Patents

Literature

34results about How to "Uniform lines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

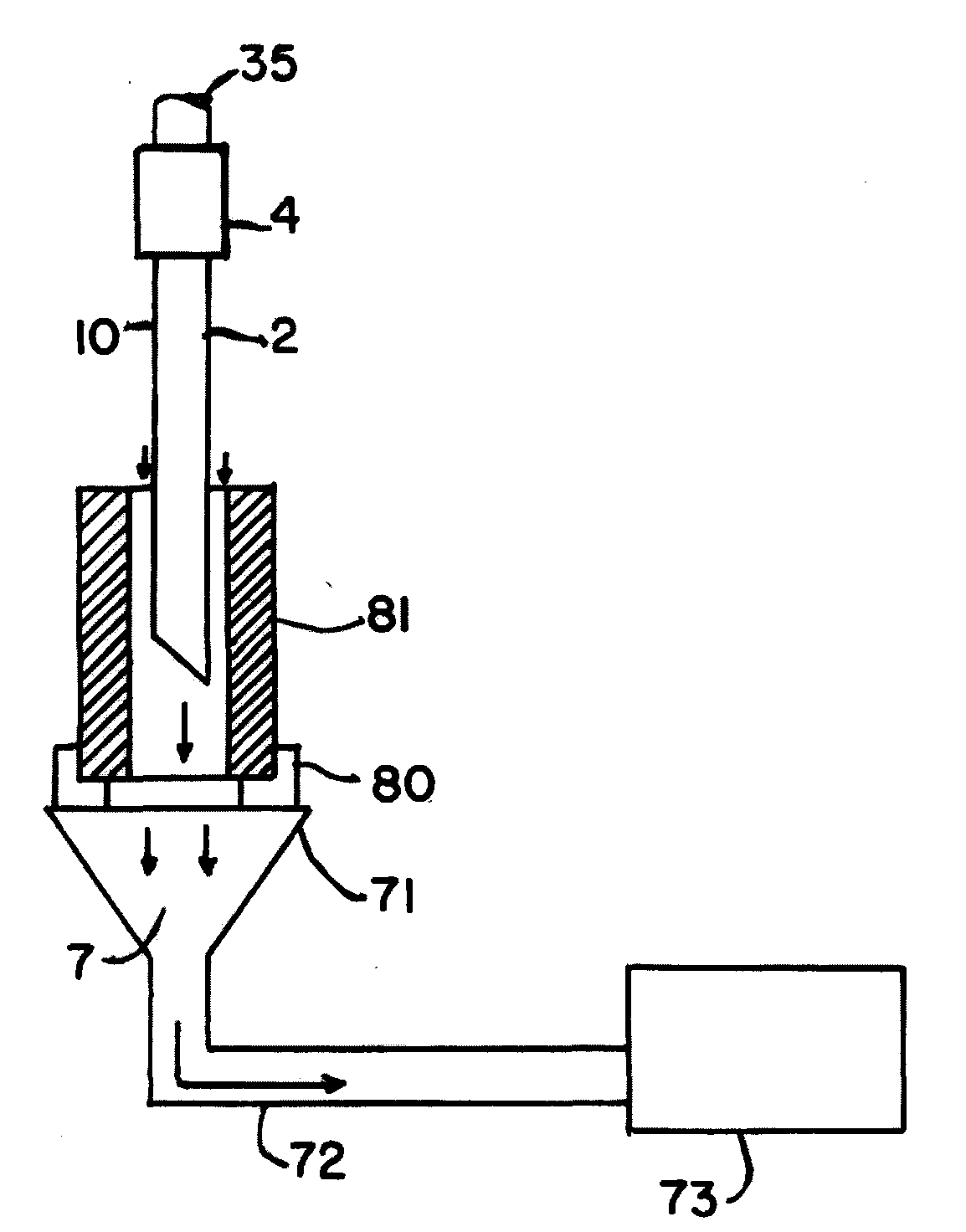

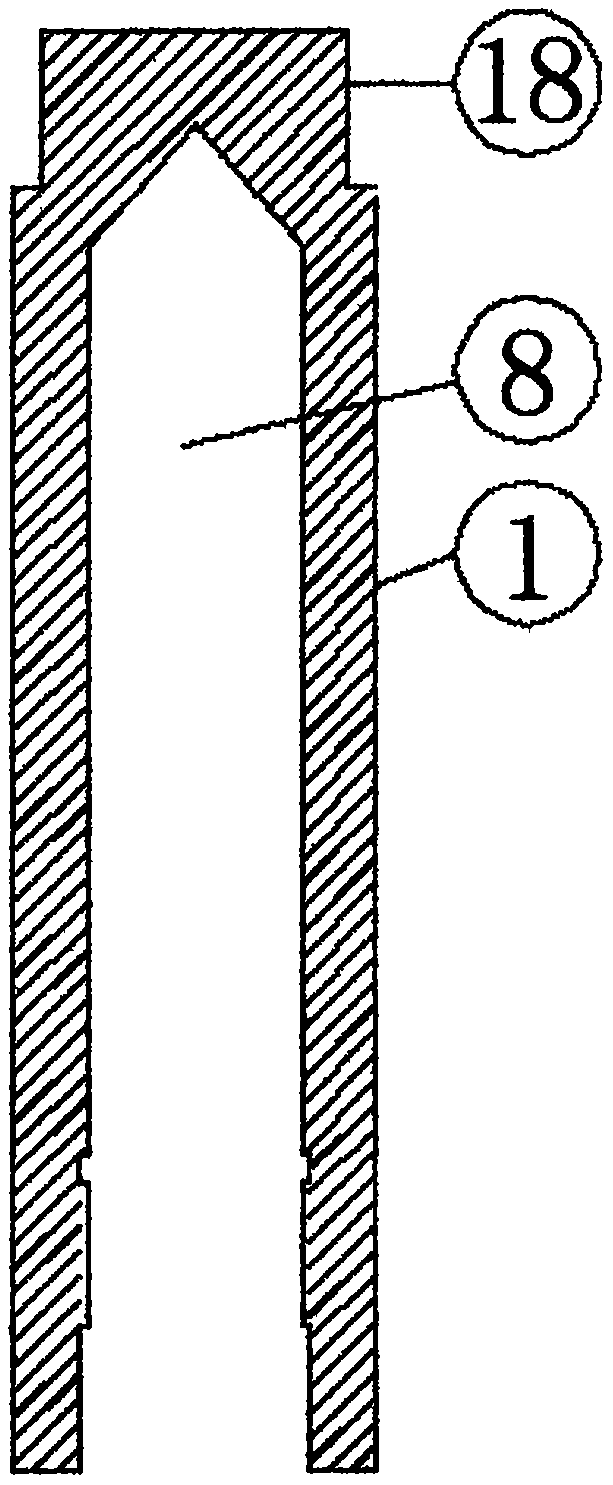

Vertical laser cladding system

ActiveUS20120100313A1Uniform linesFurnaces without endless coreLiquid surface applicatorsEngineeringLaser

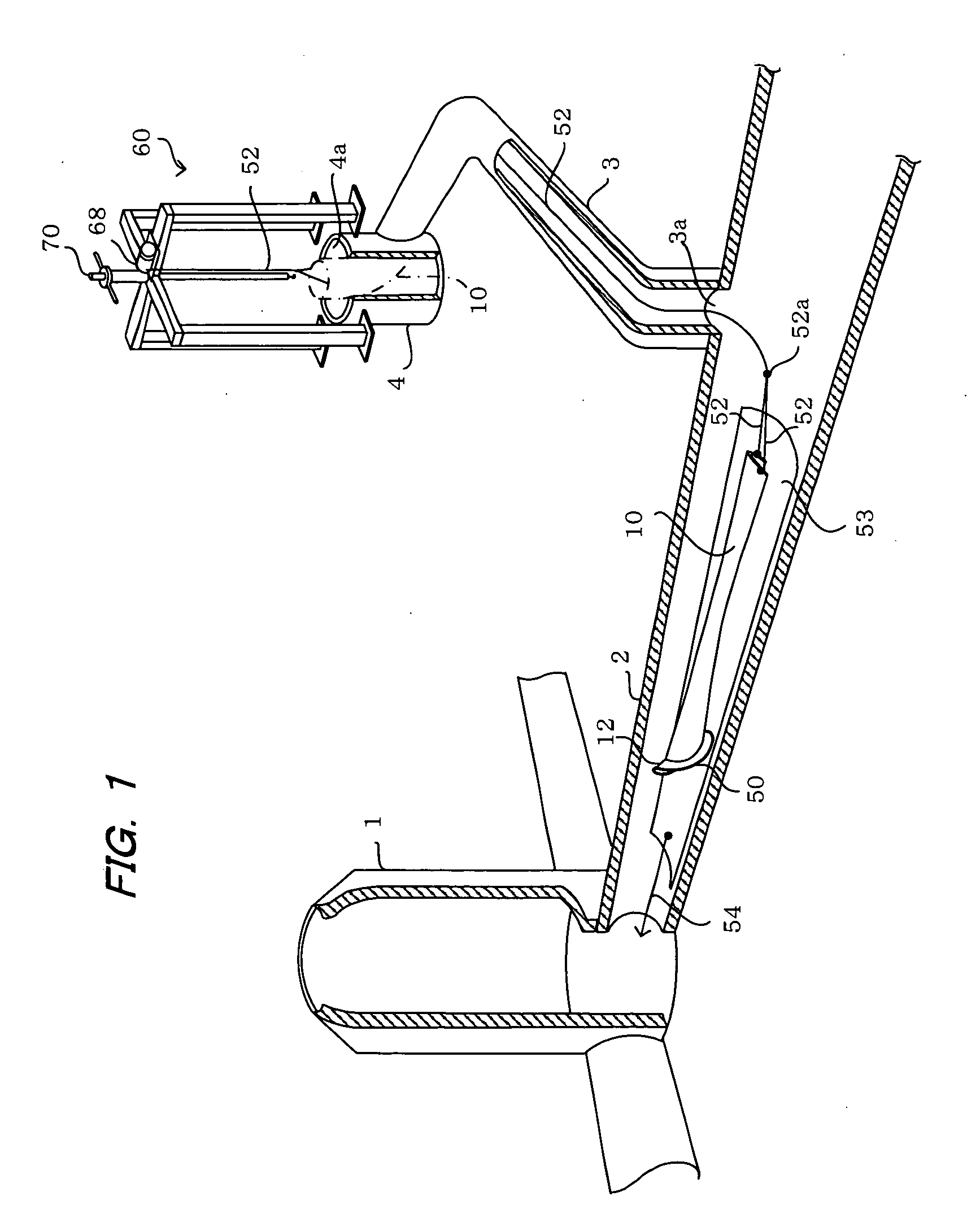

A vertical laser cladding system is particularly effective for the interior surfaces of tube-like structures. The vertical cladding process works from bottom to top, so that previously clad layers form a shelf for subsequent application of cladding powder. This system is also particularly effective for handling double-bore plasticating barrels.

Owner:XALOY INCORPORATED

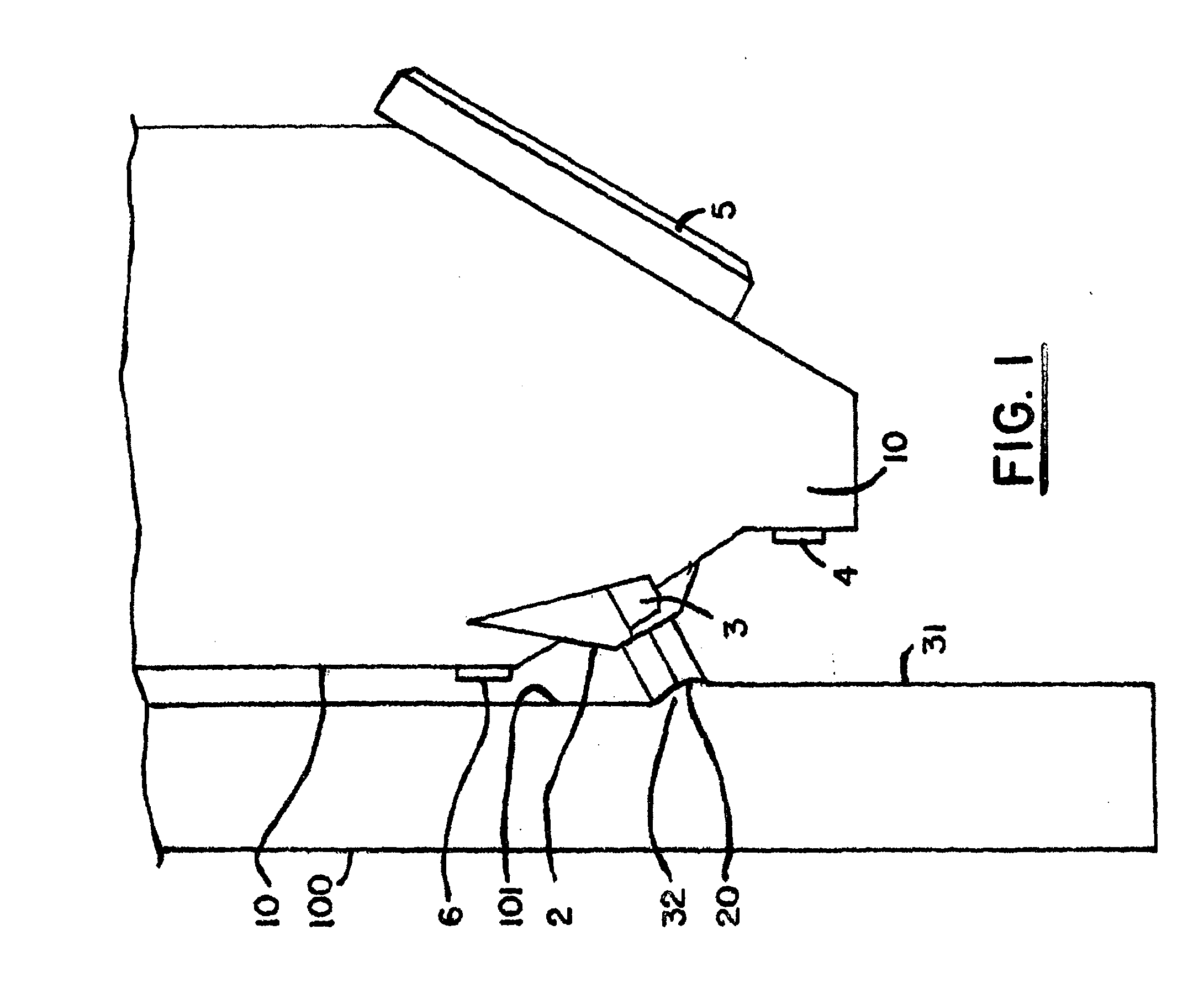

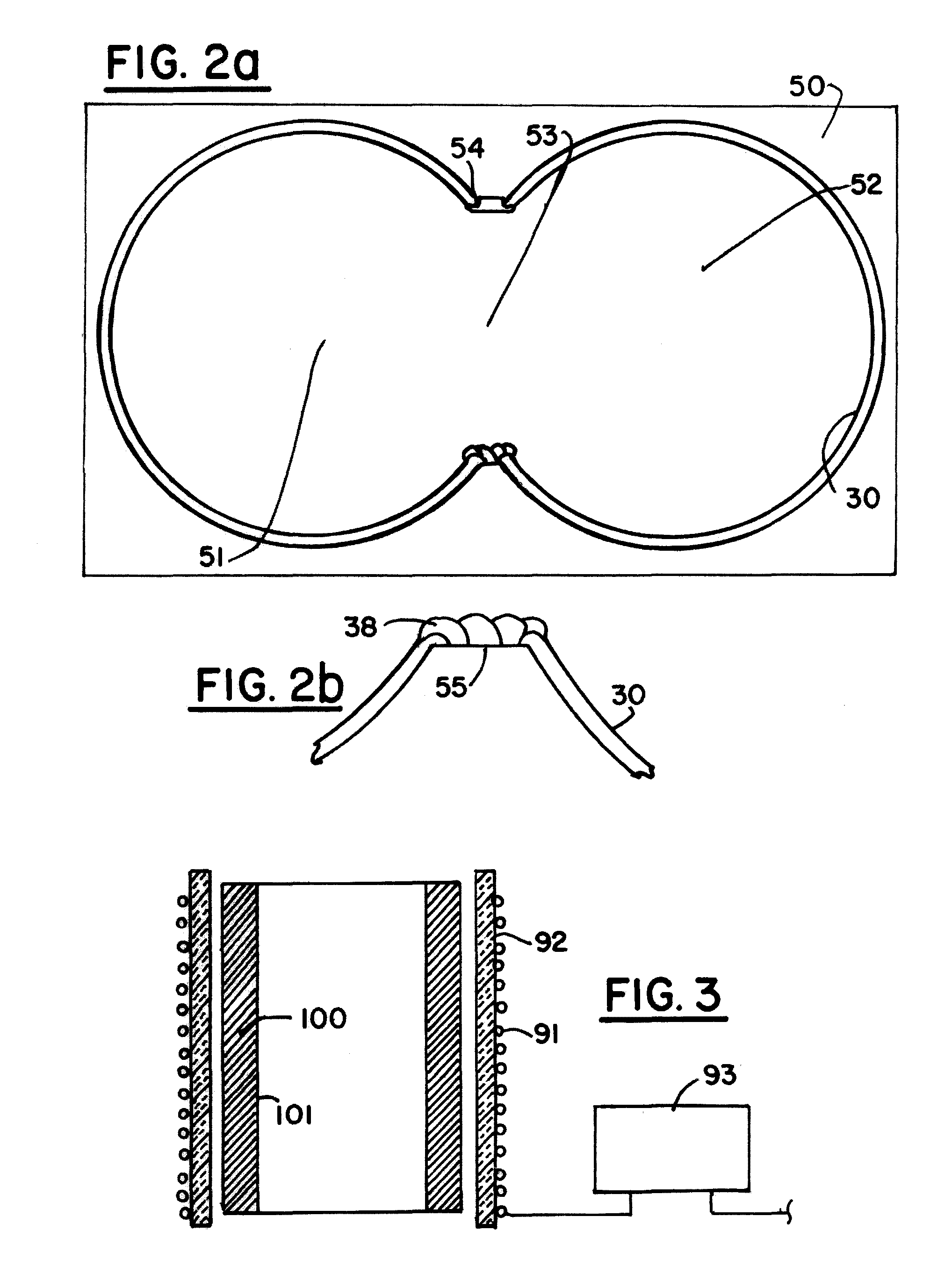

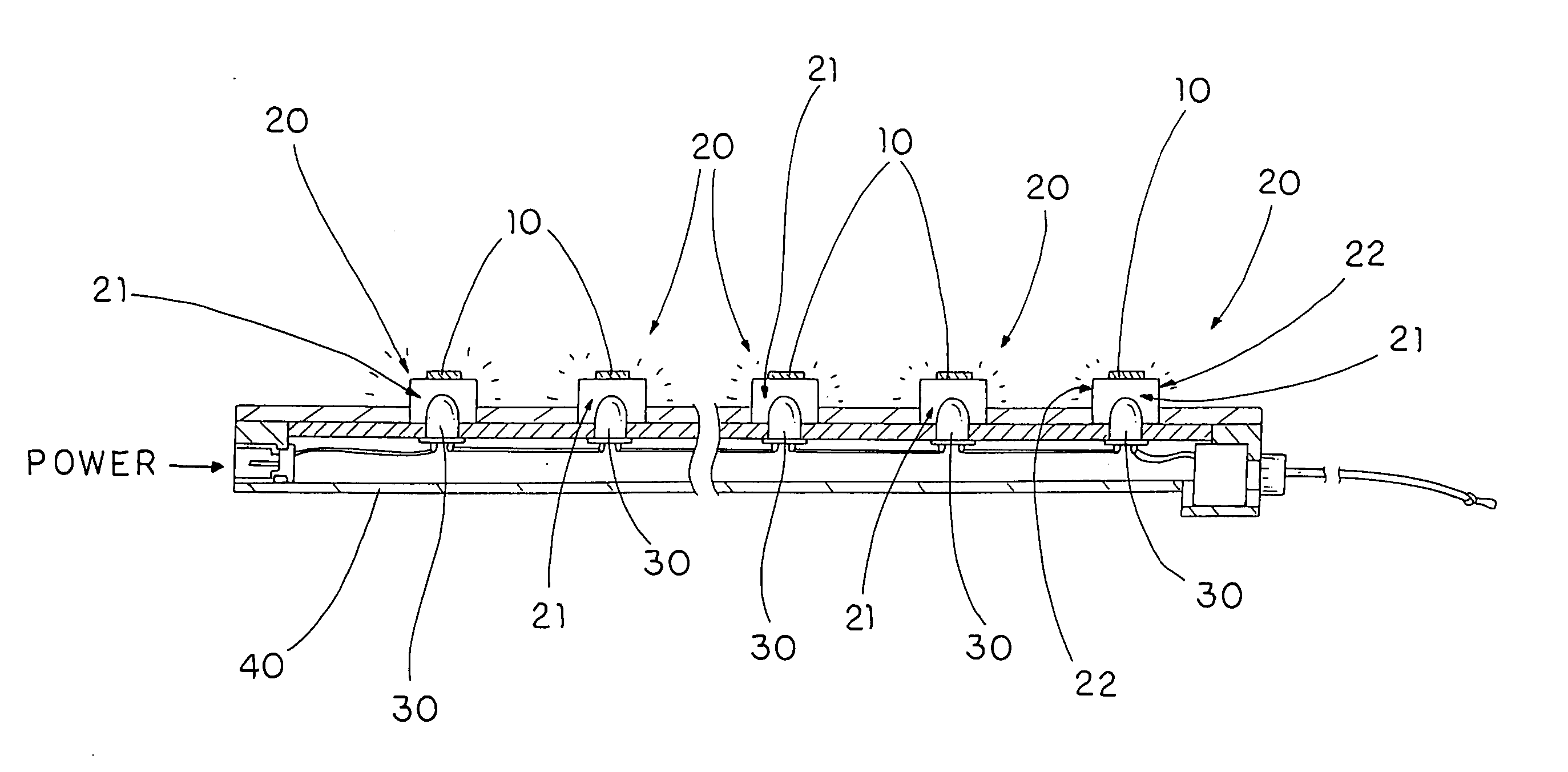

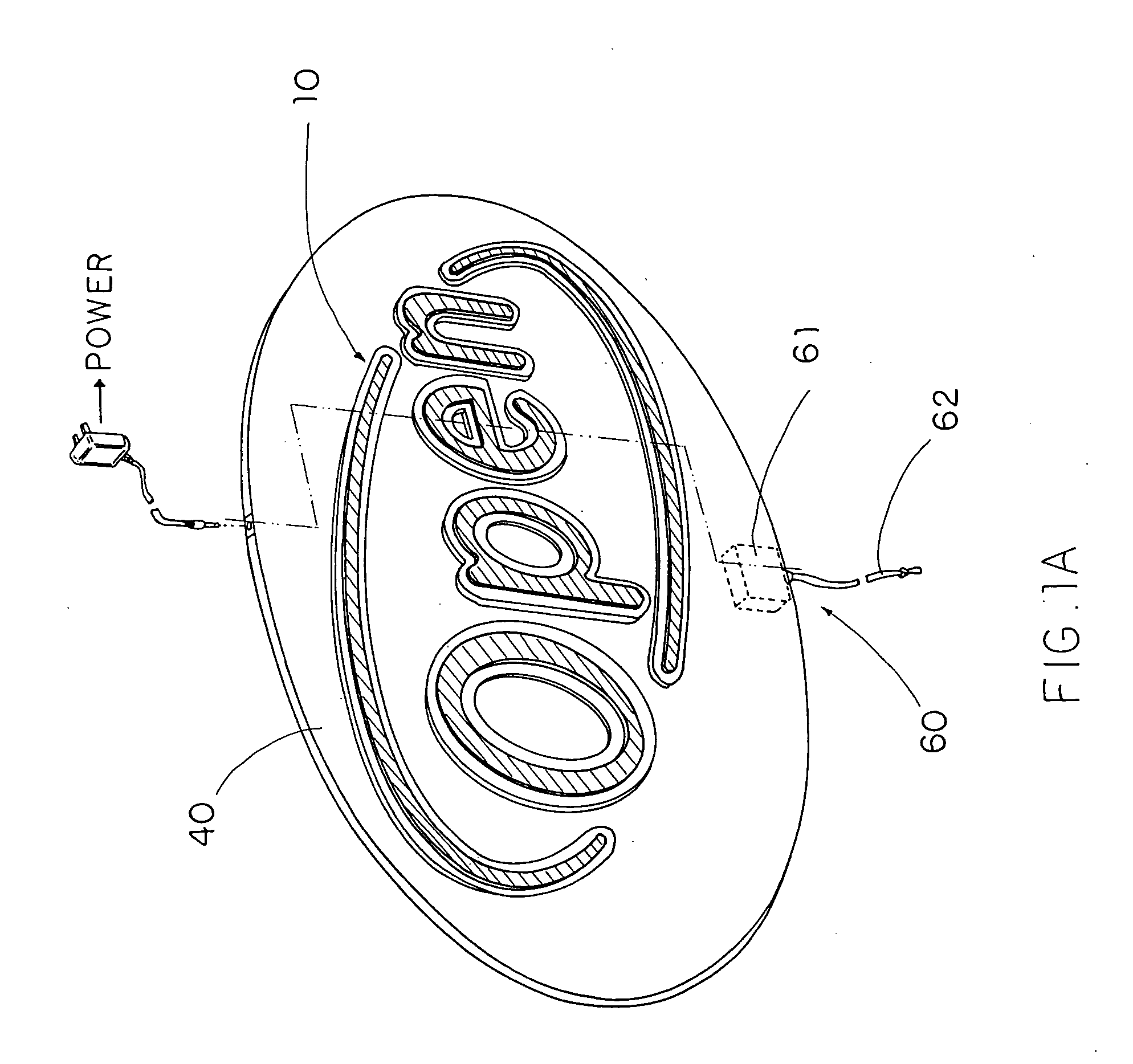

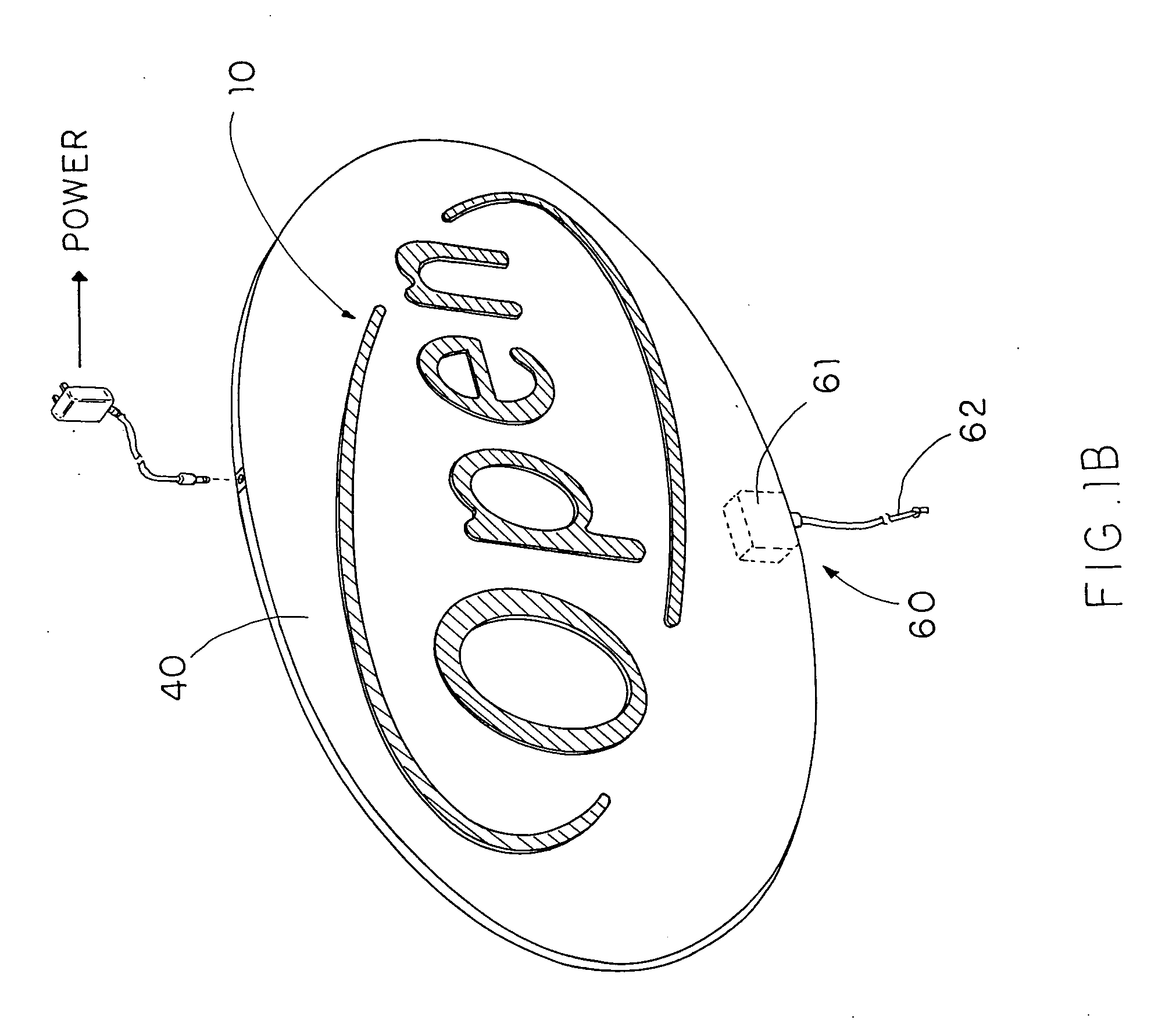

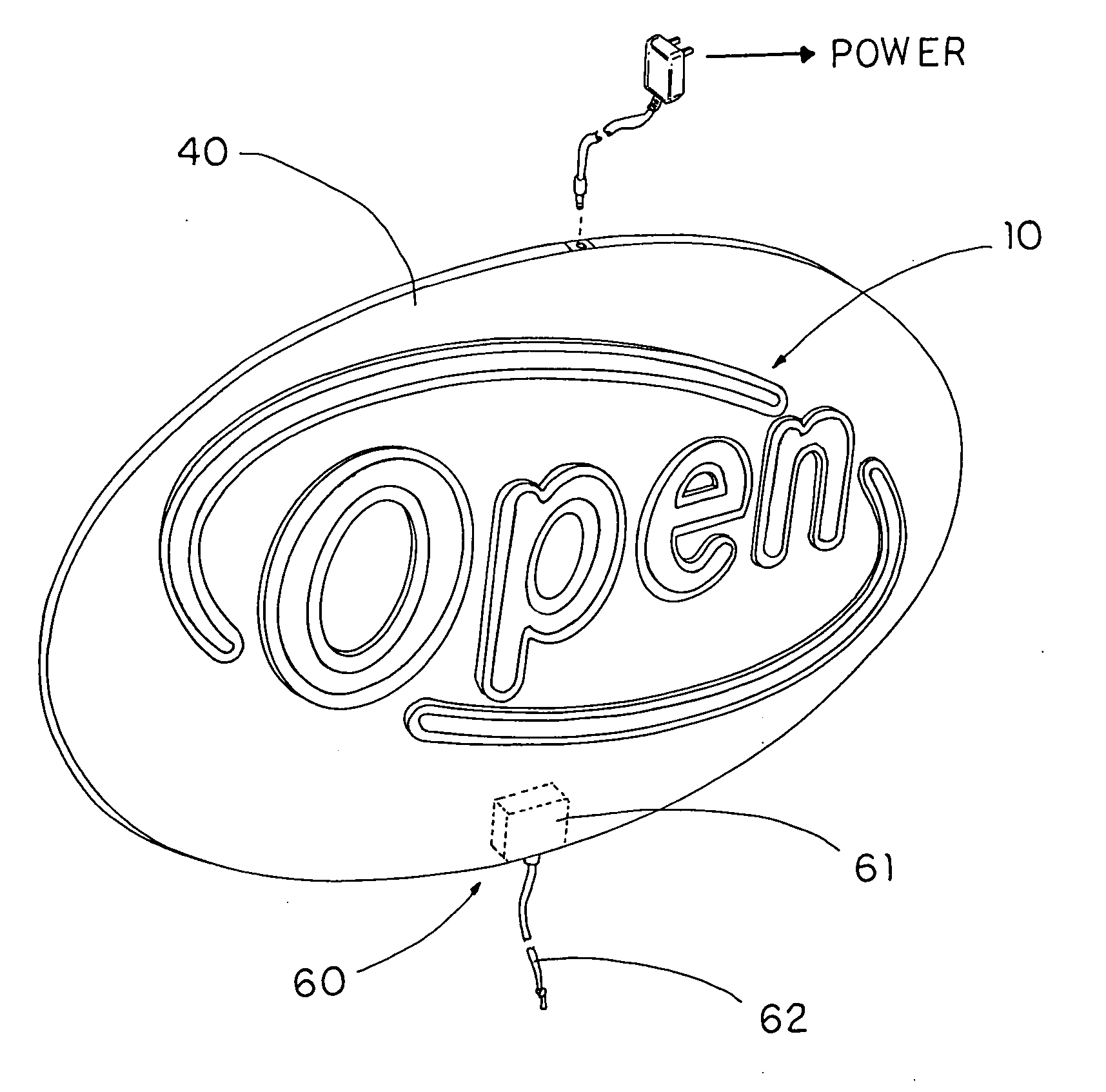

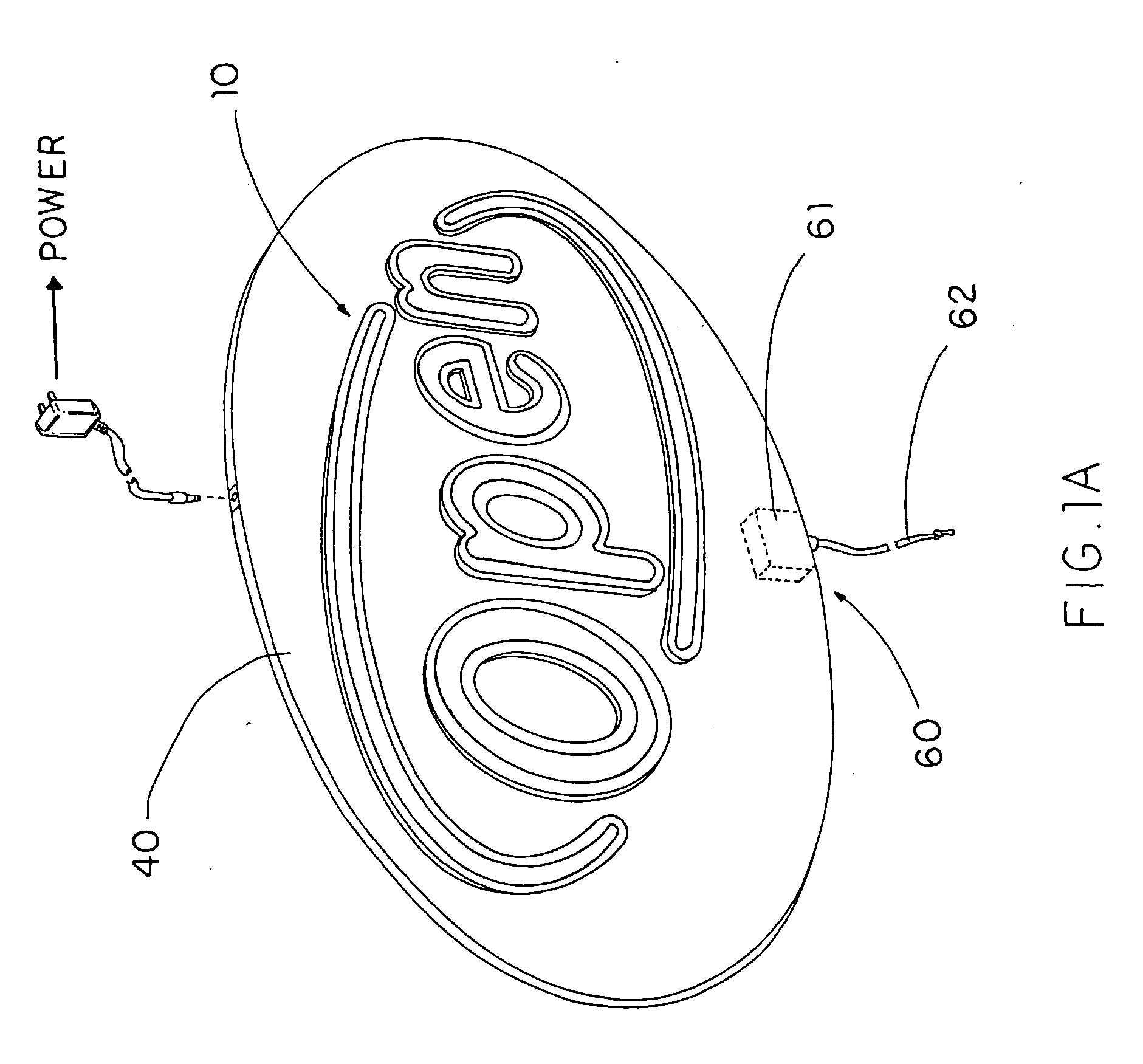

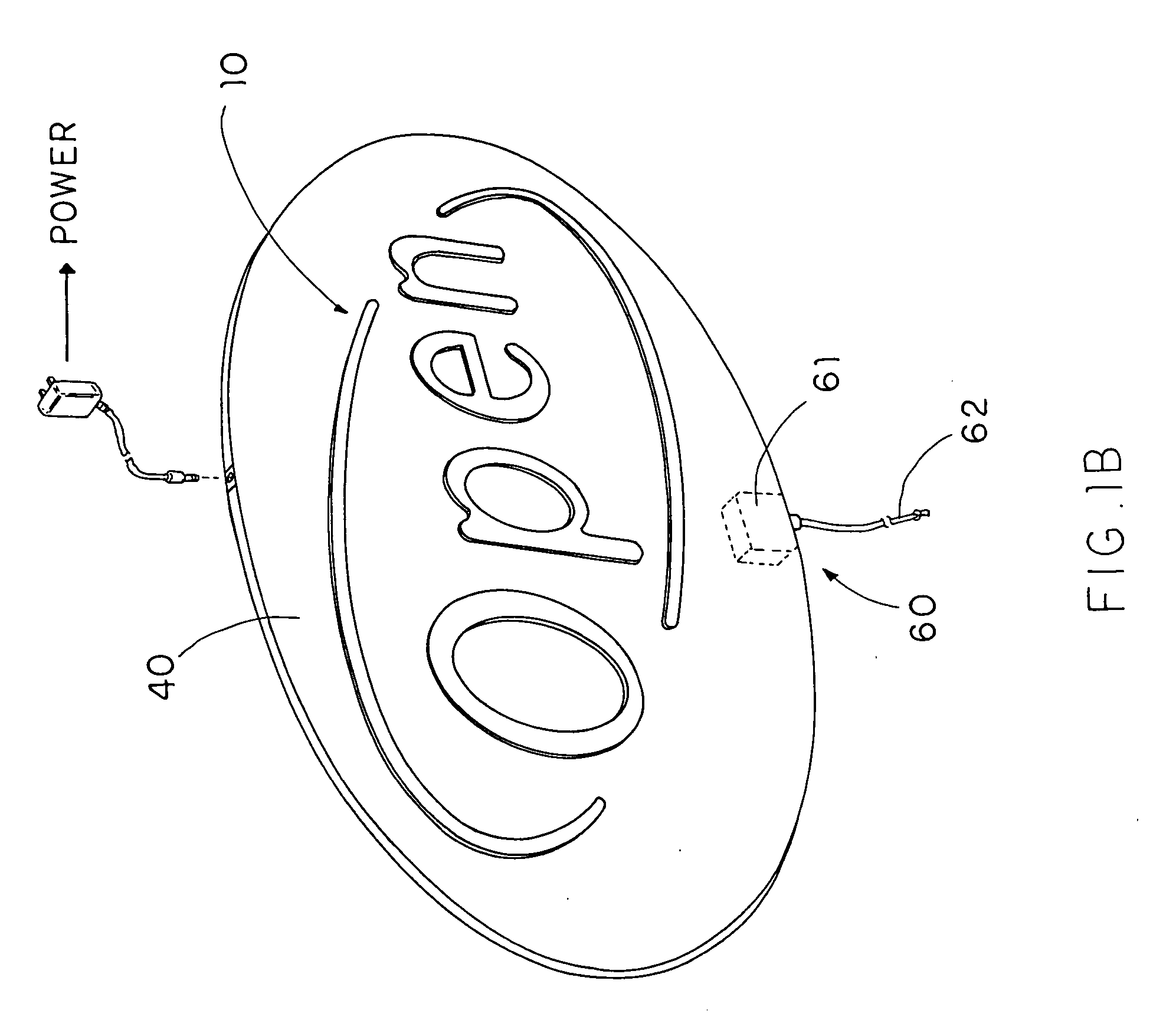

LED sign with continuous illumination effect

A LED sign includes at least a light guider, which is shaped as a sign word, defining an illumination channel therealong and a plurality of LED illuminators spacedly disposed underneath the light guider at a light diffusion distance for generating lights towards the illumination channel in such a manner that the lights are accumulated within the illumination channel to highlight the light guider so as to form a continuous illumination effect as a neon light effect.

Owner:PAN FR

Ornamental glass having etching pattern and multicolor pattern and and method for manufacturing same

InactiveCN101041555AHigh precisionFull of three-dimensional senseSurface treatment compositionsFlat glassScreen printing

The invention discloses a decorative glass with acid-frosted pattern and colored pattern and preparing method, which comprises the following steps: one, acid-frosting to acid-frosting pattern on the plate glass through acid-frosting treatment; two, cleaning; airing or drying; three, combining with self pattern of acid-frosting glass; adopting silk-printing or spraying method; printing or spraying coloured material on the acid-frosting glass; forming colored pattern; four, natural drying or drying the coloured glass; getting end product.

Owner:ZHENGZHOU HENGHAO GLASS TECH

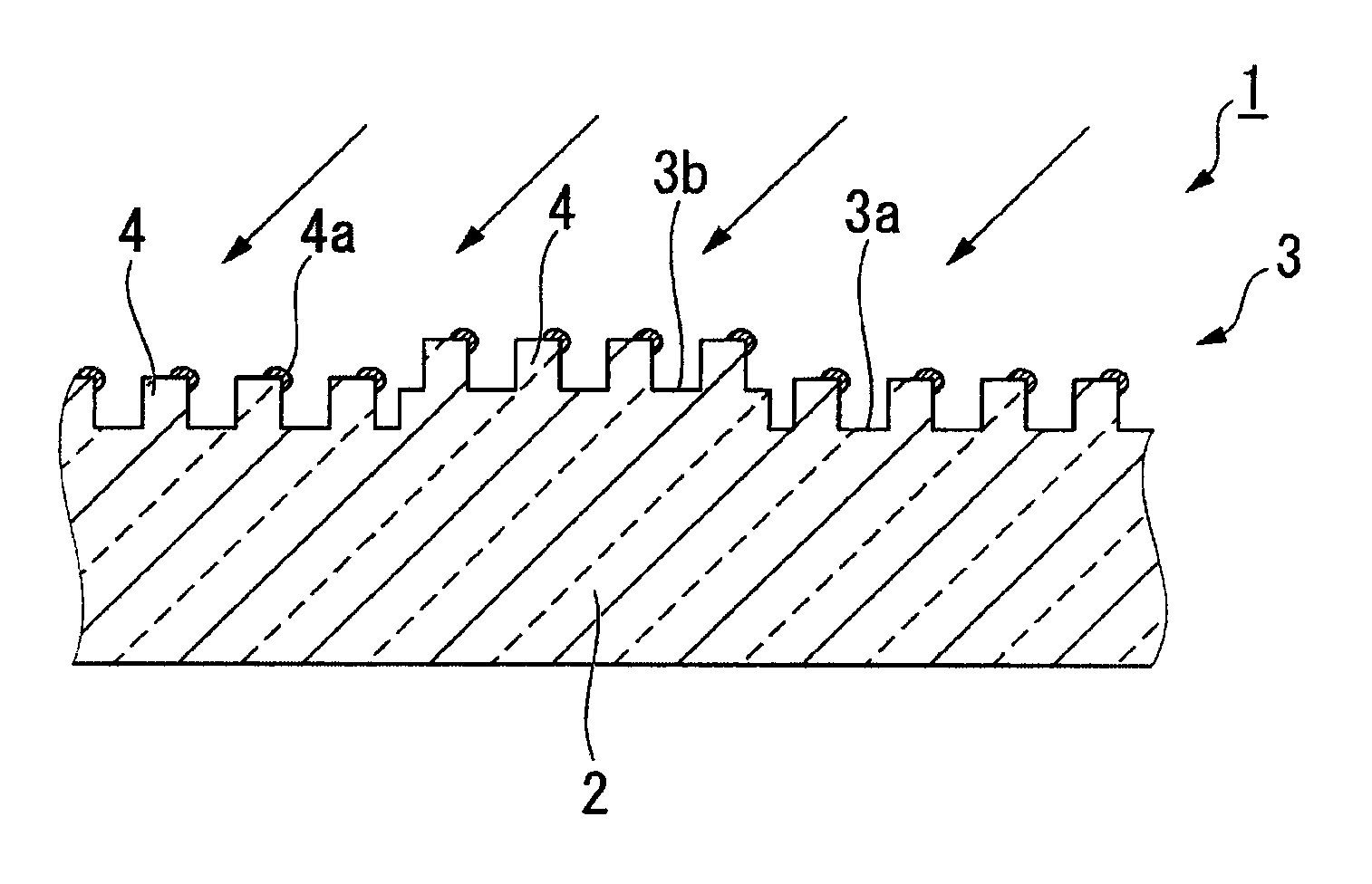

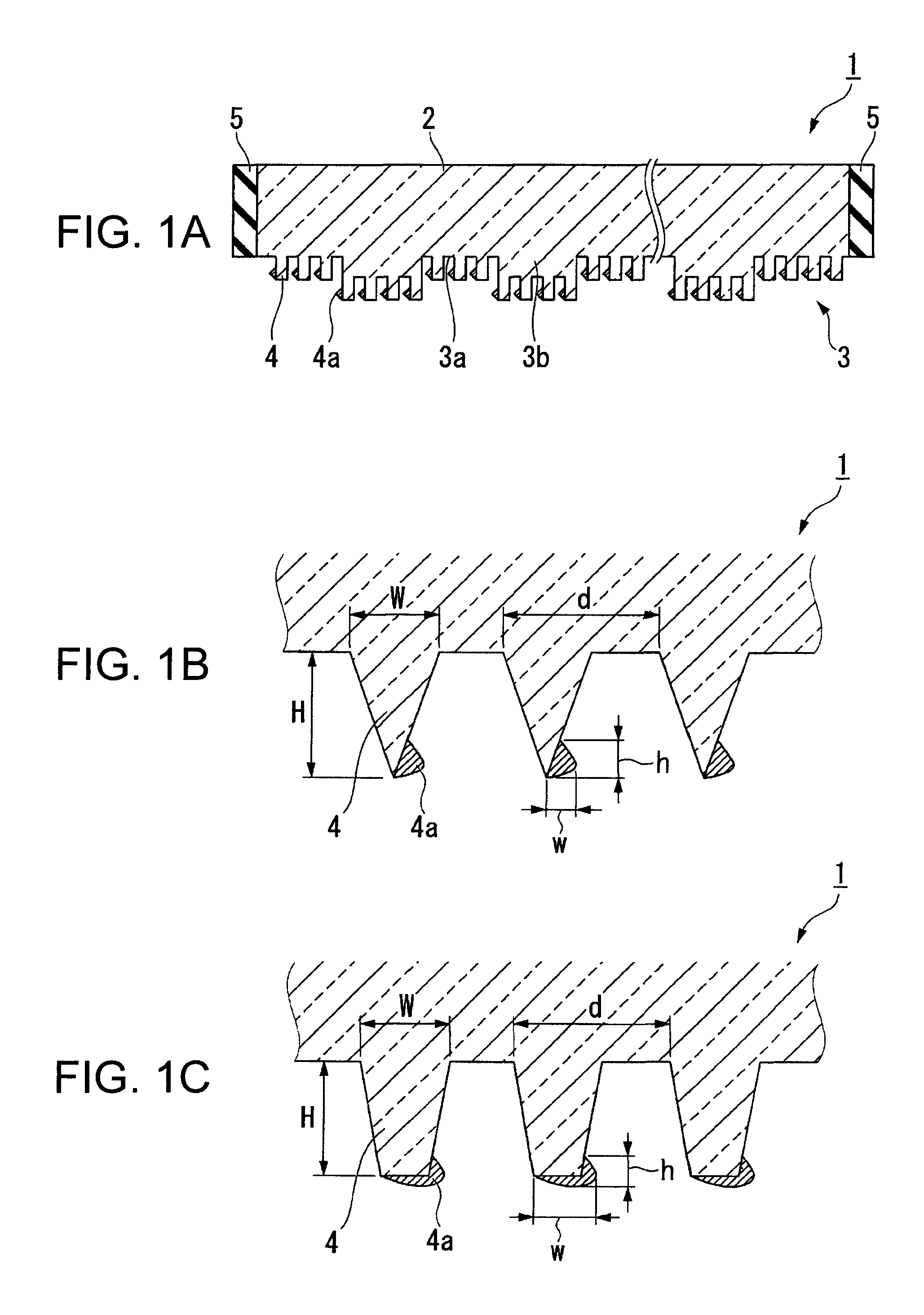

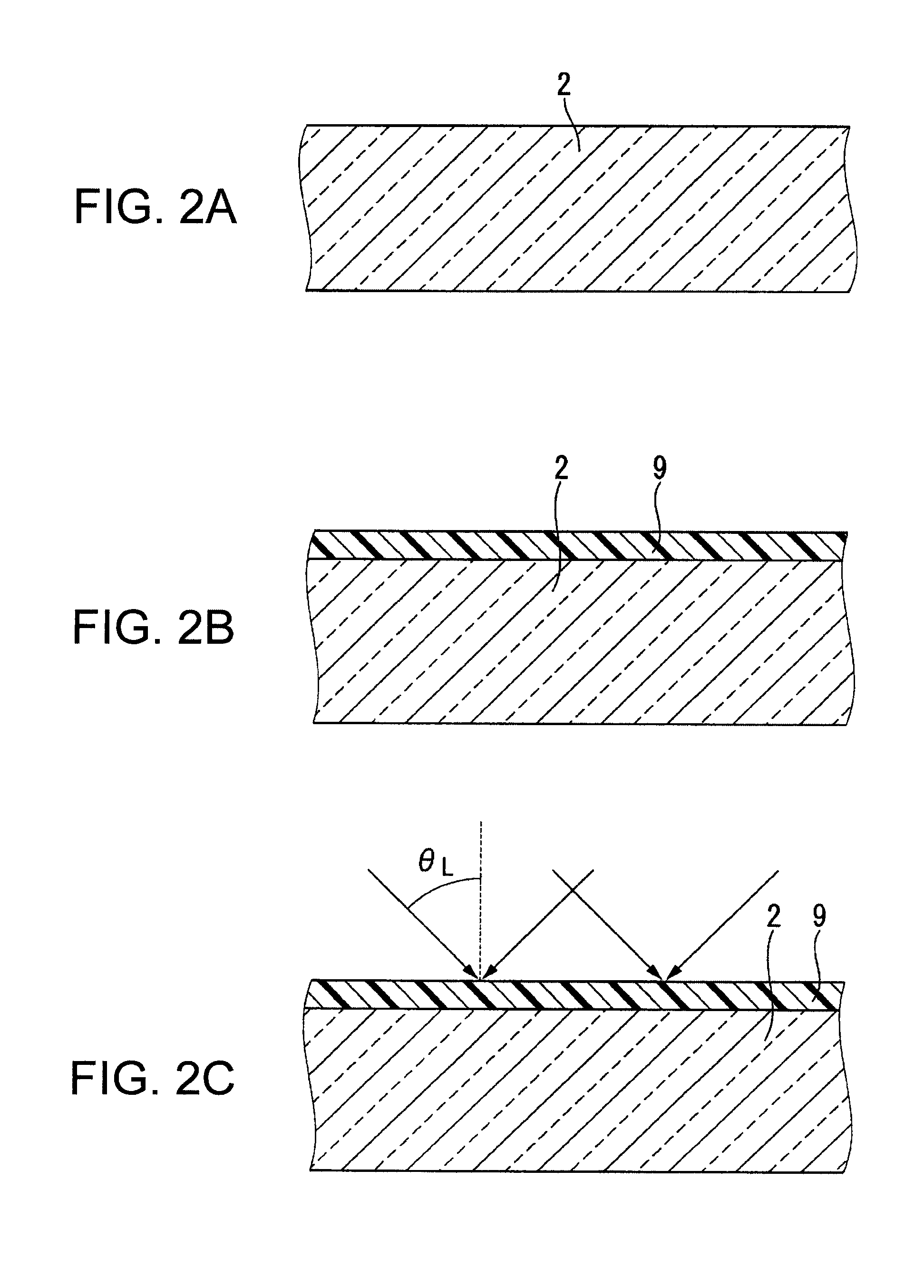

Method for manufacturing an optical element to polarize and split incident light

ActiveUS8248697B2Good optical performanceUniform widthPhotomechanical apparatusPolarising elementsResistFine line

Owner:SEIKO EPSON CORP

Novel technology for colouring on glaze during ceramic painting

The invention relates to a novel technology for colouring on glaze during ceramic painting. The novel technology for colouring on glaze during ceramic painting comprises the following steps: adopting a 18# white material, namely selecting 50% by weight of feldspar glaze, 10% by weight of quartz powder, 20% by weight of boric acid and 20% by weight of lead carbonate, mixing and placing the mixture into a ceramic crucible, melting to be bright and transparent at the temperature of 1300 DEG C, cooling into a glass fusion cake, smashing and grinding for late use; by adopting a guide pipe metal pen as a colouring tool, mixing the prepared white material with camphor oil equivalent to 60% by weight of the weight of the white material, grinding manually, then sequentially adding 20% by weight of pine distillate oil and 20% by weight of frankincense oil, and grinding into liquid paste; colouring and roasting, namely painting various glazes, colouring and roasting at the temperature of 790-820 DEG C. The novel technology for colouring on glaze during ceramic painting has the beneficial effects that high-grade ceramic or present ceramic can be prepared; the 18# white material has the advantages of high brightness, no cracking and no strict requirement on roasting atmosphere; uniform and regular lines, easy control and high production rate can be guaranteed; thickness of lines can be graded.

Owner:叶丽虹

Lubricant for drawing superfine stainless steel wire and preparation method

InactiveCN102660372AUniform lineBright surfaceLubricant compositionPolyethylene glycolStainless steel wire

The invention relates to lubricant for drawing a superfine stainless steel wire, which is characterized in that the lubricant is prepared by water, polyethylene glycol, isopropanol, extreme-pressure additive, amine oxide, polyaspartic acid and metal rust-proof agent, wherein the proportion in part by weight of each substance in the lubricant is as follows: 5 to 10 parts of polyethylene glycol, 5 to 10 parts of isopropanol, 0.5 to 2 parts of extreme-pressure additive, 5 to 20 parts of amine oxide, 0.5 part of polyaspartic acid, 0.5 to 1 part of metal rust-proof agent and 45 to 100 parts of water. By utilizing the lubricant, good lubricating performance can be maintained when the superfine stainless steel wire is drawn, the surface quality of the superfine stainless steel wire can be improved, the superfine stainless steel wire can be uniformly drawn, the surface of the superfine stainless steel wire is bright and uneasy to rust, and the wire breaking rate can be reduced.

Owner:刘彦辉

LED sign with continuous illumination effect

InactiveUS20060000128A1Uniform linesSimple structureIlluminated signsIdentification meansOptoelectronicsLed illumination

Owner:PAN FR

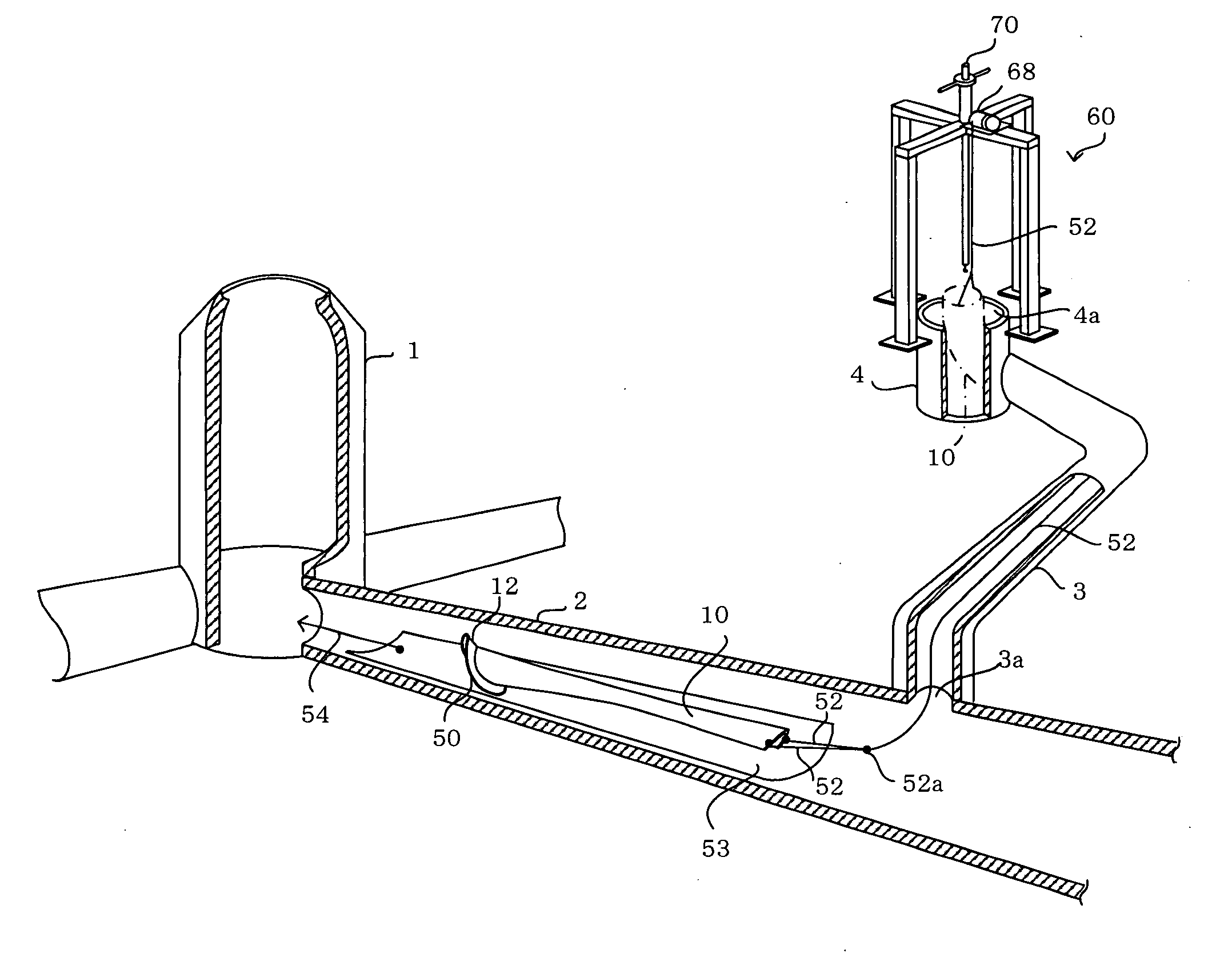

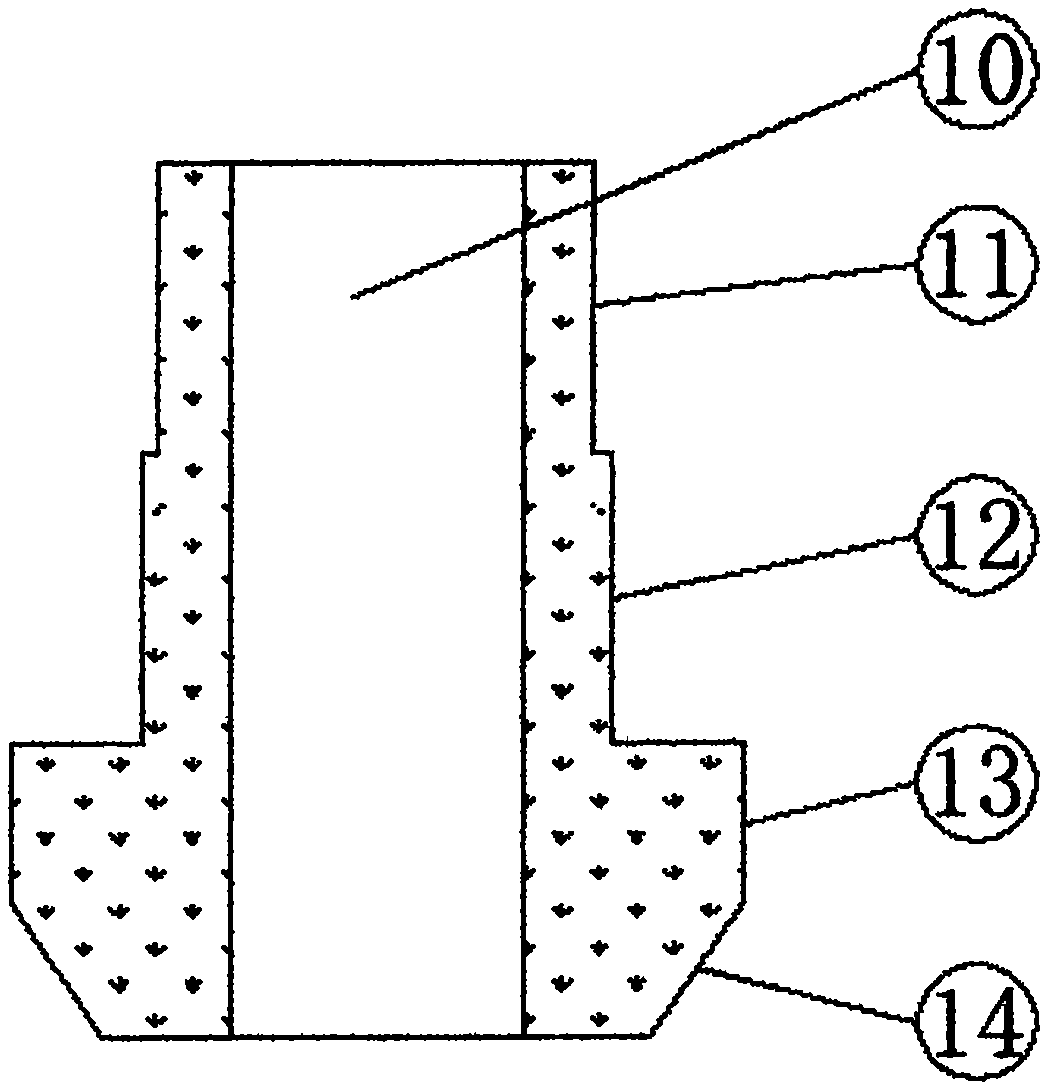

Lateral pipe lining material and lateral pipe lining method

InactiveUS20090183794A1High-quality liningHigh-quality lateral pipe liningUnderground chambersPipe elementsEngineeringClose contact

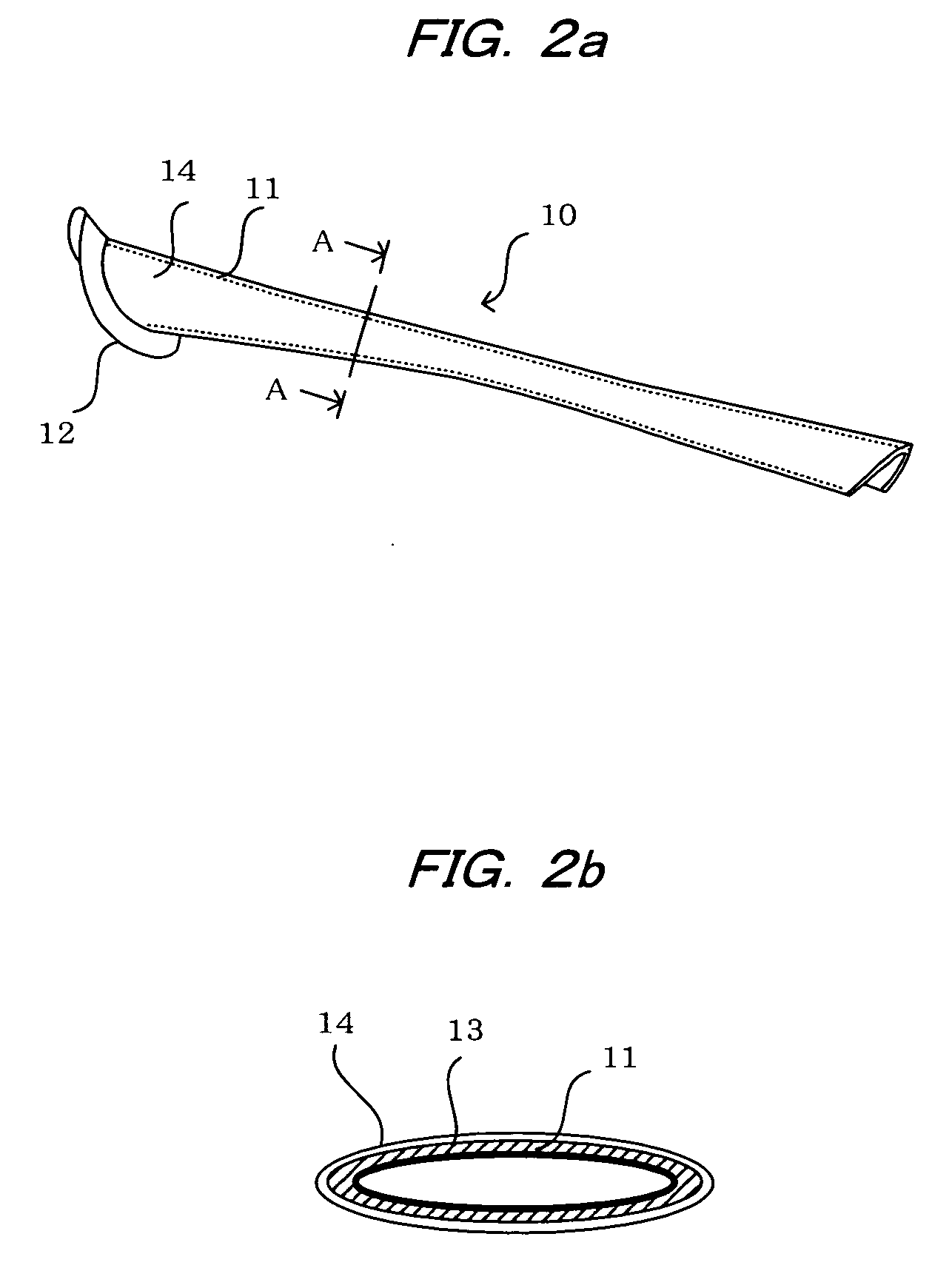

A lateral pipe lining material having a tubular resin-absorbing material impregnated with a thermosetting resin is inserted through a main pipe into the lateral pipe. The lateral pipe lining material is provided with a pushing-up member to push up a collar formed at its end of the lateral pipe lining material. When the lateral pipe lining material is drawn into the lateral pipe to the extent that the collar reaches an opening of the lateral pipe, the pushing-up member is lifted to bring the collar into close contact with the lateral pipe opening periphery of the main pipe. The lateral pipe lining material is then expanded and a heating medium is applied thereto to cure the resin impregnated in the tubular resin-absorbing material. The lateral pipe lining material can be drawn smoothly into the lateral pipe even when it is bent, enabling the lateral pipe to be lined with a high quality.

Owner:SHONAN GOSEI JUSHI SEISAKUSHO KK

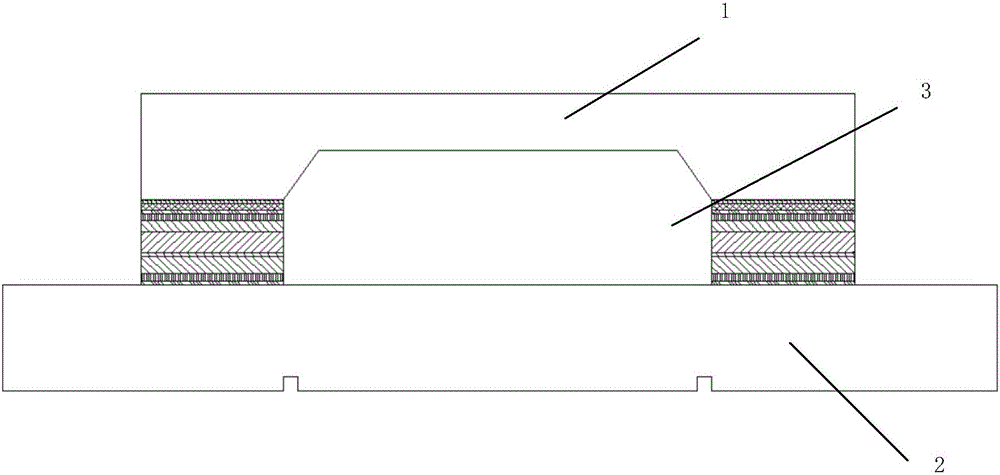

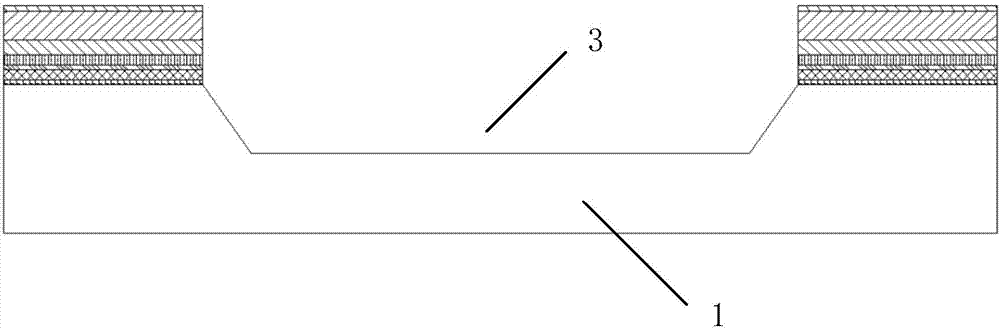

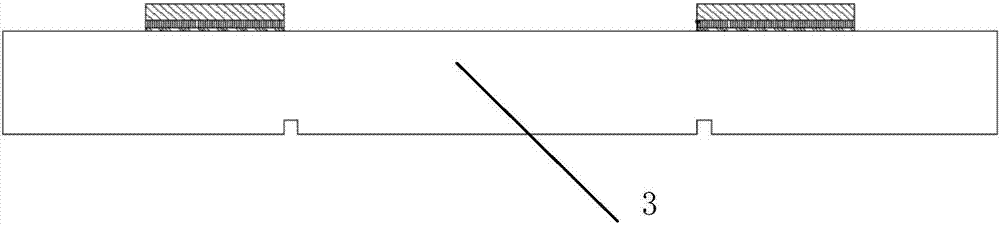

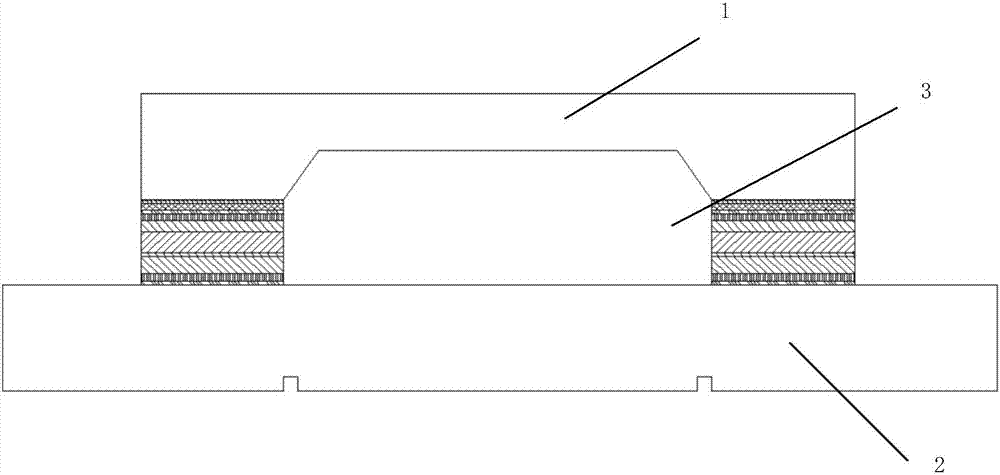

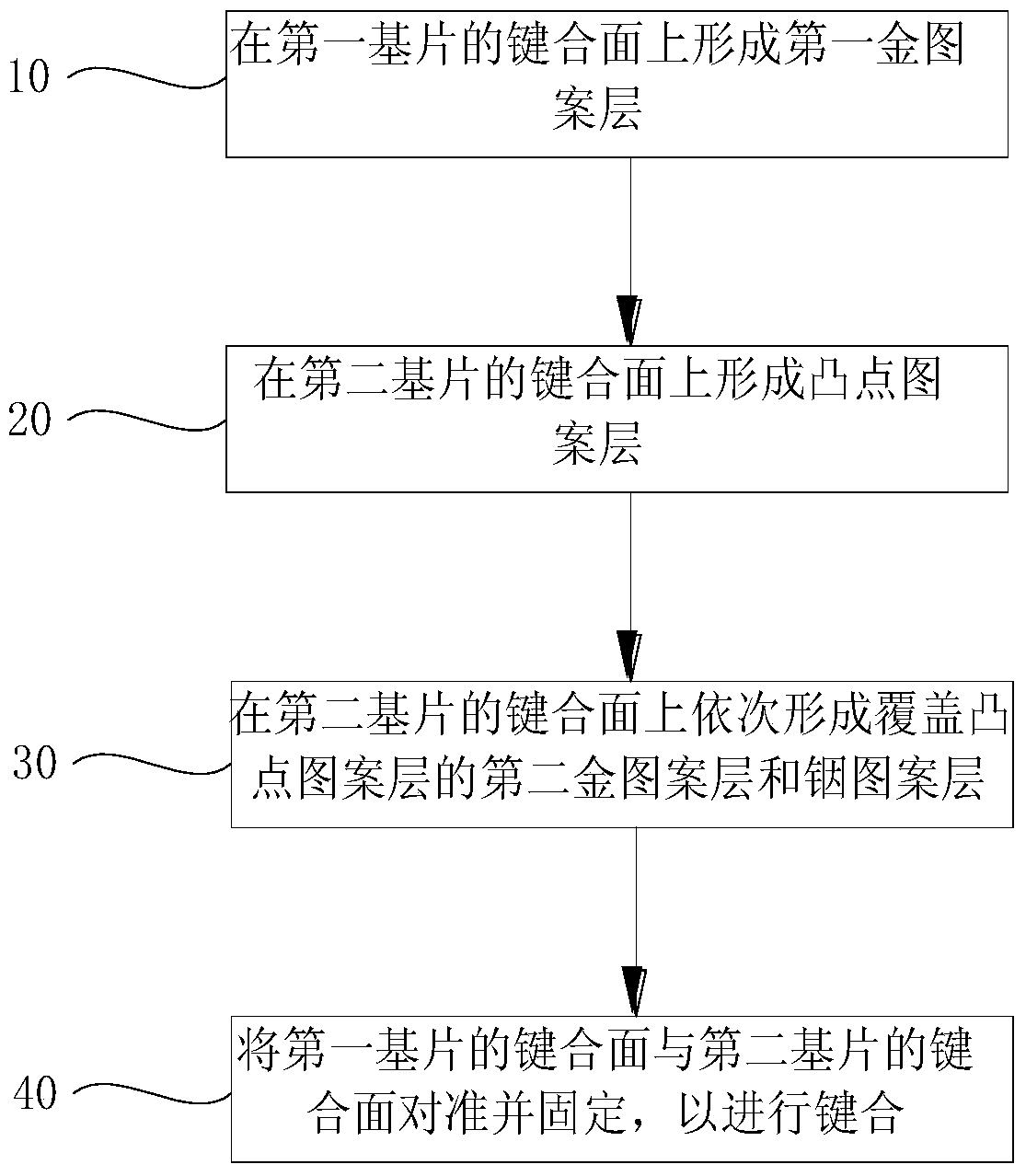

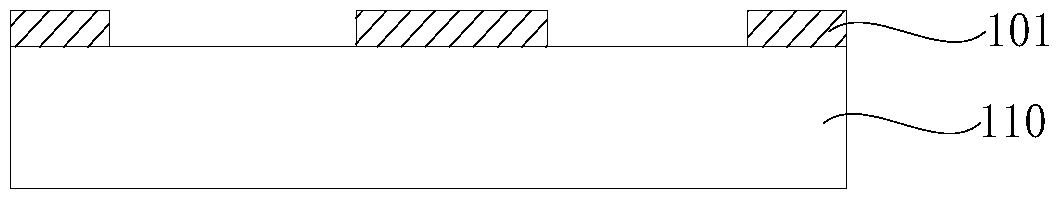

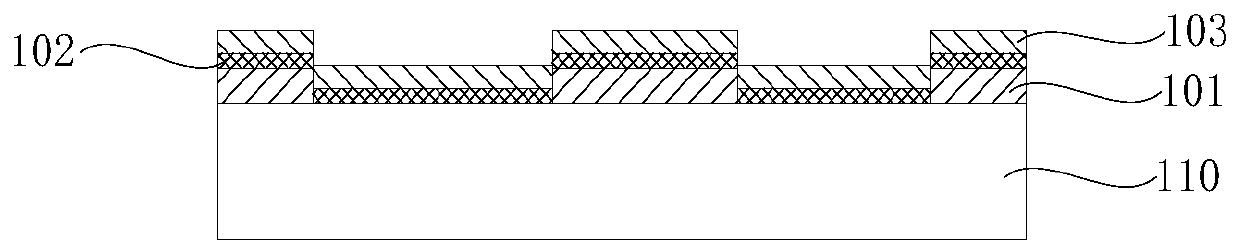

Transverse interconnection low-temperature wafer level packaging method specific to radio-frequency MEMS (Micro Electro Mechanical System) device application

ActiveCN106115608AImprove performanceReduce hardnessDecorative surface effectsSolid-state devicesSurface layerEngineering

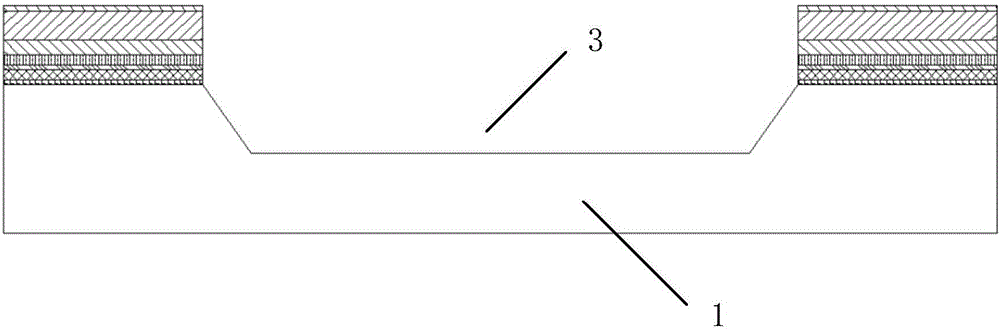

The invention relates to a transverse interconnection low-temperature wafer level packaging method specific to a radio-frequency MEMS (Micro Electro Mechanical System) device application. The method is characterized in that a low-temperature packaging process is performed on a radio-frequency device through a process which combines Au and In isothermal solidification low-temperature bonding with organic material bonding, so that the problem of lead transverse interconnection is solved, and high mechanical strength and airtightness are achieved during packaging at the same time. Meanwhile, a metal deposition way of Au and In isothermal solidification bonding is adopted, namely, Cu is taken as a barrier layer material for an Au and In isothermal solidification reaction, and a thin Au layer is deposited on a surface layer of an In layer to serve as a protection layer material for preventing the In surface layer from being oxidized. The manufacturing of a sealing ring mainly focuses on a packaging cover plate, so that the influence of packaging on the performance of a substrate chip is lowered greatly. Meanwhile, the manufacturing of the sealing ring and the manufacturing of a packaging cavity are integrated in process.

Owner:SUZHOU XIMEI MICRO NANO SYST CO LTD

Reinforcing and toughening agent for 3D printing of ABS and ABS composite

InactiveCN105482355AHigh strengthImprove toughnessAdditive manufacturing apparatusHalloysiteEngineering

The invention relates to the field of 3D printing forming materials, in particular to a reinforcing and toughening agent for 3D printing of ABS and an ABS composite prepared from the reinforcing and toughening agent, as well as preparation methods and application of the reinforcing and toughening agent and the ABS composite. The reinforcing and toughening agent for 3D printing of ABS consists of the raw materials of silane coupling agent modified halloysite nanotubes and an SBS toughening agent. Meanwhile, the invention provides a 3D printing ABS reinforcing and toughening composite prepared from the reinforcing and toughening agent, and the ABS reinforcing and toughening composite has the properties of high strength, good tenacity, good liquidity, high curing rate, good aging resistance and the like, is high in surface glossiness, stable in performance and low in probability of aging discoloration, and can be widely applied to 3D printing electronic product housings, precision instrument housings, daily necessities, automotive interior parts, artware and the like.

Owner:HUIZHOU CHANGYI TECH

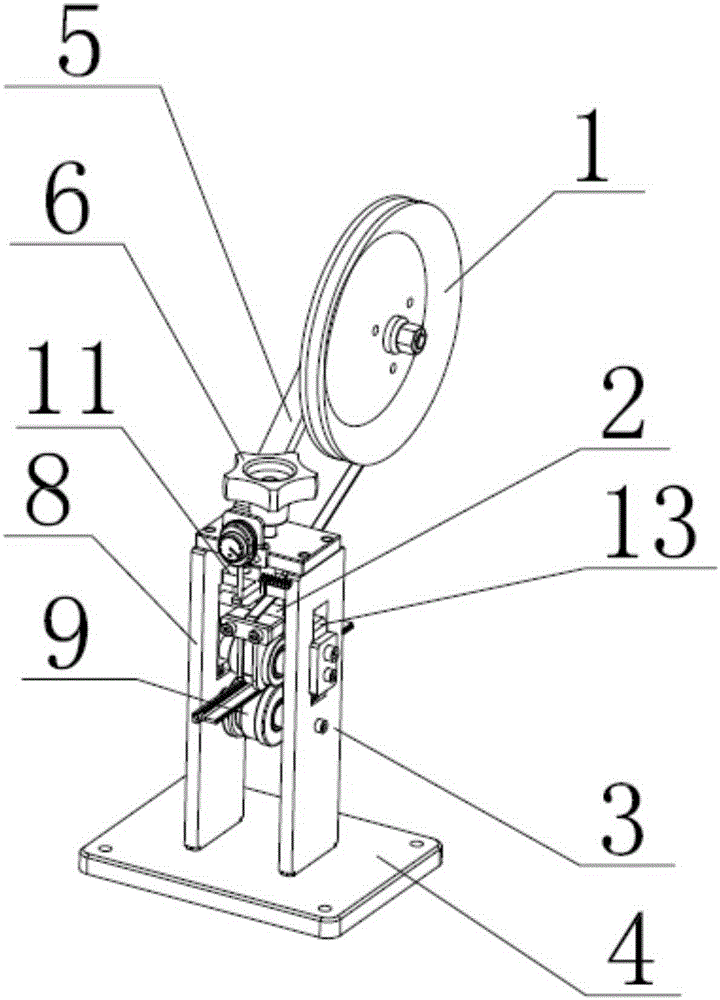

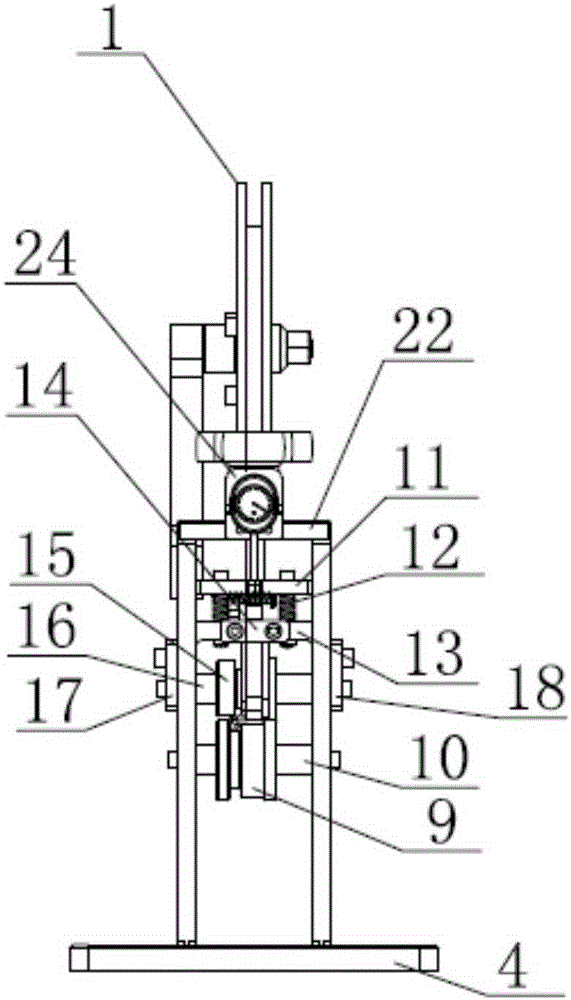

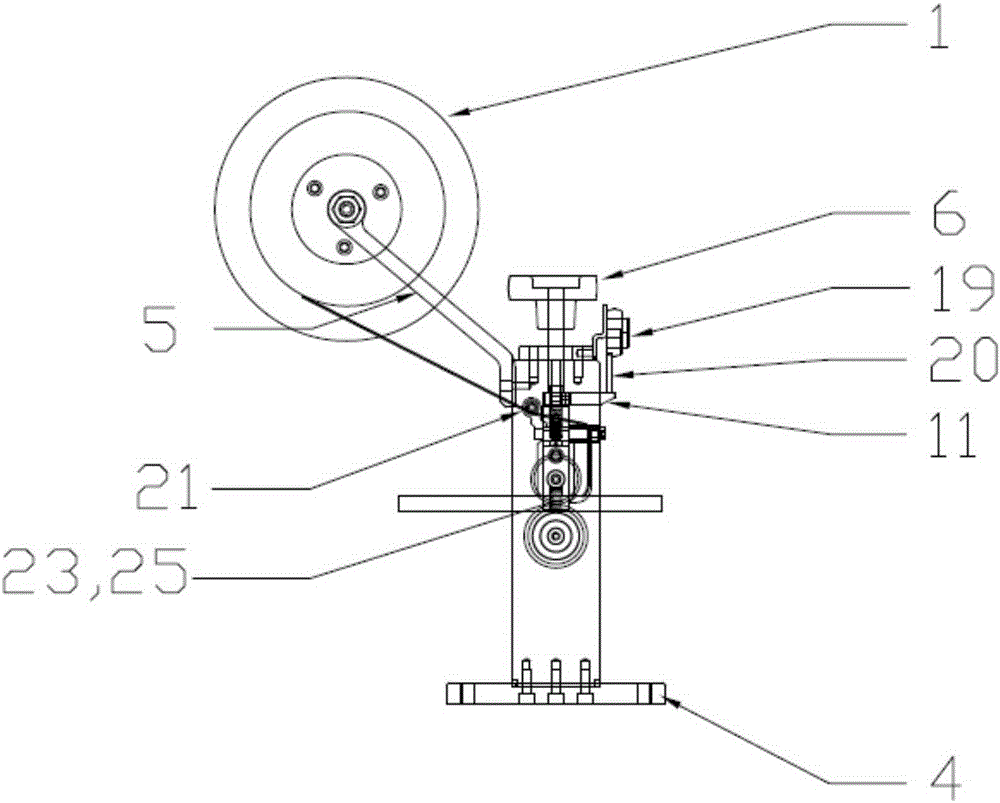

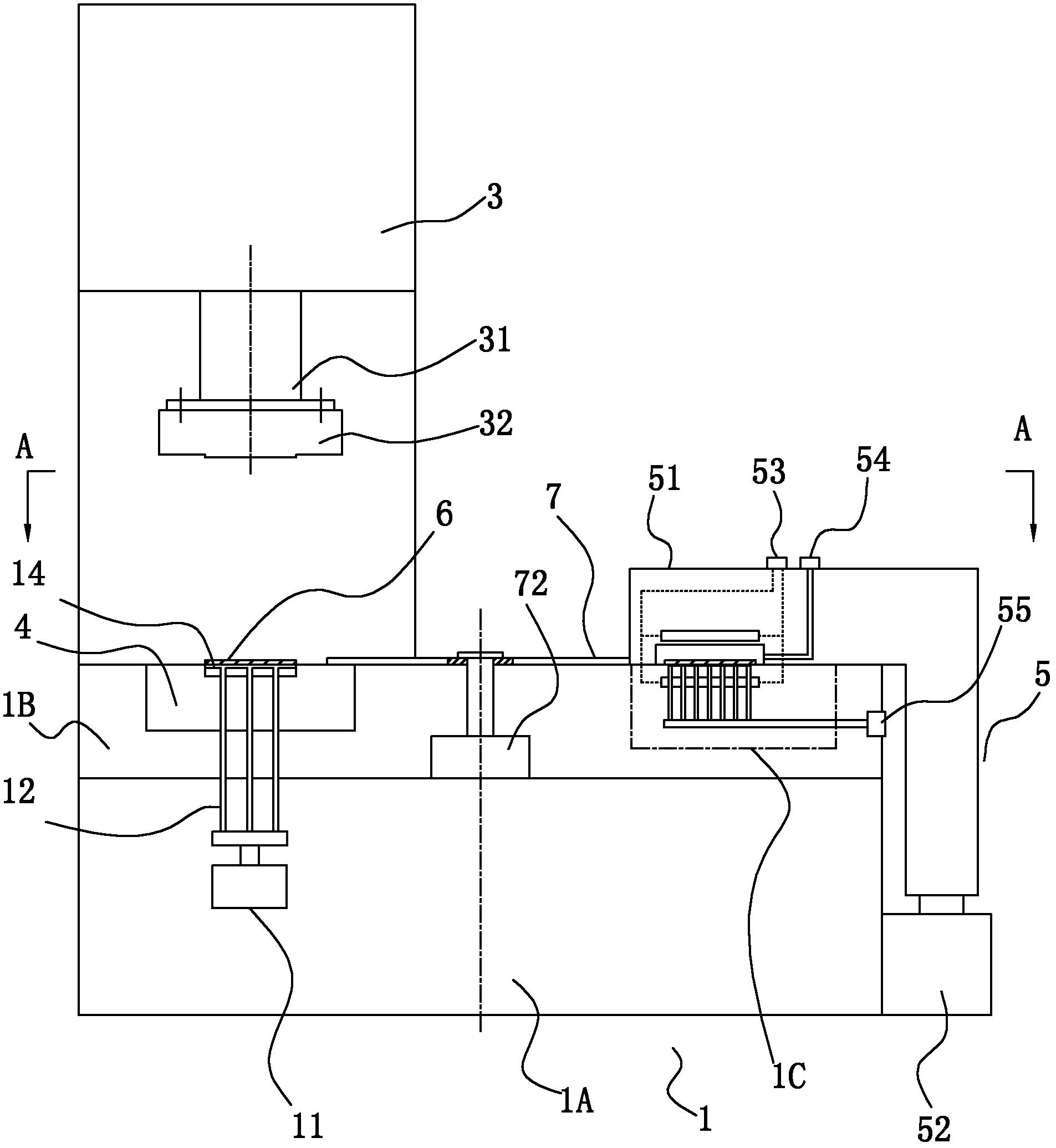

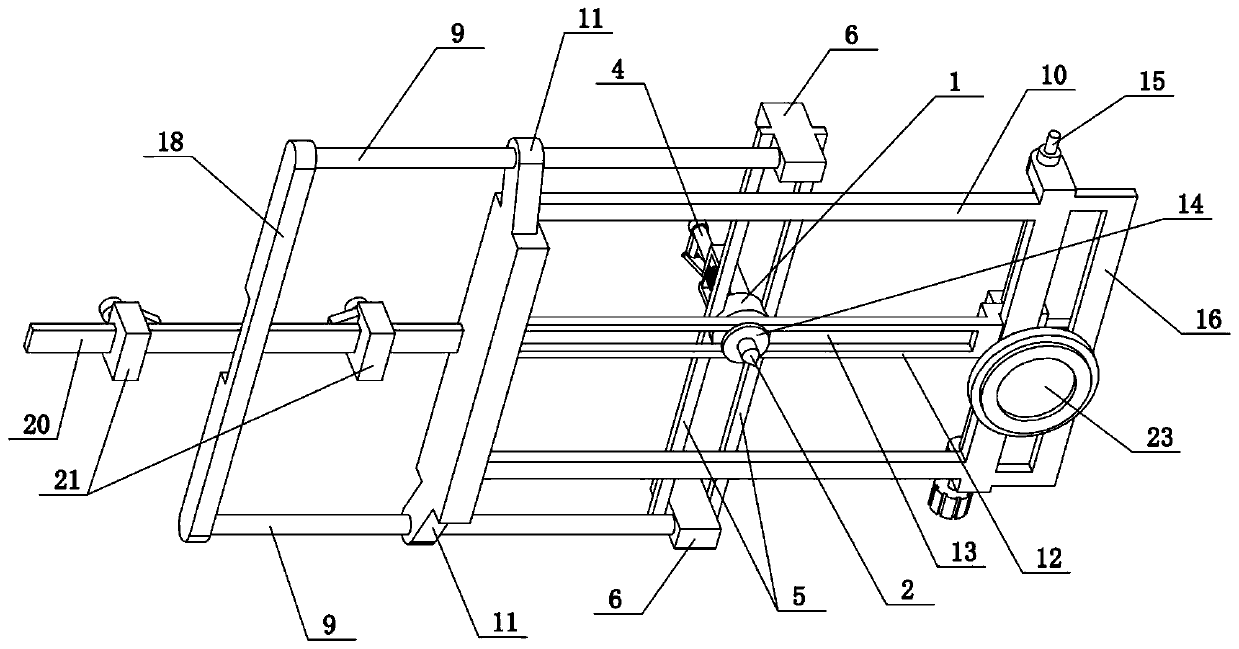

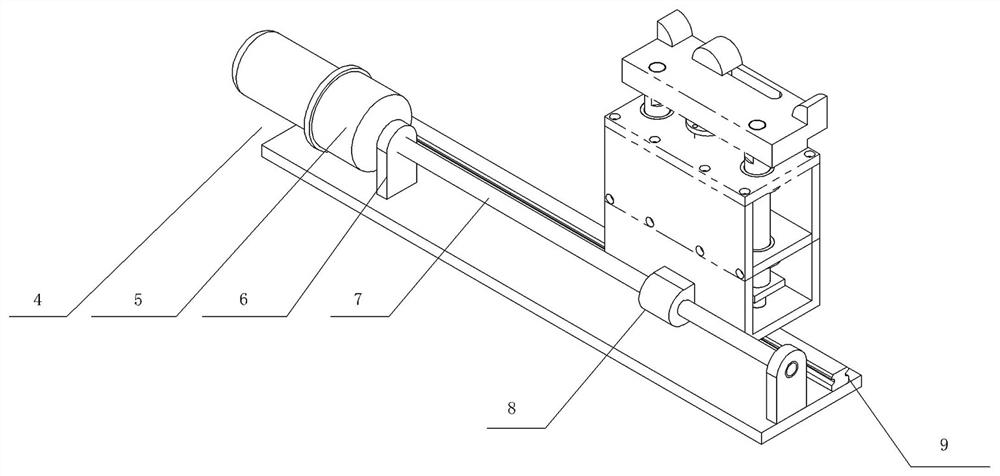

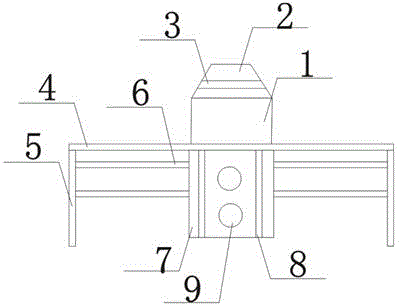

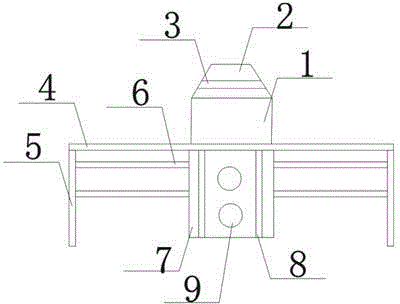

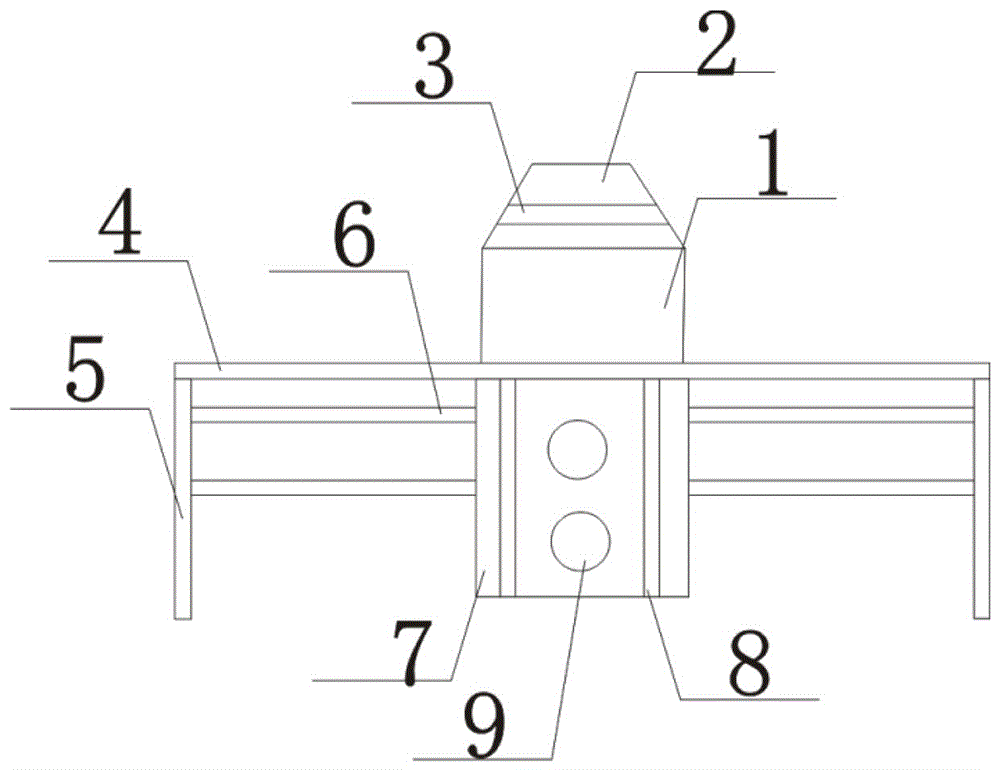

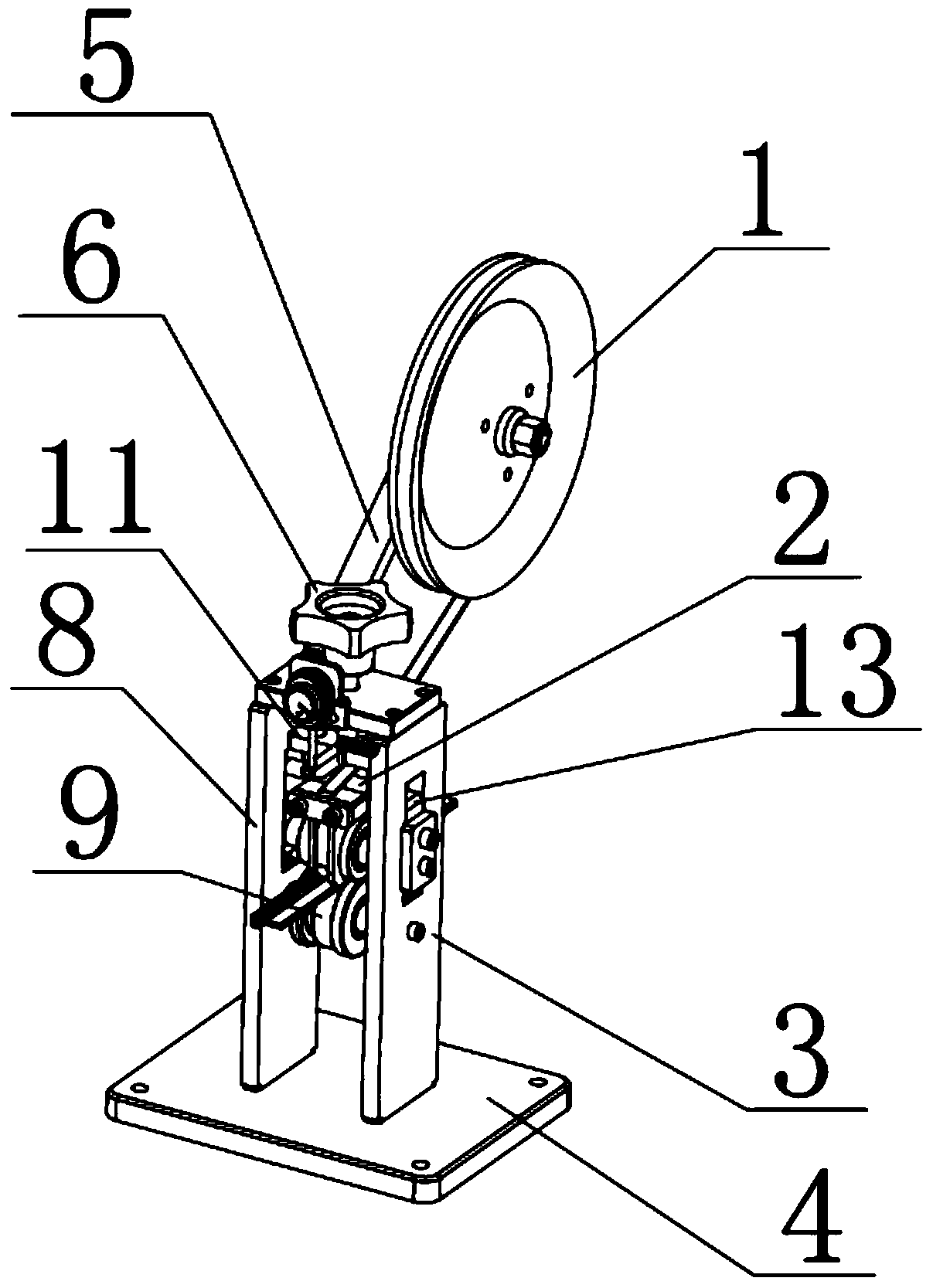

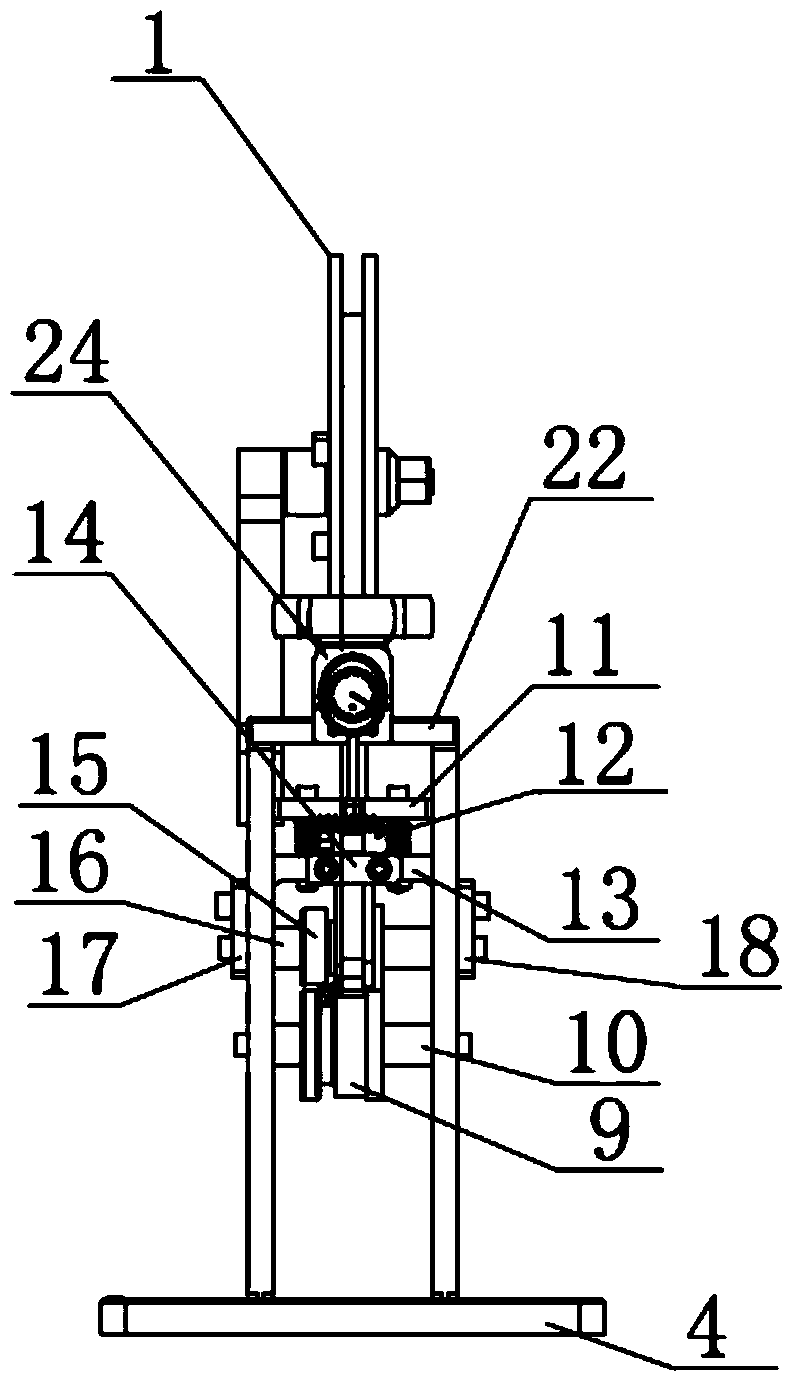

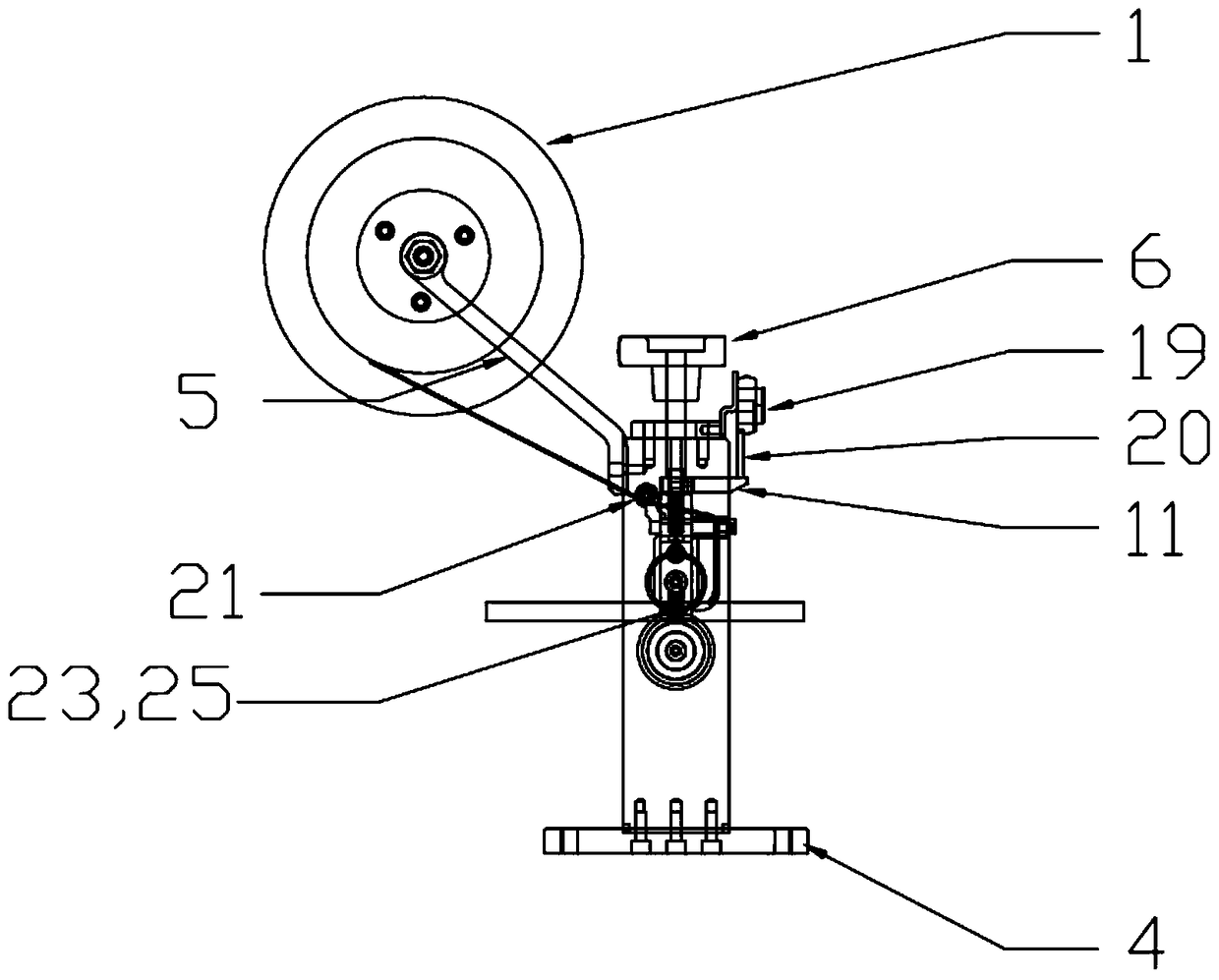

Tool device for pasting adhesive tape to decorative strips and glass clamping strips of automobile

ActiveCN105215646AIncreased or decreased pressureUniform linesMetal working apparatusEngineeringMechanical engineering

The invention relates to a tool device for pasting adhesive tape to decorative strips and glass clamping strips of an automobile. The tool device comprises an upper press wheel floating mechanism, a bottom board and a pressure adjusting handle. Side boards are arranged on the upper end face of the bottom board side by side. A top board is installed at the upper ends of the side boards. A rotary wheel shaft is installed between the side boards. The middle of the rotary wheel shaft is sleeved with a fixed wheel. The upper press wheel floating mechanism comprises a fixing support, fixing blocks and an upper press wheel. Through holes are formed in the middle portions of the side boards. The two ends of the fixing support extend into the through holes and are fixedly connected with the fixing blocks. The portions, extending into the through holes, of the fixing support are connected with the side boards through multiple springs. The rotary wheel shaft is installed at the lower end of the fixing support, the middle of the rotary wheel shaft is sleeved with the upper press wheel, the upper press wheel is provided with a press block, spring press boards are arranged above the fixing support in parallel and connected with the fixing support through the springs, and the pressure adjusting handle vertically penetrates the top board so as to be fixedly connected with the spring press boards. The tool device has the beneficial effects of being simple in structure, low in cost, high in work efficiency, high in practicality and the like.

Owner:NINGBO HONGXIECHENG AUTO PARTS CO LTD

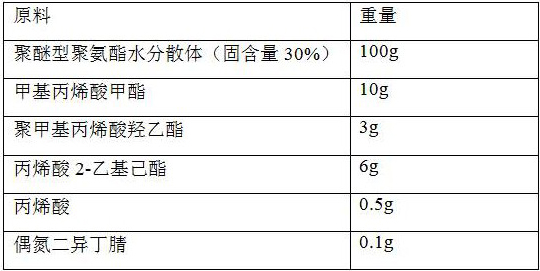

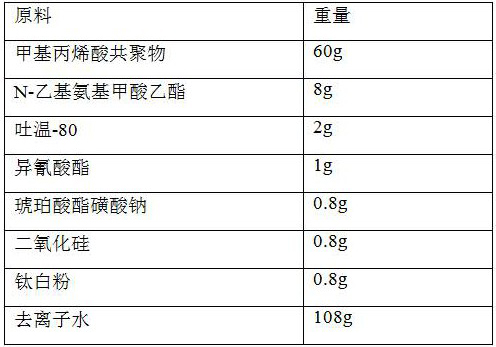

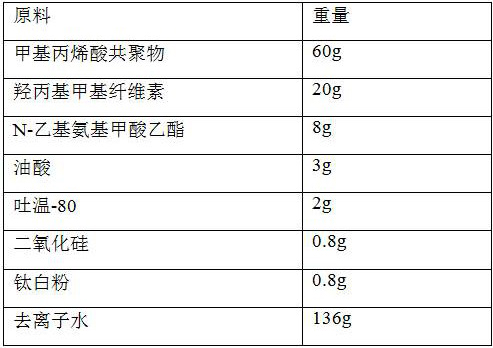

Organic adhesive for double-sided PERC aluminum paste and preparation method

InactiveCN110517805AImprove printing effectModerate printabilityNon-conductive material with dispersed conductive materialCable/conductor manufactureOrganic solventBulk resistance

The invention discloses an organic adhesive for double-sided PERC aluminum paste and a preparation method, and the organic adhesive is prepared from the following raw materials in percentage by weight: 5-10% of organic resin, 75-85% of an organic solvent, 3-6% of a thixotropic agent, 1-4% of a dispersing agent, 0.5-3% of a plasticizer and 1-5% of a slipping agent. According to the organic adhesiveprovided by the invention, the performance of the organic adhesive is improved through different matching of all the components, and the aluminum paste prepared from the organic adhesive is moderatein viscosity, good in printing performance, smooth in ink returning and free of virtual printing and grid breaking; and printed aluminum grid lines have a higher height-width ratio and are uniform, flat and full in line type. Meanwhile, an organic carrier can ensure close packing of aluminum powder particles in the paste, reduces the bulk resistance of the slurry, and is beneficial to improving the conversion efficiency of the paste.

Owner:JIANGSU HOYI TECH

Manufacturing method of platinum bar and platinum bar mould-pressing device

The invention discloses a manufacturing method of a platinum bar and a platinum bar mould-pressing device. The manufacturing method of the platinum bar comprises the following steps of: preparing materials: preparing blank materials according to a corresponding style of the platinum bar; carrying out surface treatment: immersing the blank materials into acid to remove impurities on the surfaces of the blank materials; polishing: utilizing a polishing machine provided with a cloth wheel to polish the blank materials; spraying sand: uniformly carrying out sand spraying treatment on front and rear surfaces of the blank materials; continuously and repeatedly carrying out first-annealing and second-oil-pressing for six times, wherein the annealing temperature is 950 DEG C; parameters of a mould cavity correspond to those of the blank materials; buffing: buffing six faces of the platinum bar by a flying disc of a buffing machine to remove surplus burrs, respectively; electroplating platinum bar: immersing the platinum bar after the buffing treatment into rhodium solution to carry out electroplating on the surface of the platinum bar; and checking: carrying out qualification checking on an electroplated platinum bar product. The platinum bar manufactured by the manufacturing method, provided by the invention, has the advantages of flat character fonts, qualified weight, uniform line, complete and beautiful sanded surface, uniform and smooth and mutually-vertical frames, and obvious comparison effect as a whole.

Owner:SHENZHEN BOFOOK JEWELRY

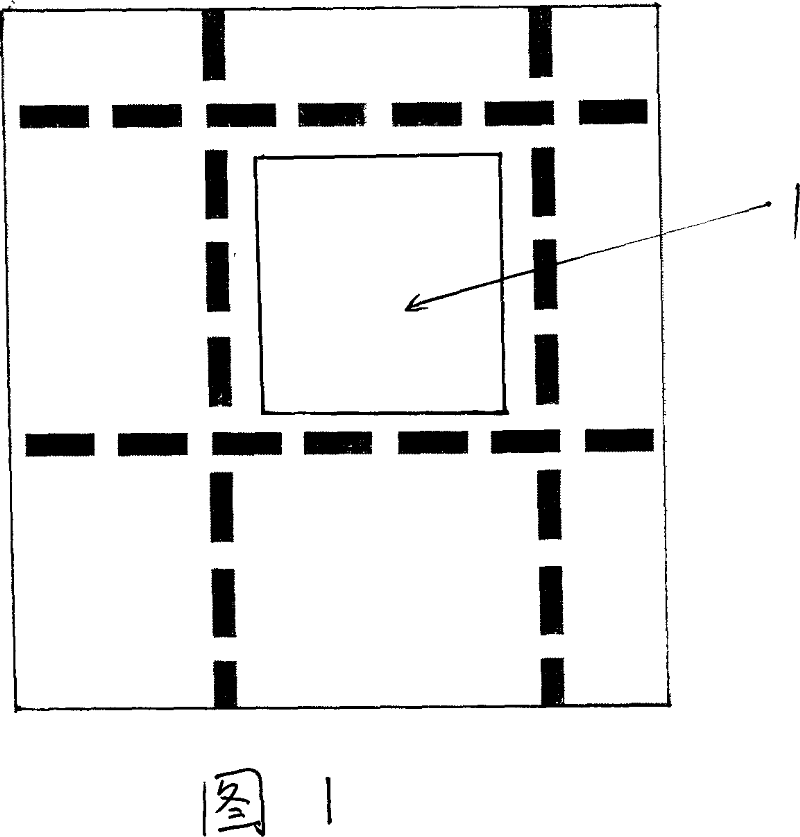

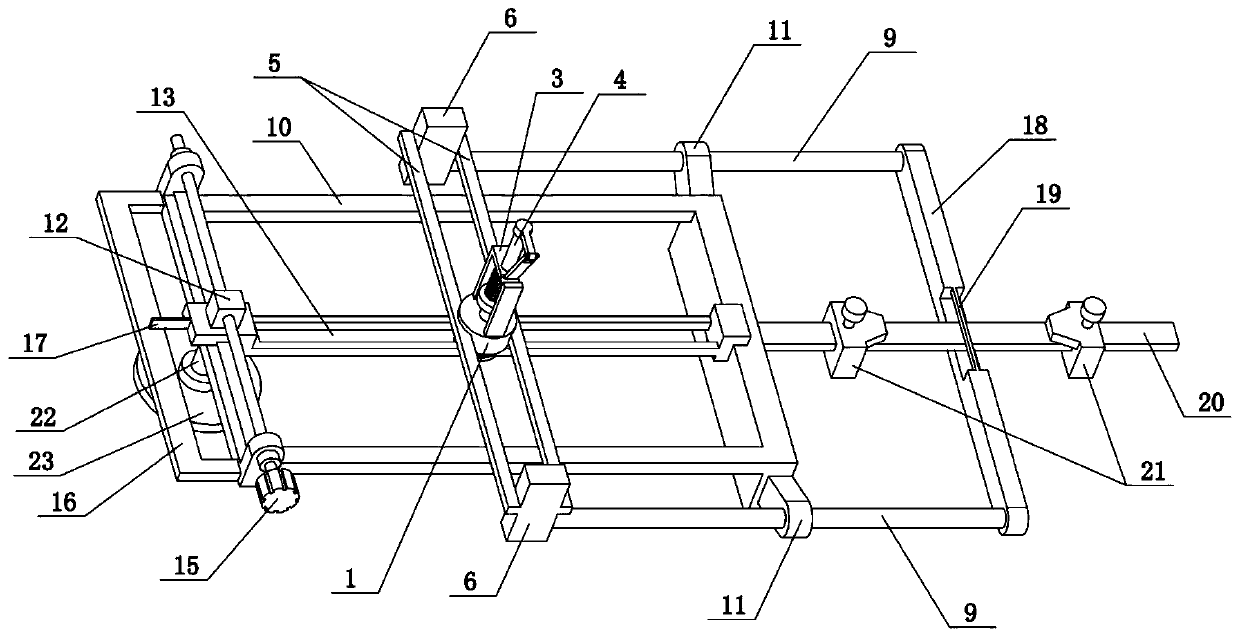

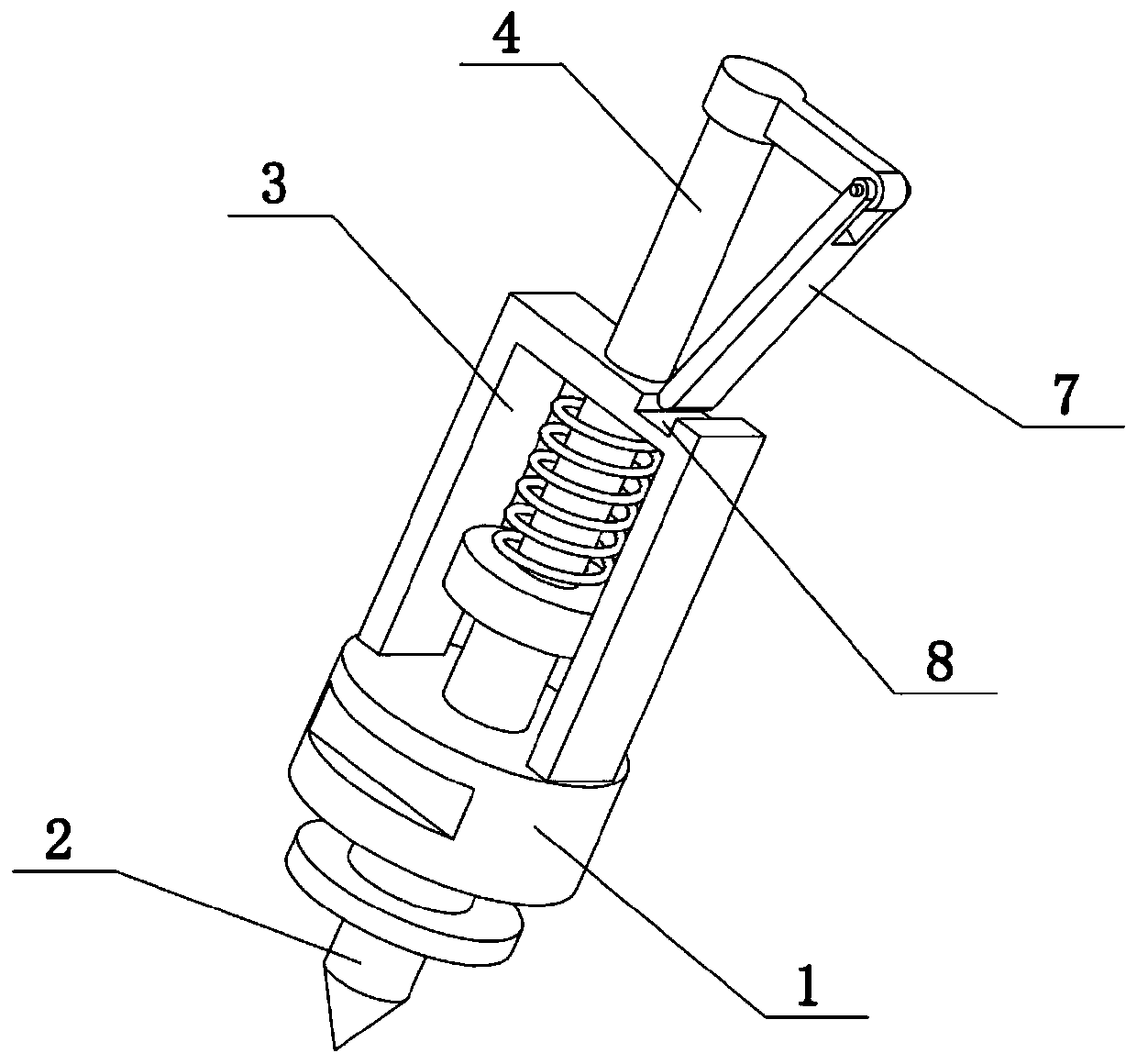

Geometric line drawing device

The invention relates to a line drawing device, in particular to a geometric line drawing device. The device comprises a round seat, a wire drawing pen, a door-shaped frame, a spring sleeve rod, sliding rail rods and seat blocks, wherein the line drawing pen is always perpendicular to the surface of paper, and compared with manual line drawing, a drawing pen can irregularly incline along with hands, lines drawn by the line drawing mode perpendicular to the surface of the paper is more uniform. The line drawing pen is vertically and slidably connected to the round seat, the door-shaped frame isarranged at the upper end of the round seat, the spring sleeve rod is vertically slidably connected to the upper end of the door-shaped frame, the lower end of the spring sleeve rod is fixedly connected to the upper end of the line drawing pen, a compression spring sleeves the spring sleeve rod, a stop block is arranged at the lower end of the spring sleeve rod, the compression spring is positioned between the stop block and the door-shaped frame, the two sliding rail rods are fixedly connected between the two seat blocks, the left end and the right end of the round seat are both provided with notches corresponding to the sliding rail rods, the round seat is slidably connected to the two sliding rail rods, and the spring sleeve rod can be pulled to the upper end and fixed.

Owner:SHAANXI SCI TECH UNIV

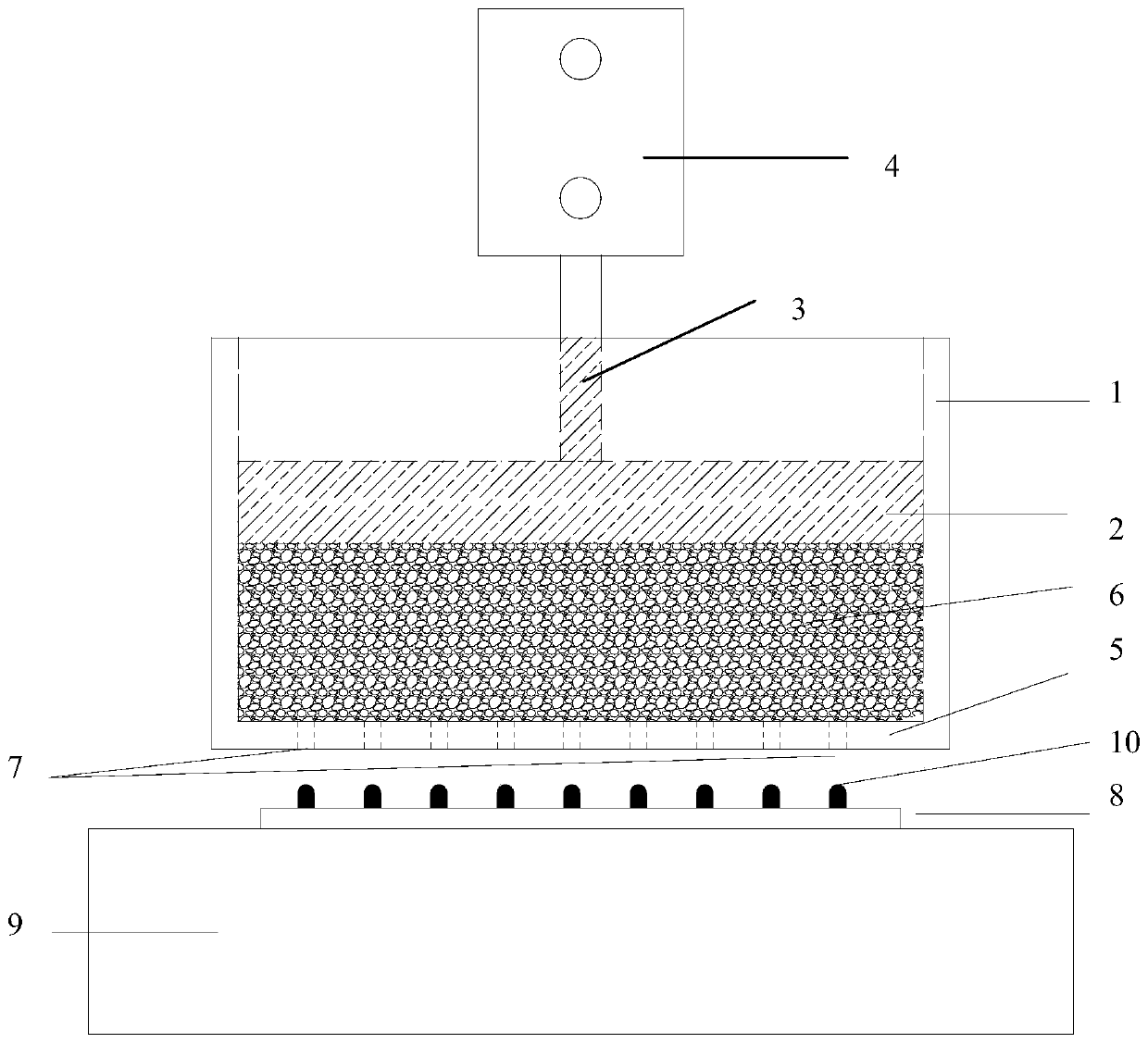

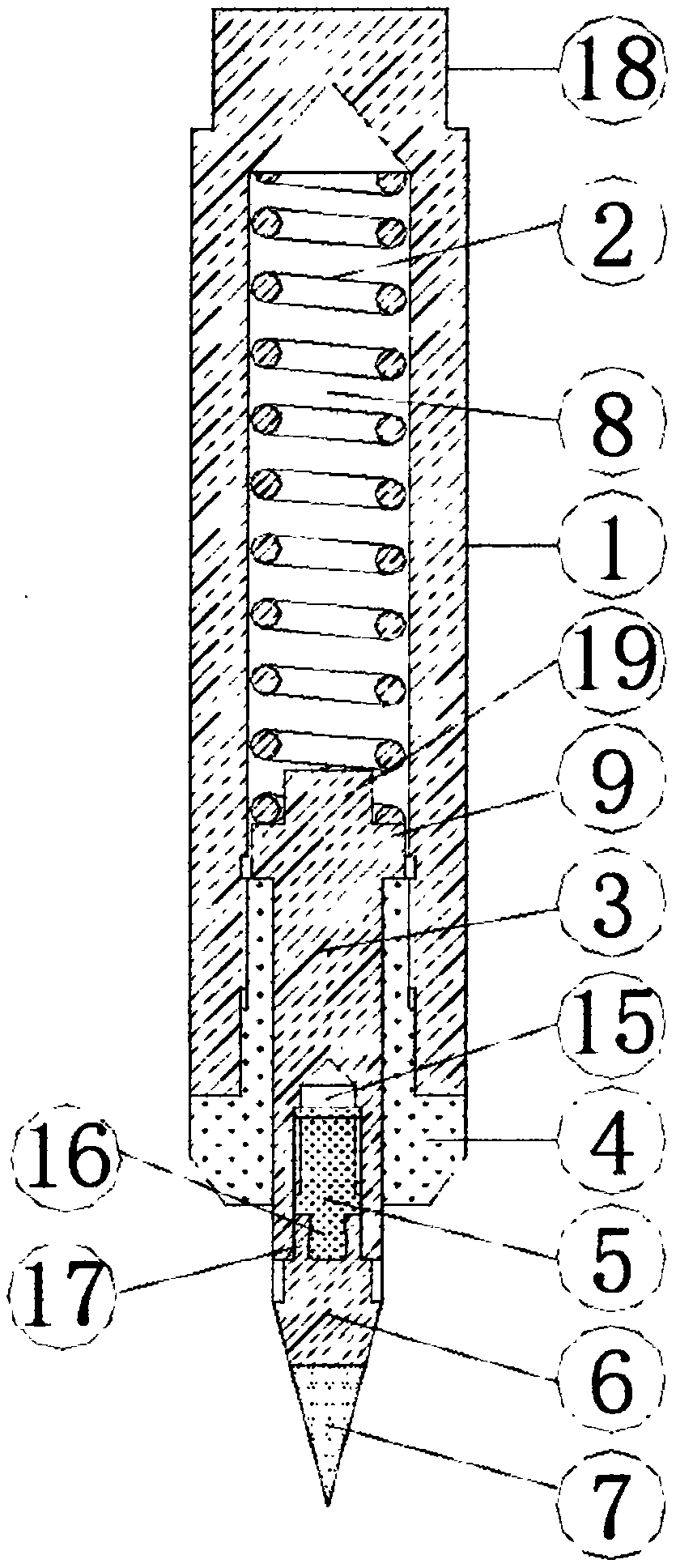

Impressing device for preparing crystalline silicon solar cell electrode

PendingCN111098586AUniform linesImprove continuityScreen printersPhotovoltaic energy generationManufacturing cost reductionEngineering

The invention discloses an impressing device for preparing a crystalline silicon solar cell electrode. The impressing device comprises a shell, a piston and a driving mechanism, wherein the bottom surface of the shell is a flat plate which is a hollow plate with a hollow grid electrode pattern, the circumference of the piston makes contact with the inner wall of the shell so as to form a closed space for containing slurry between the piston and the hollow plate, the piston can be driven to reciprocate up and down by the driving mechanism, and the slurry is extruded when the piston moves downwards, so that the slurry leaks on a silicon wafer through the hollow part of the hollow plate, and the electrode which corresponds to the shape of the hollow part is formed. Electrode grid lines prepared by the impressing device are uniform and consistent, the fluctuating condition of peaks and valleys cannot occur, the depth-width ratio of the electrode is high, the slurry leaks through extrusionin the lower closed space, solvents in the slurry are difficult to volatilize, and different proportions of components can be kept consistent for a long time; the electrode grid lines prepared by theimpressing device has good long-time continuity, so that the quality of the electrode is increased, the cell performance is improved, and the manufacturing cost is reduced.

Owner:TIANJIN AIKO SOLAR ENERGY TECH CO LTD

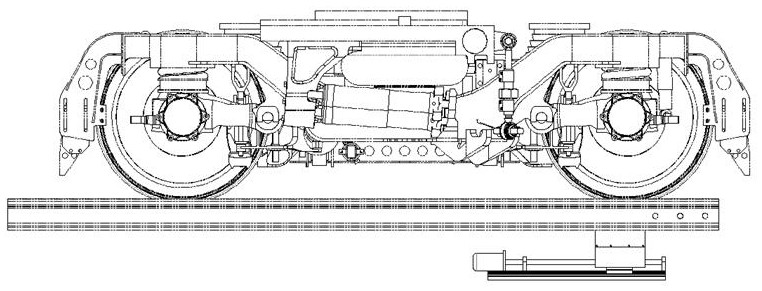

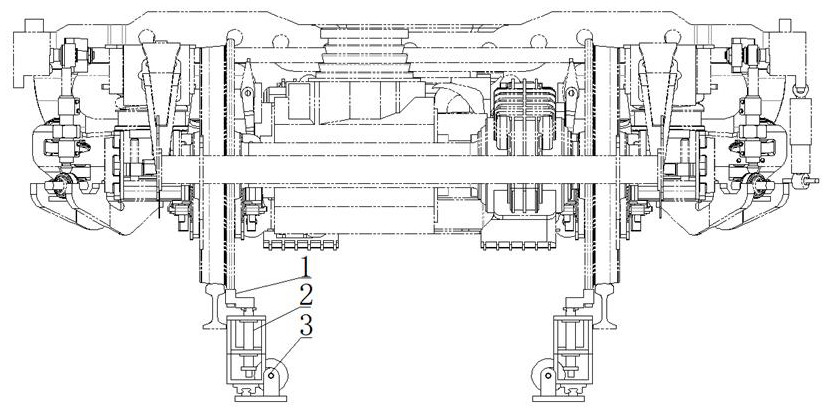

Vehicle body completion bogie moving alignment device

The invention relates to a vehicle body completion bogie moving alignment device. The alignment device comprises a rim clamping device, a lifting device, a driving device and a laser positioning device. The driving device is provided with a linear sliding rail and carries the lifting device, the rim clamping device is located on the top of the lifting device, and the laser positioning device is installed on a car lifting jack. The laser positioning device emits a cross laser ray, the laser ray is positioned at the position of a center pin of the bogie to serve as a reference point, the driving device drives the lifting device and the rim clamping device to move in the direction of the linear sliding rail, the rim clamping device drives the bogie to move, and when the center pin of the bogie coincides with the reference point positioned by the laser positioning device, alignment is completed. According to the vehicle body completion bogie moving alignment device provided by the invention, the bogie and a vehicle body can be rapidly aligned, so that the precision is high, the efficiency is high, manpower is greatly saved, the advantages of safe and stable performance, convenience in operation and high efficiency are achieved, the labor intensity is relieved, the labor productivity can be improved, and the product stability can be guaranteed, so that the product quality is improved.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

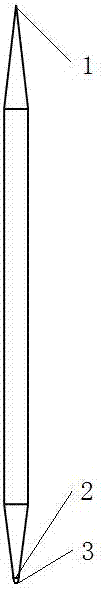

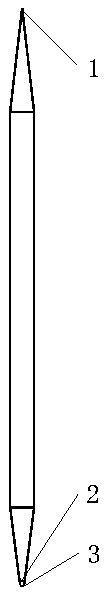

Compass point

ActiveCN106985578AReliable contactAvoid misalignmentCircular curve drawing instrumentsEngineeringCompass

The invention discloses a compass point and relates to the field of stationery. The compass point comprises a ball seat and a conical tip and is characterized in that a movable ball is arranged on the ball seat of the compass point. The effects that the compass point is flexible to use and positions accurately, and paper is intact are ensured.

Owner:冯文达

A kind of ceramic painting on-glaze stacking technology

The invention relates to a novel technology for colouring on glaze during ceramic painting. The novel technology for colouring on glaze during ceramic painting comprises the following steps: adopting a 18# white material, namely selecting 50% by weight of feldspar glaze, 10% by weight of quartz powder, 20% by weight of boric acid and 20% by weight of lead carbonate, mixing and placing the mixture into a ceramic crucible, melting to be bright and transparent at the temperature of 1300 DEG C, cooling into a glass fusion cake, smashing and grinding for late use; by adopting a guide pipe metal pen as a colouring tool, mixing the prepared white material with camphor oil equivalent to 60% by weight of the weight of the white material, grinding manually, then sequentially adding 20% by weight of pine distillate oil and 20% by weight of frankincense oil, and grinding into liquid paste; colouring and roasting, namely painting various glazes, colouring and roasting at the temperature of 790-820 DEG C. The novel technology for colouring on glaze during ceramic painting has the beneficial effects that high-grade ceramic or present ceramic can be prepared; the 18# white material has the advantages of high brightness, no cracking and no strict requirement on roasting atmosphere; uniform and regular lines, easy control and high production rate can be guaranteed; thickness of lines can be graded.

Owner:叶丽虹

Novel multi-purpose extended numerical control tool

PendingCN109693219AWith elastic functionImprove alignment efficiencyOther artistic work equipmentsOther workshop equipmentNumerical controlMachine parts

The invention discloses a novel multi-purpose extended numerical control tool. The novel multi-purpose extended numerical control tool comprises a shank, a spring, a connecting column, a fixed seat, amounting seat, a clamping block and an alloy head. The shank is of a cylindrical structure, a first circular groove is formed in the middle part of the shank, the spring is fixed to the upper end ofthe first circular groove, and the diameter of the spring is slightly smaller than the diameter of the first circular groove. The connecting column is fixed to the lower end of the spring; a limitingring is machined at the end, close to the spring, of the connecting column; and the fixed seat is fixedly disposed at the lower end of the shank, a through hole is formed in the middle part of the fixed seat, the fixed seat includes a limiting part, a first connecting part is fixedly arranged at the lower part of the limiting part, and the limiting part and the first connecting part are both disposed in the first circular groove. The novel multi-purpose extended numerical control tool has the beneficial effects that the numerical control tool has an elastic function, the numerical control toolcan automatically adjust the length according to the height and low fluctuation of a workpiece, and the parallelism and thickness of a machined part can be controlled at the accuracy of level 12 to ensure uniform lines of marking or lettering.

Owner:王明川

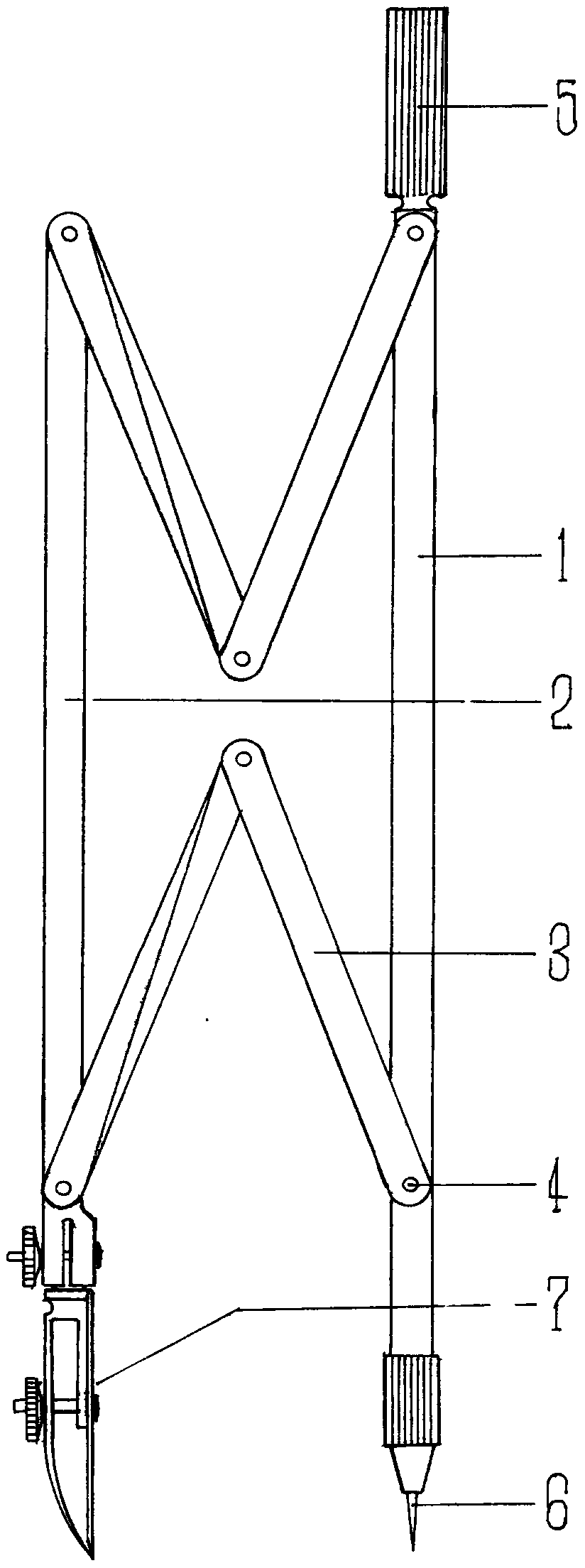

Two-leg parallel compass with single-leg horizontal stretching and retracting function

PendingCN109501494ASimple structureEasy to useCircular curve drawing instrumentsDiagonalGravity center

The invention provides a two-leg parallel compass with a single-leg horizontal stretching and retracting function. The compass comprises a fixed leg, a moving leg, hinge links, hinge shafts, a positioning pin and a brush head, and is characterized in that the fixed leg and the moving leg are vertically arranged in parallel, the number of the hinge links is four, the left and right sides are set tohave different thicknesses by four diagonal lines, every two hinge links are buckled to be square to form two opposite apex angles, and the two ends of the fixed leg and the moving leg are connectedinto a dynamic whole by the hinge shafts. Compared with the prior art, the compass has the advantages that the fixed leg is always in a vertical state during use, the gravity center of gravity is stable and easy to control, the moving leg vertically and horizontally stretches and retracts, the angle of the brush head is not affected by the radius, the lines drawn are even and smooth, the circle orarc is more stable, easy to control and attractive. Therefore, the compass has good application and promotion value.

Owner:白宇

Low-temperature wafer-level packaging method for lateral interconnection for RF mems device applications

ActiveCN106115608BImprove performanceReduce hardnessDecorative surface effectsSolid-state devicesSurface layerMetal device

The invention relates to a transverse interconnection low-temperature wafer level packaging method specific to a radio-frequency MEMS (Micro Electro Mechanical System) device application. The method is characterized in that a low-temperature packaging process is performed on a radio-frequency device through a process which combines Au and In isothermal solidification low-temperature bonding with organic material bonding, so that the problem of lead transverse interconnection is solved, and high mechanical strength and airtightness are achieved during packaging at the same time. Meanwhile, a metal deposition way of Au and In isothermal solidification bonding is adopted, namely, Cu is taken as a barrier layer material for an Au and In isothermal solidification reaction, and a thin Au layer is deposited on a surface layer of an In layer to serve as a protection layer material for preventing the In surface layer from being oxidized. The manufacturing of a sealing ring mainly focuses on a packaging cover plate, so that the influence of packaging on the performance of a substrate chip is lowered greatly. Meanwhile, the manufacturing of the sealing ring and the manufacturing of a packaging cavity are integrated in process.

Owner:SUZHOU XIMEI MICRO NANO SYST CO LTD

compass point

ActiveCN106985578BReliable contactAvoid misalignmentCircular curve drawing instrumentsClassical mechanicsEngineering

Owner:冯文达

Quick exposure device

The invention discloses a quick exposure device. The device comprises an image prime lens; a digital electronic polarizing image device is arranged on the top part of the image prime lens; a liquid crystal tube is mounted between the digital electronic polarizing image device and the image prime lens; the digital electronic polarizing image device and the image prime lens are connected through an adjustable device; the bottom part of the image prime lens is positioned on an operation platform, and the image prime lens is hinged to the operation platform; platform brackets fixedly connected with the operation platform are mounted at the lower surfaces of the operation platform, close to two side surfaces; more than one spot reflector plate is connected between the two platform brackets; guide rails are arranged on the spot reflector plates. With the adoption of the quick exposure device, the automation and intelligence degree of the device can be improved, thus the safety coefficients are greatly increased, the exposure precision is improved, and the line uniformity is increased; meanwhile, the service life is prolonged; the adjusting performance is high; the debugging is simple; the operation is convenient.

Owner:WUPING HONGXIN IND TECH DEV

A low-temperature bonding method based on au/in isothermal solidification

ActiveCN106298557BUniform linesReduced Surface Flatness RequirementsSolid-state devicesSemiconductor/solid-state device manufacturingBonding processOptoelectronics

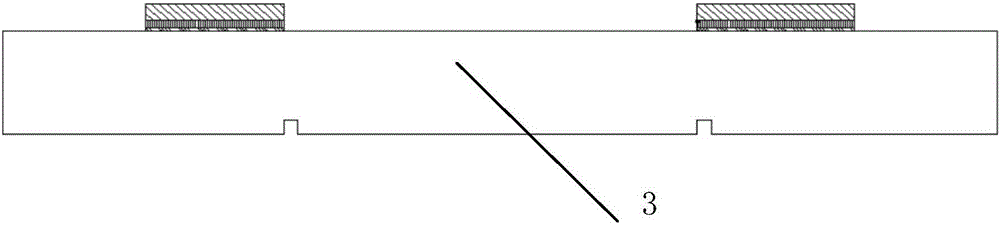

The invention discloses a low-temperature bonding method based on Au / In isothermal solidification, comprising: forming a first gold pattern layer on a bonding surface of a first substrate; forming a bump pattern on a bonding surface of a second substrate layer; on the bonding surface of the second substrate, the second gold pattern layer and the indium pattern layer covering the bump pattern layer are sequentially formed; the bonding surface of the first substrate is bonded to the second substrate Align and secure the bonding surfaces for bonding. The present invention uses a raised dot pattern layer on the bottom layer of the metal film. The raised dot pattern layer not only reduces the bonding alignment accuracy, but also enhances the contact force in the bonding process, which can greatly improve the bonding quality.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Lubricant for drawing superfine stainless steel wire and preparation method

InactiveCN102660372BUniform linesBright surfaceLubricant compositionPolyaspartic acidPolyethylene glycol

The invention relates to lubricant for drawing a superfine stainless steel wire, which is characterized in that the lubricant is prepared by water, polyethylene glycol, isopropanol, extreme-pressure additive, amine oxide, polyaspartic acid and metal rust-proof agent, wherein the proportion in part by weight of each substance in the lubricant is as follows: 5 to 10 parts of polyethylene glycol, 5 to 10 parts of isopropanol, 0.5 to 2 parts of extreme-pressure additive, 5 to 20 parts of amine oxide, 0.5 part of polyaspartic acid, 0.5 to 1 part of metal rust-proof agent and 45 to 100 parts of water. By utilizing the lubricant, good lubricating performance can be maintained when the superfine stainless steel wire is drawn, the surface quality of the superfine stainless steel wire can be improved, the superfine stainless steel wire can be uniformly drawn, the surface of the superfine stainless steel wire is bright and uneasy to rust, and the wire breaking rate can be reduced.

Owner:刘彦辉

Simple exposure device with condensation reflection plate

The invention discloses a simple exposure device with a condensation reflection plate. The simple exposure device with the condensation reflection plate comprises an image prime lens, a digital electronic polarization image device is arranged at the top of the image prime lens, a liquid crystal pipe is arranged between the digital electronic polarization image device and the image prime lens, the digital electronic polarization image device is connected with the image prime lens through an adjustable device, the bottom of the image prime lens is located on an operation platform, the image prime lens is hinged to the operation platform, platform brackets are arranged at the lower surface of the operation platform near the two lateral surfaces, the platform brackets are firmly connected with the operation platform, more than one condensation reflection plate is connected between the two platform brackets, and the condensation reflection plate is provided with a lead rail. The simple exposure device with the condensation reflection plate improves the equipment automation and intelligence degree, the lines are more uniform, the service life of the exposure equipment is prolonged, the regulating property is good, the debugging is easy to perform, and the operation is facilitated.

Owner:WUPING HONGXIN IND TECH DEV

A kind of production method of copper strip for long cable

InactiveCN103077763BImprove conductivityHigh elongation propertiesMetal/alloy conductorsCable/conductor manufactureCopperImpurity

The invention provides a copper strip for a long cable, which has the advantages of high conductivity and high extension properties and can effectively reduce the cost, and a production method. The technical scheme is that the copper strip for the long cable is characterized by being formed by following components in weight percentage of: 99.945-99.975% of copper, 0.0008-0.0050% of phosphorus, less than 0.0025% of impurity O, less than 0.0045% of Fe and less than 0.035% of the total sum of impurities. The production method of the copper strip for the long cable is characterized by comprising the following steps of: preparing materials, smelting, covering, deoxidizing, detecting, carrying out upward continuous casting, detecting components of a strip blank, sizing and coiling, milling a surface, roughly rolling, cutting edges, carrying out intermediate annealing, brushing, finely rolling, carrying out finished-product annealing, washing and passivating the surface, cutting a finished product, packaging and storing.

Owner:QINGDAO CHUANGJIA COPPER

Rapid epitaxial wafer exposure device

InactiveCN106647143AExtended service lifeImprove completenessPhotographic printingComputer scienceEnergy consumption

The invention discloses a rapid epitaxial wafer exposure device comprising an image locating device. The top part of the image locating device is provided with a digital electronic polarization frame capture structure. An exposure lamp is installed between the digital electronic polarization frame capture structure and the image locating device. The digital electronic polarization frame capture structure and the image locating device are connected through an adjustable device. The bottom part of the image locating device is arranged on an operating platform. The image locating device and the operating platform are hinged. Holders are installed on the position close to the lower surface of the two side surfaces of the operating platform. The holders and the operating platform are fixedly connected. Energy consumption plates are connected between the two holders. There are more than one energy consumption plates which are provided with guide rails. According to the rapid epitaxial wafer exposure device, the braking and intelligent degree of equipment can be enhanced so that the safety coefficient can be greatly enhanced, the exposure accuracy can be enhanced, the line is enabled to be more uniform and the service life of the exposure equipment can also be prolonged, and thus the device has great adjustment performance, simple debugging and convenient operation.

Owner:DIMENSION TECH

A tooling device capable of pasting adhesive tapes on automobile decorative strips and glass clips

ActiveCN105215646BIncreased or decreased pressureUniform linesMetal working apparatusMechanical engineering

Owner:NINGBO HONGXIECHENG AUTO PARTS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com