Novel multi-purpose extended numerical control tool

A multi-purpose and new technology, applied in drawing tools, processing models, manufacturing tools, etc., can solve problems such as unproposed solutions, low blank size accuracy, and difficulties, so as to save the surface grinder process, improve alignment efficiency, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Below, in conjunction with accompanying drawing and specific embodiment, the invention is further described:

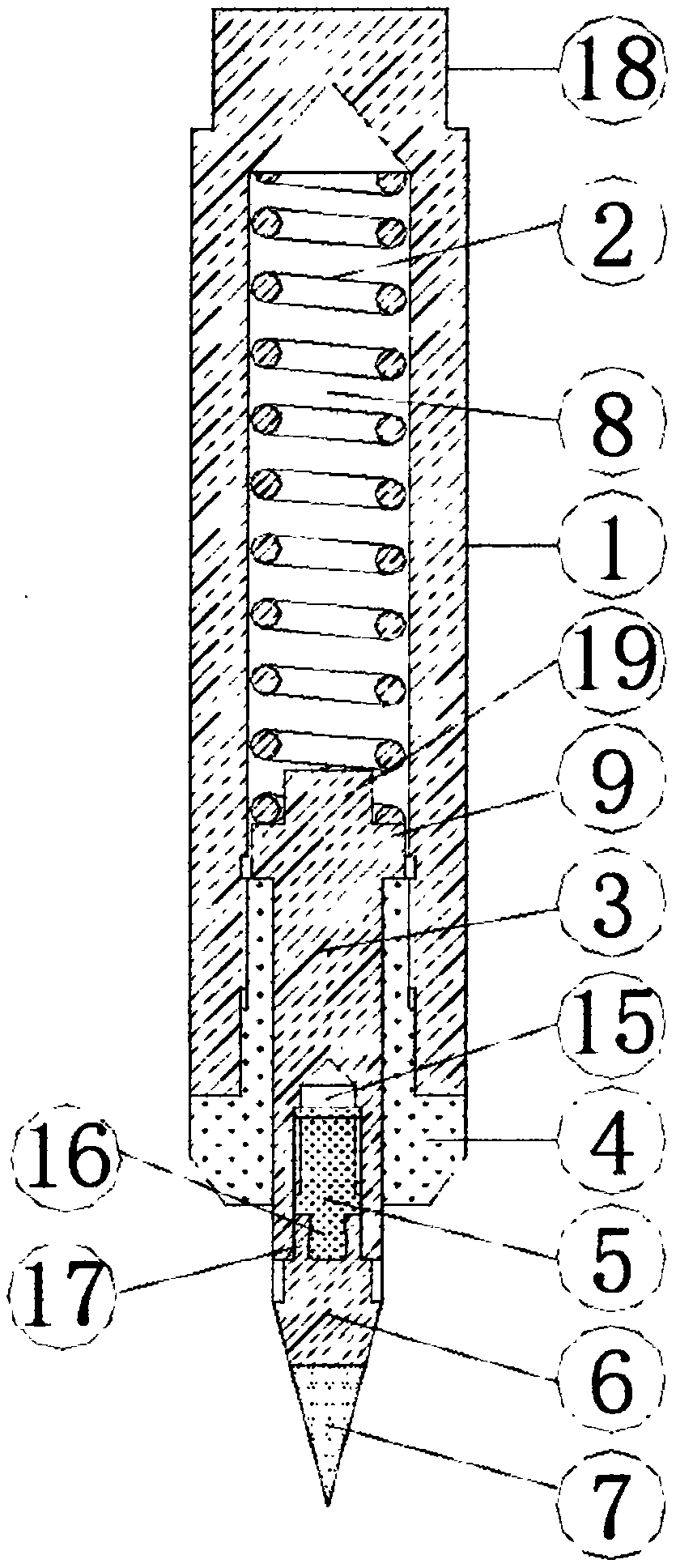

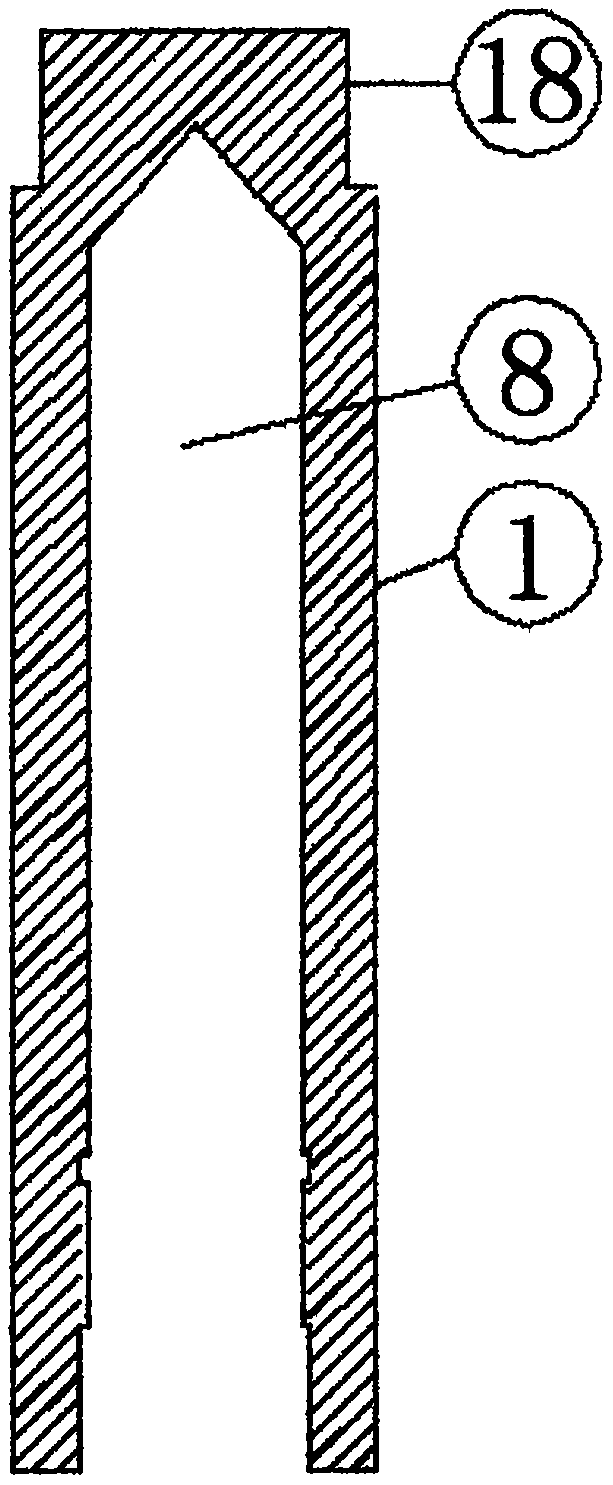

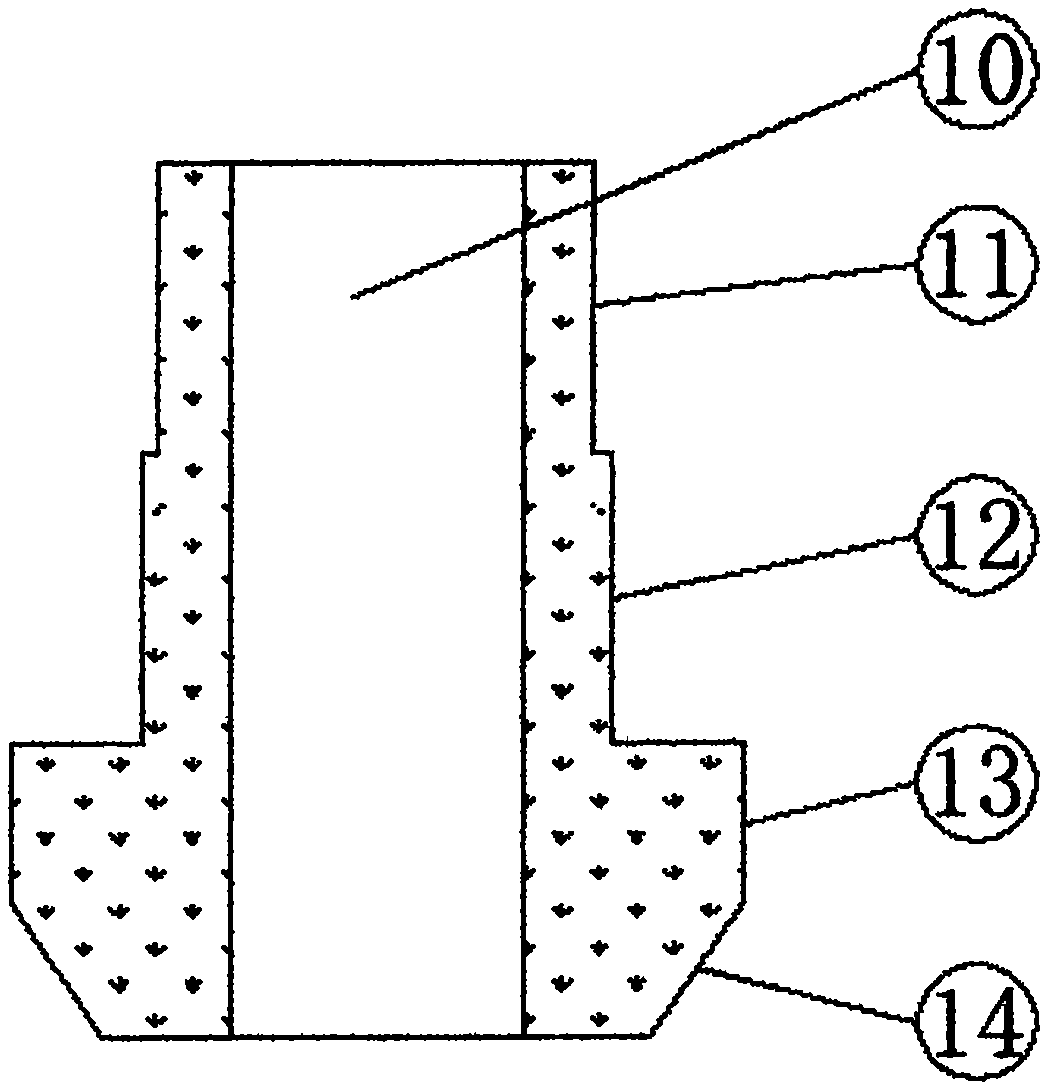

[0021] see Figure 1-3 , according to an embodiment of the present invention, a new type of multi-purpose expanded numerical control tool, including a handle 1, a spring 2, a connecting column 3, a fixed seat 4, a mounting seat 5, a block 6 and an alloy head 7, the handle 1 is a cylindrical structure, the middle part of the handle 1 is provided with a first circular groove 8, the upper end of the first circular groove 8 is fixed with a spring 2, and the diameter of the spring 2 is slightly smaller than that of the first circular groove 8 diameter, the lower end of the spring 2 is fixedly provided with a connecting column 3, and one end of the connecting column 3 near the spring 2 is processed with a limit ring 9, and the lower end of the handle 1 is fixedly provided with a fixed seat 4, and the fixed seat 4 The middle part is provided with a perforation 10, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com