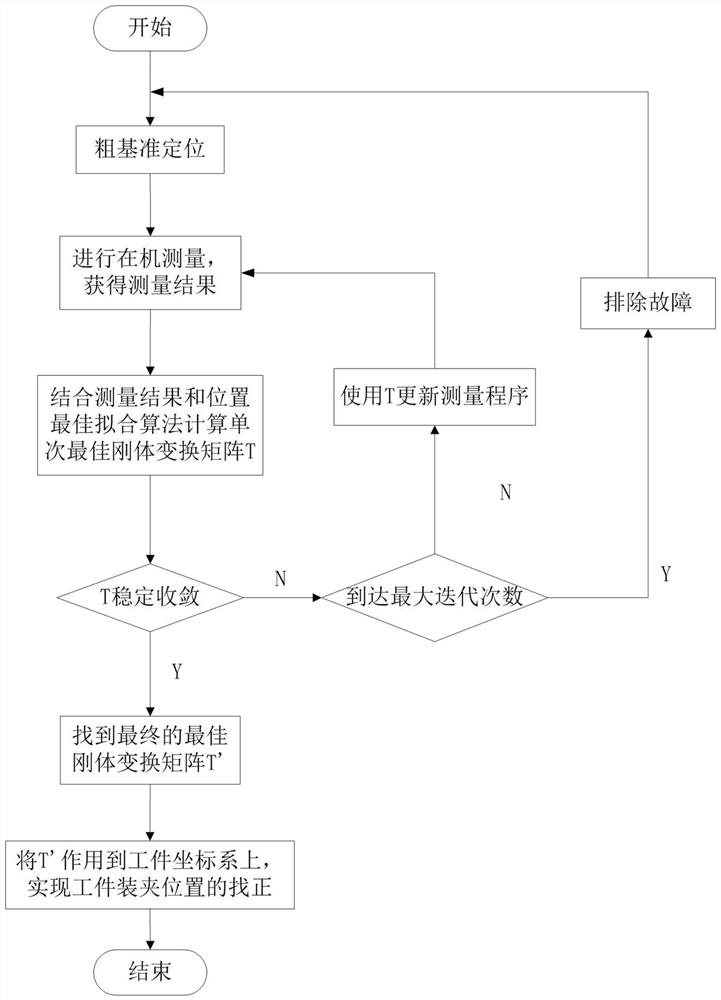

Alignment method of on-machine measurement of workpiece clamping position based on iteration

A workpiece clamping and iterative technology, used in measuring/indicating equipment, metal processing machinery parts, manufacturing tools, etc., can solve the problem that the calculation results cannot truly reflect the workpiece, etc., so as to reduce the position error of the contact point and improve the accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so that those skilled in the art can better understand the present invention and implement it, but the examples given are not intended to limit the present invention.

[0025] In the present invention, the term "comprising" is intended to cover a non-exclusive inclusion, such as a process, method, system, product or device comprising a series of steps or units, not limited to the listed steps or units but optional Optionally also includes steps or units not listed, or alternatively also includes other steps or units inherent to these processes, methods, products or devices.

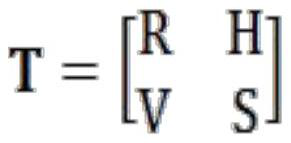

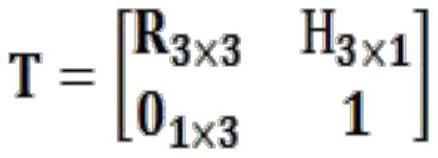

[0026] The rigid body transformation matrix T can be expressed as:

[0027]

[0028] Where R represents the rotation matrix, H represents the translation vector, V represents the perspective transformation vector, and S represents the overall scale factor. Since there is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com