Patents

Literature

37results about How to "Correct and accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

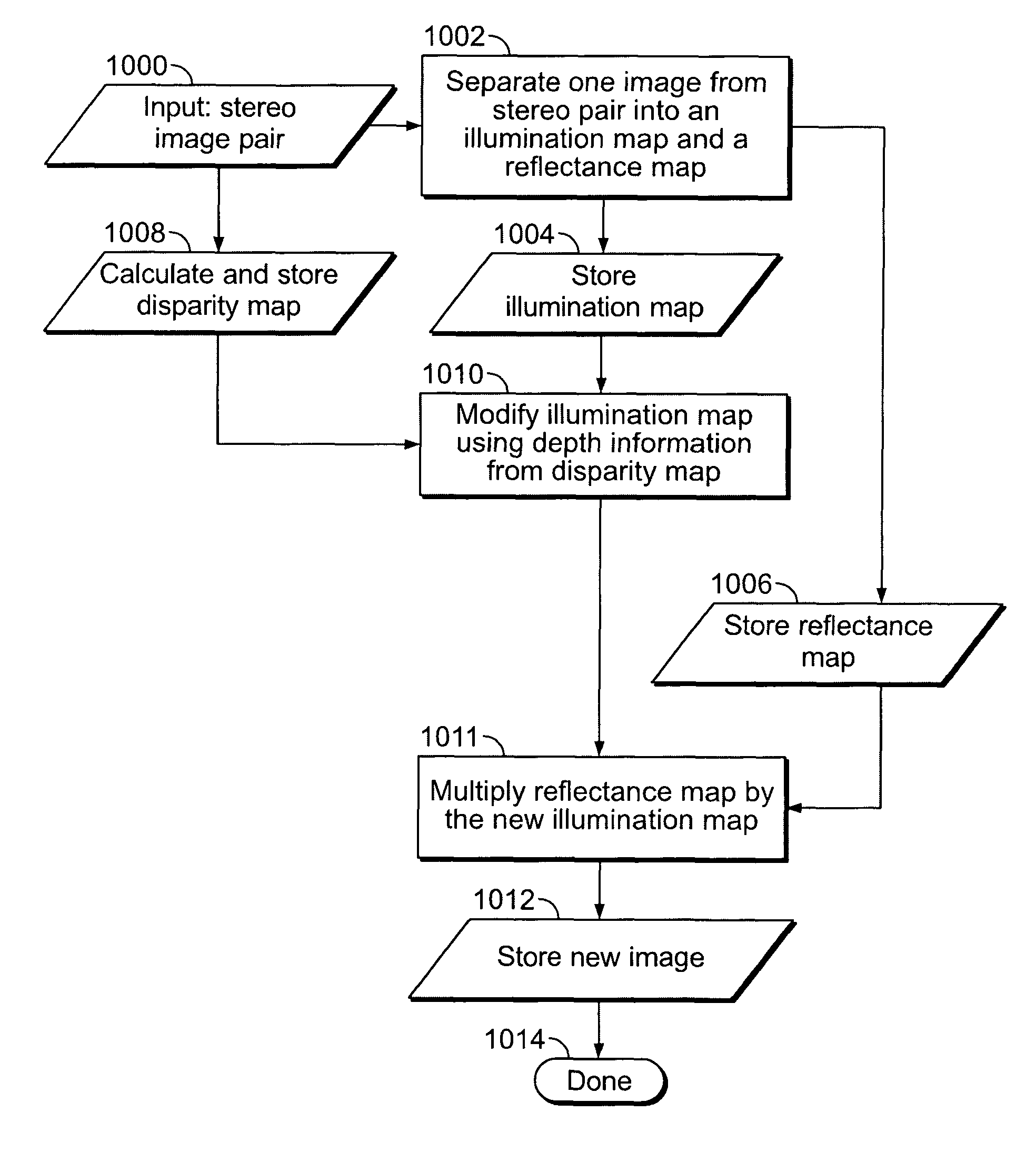

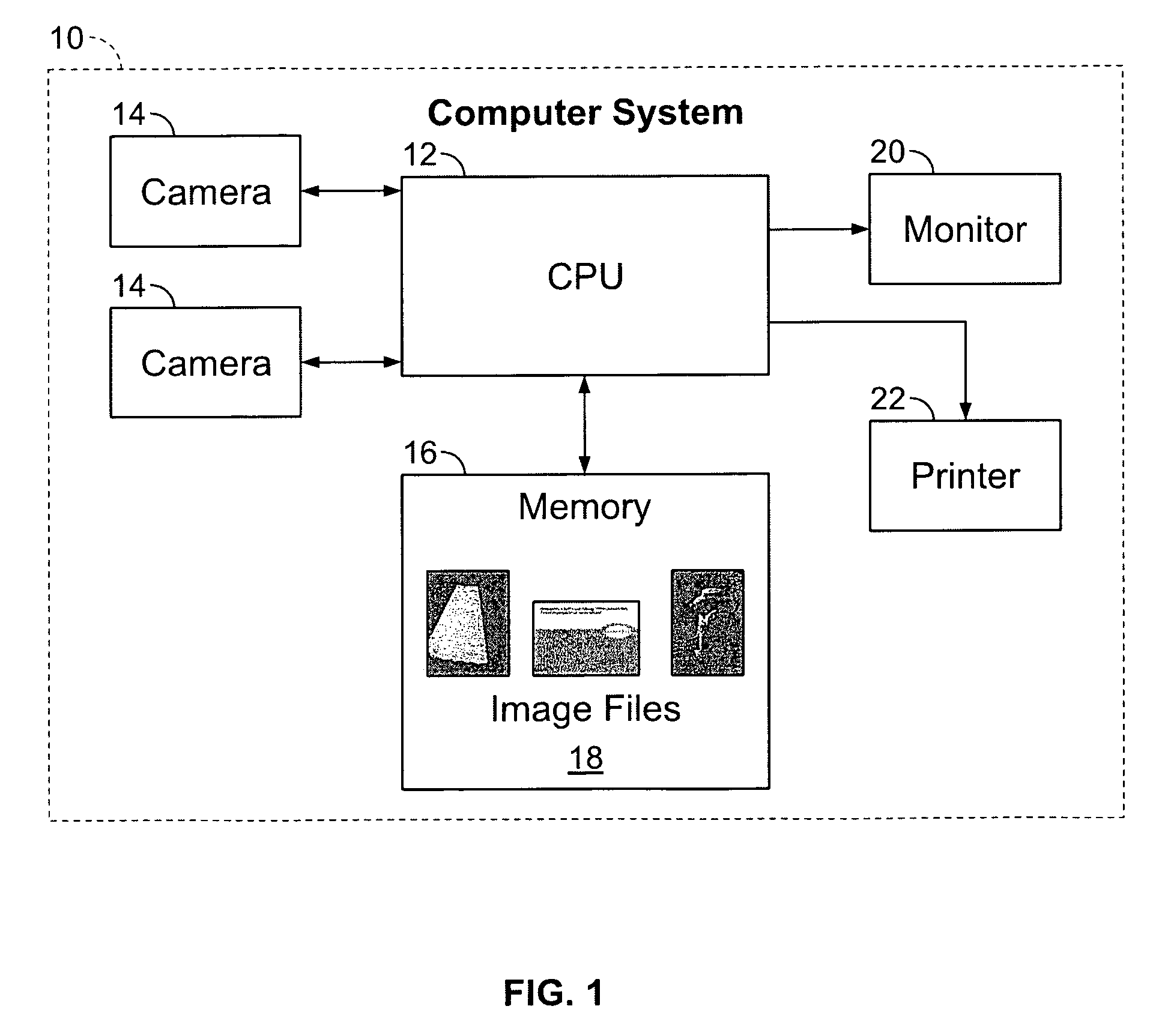

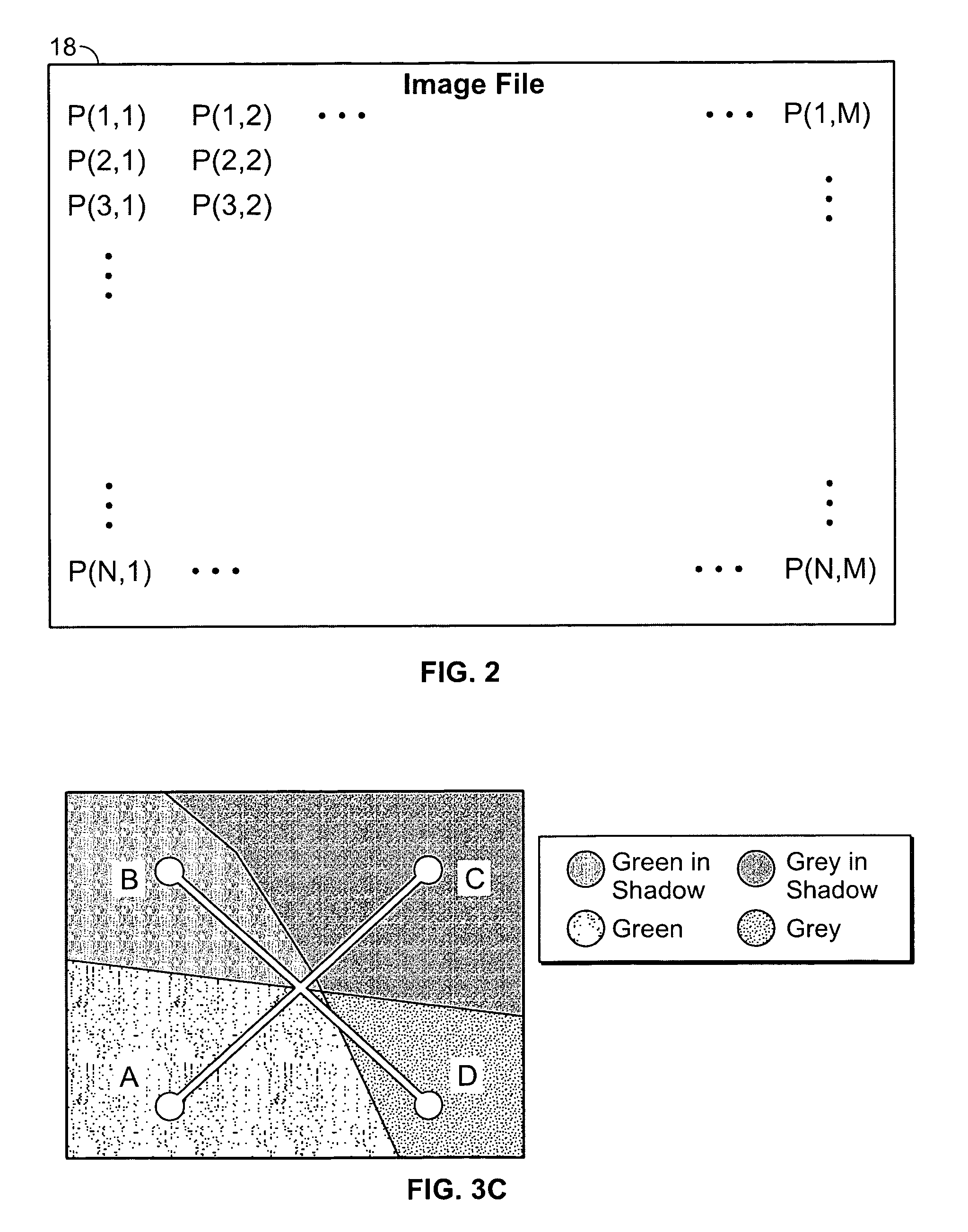

Method for using image depth information in identifying illumination fields

Owner:INNOVATION ASSET COLLECTIVE

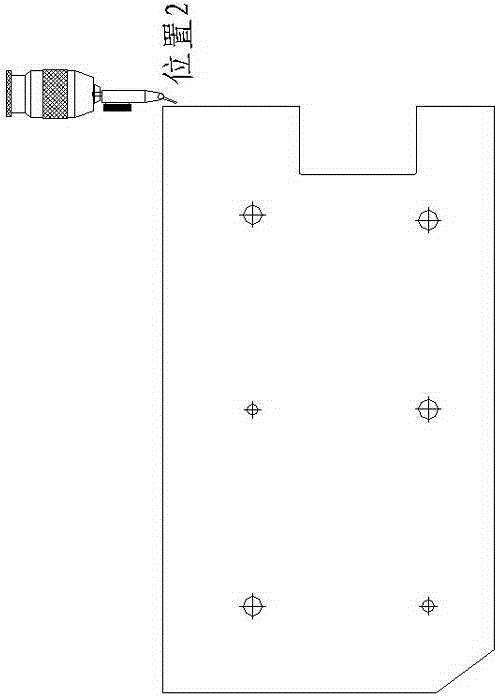

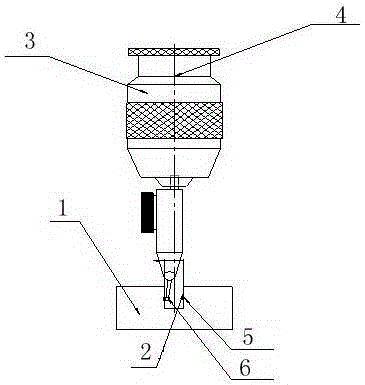

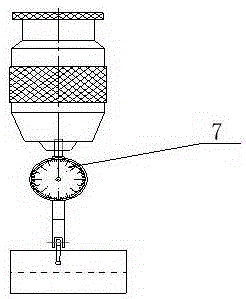

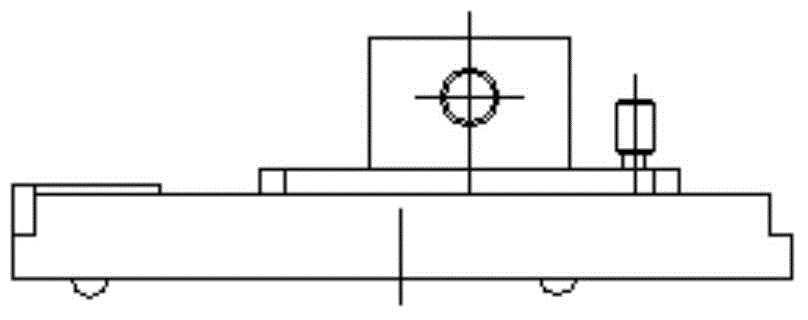

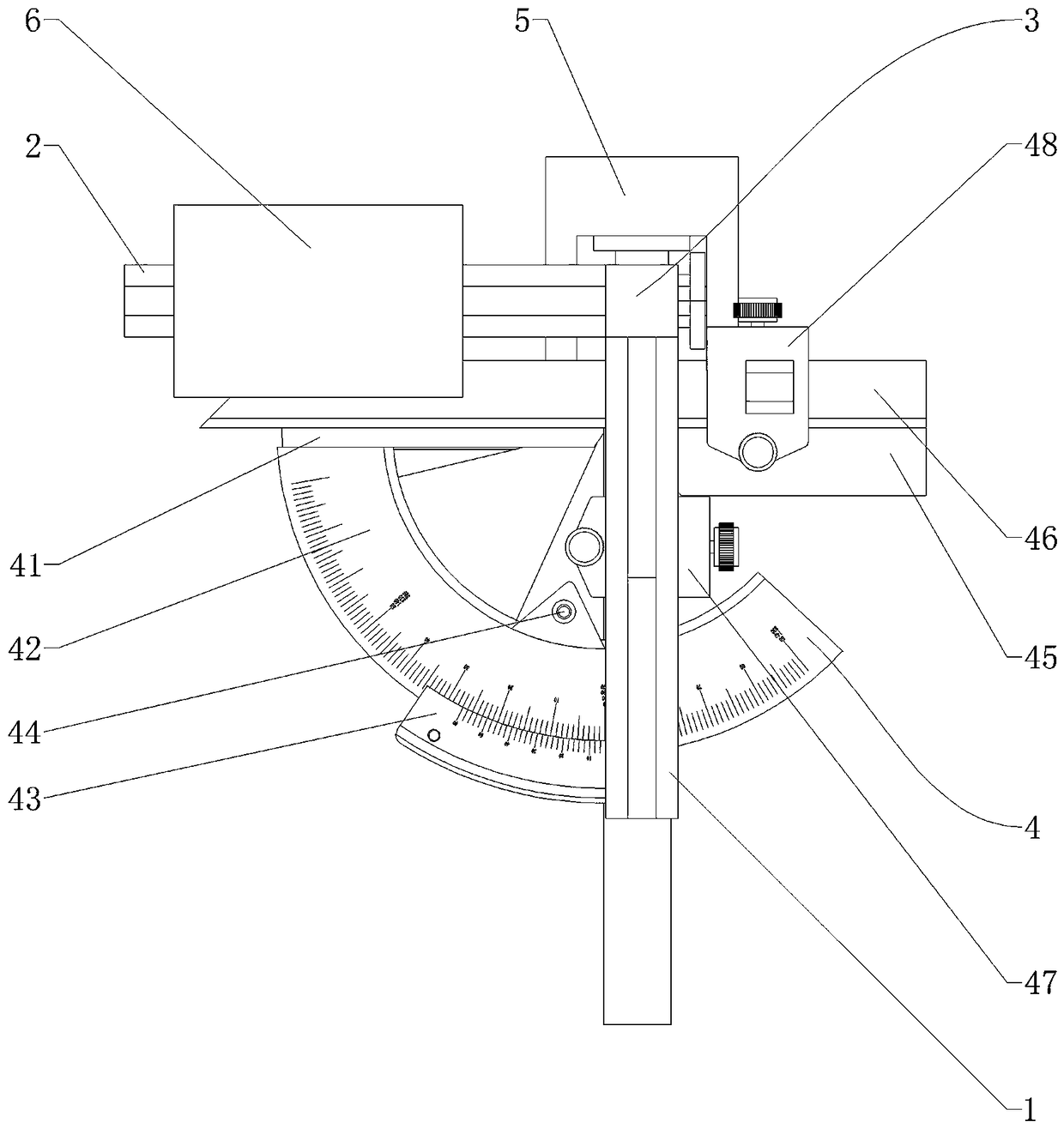

Simple tool setting and alignment method for boring-milling machining

InactiveCN105215786AReduce mistakesHigh skillAutomatic control devicesFeeding apparatusEngineeringMachine

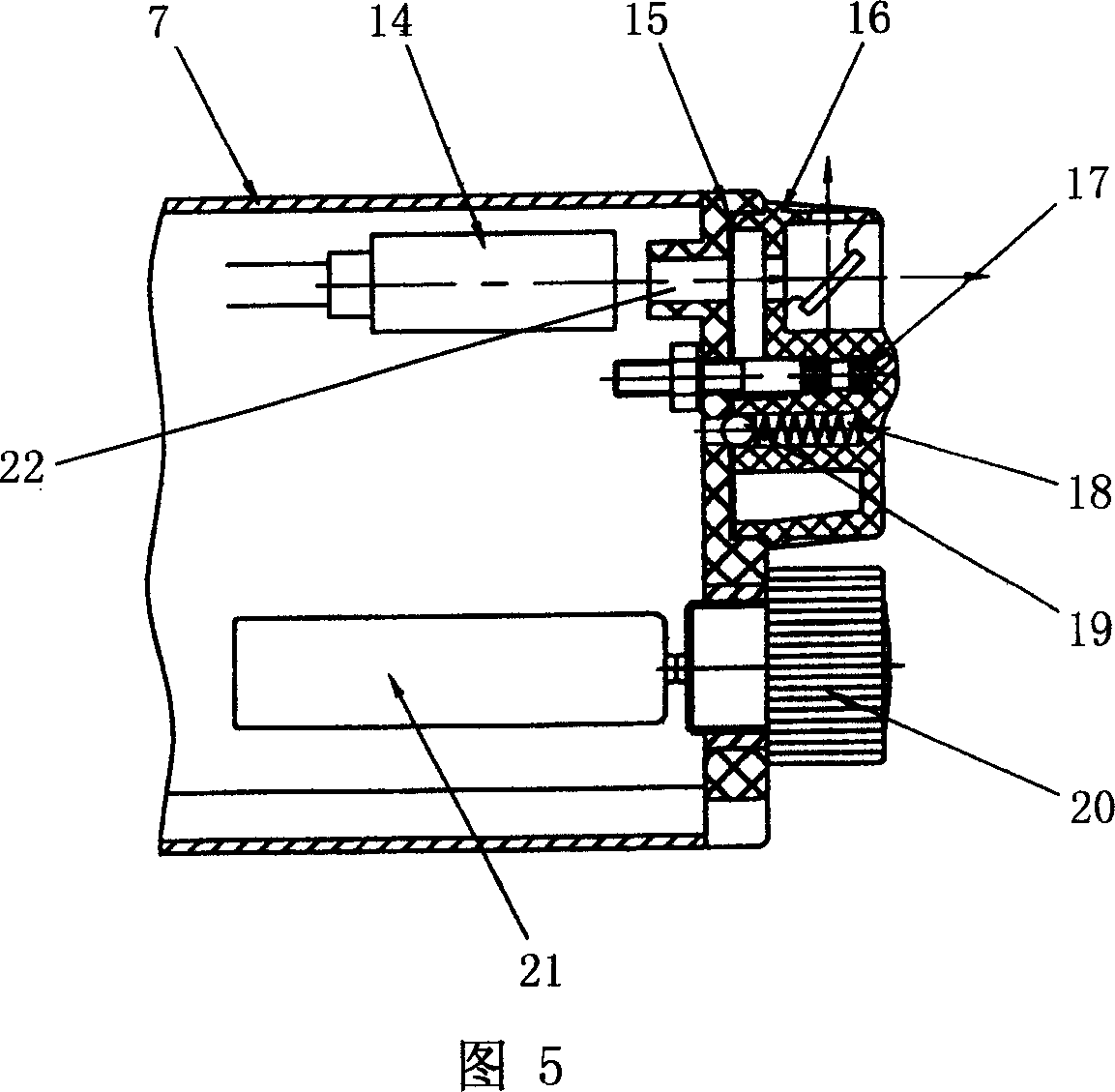

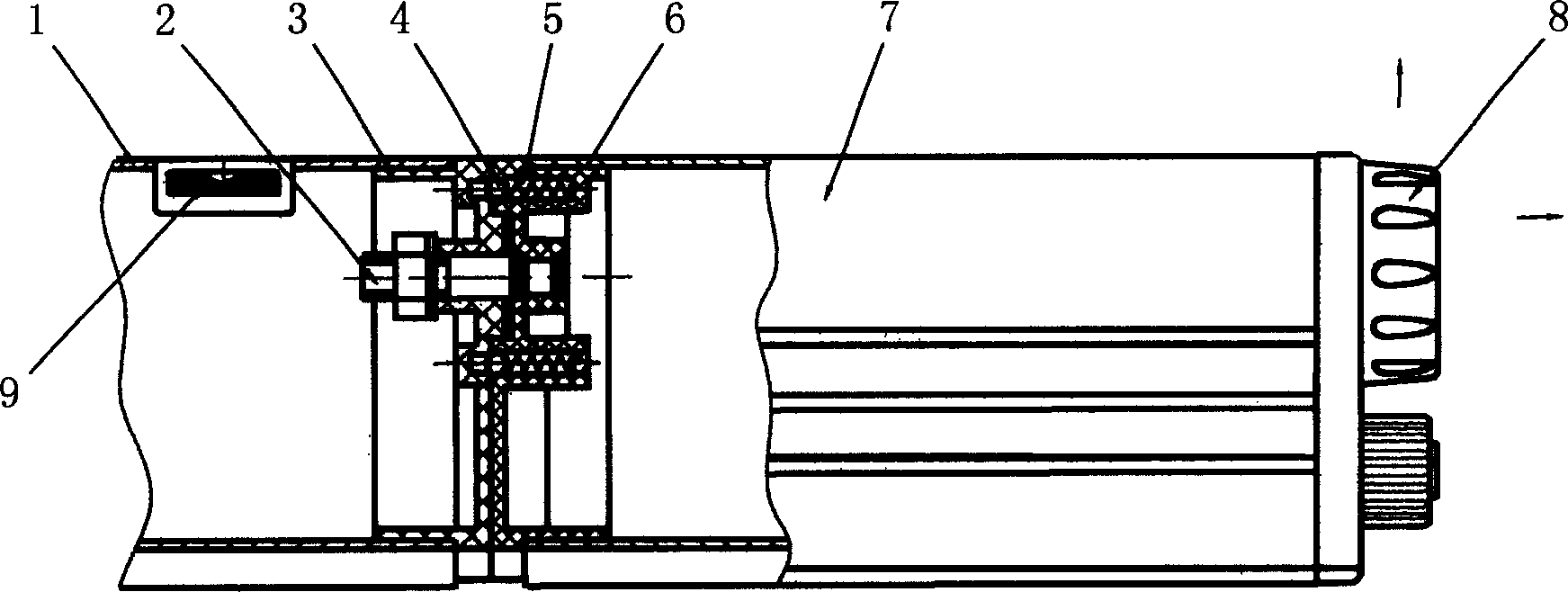

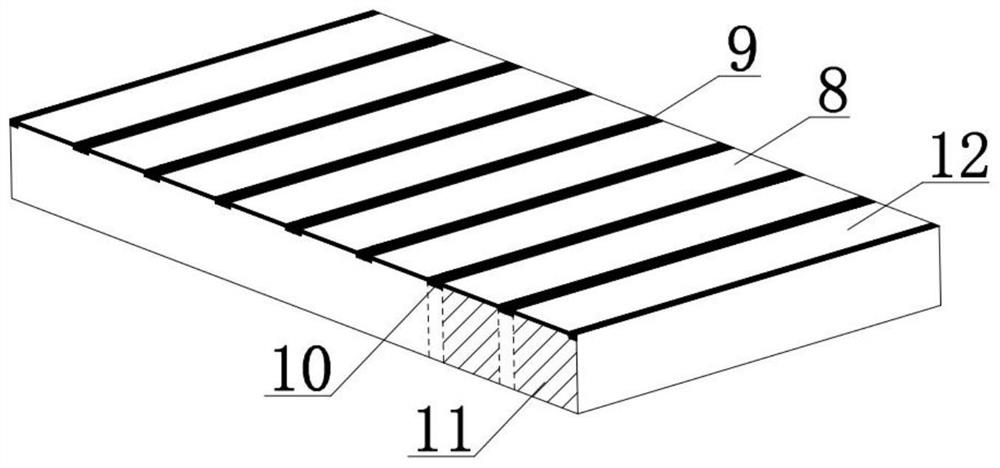

The invention relates to the field of machining, in particular to a simple tool setting and alignment method for boring-milling machining. Through the alignment method, workers can carry out alignment and tool setting conveniently, accurately and rapidly before part machining. The method includes the steps that (1) according to the size of a part to be machined and the model of equipment, a spindle tool handle is selected, a lever indicator is arranged in an ER collet chuck of the head of the tool handle, and the tool handle is arranged in a spindle of a milling machine or a boring machine; (2) an alignment block is fixed to a working table top of the milling machine or the boring machine, after the angle of the head of the lever indicator is adjusted to be within the range from 30 degrees to 80 degrees, the head of the lever indicator is descended and placed in the middle of an alignment block groove, and circles are drawn on generatrices of the two sides of the middle of the alignment block groove repeatedly until the position where the head of the lever indicator displays the maximum value is found; and (3) a console of the milling machine or a console of the boring machine is operated, so that the lever indicator in the alignment block groove is lifted.

Owner:西安西航集团莱特航空制造技术有限公司

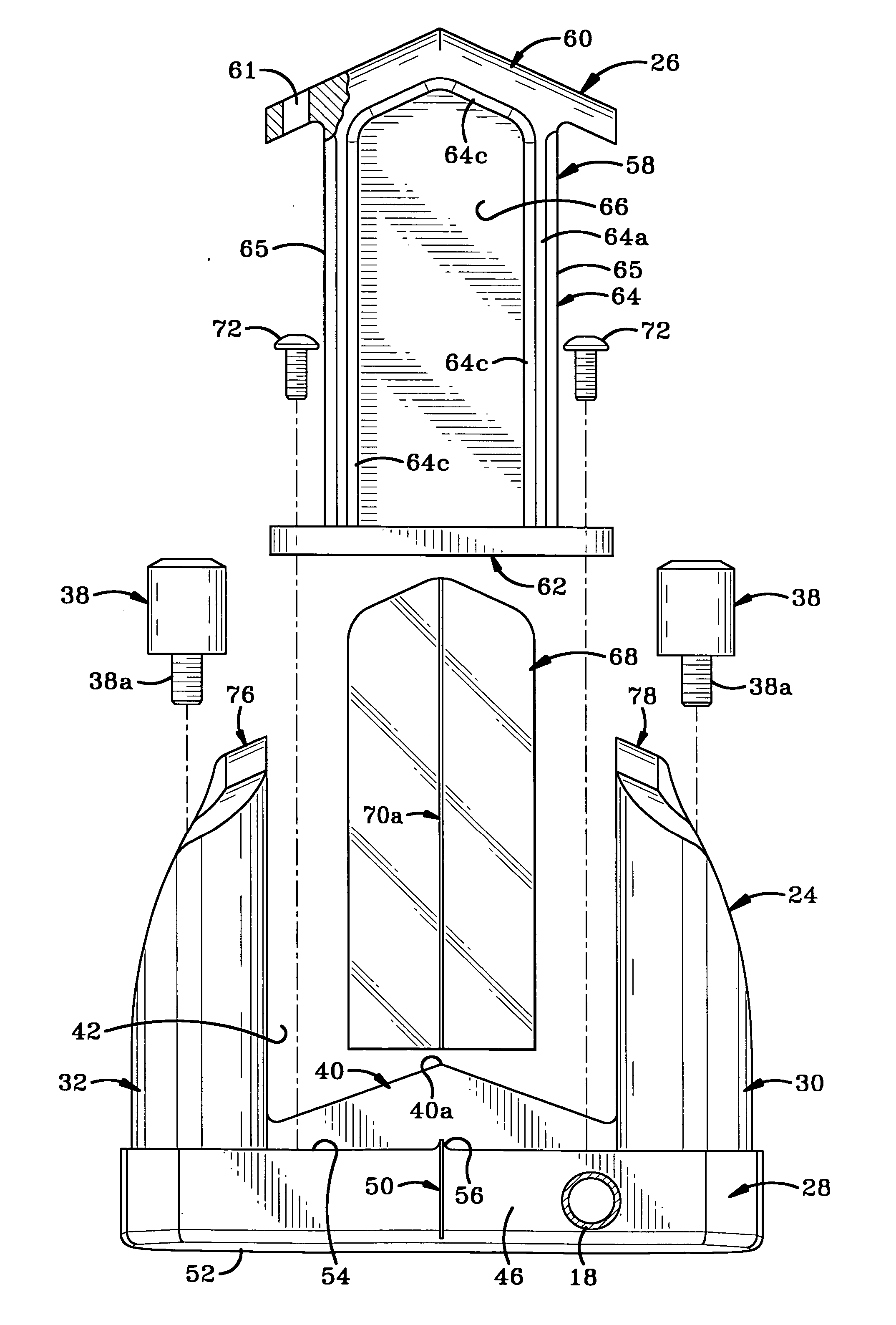

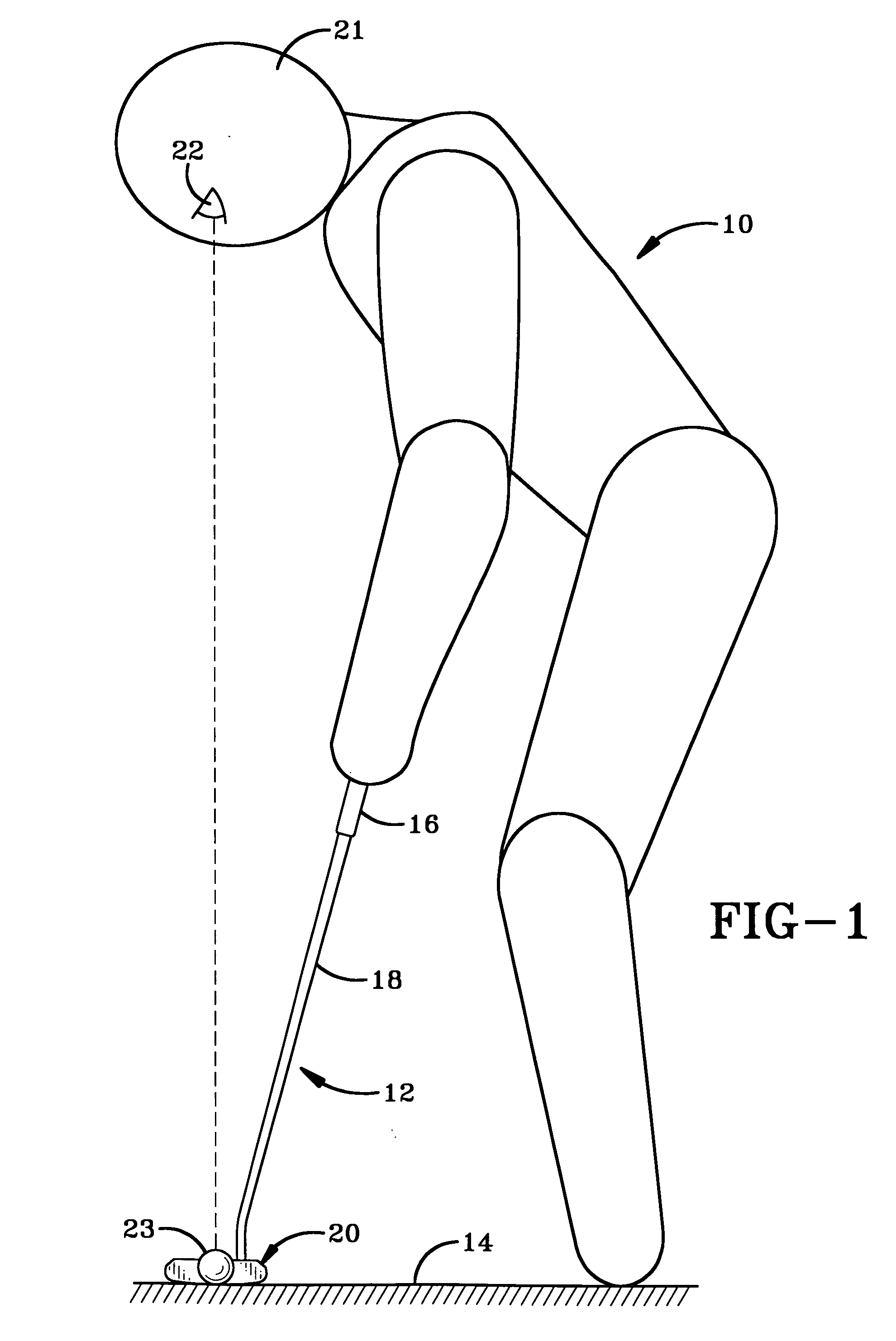

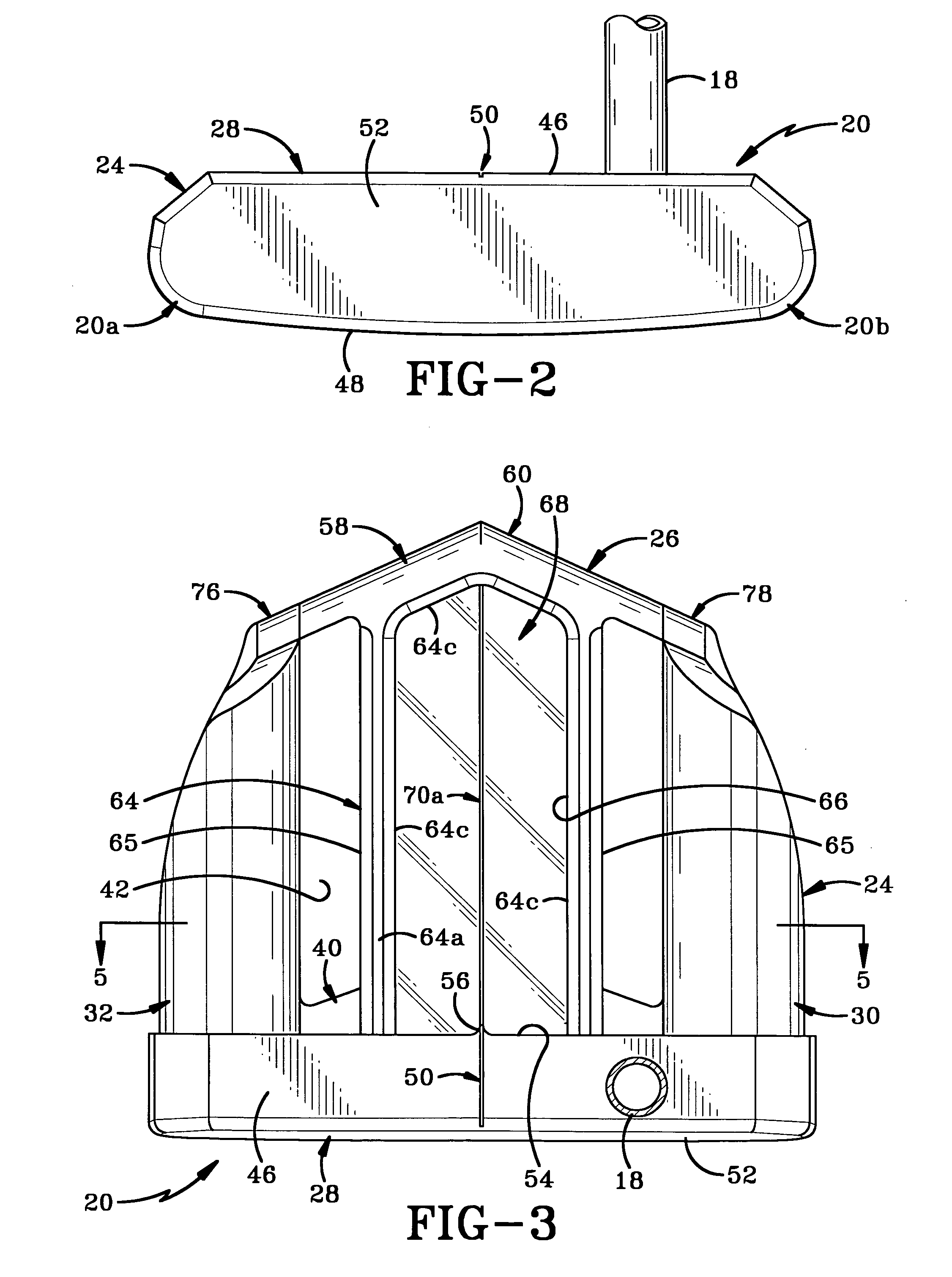

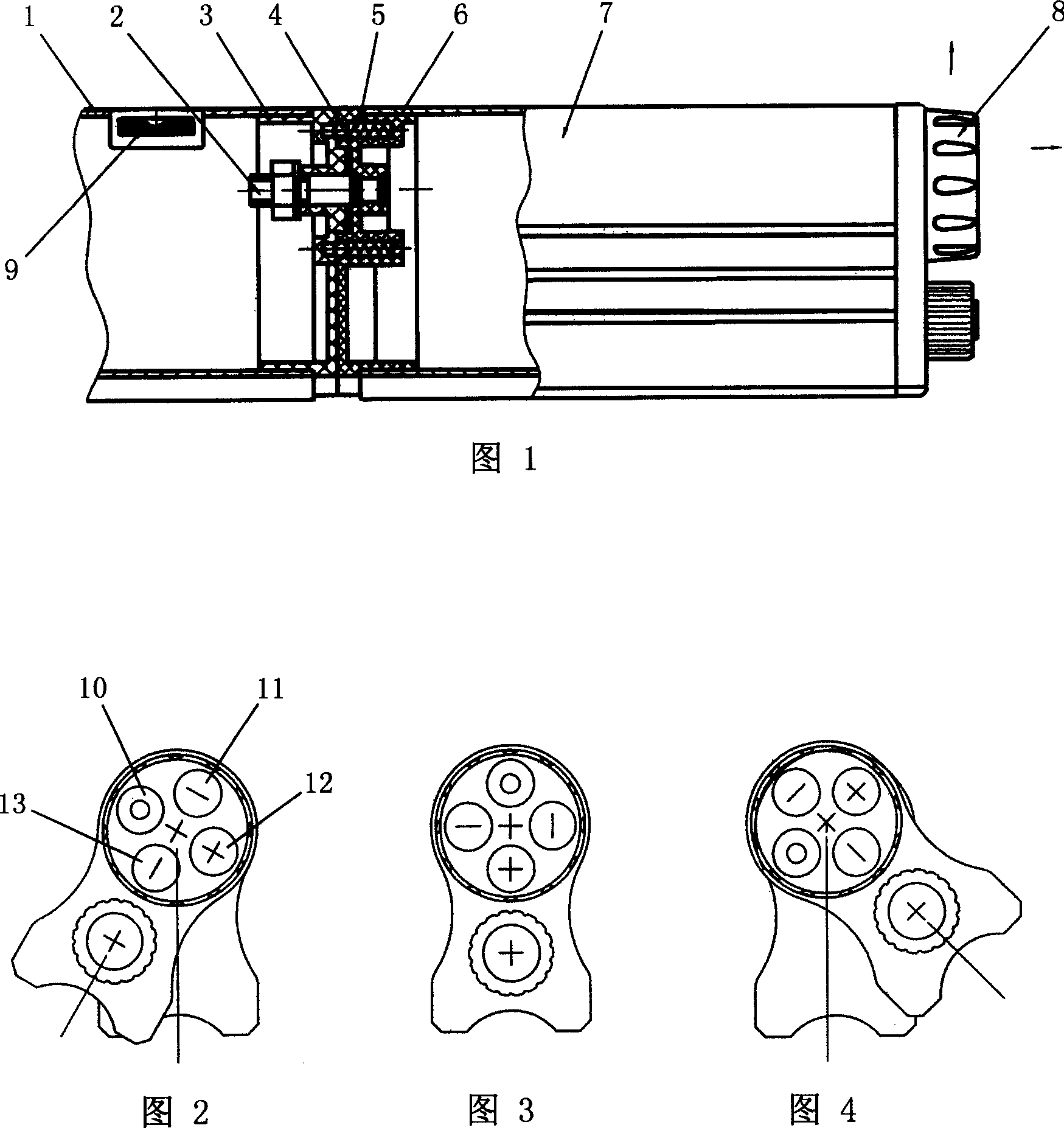

Golf putter with removeable inserts for altering the center of gravity of the putter

InactiveUS20070021230A1Quickly and easily removedCorrect and accurateGymnastic exercisingGolf clubsEngineeringBody positions

A golf putter including a plurality of physical and visual aids for assisting the golfer to more consistently assume a good head and body position and to better putt a golf ball toward a remote hole. The putter head is engaged with one of a plurality of detachable flanges. The flanges all have different lengths, weights and shapes and are selectively engaged with the putter head to change its center of gravity and thereby change the characteristics of the putter. The golfer selectively engages the appropriate one of the plurality of flanges to give the putter head the type of characteristics that best suit his personal putting abilities and deficiencies and is thereby aided in correctly and accurately striking the golf ball. Each of the detachable flanges is provided with a first reflective surface and a second non-reflective surface. The reflective surfaces are all provided with a second linear marking thereon. The second linear marker is alignable with a first linear marking on the putter head and with the remote hole toward which the ball is to be putted. The reflective surface is used during practice sessions to aid the golfer in correctly positioning his head and body. The selected flange is removed and rotated during USGA sanctioned golf games to present the non-reflective surface on the upper side of the club. The different flanges are quickly and easily engaged with the putter head, so the golfer may change the nature of the putter for each hole they encounter on the golf course.

Owner:OPITX GOLF COMPANY

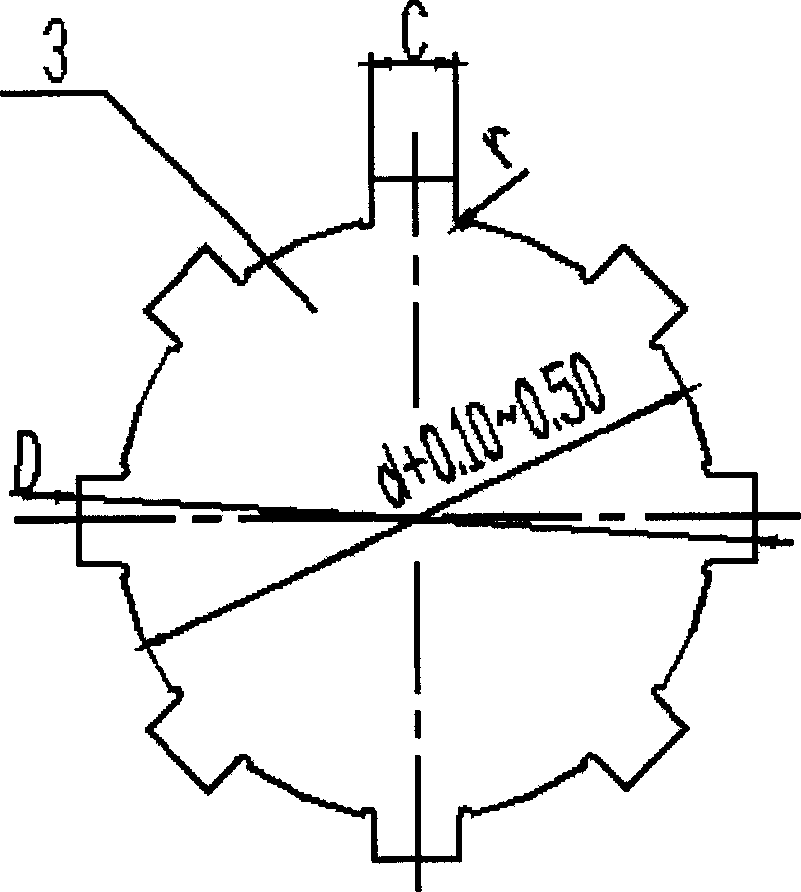

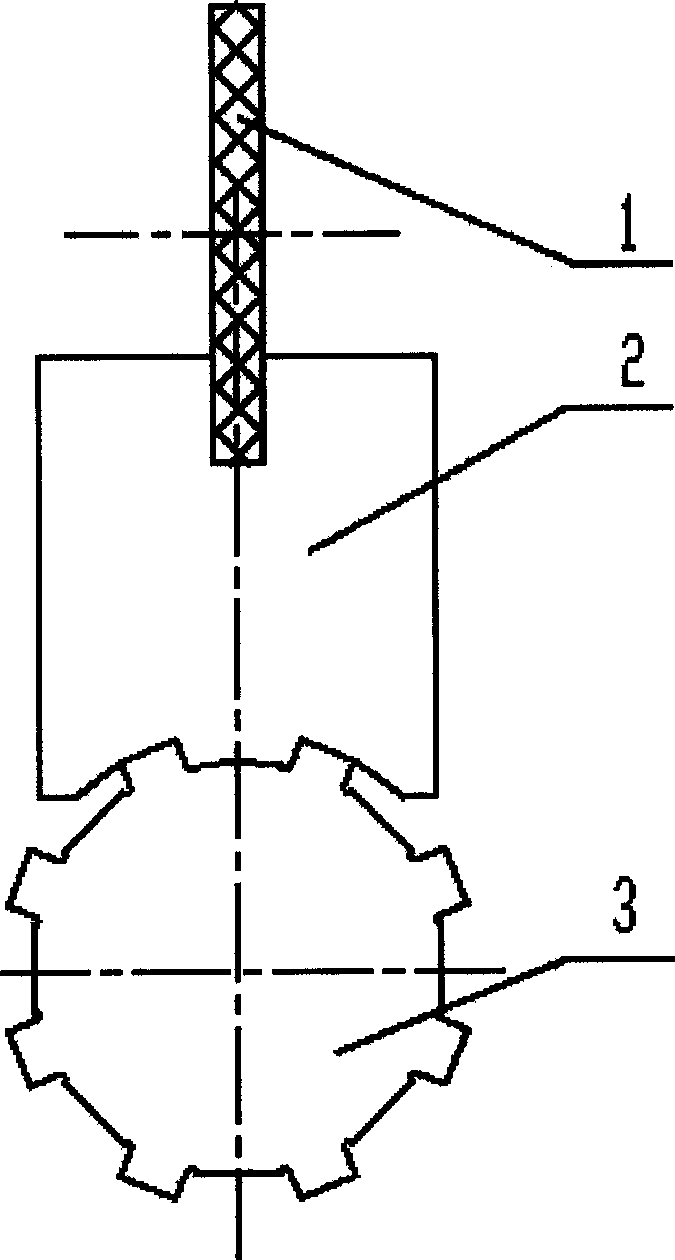

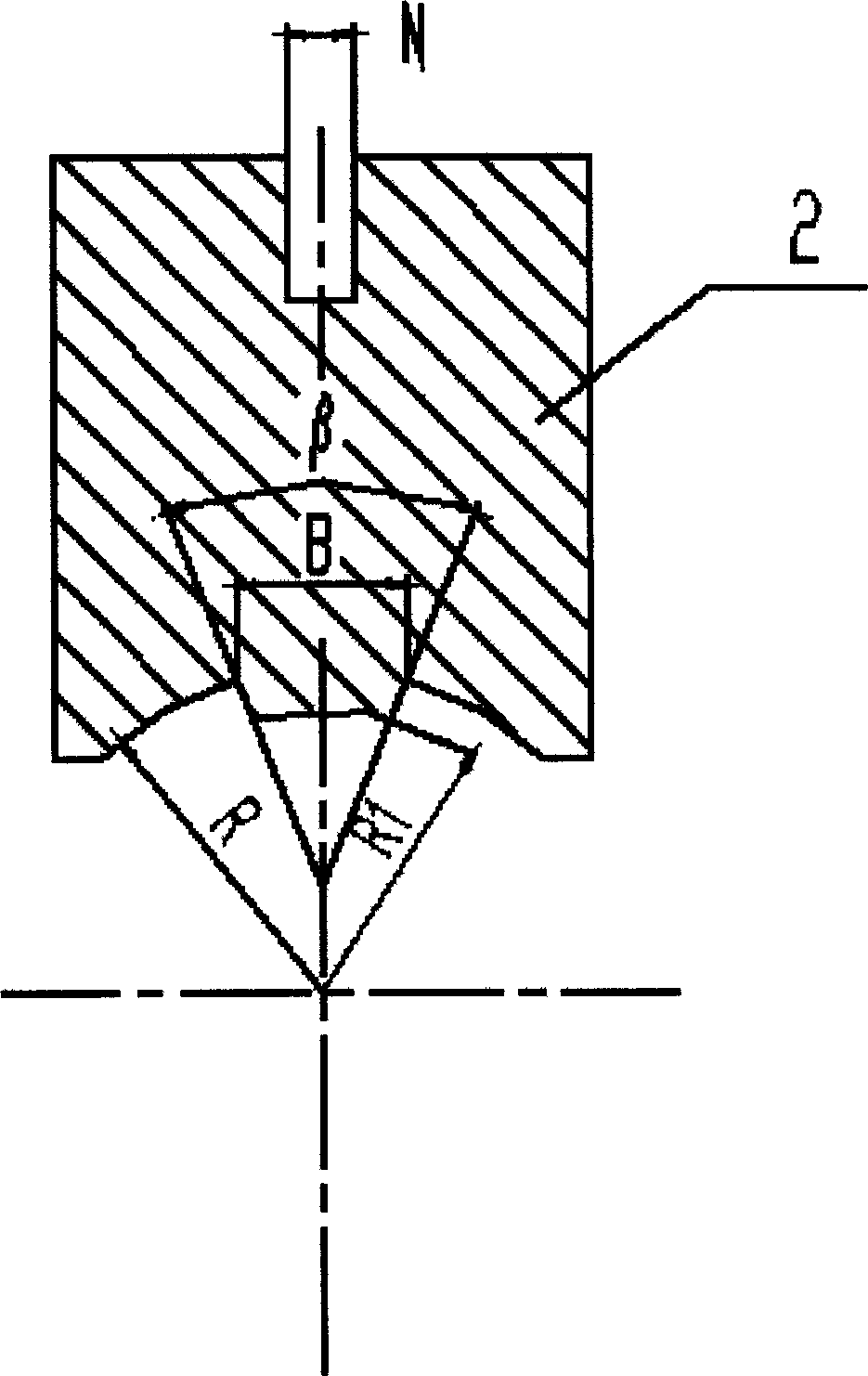

Processing method of small radius centring rectangular splined shaft

A method for machining the rectangular spline shaft by centering small diameter includes such steps as machining the width of spline to predefined size, the standard arc slot of spline tooth, and big diameter, heat treating, fixing the spline shaft onto grinding machine, centering the abrasive disc with spline tooth slot, and reciprocating grinding.

Owner:GUIZHOU QUNJIAN PRECISION MACHINERY

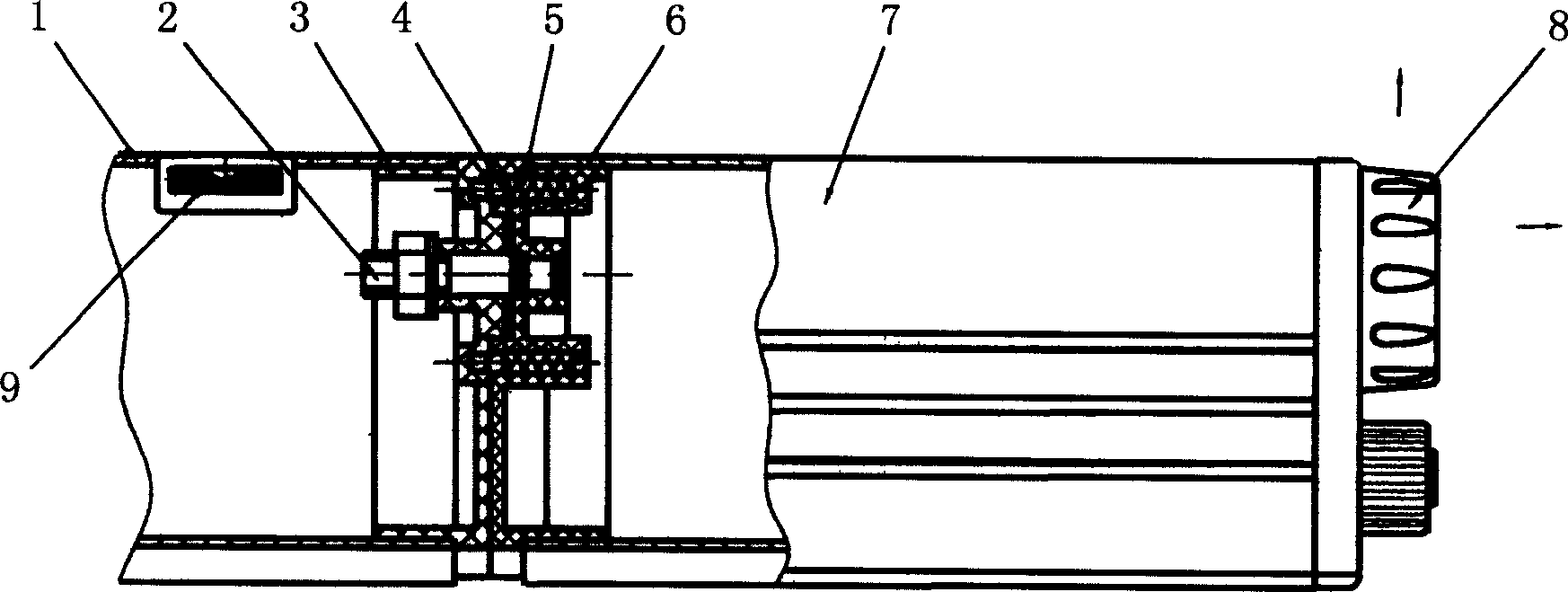

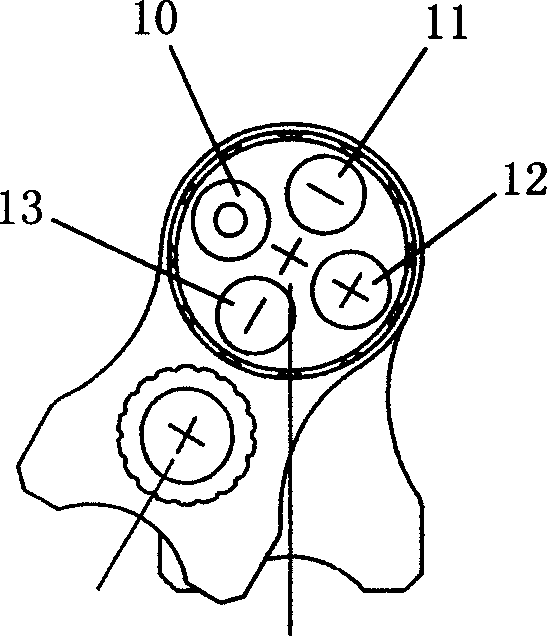

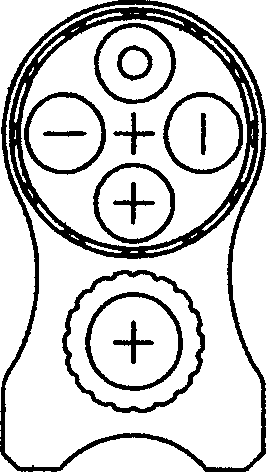

Laser leveling rod with an angle conversion mechanism

This invention relates to a laser level with an angle conversion unit, which can correct any angles accurately or draw any angle lines freely. It includes a back rule, a pin shaft, a first connector, a positioning unit, a second connector and a front rule characterizing in connecting the two connectors by the shaft, the first connector is fixed on the back rule, the second is fixed on the front rule, the back rule has an universal bubble, the front rule has a light splitting unit of laser points, laser level lines, laser cross lines and vertical lines.

Owner:ZHEJIANG RONGSHENG TOOL

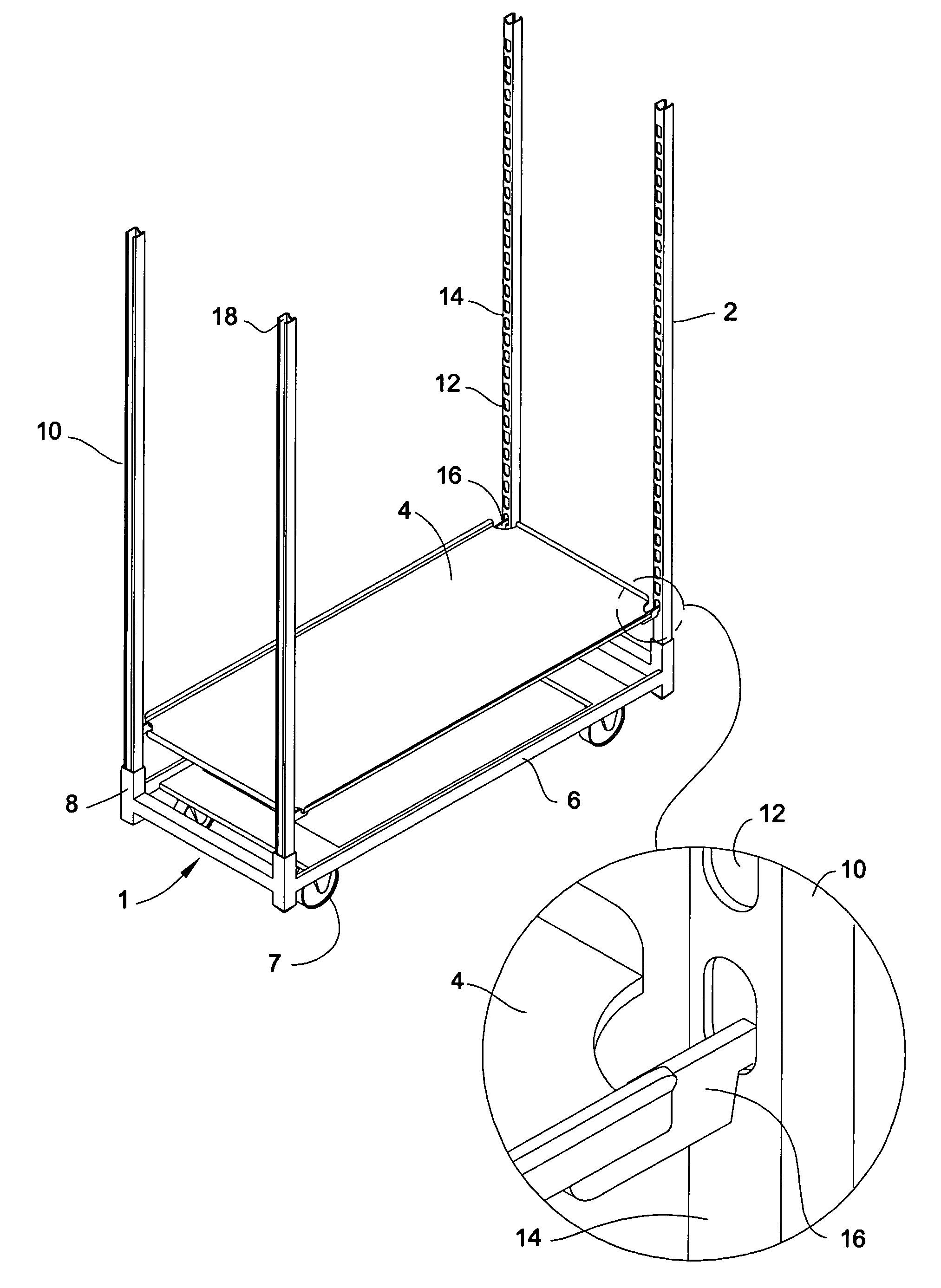

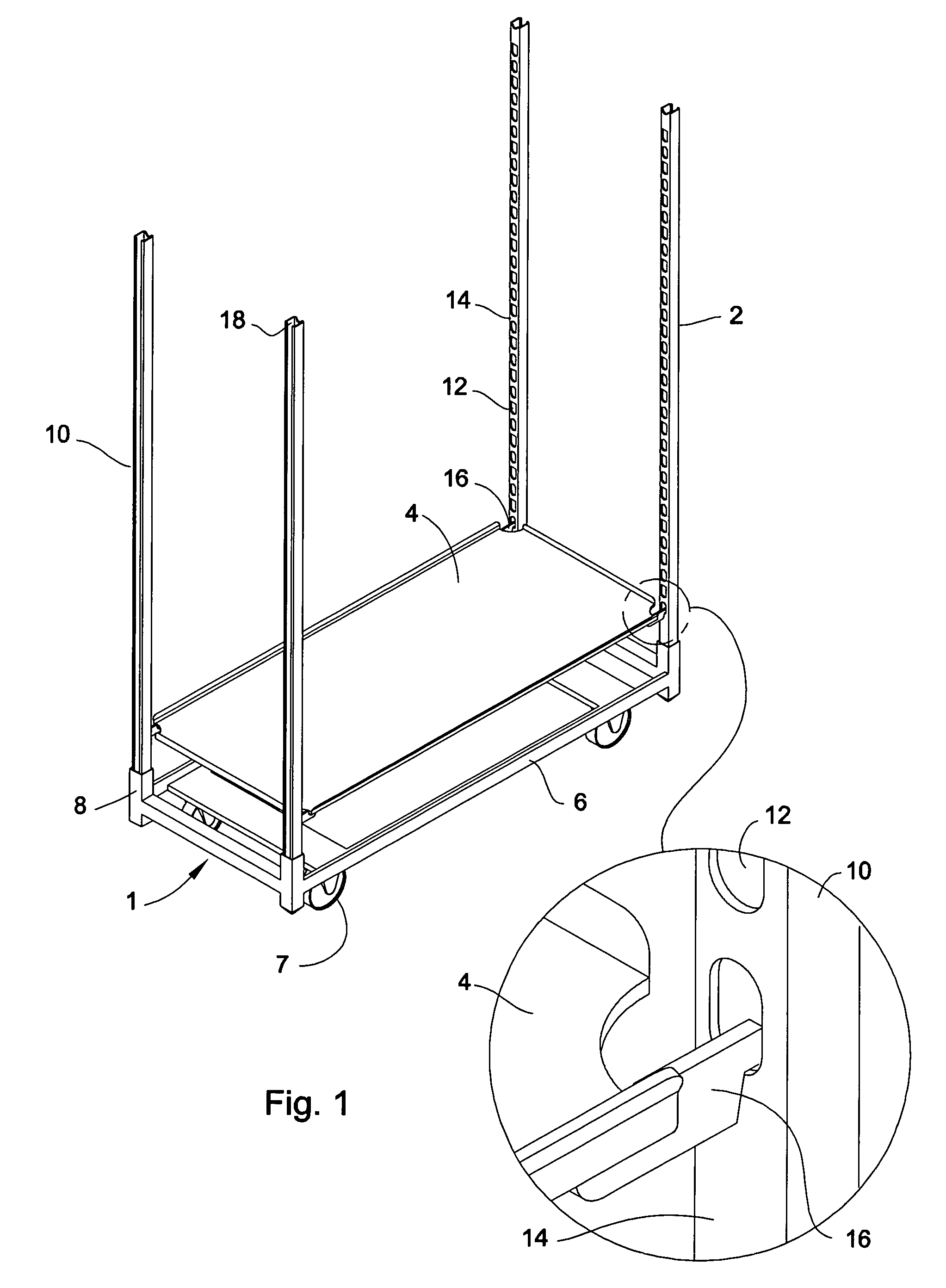

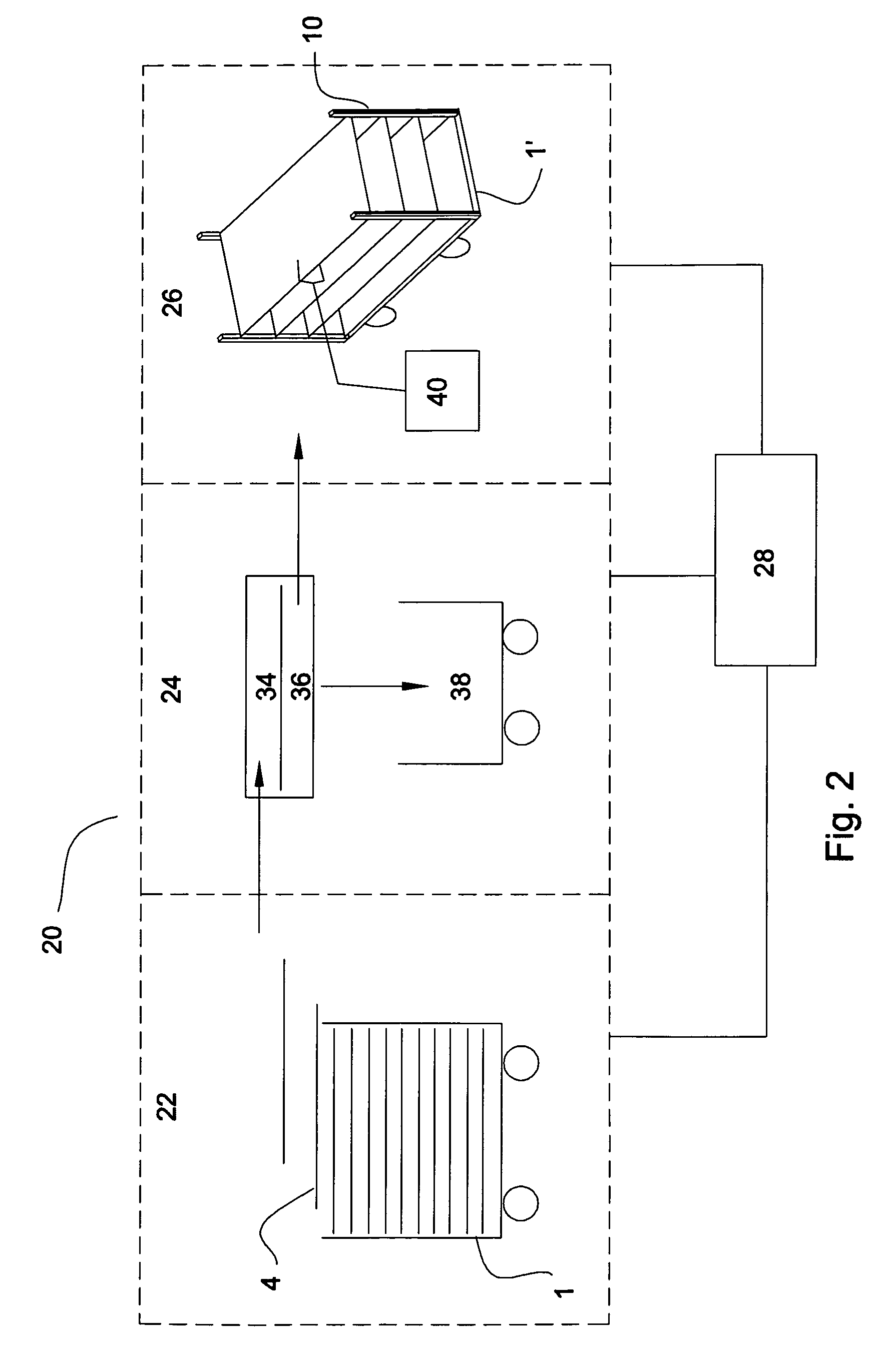

Apparatus and method for assembling shelving units

InactiveUS20080230502A1Improve processing speedReduce exerciseSledgesClimate change adaptationEngineeringControl unit

An apparatus is described for assembling a shelving unit consisting of a frame and a plurality of detachable shelves supported by the frame. The apparatus comprises a supply section for supplying a shelf, a testing section for inspecting the supplied shelf, a positioning section for gripping an approved shelf and subsequently mounting the shelf in the frame, and a control unit for controlling the apparatus. It is used in particular for carts for the transport of plants.

Owner:ISO GROEP MACHINEBOUW

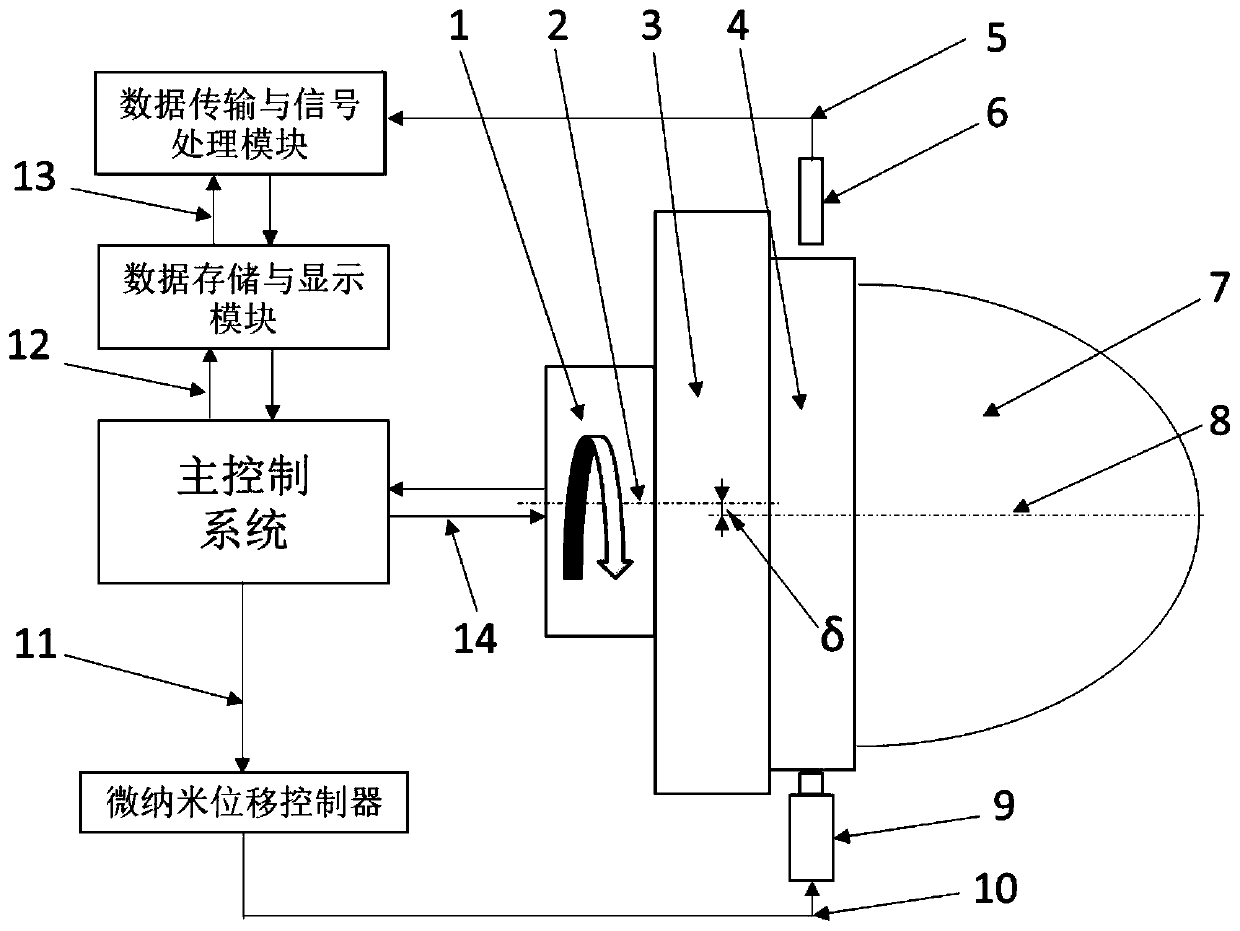

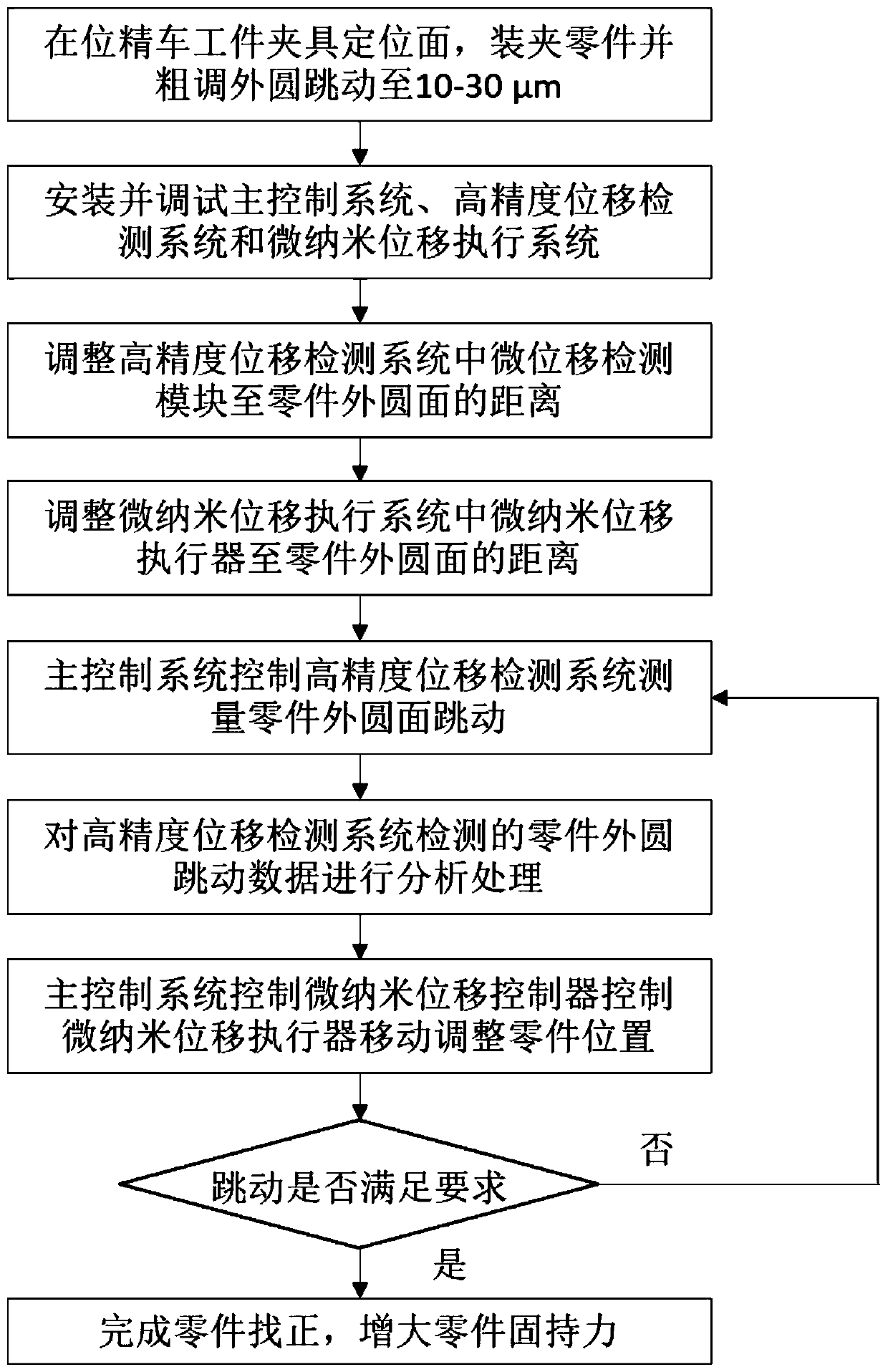

Accurate alignment method for rotary parts

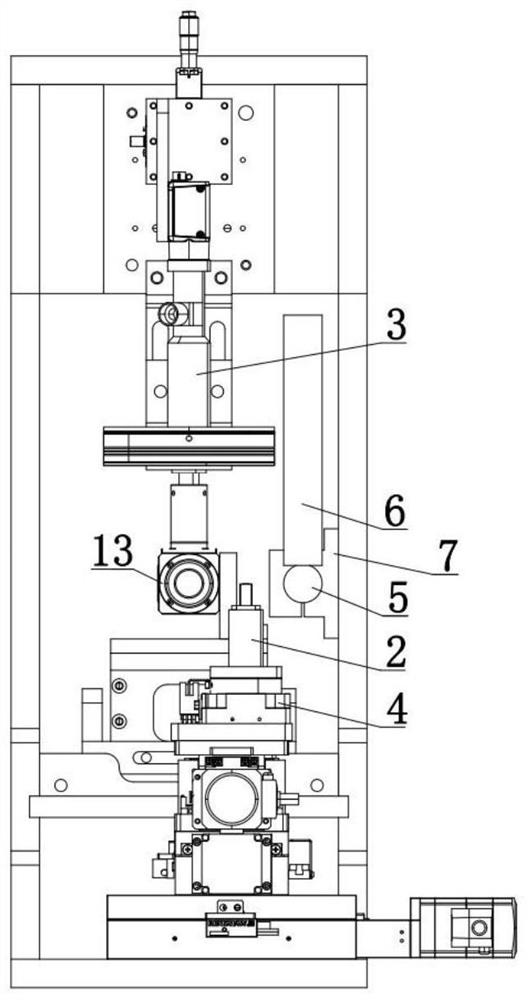

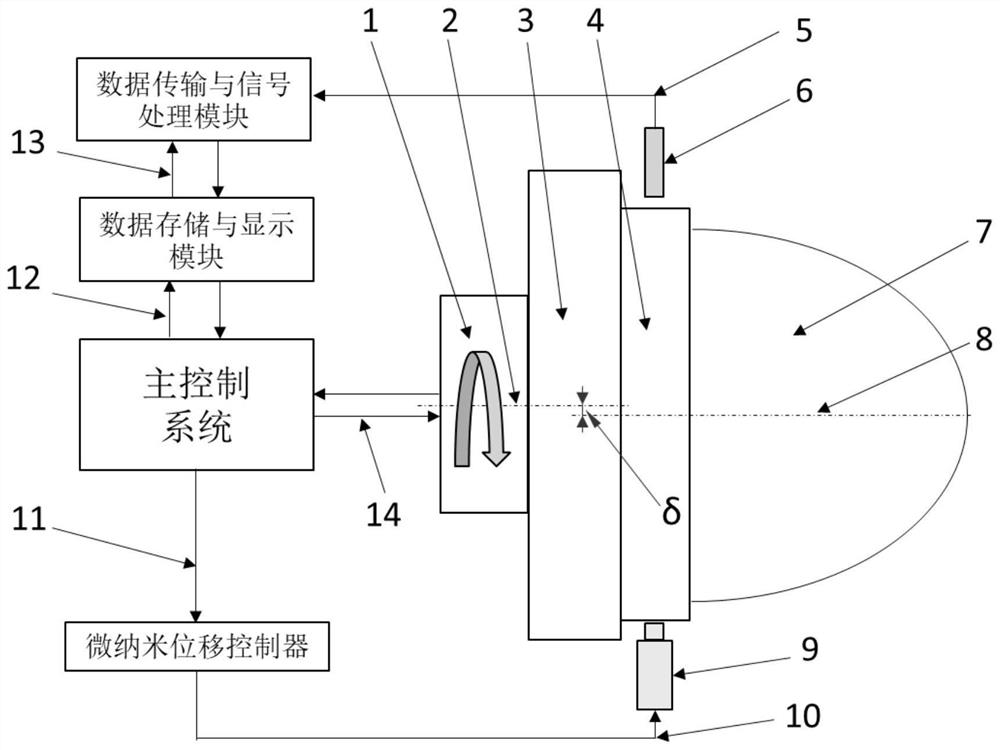

ActiveCN111571272ALow technical requirementsReduce labor intensityAutomatic control devicesFeeding apparatusMicro nanoControl system

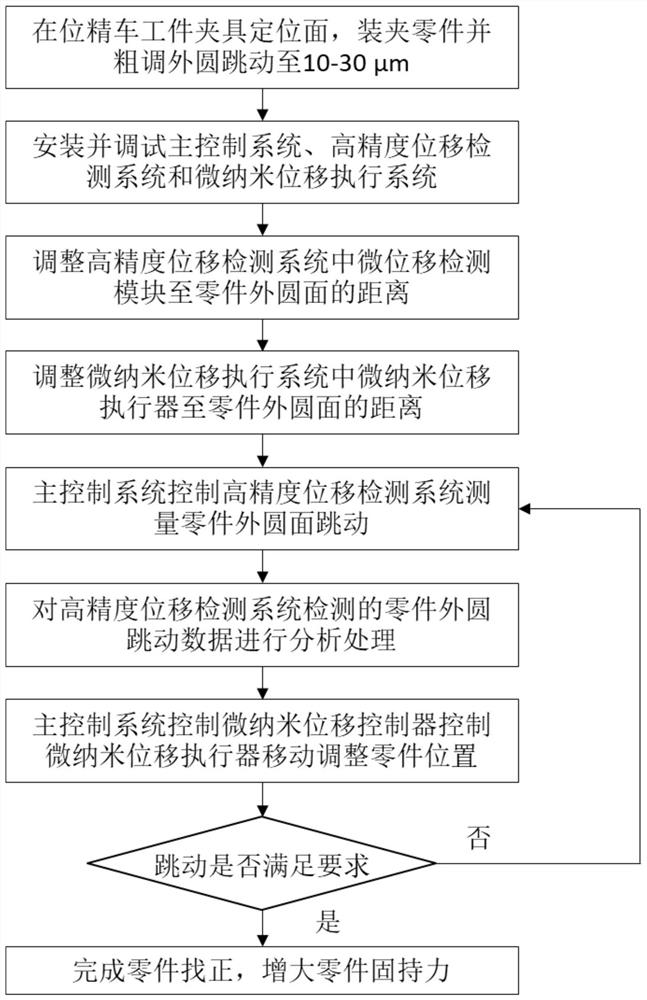

The invention relates to an accurate alignment method for rotary parts, and belongs to the field of precision ultra-precision machining. The accurate alignment method for the rotary parts comprises the following steps that 1), in-situ finish turning is carried out on a positioning mounting surface of a rotary workpiece clamp, the parts are attached to the positioning mounting surface of the rotaryworkpiece clamp, the holding force is reduced until the parts can be pushed but do not automatically slide off; a main control system, a high-precision displacement detection system and a micro-nanodisplacement execution system are installed and debugged; 2), the distance from a micro-displacement detection module in the high-precision displacement detection system to the outer circle surface ofa return part and the distance from a micro-nano displacement actuator in the micro-nano displacement execution system to the outer circle surface of the return part are adjusted; 3), the main control system controls the high-precision displacement detection system to detect the runout of the outer circle surfaces of the parts, and controls the micro-nano displacement actuator to move and push the parts to move according to the runout detection result of the outer circle surfaces of the parts; and 4), the step 3) is repeated until the jerk value of the parts is less than or equal to the maximum theoretical calculation jerk value, and alignment is completed. According to the accurate alignment method for the rotary parts, the production cost can be reduced, the alignment precision can reach a submicron level or even a nanoscale level, and the repeatability of the alignment precision is good.

Owner:DALIAN UNIV OF TECH

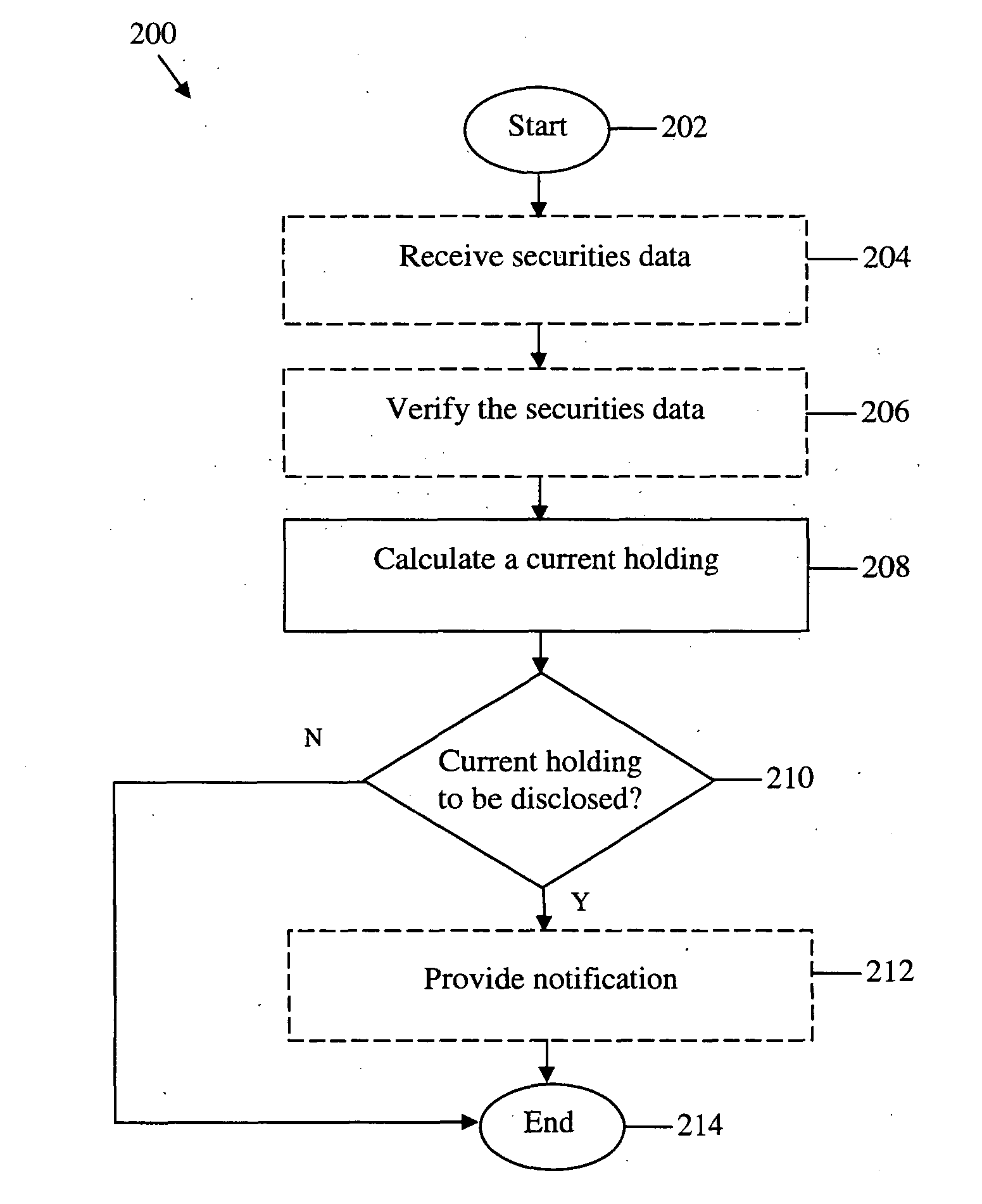

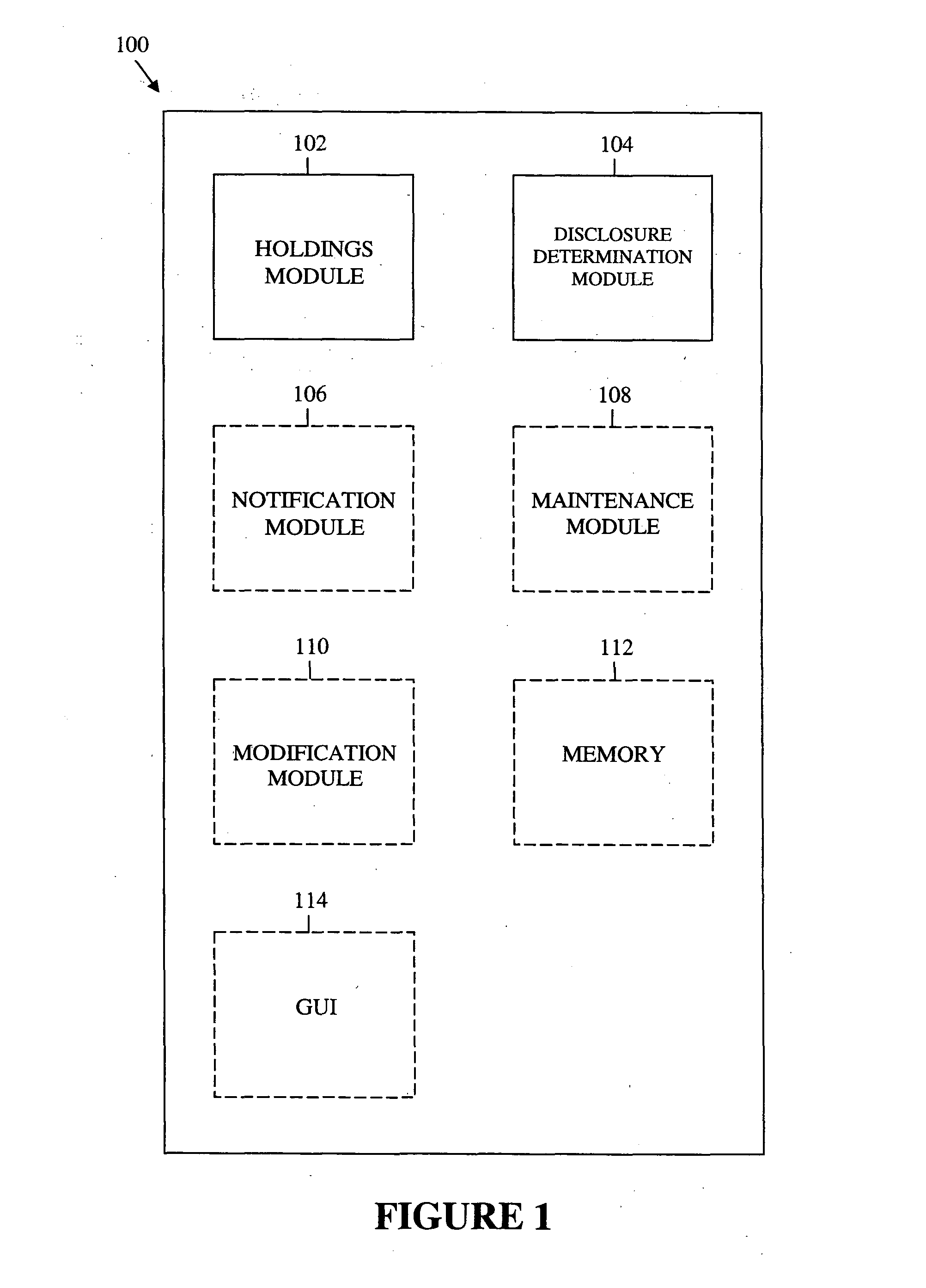

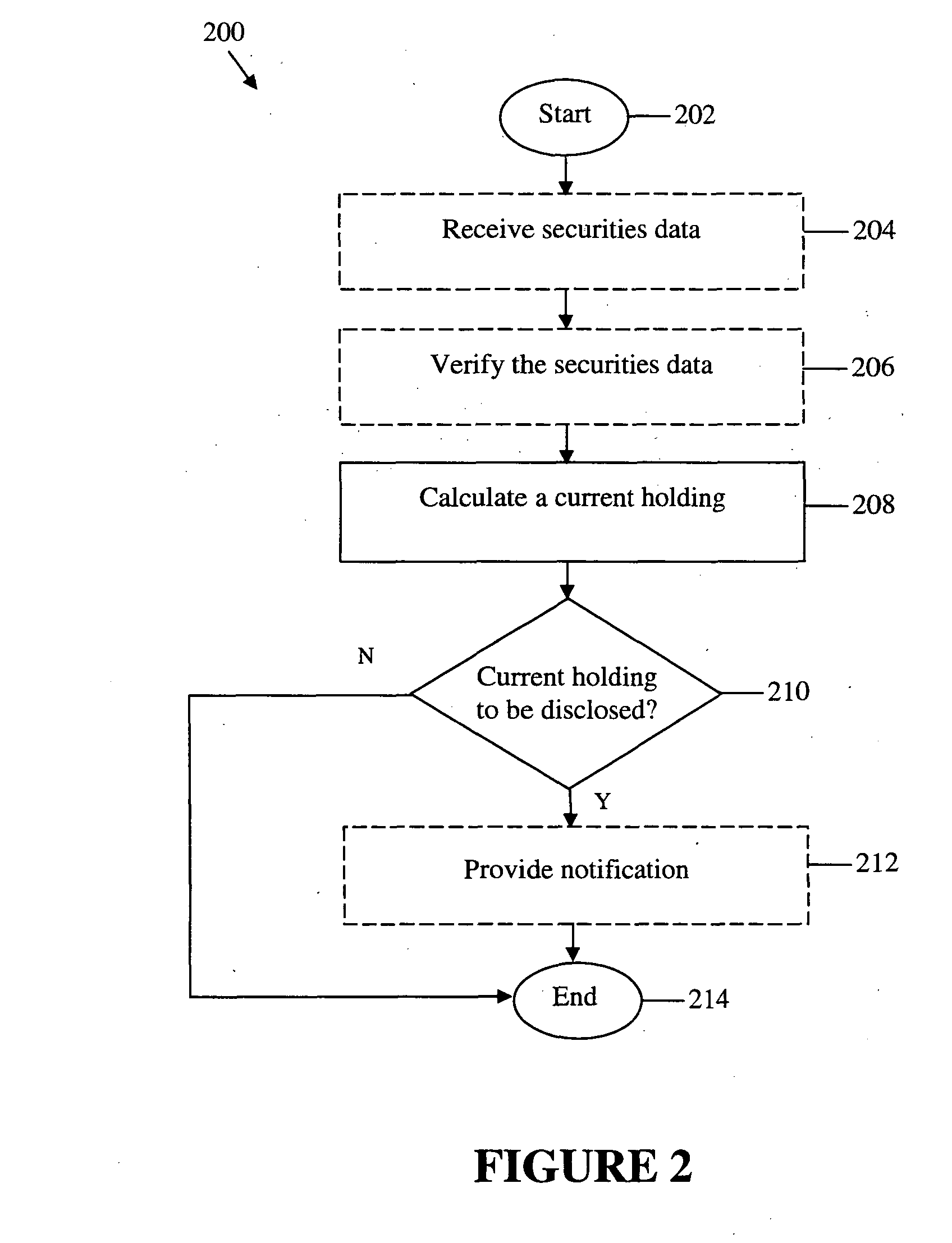

Apparatus and methods for analysing securities data

An apparatus for analysing securities data comprises a holdings module configured to determine, from the securities data, a value of a current holding in a security. The apparatus also comprises a disclosure determination module configured to determine, from a comparison of the value of a current holding with a rule stored in a database of disclosure rules, if the current holding is to be disclosed.

Owner:ABERDEEN ASSET MANAGEMENT

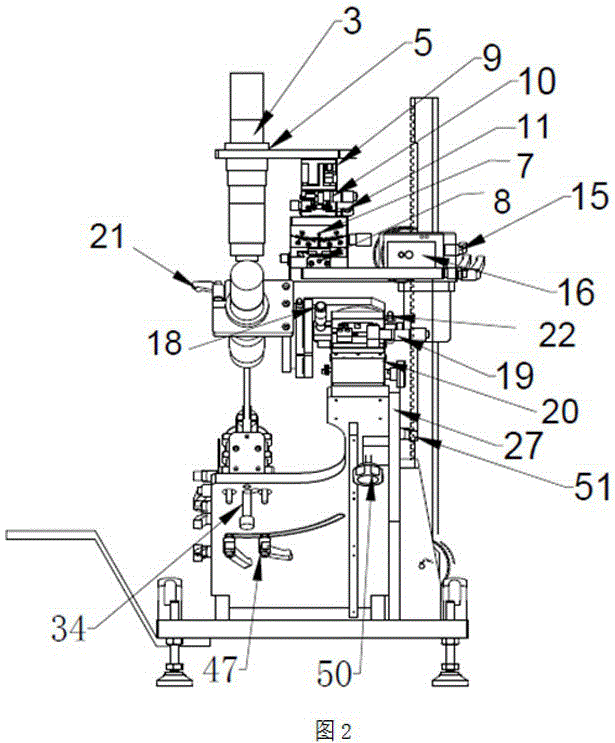

Dual-lens cutting edge image measuring chamfering machine

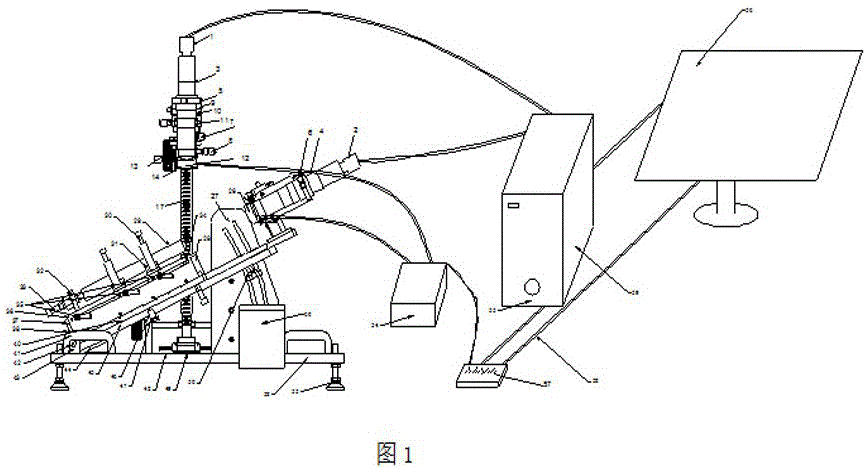

The invention discloses a dual-lens cutting edge image measuring chamfering machine comprising a vertical camera, a side camera, a vertical lens, a side lens, a cutting tool, and a slide block. The cutting tool is localized axially by a front positioning block assembly; and positioning and supporting are realized by a V-shaped block assembly, a rear limiting block assembly, an axial positioning screw rod, and a liftable cutter front-end support platform assembly. A positioning block of the front positioning block rotates inwardly at an angle of 90 degrees in a pedestal. A guide rail pedestal rotates at an angle from 0 to 90 degrees in a high-precision arc groove of an inclined plate by using a focal point overlapped point of the vertical lens and the side lens as a rotating axis; and the arc groove uses a cutting cuspidal point localized by the front positioning assembly as a center of circle. A special positioning mechanism is used for positioning at an angle of 0 degree and an angle of 90 degrees; and at any position by rotation, a guide rail pedestal quick-tightening wrench assembly arranged at the lower side of the inclined plate is used for realizing tight locking. With the vertical lens, accurate alignment is realized; and a horizontal lens is used for magnifying the cutting tool to realize cutting tool chamfering, wherein the cutting tool can be magnified by 800 times maximally.

Owner:上海旌锐精密机械有限公司

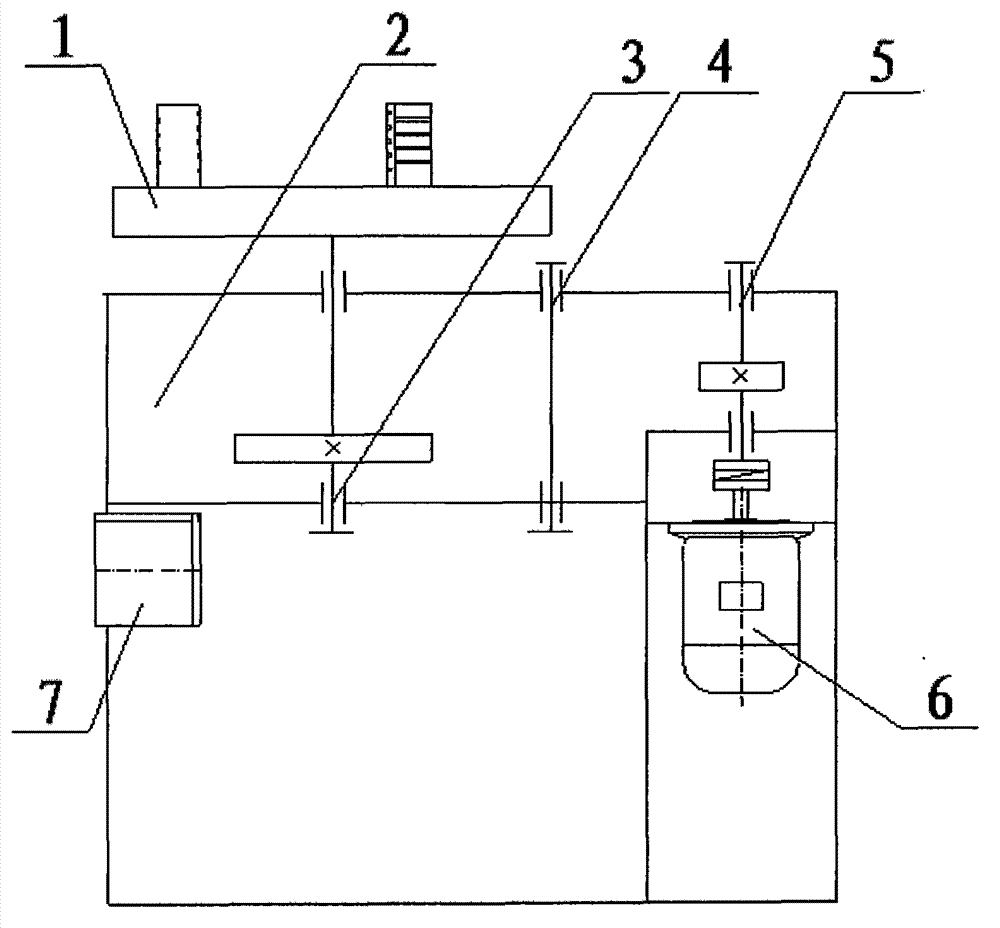

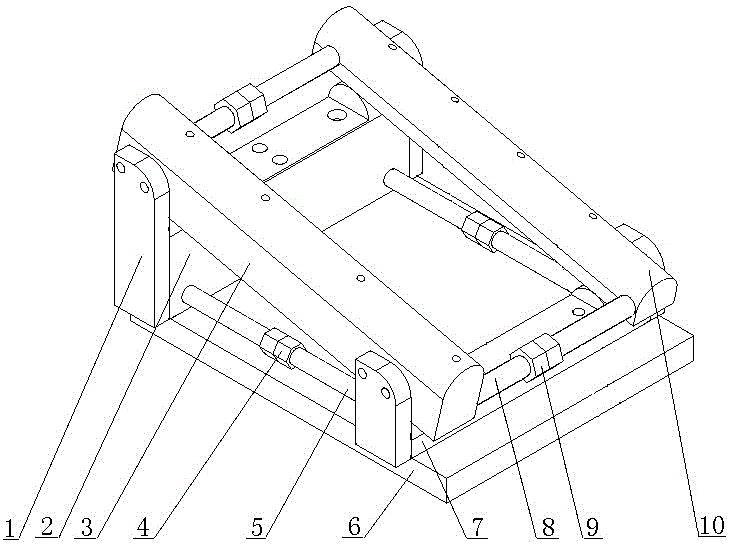

Simple automatic rotary welding platform

InactiveCN103286421AConsistent welding angleImprove welding efficiencyArc welding apparatusDrive motorWeld bead

The invention discloses a simple automatic rotary welding platform, relates to a welding fixture for gas shielded welding, and belongs to the technical field of welder fixtures. The simple automatic rotary welding platform comprises a rotary clamping platform, a support box, a driving motor and a regulating device, the gears between a middle shaft and an output shaft are engaged to decelerate so that the rotary clamping platform is driven to rotate, current is transformed in the regulating device and outputted to the driving motor when the speed is changed, the driving motor is controlled to change the speed, the current is transmitted to the rotary clamping platform by deceleration, and rotation at different rotary speeds is finished. The simple automatic rotary welding platform can serve as a welding fixture, circular (arc) welding beads for gas shielded welding are accurately aligned in real time through speed-changing rotation of welding workpieces, so that the welding beads in welding operation is uniform, welding angles in welding operation are consistent, welding efficiency and welding quality are improved, and the simple automatic rotary welding platform is simple in structure, endurable and convenient to operate.

Owner:XIANGYANG WU ER WU PUMP IND

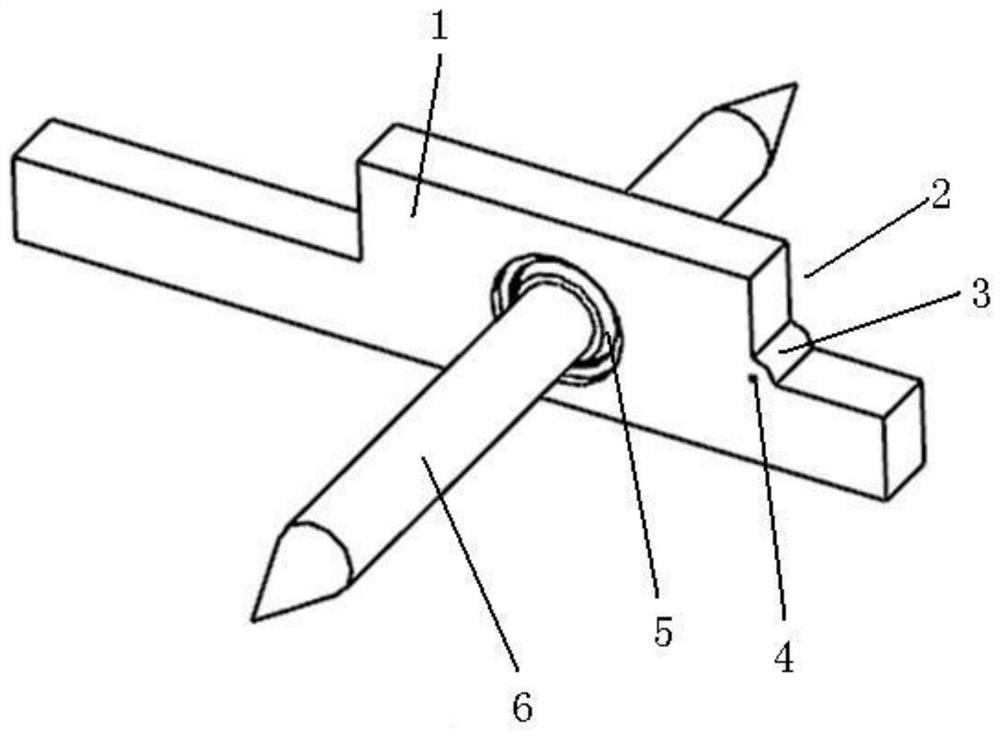

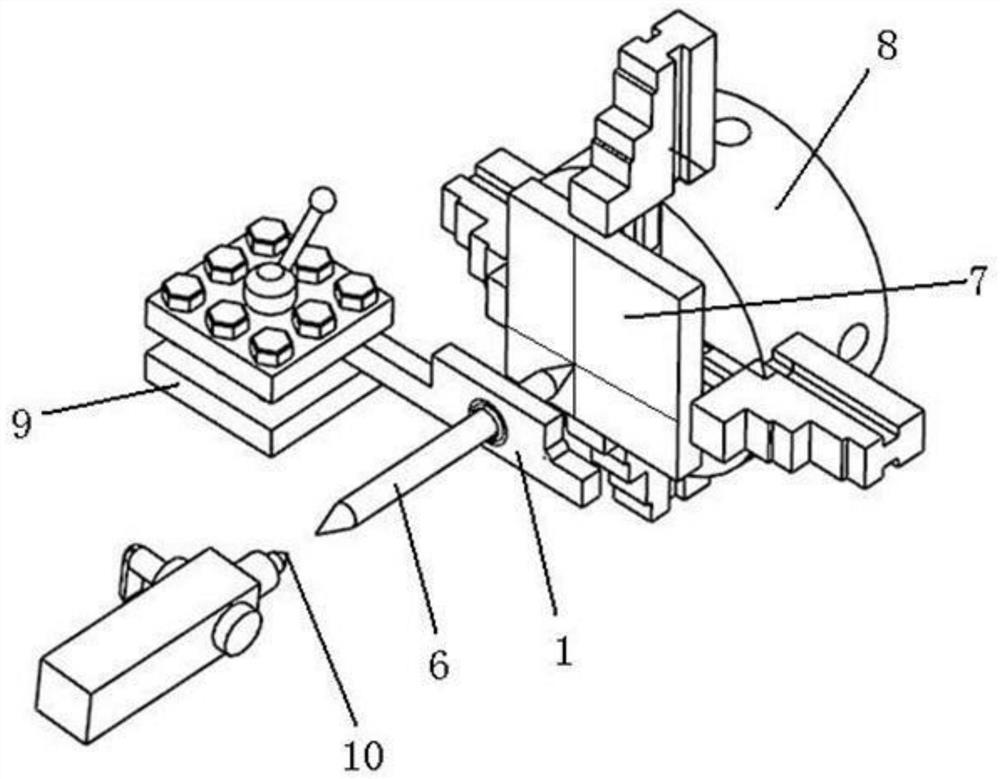

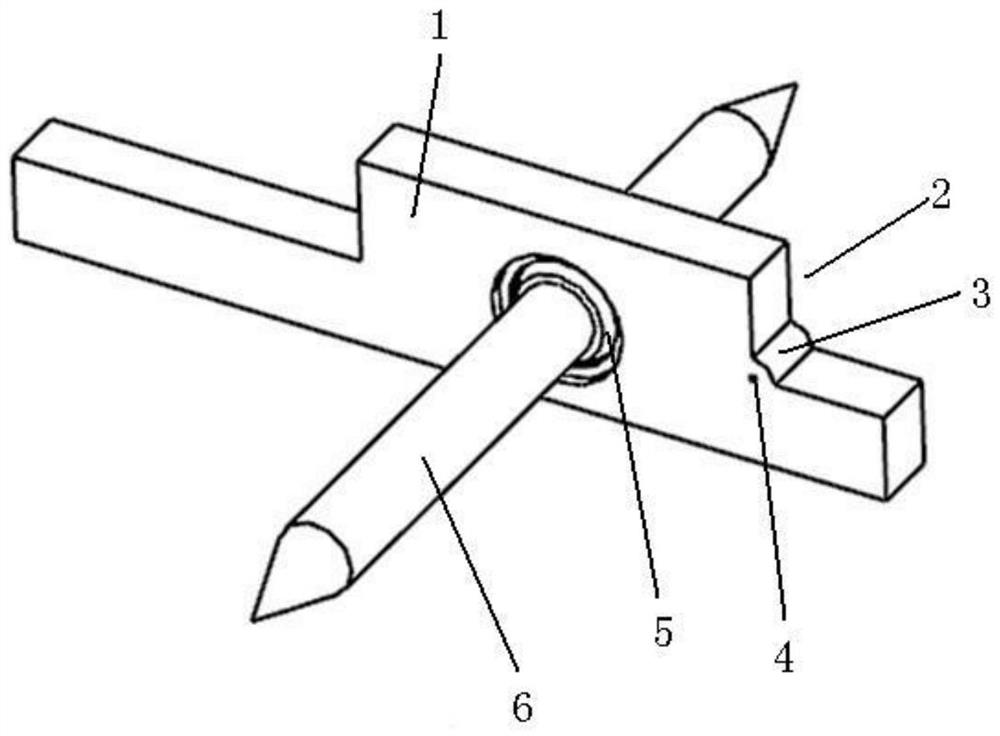

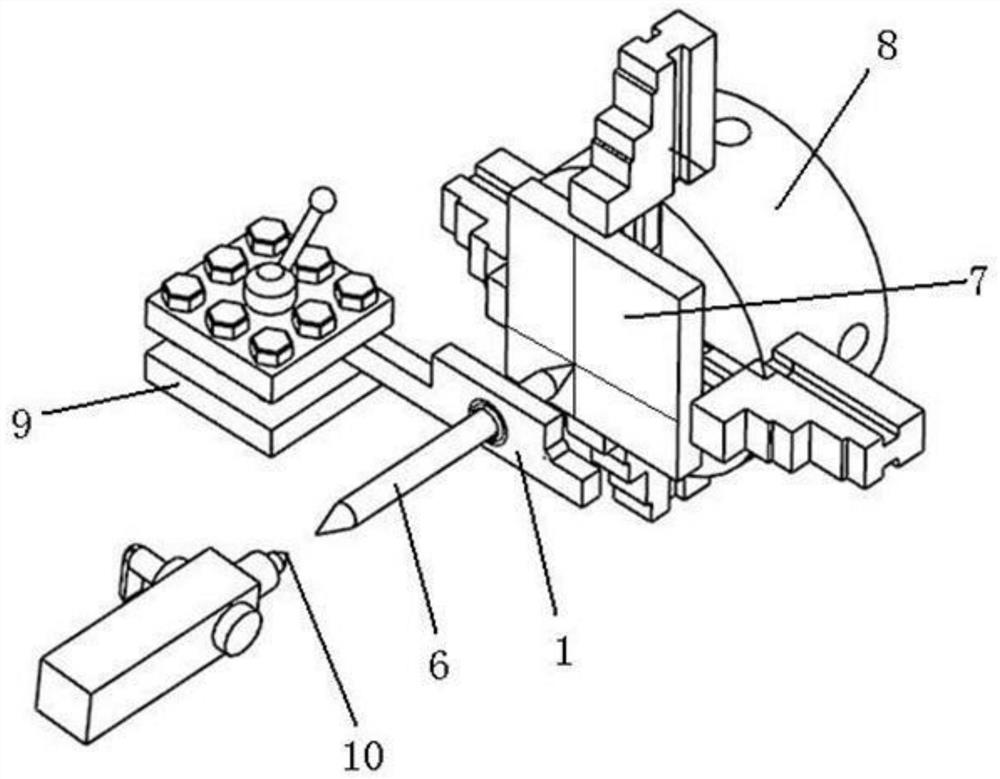

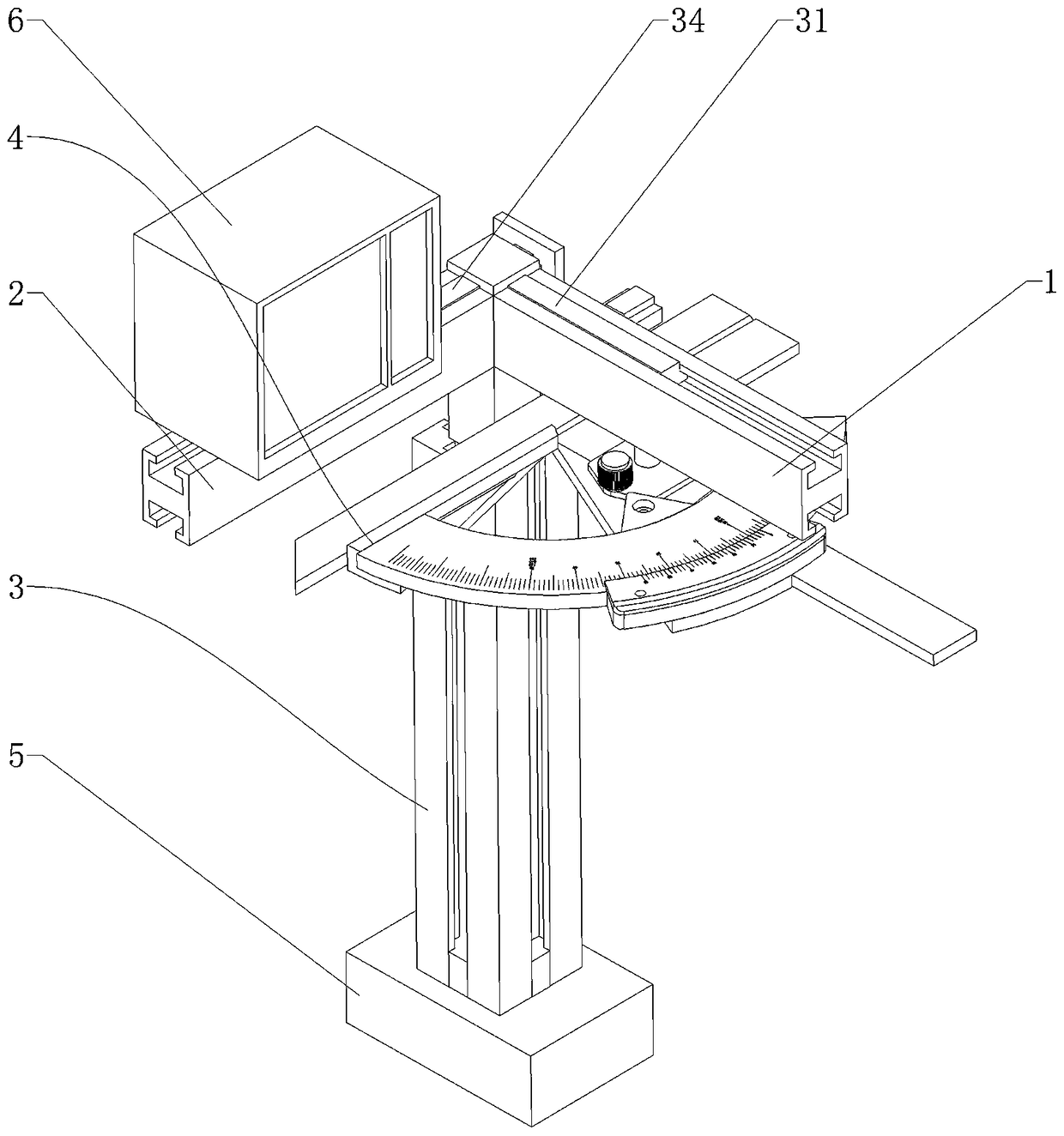

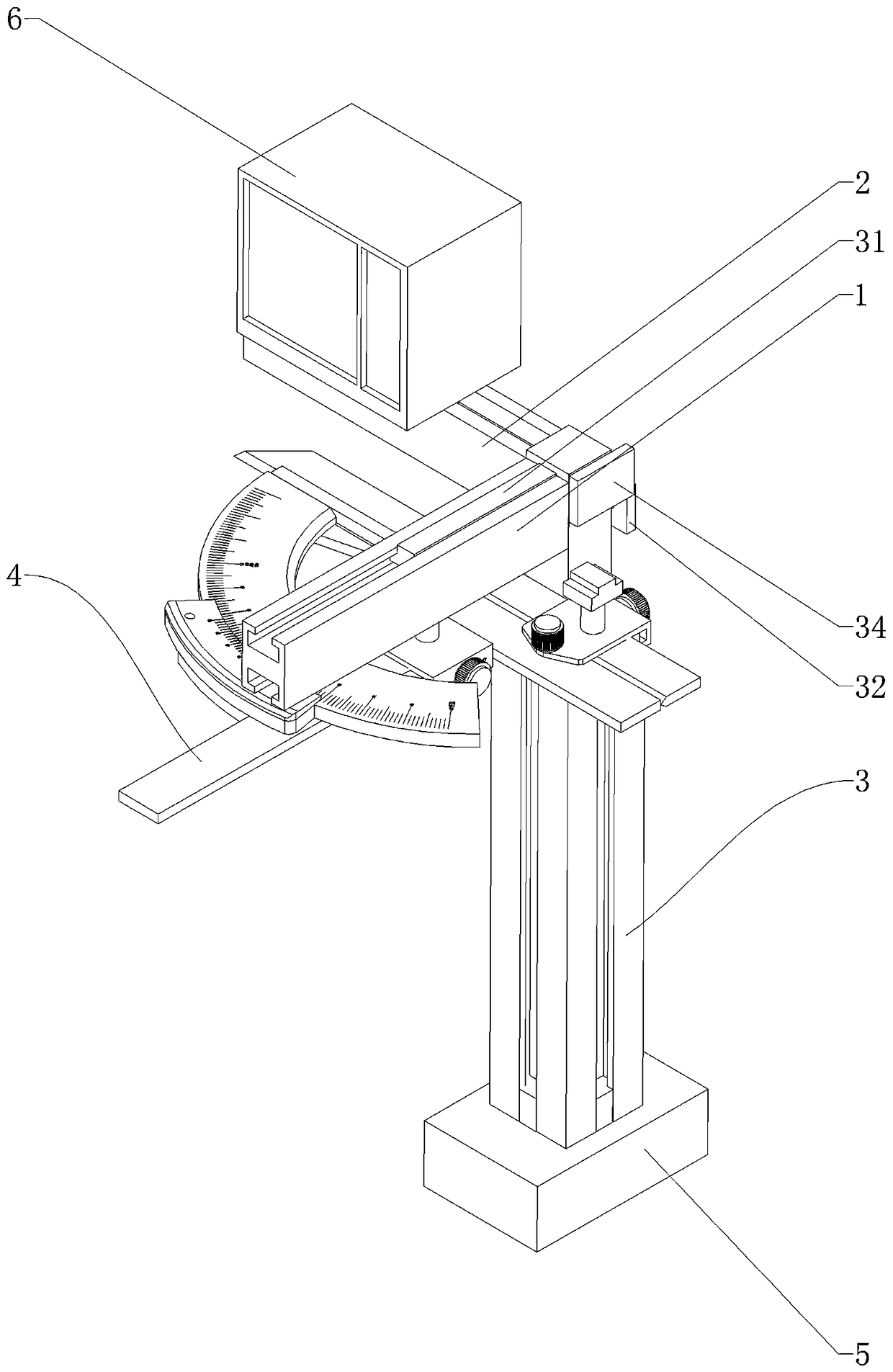

Alignment instrument for eccentricity alignment of lathe four-jaw chuck and alignment method

The invention discloses an alignment instrument for eccentricity alignment of a lathe four-jaw chuck and an alignment method. The alignment instrument comprises a pressing rod, an alignment groove is formed at the front end of the pressing rod, an arc-shaped part is arranged at the corner of the alignment groove, the circle center of the arc-shaped part coincides with the right-angle corner point of the inner wall face of the alignment groove, and a conical insertion groove is formed in the circle center of the arc-shaped part; and an inserting hole is formed at the position, close to the front end, of the pressing rod, a radial spherical plain bearing is arranged in the inserting hole, and a correcting rod is inserted into an inner ring of the radial spherical plain bearing. The alignment instrument is simple in structure and convenient to use, the clamping precision of a workpiece can be improved, the center of an eccentric part can be conveniently adjusted, the alignment method is easy to operate, and alignment can be rapidly and accurately carried out.

Owner:QINGDAO TECHN COLLEGE

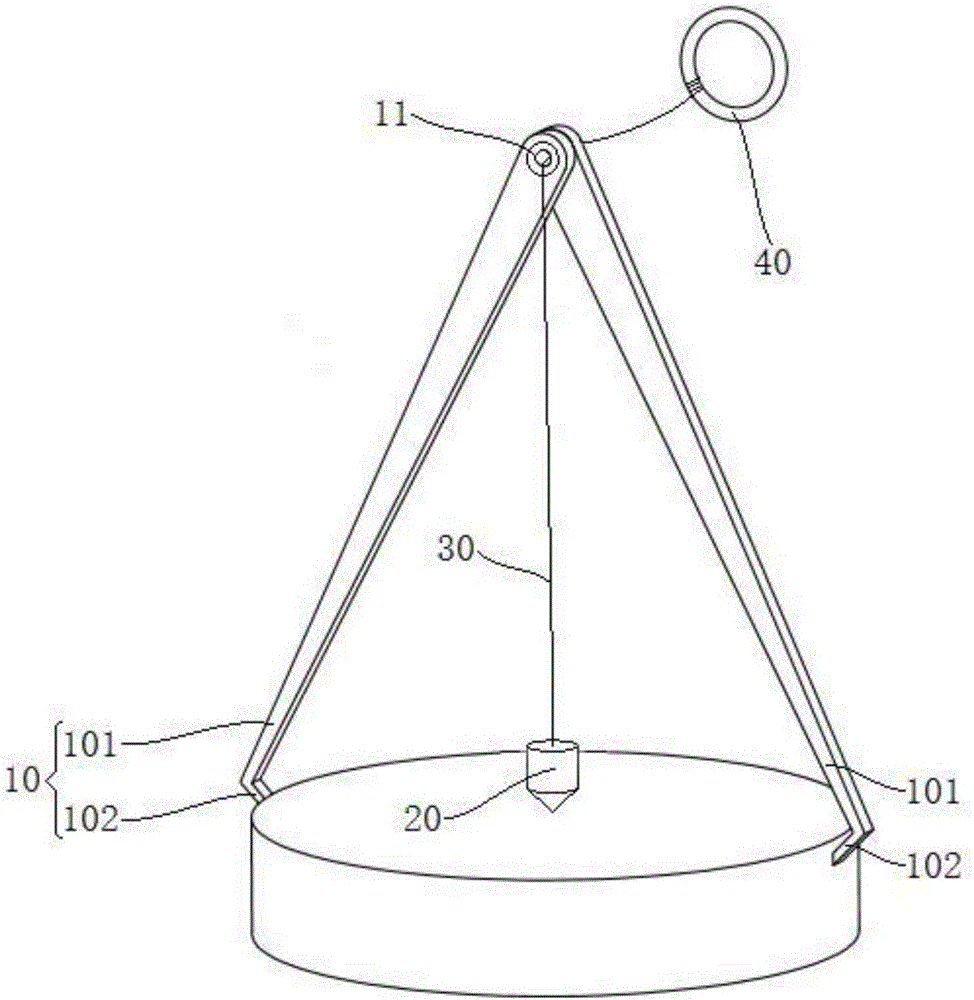

Alignment apparatus of disc-shaped forging circle center

InactiveCN106524856ACorrect and accurateSimple structureMechanical measuring arrangementsGeometric propertyEngineering

An alignment apparatus of a disc-shaped forging circle center comprises calipers, a drop hammer, a suspension wire and an adjusting pulling ring. Tail ends of two caliper arms of the calipers are mutually and movably riveted and lengths of the two caliper arms of the calipers are the same. A movable riveting position of the calipers is provided with a suspension wire hole. The suspension wire hole passes through the movable riveting position of the calipers so that the suspension wire passes through the suspension wire hole and then a suspension position of the suspension wire is restrained at the movable riveting position of the calipers. One end of the suspension wire is fixedly connected to the drop hammer and the other end of the suspension wire is winded and connected to the adjusting pulling ring so that a height of the drop hammer is adjusted through pulling through the adjusting pulling ring. In the invention, a geometric property that a middle line of a bottom edge of an isosceles triangle formed by the calipers and a height on the bottom edge are superposed is used so that the apparatus with the simple structure is provided so as to accurately align the disc-shaped forging circle center.

Owner:NINGXIA TIANDI BENNIU IND GRP

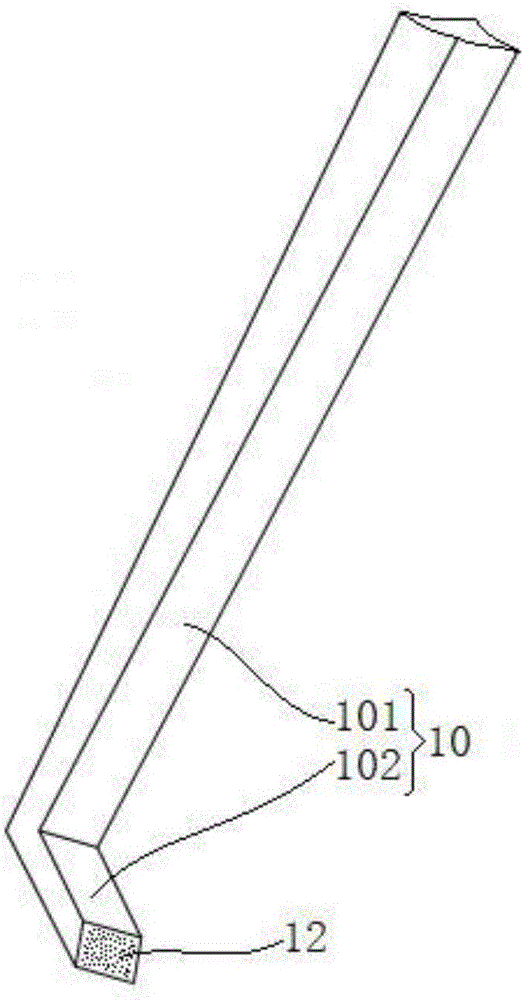

Alignment tool capable of achieving cylindrical grinding on long-axis-type part and using method of alignment tool

InactiveCN110814874ASolve processing deformationReduce pass rateRevolution surface grinding machinesGrinding work supportsPhysicsCylindrical grinding

The invention relates to the technical field of mechanical machining, in particular to an alignment tool capable of achieving cylindrical grinding on a long-axis-type part and a using method of the alignment tool. The alignment tool is installed at the outer side of one side of the installation end of the long-axis-type part and is close to one end of a grinding machine head, and comprises a sleeve and a snap ring which are integrally connected, wherein the inner diameter of the snap ring is equal to the outer diameter of the installation end of the long-axis-type part. A replaceable centre stand can be inserted in the sleeve, and a conical groove of the replaceable centre stand is matched with a centre. Four through holes with inner threads are uniformly and symmetrically formed in the snap ring, and can be in thread fit with jacking screws to squeeze the installation end of the long-axis-type part tightly. The alignment tool is utilized, and the cross alignment method of utilizing four symmetric points for clamping the part by 90 degrees is adopted. The alignment operation is precise and convenient.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

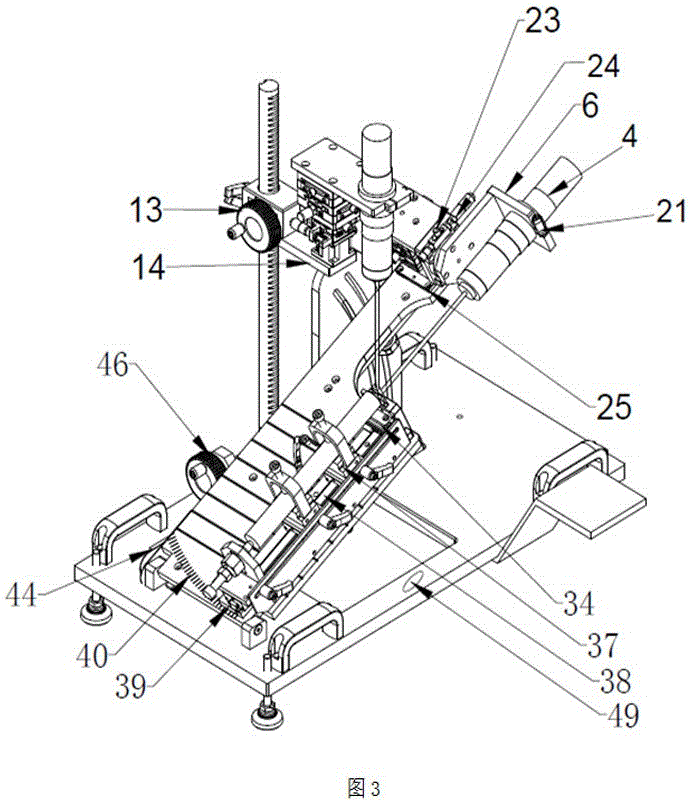

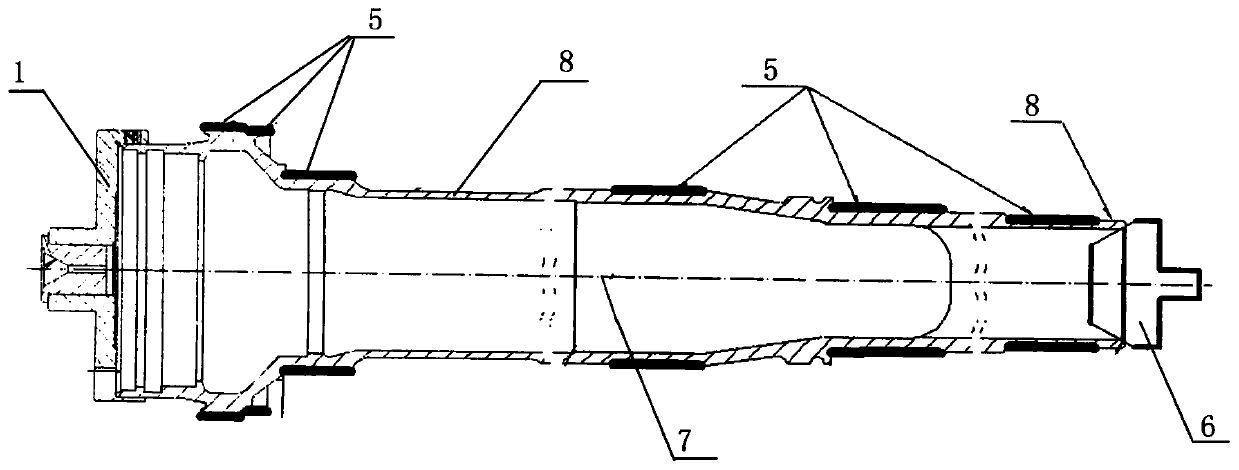

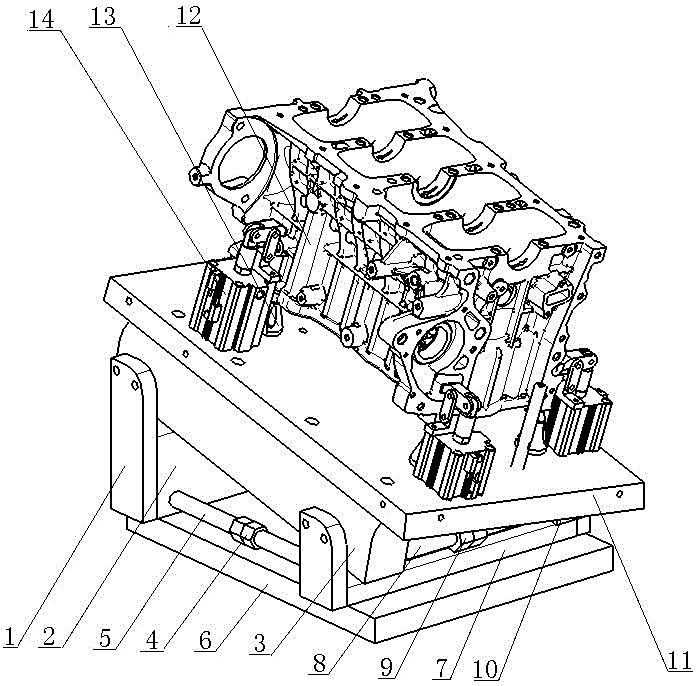

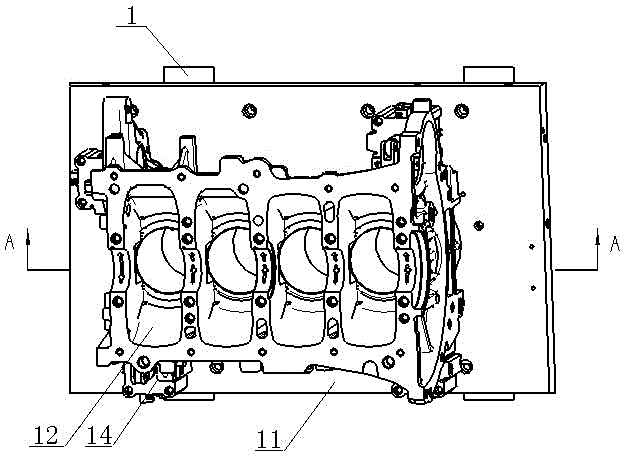

Engine cylinder oblique-hole processing clamp and aligning method thereof

ActiveCN106363425AGuaranteed accuracyCorrect and accuratePositioning apparatusMetal-working holdersEngineeringCylinder block

The invention discloses an engine cylinder oblique-hole processing clamp. The engine cylinder oblique-hole processing clamp is characterized in that a clamp plate is arranged in an inclined manner, wherein the left side surface of the clamp plate is parallel to a YZ plane of a machine tool coordinate system, and the rear side surface of the clamp plate is parallel to an XZ plane of the machine tool coordinate system; a first vertical supporting block and a second vertical supporting block are connected below the clamp plate; the top surface of the first vertical supporting block and the top surface of the second vertical supporting block are circular-arc surfaces; the bottom surface of the first vertical supporting block and the bottom surface of the second vertical supporting block are on the same plane which is parallel to the X axis and the Y axis; spacing between the first vertical supporting block and the second vertical supporting block is regulated through a transverse regulating rod; the first vertical supporting block and the second vertical supporting block are arranged on a first transverse supporting block and a second transverse supporting block; the top surface of the first transverse supporting block and the top surface of the second transverse supporting block are circular-arc surfaces, and the bottom surface of the first transverse supporting block and the bottom surface of the second transverse supporting block are on the same horizontal plane; and spacing between the first transverse supporting block and the second transverse supporting block is regulated through a vertical regulating rod. The invention also discloses an aligning method for the engine cylinder oblique-hole processing clamp.

Owner:海昱科技(台州)有限公司

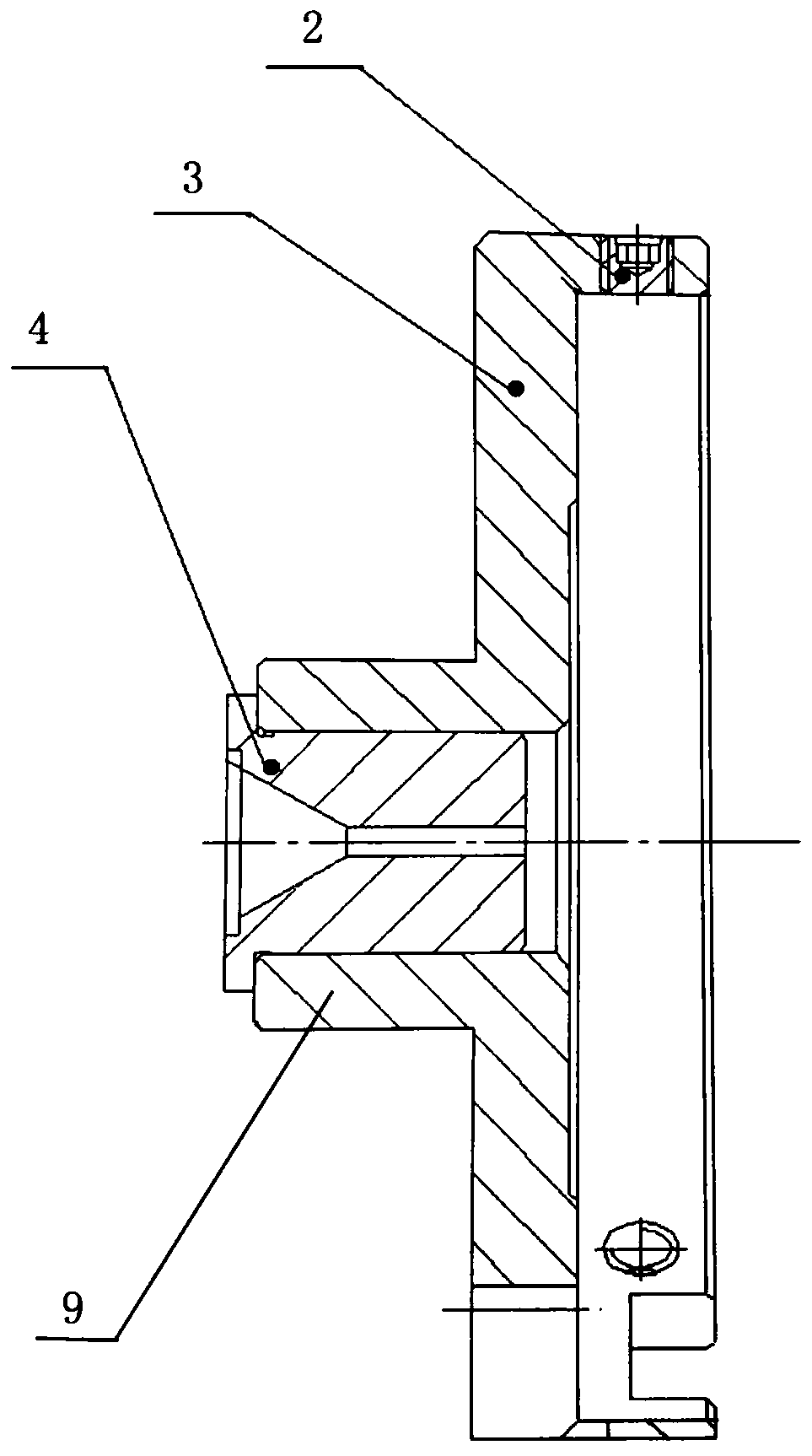

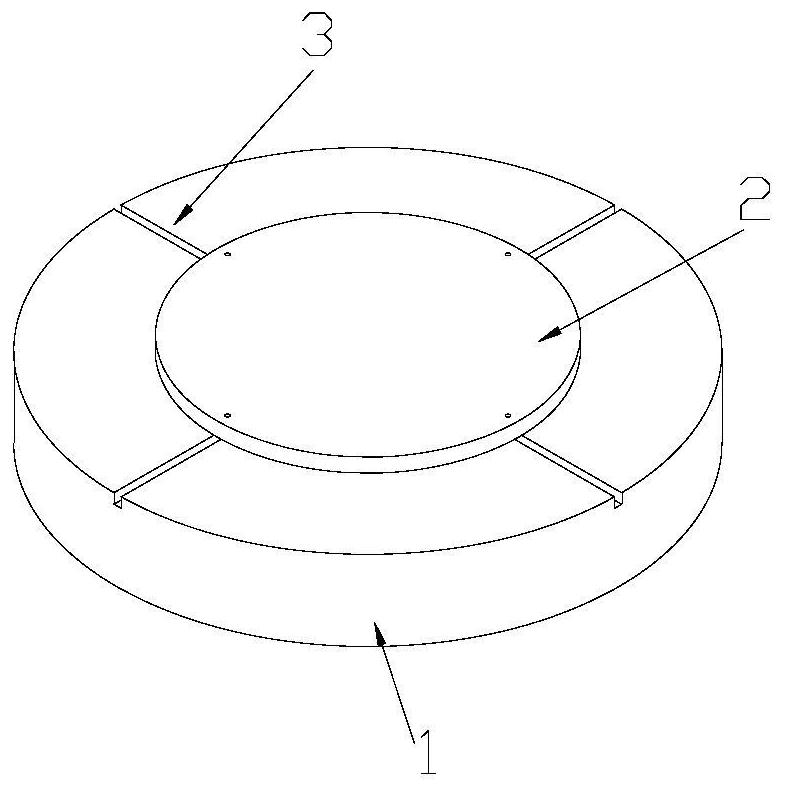

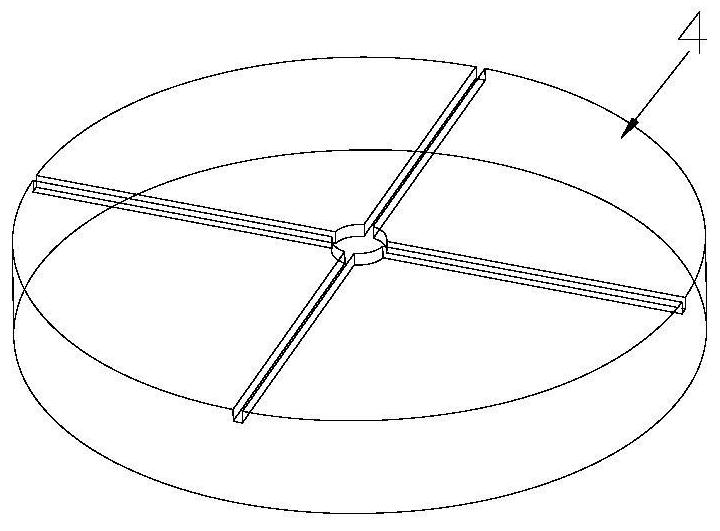

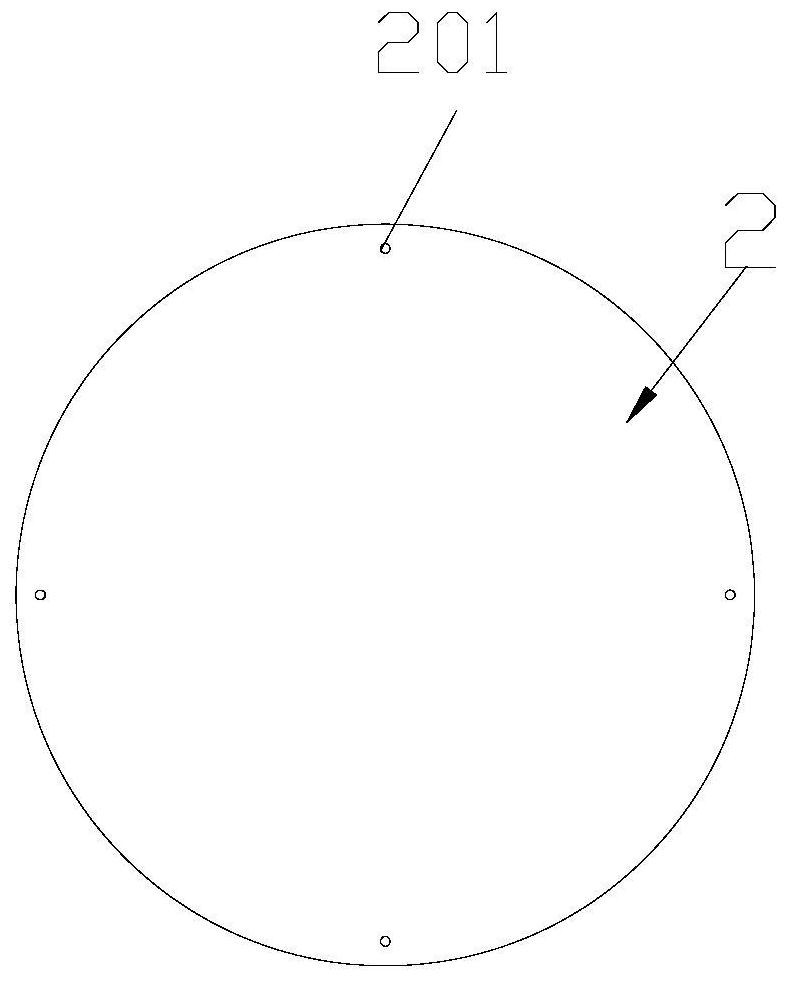

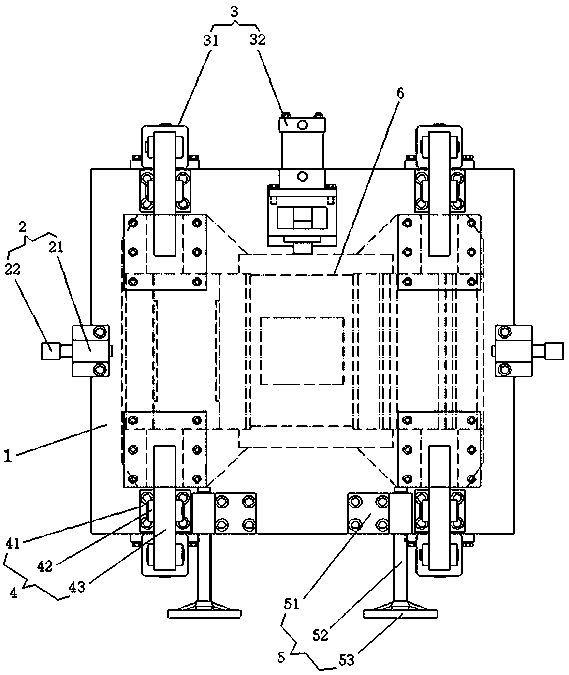

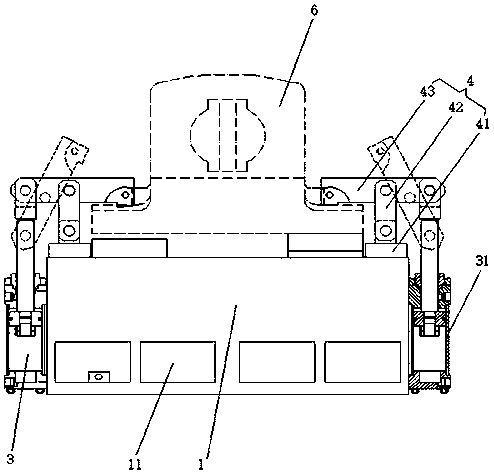

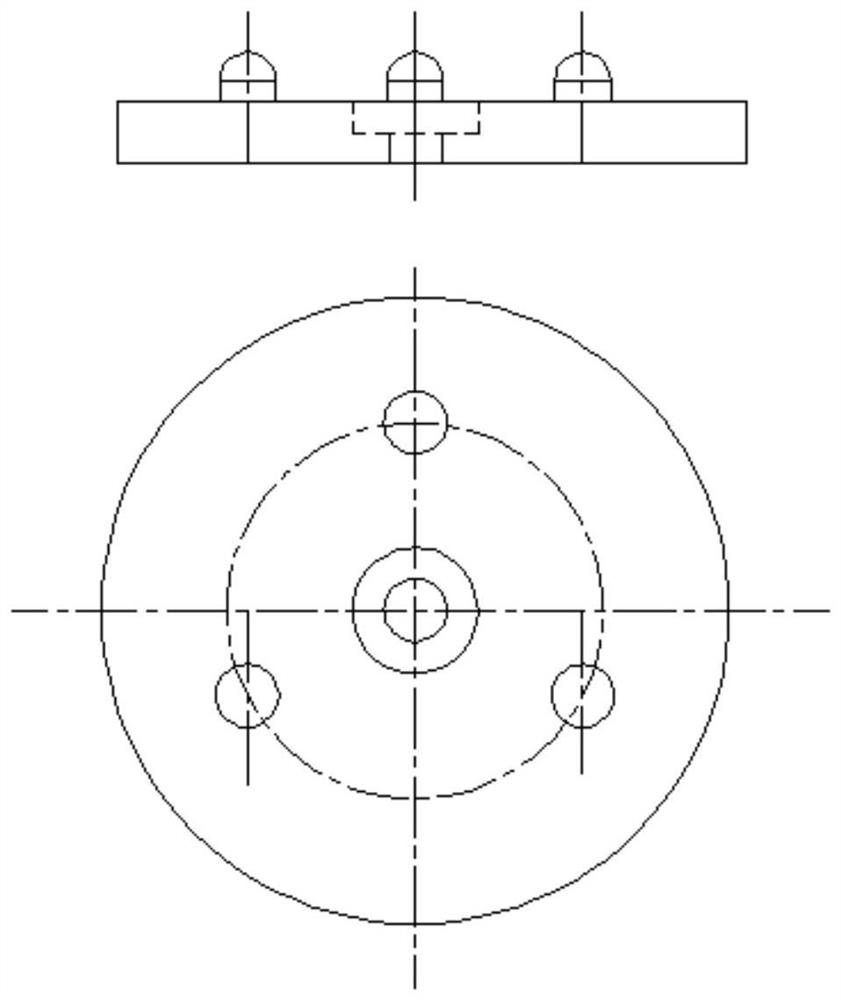

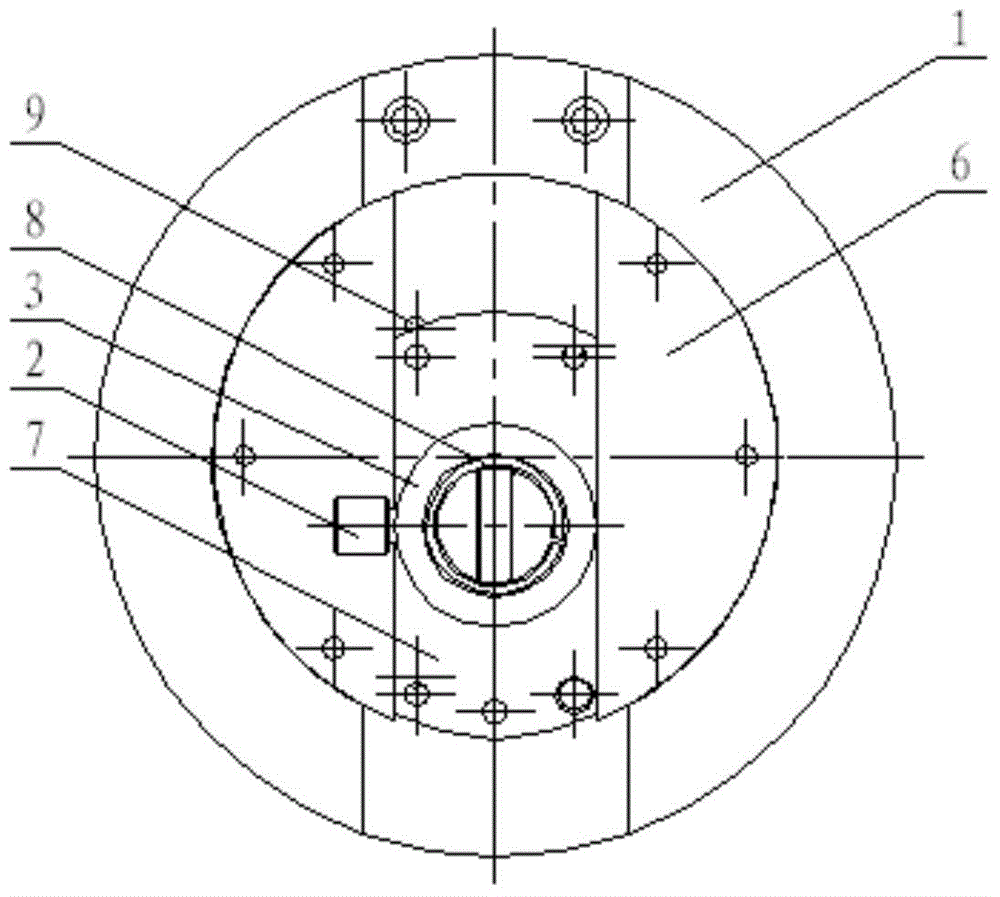

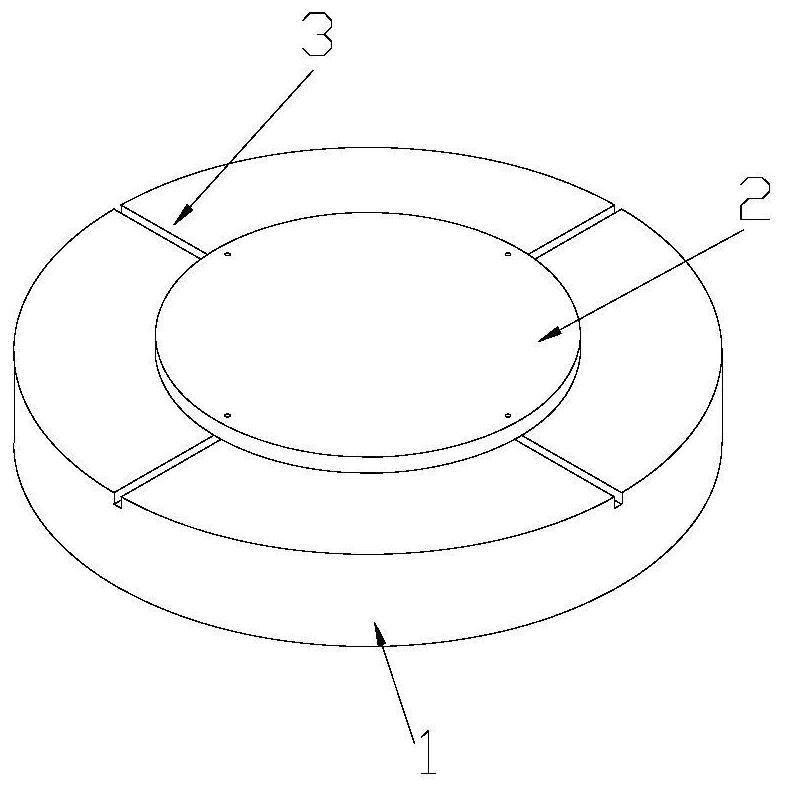

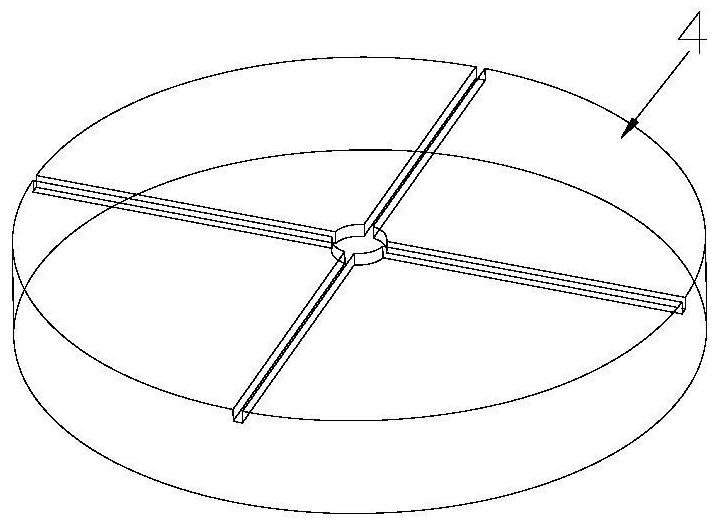

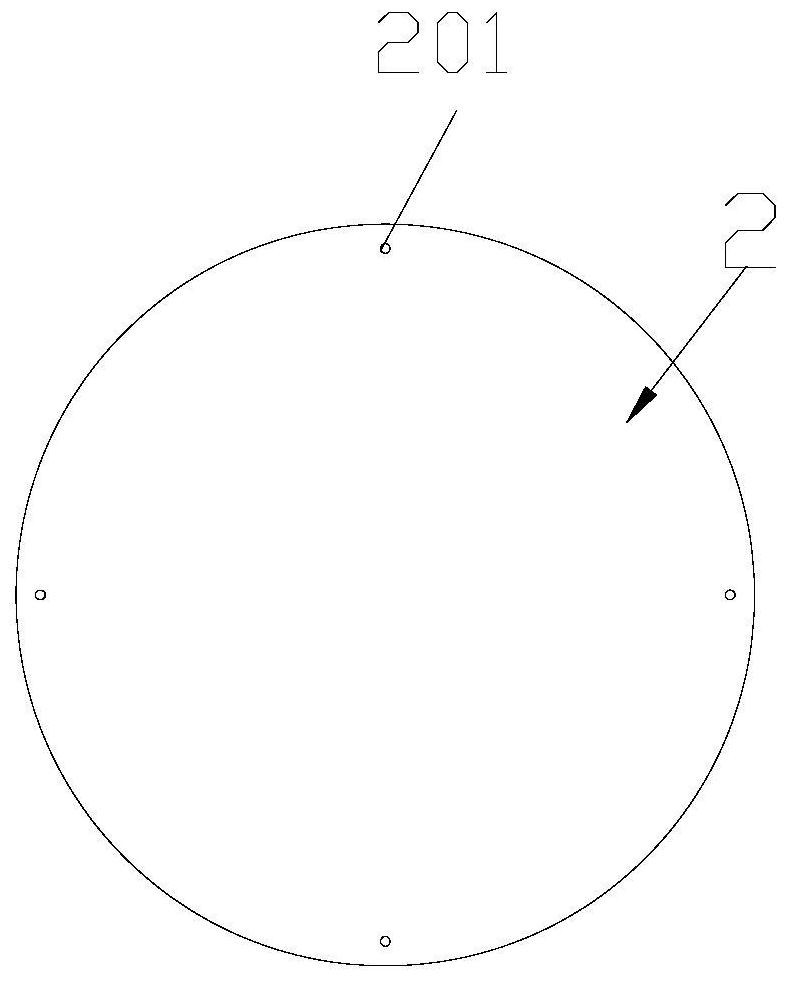

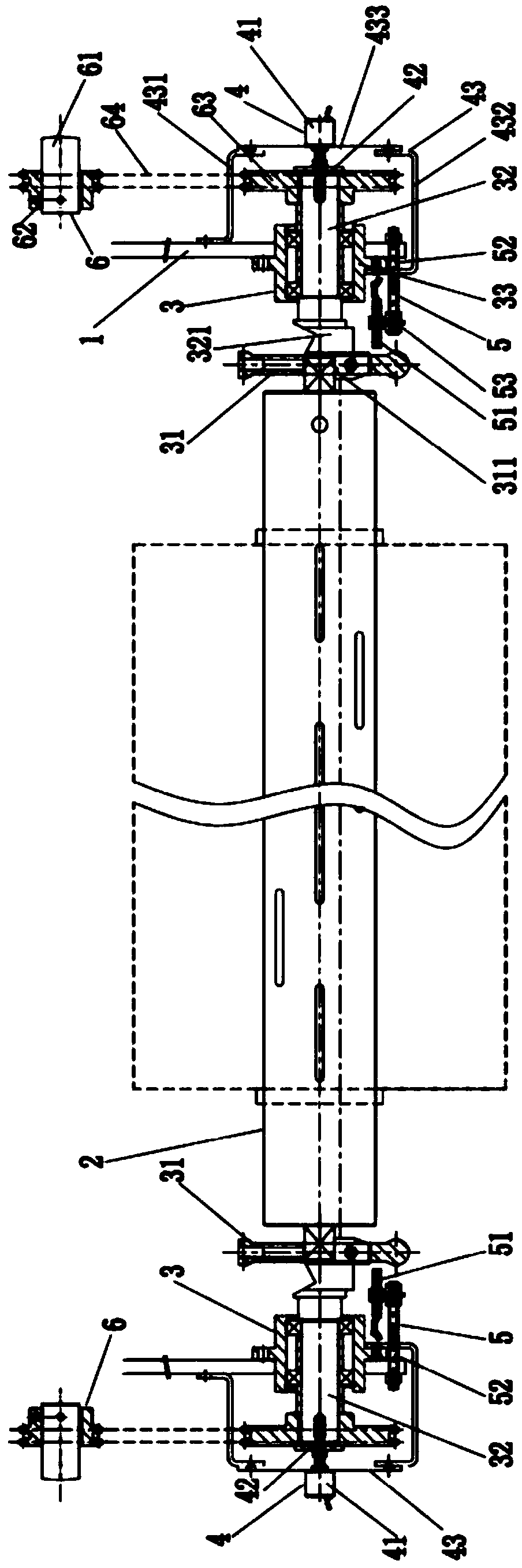

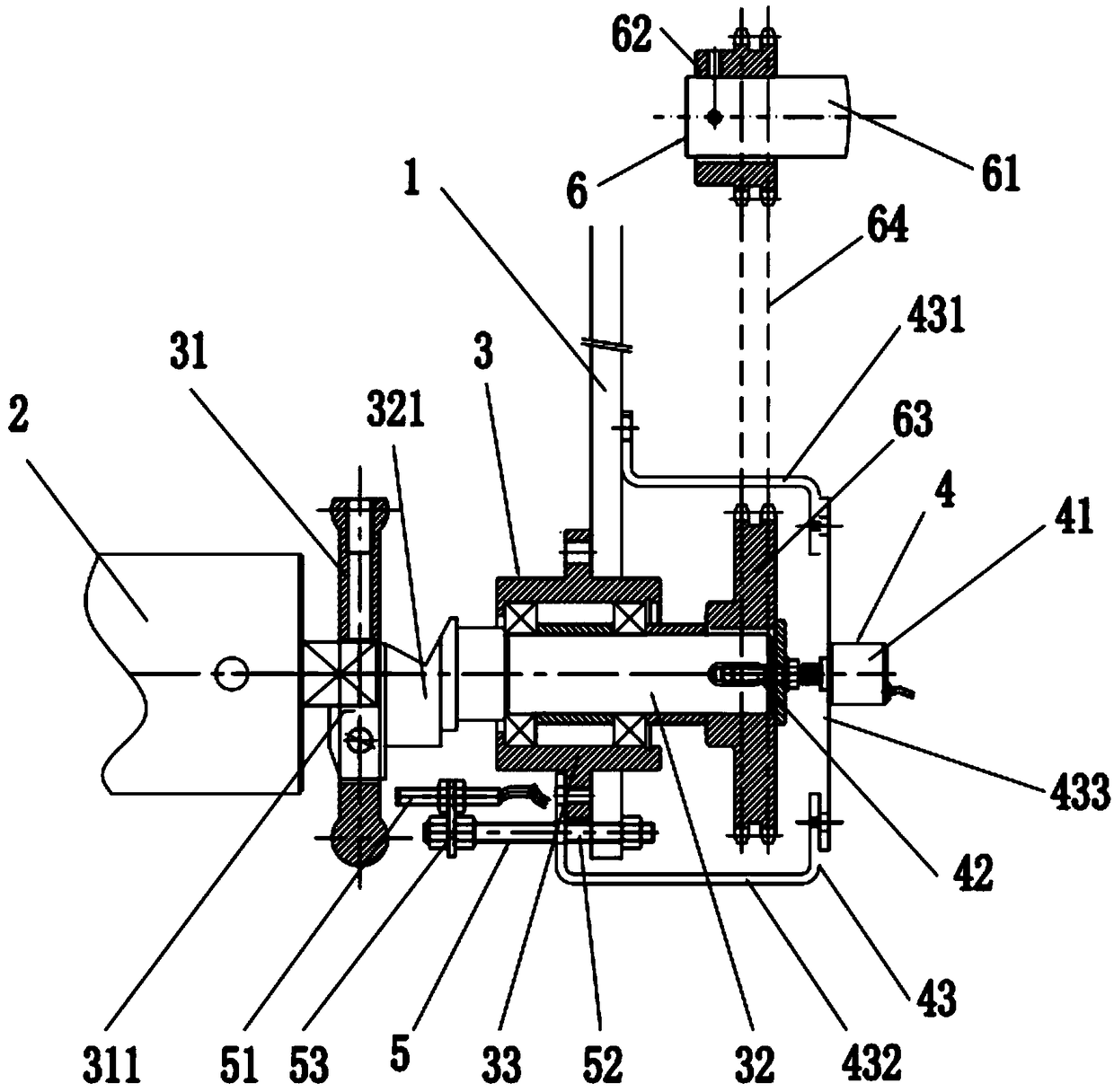

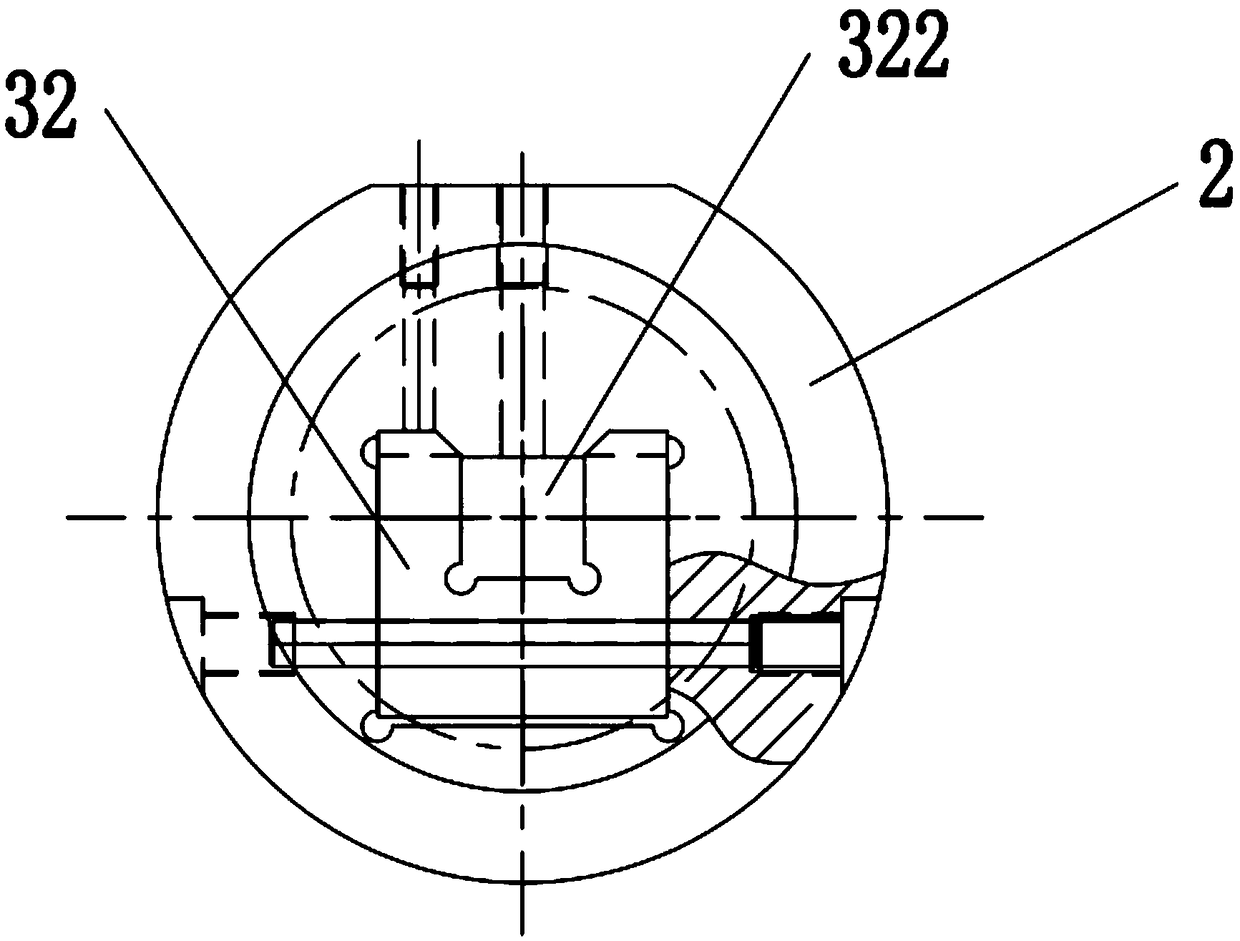

A machine tool faceplate-type centering device for a tooling fixture and a centering method thereof

ActiveCN112091658BImprove securityCorrect and accuratePositioning apparatusMetal-working holdersEngineeringMachine tool

The invention discloses a machine tool faceplate-type centering device of a tooling fixture and a centering method thereof, comprising: a machine tool faceplate; a tooling fixture carried on the machine tool faceplate and a plurality of positioning grooves opened on the machine tool faceplate, Several positioning grooves are evenly arranged along the center of the machine tool faceplate; and several positioning blocks are installed on the fixture, one end of the positioning blocks is screwed with the fixture, and the other end of the positioning blocks Installed in sliding fit with the positioning groove. The principle that the cross centers of the two objects overlap each other in the present invention enables the faceplate of the machine tool and the tooling fixture to be quickly and accurately aligned, and the centering error is greatly reduced.

Owner:AECC AERO SCI & TECH CO LTD

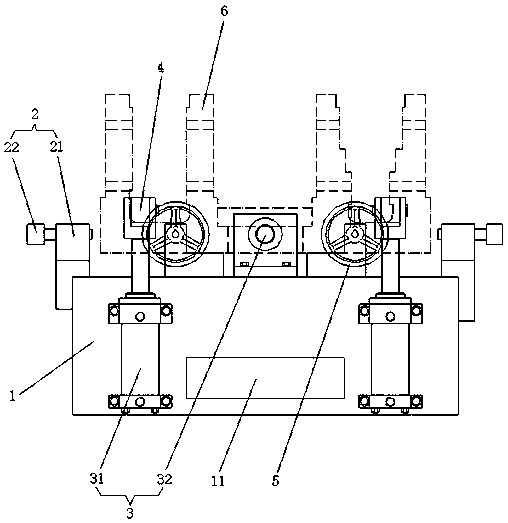

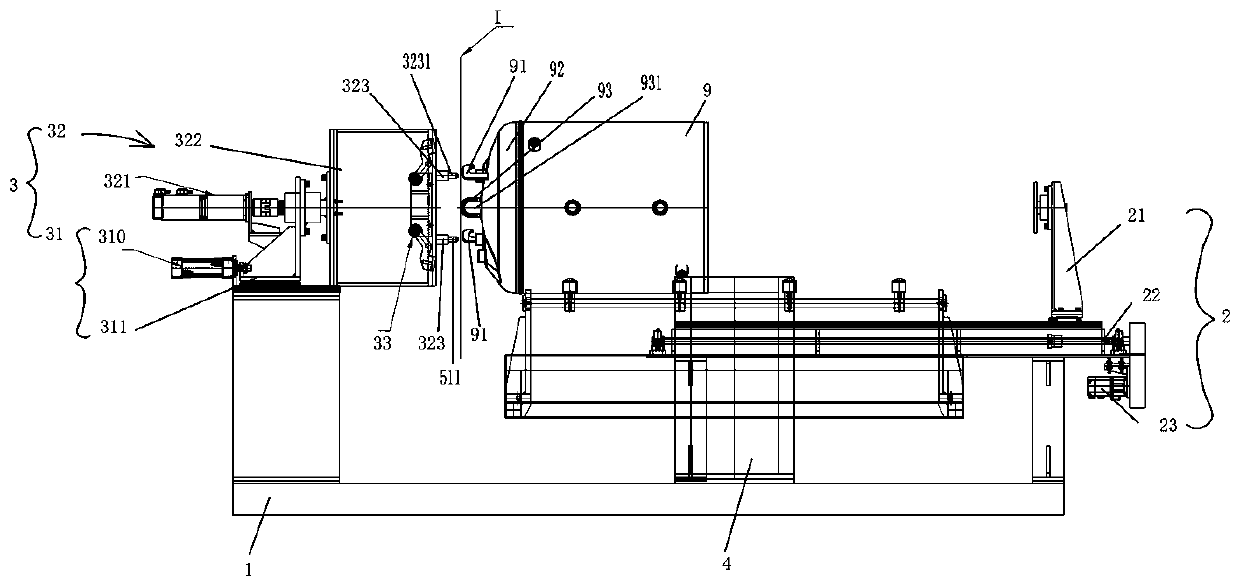

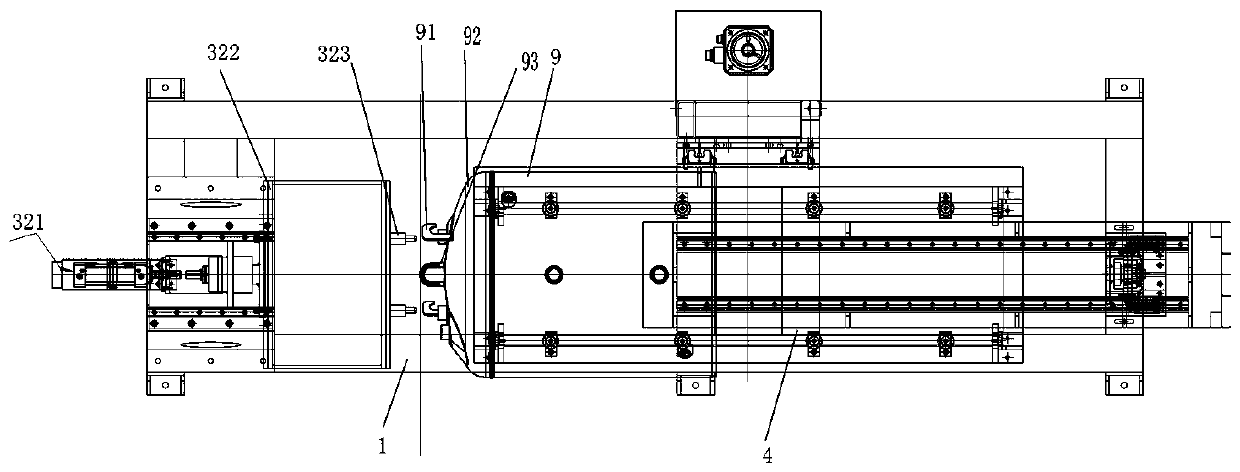

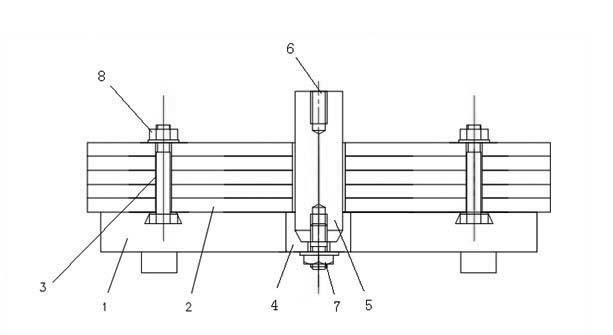

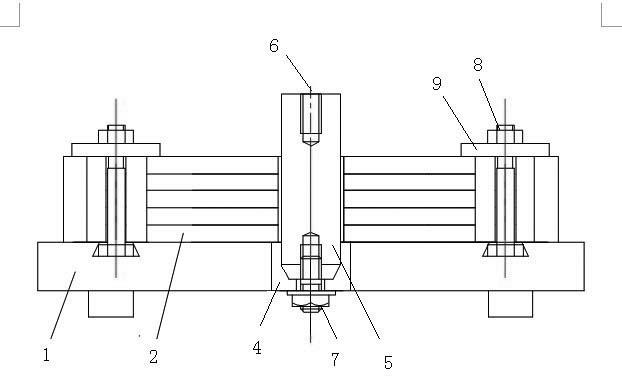

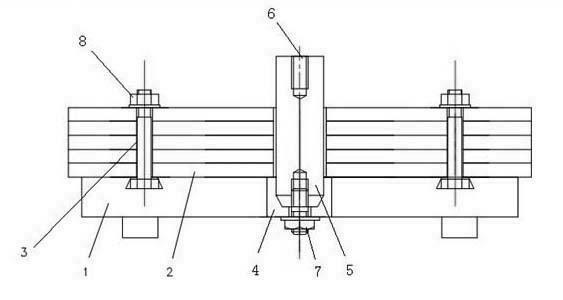

PC beam bearing machining clamping device and clamping method

PendingCN108098413AImprove machining accuracyIncrease productivityPositioning apparatusMetal-working holdersHydraulic cylinderPiston rod

The invention relates to a PC beam support machining clamping device and a clamping method. The PC beam bearing machining clamping device includes a worktable and a middle mechanism arranged on the workable, a hydraulic oil cylinder, a connecting rod mechanism and a fine tuning mechanism; the middle mechanism is symmetrically installed on the middle portion of the left side and the middle portionof the right side of the upper end of the worktable and is connected with the PC beam support placed on the worktable; the hydraulic oil cylinder is connected with the external hydraulic system. The hydraulic oil cylinder comprises a longitudinal hydraulic oil cylinder symmetrically arranged on the front and back sides of the worktable and a transverse hydraulic oil cylinder mounted on the top surface of the worktable. The connecting rod mechanism is symmetrically installed on the front and back top surface of the worktable, one end of the connecting rod mechanism is connected withthe piston rod of the longitudinal hydraulic oil cylinder, and the other end of the connecting rod mechanism connects with the PC beam support placed on the worktable, and the fine tuning mechanism is installed at the front side of the upper surface of the worktable and connected with the PC beam support placed on the worktable. The PC beam bearing machining clamping device and the clamping method have simpleand reasonable structure design, convenient installation and high efficiency, and can improve the processing precision and production efficiency of the PC beam support.

Owner:CHINA RAILWAY BAOJI BRIDGE GRP

American type water heater inner container alignment mechanism and alignment method

PendingCN111055154AFor correct grippingSimple structureMetal working apparatusRobot handElectric machine

The invention relates to an American type water heater inner container alignment mechanism and alignment method. The alignment mechanism comprises a machine frame for placing an inner container, an inner container aligning mechanism, a rotating mechanism and a lifting mechanism, wherein the inner container aligning mechanism, the rotating mechanism and the lifting mechanism are positioned on the machine frame and are used for rotating and positioning the inner container; the lifting mechanism is arranged on the inner container aligning mechanism and can synchronously move along with the innercontainer aligning mechanism, the rotating mechanism comprises a telescopic unit, a rotating servo unit, a first rotating detection unit, and a unit for detecting a straight state after rotation; therotating servo unit comprises a rotating motor, a rotating frame which is arranged on an output shaft of the rotating motor and can rotate along with the output shaft of the rotating motor, and rotating lugs; and the first rotating detection unit is arranged on the rotating frame and is used for detecting a water pipe opening of the inner container, the rotating lugs are used for being extended into the water pipe opening of the inner container and rotating the inner container under the action of the rotating motor, and the unit for detecting the straight state after rotation is used for detecting whether the inner container is rotated to return to the zero position. The alignment mechanism and method have the advantages of simpler structure, fewer parts, more accurate alignment and beingbeneficial to the correct clamping of a manipulator.

Owner:东莞市天美新自动化设备有限公司 +2

Alignment instrument for eccentric alignment of four-jaw chuck of lathe and alignment method

Owner:QINGDAO TECHN COLLEGE

Position correction device and using method thereof

PendingCN113478260ACorrect and accurateAccurate capturePositioning apparatusMetal-working holdersEngineeringMechanical engineering

Owner:共享智能铸造产业创新中心(安徽)有限公司

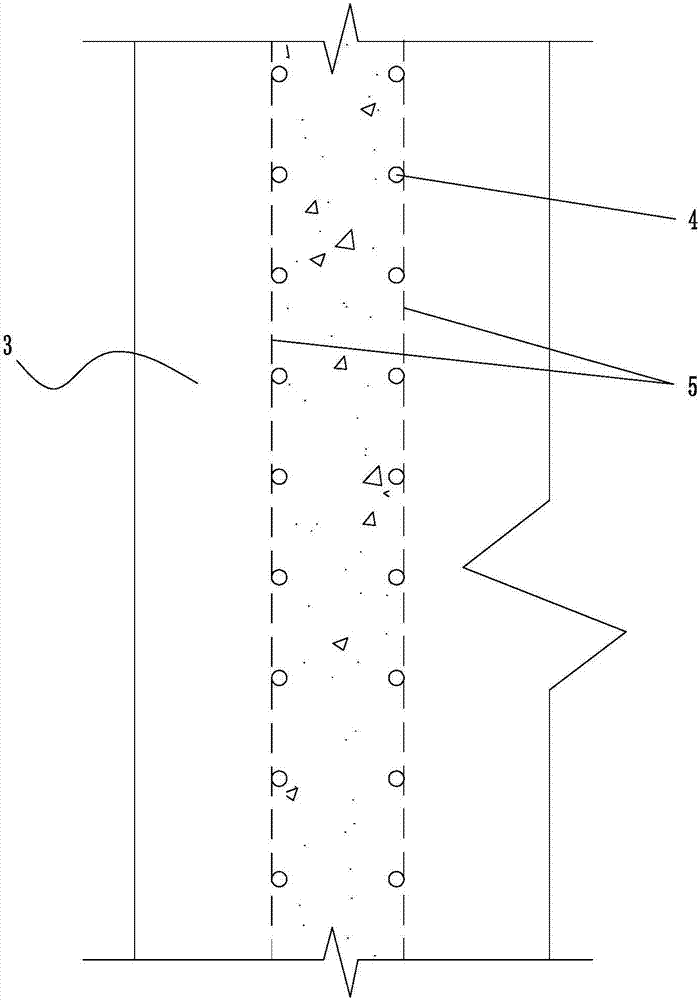

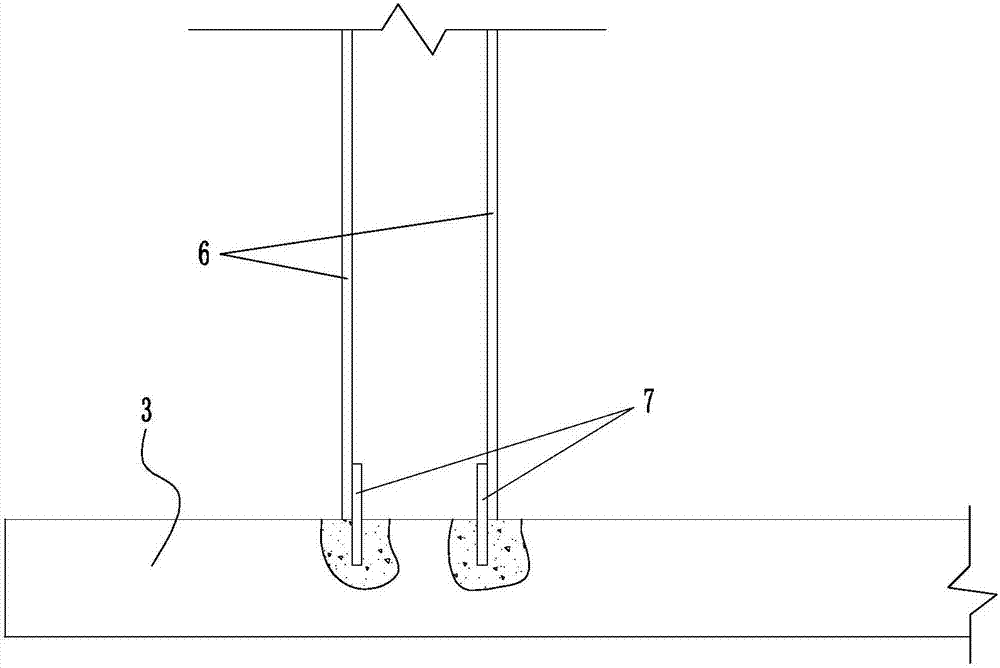

Positioning, alignment and forming method for lower portion of formwork of vertical structure

InactiveCN107013036APrecise positioningPositioning is accurateAuxillary members of forms/shuttering/falseworksBuilding material handlingEngineeringRebar

The invention discloses a positioning, alignment and forming method for the lower portion of a formwork of a vertical structure, and belongs to the field of concrete pouring of vertical building structures in engineering construction. The method comprises the steps that (1) a measurer conducts measuring and positioning on all surfaces of the bottom of the vertical structure at first, and chalk lines for installing a formwork are played on all the surfaces; (2) drilling is conducted by a concrete percussion drill along the chalk lines, the diameter of each hole is 12-14 mm, the distance between the adjacent holes on the same chalk line is 450-550 mm, the at least two holes are formed in each surface, the end of each surface is provided with one hole, and the depth of each hole is 50-80 mm; (3) a steel-bar pile with the diameter phi being 10-12 mm is driven into each hole and located on the outer side of each chalk line, the outer wall of each steel-bar pile is tangential to the corresponding chalk line, and 50-70 mm of each steel-bar pile is exposed out of the corresponding hole; and (4) the formwork of the vertical structure is installed in the mode of being attached to the steel-bar piles, and positioning, alignment and forming construction operations of the lower portion of the formwork of the vertical structure are completed in one time. Through the positioning, alignment and forming method, the technical problems that during formwork positioning and alignment in the prior art, construction is tedious, the efficiency is low, the labor intensity is high, and the construction quality is poor can be solved.

Owner:CHINA NAT CHEM ENG THIRD CONSTR

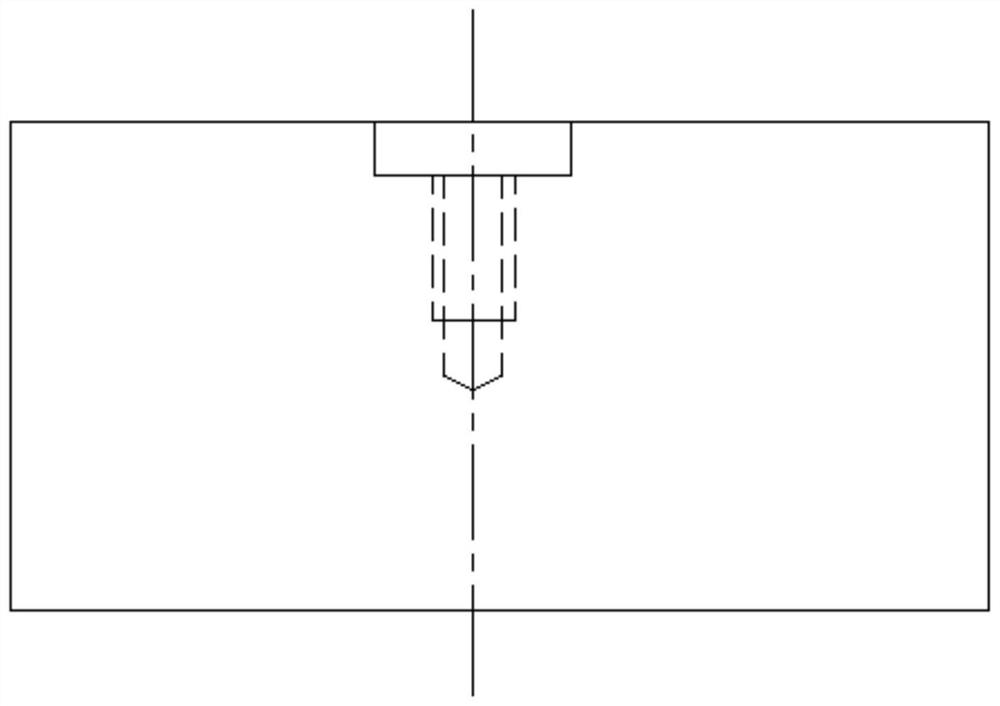

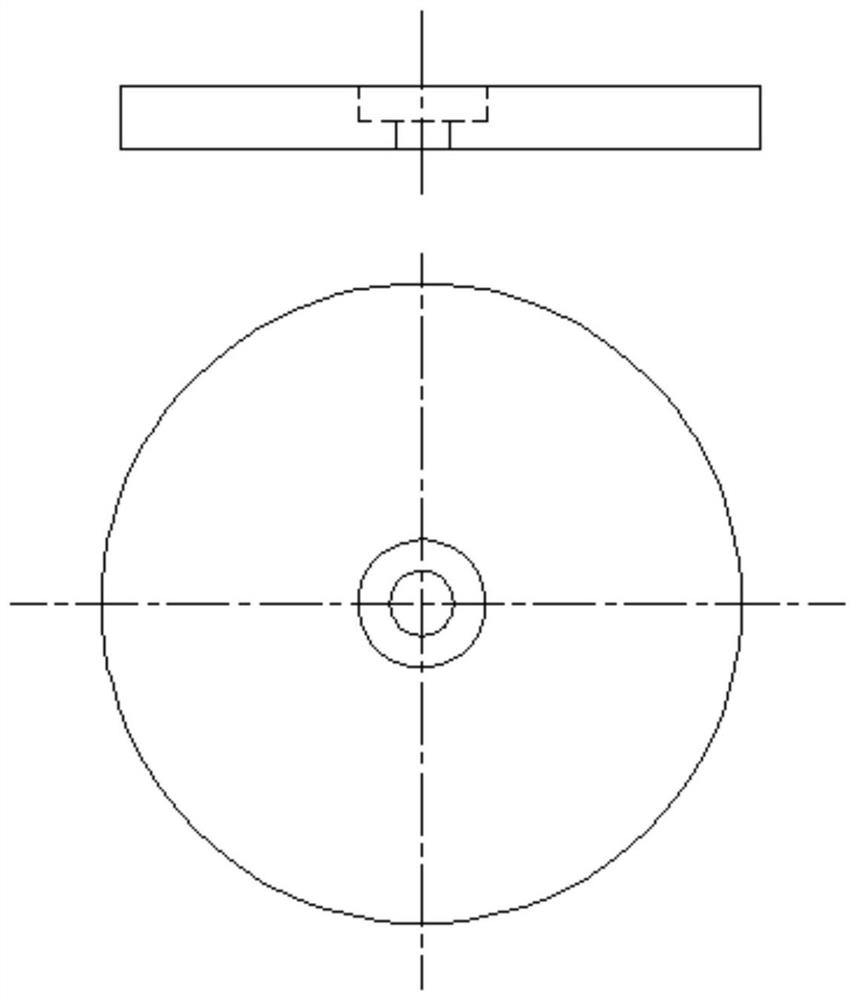

Inner and outer circle finish turning positioning device and method of circular saw web

InactiveCN102632413AGuaranteed machining accuracyCorrect and accuratePositioning apparatusMetal-working holdersCircular sawEngineering

The invention provides an inner and outer circle finish turning positioning device and method of a circular saw web, which belongs to the technical field of mechanical machining equipment, and is used for positioning the circular saw web in a machining process. The technical scheme of the invention is as follows: the inner and outer circle finish turning positioning device of the circular saw web is composed of a centering sleeve and a centering shaft, wherein the inner diameter of the centering sleeve is matched with the outer diameter of the centering shaft; the center of a vertical lathe accepting disc is provided with a through hole, and the centering sleeve is embedded into the through hole; and the upper and lower end faces of the centering shaft are provided with screw holes. The machining method comprises the following steps of: inserting the centering shaft into the centering sleeve to be fastened; aligning the centering shaft and a rotary center of a working table to the same central line; arranging central holes of a plurality of circular saw webs on the centering shaft, wherein the gap between two circular saw webs is 0.2-0.4 mm; pressing the circular saw webs through a technical hole or a pressing device, and pulling out the centering shaft; and machining an inner hole and an outer circle of each circular saw web. The device and method provided by the invention can rapidly and accurately center and align the circular saw webs when the circular saw webs are machined, so as to guarantee the machining precision of the circular saw webs and realize a very good effect.

Owner:TANGSHAN METALLURGICAL SAW BLADE

Crankshaft eccentric segment external diameter cylindricity detection device

InactiveCN105783840AGuaranteed accuracyAvoid measurement errorsMeasurement devicesEngineeringCrankshaft

The invention relates to a crankshaft eccentric segment external diameter cylindricity detection device includes a chassis, a sleeve and self-centring balls, an upper surface of the chassis is coaxially equipped with a guide rail disc, an adjustable eccentric sliding block is slidably mounted on the guide rail disc, one or more adjusting holes are manufactured on the guide rail disc, an eccentricity adjustment locating pin is mounted on the adjustable eccentric sliding block, the eccentricity adjustment positioning pin is inserted in one of the adjusting holes, and the sleeve used for inserting a crankshaft workpiece is coaxially mounted on the adjustable eccentric sliding block; the plurality of self-centering balls are embedded in a lower bottom surface of the chassis, and all the self-centering balls are arranged on the same circumference. The crankshaft eccentric segment external diameter cylindricity detection device provided by the invention is ingenious in design, simple in structure, easy to manufacture and convenient to use, and by use of the device, a crankshaft eccentric segment can be rapidly and accurately aligned, thereby ensuring that the center of rotation of a cylindricity instrument is concentric with an eccentric segment of the workpiece, and overcoming the defects of low speed, low efficiency and poor accuracy of traditional manual measurement.

Owner:TIANJIN BAOLAI PRECISION MACHINERY

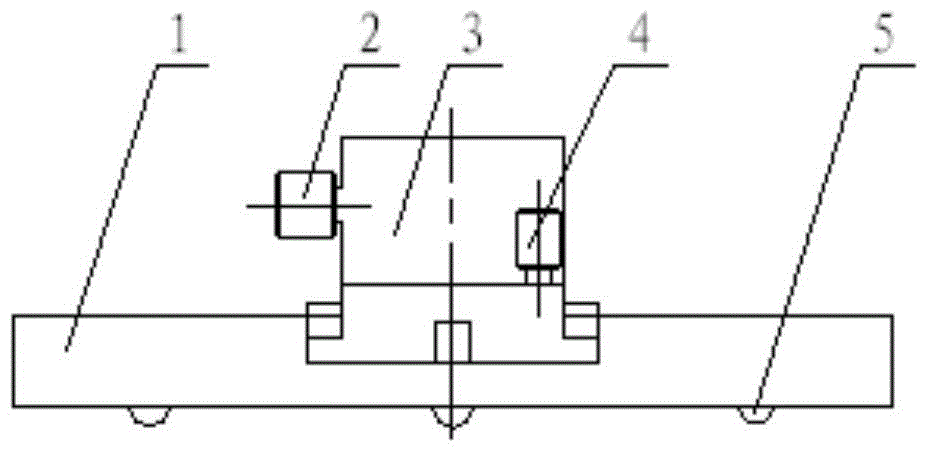

Machine tool disc chuck type centering device of tool clamp and centering method of machine tool disc chuck type centering device

ActiveCN112091658ACorrect and accurateReduce mistakesPositioning apparatusMetal-working holdersComputer hardwareEngineering

The invention discloses a machine tool disc chuck type centering device of a tool clamp and a centering method of the machine tool disc chuck type centering device. The machine tool disc chuck type centering device comprises a machine tool disc chuck, the tool clamp borne on the machine tool disc chuck, a plurality of positioning grooves formed in the machine tool disc chuck and a plurality of positioning blocks installed on the tool clamp, wherein the positioning grooves are uniformly formed along the center of the machine tool disc chuck, one end of each positioning block is in threaded connection with the tool clamp, and the other end of each positioning block is installed in the corresponding positioning groove in a sliding fit manner. According to the machine tool disc chuck type centering device and the centering method of the machine tool disc chuck type centering device, the principle that the cross centers of two objects coincide with each other is adopted, the machine tool disc chuck and the tool clamp can be rapidly and accurately aligned, and the centering error is greatly reduced.

Owner:AECC AERO SCI & TECH CO LTD

Aligning protection device for large-volume center roller flange

The invention relates to an aligning protection device for a large-volume center roller flange. The aligning protection device comprises a frame, an inflatable roller and inflatable-roller drive components. The inflatable-roller drive components are arranged at two ends of the inflatable roller, and comprise safety chucks, central shafts and bearing blocks; the bearing blocks are arranged on the frame, and the central shafts are rotatably supported on the bearing blocks; one end of the inflatable roller is detachably connected with the safety chucks; each safety chuck is hinged to one end of the corresponding central shaft. The aligning protection device is characterized in that the aligning protection device further comprises alignment mechanisms, and each alignment mechanism comprise anencoder, an encoder connecting shaft and an encoder mounting support; the encoder mounting supports are arranged on the outer sides of the central shafts and fixedly connected with the frame, each encoder is fixedly connected to one end of the corresponding encoder connecting shaft, the encoders are located on the outer sides of the encoder mounting supports, and the other ends of the encoder connecting shafts are fixedly connected with the central shafts. The aligning protection device has the advantages of simple structure and capability of aligning the safety chucks.

Owner:CHANGZHOU DIBA TEXTILE MACHINERY

Laser leveling rod with an angle conversion mechanism

This invention relates to a laser level with an angle conversion unit, which can correct any angles accurately or draw any angle lines freely. It includes a back rule, a pin shaft, a first connector, a positioning unit, a second connector and a front rule characterizing in connecting the two connectors by the shaft, the first connector is fixed on the back rule, the second is fixed on the front rule, the back rule has an universal bubble, the front rule has a light splitting unit of laser points, laser level lines, laser cross lines and vertical lines.

Owner:ZHEJIANG RONGSHENG TOOL

Alignment and detection method and application of semiconductor device

PendingCN113624162ACorrect and accurateReduce focusing timeOptically investigating flaws/contaminationUsing optical meansDevice materialEngineering

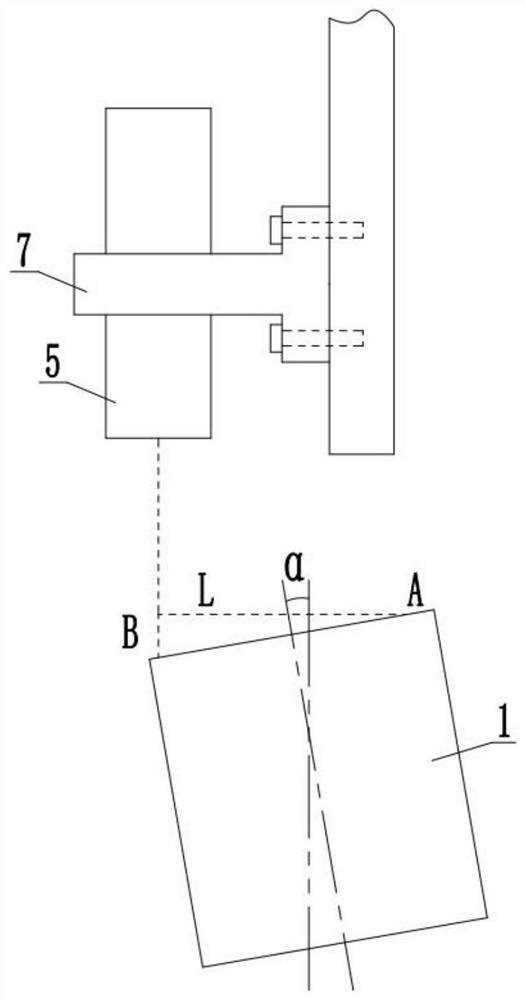

The invention discloses an alignment and detection method and application of a semiconductor device, and the method comprises the following steps: S1, a semiconductor device is placed on an adsorption assembly for adsorption and fixation, a first CCD camera collects first image information of the top surface of the semiconductor device, a moving assembly moves the adsorption assembly according to the first image information, so that the side face of the semiconductor device is located in the measuring range of a horizontally-arranged first optical displacement sensor; S2, the first optical displacement sensor measures a first point A away from the side face of the semiconductor device, the moving assembly moves by a distance L along the Y axis, and the first optical displacement sensor measures a second point B away from the side face of the semiconductor device; s3, according to the height difference value of the points A and B and the distance L, the deflection angle alpha of the semiconductor device placed on the adsorption assembly is calculated, and the moving assembly rotates the deflection angle alpha to enable the semiconductor device to be in an orthogonal state. By means of the characteristic of high-precision distance measurement of the sensor, accurate alignment of the semiconductor device is achieved, and the method can be used for high-precision detection of the semiconductor device.

Owner:武汉人和睿视科技有限公司

Accurate Alignment Method for Rotary Parts

ActiveCN111571272BLow technical requirementsReduce labor intensityAutomatic control devicesFeeding apparatusMicro nanoControl system

A method for accurately aligning rotary parts belongs to the field of precision ultra-precision machining. Small parts can be pushed but not automatically slipped; install and debug the main control system, high-precision displacement detection system and micro-nano displacement execution system. 2) Adjust the distance from the micro-displacement detection module in the high-precision displacement detection system and the micro-nano displacement actuator in the micro-nano displacement execution system to the outer circular surface of the part. 3) The main control system controls the high-precision displacement detection system to detect the runout of the outer circular surface of the part, and controls the movement of the micro-nano displacement actuator and pushes the part to move according to the runout detection result of the outer circle of the part. 4) Repeat step 3) until the runout of the part ≤ the theoretically calculated maximum runout value to complete the alignment. The invention can reduce the production cost, the alignment accuracy can reach submicron or even nanometer level, and the alignment accuracy has good repeatability.

Owner:DALIAN UNIV OF TECH

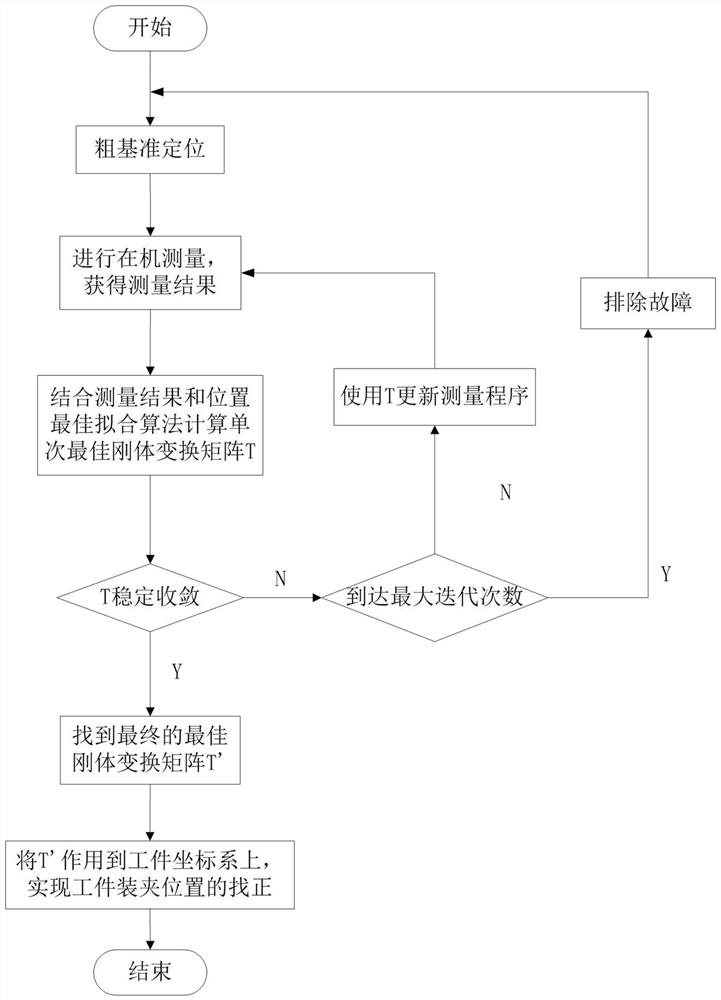

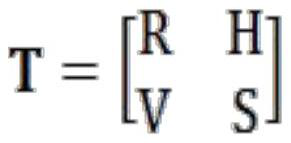

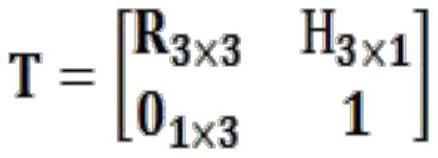

Alignment method of on-machine measurement of workpiece clamping position based on iteration

ActiveCN112296753BCorrect and accurateThe problem of reducing the position error of the contact pointMeasurement/indication equipmentsControl engineeringProcess engineering

The invention discloses a method for correcting the clamping position of a workpiece based on iterative measurement on the machine. The clamping position of the workpiece is corrected by using the method of iterative measurement, so that the actual measurement point of the machine tool probe is gradually approached to the planned theoretical measurement point, and the Calculate the position transformation of the workpiece clamping based on the last measurement result, correct the coordinate system of the workpiece, and realize the alignment of the workpiece clamping position. The invention measures and calculates through an iterative method, and gradually aligns the workpiece under the rough reference, which can greatly reduce the problem of the contact point position error existing in the traditional single measurement method, thereby improving the accuracy of on-machine measurement and realizing More accurate workpiece clamping position alignment for workpieces with complex surfaces.

Owner:苏州千机智能技术有限公司

Measuring ruler

InactiveCN108571951AEasy to disassembleEasy constructionIncline measurementVertical deflectionStructural engineering

The invention provides a measuring ruler. The measuring ruler is characterized by comprising a first horizontal ruler, a second horizontal ruler, a vertical column and an angle ruler. The first horizontal ruler, the second horizontal ruler and the vertical column are perpendicular to one another, the first horizontal ruler is detachably connected with the vertical column, the second horizontal ruler is detachably connected with the vertical column, and the angle ruler is detachably connected with the first horizontal ruler, the second horizontal ruler or the vertical column. The invention designs a measuring ruler which has a simple structure and comprises components easily disassembled and reassembled by plugging. The horizontal deflection and the vertical deflection can be mechanically measured by changing the mounting position of the measuring ruler, the measuring ruler is small in size and convenient for storage and transportation, a technician can perform construction more conveniently, and later alignment is more precise.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO QINGZHOU POWER SUPPLY CO +2

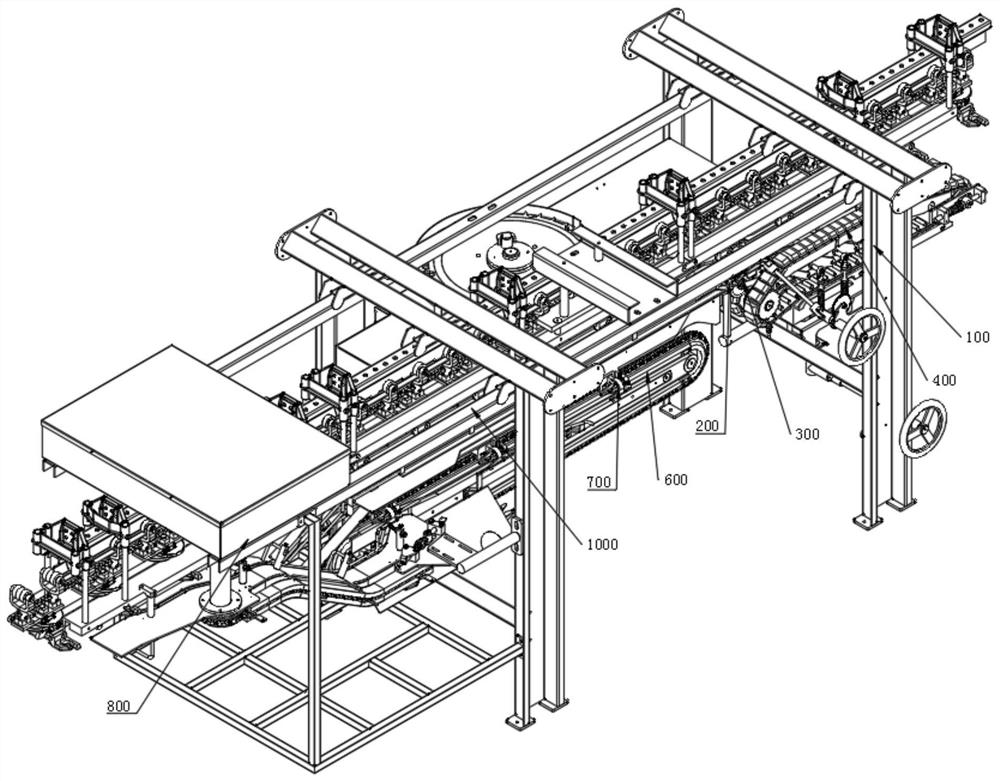

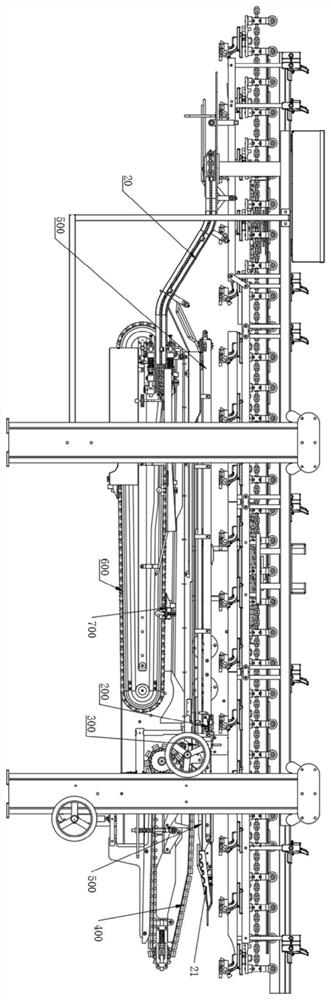

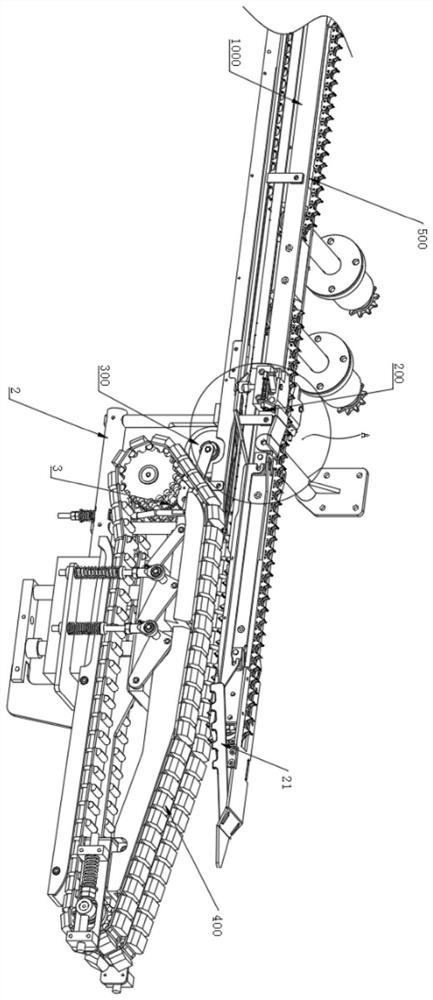

Full-leg cutting machine

ActiveCN113973885AEasy resectionAutomate excisionPoultry transferring/conveying devicesDividing poultryPhysical medicine and rehabilitationMachine

The invention discloses a full-leg cutting machine which comprises a rack, a middle conveying platform is arranged on the rack, and a full-leg pre-cutting device, a full-leg separating device and a rotating and hanging assembly are sequentially arranged on and below the middle conveying platform; the full-leg pre-cutting device comprises an upper cutter combination and a lower cutter combination, the upper cutter combination and the lower cutter combination can be automatically adjusted, and pre-cutting can be well completed. After the pre-cutting is finished, the full leg is separated from the chicken leg body by the full-leg separating device, and the clamping jaw combination on the full-leg separating device can accurately grasp a lute leg joint in the whole leg to separate the full leg; after separation, the separation group conveys the full legs to the rotating and hanging assembly, and the rotating and hanging assembly re-hangs the full legs to the chicken hanging chain; manual operation is not needed, the full leg can be better cut, the multiple procedures of skin opening, cutting and rotating hanging are combined into a whole, automatic cutting is achieved, and full-leg cutting automation is achieved.

Owner:QINGDAO RUIZHI PRECISION WEIGHING EQUIP TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com