Patents

Literature

252results about How to "Full of three-dimensional sense" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Virtual reality man-machine interaction children education experience system based on mobile terminal

InactiveCN104731343AImprove hands-on abilityGood experienceInput/output for user-computer interactionImage data processingLarge screen displayVirtual reality

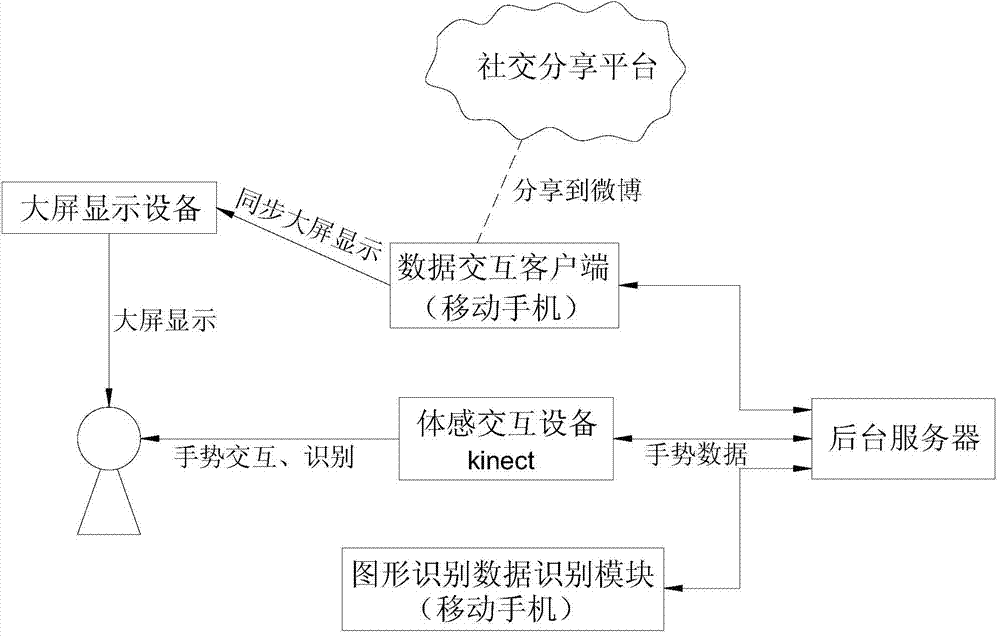

The invention relates to a virtual reality man-machine interaction children education experience system based on a mobile terminal. The virtual reality man-machine interaction children education experience system based on the mobile terminal comprises a mobile equipment terminal, large screen display equipment, somatosensory interaction equipment and a background server; the mobile equipment terminal is provided with a pattern recognition and data recognition module and a data interaction client, the pattern recognition and data recognition module and the data interaction client are connected with the background server through a network, the background server is connected with the somatosensory interaction equipment, and the somatosensory interaction equipment and the data interaction client are connected with the large screen display equipment. Compared with the prior art, the virtual reality man-machine interaction children education experience system based on the mobile terminal can be presented in a way of dynamic sound, images and interaction, teenagers can understand scientific knowledge more vividly, three-dimensionally and thoroughly, and the operational ability of children is enhanced.

Owner:SHANGHAI INFOCLOUD NETWORK TECH

Emboss roller and method for producing surface sheet using emboss roller and absorbent article employing surface sheet

ActiveCN101970211AEliminate stiffnessGood touchLamination ancillary operationsLaminationFiberMechanical engineering

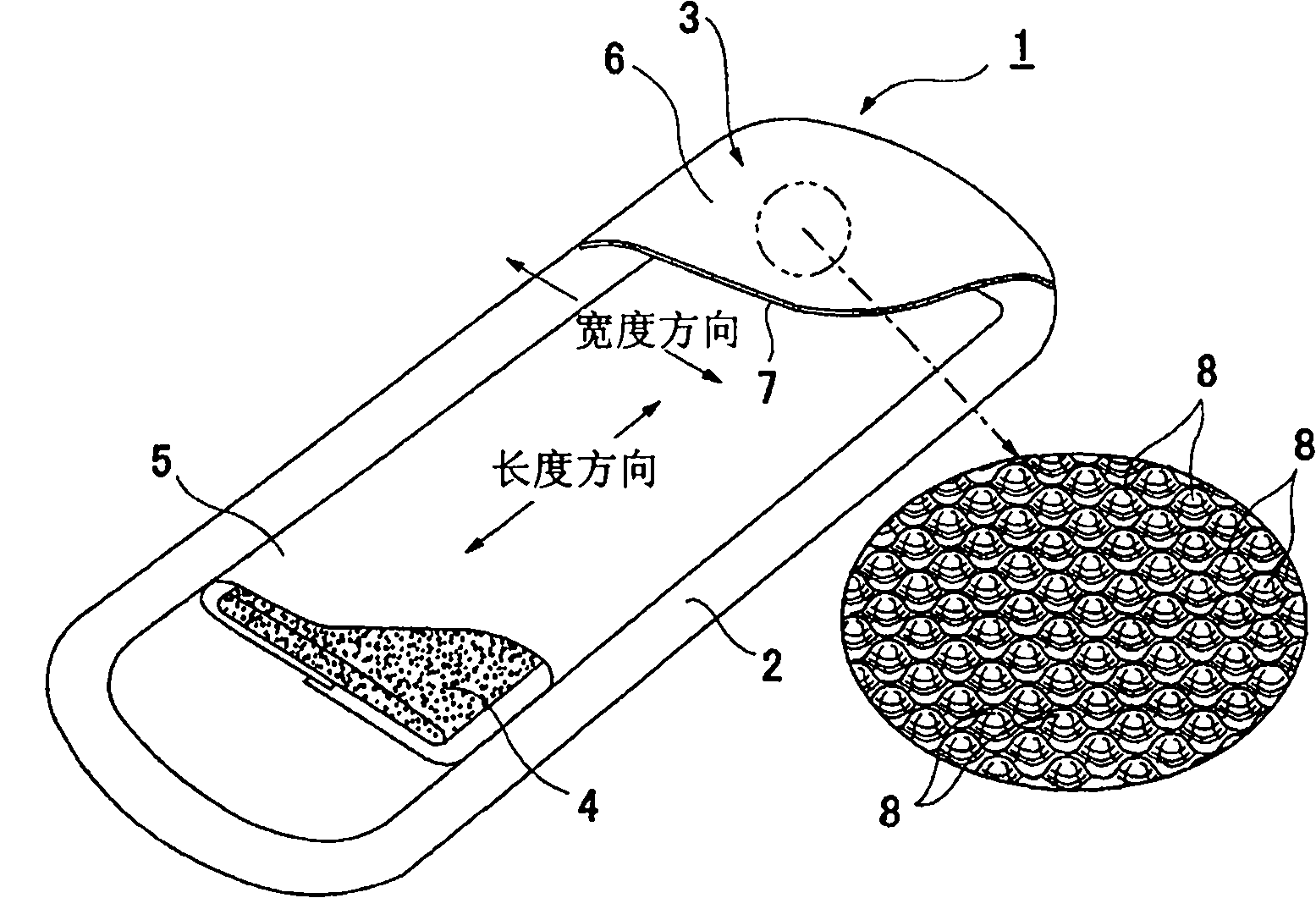

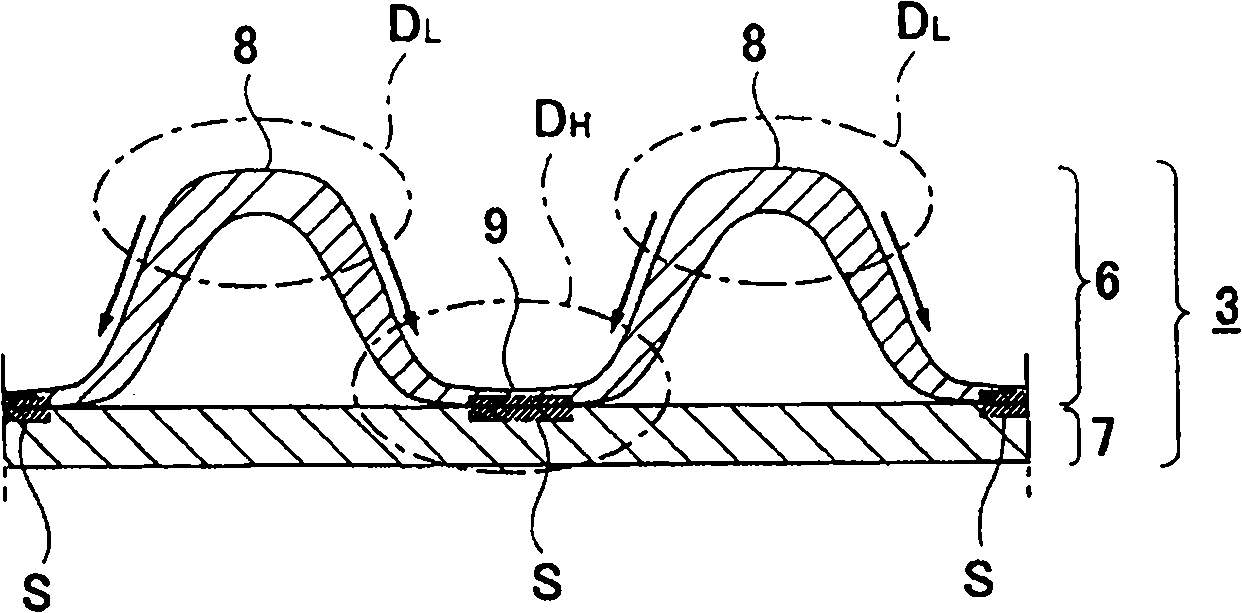

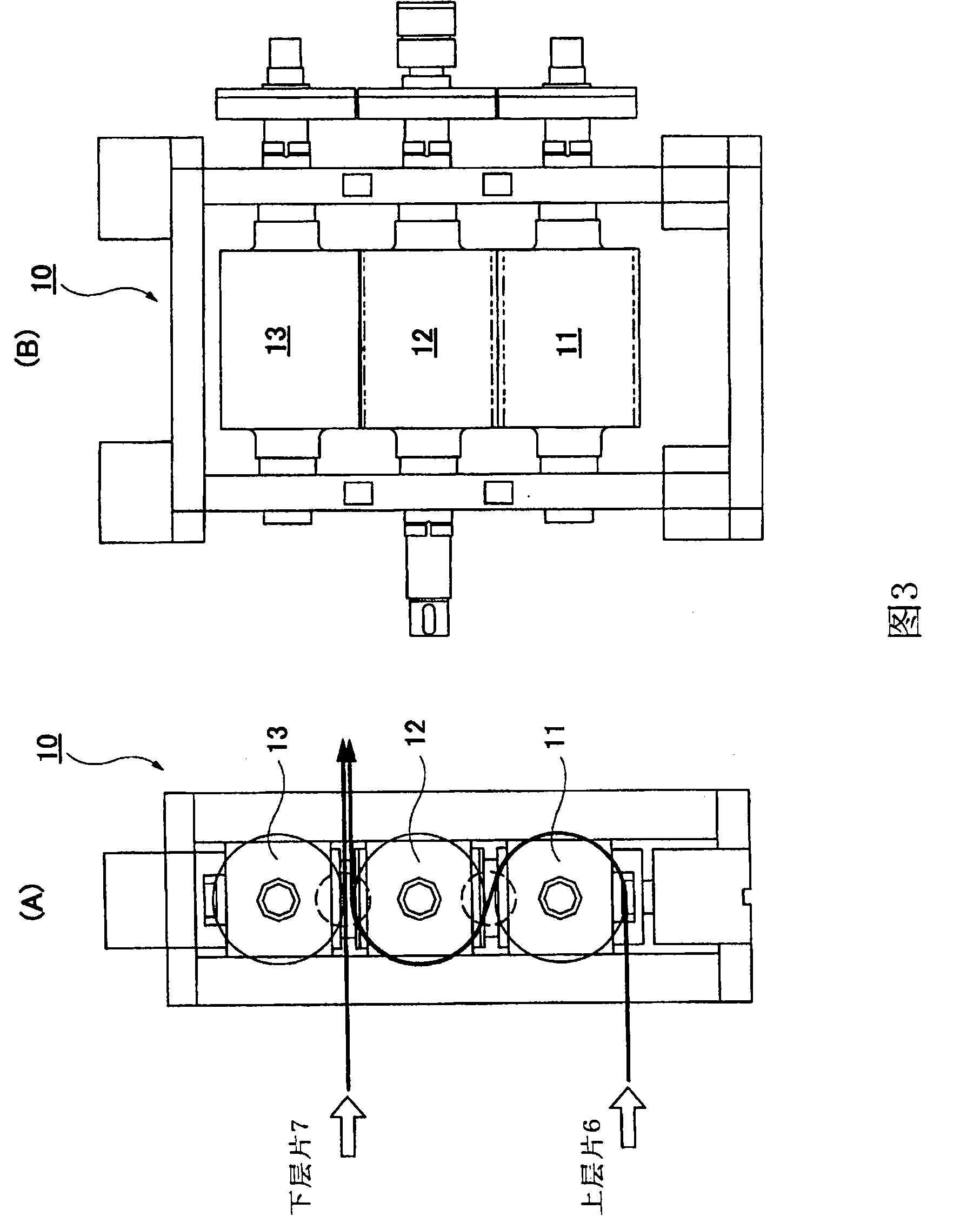

Disclosed is an emboss roller comprising a set of a first emboss roll (11) and a second emboss roll (12) and imparting an irregularly embossed shape onto a surface sheet, wherein a reference surface (14), which has a protrusion (15) protruding outward from the reference surface (14) and a recess (16) recessed from the reference surface (14), the reference surface (14) serving as the boundary, and is smooth to the peripheries of the protrusion (15) and the recess (16), exists on the surface of the first emboss roll (11), and a reference surface (17), which has a protrusion (18) protruding outward from the reference surface (17) to mesh the recess (16) in the first emboss roll (11) and a recess (19) recessed from the reference surface (17) to mesh the protrusion (15) of the first emboss roll (11), the reference surface (17) serving as the boundary, and is smooth to the peripheries of the protrusion (18) and the recess (19), exists on the surface of the second emboss roll (12).

Owner:DAIO PAPER CORP

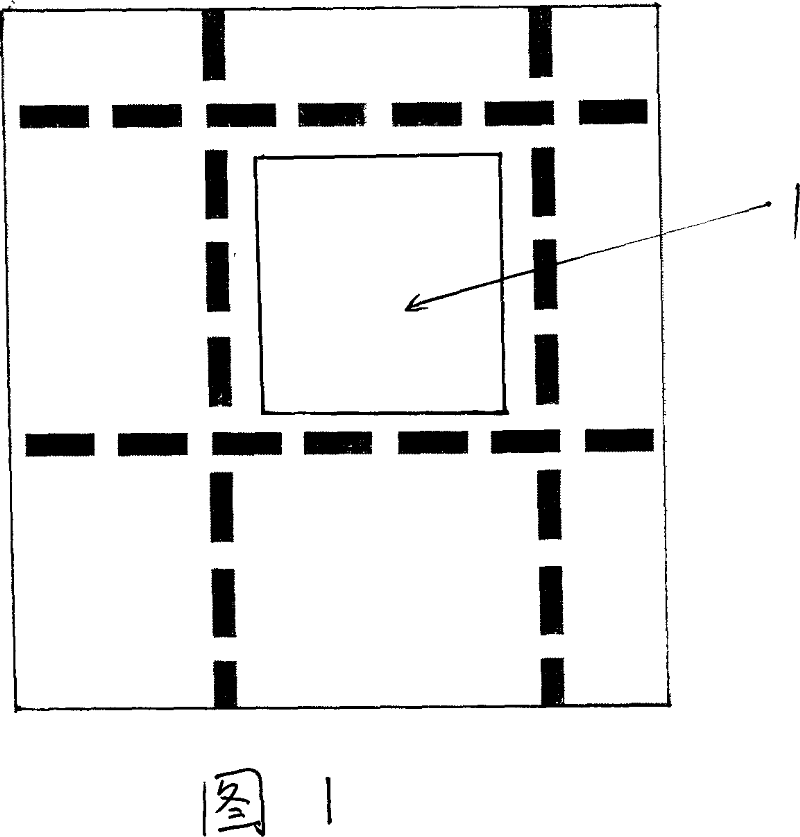

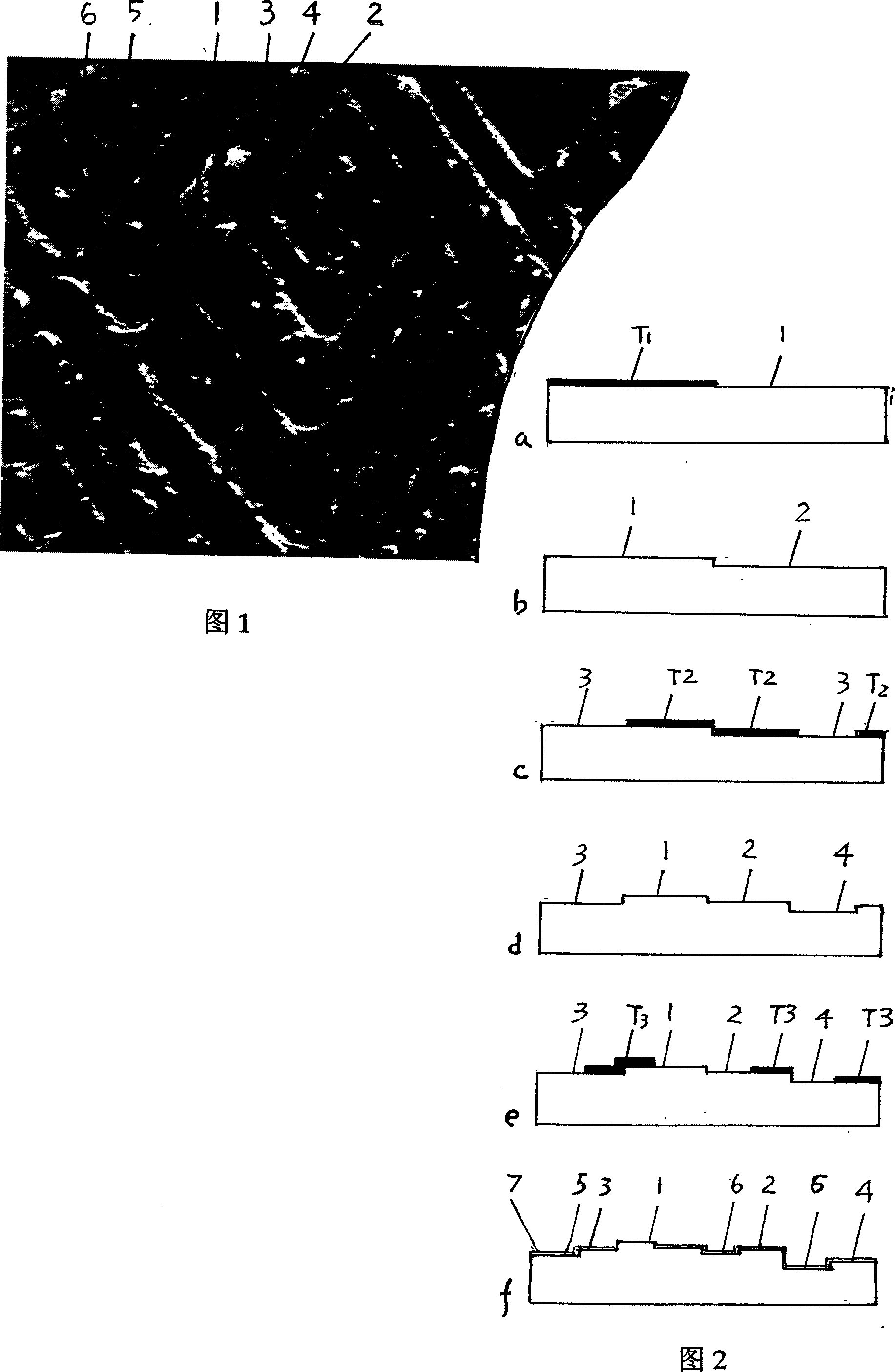

Manufacturing process for printing roller multi-depth forme

InactiveCN102423955AEmbossed effect arrivesFull of three-dimensional sensePrinting pre-treatmentForme preparationManufacturing technologyLaser engraving

The invention relates to a printing roller manufacturing technology, and concretely relates to a manufacturing process for a printing roller multi-depth foaming forme. The process comprises steps of mechanical processing, nickel plating, grinding, manuscript manufacturing, glue spraying, laser engraving, and corroding. The process is characterized in that: secondary glue spraying processing, secondary laser engraving processing, secondary corrosion processing and chrome plating processing are carried out after the corrosion step. Compared with the prior art, different patterns can have different depths on the printing roller as needed in the invention, so embossing effects on pure raw paper and nonwoven paper which can reach embossing effects on rubber surface wallpaper have rich stereoscopic and layered sense.

Owner:上海希尔彩印制版有限公司

Method for preparing anti-bacteria cool graphene slubby yarn and application thereof to home textile products

The invention discloses a method for preparing anti-bacteria cool graphene slubby yarn. The yarn is composed of, by weight parts, 30-60 parts of graphene chinlon composite fiber, 20-30 parts of bamboo fiber and 10-20 parts of viscose fiber. The fibers are spun into the slubby yarn through a ring spinning frame spinning process. The process comprises the steps of cotton blending, cotton carding, drawing, spinning and spooling. The obtained anti-bacteria cool graphene slubby yarn is formed by blending of various function fibers and integrates the advantages of the used fibers. Compared with conventional cotton yarn, the anti-bacteria cool graphene slubby yarn has viscose glue, is more excellent than natural cotton fiber in softness, moisture absorption and light self-weight and has anti-bacteria and cool performances of the bamboo fiber; the novel graphene chinlon composite fiber is adopted to intensify anti-static anti-bacteria, cool, comfortable and conformable performance and the like. The prepared yarn is applied to home textiles, and the finished home textiles are rich in layering sense and third dimension and have multiple functions.

Owner:IANGSU COLLEGE OF ENG & TECH

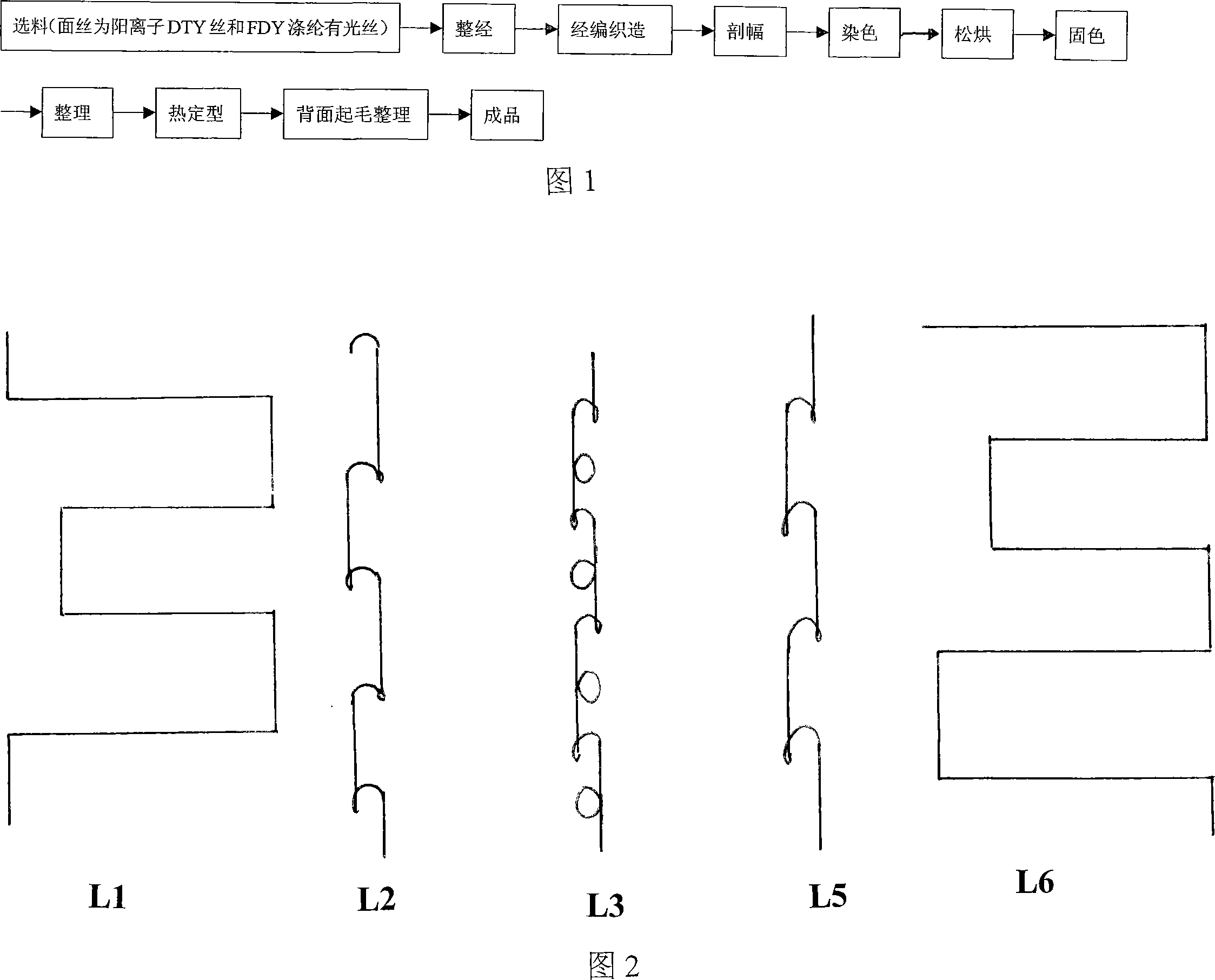

Processing method for terylene face fabric

InactiveCN101082150AFull of three-dimensional senseMeet the requirements of color diversificationWarp knittingDyeing processYarnEngineering

The present invention belongs to the field of dacron fabric producing technology, and is especially one process of producing dacron fabric. The process includes the steps of sorting material, warp beaming, warp weaving, slitting, dyeing, loosening and stoving, color fixing, finishing, hot setting and back teasing finishing. It features the sorting material including selecting facing yarn of cationic DTY filament and DTY lustrous dacron filament, and bottom yarn of FDY dacron filament. Selecting facing yarn of cationic DTY filament and DTY lustrous dacron filament fitting cationic dye and anionic dye separately makes the fabric after being dyed with these two kinds of dye exhibit different colors, resulting in dichromatic effect and stereo feeling.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

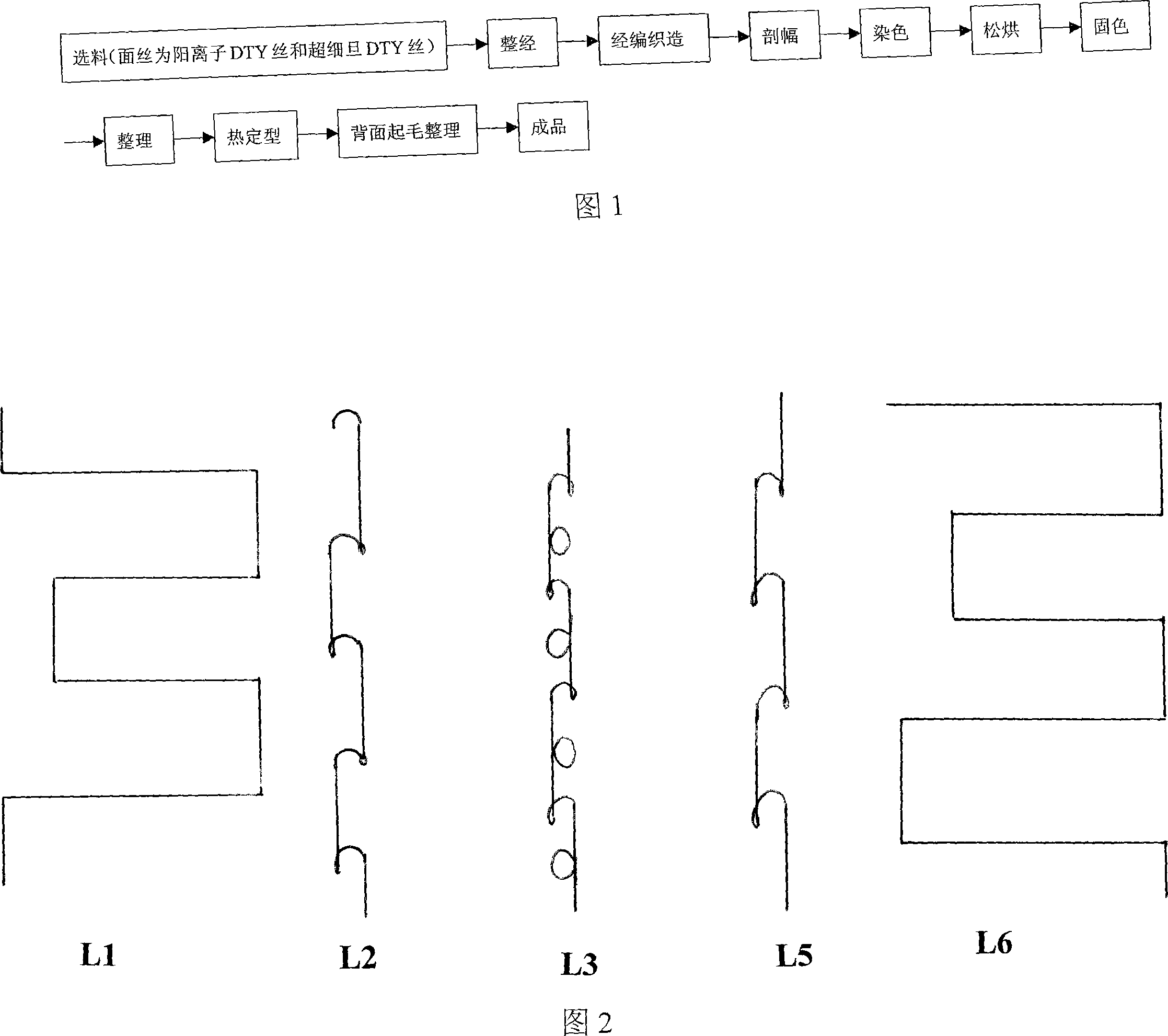

Processing method for terylene face fabric

InactiveCN101082149AFull of three-dimensional senseMeet the requirements of color diversificationWarp knittingDyeing processYarnEngineering

The present invention belongs to the field of dacron fabric producing technology, and is especially one process of producing dacron fabric. The process includes the steps of sorting material, warp beaming, warp weaving, slitting, dyeing, loosening and stoving, color fixing, finishing, hot setting and back teasing finishing. It features the sorting material including selecting facing yarn of cationic DTY filament and superfine denier DTY filament, and bottom yarn of FDY dacron filament. Selecting facing yarn of cationic DTY filament and superfine denier DTY filament fitting cationic dye and anionic dye separately makes the fabric after being dyed with these two kinds of dye exhibit different colors, resulting in dichromatic effect and stereo feeling.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

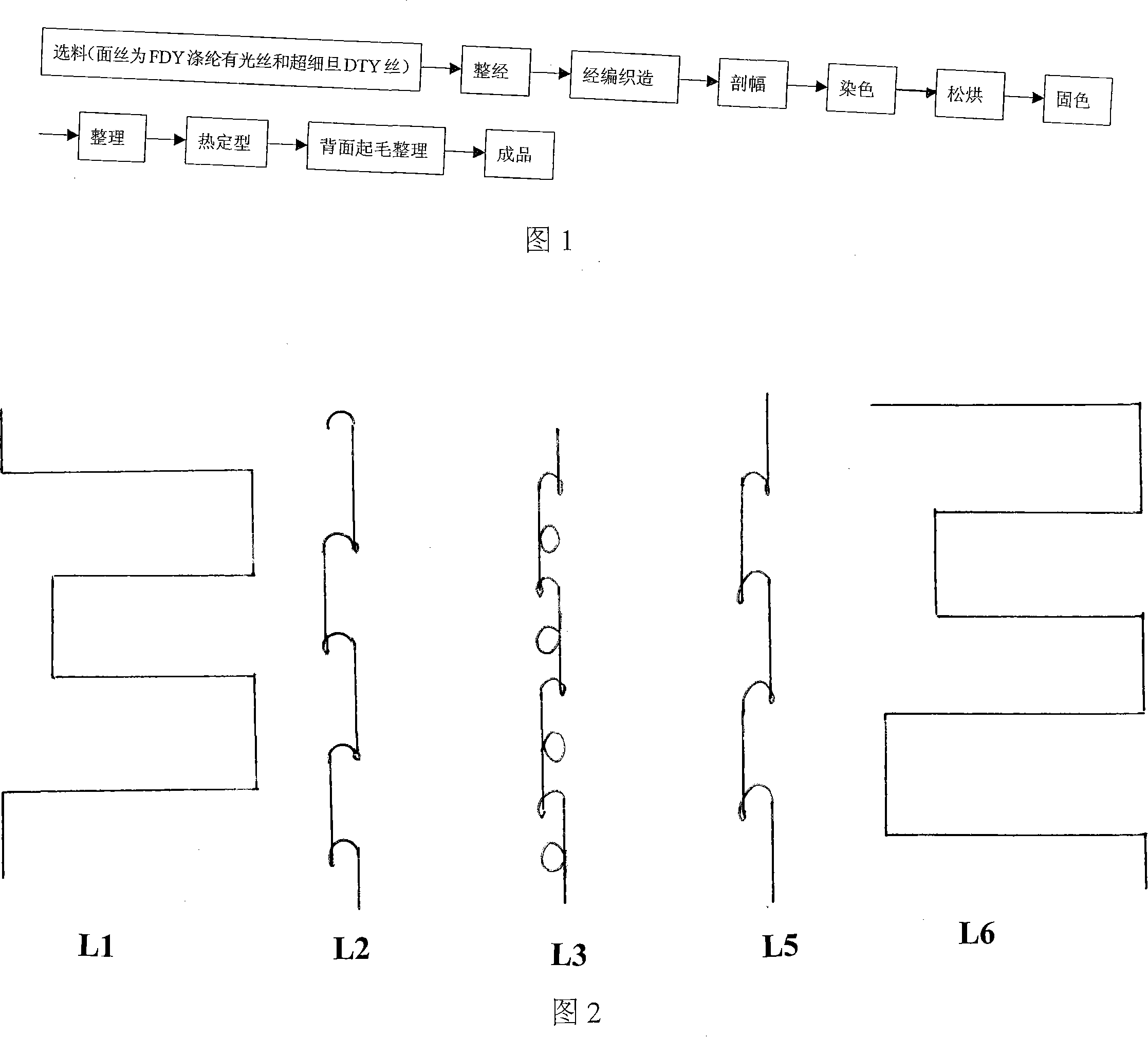

Processing technology of polyster fibric

InactiveCN101089272AFull of three-dimensional senseMeet the requirements of color diversification pursuitWarp knittingDyeing processPolyesterPulp and paper industry

The present invention relates to a processing process of polyester fabric. Said processing process includes the following several steps: selecting material, warping, warp knitting weaving, slitting, dyeing, relax drying, color fixing, finishing, thermosetting and back teasing finishing. It is characterized by that the described material selection includes selection of face yarn and selection of base yarn. The described face yarn is FDY polyester bright yarn and superfine denier DTY yarn and the described base yarn is FDY polyester filament.

Owner:CHANGSHU ZHONGWANG JINGWEI WEAVING

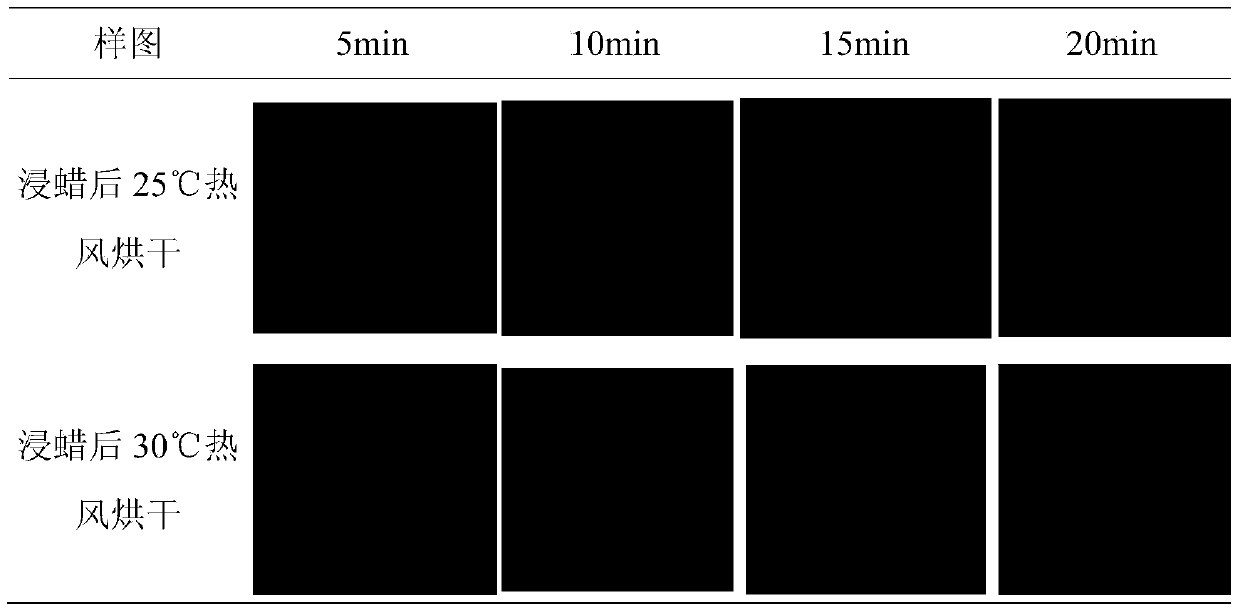

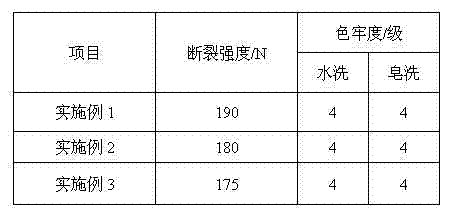

Method for distressed rapid dyeing of wool sweater

The invention relates to a method for distressed rapid dyeing of a wool sweater. The method comprises the following steps: (1) wax-dipping: weighing liquid Evo wax with the amount of 1.05-1.15 times of the wool sweater fabric weight, at the room temperature, soaking the wool sweater in the wax liquid, and repeatedly kneading and pressing until being uniform; and carrying out low temperature drying or natural drying; (2) dyeing: putting the wool sweater fabric after wax-dipping pretreatment and drying into a prepared dyeing bath; heating up to 75-80 DEG C at a speed of 3 DEG C / min, and holding for 5-10 min to achieve dyeing; (3) carrying out color fixation: after dyeing, adding a cationic color-fixing agent for color fixation for 5 min, and then taking out the fabric; (4) cleaning: washing with a non-ionic surfactant for 15 min at the temperature of 70 DEG C; and (5) drying. After the wool sweater is dyed by the rapid dyeing process, a distressed effect of distinct depth levels and uniform overall appearance appears. In addition, compared with a conventional dyeing process, the dyeing time is shortened by 60%-70%, and the color fastness is at the level of 2.5 or above.

Owner:嘉兴俊雅服饰股份有限公司

Ornamental glass having etching pattern and multicolor pattern and and method for manufacturing same

InactiveCN101041555AHigh precisionFull of three-dimensional senseSurface treatment compositionsFlat glassScreen printing

The invention discloses a decorative glass with acid-frosted pattern and colored pattern and preparing method, which comprises the following steps: one, acid-frosting to acid-frosting pattern on the plate glass through acid-frosting treatment; two, cleaning; airing or drying; three, combining with self pattern of acid-frosting glass; adopting silk-printing or spraying method; printing or spraying coloured material on the acid-frosting glass; forming colored pattern; four, natural drying or drying the coloured glass; getting end product.

Owner:ZHENGZHOU HENGHAO GLASS TECH

Technique for fabricating paints carved no paper, and preparing dedicated templates

InactiveCN1760051AColorfulFull of three-dimensional senseOutline designsDecorative surface effectsGraphicsPaperboard

A technique for making the carving picture on paper and its special template includes such steps as scanning a multi-color pattern, processing by color separating software to obtain more monochromatic patterns, printing each monochromatic pattern on paper, putting each of monochromatic patterns on a paperboard, carving the profile to obtain a template, putting each of the templates on a paper, and sequentially coating dried powder pigments to obtain said carving picture on paper.

Owner:刘树林

Method for manufacturing gold spraying plate of dyeing and printing roller

InactiveCN102407709AEmbossed effect arrivesFull of three-dimensional sensePrinting pre-treatmentForme preparationLaser engravingPulp and paper industry

The invention relates to a technology for manufacturing a roller by dyeing and printing, in particular to a method for manufacturing a gold spraying plate of the dyeing and printing roller. The method comprises the following steps of machining, nickel plating, grinding, manuscript production, glue spraying, laser engraving and etching. Compared with the prior art, the method has the advantages that different patterns can be made into patterns with different depth on a printing roller according to requirements, so that an embossing effect of pure paper or non-woven paper achieves the embossing effect of vinyl wall coverings, and the pure paper or the non-woven paper has a three-dimensional effect and hierarchy sense.

Owner:上海希尔彩印制版有限公司

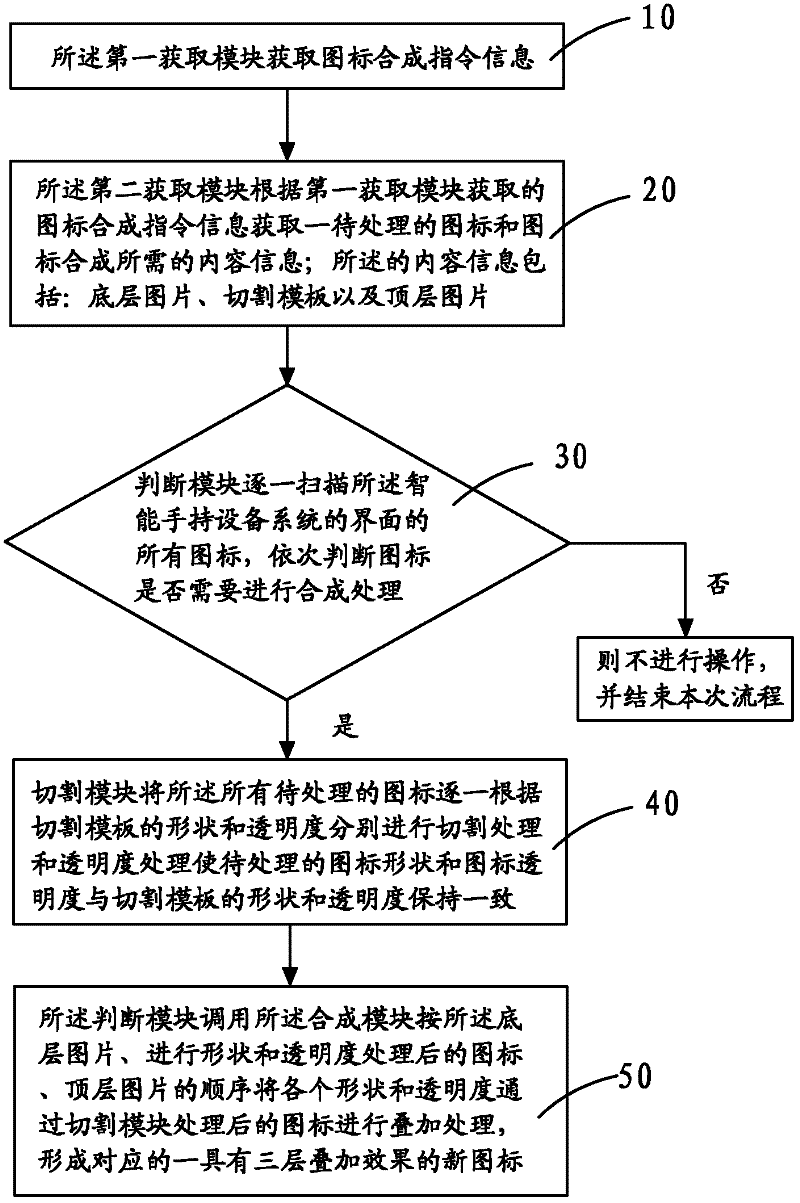

Method for synthesizing icons in interface of intelligent handheld device system

InactiveCN102495727AFull of three-dimensional senseImprove visionImage data processingSpecific program execution arrangementsComputer moduleVisual perception

The invention provides a method for synthesizing icons in an interface of an intelligent handheld device system. The intelligent handheld device system is provided with a first acquisition module, a second acquisition module, a cutting module, a judging module and a synthesizing module. Each of icons to be processed is correspondingly changed according to the shape and the transparency of the introduced cutting module, bottom-layer pictures and top-layer pictures are further introduced to realize expansion in a Z-axis direction, after the shapes and the transparencies of the various icons are processed by the cutting module, sequential overlaying processing of the corresponding bottom-layer picture, each icon and the corresponding top-layer picture is carried out, and accordingly each three-layer new icon with an overlaying effect is formed. By the aid of the method, the three-layer icons with the overlaying effects are obtained in the interface of the intelligent handheld device system, and realize stereoscopic impression, the friendly and humanized interface is provided for users, and visual improvement of the users during operation is realized.

Owner:FUZHOU BOYUAN WIRELESS NETWORK TECH

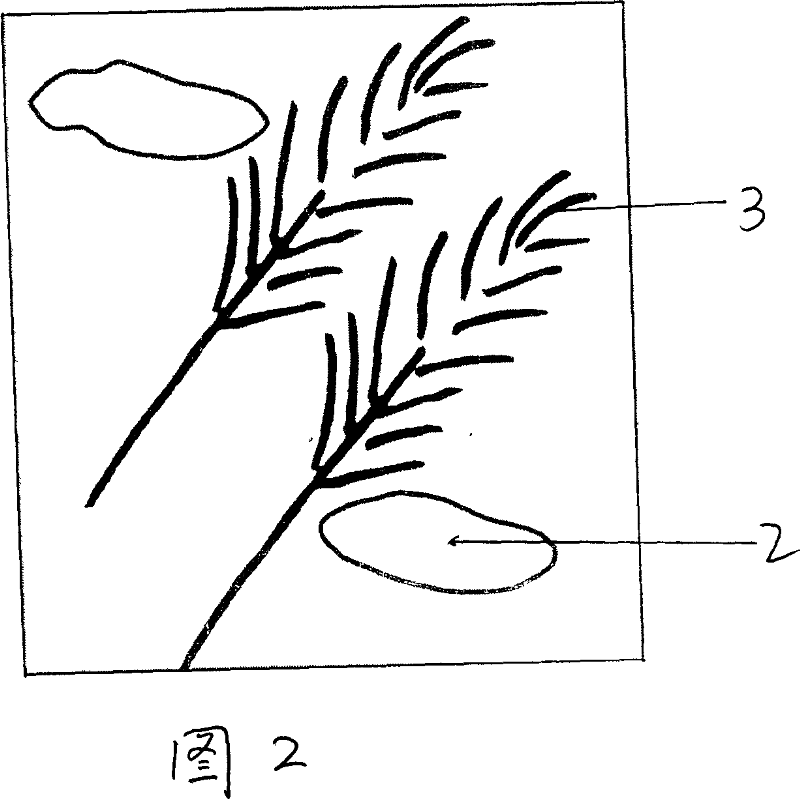

Real-wax batik process

InactiveCN104562753AReduce manufacturing costFull of three-dimensional senseDry-cleaning apparatus for textilesDyeing processWaxDyeing

The invention discloses a real-wax batik process. The process flow comprises wax printing by a roller, dyeing, piling and fixation, water washing, dewaxing and printing. Energy saving and consumption reduction measures are taken, so that the production cost is reduced. A wax printing method that the back side is printed and then the front side is printed is adopted, a wax film on the back side extends to some extent under the pressure effect of the front side, the front and back sides are slightly different during batik dyeing of a main pattern, the three-dimensional and vivid main pattern effect is produced after dewaxing, then special processing is performed on the wax film, and the main pattern is more vivid and three-dimensional. Dewaxing is realized in two steps: in the first step, physical dewaxing is performed with a roll compacting rope washing method; in the second step, an alkali and the wax have a saponification reaction, wax remaining in cloth is removed, the white place is not stained, and the dyeing brilliance is guaranteed.

Owner:QINGDAO SINGAO TEX NEW TECH COMPOSITE MATERIAL

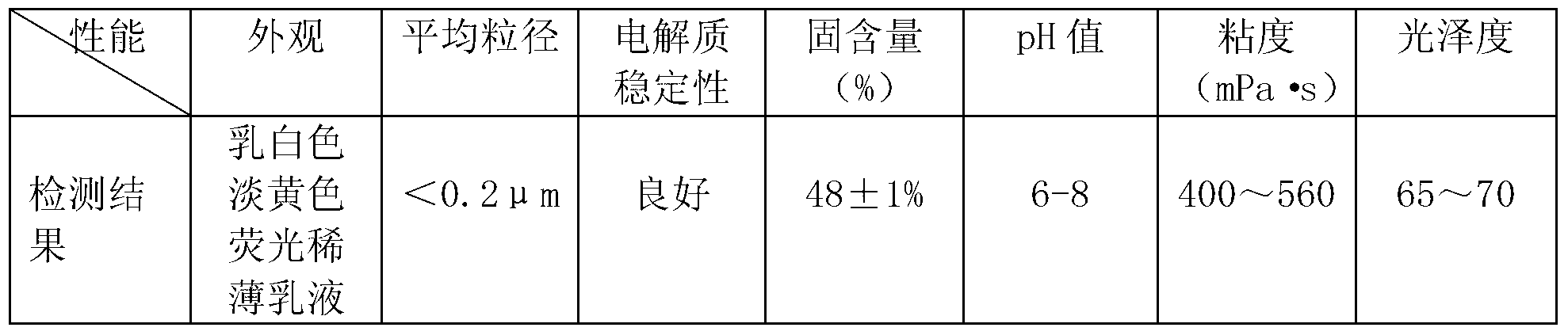

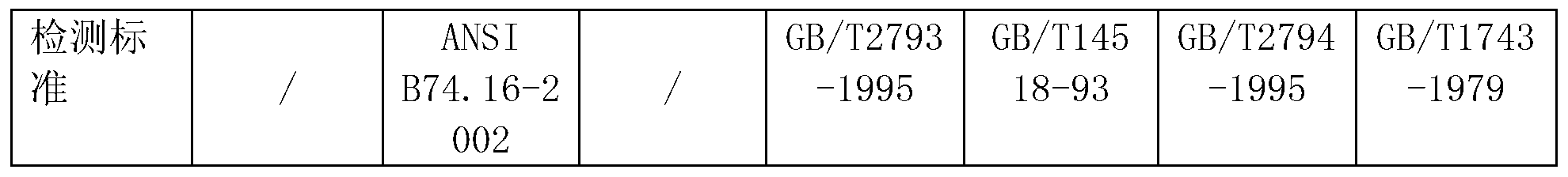

Acrylate copolymer emulsion paper-plastic composite adhesive and manufacturing method thereof

The invention relates to an acrylate copolymer emulsion paper-plastic composite adhesive which is prepared from the following raw materials in percentage by weight: 16-37% of butyl acrylate, 8-16% of acrylic acid, 5-11% of methyl methacrylate, 3-8% of acrylonitrile, 1-5% of itaconic acid, 0.1-0.3% of sodium hydroxide, 0.4-0.6% of initiator, 0.1-2% of composite emulsifier, 0.05-0.1% of ammonia water, 0.05-0.1% of defoaming agent, 2-6% of stabilizer and 15-64% of deionized water. The invention also relates to a preparation method of the acrylate copolymer emulsion paper-plastic composite adhesive. The invention has the advantages of abundant raw material sources, low synthesis cost and simple and stable production technique; and the prepared acrylate copolymer emulsion paper-plastic composite adhesive has the advantages of small and uniform particles, high drying rate and favorable storage stability, and is suitable for compounding paper-base presswork and plastics.

Owner:海南赛高新材料有限公司

High-count high-density jacquard China hemp bedding fabric and product

InactiveCN102121155AWith comfortRetain comfortBiochemical fibre treatmentDry-cleaning apparatus for textilesHigh densityEngineering

The invention discloses a high-count high-density jacquard China hemp bedding fabric. Warps are selected from tightly spun 50S China hemp yarns, and wefts are selected from vortex spun 40S China hemp yarns; the specification of the fabric is 136' tightly spun China hemp 50S * Murata vortex spinning (MVS) China hemp 40S / 173 *110; the number of total warps is 23,520; a second consecutive realistic / abstract single flower of traditional Chinese ink painting skill is applied and spread on the whole ground, wherein the flower breadth is 74 centimeters, and the flower length is 255 centimeters; at least 20 different fabric tissues are applied in the circulation of a pattern; and the heald lifting proportion is controlled at 30 to 35 percent. The fabric has necessary comfort, function and environmental friendliness of high-grade bedding fabrics. Not only main natural properties of bacteria resistance, ultraviolet resistance, moisture absorption, quick dryness and the like of China hemps are kept, but also softness and compactness of the fabric and jacquard weaving luxury reach the requirements of the high-grade fabrics. The prepared bedding also has all excellent properties of the fabric.

Owner:JIANGSU YUEDA HOME TEXTILE

Production method of carved colored-glaze artistic porcelain

InactiveCN102658753AFull of three-dimensional senseWith bas-relief effectDecorative surface effectsMicrometerEngineering

The invention discloses a production method of a carved colored-glaze artistic porcelain. The production method includes the steps: making carved colored-glaze bottom decorative patterns and carved colored-glaze convex-layer decorative patterns and outputting films of the patterns; producing screens of the carved colored-glaze bottom decorative patterns and the carved colored-glaze convex-layer decorative patterns; printing the carved colored-glaze bottom decorative patterns; printing a carved colored-glaze convex decorative layer; performing cover oil printing; performing decal; and naturally cooling after colored baking. By the aid of the method, batched carved colored-glaze porcelains can be produced in a standardized manner, and the thickness of the decorative patterns of the produced carved colored-glaze artistic porcelain can reach 60-80 micrometers, so that dermatoglyphic patterns of the porcelain are concave-convex prominently and rich in stereoscopic impression and achieve a bas-relief effect.

Owner:斯达高瓷艺发展(深圳)有限公司

Eye shadow and eye line powder block and preparation method thereof

ActiveCN101780026AWith color decorationPlay the role of color decorationCosmetic preparationsMake-upOphthalmologyPyrrolidinones

The invention relates to an eye shadow and eye line powder block and a preparation method thereof. The powder block is prepared by adopting the combined formula of ultramicro pearl powder, lysine, vitamin E, ethylhexyl methoxycinnamate, titanium dioxide and polyvinylpyrrolidone / triacontylene copolymers as the core of the product and combining the intrinsic color expression effect of the eye shadow base material, and has dual-purpose functions of the eye shadow and the eye line, namely, the novel practical formula of the same product has dual-purpose functions of the eye shadow and the eye line. The invention provides the eye shadow and eye line dual-purpose eye shadow product having the functions of color expression, aging resistance, water resistance, sun protection and the like. Not only the eye shadow can have the functions of decoration and beauty of the traditional powder block eye shadow, but also the functional components in the eye shadow have functional effects by matching the traditional Chinese medicine with modern scientific principles, the functions of the eye liner can be fully realized when the eye liner is matched with the liquid, and no side effects exist. The powder block has reasonable formula, simple process and extremely obvious use effect.

Owner:TIANJIN TIANSHI BIOLOGICAL DEV +3

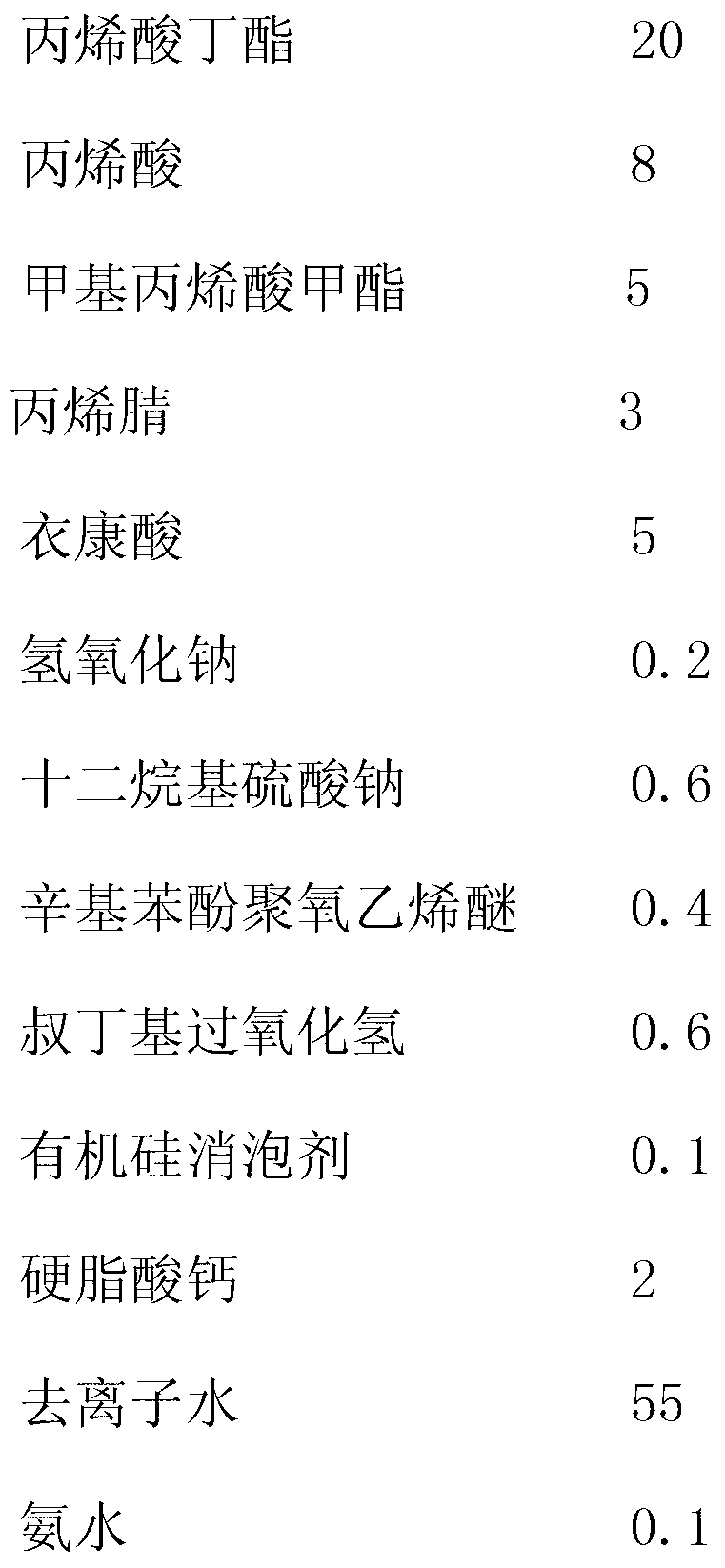

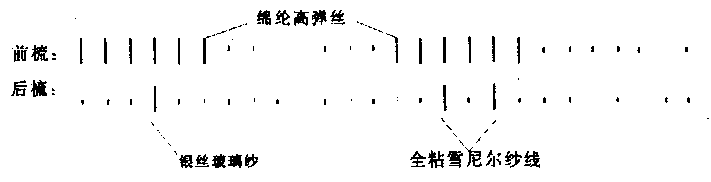

Knitting process for developing chenille silver wire maple leaf wool fabric using warp-knitting miss press stitch

InactiveCN1473973AElasticFull of three-dimensional senseYarnFlat warp knitting machinesEngineeringViscose fiber

The present invention relates to warp knitting technology, and is especially the knitting process of knitted fabric for clothing and decoration. According to the design scheme of the present invention, the materials including viscose chenille yarn, stretch Jinglun yarn and silver wire yarn are knitted in a warp knitting machine with pattern presser mechanism into the chenille maple leaf wool fabric. The present invention has the rugged chenille yarn and miss-press stitch combined, and floating yarn and shell effect combined.

Owner:JIANGNAN UNIV

Ceramic screen printing ink

The invention discloses ceramic screen printing ink. The ceramic screen printing ink comprises the following raw materials in part by weight: 10-20 parts of alkyd resin, 5-10 parts of anhydrous rosin ethanol, 50-80 parts of special pigment for ceramic products and 10-15 parts of auxiliary agent, wherein the auxiliary agent comprises a defoamer, a thickener, a drying agent and an antiseptic and bactericidal agent. The ceramic screen printing ink is simple in production process, low in cost, strong in adhesion to a ceramic product, unlikely to shed off, strong in coloring capability, excellent in printing effect and strong in three dimension, and can be widely used for printing the ceramic products.

Owner:苏州凹凸彩印厂

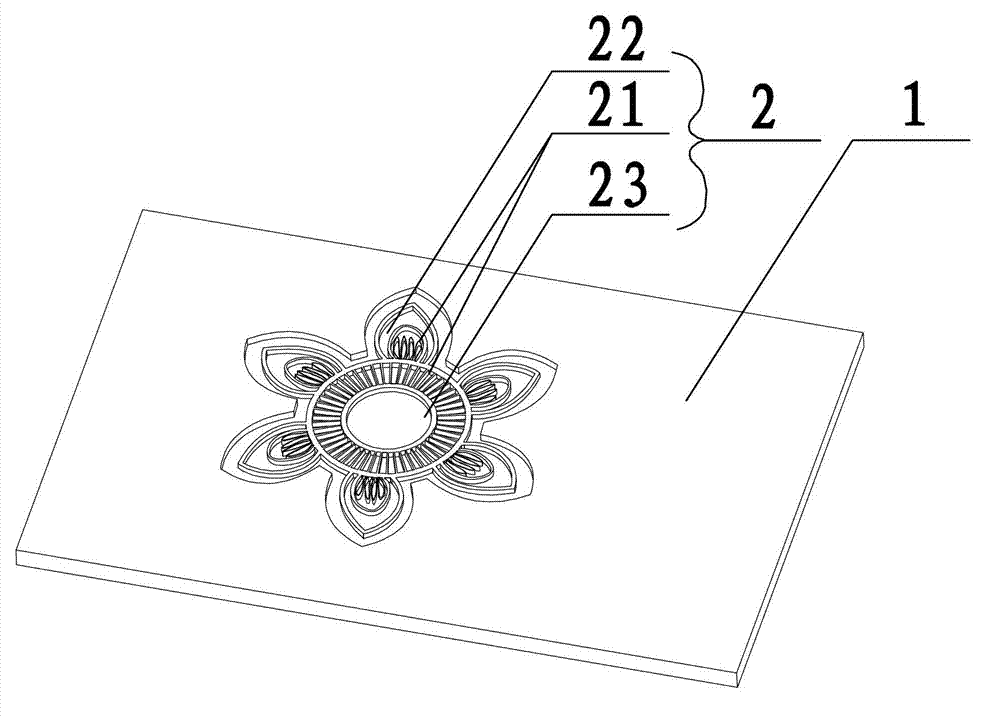

Preparation method of metal wire jewelry pendant

The invention discloses a preparation method of a metal wire jewelry pendant. The method comprises the following steps of (1) preparation material preparation: a, preparing an embroidery sheet; b, preparing a metal wire embroidery wire; c, preparing a metal framework; (2) metal wire pattern embroidering; (3) jewelry pendant assembling: putting the embroidery sheet with the embroidered metal wire patterns into an accommodating cavity of the metal framework to obtain the jewelry pendant. The method provided by the invention has the advantages that the process is simple and practical; the operation is convenient; the method is suitable for the jewelry pendant using thinner metal wires for national artware processing. The jewelry pendant manufactured by the method cannot be easily abraded, cannot easily generate color degradation, can be easily stored and has high collection artistic value; the metal wire patterns have rich metal luster and has the three-dimensional effects; high attractive effect can be given to the jewelry pendant; the practical value is realized; meanwhile, the collection value is also realized. The pendant is used as the Mongol nationality culture carrier, and is favorable for the propagandization, inheritance and protection of the national artware.

Owner:乌云高娃

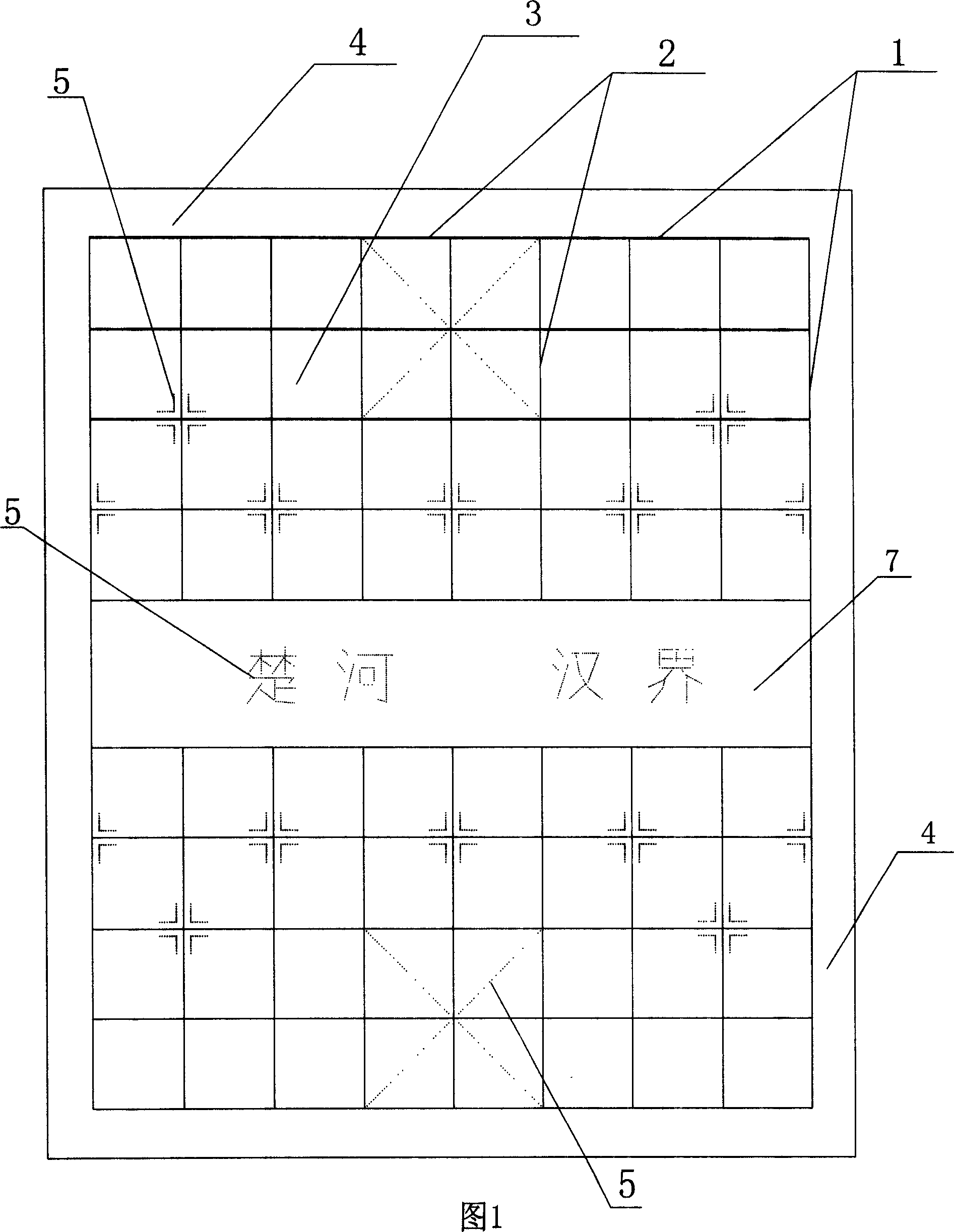

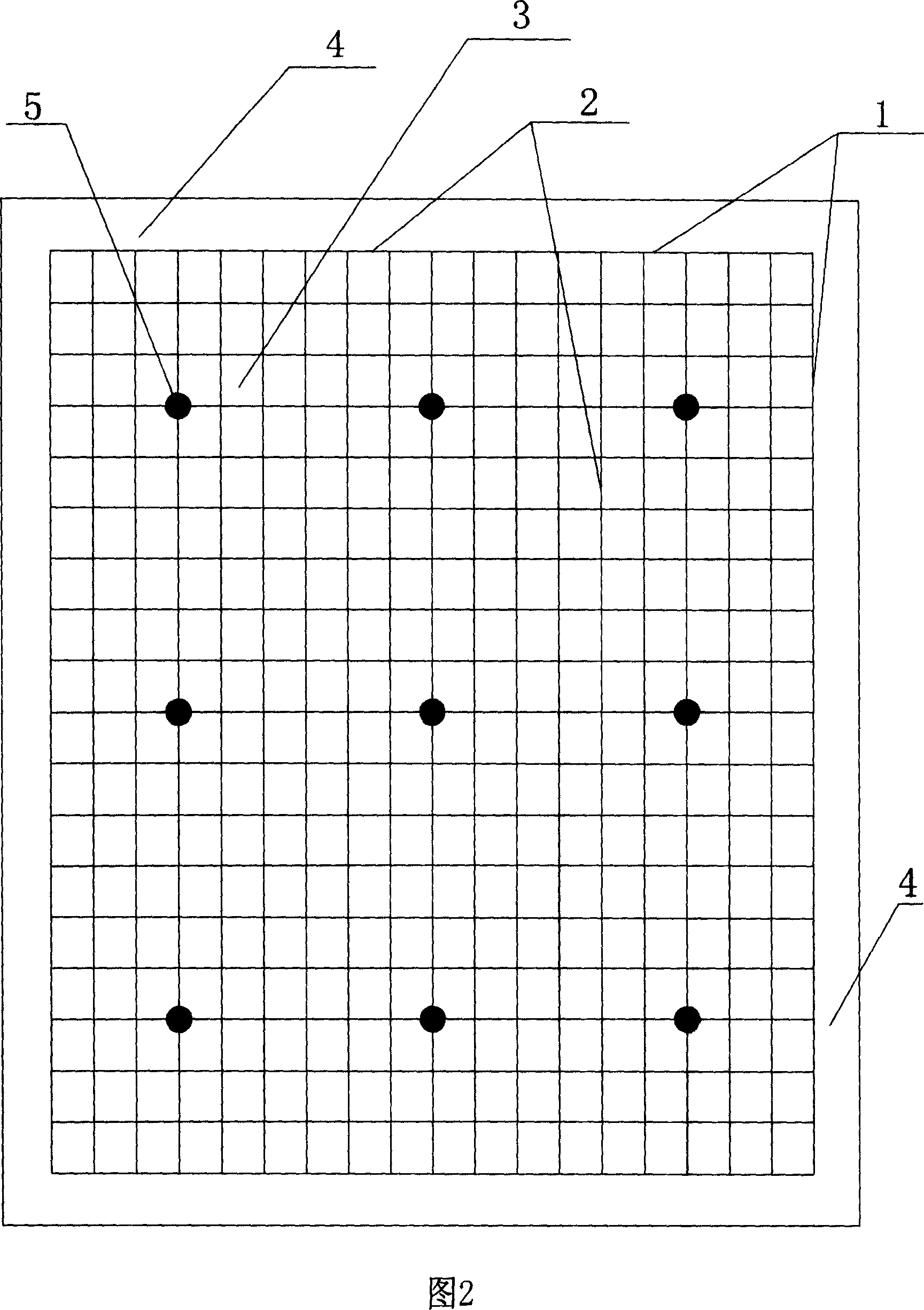

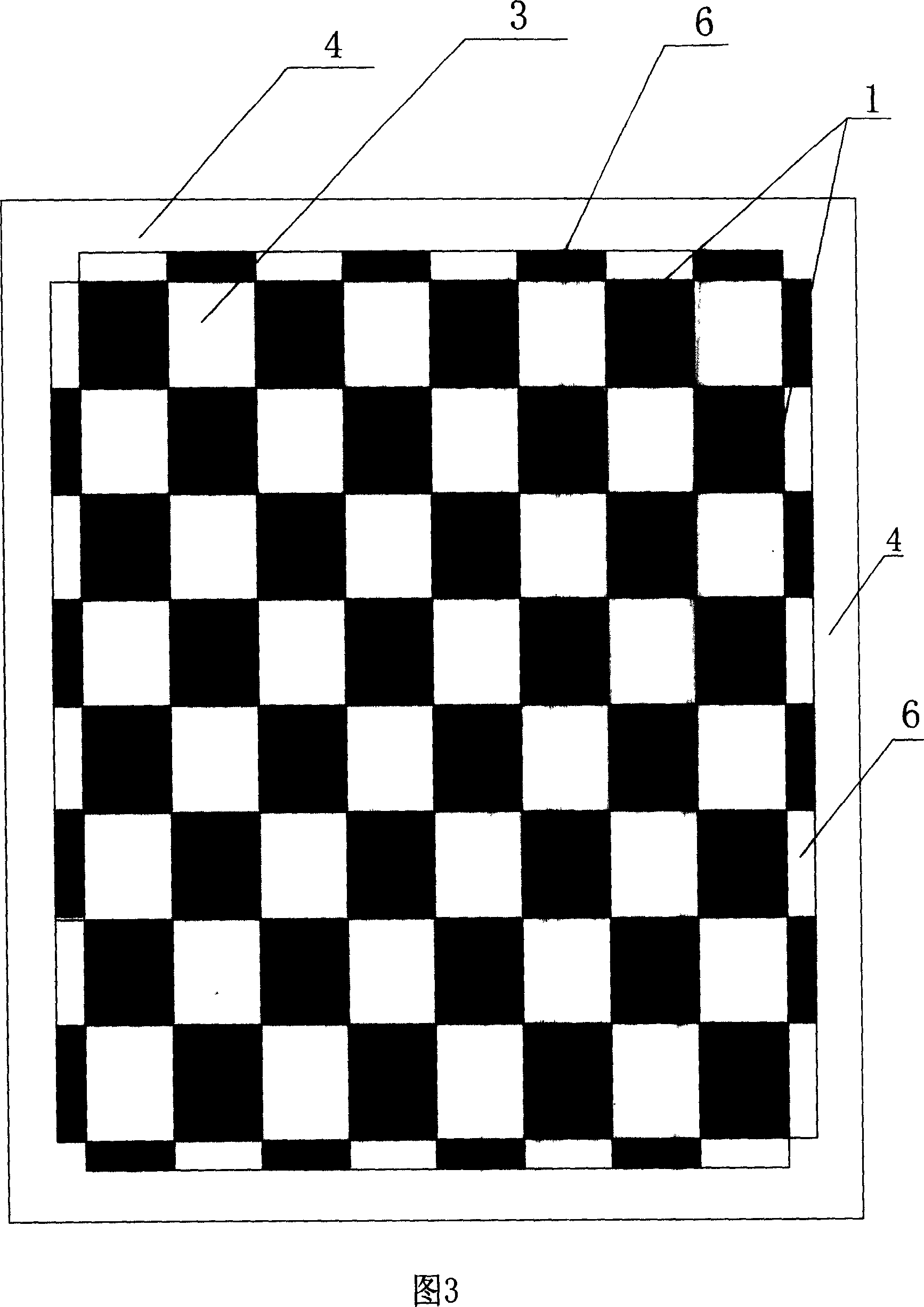

Assembled chessboard and manufacturing method thereof

The present invention discloses one kind of spliced chessboard for chess, Chinese chess and weichi chess. The spliced chessboard consists of checkers of different colors spliced by means of splicing bars of different colors. The production process of the spliced chessboard includes the steps of compartmental adhesion of checker strips in different colors, cutting and re-adhesion.

Owner:冯建明

Elastic fiber fabric solution

The invention relates to an elastic fiber fabric solution, belonging to the technical field of special woven fabrics. The solution comprises the following compositions in percentage by weight: 88% of N,N-dimethylformamide, 2% of dibutyltin dilaurate, and 10% of mineral oil. The solution and sodium alginate paste are mixed for use. By applying the technical scheme in the printing process of the elastic blended fabric, the elastic fiber dissolved fabric which is excellent in breathability, uniform in color, regular in patterns, and good in three-dimensional effect can be obtained.

Owner:ZHEJIANG GANGLONG WEAVING TECH

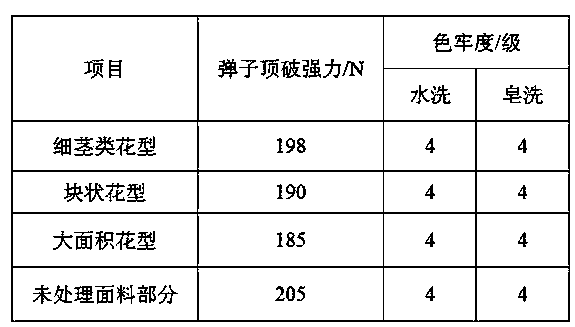

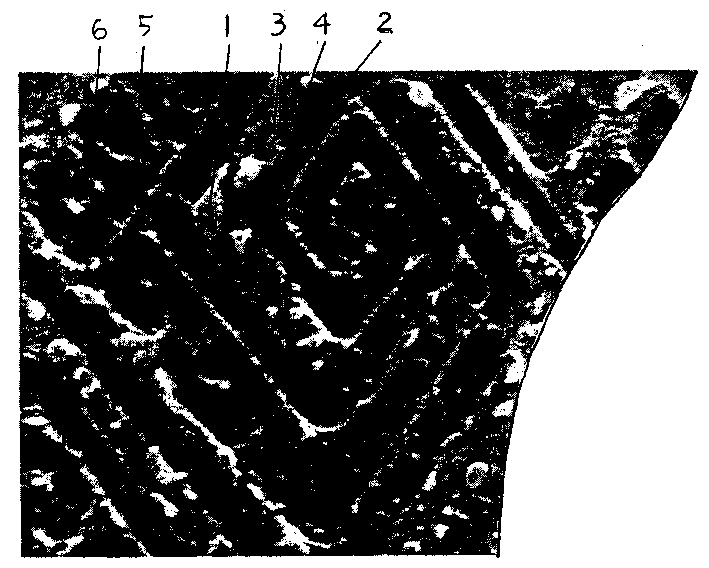

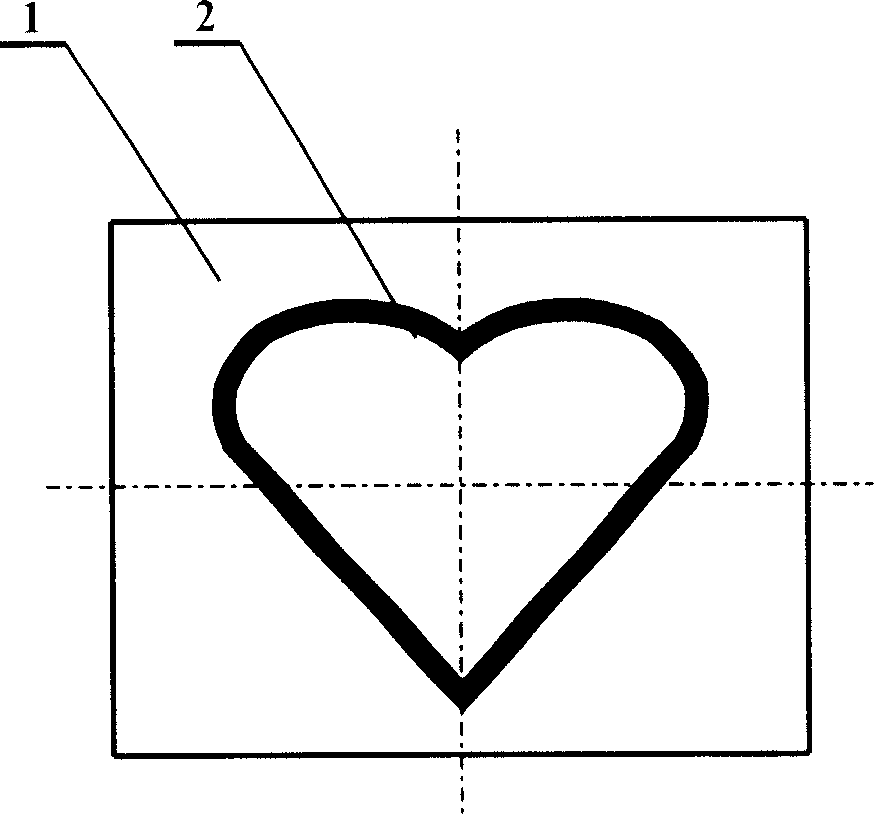

Dissolving printing technique of elastic fiber fabric

ActiveCN103774472AGuaranteed feelFeel goodHeating/cooling textile fabricsTextile decorationFiberDibutyl tin dilaurate

The invention relates to a dissolving printing technique of an elastic fiber fabric, belonging to the technical field of preparing special woven fabric. The dissolving printing technique comprises the steps of winding, loosening, pre-setting, pretreatment, printing, aging, washing, dehydration, drying and setting sequentially, the printing consists of dyeing and dissolving treatment, the solution for dissolving treatment is mixed with a dyeing auxiliary sodium alginate paste for use, after the solution and the sodium alginate paste are evenly mixed, the elastic blended fabric is dissolved into designed flower types and patterns through a mould, flat scream printing or manual smearing, and the solution comprises the following compositions in percentage by weight: 88% of N,N-dimethylformamide, 2% of dibutyltin dilaurate, and 10% of mineral oil. By adopting the technical scheme, the elastic fiber fabric has the advantages of excellent in breathability, low processing cost and good three-dimensional effect, and is convenient and fast to operate.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Multi-frame print ad show device

ActiveCN105390074AIncrease publicity effectLow costIlluminated signsIdentification meansMultiple frameAgricultural engineering

The invention discloses a multi-frame print ad show device. The multi-frame print ad show device comprises a base connected with a first support plate by a column; the base is connected with a first motor connected with a first rotary shaft; the outer side of the first rotary shaft is connected with a lower layer of ad cloth, the first support plate is connected with a second support plate by a support rod, and a drum is connected between the first support plate and the second support plate; the outer side of the drum is connected with a middle layer of ad cloth in a matching manner; the second support plate is provided with a third motor and a second rotary shaft connected with the third motor; the outer side of the second rotary shaft is connected with a barrel-shaped upper layer of ad cloth in a matching manner; the upper side of the second rotary shaft is provided with a fixing plate provided with a solar cell panel. The multi-frame print ad show device is divided into a structure of three layers, which are different in shapes and can rotate, the structure is novel, a three-dimensional feeling is realized, different pictures can be displayed at the same ad position, the propaganda effect of the ad position is increased, and a strong visual effect is generated for audience.

Owner:河南万创技术服务有限公司

Multiple etching technique for imitating cast copper, and its products

InactiveCN1480560ARealistic artistic effectFull of three-dimensional senseDecorative surface effectsEtchingCopper oxide

A multi-etching technology for preparing the pseudo-classical cast copper article includes chemically etching the designed pattern on the basal surface of copper material, locally splashing the protecting liquid drips randomly on the newly generated surface, repeating said steps at least 3 times, and treating at least one layer surface to make it show basic copper color or copper oxide color. Its advantage is lifelike artistical effect.

Owner:金星铜集团有限公司

Low-temperature rose-red glaze ceramic product and manufacturing method thereof

The invention relates to a ceramic product and a manufacturing method thereof, and specifically relates to a low-temperature rose-red glaze ceramic product and a manufacturing method thereof. The low-temperature rose-red glaze ceramic product is prepared by the following steps: applying red slurry on the surface of a ceramic blank in a glazing way, carrying out high-temperature biscuiting after the red slurry is dried, wherein the biscuiting temperature is 1150 DEG C-1200 DEG C; and applying rose-red glaze for the ceramic blank piece by adopting a glazing method after high-temperature biscuiting, carrying out low-temperature glaze firing after the rose-red glaze is dried, adopting roller kiln oxidizing flame firing at a firing temperature of 850 DEG C-950 DEG C, and discharging out of the kiln after firing. The low-temperature rose-red glaze ceramic product provided by the invention adopts a firing process of high-temperature biscuiting and low-temperature glaze firing, so that the product has high strength and high compactness and avoids pin holes, glaze shrinkage, orange glaze and blank blistering; and moreover, glaze color is full of third dimension and ceramics fired in different batches are stable in color.

Owner:江苏省宜兴彩陶工艺厂

Treating fluid for elastic fiber fabric

The invention discloses treating fluid for an elastic fiber fabric and belongs to the technical field of printing treatment for the elastic fiber fabric. The treating fluid comprises sodium alginate paste and rigidifying fluid, wherein the rigidifying fluid is matched with the sodium alginate paste for use and comprises the following components according to weight percentages: 35-40 wt% of diethylene glycol, 2-5 wt% of potassium acetate, 50-55 wt% of white oil and 5-10 wt% of alkylbenzene sulfonate. The elastic fiber fabric treated by the treating fluid for the elastic fiber fabric provided by the technical scheme of the invention has the advantages of uniform coloring, very neat patterns on the fabric even after washing for multiple times, and good stereoscopic effect. Simultaneously, the whole production process can be applied in the conventional printing equipment and printing process without adding more equipment, so that the production control is convenient, and the production cost is lower, thus being capable of being applied in the printing process and the like.

Owner:ZHEJIANG GANGLONG WEAVING TECH

Machine-made biscuit with applique

Owner:刘国田

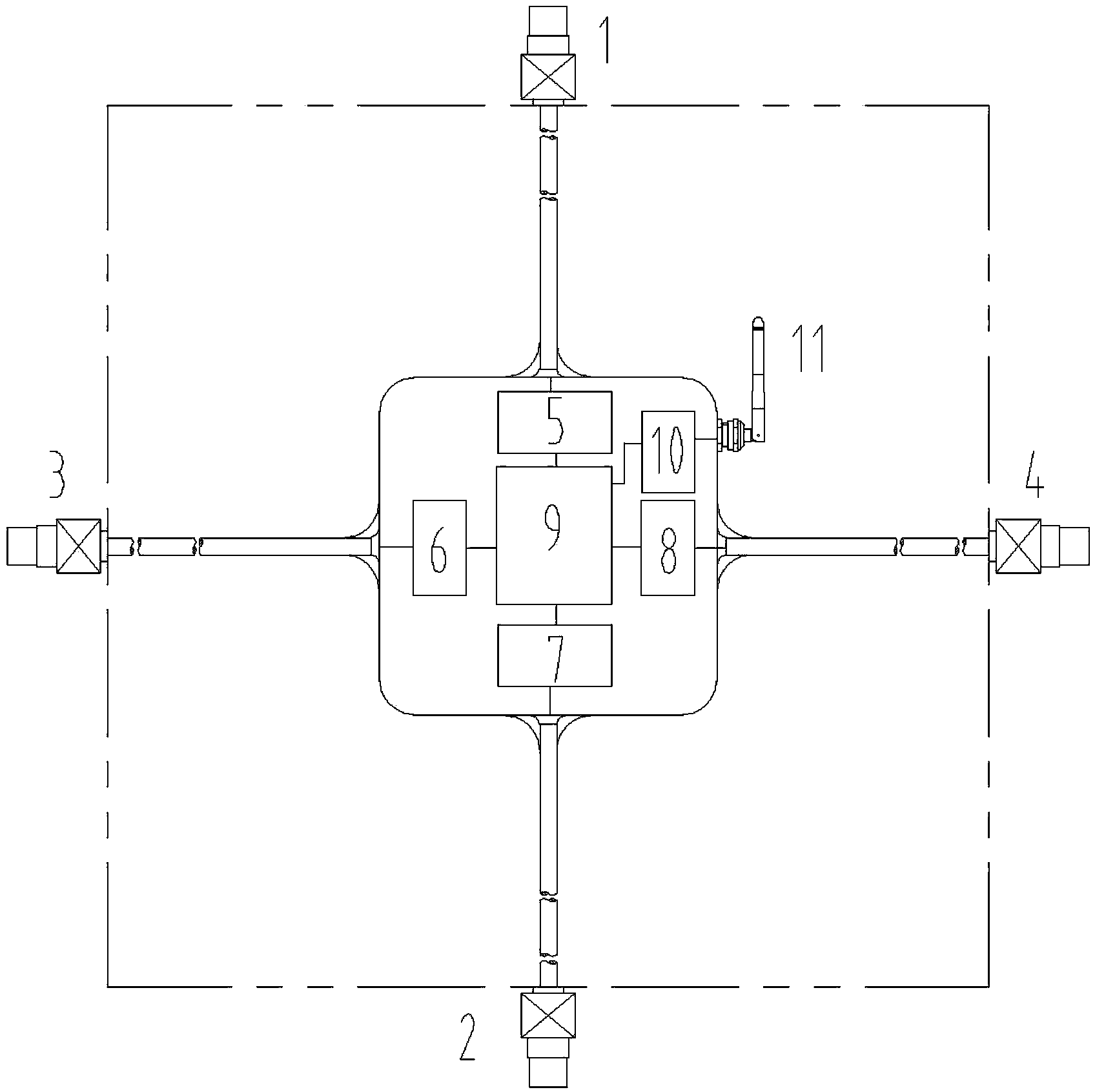

360-degree panoramic camera

InactiveCN104079875AEasy to handlePrevent deviationTelevision system detailsColor television detailsComputer hardwareSignal processing

The invention discloses a 360-degree panoramic camera and particularly relates to the 360-degree panoramic camera applied to an underground coal mine. The 360-degree panoramic camera comprises a signal transmitting portion and a signal receiving portion. The signal transmitting portion comprises a front camera located at the front position, a rear camera located at the rear position, a left camera located at the left position, a right camera located at the right position, a first video signal isolation processing module, a second video signal isolation processing module, a third video signal isolation processing module, a fourth video signal isolation processing module, a panoramic host main control board, a wireless communication signal processing module and an external antenna. The signal receiving portion comprises a wireless switch for receiving wireless signals transmitted by the external antenna and a display screen connected with the wireless switch. The 360-degree panoramic camera can provide real-time 360-degree panoramic monitoring videos for an operator in the equipment operation process so that the operator can timely and effectively deal with various sudden events; the 360-degree panoramic camera provides a fundamental guarantee for preventing accidents such as off-tracking and derailing of a locomotive.

Owner:SHANDONG COAL ELECTRIC

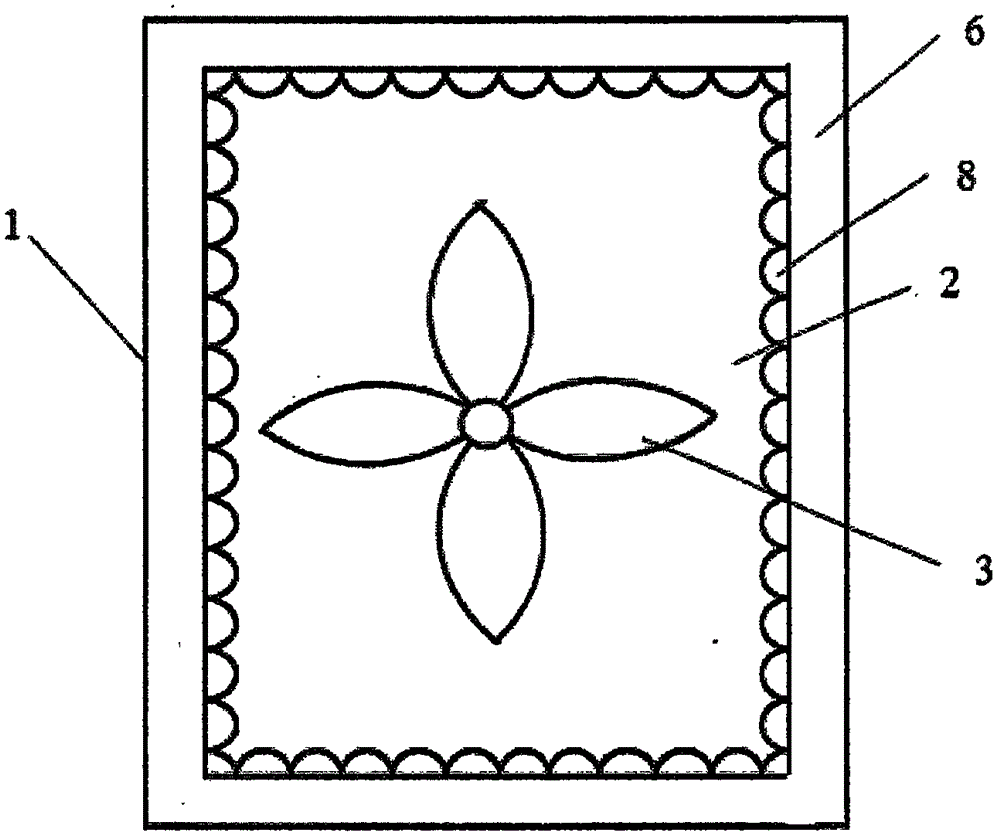

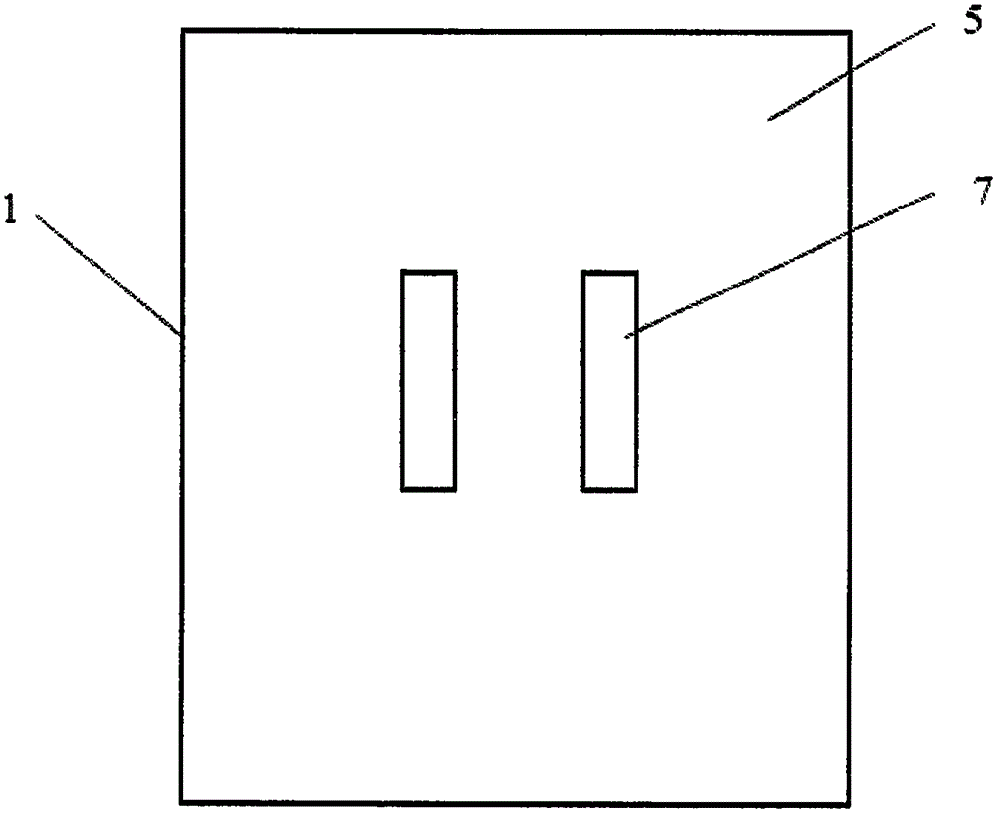

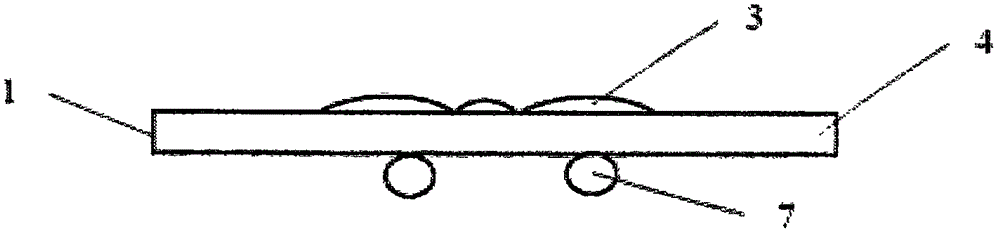

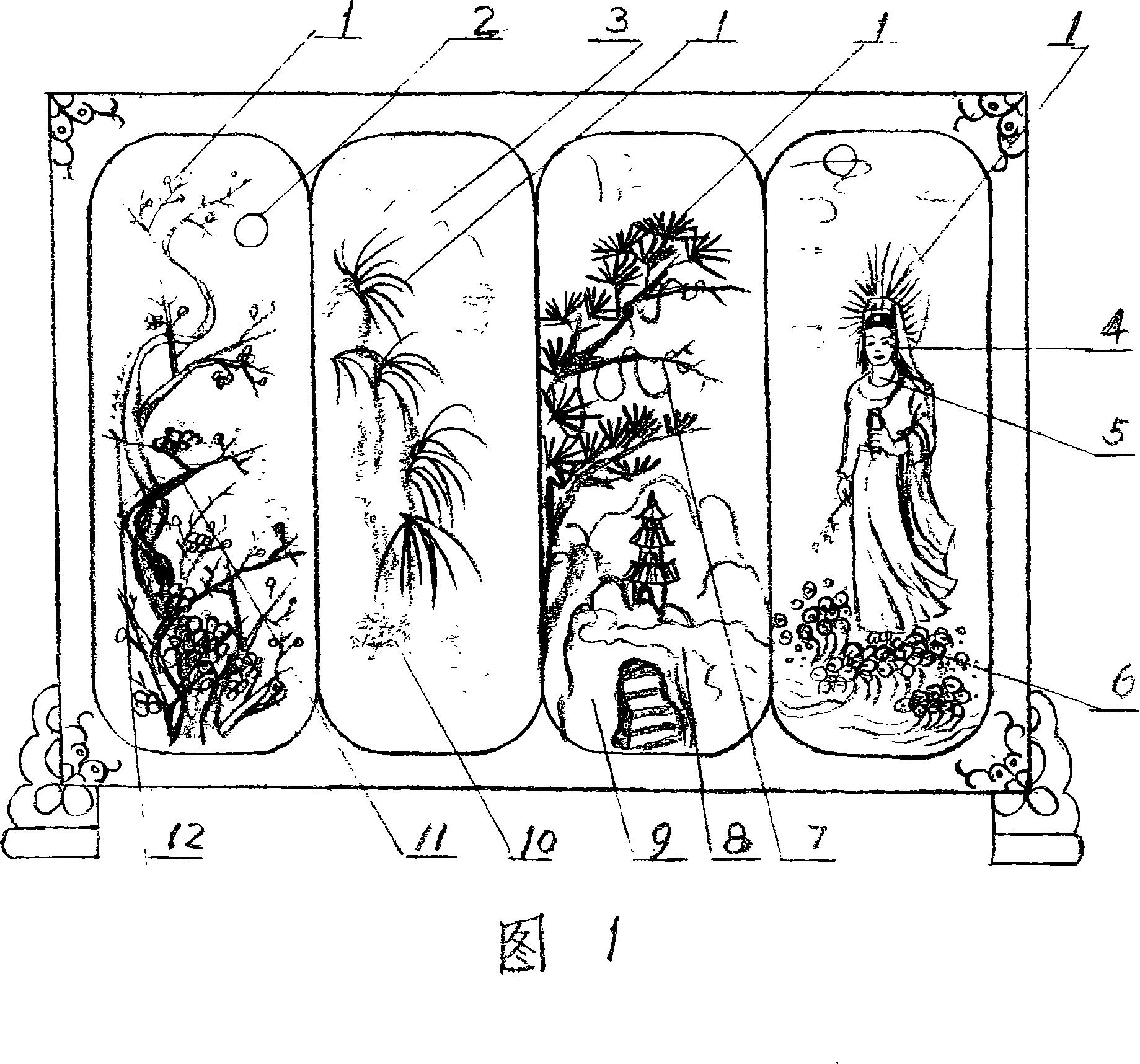

Method for making pearl embroidered handicraft picture and pearl embroidered handicraft picture

ActiveCN101077675ANovel preparation methodNovel and perfect production methodDecorative surface effectsSpecial ornamental structuresEngineeringBead embroidery

The present invention relates to handicraft, and is especially one kind of bead embroidery picture and its making process. The making process of the bead embroidery picture includes the following steps: spraying and painting background pattern and auxiliary pattern on the gauze as the base material; local treating through embroidering with glass beads, paillett and bead pipe to make bridge, suspension, etc; molding partial scenes and embedding into the picture; local building up and masking; spraying sand; and framing. The bead embroidery picture is used as indoor decoration.

Owner:胡晨光

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com