Alignment instrument for eccentricity alignment of lathe four-jaw chuck and alignment method

A four-jaw chuck and alignment technology, which is applied to chucks, turning equipment, manufacturing tools, etc., can solve problems such as difficult quality assurance, laborious alignment accuracy, and low production efficiency, and achieve simple structure and improved clamping accuracy , easy to adjust the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

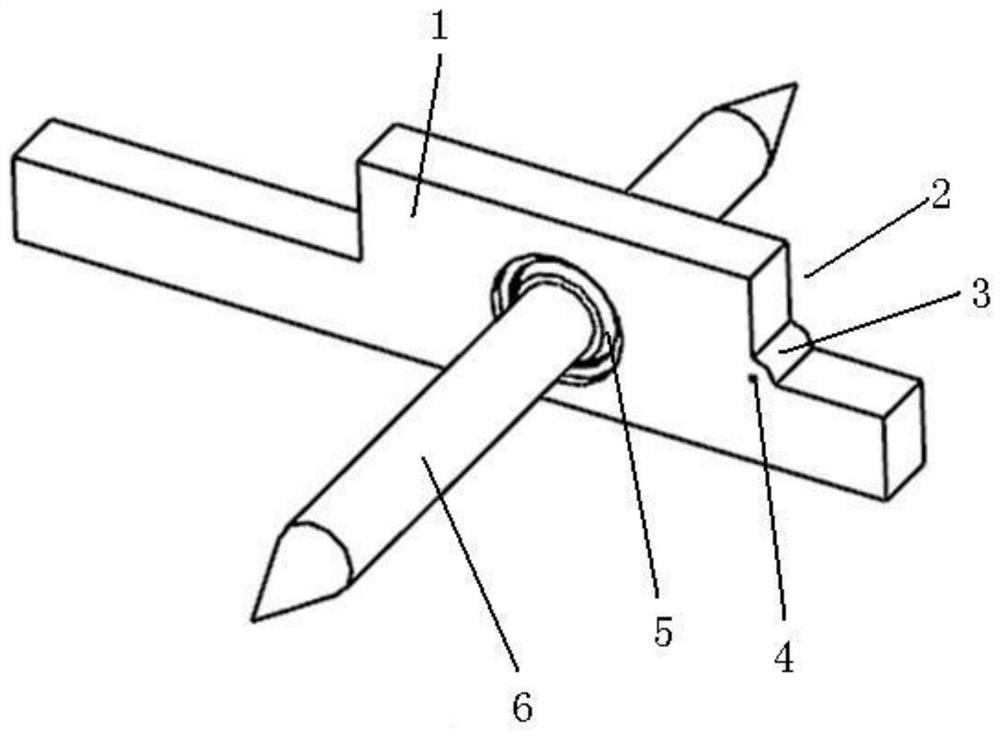

[0021] Such as figure 1 As shown, a lathe four-claw chuck eccentric is used to find a generner, including a pressure rod 1, the front end of the pressure rod 1, which is provided with a positive groove 2, and the finding groove 2 is provided with a curved portion 3. The arc-shaped portion 3 is coincident with the angular corner point of the inner wall surface of the foundation groove 2, and the arc-shaped portion 3 is provided with a tapered slot 4;

[0022] The rod 1 is provided with a plug hole adjacent to the front end position, and the insertion hole is provided with a center joint bearing 5, the center joint bearing 5 inner ring plug correction rod 6, the correction rod 6 two The end has a pointed.

Embodiment 2

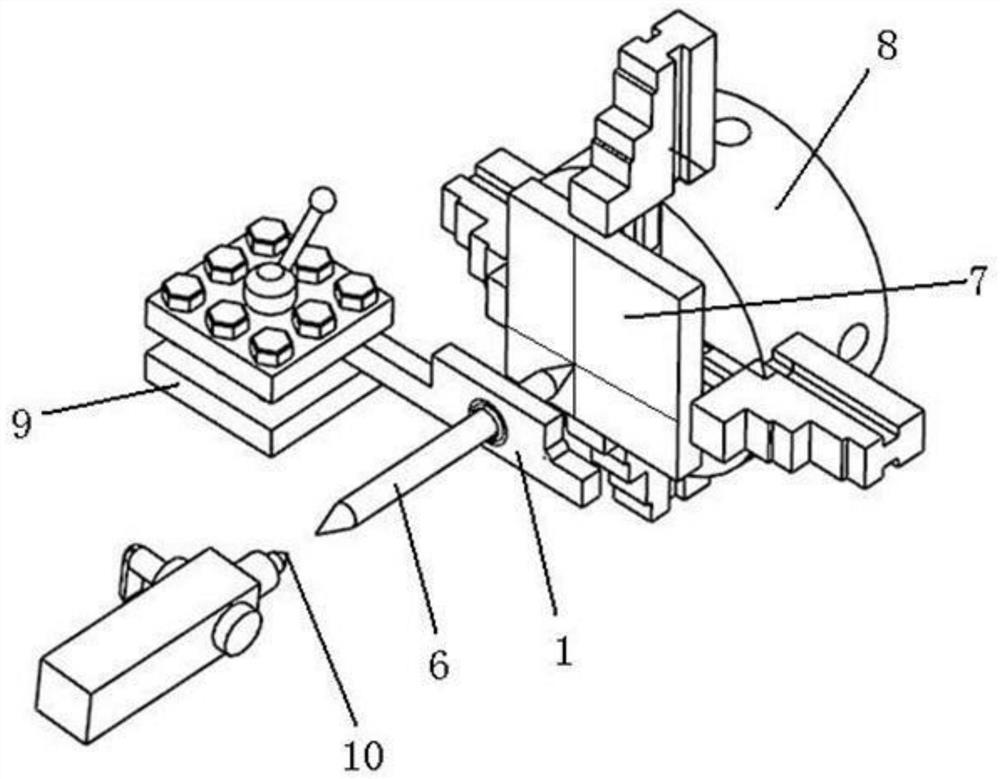

[0024] Such as figure 2 As shown, a method of finding a positive use using the finder, including the following steps:

[0025] 1) Topping the horizontal vertical cross line on the workpiece 7 to be machined, and the sample punching is processed on the cross line, and the workpiece 7 is mounted on the four-claw chuck 8, and the center line of the front and rear jaws is to be processed. The horizontal lines on the workpiece 7 are maintained, and the center line of the upper and lower jaws is consistent with the vertical lines of the workpiece 7 to be processed.

[0026] 2) Remove the correction rod 6 from the center joint bearing 5, then place the rear end of the finding instrument rod 1 in the lathe tool frame 9, adjust the pressure rod 1 position, so that the tail of the machine tool can be inserted into In the slot 4, then the lathe tool holder 9 clamps the rod 1;

[0027] 3) The axial movement finds a kit, which is close to the workpiece 7, and rotates the chuck 8, and the horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com