Simple tool setting and alignment method for boring-milling machining

A technology of tool alignment and boring and milling processing, which is applied in metal processing, metal processing equipment, metal processing machinery parts, etc., can solve the problems of large tool setting errors, achieve high production efficiency, accurate tool alignment, and The effect of the simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

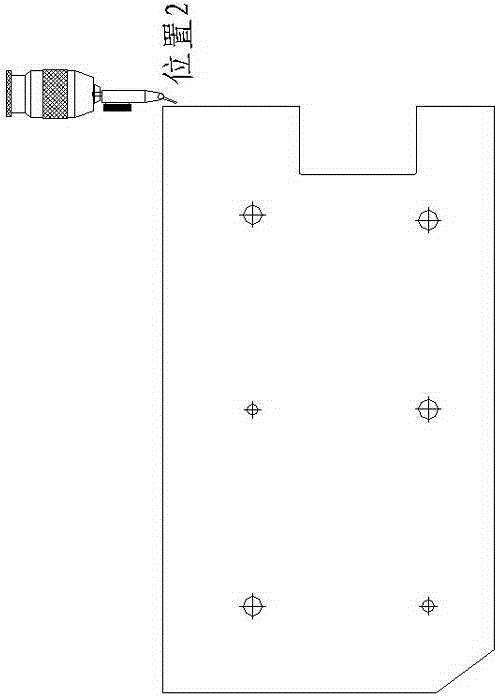

[0035] Figure 7 For the parts of the holes to be processed, 6 holes should be drilled and boring on a steel plate, and the starting points of the coordinates of the 6 holes are different corners.

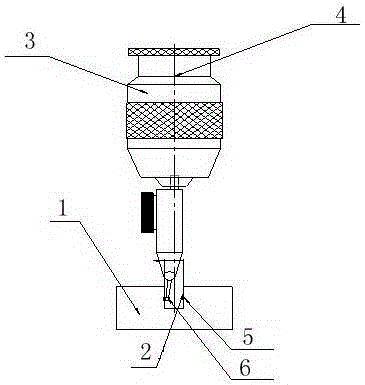

[0036] Step 1: According to the size of the part to be used, the processing equipment we choose is T4163 single-column vertical fine boring machine; the lever dial indicator is installed in the ER8 spring collet on the head of the BT50 tool holder, and the BT50 tool holder is installed in the main shaft of the equipment ;

[0037] Step 2: Fix the alignment block on the work surface of the equipment; move the main shaft of the equipment to position 1 near the alignment block (see Figure 7 ),

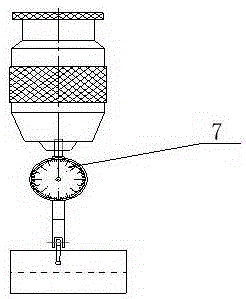

[0038] a. By lowering the spindle of the milling machine or boring machine, lower the head of the lever dial indicator to the middle of the slot with a slot width of 10mm ± 0.005mm, and when the head touches the busbar on the left side of the slot, the light is light within the range of 90°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com