Novel bidirectional pressure protection valve and method

A two-way pressure and protection valve technology, applied in the direction of valve details, safety valves, balance valves, etc., can solve the problems of heat loss, poor ability of energy storage furnace to withstand negative pressure, and reduce the heat preservation effect of energy storage furnace, etc., to achieve The effect of reducing discharge and loss and improving the effect of heat preservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

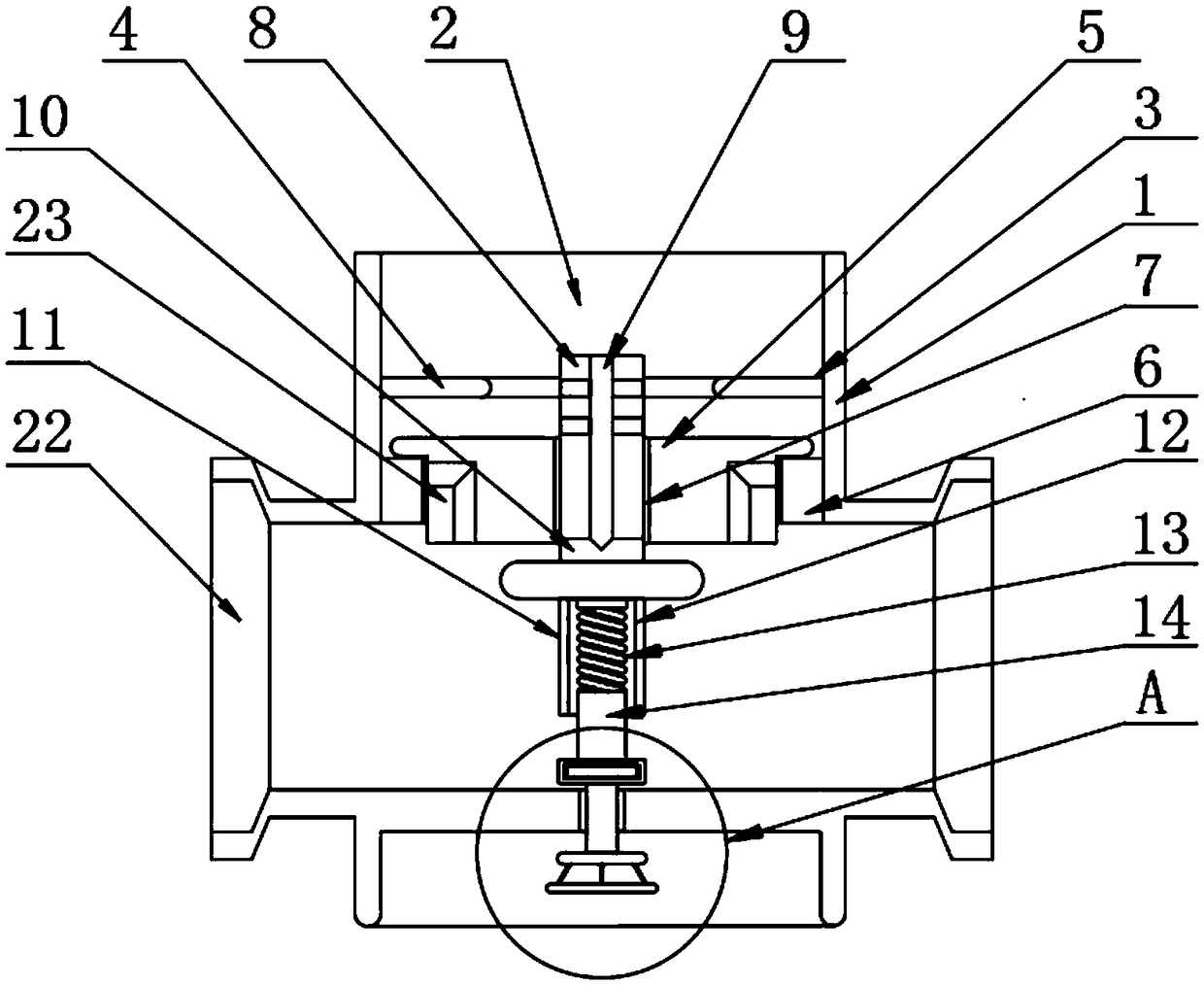

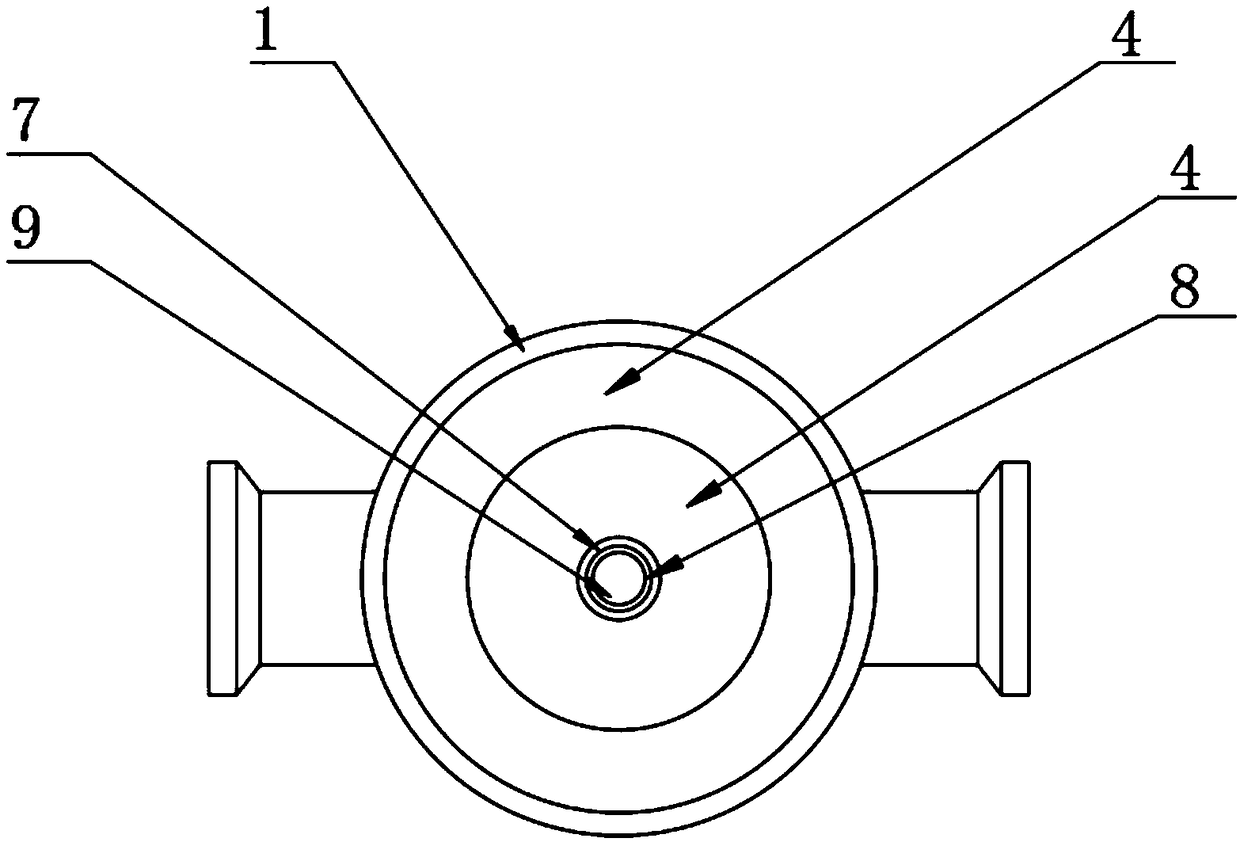

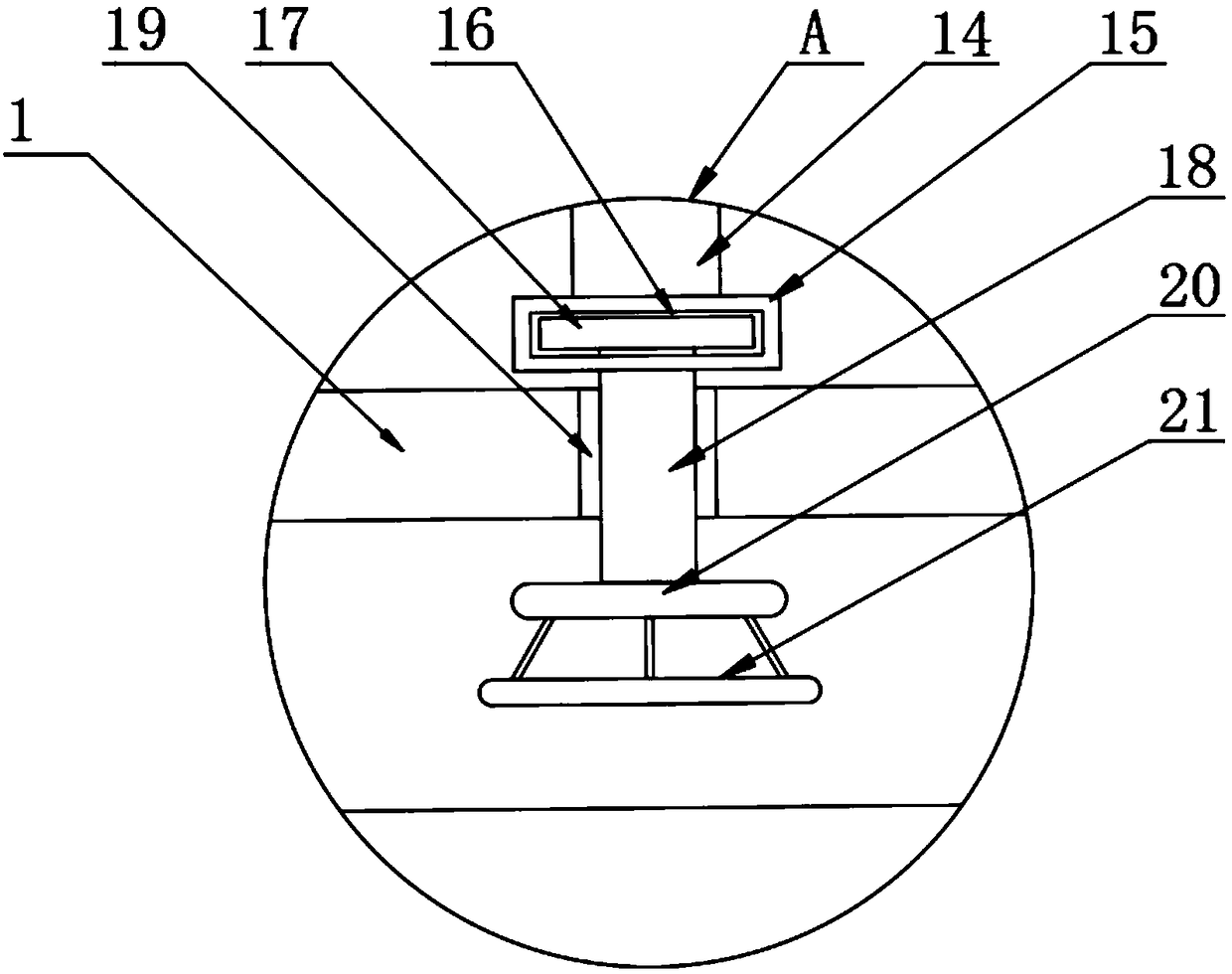

[0026] The present invention provides such as Figure 1-3 A new type of two-way pressure protection valve shown includes a valve body 1, an internal pressure port 2 is provided on the top of the valve body 1, and a two-way pressure protection device 3 is provided inside the internal pressure port 2, and the two-way pressure protection device 3 includes a first limit ring 4, a first piston 5 is provided at the bottom of the inner pressure port 2, a second limit ring 6 is provided at the bottom of the first piston 5, and the first limit ring 4 and the second The limit rings 6 are all fixedly connected to the inner wall of the inner pressure port 2, the first piston 5 is slidably connected to the inner pressure port 2, the surface of the first piston 5 is provided with a slide port 7, and the inside of the slide port 7 is provided with a second Two pistons 8, the surface of the second piston 8 is provided with an air inlet 9, and the bottom of the second piston 8 and the air inle...

Embodiment 2

[0036] A novel two-way pressure protection method, including the novel two-way pressure protection valve, also includes the following steps:

[0037] S1: the novel two-way pressure protection valve is installed at the bottom of the furnace body;

[0038] S2: adjusting and setting the setting value of the operating pressure of the novel two-way pressure protection valve through the pressure regulating device 11;

[0039] S3: When the pressure in the furnace on one side of the novel two-way pressure protection valve is greater than the setting value of the operating pressure, the pressure in the furnace pushes the second piston 8, and the flue gas is discharged;

[0040] S4: When the pressure inside the furnace is lower than the air pressure outside the furnace, the first piston 5 moves, and the outside air enters the furnace.

[0041] Preferably, the setting value of the operating pressure of the novel two-way pressure protection valve adjusted by the pressure regulating device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com