Patents

Literature

590results about How to "Improve alignment efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

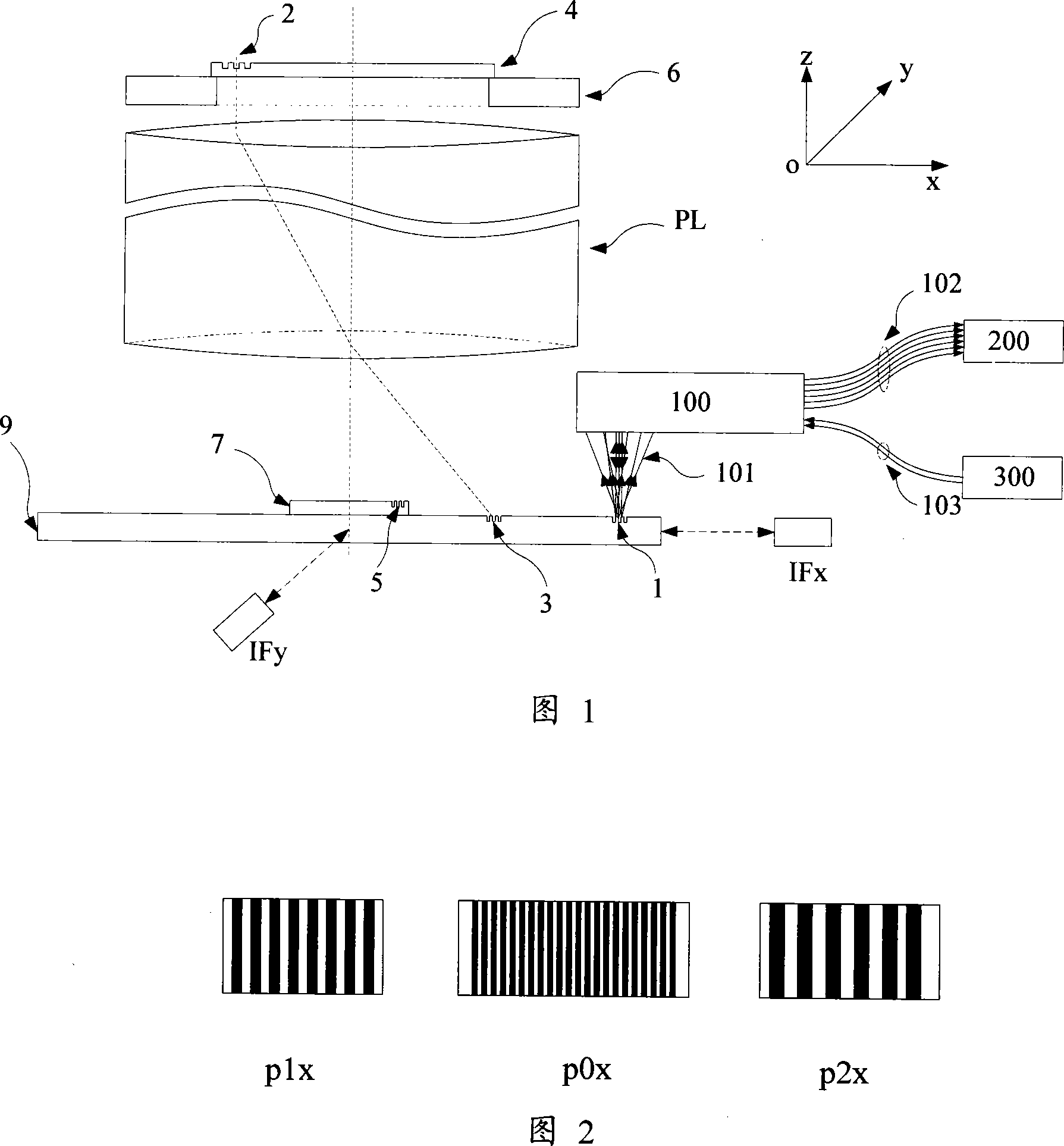

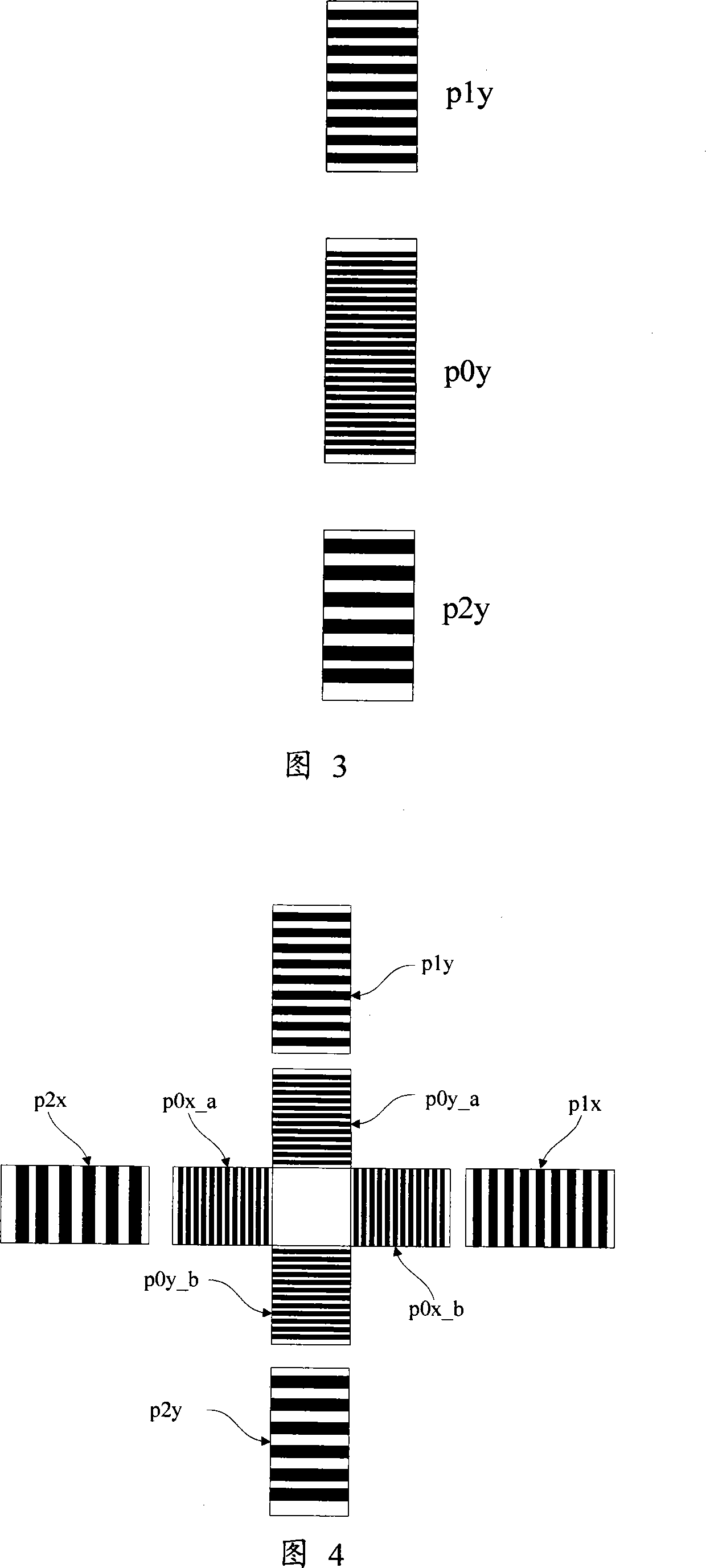

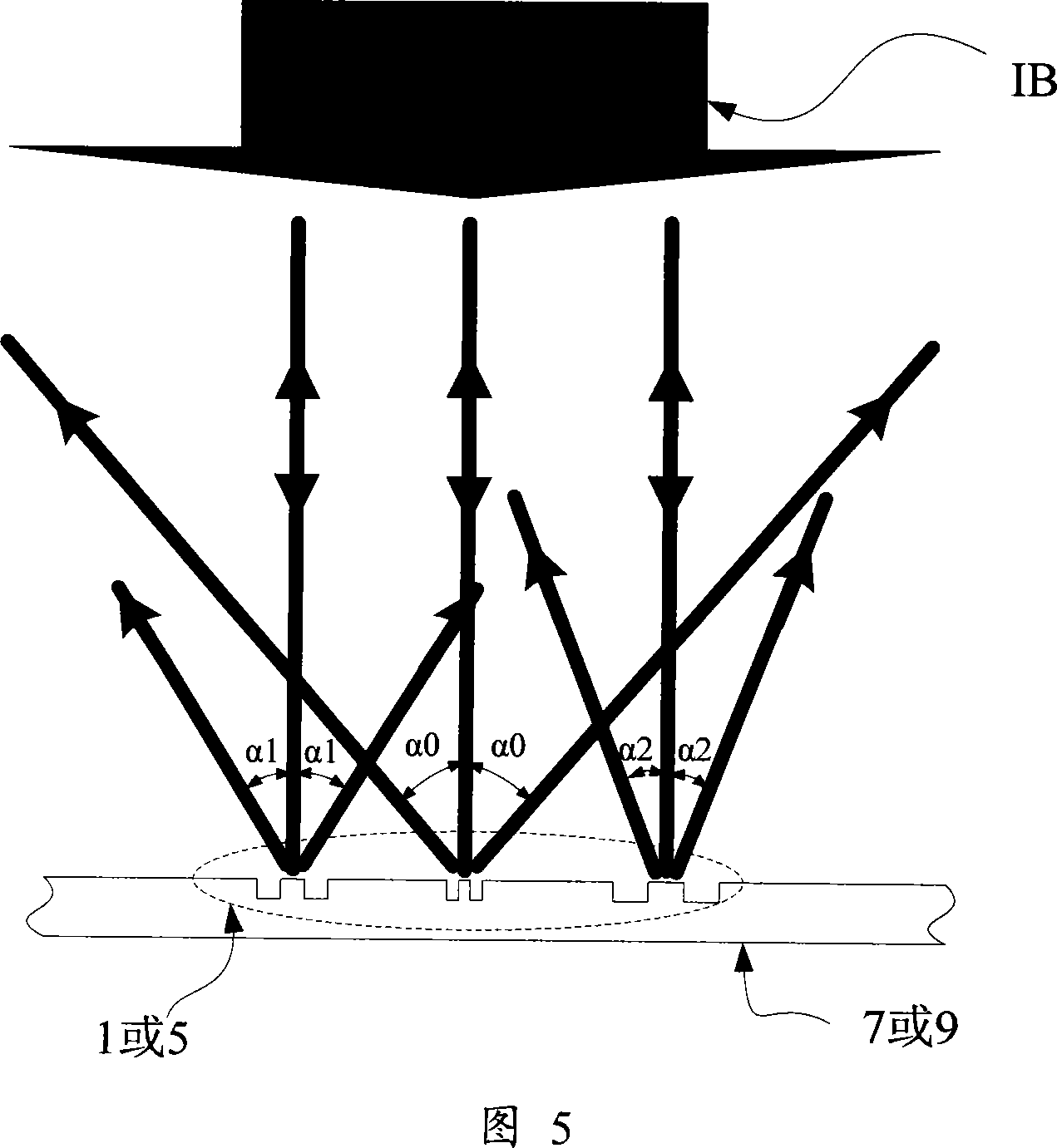

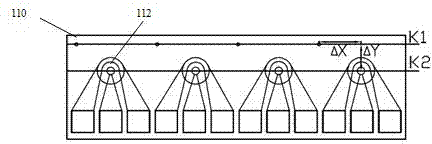

Aligning system photolithography equipment

ActiveCN101114135ASimplify design difficultySimplify debugging difficultyPhotomechanical exposure apparatusMicrolithography exposure apparatusPhase gratingLithographic artist

The invention discloses an alignment system applied in a lithography device, which uses three periods phase grating with crude precision combination in a substrate marker or a substrate station reference marker, uses a first order diffraction light of the three periods as an alignment signal, simultaneously realizes a big capture range and gets high alignment precision, gets labeled deformation information and other useful information, and through the optimum design of the match and / or the layout of the three periods, the influence on an alignment position by asymmetrical deformation of the marker is effectively reduced.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

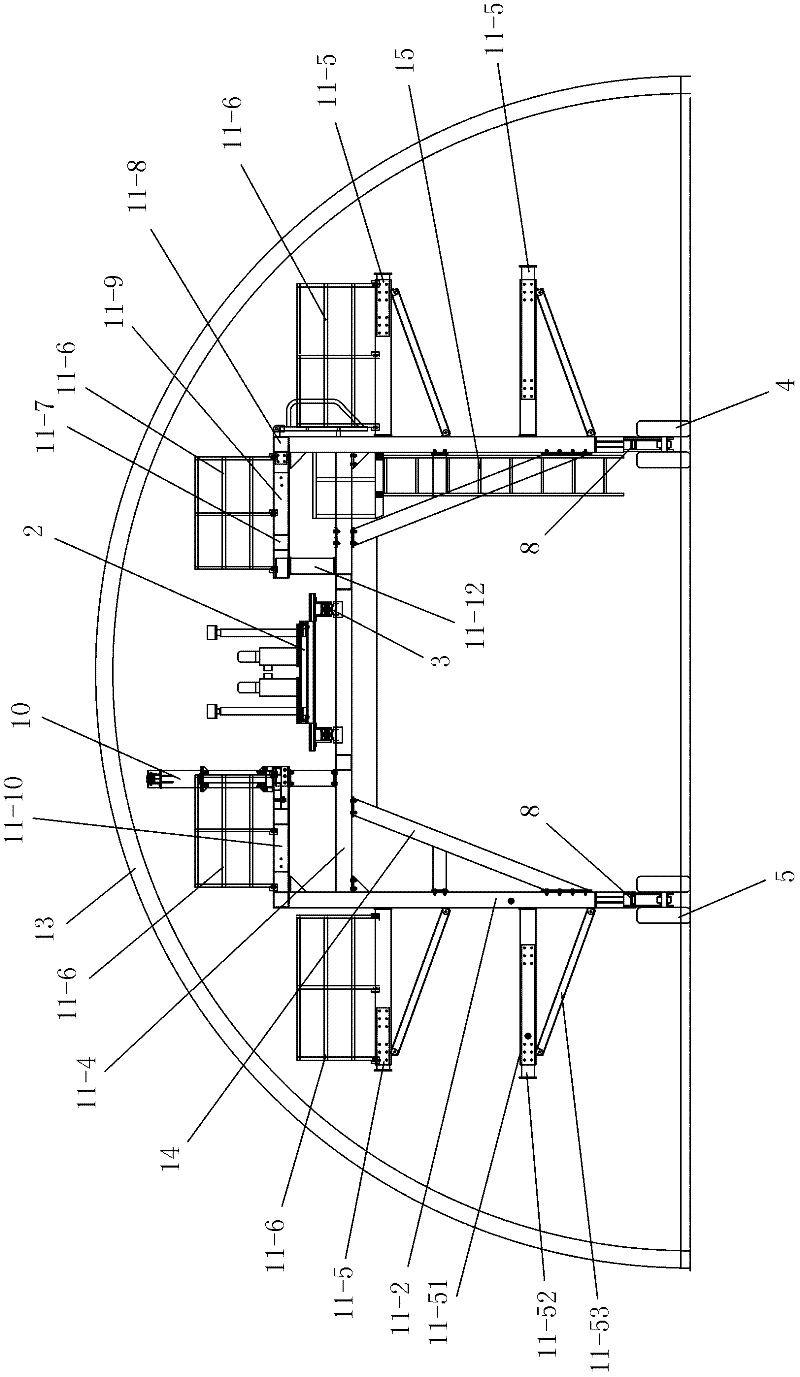

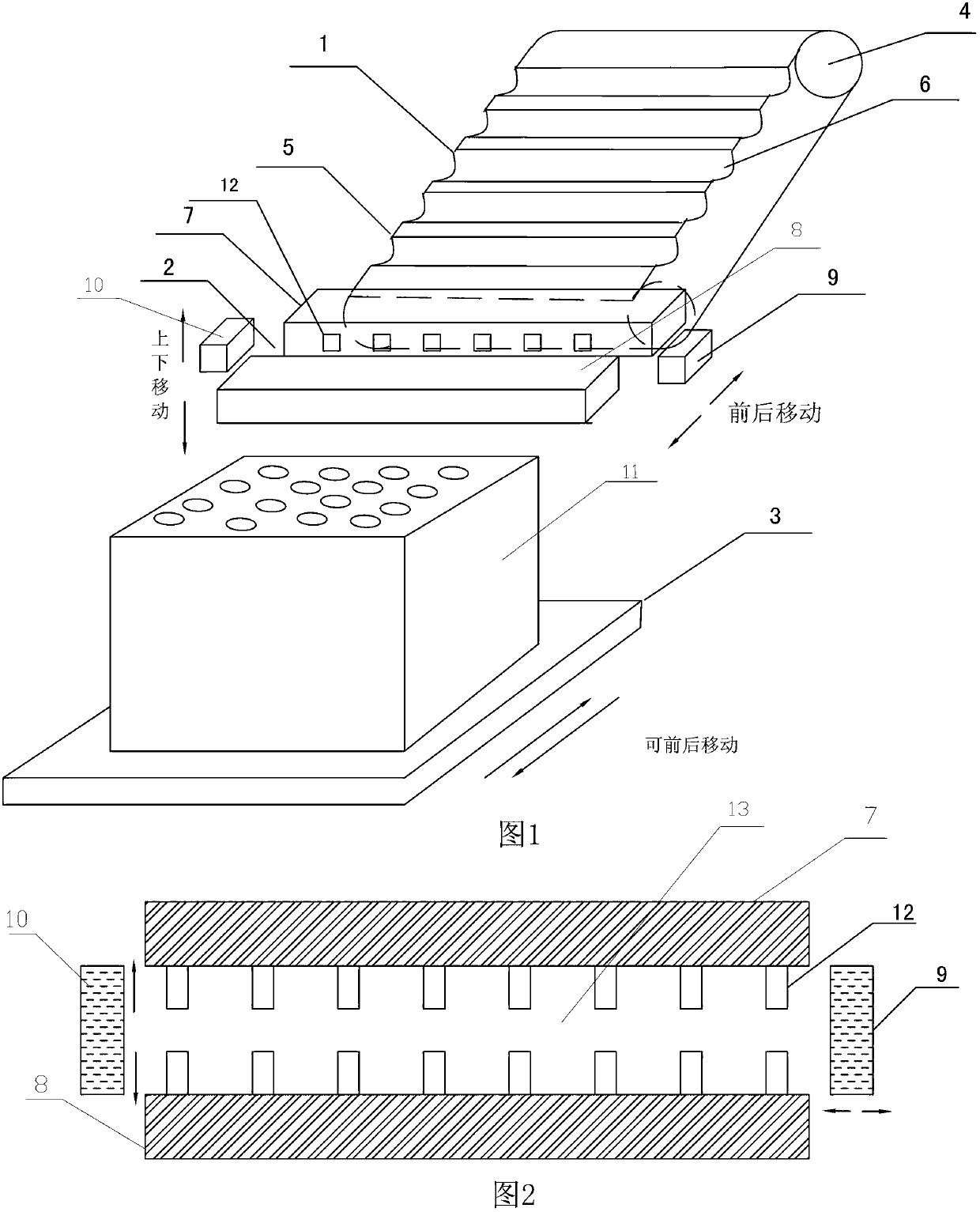

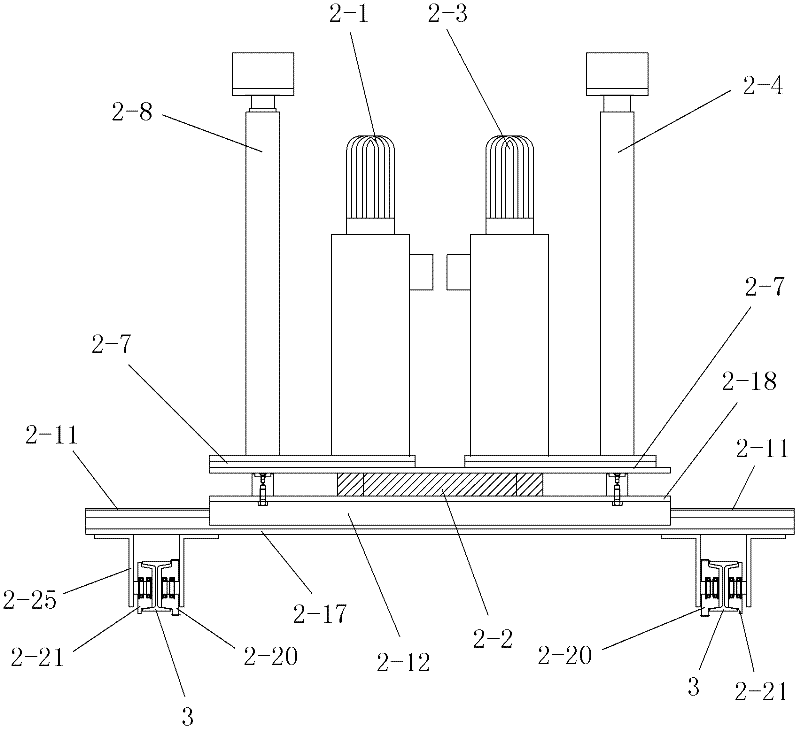

Tunnel arch installation vehicle

ActiveCN102287209ASimple structureReasonable designUnderground chambersTunnel liningWork performanceEngineering

The invention discloses a tunnel arch center installation operation vehicle. The tunnel arch center installation operation vehicle comprises a machine frame, a travelling mechanism, a traction mechanism, an arch center lifting device for lifting tunnel arch centers which are arranged on the rear part of the machine frame and are needed to be installed one by one, and an arch center transferring mechanism for transferring the arch centers which are lifted by the arch center lifting device one by one through alignment and adjustment; the arch center transferring mechanism comprises a translating trolley which can move forward and backward on the upper part of the machine frame, a lifting mechanism for stably lifting the tunnel arch centers, and a left and right movement mechanism for driving the lifting mechanism to synchronously move left and right; and the translating trolley, the left and right movement mechanism, and the lifting mechanism align and adjust the tunnel arch centers front and back, right and left and up and down respectively. The tunnel arch center installation operation vehicle has a reasonable design, is convenient to assemble, and easy and convenient to operate, safe and reliable in working performance, and good in a using effect, and can solve the problems of large working difficulty in movement and accurate positioning of steel arch centers after lifting during the installation of the conventional steel arch centers, low installation efficiency, large labor intensity and the like.

Owner:CHINA RAILWAY FIRST GRP CO LTD

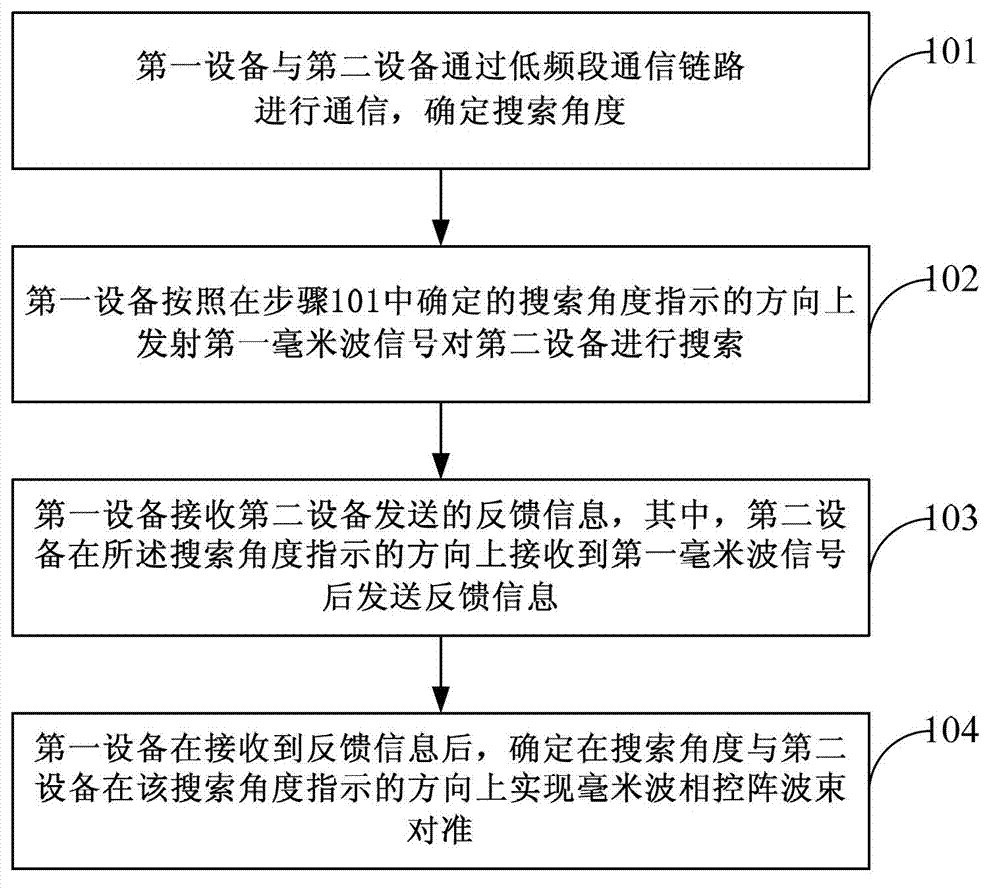

Millimeter wave phased-array wave beam aligning method and communication equipment

ActiveCN103052086AImprove alignment efficiencyReduced settling timeAntenna arraysRadio transmissionBeam searchBeam scanning

The embodiment of invention discloses a millimeter wave phased-array wave beam aligning method and communication equipment. The millimeter wave phased-array wave beam aligning method comprises the following steps that: first equipment and second equipment communicate through a low-frequency stage communication link to determine a search angle; the first equipment transmits a first millimeter wave signal in the indicated direction of the search angle to search the second equipment; the first millimeter wave signal is taken as a high-frequency millimeter wave signal; the first equipment receives the feedback information transmitted by the second equipment, and the second equipment transmits the feedback information after receiving the first millimeter wave signal in the indicated direction of the search angle; and the first equipment determines to realize millimeter wave phased-array wave beam alignment in the indicated direction of the search angle with the second equipment after receiving the feedback information. The millimeter wave phased-array wave beam aligning method disclosed by the embodiment of the invention reduces the blindness of wave beam search, greatly decreases the wave beam scanning times and improves the phased-array wave beam aligning efficiency.

Owner:HUAWEI TECH CO LTD

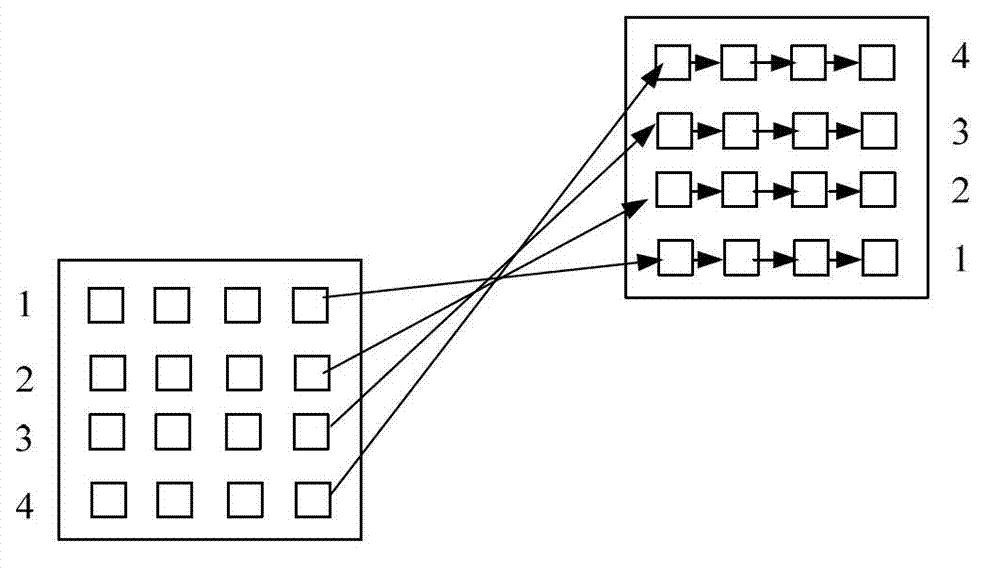

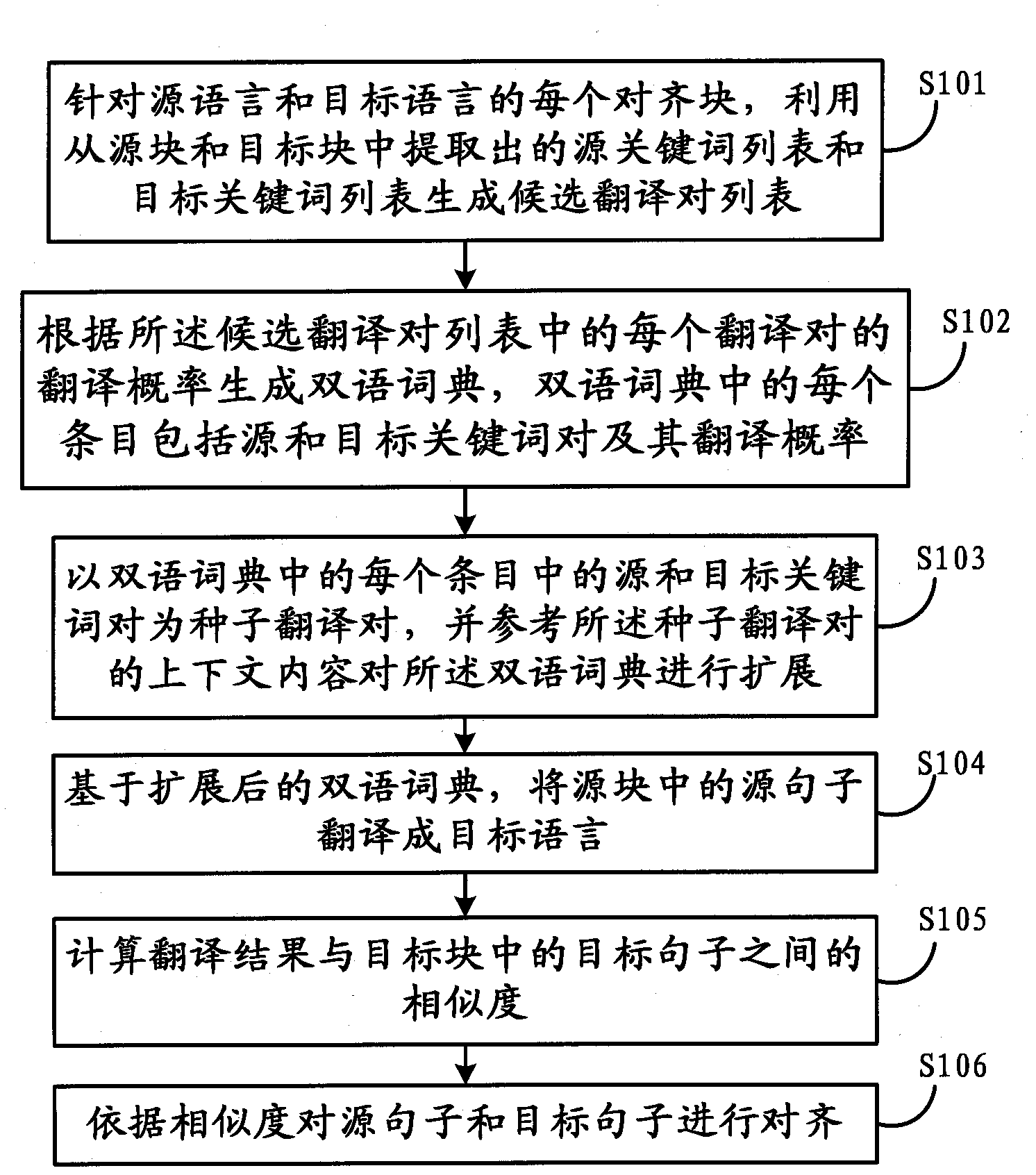

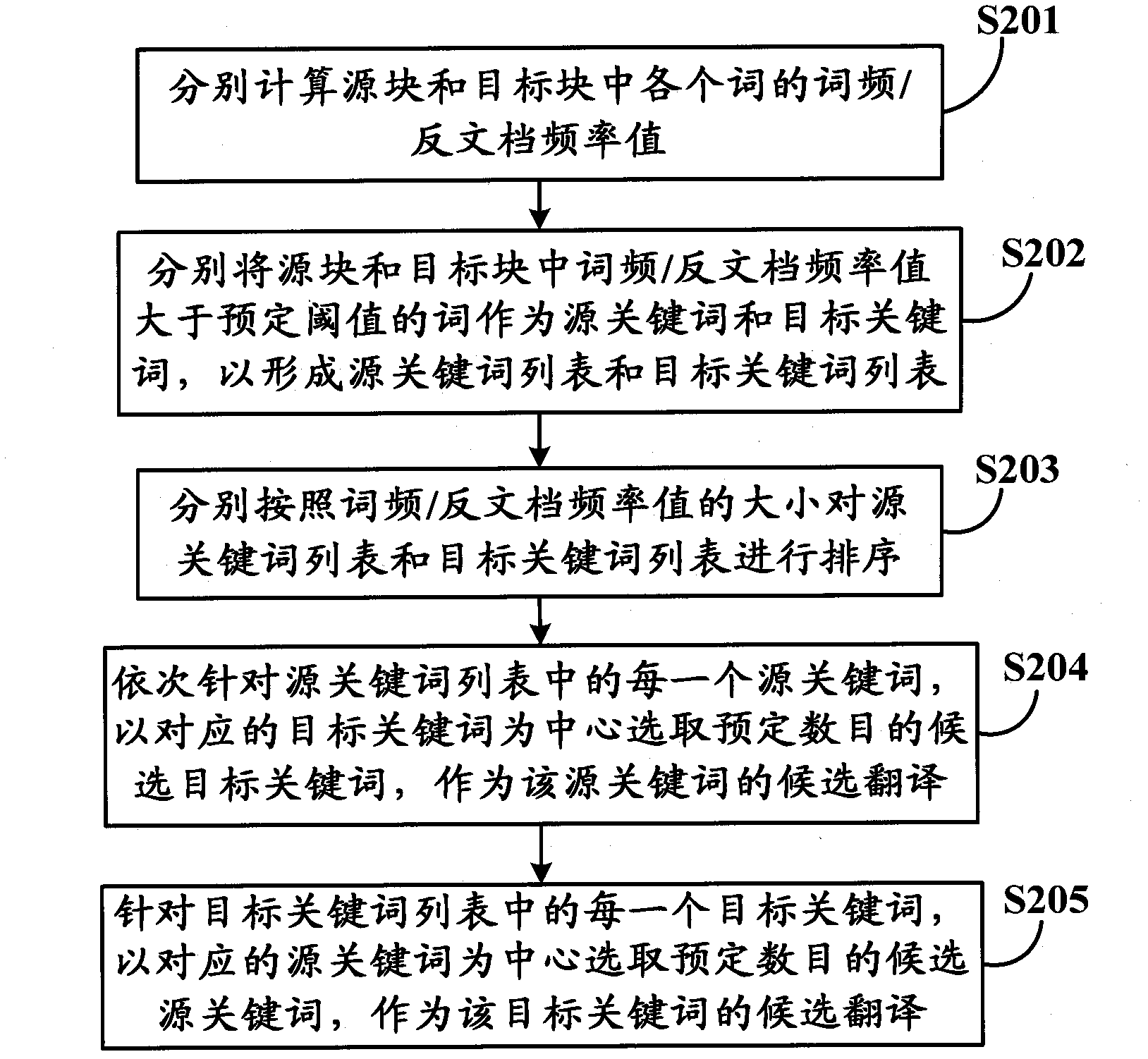

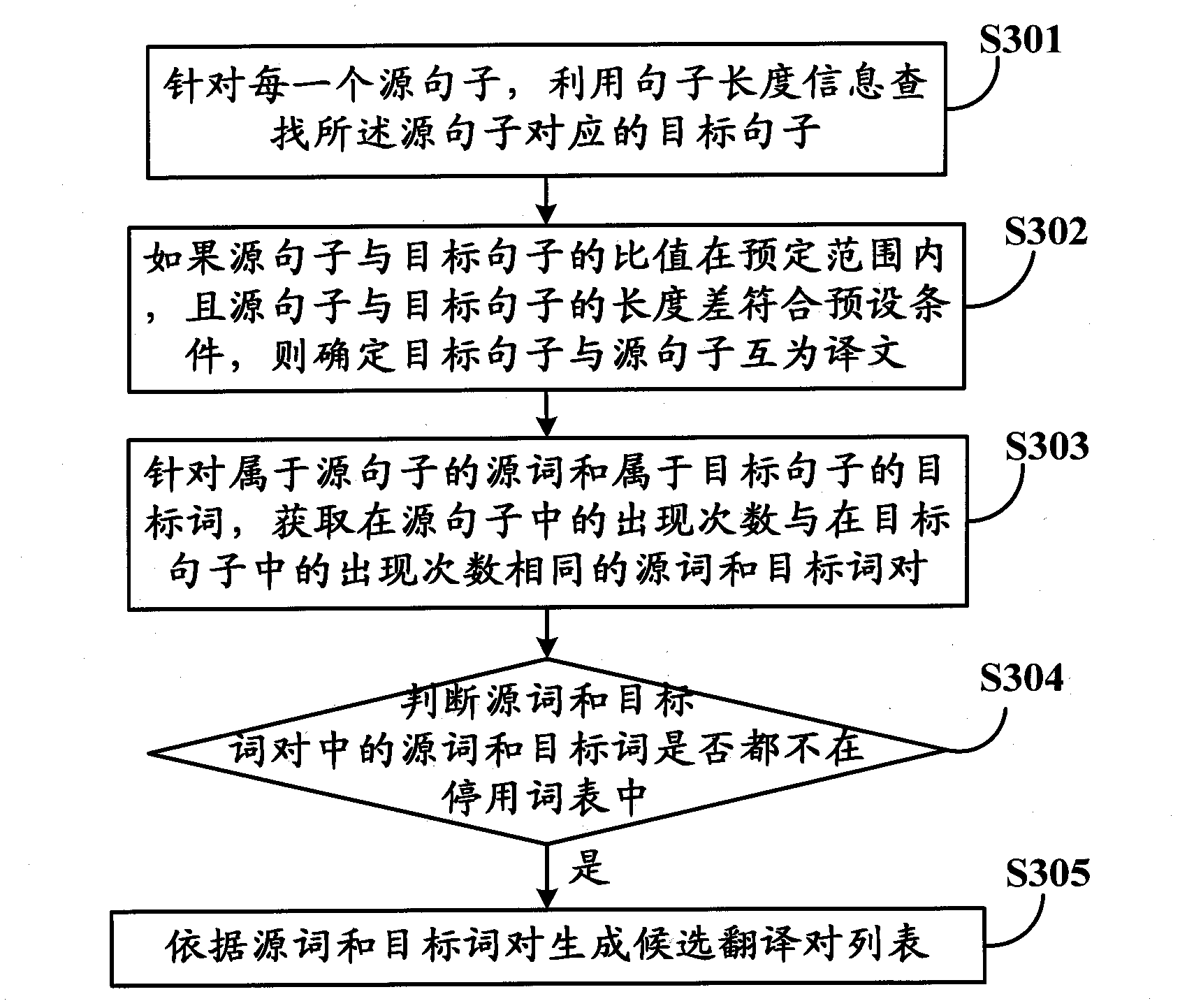

Method and device for aligning sentences in bilingual corpus

InactiveCN102855263ASimplify the alignment processQuick fixSpecial data processing applicationsBilingual dictionaryHuman language

The embodiment of the invention discloses a method and a device for aligning sentences in a bilingual corpus. A source language corpus and a target language corpus in the bilingual corpus are in block alignment. The method comprises the following steps of: aiming at each alignment block in a source language and a target language, generating a candidate translation pair list according to a source keyword list and a target keyword list which are extracted from a source block and a target block respectively; generating a bilingual dictionary according to the translation probability of each translation pair in the candidate translation pair list; expanding the bilingual dictionary by taking a source-target keyword pair in each item in the bilingual dictionary as a seed translation pair in reference to contents of a text of the seed translation pair; translating a source sentence in the source block into a target language, and calculating the similarity between a translation result and a target sentence in the target block; and aligning the source sentence to the target sentence according to the similarity. By the embodiment of the invention, the flow of aligning the sentences can be simplified and the sentence alignment efficiency is improved.

Owner:FUJITSU LTD

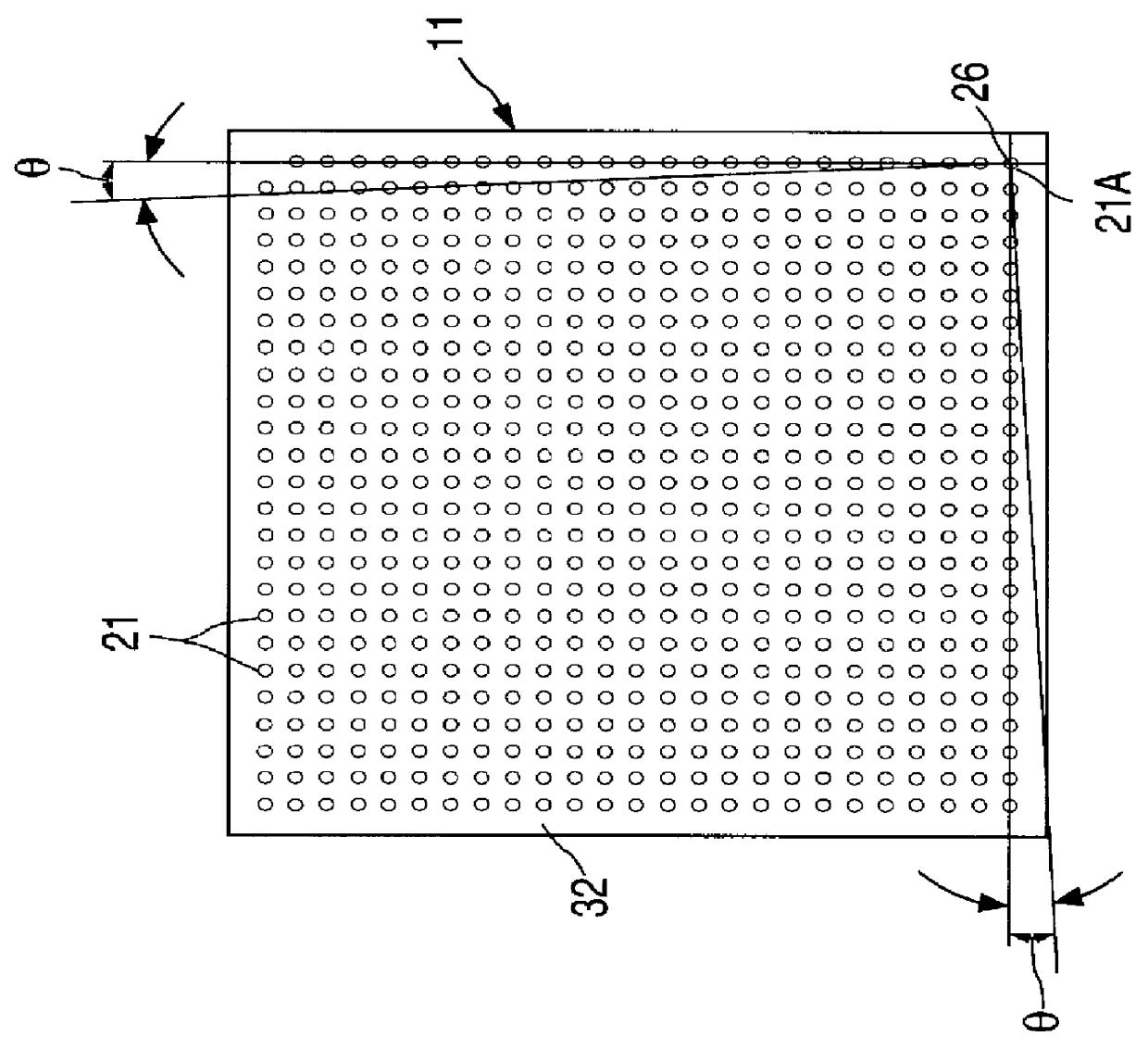

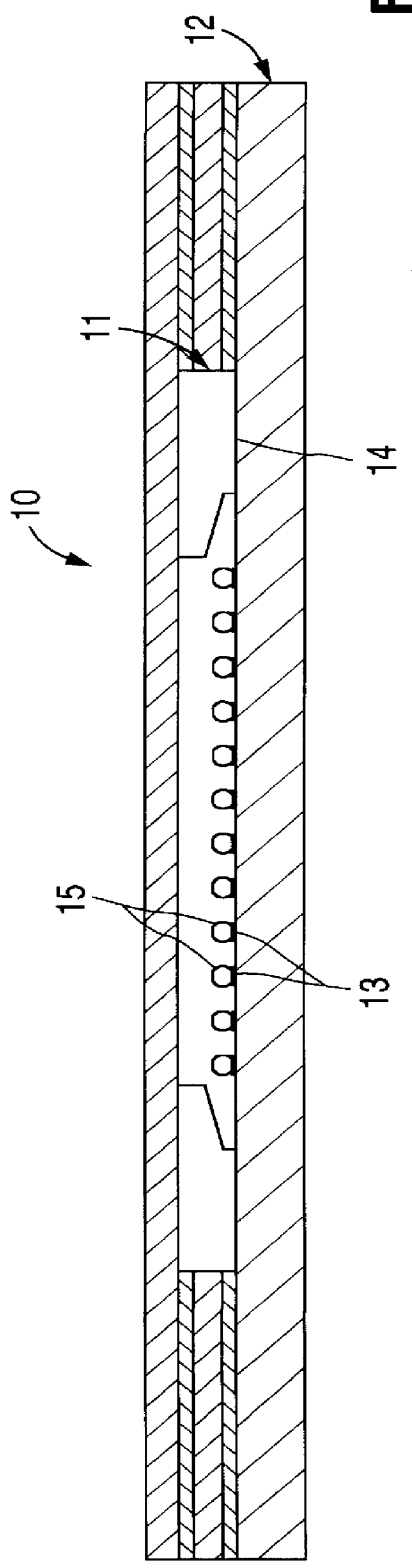

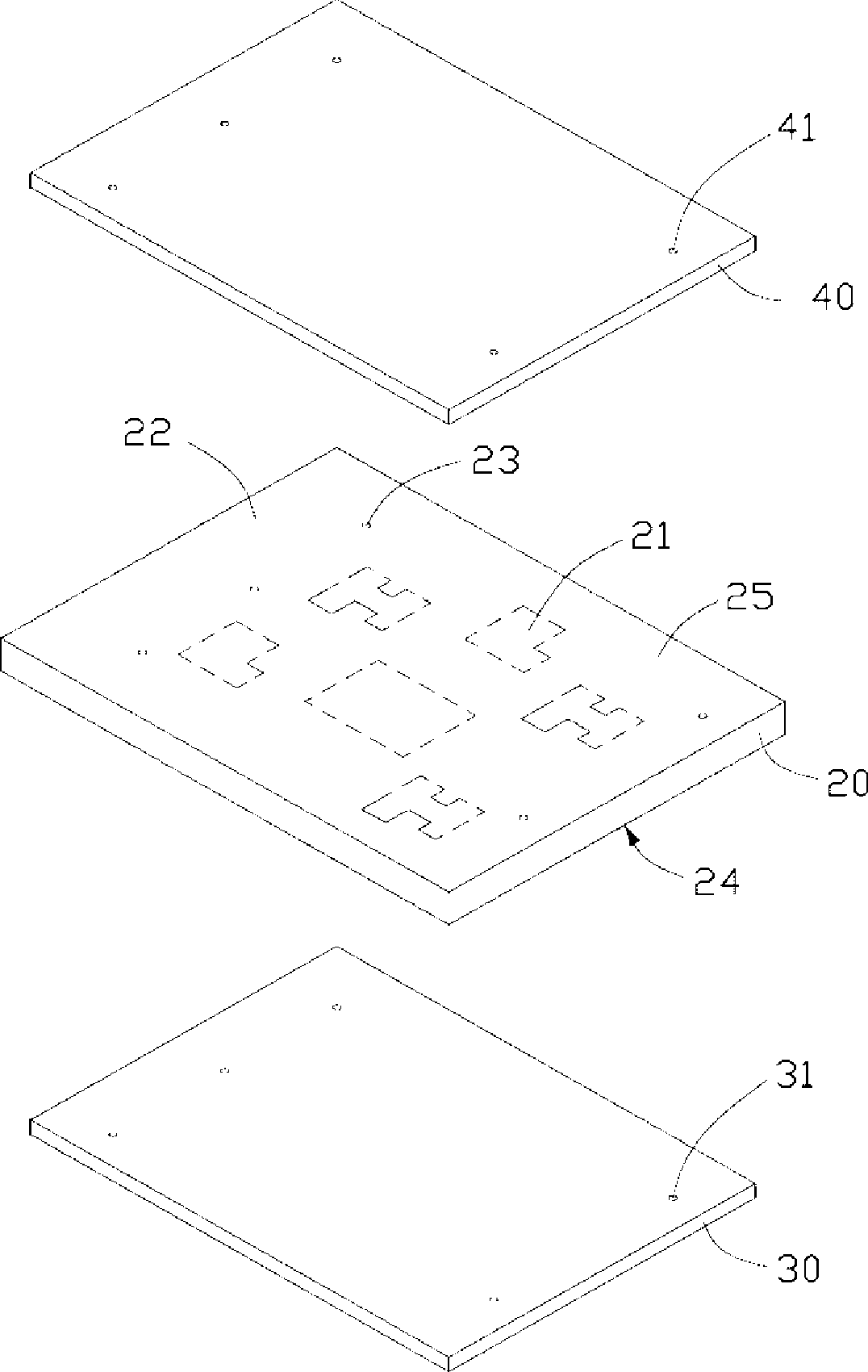

Magnetic alignment apparatus and method for self-alignment between a die and a substrate

InactiveUS6049974AReduce harmImprove alignment efficiencyPrinted circuit assemblingSolid-state devicesSemiconductorSelf alignment

A magnetic alignment apparatus (20) is provided for aligning a semiconductor die (11) and a packaging substrate (12) to enable aligned mounting therebetween. The alignment apparatus (20) includes a first magnetic device (23) coupled to the die (11) and adapted to generate a first magnetic field (25) oriented relative to a first reference point (26) of the die (11). A second magnetic device (27) is coupled to the substrate (12) and adapted to generate a second magnetic field (28) oriented relative to a second reference point (30) of the substrate (12). The first magnetic field (25) and the second magnetic field (28) cooperate to directionally align the first reference point (26) of the die substantially with the second reference point (30) of the substrate (12).

Owner:NAT SEMICON CORP

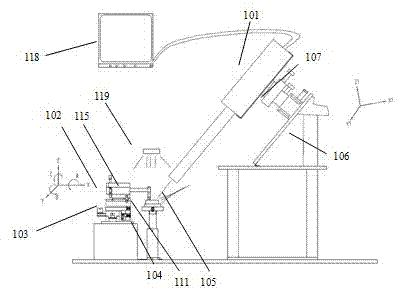

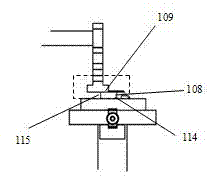

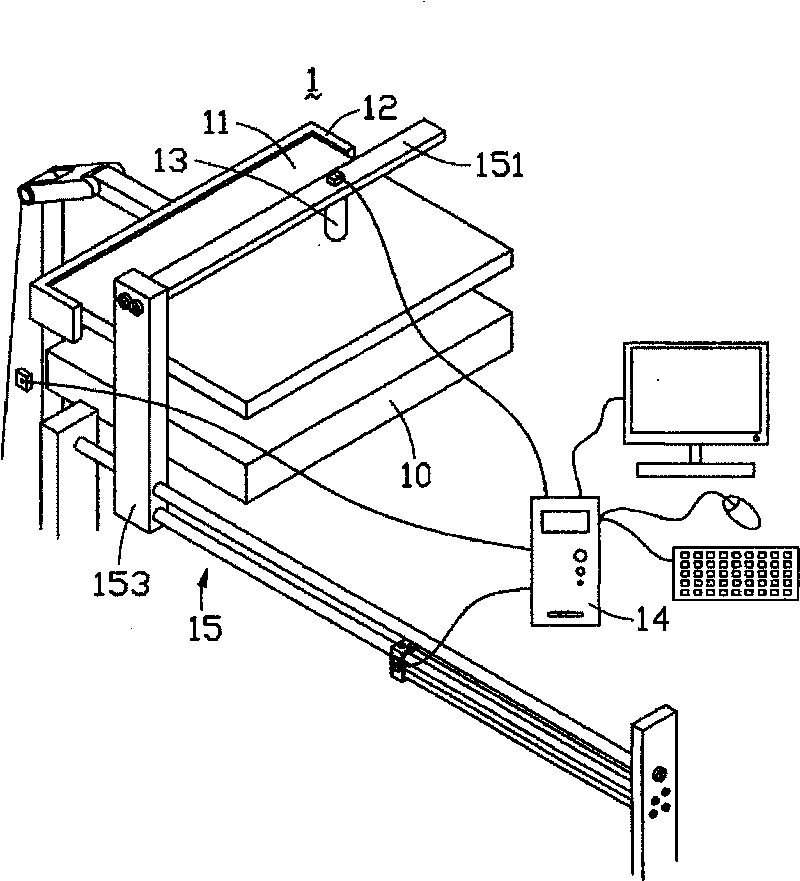

Coupling aligning device for waveguide chip and photo-diode (PD) array and aligning method applying coupling aligning device

InactiveCN102866471ACoupling and alignment are simpleEasy to operateCoupling light guidesAutomatic controlLight spot

The invention provides a coupling aligning method for a waveguide chip and a photo-diode (PD) array. An infrared light source is adopted for lighting, so that the PD array is clearly imaged in a monitoring instrument through an infrared charge coupled device (CCD); a fine adjustment frame is adjusted to control the heights and the horizontal positions of the waveguide chip and the PD array, so that a light spot reflected by the waveguide chip perpendicularly drops on a PD photosensitive surface, and further high-efficiency coupling is achieved, or a driving module is connected with a computer to automatically adjust a six-dimensional fine adjustment frame; the computer acquires infrared CCD image information through a data acquisition card; automatic control software processes an image to obtain a light spot array reflected by the waveguide chip and a slope and a position difference of a PD photosensitive surface array; the automatic control software controls an axial direction adjusted to the six-dimensional fine adjustment frame, so that the light spot array is superposed with the PD photosensitive surface array. The invention also provides a coupling aligning device for the waveguide chip and the PD array. By the method and the device, the alignment time of the waveguide chip and the PD array can be shortened, and the alignment efficiency and the repetitiveness are improved, so that the consistency of a product is guaranteed.

Owner:GUANGXUN SCI & TECH WUHAN

Alignment device, grating alignment system adopting same and alignment method thereof

ActiveCN101710202AImprove alignment accuracyImprove alignment efficiencyMountingsGratingDisplay device

The invention provides an alignment device for realizing exact alignment of a display device and a grating. The alignment device comprises a mechanical arm, an image detection element and a control module. The display device displays a reference image, and the image detection element detects image information formed by the reference image by transmitting the cylindrical grating and transmits the image information to the control module. The control module judges alignment condition of the cylindrical grating and the display device according to the image information and controls the mechanical arm to carry out alignment adjustment on the cylindrical grating according to the alignment condition. The invention realizes the automatic exact alignment of the grating and the display device and improves the assembly efficiency. Meanwhile, the invention provides a grating alignment system adopting the alignment device and an alignment method thereof.

Owner:SUPERD CO LTD

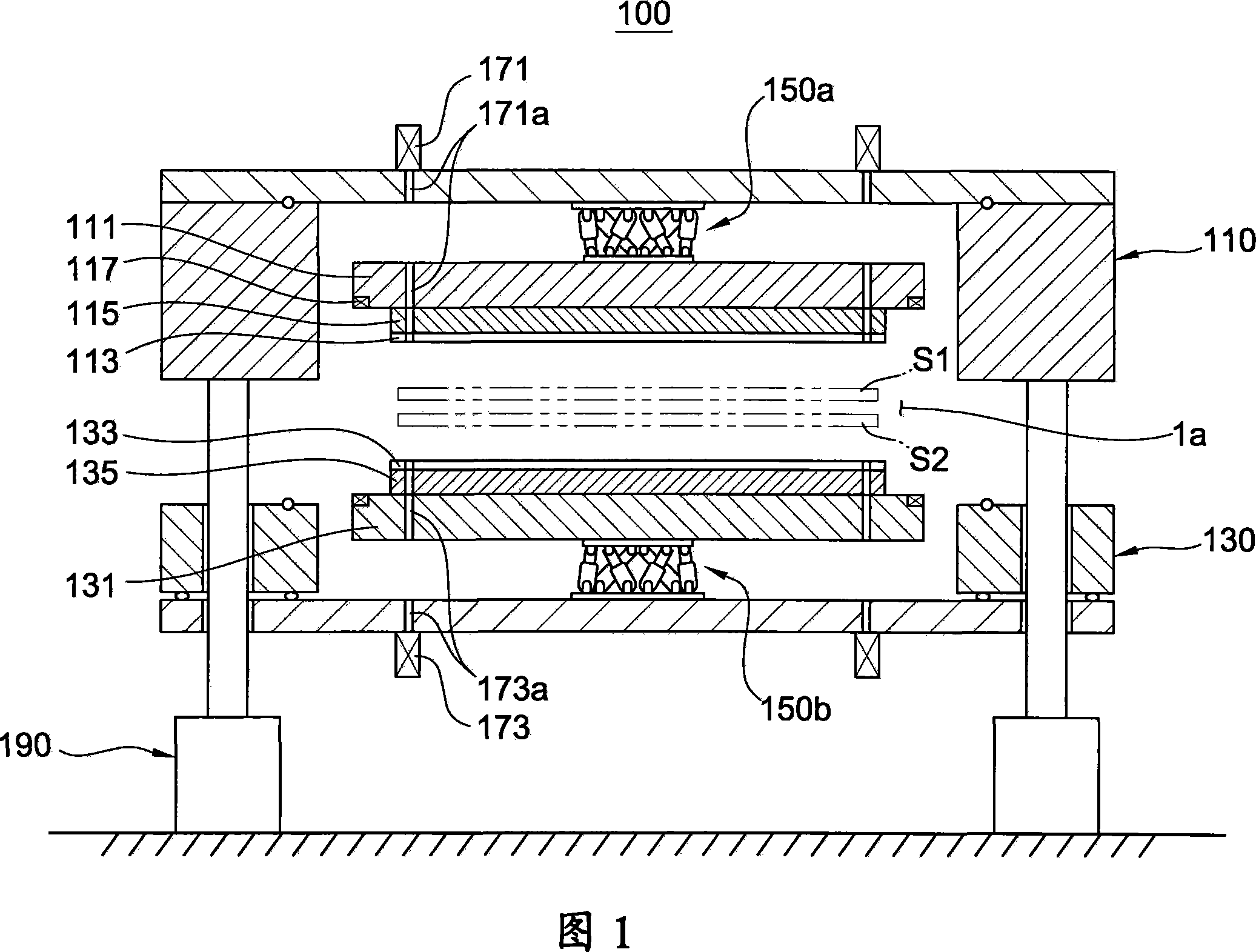

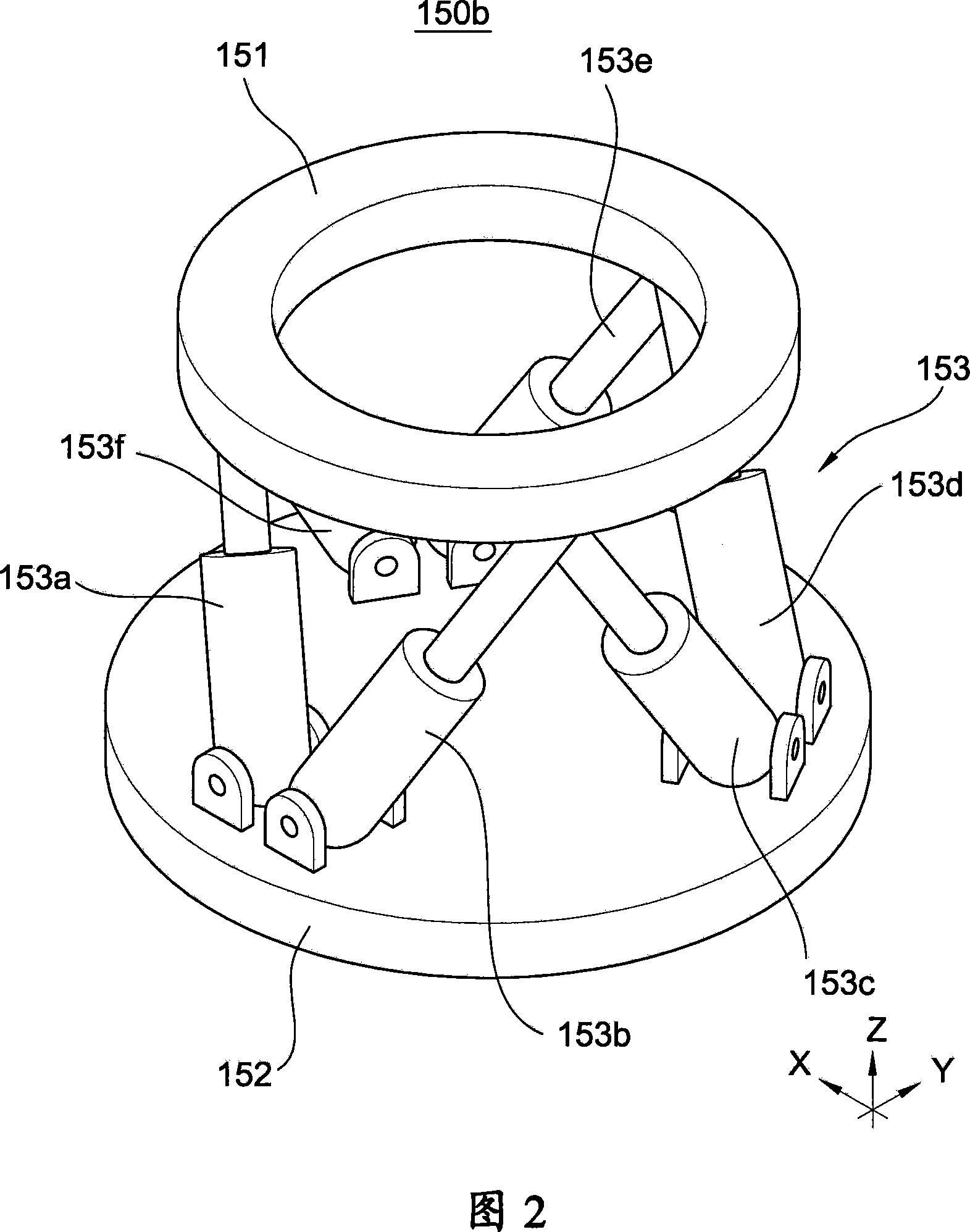

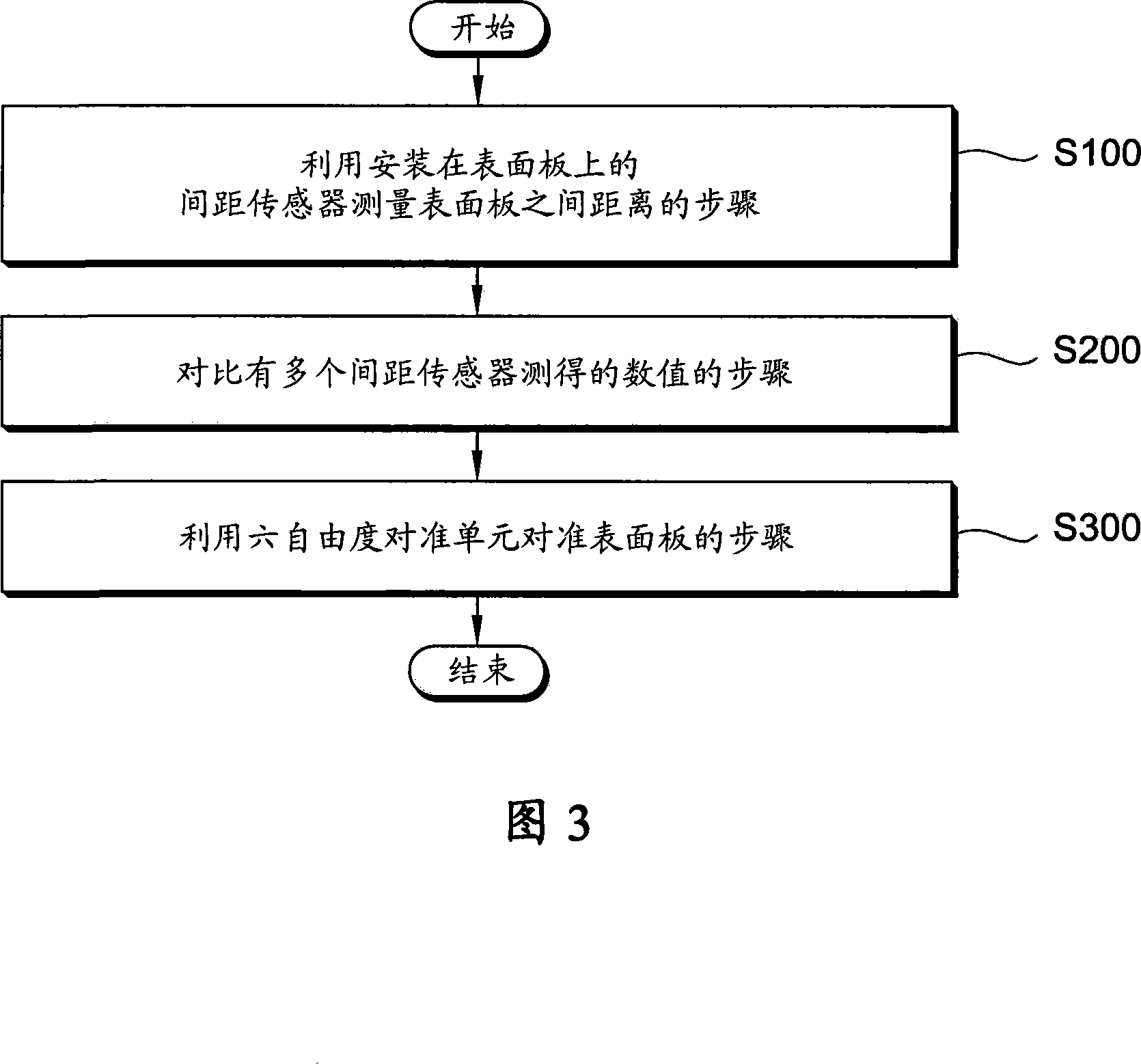

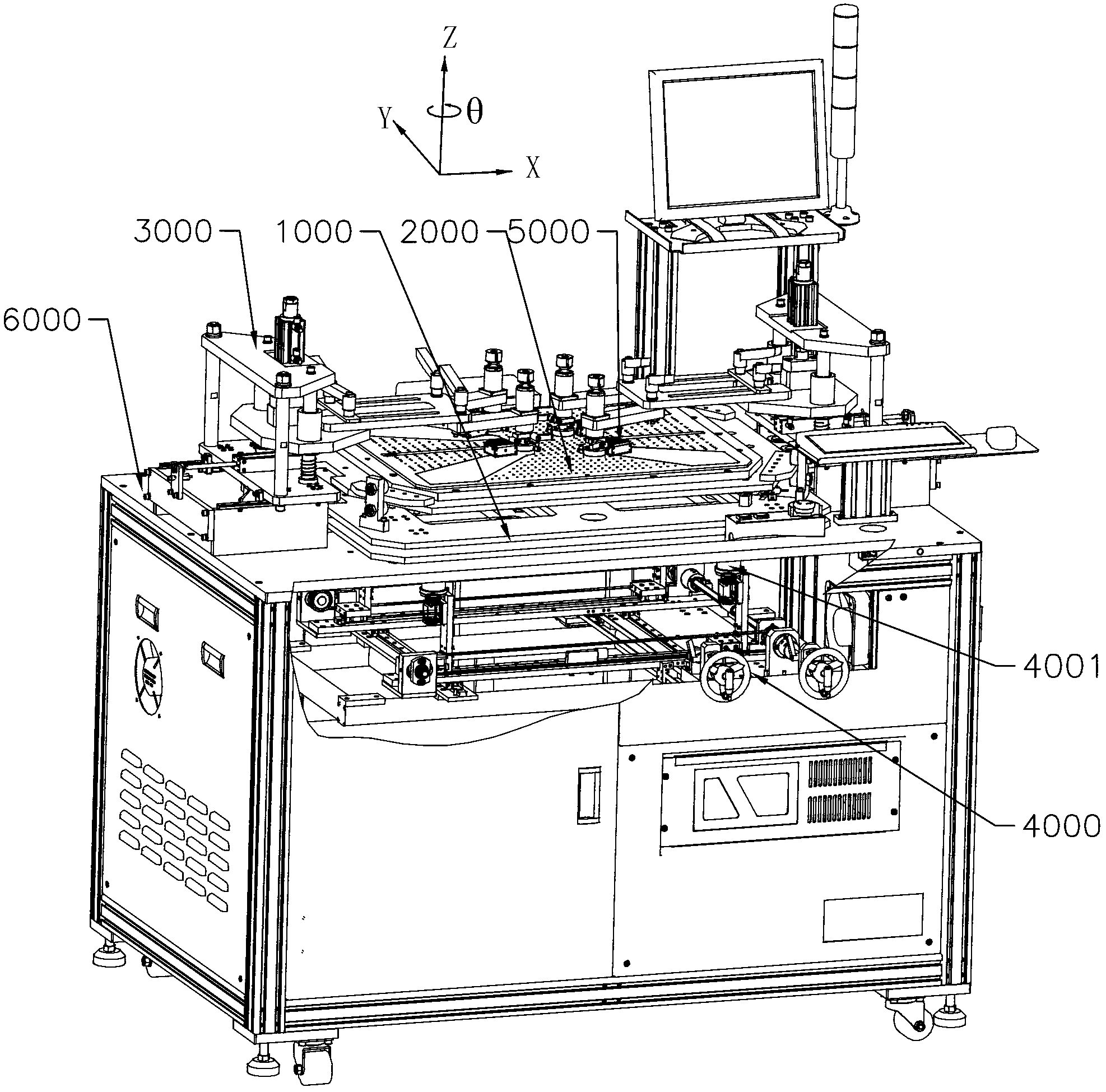

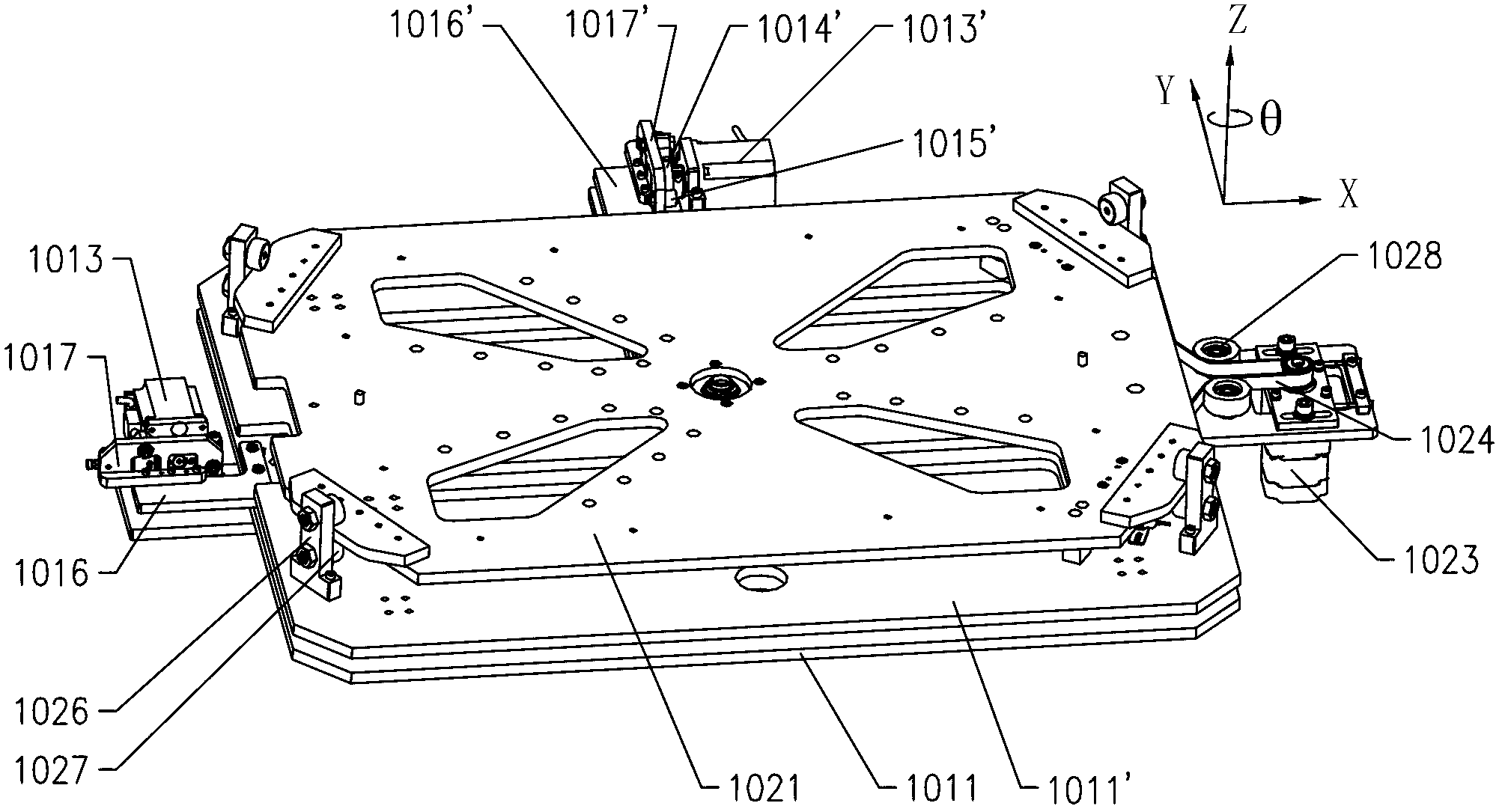

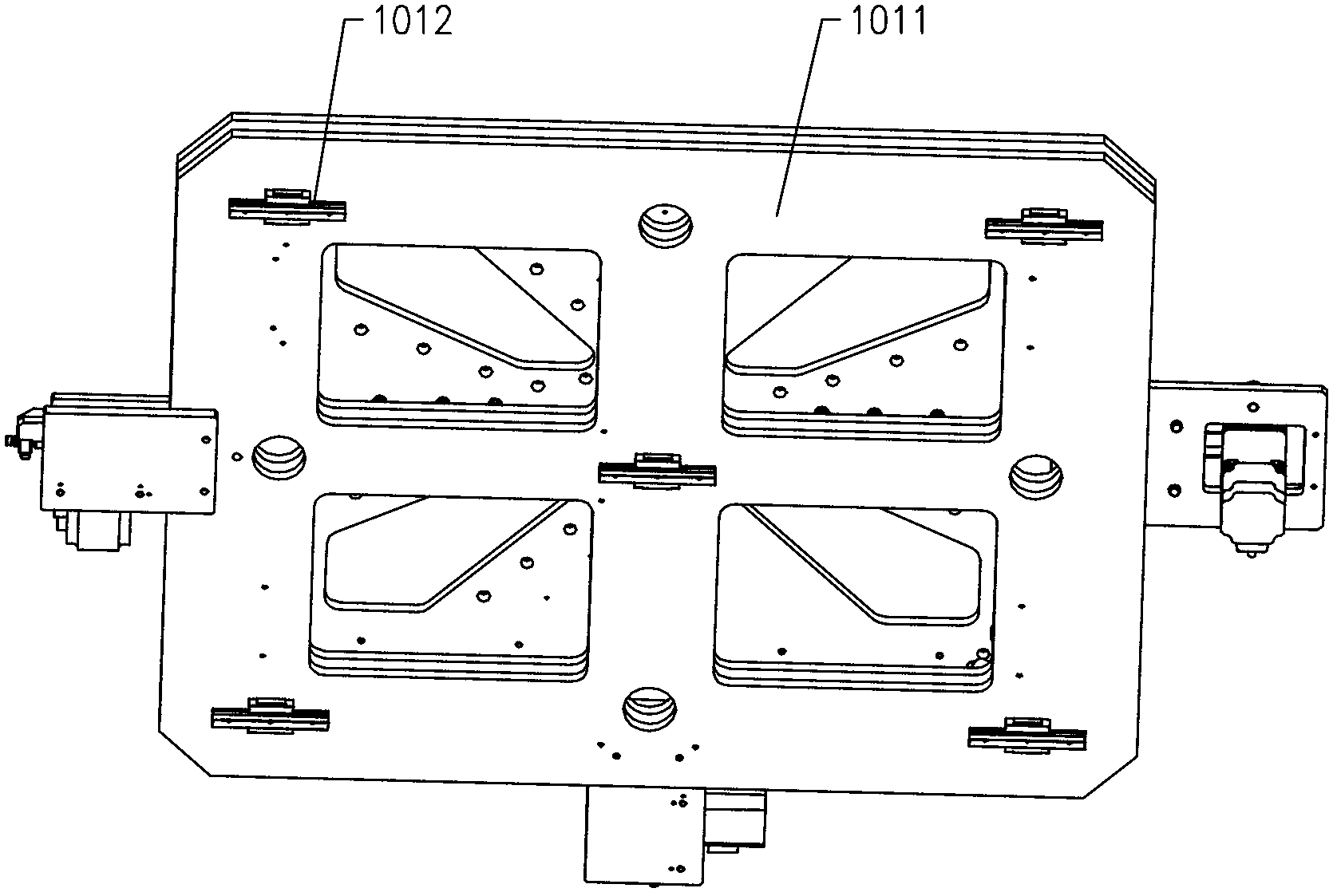

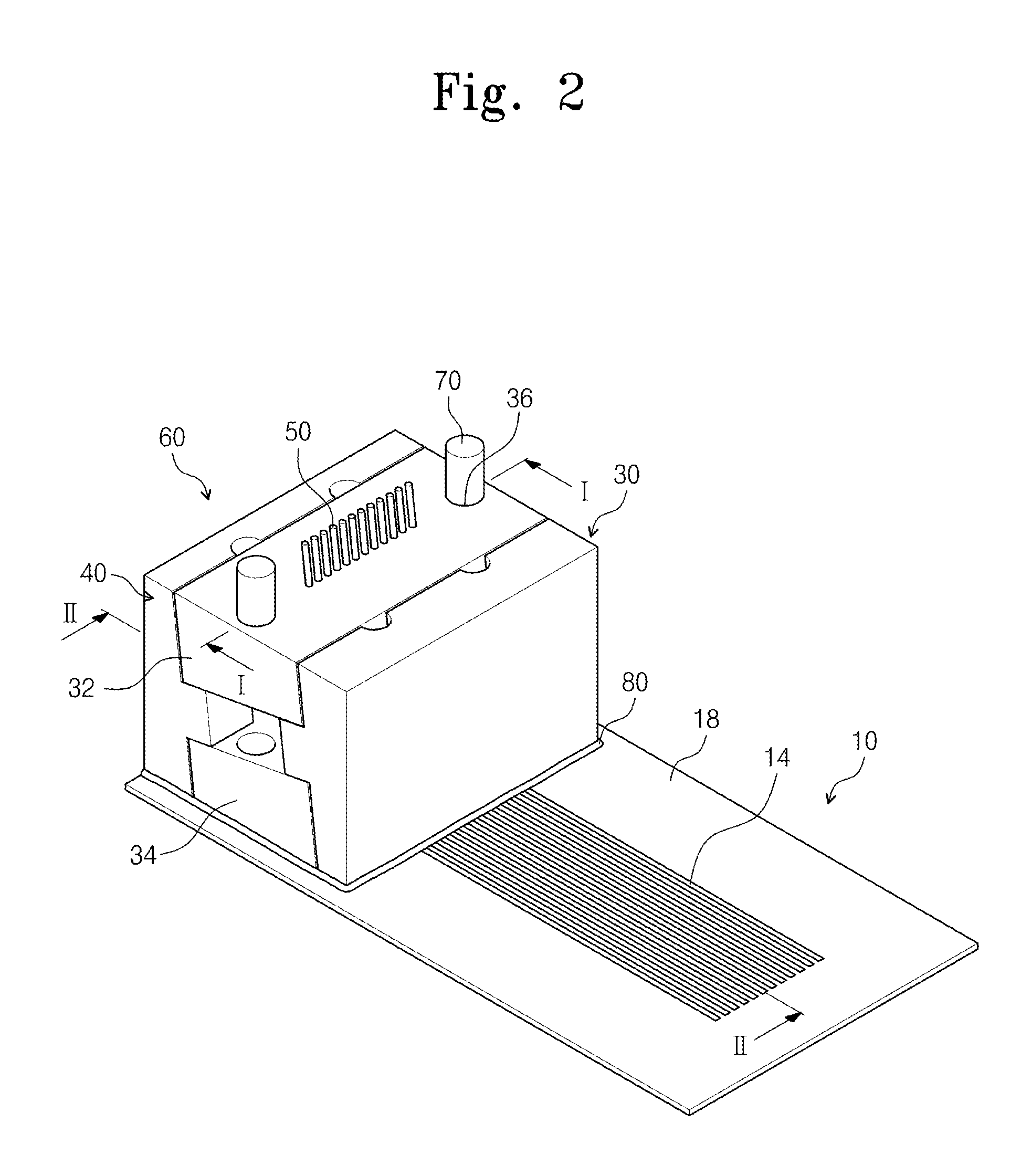

Substrate bonding apparatus having alignment unit and method of aligning substrates using the same

InactiveCN101144926AImprove alignment efficiencyHigh yieldLamination ancillary operationsLaminationEngineeringSix degrees of freedom

A substrate bonding apparatus includes a first chamber having a first surface plate where a first substrate is placed. A second chamber is disposed opposite to the first chamber. The second chamber has a second surface plate where a second substrate is placed. The second substrate is to be bonded to the first substrate. An alignment unit is installed in at least one of the first and second chambers. The alignment unit is capable of carrying out a six-degrees-of-freedom alignment between the first and second substrates. Thus, the substrates can be maintained parallel to each other, a spacing between the substrates can be automatically adjusted, and the substrates can be aligned in the X and Y axis directions.

Owner:ADVANCED DISPLAY PROCESS ENG CO LTD

PCB and film alignment device

ActiveCN103235492AAverage errorNo warpingPhotomechanical treatmentPrinted circuit manufactureIlluminanceDiagonal

The invention discloses a PCB (printed circuit board) and film alignment device, which comprises a rack and the following parts installed on the rack: an X-Y-theta three-freedom degree adjustment mechanism; a rectangular vacuum adsorption platform fixed on the X-Y-theta three-freedom degree adjustment mechanism and used for PCB adsorption, with light transmitting parts disposed at four corners of the vacuum adsorption platform and extending along diagonal lines; two two-point compression mechanisms arranged over the vacuum adsorption platform relatively; four CCD lens that are mounted below the X-Y-theta three-freedom degree adjustment mechanism, read alignment marks at four corners of the PCB and the film through the light transmitting parts, are in rectangular arrangement and mounted on one spacing adjustment mechanism, and are in connection with a controller, the control end of which is connected to the X-Y-theta three-freedom degree adjustment mechanism; and light sources for providing illuminance conditions for the four CCD lens. The alignment device disclosed in the invention improves the alignment accuracy and alignment efficiency.

Owner:GOERTEK INC

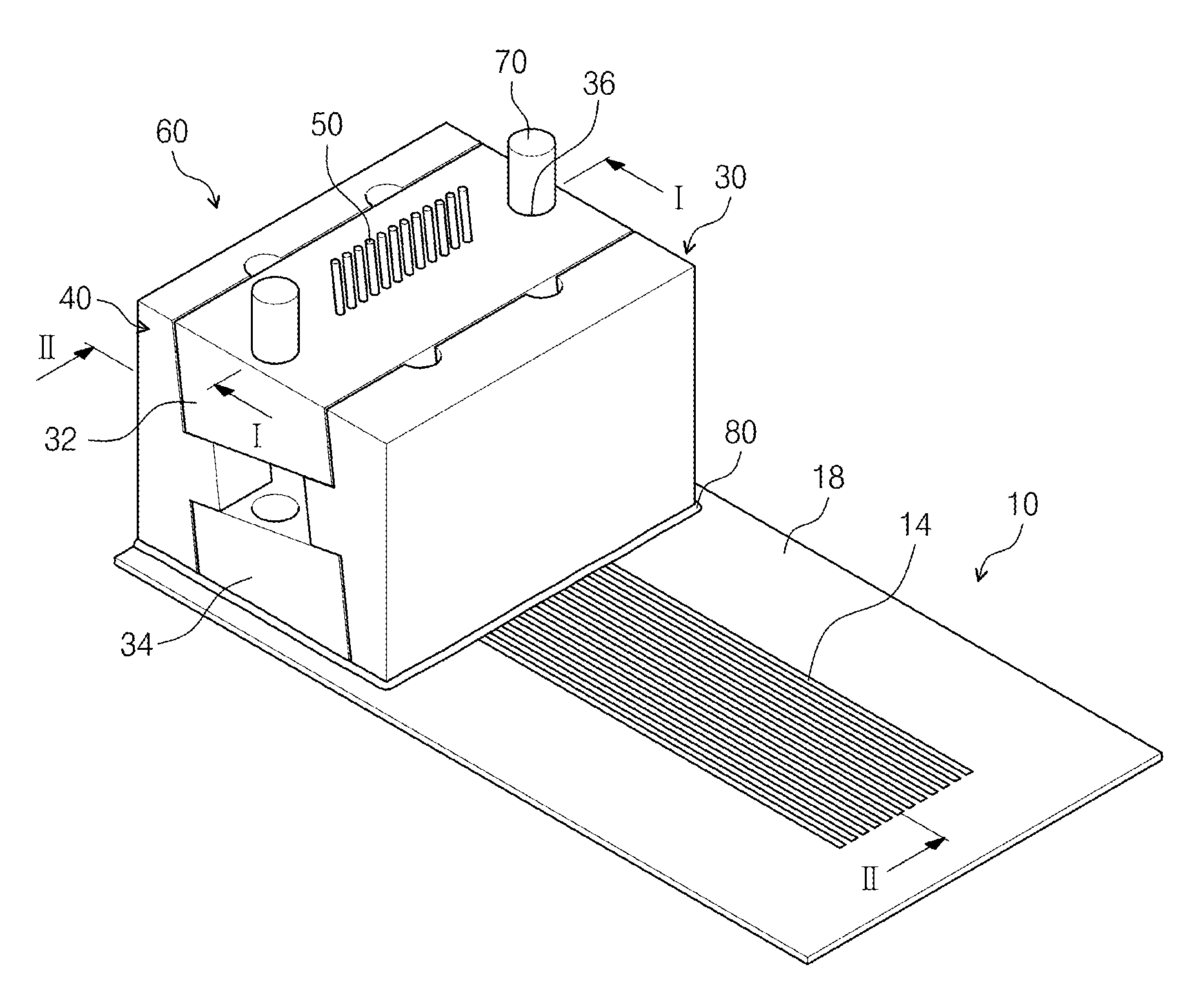

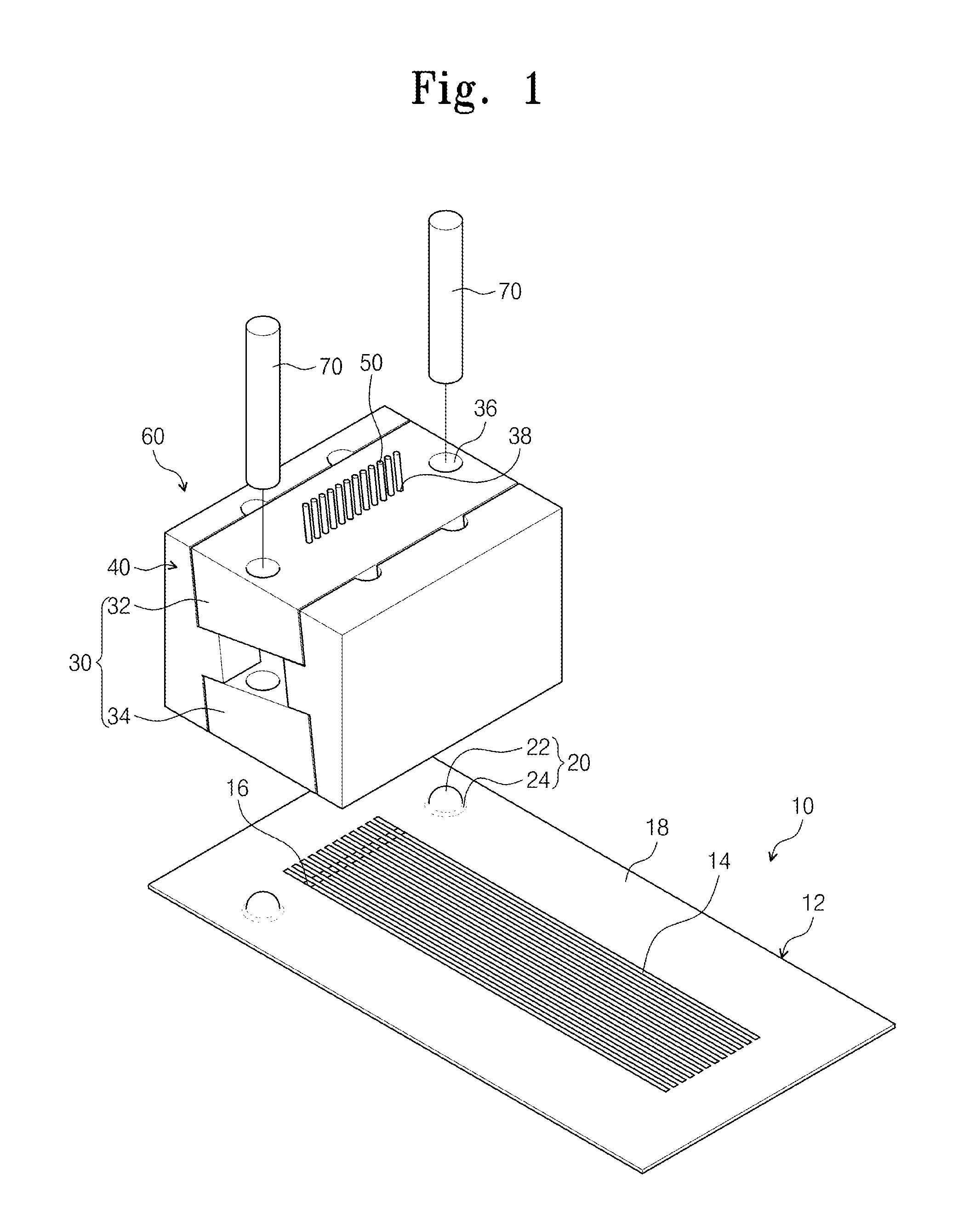

Photonics chip and optical apparatus including the same

InactiveUS20120121218A1Increase optical alignment efficiencyImprove alignment efficiencyOptical waveguide light guidePhotonic ChipOptical coupler

Provided are a photonics chip and an optical apparatus including the same. The chip may include a substrate, an optical waveguide, an optical coupler, and a plurality of alignment units. The optical waveguide is formed on the substrate. The optical coupler is formed at the optical waveguide. The alignment units align an optical connector which fixes at least one optical fiber coupled to the optical coupler, on the substrate.

Owner:ELECTRONICS & TELECOMM RES INST

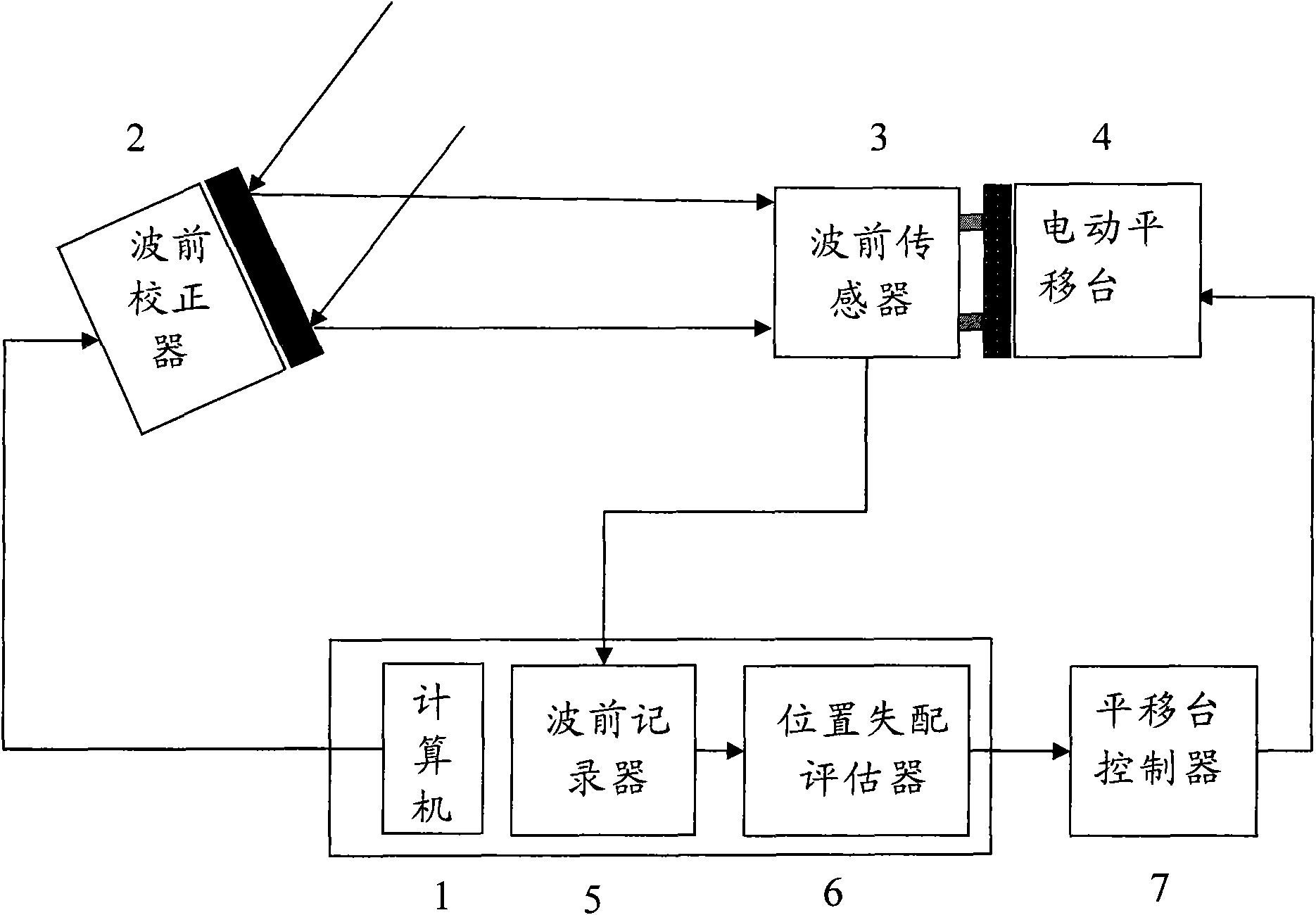

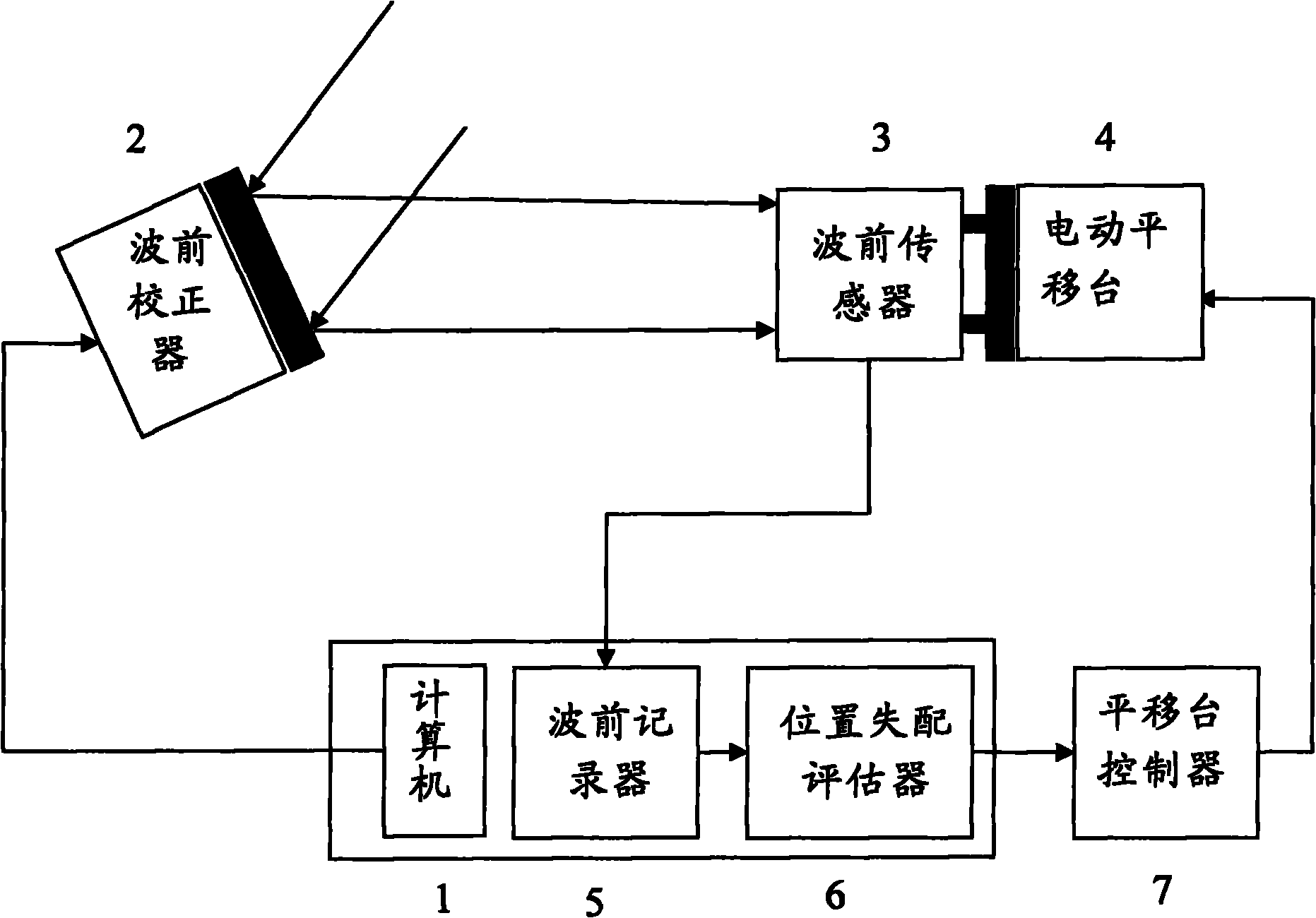

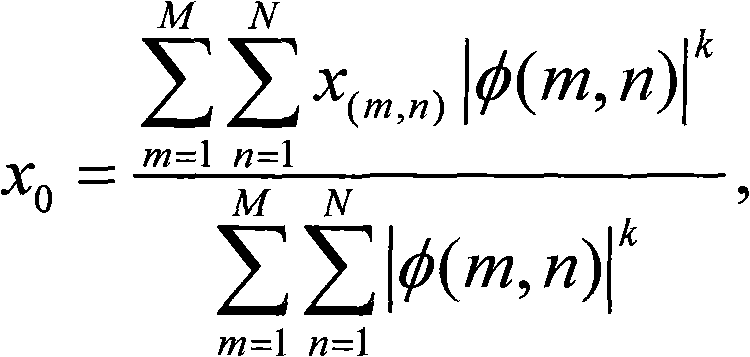

Wave-front sensor and corrector aligning device in self-adaptive optical system

ActiveCN101806957AEasy to integrateObjectiveOptical measurementsOptical elementsWavefront sensorLight beam

The invention provides a wave-front sensor and corrector aligning device in a self-adaptive optical system, which consists of a wave-front sensor, a wave-front recorder, a wave-front corrector, an electric control transverse moving table, a position mismatching evaluating device, a transverse moving table controller and a computer, wherein the electric control transverse moving table can transversely move and rotate, the position of the wave-front corrector is marked in a mode of exerting the voltage to an independent unit of the wave-front corrector through the computer, and the position mismatching between the wave-front sensor and the wave-front corrector is measured through the self wave-front detection capability of the wave-front sensor. Light beams enter the wave-front sensor through being reflected by the wave-front corrector, the face shape information of the wave-front corrector detected by the wave-front sensor is recorded by the wave-front recorder, the position mismatching evaluating device carries out the calculation according to the recorded information of the wave-front recorder and outputs the position mismatching data into the transverse moving table controller, and finally, the transverse moving table controller is used for controlling the electric control transverse moving table for completing the position regulation of the wave-front sensor. The invention can accurately align the positions of the wave-front sensor and the wave-front corrector, can greatly improve the aligning precision and the aligning efficiency of the wave-front sensor and the wave-front corrector, and can ensure the wave-front control capability of the self-adaptive system.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

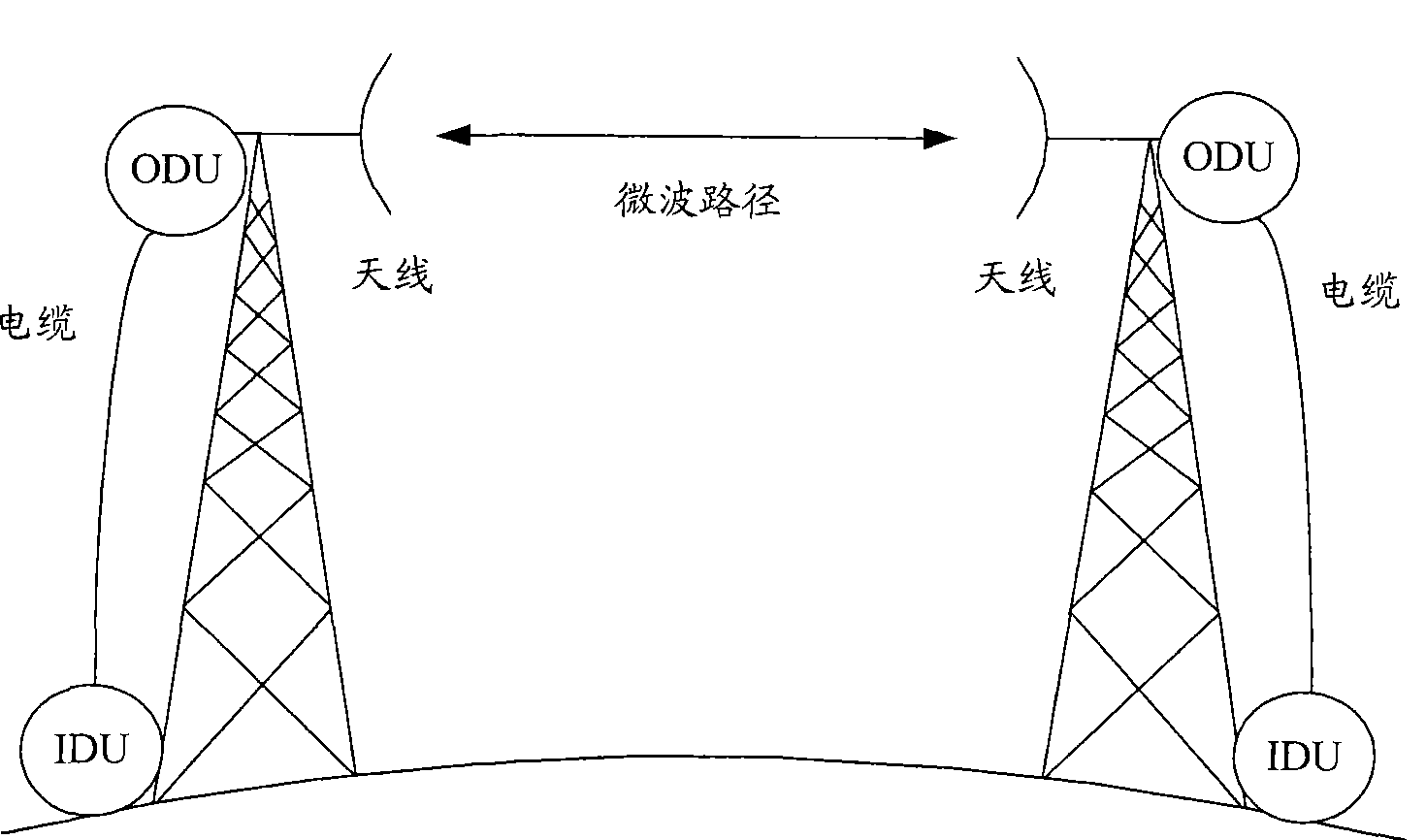

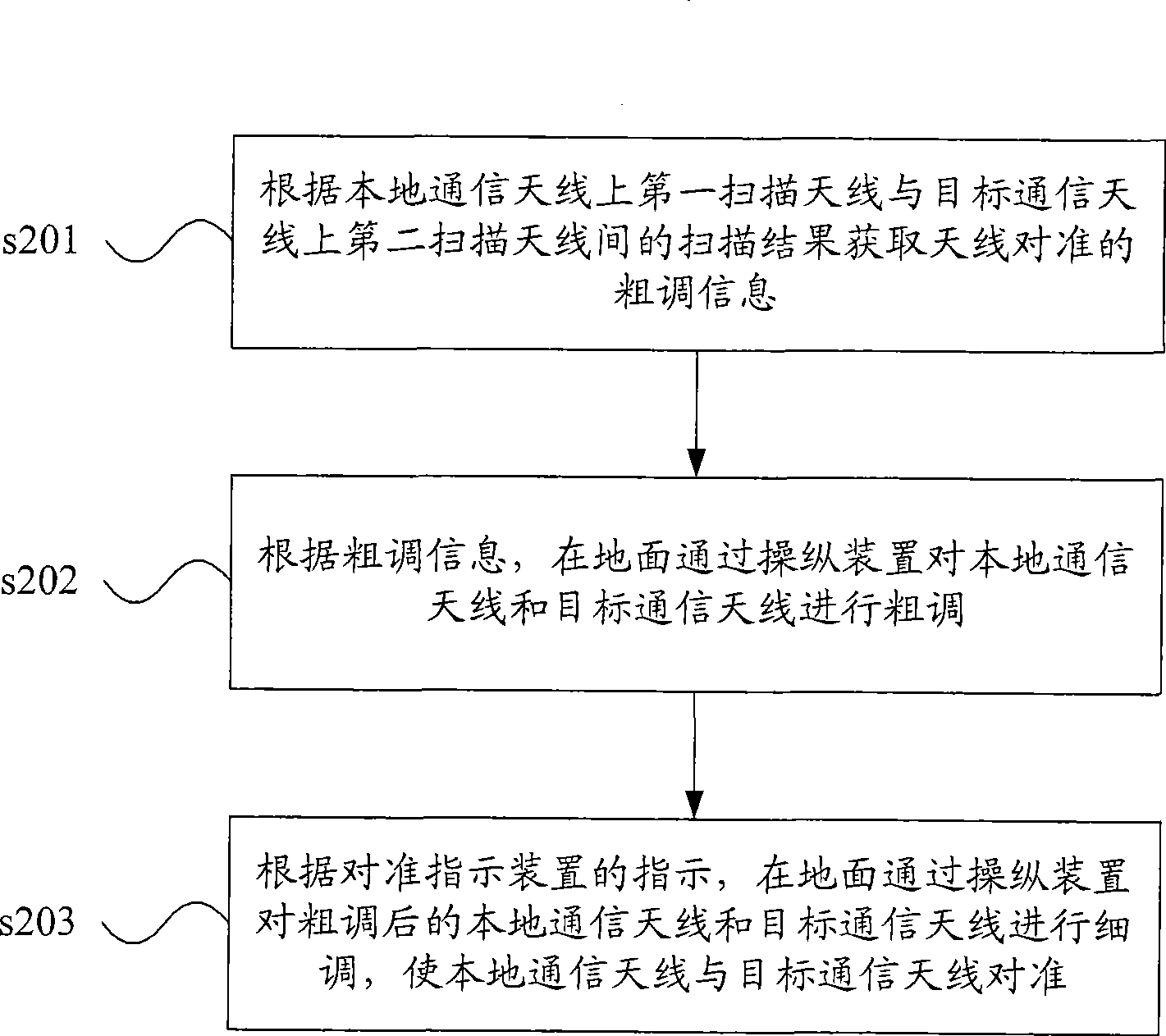

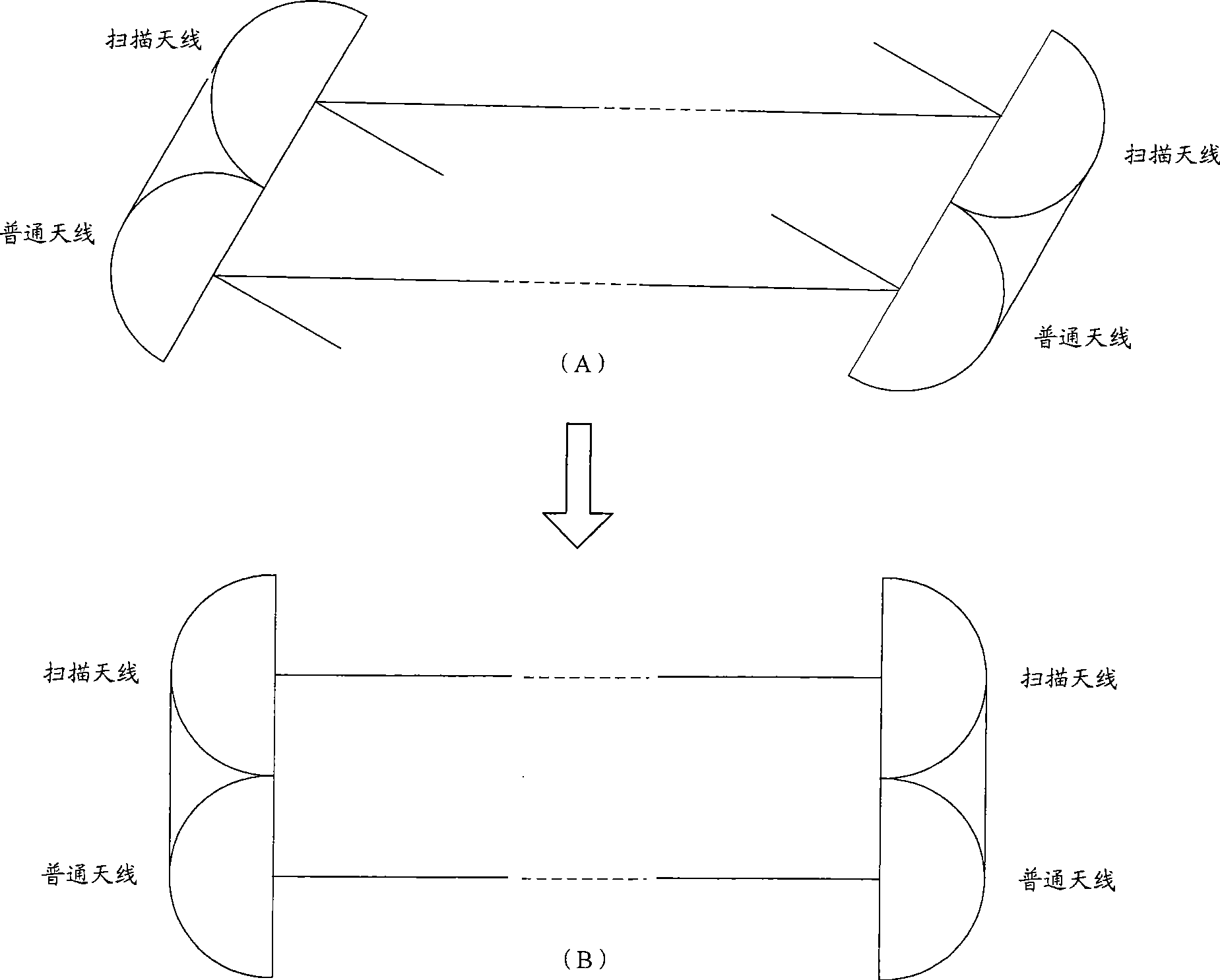

Method, system and device for aligning antenna

InactiveCN101465699AReduce riskImprove alignment efficiencyAntenna supports/mountingsTransmission monitoringTowerElectrical and Electronics engineering

The embodiment of invention discloses an antenna aligning method, a system and a device. The method includes that coarse adjustment information for antenna alignment is obtained according to scanning result between a first scanning antenna of a local communication antenna and a second scanning antenna of a target communication antenna; a control device on ground is adopted to perform coarse adjustment on the local communication antenna and the target communication antenna according to coarse adjustment information; the control device on ground is adopted to perform fine adjustment on the local communication antenna and the target communication antenna after coarse adjustment according to indication from the alignment indicating device, so the local communication antenna is aligned to the target communication antenna. In the embodiment, the control device and the alignment indicating device on ground are adopted to control the antenna direction on the tower top and finish the antenna alignment; the time in high altitude operation is reduced for installation staff, the risk in antenna alignment operation is reduced, and the antenna alignment efficiency is effectively improved; meanwhile, time and labor source are saved.

Owner:HUAWEI TECH CO LTD

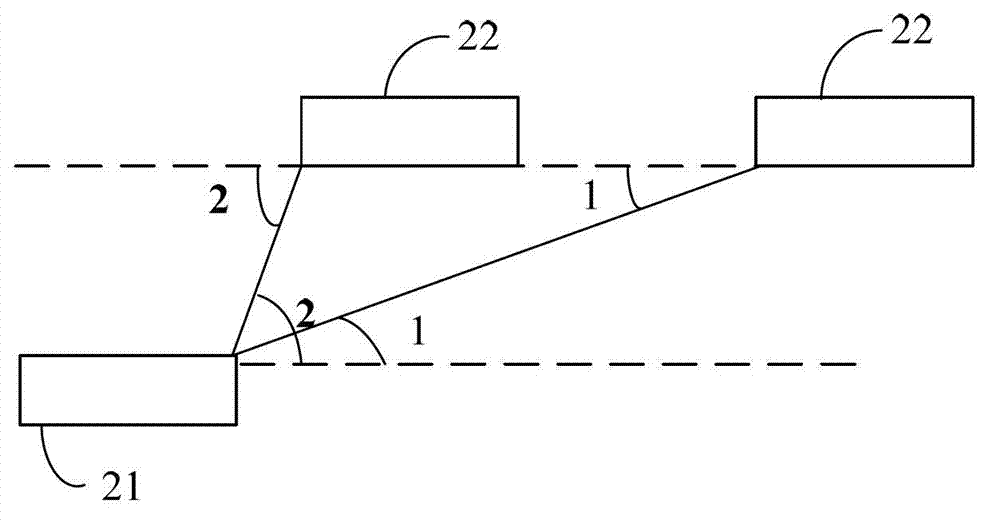

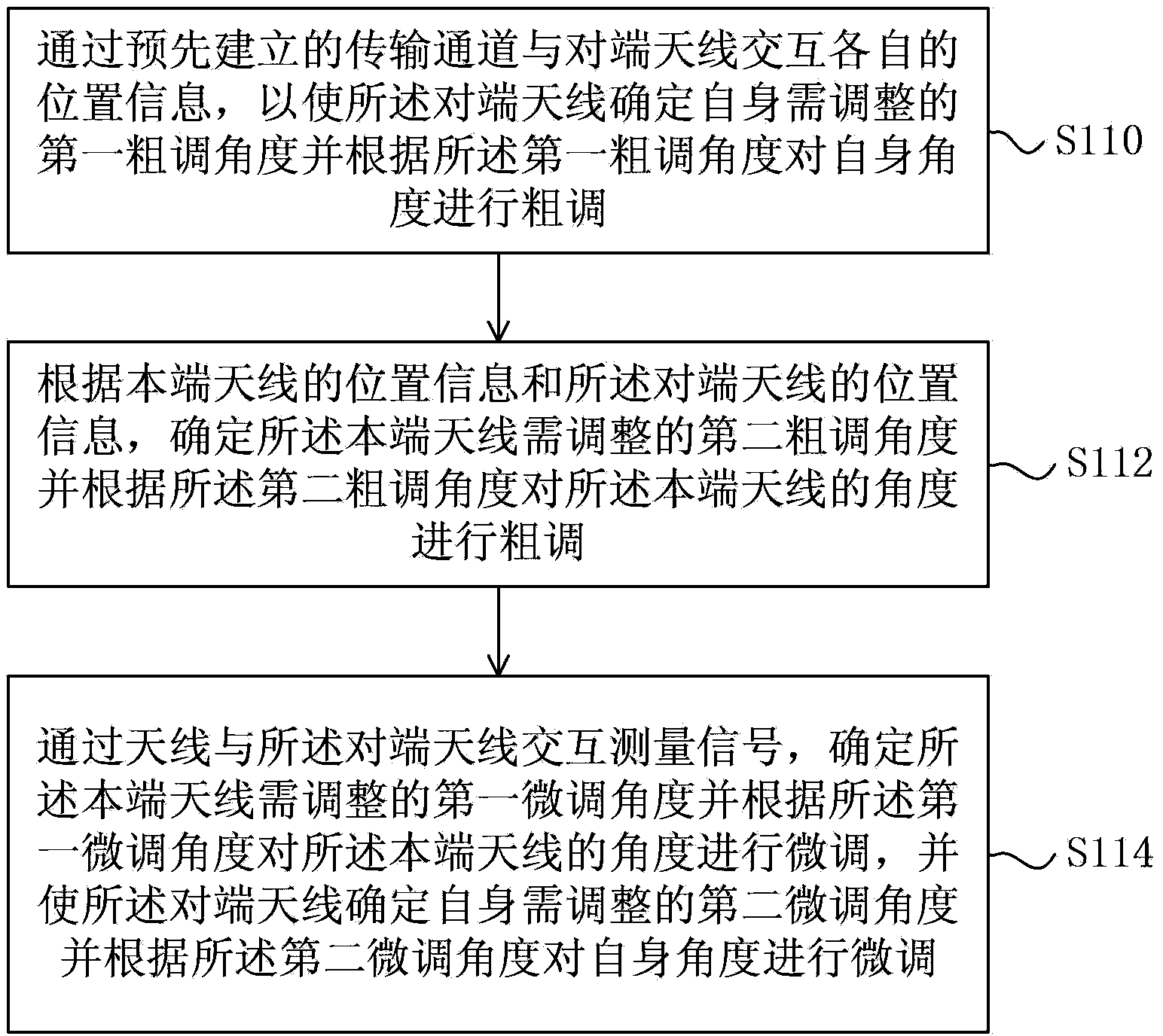

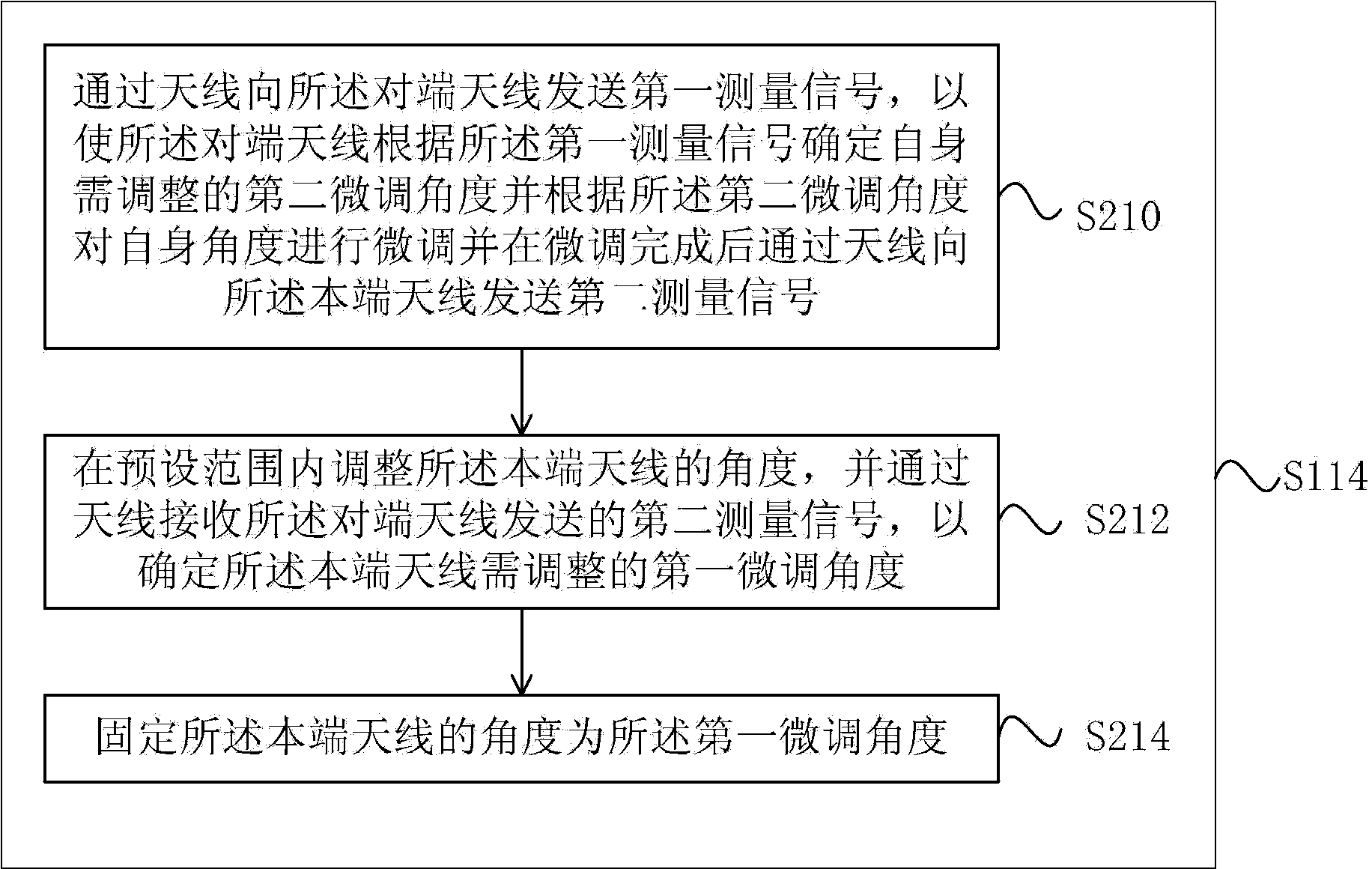

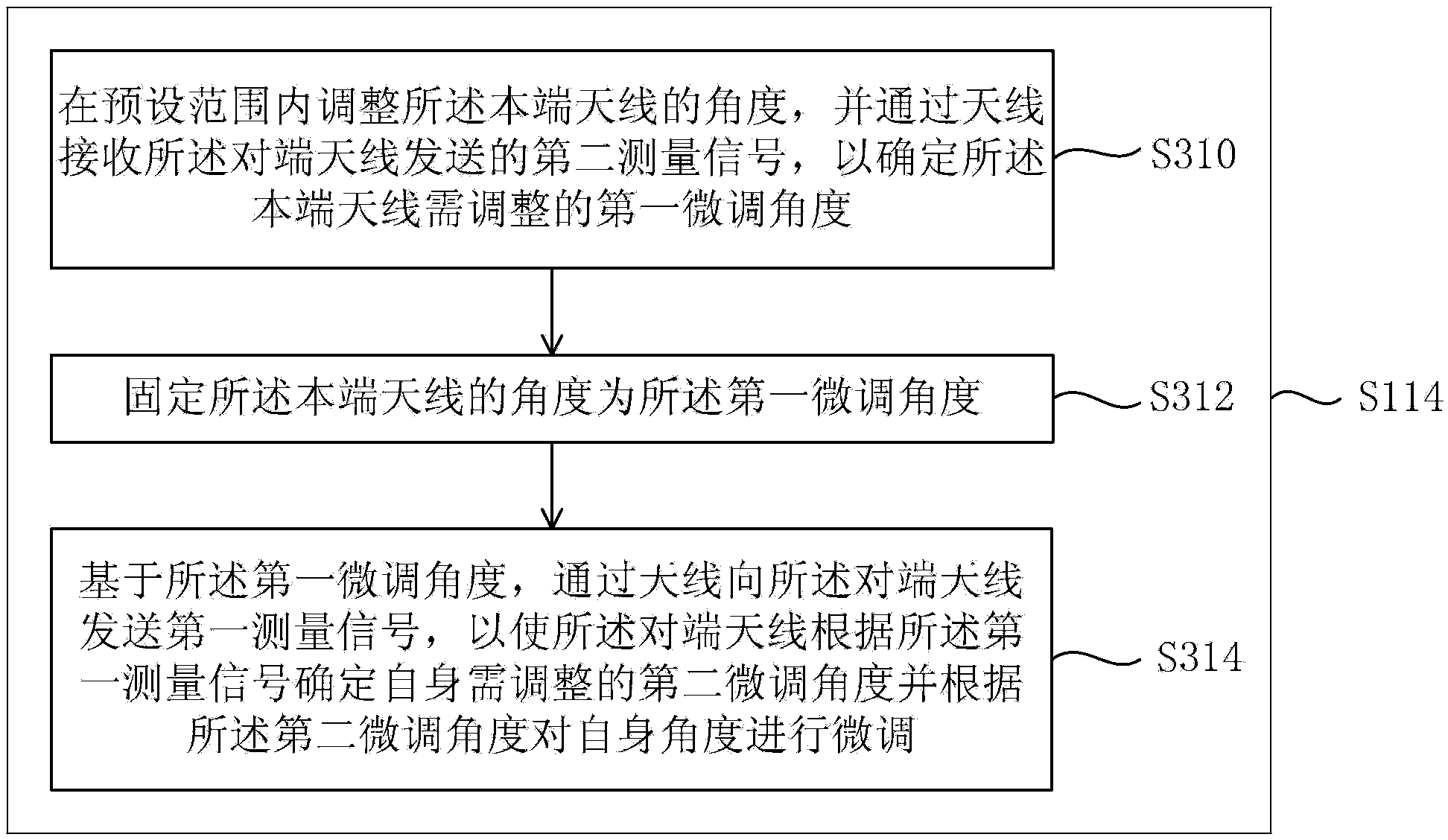

Antenna alignment method, antenna alignment device and antenna alignment system

ActiveCN104113363AImprove alignment efficiencyNo manual operationDiversity/multi-antenna systemsControl using feedbackTransmission channelSignal interaction

The embodiment of the invention provides an antenna alignment method, an antenna alignment device and an antenna alignment system. The embodiment of the invention provides an antenna alignment method comprising the following steps: position information interaction with an opposite-end antenna is performed through a pre-established transmission channel to enable the opposite-end antenna to determine a first coarse adjustment angle at which the opposite-end antenna needs to be adjusted and to coarsely adjust the angle according to the first coarse adjustment angle; a second coarse adjustment angle at which a local-end antenna needs to be adjusted is determined according to the position information of the local-end antenna and the position information of the opposite-end antenna, and the angle of the local-end antenna is coarsely adjusted according to the second coarse adjustment angle; and a first fine adjustment angle at which the local-end antenna needs to be adjusted is determined through measurement signal interaction between the local-end antenna and the opposite-end antenna, the angle of the local-end antenna is finely adjusted, and the opposite-end antenna determines a second fine adjustment angle at which the opposite-end antenna needs to be adjusted, and finely adjusts the angle according to the second fine adjustment angle. According to the embodiment of the invention, the efficiency of antenna alignment is improved.

Owner:HUAWEI TECH CO LTD

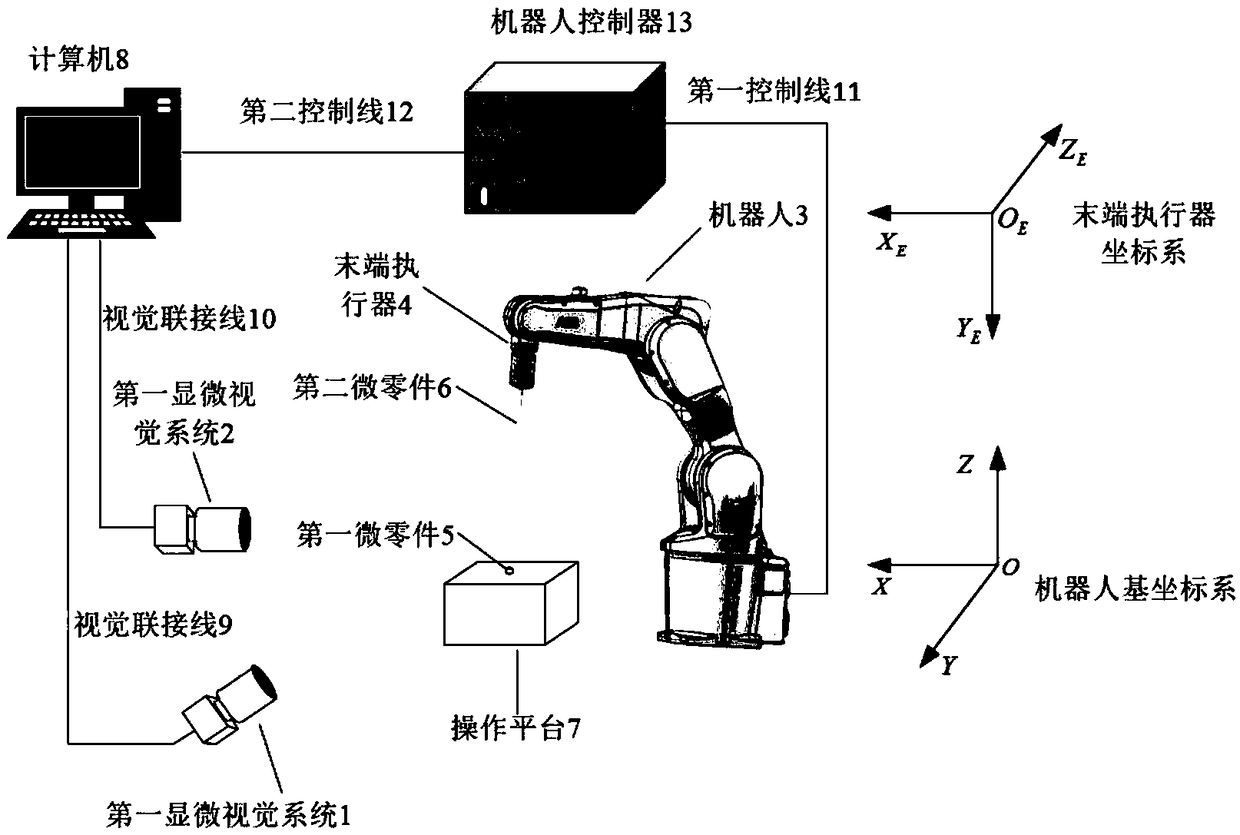

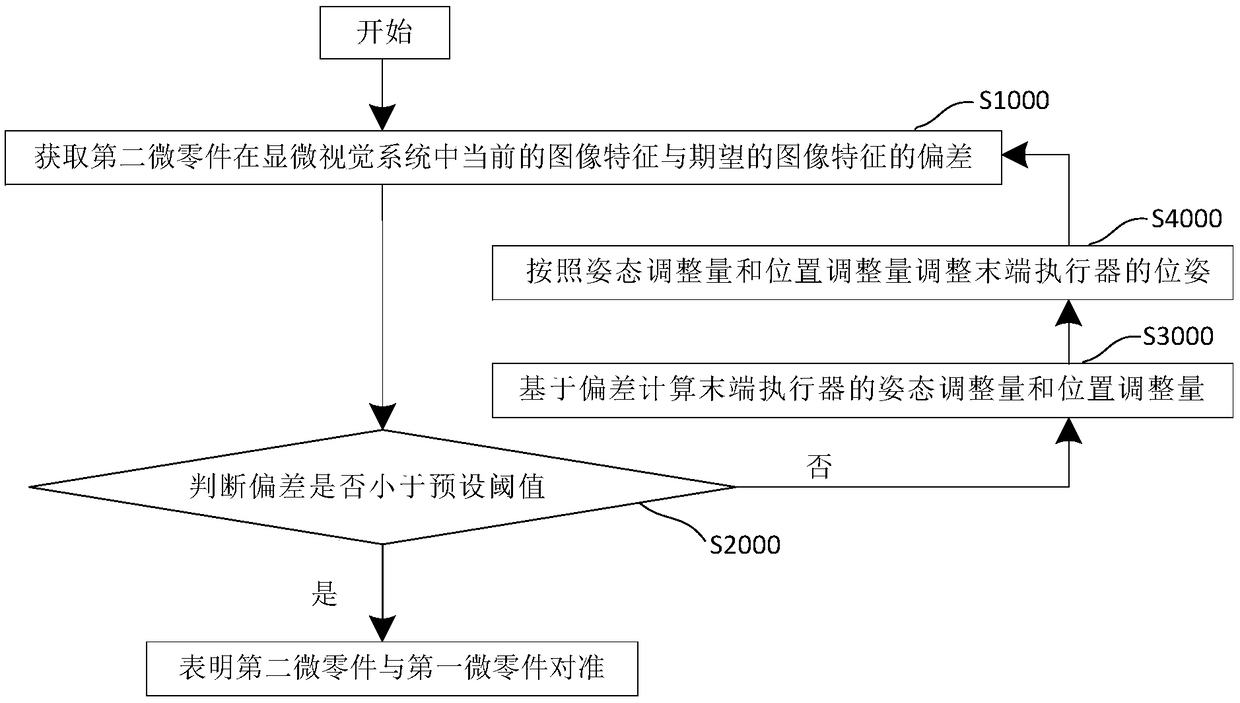

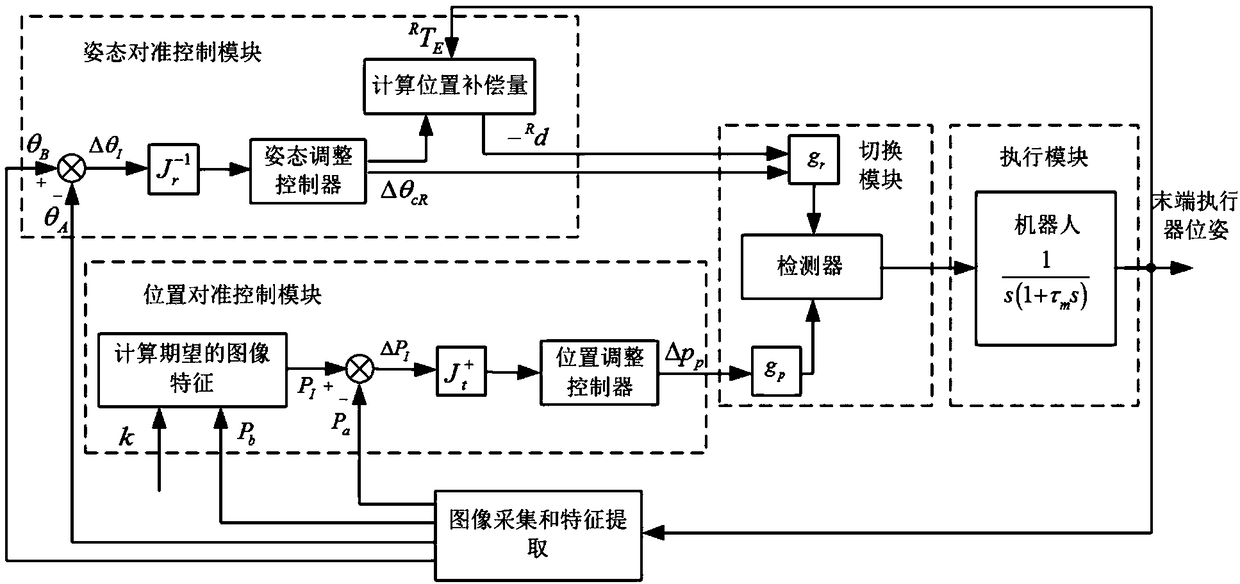

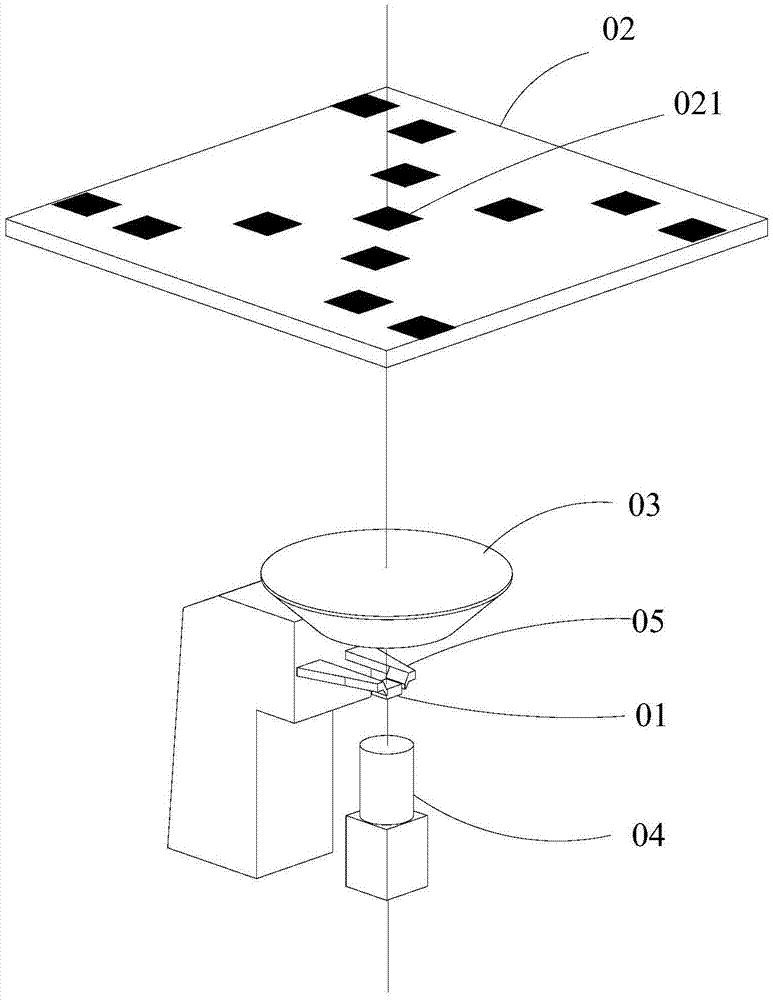

Micro-part pose automatic alignment device and method

ActiveCN108972557AReduce pose alignment errorImprove alignment accuracyImage enhancementProgramme-controlled manipulatorControl engineeringClosed loop

The invention belongs to the technical field of micro-assembly, and particularly provides a micro-part pose automatic alignment device and method. The pose automatic alignment method comprises the following steps that S1000, a deviation of a current image characteristic and an expected image characteristic of a second micro-part in a microscopic vision system is obtained; S2000, the deviation is judged whether smaller than a preset threshold value or not, if yes, the second micro-part is aligned with the first micro-part, and if not, S3000 is executed; S3000, a posture adjustment amount and aposition adjustment amount of an end effector is calculated based on the deviation; and S4000, the pose of the end effector is adjusted according to the posture adjustment amount and the position adjustment amount and returning to the S1000 is carried out, wherein the position adjustment amount comprises an adjustment amount for position alignment and a position offset compensation amount caused by compensating the posture adjustment. According to the device and method, by means of closed-loop control and position compensation, alignment errors are reduced, alignment precision and alignment efficiency are improved, and the problems that an existing micro-part pose alignment method is complex in operation process and low in alignment efficiency are solved.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

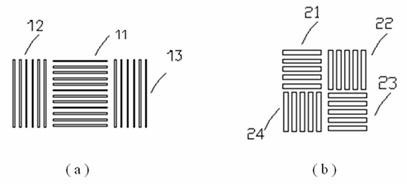

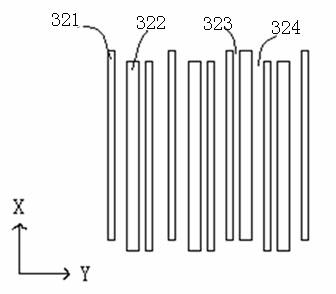

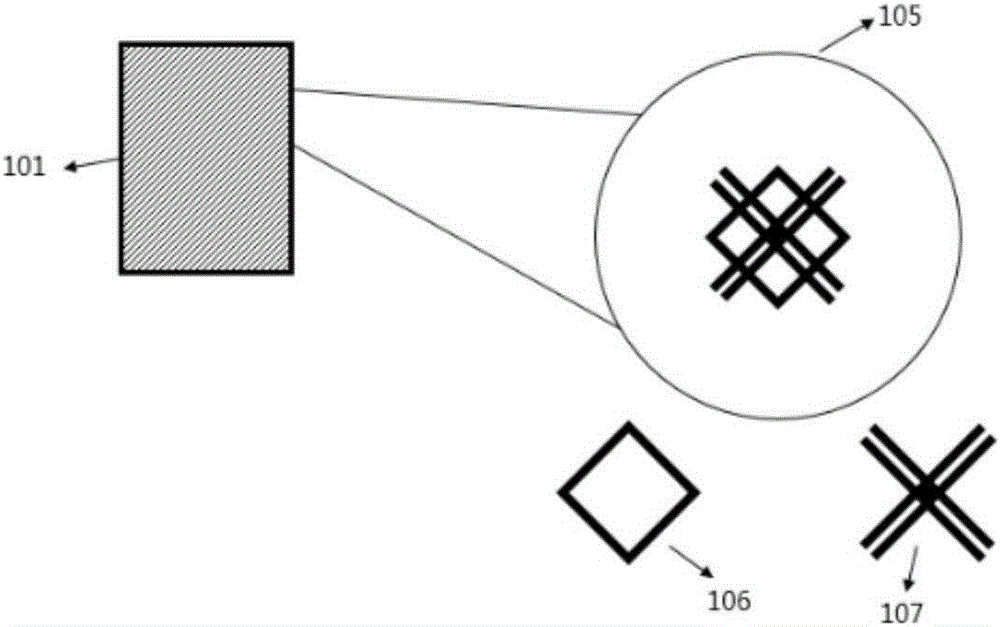

High-accuracy alignment mark structure based on machine vision alignment

InactiveCN102103336AThe impact of reducing image qualityImprove alignment accuracyPhotomechanical treatmentMachine visionImaging quality

The invention discloses a high-accuracy alignment mark structure based on machine vision alignment. The shape structure of the high-accuracy alignment mark structure based on the machine vision alignment is in an asymmetric shape, wherein the asymmetric shape comprises non-axial symmetry and non-central symmetry; the high-accuracy alignment mark structure based on the machine vision alignment at least comprises a line array, and the lines of the line array are ranked in parallel; the width of the lines in the line array is different from the width of the line seam among the lines; and the lines in the line array are ranked in a staggered mode. The high-accuracy alignment mark structure disclosed by the invention reduces the influence on the imaging quality of alignment mark figures because of process factors such as optical proximity effect, corrosion accuracy control and the like, thereby enhancing alignment accuracy and alignment efficiency.

Owner:张雯

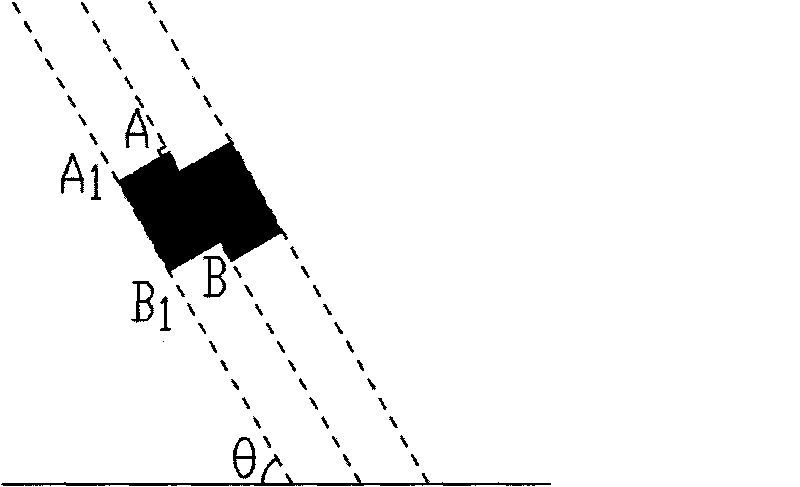

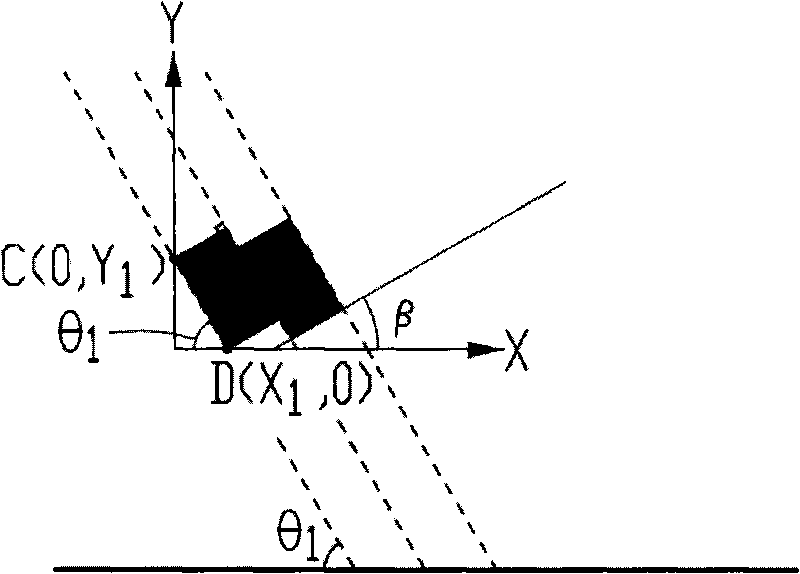

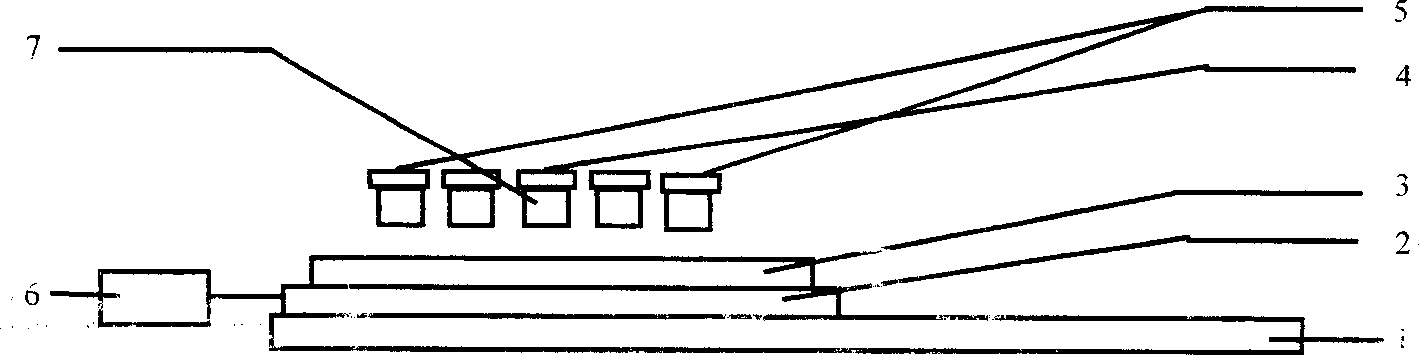

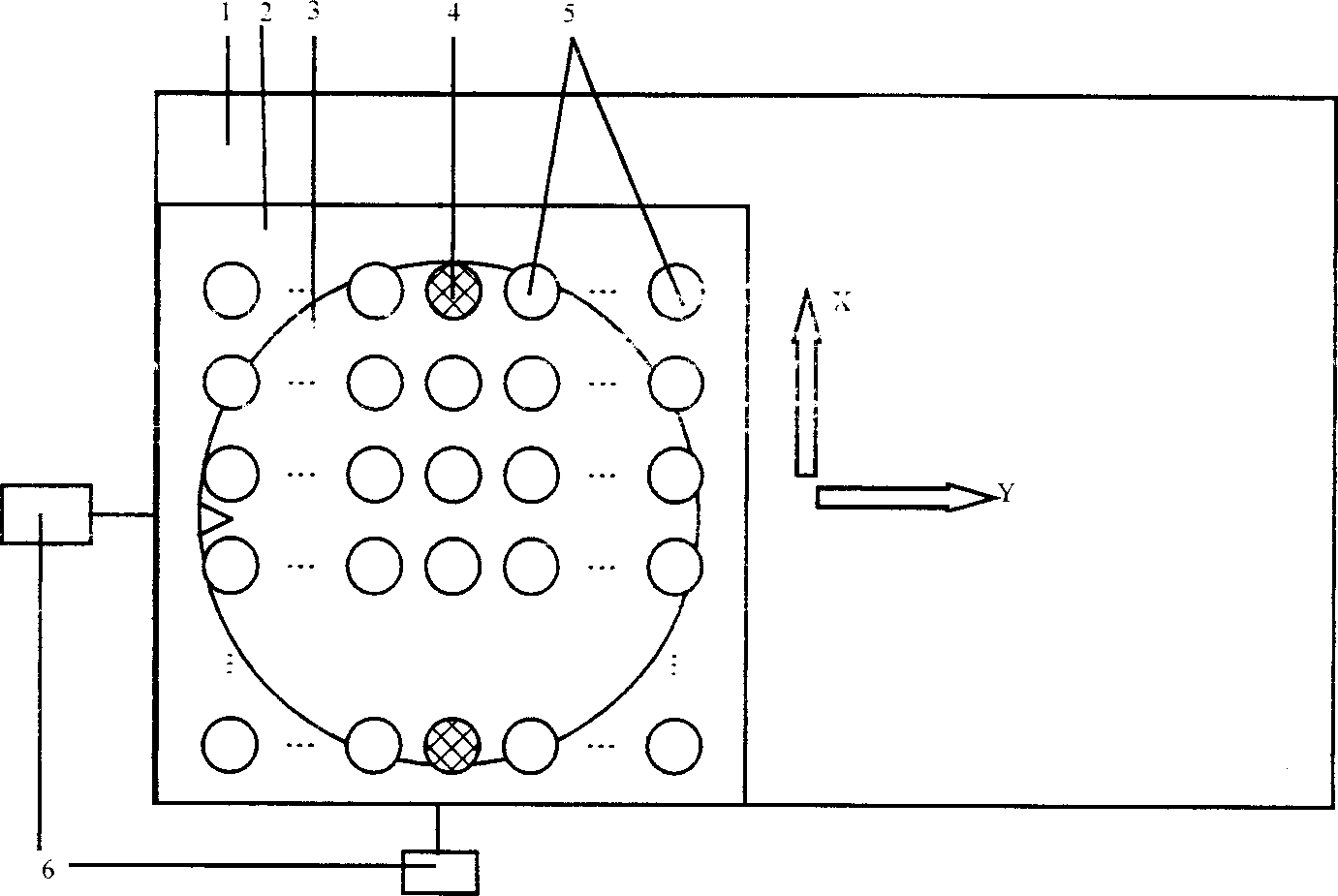

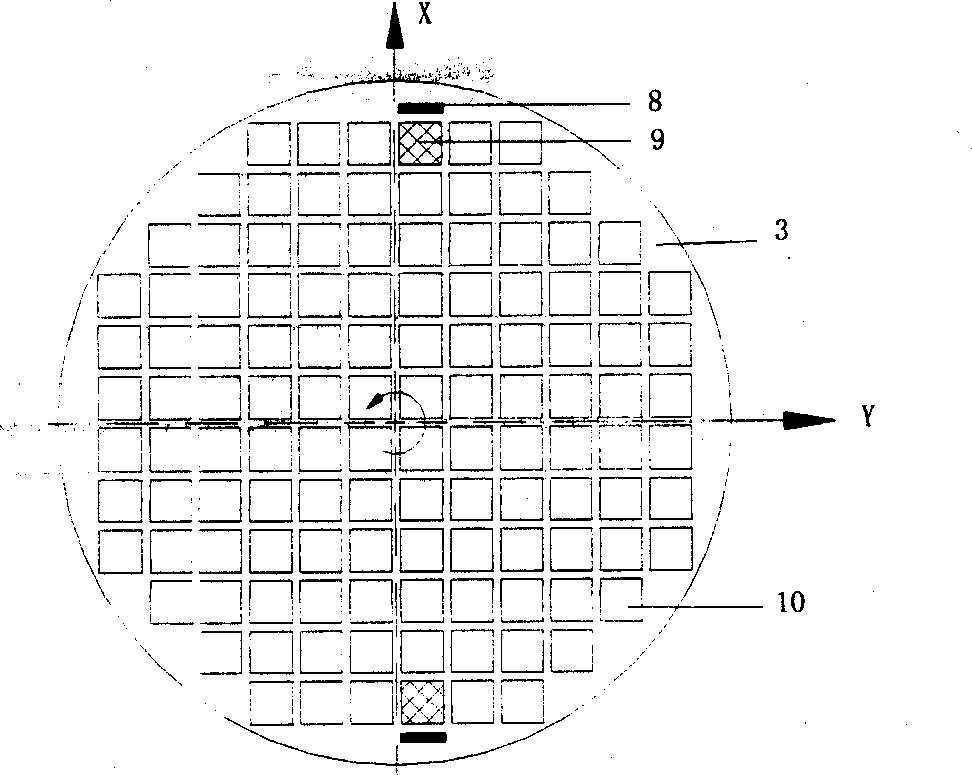

Alignment method and apparatus for array type optical probe scanning IC photoetching system

InactiveCN1333554AQuality assuranceSolve the problem of low yieldSemi-permeable membranesPhotomechanical apparatusGraphicsServo actuator

Firstly, according to the defined key points of circuit pattern, coding distinctive characteristics of circuit pattern, etching them on the silicon wafer, setting a pair a calibrating pattern, makingt he calibrating pattern position at circuit pattern place, and the calibrating pattern is formed from calibrating subpatterns. According to the key points of pattern, on the silicon wafer etching calibrating subpattern, when the alignment is made to key point of pattern, fetching calibrating subpattern coordinate and making comparison of said coordinate with recorded coordinate of calibrating subpattern. In the inveneted equipment the working table is placed on the base seat, and driven by precision servo-actuator, the silicon wafer to be worked can be fixed on the working table by means of suction cup, calibrating optical head and optical probe array are positioned over silicon wafer, a pair of calibrating optical heads is positioned in the middle of optical probe array are positioned over silicon wafer, a pair of calibrating optical heads is positioned in the middle of optical probes, the optcial probes array is arranged in the rectangular form. Said invention can save alignment time of pattern and can raise alignmant efficiency.

Owner:TSINGHUA UNIV

Arranging device for installing pipetting tips into tip box

Owner:NINGBO UNIV

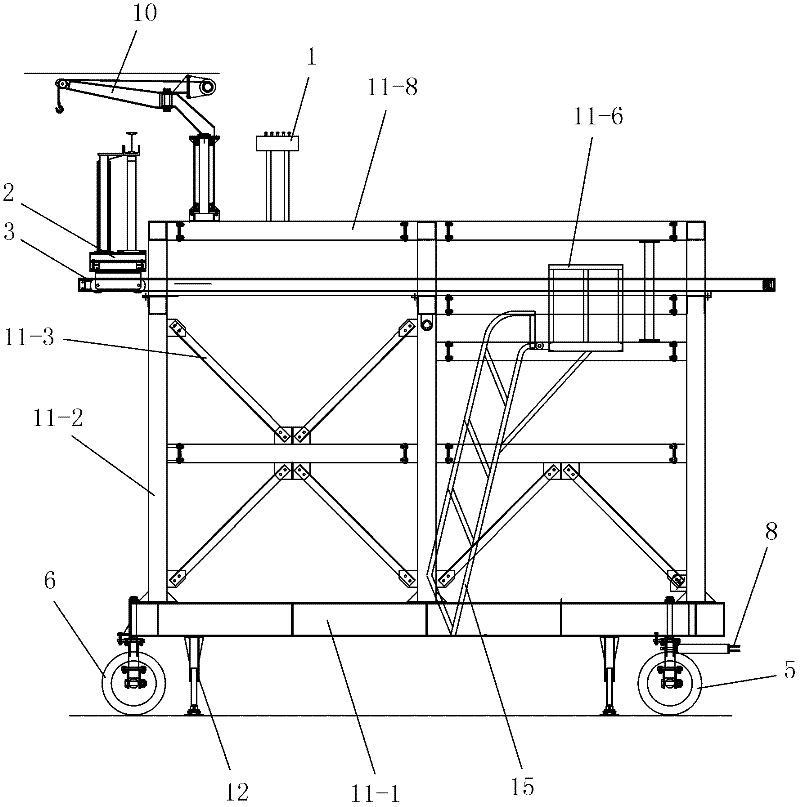

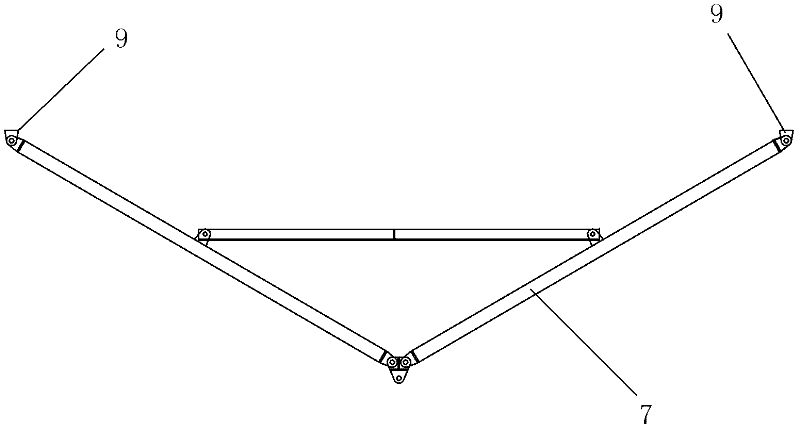

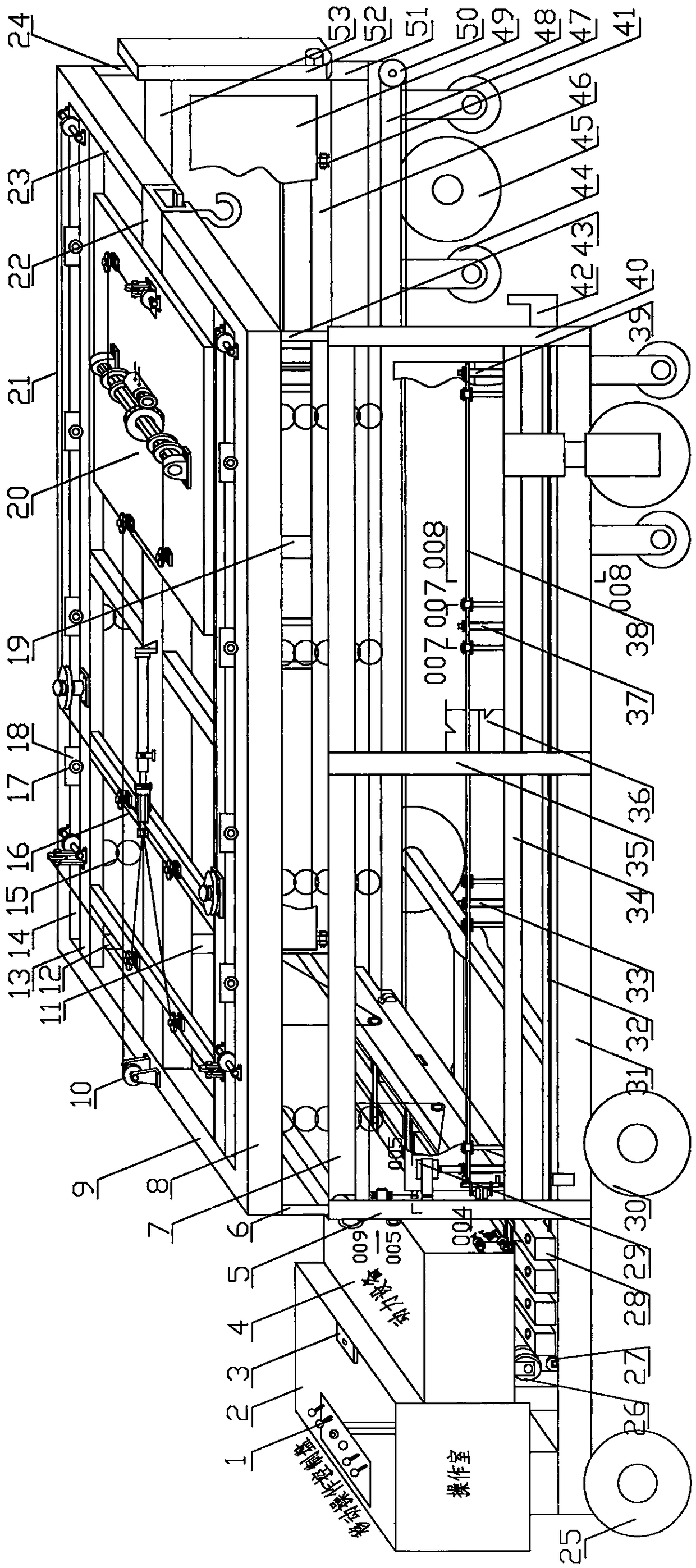

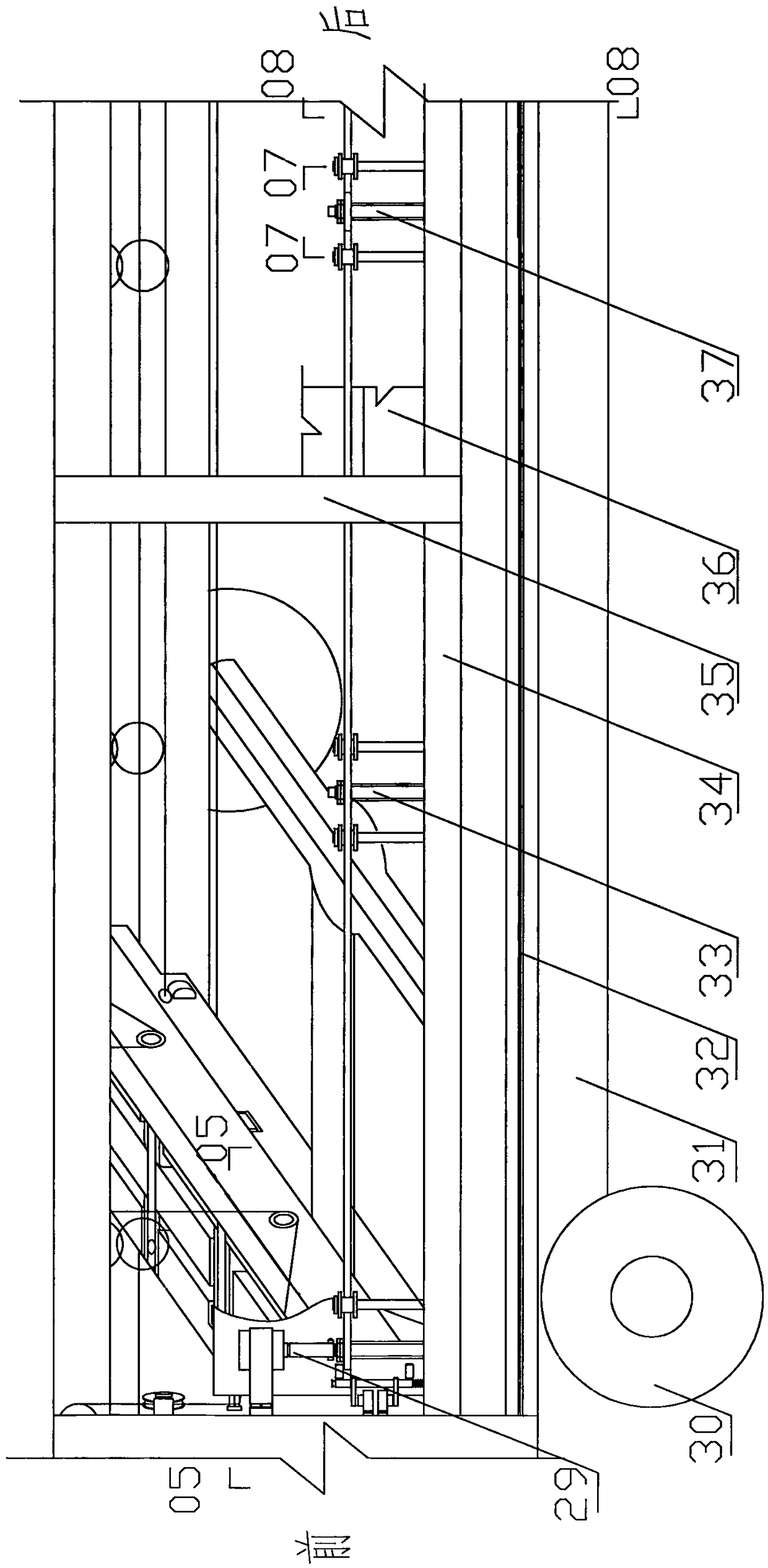

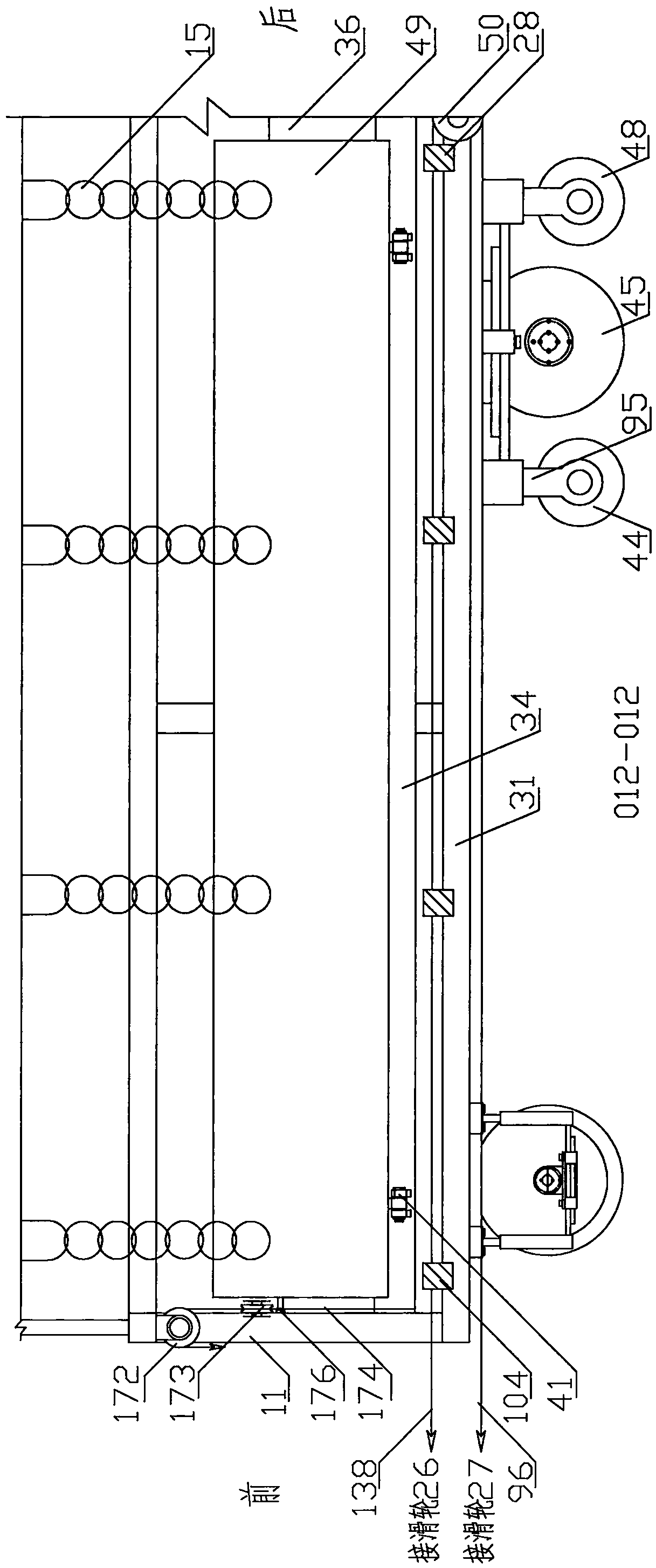

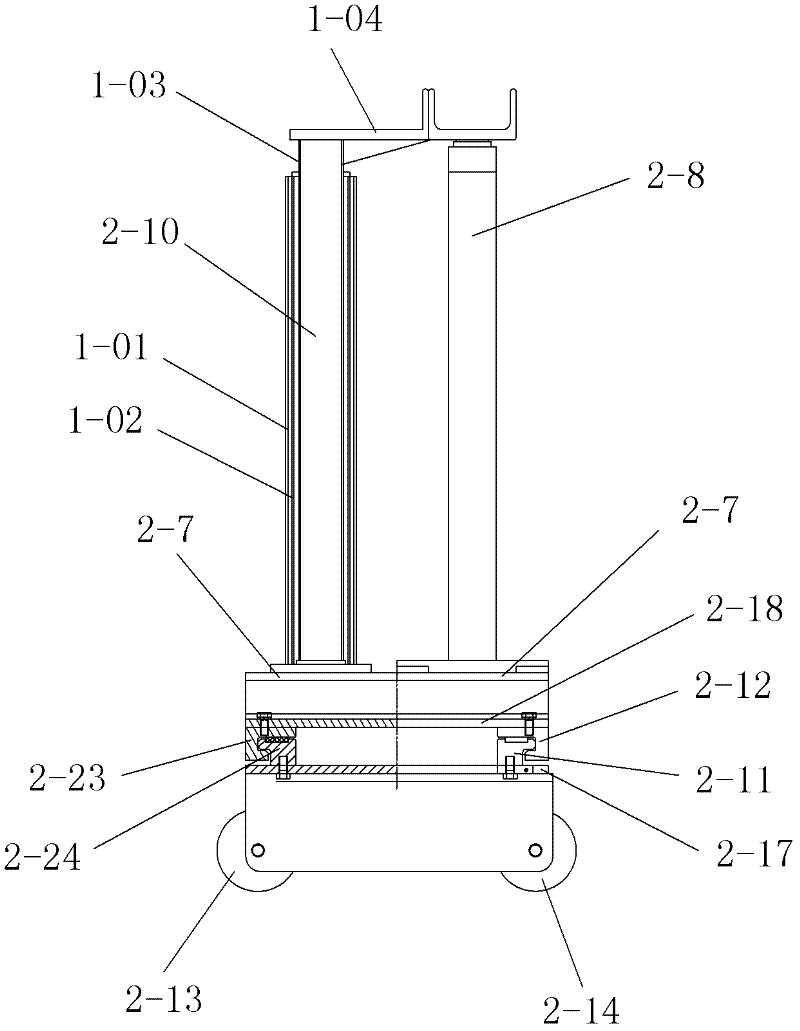

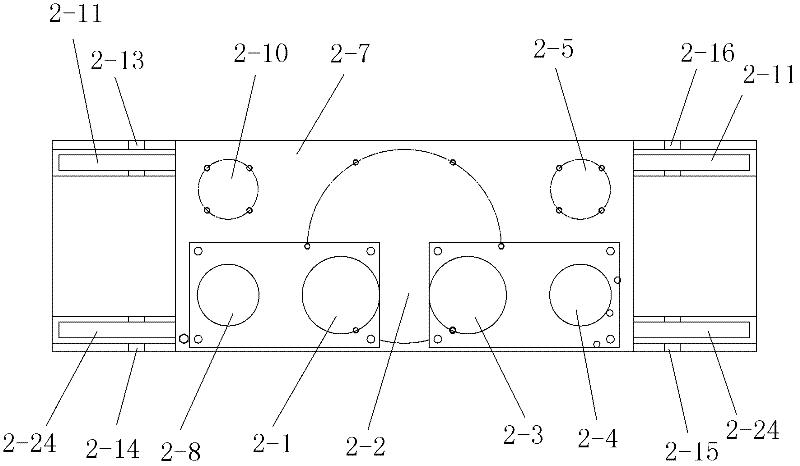

Mounting equipment car

InactiveCN108178074ARealize mechanized constructionReasonable structural stressLifting devicesTravelling gearAutomatic controlMechanical equipment

The invention discloses a mounting equipment car. The mounting equipment car consists of power equipment, a chassis, a car body, electric equipment and the like, and is characterized in that a first extension column 6, a second extension column 12, a third extension column 24 and a fourth extension column 43 are correspondingly mounted at the upper sections of inner cavities of stand columns at four corners of a box; the other end of each stand column is connected to the top of the box; the top of the box can be vertically lifted to lift equipment; an extension lifting crane is mounted at thetop in the box; more than one layers of cross beam support structures and drive connecting devices are mounted on the inner and outer sides of a channel between longitudinal components on the two sides of the box to form a rotary recovered movable plane support structure; the equipment can be carried on cross beams; the cross beams can be automatically recovered on the two sides of the box; and the section of the box is n-shaped. The mounting equipment car reduces the equipment mounting construction flow, removes various cranes, vehicles, forklifts and tools in traditional construction, once finishes lifting, transportation and installation on one car, achieves automatic control and precise installation, realizes mechanical equipment installation, and greatly improves the equipment mounting efficiency.

Owner:白天海

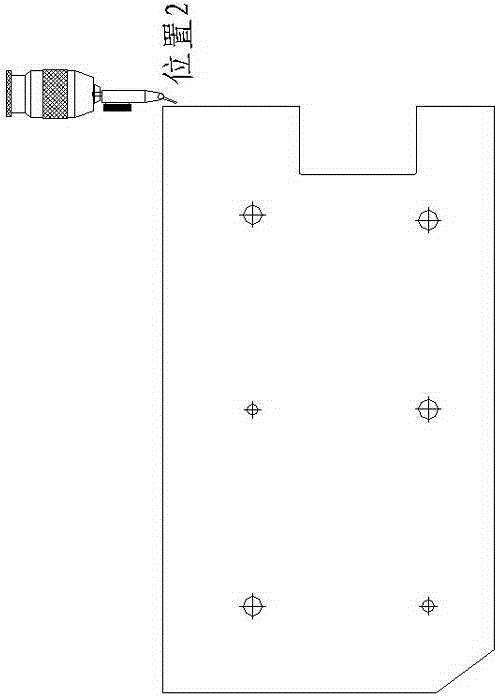

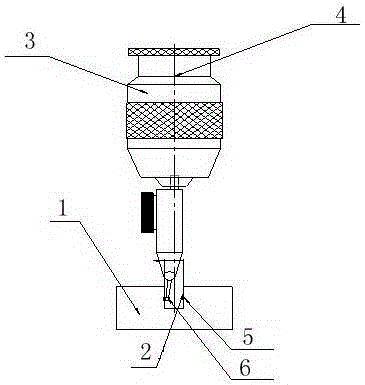

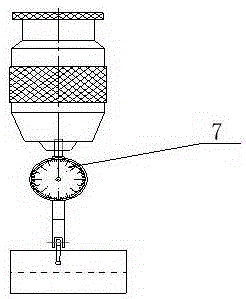

Simple tool setting and alignment method for boring-milling machining

InactiveCN105215786AReduce mistakesHigh skillAutomatic control devicesFeeding apparatusEngineeringMachine

The invention relates to the field of machining, in particular to a simple tool setting and alignment method for boring-milling machining. Through the alignment method, workers can carry out alignment and tool setting conveniently, accurately and rapidly before part machining. The method includes the steps that (1) according to the size of a part to be machined and the model of equipment, a spindle tool handle is selected, a lever indicator is arranged in an ER collet chuck of the head of the tool handle, and the tool handle is arranged in a spindle of a milling machine or a boring machine; (2) an alignment block is fixed to a working table top of the milling machine or the boring machine, after the angle of the head of the lever indicator is adjusted to be within the range from 30 degrees to 80 degrees, the head of the lever indicator is descended and placed in the middle of an alignment block groove, and circles are drawn on generatrices of the two sides of the middle of the alignment block groove repeatedly until the position where the head of the lever indicator displays the maximum value is found; and (3) a console of the milling machine or a console of the boring machine is operated, so that the lever indicator in the alignment block groove is lifted.

Owner:西安西航集团莱特航空制造技术有限公司

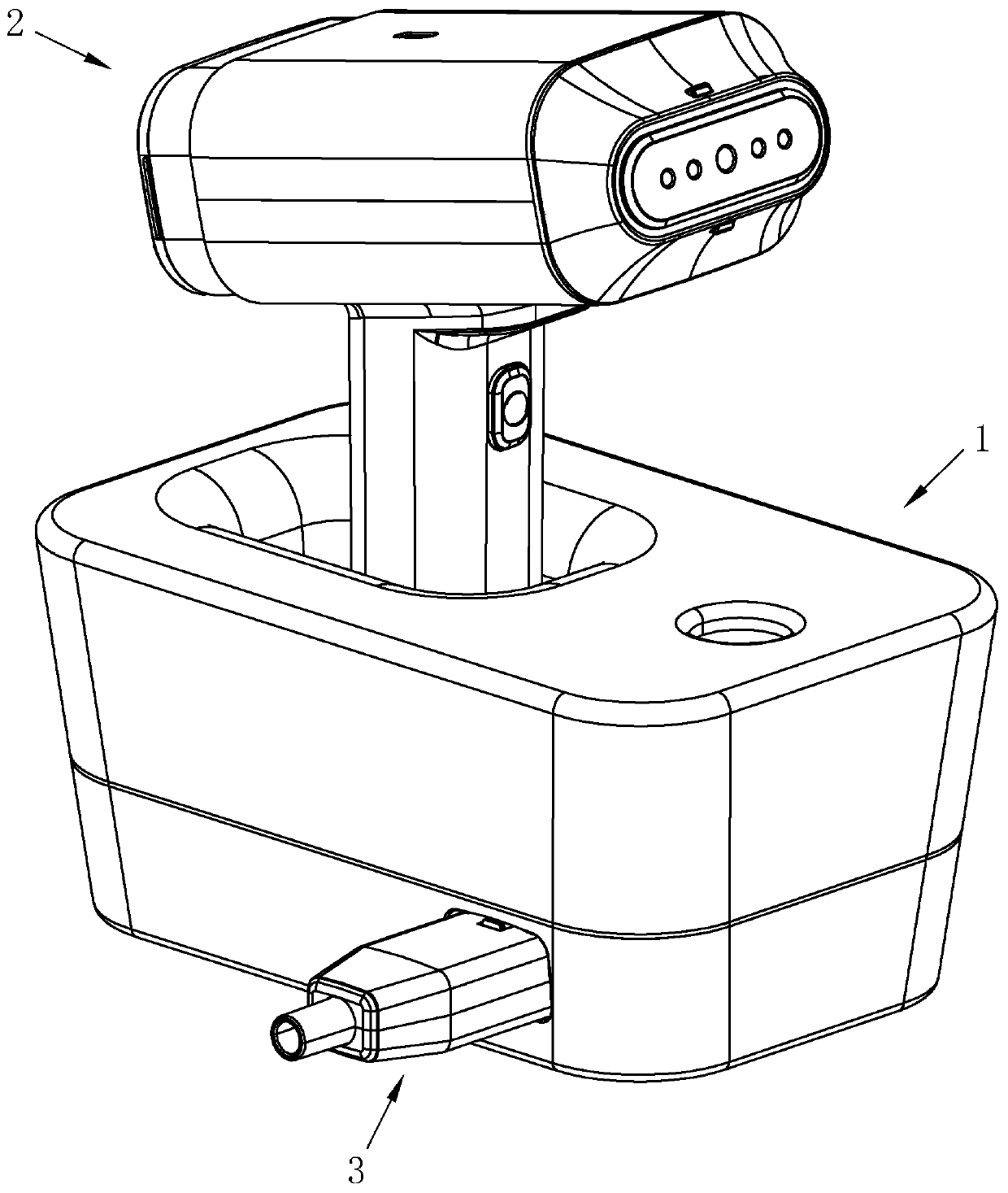

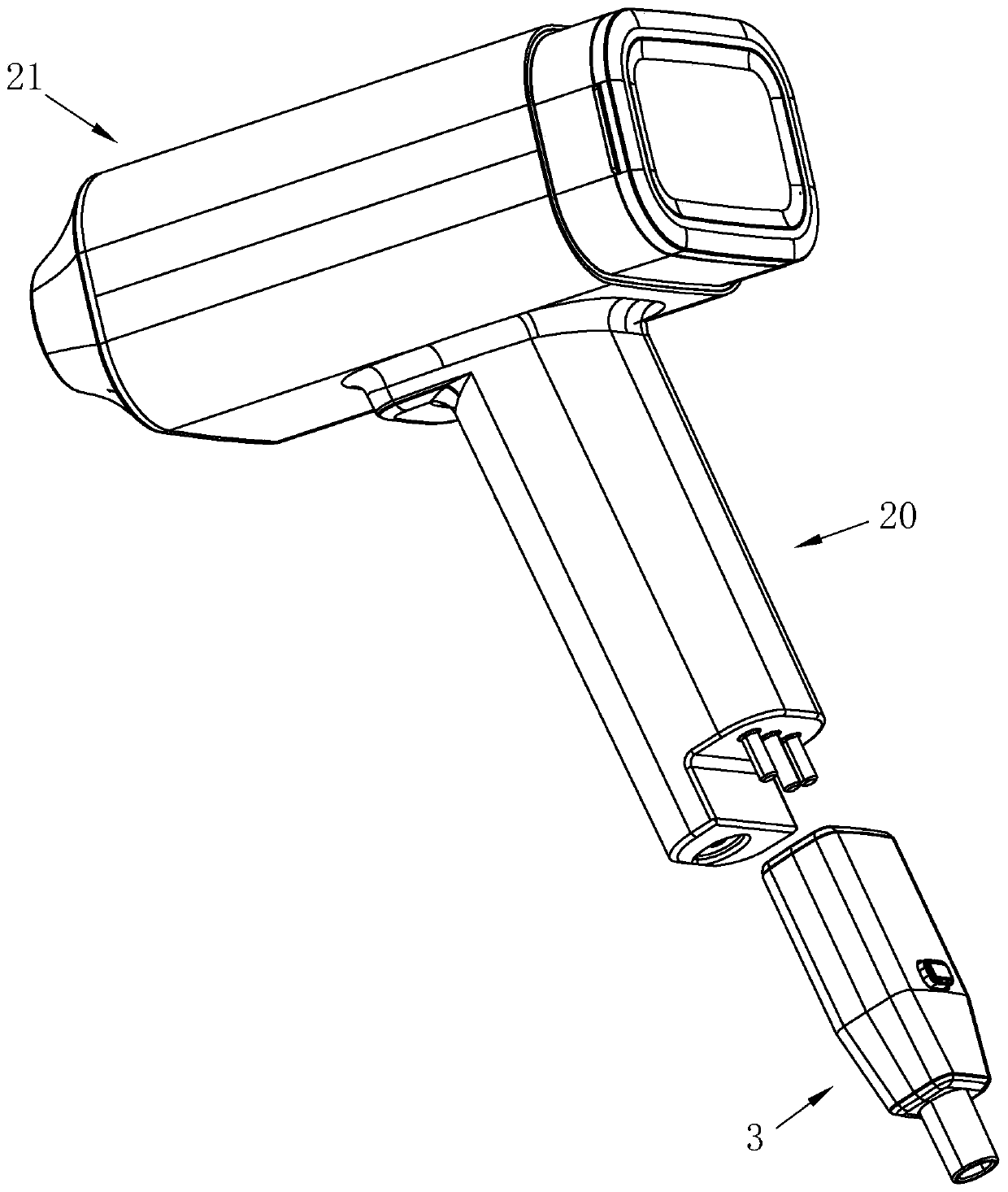

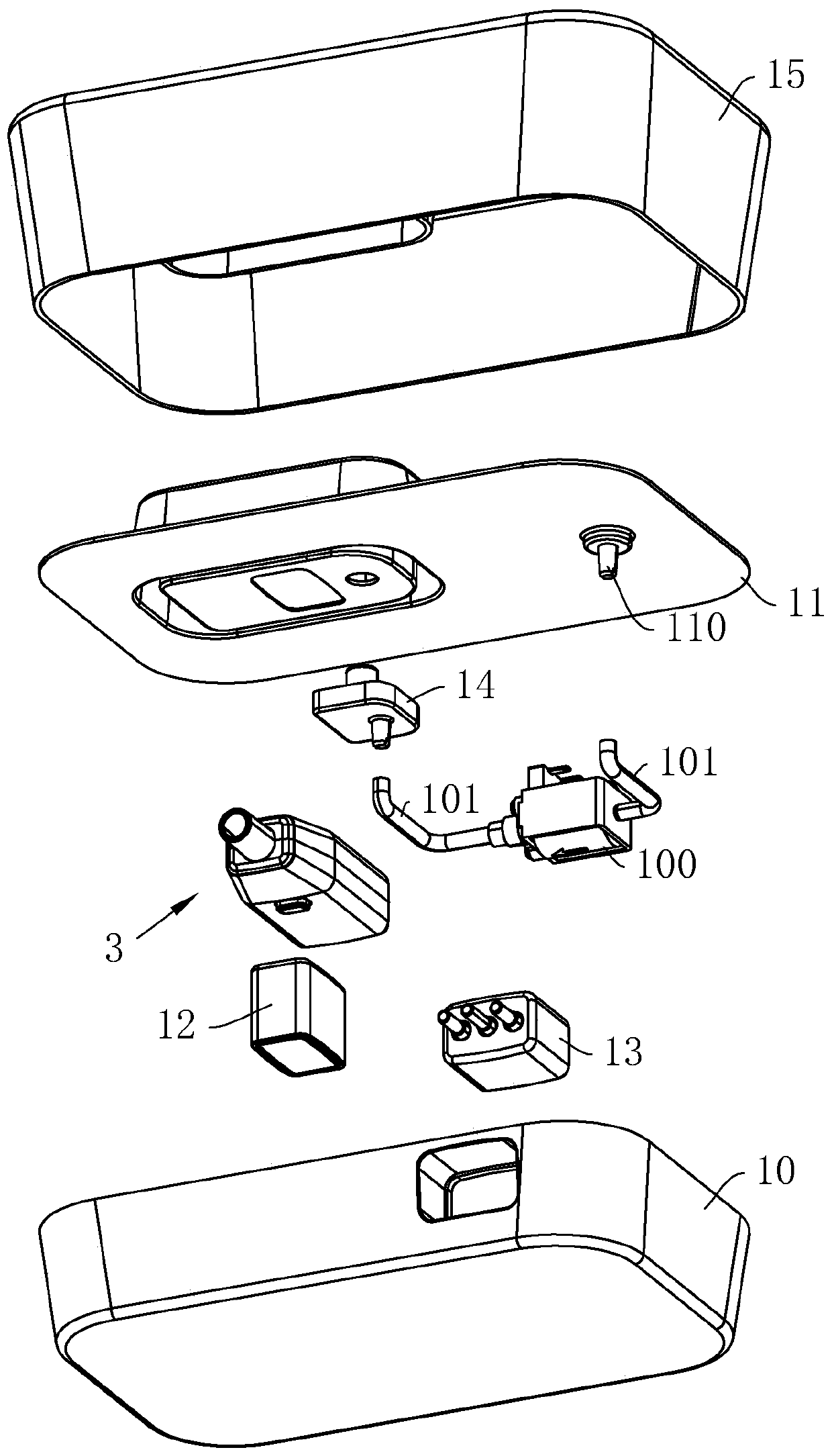

Steam brush with automatic water supplementing function

ActiveCN111576017AEasy to plug inImprove alignment efficiencyIroning apparatusElectric vehicle charging technologyThermodynamicsWater storage tank

The invention relates to a steam brush with an automatic water supplementing function, and relates to the technical field of steam ironing. The steam brush is inserted into a water supplementing base,and therefore synchronous water supplementing and charging are carried out. A battery and a water storage tank are arranged in the steam brush; after the steam brush is separated from the water supplementing base, the steam brush has the capacity of being independently used after being separated; and infrared geminate transistors carry out high-water-level induction on the water storage tank, andthe water supplementing degree is detected. The steam brush has the effects of being convenient to insert, high in aligning efficiency and synchronous in water supplementing and charging.

Owner:CUORI ELECTRICAL APPLIANCES GRP

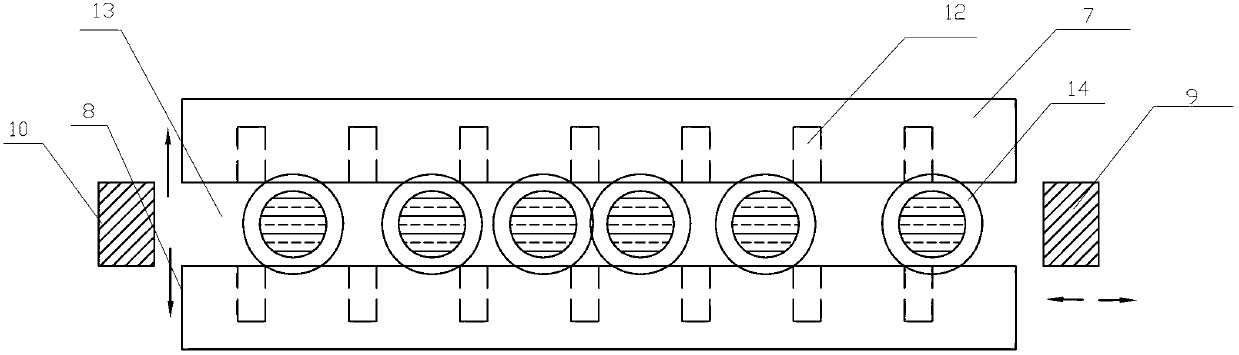

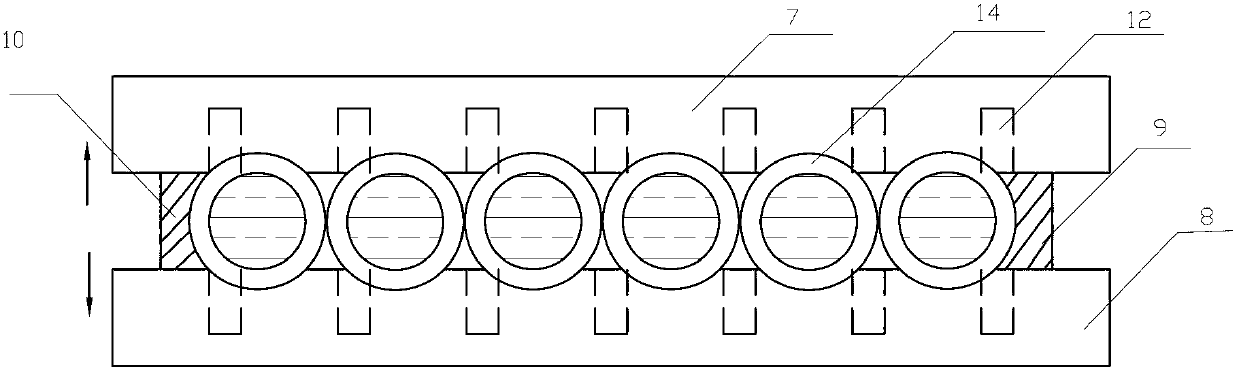

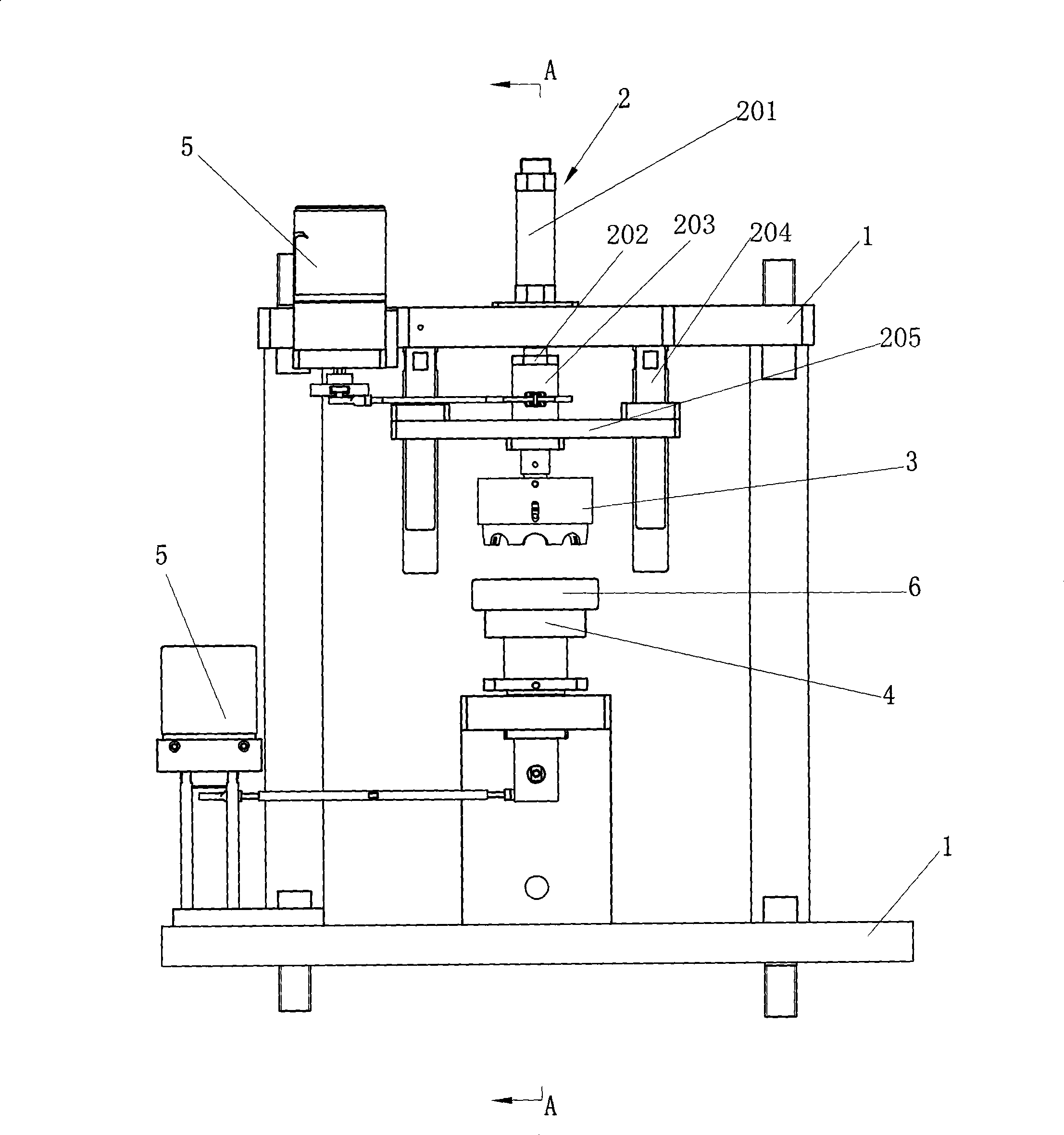

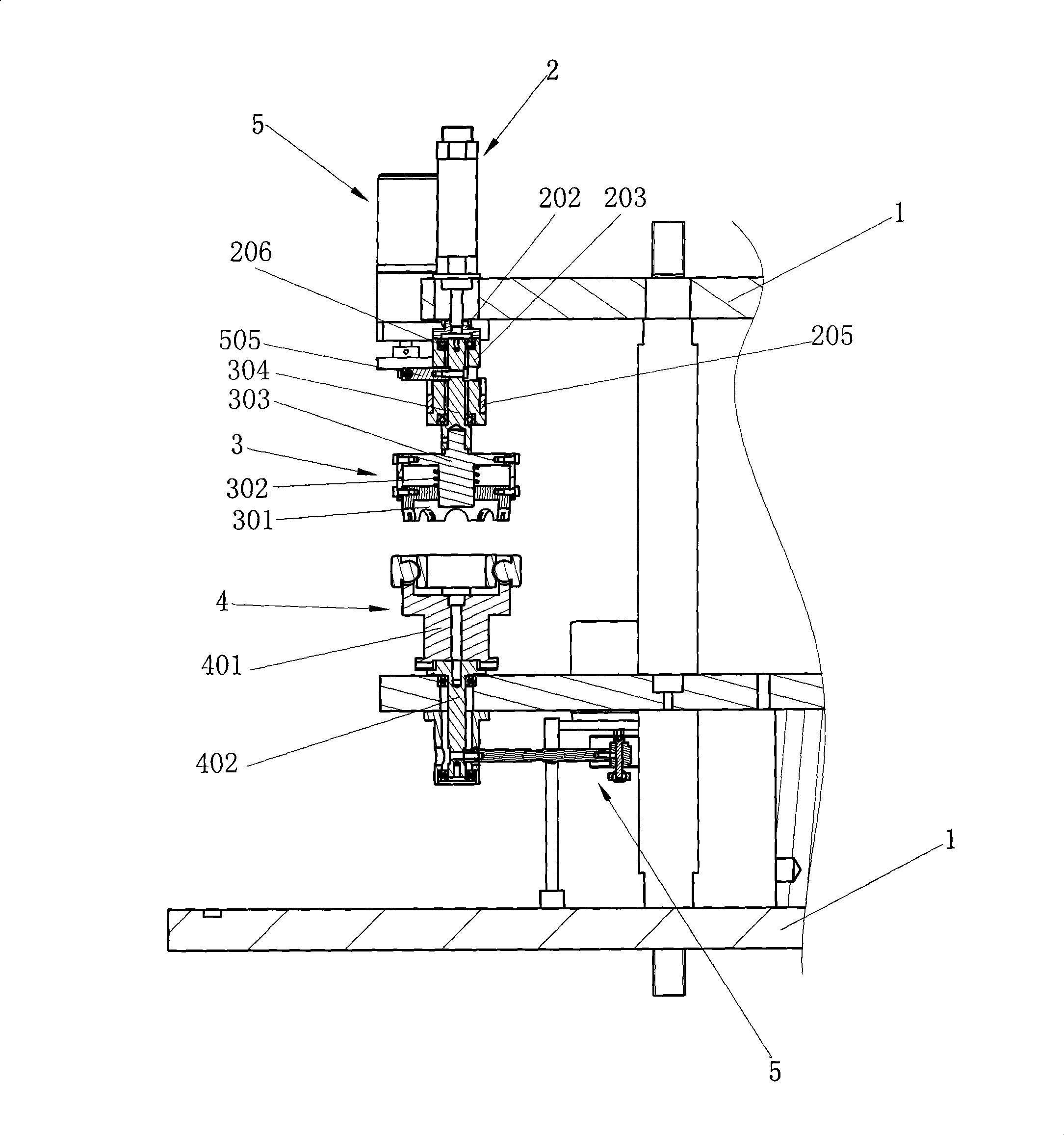

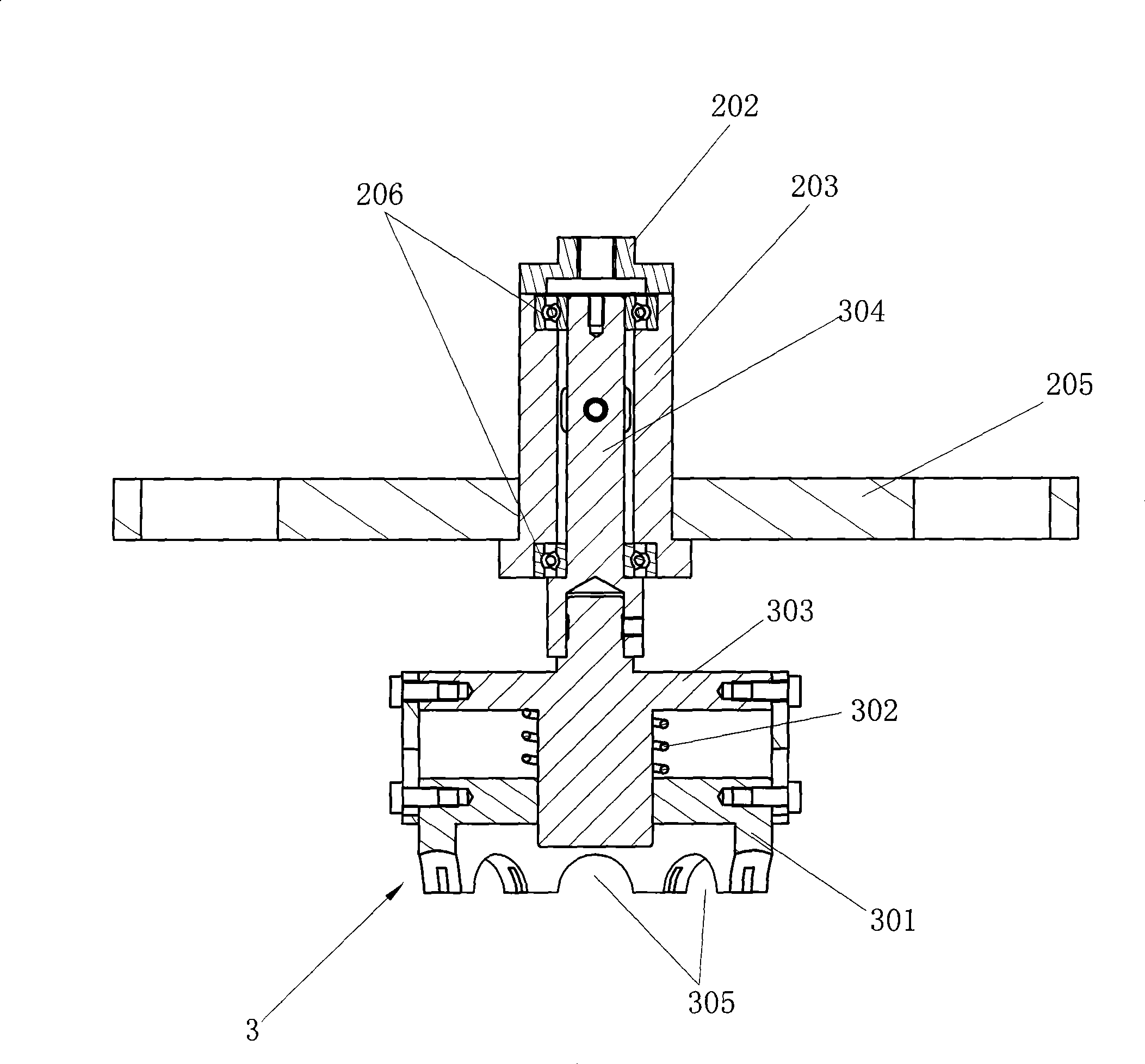

Oscillation positioning device of holder of bearing ball separating holder assembly machine

InactiveCN101363476ARealize automatic alignmentImprove alignment efficiencyBearing componentsEngineeringElectric control

The invention relates to a retainer oscillating alignment device of a bearing ball separating retainer assembly machine, and is characterized in that the retainer oscillating alignment device comprises a frame and an electric control system; an elevating mechanism is arranged at the upper part of the frame, an upper die is pivotally arranged on the elevating mechanism and an oscillating mechanism is connected with the upper die; a lower die is pivotally arranged on the frame and is connected with the oscillating mechanism. The retainer oscillating alignment device of the bearing ball separating retainer assembly machine disclosed in the invention can realize automatic alignment in the installing process of the retainer, improve the alignment efficiency and production efficiency of the bearing retainer and solve the problems of rivet shedding as well as deformation and deadlocking of the retainer.

Owner:无锡市江益轴承自动化设备有限公司

Alignment method and alignment system

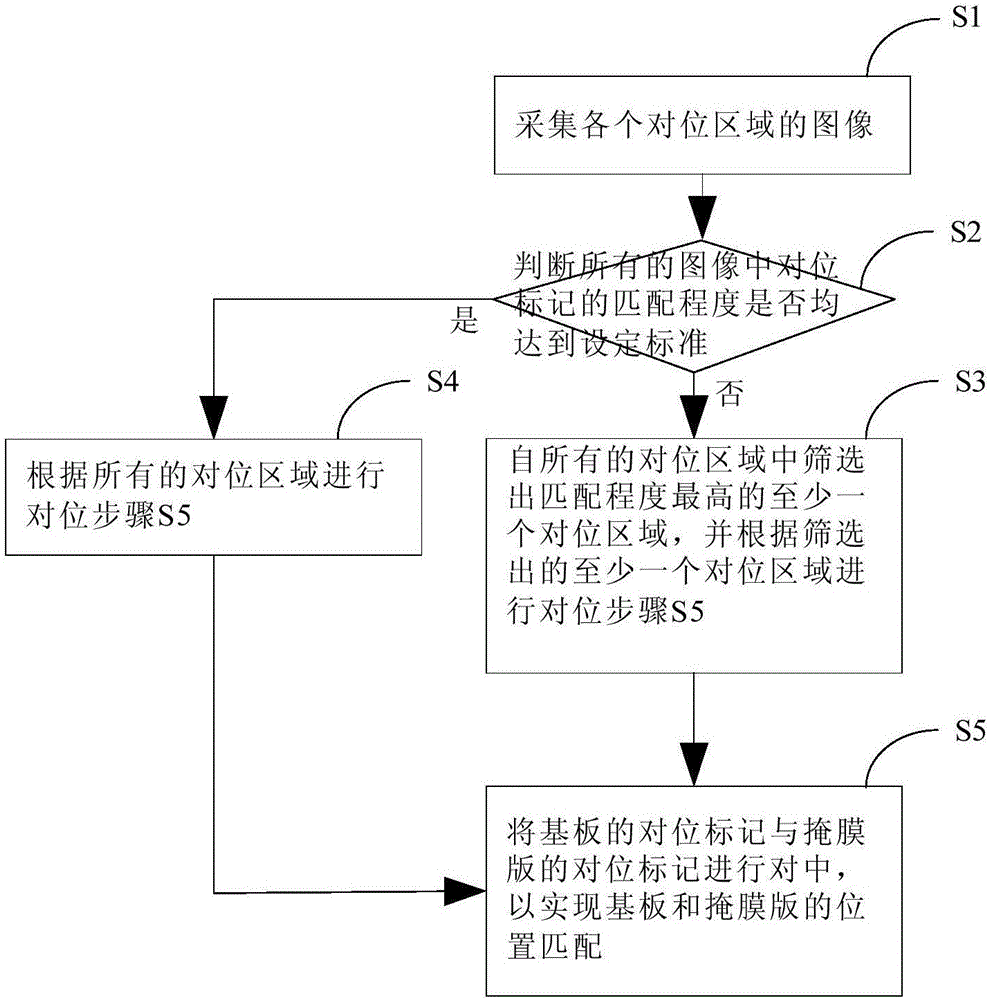

InactiveCN106054543AAvoid causing misalignment between layersIncrease success ratePhotomechanical treatmentComputer science

The invention provides an alignment method and an alignment system. The alignment method includes: 1) a collection step, collecting the images in all alignment zones; 2) a determination step: determining whether the matching degrees of alignment markers in all images reach a preset standard, and if true, performing an alignment step according to the all alignment zones, or otherwise, performing a screening step; 3) the screening step: screening at least one alignment zone, of which the matching degree is highest, from all alignment zones, and performing the alignment step according to the screened at least one alignment zone; 4) the alignment step: aligning the alignment markers on a substrate with the alignment markers on a mask plate to match the substrate with the mask plate in position. The alignment method can increase success rate of automatic alignment, so that not only is interlayer alignment deviation due to excessive high alignment error avoided, but also alignment efficiency is increased, thereby increasing productivity.

Owner:BOE TECH GRP CO LTD +1

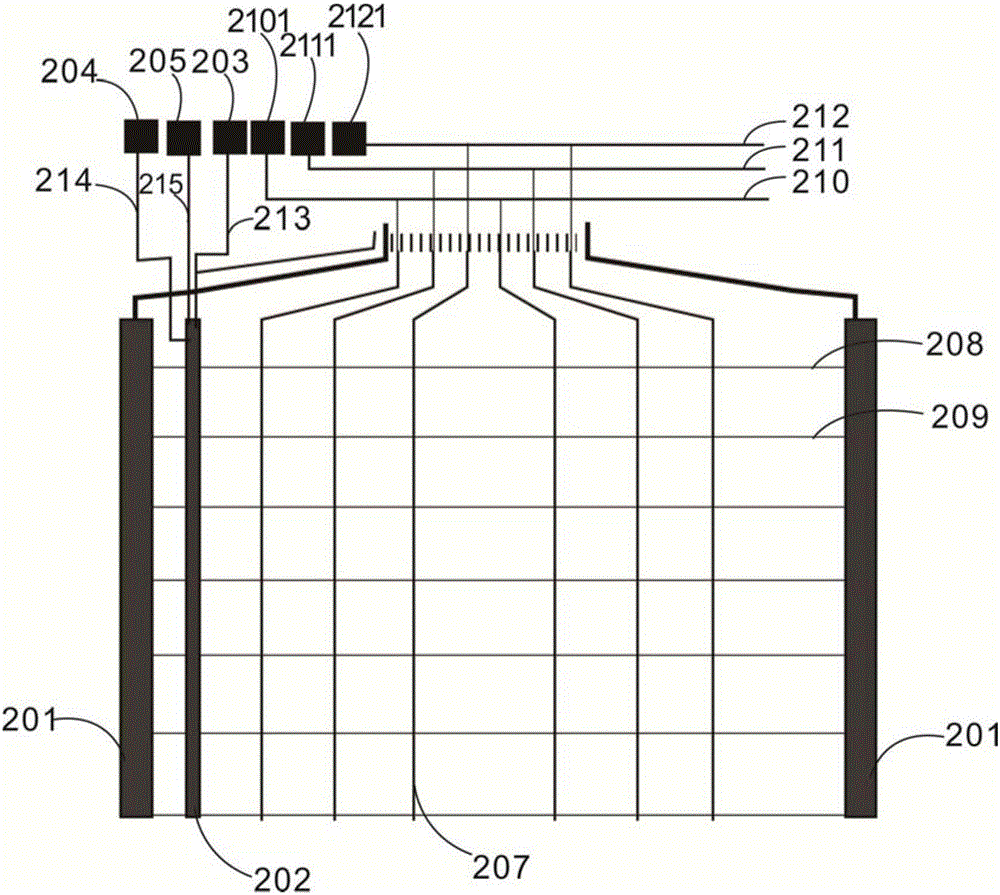

GOA (Gate Driver On Array) circuit and liquid crystal display panel

InactiveCN106200163AAvoid damageAvoid the problem of alignment failureNon-linear opticsLiquid-crystal displaySignal on

The invention provides a GOA (Gate Driver On Array) circuit which comprises an alignment terminal region, a liquid crystal alignment circuit and a field effect transistor, wherein the alignment terminal region comprises a switching signal terminal, gate signal terminals and a data signal input terminal; the output end of the liquid crystal alignment circuit is connected with the alignment terminal region; the field effect transistor outputs an alignment voltage signal on a corresponding data line to a corresponding pixel electrode according to a gate electrode signal on a scanning line. The GOA circuit has the beneficial effects that by adding an alignment circuit at the output end of the GOA circuit and separating the GOA circuit from the alignment circuit, in the liquid crystal alignment process, the alignment circuit inputs testing signals to odd and even line gate lines so as to detect whether a rear end line is conducted; opening and closing of the alignment circuit are switched by changing a voltage of a switching signal line, so that the problems of damage to the GOA circuit and alignment failure, which are easy to caused due to a large circuit load in the liquid crystal alignment process, are avoided, and liquid crystal alignment efficiency and compatibility of a liquid crystal alignment jig are improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

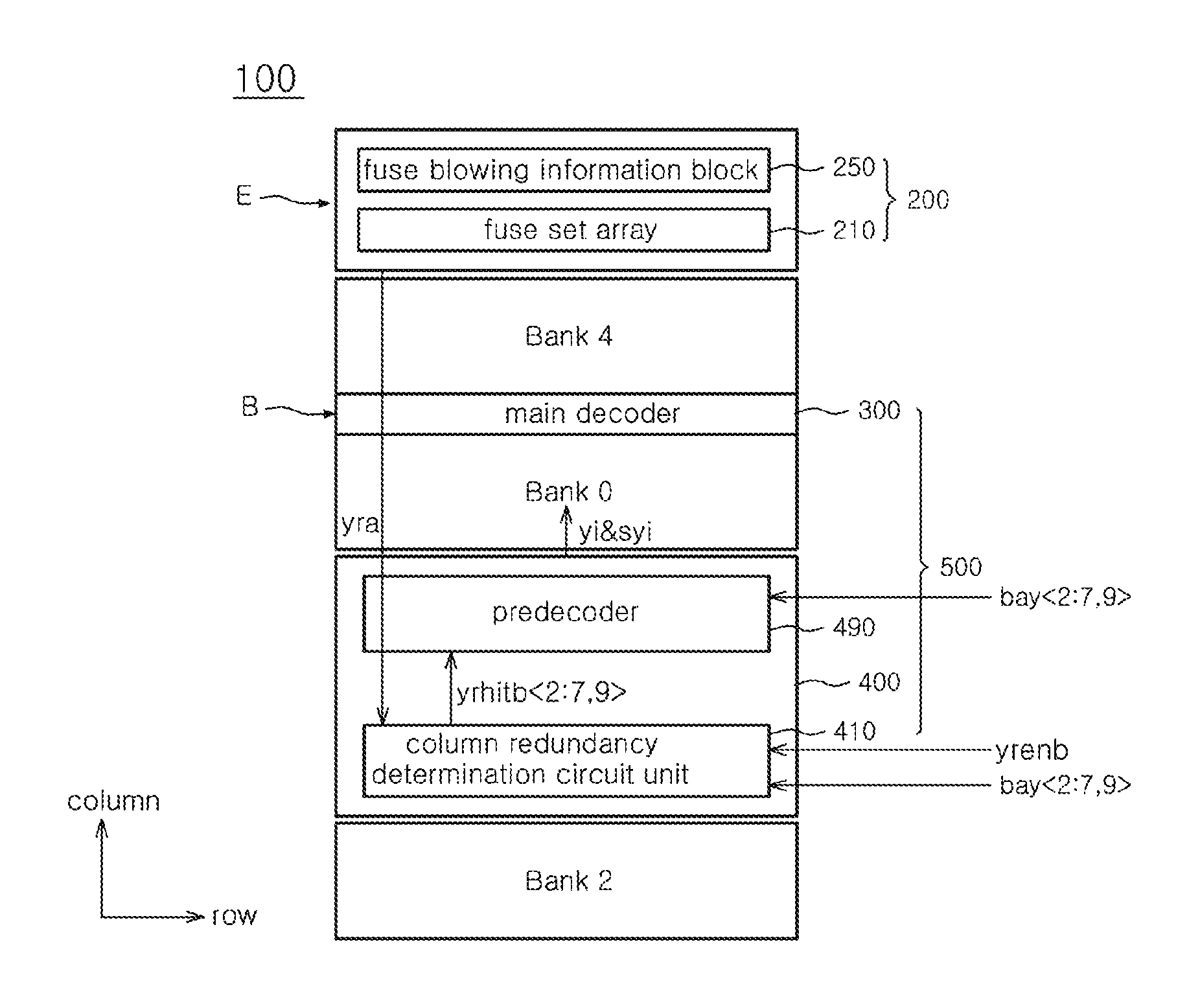

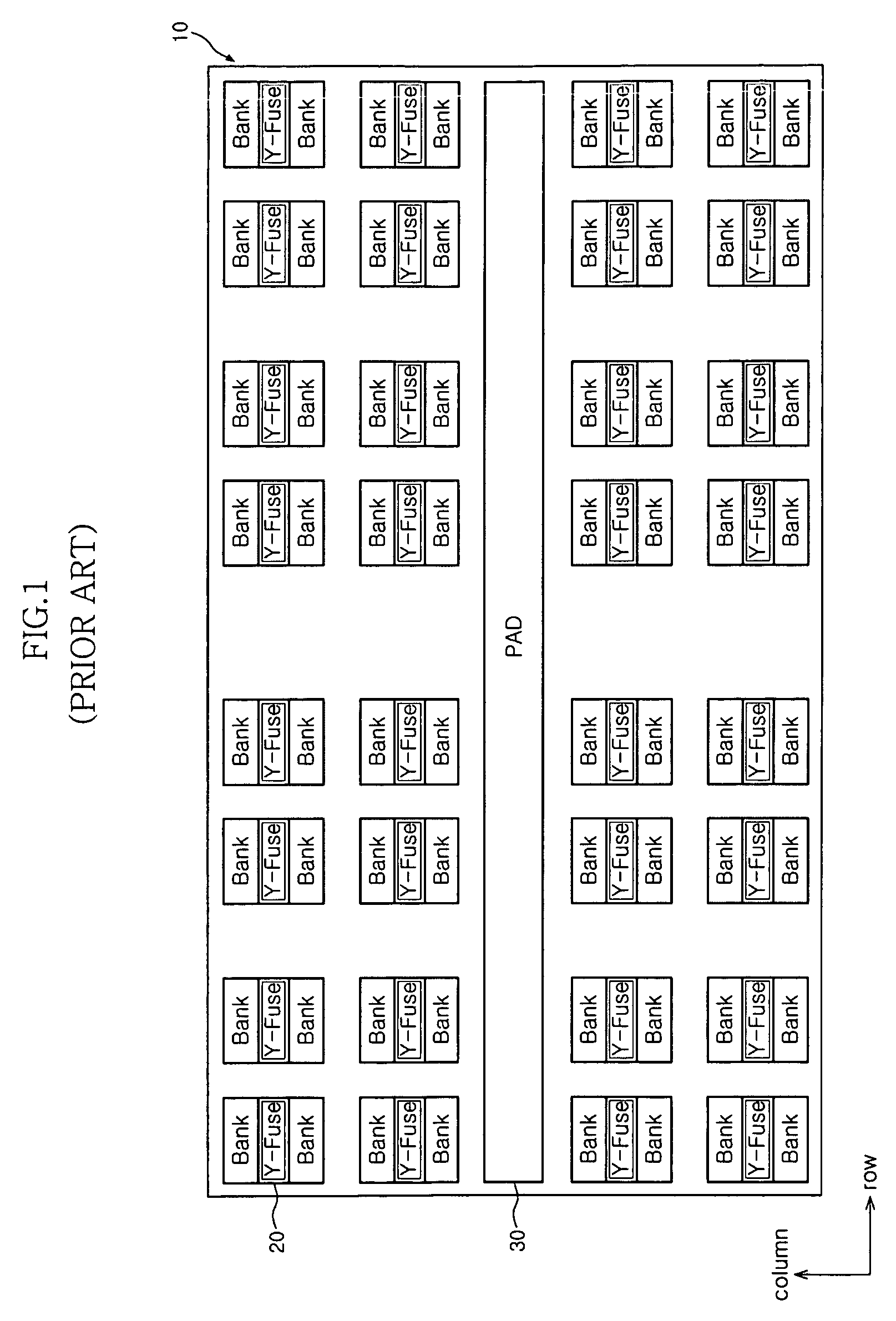

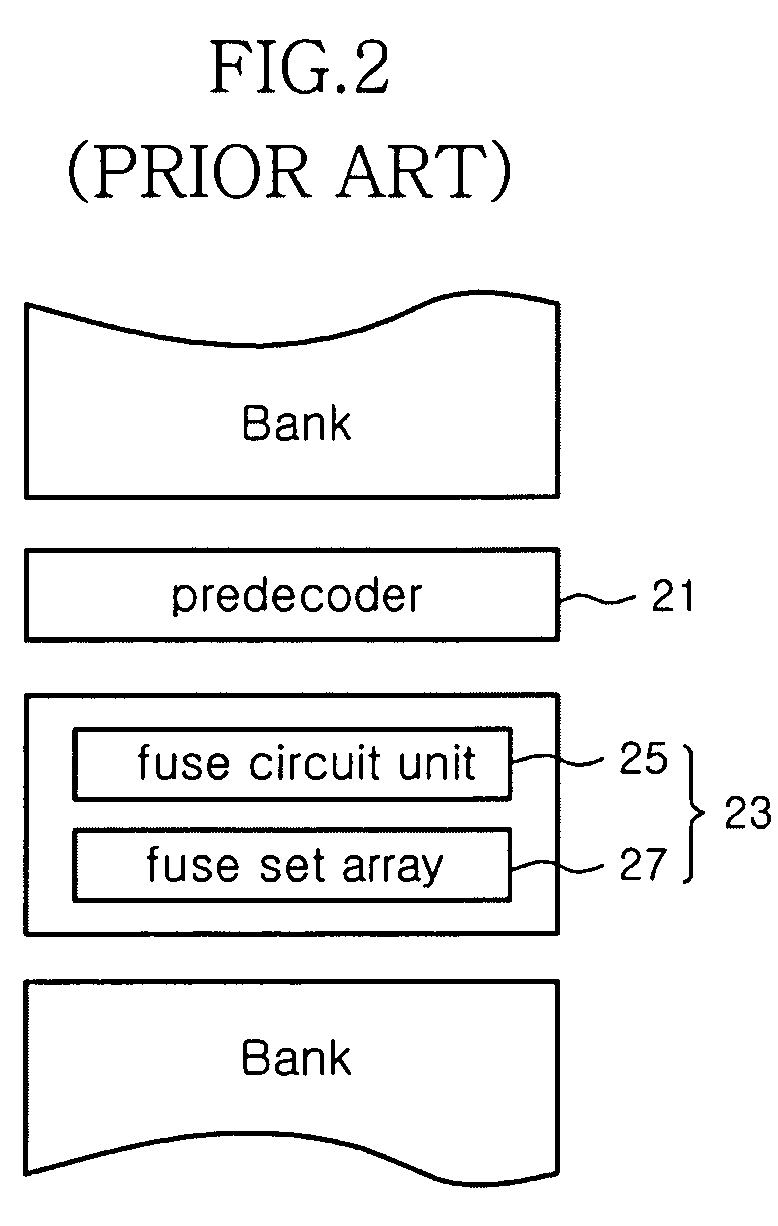

Semiconductor integrated circuit including column redundancy fuse block

ActiveUS8077531B2Improve alignment efficiencyRead-only memoriesDigital storageSemiconductor chipIntegrated circuit

A semiconductor integrated circuit includes a semiconductor chip having an edge area and a bank area located an inner portion of the edge area, and a column redundancy fuse block disposed in the edge area.

Owner:SK HYNIX INC

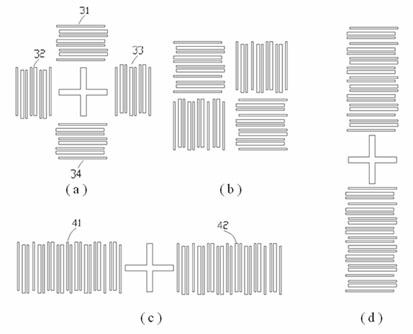

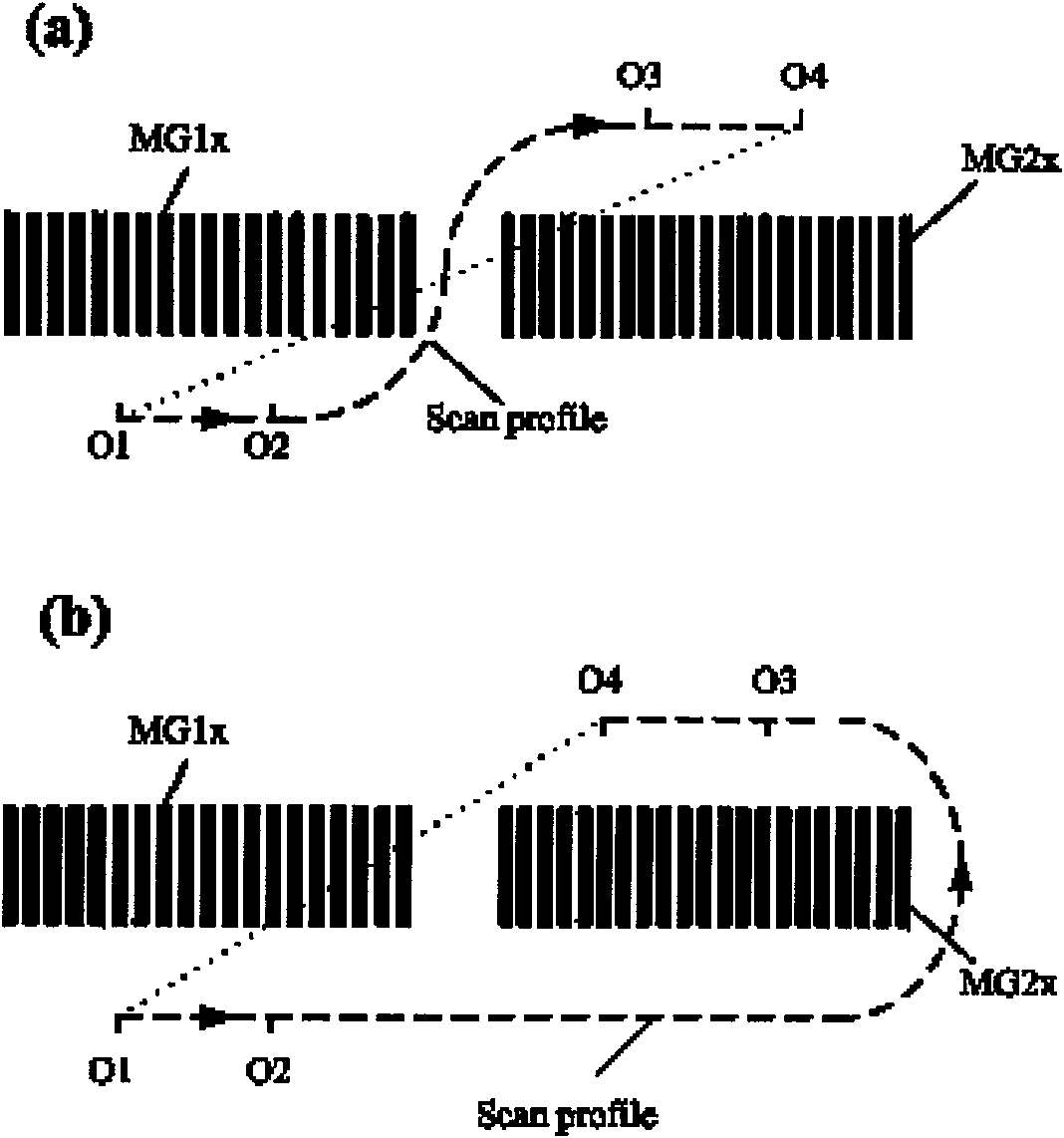

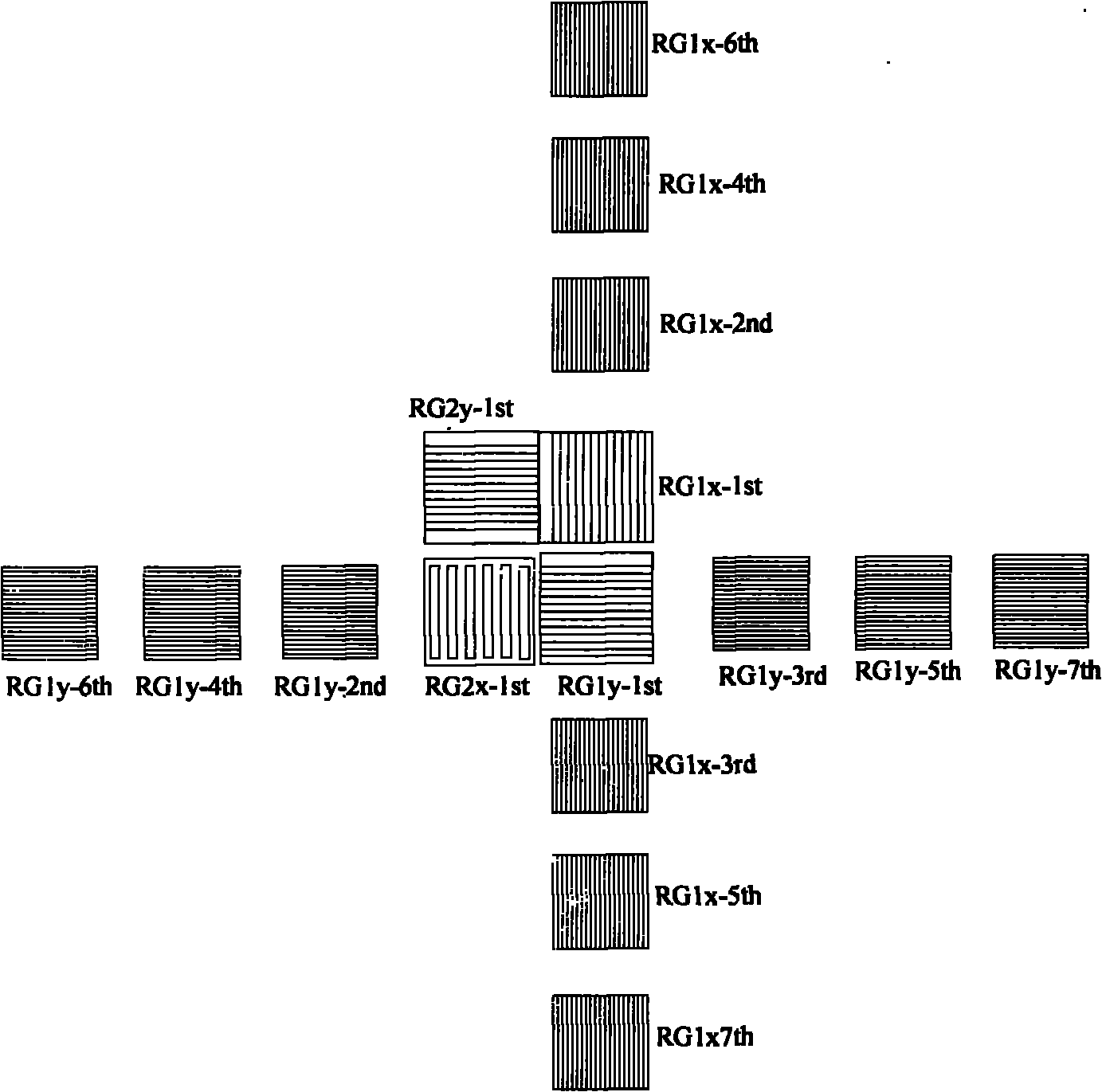

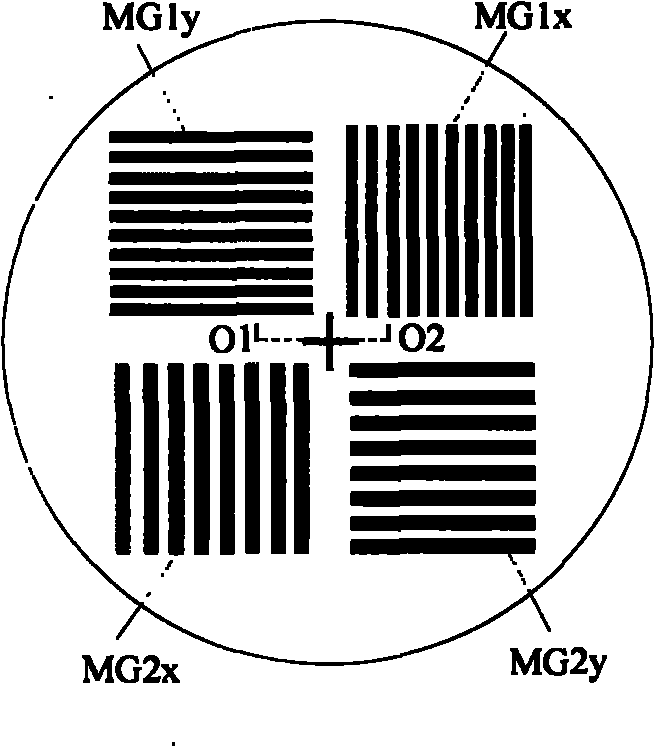

Alignment scanning method for alignment mark

ActiveCN102096347AReduce placementReduce the overall heightPhotomechanical treatmentGratingProcess module

The invention discloses an alignment scanning method for an alignment mark. The method comprises the following steps that: 1, an alignment operation and management module transmits scanning parameters to a signal acquisition and processing module and a position acquisition and motion control module; 2, the position acquisition and motion control module plans a motion track comprising a scanning track in the process of scanning various sub-gratings and a transition track connected with different scanning tracks according to the scanning parameters and performance indexes of a motion table, and reaches an agreement with the alignment operation and management module to finish synchronous negotiation; 3, the motion table takes place and moves under the control of the position acquisition and motion control module according to the planned motion track; 4, the position acquisition and motion control module acquires position information for alignment and transmits the information to the alignment operation and management module, the signal acquisition and processing module acquires light intensity signals and transmits the light intensity signals to the alignment operation and management module; and 5, the alignment operation and management module calculates an alignment position of the mark according to the light intensity signals of a plurality of marked sub-gratings and the position information.

Owner:SHANGHAI MICRO ELECTRONICS EQUIP (GRP) CO LTD

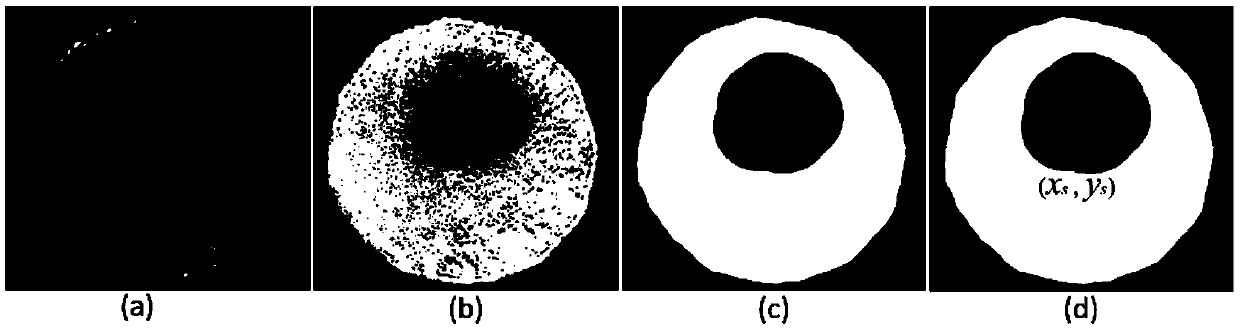

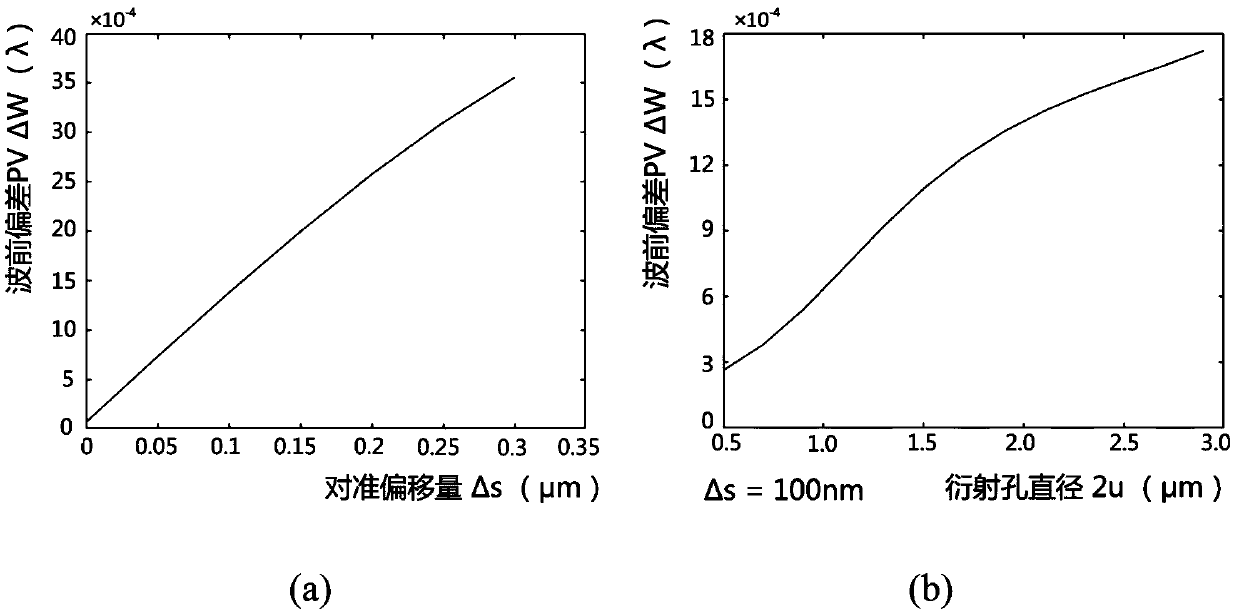

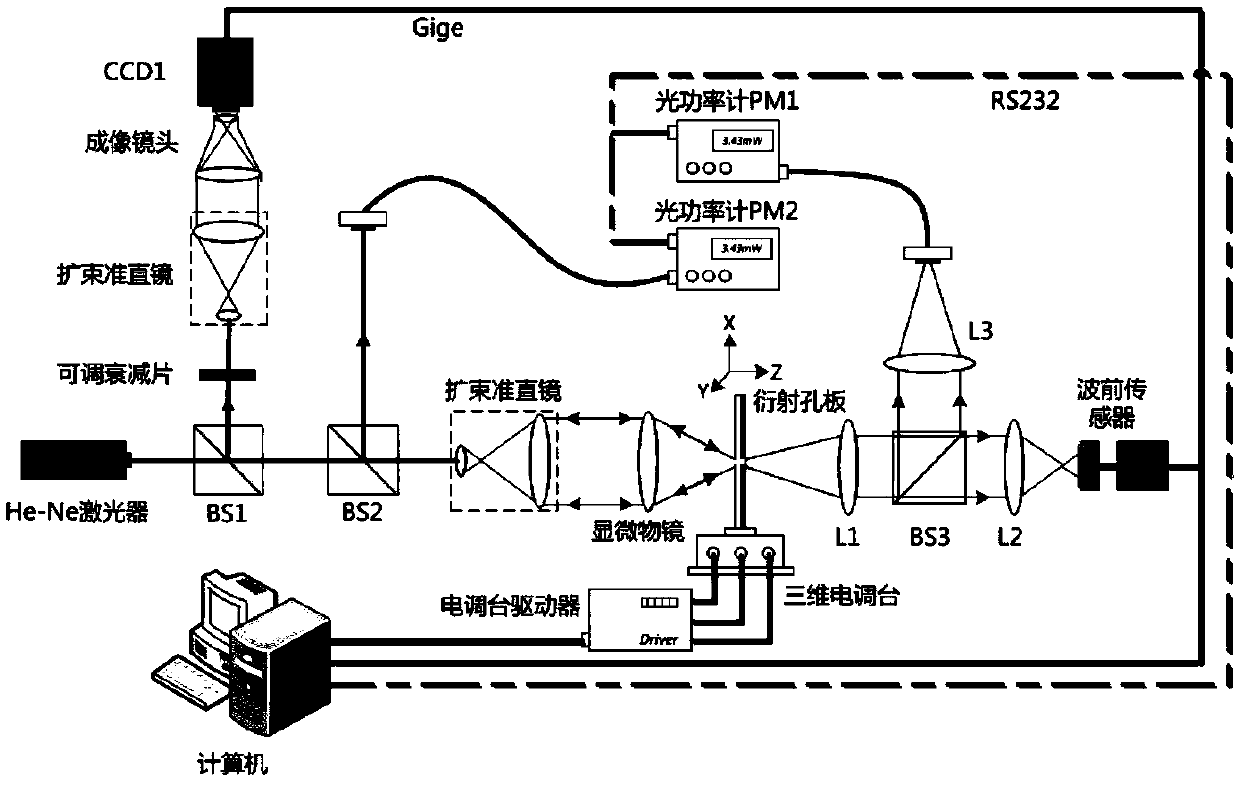

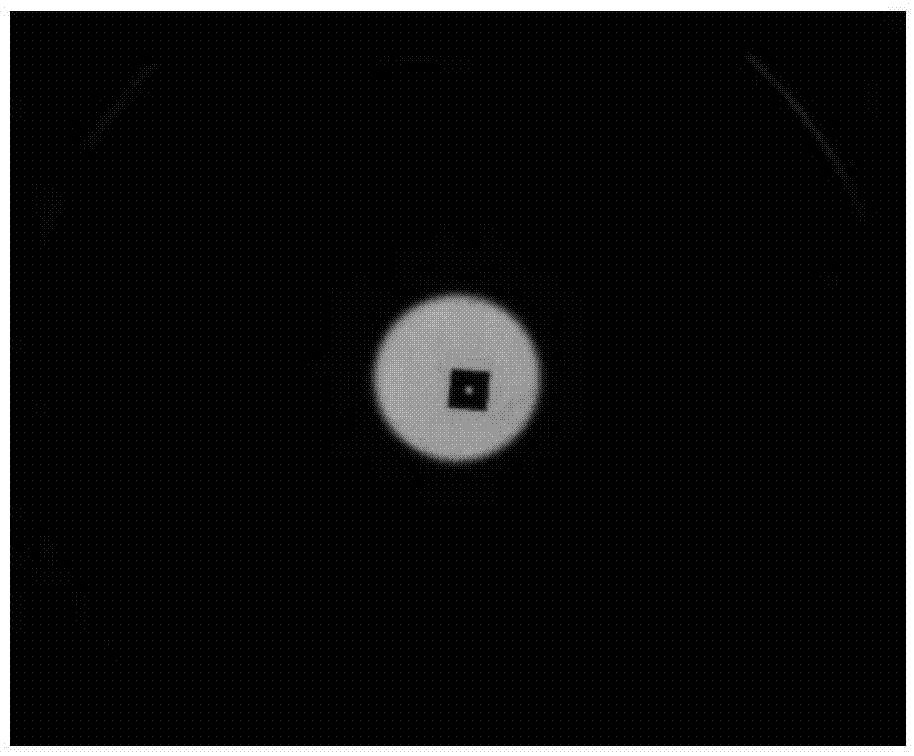

System and method for accurately calibrating optical path of point diffraction interferometer based on image information

ActiveCN109556531AAvoid damageRealize visualizationUsing optical meansOptical power meterWavefront sensor

The invention discloses a system and a method for accurately calibrating an optical path of a point diffraction interferometer based on image information. The system comprises spectroscopic prisms, abeam expanding collimation system, a diffraction orifice plate, a wave-front sensor, lenses, an optical power meter, three-dimensional precision electronically controlled translation stage and driverthereof, a CCD1 (charge-coupled device), and a computer. The method comprises the following steps of: analyzing and obtaining a mathematical relationship between an alignment error and a diffraction wave-front deviation by using the Rayleigh-Sommerfeld diffraction theory; designing an accurate optical path calibration system according to requirements to obtain a spot-hole alignment image and lightintensity before and after the diffraction orifice plate; then analyzing and measuring alignment deviation information through an image processing algorithm to establish a mathematical model betweenthe measurement quantity and the control quantity; and finally, achieving accurate calibration according to a system implementation principle. According to the system and the method for accurately calibrating the optical path of the point diffraction interferometer based on the image information, the precise alignment of the diffraction holes and the spot in the visual environment is realized, andthe influence of the alignment deviation on the detection precision of the point diffraction interferometer to some extent is eliminated. The system and the method have characteristics of high precision and high efficiency, and reduce the damage of the laser to the vision of operators during experimental operation.

Owner:XI AN JIAOTONG UNIV

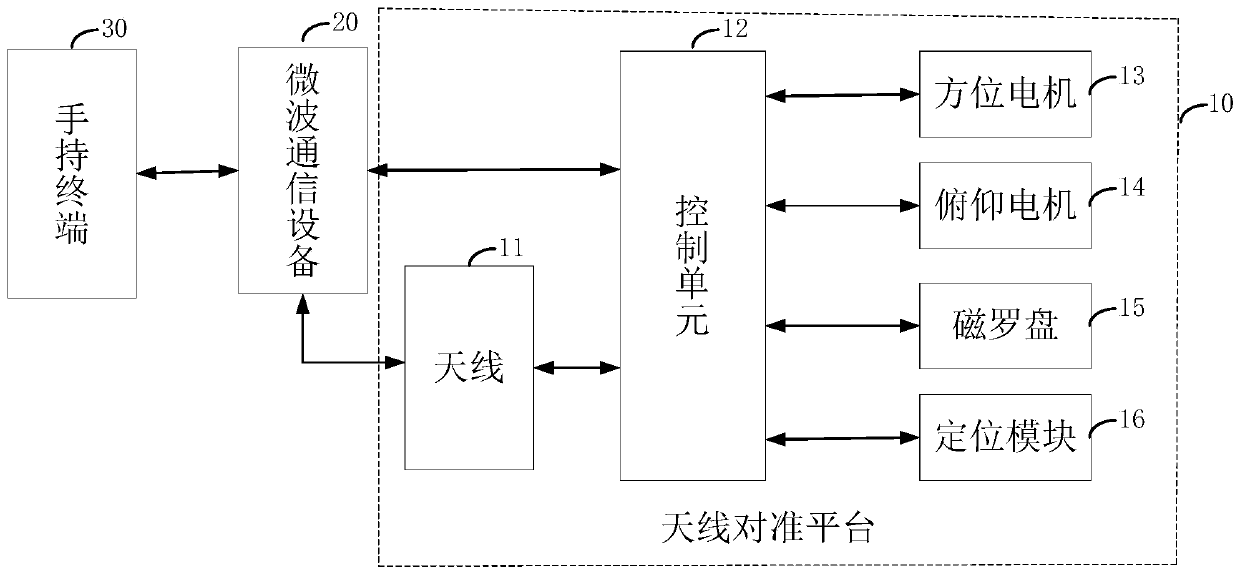

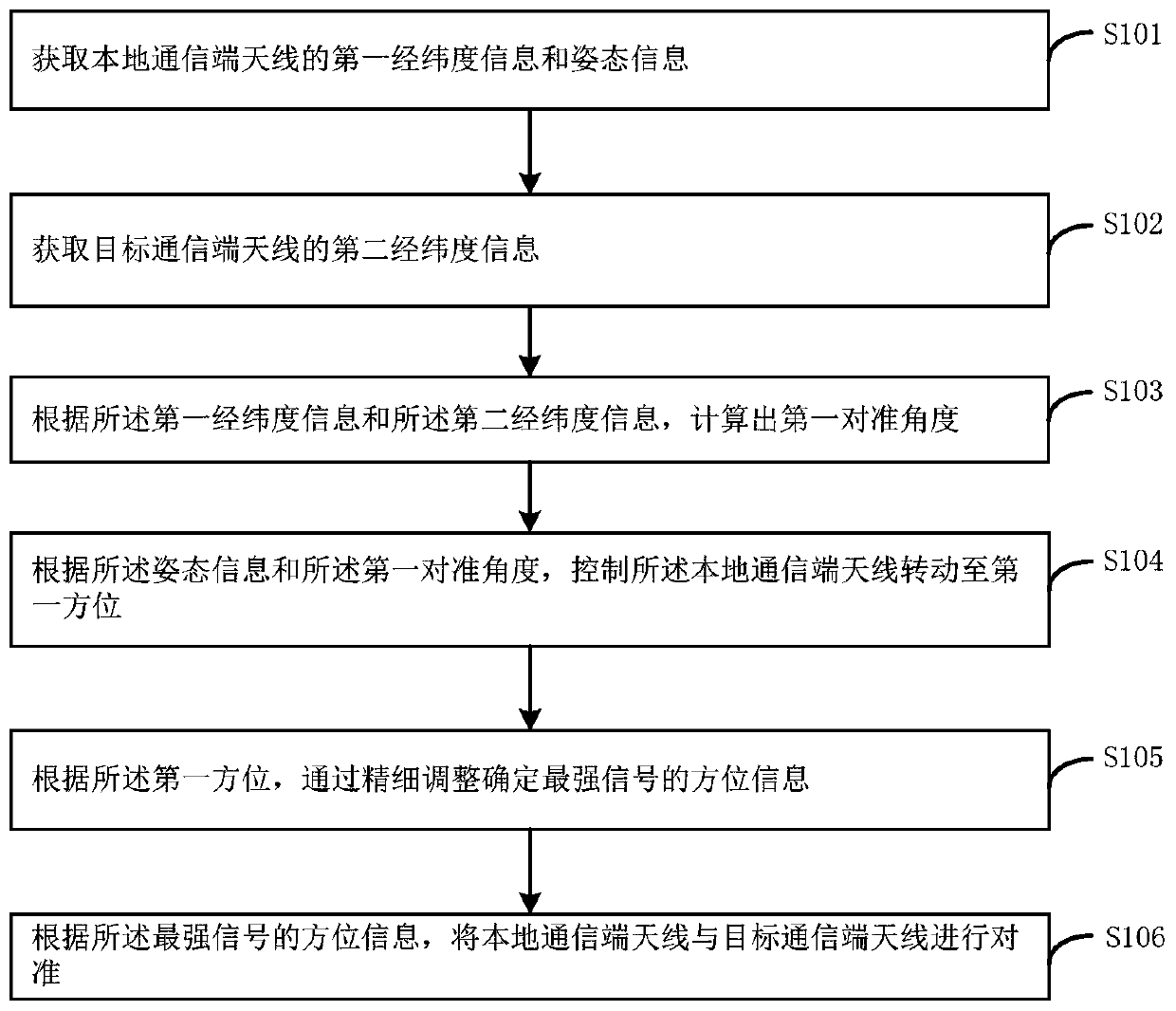

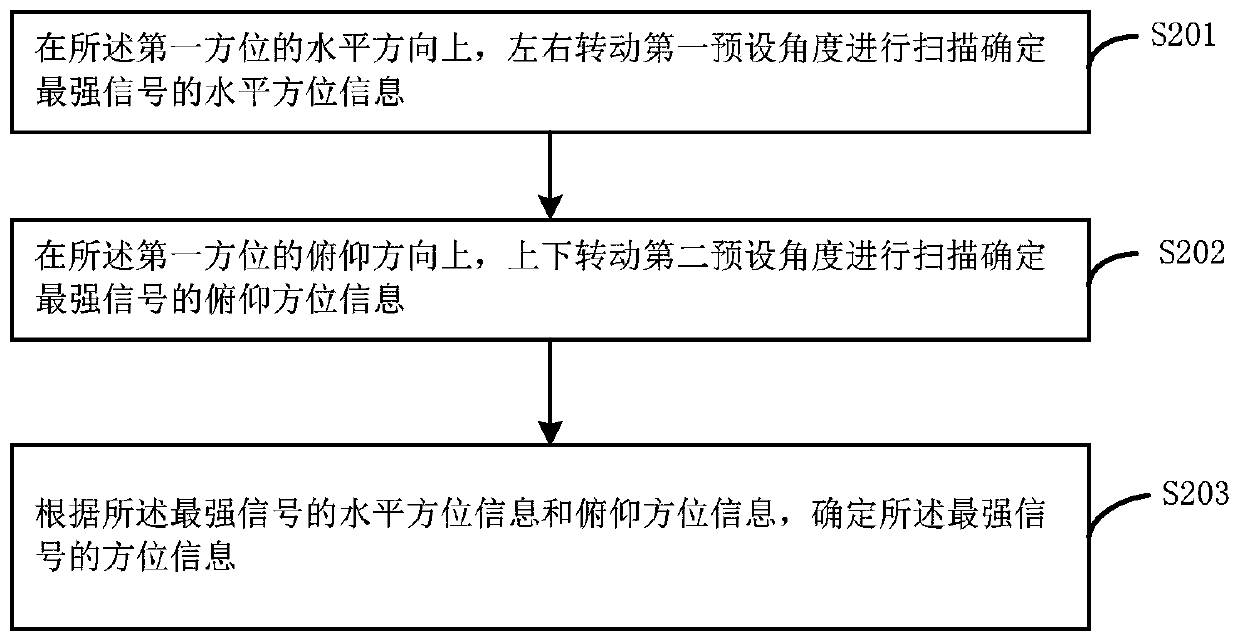

Antenna alignment method and device

PendingCN110381476AImprove alignment efficiencyFast alignmentAntennasMachine-to-machine/machine-type communication serviceLongitudeVIT signals

The invention belongs to the technical field of communication, and provides an antenna alignment method and device, and the method comprises the steps: obtaining first longitude and latitude information and attitude information of a local communication terminal antenna; acquiring second longitude and latitude information of a target communication terminal antenna; calculating a first alignment angle according to the first longitude and latitude information and the second longitude and latitude information; controlling the local communication terminal antenna to rotate to a first azimuth according to the attitude information and the first alignment angle; determining azimuth information of the strongest signal through fine adjustment according to the first azimuth; and aligning the local communication terminal antenna with the target communication terminal antenna according to the azimuth information of the strongest signal. According to the embodiment of the invention, the antenna canbe automatically rotated to the first azimuth, then the azimuth information of the strongest signal is determined, and the local communication terminal antenna and the target communication terminal antenna are aligned according to the azimuth information of the strongest signal, so that the alignment speed is high, the alignment precision is high, the manual participation is less, and the antennaalignment efficiency is effectively improved.

Owner:SHENZHEN TONGCHUANG COMM

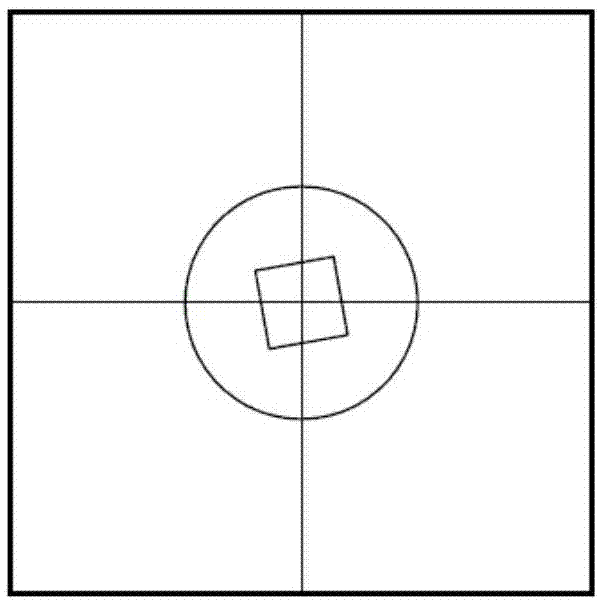

Device and method of quickly aligning optical axis of micro optical lens

InactiveCN106997103AEasy accessImprove alignment efficiencyOptical elementsCamera lensOptoelectronics

The invention is applicable to the field of precise instrument adjustment, and provides a device for quickly aligning the optical axis of a micro optical lens, which comprises a film image arranged above a to-be-aligned micro optical lens, a relay lens, a camera arranged below the micro optical lens and performing photographing from bottom to top, and an adjusting mechanism for adjusting the optical axis of the micro optical lens, wherein the relay lens is located between the film image and the micro optical lens; optical axes of the film image, the relay lens and the camera are overlapped; the center of the film image is provided with a feature graph, and the center of the feature graph is overlapped with the center of the film center. In a condition in which overlapping of the optical axes of the film image, the relay lens and the camera is met, through photographing of the camera from bottom to top, the optical axis offset of the micro optical lens can be analyzed through the film image and the feature graph image, adjustment through the adjusting mechanism is carried out, the structure of the device and the algorithm are concise and simple, operation is easy, no expensive measurement instrument is needed, the optical axis alignment efficiency and the accuracy are improved, and the cost is saved.

Owner:深圳睿晟自动化技术有限公司

A transport mechanism for tunnel construction

ActiveCN102296986ASimple structureReasonable designEarth drilling and miningUnderground transportTunnel constructionAerospace engineering

The invention discloses a transport mechanism for tunnel construction, which comprises a travelling trolley, a lift mechanism and a lateral movement mechanism, the travelling trolley can move forward and back ward along a horizontal movement track, the lift mechanism can stably lift an article to be transported, the lateral movement mechanism can drive the lift mechanism to synchronously move to the left and the right, and is mounted on the travelling trolley, the lift mechanism is firmly mounted on the lateral movement mechanism, and the travelling trolley, the lateral movement mechanism andthe lift mechanism are a forward and backward alignment mechanism, a leftward and rightward alignment mechanism and an upward and downward alignment mechanism which can respectively align the articleto be transported in longitudinal, transverse and vertical directions. The transport mechanism has the advantages of simple structure, reasonable design, safe and reliable working performance and good use effect, is convenient to assemble and easy and convenient to operate, and can effectively solve a variety of practical problems in the movement and accurate positioning of hoisted articles in the process of tunnel construction, such as high working difficulty, low mounting efficiency, high labor intensity and long construction period.

Owner:CHINA RAILWAY FIRST GRP CO LTD

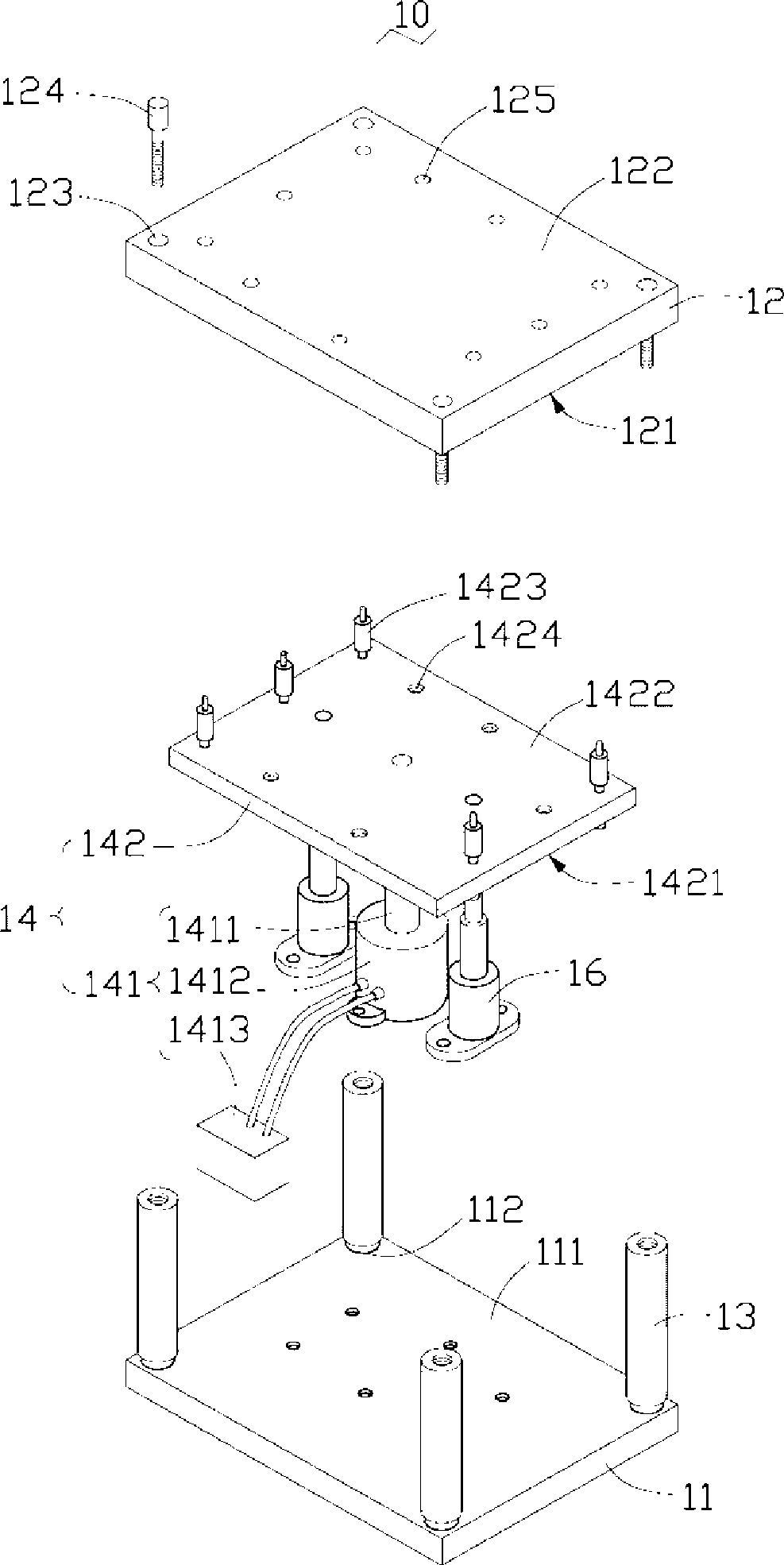

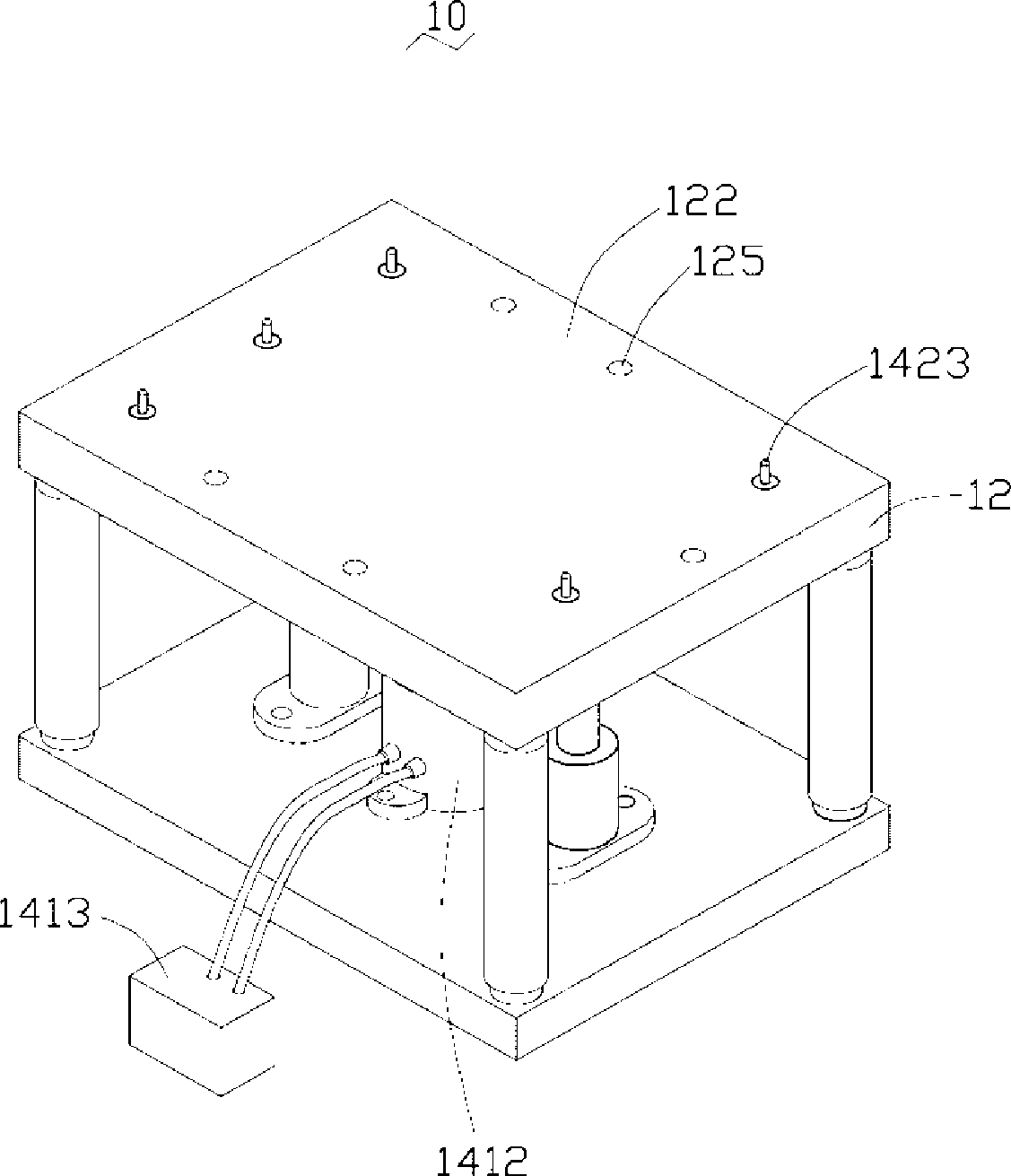

Automatic aligner

InactiveCN101452228AStrict requirementsImprove alignment efficiencyPhotomechanical exposure apparatusMicrolithography exposure apparatusMechanical engineeringEngineering

The invention provides an automatic aligning device which comprises a base platform, a bearing platform, an elevating device and a support member connecting the base platform and the bearing platform. The bearing platform is provided with at least one aligning through hole. The elevating device comprises a brake part and an elevating platform connected with the brake part. The elevating device has at least one brake part which is fixed on the base platform and is used for controlling the elevating platform to rise and fall between the base platform and the bearing platform. The elevating platform has an aligning member which is matched with the aligning through hole. The elevating platform is used for matching the aligning through hole corresponding to an object to be aligned to carry out the alignment. The automatic aligning device can improve the alignment efficiency, avoid manmade visual alignment errors and improve the alignment accuracy.

Owner:AVARY HLDG (SHENZHEN) CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com