Knitting process for developing chenille silver wire maple leaf wool fabric using warp-knitting miss press stitch

A kind of tissue development, chenille technology, applied in the field of knitted fabric weaving technology, knitted garment fabrics and decorative products, can solve the problem of inability to direct production, and achieve the effect of rich patterns, rough and elegant fabrics, and good drape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

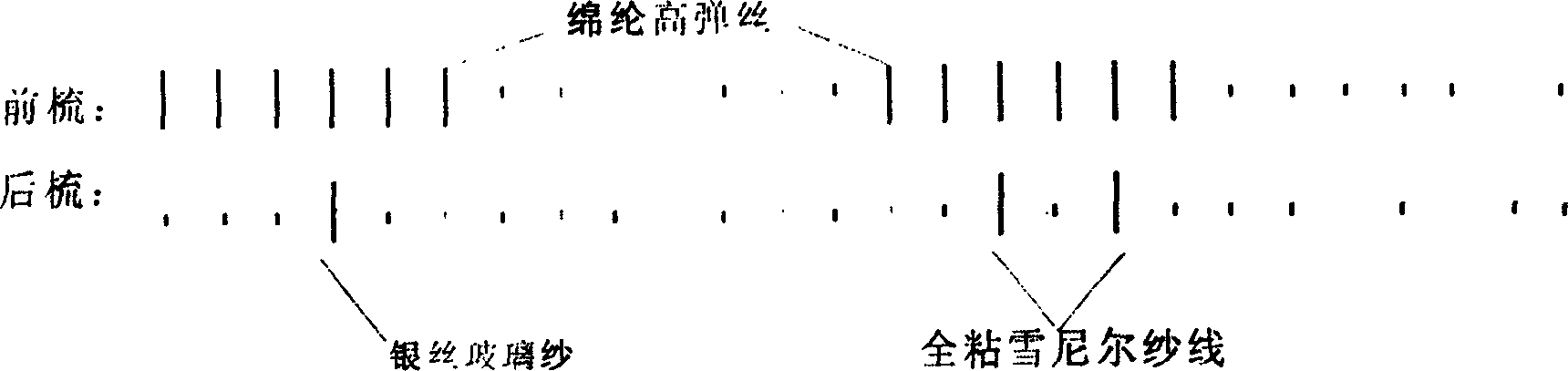

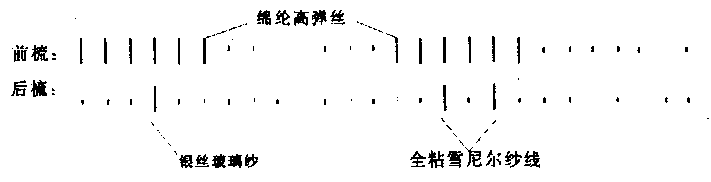

[0016] 1. Raw material: full sticky chenille yarn 4.5 s , 1550dtex nylon high elastic yarn, silver glass yarn (core yarn 111dex nylon yarn, hairiness yarn MS 12 PET silver wire).

[0017] 2. Equipment: Z303 warp knitting machine, 16 needles / 30mm, with flower platen mechanism.

[0018] 3. Arrangement of chain blocks.

[0019] Front comb: 2-0-2, 4-2-4, 6-4-6, 8-6-8, 10-8-10, 12-10-12, 14-12-14, 14-16-14 , 12-14-12, 10-12-10, 8-10-8, 8-6-8, 10-8-10, 12-10-12, 14-12-14, 16-14-16, 18 -16-18, 20-18-20, 22-20-22, 24-22-24, 26-24-26, 26-28-26, 24-26-24, 22-24-22, 20-22 -22, 20-18-20, 22-20-22, 24-22-24, 26-24-26, 28-26-28, 30-28-0, 32-30-30, 32-34-32 , 30-32-30, 28-30-28, 26-28-26, 24-26-24, 22-24-22, 20-22-22, 20-18-20, 24-22-24, 26 -24-24, 26-28-26, 24-26-24, 22-24-22, 20-22-20, 18-20-18, 16-18-16, 14-16-14, 12-14 -12, 10-12-10, 8-10-8, 8-6-8-, 10-8-10, 12-10-12, 14-12-14, 14-16-14, 12-14- 12, 10-12-10, 8-10-8, 6-8-6, 4-6-4, 2-4-2,

[0020] Back comb: 2-2-2, 2-2-4, 6-6-6, 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com