Inner and outer circle finish turning positioning device and method of circular saw web

The technology of a positioning device and positioning method is applied in the direction of positioning device, clamping, support, etc., which can solve the problems of troublesome price comparison, circular saw blades cannot be conveniently fastened to the connecting plate, etc., to ensure processing accuracy, fast centering and alignment, Improve the effect of the solution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

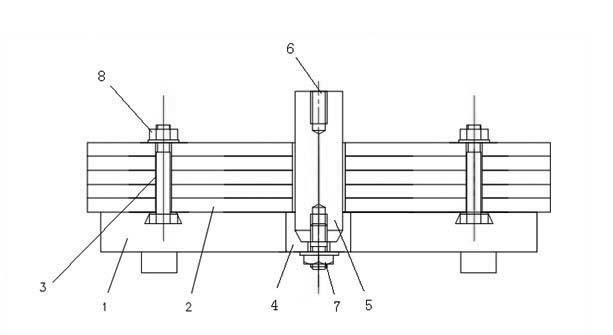

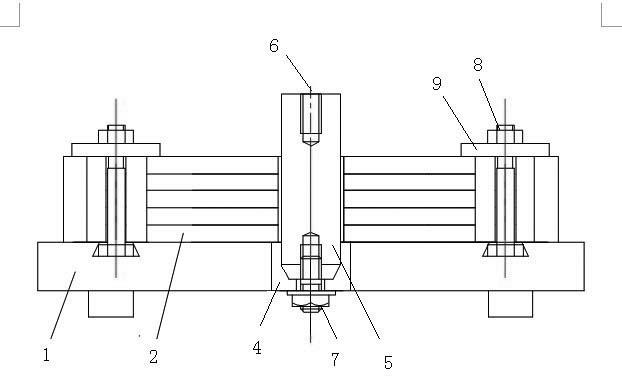

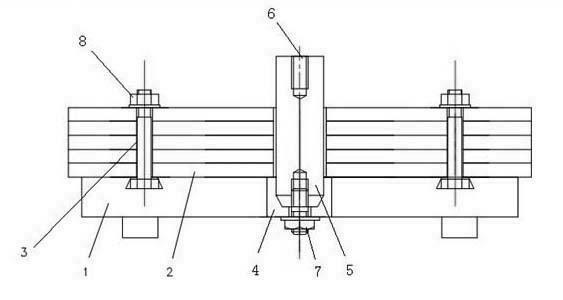

[0037] The positioning device for the inner and outer circle of the circular saw blade of the present invention is composed of a centering sleeve 4 and a centering shaft 5 .

[0038] As shown in the figure, the centering sleeve 4 is a steel sleeve, and the centering sleeve 4 is embedded in the through hole at the center of the vertical lathe adapter 1, and the lower end of the centering sleeve 4 is a tapered hole. The effect of the centering sleeve 4 is to introduce the centering shaft 5 to play a role in preliminary positioning of the centering shaft 5 .

[0039] The figure shows that the centering shaft 5 is a steel round shaft, the outer diameter of the centering shaft 5 matches the inner diameter of the centering 4 sets, and the outer diameter of the centering shaft 5 is smaller than the unmachined center hole of the processed circular saw blade 2 The diameter of the aperture, the upper and lower end faces of the centering shaft 5 have screw holes 6 perpendicular to the ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com