Processing method and equipment of spicy beef

The technology of processing equipment and processing method is applied in the field of beef marinating, which can solve the problems of single structure, low practicability, poor meat quality and taste, and achieve the effects of improving safety, improving practicability and delicious meat quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A processing method of spicy beef, comprising the following processing method:

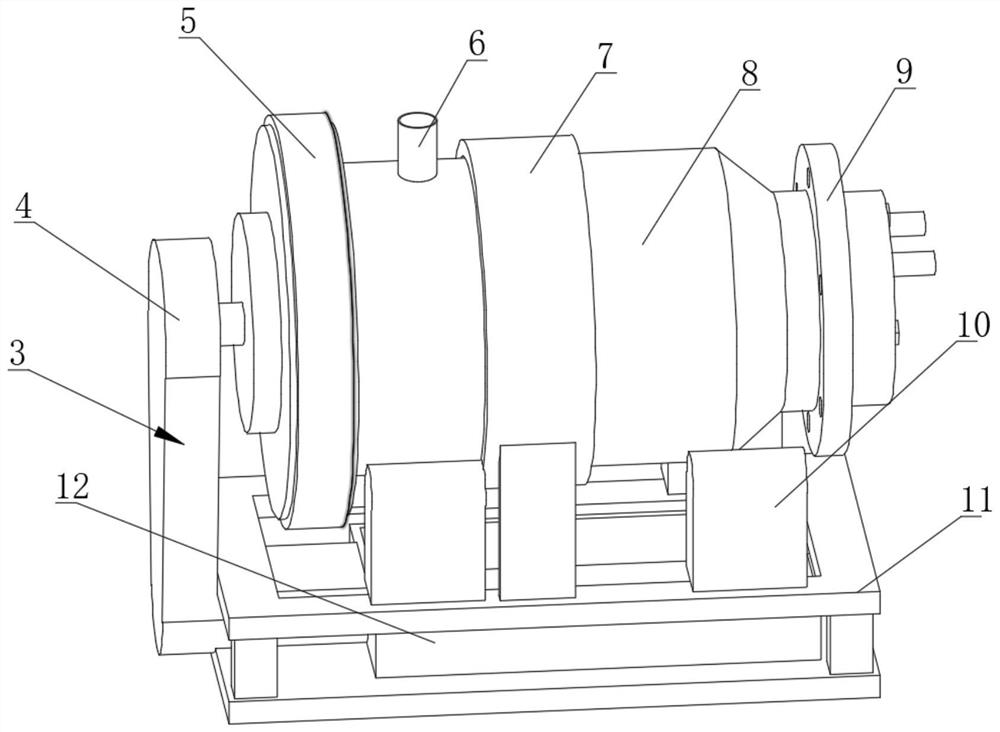

[0038]S1: put the beef, clean the beef and cut it into pieces and pour it into the curing cylinder 8, and the beef occupies 40% of the internal volume of the curing cylinder 8, and then pour the marinade into the curing cylinder 8;

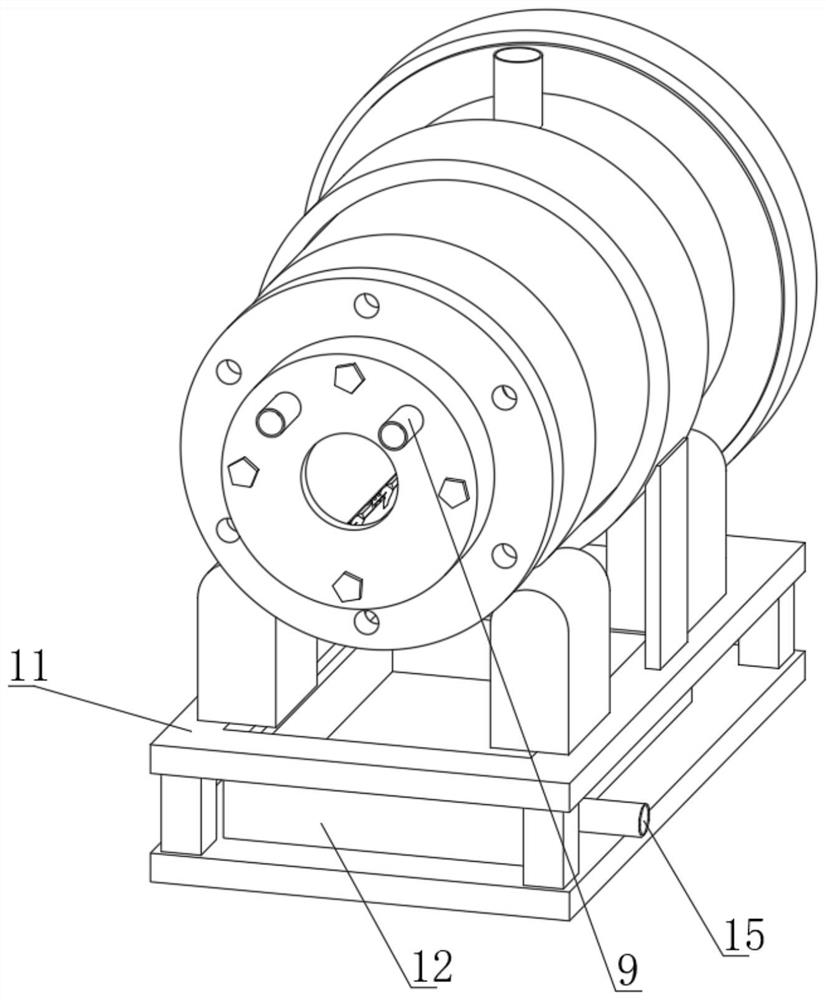

[0039] S2: The air in the inner cylinder is discharged, and then the front cover 9 is fixed on the front end of the pickling cylinder 8, and then the internal air is pumped through the pipeline of the pickling cylinder 8 to keep the inside of the pickling cylinder 8 in a vacuum state;

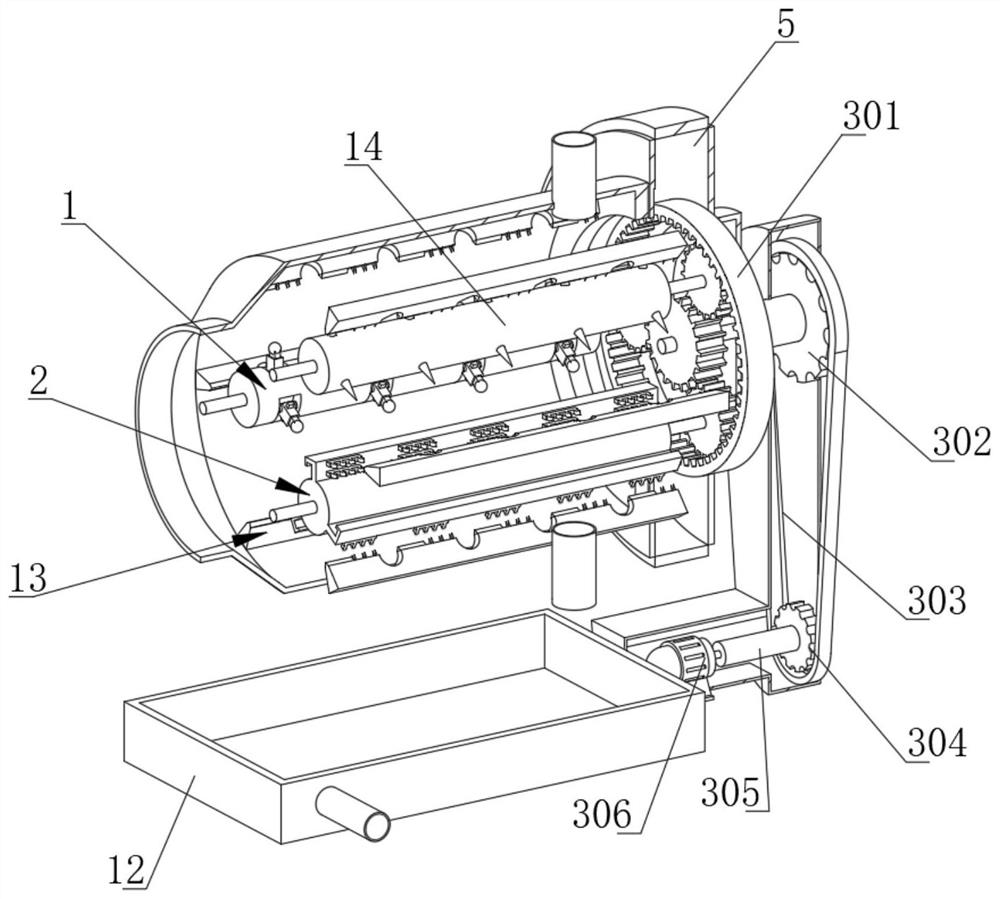

[0040] S3: marinated beef, start the motor 306 to drive the internal planetary gear plate 301 to rotate clockwise 3 and then counterclockwise 3 so reciprocating cycle, when the equipment is rotating, the meat massage ball 103 is set to rotate and beat the surface of the beef, The meat is pierced through the first piercing needle 1401 and the second piercing needle 1304, and the ...

Embodiment 2

[0049] A processing method of spicy beef, comprising the following processing method:

[0050] S1: put the beef, clean the beef and cut it into pieces and pour it into the curing cylinder 8, and the beef occupies 50% of the internal volume of the curing cylinder 8, and then pour the marinade into the curing cylinder 8;

[0051] S2: The air in the inner cylinder is discharged, and then the front cover 9 is fixed on the front end of the pickling cylinder 8, and then the internal air is pumped through the pipeline of the pickling cylinder 8 to keep the inside of the pickling cylinder 8 in a vacuum state;

[0052] S3: marinated beef, start the motor 306 to drive the internal planetary gear plate 301 to rotate clockwise for 5 minutes and then counterclockwise for 5 minutes in such a reciprocating cycle, when the equipment rotates, the meat massaging ball 103 is set to rotate and beat the surface of the beef, The meat is pierced through the first piercing needle 1401 and the second ...

Embodiment 3

[0056] A processing method of spicy beef, comprising the following processing method:

[0057] S1: put the beef, clean the beef and cut it into pieces and pour it into the curing cylinder 8, and the beef occupies 60% of the internal volume of the curing cylinder 8, then pour the marinade into the curing cylinder 8;

[0058] S2: The air in the inner cylinder is discharged, and then the front cover 9 is fixed on the front end of the pickling cylinder 8, and then the internal air is pumped through the pipeline of the pickling cylinder 8 to keep the inside of the pickling cylinder 8 in a vacuum state;

[0059] S3: marinated beef, the starter motor 306 drives the internal planetary gear plate 301 to rotate clockwise for 6 minutes and then counterclockwise for 6 minutes in such a reciprocating cycle. When the equipment is rotating, the meat massage ball 103 is used to rotate and beat the surface of the beef. The meat is pierced through the first piercing needle 1401 and the second p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com