Alignment tool capable of achieving cylindrical grinding on long-axis-type part and using method of alignment tool

A grinding, long-axis technology, used in manufacturing tools, metal processing equipment, machine tools designed for grinding the rotating surface of workpieces, etc. It can achieve obvious technical effects and economic benefits, meet the technical requirements of precision, and save the cost of fixtures.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

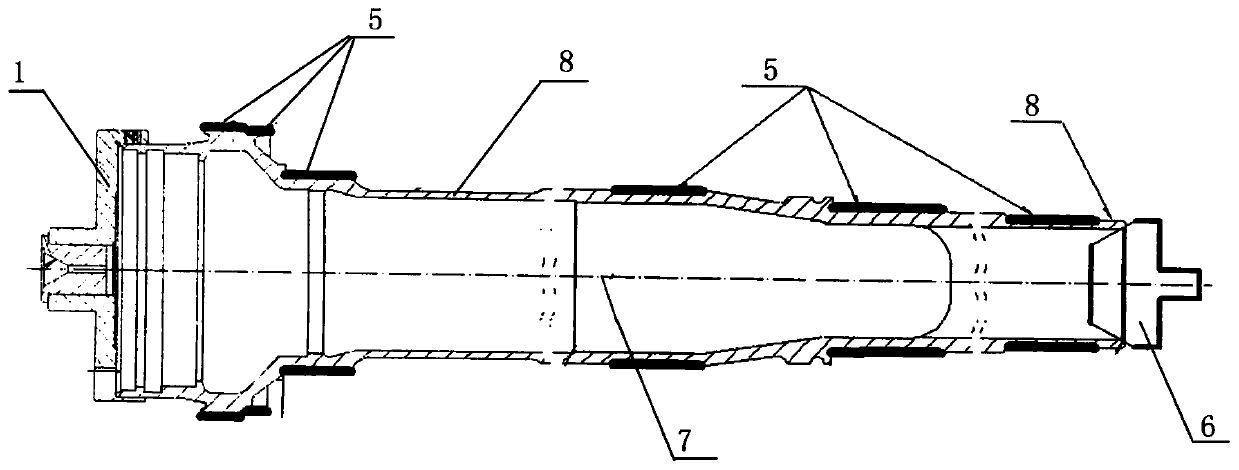

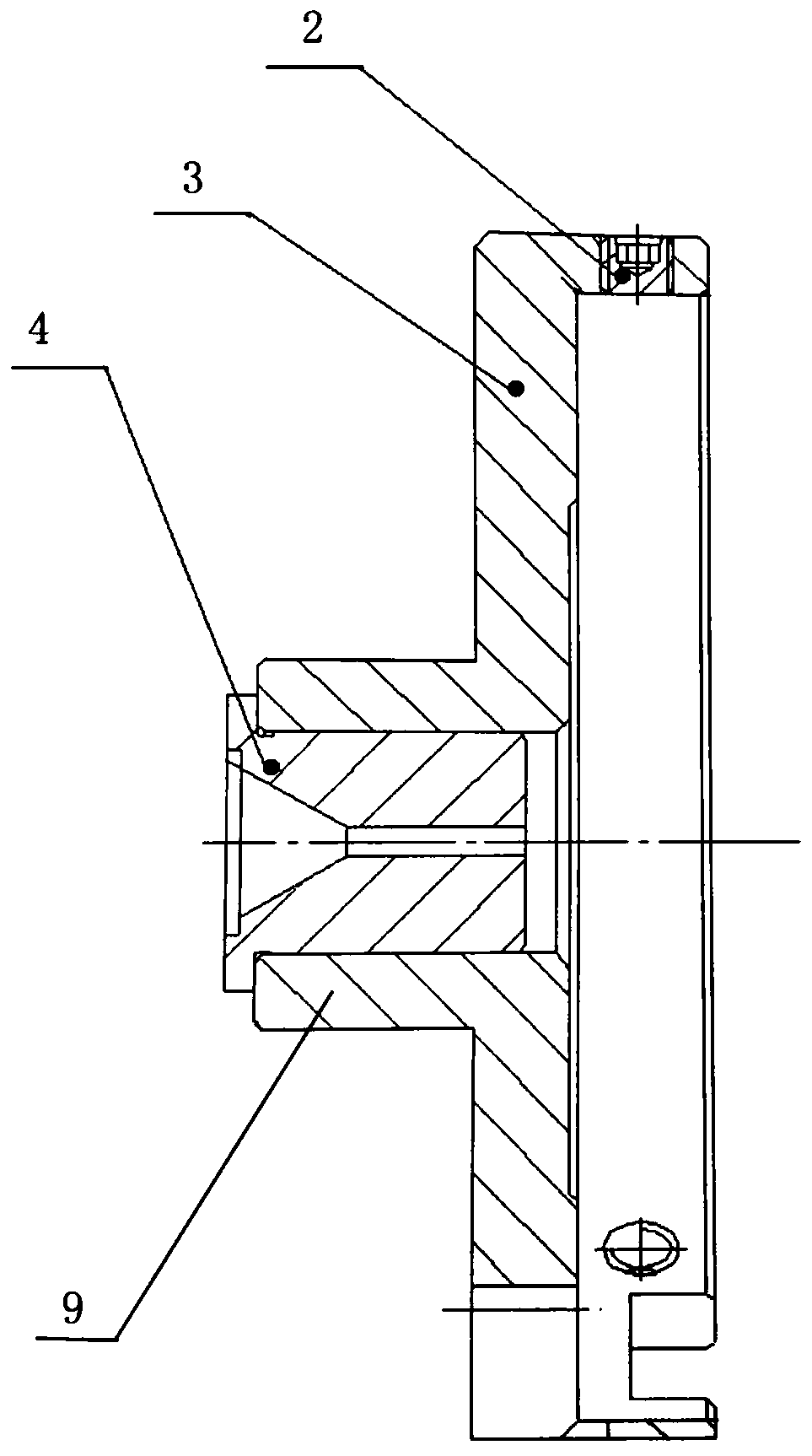

[0023] figure 1 It is the installation schematic diagram of alignment tool and long axis part of the present invention, figure 2 For the structural representation of the alignment tool of the present invention, as shown in the figure:

[0024] The straightening tool for grinding the outer circle of long-axis parts in the present invention is installed on the outside of one side of the installation end of the long-axis parts, near the end of the grinding machine head, and includes an integrally connected sleeve 9 and split ring 3, the split ring 3 The inner diameter is equal to the outer diameter of the mounting end of the long axis part; the inside of the sleeve 9 can be inserted into the replaceable center seat 4, and the tapered groove of the exchangeable center seat 4 matches the center; the split ring 3 is evenly and symmetrically divided into four strips There is a through hole of internal thread, which can cooperate with the jacking screw 2 threads to squeeze the insta...

Embodiment 2

[0032] The difference from Example 1 is that the clip is replaced by a three-jaw chuck.

Embodiment 3

[0034] The difference from Embodiment 1 is that the clip is replaced by a shift fork that can realize the rotating function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com