Ornamental glass having etching pattern and multicolor pattern and and method for manufacturing same

A color pattern and pattern technology, applied in the direction of chemical instruments and methods, surface etching compositions, etc., can solve the problems of lack of three-dimensional and layered sense of pattern, not vivid enough, lifelike, poor decorative effect, etc., to achieve rich artistic appeal The strength, scientific and simple manufacturing method, the effect of adding texture and three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

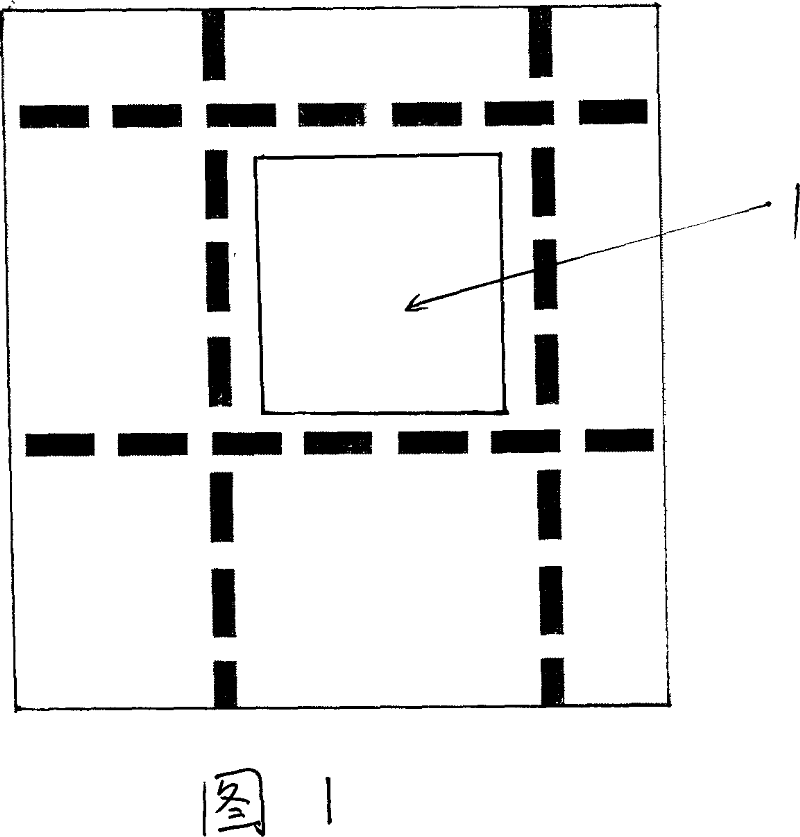

[0042] Embodiment 1: Below with reference to Fig. 1, the production technology with concavity pattern and colored pattern glass will be described, wherein in Fig. 1, reference numeral 1 represents blue square, and its manufacturing process is carried out according to the following steps:

[0043] (1) Clean the transparent flat glass first, and then perform single-sided frosting treatment;

[0044](2), the plate glass after frosting is printed anticorrosion ink on glass frosting surface with the silk screen of design pattern in advance, and pattern designed in advance is checkered pattern, it is dried after printing;

[0045] (3), stick one layer of plastic tape on the back of the glass processed by step (2);

[0046] (4), put the glass processed by step (3) into the corrosion tank filled with corrosion solution and soak for 50 minutes, wherein the composition and proportion of corrosion solution are prepared according to the following weight percentages: water 39%, sulfuric ac...

Embodiment 2

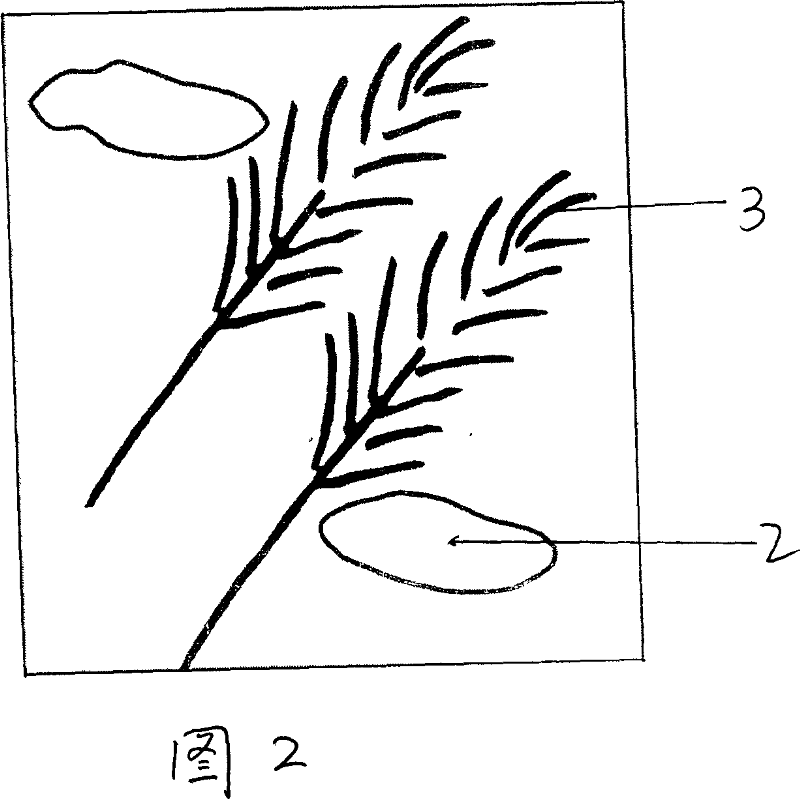

[0052] Embodiment 2: The production process of glass with concave pattern and colored pattern will be described below with reference to Fig. 2, wherein in Fig. 2, reference numeral 2 represents blue cloud, and mark 3 represents golden yellow autumn leaves, its manufacturing process Follow the steps below:

[0053] (1) Clean the transparent flat glass first, and then perform single-sided frosting treatment;

[0054] (2), the flat glass after frosting is printed anticorrosion ink on glass frosting surface with the silk screen of design pattern in advance, and pattern designed in advance is autumn leaf cloud shape pattern; After printing, it is dried;

[0055] (3) Paste a layer of plastic tape on the back of the glass treated in step (2) and put it in a corrosion tank filled with corrosive liquid and soak for 40 minutes, wherein the composition and proportion of the corrosive liquid are prepared according to the following weight percentages : Water 3%, sulfuric acid 18%, hydrofl...

Embodiment 3

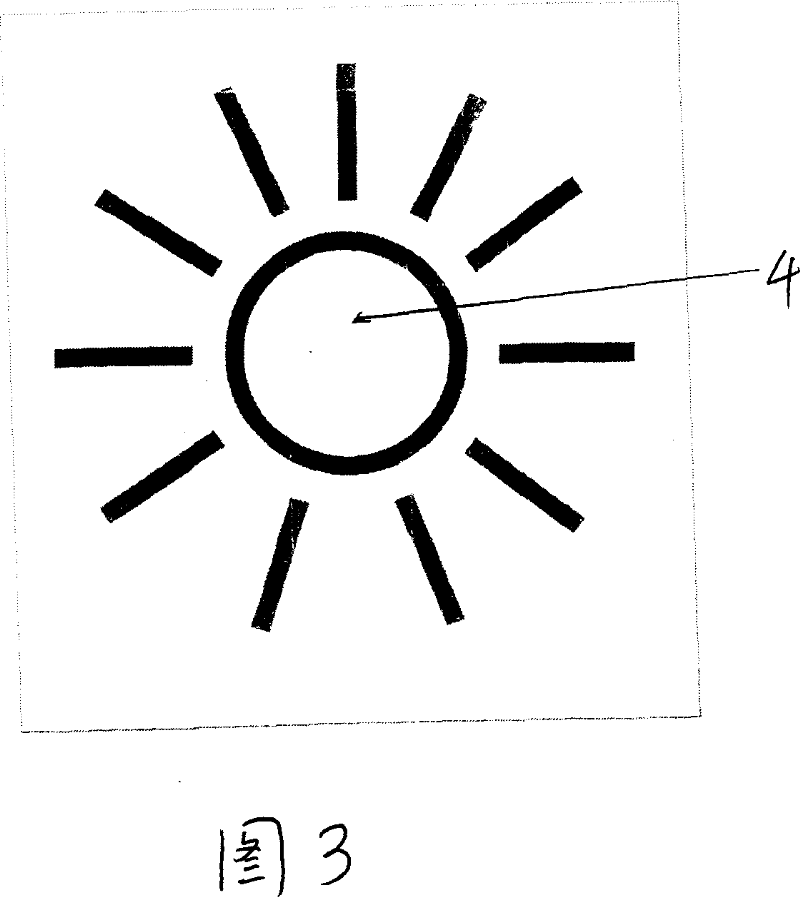

[0061] Embodiment 3: The production process of glass with multi-level patterns and colored patterns will be described below with reference to Fig. 3, wherein in Fig. 3 reference numeral 4 represents a red round handle, and its manufacturing process is carried out according to the following steps:

[0062] (1), first clean the transparent flat glass, after drying, print patterns on the glass with a pre-designed circular pattern screen, and use anti-corrosion ink for printing ink, and then dry;

[0063] (2), after drying, cover the back of the flat glass with pattern printed on it with anti-corrosion material and then carry out single-sided frosting;

[0064] (3) After clearing the ink printed for the first time, print the ink for the second time according to the screen of the radial line pattern designed in advance. The position of the center point pattern of the radial line pattern is determined and aligned to avoid pattern disorder;

[0065] (4), the glass processed by step ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com