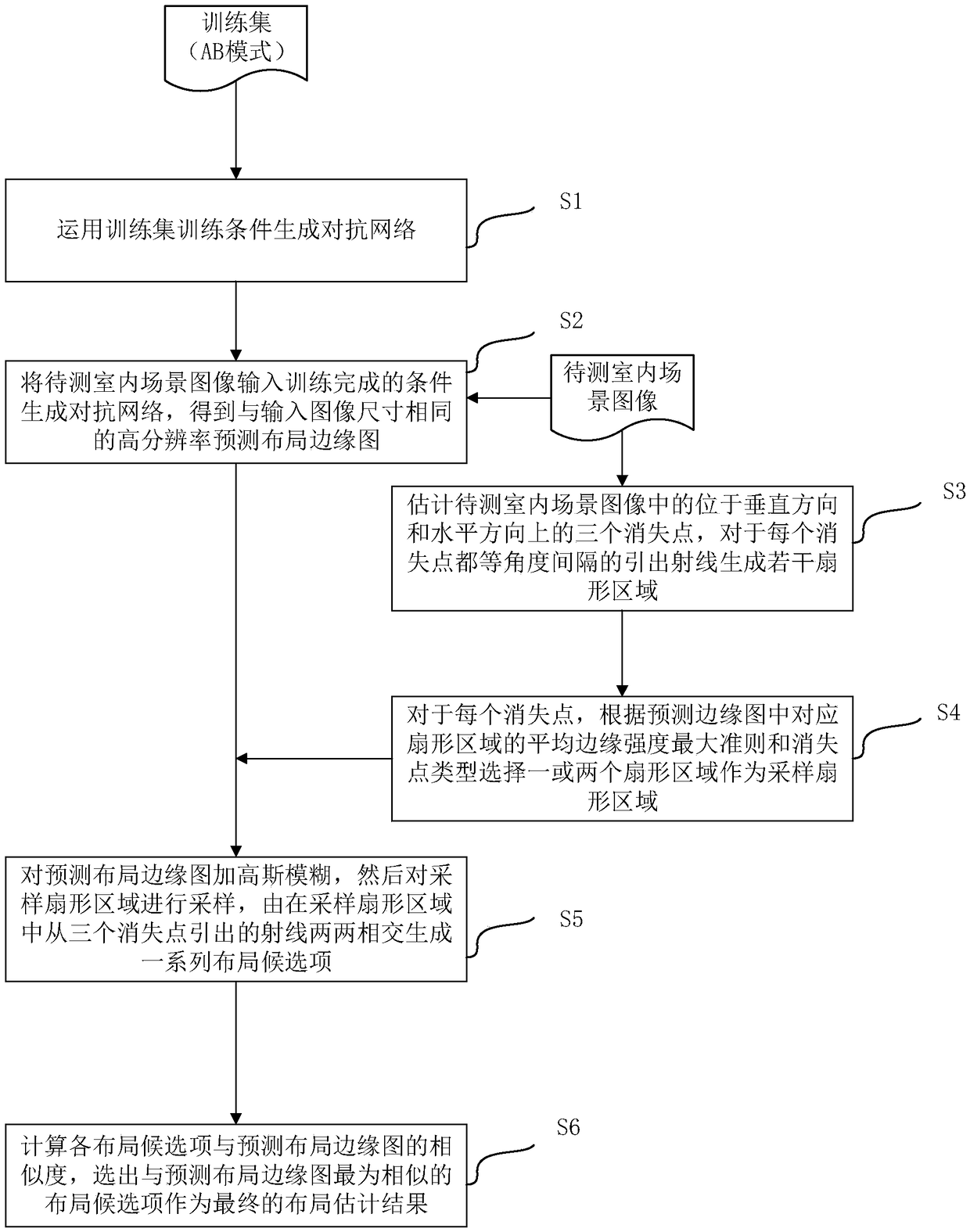

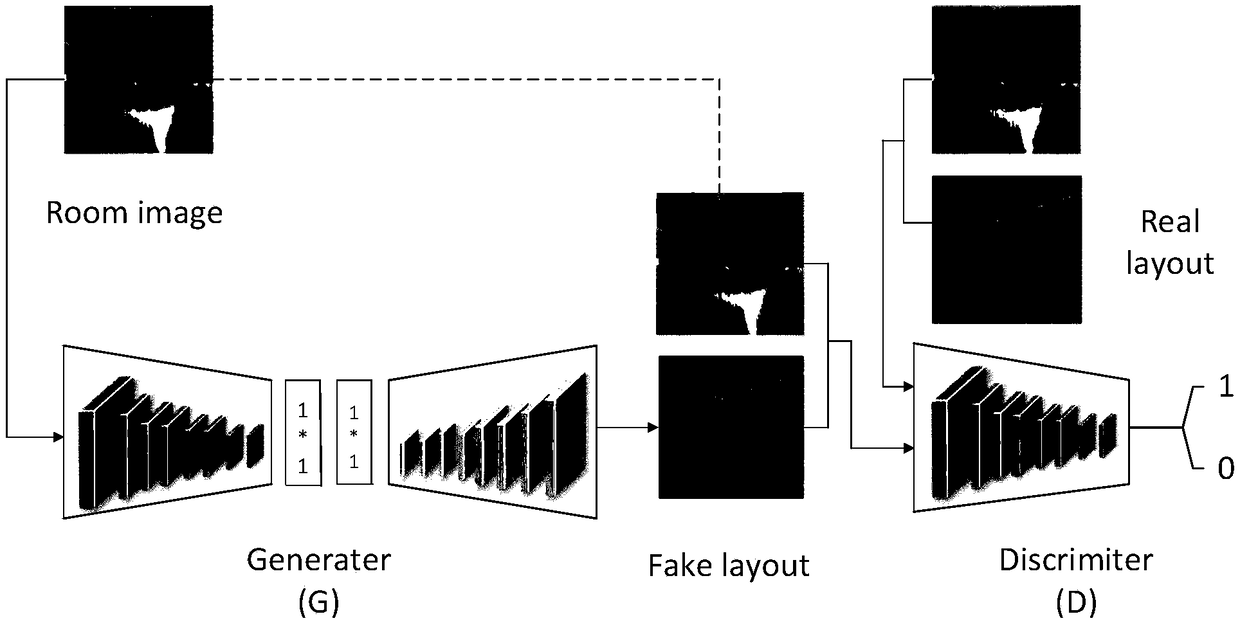

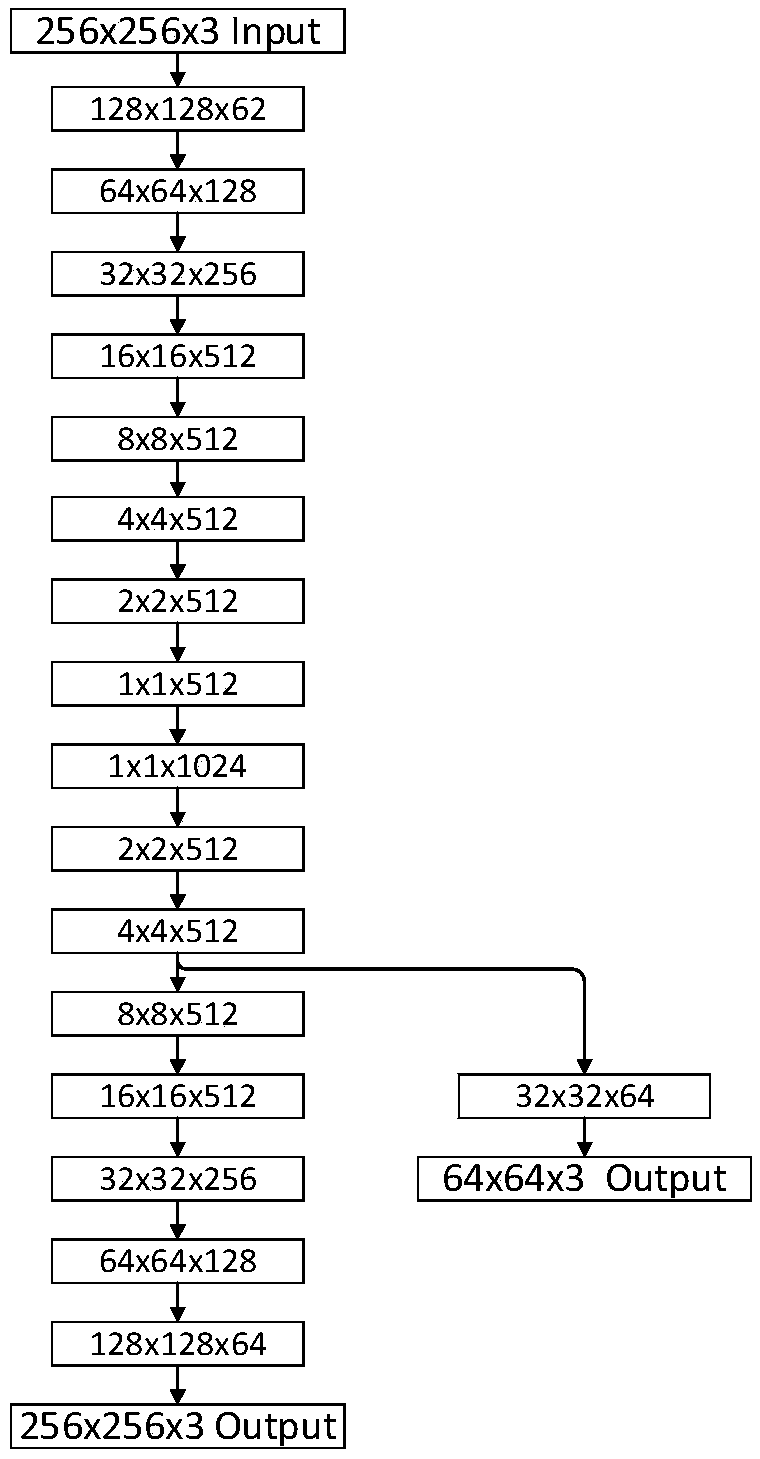

Method and apparatus for estimating indoor scene layout based on conditional generation countermeasure network

The invention discloses a method and a device for estimating indoor scene layout based on a conditional generation confrontation network. The method comprises the following steps: a confrontation network is generated by training conditions of a training set; an indoor image to be tested is inputted to a conditional generation confrontation network after training; and a layout edge map with the same size as an input image is predicted and generated. the vanishing points of the indoor image to be measured are estimated, rays are extracted from each vanishing point at equal angular intervals, anda plurality of fan-shaped regions are generated; a sampling sector region is determined according to the criterion of maximum average edge strength; Gaussian blur is added to that predict layout edgemap, and then the sampling sector region is sampled to generate a layout candidate item; The spatial layout which is most similar to the predicted layout edge map is selected as the final layout estimation result. The invention provides more complete original information for generating scene layout boundary map, does not need explicit hypothesis data parameter distribution, can improve layout estimation accuracy, and has important application value in indoor scene understanding and three-dimensional reconstruction task.

Owner:NANJING UNIV OF POSTS & TELECOMM

Flexible printed circuit (FPC) hollowed board and manufacturing method thereof

ActiveCN102238809AAvoid wrinklesAvoid damageElectrical connection printed elementsPrinted element electric connection formationPunchingCopper plating

The invention provides a flexible printed circuit (FPC) hollowed board and a manufacturing method thereof. The manufacturing method of the FPC hollowed board sequentially comprises the following steps of: S1, boring: boring a via hole in a double-faced copper foil, wherein the via hole is positioned in an area for manufacturing fingers of double-faced copper foil; S2, blackening the via hole and plating copper: blackening the via hole in the double-faced copper foil and plating copper; S3, manufacturing a circuit and the fingers: forming the circuit and a first finger on one surface of the double-faced copper foil and forming a second finger on the other surface of the double-faced copper foil; S4, adhering a covering film: adhering the covering film to the copper foil surface of the double-faced copper foil where the circuit is formed; and S5, punching: and punching off the base material at the first finger and the base material at the second finger to form a hollowed board. The FPC hollowed board has the advantages that the circuit is difficult to damage, the circuit is excellent and product yield is high.

Owner:深圳市合力泰光电有限公司

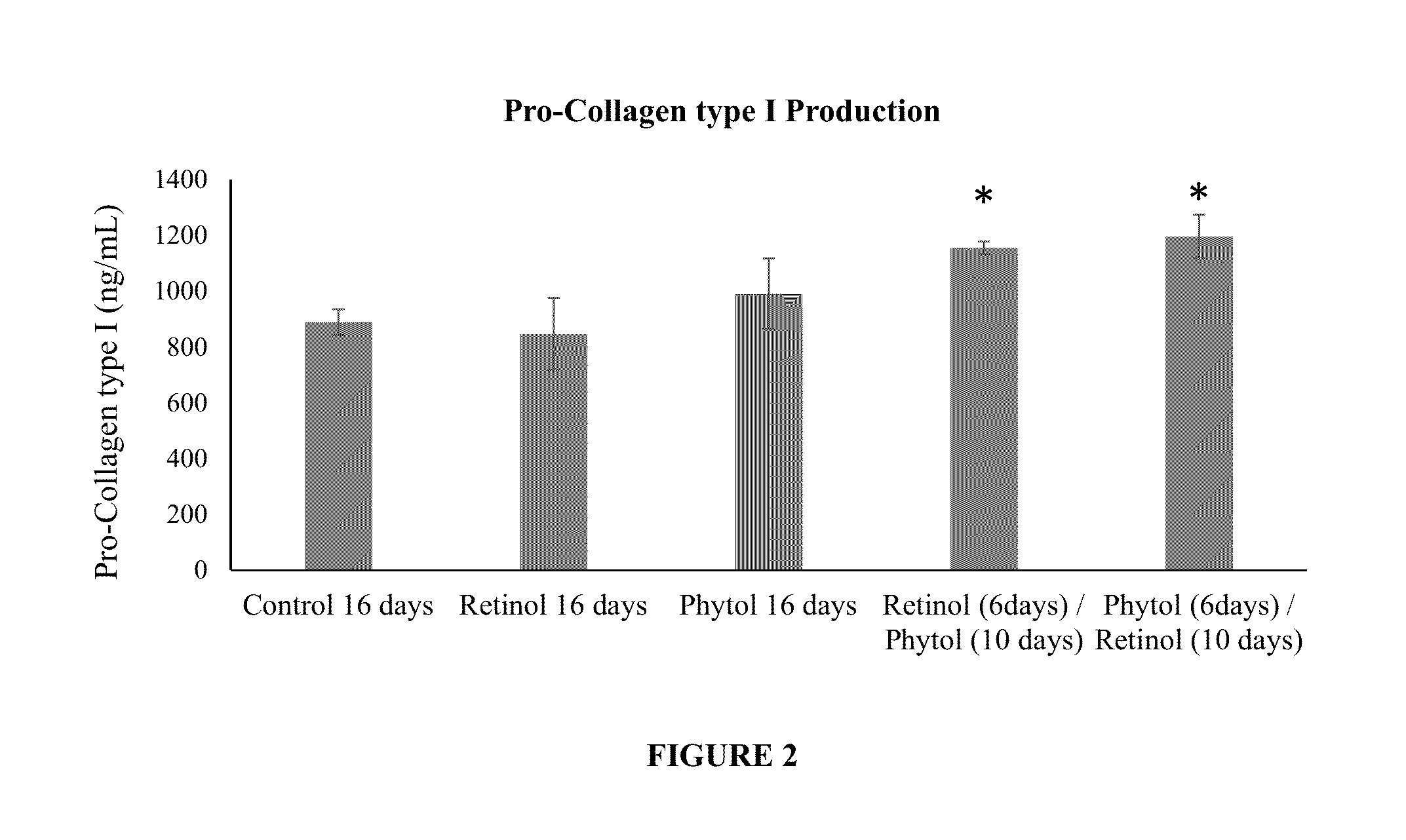

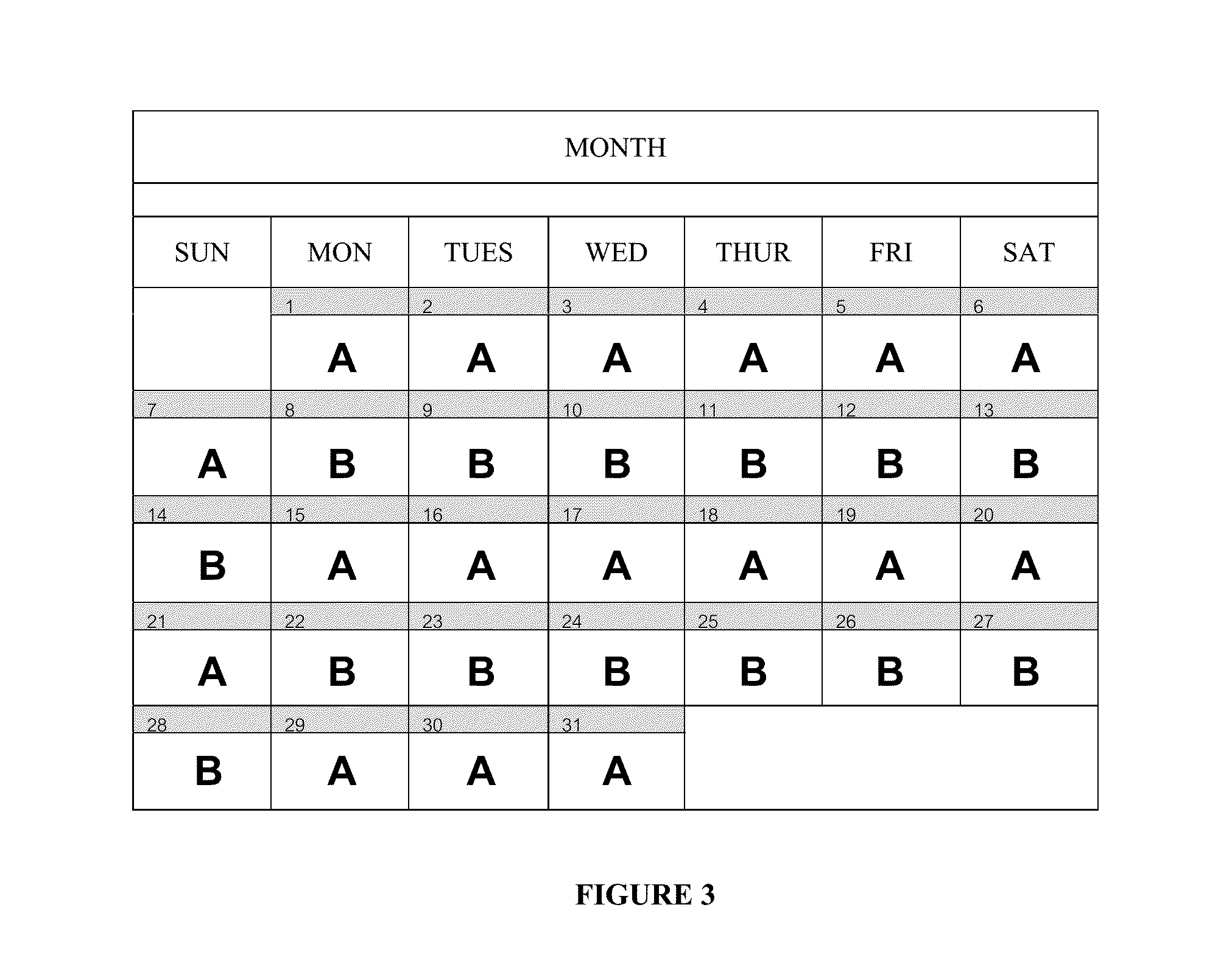

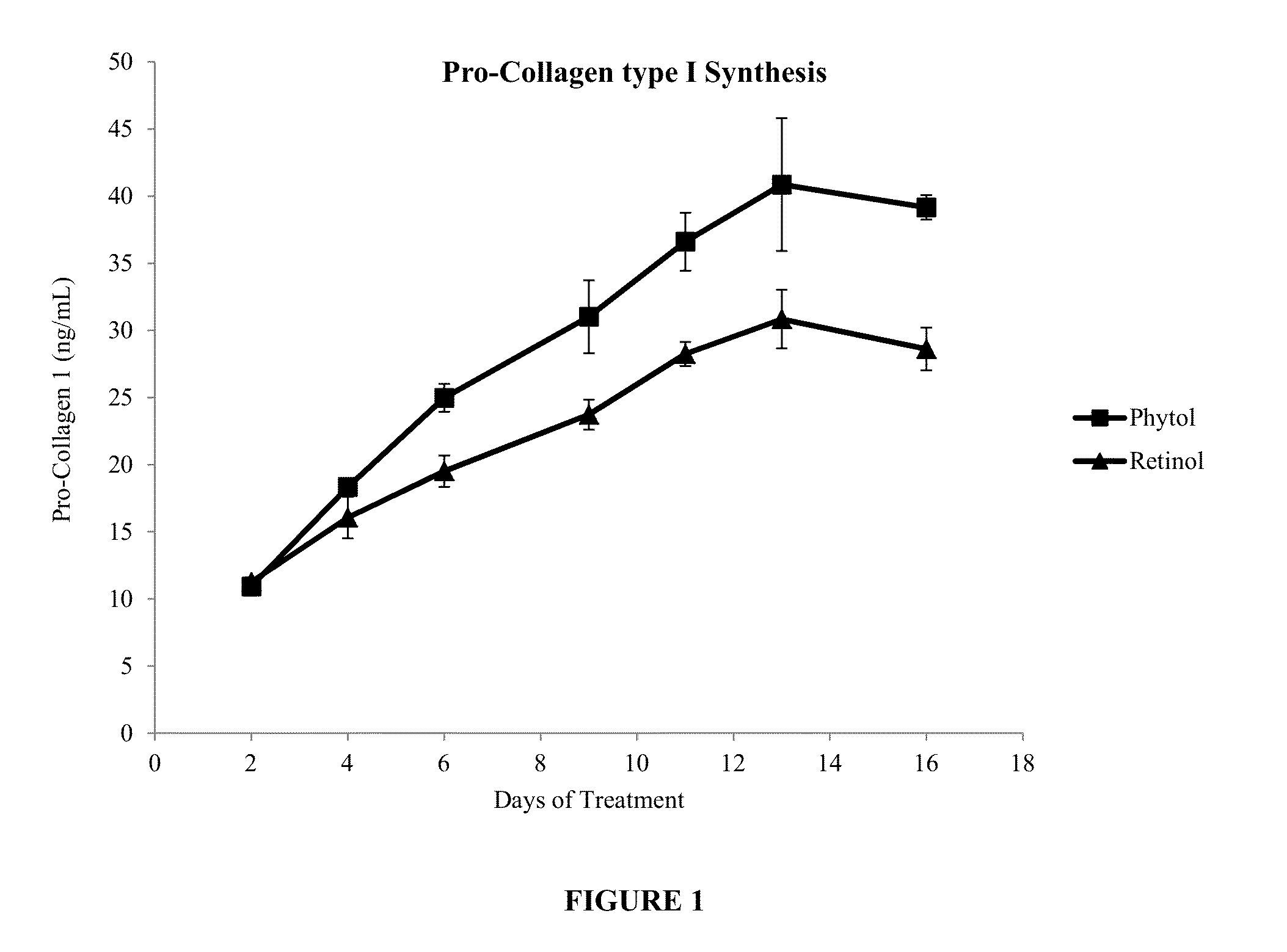

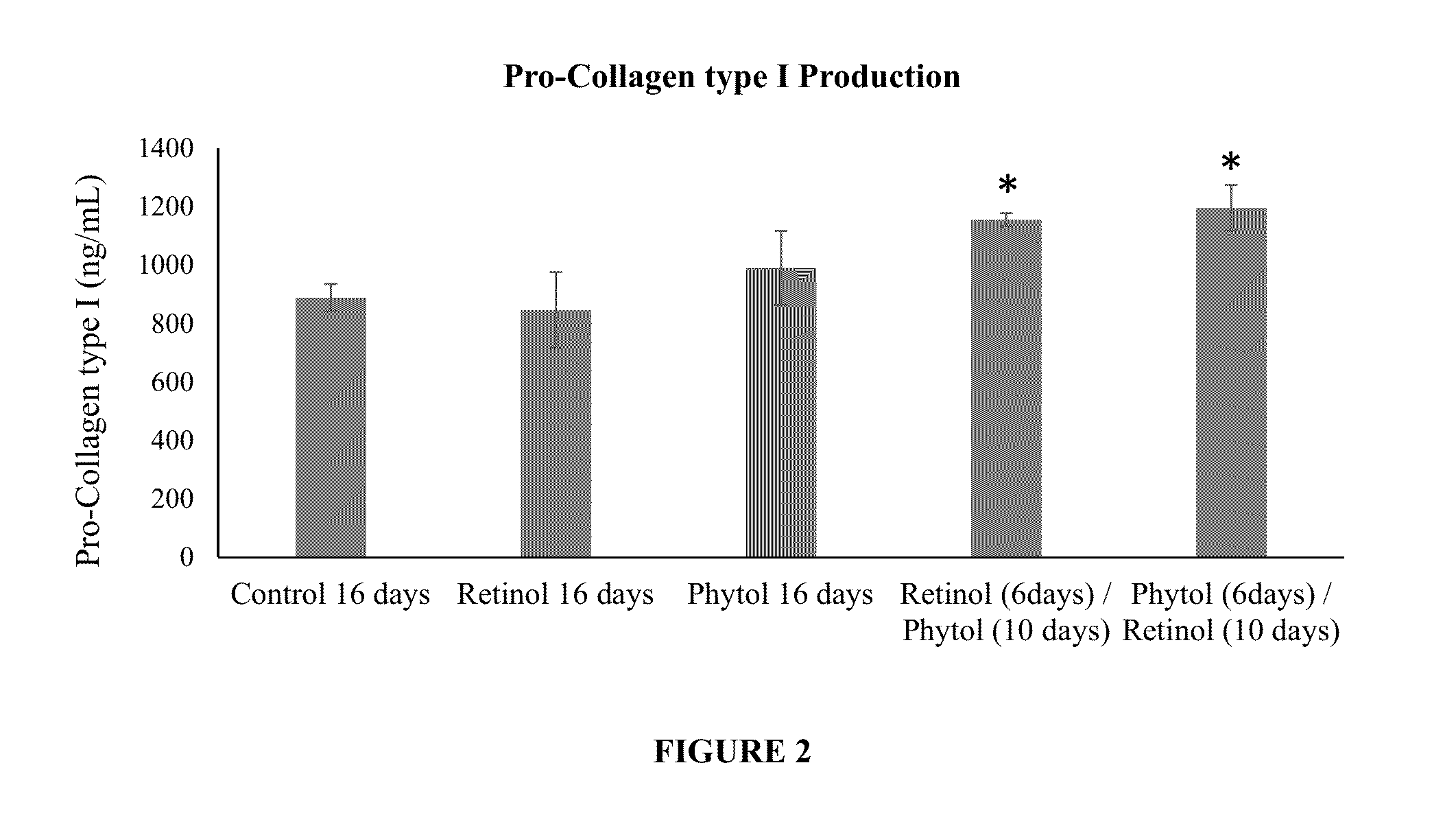

Methods for treating skin

ActiveUS20160256368A1Reduce appearance problemsBeneficial to human healthCosmetic preparationsToilet preparationsTreatment modalityPharmacology

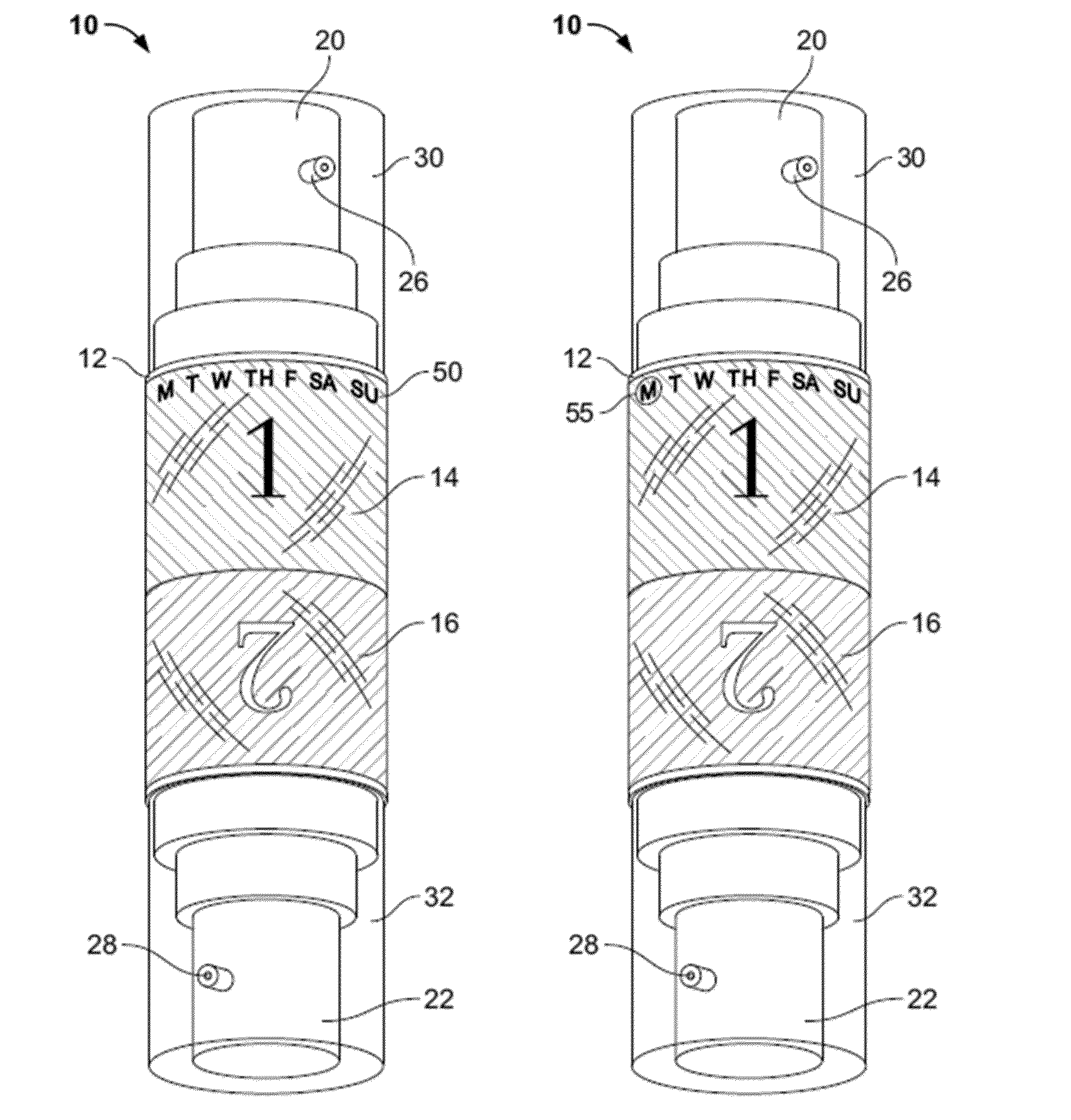

Provided are methods of treating skin with at least two alternating treatment modalities to improve the health and / or diminish signs of aging. Some methods according to the present invention may comprise topically applying at least two separate compositions, in a sequential, rotating, or alternating fashion to overcome adaptation, tolerance, or sensitization phenomena.

Owner:AVON PROD INC

Methods for treating skin

ActiveUS20160256369A1Reduce appearance problemsBeneficial to human healthCosmetic preparationsToilet preparationsMedicineTreatment modality

Provided are methods of treating skin with at least two alternating treatment modalities to improve the health and / or diminish signs of aging. Some methods according to the present invention may comprise topically applying at least two separate compositions, in a sequential, rotating, or alternating fashion to overcome adaptation, tolerance, or sensitization phenomena.

Owner:AVON PROD INC

Ornamental glass having etching pattern and multicolor pattern and and method for manufacturing same

InactiveCN101041555AHigh precisionFull of three-dimensional senseSurface treatment compositionsFlat glassScreen printing

The invention discloses a decorative glass with acid-frosted pattern and colored pattern and preparing method, which comprises the following steps: one, acid-frosting to acid-frosting pattern on the plate glass through acid-frosting treatment; two, cleaning; airing or drying; three, combining with self pattern of acid-frosting glass; adopting silk-printing or spraying method; printing or spraying coloured material on the acid-frosting glass; forming colored pattern; four, natural drying or drying the coloured glass; getting end product.

Owner:ZHENGZHOU HENGHAO GLASS TECH

Manufacturing method of composite screen printing plate

InactiveCN110039882ANot easy to wear and tearIncreased printing lifePlate printingFoil printingLine widthEngineering

The invention discloses a manufacturing method of a composite screen printing plate. The manufacturing method comprises the following steps of 1) screen pulling and compounding; 2) film layer manufacturing; 3) coating an adhesive layer; 4) coating a film; 5) drying; 6) laser; 7) cleaning; and 8) detection and packaging. By means of the mode, the manufacturing method of the composite screen plate has the advantages that when the screen printing plate is used, the film layer is not easy to wear and break, the printing life is prolonged by one time or more, the printing life of a conventional plate-making screen printing plate is averagely increased by about 50 thousand, the average energy of the screen printing life prepared by the method can reach 100 thousand or above and even higher, theprinting line at the later stage is not expanded, and the efficiency of the battery piece is obvious; and the manufactured screen printing plate is better in ink permeability, so that the limitation of the high-precision narrow line width can be greatly reduced, on the basis of the same type of ink printing, the width of the designed line can be compressed by 2-5 microns, the printing is good, theline type is good, and therefore the efficiency of the battery piece is obviously improved.

Owner:SUZHOU WOSUTE ELECTRONICS MATERIALS CO LTD

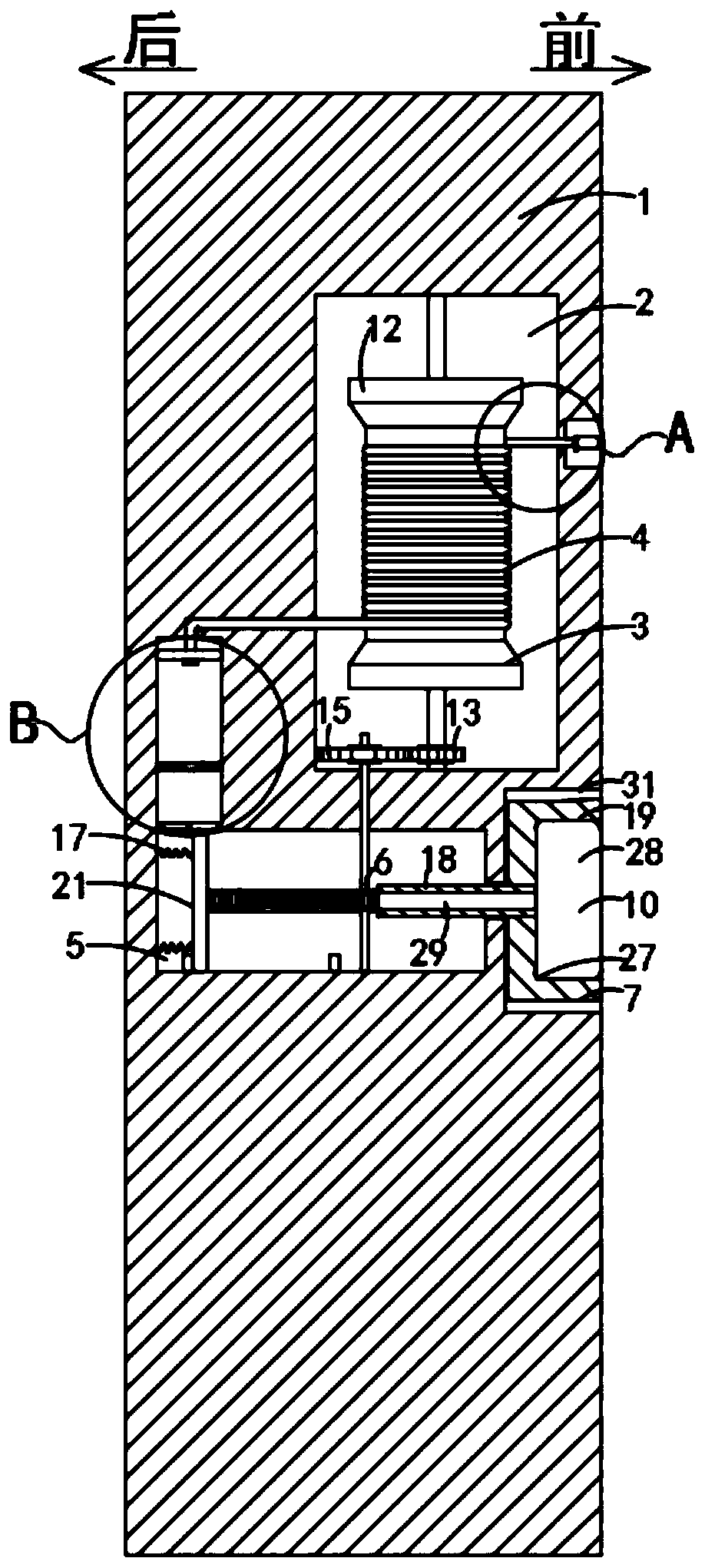

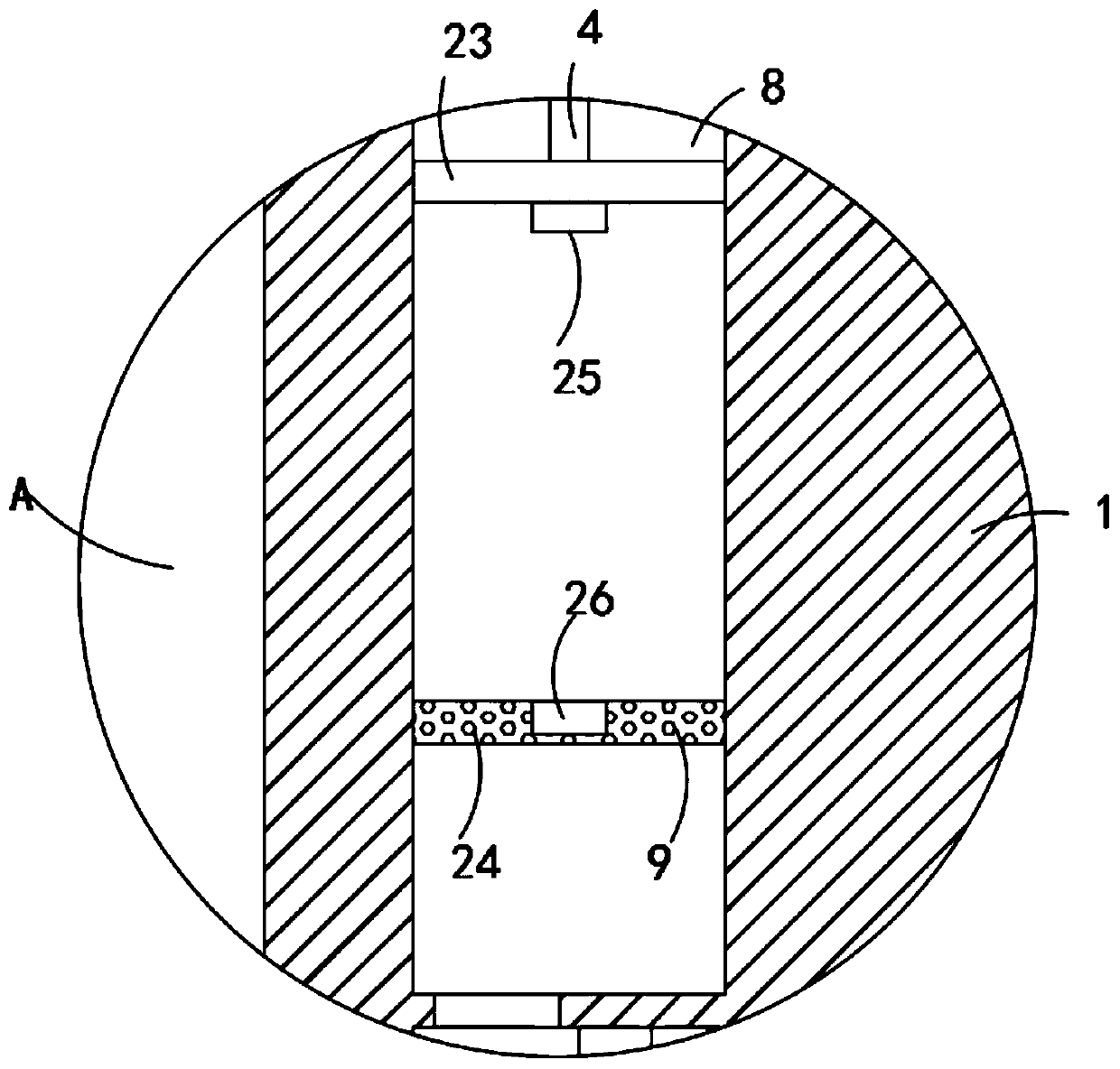

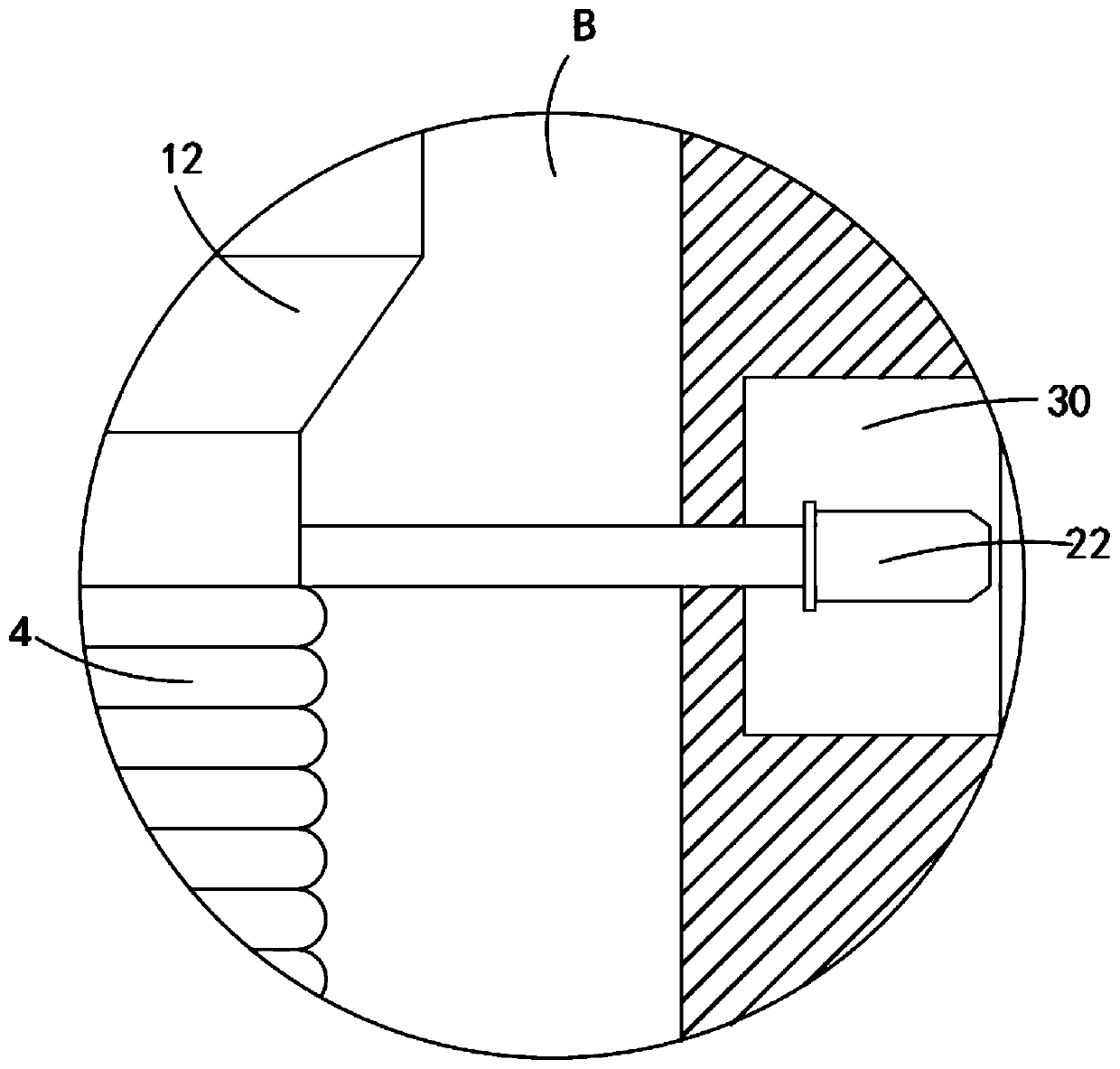

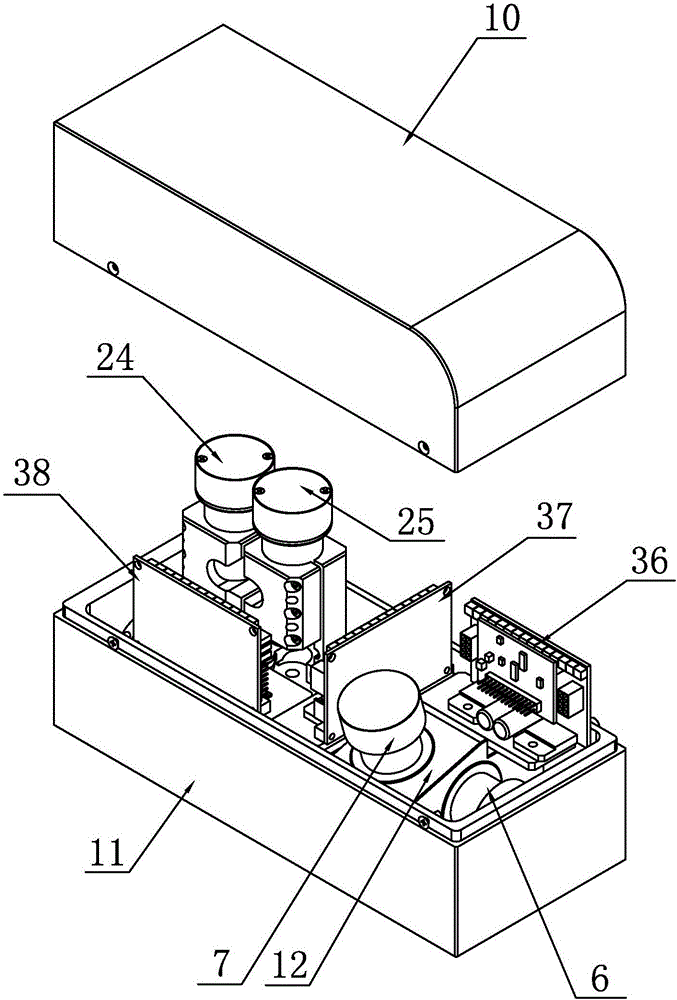

New energy vehicle charging pile

ActiveCN110040032AEnsure safetyReduce leakage accidentsCharging stationsElectric vehicle charging technologyParking spaceConductor Coil

The invention belongs to the technical field of new energy devices, and specifically relates to a new energy vehicle charging pile, which comprises a pile body.A first chamber is formed in the pile body, a wire winding mechanism is rotatably arranged in the first chamber, a charging cable is arranged in thewirewinding mechanism, the charging end of the charging cablepenetratesthrough the inner wall of the front end of the first chamber and is connected with a charging gun, a second chamber is arranged in the pile body, the second chamber is located below the first chamber, the bottom of the second chamber is rotatably connected with a driving mechanism, the driving end of the driving mechanism penetrates through the top surface of the second chamber and extends into the first chamber, thedriving mechanism is connected with the wire winding mechanism, a second groove is formed in the side wall of the front end of the pile body, a through hole communicating with the second chamber is formed in the inner wall of the second groove, and a magnetic sensing device is arranged in the through hole in a penetrating mode.Accordingto the new energy vehicle charging pile,when a vehicle parksina parking spot in front of the charging pile, the charging wire can be discharged and electrified, and the charging pile also has an anti-collision function.

Owner:SHENZHEN TECHONE TECH

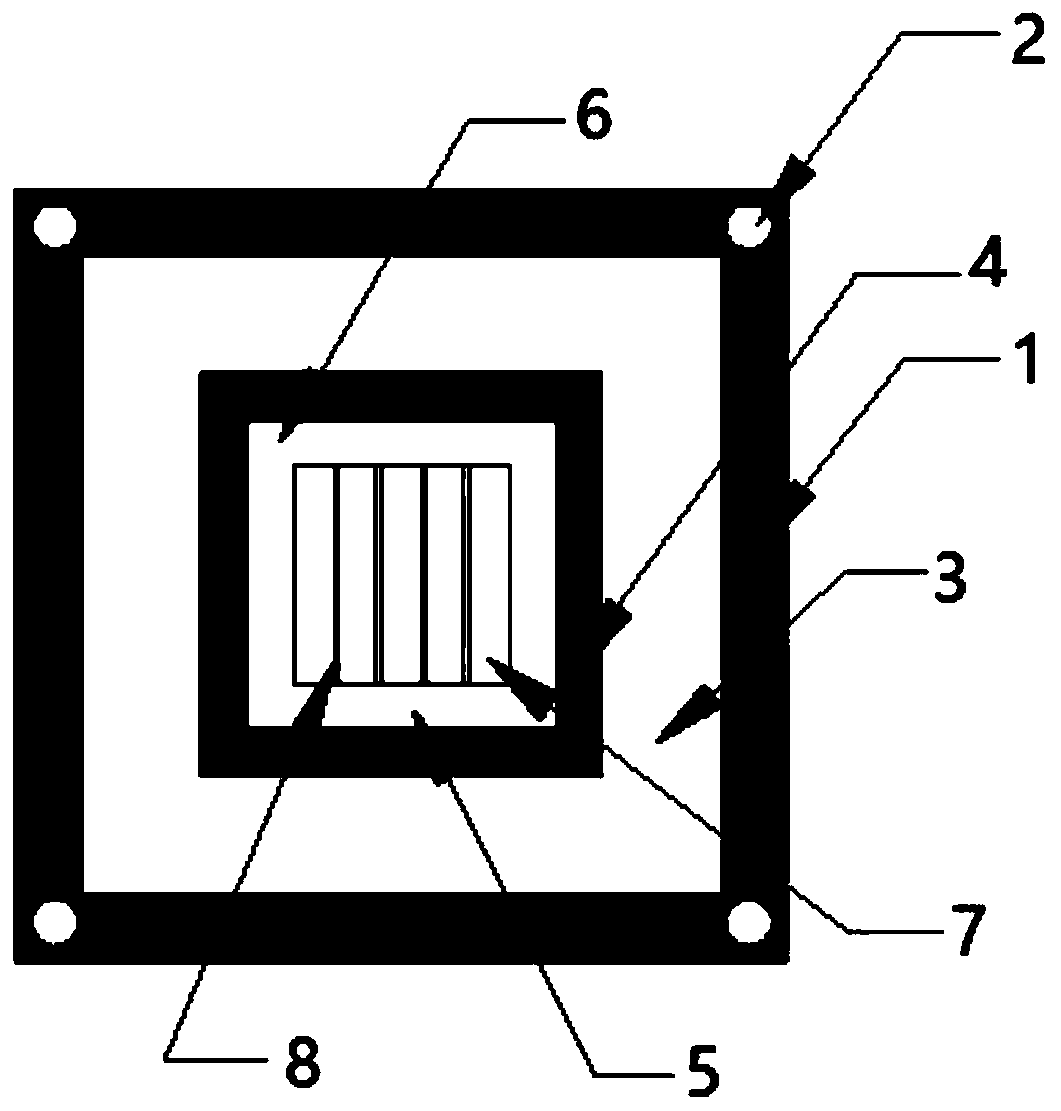

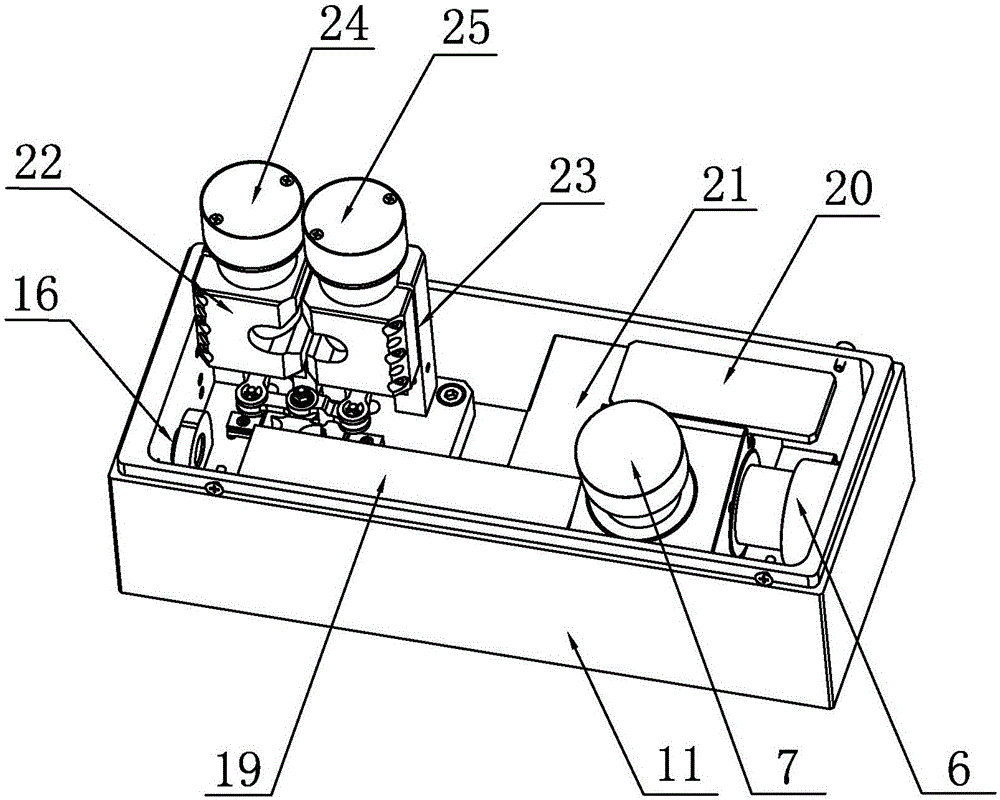

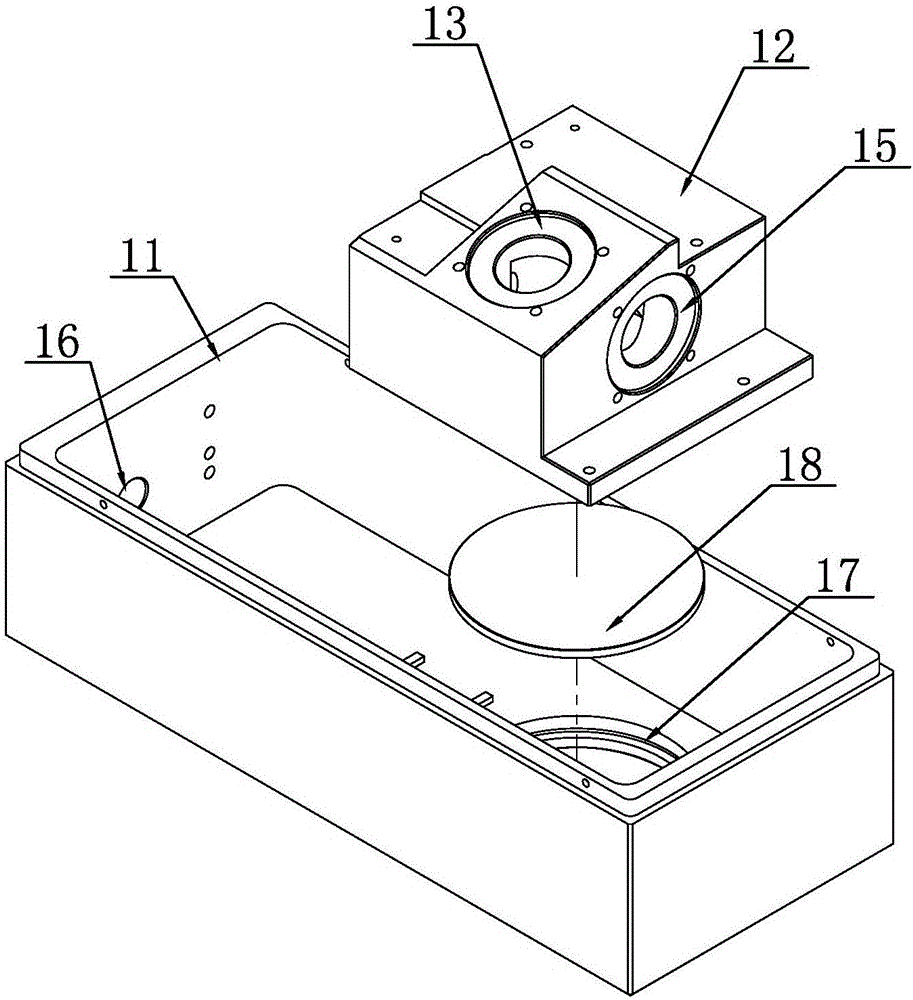

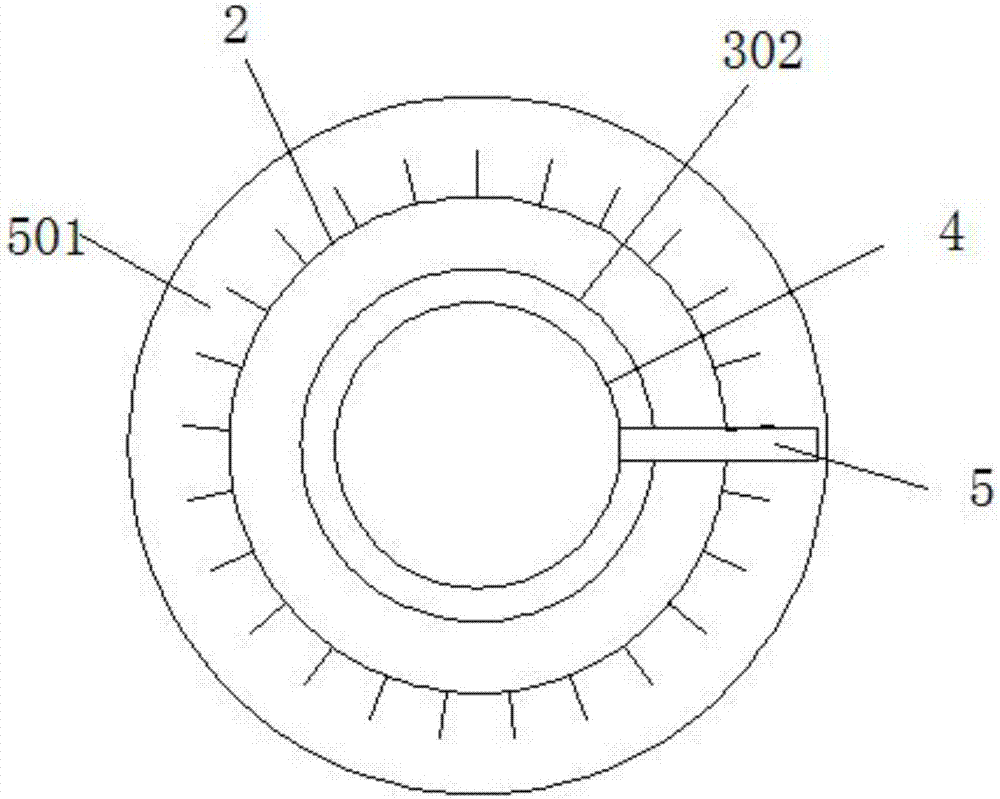

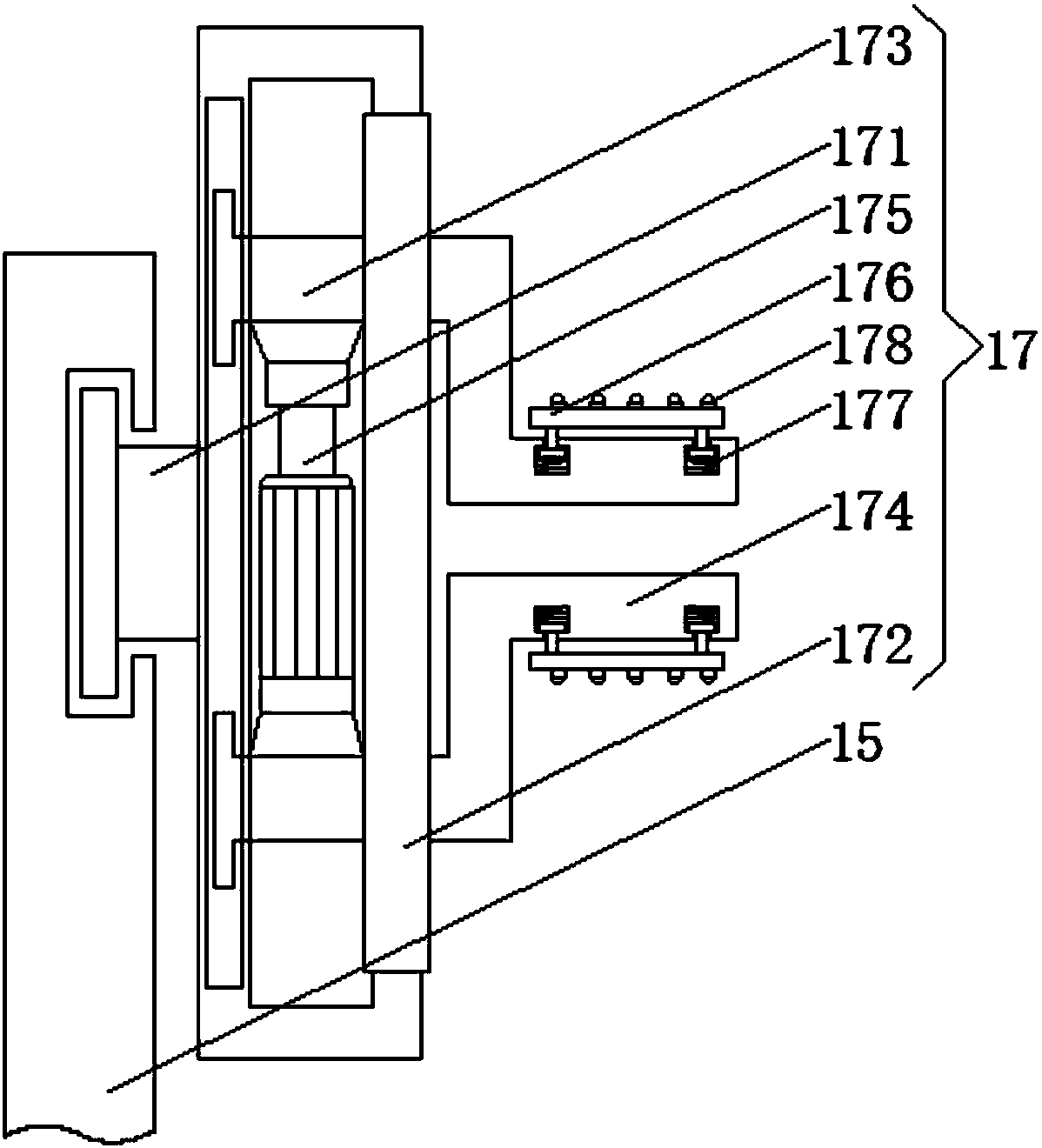

High-speed dynamic focusing laser vibrating mirror module group

PendingCN105974581AImprove marking qualityImprove marking effectLaser beam welding apparatusOptical elementsMotor driveOptoelectronics

The invention relates to a high-speed dynamic focusing laser vibrating mirror module group, and aims at providing a dynamic focusing laser vibrating mirror which is high in degree of integration, fine in marking and stable in performance. The high-speed dynamic focusing laser vibrating mirror module group comprises a shell, a dynamic focusing module, an X scanning vibrating mirror and a Y scanning vibrating mirror. The dynamic focusing module, the X scanning vibrating mirror and the Y scanning vibrating mirror are arranged in the shell. The dynamic focusing module comprises a Z-axis base, a Z-axis first motor, a Z-axis second motor, a connecting rod transmission mechanism, a zooming lens and a focusing lens set. The Z-axis adopts a double motor driving mode so that operation speed of the Z-axis can be greatly enhanced; and the dynamic focusing module is combined with the X scanning vibrating mirror and the Y scanning vibrating mirror so that the degree of integration of the product can be greatly enhanced. A shading base, the zooming lens and the focusing lens set are integrally assembled so that coaxiality of a light path can be guaranteed, high-precision and compact design of motor assembling and the light path system is performed in the whole structure, precise marking of a curved surface or large breadth is guaranteed and the overall size is reduced for one third in comparison with that of similar products.

Owner:北京金海创科技发展有限公司

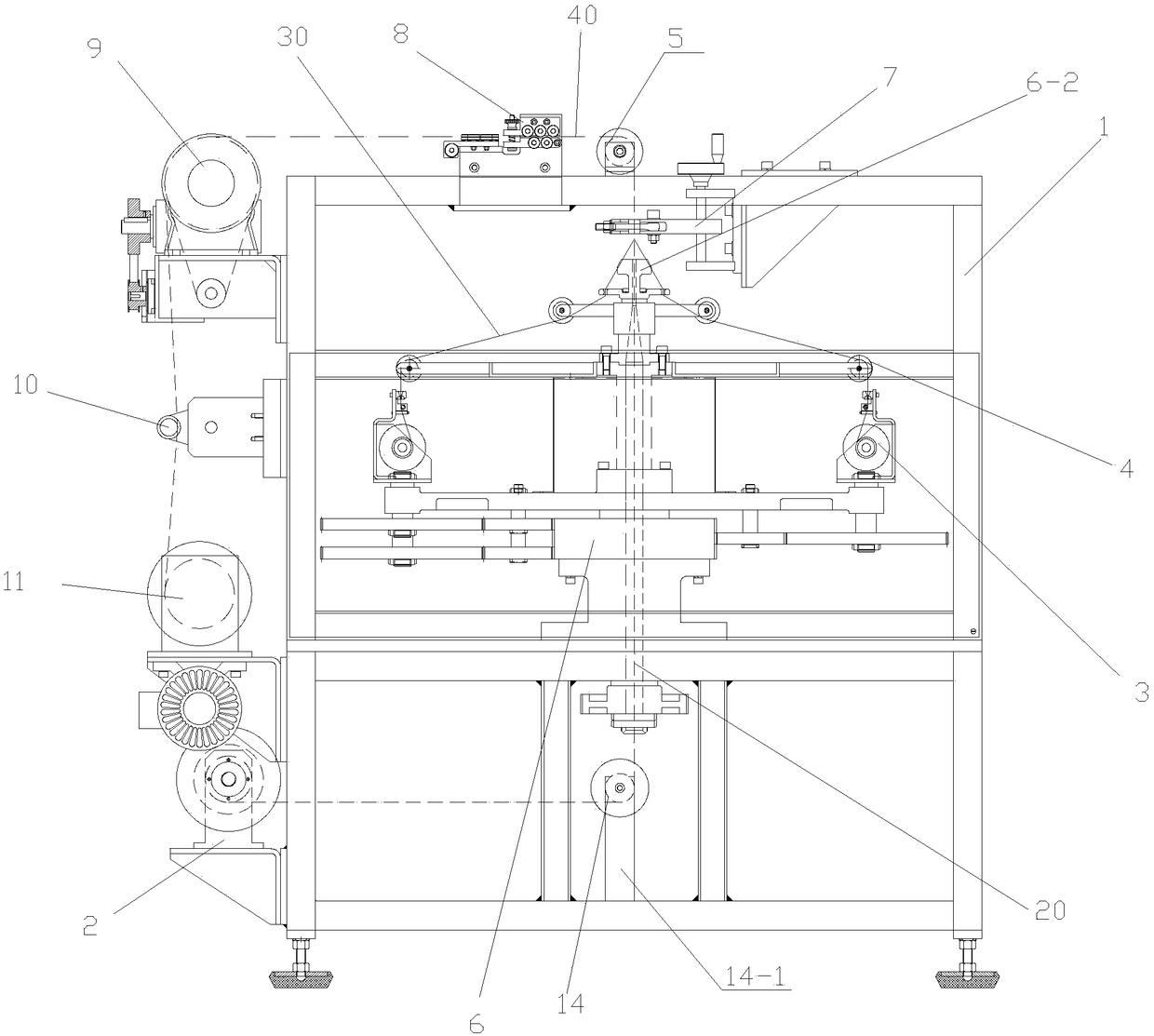

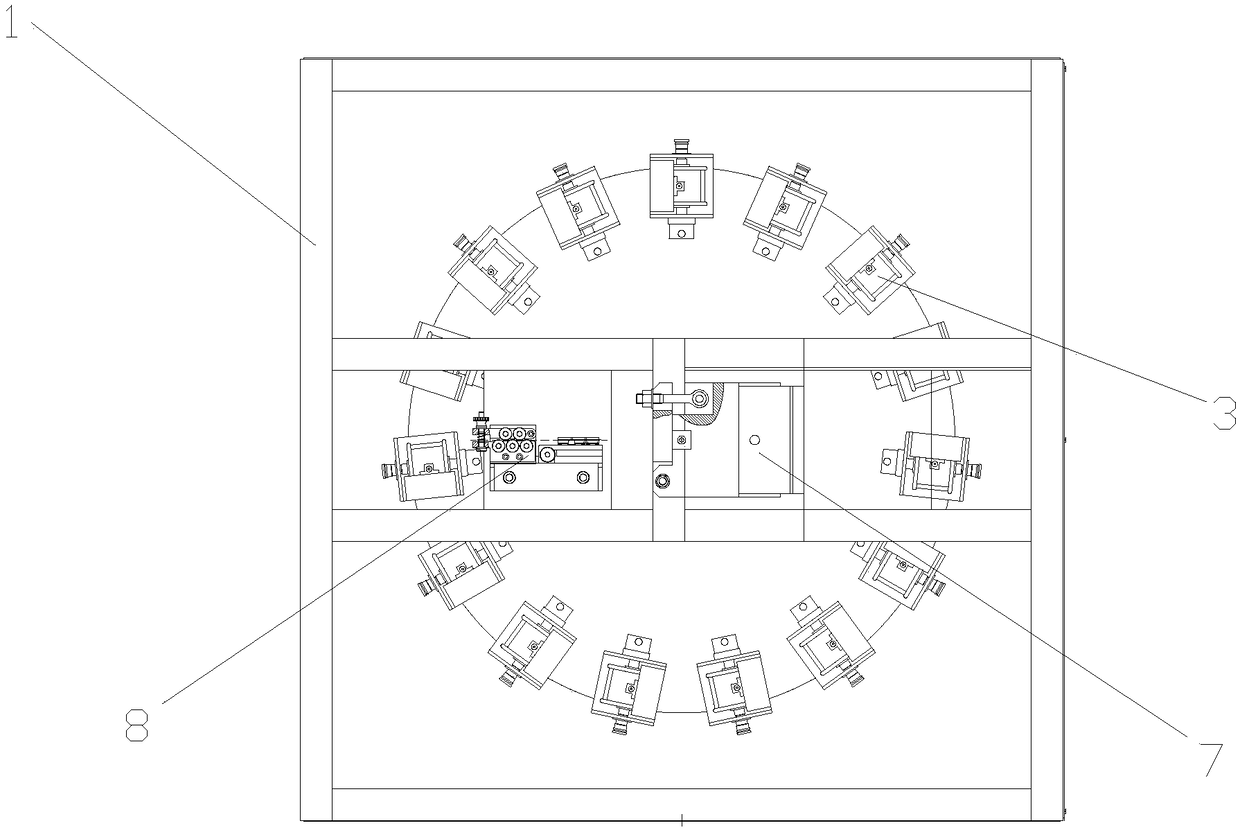

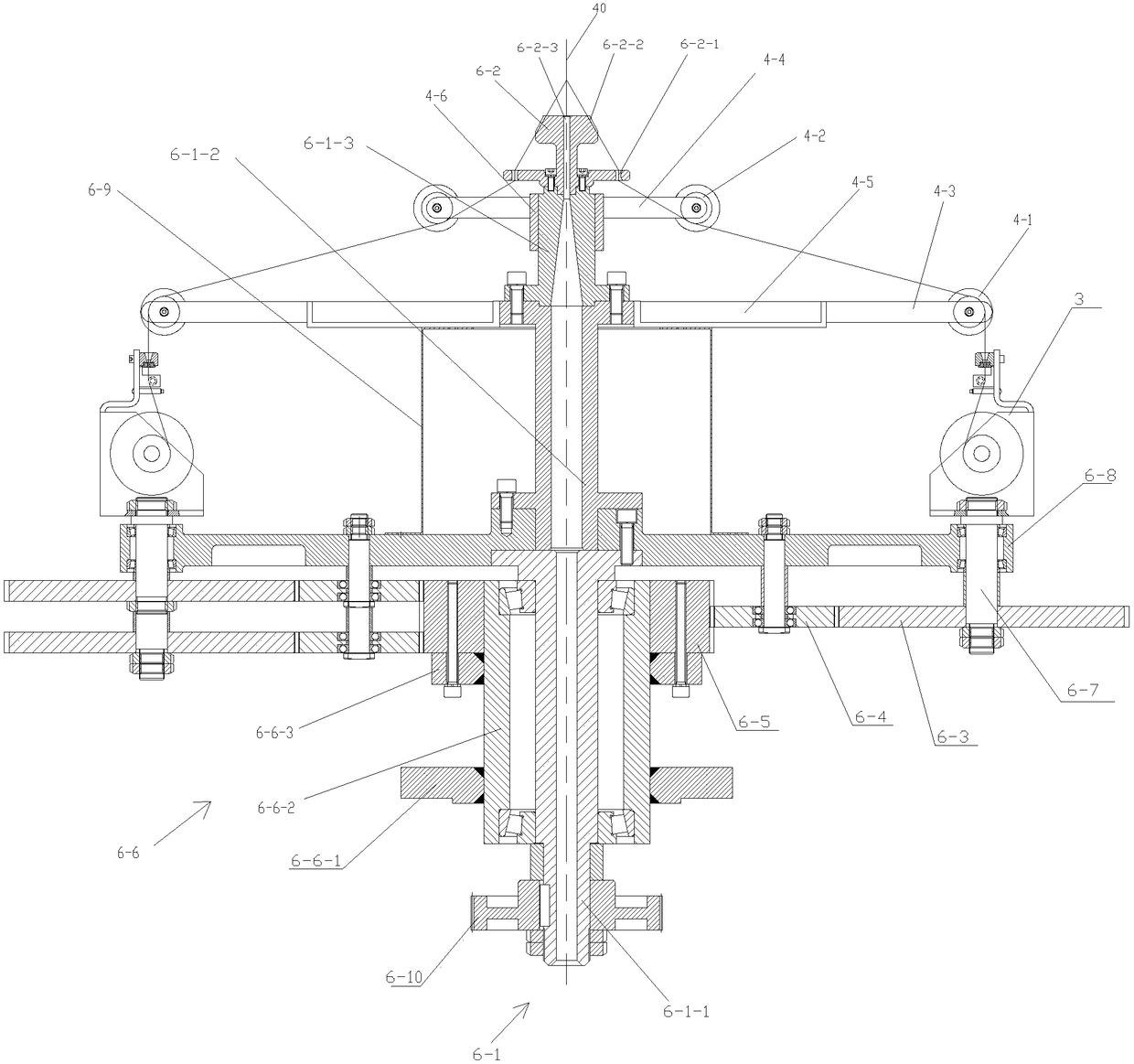

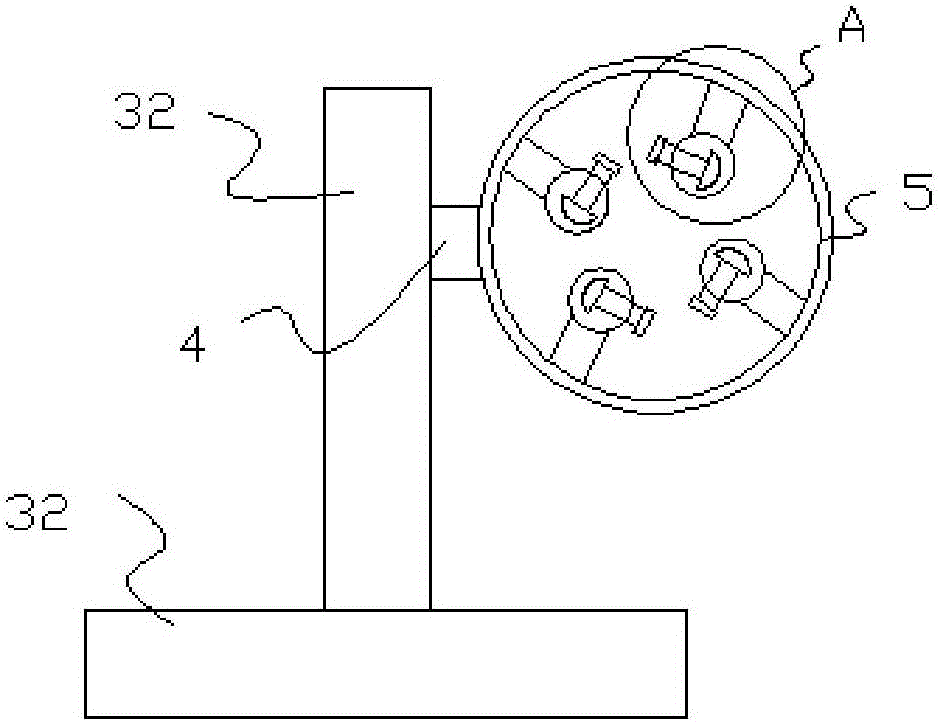

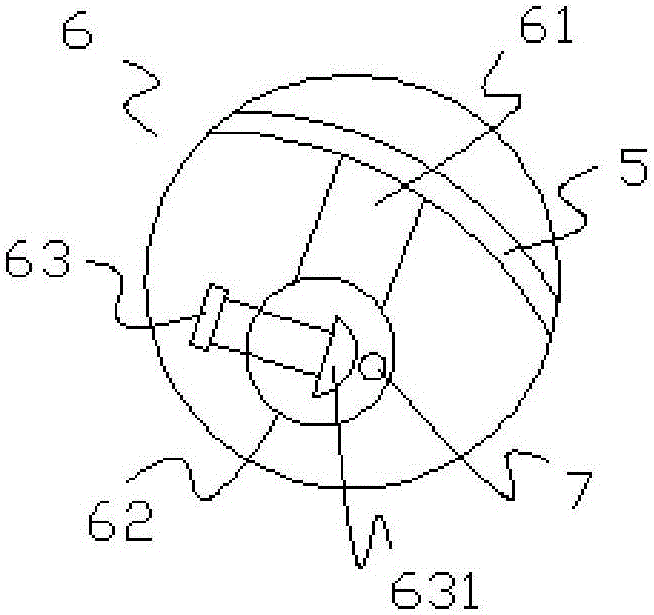

Multi-head vertical digital control twisting and winding machine

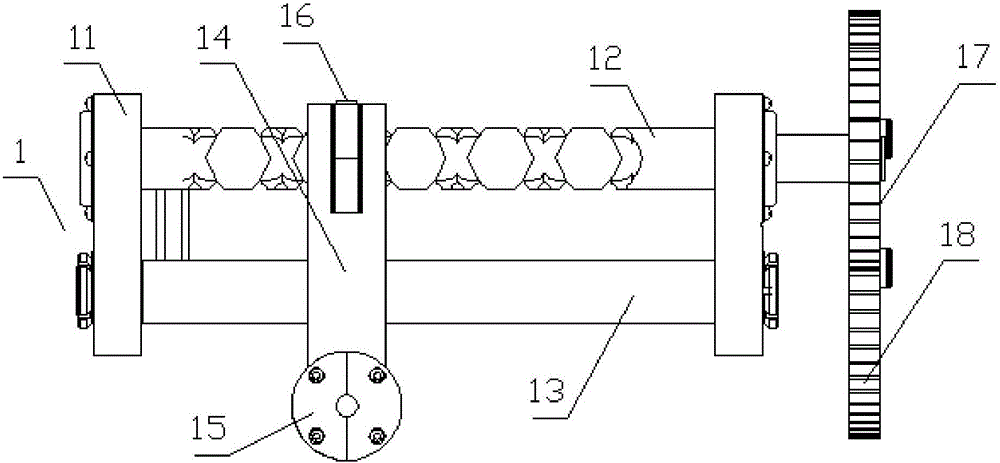

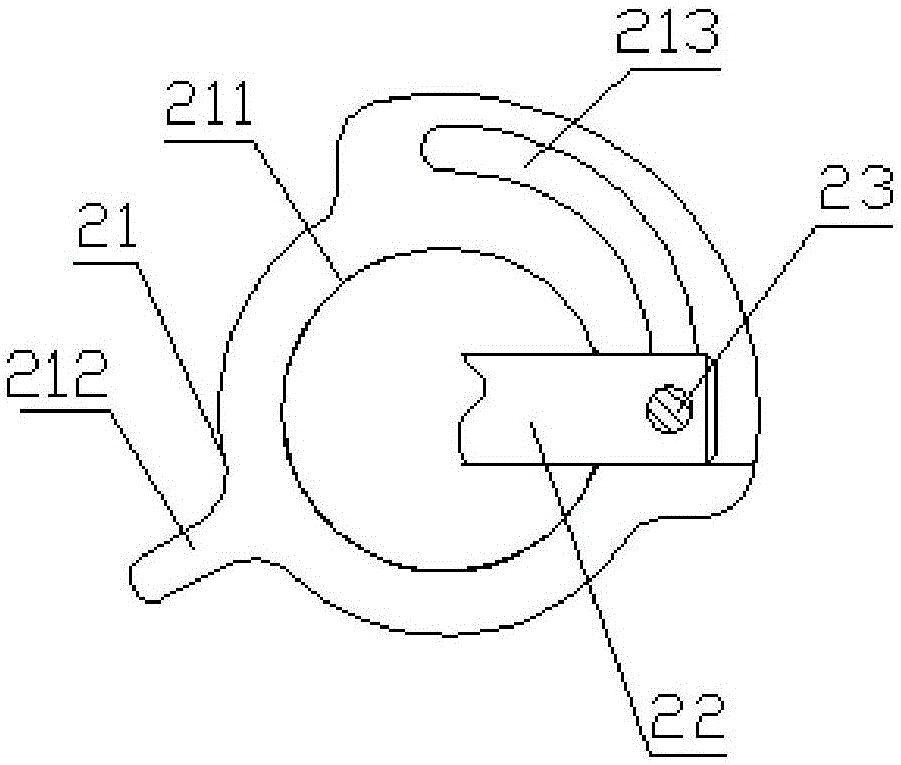

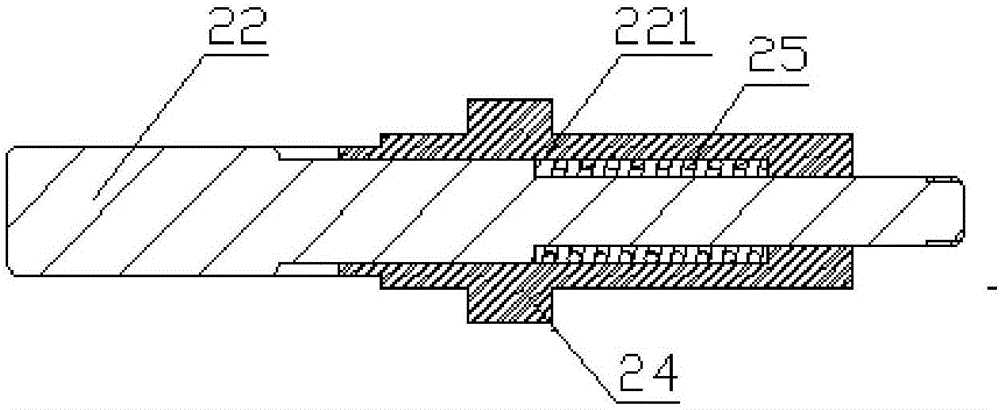

PendingCN108134307ASimple structureReasonable designLine/current collector detailsWinding machineEngineering

The invention discloses a multi-head vertical digital control twisting and winding machine. The multi-head vertical digital control twisting and winding machine comprises a rack, a twisting and winding processing apparatus and a monitoring apparatus; the twisting and winding processing apparatus comprises a wire pay-off apparatus, a wire twisting apparatus, a correction traction apparatus and a wire take-up apparatus; the wire pay-off apparatus comprises a wire pay-off mechanism, shuttle frame mechanisms and guiding mechanisms, wherein the shuttle frame mechanisms and the guiding mechanisms are the same in number; the wire twisting apparatus comprises a rotary shaft, a rotating mechanism, a wire gathering plate and a power mechanism; the correction traction apparatus comprises a shaping mechanism, a straightening mechanism and a traction mechanism; the wire take-up apparatus comprises a wire arranging mechanism and a wire take-up mechanism for winding the twisted wires; and the monitoring apparatus comprises a control apparatus, a tension detection apparatus, a rotary speed measurement unit and a traction speed measurement unit. The multi-head vertical digital control twisting andwinding machine is simple in structure and capable of realizing continuous processing of the twisted wires, improving production efficiency, lowering manual labor, ensuring diameter consistency of twisted wire harnesses and satisfying the three-layer winding requirement of fried dough twist-like contact pins.

Owner:THE NORTHWEST MACHINE

Surface metallization decoration method

InactiveCN102285299AClear outlineOvercoming rough and uneven contour linesPhotomechanical apparatusSpecial ornamental structuresMetalSurface chemical

The invention belongs to the field of surface chemical treatment or material plating with application of a metal material, relating to a method of performing metallized decoration on the surface of nonmetal material and products thereof. The method comprises the steps of: plating a metal layer on a surface of an object to be decorated, spraying UV cured photosensitive ink, and placing a negative film which is partly light-transmissive on the UV cured photosensitive ink, then exposing in UV light, wherein the ink in the light-transmissive area is cured, and the ink in the lighttight area is not cured; further processing by developing liquid, removing the ink in the lighttight area to expose the metal layer under the ink, spraying etching liquid for etching, wherein the metal layer is removed by etching and the metal layer under the cured ink layer is reserved; and then removing the ink layer on the metal layer by a film removing agent, thereby forming a metal pattern by exposing the metal layer. According to the method, lines and spaces in 50 microns or less can be obtained, and the products can present pattern decorative effects which cannot be presented by the prior art due to the degree of fineness of the obtained products.

Owner:广州圣维可电子科技有限公司

Distribution line pay-off device with braking function

ActiveCN106516859ABraking achievedSimple structureFilament handlingMechanical engineeringBrake control

The invention discloses a distribution line pay-off device with the braking function. The device comprises a pay-off rack, the pay-off rack is provided with a pay-off shaft in a rotating mode, a pay-off spool is fixed to the pay-off shaft, the pay-off shaft is fixedly connected to a rotating handle, and the pay-off rack is provided with a braking device braking the pay-off spool rotating inertially. According to the device, the braking device is arranged, by turning a braking control knob to rotate, a braking rod is driven to move axially, a braking contact surface between the braking rod and the pay-off spool is contacted so that the pay-off spool can be braked, the structure is simple and braking is convenient; and a wire arrangement device is arranged so that wires wound around the pay-off spool can be orderly arranged, the structure is simple, and the wire arrangement is convenient.

Owner:STATE GRID ZHEJIANG PINGHU POWER SUPPLY +2

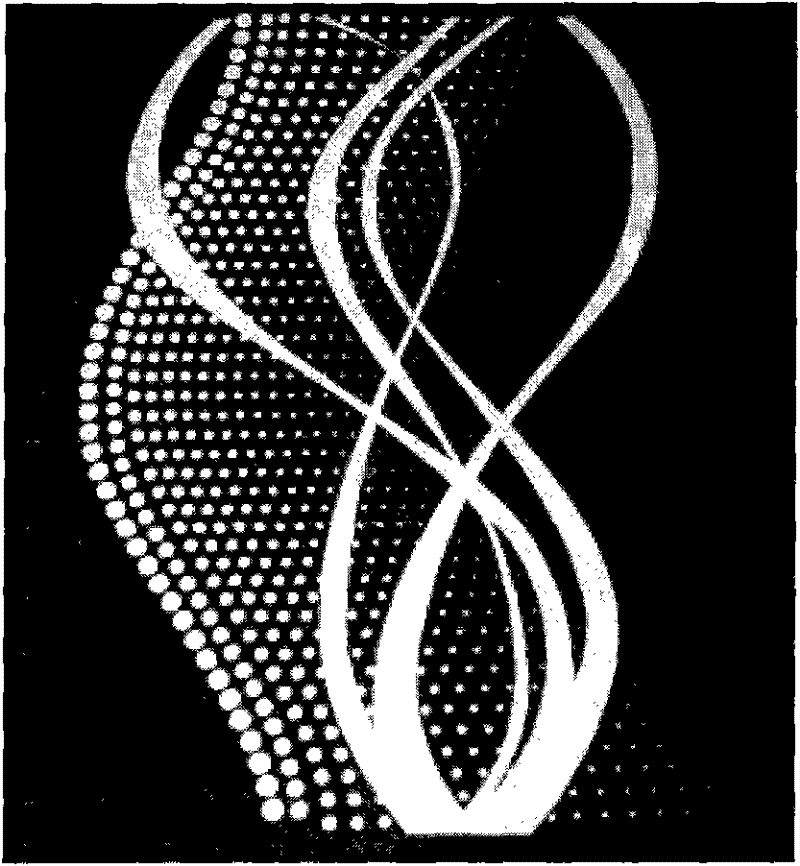

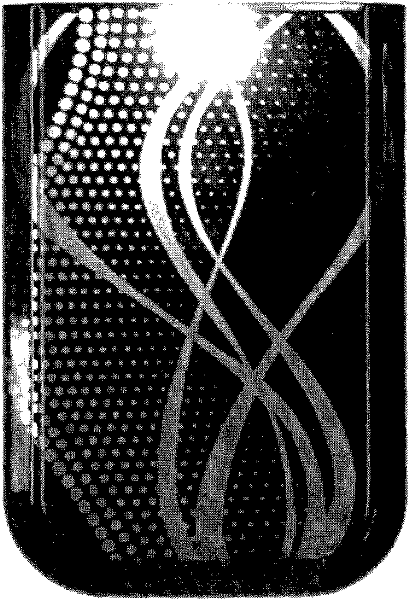

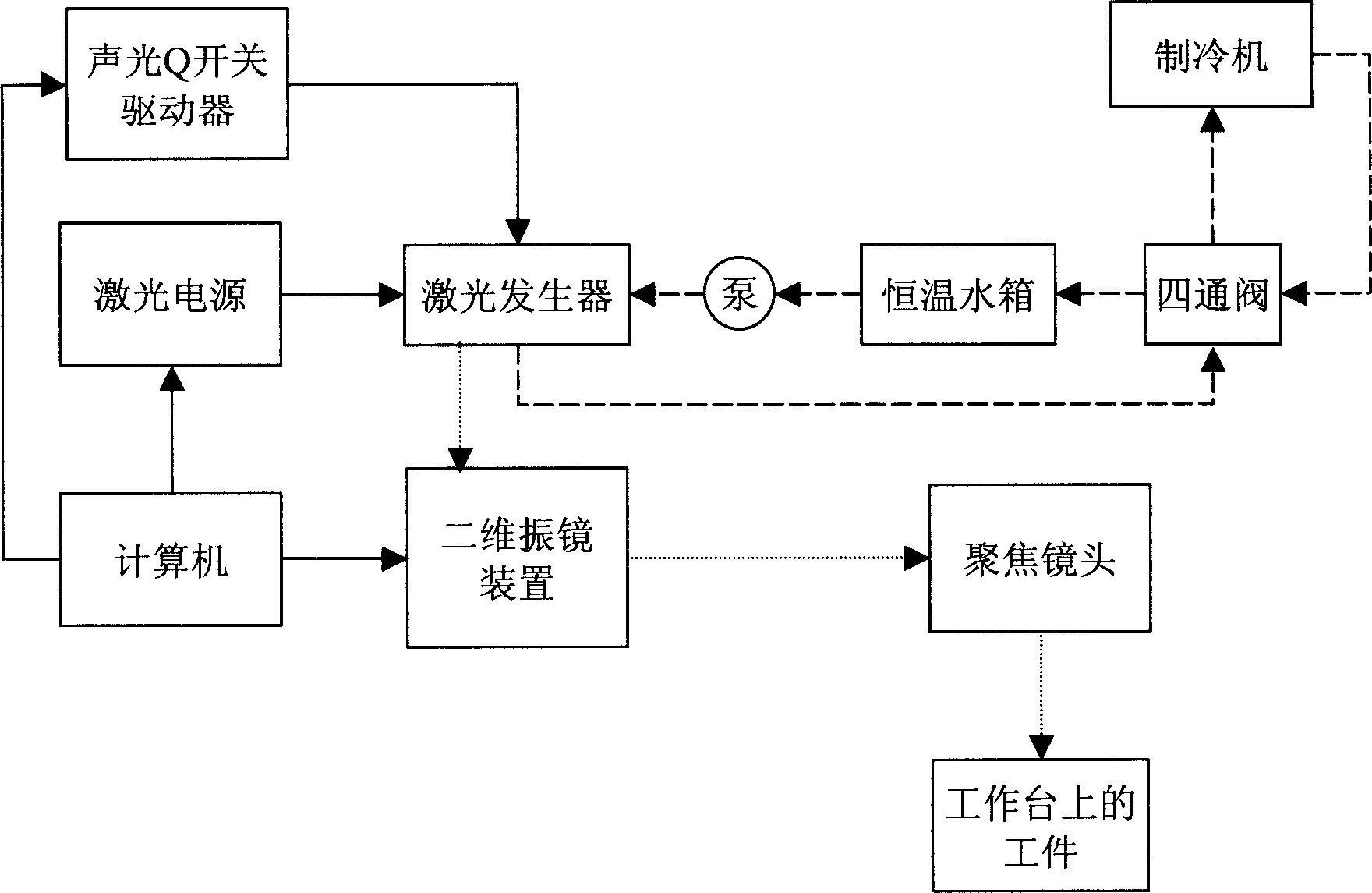

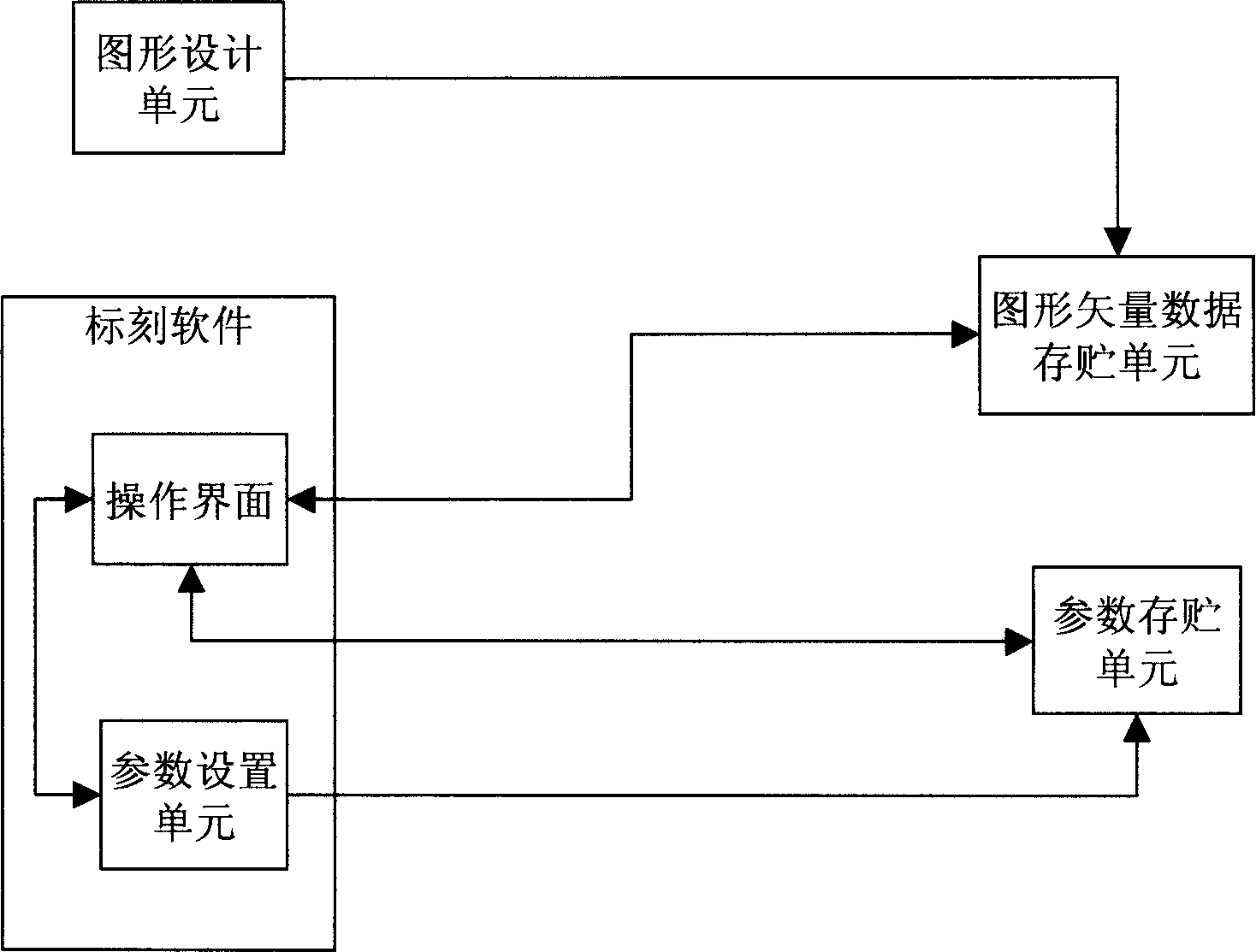

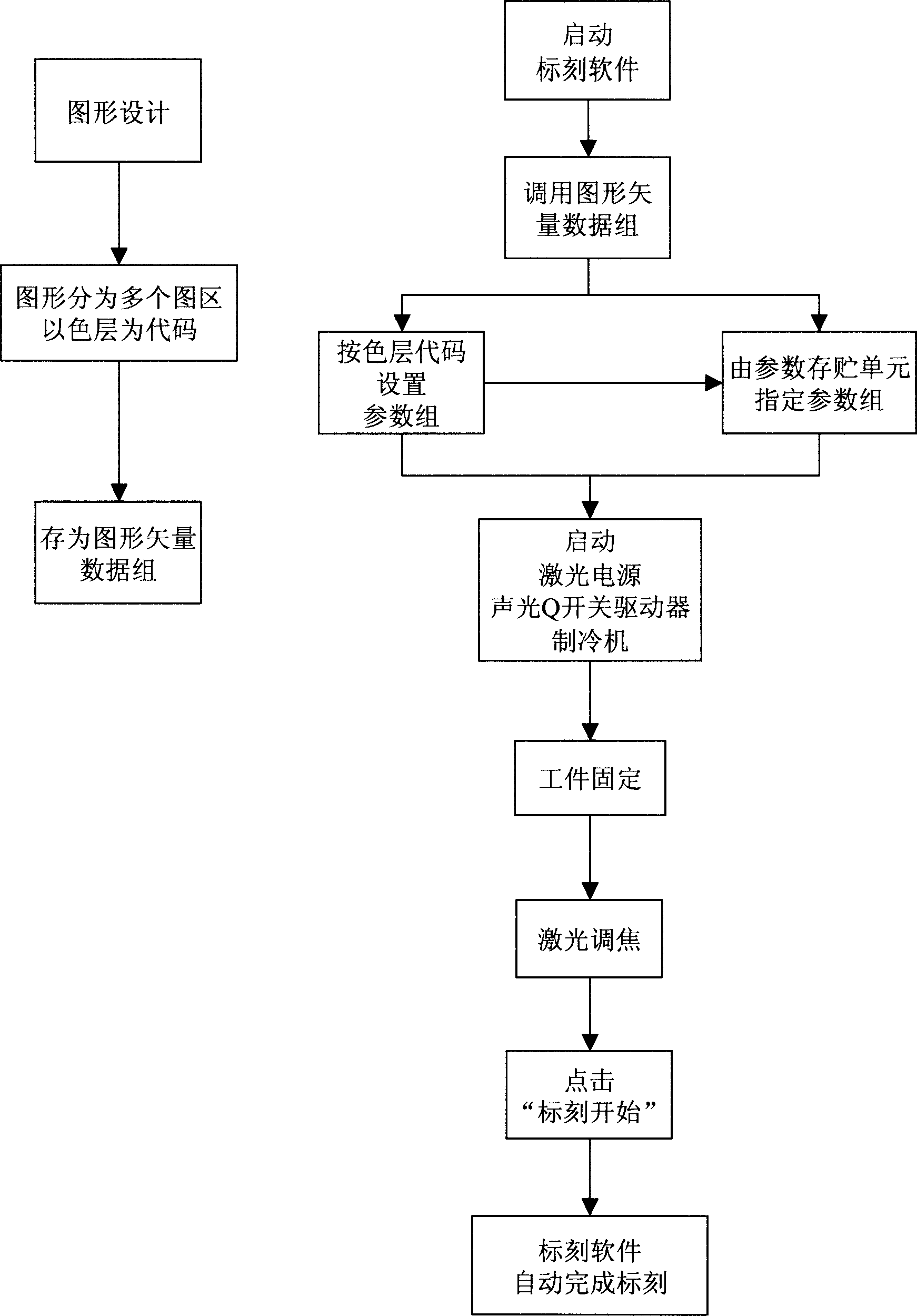

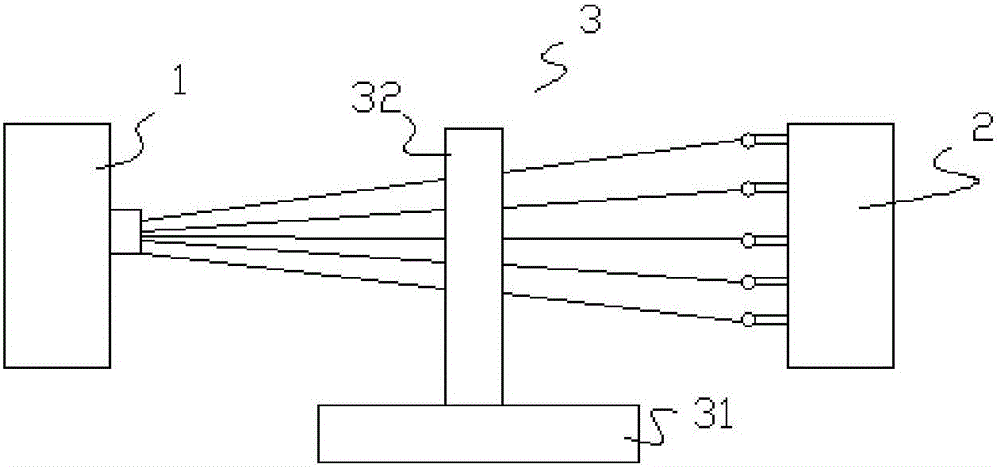

Color laser index carving system and its operation method

ActiveCN1749015ALine optimizationRich layersAblative recordingOther printing apparatusColor effectGraphics

The color laser marking and carving system includes marking and carving laser device, marking and caring computer software, graphic design unit, graphic vector data memory unit and parameter memory unit. The system has the running mode of dividing the designed pattern to be marked and carved into different graphic areas with different marking and carving effects and storing the graphic areas with the same marking and carving effects as the graphic vector data set with color layer code and same marking and carving parameter. The marking and caring computer software calls automatically the graphic vector data set and the corresponding marking and carving parameter to complete the marking and carving of several graphic areas in different effects automatically. The system has the laser controlled in constant temperature for high marked and carved color effect.

Owner:深圳市星辰智能控制有限公司

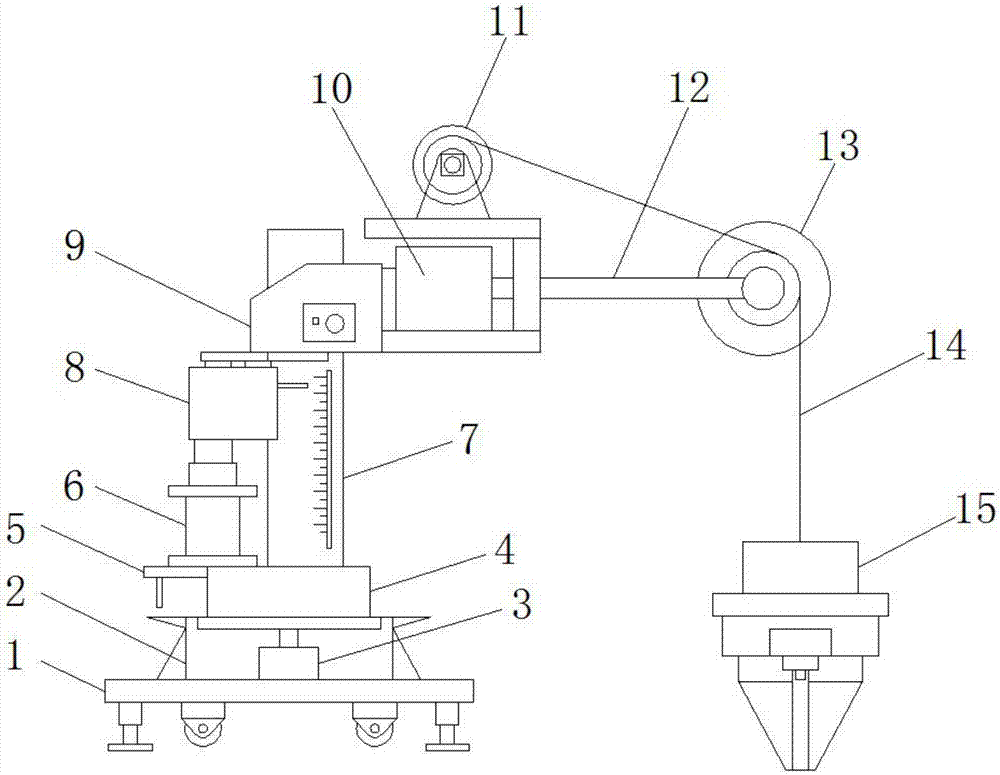

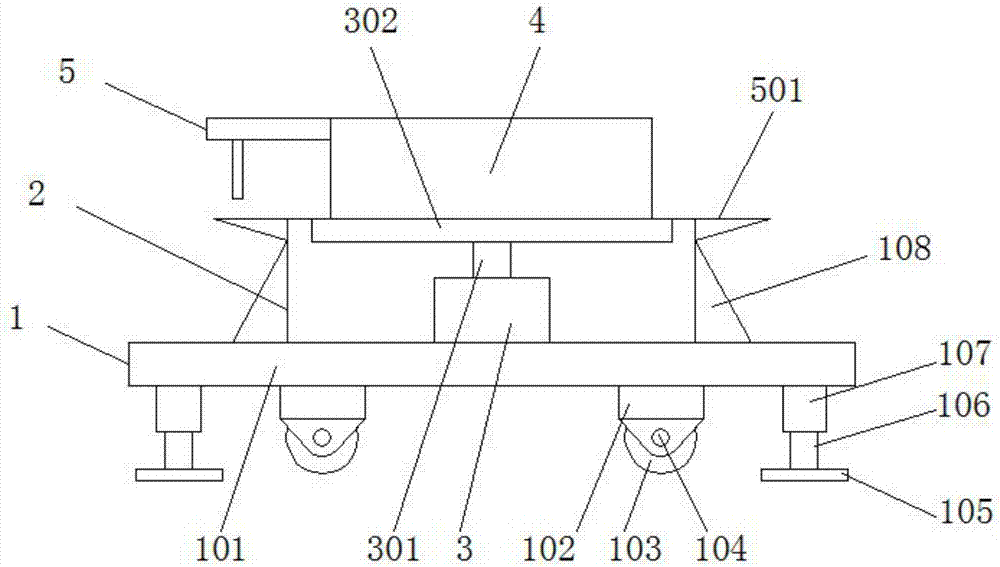

Elevator shaft perpendicularity detection device

InactiveCN107131873AStable structureEasy to operateActive open surveying meansFixed angles setting outEngineeringLaser beams

The invention discloses a verticality detection device for an elevator shaft, which comprises a load-bearing car body, a rotating pedestal, a guide column, a lifting slider, a horizontal support, a pay-off mechanism and a suspension measuring device. The middle part of the upper end of the load-bearing car body is welded with A motor is installed in the fixed base, the output end of the motor is connected to the rotating shaft, the upper end of the rotating shaft is welded with a limit turntable, and the upper part of the limit turntable is welded with a rotating pedestal; the upper end of the rotating pedestal is welded with a guide column, guiding The side of the column slides with a lifting slider, the bottom of the lifting slider is installed with a lifting cylinder, the lifting cylinder is fixed on the rotating pedestal, and the top of the vertical telescopic rod of the lifting cylinder is welded to the lifting slider; it is convenient to adjust the position of the suspension measuring device , which is convenient for laying out or winding the traction line. The laser emitting head emits a laser beam from the laser beam channel downward. The laser beam channel in the counterweight lead pendant is vertically downward, and the laser beam is irradiated vertically downward, which is convenient for elevator detection. verticality of the well.

Owner:宋衡星

Stretchable Interconnects for Flexible Electronic Surfaces

ActiveUS20170200527A1Large formatGood volume resistivityTransportation and packagingNon-conductive material with dispersed conductive materialConductive pastePolyester

A conductive paste and method of manufacturing thereof. The conductive paste comprises conductive particles dispersed in an organic medium, the organic medium comprising: (a) a solvent; and (b) a binder comprising a polyester. The conductive paste typically comprises silver and may contain various other additives. A stretchable conductive layer can be formed by curing the conductive paste.

Owner:FRY S METALS INC

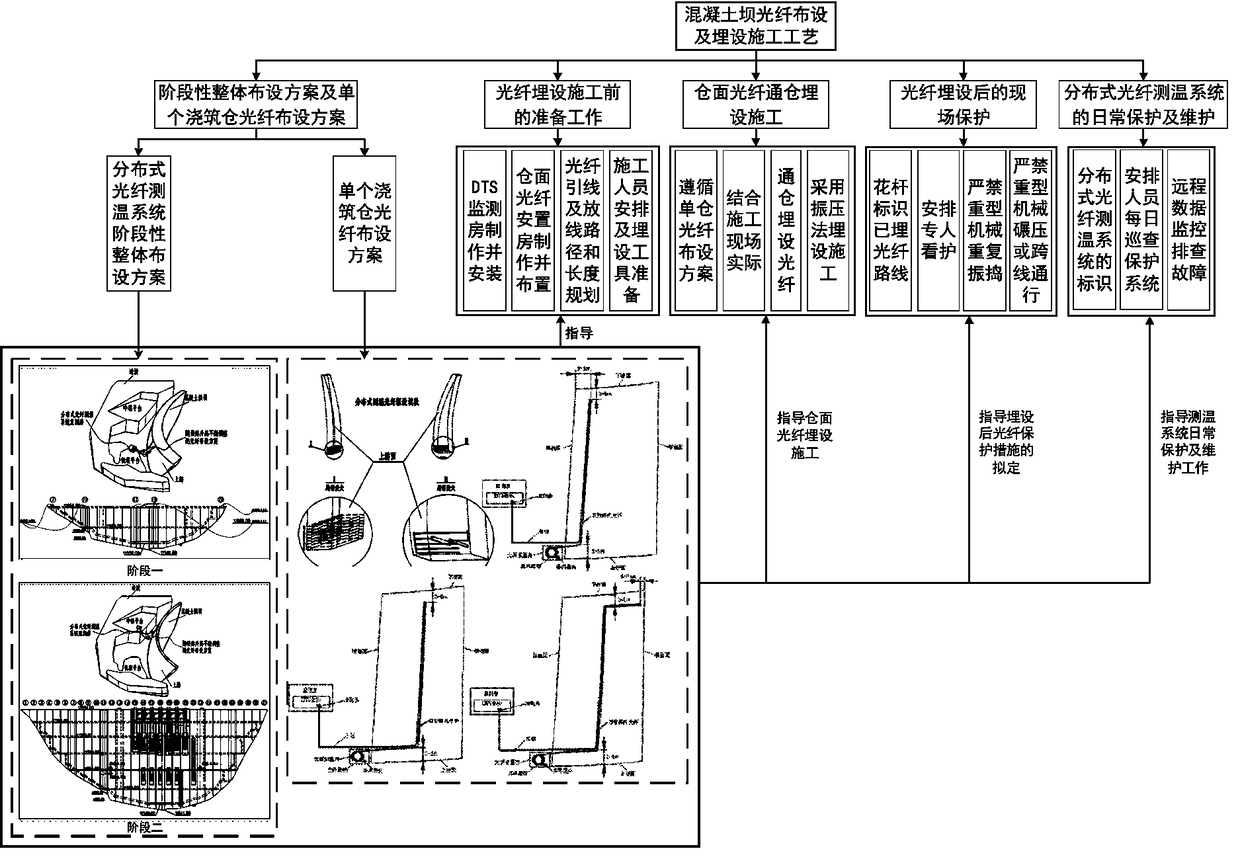

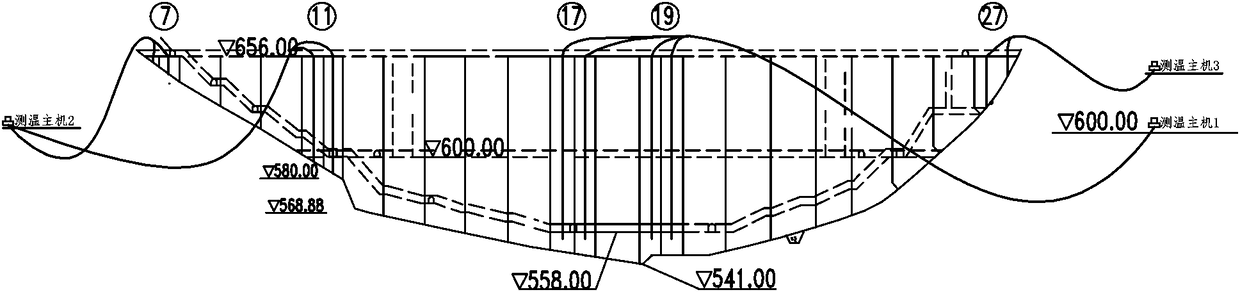

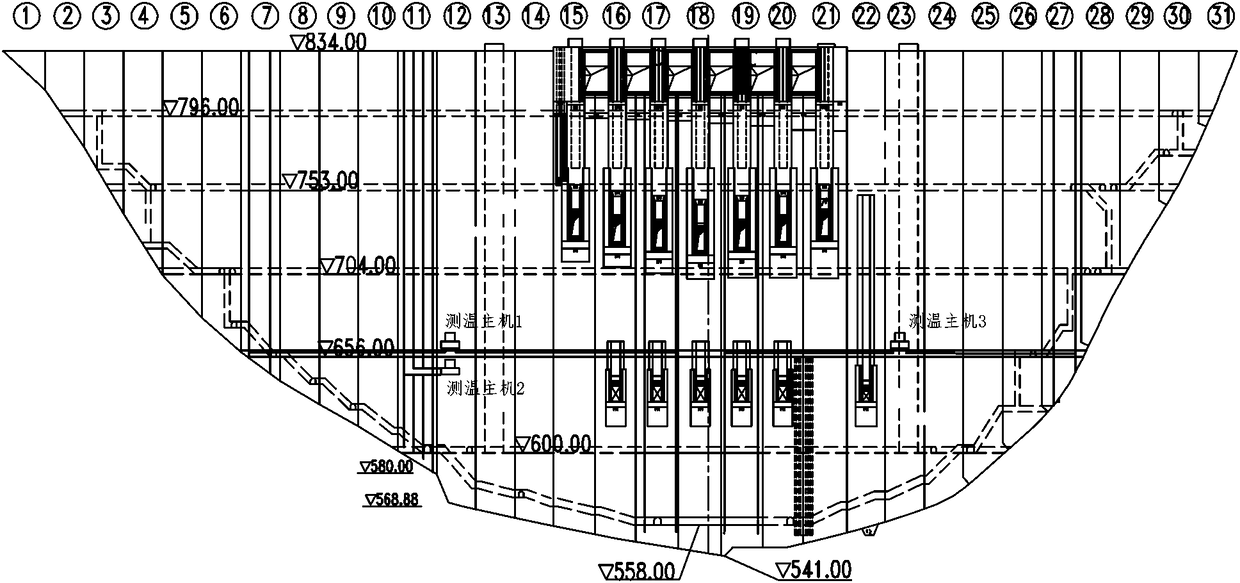

Distributed temperature measuring optical fiber laying and burying process for concrete dam

InactiveCN109000821APracticalStrong guidanceThermometers using physical/chemical changesWall damsFiberInternal temperature

The invention relates to a distributed temperature measuring optical fiber laying and burying process for a concrete dam. The process comprises the following steps: formulating a staged overall arrangement scheme and a single casting silo fiber laying scheme of a distributed optical fiber temperature sensing (DTS) system; preparing the work before the optical fiber buried construction; completingthe optical fiber general warehouse buried construction of the warehouse surface; completing the on-site protection after the optical fiber is buried; and carrying out the daily protection and maintenance of the distributed optical fiber temperature sensing (DTS) system. This construction process lays the foundation for the effective application of distributed temperature measurement optical fiberin concrete dam engineering, and ensures a high embedding survival rate of the optical fiber, better optical fiber layout and buried construction technology, and a more stable and efficient distributed optical fiber temperature measurement system, thereby ensuring that the distributed optical fiber temperature sensing (DTS) system continuously, automatically and linearly monitors the spatio-temporal distribution of the internal temperature of the concrete in real time and online.

Owner:CHINA THREE GORGES UNIV

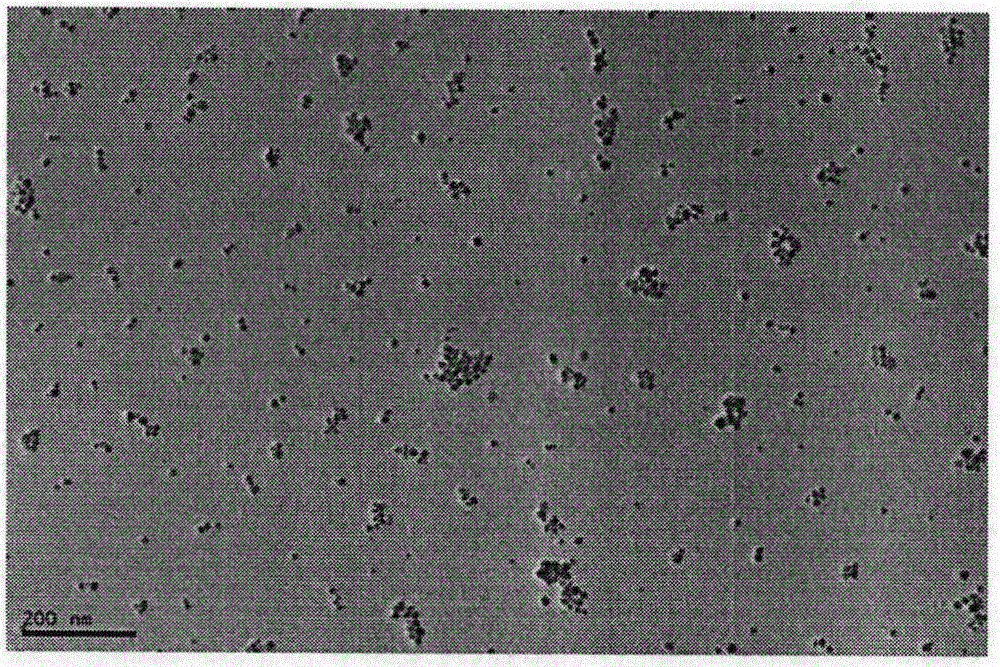

Preparation method and application of surface-enhanced-Raman-spectrum-sensitive conductive silver ink

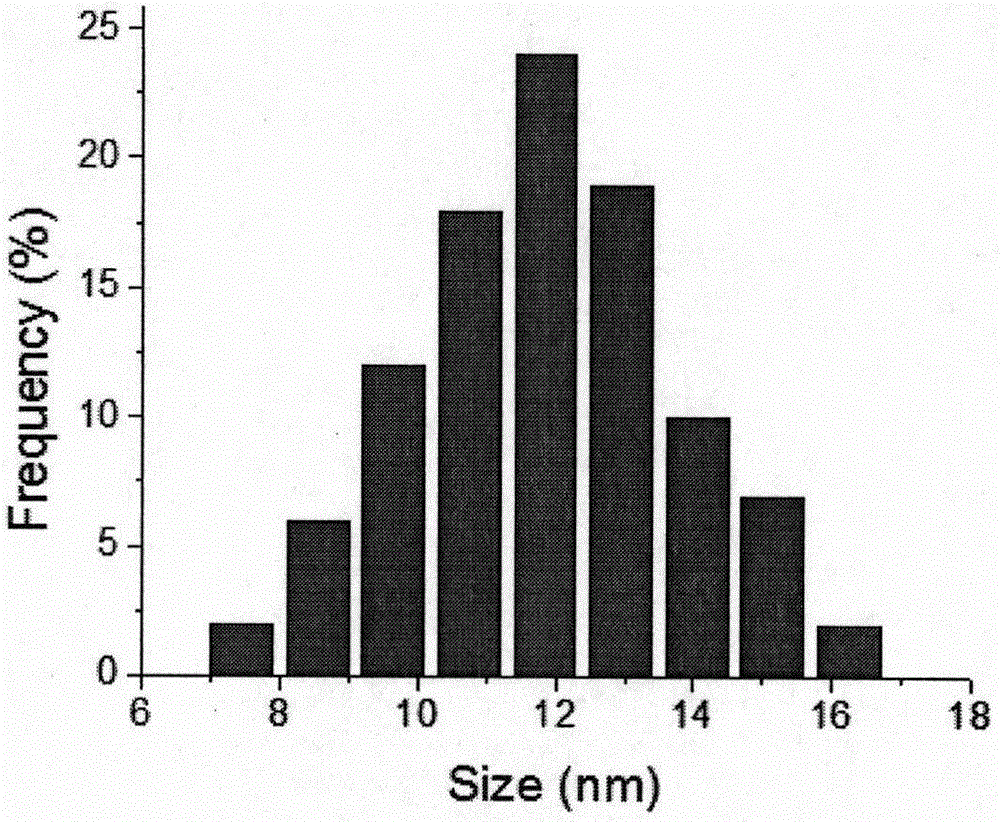

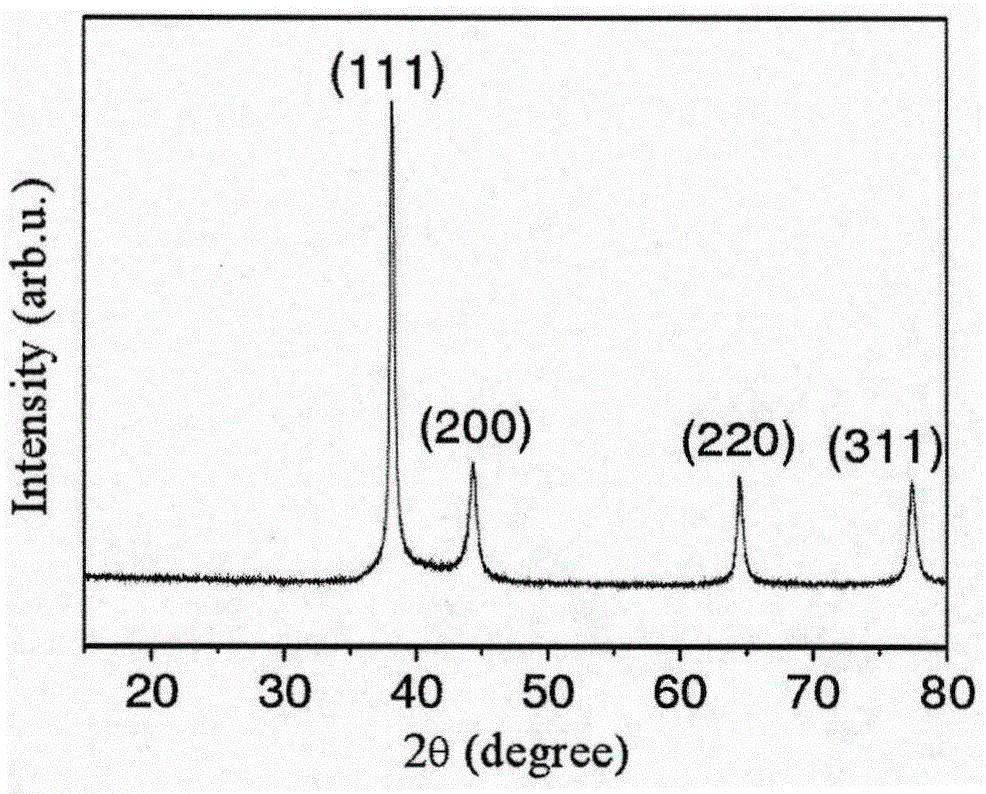

InactiveCN106280716AImprove conductivityEnhanced Raman fingerprint spectrumDuplicating/marking methodsInksSilver inkSurface-enhanced Raman spectroscopy

The invention provides a preparation method and application of a surface-enhanced-Raman-spectrum-sensitive conductive silver ink. In the method, the conductive silver ink is prepared by using polyvinylpyrrolidone-coated silver nanoparticles (prepared by chemical reduction) as a conductive phase and using triglycol monoaether, glycerol, isopropanol and other organic carriers as main components. The conductive silver ink can be used for printing favorable-linearity patterns on a flexible substrate by using a commercial piezoelectric ink-jet printer. When the conductive silver ink is used for manufacturing the radio-frequency label, the functions of the antenna circuit are ensured due to the conductive characteristic; the Raman enhanced detection can perform the functions of marking and forgery prevention; and the surface-enhanced-Raman-spectrum-sensitive conductive silver ink applicable to wireless radio-frequency label ink-jet printing is simple to prepare and convenient to use, and thus, has favorable large-scale application prospects, thereby providing multiple forgery prevention functions for the wireless radio-frequency forgery prevention labels.

Owner:NANJING NANOEAST BIOTECH

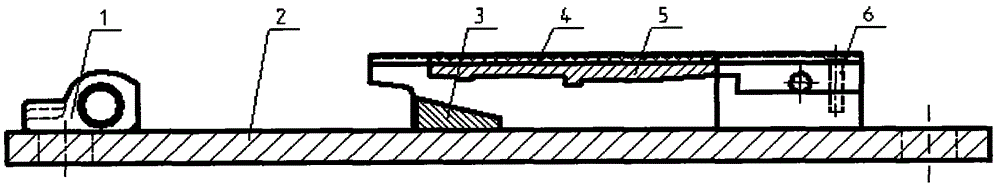

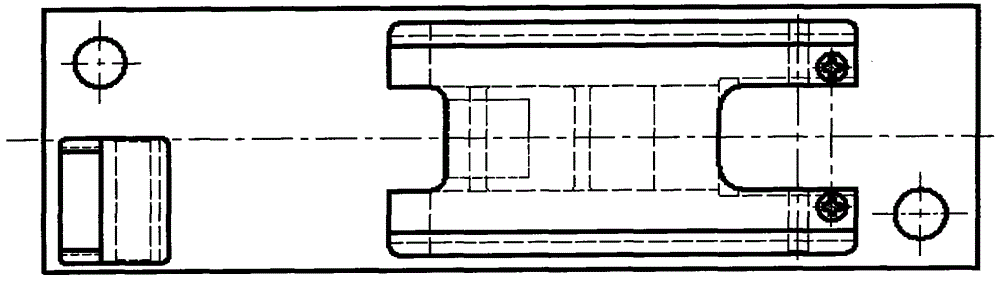

Self-lubricating slide plate and manufacturing method thereof

The invention discloses a self-lubricating slide plate and a manufacturing method thereof. The self-lubricating slide plate comprises a bottom plate, an iron base, a platen, an iron guide, an anti-friction plate and countersunk screws. The anti-friction plate is embedded into a slot in the surface of the platen and fixed onto the upper surface of the platen through the countersunk screws; the iron base, the platen and the iron guide are welded on the bottom plate. The self-lubricating slide plate reduces switching resistance and displacement insufficiency of a point rail, ensures normal working of a point switch and maintains good linearity for a turnout, enables a train to safely pass through the turnout, effectively reduces the construction cost and the maintenance cost, achieves high reliability, releases the labor load of working personnel for daily maintenance and reduces environmental pollution.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

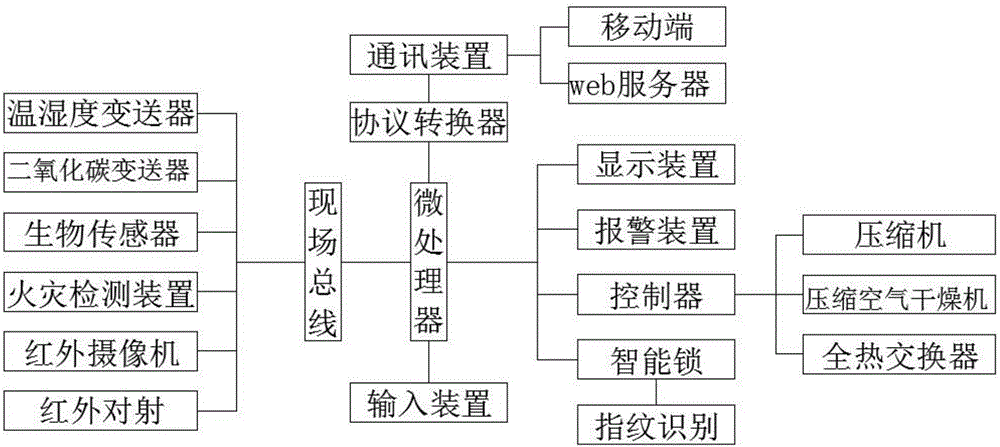

Intelligent granary environment temperature and humidity control system

InactiveCN106843332ALine optimizationImprove signal transmission efficiencyProgramme controlAgriculture tools and machinesFingerprintProtocol converter

The invention relates to the technical field of granary environment control, in particular to a granary environment temperature and humidity intelligent control system, including a compressed air dryer, a biological sensor, a liquid cooling device, a ventilation device, a communication device, a protocol converter, an intelligent lock, and fingerprint identification , controller, field bus, microprocessor, mobile terminal and web server; the invention can detect the temperature and humidity, carbon dioxide concentration and microorganisms in the granary, and cooperate with the compressed air dryer, liquid cooling device and ventilation device to realize the For the control of environmental volume, there is an intelligent lock on the granary door. It can also remotely control the switch while fingerprint recognition is possible. It is very smart while ensuring safety. Infrared beams are used to detect whether someone has broken into the granary without permission. With the help of infrared cameras It can effectively prevent theft. The field bus is used to optimize the line and improve the efficiency of signal transmission. The web server is used to upload the data detected by the microprocessor to the cloud, which is used for communication and download in the whole network. It has a strong creativity.

Owner:黄心怡

Novel disperse print thickening agent and preparation method thereof

The invention discloses a novel disperse print thickening agent. The novel disperse print thickening agent includes hydroxymethyl cellulose, sucrose fatty acid ester, an unsaturated acidic monomer, long-chain fatty alcohol-polyoxyethylene ether acrylic acid salt, polyacrylic acid, 3-propyl-2- acryloyloxy propane-1-sodium sulfonate, butanediol diacrylate, diethylene glycol diacrylate, an initiator, inorganic thickening powder, a phase inversion agent and deionized water. The disperse print thickening agent has a very good thickening effect and high viscosity, is resistant to electrolyte, can reduce the using amount of pigment printing slurry and has no adverse effect on the color brilliance, washable fastness and soft hand feel of printed fabrics.

Owner:湖州市千金丝织厂(普通合伙)

Manufacturing method of ceramic chip with fine mold textures

ActiveCN112142328ASolve the deformationRich styleCeramic materials productionTextile printerComposite material

The invention provides a manufacturing method of a ceramic chip with fine mold textures. The manufacturing method comprises the following steps: spraying ground glaze on a biscuit; spraying matte glaze; carrying out ink-jet printing and deep ink jet printing; spraying matte transparent glaze; sintering; and finishing. By adjusting the formula and the glazing amount of the matte glaze layer and thematte transparent glaze layer, the problems that a ceramic chip is easy to deform and permeate water can be well solved. According to the invention, the deep ink is utilized to discharge the matte transparent glaze to form the concave mold texture, the texture for jet printing of the deep ink is made by a computer, the texture style processed by the computer can be diversified, and the lines canbe made very fine; the pattern texture is located below the matte transparent glaze layer, and the matte transparent glaze layer can protect the pattern texture against abrasion. Pattern textures anddeep ink textures are processed by a computer in the same design, and the pattern textures and the deep ink textures can be well matched and processed, so that the final presentation effect is more optimized.

Owner:FOSHAN SANSHUI NEW PEARL CONSTR CERAMICS IND +1

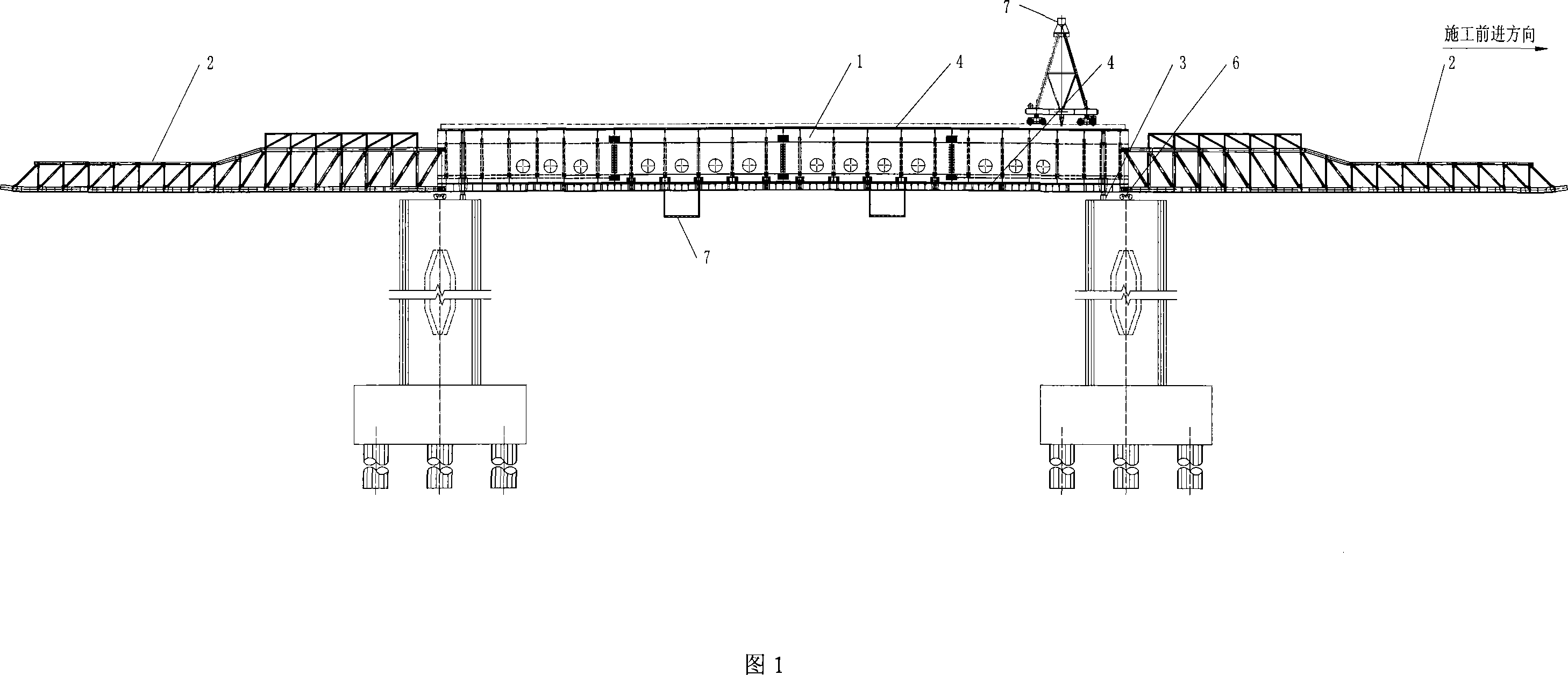

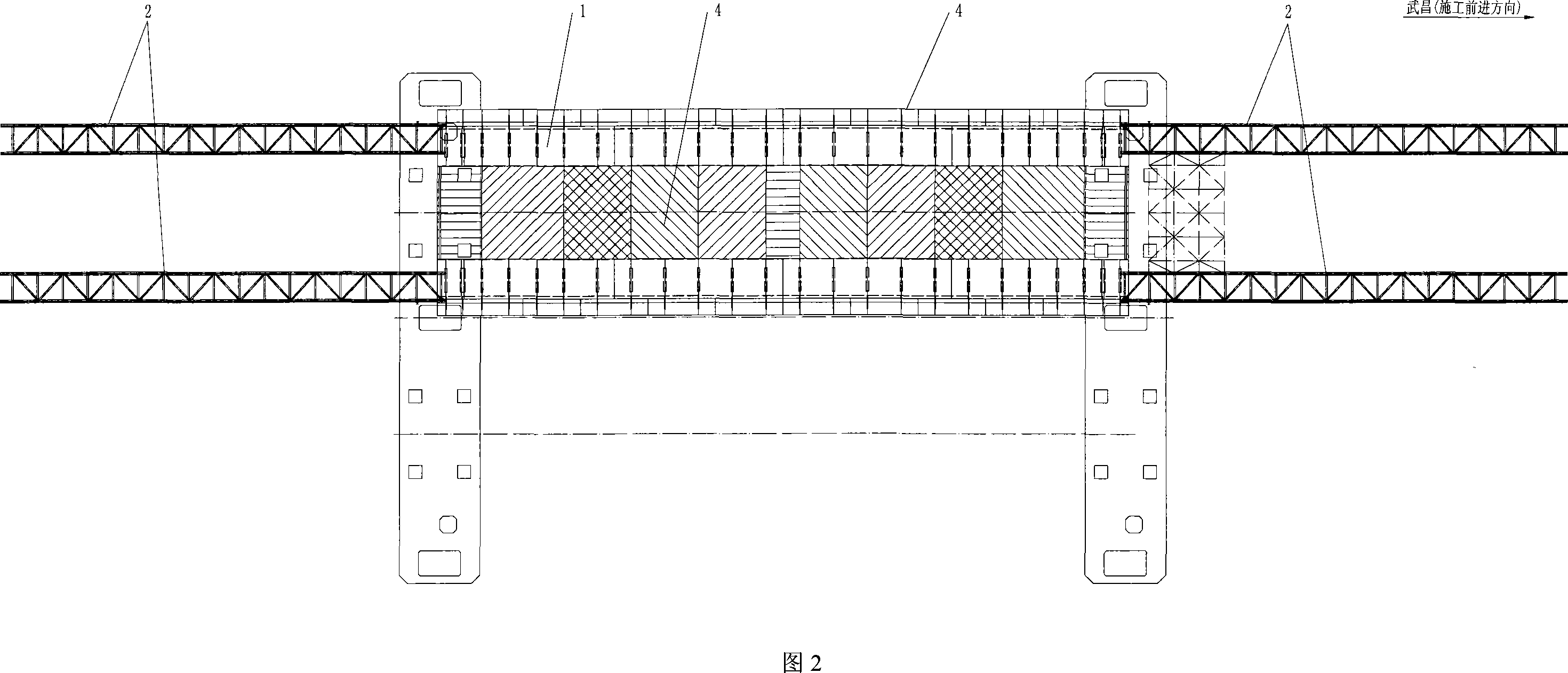

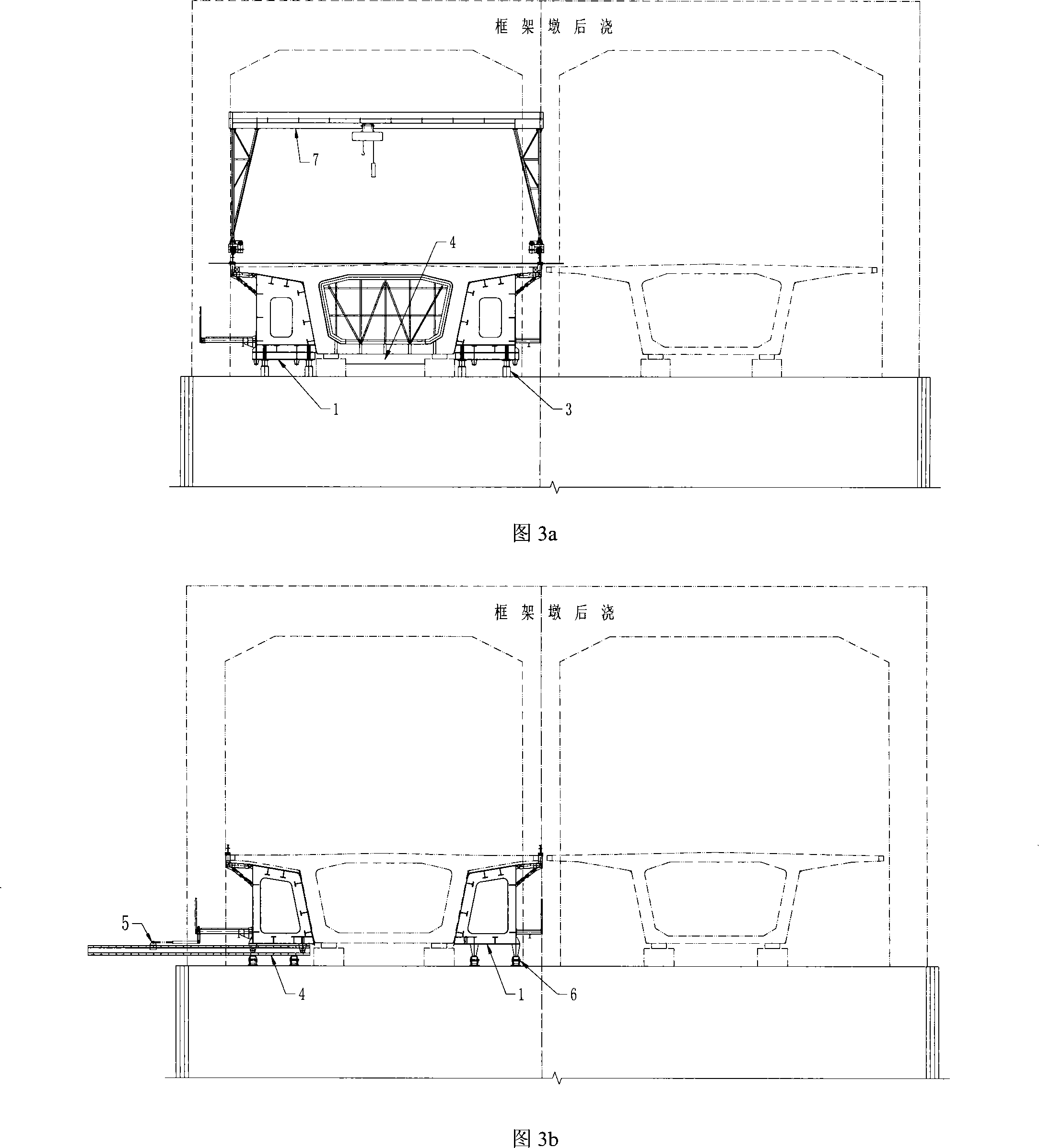

Beam-form unified movable mould frame

InactiveCN101205702ASolve the technical problems of viasReduce investmentBridge erection/assemblyAbnormal shapedBox girder

The invention discloses a beam-mold type movable die carrier which is large-scale construction equipment used in the construction of box beams of upper structures of bridges of railways and highways. A load-bearing beam of the movable die carrier is a special cross-section steel box, a top plate and an inner web of the movable die carrier are taken as external molds of a concrete box beam; a bottom die adopts a low height orthotropic plate structure and is opened and closed by single-side horizontal push. The beam-mold type movable die carrier is particularly suitable for construction under wide pier shaft conditions.

Owner:CHINA MAJOR BRIDGE ENG

Cable unwinding rack

The invention relates to the technical field of cable unwinding equipment, in particular to a cable unwinding rack. The cable unwinding rack comprises a first supporting rod and a second supporting rod which are vertically arranged above a base. The top end of the first supporting rod is provided with a first mounting base, and the top end of the second supporting rod is provided with a second mounting base. A bearing cross rod used for bearing a cable reel is arranged between the first mounting base and the second mounting base. The base is provided with a strip-shaped groove rail with an upward opening. The strip-shaped groove rail is internally provided with a first threaded rod which is sleeved with a mobile block. The mobile block is in threaded fit with the threaded rod. The bottom end of the second supporting rod is connected with the mobile block. A pressing disc is arranged on the side, facing the second mounting base, of the first mounting base and connected with the first mounting base through one or more adjustment screws which penetrate through the first mounting base, and adjustment nuts are all in threaded connection with the portions, on the two sides of the first mounting base, of the adjustment screws. A pressing disc through hole used for allowing the bearing cross rod to penetrate through is formed in the portion, corresponding to a mounting through hole, of the pressing disc. The cable unwinding rack can be well matched with cable reels of various sizes.

Owner:JIAXING GANKUN IND DESIGN

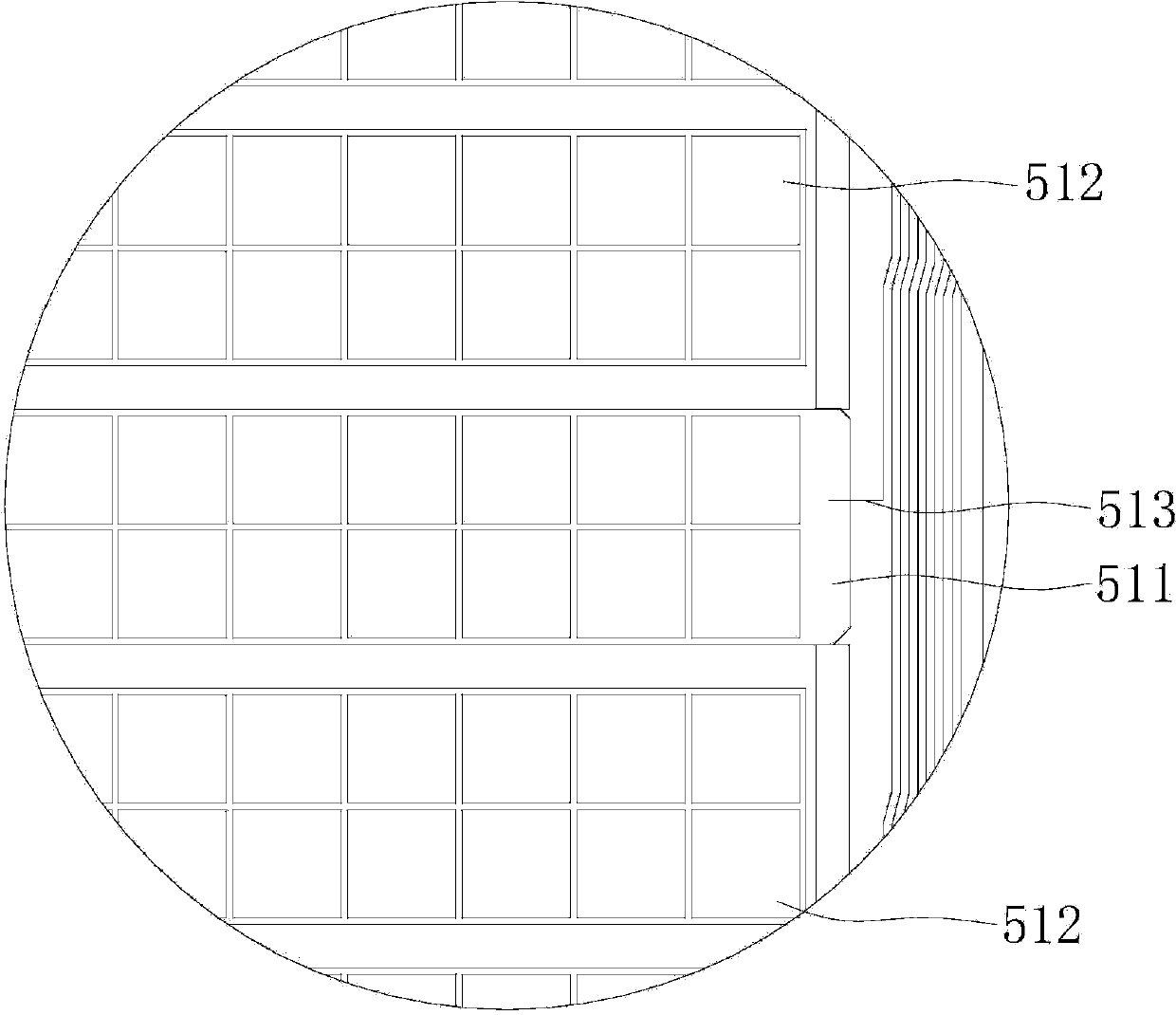

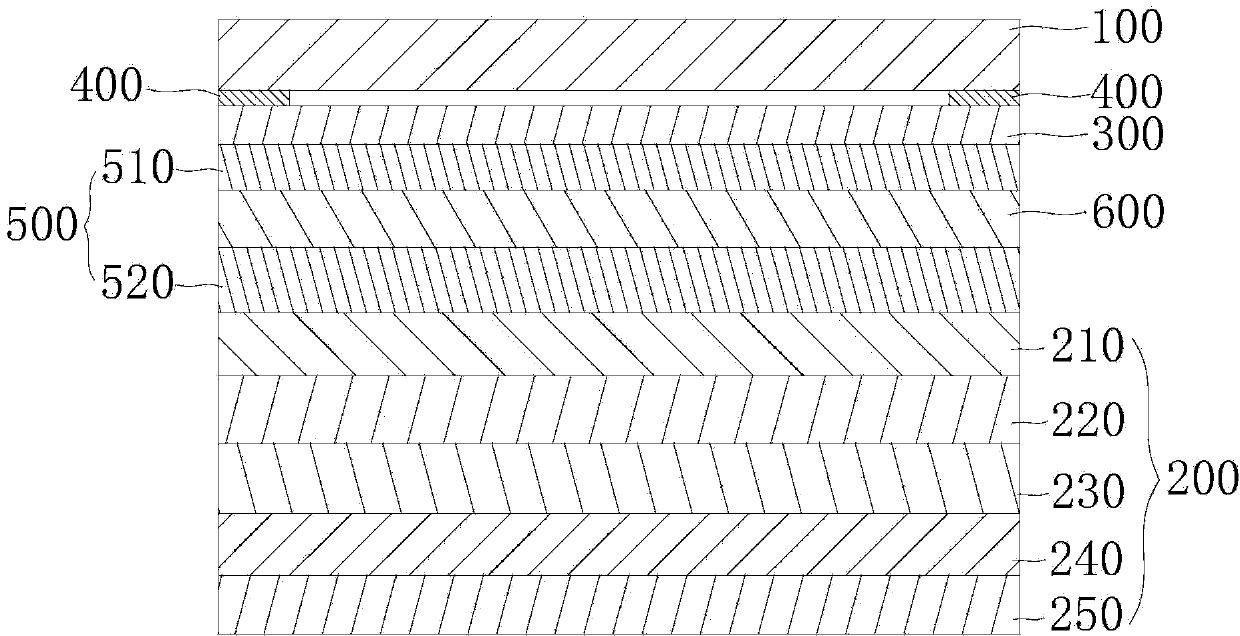

Method for manufacturing capacitive touch screen and touch-control layer, and electronic device

InactiveCN103744567AImprove accuracyImprove finenessInput/output processes for data processingControl layerEngineering

The invention is suitable for the technical field of touch screen structures, and discloses a method for manufacturing a capacitive touch screen and a touch-control layer, and an electronic device. The capacitive touch screen comprises a panel and a screen module, wherein an optical adhesive layer and a BM border layer are arranged between the panel and the screen module; the screen module comprises an upper polarizer, an upper glass substrate, a lower glass substrate, a lower polarizer and a backlight board which are sequentially arranged in a cascade manner from top to bottom, wherein a first metal conductive ink circuit layer is arranged on the panel, a second metal conductive ink circuit layer is arranged in the screen module, or both the first metal conductive ink circuit layer and the second metal conductive ink circuit layer are arranged in the screen module; each of the first metal conductive ink circuit layer and the second metal conductive ink circuit layer comprises a plurality of touch units, and each of the touch units is provided with a lead wire connected with a processor. The capacitive touch screen is sensitive in touch control and high in accuracy degree; the production method for the touch-control layer is simple, low in cost, energy-saving and environment-friendly, and capable of improving the use convenience and reliability of the electronic device with the touch screen.

Owner:SHENZHEN SUCCESS ELECTRONICS LTD

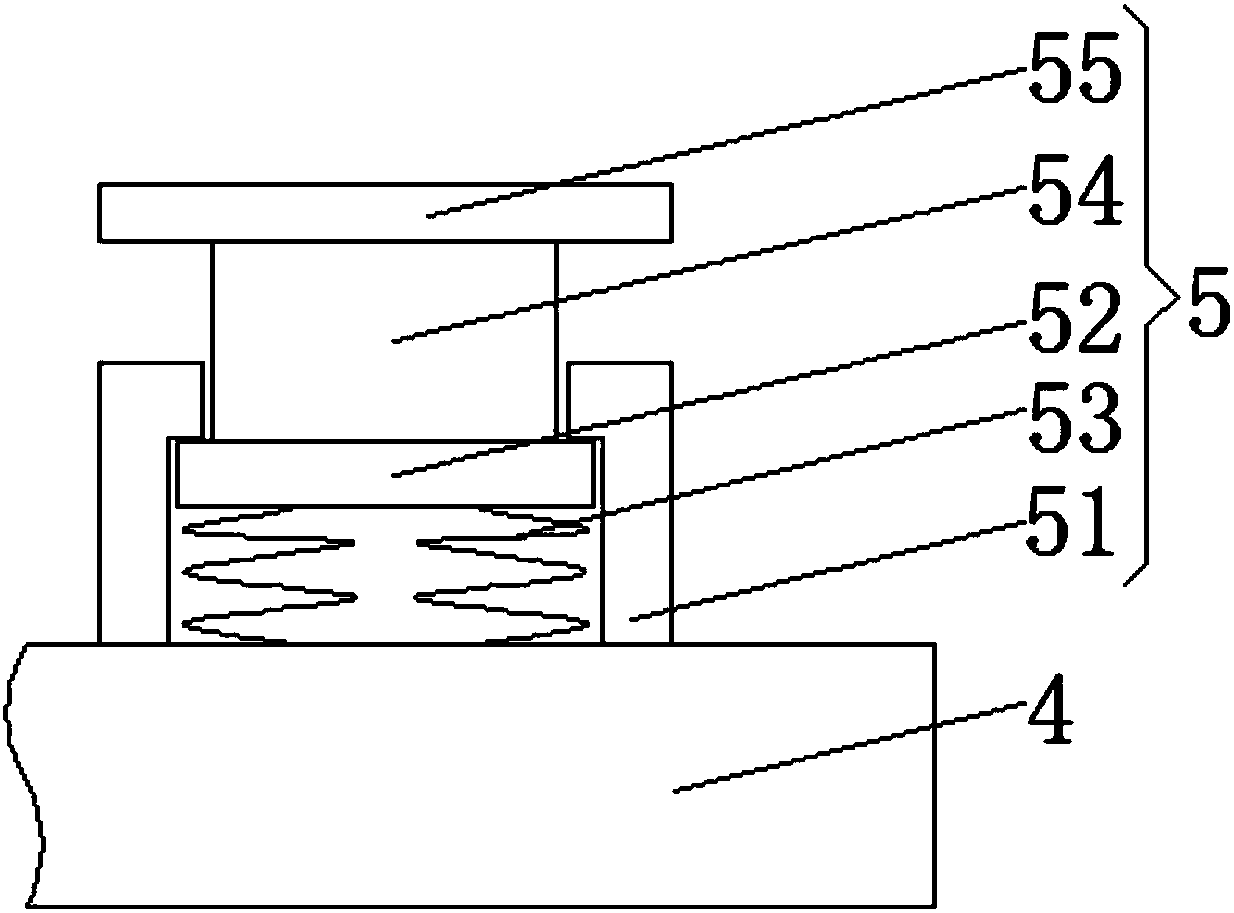

Tension adjusting device for paying-off of copper wires

InactiveCN105668330AFacilitate pay-off and strandingGood value for promotionFilament handlingCopper wireEngineering

The invention relates to the field of copper wire stranding, in particular to a tension adjusting device for copper wire pay-off, which can effectively fine-tune the tension and direction of the copper wire during pay-off, and improve the stranding quality and work efficiency. Its structure includes a stranding machine and a pay-off frame, a tension adjustment mechanism is arranged between the stranding machine and the pay-off frame; the tension adjustment mechanism includes a base, and a rod is vertically arranged on the base One side of the pole is hinged with a ring through a bracket, and the inner surface of the ring is provided with a fine-tuning mechanism; the fine-tuning mechanism includes a number of screws screwed on the inner surface of the ring, and the inner surface of the screw is The inner end is horizontally fixed with a cylinder, the side wall of the cylinder is provided with fastening bolts, the lower end of the fastening bolts is provided with a hemispherical rubber block, and the copper wire passes through the cylinder. It is easy to operate and easy to use, and is suitable for twisting various cables.

Owner:SUZHOU AORAN COMMODITY

Communication cable safety winding device

ActiveCN109755895AAvoid damageReduce labor intensityArrangements using take-up reel/drumApparatus for laying cablesEngineeringNoise reduction

The invention discloses a communication cable safety winding device. The communication cable safety winding device comprises a box body, wherein a first supporting vertical plate and a second supporting vertical plate are fixedly connected to the two sides of the bottom of the inner wall of the box body respectively; a supporting transverse plate is fixedly connected to the middle of each of the opposite sides of the first supporting vertical plate and the second supporting vertical plate separately; the top of the supporting transverse plate is fixedly connected with a damping and noise reduction device; the top of the damping and noise reduction device is fixedly connected with a first sliding frame and a second sliding frame separately; and a motor box is fixedly connected to opposite sides of the first sliding frame and the second sliding frame. The invention relates to the technical field of communication cable tool equipment. The safety winding device for the communication cablesolves the problem that due to the fact that a winding disc is large in size, the cable is prone to knotting in the laying process, and the cable is damaged; the cable laying efficiency is effectivelyimproved, and the labor intensity of workers is reduced; and in addition, the stability in the take-up or pay-off process is improved, the cable is prevented from being damaged, and the pollution tothe environment is reduced.

Owner:JIANGXI PROVINCE POST & TELECOMM CONSTR PROJECTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com