Tool device for pasting adhesive tape to decorative strips and glass clamping strips of automobile

A technology for automotive trim strips and tapes, which is applied in metal processing, manufacturing tools, metal processing equipment, etc., can solve problems such as low efficiency, manual tapes fraying the skin of fingers, and uneven manual tapes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

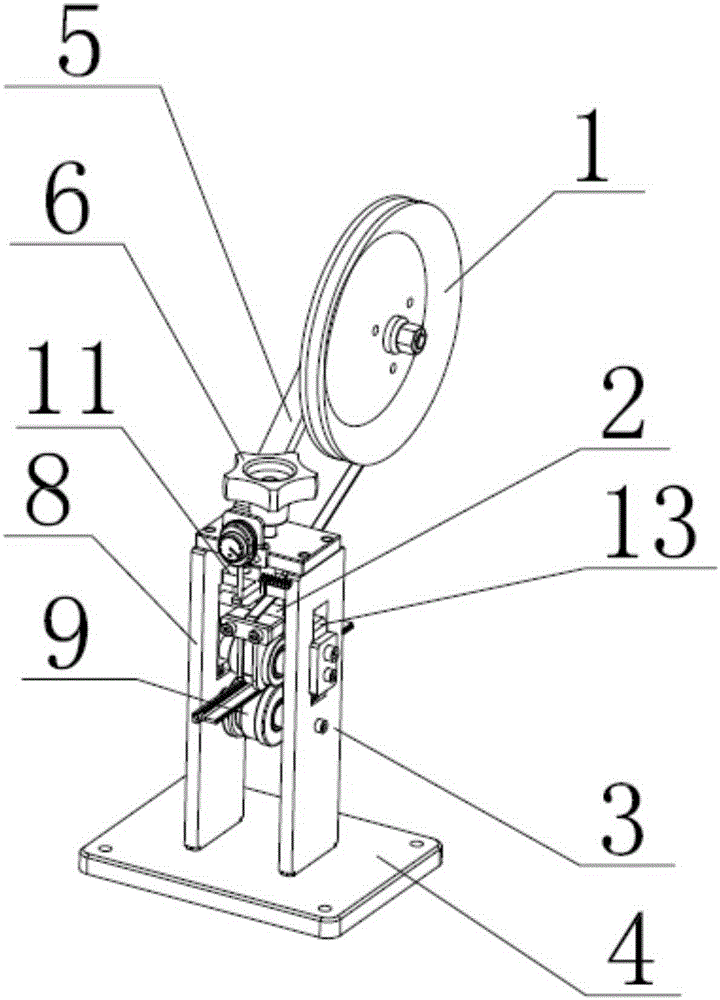

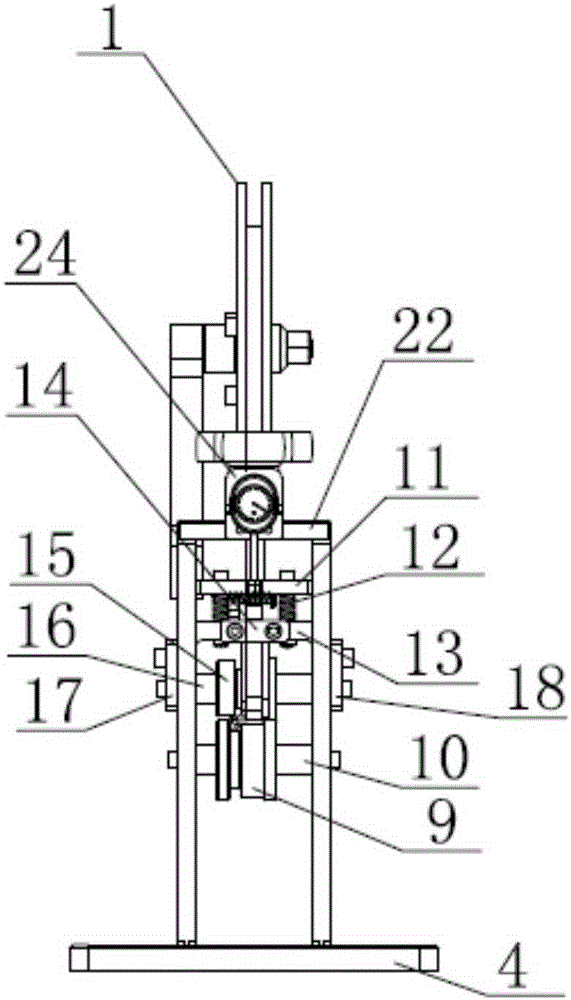

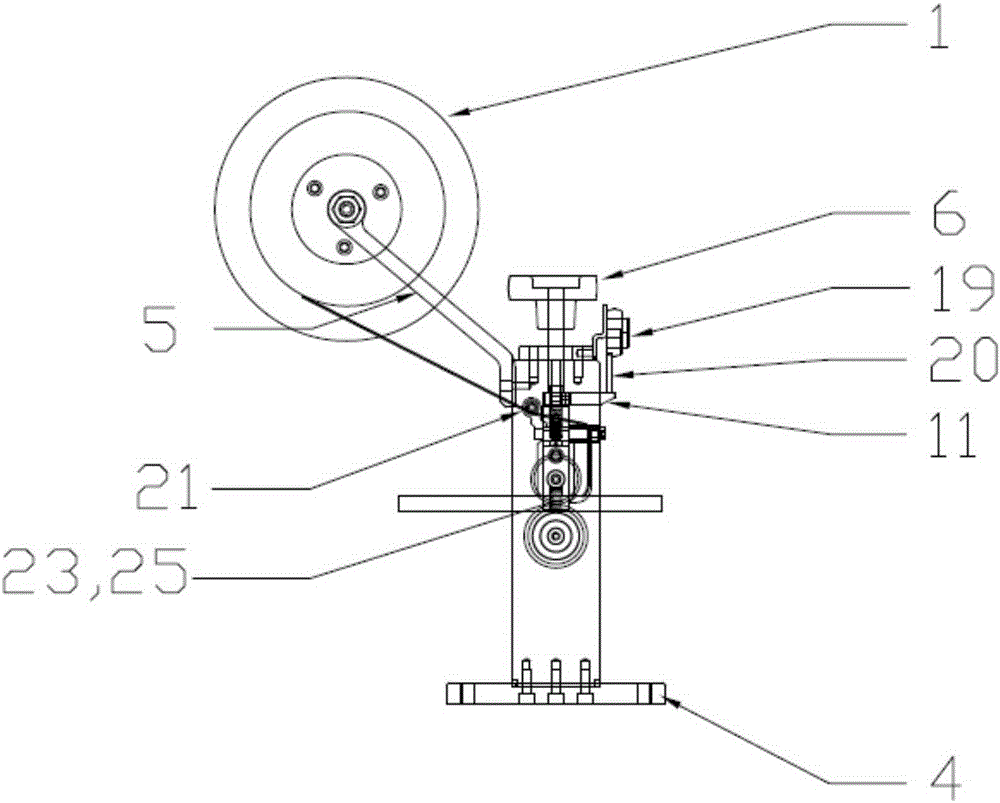

[0032] When using this tooling device to paste the tape, the device is first fixed on the workbench, the tape is drawn from the tape installation wheel 1, passed through the upper pressure roller 15 through the guide drive wheel 21, the damping guide groove 27 and the guide groove 7, and is fixed. Wheel 9, and then rotate the pressure adjustment handle 6 forward or reverse to control the spring pressing plate 11 to move up and down, so as to adjust the pressure on the tape, push or pull the product through the upper pressure wheel 15 and the fixed wheel 9, so as to realize the adhesive tape In the process, after one product is passed, the next product is followed up and launched to realize continuous tape application, and the scale value of the pressure indicator gauge 19 is recorded, so that the product can be mass-produced according to this standard. The utility model has the characteristics of simple structure, low cost, high work efficiency, and strong practicability. All p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com