Full-leg cutting machine

A splitting machine and frame technology, applied in poultry splitting, poultry transfer/conveyor, slaughtering, etc., can solve problems such as inconvenient operation, large slaughtering volume, and affecting production capacity, so as to reduce labor intensity and number of personnel , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to clearly illustrate the technical characteristics of this solution, the following will describe this solution through specific implementation modes and in conjunction with the accompanying drawings.

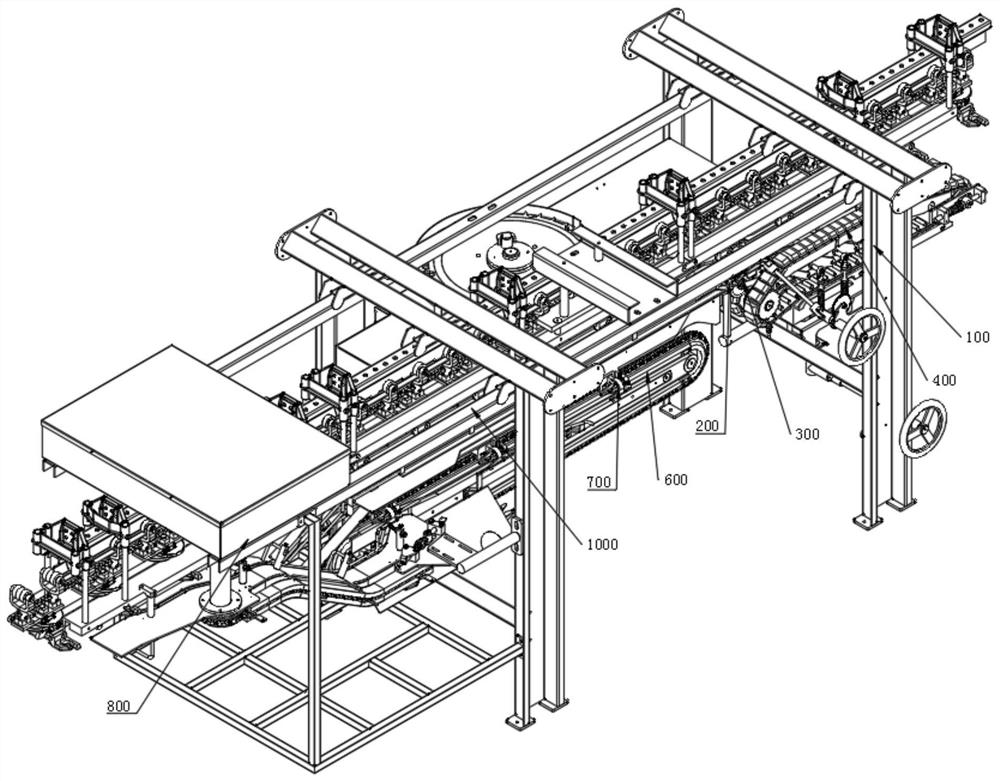

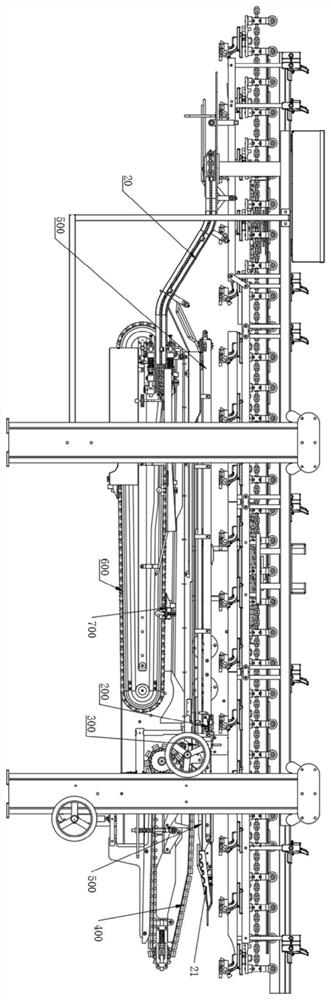

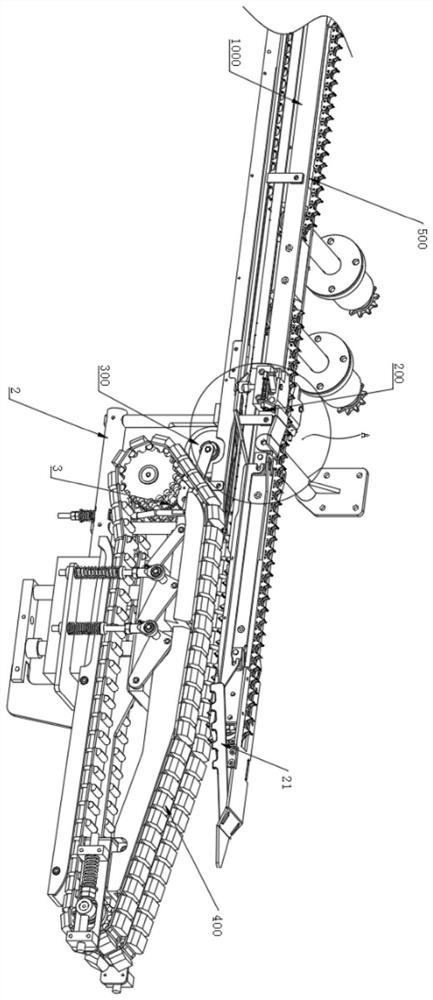

[0039] Such as Figure 1-11 As shown, a whole leg splitting machine includes a frame 100, an intermediate transfer platform 500 is set on the frame 100, and a whole leg pre-cutting device, a whole leg separating device and a transfer hanging device are sequentially arranged above and below the intermediate transfer platform 500. components;

[0040] The whole leg pre-cutting device includes a conveying assembly 400 and an upper cutter assembly 200 and a lower cutter assembly 300 arranged at one end of the conveying assembly 400, and the upper cutter assembly 200 and the lower cutter assembly 300 are correspondingly arranged; the lower cutter assembly 300 includes a skin knife 1, a skin knife mounting bracket 2, a skin knife transmission assembly 3 and a transmi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com