Accurate alignment method for rotary parts

A kind of parts and precise technology, which is applied in the field of accurate alignment of rotary parts, can solve the problems of low alignment accuracy, increased processing cost, and low processing efficiency, and achieve low alignment accuracy, reduce production costs, and reduce labor intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be described in detail below in conjunction with the accompanying drawings.

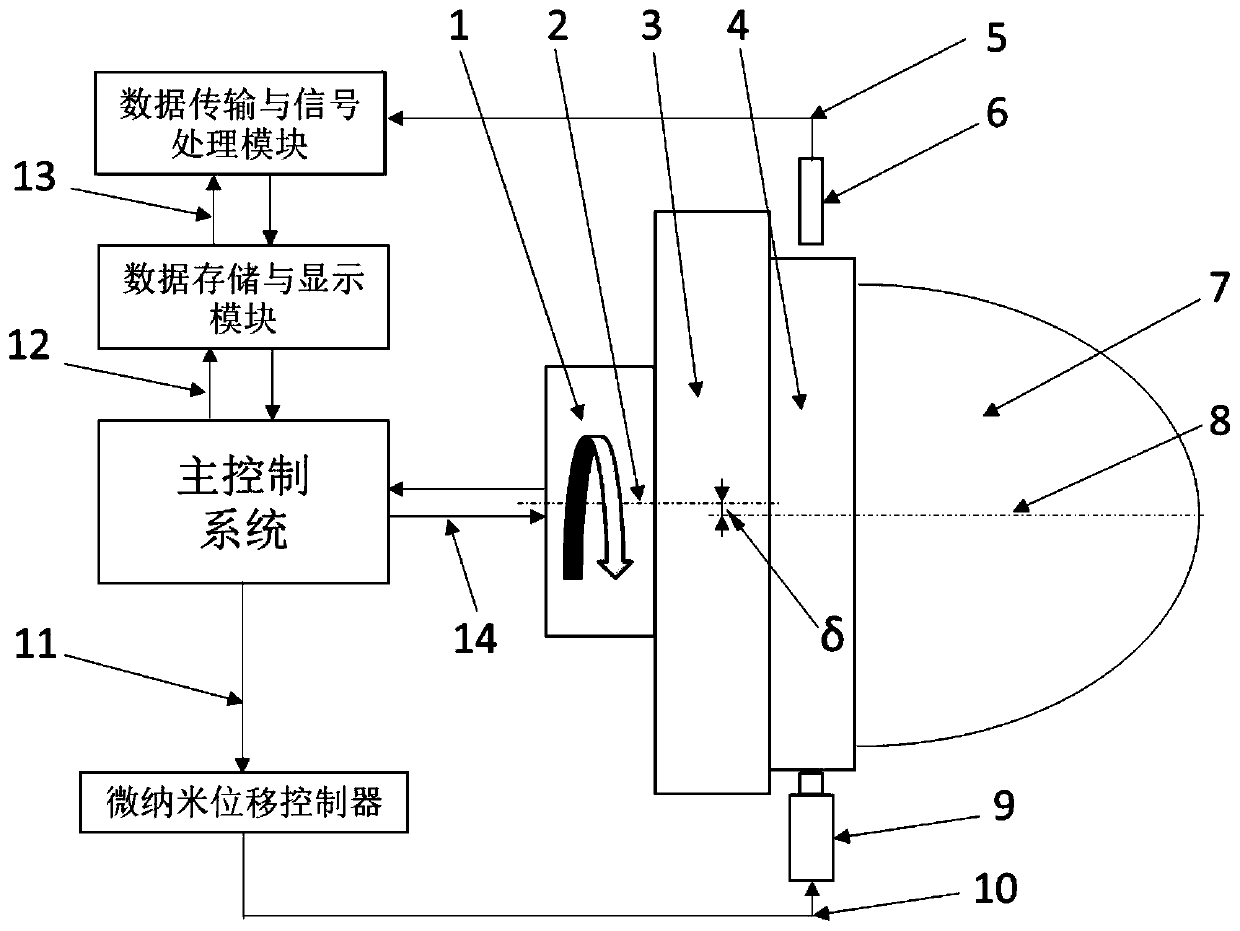

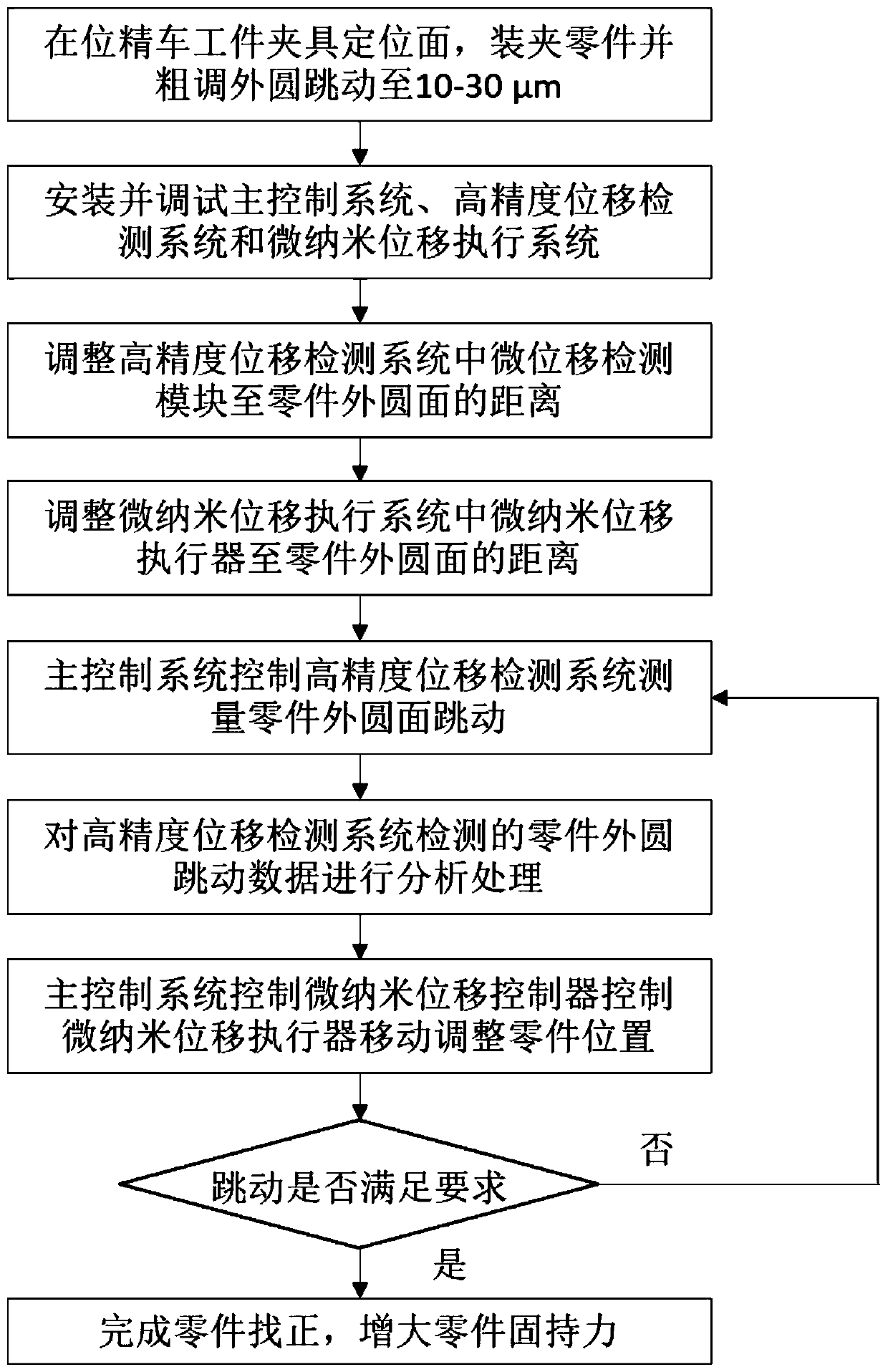

[0036] Such as figure 1 and figure 2 As shown, the precise alignment method of rotary parts includes the following steps:

[0037] A. Install the rotary workpiece fixture 3 on the machine tool spindle 1, position the rotary workpiece fixture 3 on the in-position finish car, and attach the flange 4 of the rotary curved surface part 7 to the rotary workpiece fixture 3 positioning installation surface, And adjust the holding force so that the rotary curved surface part 7 can be pushed but does not automatically slide down, install the rotary curved surface part 7 and roughly adjust the runout of the outer circle of the flange 4 to 10-30 μm.

[0038] B. Install and debug the main control system, high-precision displacement detection system and micro-nano displacement execution system;

[0039] Install and fix the micro-displacement detection module 6 near the flange ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com