Impressing device for preparing crystalline silicon solar cell electrode

A solar cell and electrode technology, which is applied in printing, circuit, printing machine, etc., can solve the problem of not being able to eliminate the peak and valley fluctuations at the top of the longitudinal section of the line, not being able to overcome the inherent defects of screen printing, and the elasticity of the steel plate is not as good as the screen screen, etc. problem, to achieve good long-term continuity, uniform electrode grid lines, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

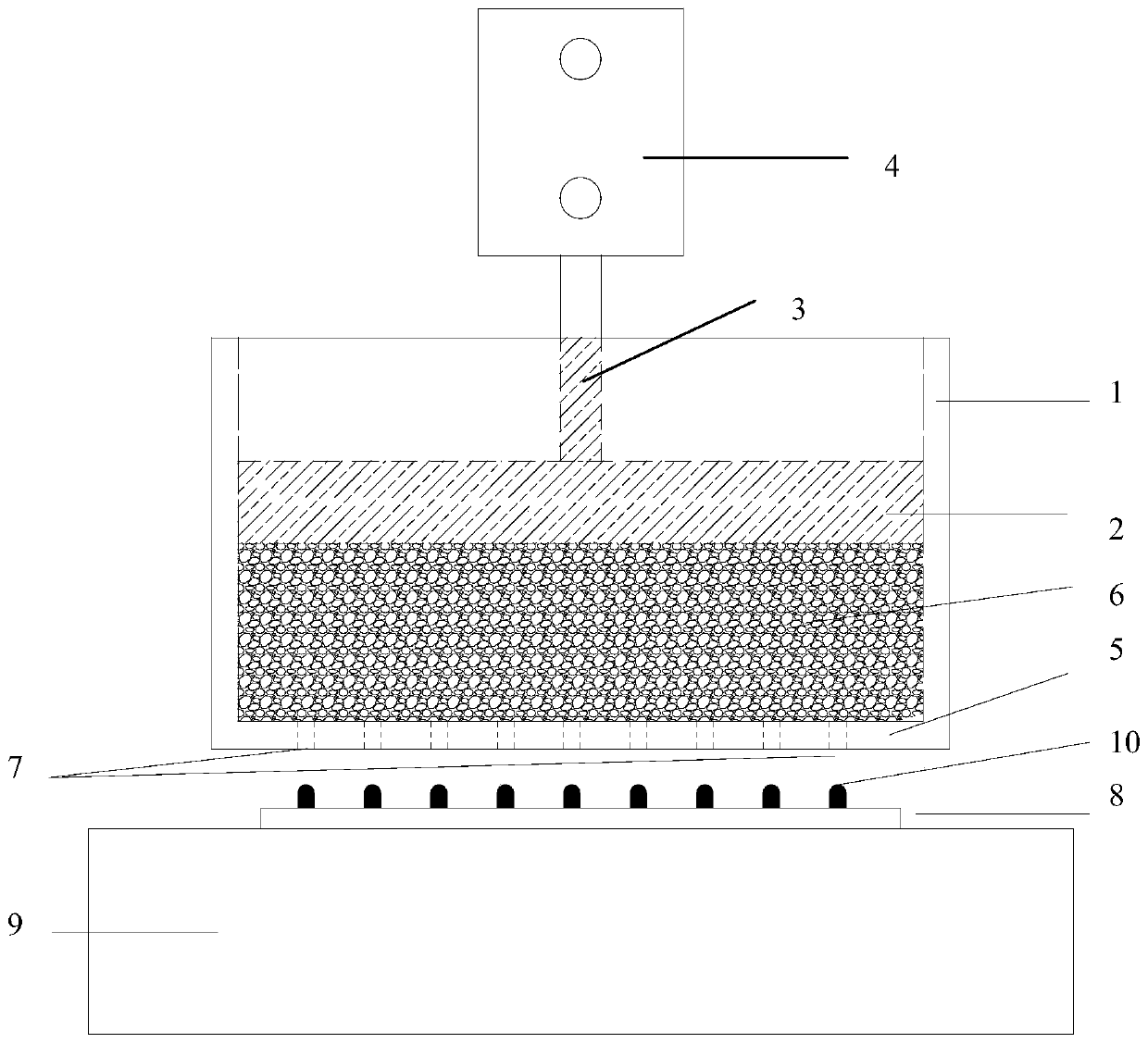

[0026] Such as figure 1 As shown, it is an imprinting device for preparing crystalline silicon solar cell electrodes according to the present invention, which includes a groove-shaped casing 1, a piston 2 built in the casing 1, a connecting rod 3 and a driving mechanism, and the casing can adopt Metal material, alloy material, glass material, organic resin material, ceramic material or carbon fiber material. In this embodiment, the driving mechanism adopts the air cylinder 4 , and in other embodiments, the driving mechanism may adopt an oil pressure cylinder, a screw slide rail electrode or a linear electrode. The bottom surface of the housing 1 is a flat plate and the flat plate is a hollow plate 5 with a hollow grid electrode pattern. The hollow part 7 on the hollow plate 5 is mainly composed of several hollow long holes arranged in parallel. The hollow long holes are a complete through hole. The periphery of the piston 2 is in contact with the inner wall of the housing 1 ...

Embodiment 2

[0030] The difference between this embodiment and Embodiment 1 lies in that: the hollowed out part on the hollowed out plate is different, and the electrode prepared in this embodiment is a rear grid line electrode. In this embodiment, the hollow part on the hollow plate is mainly composed of several hollow long holes arranged in parallel, and the hollow long holes are divided into a plurality of hole segments, and the shape of each hole segment is a triangle. In other embodiments, The shape of the hole segment can also be circular, rectangular or elliptical, etc.

[0031] The working process of this embodiment is as follows: when in use, the cylinder pushes the connecting rod to reciprocate up and down, the connecting rod pushes the piston to move up and down, the piston squeezes the slurry when it moves down, and the slurry passes through the hollow of the hollow plate under the action of the extrusion force. Parts (specifically, each hole segment) are printed on the surface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com