Beam-form unified movable mould frame

A mobile formwork and two-in-one technology, which is applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of increased construction costs and construction difficulties, and the inability to adapt to through-hole technology, so as to simplify the process and reduce investment Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

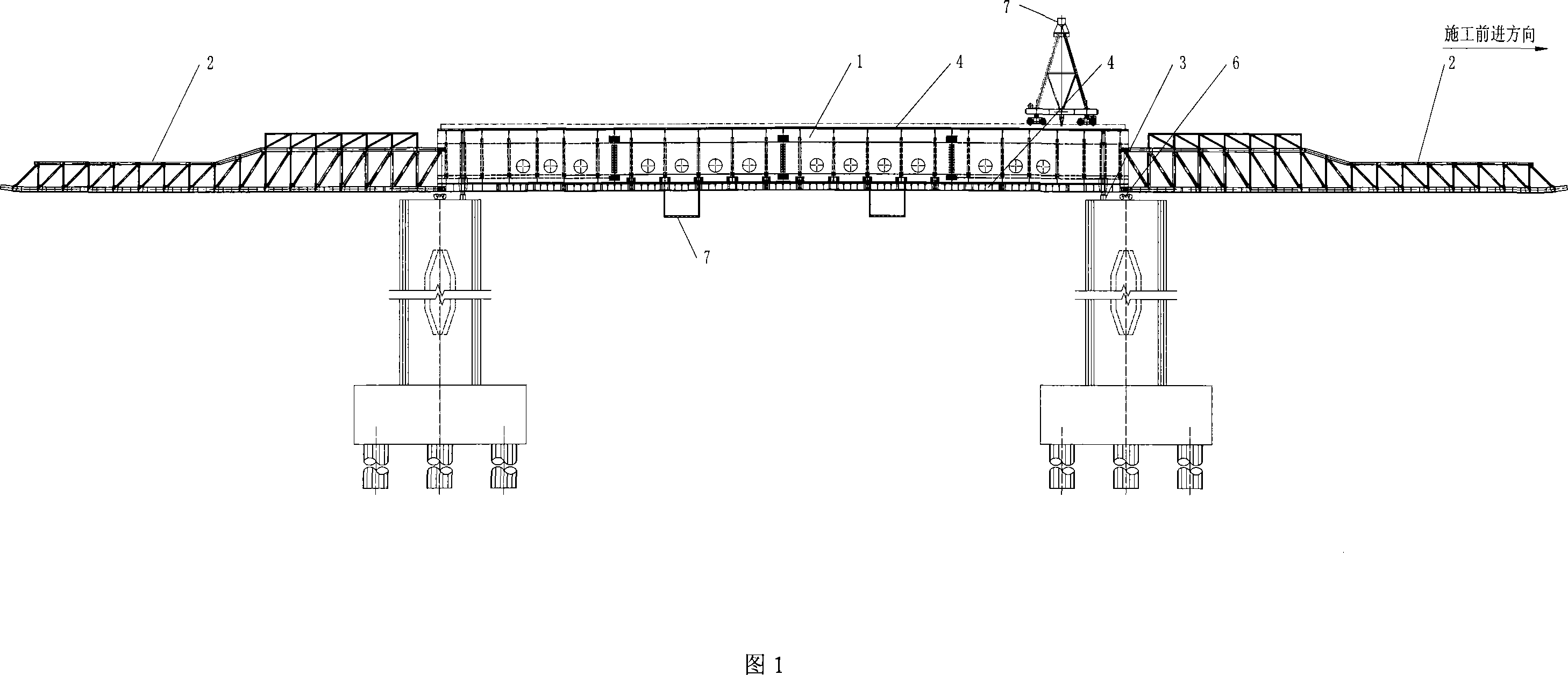

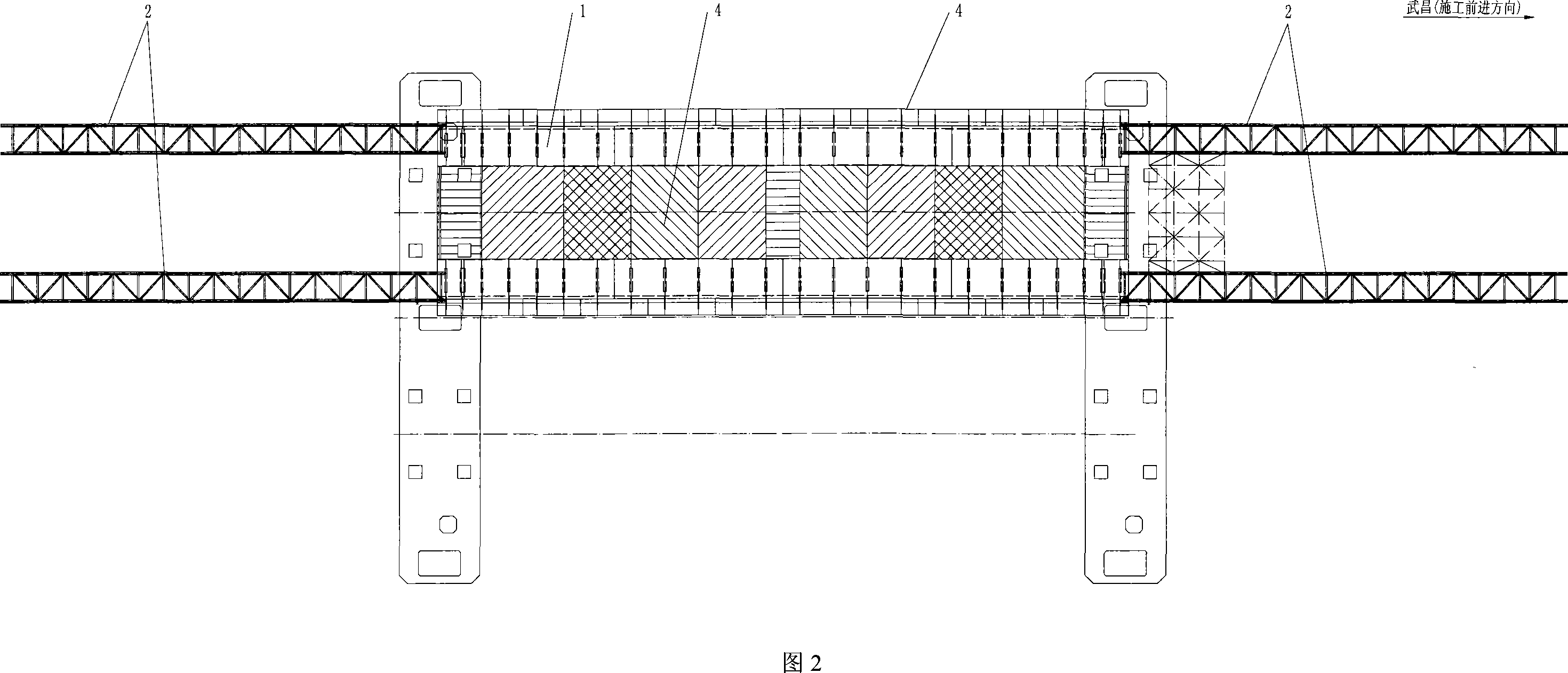

[0042] 1 and 2, the mobile formwork is composed of load-bearing main beam 1, guide beam 2, supporting device 3, formwork system 4, bottom mold opening and closing system 5, vertical and horizontal movement system 6 and auxiliary structure 7.

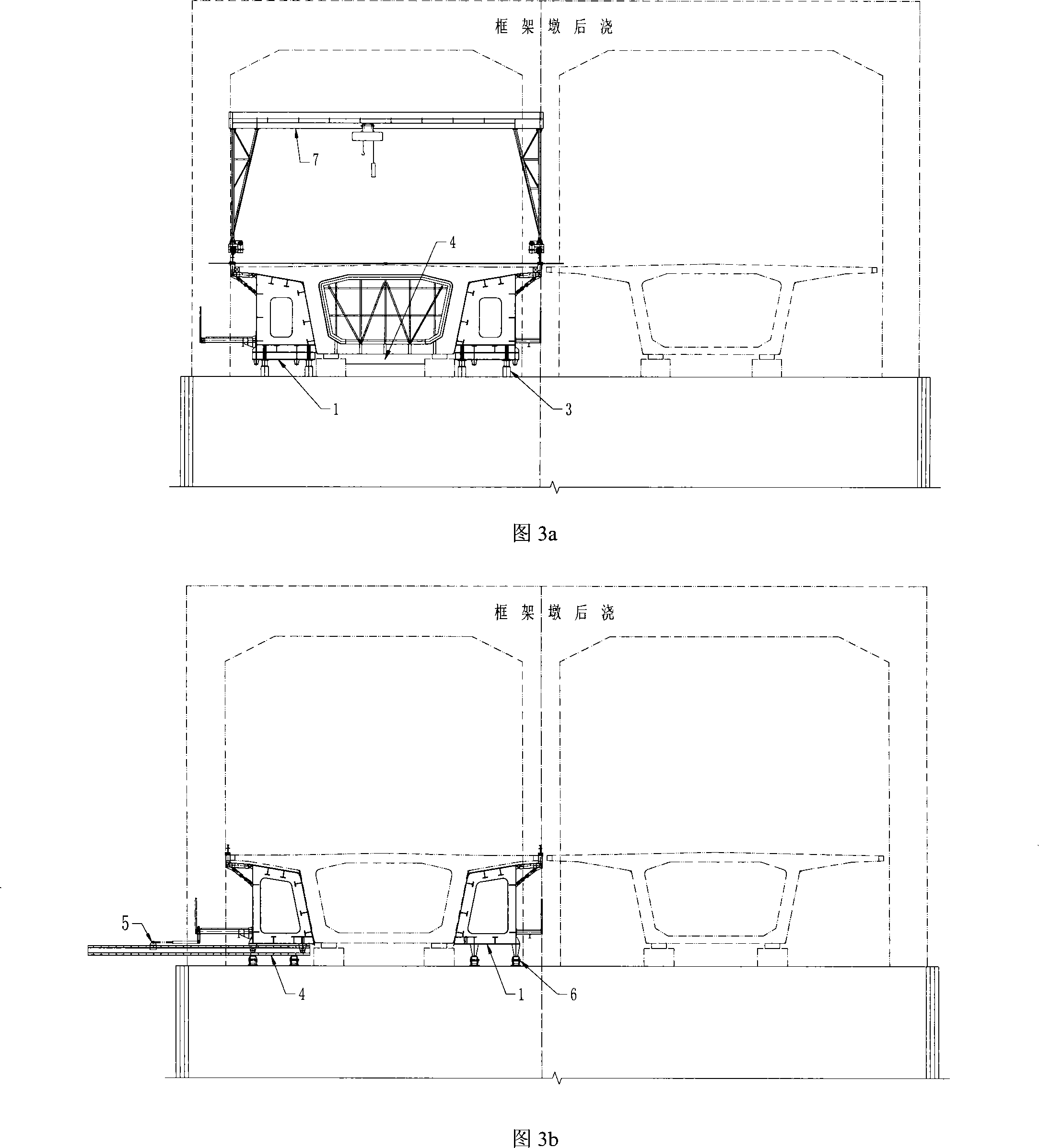

[0043] Referring to Fig. 3a, the main girder 1 of the mobile formwork is supported on the top of the pier through the supporting device 3. The door crane of the auxiliary structure 7 is arranged above the mobile formwork.

[0044] Referring to Fig. 3b, when the mobile formwork moves vertically, the bottom form 4 is opened horizontally through the bottom form opening and closing system 5, so as to avoid the bridge support pad stone on the top of the pier.

[0045] Referring to Fig. 3c, when the concrete of the box girder is poured, the bottom form 4 is hung on the main beam 1 by the suspender 8; the bottom form opening system 5 is attached to one side of the main beam 1.

[0046] Referring to Fig. 3d, when demoulding, the main girder 1 d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com