Method and system for error compensation of ac five-axis waterjet cutting

A technology of error compensation and compensation amount, which is applied in the field of AC five-axis water cutting error compensation, which can solve problems such as difficulty and complex structure of five-axis machine tools, and achieve the effect of wide application range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0072] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

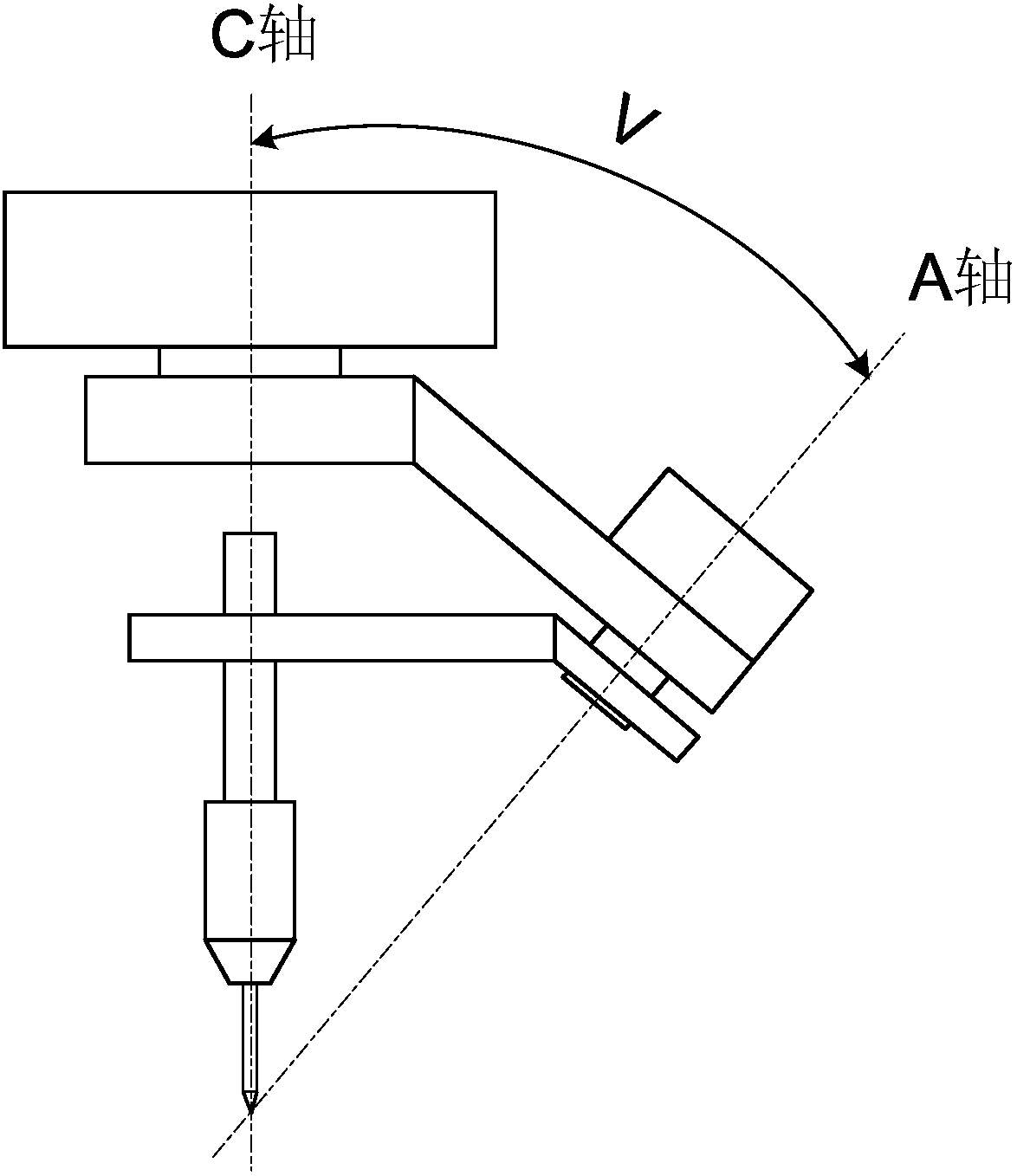

[0073] The method for error compensation of the AC five-axis waterjet cutting comprises the following steps:

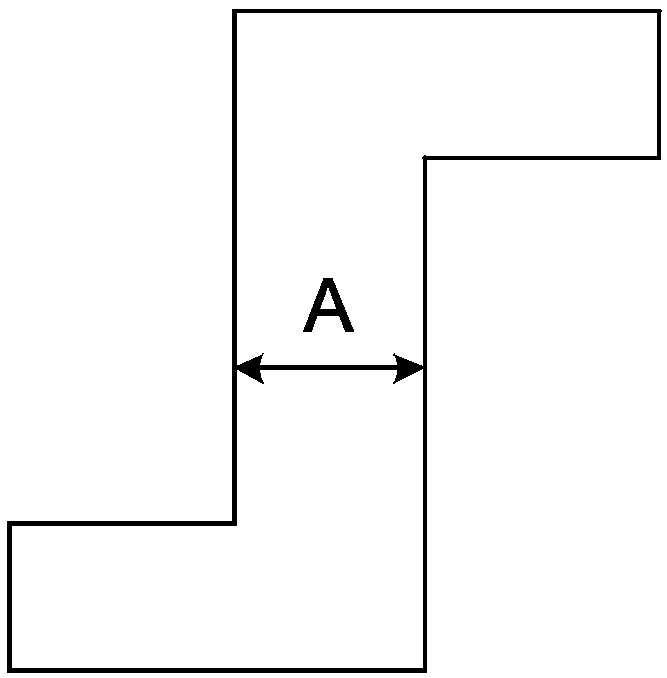

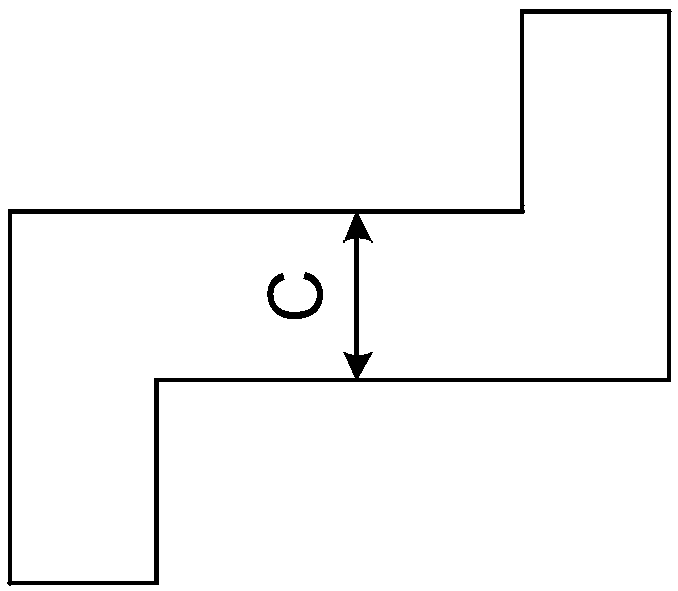

[0074] (1) Determine the first trial cutting tool path and vertically process the first workpiece according to the first trial cutting tool path, the first workpiece is a cylinder, and the top view surface of the cylinder includes at least the first A rectangle, a second rectangle and a third rectangle, the first rectangle and the third rectangle are parallel to each other and are connected vertically to the second rectangle, and are located on both sides of the second rectangle;

[0075] (2) According to the first trial cutting tool path with the inclination angle V 1 Process the second workpiece;

[0076] (3) The above-mentioned top view plane is axisymmetric and rotated 90° counterclockwise as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com