A low-temperature bonding method based on au/in isothermal solidification

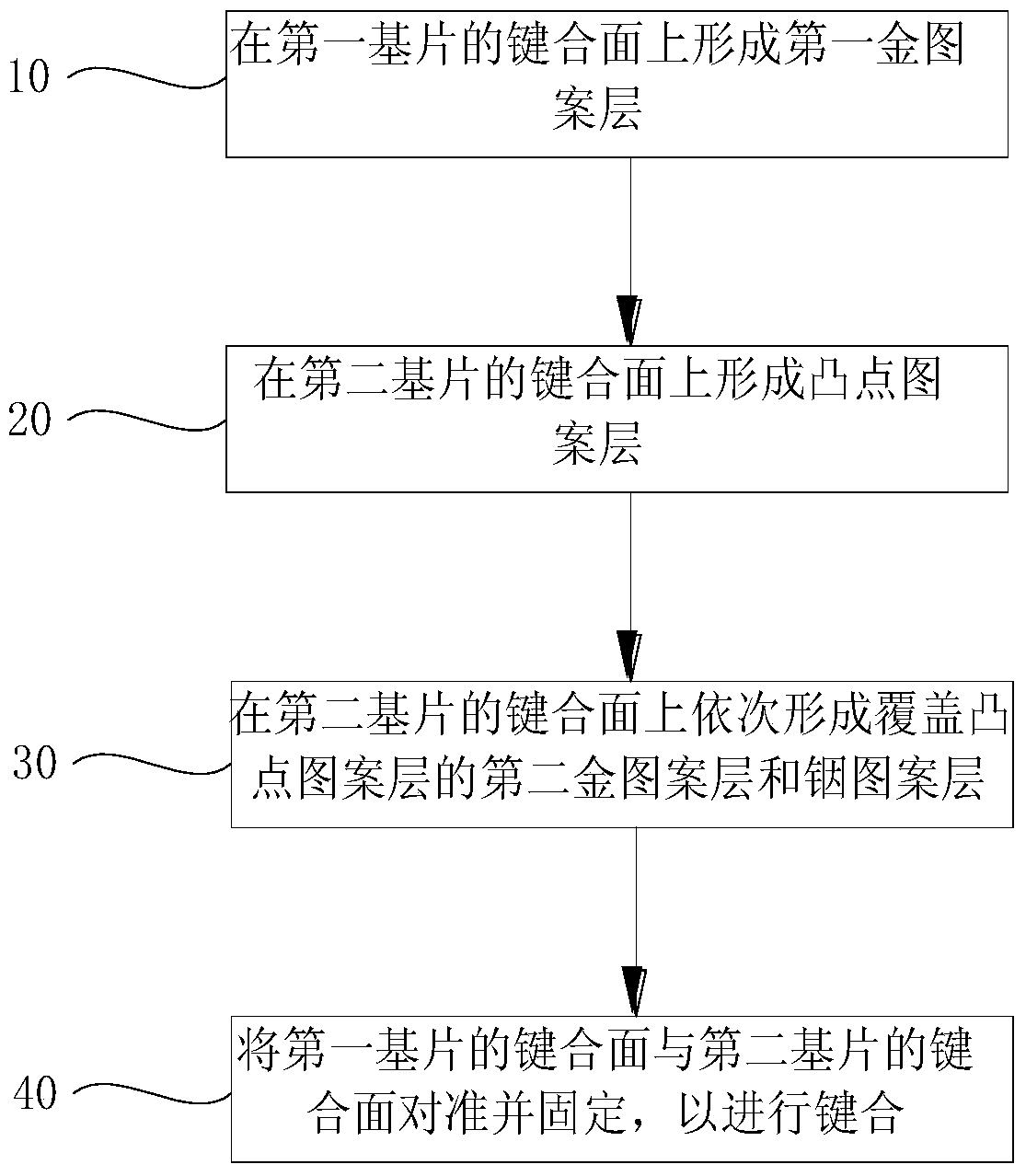

A low-temperature bonding and isothermal technology, applied in semiconductor/solid-state device manufacturing, electrical solid-state devices, semiconductor devices, etc., can solve the problem that surface-activated low-temperature bonding is difficult to meet the requirements of graphics circuits and wafer bonding, and increases the difficulty of the process. Process costs, the flatness of the surface to be bonded and other issues, to achieve the effect of strong plasticity, reduced bonding alignment accuracy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

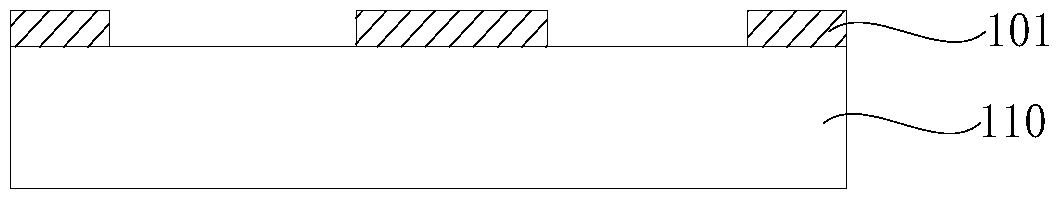

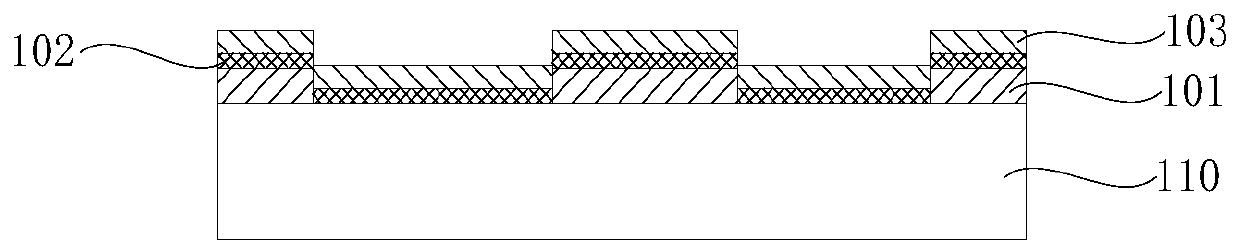

[0035] Hereinafter, embodiments of the present invention will be described in detail with reference to the accompanying drawings. This invention may, however, be embodied in many different forms and should not be construed as limited to the specific embodiments set forth herein. Rather, the embodiments are provided to explain the principles of the invention and its practical application, thereby enabling others skilled in the art to understand the invention for various embodiments and with various modifications as are suited to particular intended uses. In the drawings, the thicknesses of layers and regions are exaggerated for clarity of devices, and the same reference numerals will be used to refer to the same elements throughout the specification and drawings.

[0036] The isothermal solidification process is a liquid / solid interdiffusion and reaction process. In this process, a low-melting point element and a high-melting point element react and diffuse at a slightly highe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com